AFBR-57J7APZ

Digital Diagnostic SFP, 850nm 6.144/7.3728 Gb/s,

RoHS OBSAI/CPRI Compatible Optical Transceiver

Data Sheet

Description

Avago’s AFBR-57J7APZ optical transceiver supports

high speed serial links over multimode optical ber at

signaling rates up to 7.4 Gb/s for wireless base station applications involving the OBSAI or CPRI protocols, as well

as related applications. The transceiver is compliant with

Small Form Pluggable (SFP) multi-source agreements INF8074 and SFF-8472 for mechanical and electrical specications and FOCIS/IEC specications for optical duplex LC

connectors.

As an enhancement to the conventional SFP interfaced

dened in INF-8074, the AFBR-57J7APZ is compliant to

SFF-8472 (Digital Diagnostic Interface for Optical Transceivers). Using the 2-wire serial interface dened in SFF8472, the transceiver provides real time temperature,

supply voltage, laser bias current, laser average output

power and received input power. This information is in

addition to conventional SFP base data. The digital diagnostic interface also adds the ability to disable the transmitter and monitor the status of transmitter fault and

receiver loss of signal.

Related Products

• AFBR-57J5APZ: 850nm +3.3V LC SFP

for CPRI/OBSAI Applications

• AFCT-57J5APZ: 1310nm +3.3V LC SFP

for CPRI/OBSAI Applications

• AFCT-57J5ATPZ: 1310nm +3.3V LC SFP

for CPRI/OBSAI Applications

• AFBR-57D7APZ: 850nm +3.3V LC SFP

for 8.5/4.25/2.125 GBd Fibre Channel

• AFCT-57D5ATPZ: 1310nm +3.3V LC SFP

for 8.5/4.25/2.125 GBd Fibre Channel

• AFCT-57J7ATPZ: 1310nm +3.3V LC SFP

for CPRI/OBSAI Applications

Features

• Fully RoHS Compliant

• Diagnostic Features Per SFF-8472 “Diagnostic

Monitoring Interface for Optical Transceivers”

• Real time monitors of:

o Transmitted Optical Power

o Received Optical Power

o Laser Bias Current

o Temperature

o Supply Voltage

• Industrial Temperature and Supply Voltage Operation

(-40°C to 85°C) (3.3V ± 10%)

• Transceiver Specications per SFP (INF-8074) and SFF-

8472 (revision 10)

• Up to 200m with 50μm OM3 for 7.3728 Gb/s

• Up to 300m with 50μm OM3 for OBSAI 6.144 Gb/s

• LC Duplex optical connector interface conforming to

ANSI TIA/EIA604-10 (FOCIS 10A)

• 850nm Vertical Cavity Surface Emitting Laser (VCSEL)

Source Technology

• IEC 60825-1 Class 1/CDRH Class 1 laser eye safe

• Compatible with Fibre Channel and Gigabit Ethernet

applications

Applications

Wireless and cellular base station system interconnect

OBSAI rates 6.144 Gb/s, 3.072 Gb/s, 1.536 Gb/s

CPRI rates 7.3728 Gb/s, 4.9152 Gb/s, 2.4576 Gb/s,

1.2288 Gb/s

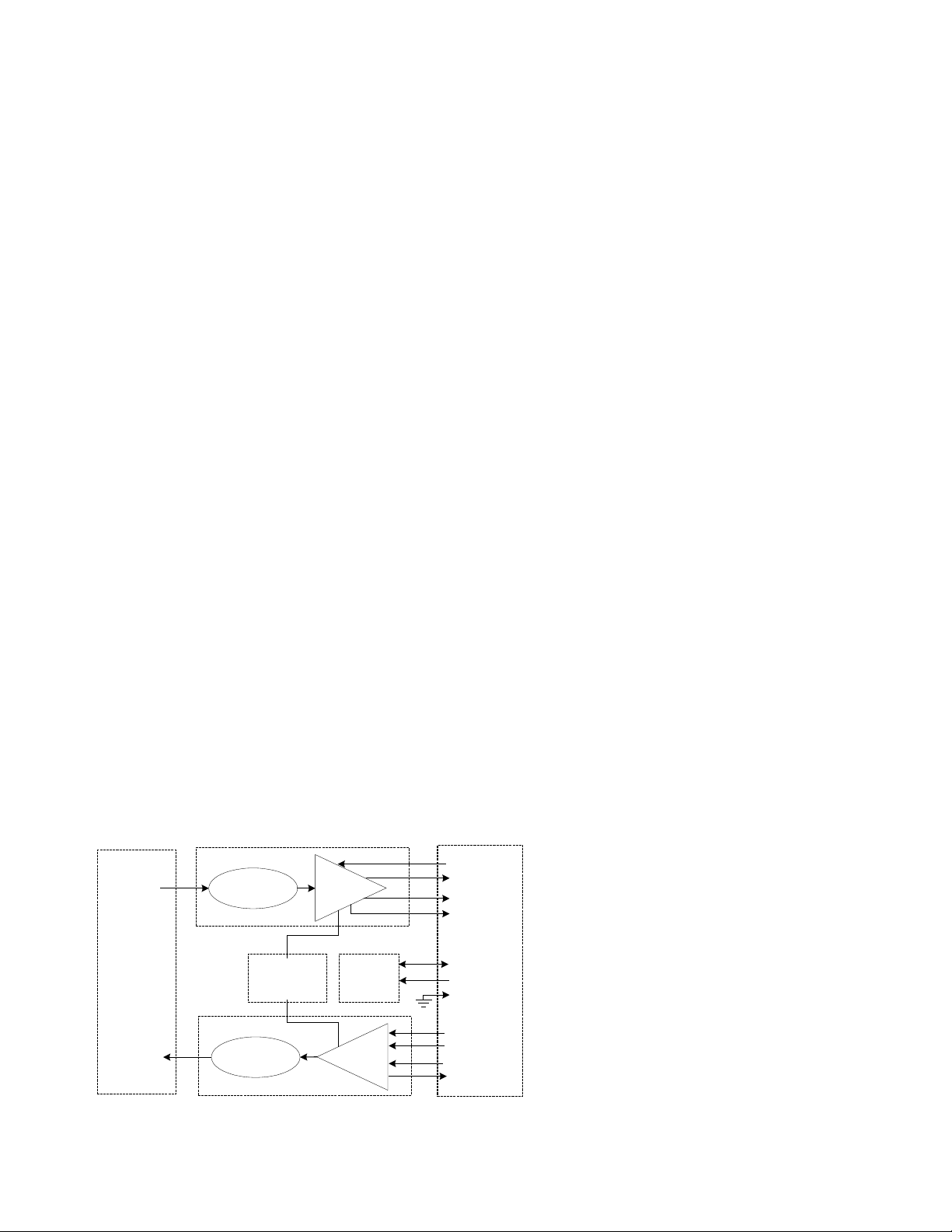

Digital Diagnostic Interface and Serial Identication

EEPROM

CONTROLLER

EEPROM

Photo-Detector

Amplification

&

Quantization

VCSEL

Laser Driver &

Safety Circuit

Electrical Interface

RD+ (Receive Data)

RD- (Receive Data)

Rx Loss Of Signal

MOD-DEF2 (SDA)

TX_DISABLE

TD+ (Transmit Data)

TD- (Transmit Data)

TX_FAULT

MOD-DEF0

MOD-DEF1 (SCL)

Receiver

Transmitter

Optical Interface

Light from Fiber

Light to Fiber

Rate Select

The 2-wire serial interface is based on ATMEL AT24C01A

series EEPROM protocol and signaling detail. Conventional EEPROM memory, bytes 0-255 at memory address

0xA0, is organized in compliance with INF-8074. New

digital diagnostic information, bytes 0-255 at memory

address 0xA2, is compliant to SFF-8472. The new diagnostic information provides the opportunity for Predictive Failure Identication, Compliance Prediction, Fault

Isolation and Component Monitoring.

Transmitter Section

The transmitter section includes consists of the Transmitter Optical SubAssembly (TOSA) and laser driver circuitry.

The TOSA, containing an 850nm VCSEL (Vertical Cavity

Surface Emitting Laser) light source, is located at the

optical interface and mates with the LC optical connector.

The TOSA is driven by a custom IC which uses the

incoming dierential high speed logic signal to modulate

the laser diode driver current. This Tx laser driver circuit

regulates the optical power at a constant level provided

the incoming data pattern is dc balanced (8B/10B code,

for example).

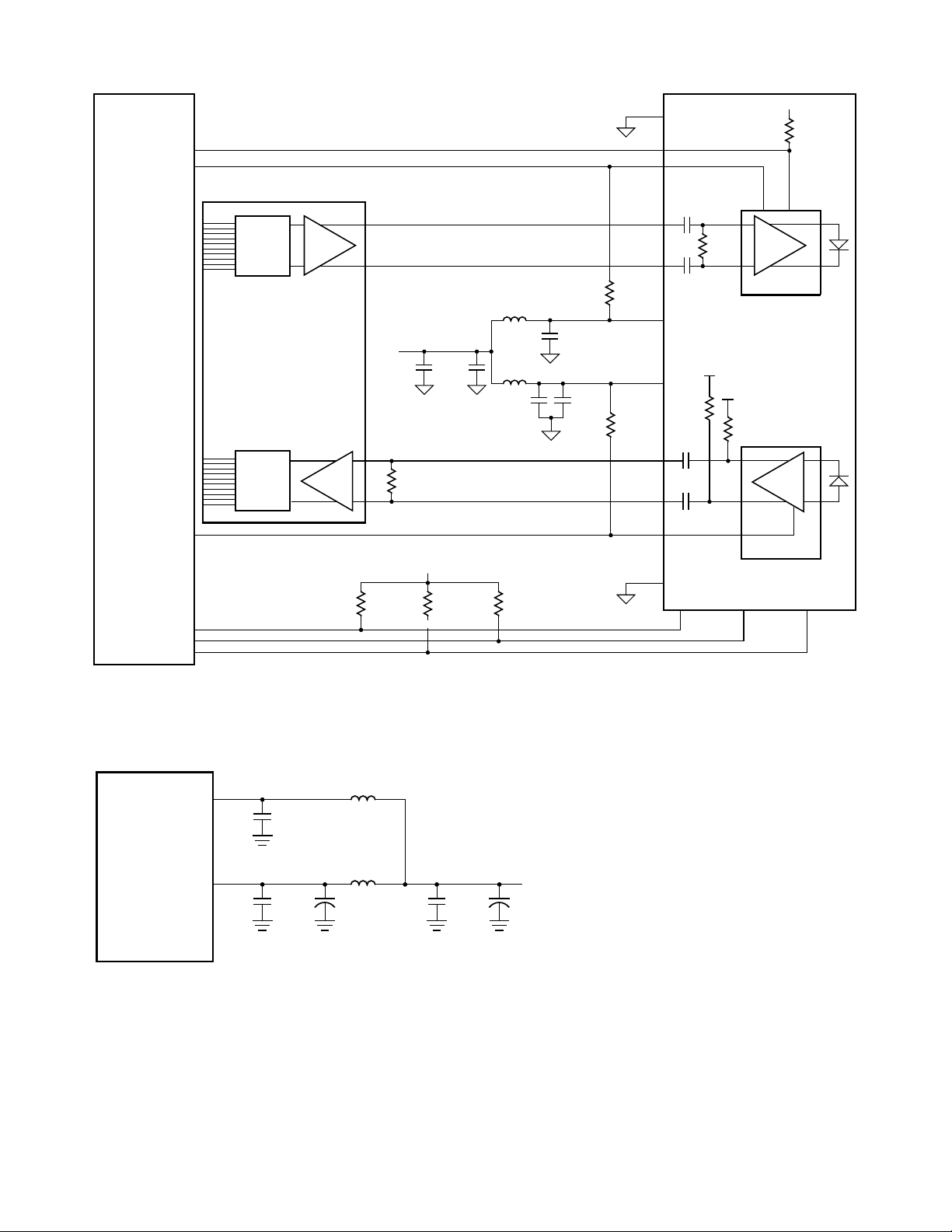

Transmit Disable (Tx_Disable)

The AFBR-57J7APZ accepts a TTL and CMOS compatible

transmit disable control signal input (pin 3) which shuts

down the transmitter optical output. A high signal implements this function while a low signal allows normal

transceiver operation. In the event of a fault (e.g. eye

safety circuit activated), cycling this control signal resets

the module as depicted in Figure 4. An internal pull up

resistor disables the transceiver transmitter until the host

pulls the input low. Host systems should allow a 10ms

interval between successive assertions of this control

signal. Tx_Disable can also be asserted via the twowire serial interface (address A2h, byte 110, bit 6) and

monitored (address A2h, byte 110, bit 7).

The contents of A2h, byte 110, bit 6 are logic OR’d with

hardware Tx_Disable (pin 3) to control transmitter

operation..

Transmit Fault (Tx_Fault)

A catastrophic laser fault will activate the transmitter

signal, TX_FAULT, and disable the laser. This signal is

an open collector output (pull-up required on the host

board). A low signal indicates normal laser operation

and a high signal indicates a fault. The TX_FAULT will

be latched high when a laser fault occurs and is cleared

by toggling the TX_DISABLE input or power cycling the

transceiver. The transmitter fault condition can also be

monitored via the two-wire serial interface (address A2,

byte 110, bit 2).

Eye Safety Circuit

The AFBR-57J7APZ provides Class 1 (single fault tolerant)

eye safety by design and has been tested for compliance

with the requirements listed in Table 1. The eye safety

circuit continuously monitors the optical output power

level and will disable the transmitter upon detecting an

unsafe condition beyond the scope of Class 1 certication. Such unsafe conditions can be due to inputs from

the host board (Vcc uctuation, unbalanced code) or a

fault within the transceiver.

Receiver Section

The receiver section includes the Receiver Optical SubAssembly (ROSA) and the amplication/quantization

circuitry. The ROSA, containing a PIN photodiode and

custom transimpedance amplier, is located at the

optical interface and mates with the LC optical connector.

The ROSA output is fed to a custom IC that provides postamplication and quantization.

Figure 1. Transceiver Functional Diagram

2

Receiver Loss of Signal (Rx_LOS)

The post-amplication IC also includes transition

detection circuitry which monitors the ac level of

incoming optical signals and provides a TTL/CMOS compatible status signal to the host (pin 8). An adequate

optical input results in a low Rx_LOS output while a high

Rx_LOS output indicates an unusable optical input. The

Rx_LOS thresholds are factory set so that a high output

indicates a denite optical fault has occurred. Rx_LOS

can also be monitored via the two-wire serial interface

(address A2h, byte 110, bit 1).

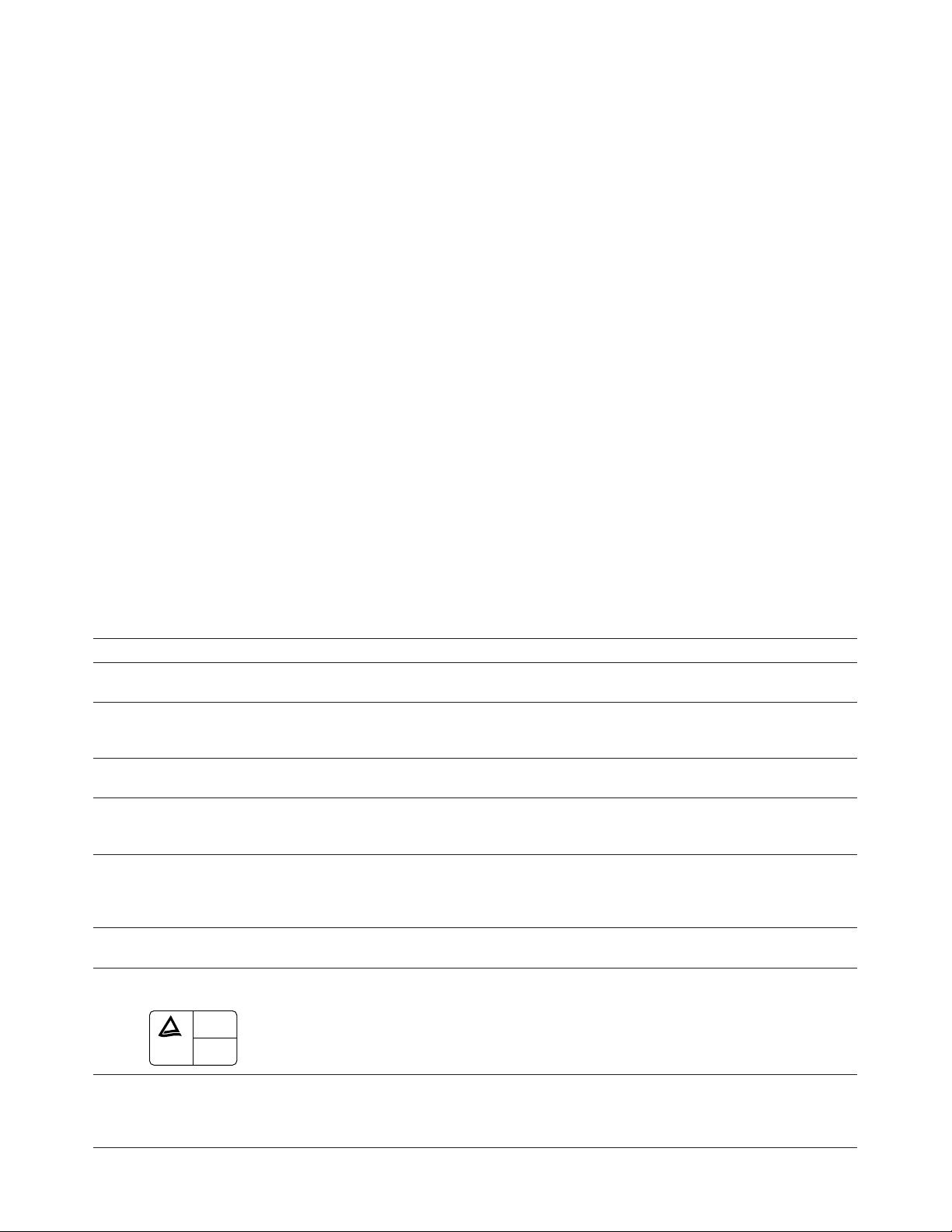

Functional Data I/O

The AFBR-57J7APZ interfaces with the host circuit board

through twenty I/O pins (SFP electrical connector) identied by function in Table 2. The board layout for this

interface is depicted in Figure 6.

The AFBR-57J7APZ high speed transmit and receive interfaces require SFP MSA, OBSAI or CPRI compliant signal

lines on the host board. To simplify board requirements,

biasing resistors and ac coupling capacitors are incorporated into the SFP transceiver module (per INF-8074) and

hence are not required on the host board. The Tx_Disable,

Tx_Fault, Rx_LOS and Rate_Select lines require TTL lines

on the host board (per INF-8074) if used. If an application

chooses not to take advantage of the functionality of

these pins care must be taken to ground Tx_Disable (for

normal operation) and Rate_Select is set to default in the

proper state.

Figure 2 depicts the recommended interface circuit to

link the AFBR-57J7APZ to supporting physical layer ICs.

Timing for MSA compliant control signals implemented

in the transceiver are listed in Figure 4.

Application Support

An Evaluation Kit and Reference Designs are available to

assist in evaluation of the AFBR-57J7APZ . Please contact

your local Field Sales representative for availability and

ordering details.

Caution

There are no user serviceable parts nor maintenance requirements for the AFBR-57J7APZ. All mechanical adjustments are made at the factory prior to shipment.

Tampering with, modifying, misusing or improperly

handling the AFBR-57J7APZ will void the product

warranty. It may also result in improper operation and

possibly overstress the laser source. Performance degradation or device failure may result. Connection of the

AFBR-57J7APZ to a light source not compliant with these

specications, operating above maximum operating

conditions or in a manner inconsistent with it’s design

and function may result in exposure to hazardous light

radiation and may constitute an act of modifying or man-

ufacturing a laser product. Persons performing such an

act are required by law to re-certify and re-identify the

laser product under the provisions of U.S. 21 CFR (Subchapter J) and TUV.

Ordering Information

Please contact your local eld sales engineer or one of

Avago Technologies franchised distributors for ordering

information. For technical information, please visit Avago

Technologies’ WEB page at www.Avago.com or contact

Avago Technologies Semiconductor Products Customer

Response Center at 1-800-235-0312. For information

related to SFF Committee documentation visit www.scommittee.org.

Regulatory Compliance

The AFBR-57J7APZ complies with all applicable laws

and regulations as detailed in Table 1. Certication level

is dependent on the overall conguration of the host

equipment. The transceiver performance is oered as a

gure of merit to assist the designer

Electrostatic Discharge (ESD)

The AFBR-57J7APZ is compatible with ESD levels found

in typical manufacturing and operating environments

as described in Table 1. In the normal handling and

operation of optical transceivers, ESD is of concern in two

circumstances.

The rst case is during handling of the transceiver prior

to insertion into an SFP compliant cage. To protect the

device, it’s important to use normal ESD handling precautions. These include using of grounded wrist straps, workbenches and oor wherever a transceiver is handled.

The second case to consider is static discharges to the

exterior of the host equipment chassis after installation.

If the optical interface is exposed to the exterior of host

equipment cabinet, the transceiver may be subject to

system level ESD requirements.

Electromagnetic Interference (EMI)

Equipment incorporating gigabit transceivers is typically

subject to regulation by the FCC in the United States,

CENELEC EN55022 (CISPR 22) in Europe and VCCI

in Japan. The AFBR-57J7APZ’s compliance to these

standards is detailed in Table 1. The metal housing and

shielded design of the AFBR-57J7APZ minimizes the EMI

challenge facing the equipment designer.

EMI Immunity (Susceptibility)

Due to its shielded design, the EMI immunity of the AFBR57J7APZ exceeds typical industry standards.

3

Flammability

BAUART

GEPRUFT

TYPE

APPROVED

TUV

Rheinland

Product Safety

¨

¨

The AFBR-57J7APZ optical transceiver is made of metal

and high strength, heat resistant, chemical resistant and

UL 94V-0 ame retardant plastic.

plant and remote transmitter. When operating out of requirements, the link cannot guarantee error free transmission.

Predictive Failure Identication

The AFBR-57J7APZ predictive failure feature allows a host

to identify potential link problems before system performance is impacted. Prior identication of link problems

enables a host to service an application via “fail over”

to a redundant link or replace a suspect device, maintaining system uptime in the process. For applications

where ultra-high system uptime is required, a digital SFP

provides a means to monitor two real-time laser metrics

associated with observing laser degradation and predicting failure: average laser bias current (Tx_Bias) and

Fault Isolation

The fault isolation feature allows a host to quickly

pinpoint the location of a link failure, minimizing

downtime. For optical links, the ability to identify a fault

at a local device, remote device or cable plant is crucial to

speeding service of an installation. AFBR-57J7APZ realtime monitors of Tx_Bias, Tx_Power, Vcc, Temperature and

Rx_Power can be used to assess local transceiver current

operating conditions. In addition, status ags Tx_Disable

and Rx Loss of Signal (LOS) are mirrored in memory and

available via the two-wire serial interface.

average laser optical power (Tx_Power).

Component Monitoring

Compliance Prediction:

Compliance prediction is the ability to determine if an

optical transceiver is operating within its operating and

environmental requirements. AFBR-57J7APZ devices

provide real-time access to transceiver internal supply

voltage and temperature, allowing a host to identify

potential component compliance issues. Received optical

power is also available to assess compliance of a cable

Table 1. Regulatory Compliance

Feature Test Method Performance

Electrostatic Discharge

(ESD) to the Electrical Pins

Electrostatic Discharge

(ESD) to the Duplex LC

Receptacle

Electrostatic Discharge

(ESD) to the Optical

Connector

Electromagnetic

Interference (EMI)

Immunity Variation of IEC 61000-4-3 Typically shows no measurable eect from a

Laser Eye Safety

and Equipment Type

Testing

Component Recognition Underwriters Laboratories and Canadian Standards

MIL-STD-883C Method 3015.4 Class 1 (> 2000 Volts)

Variation of IEC 61000-4-2 Typically, no damage occurs with 25 kV

GR1089 10 contacts of 8 KV on the electrical faceplate

Variation of IEC 801-2 Air discharge of 15kV(min) contact to

FCC Class B

CENELEC EN55022 Class B

(CISPR 22A)

VCCI Class 1

US FDA CDRH AEL Class 1

US21 CFR, Subchapter J per Paragraphs 1002.10

and 1002.12.

(IEC) EN60825-1: 1994 + A11+A2

(IEC) EN60825-2: 1994 + A1

(IEC) EN60950: 1992 + A1 + A2 + A3+ A4 + A11

Association Joint Component Recognition for

Information Technology Equipment Including

Electrical Business Equipment

Component evaluation is a more casual use of the

AFBR-57J7APZ real-time monitors of Tx_Bias, Tx_Power,

Vcc, Temperature and Rx_Power. Potential uses are as

debugging aids for system installation and design, and

transceiver parametric evaluation for factory or eld qualication. For example, temperature per module can be

observed in high density applications to facilitate thermal

evaluation of blades, PCI cards and systems.

when the duplex LC connector receptacle is

contacted by a Human Body Model probe.

with device inserted into a panel.

connector w/o damage

System margins are dependent on customer

board and chassis design.

10V/m eld swept from 10 MHz to 1 GHz.

CDRH certication # 9720151-072

TUV le # 72071411

UL File # E173874

4

LASER DRIVER

MODULE DETECT

LOSS OF SIGNAL

SCL

SDA

Tx_FAULT

Tx_DISABLE

TD+

Tx FAULT

Tx DIS

TD–

RD+

RD–

MOD_DEF2

MOD_DEF1

MOD_DEF0

GND,R

4.7 k to

10 kΩ

50 Ω

50 Ω

4.7 k to 10 kΩ4.7 k to 10 kΩ

PROTOCOL IC

VCC,T

VCC,T

VCC,R

1 µH

1 µ H

10µF 0.1µF

0.1 µF

10µF 0.1µF

3.3 V

3.3 V

SERDES IC

Rx LOS

GND,T

0.01 µ F

0.01 µ F

POST AMPLIFIER

100 Ω

4.7 k to 10 kΩ

100 Ω

6.8 kΩ

0.01 µ F

VCC,R

0.01 µ F

4.7 k to 10 kΩ

VCC,R

1 µH

1 µH

0.1 µF

VCCR

SFP MODULE

10 µF

VCCT

0.1 µF 10 µF

3.3 V

HOST BOARD

0.1 µF

NOTE: INDUCTORS MUST HAVE LESS THAN 1 Ω SERIES RESISTANCE TO LIMIT VOLTAGE DROP TO THE SFP MODULE.

Figure 2. Typical Application Conguration

Figure 3. Recommended Power Supply Filter

5

Table 2. Pin Description

Pin Name Function/Description Notes

1 VeeT Transmitter Ground

2 TX_FAULT Transmitter Fault Indication – High indicates a fault condition Note 1

3 TX_DISABLE Transmitter Disable – Module optical output disables on high or open Note 2

4 MOD-DEF2 Module Denition 2 – Two wire serial ID interface data line (SDA) Note 3

5 MOD-DEF1 Module Denition 1 – Two wire serial ID interface clock line (SCL) Note 3

6 MOD-DEF0 Module Denition 0 – Grounded in module (module present indicator) Note 3

7 no connect Internal pullup 30KW to Vcc

8 RX_LOS Loss of Signal – High indicates loss of received optical signal Note 4

9 no connect Internal Pullup 30KW to Vcc

10 VeeR Receiver Ground

11 VeeR Receiver Ground

12 RD- Inverse Received Data Out Note 5

13 RD+ Received Data Out Note 5

14 VeeR Receiver Ground

15 VccR Receiver Power + 3.3 V Note 6

16 VccT Transmitter Power + 3.3 V Note 6

17 VeeT Transmitter Ground

18 TD+ Transmitter Data In Note 7

19 TD- Inverse Transmitter Data In Note 7

20 VeeT Transmitter Ground

Notes:

1. TX_FAULT is an open collector/drain output, which must be pulled up with a 4.7k – 10kΩ resistor on the host board. When high, this output

indicates a laser fault of some kind. Low indicates normal operation. In the low state, the output will be pulled to < 0.8V.

2. TX_DISABLE is an input that is used to shut down the transmitter optical output. It is internally pulled up (within the transceiver) with a 6.8kΩ

resistor.

Low (0 – 0.8V): Transmitter on

Between (0.8V and 2.0V ): Undened

High (2.0 – Vcc max) or OPEN: Transmitter Disabled

3. The signals Mod-Def 0, 1, 2 designate the two wire serial interface pins. They must be pulled up with a 4.7k – 10kΩ resistor on the host board.

Mod-Def 0 is grounded by the module to indicate the module is present

Mod-Def 1 is serial clock line (SCL) of two wire serial interface

Mod-Def 2 is serial data line (SDA) of two wire serial interface

4. RX_LOS (Rx Loss of Signal) is an open collector/drain output that must be pulled up with a 4.7k – 10kΩ resistor on the host board. When high,

this output indicates the received optical power is below the worst case receiver sensitivity (as dened by the standard in use). Low indicates

normal operation. In the low state, the output will be pulled to < 0.8V.

5. RD-/+ designate the dierential receiver outputs. They are AC coupled 100Ω dierential lines which should be terminated with 100Ω dierential

at the host SERDES input. AC coupling is done inside the transceiver and is not required on the host board. The voltage swing on these lines will

be between 370 and 850 mV dierential (185 – 425 mV single ended) when properly terminated.

6. VccR and VccT are the receiver and transmitter power supplies. They are dened at the SFP connector pin. The maximum supply current is 300

mA and the associated in-rush current will typically be no more than 30 mA above steady state after 500 nanoseconds.

7. TD-/+ designate the dierential transmitter inputs. They are AC coupled dierential lines with 100Ω dierential termination inside the module.

The AC coupling is done inside the module and is not required on the host board. The inputs will accept dierential swings of 180 – 1200 mV (90

– 600 mV single ended).

6

Table 3. Absolute Maximum Ratings

Parameter Symbol Minimum Maximum Unit Notes

Storage Temperature T

Case Operating Temperature T

S

C

Relative Humidity RH 5 95 % Note 1

Supply Voltage V

Low Speed Input Voltage V

Notes

1. Absolute Maximum Ratings are those values beyond which damage to the device may occur if these limits are exceeded for other than a short

period of time. See Reliability Data Sheet for specic reliability performance.

2. Between Absolute Maximum Ratings and the Recommended Operating Conditions functional performance is not intended, device reliability is

not implied, and damage to the device may occur over an extended period of time.

3. The module supply voltages, VCCT and VCCR must not dier by more than 0.5V or damage to the device may occur.

ccT, R

IN

-40 100 °C Note 1,2

-40 100 °C Note 1,2

-0.5 3.8 V Note 1,2,3

-0.5 Vcc+0.5 V Note 1

Table 4. Recommended Operating Conditions

Parameter Symbol Minimum Maximum Unit Notes

Case Operating Temperature T

Supply Voltage V

C

ccT, R

Data Rate 1.288 7.3728 Gb/s Note 2

Notes

1. The Ambient Operating Temperature limitations are based on the Case Operating Temperature limitations and are subject to the host system

thermal design.

2. Recommended Operating Conditions are those values for which functional performance and device reliability is implied.

-40 85 °C Note 1,2

2.97 3.63 V Note 2

Table 5. Transceiver Electrical Characteristics (TC = -40°C to 85°C, VccT, VccR = 3.3V ± 10%)

Parameter Symbol Minimum Typical Maximum Unit Notes

AC Electrical Characteristics

Power Supply Noise Rejection (peak-peak) PSNR 100 mV Note 1

DC Electrical Characteristics

Module supply current I

Power Dissipation P

Low Speed Outputs:

Transmit Fault (TX_FAULT),

Loss of Signal (RX_LOS),

V

V

CC

DISS

OH

OL

2.0 VccT,R+0.3 V Note 2

MOD-DEF 2

Low Speed Inputs:

Transmit Disable (TX_DIS),

MOD-DEF 1, MOD-DEF 2

Notes:

1. Filter per SFP specication is required on host board to remove 10 Hz to 2 MHz content.

2. Pulled up externally with a 4.7k – 10kΩ resistor on the host board to 3.3V.

3. Mod-Def1 and Mod-Def2 must be pulled up externally with a 4.7k – 10kΩ resistor on the host board to 3.3V.

V

IH

V

IL

2.0 Vcc V Note 3

0 0.8 V

235 mA

0.825 W

0.8 V

7

Table 6. Transmitter Optical Characteristics(TC = -40°C to 85°C, VccT, VccR = 3.3V ± 10%)

Parameter Symbol Minimum Typical Maximum Unit Notes

Modulated Optical Output Power

(OMA) (Peak-to-Peak)

Average Optical Output Power Pout -8.2 dBm Note 1, 2

Center Wavelength

Spectral Width – rms

Optical Rise/Fall Time tr, tf 60 ps 20% - 80%

RIN 12 (OMA) RIN -128 dB/Hz

Transmitter Contributed

Deterministic Jitter

(2.457 to 7.3728 Gb/s)

Transmitter Contributed

Total Jitter

(2.457 to 7.3728 Gb/s)

Pout TX_DISABLE Asserted P

Notes:

1. Max Pout is the lesser of Class 1 safety limits (CDRH and EN 60825) or receiver power, max.

2. Into 50/125um (0.2 NA) multi-mode optical ber.

3. Contributed DJ is measured on an oscilloscope in average mode with 50% threshold and K28.5 pattern.

4. Contributed RJ is calculated for 1x10

5. In a network link, each component’s output jitter equals each component’s input jitter combined with each component’s contributed jitter.

Contributed DJ adds in a linear fashion and contributed RJ adds in a RMS fashion.

-12

Tx,OMA 302 µW Note 2

λ

C

σ,rms

840 860 nm

0.65 nm

DJ 25 ps -40/85°C,

Note 3

18 ps -10/85°C

TJ 50 ps -40/85°C,

Note 4, 5

40 ps -10/85°C

OFF

BER by multiplying the RMS jitter (measured on a single rise or fall edge) from the oscilloscope by 14.

-35 dBm

Table 7. Receiver Optical Characteristics (TC = -40°C to 85°C, VccT, VccR = 3.3V ± 10%)

Parameter Symbol Min Typ Max Unit Notes

Input Optical Power [Overdrive] P

Input Optical Modulation Amplitude

IN

OMA 76 µW, oma 1x10

Peak-to-Peak (2.457 to 7.3728 Gb/s)

[Sensitivity]

106 µW, oma 1x10

Return Loss 12 dB

Loss of Signal – Assert P

Loss of Signal - De-Assert P

Loss of Signal Hysteresis PD - P

Notes

1. Input Optical Modulation Amplitude (commonly known as sensitivity) requires a valid 8B/10B encoded input.

2. These average power values are specied with an Extinction Ratio of 6dB. The loss of signal circuitry responds to valid 8B/10B encoded peak to

peak input optical power, not average power.

A

D

A

-30 dBm, avg Note 2

0.5 dB

0 dBm, avg

Note 1

Note 1

-13.9 dBm, avg Note 2

-12

-15

BER ,

BER,

8

Table 8. Transmitter and Receiver Electrical Characteristics (TC = -40°C to 85°C, VccT, VccR = 3.3V ± 10%)

Parameter Symbol Minimum Typical Maximum Unit Notes

High Speed Data Input:

Transmitter Dierential Input Voltage (TD +/-)

High Speed Data Output:

Receiver Dierential Output Voltage (RD +/-)

Receiver Contributed Deterministic Jitter

(2.457 to 7.3728 Gb/s)

Receiver Contributed Total Jitter

(2.457 to 7.3728 Gb/s)

Receiver Electrical Output Rise & Fall Times

(20-80%)

Notes

1. Internally AC coupled and terminated (100 Ohm dierential).

2. Internally AC coupled but requires an external load termination (100 Ohm dierential).

3. Contributed DJ is measured on an oscilloscope in average mode with 50% threshold and K28.5 pattern

4. Contributed RJ is calculated for 1x10

5. 20%-80% electrical rise & fall times measured with a 500 MHz signal utilizing a 1010 data pattern.

6. In a network link, each component’s output jitter equals each component’s input jitter combined with each component’s contributed jitter.

Contributed DJ adds in a linear fashion and contributed RJ adds in a RMS fashion.

7. Measured at an input optical power of 154uW, OMA.

-12

BER by multiplying the RMS jitter (measured on a single rise or fall edge) from the oscilloscope by 14.

V

I

V

o

180 1200 mV Note 1

370 850 mV Note 2

DJ 15 ps Note 3, 7

TJ 40 ps Note 4,

6, 7

Tr, tf 30 85 ps Note 5

9

Table 9. Transceiver SOFT DIAGNOSTIC Timing Characteristics (TC = -40°C to 85°C, VccT, VccR = 3.3V ± 10%)

Parameter Symbol Minimum Maximum Unit Notes

Hardware TX_DISABLE Assert Time t_o 10 µs Note 1

Hardware TX_DISABLE Negate Time t_on 1 ms Note 2

Time to initialize, including reset of TX_FAULT t_init 300 ms Note 3

Hardware TX_FAULT Assert Time t_fault 100 µs Note 4

Hardware TX_DISABLE to Reset t_reset 10 µs Note 5

Hardware RX_LOS DeAssert Time t_loss_on 100 µs Note 6

Hardware RX_LOS Assert Time t_loss_o 100 µs Note 7

Software TX_DISABLE Assert Time t_o_soft 100 ms Note 9

Software TX_DISABLE Negate Time t_on_soft 100 ms Note 10

Software Tx_FAULT Assert Time t_fault_soft 100 ms Note 11

Software Rx_LOS Assert Time t_loss_on_soft 100 ms Note 12

Software Rx_LOS De-Assert Time t_loss_o_soft 100 ms Note 13

Analog parameter data ready t_data 1000 ms Note 15

Serial bus hardware ready t_serial 300 ms Note 16

Write Cycle Time t_write 10 ms Note 17

Serial ID Clock Rate f_serial_clock 100 kHz

Notes

1. Time from rising edge of TX_DISABLE to when the optical output falls below 10% of nominal.

2. Time from falling edge of TX_DISABLE to when the modulated optical output rises above 90% of nominal.

3. Time from power on or falling edge of Tx_Disable to when the modulated optical output rises above 90% of nominal.

4. From power on or negation of TX_FAULT using TX_DISABLE.

5. Time TX_DISABLE must be held high to reset the laser fault shutdown circuitry.

6. Time from loss of optical signal to Rx_LOS Assertion.

7. Time from valid optical signal to Rx_LOS De-Assertion.

8. Time from two-wire interface assertion of TX_DISABLE (A2h, byte 110, bit 6) to when the optical output falls below 10% of nominal. Measured

from falling clock edge after stop bit of write transaction.

9. Time from two-wire interface de-assertion of TX_DISABLE (A2h, byte 110, bit 6) to when the modulated optical output rises above 90% of

nominal.

10. Time from fault to two-wire interface TX_FAULT (A2h, byte 110, bit 2) asserted.

11. Time for two-wire interface assertion of Rx_LOS (A2h, byte 110, bit 1) from loss of optical signal.

12. Time for two-wire interface de-assertion of Rx_LOS (A2h, byte 110, bit 1) from presence of valid optical signal.

13. From power on to data ready bit asserted (A2h, byte 110, bit 0). Data ready indicates analog monitoring circuitry is functional.

14. Time from power on until module is ready for data transmission over the serial bus (reads or writes over A0h and A2h).

15. Time from stop bit to completion of a 1-8 byte write command.

10

Table 10. Transceiver Digital Diagnostic Monitor (Real Time Sense) Characteristics (TC = -40°C to 85°C, VccT, VccR = 3.3V ± 10%)

Parameter Symbol Min Units Notes

Transceiver Internal

Temperature Accuracy

Transceiver Internal Supply

Voltage Accuracy

Transmitter Laser DC Bias

Current Accuracy

Transmitted Average Optical

Output Power Accuracy

Received Average Optical

Input Power Accuracy

T

INT

V

INT

I

INT

P

T

P

R

+/- 3.0 °C Temperature is measured internal to the transceiver.

Valid from = -40°C to 85 °C case temperature.

+/- 0.1 V Supply voltage is measured internal to the transceiver and

can, with less accuracy, be correlated to voltage at the SFP Vcc

pin. Valid over 3.3 V ± 10%.

+/- 10 % I

+/- 3.0 dB Coupled into 50/125um multi-mode ber.

+/- 3.0 dB Coupled from 50/125um multi-mode ber.

is better than +/-10% of the nominal value.

INT

Valid from 100 uW to 500 uW, avg.

Valid from 76 uW to 500 uW, avg.

Description of the Digital Diagnostic Data

Transceiver Internal Temperature

Temperature is measured on the AFBR-57J7APZ using

sensing circuitry mounted on the internal PCB. The

measured temperature will generally be cooler than laser

junction and warmer than SFP case and can be indirectly correlated to SFP case or laser junction temperature

using thermal resistance and capacitance modeling. This

measurement can be used to observe drifts in thermal

operating point or to detect extreme temperature uctuations such as a failure in the system thermal control. For

more information on correlating internal temperature to

case or laser junction contact Avago Technologies.

Transceiver Internal Supply Voltage

Supply voltage is measured on the AFBR-57J7APZ using

sensing circuitry mounted on the internal PCB. Transmit

supply voltage (VccT) is monitored for this readback. The

resultant value can be indirectly correlated to SFP VccT

or VccR pin supply voltages using resistance modeling,

but not with the required accuracy of SFF-8472. Supply

voltage as measured will be generally lower than SFP Vcc

pins due to use of internal transient suppression circuitry.

As such, measured values can be used to observe drifts in

supply voltage operating point, be empirically correlated

to SFP pins in a given host application or used to detect

supply voltage uctuations due to failure or fault in the

system power supply environment. For more information

on correlating internal supply voltage to SFP pins contact

Avago Technologies.

Transmitter Laser DC Bias Current

Laser bias current is measured using sensing circuitry

located on the transmitter laser driver IC. Normal variations in laser bias current are expected to accommodate the impact of changing transceiver temperature

and supply voltage operating points. The AFBR-57J7APZ

uses a closed loop laser bias feedback circuit to maintain

constant optical power. This circuit compensates for

normal VCSEL parametric variations in quantum eciency, forward voltage and lasing threshold due to changing

transceiver operating points. Consistent increases in laser

bias current observed at equilibrium temperature and

supply voltage could be an indication of laser degradation. For more information on using laser bias current for

predicting laser lifetime, contact Avago Technologies.

Transmitted Average Optical Output Power

Transmitted average optical power is measured using

sensing circuitry located on the transmitter laser driver

IC and laser optical subassembly. Variations in average

optical power are not expected under normal operation

because the AFBR-57J7APZ uses a closed loop laser bias

feedback circuit to maintain constant optical power.

This circuit compensates for normal VCSEL parametric

variations due to changing transceiver operating points.

Only under extreme laser bias conditions will signicant

drifting in transmitted average optical power be observable. Therefore it is recommended Tx average optical

power be used for fault isolation, rather than predictive

failure purposes.

Received Average Optical Input Power

Received average optical power is measured using

detecting circuitry located on the receiver preamp and

quantizer ICs. Accuracy is +/- 3.0 dB, but typical accuracy

is +/- 2.0 dB. This measurement can be used to observe

magnitude and drifts in incoming optical signal level for

detecting cable plant or remote transmitter problems.

11

TX_FAULT

OCCURANCE OF FAULT

t_fault

TX_DISABLE

TRANSMITTED SIGNAL

TX_FAULT

OCCURANCE OF FAULT

TX_DISABLE

TRANSMITTED SIGNAL

t-fault: TX FAULT ASSERTED, TX SIGNAL NOT RECOVERED t-reset: TX DISABLE ASSERTED THEN NEGATED, TX SIGNAL RECOVERED

t_reset

t_init*

* SFP SHALL CLEAR TX_FAULT IN

< t_init IF THE FAILURE IS TRANSIENT

TX_FAULT

OCCURANCE OF FAULT

t_fault

TX_DISABLE

TRANSMITTED SIGNAL

OPTICAL SIGNAL

LOS

t-fault: TX DISABLE ASSERTED THEN NEGATED, TX SIGNAL NOT RECOVERED t-loss-on & t-loss-o

t_loss_on

t_init*

t_reset

* SFP SHALL CLEAR TX_FAULT IN

< t_init IF THE FAILURE IS TRANSIENT

t_loss_o

OCCURANCE

OF LOSS

TX_FAULT

VCC > 3.15V

VCC > 3.15V

VCC > 3.15V

t_init

TX_DISABLE

TRANSMITTED SIGNAL

t_init

TX_FAULT

TX_DISABLE

TRANSMITTED SIGNAL

t-init: TX DISABLE NEGATED t-init: TX DISABLE ASSERTED

TX_FAULT

t_init

TX_DISABLE

TRANSMITTED SIGNAL

t_o

TX_FAULT

TX_DISABLE

TRANSMITTED SIGNAL

t-init: TX DISABLE NEGATED, MODULE HOT PLUGGED t-o & t-on: TX DISABLE ASSERTED THEN NEGATED

INSERTION

t_on

Figure 4. Transceiver Timing Diagrams (Module Installed Except Where Noted)

12

Table 12. EEPROM Serial ID Memory Contents – Conventional SFP Memory (Address A0h)

Byte #

Decimal

Data

Notes Byte #

Hex

Decimal

Data

Hex

Notes

0 03 SFP physical device 37 00 Hex Byte of Vendor OUI 1

1 04 SFP function dened by serial ID only 38 17 Hex Byte of Vendor OUI 1

2 07 LC optical connector 39 6A Hex Byte of Vendor OUI 1

3 00 40 41 “A” - Vendor Part Number ASCII character

4 00 41 46 “F” - Vendor Part Number ASCII character

5 00 42 42 “B” - Vendor Part Number ASCII character

6 00 43 52 “R” - Vendor Part Number ASCII character

7 20 Intermediate distance (per FC-PI) 44 2D “-” - Vendor Part Number ASCII character

8 40 Shortwave laser w/o OFC (open ber control) 45 35 “5” - Vendor Part Number ASCII character

9 0C Multi-mode 50um and 62.5um optical media 46 37 “7” - Vendor Part Number ASCII character

10 00 47 4A “J” - Vendor Part Number ASCII character

11 01 Compatible with 8B/10B encoded data 48 37 “7” - Vendor Part Number ASCII character

12 4A 7400 MBit/sec nominal bit rate (7.3728 Gbit/s) 49 41 “A” - Vendor Part Number ASCII character

13 00 50 50 “P” - Vendor Part Number ASCII character

14 00 51 5A “Z” - Vendor Part Number ASCII character

15 00 52 20 “ ” - Vendor Part Number ASCII character

16 08 75m of 50/125um OM2 ber @ 7.4 GBit/sec 53 20 “ ” - Vendor Part Number ASCII character

17 03 30m of 62.5/125um OM1 ber @ 7.4 GBit/sec 54 20 “ ” - Vendor Part Number ASCII character

18 00 55 20 “ ” - Vendor Part Number ASCII character

19 14 200m of 50/125um OM3 ber @ 7.4 GBit/sec 56 20 “ ” - Vendor Part Number ASCII character

20 41 “A” - Vendor Name ASCII character 57 20 “ ” - Vendor Part Number ASCII character

21 56 “V” - Vendor Name ASCII character 58 20 “ ” - Vendor Part Number ASCII character

22 41 “A” - Vendor Name ASCII character 59 20 “ ” - Vendor Part Number ASCII character

23 47 “G” - Vendor Name ASCII character 60 03 Hex Byte of Laser Wavelength

24 4F “O” - Vendor Name ASCII character 61 52 Hex Byte of Laser Wavelength

[2]

[2]

25 20 “ ” - Vendor Name ASCII character 62 00

26 20 “ ” - Vendor Name ASCII character 63 Checksum for Bytes 0-62

[3]

27 20 “ ” - Vendor Name ASCII character 64 00

28 20 “ ” - Vendor Name ASCII character 65 1A Hardware SFP TX_DISABLE, TX_FAULT &

RX_LOS

29 20 “ ” - Vendor Name ASCII character 66 00

30 20 “ ” - Vendor Name ASCII character 67 50 80% below nominal rate tolerated

(1.288 Gb/s)

31 20 “ ” - Vendor Name ASCII character 68-83 Vendor Serial Number ASCII characters

32 20 “ ” - Vendor Name ASCII character 84-91 Vendor Date Code ASCII characters

[4]

[5]

33 20 “ ” - Vendor Name ASCII character 92 68 Digital Diagnostics, Internal Cal, Rx Pwr Avg

34 20 “ ” - Vendor Name ASCII character 93 F0 A/W, Soft SFP TX_DISABLE, TX_FAULT &

RX_LOS

35 20 “ ” - Vendor Name ASCII character 94 03 SFF-8472 Compliance to revision 10

36 00 95 Checksum for Bytes 64-94

[3]

96 - 255 00

Notes:

1. The IEEE Organizationally Unique Identier (OUI) assigned to Avago Technologies is 00-17-6A (3 bytes of hex).

2. Laser wavelength is represented in 16 unsigned bits. The hex representation of 850 (nm) is 0352.

3. Addresses 63 and 95 are checksums calculated (per SFF-8472 and SFF-8074) and stored prior to product shipment.

4. Addresses 68-83 specify the AFBR-57J7APZ ASCII serial number and will vary on a per unit basis.

5. Addresses 84-91 specify the AFBR-57J7APZ ASCII date code and will vary on a per date code basis.

13

Table 13. EEPROM Serial ID Memory Contents – Enhanced Feature Set Memory (Address A2h)

Byte #

Decimal Notes

0 Temp H Alarm MSB

1 Temp H Alarm LSB

2 Temp L Alarm MSB

3 Temp L Alarm LSB

4 Temp H Warning MSB

5 Temp H Warning LSB

6 Temp L Warning MSB

7 Temp L Warning LSB

8 Vcc H Alarm MSB

9 Vcc H Alarm LSB

10 Vcc L Alarm MSB

11 Vcc L Alarm LSB

12 Vcc H Warning MSB

13 Vcc H Warning LSB

14 Vcc L Warning MSB

15 Vcc L Warning LSB

16 Tx Bias H Alarm MSB

17 Tx Bias H Alarm LSB

18 Tx Bias L Alarm MSB

19 Tx Bias L Alarm LSB

20 Tx Bias H Warning MSB

21 Tx Bias H Warning LSB

22 Tx Bias L Warning MSB

23 Tx Bias L Warning LSB

24 Tx Pwr H Alarm MSB

25 Tx Pwr H Alarm LSB

Notes:

1. Temperature (Temp) is decoded as a 16 bit signed twos compliment integer in increments of 1/256 degrees C.

2. Supply Voltage (Vcc) is decoded as a 16 bit unsigned integer in increments of 100 uV.

3. Laser bias current (Tx Bias) is decoded as a 16 bit unsigned integer in increments of 2 uA.

4. Transmitted average optical power (Tx Pwr) is decoded as a 16 bit unsigned integer in increments of 0.1 uW.

5. Received average optical power (Rx Pwr) is decoded as a 16 bit unsigned integer in increments of 0.1 uW.

6. Bytes 55-94 are not intended for use with AFBR-57J7APZ, but have been set to default values per SFF-8472.

7. Byte 95 is a checksum calculated (per SFF-8472) and stored prior to product shipment.

[1]

[1]

[1]

[1]

[1]

[1]

[1]

[1]

[2]

[2]

[2]

[2]

[2]

[2]

[2]

[2]

[3]

[3]

[3]

[3]

[3]

[3]

[3]

[4]

[4]

Byte #

Decimal Notes

26 Tx Pwr L Alarm MSB

27 Tx Pwr L Alarm LSB

28 Tx Pwr H Warning MSB

29 Tx Pwr H Warning LSB

30 Tx Pwr L Warning MSB

31 Tx Pwr L Warning LSB

32 Rx Pwr H Alarm MSB

33 Rx Pwr H Alarm LSB

34 Rx Pwr L Alarm MSB

35 Rx Pwr L Alarm LSB

36 Rx Pwr H Warning MSB

37 Rx Pwr H Warning LSB

38 Rx Pwr L Warning MSB

39 Rx Pwr L Warning LSB

[4]

[4]

[5]

[5]

[5]

[5]

[4]

[4]

[4]

[4]

[5]

[5]

[5]

[5]

Byte #

Decimal Notes

104 Real Time Rx Pwr MSB

105 Real Time Rx Pwr LSB

106 Reserved

107 Reserved

108 Reserved

109 Reserved

110 Status/Control - See

111 Reserved

112 Flag Bits - See Table 15

113 Flag Bits - See Table 15

114 Reserved

115 Reserved

116 Flag Bits - See Table 15

117 Flag Bits - See Table 15

40-55 Reserved 118-127 Reserved

56-94 External Calibration Constants

95 Checksum for Bytes 0-94

96 Real Time Temperature MSB

97 Real Time Temperature LSB

98 Real Time Vcc MSB

[3]

99 Real Time Vcc LSB

100 Real Time Tx Bias MSB

101 Real Time Tx Bias LSB

102 Real Time Tx Power MSB

103 Real Time Tx Power LSB

[2]

[2]

[3]

[3]

[6]

128-247 Customer Writeable

[7]

[1]

[1]

[4]

[4]

248-255 Vendor Specic

[5]

[5]

Table 14

14

Table 14. EEPROM Serial ID Memory Contents – Soft Commands (Address A2h, Byte 110)

Bit # Status/Control Name Description Notes

7 TX_ DISABLE State Digital state of SFP TX_ DISABLE Input Pin (1 = TX_DISABLE asserted) Note 1

6 Soft TX_ DISABLE Read/write bit for changing digital state of TX_DISABLE function Note 1,2

5 reserved

4 reserved

3 reserved

2 TX_FAULT State Digital state of the SFP TX_FAULT Output Pin (1 = TX_FAULT asserted) Note 1

1 RX_LOS State Digital state of the SFP RX_LOS Output Pin (1 = RX_LOS asserted) Note 1

0 Data Ready (Bar) Indicates transceiver is powered and real time sense data is ready. (0 =

Ready)

Notes:

1. The response time for soft commands of the AFBR-57J7APZ is 100 msec as specied by the MSA SFF-8472

2. Bit 6 is logic OR’d with the SFP TX_DISABLE input pin 3 ... either asserted will disable the SFP transmitter.

Note 1

Table 15. EEPROM Serial ID Memory Contents – Alarms and Warnings (Address A2h, Bytes 112, 113, 116, 117)

Byte Bit Flag Bit Name Description

112 7 Temp High Alarm Set when transceiver internal temperature exceeds high alarm threshold.

6 Temp Low Alarm Set when transceiver internal temperature exceeds low alarm threshold.

5 Vcc High Alarm Set when transceiver internal supply voltage exceeds high alarm threshold.

4 Vcc Low Alarm Set when transceiver internal supply voltage exceeds low alarm threshold.

3 Tx Bias High Alarm Set when transceiver laser bias current exceeds high alarm threshold.

2 Tx Bias Low Alarm Set when transceiver laser bias current exceeds low alarm threshold.

1 Tx Power High Alarm Set when transmitted average optical power exceeds high alarm threshold.

0 Tx Power Low Alarm Set when transmitted average optical power exceeds low alarm threshold.

113 7 Rx Power High Alarm Set when received average optical power exceeds high alarm threshold.

6 Rx Power Low Alarm Set when received average optical power exceeds low alarm threshold.

0-5 reserved

116 7 Temp High Warning Set when transceiver internal temperature exceeds high warning threshold.

6 Temp Low Warning Set when transceiver internal temperature exceeds low warning threshold.

5 Vcc High Warning Set when transceiver internal supply voltage exceeds high warning threshold.

4 Vcc Low Warning Set when transceiver internal supply voltage exceeds low warning threshold.

3 Tx Bias High Warning Set when transceiver laser bias current exceeds high warning threshold.

2 Tx Bias Low Warning Set when transceiver laser bias current exceeds low warning threshold.

1 Tx Power High Warning Set when transmitted average optical power exceeds high warning threshold.

0 Tx Power Low Warning Set when transmitted average optical power exceeds low warning threshold.

117 7 Rx Power High Warning Set when received average optical power exceeds high warning threshold.

6 Rx Power Low Warning Set when received average optical power exceeds low warning threshold.

0-5 reserved

15

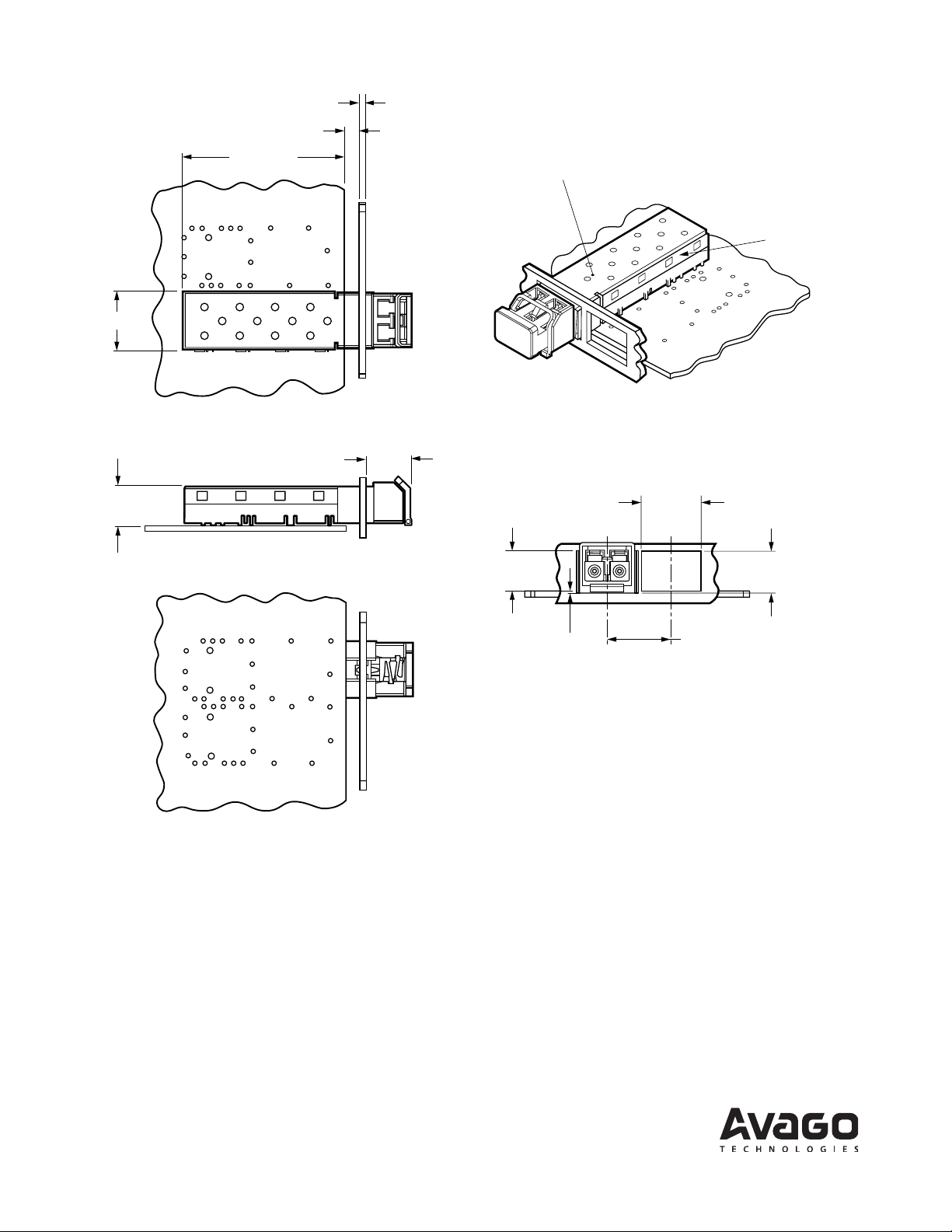

Figure 5. Module drawing

DEVICE SHOWN WITH

DUST CAP AND

BAIL DELATCH

AFBR-57J7APZ

850nm LASER PROD

21CRF(J) CLASS1

CHINA 0445

SN: A30445CD1C

A

F

B

R-57J

7A

P

Z

8

5

0

nm

L

AS

E

R

P

R

O

D

2

1

C

R

F

(

J

)

C

L

AS

S

1

C

H

I

N

A

0

4

4

5

S

N

:

A3

0

4

4

5

C

D

1

C

55.3 – 0.2

8.5 – 0.1

13.4 – 0.1

6.25 – 0.05

TX RX

1.91

13.6

12.4 – 0.2

13.6

14.9 UNCOMPRESSED

0.55 UNCOMPRESSED

1.39 UNCOMPRESSED

16

2x 1.7

20x 0.5 ± 0.03

0.9

2 ± 0.005 TYP.

0. 0 6 L A S B S

10.53

11.93

20

10

11

PIN 1

20

10

11

PIN 1

0.8

TYP .

10.93

9.6

2x 1.55 ± 0.05

3.2

5

LEGEND

1. PADS AND VIAS ARE CHASSIS GROUND

2. THROUGH HOLES, PLATING OPTIONAL

3. HATCHED AREA DENOTES COMPONENT

AND TRACE KEEPOUT (EXCEPT

CHASSIS GROUND)

4. AREA DENOTES COMPONENT

KEEPOUT (TRACES ALLOWED)

DIMENSIONS ARE IN MILLIMETERS

4

3

2

1

1

26.8

5

11x 2.0

10

3x

41.3

42.3

B

10x∅ 1.05 ± 0.01

16.25

REF .

14.25

11.08

8.58

5.68

2.0

11x

11.93

9.6

4.8

8.48

A

3.68

SEE DETAIL 1

9x 0.95 ± 0.05

2.5

7.17.2

2.5

10

3x

34.5

16.25

MIN. PITCH

Y

X

DET AIL 1

∅ 0.85 ± 0.05

PCB

EDGE

0. 0 6 L A S B S

∅ 0 .1 S

∅ 0 .1 L S

∅ 0 .1 L S

∅ 0.1 Y

S B

L A

X A

S X

X A

Figure 6. SFP host board mechanical layout

17

41.78 ±0.5

3.5 ± 0.3

1.7± 0.9

Tcase REFERENCE POINT

PCB

10 REF

(to PCB)

0.4± 0.1

(below PCB)

10.4 ± 0.1

15.25±0.1

16.25± 0.1 MIN. PITCH

DIMENSIONS ARE IN MILLIMETERS

11.73 REF

CAGE ASSEMBLY

9.8 MAX.

15 MAX.

Figure 7. SFP Assembly Drawing

For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2009 Avago Technologies. All rights reserved.

AV02-1767EN - March 18, 2009

Loading...

Loading...