Page 1

TECHNICAL

MANUAL

LSI53C180

Ultra160 SCSI

Bus Expander

Version 1.3

June 2001

®

S14041.C

Page 2

This document contains proprietary information of LSI Logic Corporation. The

information contained herein is not to be used by or disclosed to third parties

without the express written permission of an officer of LSI Logic Corporation.

LSI Logic products are not intended for use in life-support appliances, devices,

or systems. Use of any LSI Logic product in such applications without written

consent of the appropriate LSI Logic officer is prohibited.

Document DB14-000118-03, Fourth Edition (June 2001)

This document describes the LSI Logic Corporation LSI53C180 Ultra160 SCSI

Bus Expander and will remain the official reference source for all

revisions/releases of this product until rescinded by an update.

To receive product literature, visit us at http://www.lsilogic.com.

LSI Logic Corporation reserves the right to make changes to any products herein

at any time without notice. LSI Logic does not assume any responsibility or

liability arising out of the application or use of any product described herein,

except as expressly agreed to in writing by LSI Logic; nor does the purchase or

use of a product from LSI Logic convey a license under any patent rights,

copyrights, trademark rights, or any other of the intellectual property rights of

LSI Logic or third parties.

Copyright © 2000-2001 by LSI Logic Corporation. All rights reserved.

TRADEMARK ACKNOWLEDGMENT

The LSI Logic logo design, LVD Link, and TolerANT are trademarks or registered

trademarks of LSI Logic Corporation. All other brand and product names may be

trademarks of their respective companies.

MH

ii

Page 3

Audience

Preface

This manual provides a description of the LSI53C180 Ultra160 SCSI Bus

Expander chip that supports all combinations of Single-Ended and Low

Voltage Differential SCSI bus conversions.

Currently the LSI53C140 is offered in a 192-BGA package so that

customers who are designing Ultra2 can easily upgrade to Ultra160.

Refer to System Engineering Note S11006 for design considerations

using the LSI53C140 and LSI53C180.

This manual assumes some prior knowledge of current and proposed

SCSI standards. For background information, please contact:

ANSI

11 West 42nd Street

New York, NY 10036

(212) 642-4900

Ask for document number X3.131-199X (SCSI-2)

Global Engineering Documents

15 Inverness Way East

Englewood, CO 80112

(800) 854-7179 or (303) 397-7956 (outside U.S.)

FAX (303) 397-2740

Ask for document number X3.131-1994 (SCSI-2) or

X3.253 (SCSI Parallel Interface-3 (SPI-3))

Preface iii

Page 4

Organization

ENDL Publications

14426 Black Walnut Court

Saratoga, CA 95070

(408) 867-6642

Document names: SCSI Bench Reference, SCSI Encyclopedia,

SCSI Tutor

Prentice Hall

113 Sylvan Avenue

Englewood Cliffs, NJ 07632

(800) 947-7700

Ask for document number ISBN 0-13-796855-8,

SCSI: Understanding the Small Computer System Interface

LSI Logic World Wide Web Home Page

www.lsil.com

This document has the following chapters and appendixes:

• Chapter 1, Introduction, contains the general information about the

LSI53C180 product.

• Chapter 2, Functional Descriptions, describes the main functional

areas of the chip in more detail, including the interfaces to the SCSI

bus and external memory.

• Chapter 3, Specifications, contains the pin diagram, signal

descriptions, electrical characteristics, AC timing diagrams, and

mechanical drawing of the LSI53C180.

• Appendix A, Wiring Diagrams, contains wiring diagrams that show

typical LSI53C180 usage.

• Appendix B, Glossary, contains commonly used terms and their

definitions.

iv Preface

Page 5

Revision Record

Date Version Remarks

2/00 1.0 Version 1.0

11/00 1.1 All product names changed from SYM to LSI.

4/01 1.2 Changes in Chapter 2 to how Warm Swap Enable is

6/01 1.3 Changes to wiring diagrams in Appendix A.

designated. Changes in Chapter 3 to DC

Characteristics.

Preface v

Page 6

vi Preface

Page 7

Contents

Chapter 1 Introduction

1.1 General Description 1-1

1.1.1 Applications 1-3

1.1.2 Features 1-5

1.1.3 Specifications 1-6

1.2 Ultra160 SCSI 1-6

1.2.1 Double Transition (DT) Clocking 1-6

1.2.2 Cyclic Redundancy Check (CRC) 1-6

1.2.3 Domain Validation 1-7

1.2.4 Parallel Protocol Request 1-7

1.2.5 Benefits of LVD Link 1-7

Chapter 2 Functional Descriptions

2.1 Interface Signal Descriptions 2-1

2.1.1 SCSI A Side and B Side Control Blocks 2-2

2.1.2 Retiming Logic 2-4

2.1.3 Precision Delay Control 2-4

2.1.4 State Machine Control 2-4

2.1.5 DIFFSENS Receiver 2-5

2.1.6 Dynamic Transmission Mode Changes 2-5

2.1.7 SCSI Signal Descriptions 2-5

2.1.8 Control Signals 2-11

2.1.9 SCSI Termination 2-13

2.2 Internal Control Descriptions 2-14

2.2.1 Self-Calibration 2-14

2.2.2 Delay Line Structures 2-14

2.2.3 Busy Filters 2-15

Contents vii

Page 8

Chapter 3 Specifications

3.1 Signal Descriptions 3-1

3.2 Electrical Characteristics 3-7

3.2.1 DC Characteristics 3-8

3.2.2 TolerANT Technology Electrical Characteristics 3-12

3.2.3 AC Characteristics 3-16

3.2.4 SCSI Interface Timing 3-16

3.3 Mechanical Drawings 3-19

3.3.1 LSI53C180 192-Pin BGA Mechanical Drawing 3-20

Appendix A Wiring Diagrams

A.1 LSI53C180 Wiring Diagrams A-1

Appendix B Glossary

Index

Customer Feedback

Figures

1.1 LSI53C180 SCSI Bus Modes 1-2

1.2 LSI53C180 Server Clustering 1-3

1.3 LSI53C180 SCSI Bus Device 1-4

2.1 LSI53C180 Block Diagram 2-2

2.2 LSI53C180 Signal Grouping 2-6

3.1 Left Half of LSI53C180 192-Pin BGA Top View 3-2

3.2 Right Half of LSI53C180 192-Pin BGA Top View 3-3

3.3 LSI53C180 Functional Signal Grouping 3-4

3.4 LVD Driver 3-9

3.5 LVD Receiver 3-10

3.6 External Reset Circuit 3-12

3.7 Rise and Fall Time Test Conditions 3-14

3.8 SCSI Input Filtering 3-14

3.9 Hysteresis of SCSI Receivers 3-14

3.10 Input Current as a Function of Input Voltage 3-15

viii Contents

Page 9

Tables

3.11 Output Current as a Function of Output Voltage 3-15

3.12 Clock Timing 3-16

3.13 Input/Output Timing - Single Transition 3-17

3.14 Input/Output Timing - Double Transition 3-18

3.15 192-Pin PBGA (IJ, I2) Mechanical Drawing 3-20

A.1 LSI53C180 Wiring Diagram 1 of 4 A-2

A.2 LSI53C180 Wiring Diagram 2 of 4 A-3

A.3 LSI53C180 Wiring Diagram 3 of 4 A-4

A.4 LSI53C180 Wiring Diagram 4 of 4 A-5

1.1 Types of Operation 1-2

1.2 SCSI Bus Distance Requirements 1-4

1.3 Transmission Mode Distance Requirements 1-4

2.1 DIFFSENS Voltage Levels 2-5

2.2 Mode Sense Control Voltage Levels 2-11

2.3 RESET/ Control Signal Polarity 2-12

2.4 WS_ENABLE Signal Polarity 2-12

2.5 XFER_ACTIVE Signal Polarity 2-13

3.1 SCSI A Side Interface Pins 3-5

3.2 SCSI B Side Interface Pins 3-6

3.3 Chip Interface Control Pins 3-6

3.4 Power and Ground Pins 3-7

3.5 Absolute Maximum Stress Ratings 3-8

3.6 Operating Conditions 3-8

3.7 LVD Driver SCSI Signals—B_SD[15:0]±, B_SDP[1:0]±,

B_SCD±, B_SIO±, B_SMSG±, B_SREQ±, B_SACK±,

B_SBSY±, B_SATN±, B_SSEL±, B_SRST± 3-9

3.8 LVD Receiver SCSI Signals—B_SD[15:0]±, B_SDP[1:0]±,

B_SCD±, B_SIO±, B_SMSG±, B_SREQ±, B_SACK±,

B_SBSY±, B_SATN±, B_SSEL±, B_SRST± 3-9

3.9 DIFFSENS SCSI Signal 3-10

3.10 Input Capacitance 3-10

3.11 Bidirectional SCSI Signals—A_SD[15:0]/, A_SDP[1:0]/,

A_SREQ/, A_SACK/, B_SD[15:0]±, B_SDP[1:0]±,

B_SREQ±, B_SACK± 3-11

Contents ix

Page 10

3.12 Bidirectional SCSI Signals—A_SCD/, A_SIO/,

A_SMSG/, A_SBSY/, A_SATN/, A_SSEL/, A_SRST/,

B_SCD±, B_SIO±, B_SMSG±, B_SBSY±, B_SATN±,

B_SSEL±, B_SRST± 3-11

3.13 Input Control Signals—CLOCK, RESET/, WS_ENABLE 3-11

3.14 Output Control Signals—BSY_LED, XFER_ACTIVE 3-12

3.15 TolerANT Technology Electrical Characteristics 3-12

3.16 Clock Timing 3-16

3.17 Input Timing - Single Transition 3-16

3.18 Output Timing - Single Transition 3-17

3.19 Input Timing - Double Transition 3-17

3.20 Output Timing - Double Transition 3-18

x Contents

Page 11

Chapter 1

Introduction

This chapter describes the LSI53C180 Ultra160 SCSI Bus Expander and

its applications. It includes these sections:

• Section 1.1, “General Description,” page 1-1

• Section 1.2, “Ultra160 SCSI,” page 1-6

1.1 General Description

The LSI53C180 Ultra160 SCSI Bus Expander is a single chip solution

allowing the extension of SCSI device connectivity and/or cable length

limits. A SCSI bus expander couples bus segments together without any

impact to the SCSI protocol, software, or firmware. The LSI53C180

Ultra160 SCSI Bus Expander connects Single-Ended (SE) Ultra and Low

Voltage Differential (LVD) Ultra160 peripherals together in any

combination. The LSI53C180 does not support High Voltage Differential

(HVD) mode.

The LSI53C180 is capable of supporting any combination of SE or LVD

bus mode on either the A or B Side port. This provides the system

designer with maximum flexibility in designing SCSI backplanes to

accommodate any SCSI bus mode. The LSI53C180 has independent

RBIAS pins allowing margining for each bus. A 10 kΩ pull-up resistor on

RBIAS is required to provide the correct LVD levels.

LSI53C180 Ultra3 SCSI Bus Expander 1-1

Page 12

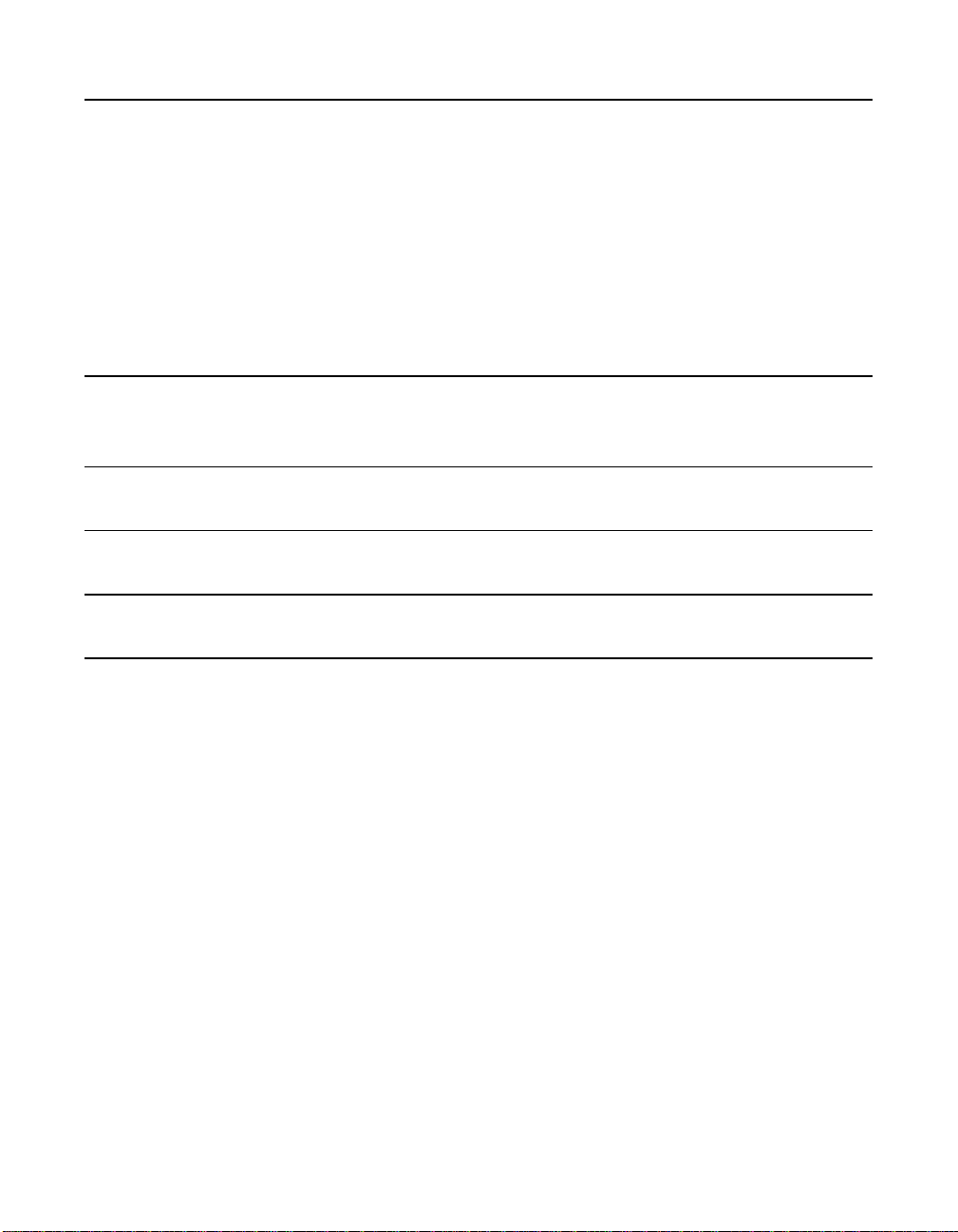

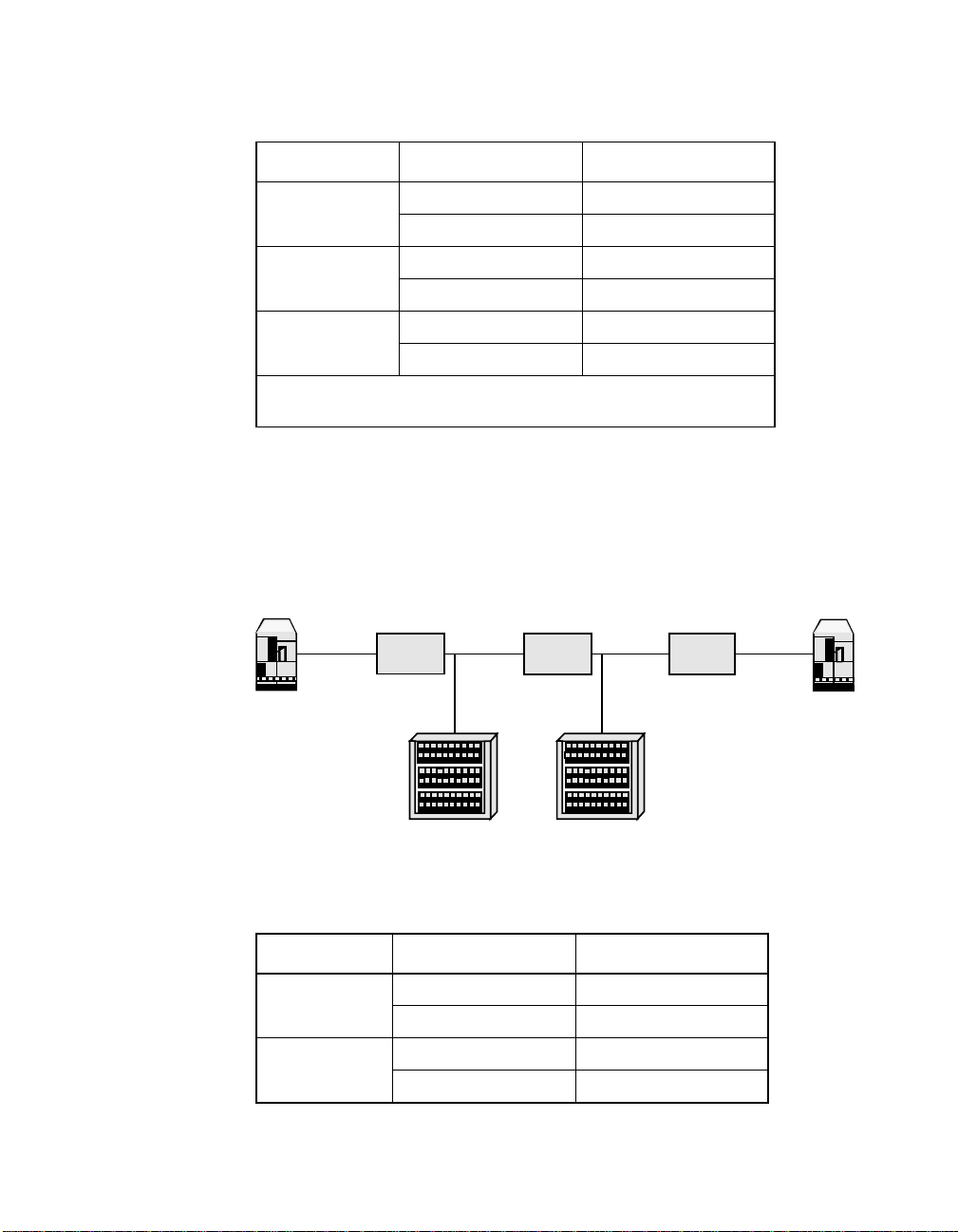

Figure 1.1 LSI53C180 SCSI Bus Modes

A Side B Side

LVD

SE

LSI53C180

SCSI Expander

192 PBGA

LVD

SE

Figure 1.1 shows the two SCSI bus modes available on the A or B Side.

LVD Link™ transceivers provide the multimode LVD or SE capability. The

LSI53C180 operates as both an expander and converter. In both SCSI

Bus Expander and Converter modes, cable segments are isolated from

each other. This feature maintains the signal integrity of each cable

segment.

Table 1.1 shows the types of operational modes for the LSI53C180.

Table 1.1 Types of Operation

Signal Type Speed

LVD to LVD Ultra160

SE to SE Ultra

LVD to SE Ultra

SE to LVD Ultra

The LSI53C180 provides additional control capability through the pin

level isolation mode (Warm Swap Enable). This feature permits logical

disconnection of both the A Side bus and the B Side bus without

disrupting SCSI transfers currently in progress. For example, devices on

the logically disconnected B Side can be swapped out while the A Side

bus remains active.

The LSI53C180 is based on previous bus expander technology, which

includes signal filtering along with retiming to maintain skew budgets.

The LSI53C180 is independent of software.

1-2 Introduction

Page 13

1.1.1 Applications

• Server clustering environments

• Expanders creating distinct SCSI cable segments that are isolated

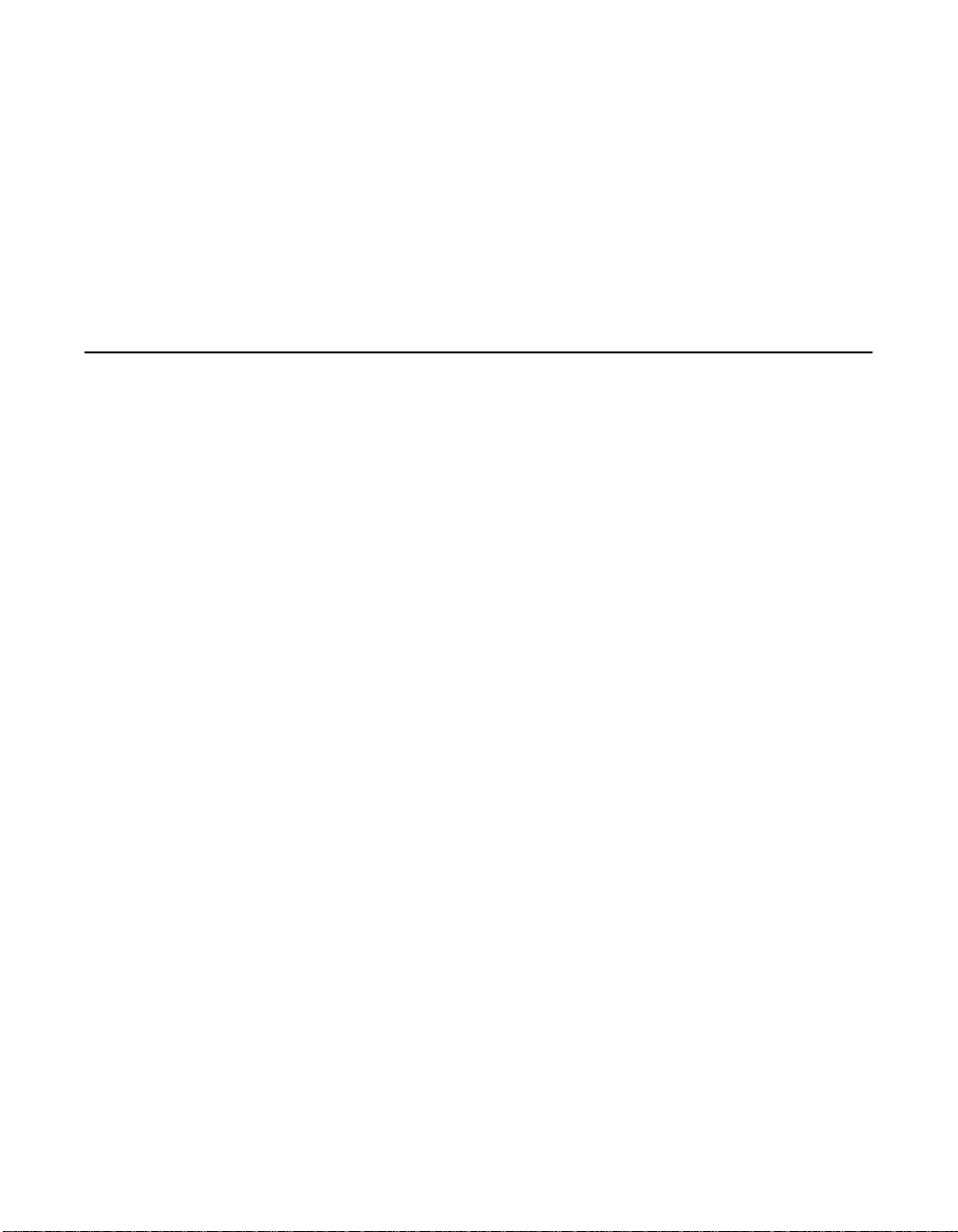

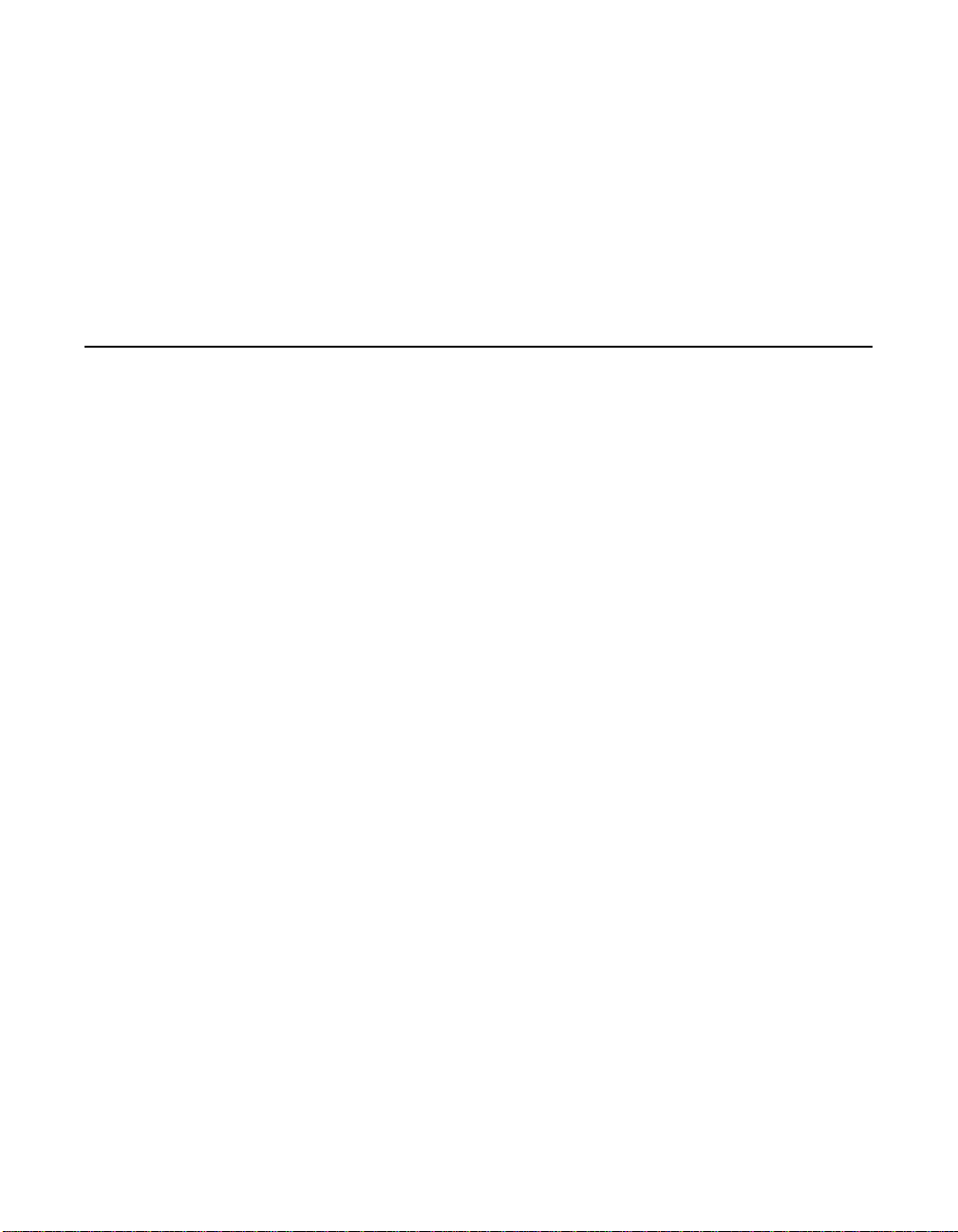

Figure 1.2 LSI53C180 Server Clustering

from each other

Primary Server

Segment A

SCSI Bus

Expander

SCSI Bus

Expander

Segment C

Shared Disk Subsystem

Segment B

Secondary Server

Figure 1.2 demonstrates how SCSI bus expanders are used to couple

bus segments together without any impact on the SCSI protocol or

software. Configurations that use the LSI53C180 SCSI Bus Expander in

the Ultra160 mode (LVD to LVD) allow the system designer to take

advantage of the inherent cable distance, device connectivity, data

reliability, and increased transfer rate benefits of LVD signaling with

Ultra160 SCSI peripherals.

In the Figure 1.2 example, two LSI53C180 expanders are used to

configure three segments. This configuration allows segment A to be

treated as a point-to-point segment. Segments B and C are treated as

load segments with at least 8 inches between every node. Table 1.2

shows the various distance requirements for each SCSI bus mode.

General Description 1-3

Page 14

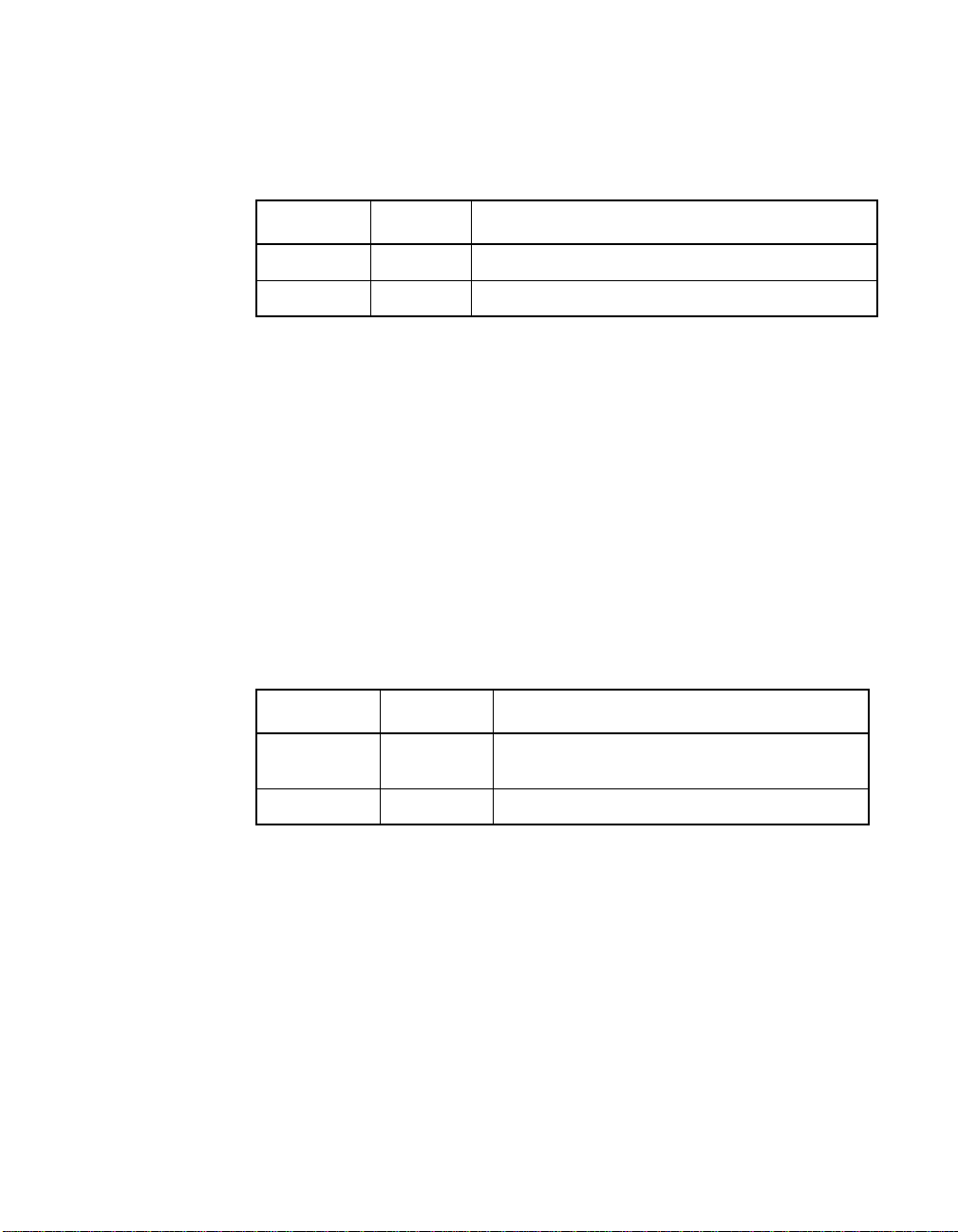

Table 1.2 SCSI Bus Distance Requirements

Segment Mode Length Limit

A LVD (Ultra160) 25 meters

SE (Ultra) 3 meters

1

B LVD (Ultra160) 12 meters

SE (Ultra) 1.5 meters

C LVD (Ultra160) 12 meters

SE (Ultra) 1.5 meters

1. The length may be more, possibly 6 meters, as no devices are

attached to it.

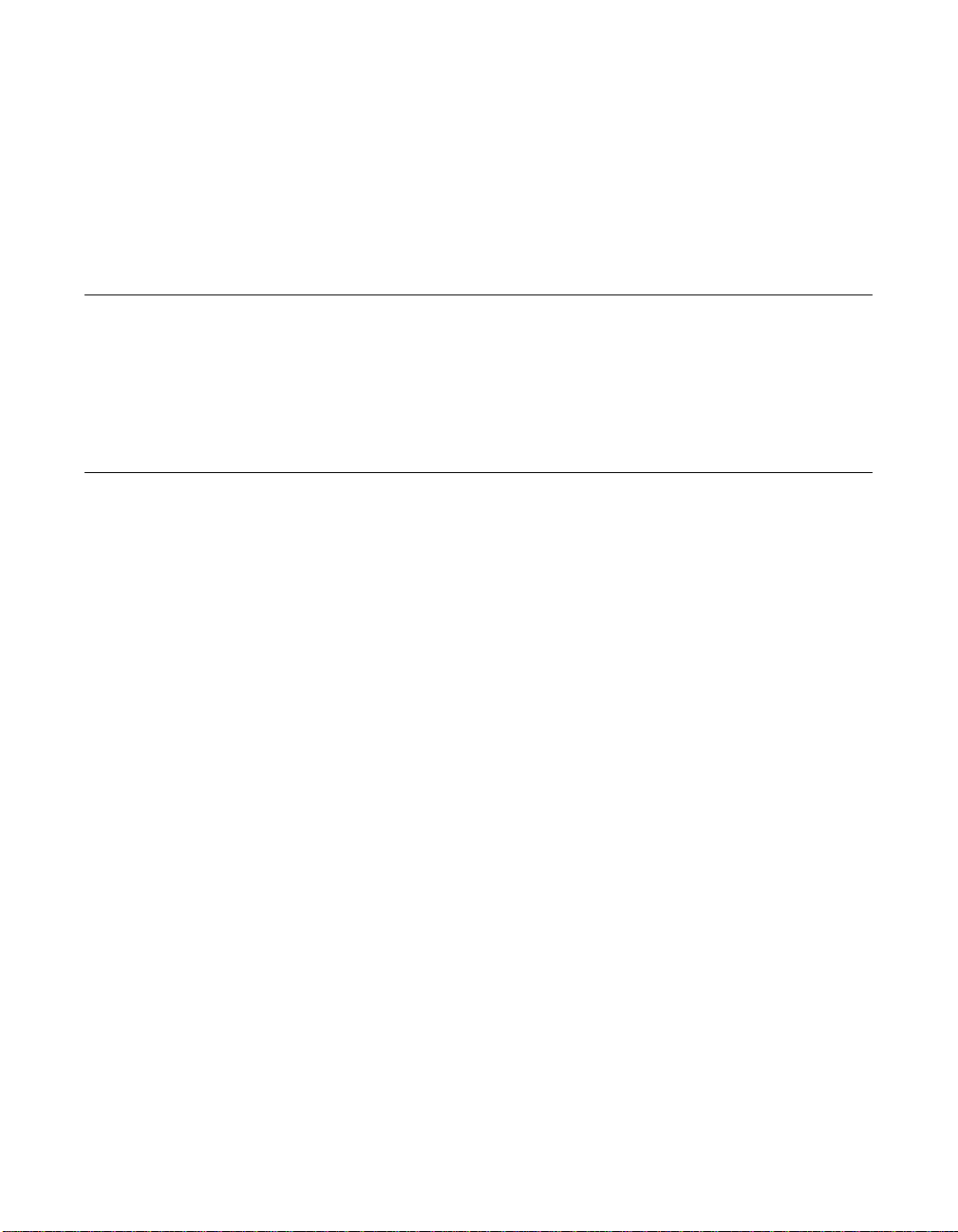

In the second example, Figure 1.3, the LSI53C180 is cascaded to

achieve four distinct SCSI segments. Segments A and D can be treated

as point-to-point segments. Segments B and C are treated as load

segments with at least 8-inch spacing between every node.

Figure 1.3 LSI53C180 SCSI Bus Device

Segment A Segment B Segment C

Primary

Server

Table 1.3 Transmission Mode Distance Requirements

Segment Mode Length Limit

A, D LVD (Ultra160) 25 meters

B, C LVD (Ultra160) 12 meters

1-4 Introduction

SCSI Bus

Expander

Shared Disk

Subsystem

SCSI Bus

Expander

Shared Disk

Subsystem

SCSI Bus

Expander

SE (Ultra) 1.5 meters

SE (Ultra) 1.5 meters

Segment D

Secondary

Server

Page 15

1.1.2 Features

• A flexible SCSI bus expander that supports any combination of LVD

or SE transceivers

• Creates distinct SCSI bus segments that are isolated from each

other

• Integrated LVD Link transceivers for direct attachment to either LVD

or SE bus segments

• Operates as a SCSI Bus Expander

– LVD to LVD (Ultra160 SCSI)

– SE to SE (Ultra SCSI)

• Operates as a SCSI Bus Converter

– LVD to SE (Ultra SCSI)

– SE to LVD (Ultra SCSI)

• Targets and initiators may be located on either the A or B Side of the

device

• Accepts any asynchronous or synchronous transfer speed up to

Ultra160 SCSI (for LVD to LVD mode only)

• Supports dynamic addition/removal of SCSI bus segments using the

isolation mode

• Does not consume a SCSI ID

• Propagates the RESET/ signal from one side to the other regardless

of the SCSI bus state

• Notifies initiator(s) of changes in transmission mode (SE/LVD) on A

or B Side segments by using the SCSI bus RESET/

• SCSI Busy LED driver for activity indicator

• Up to four LSI53C180s may be cascaded

• Does not require software

• Supports Double Transition (DT) clocking

• Supports Cyclic Redundancy Check (CRC) in DT data phases

• Supports Domain Validation

General Description 1-5

Page 16

1.1.3 Specifications

• 40 MHz Input Clock

• 192-pin Plastic Ball Grid Array package (PBGA). This package is a

drop in replacement for the LSI53C140 when the design uses the

LSI53C180 pinout.

• Compliant with the SCSI Parallel Interface-3 (SPI-3)

• Compliant with SCSI Enhanced Parallel Interface (EPI) Specifications

1.2 Ultra160 SCSI

The LSI53C180 SCSI Bus Expander supports Ultra160 SCSI. This

interface is an extension of the SCSI-3 standards that expands the

bandwidth of the SCSI bus to allow faster synchronous data transfers,

up to 160 Mbytes/s. Ultra160 SCSI provides a doubling of the data rate

over the Ultra2 SCSI interface. All new speeds after Ultra2 are wide.

1.2.1 Double Transition (DT) Clocking

Ultra160 provides DT clocking for LVD transfers where clocking is

defined on the rising and falling edges of the clock. The latching of data

on both the assertion edge and the negation edge of the REQ/ACK

signal represents DT data phases. DT data phase encompasses both the

DT Data In and the DT Data Out phase. DT data phases use only 16bit, synchronous transfers.

Information unit and data group transfers use DT data phases to transfer

data. Information unit transferstransmitallnexus, task management, task

attribute, command, data, and protection. Data group transfers transmit

all data and protection. The number of bytes transferred for an

information unit or data group is always a multiple of four. Refer to the

SCSI Parallel Interface-3 (SPI-3) for more detailed information about

DT clocking.

1.2.2 Cyclic Redundancy Check (CRC)

Ultra160 supports CRC, which represents error checking code to detect

the validity of data. CRC increases the reliability of data transfers since

four bytes of code are transferred along with data. All single bit errors,

1-6 Introduction

Page 17

two bits in error, or other error types within a single 32-bit range are

detected. Refer to SPI-3 to see how CRC generation and transmission

occur during data transfers.

1.2.3 Domain Validation

Domain Validation is a procedure that allows a host computer and target

SCSI peripheral to negotiate and find the optimal transfer speed. This

procedure improves overall reliability of the system by ensuring integrity

of the data transferred.

1.2.4 Parallel Protocol Request

Parallel Protocol Request (PPR) messages negotiate a synchronous

data transfer agreement, a wide data transfer agreement, and set the

protocol options between two SCSI devices. This message exchange

negotiates limits about data transmission and establishes an agreement

between the two SCSI devices. This agreement applies to ST Data In,

ST Data Out, DT Data In, and DT Data Out phases.

For example, a SCSI device could initiate a PPR message whenever it

is appropriate to negotiate a data transfer agreement. If the target device

is capable of supporting any of the PPR options, it will respond with a

PPR message. If not, it responds with a Message Reject message and

the two SCSI devices use either SDTR or WDTR messages to negotiate

an agreement.

1.2.5 Benefits of LVD Link

The LSI53C180 supports LVD technology for SCSI, a signaling

technology that increases the reliability of SCSI data transfers over

longer distances than those supported by SE SCSI technology. The low

current output of LVD allows the I/O transceivers to be integrated directly

onto the chip. LVD provides the reliability of HVD SCSI technology

without the added cost of external differential transceivers. LVD allows a

longer SCSI cable and more devices on the bus. LVD provides a

long-term migration path to even faster SCSI transfer rates without

compromising signal integrity, cable length, or connectivity.

For backward compatibility to existing SE devices, the LSI53C180

features multimode LVD Link transceivers that can switch between LVD

and SE modes.

Ultra160 SCSI 1-7

Page 18

Some features of integrated LVD Link multimode transceivers are:

• Supports SE or LVD technology

• Allows greater device connectivity and longer cable length

• LVD Link transceivers save the cost of external differential

transceivers

• Supports a long-term performance migration path

1-8 Introduction

Page 19

Chapter 2

Functional

Descriptions

This chapter describes all signals, their groupings, and their functions. It

includes these topics:

• Section 2.1, “Interface Signal Descriptions,” page 2-1

• Section 2.2, “Internal Control Descriptions,” page 2-14

2.1 Interface Signal Descriptions

The LSI53C180 has no programmable registers, and therefore, no

software requirements. SCSI control signals control all LSI53C180

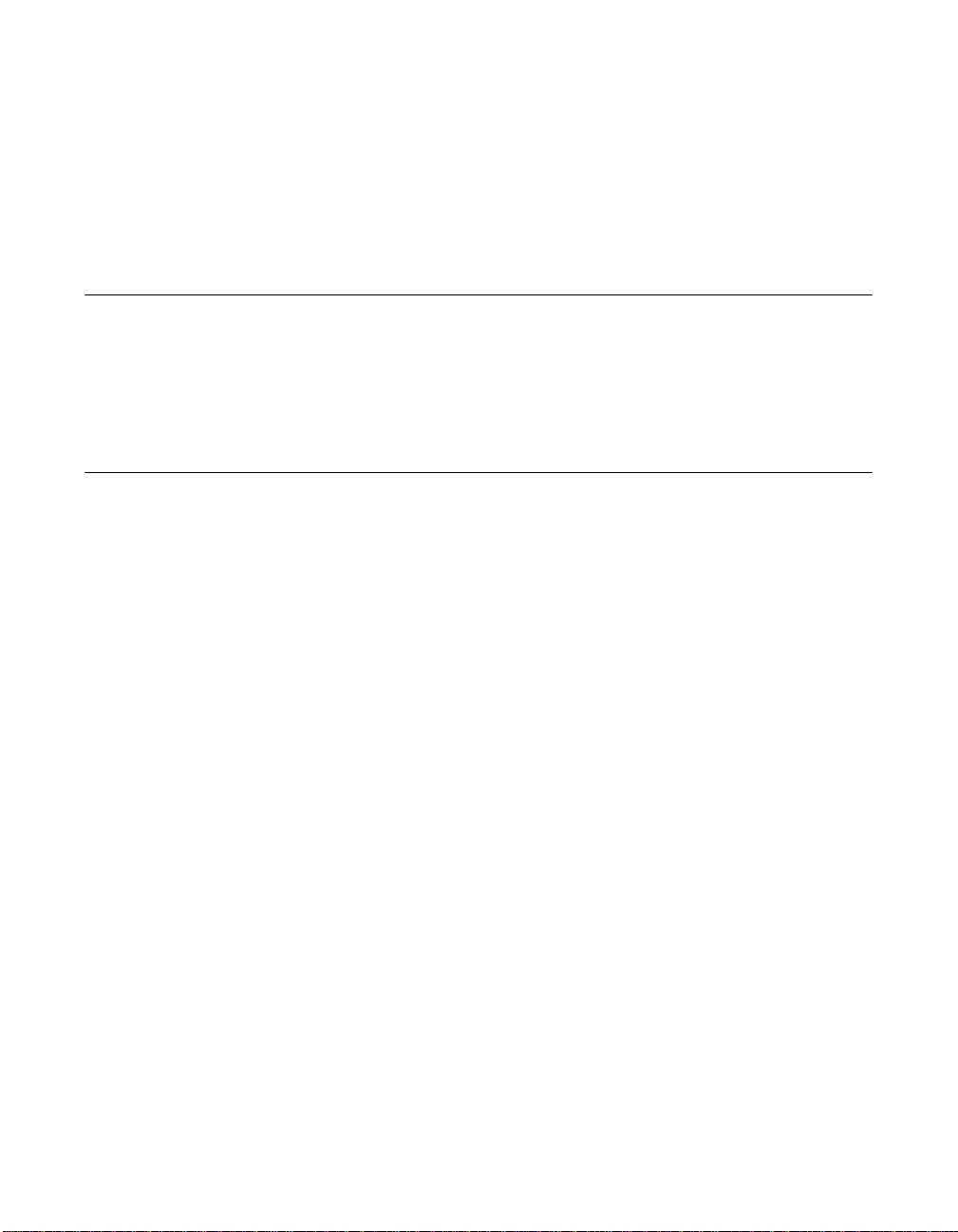

functions. Figure 2.1 shows a block diagram of the LSI53C180 device,

which is divided into these specific areas:

• A Side SCSI Control Block

– LVD and SE Drivers and Receivers

• B Side SCSI Control Block

– LVD and SE Drivers and Receivers

• Retiming Logic

• Precision Delay Control

• State Machine Control

LSI53C180 Ultra3 SCSI Bus Expander 2-1

Page 20

Figure 2.1 LSI53C180 Block Diagram

Control

Signals

LVD, Single-ended,

Wide Ultra SCSI Bus

(A Side)

ansceivers

VD Link Tr

L

ol Block

SCSI Contr

Retiming

Logic

k

ol Bloc

LVD Link Transceivers

SCSI Contr

LVD, Single-ended

Wide Ultra SCSI Bus

(B Side)

Precision

er

A_DIFFSENS B_DIFFSENS

VD

L

Control

Receiv

DIFFSENS

Delay

40 MHz Clock Input

In its simplest form, the LSI53C180 passes data and parity from a source

bus to a load bus. The side asserting, deasserting, or releasing the SCSI

signals is the source side. The model of the LSI53C180 represents

pieces of wire that allow corresponding SCSI signals to flow from one

side to the other side. The LSI53C180 monitors arbitration and selection

by devices on the bus so it can enable the proper drivers to pass the

signals along. In addition, the LSI53C180 does signal retiming to

maintain the signal skew budget from the source bus to the load bus.

2.1.1 SCSI A Side and B Side Control Blocks

The SCSI A Side pins are connected internally to the corresponding

SCSI B Side pins, forming bidirectional connections to the SCSI bus.

In the LVD/LVD mode, the SCSI A Side and B Side control blocks

connect to both targets and initiators and accept any asynchronous or

synchronous data transfer rates up to the 160 Mbytes/s rate of Wide

Ultra160 SCSI. TolerANT®and LVD Link technologies are part of both

the A Side and B Side control blocks.

State

Machine

Control

LVD

Receiver

DIFFSENS

2.1.1.1 LSI53C180 Requirements for Synchronous Negotiation

The LSI53C180 builds a table of information regarding devices on the

bus in on-chip RAM. The PPR, SDTR, and WDTR information for each

2-2 Functional Descriptions

Page 21

device is taken from the MSG bytes during negotiation. For all devices

in the configuration to communicate accurately through the LSI53C180

at Ultra160 (Fast-80) rates, it is necessary for a complete synchronous

negotiation to take place between the initiator and target(s) prior to any

data transfer. On a 16-bit bus, the LSI53C180 at Ultra160 approaches

rates of 160 Mbytes/s. The LSI53C180 defaults to Fast-20 rates when a

valid negotiation between the initiator and target has not occurred.

2.1.1.2 TolerANT Technology

In SE mode, the LSI53C180 features TolerANT technology, which

includes active negation on the SCSI drivers and input signal filtering on

the SCSI receivers. Active negation causes the SCSI Request,

Acknowledge, Data, and Parity signals to be actively driven HIGH rather

than passively pulled up by terminators.

TolerANT receiver technology improves data integrity in unreliable

cabling environments, where other devices would be subject to data

corruption. TolerANT receivers filter the SCSI bus signals to eliminate

unwanted transitions without the long signal delays associated with

RC-type input filters. This improved driver and receiver technology helps

eliminate double clocking of data, the single biggest reliability issue with

SCSI operations.

The benefits of TolerANT technology include increased immunity to noise

on the deasserting signal edge, better performance due to balanced duty

cycles, and improved SCSI transfer rates. In addition, TolerANT SCSI

devices prevent glitches on the SCSI bus at power-up or power-down, so

other devices on the bus are also protected from data corruption.

2.1.1.3 LVD Link Technology

To support greater device connectivity and longer SCSI cables, the

LSI53C180 features LVD Link technology, the LSI Logic implementation

of multimode LVD SCSI. LVD Link transceivers provide the inherent

reliability of differential SCSI, and a long-term migration path of faster

SCSI transfer rates.

LVD Link technology is based on current drive. Its low output current

reduces the power needed to drive the SCSI bus. Therefore, the I/O

drivers can be integrated directly onto the chip. This reduces the cost and

complexity compared to traditional (high power) differential designs.

Interface Signal Descriptions 2-3

Page 22

LVD Link lowers the amplitude of noise reflections and allows higher

transmission frequencies.

The LVD Link transceivers in Side A and Side B operate in the LVD or

SE modes. The LSI53C180 automatically detects the type of signal

connected, based on the voltages detected by A_DIFFSENS and

B_DIFFSENS.

2.1.2 Retiming Logic

The SCSI signals, as they propagate from one side of the LSI53C180 to

the other side, are processed by logic circuits that retime the bus signals,

as needed, to guarantee or improve the required SCSI timings. The

retiming logic is governed by the State Machine Controls that keep track

of SCSI phases, the location of initiator and target devices, and various

timing functions. In addition, the retiming logic contains numerous delay

elements that are periodically calibrated by the Precision Delay Control

block in order to guarantee specified timing such as output pulse widths,

setup and hold times, and other elements.

When a synchronous negotiation takes place between devices, a nexus

is formed, and the corresponding information on that nexus is stored in

the on-chip RAM. This information remains in place until a chip reset,

power down, or renegotiation occurs. This enables the chip to make

more accurate retiming adjustments.

2.1.3 Precision Delay Control

The Precision Delay Control block provides calibration information to the

precision delay elements in the Retiming Logic block. This calibration

information provides precise timing as signals propagate through the

device. As the LSI53C180 voltage and temperature vary over time, the

Precision Delay Control block periodically updates the delay settings in

the Retiming Logic. The purpose of these updates is to maintain constant

and precise control over bus timing.

2.1.4 State Machine Control

The State Machine Control tracks the SCSI bus phase protocol and other

internal operating conditions. This block provides signals to the Retiming

Logic that identify how to properly handle SCSI bus signal retiming based

on SCSI protocol.

2-4 Functional Descriptions

Page 23

2.1.5 DIFFSENS Receiver

The LSI53C180 contains LVD DIFFSENS receivers that detect the

voltage level on the A Side or B Side DIFFSENS lines to inform the

LSI53C180 of the transmission mode being used by the SCSI buses. A

device does not change its present signal driver or receiver mode based

on the DIFFSENS voltage levels unless a new mode is sensed

continuously for at least 100 ms.

Transmission mode detection for SE or LVD is accomplished through the

use of the DIFFSENS lines. Table 2.1 shows the voltages on the

DIFFSENS lines and modes they will cause.

Table 2.1 DIFFSENS Voltage Levels

Voltage Mode

−0.35 to +0.5 SE

+0.7 to +1.9 LVD

2.1.6 Dynamic Transmission Mode Changes

Any dynamic mode change (SE/LVD) on a bus segment is considered to

be a significant event that requires the initiator to determine whether the

mode change meets the requirements for that bus segment.

The LSI53C180 supports dynamic transmission mode changes by

notifying the initiator(s) of changes in transmission mode (SE/LVD) on A

or B Side segments by using the SCSI bus RESET. The DIFFSENS line

detects a valid mode switch on the bus segments. After the DIFFSENS

state is present for 100 ms, the LSI53C180 generates a SCSI reset on

the opposite bus from the one that the transmission mode change

occurred on. This reset informs any initiators residing on the opposite

segment about the change in the transmission mode. The initiator(s) then

renegotiates synchronous transfer rates with each device on that segment.

2.1.7 SCSI Signal Descriptions

For a description of a specific signal, see Section 3.1, “Signal

Descriptions,” in Chapter 3. For signal electrical characteristics, see

Section 3.2, “Electrical Characteristics.” For SCSI bus signal timing, see

Interface Signal Descriptions 2-5

Page 24

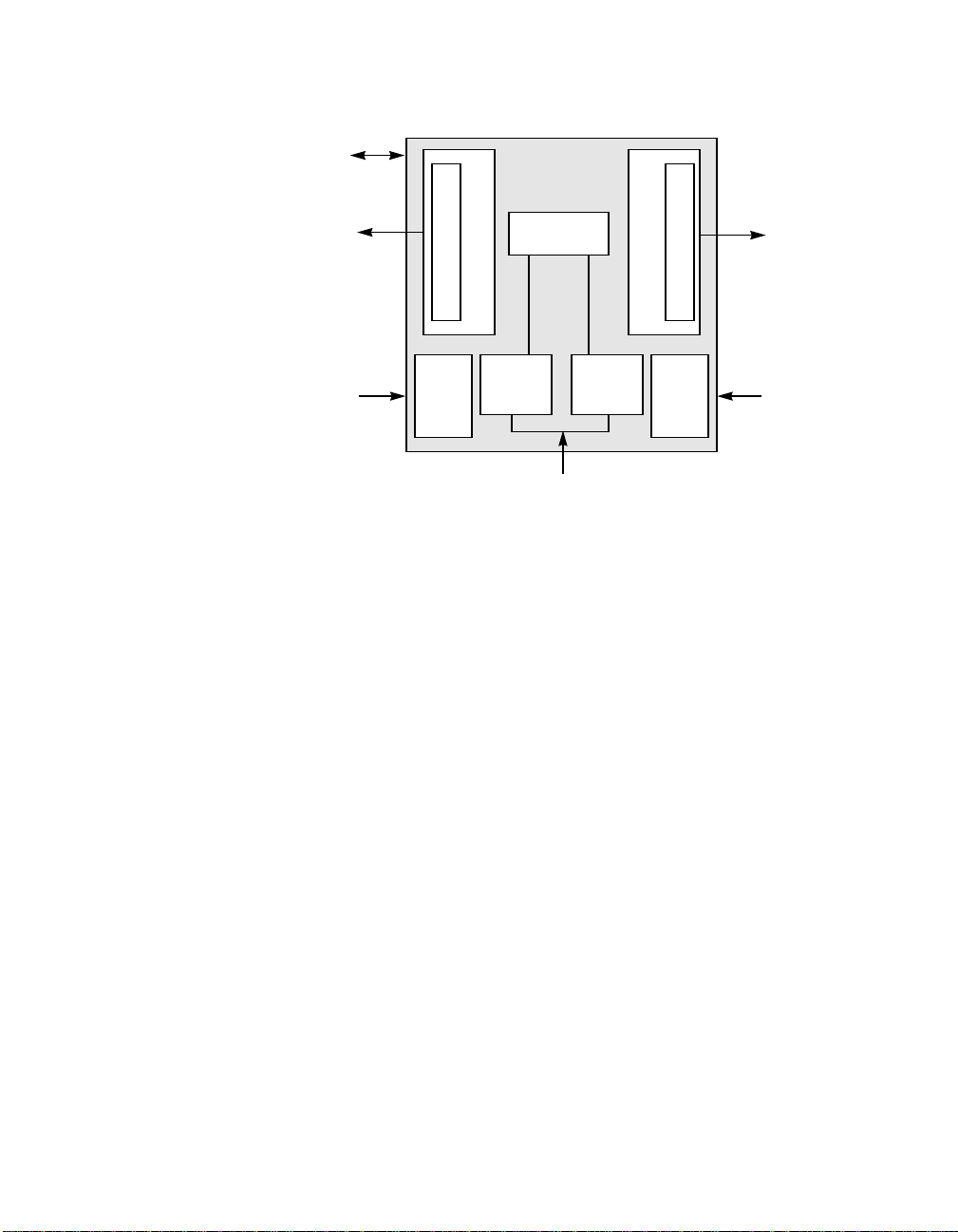

Section 3.2.4, “SCSI Interface Timing.” Figure 2.2 shows the LSI53C180

signal grouping. A description of the signal groups follows.

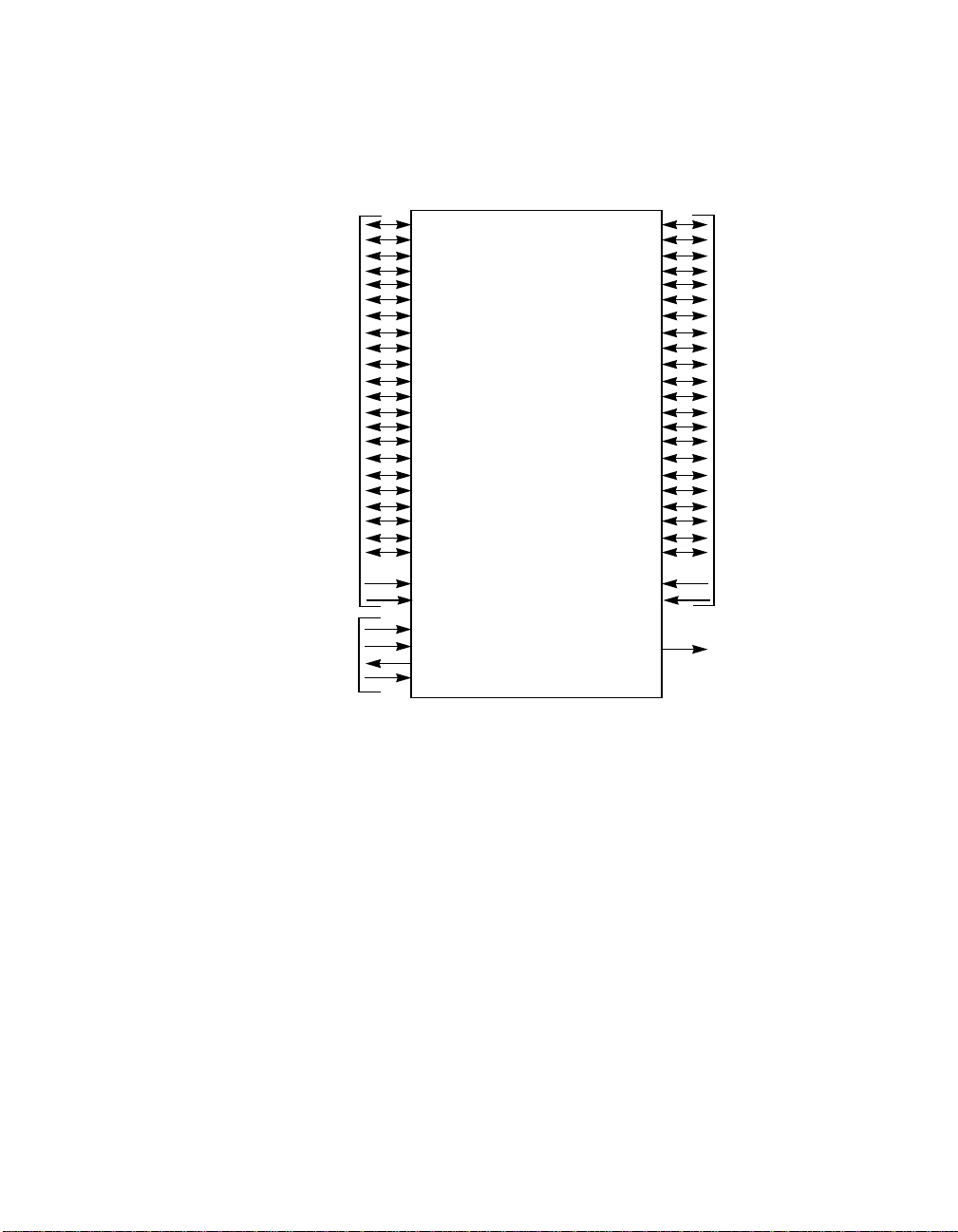

Figure 2.2 LSI53C180 Signal Grouping

A Side

LVD or SE

SCSI Interface

Control Signals

2.1.7.1 Data and Parity (SD and SDP)

A_SSEL+

A_SSELA_SBSY+

A_SBSYA_SRST+

A_SRSTA_SREQ+

A_SREQA_SACK+

A_SACKA_SMSG+

A_SMSGA_SCD+

A_SCDA_SIO+

A_SIOA_SATN+

A_SATNA_SDP[1:0]+

A_SDP[1:0]A_SD[15:0]+

A_SD[15:0]-

A_DIFFSENS

A_RBIAS B_RBIAS

RESET/

WS_ENABLE

XFER_ACTIVE

CLOCK

LSI53C180

B_SSEL+

B_SSEL-

B_SBSY+

B_SBSY-

B_SRST+

B_SRST-

B_SREQ+

B_SREQB_SACK+

B_SACK-

B_SMSG+

B_SMSG-

B_SCD+

B_SCD-

B_SIO+

B_SIO-

B_SATN+

B_SATN-

B_SDP[1:0]+

B_SDP[1:0]-

B_SD[15:0]+

B_SD[15:0]-

B_DIFFSENS

BSY_LED

B Side

LVD or SE

SCSI Interface

The signals named A_SD[15:0] and A_SDP[1:0] are the data and parity

signals from the A Side, and B_SD[15:0] and B_SDP[1:0] are the data

and parity signals from the B Side of the LSI53C180. These signals are

sent and received from the LSI53C180 by using SCSI compatible drivers

and receiver logic designed into the LSI53C180 interfaces. This logic

provides the multimode LVD and SE interfaces in the chip. This logic also

provides the necessary drive, sense thresholds, and input hysteresis to

function correctly in a SCSI bus environment.

The LSI53C180 receives data and parity signals and passes them from

the source bus to the load bus and provides any necessary edge shifting

to guarantee the skew budget for the load bus. Either side of the

LSI53C180 may be the source bus or the load bus. The side that is

2-6 Functional Descriptions

Page 25

asserting, deasserting, or releasing the SCSI signals is the source side.

These steps describe the LSI53C180 data processing:

1. Asserted data is accepted by the receiver logic as soon as it is

received. Once the clock signal (REQ/ACK) has been received, data

is gated from the receiver latch.

2. The path is next tested to ensure the signal if being driven by the

LSI53C180 is not misinterpreted as an incoming signal.

3. The data is then leading edge filtered. The assertion edge is held for

a specified time to prevent any signal bounce. The duration is

controlled by the input signal.

4. The next stage uses a latch to sample the signal. This provides a

stable data window for the load bus.

5. The final step develops pull-up and pull-down controls for the SCSI

I/O logic, including 3-state controls for the pull-up.

6. A parallel function ensures that bus (transmission line) recovery

occurs for a specified time after the last signal deassertion on each

signal line.

2.1.7.2 SCSI Bus Activity LED (BSY_LED)

Internal logic detects SCSI bus activity and generates a signal that

produces an active HIGH output. This output can be used to drive a LED

to indicate SCSI activity.

The internal circuitry is a digital one shot that is an active HIGH with a

minimum pulse width of 16 ms. The BSY_LED output current is 8 mA.

This output may have an LED attached to it with the other lead of the

LED grounded through a suitable resistor.

2.1.7.3 Select Control (SSEL)

A_SSEL and B_SSEL are control signals used during bus arbitration and

selection. Whichever side asserts, SSEL propagates it to the other side.

If both signals are asserted at the same time, the A Side receives SSEL

and sends it to the B Side. This output has pull-down control for an open

collector driver. The processing steps for the signals are:

Interface Signal Descriptions 2-7

Page 26

1. The input signal is blocked if it is being driven by the LSI53C180.

2. The next stage is a leading edge filter. This ensures that the output

does not switch for a specified time after the leading edge. The

duration of the input signal then determines the duration of the

output.

3. A parallel function ensures that bus (transmission line) recovery

occurs for a specified time after the last signal deassertion on each

signal line.

2.1.7.4 Busy Control (SBSY)

A_SBSY and B_SBSY signals are propagated from the source bus to the

load bus. The busy control signals go through this process:

1. The bus is tested to ensure the signal if being driven by the

LSI53C180 is not misinterpreted as an incoming signal.

2. The data is then leading edge filtered. The assertion edge is held for

a specified time to prevent any signal bounce. The input signal

controls the duration.

3. The signal path switches the long and short filters used in the circuit

depending upon the current state of the LSI53C180. The current

state of the LSI53C180 State Machine that tracks SCSI phases

selects the mode. The short filter mode passes data through, while

the long filter mode indicates the bus free state. When the Busy

(SBSY) and Select (SSEL) sources switch from side to side, the long

filter mode is used. This output is then fed to the output driver, which

is a pull-down open collector only.

4. A parallel function ensures that bus (transmission line) recovery is

availablefor a specified time after the last signal deassertion on each

signal line.

2.1.7.5 Reset Control (SRST)

A_SRST and B_SRST are also passed from the source to the load bus.

This output has pull-down control for an open collector driver. The reset

signals are processed in this sequence:

1. The input signal is blocked if it is already being driven by the

LSI53C180.

2-8 Functional Descriptions

Page 27

2. The next stage is a leading edge filter. This ensures that the output

will not switch during a specified time after the leading edge. The

duration of the input signal then determines the duration of the

output.

3. A parallel function ensures that bus (transmission line) recovery

occurs for a specified time after the last signal deassertion on each

signal line.

When the LSI53C180 senses a true mode change on either bus, it

generates a SCSI reset to the opposite bus. For example, when LVD

mode changes to SE mode, a reset occurs.

2.1.7.6 Request and Acknowledge Control (SREQ and SACK)

A_SREQ, A_SACK, B_SREQ, and B_SACK are clock and control

signals. Their signal paths contain controls to guarantee minimum pulse

widths, filter edges, and do some retiming when used as data transfer

clocks. In DT clocking, both leading and trailing edges are filtered, while

only the leading edge is filtered in single transition clocking. SREQ and

SACK have paths from the A Side to the B Side and from the B Side to

the A Side. The received signal goes through these processing steps

before being sent to the opposite bus:

1. The asserted input signal is sensed and forwarded to the next stage

if the direction control permits it. The direction controls are developed

from state machines that are driven by the sequence of bus control

signals.

2. The signal must then pass the test of not being regenerated by the

LSI53C180.

3. The next stage is a leading edge filter. This ensures that the output

does not switch during the specified hold time after the leading edge.

The duration of the input signal determines the duration of the output

after the hold time. The circuit guarantees a minimum pulse rate.

4. The next stage passes the signal if it is not a data clock. If SREQ or

SACK is a data clock, it delays the leading edge to improve data

output setup times. The input signal again controls the duration.

5. This stage is a trailing edge signal filter. When the signal deasserts,

the filter does not permit any signal bounce. The output signal

deasserts at the first deasserted edge of the input signal.

Interface Signal Descriptions 2-9

Page 28

6. The last stage develops pull-up and pull-down signals with drive and

3-state control.

7. A parallel function ensures that bus (transmission line) recovery

occurs for a specified time after the last signal deassertion on each

signal line.

2.1.7.7 Control/Data, Input/Output, Message, and Attention Controls

(SCD, SIO, SMSG, and SATN)

A_SCD, A_SIO, A_SMSG, A_SATN, B_SCD, B_SIO, B_SMSG, and

B_SATN are control signals that have the following processing steps:

1. The input signal is blocked if it is being driven by the LSI53C180.

2. The next stage is a leading edge filter. This ensures the output does

not switch for a specified time after the leading edge. The duration

of the input signal determines the duration of the output.

3. The final stage develops pull-up and pull-down controls for the SCSI

I/O logic, including 3-state controls for the pull-up.

4. A parallel function ensures that bus (transmission line) recovery is for

a specified time after the last signal deassertion on each signal line.

2.1.7.8 Multimode Signal Control

A_SD[15:0], A_SDP[1:0], A_SBSY, A_SSEL, A_SCD, A_SIO, A_SMSG,

A_SREQ, A_SACK, A_SATN, A_SRST, B_SD[15:0], B_SDP[1:0],

B_SBSY, B_SSEL, B_SCD, B_SIO, B_SMSG, B_SREQ, B_SACK,

B_SATN, and B_SRST are all multimode signals. The mode is controlled

by the voltage sensed at the DIFFSENS input. The A and B Sides are

independently controlled.

When the correct DIFFSENS voltage selects SE mode, the plus signal

leads are internally tied to ground and the minus SCSI signals are the

SE input/outputs.

When the correct DIFFSENS voltage selects LVD mode, the plus and

minus signal leads are the differential signal pairs.

A transition from any mode to another mode causes a SCSI RST to be

asserted on the opposite SCSI bus as a notification of state change.

2-10 Functional Descriptions

Page 29

2.1.7.9 A and B Differential Sense (A_DIFFSENS and B_DIFFSENS)

These control pins determine the mode of SCSI bus signaling that will

be expected.

Table 2.2 Mode Sense Control Voltage Levels

Voltage Mode

−0.35 to +0.5 SE

+0.7 to +1.9 LVD

For example, if a differential source is plugged into the B Side that has

been configured to run in the differential mode and if a SE source is

detected, then the B Side is disabled and no B Side signals are driven.

This protection mechanism is for SE interfaces that are connected to

differential drivers.

2.1.7.10 A and B RBIAS (LVD Current Control)

These control pins require a 10 K 1% resistor connected to VDD.

2.1.8 Control Signals

This section provides information about the RESET/, WS_ENABLE, and

XFER_ACTIVE pins. It also describes the function of the CLOCK input.

2.1.8.1 Chip Reset (RESET/)

This general purpose chip reset forces all of the internal elements of the

LSI53C180 into a known state. It brings the State Machine to an idle

state and forces all controls to a passive state. The minimum RESET/

input asserted pulse width is 100 ns.

The LSI53C180 also contains an internal Power On Reset (POR)

function that is ORed with the chip reset pin. This eliminates the need

Interface Signal Descriptions 2-11

Page 30

for an external chip reset if the power supply meets ramp up

specifications.

Table 2.3 RESET/ Control Signal Polarity

Signal Level State Effect

LOW = 0 Asserted Reset is forced to all internal LSI53C180 elements.

HIGH = 1 Deasserted LSI53C180 is not in a forced reset state.

2.1.8.2 Warm Swap Enable (WS_ENABLE/)

This input removes the chip from an active bus without disturbing the

current SCSI transaction (for Warm Swap). When the WS_ENABLE/ pin

is asserted, after detection of the next bus free state, the SCSI signals

are 3-stated. This occurs so that the LSI53C180 no longer passes

through signals until the WS_ENABLE/ pin is deasserted HIGH and both

SCSI buses enter the Bus Free state. As an indication that the chip is

idle, or ready to be warm swapped, the XFER_ACTIVE signal deasserts

LOW. An LED or some other indicator could be connected to the

XFER_ACTIVE signal. To isolate buses in certain situations, use this

Warm Swap Enable feature.

Table 2.4 WS_ENABLE/ Signal Polarity

Signal Level State Effect

LOW = 0 Asserted The LSI53C180 is requested to go off-line after

HIGH = 1 Deasserted The LSI53C180 is enabled to run normally.

2.1.8.3 Transfer Active (XFER_ACTIVE)

This output is an indication that the chip has finished its internal testing,

the SCSI bus has entered a Bus Free state, and SCSI traffic can now

2-12 Functional Descriptions

detection of a SCSI Bus Free state.

Page 31

pass from one bus to the other. The signal is asserted HIGH when the

chip is active.

Table 2.5 XFER_ACTIVE Signal Polarity

Signal Level State Effect

HIGH = 1 Asserted Indicates normal operation, and transfers through

LOW = 0 Deasserted The LSI53C180 has detected a Bus Free state

2.1.8.4 Clock (CLOCK)

This is the 40 MHz oscillator input to the LSI53C180. It is the clock

source for the protocol control state machines and timing generation

logic. This clock is not used in any bus signal transfer paths.

2.1.9 SCSI Termination

The terminator networks provide the biasing needed to pull signals to an

inactive voltage level, and to match the impedance seen at the end of

the cable with the characteristic impedance of the cable. Terminators

must be installed at the extreme ends of each SCSI segment, and only

at the ends. No SCSI segment should ever have more or less than two

terminators installed and active. SCSI host adapters should provide a

means of accommodating terminators. The terminators should be

socketed, so they may be removed if not needed. Otherwise, the

terminators should be disabled by software means.

the LSI53C180 are enabled.

due to WS_ENABLE being LOW, thus disabling

transfers through the device.

Multimode terminators are required because they provide both LVD and

SE termination, depending on what mode of operation is detected by the

DIFFSENS pins.

Important: LSI Logic recommends that active termination be used for

the bus connections to the LSI53C180. The Unitrode 5630

or Dallas 2108 commonly used for Ultra2 buses can also

be used interchangeably for Ultra160. The Unitrode 5628

can be used for Ultra160 and allows use of two devices on

the SCSI bus rather than three.

Interface Signal Descriptions 2-13

Page 32

2.2 Internal Control Descriptions

This section provides information about self-calibration, delay line

structures, and busy filters.

2.2.1 Self-Calibration

The LSI53C180 contains internal logic that adjusts the internal timing

based on analyzing the time through a long asynchronous inverter logic

chain versus a synchronous counter. The timing functions use the

resulting self-calibration value to adjust to their nominal values based on

the performance of this circuit.

The LSI53C180 has 24 critical timing chains and each has its own

calibration circuit and stored calibration value. The counter logic is

replicated four times so four calibrations can occur in parallel. This allows

the 24 calibration values to be updated by six calibration cycles.

Self-calibration is triggered every 8.1 seconds to account for temperature

and voltage changes.

2.2.2 Delay Line Structures

Some fixed delay functions are required within the signal and control

interfaces from bus to bus. The LSI53C180 uses programmable delay

lines to implement delays. The incremental points in the chain are

selected by multiplexers. Self-calibration takes care of process,

temperature, and voltage effects.

2.2.2.1 Data Path

The data path through the LSI53C180 includes two levels of latches. One

latch is in the receiver and the input clock, REQ or ACK, generates the

hold. This level captures the data that may have minimal setup and hold.

A second latch occurs to hold the data in order to transmit optimal

signals on the isolated bus. This level provides maximum setup and hold

along with a regenerated clock. The data path also provides a timer for

each data bit that protects reception from a target bus for a nominal

30 ns after the driver is deasserted.

2-14 Functional Descriptions

Page 33

2.2.2.2 REQ/ACK

These input clock signals get edge filtered and stretched to minimum

values to avoid glitches. In DT clocking, both leading and trailing edges

are filtered, while only the leading edge is filtered in single transition

clocking. These filters provide edge filtering to remove noise within the

initial signal transition. The current transmission speed selects the time

values.

2.2.3 Busy Filters

The busy control signal passes from source to load bus with filtering

selected by the current state of the SCSI bus. This filter provides a

synchronized leading edge signal that is not true until the input signal has

been stable. The trailing edge occurs within several nanoseconds of the

input being deasserted. When the BSY signal is asserted before and

after the SEL signal, the filter is on.

Internal Control Descriptions 2-15

Page 34

2-16 Functional Descriptions

Page 35

Chapter 3

Specifications

This chapter provides the pin descriptions associated with the

LSI53C180 as well as electrical characteristics. It includes these topics:

• Section 3.1, “Signal Descriptions,” page 3-1

• Section 3.2, “Electrical Characteristics,” page 3-7

• Section 3.3, “Mechanical Drawings,” page 3-20

3.1 Signal Descriptions

The LSI53C180 is packaged in a 192-pin Ball Grid Array (BGA) shown

in Figure 3.1 and Figure 3.2. The LSI53C180 signal grouping is shown in

Figure 3.3. Tables 3.1 through 3.4 list the signal descriptions grouped by

function:

• SCSI A Side Interface Pins (Table 3.1)

• SCSI B Side Interface Pins (Table 3.2)

• Chip Interface Control Pins (Table 3.3)

• Power and Ground Pins (Table 3.4)

Figure 3.1 and Figure 3.2 display the left and right halves of the

LSI53C180 192-pin BGA top view.

LSI53C180 Ultra3 SCSI Bus Expander 3-1

Page 36

Figure 3.1 Left Half of LSI53C180 192-Pin BGA Top View

A1 A2 A3 A4 A5 A6 A7 A8 A9

VDD

NC

B1 B2 B3 B4 B5 B6 B7 B8 B9

NC NC NC XFER_ACTIVE RESET/ A_DIFFSENS A_SD12-

IO

B_SD11+ B_SD11- NC NC WS_ENABLE/ BSY_LED NC

C1 C2 C3 C4 C5 C6 C7 C8 C9

B_SD10+ B_SD10- B_DIFFSENS NC

D1 D2 D3

B_SD9+ B_SD9- NC

E1 E2 E3

VDD

VDD

VDD

VDD

SCSI

SCSI

CORE

SCSI

B_SD8+ B_SD8-

F1 F2 F3

B_SIO+ B_SIO- NC

G1 G2 G3 G7 G8 G9

B_SREQ+ B_SREQ- VSS VSS VSS VSS

H1 H2 H3 H7 H8 H9

B_SCD- B_SSEL+ B_SCD+ VSS VSS VSS

J1 J2 J3 J7 J8

B_SSEL- B_SMSG+

K1 K2 K3 K7 K8 K9

B_SMSG- B_SRST+

L1 L2 L3 L7 L8 L9

B_SRST- NC VSS VSS VSS VSS

M1 M2 M3

B_SACK+ B_SACK- B_SBSY+

N1 N2 N3

B_SBSY- B_SATN+

P1 P2 P3

B_SATN- B_SDP0- B_SDP0+

R1 R2 R3 R4 R5 R6 R7 R8 R9

VDD

NC VSS CLOCK

SCSI

VDD

CORE

VSS VSS

VSS VSS VSS

A_SD12+

VDD

SCSI

B_RBIAS B_SD7+ B_SD7- NC

T1 T2 T3 T4 T5 T6 T7 T8 T9

NC B_SD6+ B_SD5+ B_SD4+ B_SD3+ B_SD2- B_SD1+ B_SD0+ B_SDP1+

U1 U2 U3 U4 U5 U6 U7 U8 U9

NC B_SD6- B_SD5- B_SD4- B_SD3- NC B_SD1-

3-2 Specifications

VDD

B_SD2+ VSS B_SD0-

SCSI

VDD

CORE

VDD

B_SDP1-

SCSI

Page 37

Figure 3.2 Right Half of LSI53C180 192-Pin BGA Top View

A10 A11 A12 A13 A14 A15 A16 A17

A_SD13- A_SD14+ A_SD15+ A_SD0- A_SD1- A_SD2- A_SD3- NC

B10 B11 B12 B13 B14 B15 B16 B17

A_SD14- A_SD15- A_SDP1- A_SD0+ A_SD1+ A_SD2+ A_SD3+ A_SD4-

C10 C11 C12 C13 C14 C15 C16 C17

A_SD13+ VSS A_SDP1+

G10 G11 G15 G16 G17

VSS VSS VSS A_SATN+ A_SATN-

H10 H11 H15 H16 H17

VSS VSS NC A_SBSY+ A_SBSY-

J10 J11 J15 J16 J17

VSS VSS VDD A_SACK+ A_SACK-

K10 K11 K15 K16 K17

VSS VSS

L10 L11 L15 L16 L17

VSS VSS VSS A_SMSG- A_SRST+

R10 R11 R12 R13 R14 R15 R16 R17

NC VSS NC

T10 T11 T12 T13 T14 T15 T16 T17

VDD

VDD

NC NC A_SD5- A_SD4+

SCSI

SCSI

D15 D16 D17

A_SD5+ A_SD6+ A_SD6-

E15 E16 E17

VDD

SCSI

F15 F16 F17

NC A_SDP0+ A_SDP0-

VDD

CORE

M15 M16 M17

A_SSEL+ A_SSEL- A_SMSG+

N15 N16 N17

VDD

SCSI

P15 P16 P17

NC A_SREQ+ A_SREQ-

A_SD10+ A_SD9- A_SIO+ A_SIO-

A_SD7+ A_SD7-

A_SRST- A_RBIAS

A_SCD+ A_SCD-

B_SD15+ B_SD14+ B_SD13+ B_SD12+ A_SD11+ A_SD10- A_SD8+ A_SD8-

U10 U11 U12 U13 U14 U15 U16 U17

B_SD15- B_SD14- B_SD13- B_SD12- A_SD11- A_SD9+ NC NC

Signal Descriptions 3-3

Page 38

Figure 3.3 LSI53C180 Functional Signal Grouping

A Side

LVD or SE

SCSI Interface

Control Signals

A_SSEL+

A_SSELA_SBSY+

A_SBSYA_SRST+

A_SRSTA_SREQ+

A_SREQA_SACK+

A_SACKA_SMSG+

A_SMSGA_SCD+

A_SCDA_SIO+

A_SIOA_SATN+

A_SATNA_SDP[1:0]+

A_SDP[1:0]A_SD[15:0]+

A_SD[15:0]-

A_DIFFSENS

A_RBIAS B_RBIAS

RESET/

WS_ENABLE

XFER_ACTIVE

CLOCK

LSI53C180

B_SSEL+

B_SSEL-

B_SBSY+

B_SBSY-

B_SRST+

B_SRST-

B_SREQ+

B_SREQ-

B_SACK+

B_SACK-

B_SMSG+

B_SMSG-

B_SCD+

B_SCD-

B_SIO+

B_SIO-

B_SATN+

B_SATN-

B_SDP[1:0]+

B_SDP[1:0]-

B_SD[15:0]+

B_SD[15:0]-

B_DIFFSENS

BSY_LED

B Side

LVD or SE

SCSI Interface

3-4 Specifications

Page 39

Table 3.1 SCSI A Side Interface Pins

SCSI A BGA Pin Type Description

A_SSEL+,− M15, M16 I/O A Side SCSI bus Select control signal.

A_SBSY+,− H16, H17 I/O A Side SCSI bus Busy control signal.

A_SRST+,− L17, K16 I/O A Side SCSI bus Reset control signal.

A_SREQ+,− P16, P17 I/O A Side SCSI bus Request control signal.

A_SACK+,− J16, J17 I/O A Side SCSI bus Acknowledge control signal.

A_SMSG+,− M17, L16 I/O A Side SCSI bus Message control signal.

A_SCD+,− N16, N17 I/O A Side SCSI bus Control and Data control signal.

A_SIO+,− R16, R17 I/O A Side SCSI bus Input and Output control signal.

A_SATN+,− G16, G17 I/O A Side SCSI bus Attention control signal.

A_SDP[1:0]+,− C12, B12, F16, F17 I/O A Side SCSI bus Data Parity signal.

A_SD[15:0]+,− A12, B11, A11, B10,

C10, A10, B9, A9,

T14, U14, R14, T15,

U15, R15, T16, T17,

E16, E17, D16, D17,

D15, C16, C17, B17,

B16, A16, B15, A15,

B14, A14, B13, A13

A_DIFFSENS A8 I A Side SCSI bus Differential Sense signal.

A_RBIAS K17 RBIAS LVD current control.

I/O A Side SCSI bus Data signals.

Signal Descriptions 3-5

Page 40

Table 3.2 SCSI B Side Interface Pins

SCSI B Pin Type Description

B_SSEL+,− H2, J1 I/O B Side SCSI bus Select control signal.

B_SBSY+,− M3, N1 I/O B Side SCSI bus Busy control signal.

B_SRST+,− K2, L1 I/O B Side SCSI bus Reset control signal.

B_SREQ+,− G1, G2 I/O B Side SCSI bus Request control signal.

B_SACK+,− M1, M2 I/O B Side SCSI bus Acknowledge control signal.

B_SMSG+,− J2, K1 I/O B Side SCSI bus Message control signal.

B_SCD+,− H3, H1 I/O B Side SCSI bus Control and Data control signal.

B_SIO+,− F1, F2 I/O B Side SCSI bus Input and Output control signal.

B_SATN+,− N2, P1 I/O B Side SCSI bus Attention control signal.

B_SDP[1:0]+,− T9, U9, P3, P2 I/O B Side SCSI bus Data Parity signal.

B_SD[15:0]+,− T10, U10, T11, U11,

T12, U12, T13, U13,

B1, B2, C1, C2,

D1, D2, E1, E2,

R2, R3, T2, U2,

T3, U3, T4, U4,

T5, U5, R6, T6,

T7, U7, T8, R8

B_DIFFSENS C3 I B Side SCSI bus Differential Sense signal.

B_RBIAS R1 RBIAS LVD current control.

I/O B Side SCSI bus Data signals.

Table 3.3 Chip Interface Control Pins

Control Pin Type Description

RESET/ A7 I Master Reset for LSI53C180, active LOW.

WS_ENABLE/ B5 I Enable/disable SCSI transfers through the LSI53C180.

XFER_ACTIVE A6 O Transfers through the LSI53C180 are enabled/disabled.

CLOCK C8 I Oscillator input for LSI53C180 (40 MHz).

BSY_LED B6 O SCSI activity LED output, 8 mA.

3-6 Specifications

Page 41

Table 3.4 Power and Ground Pins

Power and Ground Pin Type Description

VDD

VDD

VDD

SCSI

CORE

IO

C5, C9, C13, E3, E15, J3,

J15, N3, N15, R5, R9, R13

B8, K3, K15, U8 I Power supplies to the CORE logic.

A2 I Power supplies to the I/O logic.

VSS C7, C11, G3, G7, G8, G9,

G10, G11, G15, H7, H8,

H9, H10, H11, J7, J8, J10,

J11, K7, K8, K9, K10, K11,

L3, L7, L8, L9, L10, L11,

L15, R7, R11

NC A1, A3, A4, A5, A17, B3,

B4, B7, C4, C6, C14, C15,

D3, F3, F15, H15, L2, P15,

R4, R10, R12, T1, U1, U6,

U16, U17

Note:

• All V

• If the power supplies to the VDD

pins must be supplied 3.3 V. The LSI53C180 output signals drive 3.3 V.

DD

and VDD

IO

CORE

either power up the pins simultaneously or power up VDD

always power down before the VDD

CORE

pin.

3.2 Electrical Characteristics

I Power supplies to the SCSI bus I/O pins.

I Ground ring.

N/A No Connections.

pins in a chip testing environment are separated,

before VDDIO. The VDDIOpin must

CORE

This section specifies the DC and AC electrical characteristics of the

LSI53C180. These electrical characteristics are listed in four categories:

• DC Characteristics

• TolerANT Technology Electrical Characteristics

• AC Characteristics

• SCSI Interface Timing

Electrical Characteristics 3-7

Page 42

3.2.1 DC Characteristics

Table 3.5 Absolute Maximum Stress Ratings

1

Symbol Parameter Min Max Units Test Conditions

T

STG

V

V

V

IN5V

I

LP

ESD Electrostatic

Storage

−55 150 ˚C –

temperature

Supply voltage −0.5 4.5 V –

DD

Input Voltage VSS−0.3 VDD+0.3 V –

IN

Input Voltage (5 V TolerANT pins) VSS−0.3 5.25 V –

2

Latch-up current ±150 – mA –

– 2 K V MIL-STD 883C,

discharge

Method 3015.7

1. Stresses beyond those listed above may cause permanent damage to the device. These are stress

ratings only; functional operation of the device at these or any other conditions beyond those indicated in the Operating Conditions section of the manual is not implied.

2. −2V<VPIN<8V.

Table 3.6 Operating Conditions

1

Symbol Parameter Min Max Units Test Conditions

V

DD

I

DD

I

DD-I/O

I

DD

T

θ

JA

A

Supply voltage 3.13 3.47 V –

SE Mode Supply2Current (dynamic) – 200 mA –

LVD Mode Supply Current (dynamic) – 600 mA –

Supply current (static) – 1 mA –

Operating free air 0 70 ˚C –

Thermal resistance

– 35 ˚C/W –

(junction to ambient air)

1. Conditions that exceed the operating limits may cause the device to function incorrectly.

2. Core and analog supply only.

3-8 Specifications

Page 43

Table 3.7 LVD Driver SCSI Signals—B_SD[15:0]±, B_SDP[1:0]±, B_SCD±, B_SIO±,

B_SMSG

B_SRST

Symbol Parameter Min Max Units Test Conditions

I

+ Source (+) current 9.6 14.4 mA Asserted state

O

I

− Sink (−) current −9.6 −14.4 mA Asserted state

O

I

+ Source (+) current −6.4 −9.6 mA Negated state

O

I

− Sink (−) current 6.4 9.6 mA Negated state

O

1. V

I

CM

OZ

3-state leakage −20 20 µAV

= 0.7 − 1.8 V, RL=0− 110 Ω, R

±, B_SREQ±, B_SACK±, B_SBSY±, B_SATN±, B_SSEL±,

1

±

= 0 V, 3.47 V

PIN

=10kΩ.

bias

Figure 3.4 LVD Driver

R

L

+

−

IO+

IO−

2

R

L

2

+

V

CM

−

Table 3.8 LVD Receiver SCSI Signals—B_SD[15:0]±,

B_SDP[1:0]±, B_SCD±, B_SIO±, B_SMSG±, B_SREQ±,

B_SACK±, B_SBSY±, B_SATN±, B_SSEL±, B_SRST±

Symbol Parameter Min Max Units

V

V

LVD receiver voltage asserting 60 – mV –

I

LVD receiver voltage negating – −60 mV –

I

1. VCM= 0.7 − 1.8 V.

Electrical Characteristics 3-9

Conditions

1

Test

Page 44

Figure 3.5 LVD Receiver

+

V

+

V

CM

−

I

2

−

+

V

I

2

−

+

−

Table 3.9 DIFFSENS SCSI Signal

Symbol Parameter Min Max Units

LVD sense voltage 0.7 1.9 V Note 1

V

S

V

Single-ended sense

IL

voltage

I

3-state leakage −10 10 µAV

OZ

VSS−0.3 0.5 V Note 1

1. Functional test specified for each mode (VSand VIL).

Table 3.10 Input Capacitance

Symbol Parameter Min Max Units

C

C

Input capacitance of input pads – 7 pF –

I

Input capacitance of I/O pads – 10 pF –

IO

Test

Conditions

= 0 V, 5.25 V

PIN

Conditions

1

Test

3-10 Specifications

Page 45

Table 3.11 Bidirectional SCSI Signals—A_SD[15:0]/, A_SDP[1:0]/,

A_SREQ/, A_SACK/, B_SD[15:0]±, B_SDP[1:0]±,

B_SREQ±, B_SACK±

Symbol Parameter Min Max Units

V

V

V

V

I

Input high voltage 2.0 VDD+0.3 V –

IH

Input low voltage VSS-0.3 0.8 V –

IL

1

Output high

OH

voltage

Output low voltage V

OL

3-state leakage −20 20 µAV

OZ

2.0 V

SS

DD

0.5 V 48 mA

VIOH= 7.0 mA

Conditions

= 0 V, 3.47 V

PIN

1. TolerANT active negation enabled.

Table 3.12 Bidirectional SCSI Signals—A_SCD/, A_SIO/, A_SMSG/,

A_SBSY/, A_SATN/, A_SSEL/, A_SRST/, B_SCD±,

B_SIO±, B_SMSG±, B_SBSY±, B_SATN±, B_SSEL±,

B_SRST±

Symbol Parameter Min Max Units Test Conditions

Test

V

Input high voltage 2.0 VDD+0.3 V –

IH

V

V

I

Input low voltage VSS-0.3 0.8 V –

IL

Output low

OL

voltage

3-state leakage −20 20 µAV

OZ

V

SS

0.5 V 48 mA

= 0 V, 3.47 V

PIN

Electrical Characteristics 3-11

Page 46

Table 3.13 Input Control Signals—CLOCK, RESET/, WS_ENABLE

Symbol Parameter Min Max Units Test Conditions

V

V

I

Input high voltage 2.0 V

IH

Input low voltage VSS-0.3 0.8 V –

IL

3-state leakage −10 10 µAV

OZ

DD

V–

= 0 V, 5.25 V

PIN

Figure 3.6 External Reset Circuit

3.3 V

Input

3.3 V

Reset

Pin 146

0.1 µF

Table 3.14 Output Control Signals—BSY_LED, XFER_ACTIVE

Symbol Parameter Min Max Units Test Conditions

V

OH

V

I

OZ

Output high voltage 2.4 V

Output low voltage V

OL

DD

0.4 V 8 mA

SS

V8mA

3-state leakage −10 10 µA–

3-12 Specifications

Page 47

3.2.2 TolerANT Technology Electrical Characteristics

Table 3.15 TolerANT Technology Electrical Characteristics

1

Symbol Parameter Min Max Units Test Conditions

2

V

OH

V

V

V

V

V

V

V

TH-VTL

I

OH

I

OL

I

OSH

I

OSL

OL

TH

Output high voltage 2.0 VDD+0.3 V IOH=-7mA

Output low voltage V

Input high voltage 2.0 VDD+0.3 V –

IH

Input low voltage VSS−0.3 0.8 V Referenced to V

IL

Input clamp voltage −0.66 −0.77 V VDD= 4.75;

IK

SS

0.5 V IOL=48mA

Threshold, HIGH to LOW 1.0 1.2 V –

Threshold, LOW to HIGH 1.4 1.6 V –

TL

Hysteresis 300 500 mV –

2

Output high current 2.5 24 mA VOH= 2.5 V

Output low current 100 200 mA VOL= 0.5 V

2

Short-circuit output high

current

– 625 mA Output driving low,

pin shorted to V

supply

Short-circuit output low

current

– 95 mA Output driving high,

pin shorted to V

I

= −20 mA

I

3

supply

SS

DD

SS

I

LH

I

LL

I

PD

R

I

C

P

2

t

R

(Sheet 1 of 2)

Input high leakage – 20 µAV

Input low leakage −20 – µAV

V

V

DD

PIN

DD

PIN

+/- 5%,

= 2.7 V

+/- 5%,

=0V

Power down leakage – 20 VDD=0V,

V

= 1.2 V

PIN

Input resistance 20 – MΩ SCSI pins

Capacitance per pin – 15 pF PQFP

Rise time, 10% to 90% 4.0 18.5 ns Figure 3.7

Electrical Characteristics 3-13

4

Page 48

Table 3.15 TolerANT Technology Electrical Characteristics1(Cont.)

Symbol Parameter Min Max Units Test Conditions

dV

dV

t

H

L

Fall time, 90% to 10% 4.0 18.5 ns Figure 3.7

F

/dt Slew rate, LOW to HIGH 0.15 0.50 V/ns Figure3.7

/dt Slew rate, HIGH to LOW 0.15 0.50 V/ns Figure 3.7

ESD Electrostatic discharge 2 – kV MIL-STD-883C;

3015-7

Latch-up 100 – mA –

Filter delay 20 30 ns Figure 3.8

Ultra filter delay 10 15 ns Figure 3.8

Ultra3 filter delay x x ns Figure 3.8

Extended filter delay 40 60 ns Figure 3.8

(Sheet 2 of 2)

1. These values are guaranteed by periodic characterization; they are not 100% tested on every device.

2. Active negation outputs only: Data, Parity, SREQ/, SACK/. (Minus Pins) SCSI mode only.

3. Single pin only; irreversible damage may occur if sustained for one second.

4. SCSI RESET pin has 10 kΩ pull-up resistor.

Figure 3.7 Rise and Fall Time Test Conditions

47 Ω

3-14 Specifications

20 pF

+

2.5 V

−

Page 49

Figure 3.8 SCSI Input Filtering

t

1

REQ/ or ACK/ Input

V

TH

Note: t1is the input filtering period.

Figure 3.9 Hysteresis of SCSI Receivers

1.1 1.3

1

0

Received Logic Level

1.5 1.7

Input Voltage (Volts)

Figure 3.10 Input Current as a Function of Input Voltage

+40

+20

0

-0.7 V

-20

Input Current (milliamperes)

-40

-4 0 4 8 12 16

8.2 V

OUTPUT

ACTIVE

Input Voltage (Volts)

14.4 V

HI-Z

Electrical Characteristics 3-15

Page 50

Figure 3.11 Output Current as a Function of Output Voltage

0

-200

-400

-600

Output Sink Current (milliamperes)

-800

012345

Output Voltage (Volts)

100

80

60

40

20

Output Source Current (milliamperes)

0

012345

Output Voltage (Volts)

3-16 Specifications

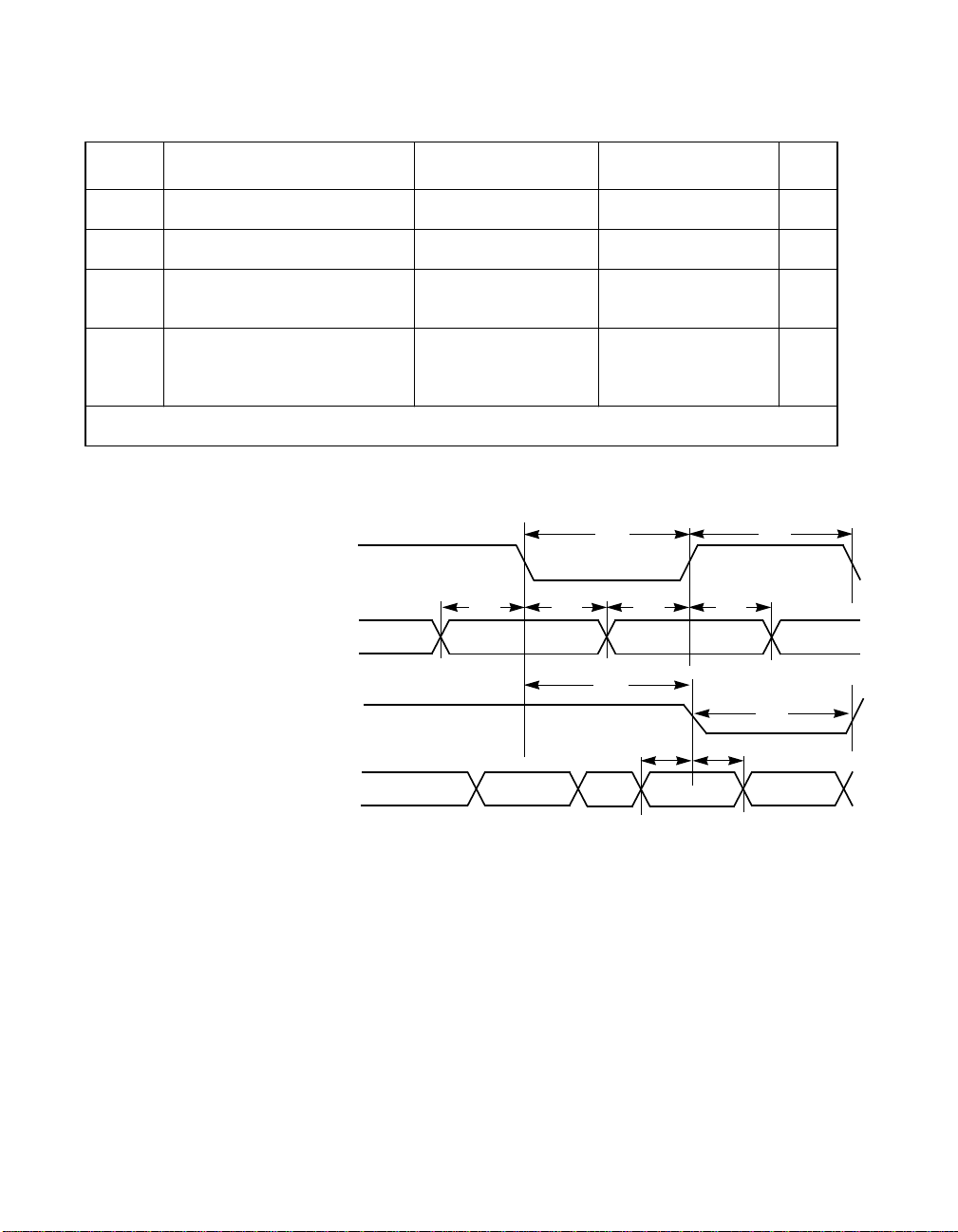

Page 51

3.2.3 AC Characteristics

The AC characteristics described in this section apply over the entire

range of operating conditions (refer to DC Characteristics in this chapter).

Chip timing is based on simulation at worst case voltage, temperature,

and processing. The LSI53C180 requires a 40 MHz clock input.

Table 3.16 Clock Timing

Symbol Parameter Min Max Units

t

1

t

2

t

3

t

4

Clock period 24.75 25.25 ns

Clock low time 10 15 ns

Clock high time 10 15 ns

Clock rise time 1 – V/ns

Figure 3.12 Clock Timing

t

Clock

t

3.2.4 SCSI Interface Timing

Table 3.17 Input Timing - Single Transition

Symbol Parameter Min Max Units

t

t

t

t

ST1

ST2

ST3

ST4

Input data setup 4.5 – ns

Input data hold 4.5 – ns

Input REQ/ACK assertion pulse width 6.5 – ns

Input REQ/ACK deassertion pulse width 6.5 – ns

1

t

3

t

2

4

Electrical Characteristics 3-17

Page 52

Table 3.18 Output Timing - Single Transition

Symbol Parameter Min Max Units

t

ST5

t

ST6

t

ST7

t

ST8

Output data setup Nominal: negotiated/2 – ns

Output data hold Nominal: negotiated/2 – ns

Output REQ/ACK pulse width max [negotiated ns,

t

−5]

ST3

REQ/ACK transport delay 25 ns if REQ/ACK is

clock for input data,

10 ns if not

max [negotiated ns,

t

+5]

ST3

50 ns if REQ/ACK is

clock for input data,

30 ns if not

Note: Pulse width is a negotiated value and ranges from 12.5 to over 1000 ns.

Figure 3.13 Input/Output Timing - Single Transition

t

t

ST8

ST3

t

ST2

t

ST5

SREQ/SACK

Receive Data

(SD[15:0]/)

Output

REQ/ACK

Send Data

(SD[15:0]/

t

ST1

t

t

ST7

ST6

t

ns

ns

ST4

Table 3.19 Input Timing - Double Transition

Symbol Parameter Min Max Units

t

DT1

t

DT2

t

DT3

t

DT4

3-18 Specifications

Input data setup 1.25 – ns

Input data hold 1.25 – ns

Input REQ/ACK assertion pulse width 10 – ns

Input REQ/ACK deassertion pulse width 10 – ns

Page 53

Table 3.20 Output Timing - Double Transition

Symbol Parameter Min Max Units

t

DT5

t

DT6

t

DT7

t

DT8

Output data setup Nominal: negotiated/2 – ns

Output data hold Nominal: negotiated/2 – ns

Output REQ/ACK pulse width max [negotiated ns,

t

−5]

DT3

REQ/ACK transport delay 25 ns if REQ/ACK is

clock for input data,

10 ns if not

max [negotiated ns,

t

+5]

DT3

50 ns if REQ/ACK is

clock for input data,

30 ns if not

Note: Pulse width is a negotiated value and ranges from 12.5 to over 1000 ns.

Figure 3.14 Input/Output Timing - Double Transition

t

DT3

SREQ/SACK

Receive Data

(SD[15:0]/)

Output

REQ/ACK

Send Data

(SD[15:0]/)

t

DT1

t

DT2

t

DT8

t

DT1

t

DT5

t

t

DT2

DT6

t

t

DT7

ns

ns

DT4

Electrical Characteristics 3-19

Page 54

3.3 Mechanical Drawings

LSI Logic component dimensions conform to a current revision of the

JEDEC Publication 95 standard package outline, using ANSI 14.5Y

“Dimensioning and Tolerancing” interpretations. As JEDEC drawings are

balloted and updated, changes may have occurred. To ensure the use

of a current drawing, the JEDEC drawing revision level should be

verified. Visit www.jedec.org representing the Solid State Technology

Association. Search for Publication 95 and click on MO Mechanical

Outlines for drawings and revision levels.

For printed circuit board land patterns that will accept LSI Logic

components, it is recommended that customers refer to the IPC

standards (Institute for Interconnecting and Packaging Electronic

Circuits). Specification number IPC-SM-782, “Surface Mount Design and

Land Pattern Standard” is an established method of designing land

patterns. Feature size and tolerances are industry standards based on

IPC assumptions.

3-20 Specifications

Page 55

3.3.1 LSI53C180 192-Pin BGA Mechanical Drawing

The LSI53C180 is packaged in a 192-pin Plastic Ball Grid Array (PBGA).

Figure 3.15 192-Pin PBGA (IJ, I2) Mechanical Drawing

Important: This drawing may not be the latest version. For board layout and manufacturing, obtain the

most recent engineering drawings from your LSI Logic marketing representative by

requesting the outline drawing for package code IJ, I2.

Mechanical Drawings 3-21

Page 56

3-22 Specifications

Page 57

Appendix A

Wiring Diagrams

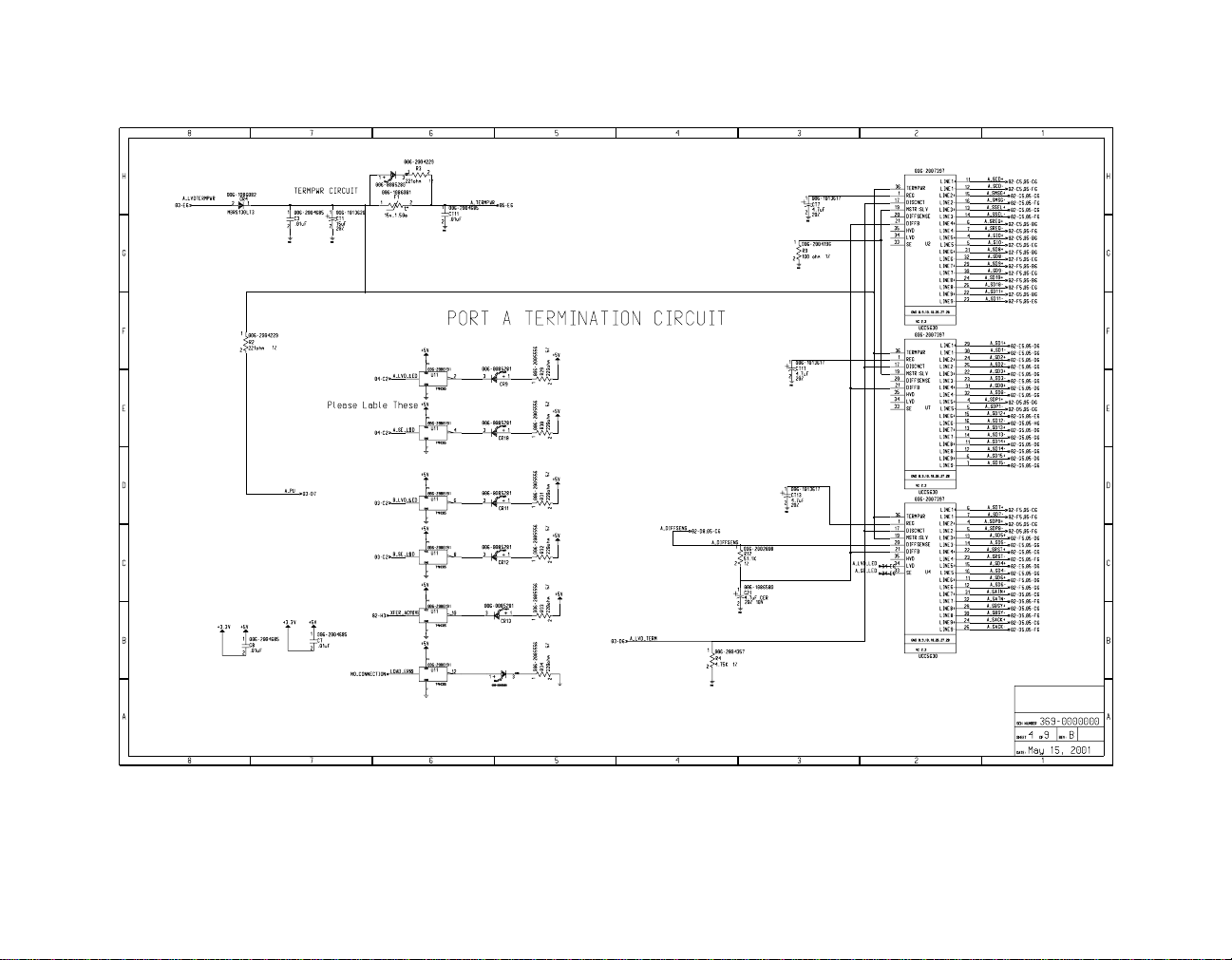

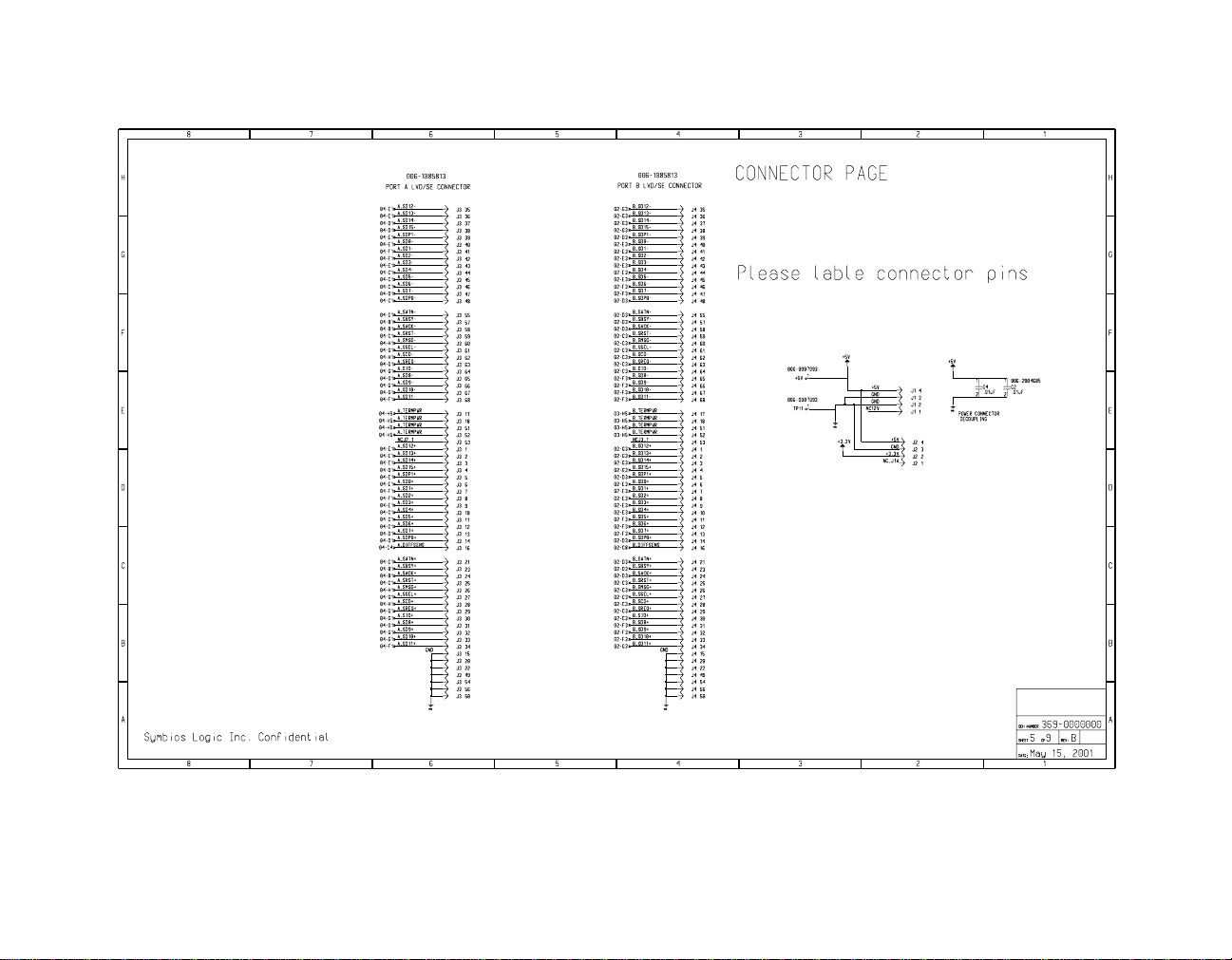

A.1 LSI53C180 Wiring Diagrams

The following four pages of wiring diagrams are of a typical LSI53C180

in a evaluation test board application.

LSI53C180 Ultra3 SCSI Bus Expander A-1

Page 58

A-2 LSI53C180 Wiring Diagrams

Figure A.1 LSI53C180 Wiring Diagram 1 of 4

LSI LOGIC

Storage Systems, Inc.

Page 59

LSI53C180 Wiring Diagrams A-3

Figure A.2 LSI53C180 Wiring Diagram 2 of 4

LSI LOGIC

Storage Systems, Inc.

Page 60

A-4 LSI53C180 Wiring Diagrams

Figure A.3 LSI53C180 Wiring Diagram 3 of 4

LSI LOGIC

Storage Systems, Inc.

Page 61

LSI53C180 Wiring Diagrams A-5

Figure A.4 LSI53C180 Wiring Diagram 4 of 4

LSI LOGIC

Storage Systems, Inc.

Page 62

A-6 Wiring Diagrams

Page 63

Appendix B

Glossary

ACK/ Acknowledge – Driven by an initiator, ACK/ indicates an acknowledgment

or a SCSI data transfer. In the target mode, ACK/ is received as a

response to the REQ/ signal.

ANSI American National Standards Institute.

Arbitration The process of selecting one respondent from a collection of several

candidates that request service concurrently.

Asserted A signal is asserted when it is in the state that is indicated by the name of

the signal. Opposite of negated or deasserted.

Assertion The act of driving a signal to the true state.

Asynchronous

Transmission

ATN/ Attention – Driven by an initiator, indicates an attention condition. In the

Block A block is the basic 512 byte size of storage that the storage media is

BSY/ Busy – Indicates that the SCSI Bus is being used. BSY/ can be driven by

Bus A collection of unbroken signal lines that interconnect computer modules.

Bus Expander Bus expander technology permits the extension of a bus by providing

Transmission in which each byte of the information is synchronized

individually through the use of Request (REQ/) and Acknowledge (ACK/)

signals.

target role, ATN/is received and is responded to by entering the Message

Out Phase.

divided into. The Logical Block Address protocol uses sequential block

addresses to access the media.

the initiator or the target device.

The connections are made by taps on the lines.

some signal filtering and retiming to maintain signal skew budgets.

LSI53C180 Ultra3 SCSI Bus Expander B-1

Page 64

Cable Skew

Delay

Cable skew delay is the minimum difference in propagation time allowed

between any two SCSI bus signals measured between any two SCSI

devices.

C_D/ Control/Data – Driven by a target. When asserted, indicates Control or

Data Information is on the SCSI Bus. This signal is received by the

initiator.

Connect The function that occurs when an initiator selects a target to start an

operation, or a target reselects an initiator to continue an operation.

Control Signals The set of nine lines used to put the SCSI bus into its different phases.

The combinations of asserted and negated control signals define the

phases.

Controller A computer module that interprets signals between a host and a

peripheral device. Often, the controller is a part of the peripheral device,

such as circuitry on a disk drive.

DB[7:0]/ SCSI Data Bits – These eight Data Bits (DB[7:0]/), plus a Parity Bit

(DBP/), form the SCSI bus. DB7/ is the most significant bit and has the

highest priority ID during the Arbitration Phase. Data parity is odd. Parity

is always generated and optionally checked. Parity is not valid during

arbitration.

Deasserted The act of driving a signal to the false state or allowing the cable

terminators to bias the signal to the false state (by placing the driver in the

high impedance condition).

A signal is deasserted or negated when it is in the state opposite to that

which is indicated by the name of the signal. Opposite of asserted.

Device A single unit on the SCSI bus, identifiable by a SCSI address. It can be a

processor unit, a storage unit (such as a disk or tape controller or drive),

an output unit (such as a controller or printer), or a communications unit.

Differential A signaling alternative that employs differential drivers and receivers to

improve signal-to-noise ratios and increase maximum cable lengths.

Disconnect The function that occurs when a target releases control of the SCSI bus,

allowing the bus to go to the Bus Free phase.

Driver When used in the context of electrical configuration, “driver” is the

circuitry that creates a signal on a line.

B-2 Glossary

Page 65

External

Configuration

All SCSI peripheral devices are external to the host enclosure.

External

Terminator

The terminator that exists on the last peripheral device that terminates the

end of the external SCSI bus.

Free In the context of Bus Free phase, “free” means that no SCSI device is

actively using the SCSI bus and, therefore, the bus is available for use.

Host A processor, usually consisting of the central processing unit and main

memory. Typically, a host communicates with other devices, such as

peripherals and other hosts. On the SCSI bus, a host has a SCSI

address.

Host Adapter Circuitry that translates between a processor's internal bus and a different

bus, such as SCSI. On the SCSI bus, a host adapter usually acts as an

initiator.

Initiator A SCSI device that requests another SCSI device (a target) to perform an

operation. Usually, a host acts as an initiator and a peripheral device acts

as a target.

Internal

All SCSI peripheral devices are internal to the host enclosure.

Configuration

Internal

Terminator

The terminator that exists within the host that terminates the internal end

of the SCSI bus.

I/O Input/Output – Driven by a target. I/O controls the direction of data

transfer on the SCSI bus. When active, this signal indicates input to the

initiator. When inactive, this signal indicates output from the initiator. This

signal is also used to distinguish between the Selection and Reselection

Phases.

I/O Cycle An I/O cycle is an Input (I/O Read) operation or Output (I/O Write)

operation that accesses the PC Card’s I/O address space.

Logical Unit The logical representation of a physical or virtual device, addressable

through a target. A physical device can have more than one logical unit.

Low (logical

A signal is at the low logic level when it is below approximately 0.5 volts.

level)

B-3

Page 66

LSB Abbreviation for Least Significant Bit or Least Significant Byte. That

portion of a number, address or field that occurs right-most when its value

is written as a single number in conventional hexadecimal or binary

notation. The portion of the number having the least weight in a