Page 1

HDSP-253x Series

Eight Character 5 mm Smart Alphanumeric Display

Data Sheet

Description

The HDSP-253x is ideal for applications where displaying

eight or more characters of dot matrix information in an

aesthetically pleasing manner is required. These devices

are eight-digit, 5 x 7 dot matrix, alphanumeric displays.

The 5.0 mm (0.2 inch) high characters are packaged in a

0.300 inch (7.62 mm) 30 pin DIP. The on-board CMOS IC

has the ability to decode 128 ASCII characters, which are

permanently stored in ROM. In addition, 16 programmable

symbols may be stored in on-board RAM. Seven brightness

levels provide versatility in adjusting the display intensity

and power consumption. The HDSP-253x is designed for

standard microprocessor interface techniques. The display

and special features are accessed through a bidirectional

eight-bit data bus.

Features

• XY stackable

• 128 character ASCII decoder

• Programmable functions

• 16 user denable characters

• Multi-level dimming and blanking

• TTL compatible CMOS IC

• Wave solderable

Applications

• Avionics

• Computer peripherals

• Industrial instrumentation

• Medical equipment

• Portable data entry devices

• Telecommunications

• Test equipment

Device Selection Guide

AlGaAs Red HER Orange Yellow Green

HDSP-2534 HDSP-2532 HDSP-2530 HDSP-2531 HDSP-2533

ESD WARNING: Normal CMOS handling precautions should be observed to avoid static discharge.

Page 2

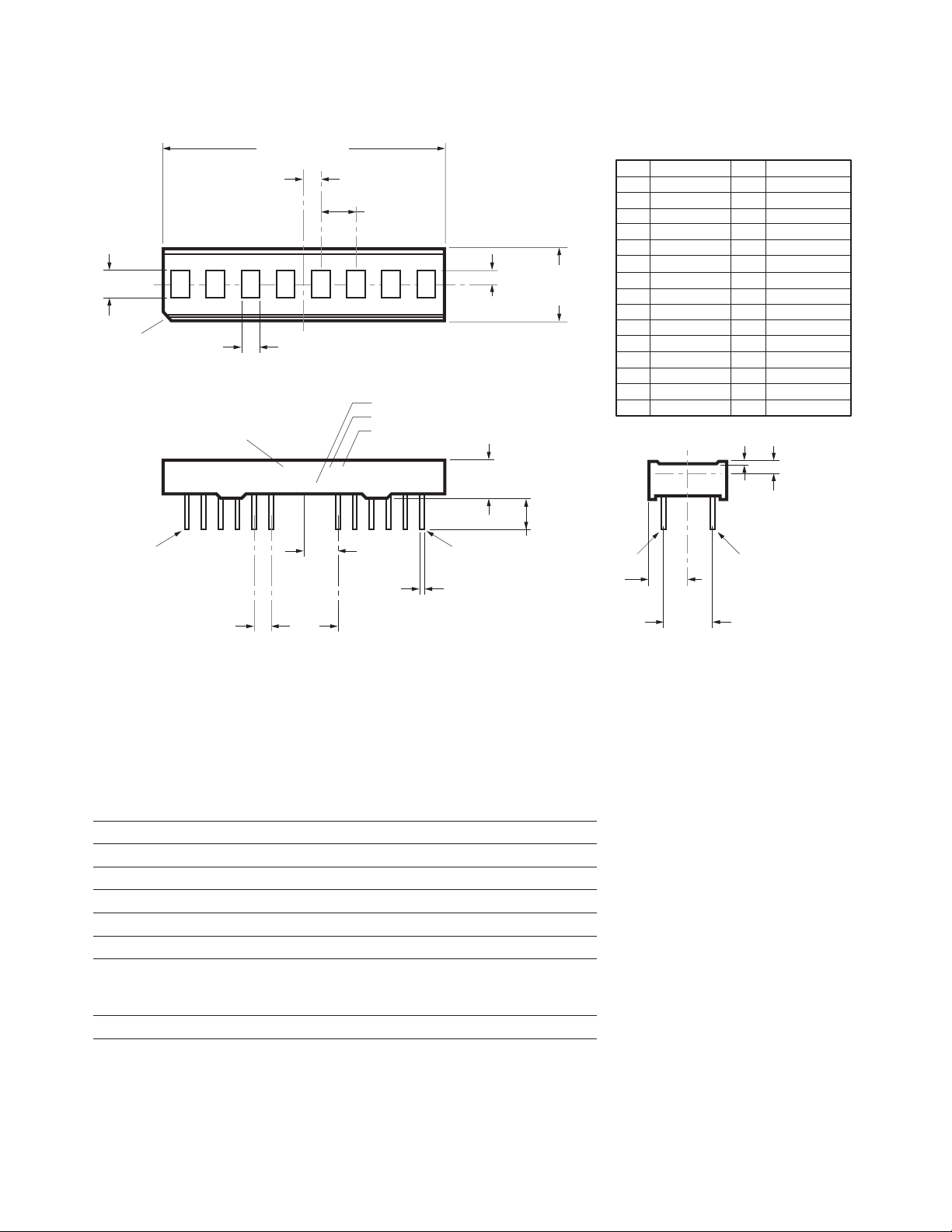

Package Dimensions

PIN # 15

SYM.

TYP.

DATE CODE (YEAR, WEEK)

LUMINOUS INTENSITY CATEGORY

COLOR BIN (3)

3.81

(0.150)

PIN # 16

1.52

(0.060)

5.31

(0.209)

2.29

(0.090)

4.57

(0.180)

[4]

4.01

(0.158)

SYM.

5.08

(0.200)

10.16

(0.400)

TYP.

0.46 0.13

(0.018 0.005)

TYP.

PIN #1

PART NUMBER

2.54 0.13

(0.100 0.005)

(TOL. NON ACCUM.)

7.62

(0.300)

REF.

0.25

(0.010)

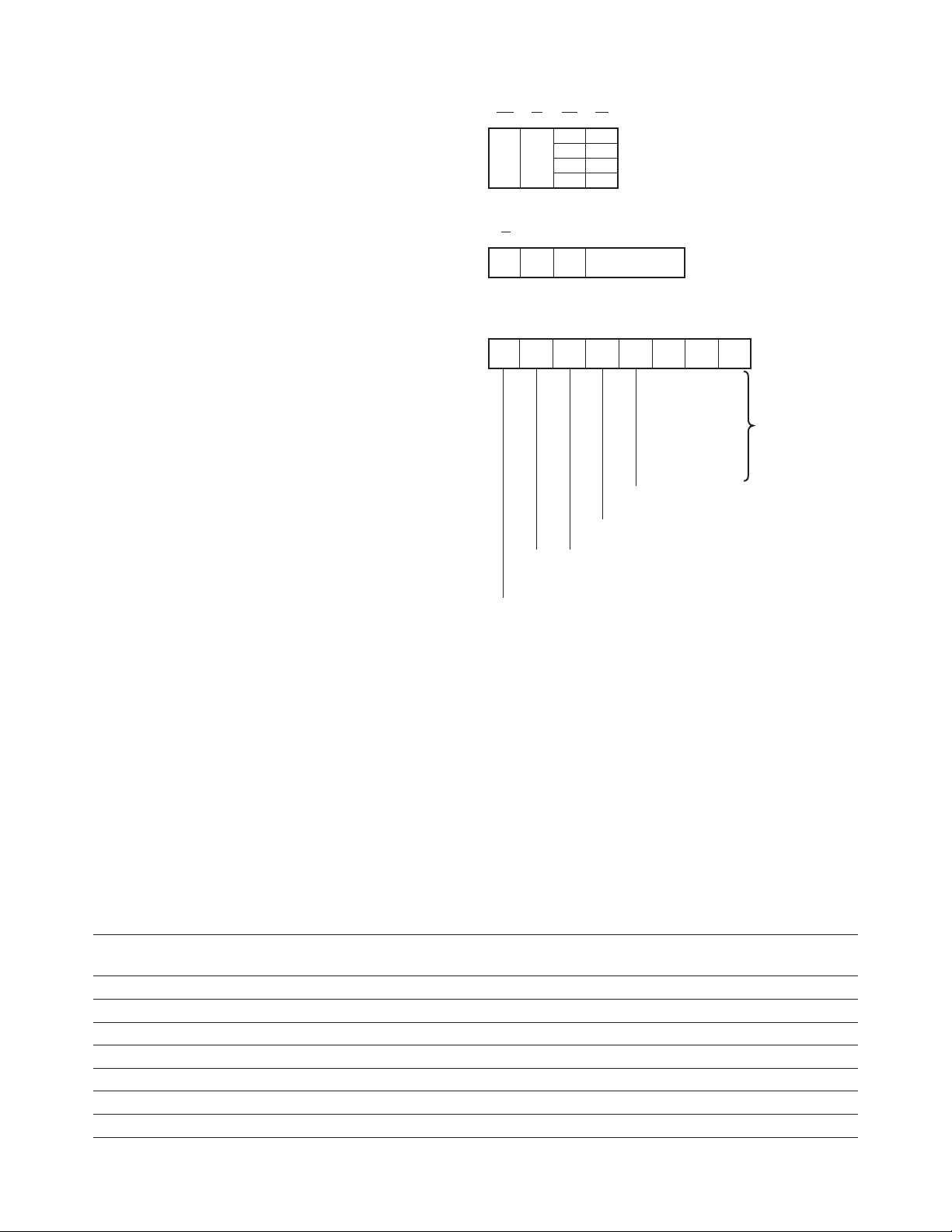

PIN # FUNCTION PIN # FUNCTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

RST

FL

A0

A1

A2

A3

NO PIN

NO PIN

NO PIN

A4

CLS

CLK

WR

CE

V

DD

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

GND (SUPPLY)

THERMAL TEST

GND (LOGIC)

RD

D0

D1

NO PIN

NO PIN

NO PIN

D2

D3

D4

D5

D6

D7

PIN FUNCTION ASSIGNMENT TABLE

3 4 5 6 7

TYP.

SYM.

11.43

(0.450)

MAX.

TYP.

2.54

(0.100)

SYM.

2.68

(0.105)

42.93 (1.690) MAX.

TYP.

5.36

(0.211)

PIN #15

PIN #1 IDENTIFIER

HDSP-253x X Z

YYWW

210

Notes:

1. Dimensions are in mm (inches).

2. Unless otherwise specied, tolerance on dimensions is ±0.25 mm (0.010 inch).

3. For yellow and green displays only.

4. Marking is on side opposite pin 1.

Absolute Maximum Ratings

Supply Voltage, VDD to Ground

Operating Voltage, VDD to Ground

Input Voltage, Any Pin to Ground -0.3 V to VDD +0.3 V

Free Air Operating Temperature Range, T

Relative Humidity (Noncondensing) 85%

Storage Temperature Range, TS -55°C to 100°C

Soldering Temperature [1.59 mm (0.063 in.) Below Body]

Solder Dipping 260°C for 5 secs

Wave Soldering 250°C for 3 secs

ESD Protection @ 1.5 kΩ, 100 pF 4 kV (each pin)

Notes:

1. Maximum voltage is with no LEDs illuminated.

2. 20 dots ON in all locations at full brightness.

3. See Thermal Considerations section for information about operation in high temperature

ambients.

2

[1]

-0.3 V to 7.0 V

[2]

5.5 V

A

[3 ]

-40°C to + 85°C

Page 3

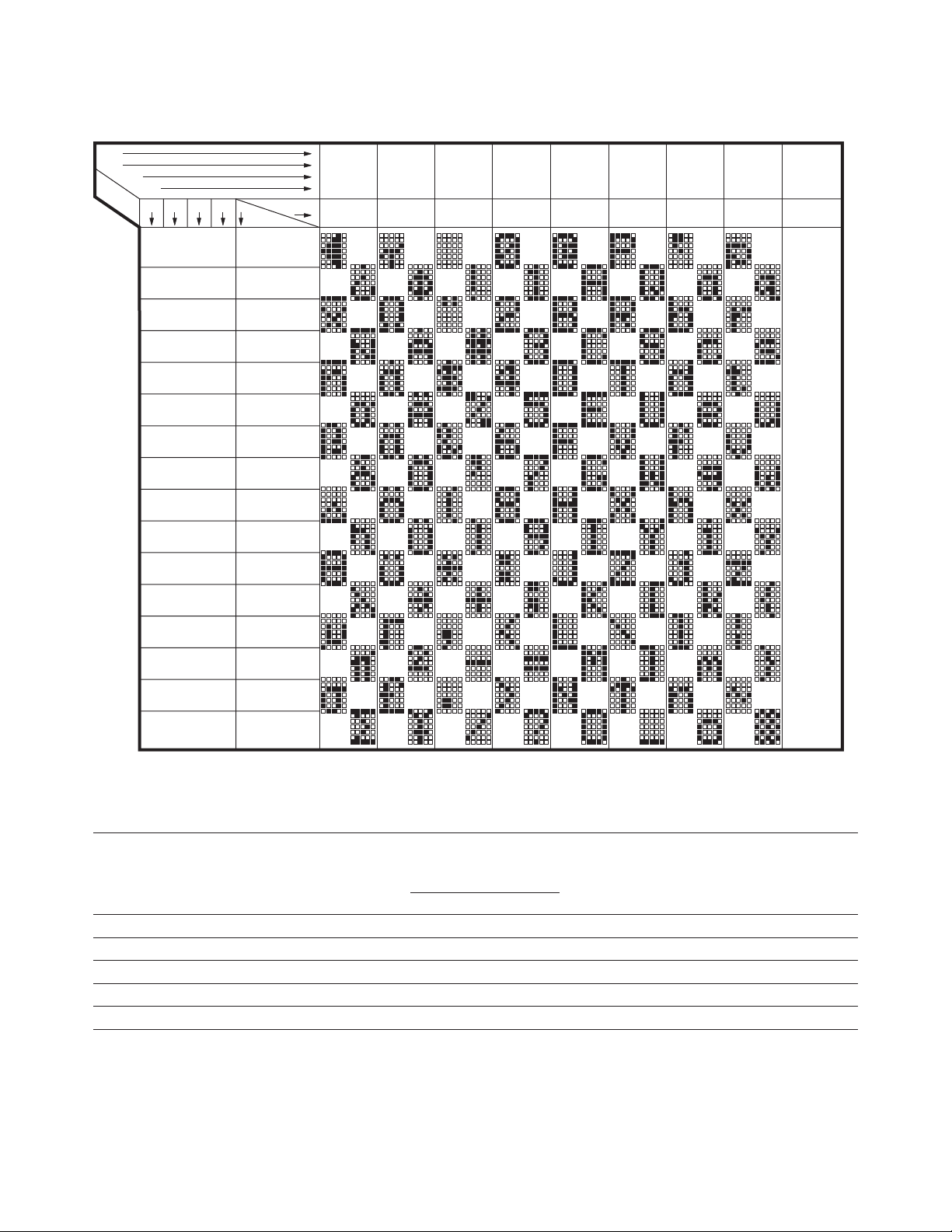

ASCII Character Set

D7

D6

D5

D4

BIT

S

D3 D0D2 D1

ROW

COLUMN

0000 0

0001 1

0010 2

0011 3

0100 4

0101 5

0110 6

0111 7

1000 8

1001 9

1010 A

1011 B

1100 C

1101 D

1110 E

1111 F

0

0

0

0

0

0

0

0

1

1

0

0

1

0

2

0

0

1

1

3

0

1

0

0

4

0

1

0

1

5

0

1

1

0

6

0

1

1

1

7

1

X

X

X

8–F

16

U

S

E

R

D

E

F

I

N

E

D

C

H

A

R

A

C

T

E

R

S

Optical Characteristics at 25°C

VDD = 5.0 V at Full Brightness

Luminous Intensity Peak Dominant

Character Average (#) Wavelength Wavelength

IV (mcd) l

LED Color Part Number Min. Typ. Typ. Typ.

AlGaAs Red HDSP-2534 5.1 25 645 637

High Eciency Red HDSP-2532 2.5 7.5 635 626

Orange HDSP-2530 2.5 7.5 600 602

Yellow HDSP-2531 2.5 7.5 583 585

Green HDSP-2533 2.5 7.5 568 574

Notes:

1. Refers to the initial case temperature of the device immediately prior to measurement.

2. Dominant wavelength, ld, is derived from the CIE chromaticity diagram, and represents the single wavelength which denes the color of the device.

[1]

PEAK

(nm) ld (nm)

[2]

3

Page 4

Recommended Operating Conditions

Parameter Symbol Minimum Nominal Maximum Units

Supply Voltage VDD 4.5 5.0 5.5 V

Electrical Characteristics over Operating Temperature Range

4.5 < VDD < 5.5 unless otherwise specied

25°C 25°C

Parameter Symbol Min. Typ.

Input Leakage II -1.0 1.0 mA VIN = 0 to VDD, Pins CLK,

(Input without Pull-up) D0-D7, A0-A

Input Current IIP -30 -11 -18 0 mA VIN = 0 to VDD, Pins CLS,

(Input with Pull-up) RST, WR, RD, CE, FL

I

Blank IDD(BL) 0.5 3.0 4.0 mA VIN = V

DD

IDD 8 Digits 12 Dots/Char

(AlGaAs)

IDD 8 Digits 20 Dots/Char

(AlGaAs)

IDD 8 Digits 12 Dots/Char

(All Colors Except AlGaAs)

IDD 8 Digits 20 Dots/Char

(All Colors Except AlGaAs)

Input Voltage High VIH 2.0 VDD V

+0.3 V

Input Voltage Low VIL GND 0.8 V

-0.3 V

Output Voltage High VOH 2.4 V VDD = 4.5 V, IOH = -40 µA

Output Voltage Low D0-D7 VOL 0.4 V VDD = 4.5 V, IOL = 1.6 mA

Output Voltage Low CLK VOL 0.4 V V

Thermal Resistance IC Rq

Junction-to-PIN

Notes:

1. VDD = 5.0 V.

2. See Thermal Considerations Section for information about operation in high temperature ambients.

3. Average IDD measured at full brightness. See Table 2 in Control Word Section for IDD at lower brightness levels. Peak IDD = 28/15 x IDD(#).

4. Maximum IDD occurs at -55°C.

[2,3,4]

IDD(V) 230 295 390 mA “V” On in All 8 Locations

[2,3,4]

IDD(#) 330 410 480 mA “#” On in All 8 Locations

[2,3,4]

IDD(V) 200 255 330 mA “V” On in All 8 Locations

[2,3,4]

IDD(#) 300 370 430 mA “#” On in All 8 Locations

16 °C/W Measured at Pin 17

J-PIN

[1]

Max.

[1]

Max. Units Test Conditions

DD

= 4.5 V, IOL = 40 µA

DD

4

4

Page 5

AC Timing Characteristics over Temperature Range

VDD = 4.5 to 5.5 V unless otherwise specied.

Reference

Number Symbol Description Min.

1 t

Write 210

Read 230 ns

2 t

3 tCE Chip Enable Active Time

Write 140

Read 160 ns

4 t

5 t

6 t

Write 140

Read 160 ns

7 t

8 tW Write Active Time 100 ns

9 tWD Data Valid Prior to Rising Edge of Write Signal 50 ns

10 tDH Data Write Hold Time 20 ns

11 tR Chip Enable Active Prior to Valid Data 160 ns

12 tRD Read Active Prior to Valid Data 75 ns

13 tDF Read Data Float Delay 10 ns

tRC Reset Active Time

Notes:

1. Worst case values occur at an IC junction temperature of 125°C.

2. For designers who do not need to read from the display, the Read line can be tied to VDD and the Write and Chip Enable lines can be tied

together.

3. Changing the logic levels of the Address lines when CE = “0” may cause erroneous data to be entered into the Character RAM, regardless of the

logic levels of the WR and RD lines.

4. The display must not be accessed until after 3 clock pulses (110 µs min. using the internal refresh clock) after the rising edge of the reset line.

Display Access Time

ACC

Address Setup Time to Chip Enable 10 ns

ACS

[2, 3]

Address Hold Time to Chip Enable 20 ns

ACH

Chip Enable Recovery Time 60 ns

CER

Chip Enable Active Prior to Rising Edge of

CES

Chip Enable Hold Time to Rising Edge of Read/Write Signal

CEH

[4]

300 ns

[2, 3]

[2,3]

0 ns

[1]

Units

Symbol Description 25°C Typical Minimum

F

Oscillator Frequency 57 28 kHz

OSC

[5]

F

Display Refresh Rate 256 128 Hz

RF

[6]

F

Character Flash Rate 2 1 Hz

FL

[7]

t

Self Test Cycle Time 4.6 9.2 sec

ST

Notes:

5. FRF = F

6. FFL = F

7. tST = 262,144/F

OSC

OSC

/224.

/28,672.

OSC

.

[1]

5

Units

Page 6

Write Cycle Timing Diagram

1

9

8

6

3

2

CE

7

10

4 2

5

A0 -A

4

FL

D0 -D

7

WR

1

12

11

6

3

2

CE

7

13

4

2

5

A0 -A

4

FL

D0 -D

7

RD

Input Pulse Levels: 0.6 V to 2.4 V

Read Cycle Timing Diagram

Input Pulse Levels: 0.6 V to 2.4 V

Output Reference Levels: 0.6 V to 2.2 V

Output Loading = 1 TTL Load and 100 pF

6

Page 7

Electrical Description

Pin Function Description

RESET (RST, pin 1) Reset initializes the display.

FLASH (FL, pin 2) FL low indicates an access to the Flash RAM and is unaected by the state of address

lines A3-A4.

ADDRESS INPUTS Each location in memory has a distinct address. Address inputs (A0-A2) select a specic

(A0-A4, pins 3-6, 10) location in the Character RAM, the Flash RAM or a particular row in the UDC (User-

Dened Character) RAM. A3-A4 are used to select which section of memory is accessed.

Table 1 shows the logic levels needed to access each section of memory.

Table 1. Logic Levels to Access Memory

FL A4 A3 Section of Memory A2 A1 A

0 X X Flash RAM Character Address

1 0 0 UDC Address Register Don’t Care

1 0 1 UDC RAM Row Address

1 1 0 Control Word Register Don’t Care

1 1 1 Character RAM Character Address

CLOCK SELECT (CLS, pin 11) This input is used to select either an internal (CLS = 1) or external (CLS = 0) clock source.

CLOCK INPUT/OUTPUT Outputs the master clock (CLS = 1) or inputs a clock (CLS = 0) for slave displays.

(CLK, pin 12)

0

WRITE (WR, pin 13) Data is written into the display when the WR input is low and the CE input is low.

CHIP ENABLE (CE, pin 14) This input must be at a logic low to read or write data to the display and must go high

between each read and write cycle.

READ (RD, pin 19) Data is read from the display when the RD input is low and the CE input is low.

DATA Bus The Data bus is used to read from or write to the display.

(D0-D7, pins 20, 21, 25-30)

GND (SUPPLY) (pin 16) This is the analog ground for the LED drivers.

GND (LOGIC) (pin 18) This is the digital ground for internal logic.

VDD (POWER) (pin 15) This is the positive power supply input.

Thermal Test (pin 17) This pin is used to measure the IC junction temperature. Do not connect.

7

Page 8

A3A

4

FL

EN

UDC ADDR REGISTER

UDC

ADDR

RDWRD

0

-D

7

CLR

PRE SET

CE

A3A

4

A

0

-A

2

D

0

-D

7

FL

CE

WR

RD

A3A

4

FL

CE

FL

CE

A3A

4

FL

CE

A3A

4

FL

CE

EN

8 x 8

CHARACTER

RAM

D

0

-D

6

RDWRD

0

-D

7

A

0

-A

2

RESET

CHAR ADDR

D

7

EN

FLASH

RAM

FLASH

DATA

RDWRD0A

0

-A

2

RESET

CHAR ADDR

EN

UDC RAM

DOT

DATA

RDWRD

0

-D

4

D

0

-D

4

A

0

-A

2

UDC ADDR

ROW SETENEN

ROW

SEL

SELF

TEST

DECODER(*)

DOT

DATA

D

0

-D

6

TIMING

TIMING

DOT

DRIVERS

DOT

DATA

EN

FLASH

CONTROL WORD

REGISTER

0

1

RD

WR

RST

CLK

OCS

CLS

CLR1

CLR2

D

0

-D

7

RESET

SELF TEST

RESULT

234

6

7

SELF

TEST

IN

SELF TEST

SELF TEST

SELF

TEST

START

8 5x7

LED

CHARACTERS

ROW DRIVERS

VISUAL

TEST

ROM

TEST

CLR

TEST OK

TEST OK

INTENSITY

INTENSITY

FLASH

FLASH

BLINK

BLINK

RESET

RESET

CLOCK

TIMING

AND

CONTROL

CHAR

ADDR

ROW SET

TIMING

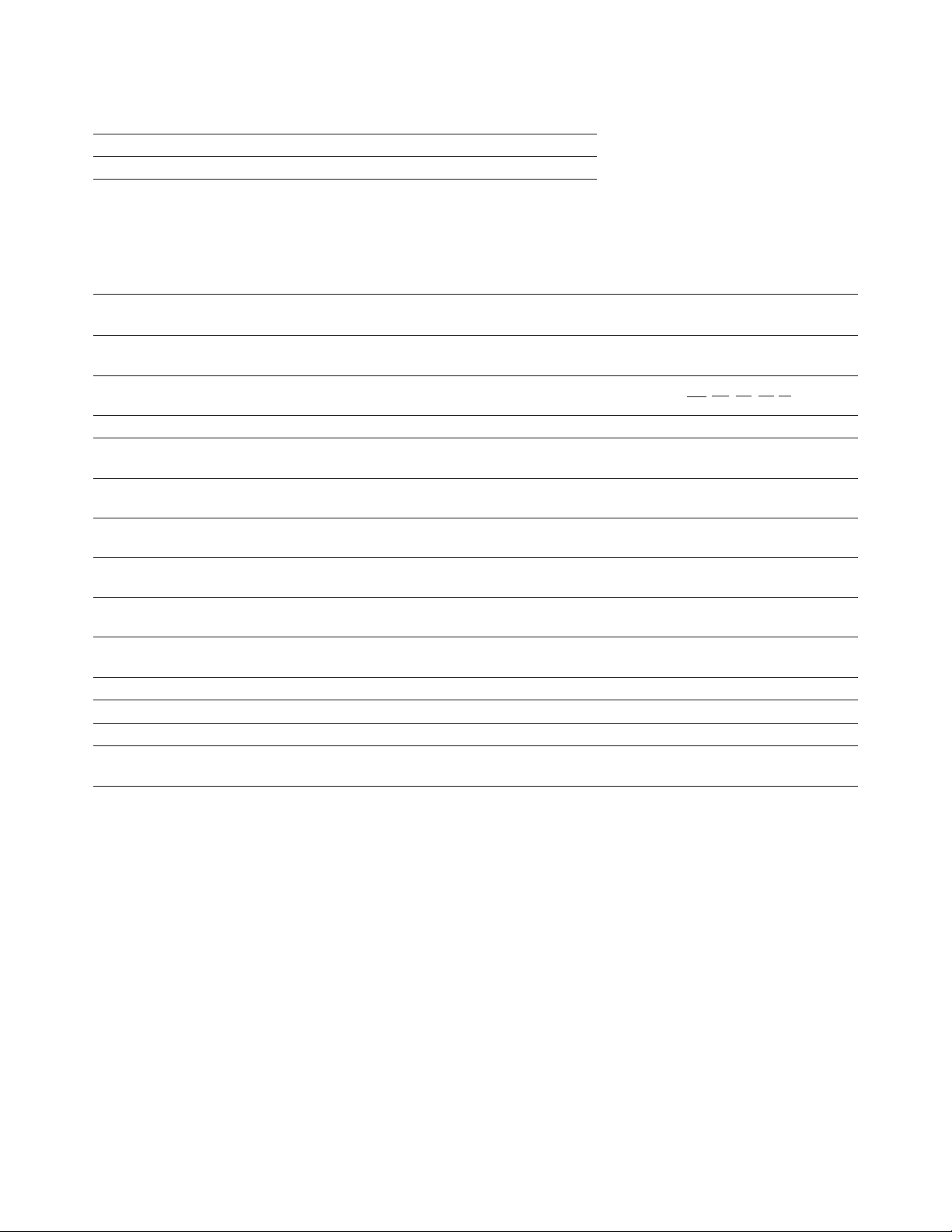

Figure 1. HDSP-253X internal block diagram.

8

Page 9

Display Internal Block Diagram

CE

FL A

4

A

3

A

2

A

1

A

0

RST WR RD

CHARACTER

ADDRESS

SYMBOL IS ACCESSED IN LOCATION

SPECIFIED BY THE CHARACTER ADDRESS ABOVE

01

0 0

0 1

1

1 11

0

1 1

UNDEFINED

CONTROL SIGNALS

CHARACTER RAM ADDRESS

CHARACTER RAM DATA FORMAT

WRITE TO DISPLAY

READ FROM DISPLAY

UNDEFINED

000 = LEFT MOST

111 = RIGHT MOST

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

0 128 ASCII CODE

X X X UDC CODE1

DISPLAY

0 = LOGIC 0; 1 = LOGIC 1; X = DO NOT CARE

DIG0DIG1DIG2DIG3DIG4DIG5DIG6DIG

7

001 010 011 100 101 110 111000

Figure 1 shows the internal block diagram of the HDSP253X display. The CMOS IC consists of an 8 byte Character

RAM, an 8 bit Flash RAM, a 128 character ASCII decoder, a

16 character UDC RAM, a UDC Address Register, a Control

Character RAM This RAM stores either ASCII character data or a UDC RAM address.

Flash RAM This is a 1 x 8 RAM which stores Flash data.

User-Dened Character RAM This RAM stores the dot pattern for custom characters.

(UDC RAM)

User-Dened Character This register is used to provide the address to the UDC RAM when

Address Register the user is writing or reading a custom character.

(UDC Address Register)

Control Word Register This register allows the user to adjust the display brightness, ash

individual characters, blink, self test or clear the display.

Character Ram

Figure 2 shows the logic levels needed to access the HDSP253X Character RAM. During a normal access the CE = “0”

and either RD = “0” or WR = “0”. However, erroneous data

may be written into the Character RAM if the Address lines

are unstable when CE = “0” regardless of the logic levels of

the RD or WR lines. Address lines A0-A2 are used to select

the location in the Character RAM. Two types of data can

be stored in each Character RAM location: an ASCII code

or a UDC RAM address. Data bit D7 is used to dierentiate between the ASCII character and a UDC RAM address.

D7 = 0 enables the ASCII decoder and D7 = 1 enables the

UDC RAM. D0-D6 are used to input ASCII data and D0-D3

are used to input a UDC address.

Word Register and the refresh circuitry necessary to synchronize the decoding and driving of eight 5 x 7 dot

matrix characters. The major user accessible portions of

the display are listed below:

9

Figure 2. Logic levels to access the character RAM.

Page 10

CE

FL A4A3A2A1A

0

RST WR RD

01

0 0

0 1

1

0 01 X X X

0

1 1

UNDEFINED

CONTROL SIGNALS

UDC ADDRESS REGISTER ADDRESS

UDC ADDRESS REGISTER DATA FORMAT

WRITE TO DISPLAY

READ FROM DISPLAY

UNDEFINED

000 = ROW 1

110 = ROW 7

D7D6D5D4D3D2D1D

0

X UDC CODE

X X X

FL A4A3A2A1A

0

0 11 ROW SELECT

UDC RAM ADDRESS

UDC RAM C C

DATA FORMAT O O

L L

1 5

0 = LOGIC 0; 1 = LOGIC 1; X = DO NOT CARE

D7D6D5D4D3D2D1D

0

X DOT DATA

X X

CERST WR RD

01

0 0

0 1

1 0

1 1

UNDEFINED

CONTROL SIGNALS

WRITE TO DISPLAY

READ FROM DISPLAY

UNDEFINED

C C C C C

O O O O O

L L L L L

1 2 3 4 5

D4 D3 D2 D1 D0 UDC CHARACTER HEX CODE

1 1 1 1 1 ROW 1 • • • • • 1F

1 0 0 0 0 ROW 2 • 10

1 0 0 0 0 ROW 3 • 10

1 1 1 1 0 ROW 4 • • • • 1E

1 0 0 0 0 ROW 5 • 10

1 0 0 0 0 ROW 6 • 10

1 0 0 0 0 ROW 7 • 10

IGNORED

0 = LOGIC 0; 1 = LOGIC 1; * = ILLUMINATED LED

CE

FL A4A3A2A1A

0

RST WR RD

01

0 0

0 1

1

X X0

0

1 1

UNDEFINED

REMOVE FLASH AT

SPECIFIED DIGIT LOCATION

STORE FLASH AT

SPECIFIED DIGIT LOCATION

CONTROL SIGNALS

FLASH RAM ADDRESS

FLASH RAM DATA FORMAT

0 = LOGIC 0; 1 = LOGIC 1; X = DO NOT CARE

WRITE TO DISPLAY

READ FROM DISPLAY

UNDEFINED

D7D6D5D4D3D2D1D

0

X

X X X X X X

0

1

CHARACTER

ADDRESS

000 = LEFT MOST

111 = RIGHT MOST

UDC RAM and UDC Address Register

Figure 3 shows the logic levels needed to access the UDC

RAM and the UDC Address Register. The UDC Address

Register is eight bits wide. The lower four bits (D0-D3) are

used to select one of the 16 UDC locations. The upper four

bits (D4-D7) are not used. Once the UDC address has been

stored in the UDC Address Register, the UDC RAM can be

accessed.

To completely specify a 5 x 7 character requires eight write

cycles. One cycle is used to store the UDC RAM address in

the UDC Address Register. Seven cycles are used to store

dot data in the UDC RAM. Data is entered by rows. One

cycle is needed to access each row. Figure 4 shows the

organization of a UDC character assuming the symbol to

be stored is an “F.” A0-A2 are used to select the row to be

accessed and D0-D4 are used to transmit the row dot data.

The upper three bits (D5-D7) are ignored. D0 (least signicant bit) corresponds to the right most column of the 5 x 7

matrix and D4 (most signicant bit) corresponds to the left

most column of the 5 x 7 matrix.

Flash RAM

Figure 5 shows the logic levels needed to access the Flash

RAM. The Flash RAM has one bit associated with each

location of the Character RAM. The Flash input is used

to select the Flash RAM. Address lines A3-A4 are ignored.

Address lines A0-A2 are used to select the location in the

Flash RAM to store the attribute. D0 is used to store or

remove the ash attribute. D0 = “1” stores the attribute

and D0 = “0” removes the attribute.

When the attribute is enabled through bit 3 of the Control

Word and a “1” is stored in the Flash RAM, the corresponding character will ash at approximately 2 Hz. The actual

rate is dependent on the clock frequency. For an external

clock the ash rate can be calculated by dividing the clock

frequency by 28,672.

Figure 4. Data to load “”F’’ into the UDC RAM.

10

Figure 3. Logic levels to access a UDC character.

Figure 5. Logic levels to access the Flash RAM.

Page 11

Control Word Register

CE

FL A4A3A2A1A

0

RST WR RD

01

0 0

0 1

1

1 0 X X X1

0

1 1

UNDEFINED

CONTROL SIGNALS

CONTROL WORD ADDRESS

CONTROL WORD DATA FORMAT

0 = LOGIC 0; 1 = LOGIC 1; X = DO NOT CARE

0 DISABLE FLASH

1 ENABLE FLASH

BRIGHTNESS

CONTROL

LEVELS

0 DISABLE BLINKING

1 ENABLE BLINKING

0 NORMAL OPERATION

1 CLEAR FLASH AND CHARACTER RAMS

0 X NORMAL OPERATION; X IS IGNORED

1 X START SELF TEST; RESULT GIVEN IN X

X = 0 FAILED X = 1 PASSED

WRITE TO DISPLAY

READ FROM DISPLAY

UNDEFINED

D7D6D5D4D3D2D1D

0

C

S S BL F B

0 0 0 100%

0 0 1 80%

0 1 0 53%

0 1 1 40%

1 0 0 27%

1 0 1 20%

1 1 0 13%

1 1 1 0%

B B

Figure 6 shows how to access the Control Word Register.

This is an eight bit register which performs ve functions.

They are Brightness control, Flash RAM control, Blinking,

Self Test and Clear. Each function is independent of the

others. However, all bits are updated during each Control

Word write cycle.

Brightness (Bits 0-2)

Bits 0-2 of the Control Word adjust the brightness of the

display. Bits 0-2 are interpreted as a three bit binary code

with code (000) corresponding to maximum brightness

and code (111) corresponding to a blanked display. In

addition to varying the display brightness, bits 0-2 also

vary the average value of IDD. IDD can be calculated at

any brightness level by multiplying the percent brightness level by the value of IDD at the 100% brightness level.

These values of IDD are shown in Table 2.

Flash Function (Bit 3)

Bit 3 determines whether the ashing character attribute

is on or o. When bit 3 is a “1,” the output of the Flash RAM

is checked. If the content of a location in the Flash RAM is

a “1,” the associated digit will ash at approximately 2 Hz.

For an external clock, the blink rate can be calculated by

dividing the clock frequency by 28,672. If the ash enable

bit of the Control Word is a “0,” the content of the Flash

RAM is ignored. To use this function with multiple display

systems see the Reset section.

Blink Function (Bit 4)

Bit 4 of the Control Word is used to synchronize blinking of

all eight digits of the display. When this bit is a “1” all eight

digits of the display will blink at approximately 2 Hz. The

actual rate is dependent on the clock frequency. For an

external clock, the blink rate can be calculated by dividing

the clock frequency by 28,672. This function will override

the Flash function when it is active. To use this function

with multiple display systems see the Reset section.

Figure 6. Logic levels to access the control word register.

Table 2. Current Requirements at Dierent Brightness Levels for All Colors Except AlGaAs

% VDD = 5.0 V

Symbol D2 D1 D0 Brightness 25°C Typ. Units

IDD (V) 0 0 0 100 200 mA

0 0 1 80 160 mA

0 1 0 53 106 mA

0 1 1 40 80 mA

1 0 0 27 54 mA

1 0 1 20 40 mA

1 1 0 13 26 mA

11

Page 12

Self Test Function (Bits 5, 6)

CERST WR RD

0 = LOGIC 0; 1 = LOGIC 1; X = DO NOT CARE

FL

0

1 X X X X X

A4 -A0D7 -D

0

Display Reset

Bit 6 of the Control Word Register is used to initiate the self

test function. Results of the internal self test are stored in

bit 5 of the Control Word. Bit 5 is a read only bit where bit

5 = “1” indicates a passed self test and bit 5 = “0” indicates

a failed self test.

Setting bit 6 to a logic 1 will start the self test function.

The built-in self test function of the IC consists of two

internal routines which exercises major portions of the

IC and illuminates all of the LEDs. The rst routine cycles

the ASCII decoder ROM through all states and performs a

checksum on the output. If the checksum agrees with the

correct value, bit 5 is set to “1.” The second routine provides

a visual test of the LEDs using the drive circuitry. This is accomplished by writing checkered and inverse checkered

patterns to the display. Each pattern is displayed for

approximately 2 seconds.

During the self test function the display must not be

accessed. The time needed to execute the self test

function is calculated by multiplying the clock period by

262,144. For example, assume a clock frequency of 58 KHz,

then the time to execute the self test function frequency is

equal to (262,144/58,000) = 4.5 second duration.

At the end of the self test function, the Character RAM

is loaded with blanks, the Control Word Register is set to

zeros except for bit 5, and the Flash RAM is cleared and the

UDC Address Register is set to all ones.

Clear Function (Bit 7)

Bit 7 of the Control Word will clear the Character RAM

and the Flash RAM. Setting bit 7 to a “1” will start the

clear function. Three clock cycles (110 ms min. using the

internal refresh clock) are required to complete the clear

function. The display must not be accessed while the

display is being cleared. When the clear function has been

completed, bit 7 will be reset to a “0.” The ASCII character

code for a space (20H) will be loaded into the Character

RAM to blank the display and the Flash RAM will be loaded

with “1”s. The UDC RAM, UDC Address Register and the remainder of the Control Word are unaected.

Figure 7 shows the logic levels needed to reset the display.

The display should be reset on Power-up. The external

Reset clears the Character RAM, Flash RAM, Control Word

and resets the internal counters. After the rising edge of

the Reset signal, three clock cycles (110 ms min. using the

internal refresh clock) are required to complete the reset

sequence. The display must not be accessed while the

display is being reset. The ASCII Character code for a space

(20H) will be loaded into the Character RAM to blank

the display. The Flash RAM and Control Word Register

are loaded with all “0”s. The UDC RAM and UDC Address

Register are unaected. All displays which operate with

the same clock source must be simultaneously reset to

synchronize the Flashing and Blinking functions.

Mechanical Considerations

The HDSP-253X is assembled by die attaching and wire

bonding 280 LED chips and a CMOS IC to a thermally conductive printed circuit board. A polycarbonate lens placed

over the pcb creates an air gap over the LED wire bonds. A

backll epoxy seals the display package.

Figure 8 shows the proper method to insert the display

by hand. To prevent damage to the LED wire bonds, apply

pressure uniformly with ngers located at both ends of

the part. Using a tool, shown in Figure 9, such as a screwdriver or pliers to push the display into the printed circuit

board or socket may damage the LED wire bonds. The

force exerted by a screwdriver is sucient to push the lens

into the LED wire bonds. The bent wire bonds cause shorts

or opens that result in catastrophic failure of the LEDs.

Note:

If RST, CE, and WR are low, unkown data may be written into the display.

Figure 7. Logic levels to reset the display.

12

Page 13

Figure 8. Proper method to manually insert a display.

Thermal Considerations

Figure 9. Improper method to manually insert a display.

The HDSP-253X can operate from -40°C to +85°C. The

display’s low thermal resistance allows heat to ow from

the CMOS IC to the 24 package pins. Typically, this heat

is conducted through the printed circuit board traces to

free air. For most applications, no additional heatsinking

is needed. Illuminating all 280 LEDs simultaneously at full

brightness is not recommended for continuous operation.

However, all 280 LEDs can be illuminated simultaneously

at full brightness for 10 seconds at 25°C as a lamp test.

The IC has a maximum allowable junction temperature of

150°C. The IC junction temperature can be calculated with

the following equation:

TJMAX = TA + (PD x Rq

J-A

)

TJMAX is the maximum allowable IC junction temperature.

TA is the ambient temperature surrounding the display.

PD is the power dissipated by the IC.

Rq

is the thermal resistance from the IC through the

J-A

display package and printed circuit board to the ambient.

A typical value for Rq

is 39°C/W. This value is typical for

J-A

a display mounted in a socket and covered with a plastic

lter. The socket is soldered to a 0.062 in. thick printed

circuit board with 0.020 in. wide one-ounce copper

traces.

PD can be calculated as follows:

PD = VDD x I

DD

VDD is the supply voltage and IDD is the supply current.

VDD can vary from 4.5 V to 5.5 V.

IDD changes with VDD, temperature, brightness level, and

number of on-pixels.

For AlGaAs

IDD (#) = (83.8 x VDD -0.35 x TJ) x B x N/8

IDD(V) = (63 x VDD -0.79 x TJ) x B x N/8

For the other colors

IDD (#) = (75.4 x VDD -0.28 x TJ) x B x N/8

IDD(V) = (54 x VDD -0.6 x TJ) x B x N/8

IDD (#) is the supply current using “#” as the displayed

character.

IDD(V) is the supply current using “V” as the displayed

character.

TJ is the IC junction temperature.

B is the percent brightness level.

N is the number of characters illuminated.

Operation in high temperature ambients may require

power derating or heatsinking. Figure 10 shows how to

derate the power for an HDSP-253X. You can reduce the

power by tighter supply voltage regulation or lowering

the brightness level.

13

Page 14

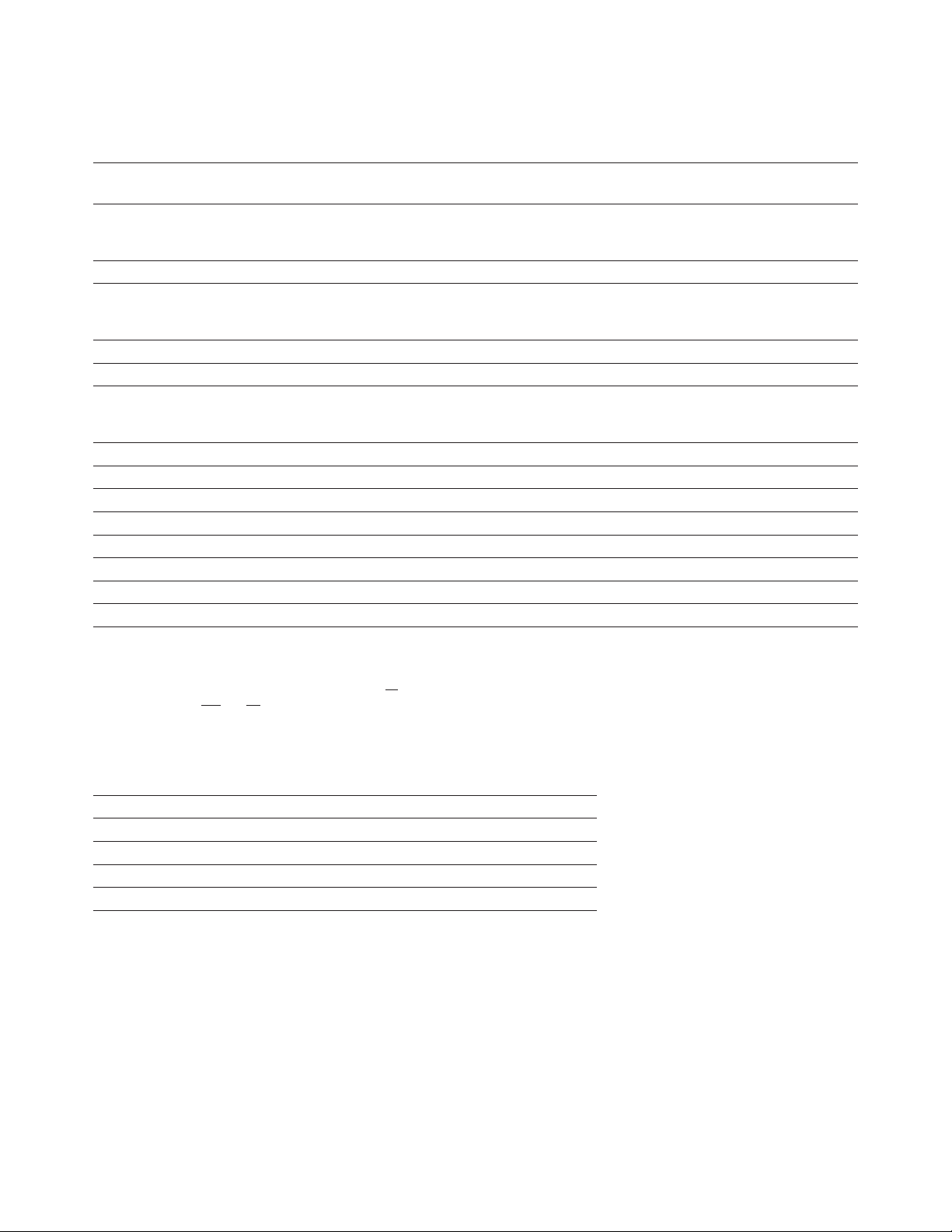

Table 3 shows the calculated maximum allowable ambient

P

D

MAX. – MAXIMUM POWER DISSIPATION – W

50

1.5

TA – AMBIENT TEMPERATURE – C

8555 60 80 90

2.3

2.2

2.1

1.8

1.7

1.6

70 7565

2.0

1.9

AlGaAs

Rθ

J-A

= 39C/W

ALL OTHER COLORS

temperature for several dierent sets of operating conditions. The worst case alphanumeric characters (#,@,B)

have 20 pixels. Displaying eight 20-pixel characters will

not occur in normal operation. Thus, using eight 20-pixel

characters to calculate power dissipation will over estimate

the power and the IC junction temperature. The average

number of pixels per character, supply voltage, brightness

level, and number of characters are needed to calculate

the power dissipated by the IC. The ambient temperature,

power dissipated by the IC, and the thermal resistance

are then used to calculate IC junction temperature. The

typical alphanumeric character is 15 pixels. For conditions

not listed in Table 3, you can calculate the power dissipated by the IC and use Figure 10 to determine the maximum

ambient temperature.

Figure 10. Maximum allowable power dissipation vs. ambient temperature.

TJMAX = 150°C or 120°C.

Table 3. Maximum Allowable Ambient Temperature for Various Operating Conditions

AlGaAs Red

Number of Brightness VDD IDD PD Rq

Character Characters Level V mA W °C/W °C

# (20 dots) 8 100% 5.5 408 2.2 39 64

# (20 dots) 8 100% 5.25 387 2.0 39 72

# (20 dots) 8 100% 5.0 366 1.8 39 80

# (20 dots) 7 100% 5.5 357 2.0 39 72

# (20 dots) 6 100% 5.5 306 1.7 39 84

# (20 dots) 8 80% 5.5 327 1.8 39 80

# (20 dots) 8 80% 5.25 310 1.6 39 85

# (20 dots) 8 53% 5.5 216 1.2 39 85

V (12 dots) 8 100% 5.5 228 1.3 39 85

TAMAX

J-A

Table 4. Maximum Allowable Ambient Temperature for Various Operating Conditions (cont’d.)

All Colors Except AlGaAs Red

Number of Brightness VDD IDD PD Rq

Character Characters Level V mA W °C/W °C

# (20 dots) 8 100% 5.5 373 2.0 39 72

# (20 dots) 8 100% 5.25 354 1.9 39 77

# (20 dots) 8 100% 5.0 335 1.67 39 85

# (20 dots) 7 100% 5.5 326 1.8 39 80

# (20 dots) 6 100% 5.5 280 1.5 39 85

# (20 dots) 8 80% 5.5 298 1.6 39 85

V (12 dots) 8 100% 5.5 207 1.1 39 85

The actual IC temperature is easy to measure. Pin 17 is thermally and electrically connected to the IC substrate. The thermal resistance from pin 17 to

the IC is 16°C/W. The procedure to measure the IC junction temperature is as follows:

1. Measure VDD and IDD for the display. Measure VDD between pins 15 and 16. Measure the current entering pin 15.

2. Measure the temperature of pin 17 after 45 minutes. Use an electrically isolated thermal couple probe.

3. TJ(IC) = T

+ VDD x IDD x 16°C/W.

pin

14

TAMAX

J-A

Page 15

Ground Connections

Two ground pins are provided to keep the internal IC logic

ground clean. The designer can, when necessary, route

the analog ground for the LED drivers separately from

the logic ground until an appropriate ground plane is

available. On long interconnections between the display

and the host system, the designer can keep voltage drops

on the analog ground from aecting the display logic

levels by isolating the two grounds.

The logic ground should be connected to the same ground

potential as the logic interface circuitry. The analog ground

and the logic ground should be connected at a common

ground which can withstand the current induced by the

switching LED drivers. When separate ground connections

Intensity Bin Limits for HDSP-2534

Intensity Range (mcd)

Bin Min. Max.

I 5.12 9.01

J 7.68 13.52

K 11.52 20.28

L 17.27 30.42

M 25.91 45.63

Note:

Test conditions as specied in Optical Characteristic table.

Intensity Bin Limits for HDSP-253x

Intensity Range (mcd)

Bin Min. Max.

G 2.50 4.00

H 3.41 6.01

I 5.12 9.01

J 7.68 13.52

K 11.52 20.28

Note:

Test conditions as specied in Optical Characteristic table.

are used, the analog ground can vary from -0.3 V to +0.3 V

with respect to the logic ground. Voltage below -0.3 V can

cause all dots to be on. Voltage above +0.3 V can cause

dimming and dot mismatch.

Solder and Post Solder Cleaning

Note: Freon vapors can cause the black paint to peel o

the display. See Application Note 1027 for information on

soldering and post solder cleaning.

Contrast Enhancement (Filtering)

See Application Note 1015 for information on contrast

enhancement.

Color Bin Limits

Color Range (nm)

Color Bin Min. Max.

Green 1 576.0 580.0

2 573.0 577.0

3 570.0 574.0

4 567.0 571.0

Yellow 3 581.5 585.0

4 584.0 587.5

5 586.5 590.0

6 589.0 592.5

7 591.5 595.0

Note:

Test conditions as specied in Optical Characteristic table.

For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2009 Avago Technologies. All rights reserved. Obsoletes 5989-3184EN

AV02-2018EN - July 15, 2009

Loading...

Loading...