Page 1

TECHNICAL

MANUAL

LSI53C320

Ultra320 SCSI

Bus Expander

Version 2.2

September 2003

®

DB14-000163-05

Page 2

LSI Logic products are not intended for use in life-support appliances, devices,

or systems. Use of any LSI Logic product in such applications without written

consent of the appropriate LSI Logic officer is prohibited.

Document DB14-000163-05, September 2003

This document describes the LSI Logic LSI53C320 Ultra320 SCSI Bus Expander

and will remain the official reference source for all revisions/releases of this

product until rescinded by an update.

LSI Logic Corporation reserves the right to make changes to any products herein

at any time without notice. LSI Logic does not assume any responsibility or

liability arising out of the application or use of any product described herein,

except as expressly agreed to in writing by LSI Logic; nor does the purchase or

use of a product from LSI Logic convey a license under any patent rights,

copyrights, trademark rights, or any other of the intellectual property rights of

LSI Logic or third parties.

Copyright © 2003 by LSI Logic Corporation. All rights reserved.

TRADEMARK ACKNOWLEDGMENT

LSI Logic, the LSI Logic logo design, LVDlink, SureLINK, and TolerANT are

trademarks or registered trademarks of LSI Logic Corporation. All other brand

and product names may be trademarks of their respective companies.

To receive product literature, visit us at http://www.lsilogic.com.

For a current list of our distributors, sales offices, and design resource

centers, view our web page located at

http://www.lsilogic.com/contacts/index.html

KL

ii

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 3

Audience

Preface

This manual provides a description of the LSI53C320 Ultra320 SCSI Bus

Expander chip that supports all combinations of Single-Ended (SE) and

Low Voltage Differential (LVD) SCSI bus conversions.

This manual assumes prior knowledge of the current and proposed SCSI

standards. This manual also assumes that you are familiar with

microprocessors and related support devices. The people who benefit

from this book are

• engineers and/or managers who are evaluating the LSI53C320 for

use in a system

• engineers who are designing the LSI53C320 into a system.

Related Publications

For background information, please contact:

LSI Logic World Wide Web Home Page

ANSI

www.ansi.org

Global Engineering Documents

www.global.ihs.com

Ask for document number X3.131-1994 (SCSI-2) or X3.253

(SCSI-3 Parallel Interface)

LSI53C320 Ultra320 SCSI Bus Expander Technical Manual iii

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

www.lsilogic.com

Page 4

Organization

ENDL Publications

www.rahul.net/endl/

(408) 867-6630

Document names: SCSI Bench Reference, SCSI Encyclopedia, SCSI

Tutor

This document has the following chapters and appendixes:

• Chapter 1, Introduction, contains the general information about the

LSI53C320 product.

• Chapter 2, Functional Descriptions, describes the block diagram

and operation of the LSI53C320.

• Chapter 3, Signal Description, provides signal descriptions for the

LSI53C320.

• Chapter 4, Specifications, contains the electrical characteristics,

timing diagrams, 272-PBGA diagram, and mechanical drawings for

the LSI53C320.

• Appendix A, Wiring Diagrams, contains wiring diagrams for a typical

LSI53C320 usage.

• Appendix B, Glossary, defines commonly used terms.

Revision Record

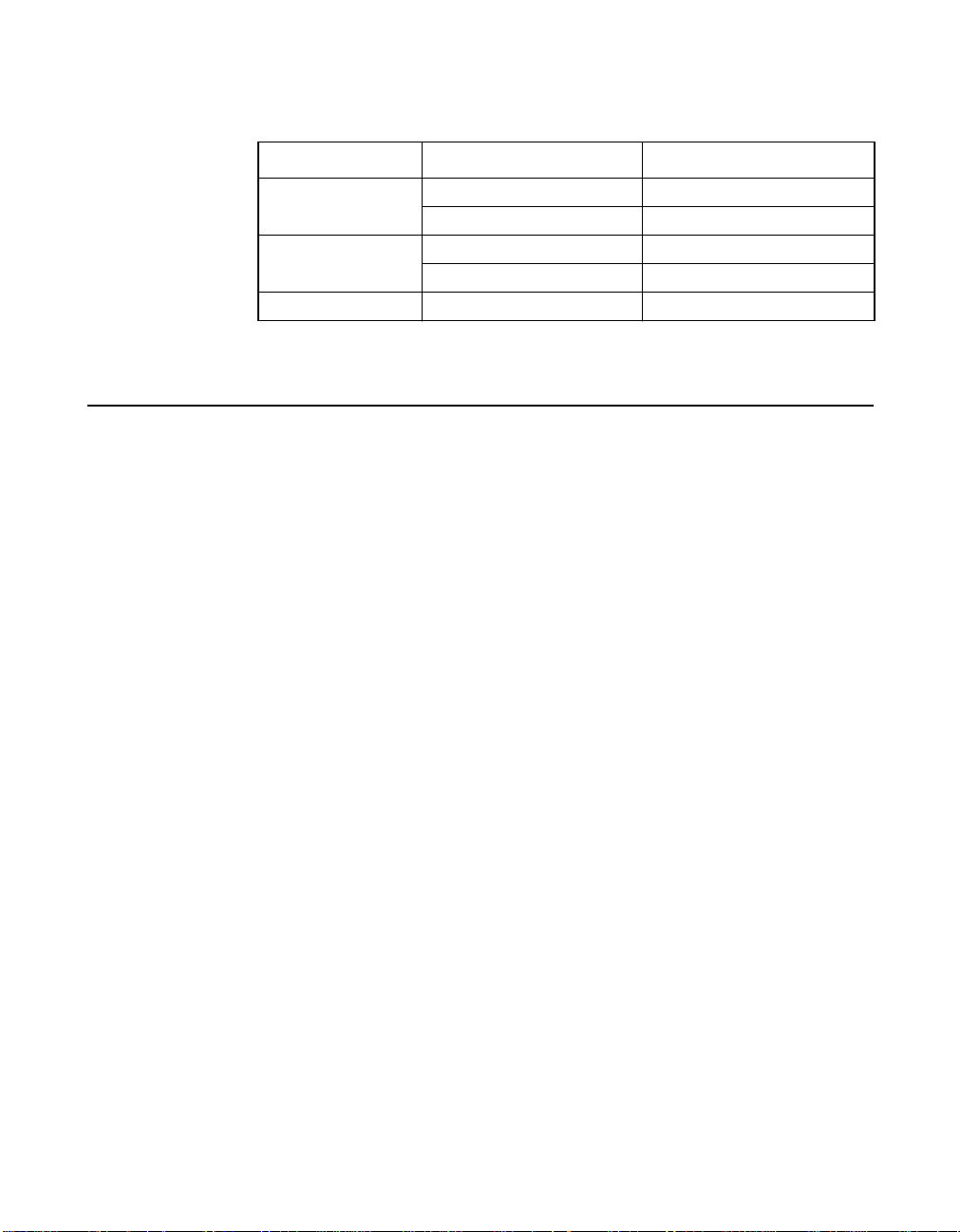

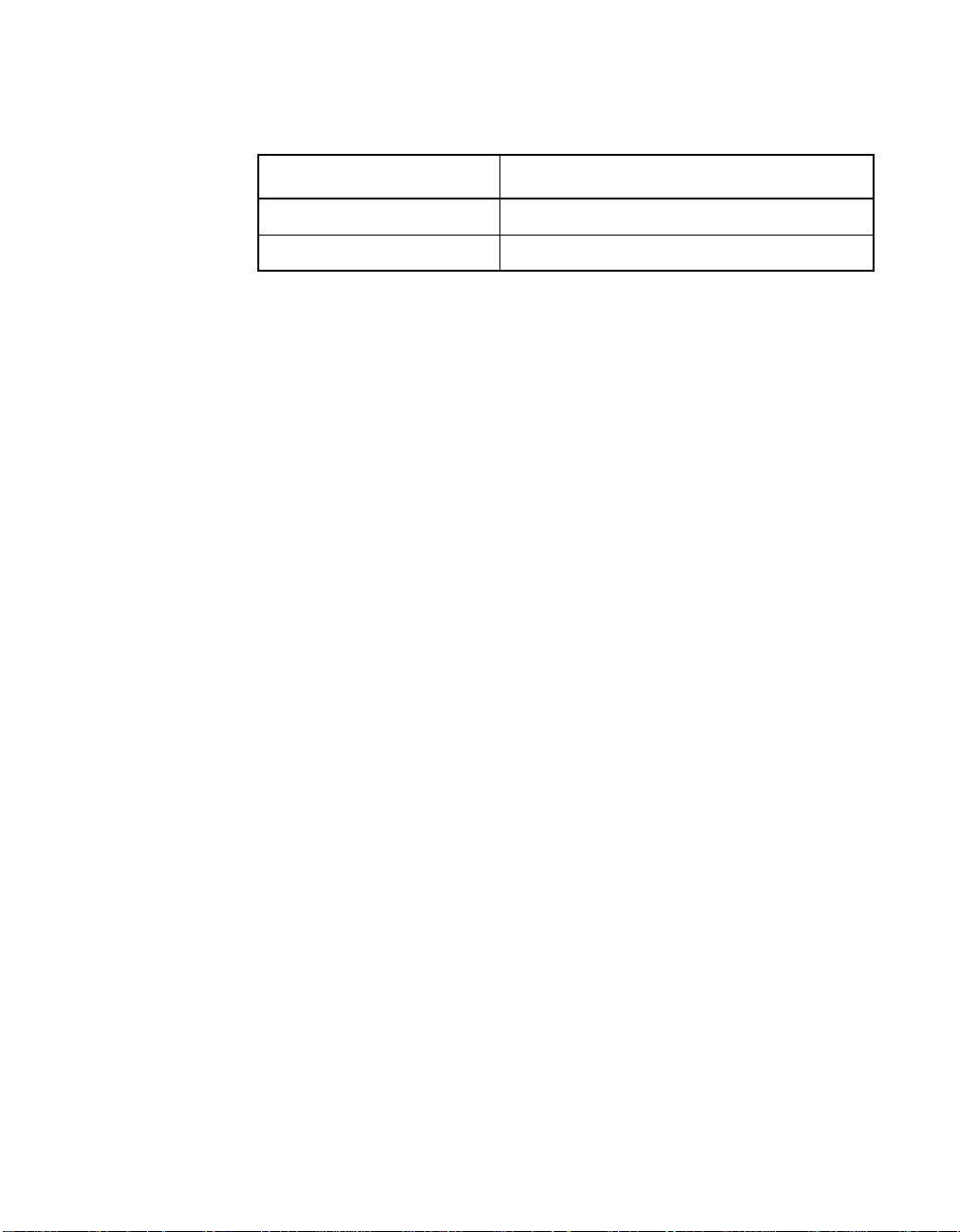

Date Version Remarks

2/2001 1.0 Advance/Confidential - includes 272 PBGA mechanical drawing

9/2002 1.1 Rearranged Chapters 2-3 into Chapters 2-4.

5/2003 2.0 Final Version for GCA.

5/2003 2.1 Added disclaimer on the EPBGA mechanical drawing.

9/2003 2.2 Added ground to address lines in Figure 2.5 and Figure A.1.

iv Preface

Updated the Specifications chapter for G12 processes.

Rewrote in active voice.

Added the serial EEPROM interface information.

Added the maximum cable length information.

Noted that QAS is not supported in the Ultra160 SCSI mode.

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 5

Contents

Chapter 1 Introduction

1.1 General Description 1-1

1.2 Applications 1-3

1.3 Benefits of Ultra320 SCSI 1-5

1.4 Benefits of SureLINK™ (Ultra320 SCSI Domain Validation) 1-6

1.5 Benefits of LVDlink™ Technology 1-6

1.6 Benefits of TolerANT®Technology 1-7

1.7 Features 1-7

Chapter 2 Functional Descriptions

2.1 LSI53C320 Block Diagram Description 2-1

2.1.1 SCSI Control Blocks 2-2

2.1.2 Retiming Logic Block 2-2

2.1.3 Precision Delay Control Block 2-3

2.1.4 State Machine Control Block 2-3

2.1.5 DIFFSENS Receiver Block 2-3

2.2 Ultra320 SCSI Functional Description 2-3

2.2.1 Ultra320 SCSI Features 2-3

2.2.2 SCSI Bus Interface 2-7

2.2.3 Maximum Cable Lengths 2-8

2.3 SCSI Signal Processing 2-11

2.3.1 Data and Data Parity Signals 2-11

2.3.2 Select Signal 2-11

2.3.3 Busy Signal 2-12

2.3.4 Reset Signal 2-12

2.3.5 Request and Acknowledge Signals 2-13

2.3.6 Control/Data, Input/Output, Message, and Attention

Signals 2-14

2.4 Internal Control Descriptions 2-14

Contents v

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 6

2.4.1 Self-Calibration 2-14

2.4.2 Delay Line Structures 2-14

2.4.3 Busy Filters 2-15

2.5 Serial EEPROM Connection 2-15

Chapter 3 Signal Description

3.1 Signal Grouping 3-1

3.2 SCSI Interface Signals 3-3

3.3 Interface Control Signals 3-5

3.4 Serial EEPROM Signals 3-6

3.5 Power and Ground Signals 3-6

3.6 Test Signals 3-7

3.7 Signal Layout Considerations 3-8

Chapter 4 Specifications

4.1 Electrical Characteristics 4-1

4.1.1 DC Characteristics 4-1

4.1.2 TolerANT Technology Electrical Characteristics 4-6

4.1.3 AC Characteristics 4-7

4.2 Chip Drawings 4-8

4.2.1 Mechanical Drawing 4-8

4.2.2 BGA Drawing 4-11

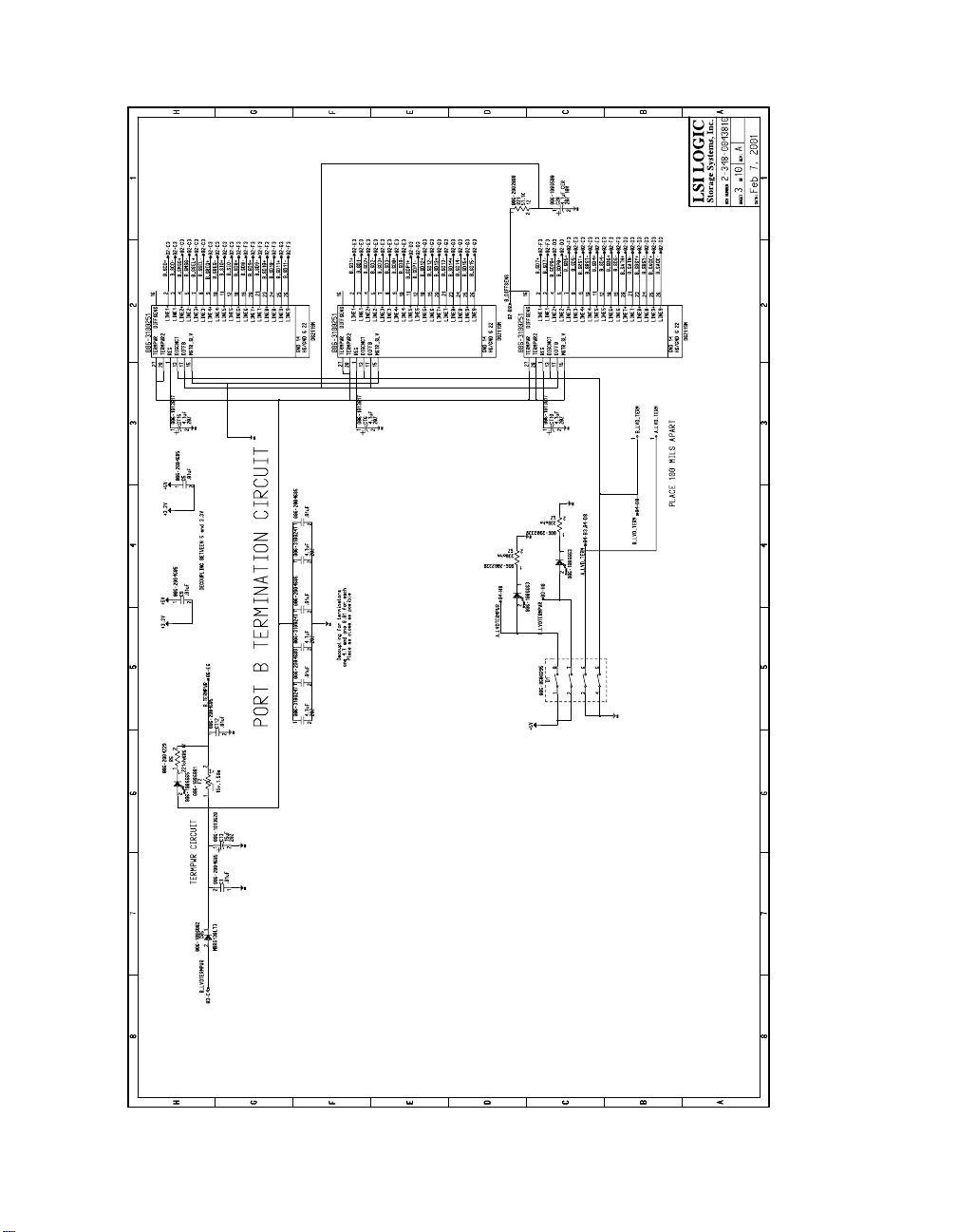

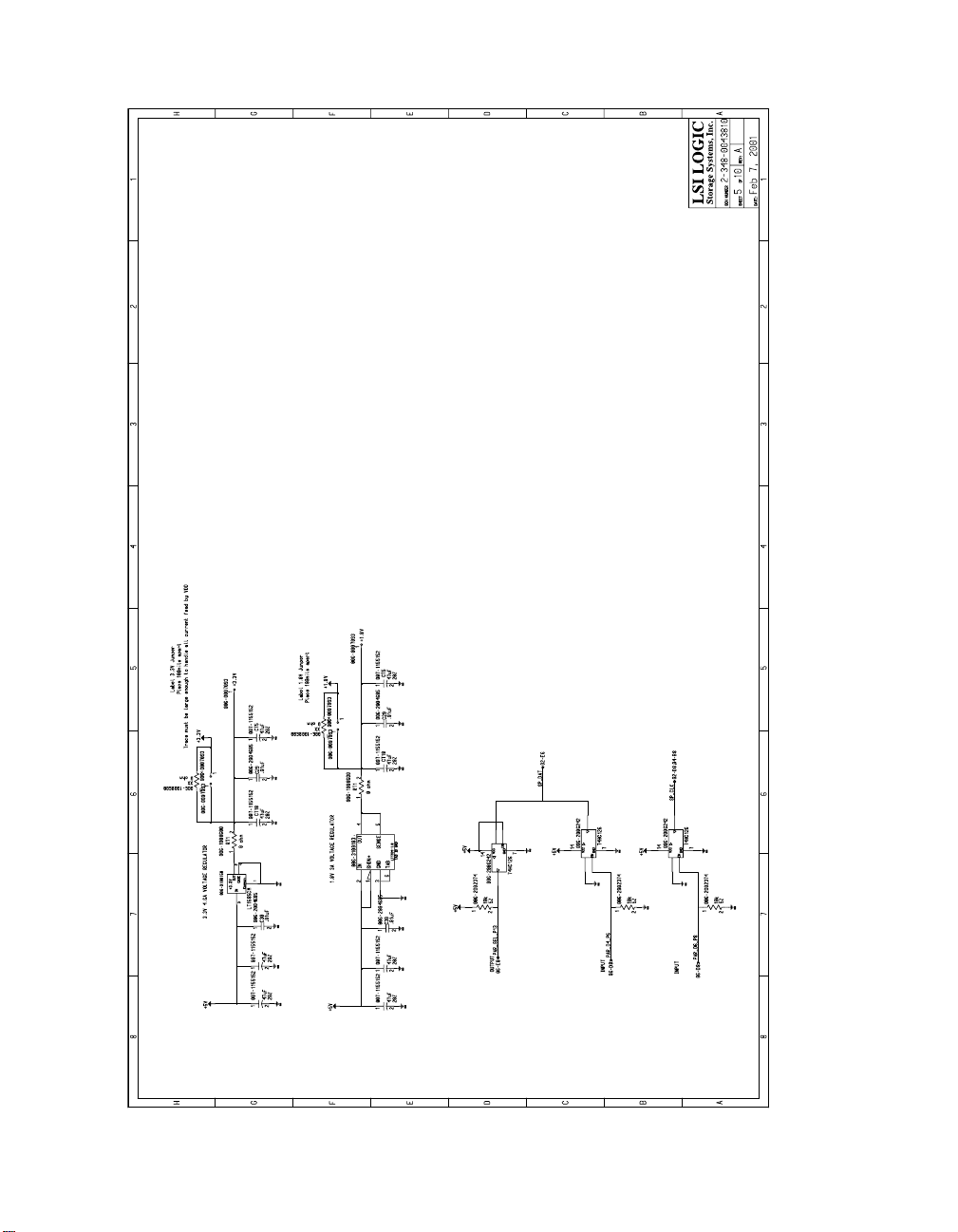

Appendix A Wiring Diagrams

A.1 LSI53C320 Wiring Diagrams A-1

Appendix B Glossary

Index

Customer Feedback

vi Contents

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 7

Figures

1.1 LSI53C320 SCSI Bus Modes 1-2

1.2 LSI53C320 Server Clustering 1-3

1.3 LSI53C320 SCSI Bus Device 1-4

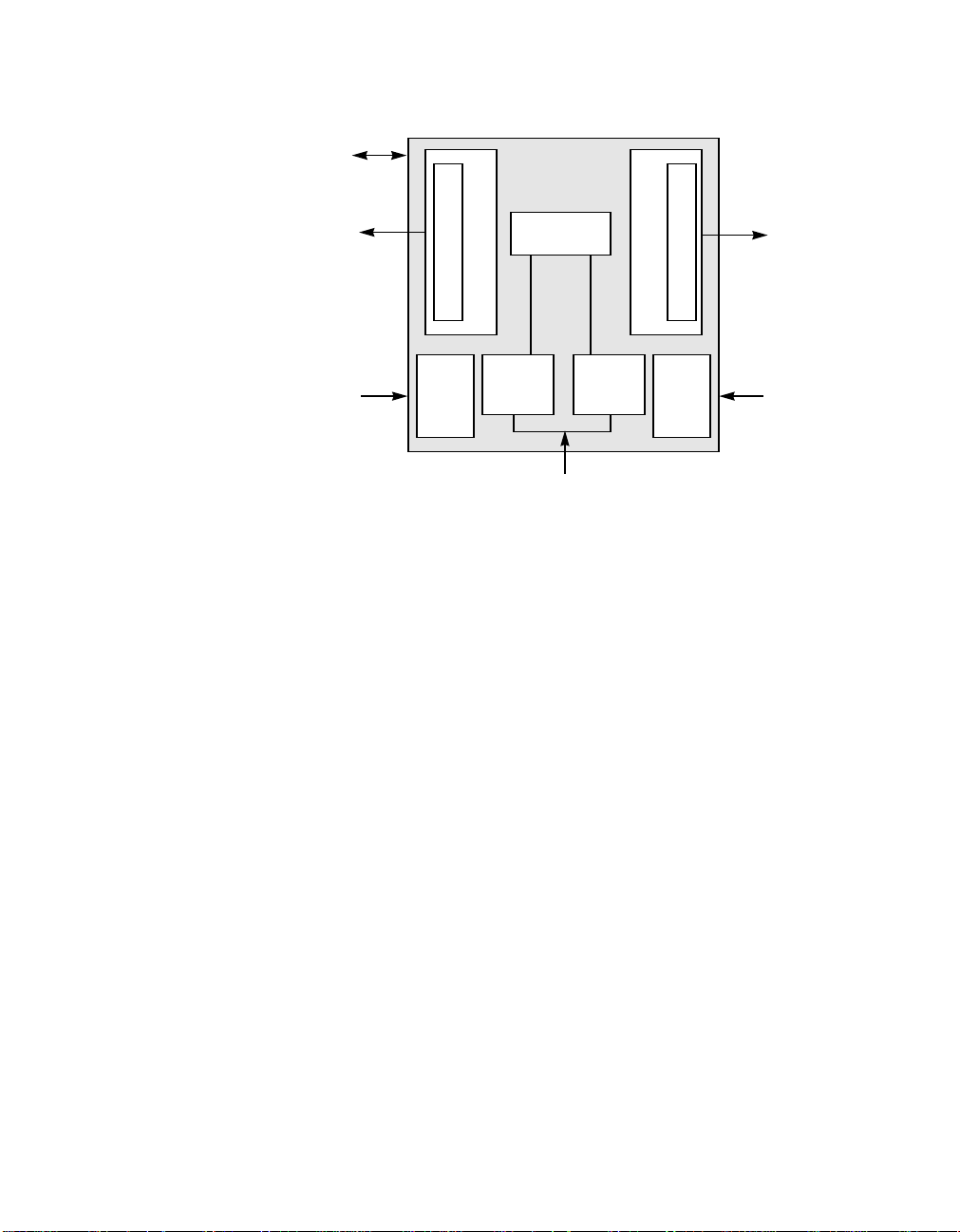

2.1 LSI53C320 Block Diagram 2-2

2.2 Paced Transfer Example 2-5

2.3 Example of Precompensation 2-6

2.4 Electrical Cable Lengths at Ultra320 SCSI Speeds 2-10

2.5 Serial EEPROM Connection 2-16

3.1 LSI53C320 Functional Signal Grouping 3-2

4.1 LVD Driver 4-3

4.2 LVD Receiver 4-3

4.3 Rise and Fall Time Test Conditions 4-7

4.4 Clock Timing 4-8

4.5 272-Ball-Count PBGA (VG) Mechanical Drawing 4-9

4.6 LSI53C320 272-Ball BGA Top View 4-12

A.1 LSI53C320 Wiring Diagram 1 of 4 A-2

A.2 LSI53C320 Wiring Diagram 2 of 4 A-3

A.3 LSI53C320 Wiring Diagram 3 of 4 A-4

A.4 LSI53C320 Wiring Diagram 4 of 4 A-5

Contents vii

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 8

viii Contents

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 9

Tables

1.1 Types of Operation 1-2

1.2 SCSI Bus Length Limits in a Clustering Configuration 1-4

1.3 SCSI Bus Length Limits 1-5

2.1 DIFFSENS Voltage Levels 2-8

2.2 Total Cable Length for Ultra320 SCSI Using the

LSI53C320 2-10

3.1 SCSI A Side Interface Signals 3-3

3.2 SCSI B Side Interface Signals 3-4

3.3 Chip Interface Control Signals 3-5

3.4 Serial EEPROM Signals 3-6

3.5 Power and Ground Pins 3-6

3.6 Test Signals for LSI Logic Only 3-7

4.1 Absolute Maximum Stress Ratings 4-1

4.2 Operating Conditions 4-2

4.3 LVD Driver SCSI Signals—SD[15:0]±, SDP[1:0]±,

SCD±, SIO±, SMSG±, SREQ±,SACK±, SBSY±,

SATN±, SSEL±, SRST± 4-2

4.4 LVD Receiver SCSI Signals—SD[15:0]±, SDP[1:0]±,

SCD±, SIO±, SMSG±, SREQ±,SACK±, SBSY±,

SATN±, SSEL±, SRST± 4-3

4.5 Bidirectional SCSI Signals—SD[15:0]/, SDP[1:0]/, SREQ/,

SACK/, SD[15:0]±, SDP[1:0]±, SREQ±,SACK± 4-4

4.6 Bidirectional SCSI Control Signals—SCD/, SIO/, SMSG/,

SBSY/, SATN/, SSEL/, SRST/, SCD±, SIO±, SMSG±,

SBSY±,SATN±, SSEL±, SRST± 4-4

4.7 DIFFSENS SCSI Signal 4-4

4.8 Input Capacitance 4-5

4.9 Input Control Signals—CLOCK, CHIP_RESET/,

WS_ENABLE/ 4-5

4.10 Output Control Signals—BSY_LED, XFER_ACTIVE 4-5

4.11 TolerANT Technology Electrical Characteristics 4-6

4.12 Clock Timing 4-8

Contents ix

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 10

x Contents

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 11

Chapter 1

Introduction

This chapter describes the LSI53C320 Ultra320 SCSI Bus Expander and

includes these sections:

• Section 1.1, “General Description,” page 1-1

• Section 1.2, “Applications,” page 1-3

• Section 1.3, “Benefits of Ultra320 SCSI,” page 1-5

• Section 1.4, “Benefits of SureLINK™ (Ultra320 SCSI Domain

Validation),” page 1-6

• Section 1.5, “Benefits of LVDlink™ Technology,” page 1-6

• Section 1.6, “Benefits of TolerANT

• Section 1.7, “Features,” page 1-7

®

Technology,” page 1-7

1.1 General Description

The LSI53C320 Ultra320 SCSI Bus Expander is a single-chip solution

allowing the extension of SCSI device connectivity and/or cable length

limits. A SCSI bus expander couples bus segments without impact to the

software, firmware, or SCSI protocol implementation. The LSI53C320

Ultra320 SCSI Bus Expander connects Single-Ended (SE) Ultra SCSI

and Low Voltage Differential (LVD) Ultra320 SCSI peripherals together in

any combination. The LSI53C320 does not support High Voltage

Differential (HVD) mode.

The LSI53C320 supports any combination of the SE or LVD bus modes

on either the A Side or B Side port. This provides the system designer

with maximum flexibility in designing SCSI backplanes to accommodate

any SCSI bus mode. Each bus side on the LSI53C320 has an

independent RBIAS pin to allow for margining of each bus.

LSI53C320 Ultra320 SCSI Bus Expander Technical Manual 1-1

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 12

Figure 1.1 shows the two SCSI bus modes available on the A or B Side.

LVDlink transceivers provide the multimode LVD or SE capability. The

LSI53C320 operates as both an expander and a converter. In both SCSI

Bus Expander and Converter modes, the LSI53C320 isolates the cable

segments on the A Side and the B Side. This feature maintains the signal

integrity of each cable segment.

Figure 1.1 LSI53C320 SCSI Bus Modes

A Side B Side

LVD

SE

LSI53C320

SCSI Expander

LVD

SE

Table 1.1 shows the types of operational modes for the LSI53C320.

Table 1.1 Types of Operation

Signal Type Speed

LVD to LVD Up to Ultra320 SCSI

SE to SE Up to Ultra SCSI

LVD to SE Up to Ultra SCSI

SE to LVD Up to Ultra SCSI

The LSI53C320 provides additional control capability through the pinlevel isolation mode (Warm Swap Enable). This feature permits logical

disconnection of the A Side bus or the B Side bus without disrupting

SCSI transfers currently in progress. For example, users can logically

disconnect the B Side bus while the A Side bus remains active.

The LSI53C320 is based on proven LSI Logic bus expander technology,

which includes signal filtering along with retiming to maintain skew

budgets. The LSI53C320 is independent of software. However, Domain

Validation technology does require software control.

Note: The LSI53C320 does not support Quick Arbitration and

1-2 Introduction

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Selection (QAS) while operating at Ultra160 SCSI rates.

Page 13

1.2 Applications

The LSI53C320 supports

• server clustering environments

• expanders creating distinct SCSI cable segments that are isolated

Configurations that use the LSI53C320 SCSI Bus Expander in the LVD

to LVD mode allow the system designer to take advantage of the inherent

cable distance, device connectivity, data reliability, and increased transfer

rate benefits of LVD signaling with Ultra320 SCSI peripherals. Section

2.2.3, “Maximum Cable Lengths,” discusses additional limits on the total

SCSI cable length for systems operating at Ultra320 SCSI transfer rates.

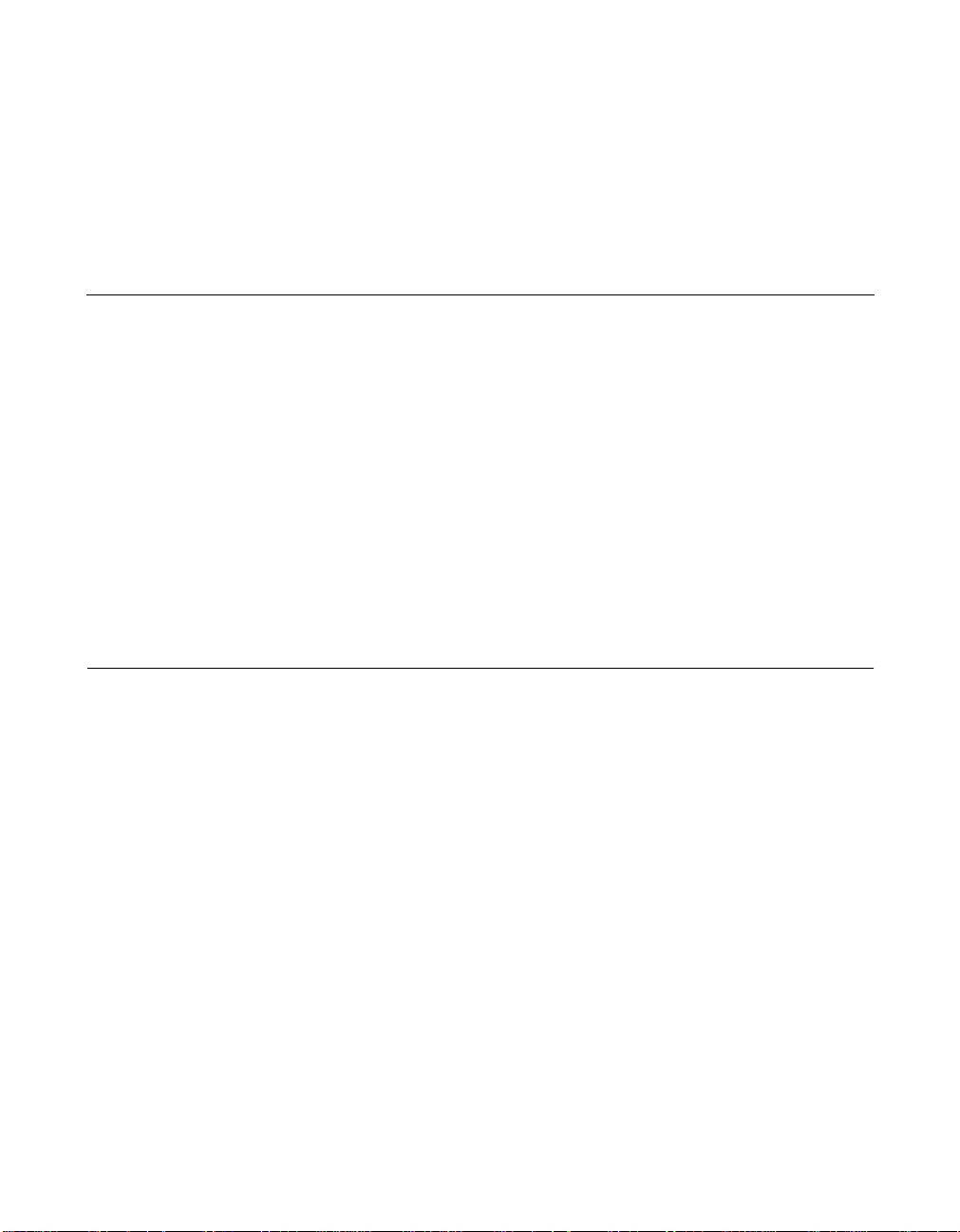

Figure 1.2 shows how SCSI bus expanders couple bus segments with no

impact on the SCSI protocol or software. Two LSI53C320 expanders

configure three bus segments. Segment A is a point-to-point segment.

Segments B and C are load segments and have at least 8 inches

between every node. Table 1.2 shows the various distance requirements

for each SCSI bus segment.

Figure 1.2 LSI53C320 Server Clustering

from each other

Segment A

Primary Server

Applications 1-3

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

SCSI Bus

Expander

SCSI Bus

Expander

Segment C

Shared Disk Subsystem

Segment B

Secondary Server

Page 14

Table 1.2 SCSI Bus Length Limits in a Clustering Configuration

Segment Mode Length Limit

A LVD (Ultra320 SCSI) Up to 12 meters

SE (Ultra SCSI) Up to 3 meters

1

B LVD (Ultra320 SCSI) Up to 12 meters

SE (Ultra SCSI) Up to 1.5 meters

C LVD (Ultra320 SCSI) Up to 12 meters

SE (Ultra SCSI) Up to 1.5 meters

A + B + C + D Ultra320 SCSI (only) Less than 29 meters

2

1. The cable length can be more than 1.5 meters, since this is a point-to-point

connection.

2. Refer to Section 2.2.3, “Maximum Cable Lengths,” for more information on

cable length limits in an Ultra320 SCSI environment.

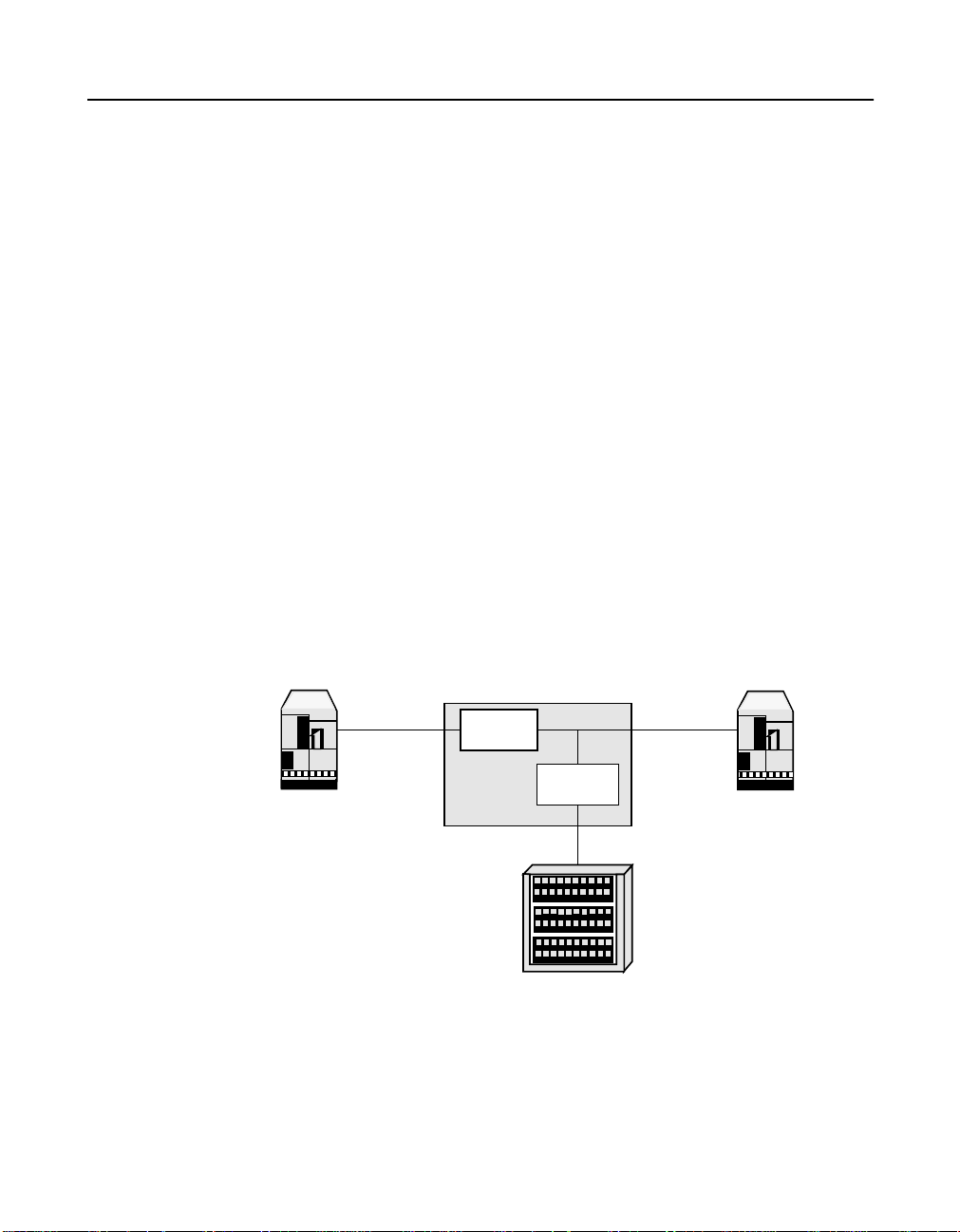

Figure 1.3 shows cascading of the LSI53C320 to achieve four distinct

SCSI segments. Segments A and D are point-to-point segments.

Segments B and C are load segments and have at least 8-inch spacing

between every node. Table 1.3 shows the distance requirements for each

SCSI bus segment.

Figure 1.3 LSI53C320 SCSI Bus Device

Segment A Segment B Segment C

Primary

Server

1-4 Introduction

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

SCSI Bus

Expander

Shared Disk

Subsystem

SCSI Bus

Expander

Shared Disk

Subsystem

SCSI Bus

Expander

Segment D

Secondary

Server

Page 15

Table 1.3 SCSI Bus Length Limits

Segment Mode Length Limit

A, D LVD (Ultra320 SCSI) Up to 12 meters

SE (Ultra SCSI) Up to 1.5 meters

B, C LVD (Ultra320 SCSI) Up to 12 meters

SE (Ultra SCSI) Up to 1.5 meters

A + B + C + D Ultra320 SCSI (only) Less than 25 meters

1. Refer to Section 2.2.3, “Maximum Cable Lengths,” for more information on

cable length limits in an Ultra320 SCSI environment.

1.3 Benefits of Ultra320 SCSI

The LSI53C320 SCSI Bus Expander supports Ultra320 SCSI. This

interface expands the bandwidth of the SCSI bus to allow faster

synchronous data transfers of up to 320 Mbytes/s. Ultra320 SCSI

provides double the data transfer rate of the Ultra160 SCSI interface.

The LSI53C320 performs 16-bit, Ultra320 SCSI synchronous data

transfers as fast as 320 Mbytes/s on the side of the device. This

advantage is most noticeable in heavily loaded systems or large block

size applications, such as video on-demand and image processing.

1

Ultra320 SCSI doubles both the data and clock frequencies from

Ultra160 SCSI. Due to the increased data and clock speeds, Ultra320

SCSI introduces skew compensation and intersymbol interference (ISI)

compensation. These new features simplify system design by resolving

timing issues at the chip level. Skew compensation adjusts for timing

differences between data and clock signals caused by cabling, board

traces, and so on. ISI compensation enhances the first pulse after a

change in state to ensure data integrity. The LSI53C320 performs skew

compensation on the receiver side of the device and ISI compensation

on the driver side of the device.

Ultra320 SCSI supports Cyclic Redundancy Check (CRC), which

provides error checking code to detect the validity of data. CRC

increases the reliability of data transfers by transferring four bytes of

code along with data. CRC detects all single bit errors, two bits in error,

or other error types within a single 32-bit range.

Benefits of Ultra320 SCSI 1-5

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 16

1.4 Benefits of SureLINK™ (Ultra320 SCSI Domain Validation)

SureLINK Domain Validation is a procedure that allows a host computer

and target SCSI peripheral to negotiate and find the optimal transfer

speed. This procedure improves overall reliability of the system by

ensuring data integrity.

Domain Validation software ensures robust SCSI interconnect

management and low risk Ultra320 SCSI implementations by extending

the domain validation guidelines documented in the SPI-4 specifications.

Domain validation verifies that the system is capable of transferring data

at Ultra320 SCSI speeds, allowing the LSI53C320 to renegotiate to a

lower data transfer speed and bus width if necessary. SureLINK Domain

Validation is the software control for the domain validation manageability

enhancements in the LSI53C320. SureLINK Domain Validation software

provides domain validation management at boot time as well as during

system operation.

SureLINK Domain Validationensures robust system operation by providing

three levelsof integrity checking on a per-device basis: Basic (Lev el1) with

inquiry command; Enhanced (Level2) with read/write buffer; and Margined

(Level 3) with margining of drive strength and slew rates.

1.5 Benefits of LVDlink™ Technology

The LSI53C320 supports LVDlink technology for SCSI, a signaling

technology that increases the reliability of SCSI data transfers over

longer distances than those supported by SE SCSI technology. The low

current output of LVD allows the I/O transceivers to be integrated directly

onto the chip. For backward compatibility to existing SE devices, the

LSI53C320 features multimode LVDlink transceivers that can switch

between LVD and SE modes.

Some features of integrated LVDlink transceivers are listed below:

• supports SE or LVD modes

• allows greater device connectivity and longer cable length

• saves the cost of external differential transceivers

• provides a long-term performance migration path

1-6 Introduction

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 17

1.6 Benefits of TolerANT®Technology

The LSI53C1320 features TolerANT technology, which provides active

negation on the SCSI drivers and input signal filtering on the SCSI

receivers. Active negation causes the SCSI Request, Acknowledge,

Data, and Parity signals to be actively driven HIGH rather than passively

pulled up by terminators.

TolerANT receiver technology improves data integrity in unreliable

cabling environments where other devices would be subject to data

corruption. TolerANT receivers filter the SCSI bus signals to eliminate

unwanted transitions, without the long signal delay associated with

RC-type input filters. This improved driver and receiver technology helps

ensure correct clocking of data.

TolerANT technology increases noise immunity, balances duty cycles,

and improves SCSI transfer rates. In addition, TolerANT SCSI devices do

not cause glitches on the SCSI bus at power-up or power-down, which

protects other devices on the bus from data corruption. When used with

the LVDlink transceivers, TolerANT technology provides excellent signal

quality and data reliability in real world cabling environments.

1.7 Features

The LSI53C320

• complies with the SCSI Parallel Interface 4 (SPI-4) Specifications

– complies with SCSI Enhanced Parallel Interface (EPI)

Specifications

– supports Double Transition (DT) clocking

– supports CRC in DT data phases

– supports Domain Validation technology

– supports Ultra320 SCSI Packetized Transfers

– provides SCSI signal and timing calibration

– is backward-compatible with previous revisions of the SCSI

specification

Benefits of TolerANT®Technology 1-7

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 18

• provides a flexible SCSI bus expander

• supports any combination of LVD or SE transceivers

• creates distinct SCSI bus segments that are isolated from each other

• uses integrated LVDlink transceivers for direct attachment to either

LVD or SE bus segments

• operates as a SCSI Bus Expander or a SCSI Bus Converter

– LVD to LVD (Ultra320 SCSI or Ultra160 SCSI)

– SE to SE (up to Ultra SCSI)

– LVD to SE (up to Ultra SCSI)

– SE to LVD (up to Ultra SCSI)

• handles targets and initiators on either the A Side bus or B Side bus

• accepts any asynchronous or synchronous transfer speeds up to

Ultra320 SCSI (for LVD to LVD mode only)

• supports dynamic addition/removal of SCSI bus segments using the

isolation mode

• does not consume a SCSI ID

• propagates the RESET/ signal from one side to the other regardless

of the SCSI bus state

• notifies initiator(s) of changes in transmission mode (SE/LVD) on A

or B Side segments by using the SCSI bus RESET/

• provides a SCSI Busy LED driver for an activity indicator

• supports cascading of up to four LSI53C320s

• does not require software

• requires a 40 MHz Input Clock

• has a 272-pin Plastic Ball Grid Array package (PBGA).

1-8 Introduction

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 19

Chapter 2

Functional

Descriptions

This chapter describes all signals, their groupings, and their functions. It

includes these topics:

• Section 2.1, “LSI53C320 Block Diagram Description,” page 2-1

• Section 2.2, “Ultra320 SCSI Functional Description,” page 2-3

• Section 2.3, “SCSI Signal Processing,” page 2-11

• Section 2.4, “Internal Control Descriptions,” page 2-14

• Section 2.5, “Serial EEPROM Connection,” page 2-15

2.1 LSI53C320 Block Diagram Description

The LSI53C320 has no user programmable registers and does not

require software. SCSI control signals control all LSI53C320 functions.

Figure 2.1 shows a block diagram of the LSI53C320 device, which

consists of these specific areas:

• A Side SCSI Control Block

– LVD and SE Drivers and Receivers

• B Side SCSI Control Block

– LVD and SE Drivers and Receivers

• Retiming Logic

• Precision Delay Control

• State Machine Control

LSI53C320 Ultra320 SCSI Bus Expander Technical Manual 2-1

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 20

Figure 2.1 LSI53C320 Block Diagram

Control

Signals

k

A Side Signals

A_DIFFSENS B_DIFFSENS

The LSI53C320 passes data and parity from a source bus to a load bus.

The source bus receives the SCSI signals from the initiator. The load bus

transmits the SCSI signals to the target. The LSI53C320 retimes signals

to maintain the signal skew budget from the source bus to the load bus.

2.1.1 SCSI Control Blocks

The SCSI A Side pins internally connect to the corresponding SCSI B

Side pins. In the LVD/LVD mode, the A Side and B Side control blocks

connect to SCSI devices and accept any asynchronous or synchronous

Ultra320 SCSI data transfer rates. The SCSI control block supports

TolerANT and LVDlink technologies to enable the SCSI bus transfers.

For more information on these technologies, refer to Section 2.2.2.1,

“SCSI Bus Modes.”

ansceivers

VDlink Tr

L

er

VD

L

Receiv

DIFFSENS

Retiming

ol Block

SCSI Contr

Logic

Precision

Delay

Control

40 MHz Clock Input

State

Machine

Control

ol Bloc

LVDlink Transceivers

SCSI Contr

LVD

Receiver

DIFFSENS

B Side Signals

2.1.2 Retiming Logic Block

As SCSI signals propagate through the LSI53C320, the chip retimes the

signals to improve the SCSI timing. The Retiming Logic block contains

numerous delay elements, which the Precision Delay Control block

periodically calibrates to guarantee the output pulse widths, setup times,

and hold times.

2-2 Functional Descriptions

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 21

A synchronous negotiation between devices forms a nexus, for which the

on-chip RAM stores information. This information remains in place until

a chip reset, power down, or renegotiation. The nexus information

enables the LSI53C320 to make accurate retiming adjustments.

2.1.3 Precision Delay Control Block

The Precision Delay Control block provides calibration information to the

precision delay elements in the Retiming Logic block. Since the

LSI53C320 voltage and temperature vary with time, the Precision Delay

Control block periodically updates the delay settings in the Retiming

Logic block to maintain constant and precise control over the bus timing.

2.1.4 State Machine Control Block

The State Machine Control block monitors the SCSI bus phases, the

initiator and target device IDs, and various timing functions. This block

controls the SCSI bus signal retiming and SCSI protocol implementation.

2.1.5 DIFFSENS Receiver Block

The LSI53C320 can operate with SE or LVD SCSI buses. The

DIFFSENS Receiver block determine the operating mode of the SCSI

bus by monitoring the voltage level on the DIFFSENS signal. For more

information, refer to Section 2.2.2.1, “SCSI Bus Modes.”

2.2 Ultra320 SCSI Functional Description

The LSI53C320 supports Ultra320 SCSI. This interface expands the

bandwidth of the SCSI bus to allow faster synchronous data transfers of

up to 320 Mbytes/s. Ultra320 SCSI doubles the data transfer rate as

compared to the Ultra160 SCSI interface. This section describes how the

LSI53C320 implements the features in the SPI-4 draft specification.

2.2.1 Ultra320 SCSI Features

This section describes the Ultra320 SCSI features in the LSI53C320.

Ultra320 SCSI Functional Description 2-3

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 22

2.2.1.1 Double Transition (DT) Clocking

Ultra160 SCSI and Ultra320 SCSI implement DT clocking to provide

speeds up to 80 megatransfers per second (megatransfers/s) for

Ultra160 SCSI, and up to 160 megatransfers/s for Ultra320 SCSI. When

implementing DT clocking, a SCSI device samples data on both the

asserting and deasserting edge of REQ/ACK. DT clocking is only valid

using an LVD SCSI bus.

2.2.1.2 Intersymbol Interference (ISI) Compensation

ISI Compensation uses paced transfers and precompensation to enable

high data transfer rates. Ultra320 SCSI data transfers require the use of

ISI Compensation.

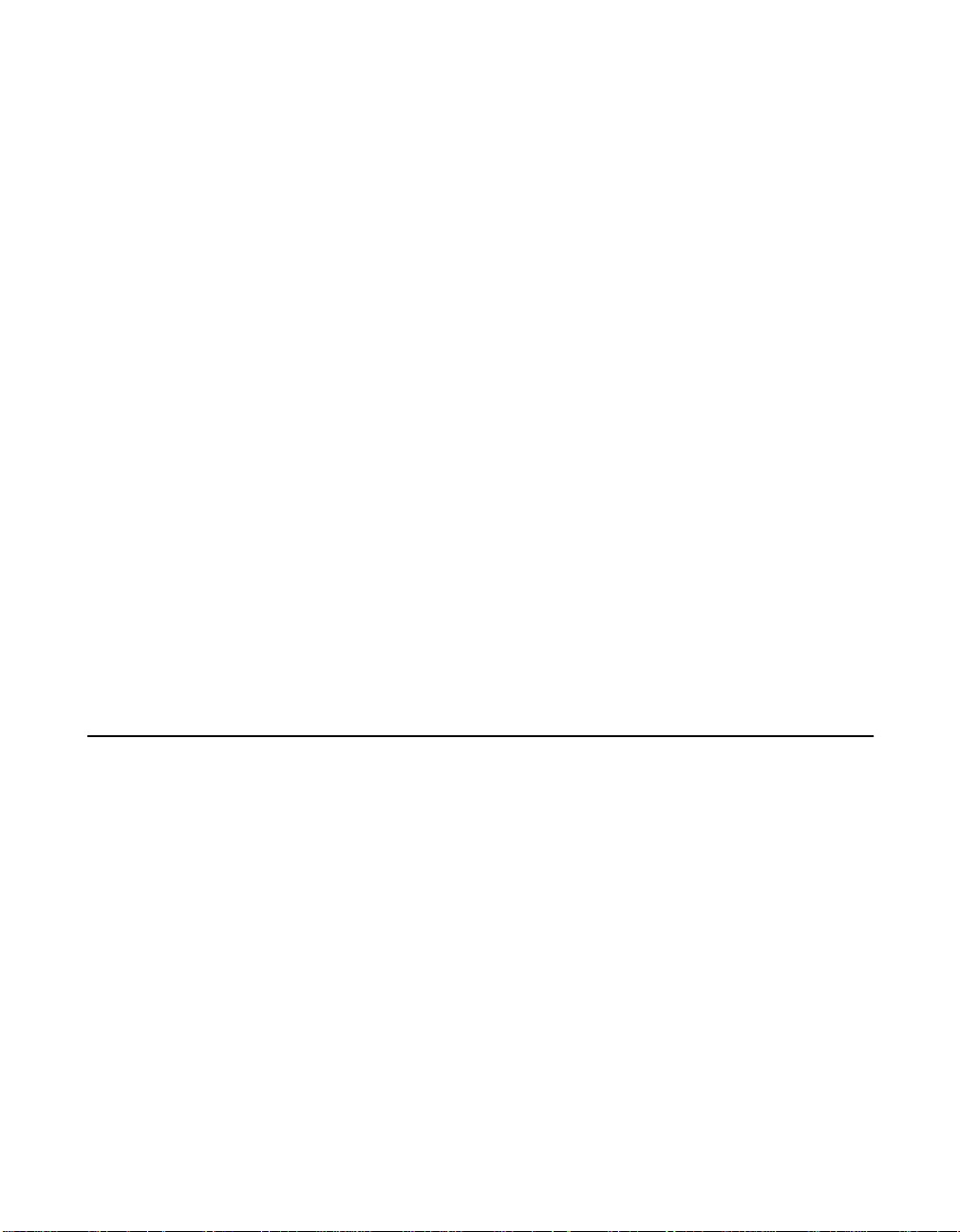

Paced Transfers – The initiator and target must establish a paced

transfer agreement that specifies the REQ/ACK offset and the transfer

period before using this feature. Devices can only perform paced

transfers during Ultra320 SCSI DT data phases. In paced transfers, the

device sourcing the data drives the REQ/ACK signal as a free running

clock. The transition of the REQ/ACK signal, either the assertion or the

negation, clocks data across the bus. For successful completion of a

paced transfer, the number of ACK transitions must equal the number of

REQ transitions, and both the REQ and ACK lines must be negated.

The P1 line indicates valid data in 4-byte quantities by using its phase.

The transmitting device indicates the start of valid data state by holding

the state of the P1 line for the first two data transfer periods. Beginning

on the third data transfer period, the transmitting device continues the

valid data state by toggling the state of the P1 line every two data

transfer periods for as long as the data is valid. The transmitting device

must toggle the P1 line coincident with the REQ/ACK assertion. This

method provides a minimum valid data period of two transfer periods.

To pause the data transfer, the transmitting device reverses the phase of

P1 by withholding the next transition of P1 at the start of the first two

invalid data transfer periods. Beginning with the third invalid data transfer

period, the transmitting device toggles the P1 line every two invalid data

transfer periods until it sends valid data. The transmitting device returns

to the valid data state by reversing the phase of the P1 line. The invalid

data state must experience at least one P1 transition before returning to

2-4 Functional Descriptions

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 23

the valid data state. This method provides a minimum invalid data period

of four transfer periods.

Figure 2.2 provides a waveform diagram of paced data transfers and

illustrates the use of the P1 line.

Figure 2.2 Paced Transfer Example

Invalid DataValid Data Valid Data Invalid Data

REQ

ACK

P1

DATA

The LSI53C320 uses the PPR negotiation that the SPI-4 draft standard

describes to establish a paced transfer agreement with the initiator on

the source bus and the target on the load bus.

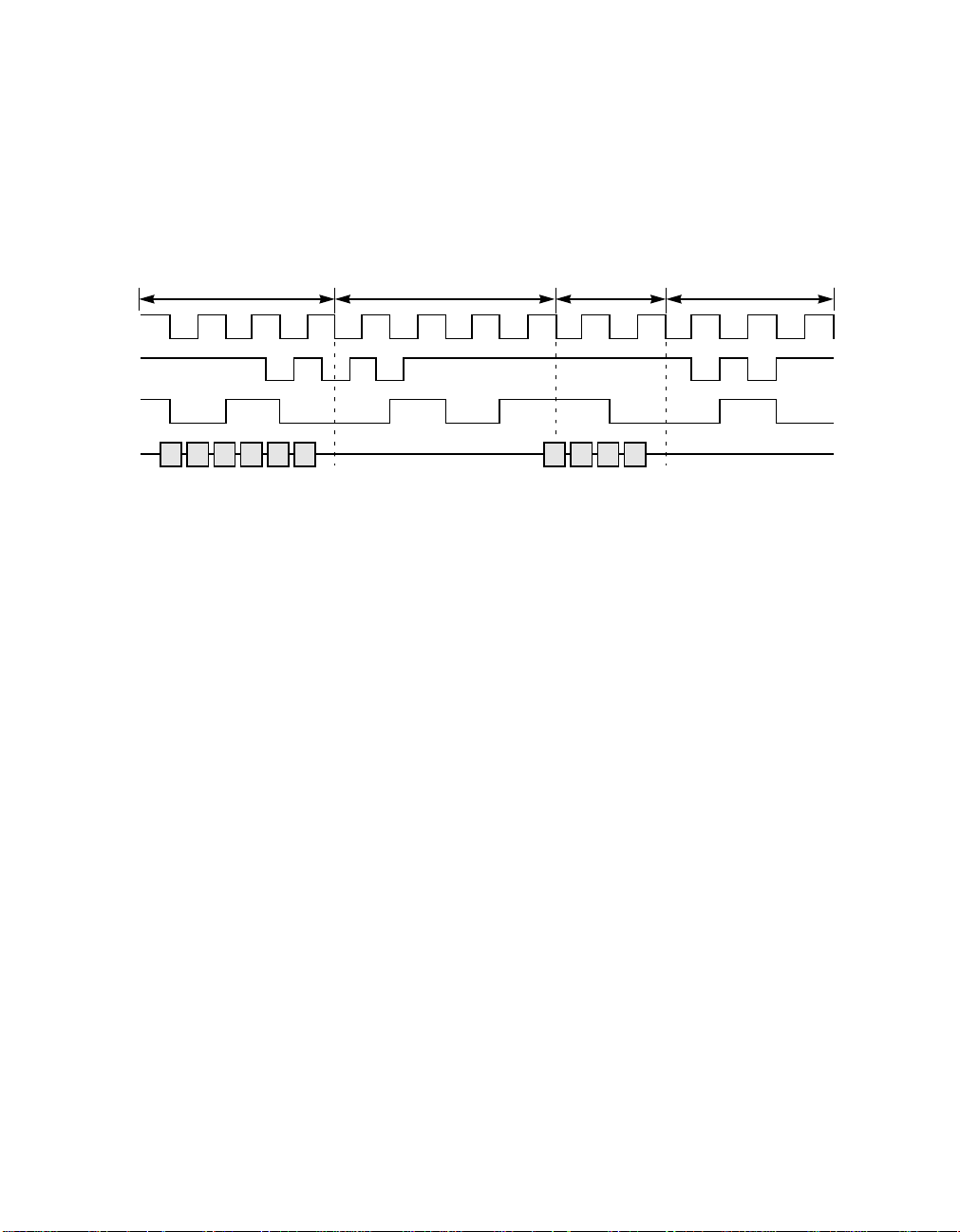

Precompensation – When transmitting in the Ultra320 SCSI mode, the

LSI53C320 can use precompensation to adjust the strength of the REQ,

ACK, parity, and data signals. When a signal transitions to HIGH or LOW,

the LSI53C320 drives the signal at the signal drive strength for the first

data transfer period, and then lowers the signal drive strength on the

second data transfer period if the signal remains in the same state. The

LSI53C320 maintains the lower signal drive strength until the signal

again transitions HIGH or LOW. Figure 2.3 illustrates the drivers

performance with precompensation enabled and disabled.

Ultra320 SCSI Functional Description 2-5

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 24

Figure 2.3 Example of Precompensation

a. Drivers with Precompensation Disabled

Normal Drive Strength

b. Drivers with Precompensation Enabled

Normal Drive Strength

2.2.1.3 Packetized Transfers

Packetized transfers are also referred to as information unit transfers.

They reduce overhead on the SCSI bus by merging several of the SCSI

bus phases.

2.2.1.4 Skew Compensation

The LSI53C320 provides a method to account for and control system

skew between the clock and data signals. Skew compensation is only

available when the device operates in the Ultra320 SCSI mode. The

initiator-target pair uses the training sequences in the SPI-4 draft

standard to determine the skew compensation. The LSI53C320 passes

the training patterns between the initiator and target. The LSI53C320

stores the adjustment parameters and recalls them on subsequent

connections with the given device pair (nexus).

Reduced Drive Strength

2-6 Functional Descriptions

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 25

2.2.1.5 Cyclic Redundancy Check (CRC)

Ultra320 SCSI and Ultra160 SCSI devices employ CRC as an error

detection code during the DT Data phases. The LSI53C320 handles

CRC as another data phase with the appropriate specific timing values.

2.2.1.6 LSI53C320 Requirements for Synchronous SCSI Negotiation

The LSI53C320 builds a table of information regarding devices on the

bus in on-chip RAM. The LSI53C320 reads the PPR, Synchronous Data

Transfer Request (SDTR), and Wide Data Transfer Request (WDTR)

information for each device from the MSG bytes during negotiation.

For devices to communicate accurately through the LSI53C320 at

Ultra320 SCSI rates, it is necessary for a complete asynchronous

negotiation to occur between the initiator and target(s) prior to any

synchronous data transfer. The LSI53C320 defaults to Ultra SCSI rates

when a valid negotiation between the initiator and target does not occur.

2.2.2 SCSI Bus Interface

This section describes the SCSI bus interfaces on the LSI53C320.

2.2.2.1 SCSI Bus Modes

To support greater device connectivity and longer SCSI cables, the

LSI53C320 features LVDlink technology, the LSI Logic implementation of

multimode LVD SCSI. The LVDlink transceivers can operate in the LVD

or SE modes.

The voltage levels on the A_DIFFSENS and B_DIFFSENS signals

determine the SCSI bus mode. The LSI53C320 DIFFSENS receivers

detect the voltage level on the A Side or B Side DIFFSENS lines

independently. The LSI53C320 does not change the present signal mode

until it continuously senses a new DIFFSENS voltage level for 100 ms.

Table 2.1 shows the voltages on the DIFFSENS lines.

Ultra320 SCSI Functional Description 2-7

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 26

Table 2.1 DIFFSENS Voltage Levels

Mode Voltage

SE −0.35 to +0.5

LVD +0.7 to +1.9

When the DIFFSENS voltage selects SE mode, the LSI53C230 internally

ties the plus signals to ground and the minus SCSI signals become the

SE input/outputs. When the DIFFSENS voltage selects LVD mode, the

plus and minus signals are the differential signal pairs.

Any dynamic mode change (SE-to-LVD or LVD-to-SE) on a bus segment

is a significant event, and the initiator must determine if the new bus

mode meets the requirements for the bus segment. The LSI53C320

supports dynamic transmission mode changes by notifying the initiator(s)

of changes in the transmission mode with a SCSI bus RESET/. The

DIFFSENS line detects a valid mode switch on a bus segment. After the

DIFFSENS state is continuously present for 100 ms, the LSI53C320

generates a SCSI reset on the bus opposite the bus on which the

transmission mode change occurred. This reset informs initiators residing

on the opposite bus segment of the change in the transmission mode.

The initiator(s) then renegotiates synchronous transfer rates with each

device on that segment.

If the LSI53C320 detects the HVD mode on a SCSI bus segment, the

LSI53C320 3-states its outputs.

2.2.2.2 SCSI Termination

The terminator networks pull signals to an inactive voltage level and

match the impedance seen at the end of the cable with the characteristic

impedance of the cable. Install terminators at the ends of each SCSI

segment, and only at the ends; all SCSI buses must have exactly two

terminators.

2.2.3 Maximum Cable Lengths

The electrical length of a bus is the time required for round-trip signal

propagation between bus ends. This section discusses the maximum

electrical and physical cable lengths when cascading LSI53C320

2-8 Functional Descriptions

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 27

expanders. For Ultra320 SCSI environments, the information in this

section takes precedence over the information in Section 1.2,

“Applications.”

2.2.3.1 Maximum Electrical Cable Length

The SCSI Parallel Interface-4 (SPI-4) standard states that the electrical

length between the hosts arbitrating on different ends of a SCSI bus

must not exceed 800 nanoseconds (ns), when operating at Ultra320

SCSI data transfer rates. Due to this constraint, LSI Logic specifies that

a maximum of four expanders can be cascaded on a SCSI bus.

There are additional electrical length constraints imposed by the SPI-4

standard. When ending a paced transfer from DT

the target must wait 800 ns before issuing a REQ. The SPI-4 standards

allows 200 ns for the host to recognize the phase change and stop the

free running ACK. This requirement reduces the electrical length of the

bus to 600 ns.

Because the expander resides in the middle of the bus and retimes data

to the active free running clock, the expander must switch its internal

logic from ACK to REQ. The expander performs this switch 600 ns after

detecting the phase change. Activity on the ACK or REQ line during this

period adversely affects the expander. This reduces the electrical length

of the bus to 400 ns.

to any other phase,

OUT

Figure 2.4 illustrates the bus timing. Assuming a 400 ns electrical length

and that the host uses the full 200 ns time allotment, the last free running

ACK from the host returns to the expander at the 600 ns mark.

Ultra320 SCSI Functional Description 2-9

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 28

Figure 2.4 Electrical Cable Lengths at Ultra320 SCSI Speeds

800 ns from the phase change to the first REQ of the new phase

600 ns: Requirement for expander

200 ns:

Phase change

delay to the host

200 ns:

Host delay to stop

free-running ACKS

200 ns:

Delay until the last ACK

arrives at the LSI53C320

2.2.3.2 Maximum Physical Cable Length

Table 2.2 provides information concerning the maximum physical cable

length when operating the LSI53C320 at Ultra320 SCSI transfer rates.

Table 2.2 Total Cable Length for Ultra320 SCSI Using the LSI53C320

Number of Cascaded

Expanders

1 37

2 29

3 25

4 21

Maximum Physical Cable

Length in Meters (m)

Comments

LSI Logic recommends limiting the 25 m

point-to-point bus cable length to 20 m and

the fully-loaded bus cable length to 12 m.

The SPI-4 standard allows a maximum point-to-point physical cable

length of 25 m and a maximum fully loaded physical cable length 12 m.

This limits the total physical cable length to 37 m. To allow for board

capacitance and signal propagation through the expander, LSI Logic

recommends limiting the point-to-point physical cable length to 20 m.

This limits the total physical cable length to 32 m.

Table 2.2 provides the total maximum cable length depending on the

number of expanders that are cascaded on the bus. As long as the total

cable length between expanders, hosts, and drives does not exceed

these limits, the 400 ns electrical cable length requirement will be met.

2-10 Functional Descriptions

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 29

In designs that use a back plane, designers must additionally consider

the signal propagation velocity through the back plane to ensure that the

400 ns electrical cable length requirement is met.

2.3 SCSI Signal Processing

Figure 3.1 shows the LSI53C320 signal grouping. The following sections

describes the signal processing for the LSI53C320 SCSI signals. Refer

to Section Chapter 3, “Signal Description,” and Section Chapter 4,

“Specifications,” for more information on individual signals.

2.3.1 Data and Data Parity Signals

The LSI53C320 passes the data and parity signals from the source bus

to the load bus and provides the necessary edge shifting to guarantee

the skew budget for the load bus. Either side of the LSI53C320 can act

as the source bus or the load bus. The side that the LSI53C320 receives

signals on is the source bus. The side that the LSI53C320 drives signals

on is the load bus. These steps describe the LSI53C320 data

processing:

1. The receiver logic accepts the data. Once the clock signal

(REQ/ACK) is received, the LSI53C320 gates the data from the

receiver latch.

2. The LSI53C320 holds the asserting edge for a specified time to

3. The LSI53C320 samples the bus using a latch, which provides a

4. In the last stage, the LSI53C320 3-states the outputs.

5. To assure that the LSI53C320 does not sample its own signals, the

2.3.2 Select Signal

A_SSEL and B_SSEL perform bus arbitration and selection. When a bus

asserts the SSEL signal, the LSI53C320 propagates the signal assertion

SCSI Signal Processing 2-11

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

prevent signal bounce. The input signal controls the duration of the

hold time.

stable data window for the load bus.

LSI53C320 delays sampling until a specified time after the last signal

deassertion.

Page 30

to the other bus. When both buses assert SSEL simultaneously, A_SSEL

takes precedence over B_SSEL. The SSEL output has a pull-down

control for an open collector driver. The following steps describe the

select control signal process:

1. If the LSI53C320 is driving the SSEL signal, the LSI53C320 blocks

2. The LSI53C320 filters the leading edge of the SSEL signal to ensure

3. To assure that the LSI53C320 does not sample its own signals, the

2.3.3 Busy Signal

The controller propagates the A_SBSY and B_SBSY signals from the

source bus to the load bus. The following steps describe the busy control

signal process:

1. The LSI53C320 filters the leading edge of the SBSY signal. The

the SSEL input signal on the other bus.

that the output does not switch for a specified time after the leading

edge. The duration of the input signal determines the duration of the

output signal.

LSI53C320 delays sampling until a specified time after the last signal

deassertion.

LSI53C320 holds the assertion edge for a specified time to prevent

signal bounce. The duration of the input signal determines the

duration of the output signal.

2. To assure that the LSI53C320 does not sample its own signals, the

LSI53C320 delays sampling until a specified time after the last signal

deassertion.

2.3.4 Reset Signal

The controller passes the A_SRST and B_SRST signals from the source

to the load bus. This output has pull-down control for an open collector

driver. The following steps describe the processing of the reset signals:

1. If the LSI53C320 is driving the SRST signal, the LSI53C320 blocks

the SRST input signal on the other bus.

2. The LSI53C320 filters the leading edge of the signal to ensure that

the output does not switch during a specified time after the leading

2-12 Functional Descriptions

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 31

edge. The duration of the input signal determines the duration of the

output signal.

3. To assure that the LSI53C320 does not sample its own signals, the

LSI53C320 delays sampling until a specified time after the last signal

deassertion.

2.3.5 Request and Acknowledge Signals

The SREQ and SACK signal paths contain controls that guarantee

minimum pulse widths, filter edges, and perform signal retiming.

When performing DT clocking, the LSI53C320 filters both the leading and

trailing signal edges. When performing ST clocking, the LSI53C320 filters

only the leading signal edge. The SREQ and SACK paths are from the

A Side to the B Side and from the B Side to the A Side. The following

steps describe the SREQ and SACK signal processing:

1. The LSI53C320 senses the asserted input signal and forwards it to

the next stage if the direction control permits. The LSI53C320 state

machine develops the direction controls from the sequence of the

bus control signals.

2. The LSI53C320 filters the leading edge of the input and output signal

to ensure that the signal does not switch during the specified hold

time after the leading edge. The duration of the input signal

determines the duration of the output signal after the hold time. The

LSI53C320 guarantees a minimum pulse width.

3. The LSI53C320 passes the signal to the load bus if the signal is not

a data clock. If SREQ or SACK is a data clock, it delays the leading

edge to improve data output setup times. The duration of the input

signal determines the duration of the output signal.

4. The LSI53C320 filters the trailing edge of the signal to prevent signal

bounce after the signal deasserts. The LSI53C320 deasserts the

output signal at the first deasserted edge of the input signal.

5. In the last stage, the LSI53C320 3-states the outputs.

6. To assure that the LSI53C320 does not sample its own signals, the

LSI53C320 delays sampling until a specified time after the last signal

deassertion.

SCSI Signal Processing 2-13

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 32

2.3.6 Control/Data, Input/Output, Message, and Attention Signals

The following steps describe the processing of these signals:

1. If the LSI53C320 is driving the signal, the LSI53C320 blocks the

input signal on the other bus.

2. The LSI53C320 filters the leading edge of the signal to ensure that

the output does not switch for a specified time after the leading edge.

The duration of the input signal determines the duration of the output

signal.

3. In the last stage, the LSI53C320 3-states the outputs.

4. To assure that the LSI53C320 does not sample its own signals, the

LSI53C320 delays sampling until a specified time after the last signal

deassertion.

2.4 Internal Control Descriptions

This section provides information about self-calibration, delay line

structures, and busy filters.

2.4.1 Self-Calibration

The LSI53C320 triggers self-calibration to adjust for variations in

temperature, process, and voltage every second during bus free states.

2.4.2 Delay Line Structures

The signal and control interfaces for bus to bus transfers require fixed

delay functions. The LSI53C320 uses programmable delay lines to

implement the delay functions. Multiplexers select the incremental points

in the delay chain. The LSI53C320 self-calibration manages the effects

of temperature and voltage changes.

2.4.2.1 Data Path

The data path through the LSI53C320 includes two levels of latches. The

first latch in the data path is located in the receiver and the REQ/ACK

input clock and generates a hold. This latch holds the received data to

capture incoming data that might have minimal setup and hold times. A

2-14 Functional Descriptions

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 33

second latch is located on the transmitter side of the LSI53C320 and

holds the data to enable optimal signal transmission on the isolated bus.

This latch provides a regenerated clock signal and the maximum setup

and hold times.

The data path also provides a timer for each data bit. This timer protects

against reception from a target bus for a nominal 30 ns after the driver

deasserts.

2.4.2.2 REQ/ACK Retiming

The LSI53C320 edge filters the REQ/ACK input clock signals. The chip

also stretches these signals to their minimum timing values to avoid

glitches. In double transition clocking, the chip filters both the leading and

trailing edges. In single transition clocking, the chip filters only the

leading edge. The filters remove noise within the initial signal transition.

The current transmission speed determines the filter time values.

2.4.3 Busy Filters

The busy control signal passes from source to load bus. The current

state of the SCSI bus determines the filtering. This filter provides a

synchronized leading edge signal that is not true until the input signal

stabilizes. The trailing edge occurs within several nanoseconds of the

input deasserting. When the BSY signal asserts before and after the SEL

signal, the filter is on.

2.5 Serial EEPROM Connection

The serial EEPROM connects to the LSI53C320 through a 2-wire serial

interface. SP_CLK (Ball C7) on the LSI53C320 connects to the serial

EEPROM clock line and SP_DAT (Ball B6) on the LSI53C320 connects

to the serial EEPROM data line. These two lines are pulled HIGH

through resistors.

The LSI53C320 produces the 50 kHz SP_CLK for downloading data from

the serial EEPROM. The LSI53C320 3-states the SP_CLK and SP_DAT

lines during chip reset and after a successful download. The LSI53C320

continues to drive SP_CLK LOW if the download is unsuccessful, which

enables detection of download failure by monitoring this signal.

Serial EEPROM Connection 2-15

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 34

LSI Logic recommends using a 3.3 V, 2 Kbyte (256 x 8 bit) serial

EEPROM that can accept a 50 KHz clock. Figure 2.5 provides a sample

layout.

Figure 2.5 Serial EEPROM Connection

3.3 V

1.0 µF

10%

3.3 V

4.75 KΩ

10%

VCC

A2

A1

A0

WP

Serial EEPROM

(24C16)

3.3 V 3.3 V

CLK

DAT

4.75 KΩ

10%

4.75 KΩ

10%

C7

B6

LSI53C320

S_CLK

S_DATA

2-16 Functional Descriptions

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 35

Chapter 3

Signal Description

This chapter provides the signal descriptions and electrical

characteristics for the LSI53C320. It includes these topics:

• Section 3.1, “Signal Grouping,” page 3-1

• Section 3.2, “SCSI Interface Signals,” page 3-3

• Section 3.3, “Interface Control Signals,” page 3-5

• Section 3.4, “Serial EEPROM Signals,” page 3-6

• Section 3.5, “Power and Ground Signals,” page 3-6

• Section 3.6, “Test Signals,” page 3-7

• Section 3.7, “Signal Layout Considerations,” page 3-8

3.1 Signal Grouping

Figure 3.1 illustrates the LSI53C320 signal grouping.

LSI53C320 Ultra320 SCSI Bus Expander Technical Manual 3-1

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 36

Figure 3.1 LSI53C320 Functional Signal Grouping

A Side

LVD or SE

SCSI Interface

Control

Signals

A_SSEL+

A_SSELA_SBSY+

A_SBSYA_SRST+

A_SRSTA_SREQ+

A_SREQA_SACK+

A_SACKA_SMSG+

A_SMSGA_SCD+

A_SCDA_SIO+

A_SIOA_SATN+

A_SATNA_SDP[1:0]+

A_SDP[1:0]A_SD[15:0]+

A_SD[15:0]-

A_DIFFSENS

A_RBIAS

CHIP_RESET/

WS_ENABLE/

XFER_ACTIVE

CLOCK

BSY_LED

LSI53C320

B_SSEL+

B_SSEL-

B_SBSY+

B_SBSY-

B_SRST+

B_SRST-

B_SREQ+

B_SREQ-

B_SACK+

B_SACK-

B_SMSG+

B_SMSG-

B_SCD+

B_SCD-

B_SIO+

B_SIO-

B_SATN+

B_SATN-

B_SDP[1:0]+

B_SDP[1:0]-

B_SD[15:0]+

B_SD[15:0]-

B_DIFFSENS

B_RBIAS

S_SLC

S_DATA

B Side

LVD or SE

SCSI Interface

Serial

EEPROM

Signals

3-2 Signal Description

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 37

3.2 SCSI Interface Signals

Table 3.1 describes the SCSI interface signals for the A Side of the

LSI53C320.

Table 3.1 SCSI A Side Interface Signals

Signal Name BGA Pin Type Description

A_SSEL+

A_SSEL-

A_SBSY+

A_SBSY-

A_SRST+

A_SRST-

A_SREQ+

A_SREQ-

A_SACK+

A_SACK-

A_SMSG+

A_SMSG-

A_SCD+

A_SCD-

A_SIO+

A_SIO-

A_SATN+

A_SATN-

A_SDP[1:0]+

A_SDP[1:0]-

A_SD[15:0]+

G1

H3

K3

K1

J3

J2

F2

F1

J1

K2

H2

H1

G3

G2

E1

F3

L2

L3

V2, M1

W1, M2

W3, W4, Y3, V5, B1, D2, C1, E3,

N1, N3, P2, P3, T1, T2, T3, V1,

I/O A Side Select signal.

I/O A Side Busy signal.

I/O A Side Reset signal.

I/O A Side Request signal.

I/O A Side Acknowledge signal.

I/O A Side Message signal.

I/O A Side Control and Data signal.

I/O A Side Input and Output signal.

I/O A Side Attention signal.

I/O A Side Data Parity signals.

I/O A Side Data signals.

A_SD[15:0]-

A_DIFFSENS B3 I A Side Differential Sense signal.

A_RBIAS M3 RBIAS A Side current control. Attach a

Y2, V4, Y4, W5, C2, D3, D1, E2,

N2, P1, R1, R2, R3, U1, U2, U3

10 kΩ pull-up resistor on RBIAS

to provide the correct bias level.

SCSI Interface Signals 3-3

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 38

Table 3.2 describes the SCSI interface signals for the B Side of the

LSI53C320.

Table 3.2 SCSI B Side Interface Signals

Signal Name Pin Type Description

B_SSEL+

B_SSEL-

B_SBSY+

B_SBSY-

B_SRST+

B_SRST-

B_SREQ+

B_SREQ-

B_SACK+

B_SACK-

B_SMSG+

B_SMSG-

B_SCD+

B_SCD-

B_SIO+

B_SIO-

B_SATN+

B_SATN-

B_SDP[1:0]+

B_SDP[1:0]−

B_SD[15:0]+,

H19

H18

F18

E19

F20

G18

J20

J19

F19

E20

G20

G19

J18

H20

K19

K18

D20

E18

A14, D19

C13, C20

B13, C12, A12, C11, N19, M18,

M20, L18, C19, A19, B17, A18,

C16, A16, B15, C14

I/O B Side Select signal.

I/O B Side Busy signal.

I/O B Side Reset signal.

I/O B Side Request signal.

I/O B Side Acknowledge signal.

I/O B Side Message signal.

I/O B Side Control and Data signal.

I/O B Side Input and Output signal.

I/O B Side Attention signal.

I/O B Side Data Parity signals.

I/O B Side Data signals.

B_SD[15:0]−

B_DIFFSENS B2 I B Side Differential Sense signal.

B_RBIAS D18 RBIAS LVD current control. Attach a 10

3-4 Signal Description

A13, B12, B11, A11, N20, M19,

L19, L20, B20, B18, C17, A17,

B16, C15, A15, B14

kΩ pull-up resistor on RBIAS to

provide the correct bias level.

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 39

3.3 Interface Control Signals

Table 3.3 describes the interface control signals for the LSI53C320. The

LSI53C320 requires an external POR, which is implemented using the

CHIP_RESET/ signal. Figure A.1 provides an example external POR

circuit.

Table 3.3 Chip Interface Control Signals

Signal Name Pin Type Description

CHIP_RESET/ C10 I The active LOW Master Reset signal provides a general purpose

WS_ENABLE/ A7 I TheActive LOW Warm Swap Enable signal enables and disables

XFER_ACTIVE A8 O The Transfer Active signal enables and disables SCSI transfers

CLOCK A9 I CLOCK provides the 40 MHz oscillator input to the LSI53C320. It

BSY_LED B9 O The Busy LED signal provides an 8 mA SCSI activity LED output.

chip reset that forces the internal elements of the LSI53C320 to a

known state. Asserting this signal places the LSI53C320 state

machine in an idle state and places all controls in a passive state.

The minimum CHIP_RESET/ asserted pulse width is 100 ns.

SCSI transfers through the LSI53C320. The WS_ENABLE/ input

removes the chip from an active bus without disturbing the current

SCSI transaction. When Warm Swap Enable asserts, the

LSI53C320 3-states the SCSI signals after it detects the next bus

free state. The LSI53C320 no longer passes on signals until the

WS_ENABLE/ pin deasserts and both SCSI buses enter the Bus

Free state.

through the LSI53C320. The LSI53C320 asserts this signal when

the chip is active to indicate that the chip completed its internal

testing, the SCSI bus has entered a bus free state, or that SCSI

traffic can now pass from one side of the chip to the other side of

the chip. The LSI53C320 deasserts this signal to detect a Bus

Free state due to the WS_ENABLE/ signal being LOW.

Deasserting this signal disables transfers through the device.

is the clock source for the protocol control state machines and

timing generation logic. The bus signal transfer paths do not use

this clock.

The LSI53C320 asserts this signal to indicate SCSI bus activity.

Interface Control Signals 3-5

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 40

3.4 Serial EEPROM Signals

Table 3.4 describes the serial EEPROM signals for the LSI53C320.

Table 3.4 Serial EEPROM Signals

Signal Name Pin Type Description

S_CLK C7 O The LSI53C320 uses the serial EEPROM clock signal to provide

the 50 kHz clock for downloading the serial EEPROM data.

S_DATA B6 I/O The LSI53C320 uses the serial EEPROM data signal to

download data from the serial EEPROM.

3.5 Power and Ground Signals

Table 3.5 describes the power and ground signals for the LSI53C320.

Table 3.5 Power and Ground Pins

Signal Name Pin Type Description

SCSI

CORE

3, 4

IO

SCSI

CORE

IO

1

D6, D11, D15, F4, F17, K4, L17, R4, R17,

U6, U10, U15

2

A2, B19, D10, K17, L4, U11, W2, W19 I Power supplies to the CORE

I Power supplies to the SCSI bus

I/O pins.

logic.

C8 I Power supplies to the I/O logic.

A1, D4, D8, D13, D17, H4, H17, J9, J10,

I Ground ring.

J11, J12, K9, K10, K11, K12, L9, L10, L11,

L12, M9, M10, M11, M12, N4, N17, U4,

U8, U13, U17

4

A20, B10, C3, K20, L1, Y1, Y11, Y20 I Ground ring.

B7 I Ground ring.

VDD

VDD

VDD

VSS

VSS

VSS

3-6 Signal Description

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 41

Table 3.5 Power and Ground Pins (Cont.)

Signal Name Pin Type Description

NC A3, A5, A6, A10, B8, C4, C6, C9, C18, D5,

D7, D9, D12, D14, D16, E4, E17, G4,

G17, J4, J17, M4, M17, N18, P4, P17,

P18, P19, P20, R18, R19, R20, T4, T17,

T18, T19, T20, U5, U7, U9, U12, U14,

U16, U18, U19, U20, V3, V6, V7, V8, V9,

V10, V11, V12, V13, V14, V15, V16, V17,

V18, V19, V20, W6, W7, W8, W9, W10,

W11, W12, W13, W14, W15, W16, W17,

W18, W20, Y5, Y6, Y7, Y8, Y9, Y10, Y12,

Y13, Y14, Y15, Y16, Y17, Y18, Y19

1. VDD

2. VDD

3. VDD

4. The VDD

must be supplied with 3.3 V.

SCSI

pins must be supplied 1.8 V.

CORE

must be supplied with 3.3 V.

IO

pin must always power down before the VDD

IO

3.6 Test Signals

Table 3.6 lists the LSI53C320 test signals and their associated ball

number. These test signals are for use by LSI Logic only.

Note: Connect the tests signals to either test point or a header for

debugging purposes.

N/A No Connections.

pin.

CORE

Table 3.6 Test Signals for LSI Logic Only

Signal Ball

TEST_3 A4

TEST_4 C5

TEST_5 B5

TEST_6 B4

Test Signals 3-7

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 42

3.7 Signal Layout Considerations

The pinout of the LSI53C320 package ensures that each signal requires

the shortest possible trace length. Use active termination for the bus

connections to the LSI53C320. When choosing an active terminator, set

the load capacitance of the terminator as low as possible.

LSI Logic recommends the use of strip line. Strip line allows tighter

connector placement, which reduces the noise effects from both internal

and external sources. On long trace runs, such as those in a backplane

environment, snaking of traces to equalize their length is appropriate.

Place the decoupling capacitors as close as possible to the via attached

to each corresponding voltage plane.

3-8 Signal Description

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 43

Chapter 4

Specifications

This chapter provides the electrical and environmental specifications for

the LSI53C320 and consists of these topics:

• Section 4.1, “Electrical Characteristics,” page 4-1

• Section 4.2, “Chip Drawings,” page 4-8

4.1 Electrical Characteristics

This section provides the electrical characteristics of the LSI53C320.

4.1.1 DC Characteristics

Table 4.1 through 4.10 give the current and voltage specifications.

Figure 4.1 and Figure 4.2 illustrate the driver and receiver schematics.

Table 4.1 Absolute Maximum Stress Ratings

Symbol Parameter Min Max Unit Test Conditions

T

STG

V

DD-Core

V

DD-IO

V

IN

I

LP

ESD Electrostatic Discharge – 2000 V MIL-STD 883C,

1. Stresses beyond those listed can damage the device. These are stress ratings; functional operation

at or beyond these values is not implied.

Storage Temperature –40 125 ˚C –

Supply Voltage –0.3 2.2 V –

IO Supply Voltage −0.3 3.9 V –

Input Voltage −0.5 VDD+ 0.5 V –

Latch-up current ±150 – mA −2V<VPIN<8V

LSI53C320 Ultra320 SCSI Bus Expander Technical Manual 4-1

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

1

Method 3015.7

Page 44

Table 4.2 Operating Conditions

1

Symbol Parameter Min Nominal Max Unit Test Conditions

V

DD-Core

V

DD-IO

I

DD-Core

I

DD-IO

2

I

LP

T

j

T

A

θ

JA

Supply voltage 1.71 1.80 1.89 V –

I/O Supply voltage 3.13 3.30 3.47

Core and Analog Supply

– 275 360 mA –

Current (Dynamic)

I/O Supply Current

(Dynamic)

– 450 590 mA RBIAS = 10 kΩ 1%

VDD= 3.3 V

Latch-up Current 150 – – mA –

Junction Temperature – 60 115 ˚C –

Operating free air 0 – 70 ˚C –

Thermal resistance

– – 16.4 ˚C/W –

(junction to ambient air)

1. Conditions that exceed the operating limits can cause the device to function incorrectly.

2. SCSI pins only.

Table 4.3 LVD Driver SCSI Signals—SD[15:0]±, SDP[1:0]±, SCD±, SIO±, SMSG±,

SREQ±,SACK±, SBSY±,SATN±, SSEL±, SRST±

1

Symbol Parameter Min Max Units Test Conditions

I

+ Source (+) current 9.6 14.4 mA Asserted state

O

I

− Sink (−) current −9.6 −14.4 mA Asserted state

O

I

+ Source (+) current −6.4 −9.6 mA Negated state

O

I

− Sink (−) current 6.4 9.6 mA Negated state

O

1. V

I

CM

OZ

3-state leakage −20 20 µA–

= 0.7 − 1.8 V, R

bias

=10kΩ.

4-2 Specifications

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 45

Figure 4.1 LVD Driver

R

L

+

−

IO+

IO−

2

R

L

2

+

V

CM

−

Table 4.4 LVD Receiver SCSI Signals—SD[15:0]±, SDP[1:0]±,

SCD±, SIO±, SMSG±, SREQ±,SACK±, SBSY±,SATN±,

SSEL±, SRST±

1

Symbol Parameter Min Max Units

V

LVD receiver voltage asserting 60 – mV –

I

V

LVD receiver voltage negating – −60 mV –

I

1. VCM= 0.7 − 1.8 V.

Figure 4.2 LVD Receiver

+

V

+

V

CM

−

I

2

−

+

V

I

2

−

+

−

Test

Conditions

Electrical Characteristics 4-3

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 46

Table 4.5 Bidirectional SCSI Signals—SD[15:0]/, SDP[1:0]/,

SREQ/, SACK/, SD[15:0]±, SDP[1:0]±, SREQ±,SACK±

Symbol Parameter Min Max Unit

V

V

V

OH

V

OL

I

OZ

Input high voltage 1.9 V

IH

Input low voltage V

IL

1

Output high voltage 2.0 V

Output low voltage V

DD

1.0 V –

SS

DD

0.5 V 48 mA

SS

V–

VIOH= 7.0 mA

3-state leakage −10 10 µA–

Conditions

1. TolerANT active negation enabled.

Table 4.6 Bidirectional SCSI Control Signals—SCD/, SIO/, SMSG/,

SBSY/, SATN/, SSEL/, SRST/, SCD±, SIO±, SMSG±,

SBSY±,SATN±, SSEL±, SRST±

Symbol Parameter Min Max Unit Test Conditions

Test

V

V

V

I

OZ

Input high voltage 1.9 V

IH

Input low voltage V

IL

Output low voltage V

OL

DD

1.0 V –

SS

0.5 V 48 mA

SS

V–

3-state leakage −10 10 µA–

Table 4.7 DIFFSENS SCSI Signal

Symbol Parameter Min Max Unit

V

V

I

4-4 Specifications

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

LVD sense voltage 0.7 1.9 V –

S

Single-ended sense voltage VSS− 0.3 0.5 V –

IL

3-state leakage −10 10 µA–

OZ

Test

Conditions

Page 47

Table 4.8 Input Capacitance

Symbol Parameter Min Max Unit

C

Input capacitance of input pads – 7 pF –

I

C

Input capacitance of I/O pads – 10 pF –

IO

Conditions

Table 4.9 Input Control Signals—CLOCK, CHIP_RESET/,

WS_ENABLE/

Test

Symbol Parameter Min Max Unit Test Conditions

V

V

I

Input high voltage 2.0 V

IH

Input low voltage V

IL

3-state leakage −10 10 µA–

OZ

SS

DD

0.8 V –

V–

Table 4.10 Output Control Signals—BSY_LED, XFER_ACTIVE

Symbol Parameter Min Max Unit Test Conditions

V

V

I

OZ

Output high voltage 2.4 V

OH

Output low voltage V

OL

0.4 V 8 mA

SS

V8mA

DD

3-state leakage −10 10 µA–

Electrical Characteristics 4-5

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 48

4.1.2 TolerANT Technology Electrical Characteristics

Table 4.11 provides the minimum and maximum values in units for the

TolerANT Technology electrical characteristics.

Table 4.11 TolerANT Technology Electrical Characteristics

Symbol Parameter Min Max Units Test Conditions

1

V

OH

V

OL

V

IH

V

IL

V

IK

V

TH

V

TL

V

TH-VTL

I

OH

I

OL

I

OSH

I

OSL

I

LH

I

LL

R

I

C

P

2

t

R

t

F

dV

H

Output high voltage 2.0 VDD+ 0.3 V IOH=7mA

Output low voltage V

SS

0.5 V IOL=48mA

Input high voltage 2.0 VDD+ 0.3 V –

Input low voltage VSS− 0.3 0.8 V Referenced to V

Input clamp voltage −0.66 −0.77 V VDD= 4.75;

I

= −20 mA

I

Threshold, HIGH to LOW 1.0 1.2 V –

Threshold, LOW to HIGH 1.4 1.6 V –

Hysteresis 300 500 mV –

2

Output high current 2.5 24 mA VOH= 2.5 V

Output low current 100 200 mA VOL= 0.5 V

2

Short-circuit output high current – 625 mA Output driving low, pin

shorted to V

DD

Short-circuit output low current – 95 mA Output driving high, pin

shorted to V

Input high leakage – 20 µA −0.5<VDD<5.25

V

PIN

= 2.7 V

SS

3

Input low leakage – −20 µA −0.5<VDD<5.25

V

= 0.5 V

PIN

Input resistance 20 – MΩ Receivers Disabled

Capacitance per pin – 15 pF PQFP

Rise time, 10% to 90% 4.0 18.5 ns Refer to Figure 4.3

Fall time, 90% to 10% 4.0 18.5 ns Refer to Figure 4.3

/dt Slew rate, LOW to HIGH 0.15 0.50 V/ns Refer to Figure 4.3

SS

supply

supply

3

2

4-6 Specifications

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 49

Table 4.11 TolerANT Technology Electrical Characteristics (Cont.)

Symbol Parameter Min Max Units Test Conditions

dVL/dt Slew rate, HIGH to LOW 0.15 0.50 V/ns Refer to Figure 4.3

ESD Electrostatic discharge 2 – kV MIL-STD-883C; 3015-7

Latch-up 100 – mA –

Filter delay 20 30 ns –

Ultra filter delay 10 15 ns –

Extended filter delay 40 60 ns –

1. Active negation outputs only: Data, Parity, SREQ/, and SACK/. SCSI SE mode only (minus signals).

2. Single pin only; irreversible damage may occur if sustained for one second.

3. SCSI RESET pin has a 10 kΩ pull-up resistor.

Figure 4.3 Rise and Fall Time Test Conditions

47 Ω

4.1.3 AC Characteristics

The AC characteristics described in this section apply over the entire

range of operating conditions. Chip timing is based on simulation at worst

case voltage, temperature, and processing. The LSI53C320 requires a

40 MHz clock input. Table 4.12 and Figure 4.4 provide clock timing data.

Electrical Characteristics 4-7

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

20 pF

+

2.5 V

−

Page 50

Table 4.12 Clock Timing

Symbol Parameter Min Max Units

t

1

t

2

t

3

t

4

Figure 4.4 Clock Timing

Clock

4.2 Chip Drawings

This section provides the BGA and mechanical drawings for the

LSI53C320.

4.2.1 Mechanical Drawing

Clock period 24.75 25.25 ns

Clock low time 10 15 ns

Clock high time 10 15 ns

Clock rise time 1 – V/ns

t

1

t

3

t

t

2

4

Figure 4.5 illustrates the LSI53C320 mechanical drawing. The

LSI53C320 uses a 272-ball, PBGA package with a VG package code.

4-8 Specifications

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 51

Figure 4.5 272-Ball-Count PBGA (VG) Mechanical Drawing (Sheet 1 of 2)

Important: This drawing may not be the latest version. For board layout and manufacturing, obtain

the most recent engineering drawings from your LSI Logic marketing representative by

requesting the outline drawing for package code VG.

Chip Drawings 4-9

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 52

Figure 4.5 272-Ball-Count PBGA (VG) Mechanical Drawing (Sheet 2 of 2)

Important: This drawing may not be the latest version. For board layout and manufacturing, obtain

the most recent engineering drawings from your LSI Logic marketing representative by

requesting the outline drawing for package code VG.

4-10 Specifications

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 53

4.2.2 BGA Drawing

Figure 4.6 provides the BGA drawing for the LSI53C320. This drawing

provides the pinout view when looking down on the chip from the top.

Table 4.13 and Table 4.14 provide the pin lists for the LSI53C320.

Chip Drawings 4-11

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

Page 54

WS_ENABLE/

VSS

IO

NC

1

XFER_ACTIVE

NC BSY_LED

VDD

IO

VSS

SCSI

CLOCK NC

NC

NC

VSS

SCSI

VSS

SCSI

VSS

SCSI

VSS

SCSI

Figure 4.6 LSI53C320 272-Ball BGA Top View

A1 A2 A3 A4 A5 A6 A7 A8 A9 A10

VSS

B1 B2 B3 B4 B5 B6 B7 B8 B9 B10

A_SD11+

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10

A_SD9+ A_SD11-

D1 D2 D3 D4 D5 D6 D7 D8 D9 D10

A_SD9- A_SD10+ A_SD10-

E1 E2 E3 E4

A_SIO+ A_SD8- A_SD8+ NC

F1 F2 F3 F4

A_SREQ- A_SREQ+ A_SIO-

G1 G2 G3 G4

A_SSEL+ A_SCD- A_SCD+ NC

H1 H2 H3 H4

A_SMSG- A_SMSG+ A_SSEL-

J1 J2 J3 J4 J9 J10

A_SACK+ A_SRST- A_SRST+ NC

K1 K2 K3 K4 K9 K10

A_SBSY- A_SACK- A_SBSY+

L1 L2 L3 L4 L9 L10

VSS

M1 M2 M3 M4 M9 M10

A_SDP0+ A_SDP0- A_RBIAS NC

N1 N2 N3 N4

A_SD7+ A_SD7- A_SD6+

P1 P2 P3 P4

VDD

SCSI

CORE

CORE

B_DIFFSENS A_DIFFSENS

A_SATN+ A_SATN-

NC TEST_3 NC NC

TEST_6 TEST_5 S_DATA

VSS

CORE

NC TEST_4 NC S_CLK

VSS

VDD

VSS

VDD

VDD

VSS

SCSI

SCSI

SCSI

SCSI

CORE

SCSI

NC

VDD

SCSI

VSS

CORE

CHIP_RESET/

VDD

CORE

VSS

SCSI

VSS

SCSI

VSS

SCSI

VSS

SCSI

A_SD6- A_SD5+ A_SD4+ NC

R1 R2 R3 R4

A_SD5- A_SD4- A_SD3-

T1 T2 T3 T4

A_SD3+ A_SD2+ A_SD1+ NC

U1 U2 U3 U4 U5 U6 U7 U8 U9 U10

A_SD2- A_SD1- A_SD0-

V1 V2 V3 V4 V5 V6 V7 V8 V9 V10

A_SD0+ A_SDP1+ NC A_SD14- A_SD12+ NC NC NC NC NC

W1 W2 W3 W4 W5 W6 W7 W8 W9 W10

A_SDP1-

Y1 Y2 Y3 Y4 Y5 Y6 Y7 Y8 Y9 Y10

VSS

VDD

A_SD15- A_SD13+ A_SD13- NC NC NC NC NC NC

CORE

A_SD15+ A_SD14+ A_SD12- NC NC NC NC NC

CORE

VDD

VSS

SCSI

SCSI

VDD

NC

SCSI

NC

1. The top view drawings provides the chip pinout from the top side of the chip.

4-12 Specifications

Version 2.2 Copyright © 2003 by LSI Logic Corporation. All rights reserved.

VSS

SCSI

VDD

NC

SCSI

Page 55

Figure 4.6 LSI53C320 272-Ball BGA Top View (Cont.)

A11 A12 A13 A14 A15 A16 A17 A18 A19 A20

CORE

VSS

B_SD7-

VSS

B_SD12- B_SD13+ B_SD15- B_SDP1+ B_SD1- B_SD2+ B_SD4- B_SD4+ B_SD6+

B11 B12 B13 B14 B15 B16 B17 B18 B19 B20

B_SD13- B_SD14- B_SD15+ B_SD0- B_SD1+ B_SD3- B_SD5+ B_SD6-

C11 C12 C13 C14 C15 C16 C17 C18 C19 C20

B_SD12+ B_SD14+ B_SDP1- B_SD0+ B_SD2- B_SD3+ B_SD5- NC B_SD7+ B_SDP0-

D11 D12 D13 D14 D15 D16 D17 D18 D19 D20

VDD

SCSI

J11 J12 J17 J18 J19 J20

VSS

K11 K12 K17 K18 K19 K20

VSS

L11 L12 L17 L18 L19 L20

VSS

M11 M12 M17 M18 M19 M20

VSS

SCSI

SCSI

SCSI

SCSI

VSS

VSS

VSS

VSS

VSS

NC

SCSI

SCSI

SCSI

SCSI

SCSI

VDD

NC

SCSI

VSS

NC

E17 E18 E19 E20

F17 F18 F19 F20

VDD

G17 G18 G19 G20

H17 H18 H19 H20

VSS

B_RBIAS B_SDP0+ B_SATN+

SCSI

NC B_SATN- B_SBSY- B_SACK-

B_SBSY+ B_SACK+ B_SRST+

SCSI

NC B_SRST- B_SMSG- B_SMSG+

B_SSEL- B_SSEL+ B_SCD-

SCSI

NC B_SCD+ B_SREQ- B_SREQ+

VDD

CORE

VDD

N17 N18 N19 N20

VSS

P17 P18 P19 P20

B_SD8+ B_SD9- B_SD8-

SCSI

NC B_SD10+ B_SD10- B_SD9+

SCSI

VDD

B_SIO- B_SIO+

NC B_SD11+ B_SD11-

CORE

CORE

NC NC NC NC

R17 R18 R19 R20

VDD

T17 T18 T19 T20

U11 U12 U13 U14 U15 U16 U17 U18 U19 U20

VDD

CORE

V11 V12 V13 V14 V15 V16 V17 V18 V19 V20

NC NC NC NC NC NC NC NC NC NC

W11 W12 W13 W14 W15 W16 W17 W18 W19 W20

NC NC NC NC NC NC NC NC

Y11 Y12 Y13 Y14 Y15 Y16 Y17 Y18 Y19 Y20

VSS

CORE

VSS

NC

SCSI

VDD

NC

SCSI

NC