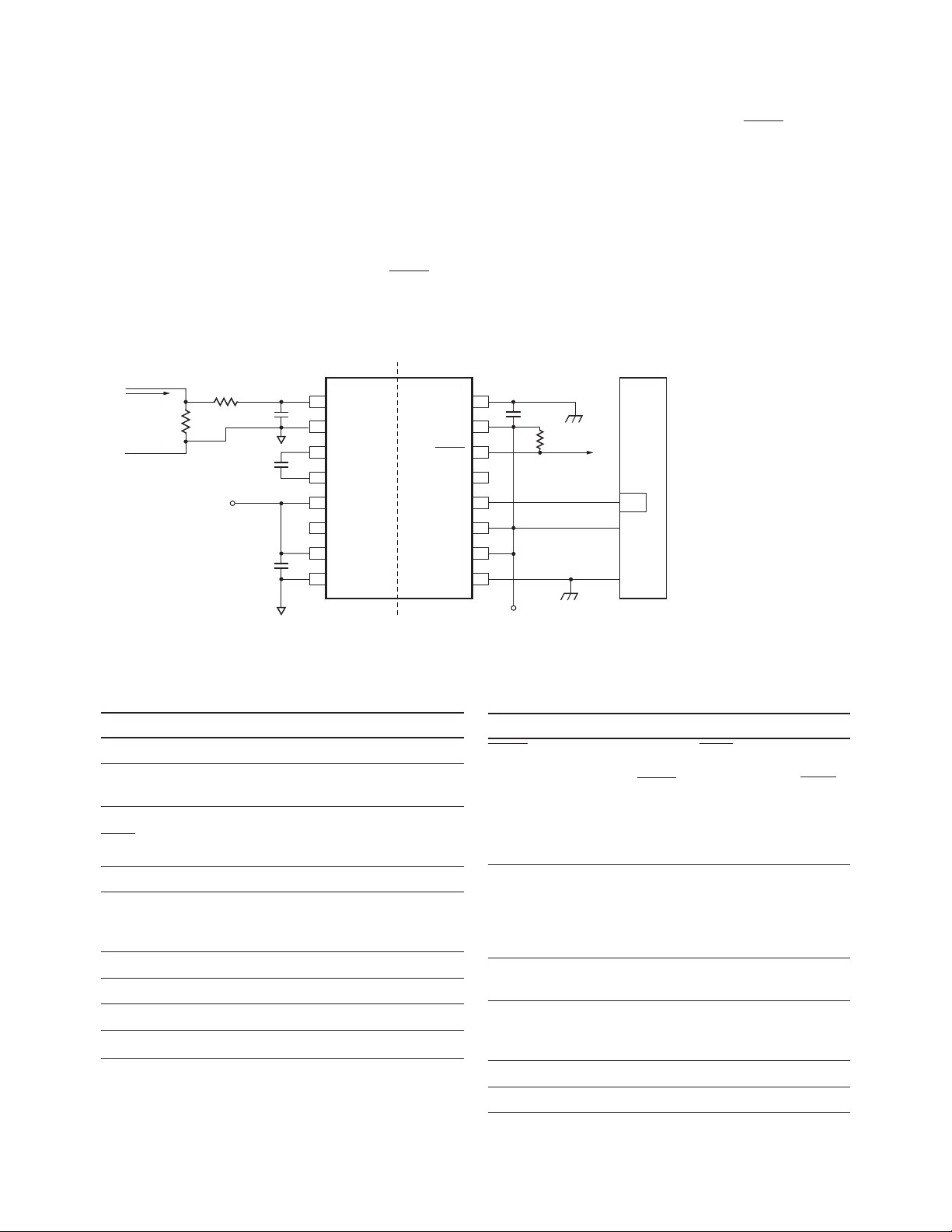

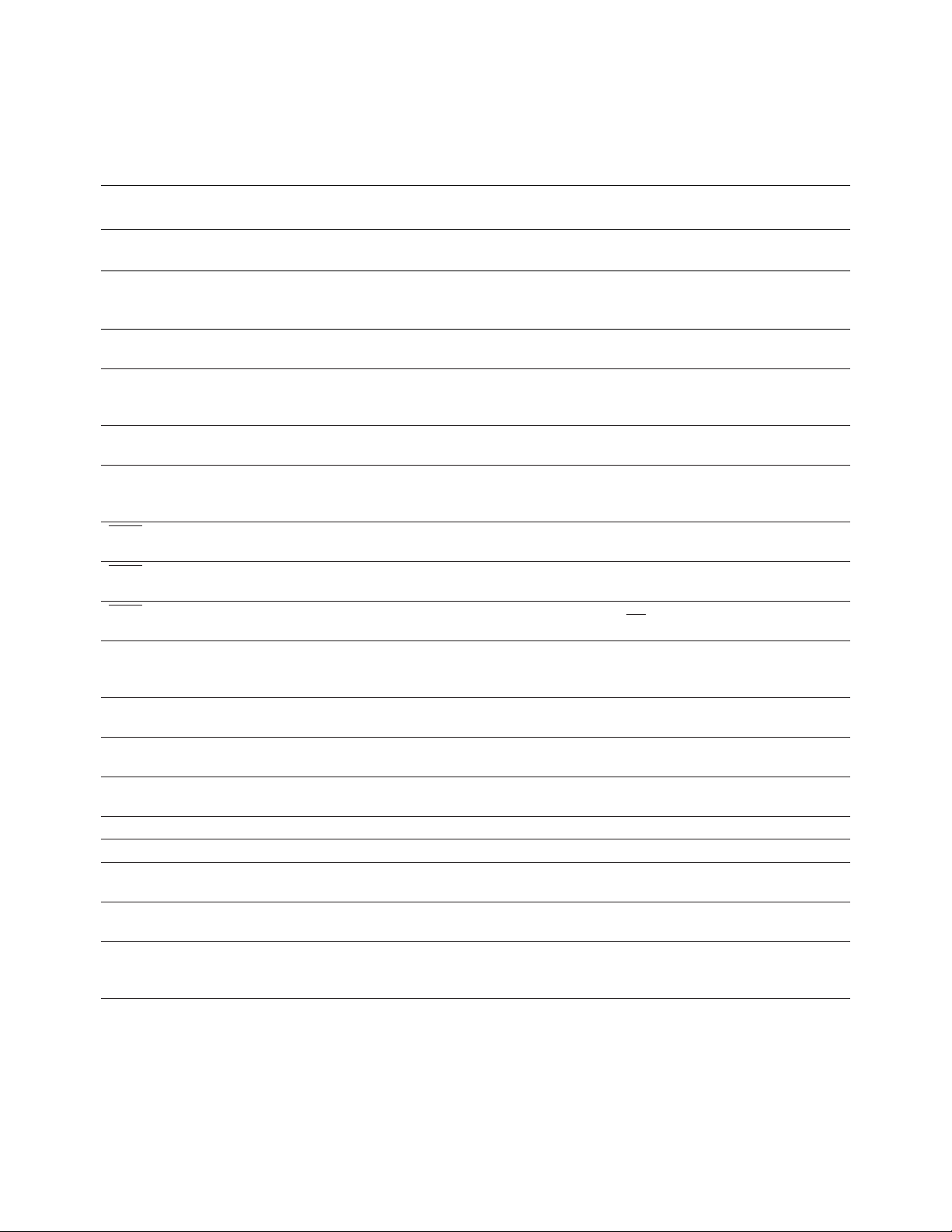

Avago ACPL-785J Schematic [ru]

ACPL-785J

Lead (Pb) Free

RoHS 6 fully

compliant

RoHS 6 fully compliant options available;

-xxxE denotes a lead-free product

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

FAULT

ABSVAL

V

OUT

V

REF

V

IN+

V

IN-

R

SENSE1

SHORT CIRCUIT FAULT

ISOLATION BOUNDARY

A/D

CONVERTER

MICRO

CONTROLLER

ACPL-785J

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

FAULT

ABSVAL

V

OUT

V

REF

V

IN+

V

IN-

R

SENSE2

ISOLATION BOUNDARY

ACPL-785J

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

FAULT

ABSVAL

V

OUT

V

REF

V

IN+

V

IN-

R

SENSE3

ISOLATION BOUNDARY

ACPL-785J

M

+5 V

OVERLOAD

FAULT

+

–

+

–

3 PHASE ABSOLUTE

VALUE OUTPUT

V

REF

V

TH

3 PHASE

MOTOR

Isolation Amplifier with Short Circuit and Overload Detection

Data Sheet

Description

Avago’s Isolation Amplifier with Short Circuit and

Overload Detection makes motor phase current sensing

compact, affordable and easy-to-implement while satisfying worldwide safety and regulatory requirements.

Applications

• Motor phase and rail current sensing

• Power inverter current and voltage sensing

• Industrial process control

• Data acquisition systems

• General purpose current and voltage sensing

• Traditional current transducer replacements

Features

• Output Voltage Directly Compatible with A/D

Converters (0 V to V

• Fast (3 µs) Short Circuit Detection with Transient Fault

Rejection

• Absolute Value Signal Out put for Overload Detection

• 1 µV/°C Offset Change vs. Temperature

• SO-16 Package

• -40°C to +85°C Operating Temperature Range

• 25 kV/µs Isolation Transient Immunity

• Regulatory Approvals: UL, CSA, IEC/EN/DIN EN

60747-5-5 (891 Vpeak Working Voltage)

Low Cost Three Phase Current Sensing with Short Circuit and Overload Detection

REF

)

CAUTION: It is advised that normal static precautions be taken in handling and assembly of

this component to prevent damage and/or degradation which may be induced by ESD.

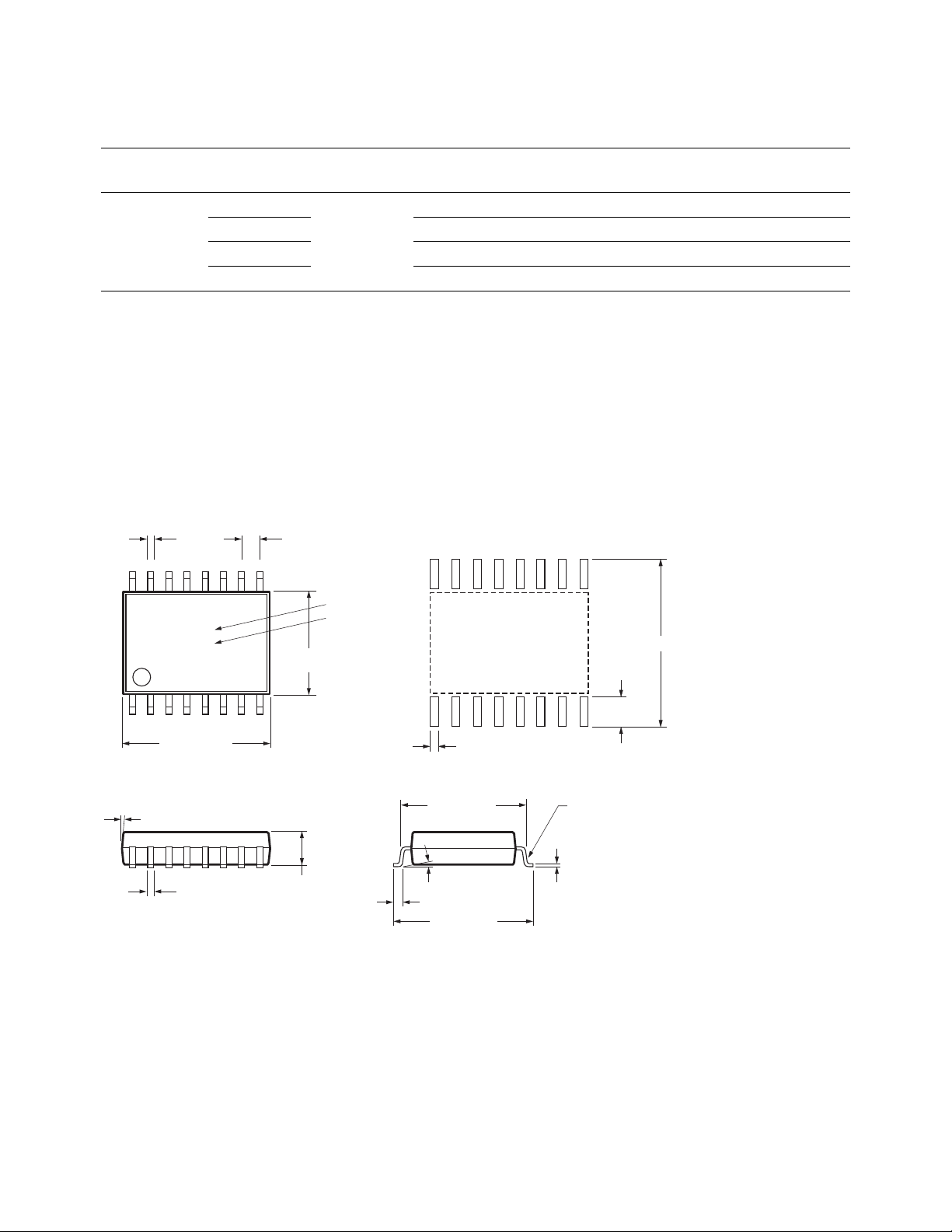

Description

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

GND

2

V

DD2

FAULT

ABSVAL

V

OUT

V

REF

V

DD2

GND

2

V

IN+

V

IN-

C

H

C

L

V

DD1

V

LED+

V

DD1

GND

1

R

SHUNT

0.02

ISOLATED +5 V

4.7 k

39

.01 F

0.1 F

0.1 F

ISOLATION BOUNDARY

INPUT

CURRENT

+5 V

A/D

V

REF

GND

C

TO OTHER

PHASE

OUTPUTS

+

0.1 F

ACPL-785J

The ACPL-785J isolation amplifier is designed for current

sensing in electronic motor drives. In a typical implementation, motor currents flow through an external resistor

and the resulting analog voltage drop is sensed by the

ACPL-785J. A larger analog output voltage is created

on the other side of the ACPL-785J’s optical isolation

barrier. The output voltage is proportional to the motor

current and can be connected directly to a single-supply

A/D converter. A digital over-range output (FAULT) and

an analog rectified output (ABSVAL) are also provided.

The wire OR-able over-range output (FAULT) is useful

for quick detec tion of short circuit con ditions on any

of the motor phases. The wire-OR-able rectified output

(ABSVAL), simplifies measure-ment of motor load since

it performs polyphase rectification. Since the commonmode voltage swings several hundred volts in tens of

nanoseconds in modern electronic motor drives, the

ACPL-785J was designed to ignore very high commonmode transient slew rates (10 kV/µs).

Figure 1. Current sensing circuit.

Pin Descriptions

Symbol Description

V

Positive input voltage (±200 mV recommended).

IN+

V

Negative input voltage (normally connected to

IN-

GND1).

CH Internal Bias Node. Connections to or between CH

and CL other than the re quired 0.1 µF capacitor

C

L

shown, are not recommended.

V

Supply voltage input (4.5 V to 5.5 V).

DD1

V

LED anode. This pin must be left uncon nected for

LED+

guaranteed data sheet perfor mance. (For optical

coupling testing only.)

V

Supply voltage input (4.5 V to 5.5 V).

DD1

GND1 Ground input.

GND2 Ground input.

V

2

Supply voltage input (4.5 V to 5.5 V).

DD2

Symbol Description

FAULT Short circuit fault output. FAULT changes from a

high to low output voltage within 6 µs after

V

is an open drain output which allows outputs from

all the ACPL-785Js in a circuit to be connected

together (“wired-OR”) forming a single fault signal

for interfacing directly to the micro-controller.

ABSVAL Absolute value of V

when VIN=0 and increases toward V

approaches +256 mV or -256 mV. ABSVAL is

“wired-OR” able and is used for detecting

overloads.

V

Voltage output. Swings from 0 to V

OUT

The nominal gain is V

V

Reference voltage input (4.0 V to V

REF

voltage establishes the full scale output ranges

and gains of V

V

Supply voltage input (4.5 V to 5.5 V).

DD2

GND2 Ground input.

exceeds the FAULT Detection Threshold. FAULT

IN

output. ABSVAL is 0 V

OUT

/504 mV.

REF

and ABSVAL.

OUT

DD2

REF

.

REF

). This

as VIN

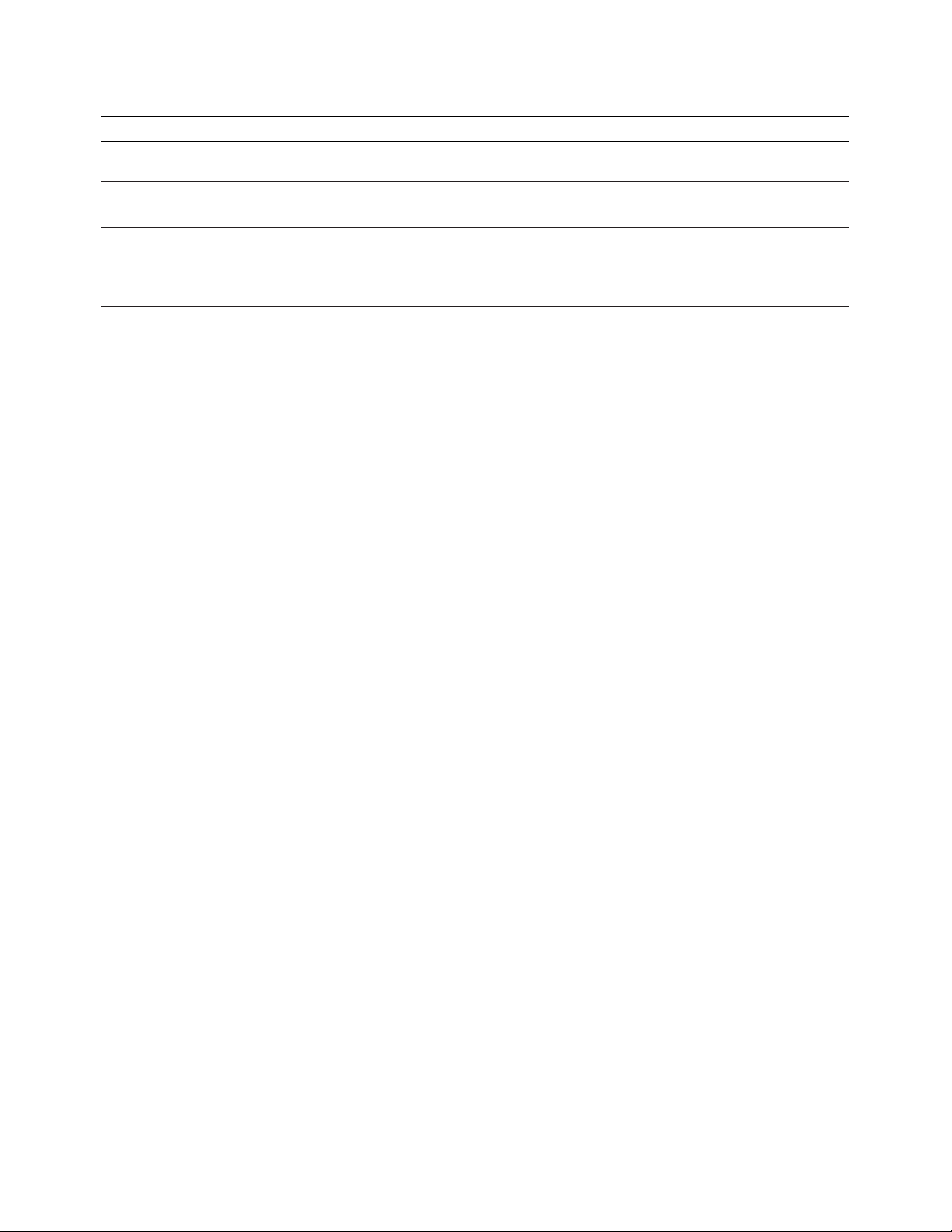

Ordering Information

9

0.295 ± 0.010

(7.493 ± 0.254)

10111213141516

87654321

0.018

(0.457)

0.138 ± 0.005

(3.505 ± 0.127)

9°

0.406 ± 0.10

(10.312 ± 0.254)

0.408 ± 0.010

(10.160 ± 0.254)

0.025 MIN.

0.008 ± 0.003

(0.203 ± 0.076)

STANDOFF

0.345 ± 0.010

(8.986 ± 0.254)

0–8°

0.018

(0.457)

0.050

(1.270)

ALL LEADS

TO BE

COPLANAR

± 0.002

A 785J

YYWW

TYPE NUMBER

DATE CODE

0.458 (11.63)

0.085 (2.16)

0.025 (0.64)

LAND PATTERN RECOMMENDATION

ACPL-785J is UL Recognized with 3750 Vrms for 1 minute per UL1577.

Part number

ACPL-785J

Option (RoHS

Compliant) Package Surface Mount Tape & Reel

-000E

-060E X X 45 per tube

SO-16

X 45 per tube

IEC/EN/DIN EN

60747-5-5 Quantity

-500E X X 850 per reel

-560E X X X 850 per reel

To order, choose a part number from the part number column and combine with the desired option from the option

column to form an order entry.

Example:

ACPL-785J-560E to order product of 16-Lead Surface Mount package in Tape and Reel packaging with IEC/EN/DIN EN

60747-5-5 Safety Approval and RoHS compliant.

Package Outline Drawings

16-Lead Surface Mount

Dimensions in inches (millimeters)

3

Note: Initial and continued variation in the color of the white mold

compound is normal and does not affect device performance or

reliability.

Note: Floating lead protrusion is 0.25 mm (10 mils) max.

Package Characteristics

Parameter Symbol Min. Typ. Max. Units Test Conditions Fig. Notes

Input-Output Momentary

Withstand Voltage

Resistance (Input-Output) R

Capacitance (Input-Output) C

Input IC Junction-to-Case

Thermal Resistance

Output IC Junction-to-Case

Thermal Resistance

V

ISO

I-O

I-O

θjci

θjco

3750 Vrms RH < 50%, t = 1 min.,

TA = 25°C

9

>10

Ω

V

I-O

= 500 V

DC

1.3 pF f = 1 MHz 3

120 °C/W TA = 85°C

100 °C/W TA = 85°C

1,2,3

3

Recommended Pb-Free IR Profile

Recommended reflow condition as per JEDEC Standard,

J-STD-020 (latest revision). Non-Halide Flux should be

used.

Regulatory Information

The ACPL-785J is pending for approvals by the following organizations:

IEC/EN/DIN EN 60747-5-5

Approved with Maximum Working Insulation Voltage

V

IORM

= 891 V

peak

.

UL

Approval under UL 1577, component recognition

program up to V

= 3750 Vrms/1min. File E55361.

ISO

CSA

Approval under CSA Component Acceptance Notice #5,

File CA 88324

4

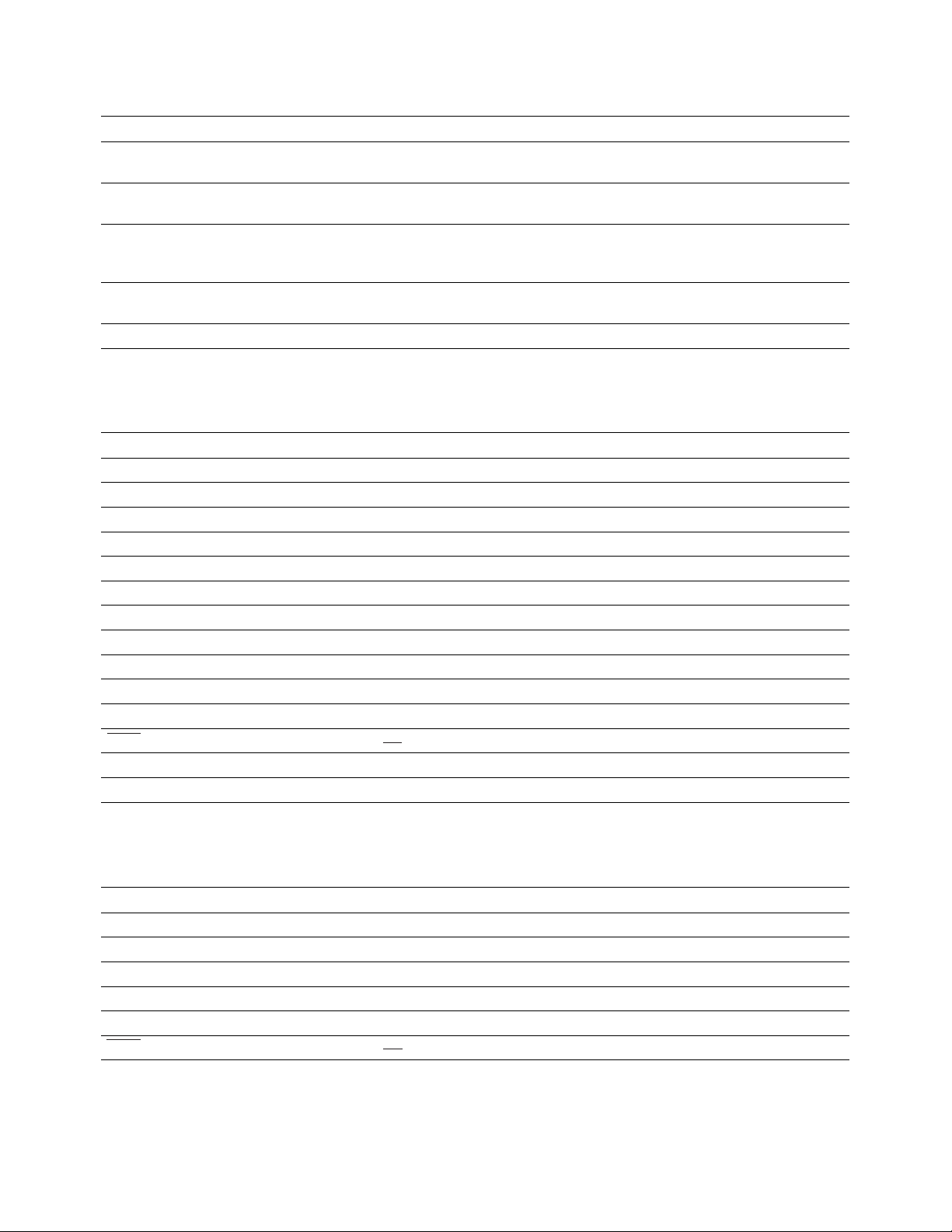

IEC/EN/DIN EN 60747-5-5 Insulation Characteristics*

P

s

– POWER – mW

0

0

TS – CASE TEMPERATURE – °C

20025

800

50 75 100

200

150 175125

400

600

Psi – OUTPUT

Psi – INPUT

Description Symbol Characteristic Unit

Installation classification per DIN VDE 0110/1.89, Table 1

for rated mains voltage ≤ 300 V

for rated mains voltage ≤ 300 V

for rated mains voltage ≤ 600 V

rms

rms

rms

Climatic Classification 55/85/21

Pollution Degree (DIN VDE 0110/1.89) 2

Maximum Working Insulation Voltage V

Input to Output Test Voltage, Method b**

V

x 1.875 = VPR, 100% Production Test with

IORM

tm = 1 sec, Partial discharge < 5 pC

Input to Output Test Voltage, Method a**

V

x 1.6 = VPR, Type and Sample Test, tm = 10 sec,

IORM

Partial discharge < 5 pC

Highest Allowable Overvoltage (Transient Overvoltage t

= 60 sec) V

ini

IORM

V

PR

V

PR

IOTM

Safety-limiting values — maximum values allowed in the

event of a failure, also see Figure 2.

Case Temperature

Input Power

Output Power

Insulation Resistance at T

* Isolation characteristics are guaranteed only within the safety maximum ratings which must be ensured by protective circuits within the

application. Surface Mount Classification is class A in accordance with CECC00802.

** Refer to the optocoupler section of the isolation and Control Components Designer’s Catalog, under Product Safety Regulations section IEC/EN/

DIN EN 6747-5-5, for a detailed description of Method a and Method b partial discharge test profiles.

= 500 V R

SI, VIO

T

S

P

S1, INPUT

P

S1, OUTPUT

S

I-IV

I-III

I-II

891 V

1670 V

1425 V

6000 V

175

400

600

9

>10

PEAK

PEAK

PEAK

PEAK

°C

mW

mW

Ω

Figure 2. Dependence of safety-limiting values on temperature.

5

Insulation and Safety Related Specifications

Parameter Symbol Min. Max. Conditions

Minimum External Air Gap

(Clearance)

Minimum External Tracking

(Creepage)

Minimum Internal Plastic Gap 0.5 mm Through insulation distance conductor to conductor,

Tracking Resistance CTI >175 Volts DIN IEC 112/VDE 0303 Part 1

Isolation Group IIIa Material Group (DIN VDE 0110, 1/89, Table 1)

L(101) 8.3 mm Measured from input terminals to output terminals,

shortest distance through air.

L(102) 8.3 mm Measured from input terminals to output terminals,

shortest distance path along body.

usually the straight line distance thickness between the

emitter and detector.

Comparative Tracking Index)

Absolute Maximum Ratings

Parameter Symbol Min. Max. Units Note

Storage Temperature T

Operating Temperature T

Supply Voltages V

Steady-State Input Voltage V

2 Second Transient Input Voltage V

Output Voltage V

S

A

DD1

IN+

IN+

OUT

, V

, V

, V

DD2

IN-

IN-

Absolute Value Output Voltage ABSVAL -0.5 V

Reference Input Voltage V

Reference Input Current I

Output Current I

Absolute Value Current I

FAULT Output Current I

Input IC Power Dissipation P

Output IC Power Dissipation P

REF

REF

VOUT

ABSVAL

FAU LT

I

O

-55 125 °C

-40 100 °C

0.0 5.5 V 4

-2.0 V

-6.0 V

-0.5 V

0 V

+ 0.5 V

DD1

+ 0.5 V

DD1

+ 0.5 V

DD2

+ 0.5 V

DD2

+ 0.5 V V 5

DD2

20 mA

20 mA

20 mA

20 mA

200 mW

200 mW

Recommended Operating Conditions

Parameter Symbol Min. Max. Units Note

Ambient Operating Temperature T

Supply Voltages V

Input Voltage (accurate and linear) V

Input Voltage (functional) V

Reference Input Voltage V

FAULT Output Current I

6

A

DD1

IN+

IN+

REF

FAU LT

, V

, V

, V

DD2

IN-

IN-

-40 85 °C

4.5 5.5 V

-200 200 mV

-2 2 V

4.0 V

DD2

V

4 mA

DC Electrical Specifications

Unless otherwise noted, all typicals and figures are at the nominal operating conditions of V

4.0 V, V

DD1

= V

= 5 V and TA = 25°C; all Minimum/Maximum specifications are within the Recommended Operating

DD2

Conditions.

Test

Parameter Symbol Min. Typ. Max. Units

Input Offset

Voltage

Magnitude of Input

Offset Change vs.

Temperature

V

Gain G V

OUT

Magnitude of V

Gain Change vs.

OUT

Temperature

V

200 mV

OUT

Nonlinearity

Maximum Input

Voltage Before

V

Clipping

OUT

FAULT Detection

Threshold

FAULT Low

Output Voltage

FAULT High

Output Current

ABSVAL Output

Error

Input Supply

Current

Output Supply

Current

Reference Voltage

Input Current

Input Current I

Input Resistance R

V

Output

OUT

Resistance

ABSVAL Output

Resistance

Input DC CommonMode Rejection

Ratio

V

OS

|∆VOS/∆TA|

|∆G/∆TA|

NL

200

|V

IN+|MAX

|V

| 230 256 280 mV 10 9

THF

V

OLF

I

OHF

e

ABS

-3 0 3 mV V

/504

REF

mV - 5%

1 10

V

/504 mVV

REF

/504

REF

mV + 5%

µV/°C

V/V |V

50 300 ppm/°C |V

0.06 0.4 % |V

256 mV

350 800 mV IOL = 4 mA

0.2 15

µA

0.6 2 % of

full scale

output

I

DD1

I

DD2

I

VREF

IN+

IN

R

OUT

R

ABS

CMRR

IN

10.7 20 mA

10.4 20 mA

0.26 1 mA

-350 nA V

800

0.2

0.3

kΩ

Ω

Ω

85 dB 11

Conditions Fig. Note

= 0 V,

IN+

TA = –40°C to +85°C

V

= 0 V,

IN+

TA = –40°C to +85°C

| < 200 mV,

IN+

TA = 25°C

| < 200 mV,

IN+

TA = 25°C

| < 200 mV,

IN+

TA = –40°C to +85°C

V

= V

FAU LT

DD2

= 0 V

IN+

V

= 0 V

IN+

= 0, V

IN+

= 0 V, V

IN-

3, 4,

6

5

7

6,7,

8,9

6,7,

8,9

6,7,

8,9

11 10

=

REF

8

7

Loading...

Loading...