ACPL-061L, ACPL-064L, ACPL-M61L,

ACPL-W61L, ACPL-K64L

Ultra Low Power 10 MBd Digital CMOS Optocouplers

Data Sheet

Lead (Pb) Free

RoHS 6 fully

compliant

RoHS 6 fully compliant options available;

-xxxE denotes a lead-free product

Description

The Avago ultra low power ACPL-x6xL digital optocouplers

combine an AlGaAs light emitting diode (LED) and an

integrated high gain photodetector. The optocoupler

consumes extremely low power, at maximum 1.3mA I

current per channel across temperature. With a forward

LED current as low as 1.6 mA most microprocessors can

directly drive the LED.

An internal Faraday shield provides a guaranteed common

mode transient immunity specification of 20 kV/Ps.

Maximum AC and DC circuit isolation is achieved while

maintaining TTL/CMOS compatibility.

The optocouplers CMOS outputs are slew-rate controlled

and is designed to allow the rise and fall time to be controlled over a wide load capacitance range.

The ACPL-x6xL series operates from both 3.3 V and 5 V

supply voltages with guaranteed AC and DC performance

from –40°C to +105°C.

These low-power optocouplers are suitable for high speed

logic interface applications.

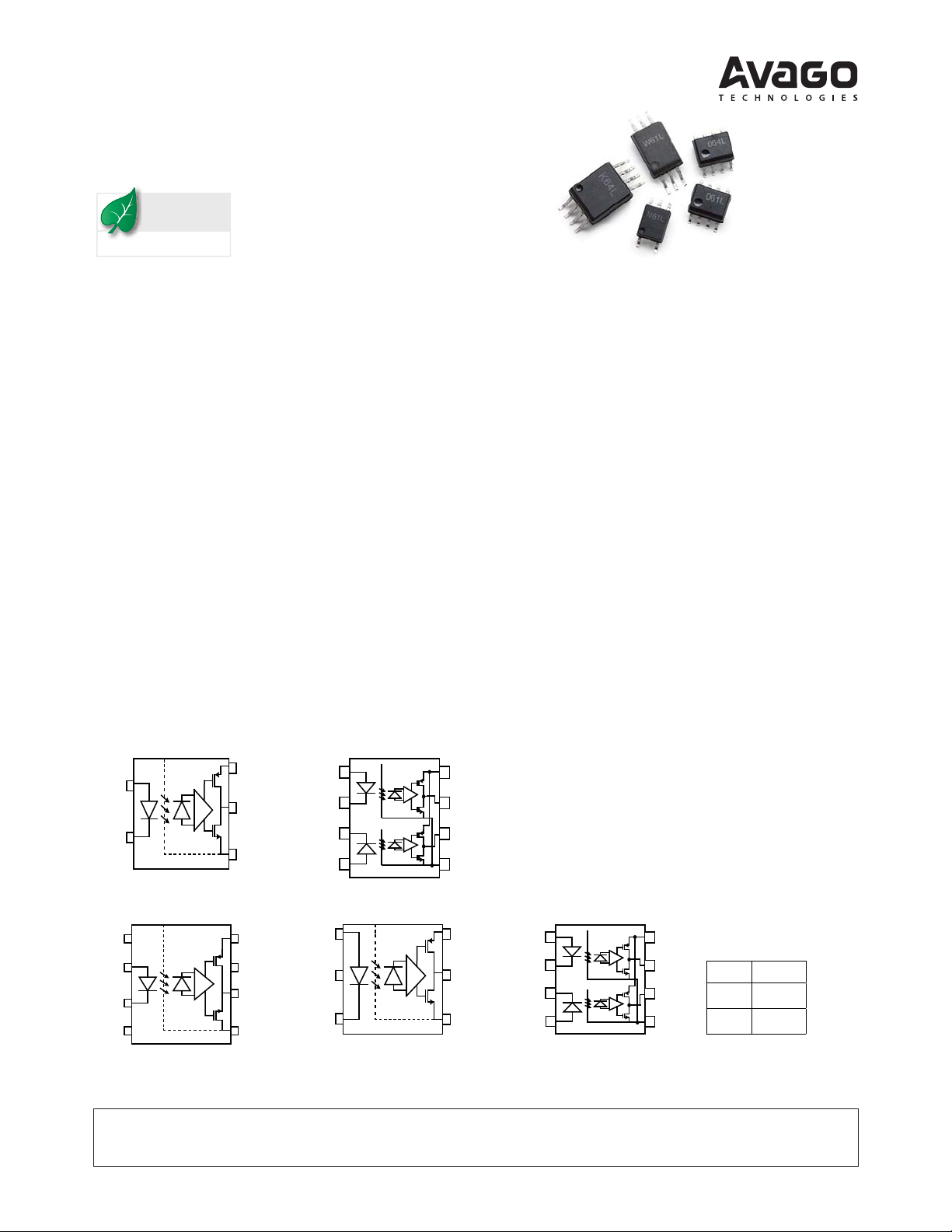

Functional Diagrams

Anode

Cathode

ACPL-M61L

1

3

6

V

DD

5

Vo

Anode1

Cathode1

Cathode2

4

GND

Anode2

ACPL-064L

1

2

3

4

SHIELD

Features

x Ultra-low IDD current: 1.3 mA/channel maximum

x Low input current: 1.6 mA

x Built-in slew-rate controlled outputs

DD2

x 20 kV/Ps minimum Common Mode Rejection (CMR) at

V

= 1000 V

CM

x High speed: 10 MBd minimum

x Guaranteed AC and DC performance over wide

temperature: –40°C to +105°C

x Wide package selection: SO-5, SO-8, stretched SO-6

and stretched SO-8

x Safety approval

– UL 1577 recognized – 3750 Vrms for 1 minute for

ACPL-061L/064L/M61L and 5000 Vrms* for 1 minute

for ACPL-W61L/K64L

– CSA Approval

– IEC/EN/DIN EN 60747-5-5 approval for Reinforced

Insulation (approved for ACPL-M61L, pending

approval for ACPL-064L/W61L/K64L/061L)

x RoHS compliant

Applications

x Communication interfaces: RS485, CANBus and I2C

8

V

DD

x Microprocessor system interfaces

7

Vo

1

x Digital isolation for A/D and D/A convertors

6

Vo

2

GND

5

NC

Anode

Cathode

NC

ACPL-061L^

1

2

3

8

V

DD

7

NC

6

Vo

Preliminary Information

4

SHIELD

* Pin 7 of the ACPL-061L is not connected

A 0.1

PF bypass capacitor must be connected betwee

^ Advanced information, may subject to changes.

5

GND

CAUTION: It is advised that normal static precautions be taken in handling and assembly

of this component to prevent damage and/or degradation which may be induced by ESD.

Anode

NC*

Cathode

ACPL-W61L

1

2

3

SHIELD

n pins VDD and GND.

ACPL-K64L

6

V

DD

5

Cathode1

Vo

Cathode2

4

GND

Anode1

Anode2

1

2

3

4

SHIELD

8

V

7

Vo

6

Vo

GND

5

DD

1

2

TRUTH TABLE

(POSITIVE LOGIC)

LED OUTPUT

ON L

OFF H

Ordering Information

The ACPL-061L, ACPL-064L and ACPL-M61L are UL Recognized with an isolation voltage of 3750 V

UL1577. The ACPL-W61L and ACPL-K64L are UL Recognized with an isolation voltage of 5000 V

for 1 minute per

rms

for 1 minute per

rms

UL1577. All devices are RoHS compliant.

Option

RoHS

Part number

ACPL-061L

ACPL-064L -000E SO-8 X 100 per tube

ACPL-M61L -000E SO-5 X 100 per tube

ACPL-W61L -000E Stretched

ACPL-K64L -000E Stretched

^

Compliant

-000E SO-8 X 100 per tube

-500E X X 1500 per reel

-560E X X X 1500 per reel

-500E X X 1500 per reel

-560E X X X 1500 per reel

-500E X X 1500 per reel

-560E X X X 1500 per reel

-500E X X X 1000 per reel

-560E XXXX1000 per reel

-500E X X X 1000 per reel

-560E XXXX1000 per reel

Package Surface Mount

X X 100 per tube

S06

X X 80 per tube

S08

Tape

& Reel

UL 5000 V

1 Minute

rating

rms

/

IEC/EN/

DIN EN

60747-5-5 Quantity

To form an ordering part number, choose a part number from the part number column and combine it with the desired

option from the option column.

Example 1:

The part number ACPL-M61L-560E describes an optocoupler with a surface mount SO-5 package; delivered in Tape and

Reel with 1500 parts per reel; with IEC/EN/DIN EN 60747-5-5 Safety Approval; and full RoHS compliance.

Option datasheets are available. Contact your Avago sales representative or authorized distributor for information.

^ Advanced information, may subject to changes.

2

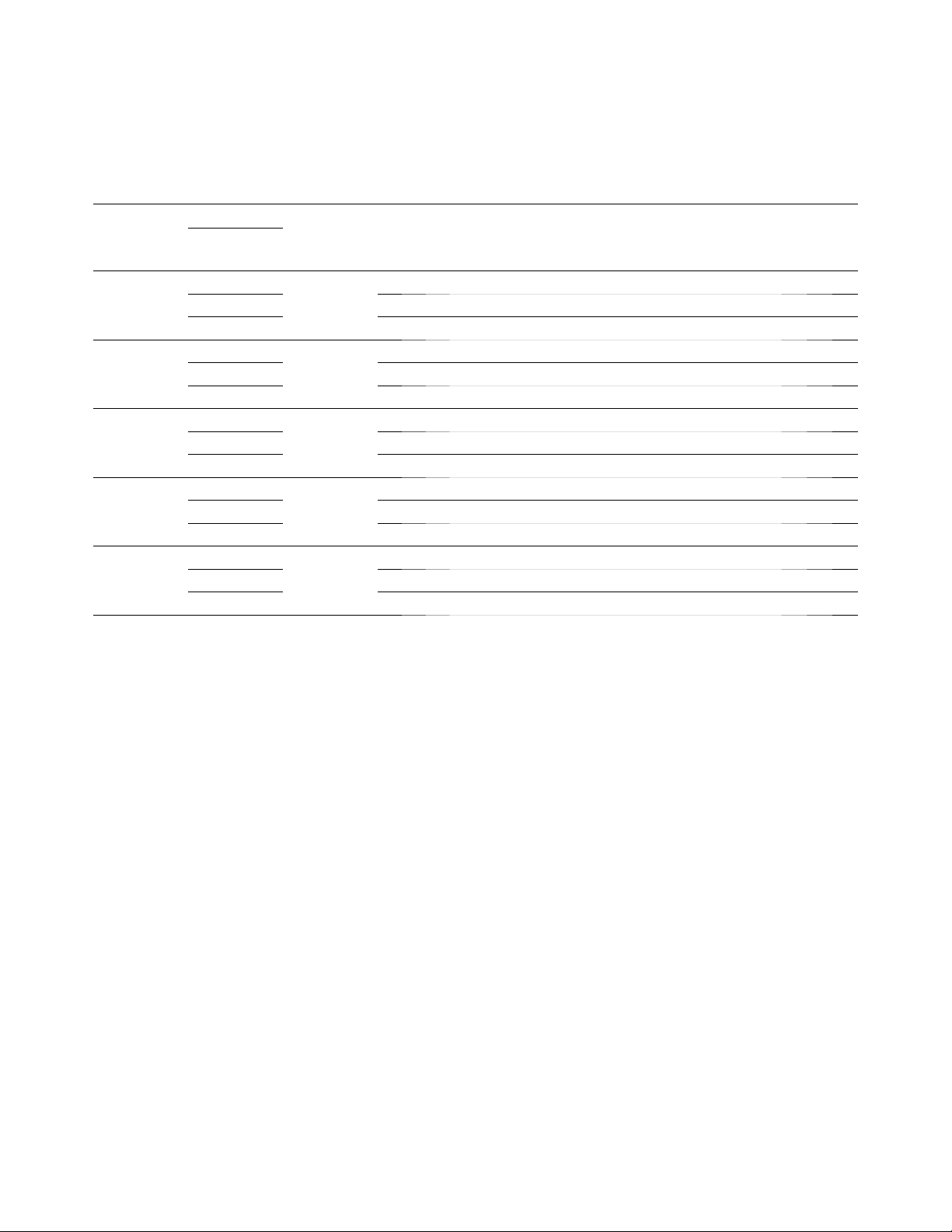

Package Outline Drawings

ACPL-061L and ACPL-064L SO-8 Package

8765

3.937 ± 0.127

(0.155 ± 0.005)

PIN ONE

0.406 ± 0.076

(0.016 ± 0.003)

*

(0.200 ± 0.005)

3.175 ± 0.127

(0.125 ± 0.005)

Total package length (inclusive of mold flash)

*

5.207 ± 0.254 (0.205 ± 0.010)

Dimensions in Millimeters (Inches).

Lead coplanarity = 0.10 mm (0.004 inches) max.

Option number 500 not marked.

Note: Floating lead protrusion is 0.15 mm (6 mils) max.

XXXV

YWW

4321

1.270

(0.050)

5.080 ± 0.127

5.994 ± 0.203

(0.236 ± 0.008)

TYPE NUMBER

(LAST 3 DIGITS)

DATE CODE

BSC

1.524

(0.060)

0 ~ 7°

7°

LAND PATTERN RECOMMENDATION

0.64 (0.025)

0.432

45° X

(0.017)

0.203 ± 0.102

(0.008 ± 0.004)

0.305

MIN.

(0.012)

7.49 (0.295)

1.9 (0.075)

0.228 ± 0.025

(0.009 ± 0.001)

ACPL-M61L SO-5 Package

4.4 ± 0.1

(0.173 ± 0.004)

2.5 ± 0.1

(0.098 ± 0.004)

1.27

(0.050)

Dimensions in Millimeters (Inches)

* Maximum mold flash on each side is 0.15 mm (0.006)

Note: Floating lead protrusion is 0.15 mm (6 mils) max.

3

XXX

3.6 ± 0.1*

(0.142 ± 0.004)

BSC

MXXX

7.0 ± 0.2

(0.276 ± 0.008)

0.4 ± 0.05

(0.016 ± 0.002)

0.102 ± 0.102

(0.004 ± 0.004)

0.71

(0.028)

MIN

(0.0085 ± 0.0015)

MAX. LEAD COPLANARITY

= 0.102 (0.004)

0.216 ± 0.038

7° MAX.

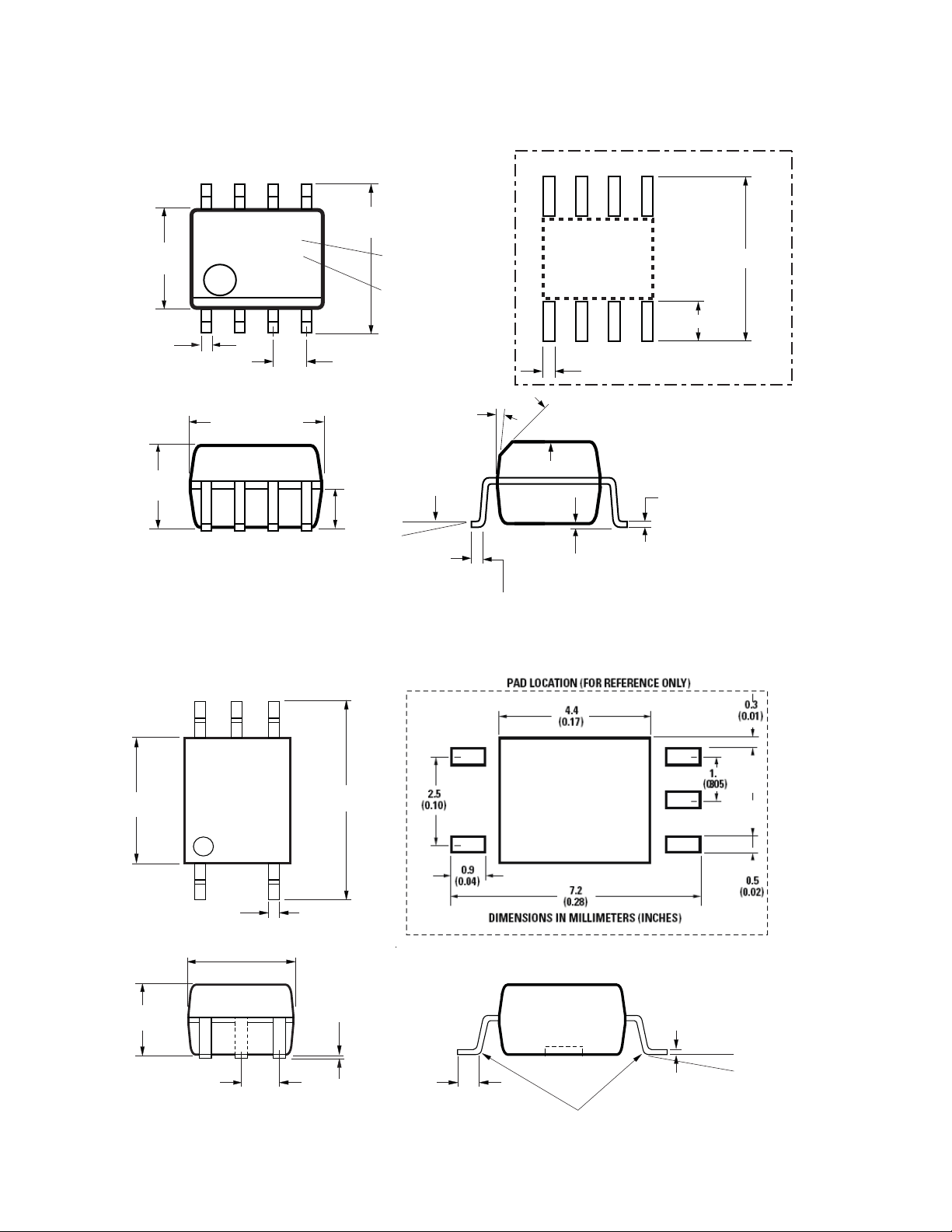

ACPL-W61L Stretched SO-6 Package

0.381 0.127

(0.015 0.005)

0.45 (0.018)

1

2

3

6.807

0.268

7°

45°

+0.127

0

+0.005

- 0.000

1.27 (0.050) BSG

6

5

4

)(

1.590 0.127

(0.063 0.005)

4.580

(

0.180

+0.254

0

+0.010

- 0.000

LAND PATTERN RECOMMENDATION

12.65 (0.498)

0.76 (0.030)

)

1.91 (0.075)

7°

0.20 0.10

(0.008 0.004)

0.750 0.250

(0.0295 0.010)

11.50 0.250

(0.453 0.010)

ACPL-K63L Stretched SO-8 Package

0.381 0.13

(0.015 0.005)

0.450 (0.018)

1

2

3

4

7°

45°

1.270 (0.050) BSG

8

7

6

5

1.590 0.127

(0.063 0.005)

3.180 0.127

(0.125 0.005)

+0.25

5.850

0

+0.010

(

0.230

- 0.000

Dimensions in Millimeters (Inches).

Lead coplanarity = 0.1 mm (0.004 inches).

LAND PATTERN RECOMMENDATION

12.650 (0.5)

)

1.905 (0.1)

7°

0.200 0.100

(0.008 0.004)

0.750 0.250

(0.0295 0.010)

4

6.807 0.127

(0.268 0.005)

11.5 0.250

(0.453 0.010)

3.180 0.127

(0.125 0.005)

Dimensions in Millimeters (Inches).

Lead coplanarity = 0.1 mm (0.004 inches).

Reflow Soldering Profile

The recommended reflow soldering conditions are per JEDEC Standard J-STD-020 (latest revision). Non-halide flux

should be used.

Regulatory Information

The ACPL-061L, ACPL-064L, ACPL-M61L, ACPL-W61L and ACPL-K64L are pending approval by the following organizations:

IEC/EN/DIN EN 60747-5-5 (Option 060 only)

UL

Approval under UL 1577 component recognition program up to V

V

= 5000 V

ISO

for the ACPL-W61L/K64L, File E55361.

RMS

CSA

Approval under CSA Component Acceptance Notice #5, File CA 88324.

Insulation and Safety Related Specifications

= 3750 V

ISO

for the ACPL-M61L/061L/064L and

RMS

ACPL-061L

Parameter Symbol

Minimum External

Air Gap

(External Clearance)

Minimum External

Tracking

(External Creepage)

Minimum Internal

Plastic Gap

(Internal Clearance)

Tracking Resistance

(Comparative Tracking

Index)

Isolation Group IIIa IIIa IIIa Material Group

L(101) 4.9 5 8 mm Measured from input terminals to

L(102) 4.8 5 8 mm Measured from input terminals to

CTI 175 175 175 V DIN IEC 112/VDE 0303 Part 1

ACPL-064L ACPL-M61L

0.08 0.08 0.08 mm Through insulation distance

ACPL-W61L

ACPL-K64L Units Conditions

output terminals, shortest distance

through air.

output terminals, shortest distance

path along body.

conductor to conductor, usually

the straight line distance thickness

between the emitter and detector.

(DIN VDE 0110, 1/89, Table 1)

5

IEC/EN/DIN EN 60747-5-5 Insulation Characteristics* (Option 060)

Characteristic

ACPL-061L^/

ACPL- 064L/

Description Symbol

Installation classification per DIN VDE 0110/39, Table 1

for rated mains voltage ≤ 150 V

for rated mains voltage ≤ 300 V

for rated mains voltage ≤ 600 V

for rated mains voltage ≤ 100 V

Climatic Classification 55/105/21 55/105/21

Pollution Degree (DIN VDE 0110/39) 2 2

Maximum Working Insulation Voltage V

Input to Output Test Voltage, Method b*

V

x 1.875=VPR, 100% Production Test with tm =1 sec,

IORM

Partial discharge < 5 pC

Input to Output Test Voltage, Method a*

V

x 1.6=VPR, Type and Sample Test, tm = 10 sec,

IORM

Partial discharge < 5 pC

Highest Allowable Overvoltage (Transient Overvoltage t

Safety-limiting values – maximum values allowed in the event of a failure.

Case Temperature

Input Current**

Output Power**

Insulation Resistance at T

* Refer to the optocoupler section of the Isolation and Control Components Designer’s Catalog, under Product Safety Regulations section, (IEC/EN/

DIN EN 60747-5-5) for a detailed description of Method a and Method b partial discharge test profiles.

** Refer to the following figure for dependence of PS and IS on ambient temperature.

, VIO = 500 V R

S

rms

rms

rms

rms

= 60 sec) V

ini

IORM

V

PR

V

PR

IOTM

T

S

I

S, INPUT

P

S, OUTPUT

S

ACPL- M61L

I – IV

I – III

I – II

560 1140 V

1063 2137 V

896 1824 V

6000 8000 V

150

150

600

9

>10

ACPL-W61L/

ACPL- K64L

I – IV

I – IV

I – III

I – III

175

230

600

9

>10

Unit

peak

peak

peak

peak

°C

mA

mW

:

Absolute Maximum Ratings

Parameter Symbol Min Max Units Condition

Storage Temperature T

Operating Temperature T

Reverse Input Voltage V

Supply Voltage V

Average Forward Input Current I

Peak Forward Input Current

S

A

R

DD

F

I

F(TRAN)

(IF at 1 Ps pulse width, <10% duty cycle)

Output Current I

Output Voltage V

Input Power Dissipation P

Output Power Dissipation P

Lead Solder Temperature T

O

O

I

O

LS

Solder Reflow Temperature Profile See Package Outline Drawings section

-55 125 °C

-40 105 °C

5V

6.5 V

–8 mA

–1 A

≤1 Ps Pulse Width,

<300 pulses per second

80 mA ≤1 Ps Pulse Width,

<10% Duty Cycle

10 mA

–0.5 VDD +0.5 V

14 mW

20 mW

260°C for 10 sec., 1.6 mm below seating plane

6

Recommended Operating Conditions

Parameter Symbol Min Max Units

Operating Temperature T

Input Current, Low Level I

Input Current, High Level I

Power Supply Voltage V

Forward Input Voltage V

Logic Low Input Voltage V

A

FL

FH

DD

F (OFF)

IL

- 40 105 °C

0 250 PA

1.6 6.0 mA

2.7 5.5 V

0.8 V

0 0.8 V

Electrical Specifications (DC)

Over the recommended temperature (TA = –40°C to +105°C) and supply voltage (2.7 V ≤ VDD ≤ 5.5 V). All typical specifications are at V

Parameter Symbol Min Typ Max Units Test Conditions

Input Forward Voltage V

Input Reverse

Breakdown Voltage

Logic High Output Voltage V

Logic Low Output Voltage V

Input Threshold Current I

Logic Low Output Supply

Current

Logic High Output Supply

Current

Input Capacitance C

Input Diode Temperature

Coefficient

= 5 V and TA = 25°C.

DD

BV

TH

I

DDL

I

DDH

'V

F

OH

OL

IN

R

F

/'T

0.95 1.3 1.7 V IF = 2 mA

35 VI

VDD - 0.1 V

VDD - 1.0 V

DD

DD

VI

VI

0.03 0.1 V IF = 2 mA, VI = 5 V (RT = 1.68 k:) or

0.18 0.4 V I

0.7 1.3 mA

0.8 1.3 mA

0.8 1.3 mA

60 pF f = 1 MHz, VF = 0 V

A

-1.6 mV/°C IF = 2 mA

= 10 PA

R

= 0 mA, VI = 0 V (RT = 1.68 k:) or

F

(RT = 870 :), IO = -20 PA

Figure 11

= 0 mA, VI = 0 V (RT = 1.68 k:) or

F

(RT = 870 :), IO = -3.2 mA

Figure 11

VI = 3.3V (RT = 870 :), IO = 20 PA

Figure 11

= 2 mA, VI = 5 V (RT = 1.68 k:) or

F

VI = 3.3V (RT = 870 :), IO = 3.2 mA

Figure 11

7

Switching Specifications (AC)

Over the recommended temperature (TA = –40°C to +105°C) and supply voltage (2.7 V ≤ VDD ≤ 5.5 V). All typical specifications are at V

Parameter Symbol Min Typ Max Units Test Conditions

Propagation Delay Time

to Logic Low Output

Propagation Delay Time

to Logic High Output

Pulse Width t

Pulse Width Distortion

Propagation Delay Skew

Output Rise Time

(10% – 90%)

Output Fall Time

(90% - 10%)

Static Common Mode

Transient Immunity at

Logic High Output

Static Common Mode

Transient Immunity at

Logic Low Output

Dynamic Common Mode

Transient Immunity

= 5 V, TA = 25°C.

DD

[1]

[1]

[2]

[3]

[4]

[5]

[6]

t

PHL

t

PLH

PW

100 ns

PWD 6 30 ns

t

PSK

t

R

46 80 ns IF = 2 mA, VI = 5 V, RT = 1.68 k:,

C

= 15 pF, CMOS Signal Levels.

L

40 80 ns

IF = 2 mA, VI = 3.3 V, RT = 870 :,

CL = 15 pF, CMOS Signal Levels.

Figure 11

30 ns

12 ns IF = 2 mA, VI = 5 V, RT = 1.68 k:,

CL = 15 pF, CMOS Signal Levels.

Figure 11

10 ns IF = 2 mA, VI = 3.3 V, RT = 870 :,

= 15 pF, CMOS Signal Levels.

C

L

Figure 11

t

F

12 ns IF = 2 mA, VI = 5 V, RT = 1.68 k:,

CL = 15 pF, CMOS Signal Levels.

Figure 11

10 ns I

= 2 mA, VI = 3.3 V, RT = 870 :,

F

C

= 15 pF, CMOS Signal Levels.

L

Figure 11

| CMH | 20 35 kV/PsVCM = 1000 V, TA = 25°C, IF = 0 mA,

V

= 0 V (RT =1.68 k:) or (RT = 870:),

I

CL = 15 pF, CMOS Signal Levels.

Figure 11

| CML | 20 35 kV/PsVCM = 1000 V, TA = 25°C, VI = 5 V

(RT = 1.68 k:) or VI = 3.3 V

(R

= 870:), IF = 2 mA, CL= 15 pF,

T

CMOS Signal Levels.

Figure 11

CMR

D

35 kV/PsVCM = 1000 V, TA = 25°C, IF = 2 mA,

= 5 V (RT = 1.68 k:) or VI = 3.3 V

V

I

(R

= 870:), 10MBd datarate, the

T

absolute increase of PWD < 10ns

Figure 11

8

Package Characteristics

All typicals are at TA = 25°C.

Parameter Symbol Part Number Min Typ Max Units Test Conditions

Input-Output Insulation V

Input-Output Resistance R

Input-Output Capacitance C

^ Advanced information, may subject to changes.

Notes:

1. t

propagation delay is measured from the 50% (Vin or IF) on the rising edge of the input pulse to the 50% VDD of the falling edge of the VO signal.

PHL

t

propagation delay is measured from the 50% (Vin or IF) on the falling edge of the input pulse to the 50% level of the rising edge of the VO

PLH

signal.

2. PWD is defined as |t

3. t

is equal to the magnitude of the worst case difference in t

PSK

recommended operating conditions.

4. CMH is the maximum tolerable rate of rise of the common mode voltage to assure that the output will remain in a high logic state.

5. CML is the maximum tolerable rate of fall of the common mode voltage to assure that the output will remain in a low logic state.

6. CM

is the maximum tolerable rate of the common mode voltage during data transmission to assure that the absolute increase of the PWD is less

D

than 10 ns.

PHL

- t

PLH

ISO

I-O

I-O

|.

ACPL-061L^

ACPL-064L

ACPL-M61L

ACPL-W61L

ACPL-K64L

3750 V

5000

12

10

0.6 pF f = 1 MHz, TA = 25°C

PHL

and/or t

that will be seen between units at any given temperature within the

PLH

rms

:

RH < 50% for 1 min.

= 25°C

T

A

= 500 V

V

I-O

9

10

1

0.8

1

TA = 25°C

0.6

I

F

0.4

0.1

V

- FORWARD CURRENT - mA

F

I

0.01

1.1 1.2 1.3 1.4 1.5

V

- FORWARD VOLTAGE - V

F

F

0.2

- INPUT THRESHOLD CURRENT - mA

th

I

0

-40 -20 0 20 40 60 80 100 120

TA - TEMPERATURE - °C

Figure 1. Typical input diode forward current characteristic. Figure 2. Typical input threshold current versus temperature.

3.3v

5v

1

0.9

0.8

0.7

0.6

0.5

0.4

CURRENT - mA

0.3

- LOGIC HIGH OUTPUT SUPPLY

0.2

DDH

I

0.1

0

-40 0 40 80 120

T

- TEMPERATURE - °C

A

3.3V

5V

1

0.9

0.8

0.7

0.6

0.5

0.4

CURRENT - mA

0.3

- LOGIC LOW OUTPUT SUPPLY

0.2

DDL

I

0.1

0

-40 0 40 80 120

T

- TEMPERATURE - °C

A

3.3V

5V

Figure 3. Typical logic high output supply current versus temperature. Figure 4. Typical logic low output supply current versus temperature.

60

50

40

30

20

10

- PROPAGATION DELAY;

p

t

T

_5.0V

PHL

T

_5.0V

PLH

PWD_5.0V

0

PWD-PULSE WIDTH DISTORTION - ns

-10

1.5 2 2.5 3 3.5 4 4.5 5 5.5 6

I

- PULSE INPUT CURRENT - mA

F

Figure 5. Typical switching speed versus pulse input with a 5 V supply

voltage.

60

50

40

30

20

10

- PROPAGATION DELAY;

p

t

T

_3.3V

PHL

T

_3.3V

PLH

PWD_3.3V

0

PWD-PULSE WIDTH DISTORTION - ns

-10

1.5 2 2.5 3 3.5 4 4.5 5 5.5 6

I

- PULSE INPUT CURRENT -mA

F

Figure 6. Typical switching speed versus pulse input current with a 3.3 V

supply voltage.

10

1.8

1.7

1.6

1.5

1.4

1.3

- FORWARD VOLTAGE - V

1.2

F

V

1.1

1

-40 -20 0 20 40 60 80 100

- Temperature - °C

T

A

Figure 7. Typical V

versus temperature.

F

Supply Bypassing, LED Bias Resistors and PC Board

Layout

The ACPL-x6xL optocouplers are extremely easy to use

and feature high speed, push-pull CMOS outputs. Pull-up

resistors are not required.

The external components required for proper operation

are the input limiting resistors and the output bypass

capacitor. Capacitor values should be 0.1 PF.

For each capacitor, the total lead length connecting the

capacitor to the V

20 mm.

and GND pins should not exceed

DD

For ACPL-M61L/W61L:

V

= 3.3 V: R1 = 510 : ± 1%, R2 = 360 : ± 1%

DD

VDD = 5.0 V: R1 = 1000 : ± 1%, R2 = 680 : ± 1%

RT = R1 + R2 R1/R2 ≈ 1.5

R

1

I

V

I

F

1

YWW

XXX

6

C

5

R

2

GND

1

3

GND

4

ACPL-M61L

R

1

I

F

1

YWW

XXX

2

R

2

3

6

C

5

GND

4

GND

V

I

1

For ACPL-061L/064L/K64L:

V

= 3.3 V: R1 = 430 : ± 1%, R2 = 430 : ± 1%

DD

VDD = 5.0 V: R1 = 845 : ± 1%, R2 = 845 : ± 1%

RT = R1 + R2 R1/R2 ≈ 1

C

GND

V

DD

V

o

2

V

DD

V

o

GND

2

R

1

I

F

V

I

R

1

2

2

3

YWW

XXX

4

81

7

6

5

ACPL-061L

R

1

I

V

GND

GND

I

1

2

V

I

V

DD

V

o

2

F

R

2

2

R

2

3

R

1

I

F

4

YWW

XXX

81

7

6

5

C

GND

V

DD

V

o1

V

o2

2

ACPL-W61L ACPL-064L/K64L

C = 0.1PF

Figure 8. Recommended printed circuit board layout and input current limiting resistor selection.

11

Propagation Delay, Pulse-Width Distortion and Propagation Delay Skew

Propagation delay is a figure of merit which describes how

quickly a logic signal propagates through a system. The

propagation delay from low-to-high (t

) is the amount

PLH

of time required for an input signal to propagate to the

output, causing the output to change from low to high.

Similarly, the propagation delay from high-to-low (t

PHL

)

is the amount of time required for the input signal to

propagate to the output, causing the output to change

from high-to-low (see Figure 9).

Pulse-width distortion (PWD) results when t

PLH

and t

PHL

differ in value. PWD is defined as the difference between

t

PLH

and t

PWD determines the maximum data rate of

PHL.

a transmission system. PWD can be expressed in percent

by dividing the PWD (in ns) by the minimum pulse width

(in ns) being transmitted. Typically, a PWD of 20-30% of

the minimum pulse width is tolerable; the exact figure

depends on the particular application (RS232, RS422,

T-1, etc.).

Propagation delay skew, t

, is an important parameter

PSK

to consider in parallel data applications where synchronization of signals on parallel data lines is a concern.

If the parallel data is being sent through a group of optocouplers, differences in propagation delays will cause

the data to arrive at the outputs of the optocouplers at

different times. If this difference in propagation delays is

large enough, it will determine the maximum rate at which

parallel data can be sent through the optocouplers.

Propagation delay skew is defined as the difference

between the minimum and maximum propagation

delays, either t

PLH

or t

, for any given group of opto-

PHL

couplers which are operating under the same conditions

(i.e., the same supply voltage, output load, and operating

temperature). As shown in Figure 10, if the inputs of a

group of optocouplers are switched either ON or OFF at

the same time, t

propagation delay, either t

propagation delay, either t

earlier, t

can determine the maximum parallel data

PSK

is the difference between the shortest

PSK

PLH

PLH

or t

or t

, and the longest

PHL

. As mentioned

PHL

transmission rate.

Figure 10 is the timing diagram of a typical parallel data

application with both the clock and the data lines being

sent through optocouplers. The figure shows data and

clock signals at the inputs and outputs of the optocouplers. To obtain the maximum data transmission rate, both

edges of the clock signal are being used to clock the data;

if only one edge were used, the clock signal would need

to be twice as fast.

Propagation delay skew represents the uncertainty of

where an edge might be after being sent through an

optocoupler.

Figure 10 shows that there will be uncertainty in both

the data and the clock lines. It is important that these

two areas of uncertainty not overlap, otherwise the clock

signal might arrive before all of the data outputs have

settled, or some of the data outputs may start to change

before the clock signal has arrived.

From these considerations, the absolute minimum pulse

width that can be sent through optocouplers in a parallel

application is twice t

. A cautious design should use a

PSK

slightly longer pulse width to ensure that any additional

uncertainty in the rest of the circuit does not cause a

problem.

The t

specified optocouplers offer the advantages of

PSK

guaranteed specifications for propagation delays, pulsewidth distortion and propagation delay skew over the

recommended temperature, and power supply ranges.

V

V

12

V

I

O

V

I

O

50%

50%

2.5 V,

CMOS

DATA

INPUTS

CLOCK

t

PSK

DATA

OUTPUTS

CLOCK

2.5 V,

CMOS

Figure 10. Parallel data transmission exampleFigure 9. Propagation delay skew waveform

t

PSK

t

PSK

Optocoupler CMR Performance

The principal protection against common mode noise,

comes from the fundamental isolation properties of the

optocoupler, and this in turn is directly related to the

Input-Output leakage capacitance of the optocoupler.

To provide maximum protection to circuitry connected to

the input or output of the optocoupler the leakage capacitance is minimized by having large separation distances

at all points in the optocoupler construction, including

the LED/photodiode interface.

In addition to the optocouplers basic physical construction, additional circuit design steps mitigate the effects of

common mode noise. The most important of these is the

Faraday shield on the photodetector stage.

A Faraday shield is effective in optocouplers because

the internal modulation frequency (light) is many orders

of magnitude higher than the common mode noise

frequency.

Improving CMR Performance at the Application Level

In an end application it desirable that the optocouplers

common mode isolation be as close as possible to that

indicated in the data sheet specifications. The first step

in meeting this goal is to ensure maximum separation

between PCB interconnects on either side of the optocoupler is maintained and that PCB tracks beneath the

optocoupler are avoided.

It is inevitable that a certain amount of CMR noise will be

coupled into the inputs and this can potentially result in

false-triggering of the input. This problem is frequently

observed in devices with input high input impedance.

In some cases this can cause momentary missing pulses

and may even cause input circuitry to latch-up in some

alternate technologies.

The ACPL-x6xL optocoupler family does not have an input

latch-up issue. Even at very high CMR levels such as those

experienced in end equipment level tests (for example

IEC61000-4-4) the ACPL-x6xL series is immune to latch-up

because of the simple diode structure of the LED.

In some cases achieving the rated data sheet CMR performance level is not possible in an application. This is

often because of the practical need to actually connect

the isolator input to the output of a dynamically changing

signal rather than tying the input statically to V

A data sheet CMR “specmanship” issue is often seen with

alternative technology isolators that are based on AC

encoding techniques.

or GND.

DD

To address the need to define achievable end application

performance on data sheets, the ACPL-x6xL optocouplers

include an additional typical performance specification

for dynamic CMR in the electrical parameter table. The

dynamic CMR specification indicates the typical achievable CMR performance as the input is being toggled on or

off during a CMR transient.

The logic output the ACPL-x6xL optocouplers is mainly

controlled by LED current level, and since the LED current

features very fast rise and fall times, dynamic noise

immunity is essentially the same as static noise immunity.

Despite their immunity to input latch-up and the

excellent dynamic CMR immunity, ACPL-x6xL optocoupler devices are still potentially vulnerable to missoperation caused by the LED being turned either on

or off during a CMR disturbance. If the LED status could

be ensured by design, the overall application level CMR

performance would be that of the photodetector. To

benefit from the inherently high CMR capabilities of the

ACPL-x6xL family, some simple steps about operating the

LED at the application level should be taken.

In particular, ensure that the LED stays either on or off

during a CMR transient. Some common design techniques

to accomplish this are:

Keep the LED On:

i) Overdrive the LED with a higher than required forward

current.

Keep the LED Off:

i) Reverse bias the LED during the off state.

ii) Minimize the off-state impedance across the anode

and cathode of the LED during the off state.

All these methods allow the full CMR capability of the

ACPL-x6xL family to be achieved, but they do have

practical implementation issues or require a compromise

on power consumption.

There is, however, an effective method to meet the goal

of maintaining the LED status during a CMR event with

no other design compromises other than adding a single

resistor.

This CMR optimization takes advantage of the differential

connection to the LED. By ensuring the common mode

impedances at both the cathode and anode of the LED

are equal, the CMR transient on the LED is effectively

canceled. As shown in Figure 11, this is easily achieved by

using two, instead of one, input bias resistors.

13

Split LED Bias Resistor for Optimum CMR

Figure 11 shows the recommended drive circuit for the

ACPL-x6xL that gives optimum common-mode rejection.

The two current setting resistors balance the common

mode impedances at the LED’s anode and cathode.

Common-mode transients can capacitively couple from

the LED anode (or cathode) to the output-side ground

causing current to be shunted away from the LED (which

is not wanted when the LED should be on) or conversely

cause current to be injected into the LED (which is not

wanted when the LED should be off).

Figure 12 shows the parasitic capacitances (C

and

LA

CLC) between the LED’s anode and cathode, and output

ground. Also shown in Figure 12 on the input side is an

AC-equivalent circuit.

Table 1 shows the directions of I

and ILN depend on the

LP

polarity of the common-mode transient. For transients

occurring when the LED is on, common-mode rejection

(CM

, since the output is at "low" state) depends on

L

LED current (IF). For conditions where IF is close to the

For ACPL-M61L/W61L:

V

= 3.3 V: R1 = 510 : ± 1%, R2 = 360 : ± 1%

DD2

V

= 5.0 V: R1 = 1000 : ± 1%, R2 = 680 : ± 1%

DD2

R

= R1 + R2 R1/R2 ≈ 1.5

T

switching threshold (I

to which I

and ILN balance each other. In other words,

LP

), CML also depends on the extent

TH

any condition where a common-mode transient causes a

momentary decrease in I

(i.e. when dVCM/dt > 0 and |IFP|

F

> |IFN|, referring to Table 1). will cause a common-mode

failure for transients which are fast enough.

Likewise for a common-mode transient that occurs when

the LED is off (i.e. CM

, since the output is at "high" state),

H

if an imbalance between ILP and ILN results in a transient

IF equal to or greater than the switching threshold of the

optocoupler, the transient “signal” may cause the output

to spike below 2 V, which constitutes a CMH failure.

The resistors recommended in Figure 11 include both

the output impedance of the logic driver circuit and

the external limiting resistor. The balanced I

LED

-setting

resistors help equalize the common mode voltage change

at the anode and cathode. This reduces I

changes

LED

caused by transient coupling through the parasitic capacitors CLA and CLC shown in Figure 12.

For ACPL-061L/064L/K64L:

VDD = 3.3 V: R1 = 430 : ± 1%, R2 = 430 : ± 1%

VDD = 5.0 V: R1 = 845 : ± 1%, R2 = 845 : ± 1%

R

= R1 + R2 R1/R2 ≈ 1

T

R

1

V

DD

R

2

74LS04 or any

totem-pole output

logic gate

GND

1

Figure 11. Recommended high-CMR drive circuit for the ACPL-x6xL.

Shield

0.1PF

V

DD2

V

O

GND

2

14

For ACPL-M61L/W61L:

V

= 3.3 V: R1 = 510 : ± 1%, R2 = 360 : ± 1%

DD2

V

= 5.0 V: R1 = 1000 : ± 1%, R2 = 680 : ± 1%

DD2

RT = R1 + R2 R1/R2 ≈ 1.5

R

1

I

LP

C

LA

R

2

I

LN

C

LC

0.1PF

Shield

Figure 12. AC equivalent circuit of ACPL-x6xL.

Table 1. Common Mode Pulse Polarity and LED Current Transients

For ACPL-061L/064L/K64L:

V

= 3.3 V: R1 = 430 : ± 1%, R2 = 430 : ± 1%

DD

VDD = 5.0 V: R1 = 845 : ± 1%, R2 = 845 : ± 1%

RT = R1 + R2 R1/R2 ≈ 1

V

DD2

V

O

GND

2

If dVCM/dt Is: Then ILP flows: and ILN flows:

positive (> 0) away from the LED

anode through C

negative (< 0) toward the LED

anode through C

LA

LA

away from the LED

cathode through C

toward the LED

cathode through C

| < |ILN|

If |I

LP

LED current I

F

is momentarily:

| > |ILN|

If |I

LP

LED Current I

F

is momentarily:

increased decreased

LC

decreased increased

LC

15

Glitch Free Power-up and Power-Down Feature.

Upon Powering-up or Powering-down of the optocoupler,

glitches produced in the output are undesirable. Glitches

can lead to false data in the optocoupler application.

ACPL-x6xL has a feature that holds the output in a known

state until V

is at a safe level. Figure 13 and 14 show

DD

typical output waveforms during Power-up and Powerdown process.

Slew-rate controlled outputs Feature

Typically, the output slew rate (rise and fall time) will vary

with the output load, as more time is needed to charge up

the higher load. The propagation delay and the PWD will

increase with the load capacitance. This will be an issue

especially in parallel communication because different

communication line will have different load capacitances.

However, Avago’s new optocoupler ACPL-x6xL has built in

slew-rate controlled feature, to ensure that the output rise

and fall time remain stable across wide load capacitance.

Figure 15 shows the rise time and fall time for ACPL-x6xL

at 3.3V and 5V.

V

V

DD2

=1V (typ)

DD2

30

25

20

15

Rise Time (nS)

10

5

0

25

20

15

10

Fall Time (nS)

5

0

25

10pF 15pF

33pF

-40 -20 0 20 40 60 80 100

10pF 15pF

33pF

-40 -20 0 20 40 60 80 100

Rise Time (VDD = 5.0V)

22pF

47pF 100pF

Temperature (°C)

Fall Time (VDD = 5.0V)

22pF

47pF 100pF

Temperature (°C)

Rise Time (V

DD

= 3.3V)

High

Impedence

500μs

Figure 13. VDD Ramp when LED is off.

V

=2V (typ)

DD2

V

=1V (typ)

DD2

High

Impedence

500μs

Figure 14. VDD Ramp when LED is on. Figure 15. Rise and Fall time of ACPL-x6xL across wide load capacitance

Output

i. LED is off

V

DD2

Output

ii. LED is on

discharge delay,

depending on the power

supply slew rate

Impedence

High

Impedence

High

20

15

10

Rise Time (nS)

5

0

-40 -20 0 20 40 60 80 100

25

20

15

10

Rise Time (nS)

5

0

-40 -20 0 20 40 60 80 100

10pF 15pF 22pF

33pF 47pF 100pF

Temperature (°C)

Fall Time (V

Temperature (°C)

= 3.3V)

DD

10pF 15pF 22pF

33pF 47pF 100pF

16

Speed Improvement

A peaking capacitor can be placed across the input current

limit resistor (Figure 11) to achieve enhanced speed performance. The value of the peaking cap is dependent

to the rise and fall time of the input signal and supply

voltages and LED input driving current (I

shows significant improvement of propagation delay and

pulse with distortion with added peak capacitor at driving

current of 2mA and 3.3V/5V power supply.

). Figure 12

F

60

50

40

30

or PWD (ns)

P

20

t

10

V

= 5 V, IF= 2 mA

DD2

T

PHL

T

PHL

PWD

T

PLH

T

PLH

No Peaking

With Peaking

C

peak

V

+

V

in

−

GND

1

R

1

V

0.1μF

R

2

SHIELD

GND

Figure 16. Connection of peaking capacitor (Cpeak) in parallel of the input

limiting resistor (R1) to improve speed performance

0

-40 -20 0 20 40 60 80 100

DD2

O

(i) V

= 5V, Cpeak = 47pF, R1 = 845Ω

DD2

60

50

2

40

30

or PWD (ns)

P

20

t

T

PHL

10

Temp (°C)

V

= 3.3 V, IF= 2 mA

DD2

T

PHL

T

PLH

PWD

T

PLH

0

-40 -20 0 20 40 60 80 100

Temp (°C)

(ii) V

= 3.3V, Cpeak = 47pF, R1 = 430Ω

DD2

Figure 17. Improvement of tp and PWD with added 47pF peaking capacitor

in parallel of input limiting resistor.

No Peaking

With Peaking

For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, the A logo and R2Coupler™ are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2010 Avago Technologies. All rights reserved.

AV02-2150EN - April 8, 2010

Loading...

Loading...