HFBR-RXXYYYZ Series (POF)

HFBR-EXXYYYZ Series (POF)

Plastic Optical Fiber Cable and Accessories

for V ersatile Link

Data Sheet

Cable Description

The HFBR-R/EXXYYYZ series of plastic fiber optic

cables are constructed of a single step-index fiber

sheathed in a black polyethylene jacket. The duplex

fiber consists of two simplex fibers joined with a

zipcord web.

Standard attenuation and extra low loss POF cables

are identical except for attenuation specifications.

Polyethylene jackets on all plastic fiber cables comply

with UL VW-1 flame retardant specification (UL file #

E89328).

Cables are available in unconnectored or connectored

options. Refer to the Ordering Guide for part number

information.

500

400

300

Features

• Compatible with Avago Versatile Link family of

connectors and fiber optic components

•1 mm diameter Plastic Optical Fiber (POF) in two

grades: low cost standard POF with 0.22 dB/m typical

attenuation, or high performance extra low loss POF

with 0.19 dB/m typical attenuation

Applications

• Industrial data links for factory automation and plant

control

• Intra-system links; board-to-board, rack-to-rack

• Telecommunications switching systems

• Computer-to-peripheral data links, PC bus extension

• Proprietary LANs

• Digitized video

• Medical instruments

• Reduction of lightning and voltage transient

susceptibility

• High voltage isolation

200

– ATTENUATION – dB/km

R

α

100

620

Figure 1. Typical POF attenuation vs. wavelength.

660

λ – WAVELENGTH – nm

680640 700

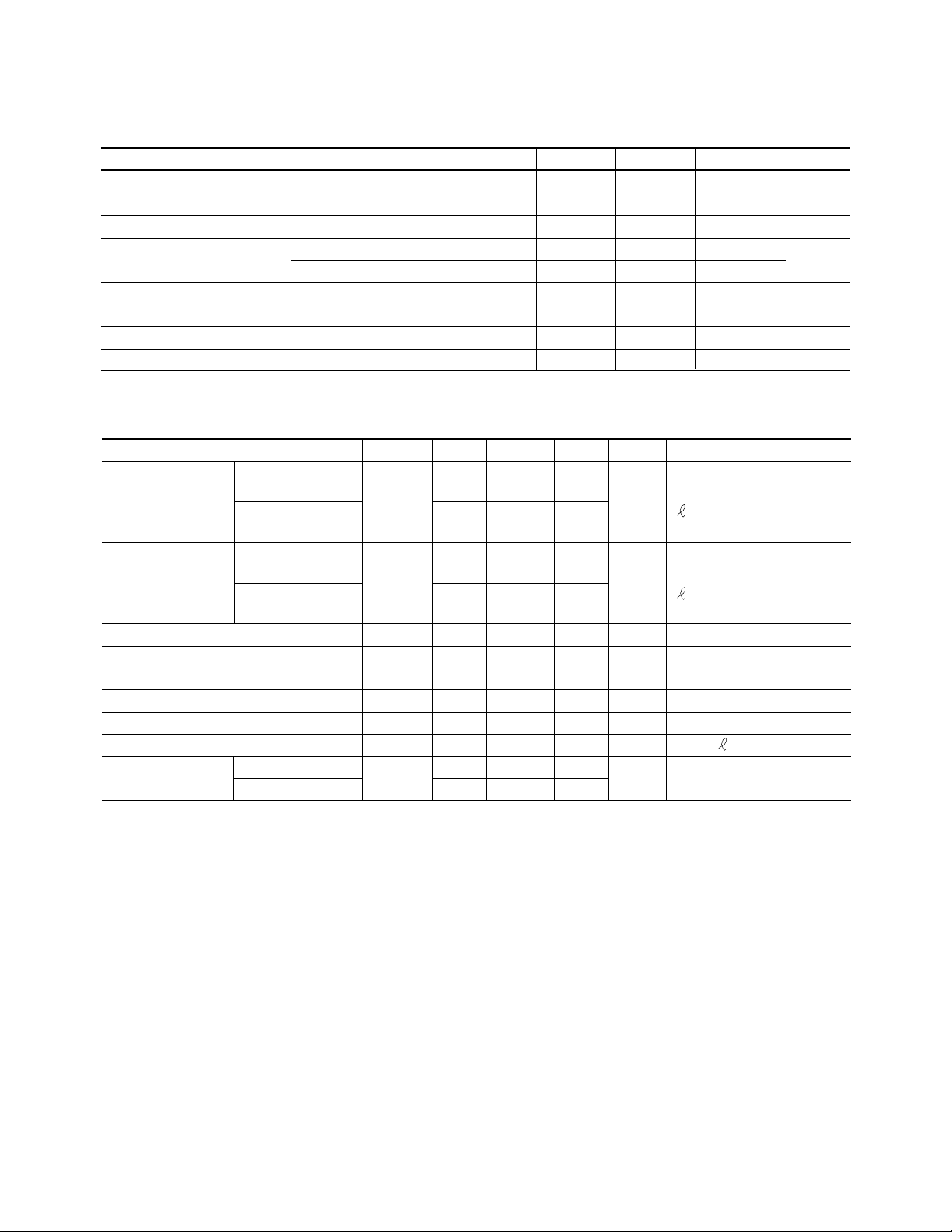

Plastic Optical Fiber Specifications: HFBR-R/EXXYYYZ

Absolute Maximum Ratings

Parameter Symbol Min. Max. Unit Note

Storage and Operating Temperature T

Recommended Operating Temperature T

Installation Temperature T

Short Term Tensile Single Channel F

Force

Dual Channel F

S,O

O

I

T

T

-55 +85 °C

-40 +85 °C

-20 +70 °C1

50 N 2

100 N

Short Term Bend Radius r 25 mm 3, 4

Long Term Bend Radius r 35 mm

Long Term Tensile Load F

T

1N

Flexing 1000 Cycles 4

Mechanical/Optical Characteristics, TA = -40 to +85°C unless otherwise specified.

Parameter Symbol Min. Typ.

Cable Standard Cable, α

O

0.15 0.22 0.27 dB/m Source is HFBR-15XXZ

[5]

Max. Unit Condition

Attenuation Type "R" (660 mm LED, 0.5 NA)

Extra Low Loss, 0.15 0.19 0.23 = 50 meters

Type "E"

Reference Standard Cable, α

R

0.12 0.19 0.24 dB/m Source is 650 nm,

Attenuation Type "R" 0.5 NA monochrometer,

Extra Low Loss, 0.12 0.16 0.19 = 50 meters

Type "E" Note 7, Figure 1

Numerical Aperture NA 0.46 0.47 0.50 >2 meters

Diameter, Core and Cladding D

Diameter, Jacket D

C

J

0.94 1.00 1.06 mm

2.13 2.20 2.27 mm Simplex Cable

Propagation Delay Constant l/v 5.0 ns/m Note 6

Mass per Unit Length/Channel 5.3 g/m Without Connectors

Cable Leakage Current I

L

12 nA 50 kV, = 0.3 meters

Refractive Index Core n 1.492

Cladding 1.417

Notes:

1. Installation temperature is the range over which the cable can be bent and pulled without damage. Below -20°C the cable becomes brittle and

should not be subjected to mechanical stress.

2. Short Term Tensile Force is for less than 30 minutes.

3. Short Term Bend Radius is for less than 1 hour nonoperating.

4. 90° bend on 25 mm radius mandrel. Bend radius is the radius of the mandrel around which the cable is bent.

5. Typical data are at 25°C.

6. Propagation delay constant is the reciprocal of the group velocity for propagation delay of optical power. Group velocity is v=c/n where c is the

velocity of light in free space (3xl08 m/s) and n is the effective core index of refraction.

7. Note that αR rises at the rate of about 0.0067 dB/°C, where the thermal rise refers to the LED temperature changes above 25°C. Please refer to

Figure 1 which shows the typical plastic optical fiber attenuation versus wavelength at 25°C.

2

Plastic Fiber Connector Styles

Connector Description

Four connector styles are available

for termination of plastic optical

fiber: simplex, simplex latching,

duplex and duplex latching. All

connectors provide a snap-in

action when mated to Versatile

Link components. Simplex

connectors are color coded to

facilitate identification of transmitter and receiver connections.

Duplex connectors are keyed so

that proper orientation is ensured

during insertion. If the POF cable/

connector will be used at extreme

operating temperatures or

experience frequent and wide

temperature cycling effects, the

cable/connector attachment can

be strengthened with an RTV

adhesive (see Plastic Connectoring Instructions for more detail).

The connectors are made of a

flame retardant VALOX UL94 V-0

material (UL file # E121562).

SIMPLEX CONNECTOR STYLES

HFBR-4501Z/4511Z – Simplex

, HFBR-4525Z

HFBR-4503Z/4513Z – Simplex Latching

HFBR-4525Z

The simplex latching connector is

designed for rugged applications

requiring a greater retention force

— 80 Newtons ( 18 lb.) — than

provided by a simplex nonlatching

connector. When inserting the

simplex latching connector into a

module, the connector latch

mechanism should be aligned with

the top surface of the horizontal

modules, or with the tall vertical

side of the vertical modules.

Misalignment of an inserted

latching connector into either

module will not result in a positive

latch. The connector is released

by depressing the rear section of

the connector lever, and then

pulling the connector assembly

away from the module housing.

The simplex latching connector is

available in gray (HFBR-4503Z) or

blue (HFBR-4513Z).

DUPLEX CONNECTOR STYLES

HFBR-4506Z – Duplex

latching connector is available in

parchment, off-white (HFBR4506Z).

HFBR-4516Z – Duplex Latching

HFBR-4526Z

The duplex latching connector is

designed for rugged applications

requiring greater retention force

than the nonlatching duplex connector. When inserting the duplex

latching connector into a module,

the connector latch mechanism

should be aligned with the top

surface of the dual combination of

horizontal or vertical Versatile Link

components. The duplex latching

connector is available in gray

(HFBR-4516Z).

,

Feedthrough/Splice

HFBR-4505Z/4515Z Bulkhead Adapter

The simplex connector provides a

quick and stable connection for

applications that require a

component-to-connector retention

force of 8 Newtons (1.8 lb.).

These connectors are available in

gray (HFBR-4501Z) or blue

(HFBR-4511Z).

3

HFBR-4526Z

Duplex connectors provide convenient duplex cable termination

and are keyed to prevent incorrect

insertion into duplex configured

modules. The duplex connector is

compatible with dual combinations of horizontal or vertical

Versatile Link components (e.g.,

two horizontal transmitters, two

vertical receivers, a horizontal

transmitter with a horizontal

receiver, etc.). The duplex non-

The HFBR-4505Z/4515Z adapter

mates two simplex connectors for

panel/bulkhead feedthrough of

HFBR-4501Z/4511Z terminated

plastic fiber cable. Maximum panel

thickness is 4.1 mm (0.16 inch).

This adapter can serve as a cable

in-line splice using two simplex

connectors. The adapters are

available in gray (HFBR-4505Z)

and blue (HFBR-4515Z). This

adapter is not compatible with POF

duplex, POF simplex latching, or

HCS connectors.

Plastic Optical Fiber Connector Absolute Maximum Ratings

Parameter Symbol Min. Max. Unit Note

Storage and Operating Temperature T

Recommended Operating Temperature T

Installation Temperature T

Nut Torque T

S,O

O

l

N

HFBR-4505Z/4515Z Adapter

Notes:

1. Storage and Operating Temperatures refer to the ranges over which the connectors can be used when not subjected to mechanical stress.

Installation Temperature refers to the ranges over which connectors may be installed onto the fiber and over which connectors can be connected

and disconnected from transmitter and receiver modules.

2. Recommended nut torque is 0.57 N-m.

-40 85 °C1

-40 85 °C1

070 °C1

0.7 N-m 2

100 OzF-in.

Plastic Optical Fiber Connector Mechanical/Optical Characteristics

TA = -40 to +85°C, Unless Otherwise Specified.

Parameter Part Number Symbol Min. Typ.

Retention Force, Simplex, F

R-C

78 N +25 2

[1]

Max. Units Temp. °C Note

Connector to HFBR-4501Z/4511Z 3 -40 to +85

Versatile Link

Transmitters and

Receivers

Simplex Latching, 47 80 +25

HFBR-4503Z/4513Z 11 -40 to +85

Duplex, 7 12 +25

HFBR-4506Z 4 -40 to +85

Duplex Latching, 50 80 +25

HFBR-4516Z 15 -40 to +85

Tensile Force, Simplex, F

8.5 22 N 3

T

Connector to Cable HFBR-4501Z/4511Z

Simplex Latching, 8.5 22

HFBR-4503Z/4513Z

Duplex, HFBR-4506Z 14 35

Duplex Latching, 14 35

HFBR-4516Z

Adapter Connector HFBR-4505Z/4515Z with α

CC

0.7 1.5 2.8 dB 25 4, 5

to Connector Loss HFBR-4501Z/4511Z

Retention Force HFBR-4505Z/4515Z with F

R-B

78 N

Connector to Adapter HFBR-4501Z/4511Z

Insertion Force, Simplex, F

Connector to Versatile

Link Transmitters and

Receivers

HFBR-4501Z/4511Z

Simplex Latching, 16 35

HFBR-4503Z/4513Z

I

830N 6

Duplex, HFBR-4506Z 13 46

Duplex Latching 22 51

HFBR-4516Z

Notes:

1. Typical data are at +25°C.

2. No perceivable reduction in retention force was observed after 2000 insertions. Retention force of non-latching connectors is lower at elevated

temperatures. Latching connectors are recommended for applications where a high retention force at high temperatures is desired.

3. For applications where frequent temperature cycling over temperature extremes is expected, please contact Avago Technologies for alternate

connectoring techniques.

4. Minimum and maximum limit for αCC for 0°C to +70°C temperature range. Typical value of αCC is at +25°C.

5. Factory polish or field polish per recommended procedure.

6. Destructive insertion force was typically at 178 N (40 lb.).

4

Step-by-Step Plastic Cable

Connectoring Instructions

The following step-by-step guide

describes how to terminate plastic

fiber optic cable. It is ideal for

both field and factory installation.

Connectors can be easily installed

on cable ends with wire strippers,

cutters and a crimping tool.

Finishing the cable is accomplished with the Avago

HFBR-4593Z Polishing Kit,

consisting of a Polishing Fixture,

600 grit abrasive paper and 3 µm

pink lapping film (3M Company,

OC3-14). The connector can be

used immediately after polishing.

Materials needed for plastic fiber

termination are:

1. Avago Plastic Optical Fiber

Cable (Example: HFBRRUS500Z, HFBR-RUD500Z,

HFBR-EUS500Z, or HFBREUD500Z)

2. Industrial Razor Blade or Wire

Cutters

3. 16 Gauge Latching Wire

Strippers (Example: Ideal

StripmasterTM type 45-092).

4. HFBR-4597Z Crimping Tool

5. HFBR-4593Z Polishing Kit

6. One of the following

connectors:

a) HFBR-4501Z/4503Z Gray

Simplex/Simplex Latching

Connector and HFBR-4525Z

Simplex Crimp Ring

b) HFBR-4511Z/4513Z Blue

Simplex/Simplex Latching

Connector and HFBR-4525Z

Simplex Crimp Ring

c) HFBR-4506Z Parchment

(off-white) Duplex

Connector and HFBR-4526Z

Duplex Crimp Ring

d) HFBR-4516Z Gray Latching

Duplex Connector and

HFBR-4526Z Duplex Crimp

Ring

Step 1

The zip cord structure of the

duplex cable permits easy

separation of the channels. The

channels should be separated a

minimum of 100 mm (4 in) to a

maximum of 150 mm (6 in) back

from the ends to permit

connectoring and polishing.

After cutting the cable to the

desired length, strip off approximately 7 mm (0.3 in.) of the outer

jacket with the 16 gauge wire

strippers. Excess webbing on the

duplex cable may have to be

trimmed to allow the simplex or

simplex latching connector to

slide over the cable.

When using the duplex connector

and duplex cable, the separated

duplex cable must be stripped to

equal lengths on each cable. This

allows easy and proper seating of

the cable into the duplex

connector.

Step 2

Place the crimp ring and connector over the end of the cable; the

fiber should protrude about 3 mm

(0.12 in.) through the end of the

connector. Carefully position the

ring so that it is entirely on the

connector with the rim of the

crimp ring flush with the connector, leaving a small space between

the crimp ring and the flange.

Then crimp the ring in place with

the crimping tool. One crimp tool

is used for all POF connector

crimping requirements.

For applications with extreme

temperature operation or frequent

temperature cycling, improved

connector to cable attachment

can be achieved with the use of an

RTV (GE Company, RTV-128 or

Dow Corning 3145-RTV)

adhesive. The RTV is placed into

the connector prior to insertion of

the fiber and the fiber is crimped

normally. The connector can be

polished after the RTV has cured

and is then ready for use.

Note: By convention, place the

gray connector on the transmitter cable end and the blue

connector on the receiver cable

end to maintain color coding

(different color connectors are

mechanically identical).

Simplex connector crimp rings

cannot be used with duplex connectors and duplex connector

crimp rings cannot be used

with simplex connectors because

of size differences. The simplex

crimp has a dull luster appearance; the duplex ring is glossy

and has a thinner wall.

5

Step 3

Any excess fiber protruding from

the connector end may be cut off;

however, the trimmed fiber

should extend at least 1.5 mm

(0.06 in) from the connector end.

dot is no longer visible.

Typically, the polishing fixture

can be used 10 times; 10 duplex

connectors or 20 simplex

connectors, two at a time.

Place the 600 grit abrasive paper

on a flat smooth surface, pressing

down on the connector, polish the

fiber and the connector using a

figure eight pattern of strokes

until the connector is flush with

the bottom of the polishing

fixture. Wipe the connector and

fixture with a clean cloth or

tissue.

Step 4

Place the flush connector and

polishing fixture on the dull side

of the 3 µm pink lapping film and

continue to polish the fiber and

connector for approximately 25

strokes. The fiber end should be

flat, smooth and clean.

Note: Use of the pink lapping

film fine polishing step results

in approximately 2 dB

improvement in coupling

performance of either a

transmitter-receiver link or a

bulkhead/splice over a 600 grit

polish alone. This fine polish is

comparable to the Avago

factory polish. The fine

polishing step may be omitted

where an extra 2 dB of optical

power is not essential, as with

short link lengths. Proper

polishing of the tip of the fiber/

connector face results in a tip

diameter between 2.5 mm

(0.098 in.) minimum and 3.2

mm (0.126 in.) maximum..

HFBR-4593Z Polishing Kit

Insert the connector fully into the

polishing fixture with the trimmed

fiber protruding from the bottom

of the fixture. This plastic polishing fixture can be used to polish

two simplex connectors or simplex

latching connectors simultaneously, or one duplex connector.

Note: The four dots on the

bottom of the polishing fixture

are wear indicators. Replace

the polishing fixture when any

This cable is now ready for use.

6

Ordering Guide for POF Connectors and Accessories

Plastic Optical Fiber Connectors

HFBR-4501Z Gray Simplex Connector/Crimp Ring

HFBR-4511Z Blue Simplex Connector/Crimp Ring

HFBR-4503Z Gray Simplex Latching Connector with Crimp Ring

HFBR-4513Z Blue Simplex Latching Connector with Crimp Ring

HFBR-4506Z Parchment Duplex Connector with Crimp Ring

HFBR-4516Z Gray Duplex Latching Connector with Crimp Ring

HFBR-4505Z Gray Adapter (Bulkhead/Feedthrough)

HFBR-4515Z Blue Adapter (Bulkhead/Feedthrough)

Plastic Optical Fiber Accessories

HFBR-4522Z 500 HFBR-0500Z Products Port Plugs

HFBR-4525Z 1000 Simplex Crimp Rings

HFBR-4526Z 500 Duplex Crimp Rings

HFBR-4593Z Polishing Kit (one polishing tool, two pieces 600 grit

abrasive paper, and two pieces 3 µm pink lapping film)

HFBR-4597Z Plastic Fiber Crimping Tool

Ordering Guide for POF Cable

For Example:

HFBR-RUD500Z is a Standard

Attenuation, Unconnectored,

Duplex, 500 meter cable.

HFBR-RLS001Z is a Standard

Attenuation, Latching Simplex

Connectored, Simplex, 1 meter

cable.

Cable Code

R = Standard Attenuation POF

E = Extra Low Loss POF

Connector Code

U = Unconnectored

N = Standard Simplex Connectors

L = Latching Simplex Connectors

M = Standard Duplex Connectors

T = Latching Duplex Connectors

HFBR-RMD010Z is a Standard

Attenuation, Standard Duplex

Connectored, Duplex, 10 meter

cable.

HFBR-RMD100Z is a Standard

Attenuation, Standard Duplex

Connectored, Duplex, 100 meter

cable.

HFBR-

Z

Channel Code

S = Simplex Cable

D = Duplex Zipcord Cable

Cable Length Tolerances:

The plastic cable length

tolerances are: +10%/-0%.

NOTE: By convention, preconnectored simplex POF cables

have gray and blue colored

connectors on the opposite ends

of the same fiber; although

oppositely colored, the

connectors are mechanically

identical. Duplex POF cables with

duplex connectors use colorcoded markings on the duplex

fiber cable to differentiate

between the channel.

RoHS Compliant

Length Code (measured from tip of

connector to tip of connector)

Maximum 500 meters (not in 1 meter

increments).

See www.avagotech.com/fiber/cables

e.g., 015 = 15 meters

Note: Not all possible combinations reflect available part numbers. Please contact your local

Avago representative for a list of current available cable part numbers.

7

Connector Applications

Attachment to Avago Versatile Link Fiber Optic Components

Bulkhead Feedthrough or Panel Mounting for HFBR-4501Z/4511Z Simplex Connectors

Versatile Link Mechanical Dimensions

All dimensions in mm (inches).

All dimensions ± 0.25 mm unless otherwise specified.

Fiber Optic Cable Dimensions

1.0 POF

(0.039)

0.230

HCS

(0.009)

HFBR-4505Z (Gray)/4515Z (Blue) Adapters

Panel Mounting – Bulkhead Feedthrough

Bulkhead Feedthrough with Two HFBR-4501Z/4511Z Connectors

Versatile Link Mechanical Dimensions, continued

HFBR-4516Z (Parchment) Duplex Latching Connector

HFBR-4503Z (Gray)/4513Z (Blue) Simplex Latching

Connector

HFBR-4506Z (Parchment) Duplex Connector

HFBR-4501Z (Gray)/4511Z (Blue) Simplex Connector

10

For product information and a complete list of distributors, please go to our website: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies Limited in the United States and other countries.

Data subject to change. Copyright © 2006 Avago Technologies Limited. All rights reserved.

AV01-0150EN May 14, 2006

Loading...

Loading...