APDS-9800

Integrated Ambient Light and Proximity Sensor

Data Sheet

Description

The APDS-9800 integrates ambient light sensor (ALS),

proximity sensor (PS) and ambient light cancelation

functions in a single module. The module contains three

chips in one small package: an ambient light sensor

IC, a proximity sensor signal conditioning circuit and a

proximity sensor that includes both an LED emitter and

detector.

The ambient light sensor has a spectral response close to

the CIE standard photopic observer and a current output.

The proximity sensor signal conditioning circuit has an

LED driver and a receiver circuit that has both analog and

digital outputs. With the built-in LED, the proximity sensor

is able to sense the proximity of an object, such as a finger,

hand or head that is close to a portable device. The PS also

features an excellent ambient light cancellation circuit for

operation in direct sunlight.

By detecting the ambient light illuminance level, the

ambient light sensor can control the brightness of display

backlights.

The proximity sensor makes many interesting and useful

applications possible. For example, a proximity sensor

can detect the proximity of a mobile phone user’s head

and turn off or on the phone keypad and LCD backlight.

By combining an ambient light sensor and proximity

sensor in a single compact module, mobile phones, PDAs

and notebooks can have additional features or benefit

from increased performance, such as in battery life.

Features

• Integrated module with ambient light sensor, proximity

sensor and signal conditioning IC

• Small form factor: L 4.95 x W 3.0 x H 1.45 mm

• Supply voltage range: 2.4 V to 3.6 V

• Spectral responsivity closely matches the human eye

• Built-in LED and detector for proximity detection

• Low sensitivity variation across various light sources

• Linear output across a wide illumination range

• Operates under strong sunlight and artificial light

• Controlled LED driving current, pulse and burst

parameters

• Controlled output voltage and integration time with

an external resistor and capacitor

• LED stuck High protection

• Both analog and digital outputs available

• Shutdown mode for low current consumption

• Lead-free and RoHS compliant

Applications

• PDAs

• Mobile phones

• Portable and handheld devices

• Personal computers, netbooks and notebooks

• Amusement products

• Games

• Vending Machines

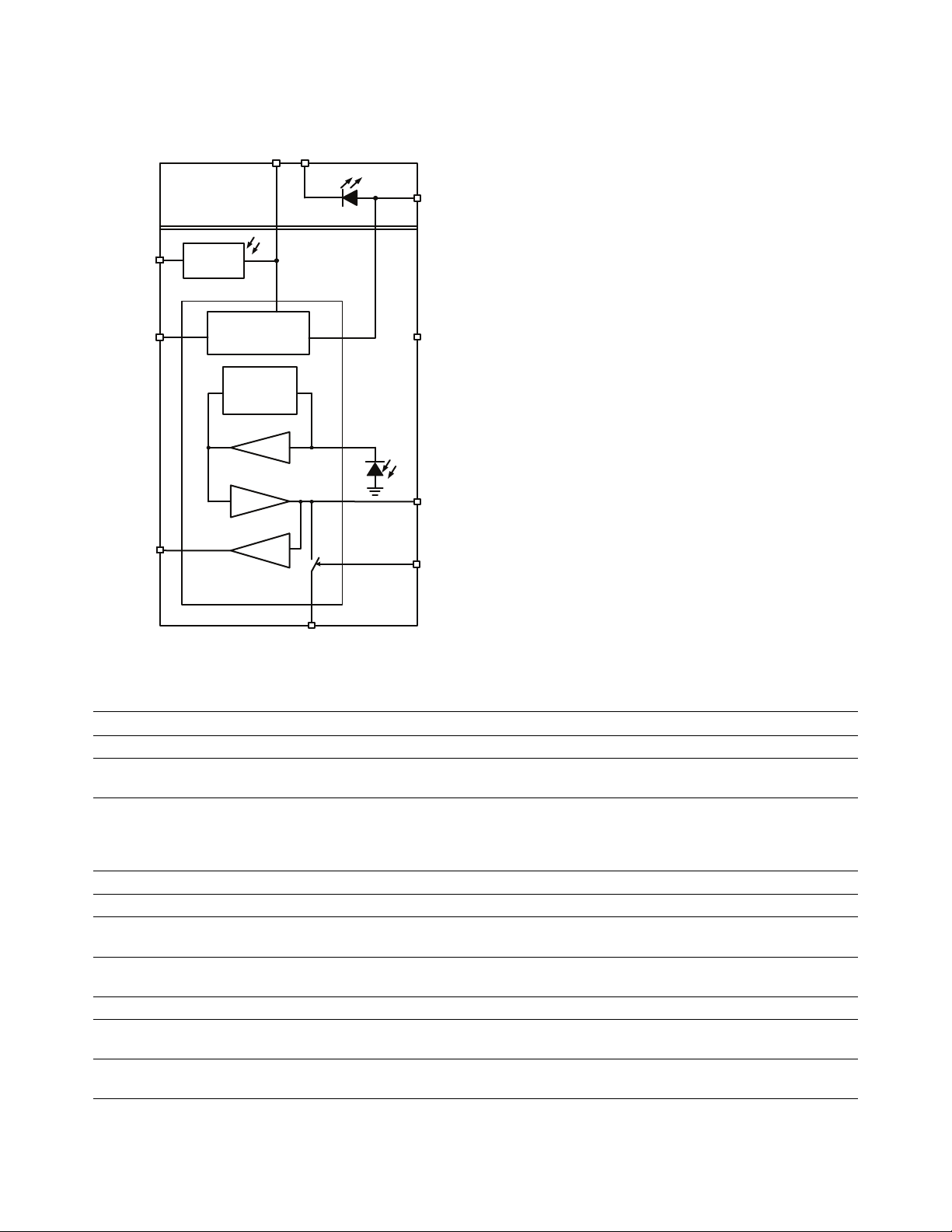

Functional Block Diagram

(7) ALS_IOUT

(2) LEDON

(3) PS_DOUT

Ambient Light

Sensor

LED Driver with

Stuck High Protection

Cancellation

V-I Converter

Hysteresis

Comparator

Proximity Sensor ASIC

(4) Vcc

Sunlight

TIA

(10) LEDK

(1) NC

LED

(5) NC

PIN

(6) PS_PFILT

(9) PS_ENB

(8) GND

I/O Pins Configuration Table

Pin Symbol Type Description

1 NC – No Connection

2 LEDON Digital I/P LED Driver Input

LEDA will turn off when LEDON is stuck in high state for > Max-PW

3 PS_DOUT Digital O/P PS Digital Output

(Open drain output that requires a pull-up resistor of recommended value 10kΩ)

PS_DOUT = LOW when PS_VPFILT > VTH

PS_DOUT = HIGH when PS_VPFILT < VTH

4 Vcc Supply Voltage Supply

5 NC – No Connection

6 PS_PFILT Analog O/P PS Analog Output

Connect to integration circuit (R3 and C3)

7 ALS_IOUT Analog O/P ALS analog current output

Connect to external load resistor R4. Recommended value 1kΩ.

8 GND Ground Ground

9 PS_ENB Digital I/P PS Power Down Enable

ENB = 0 Normal mode operation, ENB = 1 Shut down mode

10 LEDK Analog O/P Connect to Cathode of LED (proximity sensor)

External current limiting resistor is used to control current flow in the LED

2

Ordering Information

Part Number Packaging Quantity

APDS-9800-021 Tape & Reel 2500 per reel

Absolute Maximum Ratings

Parameter Symbol Min. Max. Units Conditions

Supply Voltage V

Input Logic Voltage VI 0 4 V TA = 25°C

Reflow Soldering Temperature 260 °C

CC

0 4 V TA = 25°C

Recommended Operating Conditions

Parameter Symbol Min. Max. Units Conditions

Operating Temperature T

Storage Temperature T

Supply Voltage V

A

S

CC

-40 85 °C

-40 85 °C

2.4 3.6 V

3

Electrical & Optical Specifications (Ta=25°C)

Parameters Symbol Minimum Typical Maximum Units Conditions

ALS+PS Module

Shutdown Current I

SD

Idle Current Icc 325 500 675 μA Vcc = 3 V, PS_ENB = 0 V, Lux = 0

ALS Output

Photo Current I_PH1 15 26 – μA Vcc =3 V, Lux = 100

Dark Current I_DARK – 300 – nA Vcc = 3 V, Lux = 0

Light Current Ratio – 1.2 – – Incandescent / Fluorescent

Rise Time Tr – 5 – ms R4 = 1k Ω, Lux = 100

Fall Time Tf – 5 – ms R4 = 1k Ω, Lux = 100

Propagation delay Td – 5 – ms R4 = 1k Ω, Lux = 100

Saturation voltage Vsat 1.0 – – V R4 = 150k Ω, Vcc = 3 V, Lux = 100

PS Input

Logic High Voltage, LEDON V

Logic High Voltage, PS_ENB V

Logic Low Voltage, LEDON V

Logic Low Voltage, PS_ENB V

Logic High Input Current, LEDON I

Logic High Input Current, PS_ENB I

Logic Low Input Current, LEDON I

Logic Low Input Current, PS_ENB I

IH

IH

IL

IL

IH

IH

IL

IL

PS Output

Analog Output VPFILT 0.65 1.9 3.0 V VCC = 3 V, ENB = 0 V,

Digital Output Low Level, PS_DOUT V

OL

Crosstalk VPFILT

@

Crosstalk

Max I

I

Pulse Width Max-PW – 120 – μs Vcc = 3 V, PS_ENB = 0 V

LED

Pulse Current I

LED

LED

Transmitter

Rise Time (LEDA) T

Fall Time (LEDA) T

R

F

PS Receiver

Rise Time(PS_DOUT) T

Fall Time(PS_DOUT) T

R

F

PS Hysteresis Comparator

Hysteresis V

Threshold Voltage V

HYS

TH

PS Sunlight Cancellation

Sun Light Illuminance Isun 100K Lux Vcc= 3 V

Note:

1. White LED is used as light source.

– 0.3 1 μA Vcc = 3 V, PS_ENB = 3 V, Lux = 0

(1)

1.8 – – V

1.8 – – V

0 – 0.3 V

0 – 0.3 V

– 0.1 1 μA VI ≥ V

– 0.1 1 μA VI ≥ V

– 0.1 1 μA VI ≤ V

– 0.1 1 μA VI ≤ V

0 – 0.4 V

IH

IH

IL

IL

LEDON = 10k Hz, 50% DC,

50 pulses; R3 = 1M ohm,

C3 = 3.3 nF;

Kodak 18% Grey card at

detectable distance = 20 mm

from the APDS-9800.

0 – 0.2 V VCC = 3 V, ENB = 0 V,

LEDON = 10k Hz, 50% DC,

50 pulses; R3 = 1M ohm,

C3 = 3.3 nF;

No blocking object

– 120 – mA Vcc = 3 V, R1 = 10 Ω

– 40 – ns Vcc = 3 V , ILED = 120 mA,

– 40 – ns

Freq = 10k Hz

– 1 – μs Vcc = 3 V, R2 = 10k Ω,

– 1 – μs

Frequency = 10k Hz

– 40 – mV Vcc= 3 V

– 655 – mV Vcc= 3 V

4

Typical Application Circuit

R1

PWM/GPIO

MCU

ADC

GPIO

GPIO

ADC

C1 C2

(7) ALS_IOUT

R4

(2) LEDON

Vdd

R2

(3) PS_DOUT

(4) Vcc

Ambient

Light

C4

Sensor

LED Driver with

Stuck High

Protection

Sunlight

Cancellation

V-I Converter

Hysteresis

Comparator

Proximity Sensor ASIC

(10) LEDK

(1) NC

LED

(5) NC

TIA

PIN

(6) PS_PFILT

R3C3

(9) PS_ENB

(8) GND

Component Recommended Values

R1 10 Ω

R2 10k Ω

R3 1M Ω

R4 1k Ω

C1 100 nF

C2 6.8 uF

C3 3.3 nF

C4 10 uF

Note: Do NOT make connects to the NC pins.

5

Ambient Light Sensor Performance Chart

1

0.9

0.8

0.7

0.6

0.5

0.4

RESPONSE (a.u.)

0.3

0.2

0.1

0

300 400 500 600 700 800 900 1000 1100

WAVELENGTH (nm)

Figure 1. Normalized Sensor Spectral Response Figure 2. ALS Average Iout versus Lux (Vcc = 3.0V, T=25°C, White LED source)

1000

900

800

700

600

500

IDARK (nA)

400

300

200

100

0

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

APDS-9800

Eye Response

300

250

200

150

IOUT (µA)

100

50

0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200

LIGHT INTENSITY (LUX)

Vcc

ENB

LEDON

PFILT

DOUT

>50ns

>20us

V

TH

Burst Pulses

Figure 3. ALS Dark Current versus Temperature (Vcc = 3.0V) Figure 4. Proximity Sensor Typical Timing Waveforms

Proximity Sensor Performance Charts

0.7

0.6

0.5

0.4

0.3

TYPICAL ILED (A)

0.2

0.1

0

2 3 4 5 6 7 8 9 10

RLED (OHM)

Figure 5. ILED versus RLED (TA=25°C) Figure 6. Normalized Idle Icc versus Temperature (Vcc =3V)

6

Vcc=2.4V

Vcc=2.7V

Vcc=3V

Vcc=3.3V

Vcc=3.6V

1.20

1.10

1.00

0.90

NORMALIZED ICC-IDLE

0.80

0.70

-60 -40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

APDS-9800 Package Outline

A A

1.230.98

LED

0.15

TOP VIEW

ALS

4.95

+ 0.20

0

0.43

0.56

0.56

0.73

1.19

1.80

0.38 0.70 0.70 0.70 0.38

2.20

1 2 3 4 5

0.38

0.38

0.07

0.38

SIDE VIEW

Photo Detector

1.45±0.10

0.711.19

0

+ 0.2

3

0.40

678910

0.15

0.40

0.38

Notes:

1. All dimensions are in millimeters.

2. Standard tolerance, unless otherwise stated:

PIN CONFIGURATION

Pin 1: NC

Pin 2: LEDON

Dimension

Pin 3: PS_DOUT

Decimal

Pin 4: VCC

Pin 5: NC

XX ±0.5 mm

Pin 6: PS_PFILT

XX.X ±0.2 mm

Pin 7: ALS_IOUT

XX.XX ±0.1 mm

Pin 8: GND

Pin 9: PS_ENB

All others ±0.1 mm

Standard

Tolerance

Pin 10: LEDK

APDS-9800 Pin Configuration

1 2 3 4 5

7

BOTTOM VIEW

Recommended Land Pattern

0.50

Pin 1 : NC

0.90 0.90 0.90

Pin 2 : LEDON

Pin 3 : PS_DOUT

Pin 4 : VCCPin 5: NC

Pin 6 : PS_PFILT

Pin 7 : ALS_IOUT

2.30

Pin 8 : GND

Pin 9 : PS_ENB

Pin 10 : LEDKTOP

678910

0.18

Notes:

1. All dimensions are in millimeters.

2. Do NOT connect NC pins.

0.18

0.18

0.50

0.45

0.18

0.45

APDS-9800 Tape & Reel Dimensions

Tape Dimensions

8.00

+0.30

-0.10

4.00 ± 0.10

5.19 ± 0.10

8.00 ± 0.10

User Direction of Feed

8° MAX

1.68 ± 0.10

2.00 ± 0.05

Ø 1.50 ± 0.10

Ø 1.00 ± 0.05

0.25 ± 0.02

3.23 ± 0.10

A. K. B.

1.75 ± 0.10

3.50 ± 0.05

6° MAX

Reel Dimensions:

Unit: millimeter

W 330.0 ± 1.5

N 100.0 ± 1.5

T1 8.5 ± 0.2/-0.1

E 2.0 ± 0.5

T2 13.5 ± 0.2

C 13.0 ± 0.5/-0.2

8

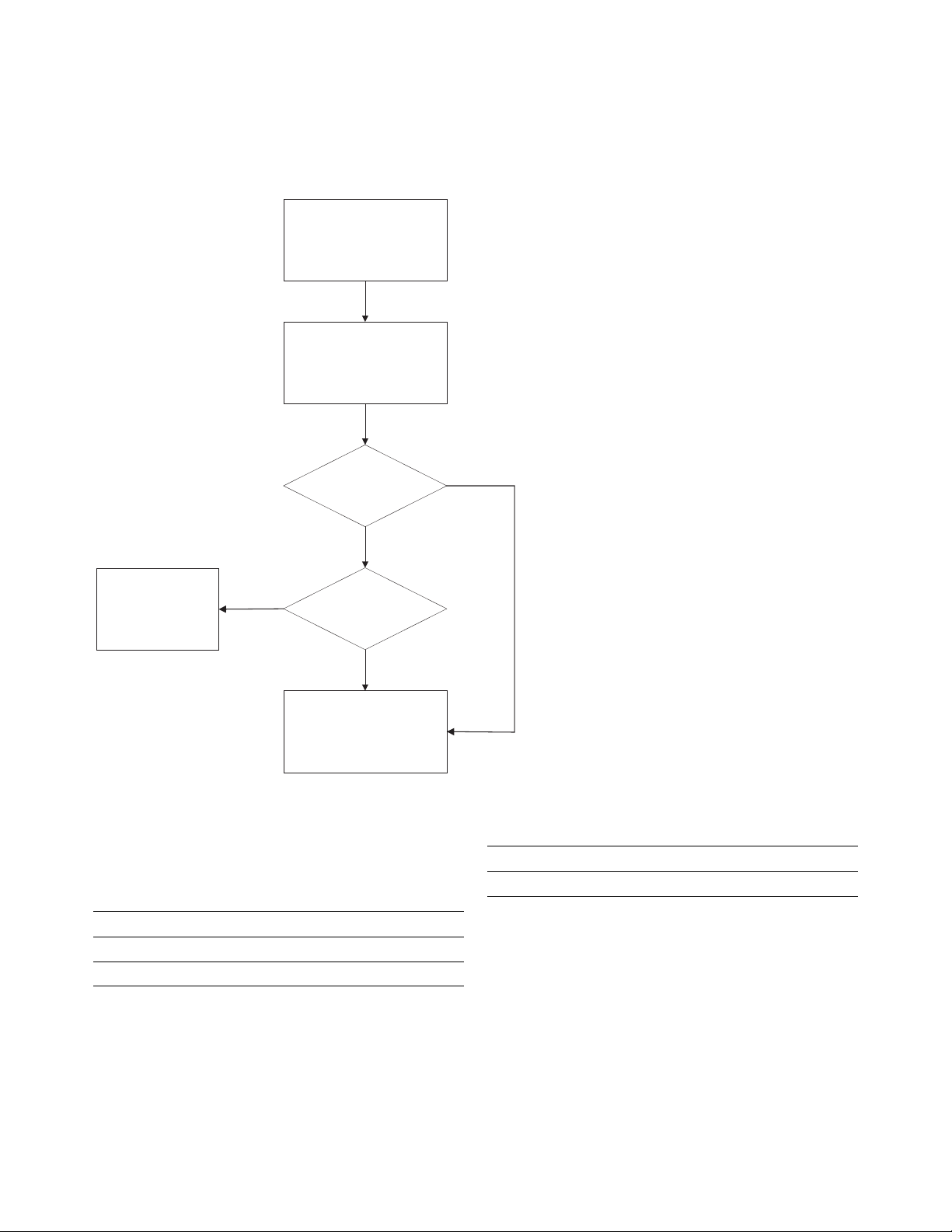

Moisture Proof Packaging

All APDS-9800 options are shipped in a moisture proof package. Once opened, moisture absorption begins. This part is

compliant to JEDEC Level 3.

Units in a sealed

moisture-proof

package

Package Is

opened (Unsealed)

Environment

less than 30 °C and less

than 60% RH ?

Yes

Baking

is not necessary

Yes

Package Is

open less

than 168 hours ?

No

Perform recommended

bake

Baking Conditions:

If the parts are not stored in dry conditions, they must be

baked before reflow soldering to prevent damage to the

parts.

Package Temperature Time

In Reel 60°C 48 hours

In Bulk 100°C 4 hours

Baking should only be done once.

No

Recommended Storage Conditions:

Storage Temperature 10°C to 30°C

Relative Humidity below 60% RH

Recommended Time from Unsealing to Soldering:

After removal from the bag, the parts should be soldered

within 168 hours if stored at the recommended storage

conditions. If times longer than 168 hours are needed, the

parts must be stored in a dry box.

9

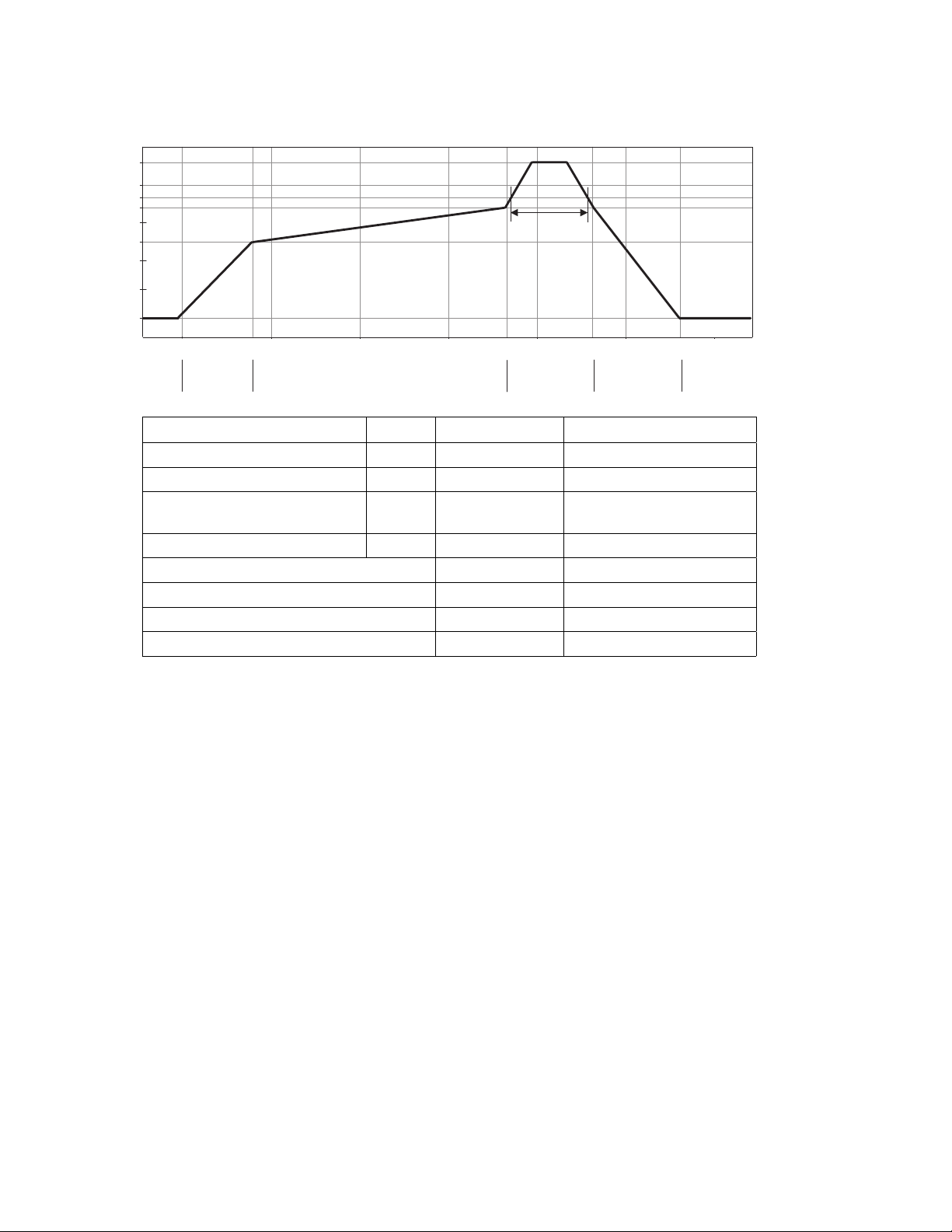

Recommended Reflow Profile

255

230

217

200

180

150

120

T - TEMPERATURE (°C)

80

25

0

R1

P1

HEAT

UP

R2

50 100 300150 200 250

P2

SOLDER PASTE DRY

MAX 260C

R3

60 sec to 90 sec

Above 217 C

P3

SOLDER

REFLOW

R4

R5

P4

COOL DOWN

Process Zone Symbol ∆T Maximum ∆T/∆time or Duration

Heat Up P1, R1 25°C to 150°C 3°C/s

Solder Paste Dry P2, R2 150°C to 200°C 100s to 180s

Solder Reflow P3, R3

P3, R4

Cool Down P4, R5 200°C to 25°C -6°C/s

Time Maintained Above Liquidus Point, 217°C > 217°C 60s to 120s

Peak Temperature 260°C –

Time within 5°C of Actual Peak Temperature > 255°C 20s to 40s

Time 25°C to Peak Temperature 25°C to 260°C 8minutes

200°C to 260°C

260°C to 200°C

3°C/s

-6°C/s

t-TIME

(SECONDS)

The reflow profile is a straight-line representation of

a nominal temperature profile for a convective reflow

solder process. The temperature profile is divided into

four process zones, each with different ∆T/∆time temperature change rates or duration. The ∆T/∆time rates or

duration are detailed in the above table. The temperatures

are measured at the component to printed circuit board

connections.

In process zone P1, the PC board and component pins are

heated to a temperature of 150°C to activate the flux in

the solder paste. The temperature ramp up rate, R1, is

limited to 3°C per second to allow for even heating of both

the PC board and component pins.

Process zone P2 should be of sufficient time duration (100

to 180 seconds) to dry the solder paste. The temperature

is raised to a level just below the liquidus point of the

solder.

Process zone P3 is the solder reflow zone. In zone P3, the

temperature is quickly raised above the liquidus point of

solder to 260°C (500°F) for optimum results. The dwell time

above the liquidus point of solder should be between 60

and 120 seconds. This is to assure proper coalescing of the

solder paste into liquid solder and the formation of good

solder connections. Beyond the recommended dwell

time the intermetallic mm growth within the solder connections becomes excessive, resulting in the formation of

weak and unreliable connections. The temperature is then

rapidly reduced to a point below the solidus temperature

of the solder to allow the solder within the connections to

freeze solid.

Process zone P4 is the cool down after solder freeze. The cool

down rate, R5, from the liquidus point of the solder to

25°C (77°F) should not exceed 6°C per second maximum.

This limitation is necessary to allow the PC board and

component pins to change dimensions evenly, putting

minimal stresses on the component.

It is recommended to perform reflow soldering no more

than twice.

10

Window and Light Guide Recommendations

Transparent window with IR coating (IR pass of around 90% and minimum 30% visible pass) is recommended in order to

pass both visible and infrared light. The material of the window is recommended to be polycarbonate. The surface finish

of the plastic should be smooth, without any texture.

The recommended plastic material for use as a window is available from Bayer AG and Bayer Antwerp N. V. (Europe),

Bayer Corp.(USA) and Bayer Polymers Co., Ltd. (Thailand), as shown in Table below.

Recommended Plastic Materials

Material number Visible light transmission* Refractive index

Makrolon LQ2647 87% 1.587

Makrolon LQ3147 87% 1.587

Makrolon LQ3187 85% 1.587

* Transmittance of visible light will reduce if plastic window is coated with IR ink

To ensure that the performance of the APDS-9800 will not be affected by improper window design, there are some

constraints on the dimensions and design of the window so that the maximum size of the window, which is placed in

front of the photo light sensor, will not affect the angular response of the APDS-9800. This maximum dimension that is

recommended will ensure an acceptable light reception cone.

Plastic Window

IR absorbing area

IR pass area

0.7 mm

Air gap

APDS-9800

Side view of IR pass areas for window design

1.2 mm

3 mm

0.7 mm

Top view of IR pass areas for window design

Windows thickness

Filter

IR pass areas

The distance between the bottom of the window and the sensor top–the air gap– should be as close as possible and not

more than 0.2 mm. For optimum performance, windows thickness should be limited to not more than 0.8mm.

For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2009 Avago Technologies. All rights reserved.

AV02-2132EN - September 7, 2009

Loading...

Loading...