Page 1

ZoningZoning

Zoning

ZoningZoning

Design GuideDesign Guide

Design Guide

Design GuideDesign Guide

Page 2

Zone

Zone

8500 NW River Park Drive • Parkville , MO 64152

PH: (816) 505-1100 • FX: (816) 505-1101 • E-mail: mail@wattmaster.com

Visit our website at www.wattmaster.com

Form: WM-AZA-ZDG-01B Copyright 2001 WattMaster Controls, Inc.

Auto-Zone & System Manager are registered trademarks of WattMaster Controls, Inc.

WattMaster Controls assumes no responsibility for errors, or omissions.

This document is subject to change without notice. All rights reserved.

Page 3

Table Of Contents

How Auto-Zone Works ..........................................................................................................5

Why Should I Use Auto-Zone?..............................................................................................6

What Is Unique About Auto-Zone? ....................................................................................6-8

Zoning Systems Versus True VAV Systems .......................................................................... 9

Basics Of Designing A Zoning System................................................................................ 10

Design Considerations ................................................................................................... 11-12

Zoning Design Procedures.............................................................................................13-21

System Installation .........................................................................................................22-26

Application Notes ................................................................................................................27

Table Of Figures & Tables

Figure 1-1: Auto-Zone Plus System Overview .................................................................... 5

Figure 1-2: Zones Affected By Outdoor Load...................................................................13

Figure 1-3: Zone Layout With External Zones Only ......................................................... .14

Figure 1-4: Zones With North And South Exposures ....................................................... .14

Figure 1-5: Zoning And Constant Volume Units ................................................................14

Figure 1-6: Round Bypass Damper.................................................................................. .16

Figure 1-7: Rectangular Bypass Damper & Kit ................................................................ .16

Figure 1-8 Preferred Sensor Location ..............................................................................1 7

Figure 1-9: Acceptable Sensor Location ........................................................................... 17

Figure 1-10: Least Desirable Sensor Location .................................................................... 17

Figure 1-11: Pressure Dependent Damper .........................................................................1 8

Figure 1-12: Pressure Independent Damper.......................................................................1 8

Figure 1-13: WattMaster Communications Wire ................................................................. 23

Figure 1-14: Auto-Zone Basic System Communications Loop Wiring ................................2 4

Figure 1-15: Auto-Zone Plus System Communications Loop Wiring .................................. 24

Figure 1-16: Transformer & Wire Sizing Considerations.....................................................26

Table 1-1: Round Damper Selection Data.......................................................................... 19

Table 1-2: Rectangular Damper Selection Data .................................................................2 0

Page 4

Page 5

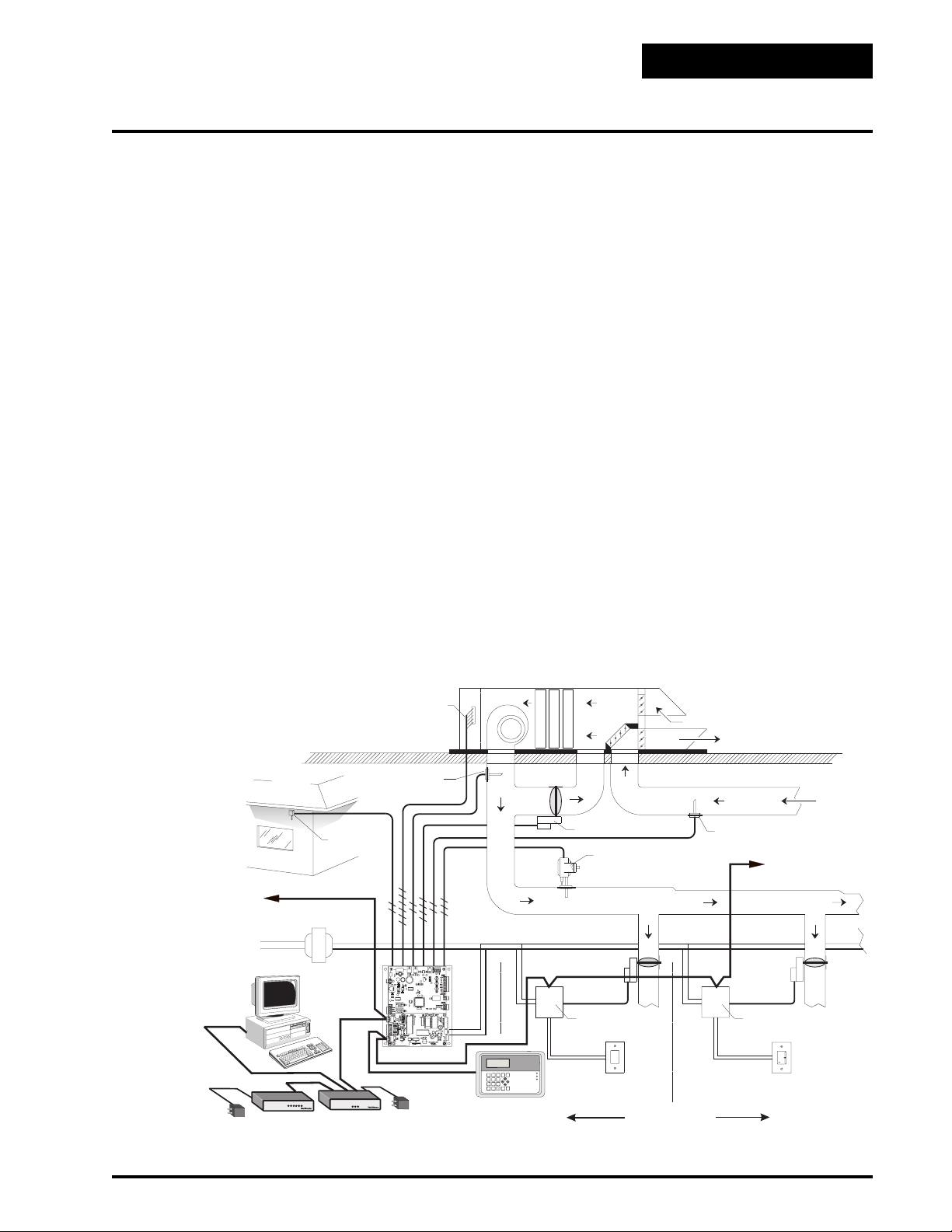

How Auto-Zone Works

Zoning Design Guide

The Auto-Zone control system converts single-zone

constant volume rooftop packaged or split system

HVAC units into variable air volume/variable temperature multiple zone systems. The microprocessor based

Zone Manager calculates the heating and cooling requirements for each zone based on real time information received from each Zone Controller/Damper. The

Zone Manager then directs the HVAC unit to provide

the appropriate amount of heating, cooling, and ventilation to satisfy each zone’s requirements. A bypass

damper controlled, by a static air pressure sensor, modulates a bypass damper to maintain constant duct pressure.

The Auto-Zone system uses a unique 3 tier approach to

controlling the system:

• Voting Zones

• System Demand

• Priority

This 3 tier system works in an integrated fashion to

maintain proper control of the equipment and effective

control of comfort in the zone.

First the zone must initiate a vote to the HVAC unit.

This occurs when a zone becomes more than 1 degree

off setpoint. At this time a vote is placed for heating or

cooling. Next the controller evaluates the total cooling

demand or heating demand within the entire building

to see which requirement is more critical. Finally, the

system looks for any priority conditions, which would

take precedence over other zones. All three of these

elements working together provide accurate and stable

control of comfort.

Additional control features are taken into account to

provide a very effective control of the system. Some of

these include priority override, supply air temperature

limits, outside air temperature lockouts, and min./max.

control over damper position.

Substantial savings can be realized using the Auto-Zone

Zoning system instead of having to install multiple rooftop units to accommodate multiple zone requirements.

The Auto-Zone Zoning system is versatile and can be

used with any packaged roof top unit or split system. It

controls a variety of terminal unit functions including

single duct pressure dependent, pressure independent,

series fan and parallel fan terminals.

CONNECT TO OTHER

ZONE MANAGERS

120/9 VAC

TRANSFORMER

AVOID

DIRECT

SUNLIGHT

NETWORK COMM LOOP

AC LINE

VOLTAGE

COMPUTER

(OPTIONAL)

RemoteLink

CONTROLS

REMOTE LINK

(OPTIONAL MODEM)

2 CONDUCTOR

24 GA.

OUTSIDE AIR

SENSOR

24 VAC

GROUND

COMMLINKII

CONTROLS

COMM LINK II

INTERFACE

( OPTIONAL )

CONTROL CABLE

SUPPLY AIR

TEMPERATURE

SENSOR

2 CONDUCTOR

ZONE MANAGER

LOCAL COMM LOOP

120/24 VAC

TRANSFORMER

24 GA.

SYSTEM MANAGER

FAN

0

1

4

7

c.

e

D

*

H

C

F

E

O

I

A

L

O

MIXED

T

T

L

I

I

AIR

E

N

N

R

G

G

OUTSIDE AIR

EXHAUST AIR

RETURN AIR

MODULATING

3 CONDUCTOR

24 GA.

LO

BYPASS DAMPER

STATIC PRESSURE SENSOR

& PICKUP TUBE

HI

2 CONDUCTOR

24 GA.

RETURN AIR SENSOR

CONNECT TO OTHER

ZONE CONTROLLERS

OR CV UNITS

SUPPLY AIR DUCT

MODULATING

DAMPER

ZONE

CONTROLLER

V

C

e

n

o

Z

-

o

t

u

A

N

O

M

M

P

8

3

:

2

0

8

9

/

0

2

/

7

D

E

I

P

U

C

C

O

S

M

R

A

L

A

O

N

SYSTEM

MANAGER

m

r

la

A

sc

E

u

n

e

M

2

3

n

o

ti

a

ic

n

u

m

m

o

C

e

d

i

r

r

e

v

O

6

5

8

9

s

u

in

M

r

te

n

E

r

a

le

C

0

.

C

N

I

S

L

O

R

T

N

O

C

R

E

T

S

A

M

T

T

A

W

ZONE 1

TEMPERATURE SENSOR

MODULATING

DAMPER

ZONE

CONTROLLER

WARMER

NORMAL

COOLER

OVR

ZONE 2

TEMPERATURE SENSOR

W/OVERRIDE AND SETPOINT ADJUST

UP TO 16 ZONES

Figure 1-1: Auto-Zone Plus System Overview

Auto-Zone Systems 5

Page 6

Zoning Design Guide

Why Should I Use Auto-Zone?

Auto-Zone is a proven system with a long history of

successful installations. Our systems have been refined

over the years with the help of feedback from people in

the field who work and live with these systems on a

daily basis. Our success is greatly due to the fact that

we have implemented changes and enhancements based

on real world experience not from tinkering with equipment in an isolated lab environment. This real world

approach provides engineers, contractors, and end users with a zone control system that is efficient, reliable,

and most importantly, keeps the customers comfortable!

What Is Unique About Auto-Zone?

Auto-Zone is unique because it has many features not

found on other systems. These features include

Non-Proprietary Design

Auto-Zone will work on any manufacturers HVAC

equipment that will accept a standard thermostat connection. This protects the end user from being locked in

to one source for service and support. In addition, AutoZone Systems include very comprehensive documentation, which was written in a format specifically for a

“non-controls technician”. Because the manuals are so

user friendly, it prevents the end user from being

“locked-in” to one contractor for service. Any new contractor needs only a copy of the system manual to have

as much technical information as any previous contractor.

Pre-Engineered Software

System design, software, and documentation has already

been done for you. This eliminates the costly expense

usually associated with conventional DDC systems,

making the Auto-Zone system more competitive and

easier to install and operate.

One System for Zoned or Single Zone

Systems

Not only does Auto-Zone provide a networked zone

control system for one or multiple zoned HVAC units,

you can also connect individual single zone units to the

system eliminating the need to use programmable thermostats.

Easy to Configure

Since Auto-Zone components are grouped into packages, configuring a system has been simplified. This

reduces the chance of ordering errors and makes system layout effortless!

User Friendly Set Up

Since the Auto-Zone comes with menu driven, fill in

the blank programming, system setup is simple. The

system manual takes you step by step through the set

up process. Default parameter values are programmed

into permanent memory so the system can be operational at start-up. Specialized training is not required.

6 Auto-Zone Systems

Page 7

Zoning Design Guide

True Network Communications

The Auto-Zone uses a three wire, RS-485 loop for communication between all controllers in the system. This

provides a very reliable form of communication with

flexibility of installation. The loop can be wired in a

“daisy chain” or “star” configuration. Many other zoning systems utilize “home run” wiring that requires all

communication cables to be brought back to a central

point adding additional cost to the project and complicating wiring.

High Integrity Communications

Many communicating control systems are susceptible

to electrical interference. One major manufacturer of

zoning systems recommends that their communication

cable should not be strapped to conduit because of potential interference. The Auto-Zone Systems have a

communication bus that is almost immune to any noise

problems that may be found in most commercial facilities.

Microprocessor Controllers

All controllers in the Auto-Zone have an on board

microprocessor. This is what gives the Auto-Zone its

powerful features and capabilities not found in other

systems.

Stand Alone Systems

All Auto-Zone Systems are true stand-alone and do not

require a computer to operate. Unit controllers maintain their own 7 day time clock, 365 day holiday scheduling, and setpoints within each controller.

Menu Driven Operators’ Interface

All Auto-Zone systems have an operators’ keypad and

display terminal. This gives you access to system status and parameter values without the need for a computer. The 4 line by 20 character display is backlighted

making it easy to read even in low light environments.

Menu driven programming makes the system extremely

user friendly. In addition, the interface panel is password protected to keep unauthorized users from accessing the system.

Communications Via Optional Modem

The Remote Link is used for achieving remote communications with the Auto-Zone system. It connects to the

CommLink II communications interface and a local

phone line. With the Remote Link, the Auto-Zone system can be monitored and controlled from a remote location, using a computer and the ZoneView AZ or Plus

software packages.

Memory Backup

Instead of batteries, which have to be replaced, AutoZone utilizes super capacitors to provide power for

memory backup during power outages. The major advantages to this approach is that super capacitors are

more reliable than batteries and they recharge in a matter of seconds instead of hours. T ypical memory backup

is good for a minimum of 10 days.

Modulating, Heavy Duty Actuators with

Real Time Feedback

All Auto-Zone actuators utilize true modulating control unlike many systems, which are two position. This

gives the system-improved control, which translates, to

better comfort levels. Our actuators are also rated for

2-½ million cycles, making our actuators some of the

most reliable in the industry. One other critical feature

is the real time feedback. Many other systems have no

feedback at all. They blindly estimate the travel time of

their actuator, which, in the real world, is not a very

repeatable estimate. To help correct the problems inherent with this approach, they recycle all the actuators

in the system once or twice a day . They may save a few

dollars by not including feedback but they sacrifice system performance. Not so with Auto-Zone.

Commercial Grade – Insulated Round

Zone Dampers

Auto-Zone only uses commercial grade zone dampers,

not cheap, flimsy, “light commercial” or “residential”

style dampers like many other manufacturers. Our round

damper is ARI certified and comes from the factory

fully insulated. Why? When many zone dampers are

installed they are improperly insulated or not insulated

at all. This can cause problems with the damper “sweating” from condensation. With factory insulated zone

dampers, we eliminate a common problem for the contractor while insuring the end user will not have problems with condensation dripping down onto the ceiling.

Auto-Zone Systems 7

Page 8

Zoning Design Guide

What Is Unique About Auto-Zone?

Rectangular Dampers

Auto-Zone uses only top of the line, aluminum air foil

rectangular control dampers. No other zone system on

the market today utilizes a damper of this quality and

performance!

Patented Flush Mount Room Sensors

Our flush mount room sensors are so unique, they are

patented (U.S. Patent No. 4,659,236). Even though part

of the sensor is recessed into the wall to provide an

attractive yet tamper proof flush mounting, internal wall

temperatures do not influence the sensor. A special plate

on the face of the sensor accurately senses space temperature. Even though the attractive off white plastic

housing is a preferred color, the sensor housing can be

painted or wallpapered to blend with room decor without affecting sensor performance. The sensors are offered in four different configurations:

• Sensor

• Sensor w/override

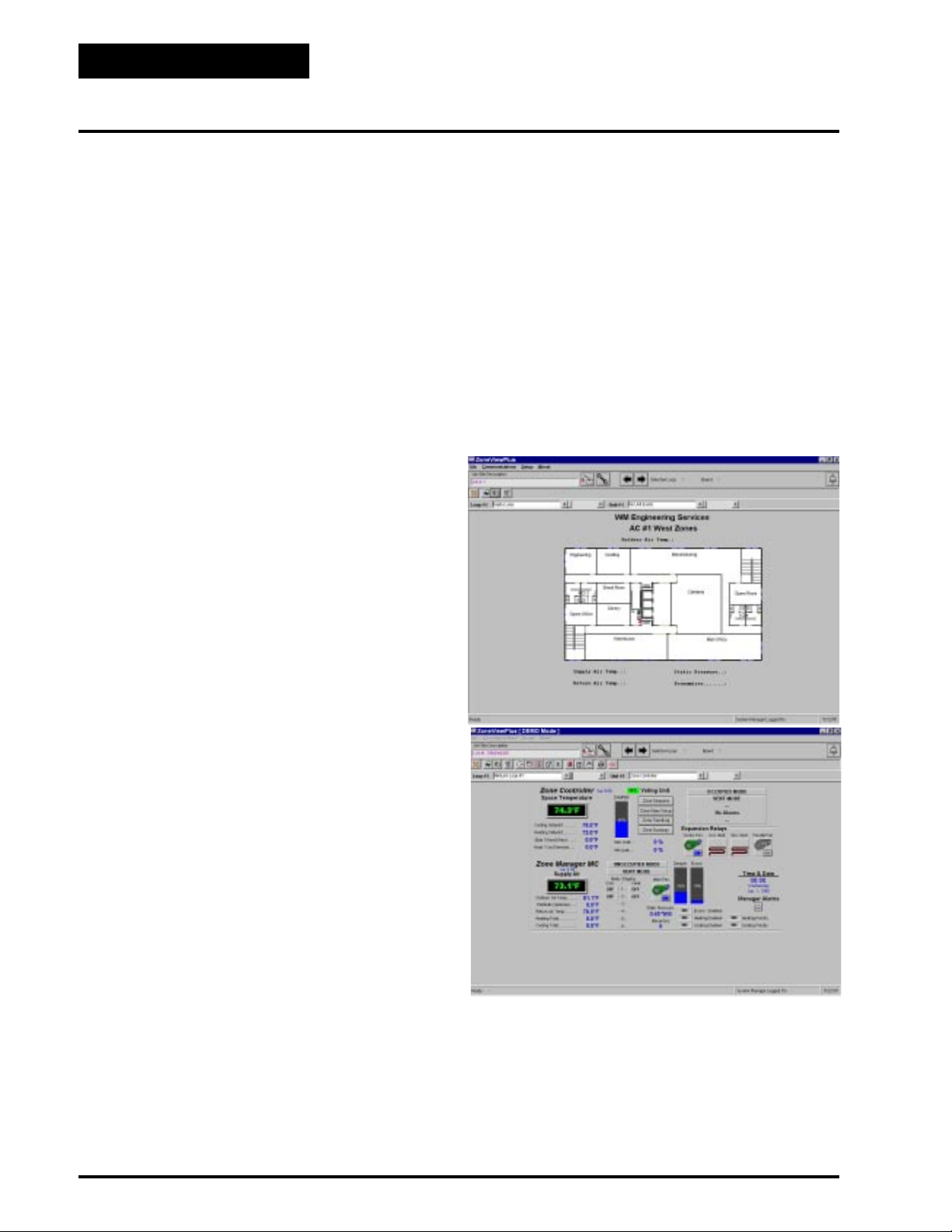

hundreds. ZoneView is not copy protected so it can be

installed on multiple PC’s’ without additional expense.

Just some of its many features include but are not limited to:

• Pre-designed status screens for all controllers

• Alarm dial out capability

• Programming of all system parameters

• Trend logging to Excel™ spreadsheets

• Alarm Handling

• Custom graphics capability

• Sensor w/setpoint adjustment

• Sensor w/setpoint adjustment & override

Modular Connections

Many Auto-Zone auxiliary devices are connected to the

controllers via modular plugs like the ones used on telephones. This simplifies installation and eliminates the

possibility of wiring errors. The devices, which utilize

this method, are damper actuators for zone and bypass

control, auxiliary relay boards, and static pressure/air

flow sensors. There is one interesting side note about

the auxiliary relay board and airflow sensors. These

devices are typically used on the zone controllers in the

Auto-Zone Basic & Plus systems. When the system is

powered up, it automatically looks to see if these devices are connected to the controller. If they are, the

controller automatically reconfigures itself to utilize

these devices and activates the appropriate set up screens

back at the operators interface. Pretty neat don’t you

think!

FREE! Windows™ Graphics Software

Each Auto-Zone system can be monitored on site or

remotely using a PC and our ZoneView Plus™ Windows 98 software. This full-featured package is very

user friendly and can be used to monitor one system or

Open Protocol System

Auto-Zone is an open protocol based system allowing

other manufacturers to develop direct interfaces to the

communications loop. This gives you the ability to integrate the Auto-Zone system into products from other

vendors. Our engineering staff will be glad to assist any

vendor in this process.

8 Auto-Zone Systems

Page 9

Zoning Design Guide

Zoning Systems Versus True VAV Systems

General

Even though there are some similarities between zone

control systems and Variable Air Volume (VAV) systems, there are some major differences. In many cases

systems will be called VAV when in fact they are really

a zoning system or are referred to as a zoning system

when they are really a VAV system. Always make sure

that you do not try to adapt a zoning system to a VAV

design system. Understanding the differences will help

you to prevent misapplication of the Auto-Zone zoning

system. In the paragraphs that follow we will try to explain the differences, advantages and disadvantages of

each and explain their operation.

V AV Systems

These systems consist of an HVAC unit that is generally a cooling only unit and VAV terminal units located

in the downstream ductwork that are used to control

the amount of constant temperature air delivered to the

various building zones. Sometimes the HV AC unit may

have gas or electric heat, but it is typically sized and

applied for morning warm-up purposes. The HV AC unit

is designed to vary the volume of air that is supplied to

the duct system by using either inlet vanes or an electronic variable frequency drive. These devices modulate to control the air flow through the supply fan in

response to the static pressure in the duct system. VAV

systems typically use high velocity VAV terminal units

to distribute the air to the zones. As the various VAV

terminal units in the different zones open and close to

supply the constant temperature air to the spaces, the

HVAC unit varies the volume of constant temperature

air based on the static pressure in the ductwork. The

HV AC unit is designed to maintain a constant cold supply air temperature regardless of the air flow volume in

the system. The HVAC unit cycles it’s cooling stages

to maintain a constant predetermined supply air temperature. It typically runs continuously based on a schedule. For perimeter zones requiring heat, reheat coils

(electric or hot water) located in the terminal units are

used to supply heated air to the space. Many times fan

powered terminal boxes are used and in many cases

also incorporate electric or hot water heating coils to

provide perimeter zone heating. In summary a true V AV

system uses a variable volume fan supplying constant

temperature air to the system with variable volume terminal units used to control the volume of constant temperature air delivered to the space. Generally these systems use pressure independent damper control.

Auto Zone Systems

The Auto-Zone zoning system is completely different

in operation and design from the VAV system previously discussed. One of the major differences between

the zoning system and a true VAV system is that the

HVAC unit used on a zoning system utilizes a constant

volume fan. Air volume control of the zoning system is

achieved by bypassing air from the HVAC unit supply

duct back into the HVAC unit return air duct on the unit

inlet. This bypass air is controlled based on a static pressure sensor located in the supply air duct downstream

of the unit supply air discharge. The bypass damper

modulates open and closed based on the static pressure

in the duct. The temperature at the HV AC unit dischar ge

varies in relation to the demand from the zones. Typically the HVAC units used for the zoning system will

have both heating and cooling capabilities. The fan supplies a constant volume of cold or hot air to the duct

system and which is fed to the individual zones by modulating zone dampers. Each zone controller relays its heating or cooling demand to the HVAC unit controller. The

HVAC unit controller determines its mode of operation

(heating, cooling or vent mode) depending on the demand from the zone controllers. The unit controller utilizes a voting system to determine the correct mode of

operation. Each zone controller determines (based on

its heating and cooling setpoints) whether or not to use

the air being supplied by the HVAC unit. For example,

one of the zones is calling for cooling when the temperature in the duct is above the zones cooling setpoint.

This zone will move to its minimum cooling position

to prevent warm air being introduced into the space.

With the zoning system the zone dampers are generally

pressure dependent. Pressure independent operation is

available but is not very common. Reheat and/or fan

powered terminal units can be used but aren’t commonly

part of the typical zoning system.

Conclusion

In many cases VAV systems go over budget because of

the increased cost of a VAV, HVAC unit and the expensive VAV controls associated with the system. Many

times the system can be redesigned to a zoning system

using Auto-Zone controls with a significant cost savings and equal or better performance and comfort than

the VAV system would provide. Be sure to follow the

instructions in this design guide for your zoning system.

Auto-Zone Systems 9

Page 10

Zoning Design Guide

Basics of Designing A Zoning System

This is a summary of the key items you need to consider for the design and layout of a successful zoning

system.

It is important that you study the design guide for a

more in depth understanding of proper system design.

By following the design guide and these tips you can

eliminate many unnecessary headaches that occur when

the basic rules of zoning are not followed. Always contact WattMaster Controls if you have any questions.

• Always group zones with similar load

profiles on the same HVAC unit.

• Never mix perimeter zones with interior

zones on the same HVAC unit.

• Each zoned HVAC unit should have a

minimum of 3 to 4 zones. Any less and you

should consult the factory.

• If you have electric reheat coils mounted on

VAV boxes, it is recommended that a fan

powered box be used. Consult the factory for

further details concerning this application.

• If there is an economizer on the HVAC unit,

it is highly recommended, though not

required, that the Zone Manager control the

economizer.

• Pressure Independent Zones must always use

round dampers or VAV boxes, never

rectangular - no exceptions!

• Never attempt to use a zone control system

on a true VAV application. See “ Zoning

Systems Versus True VAV Systems” on page

9 of this guide for detailed information.

• Each zoned HVAC unit can support a

maximum of 16 voting zones. Any

zones and you should contact the factory.

• When using auxiliary heat for individual

zones, perimeter heat such as baseboard is

always preferred and more economical to

operate than a fan terminal unit with reheat.

more

• Bypass dampers should always be sized for

60%-70% of the HVAC units rated CFM.

• Even though the Auto-Zone system has

certain features to help protect your

equipment,

safety devices associated with the HVAC

unit.

never override or disconnect any

10 Auto-Zone Systems

Page 11

Design Considerations

Zoning Design Guide

Load Diversity

A zoning system is designed to improve tenant comfort

by dynamically rebalancing the air distribution when

used with a typical constant volume rooftop heating/

cooling unit. If zones with extremely different load conditions are serviced by a single rooftop unit, the result

will be poor control and excessive wear due to cycling

of the equipment.

It is especially important to avoid mixing interior zones

(which require cooling all year) with exterior zones

(which may require constant heat during winter months).

If you must mix zones under these conditions, consider

using either VAV boxes with heat or separate external

heat on perimeter zones. Auto-Zone Zoning systems

offer a variety of methods to control additional zone

heat to help you avoid problems.

Group similar loads on an individual unit and use more

than one zoned unit if required. Any special loads can

be handled by using separate constant volume units.

The Auto-Zone Plus system offers the designer considerable flexibility by allowing both multiple-zoned units

and single-zone units to be connected within a single

simple system.

Cooling - Partial Load Conditions

The engineer must be aware of several potential problems when applying a zoning system for cold weather

operation.

on utilities and provide comfort under conditions when

it is not possible to operate the mechanical cooling system.

2.) Low Supply Air Temperatures. Under lightly

loaded conditions much of the supply air may be bypassed back into the return air side of the HVAC unit.

This bypassing will result in the lowering of the supply

air temperature, which may result in the supply air temperature reaching the low temperature safety limit. If

the supply air low temperature safety limit is exceeded,

the control system will “cut off” the mechanical cooling to protect it from damage. Excessive cycling of the

mechanical system will result if this condition persists.

Comfort may also suffer if the system cannot run long

enough to satisfy cooling demands.

A number of things can be done to reduce this problem.

Some of these things depend upon the type of installation.

A void oversizing the unit. Do your all load calculations

carefully. Since the zoning system directs the heating

or cooling to the zones which require it, you may find

that you can use a smaller unit in many cases. Oversizing

is the number one cause of excessive low supply air

temperature cycling.

Use an economizer. Although this is not a cure-all, it

greatly improves operation during cool weather when

cooling loads are minimal. Using an economizer also

improves ventilation and lowers operating costs.

1.) Low Ambient T emperature Lockout. During very

cold weather it is common for mechanical systems to

have “low temperature lockouts” which protect equipment from damage if operated under these conditions.

Auto-Zone also provides user programmed lockouts for

protection purposes, although mechanical safeties

should always be used as the final stage of protection.

If the rooftop unit services interior zones with thermal

loads, which require cooling when outside temperatures

are below the safe operating limits for your equipment,

you should seriously consider installing an economizer

on your rooftop unit. The Auto-Zone control system is

designed to take advantage of an economizer if it is

installed. The use of an economizer will save money

Increase cooling minimum airflow. Increase your cooling minimum airflow or damper position settings to allow more air during cooling operation. Be careful to

avoid minimum settings that are so high they may cause

over cooling of the spaces.

Bypass the air into the ceiling plenum. If you have a

system without ducted return, bypass the air into the

ceiling plenum instead of into the return air intake. Be

careful if you use this method since you may get “dumping” of cold air from your return air grilles. This method

works best with plenum returns. Do not use this method

with ducted returns.

Auto-Zone Systems 11

Page 12

Zoning Design Guide

Design Considerations

Increase your static pressure setpoint. This will help

reduce the amount of air being bypassed. Be aware of

increased noise levels and the cost of operation if you

use excessive static pressures. This will not work if you

are using pressure independent zone controllers, since

they will maintain a constant flow of air to the zones

regardless of duct static pressure. This technique will

likely cause over cooling of the spaces due to increased

airflow at minimum positions.

Warning:

If the fan system has the capability of producing static

pressures which could damage ductwork you must provide a manual reset, high pressure limit switch (Dwyer

1900-5-MR or equal) to cut off the fan system in the

event of high duct static. Do not use your Auto-Zone

Zoning system as a safety device!

Heating - Partial Load Conditions

Heating difficulties are less common than cooling difficulties. They are similar in nature, however, and the

cures are generally the same. Again, a number of things

can be done to reduce the effects of this problem.

Increase heating minimum airflow. Increase your heating minimum airflow or damper position settings to

allow more air during heating operation. Be careful to

avoid minimum settings that are so high they may cause

over heating of the spaces.

method works best with plenum returns. Do not use

this method with ducted returns

Use auxiliary heat . Use an auxiliary heat source in

either your VAV boxes or use baseboard heaters.

Auto-Zone has a number of auxiliary heat control options which provide solutions to most problems. Refer

to the Auxiliary Heat Control Options topic near the

end of this section.

Override Conditions

After-hours overrides can produce aggravated partial

load conditions in both the heating and cooling modes.

A single zone being overridden for after-hours use most

commonly causes the problem. This causes the rooftop

equipment to operate for only one zone. The Auto-Zone

system offers an improved solution to this common

problem by allowing a single override to trigger a group

of zones via a “global” override. This allows the system to operate with sufficient load to reduce cycling

caused by light load conditions.

Building Pressurization

If you are using an economizer, building pressurization

must be addressed. Failure to properly handle building

pressurization may result in doors remaining open when

the economizer is operating. Pressurization problems

can render economizer operation useless. The following suggestions will help to avoid potential problems.

Increase the static pressure. Set the static pressure

setpoint to be as high as practical. Increasing static pressure does not help if you are using pressure independent control operation.

A void oversizing the unit. Do your all load calculations

carefully. Since the zoning system directs the heating

or cooling to the zones which require it, you may find

that you can use a smaller unit in many cases.

Bypass the air into the ceiling plenum. If you have a

system without ducted return, bypass the air into the

ceiling plenum instead of into the return air intake. This

Use powered exhaust. A power exhaust fan(s) must be

used when the system utilizes ducted returns. The return duct pressure drop will cause most barometric relief dampers to function poorly or not at all. Auto-Zone

has the ability to control a powered exhaust whenever

the economizer is operating.

Use a separate building pressure control. Use a control that operates a relief fan or dampers to relieve building pressure

12 Auto-Zone Systems

Page 13

Zoning Design Procedures

Zoning Design Guide

General

There are six basic steps to designing an Auto-Zone

Zoning system:

1.) Determining the number and location of zones

2.) Sizing the central unit

3.) Duct Considerations

4.) Room air motion and diffuser selection

5.) Bypass damper sizing

6.) Sizing the zone dampers

Step #1 - Determining The Number And

Location Of Zones

A single air handler unit can have no more than sixteen

zones and no fewer than 3 zones. If the number of zones

exceeds sixteen then more than one Zone Manager will

be required.

on the wall, ceiling and floor material and location

within the building (e.g. top or middle floor), a typical

floor of a building usually has several distinct temperature or control zones that are affected uniquely by the

outdoor load. These zones are depicted in Figure 1-2.

Depending on the size of the building and partition layout, some of these zones may overlap or be insignificant from a zoning standpoint. For example, Zone 11

could be multiple conference or computer rooms where

additional zoning would be required, or it could be as

small as a corridor where no zoning is required. Similarly, zones 7 and 8 could have no external windows

and no partitions between them and could be considered a single zone. Some zones could be divided into

multiple offices with full partitions between them, thus

requiring separate Zone Controllers because of different internal loads, but the same external load.

Generally, the greater the number of individual Zone

Controllers, the greater the comfort. The designer will

have to look at the specific building, balancing the costs

of multiple zones with the added comfort possible with

multiple zones, to match the owner’s requirements.

The primary precaution to be taken in applying the AutoZone Zoning System is to select the zoning so that no

zone will be at maximum (design) heating (or cooling)

load when any other zone requires the opposite temperature air to satisfy its load. For example, depending

Figure 1-2: Zones Affected by the Outdoor Load

It is important to recognize that there are purely internal zones, such as Zone 11 in Figure 1-2, which may

contain separate offices/conference/computer rooms.

These internal zones could easily have high cooling requirements while external zones (1,2,3, etc.) could be

at or near design heating load. This is a misapplication

of the Auto-Zone, zoning (or any heating/cooling

change-over) system. The interior zones with cooling

only loads should be served by a separate single zone

rooftop HVAC unit (that could be zoned between multiple rooms with a similar load profile). Supplemental

heat could be added to the perimeter zones and controlled with the auxiliary heat control board from the

Zone Controller. System performance will generally be

compromised and frequent change-over from the heating to the cooling mode will occur during the heating

season if purely internal zones are combined on the same

air-conditioning unit serving perimeter zones. The exposure to the sun has a large affect on the loading of the

building. With the building zoned as shown below, for

the best control, zones 6, 7, 8, 9 and 10 should be put

on one HVAC unit, and zones 1, 2, 3, 4 and 5 on another HV AC unit. Zone 1 1 should be on a separate single

zone constant volume HVAC unit.

Auto-Zone Systems 13

Page 14

Zoning Design Guide

Zoning Design Procedures

Here is another example of the building’s exposure affecting the zoning. Figure 1-3 below

shows a building

layout with 7 zones, it has 3 zones with an eastern exposure, 4 zones with a western exposure and two each

north and south exposures. This building can be controlled from a single, constant volume air handler. All

of the zones have exterior surfaces and there are no

totally internal zones, so they will have similar load

requirements.

Figure 1-4: Zones With North And South Exposures.

Figure 1-3: Zone Layout With External Zones Only.

Figure 1-4 shows a building with 7 zones, 4 of the zones

have a north exposure and the other 3 have a south exposure. Since there is a big difference in the affect on

the building between north and south exposures, this

situation should use two zoned HVAC units.

Figure 1-5 shows a combination manufacturing

facility and office area. The space temperature in the

individual zones numbered 1 through 7, would all be

controlled by a single HVAC unit. A single constant

volume HVAC unit would be used for each of the

zones 8 through 12.

Figure 1-5: Zoning And Constant Volume Units

14 Auto-Zone Systems

Page 15

Zoning Design Guide

Step #2 - Sizing the Central Unit

Because the zones are controlled with variable air volume, it is unlikely that all zones will be at design load

at the same time. The zoning allows for the diversity of

loads to be taken into account and will often provide

better comfort with a smaller HVAC unit.

In sizing the system, the individual zone loads should

be calculated using any dependable load estimating program. Because of diversity, the central unit should be

selected for the instantaneous peak load, not the sum of

the peak loads, as would be done with a constant volume single zone system. Consider the following when

sizing the central unit.

• Size the peak cooling load based on the

month day hour of the greatest total building

system load

• Heating should be sized for the lowest design

temperature with an additional margin for

morning “pickup”. This margin is generally

recommended to be 20 to 25 percent of base

design.

Step #3 - Duct Design Considerations

The Auto-Zone system uses a typical low pressure duct

design. T o reduce noise problems duct pressures should

not exceed 1 inch W.C.

Primary trunk ducts should not be “undersized.” This

is especially true for “pressure dependent” systems.

Pressure dependent refers to the typical Auto-Zone,

Zone Controller without the airflow sensor. W ith larger

trunk ducts, it is easier to assure relatively constant pressure to each zone. Runs should be as short as possible,

and the trunk duct system kept as symmetrical as possible to facilitate system balancing. Wherever possible,

run the trunk ducts above corridors and locate the zone

dampers above corridors to reduce the noise in the space

and facilitate service of the units. Trunk ducts should

be sized for no more than 0.1 inch W.C. drop per 100

feet., and a maximum duct velocity of 2000 FPM.

Note For pressure independent terminal units

with velocity sensors and conventional

“VAV” boxes properly selected for

“quiet” operation, this 2000 FPM rule

can be exceeded by up to 50 percent. The

designer, however, should be very

experienced in VAV system design before

considering modification of this general

rule.

T ypical VAV systems with pressure independent terminals use the static regain method for sizing ducts. The

typical Auto-Zone Zoning system is a low-pressure,

pressure dependent system that utilizes conventional

unitary air-conditioning units. These systems should use

the equal-friction method of sizing the ducts, and use

the maximum loss of 0.1 inch per 100 feet as described

above.

Step #4 - Air Motion/Diffuser Selection

Air motion is a consideration for occupant comfort. The

selection of diffusers for an Auto-Zone Zoning system

requires more care than a constant volume system due

to varying flow of air into the zones. Slot diffusers are

recommended due to their superior performance at low

airflows. Because the zone airflow is variable volume,

lower cost round or rectangular diffusers that were satisfactory for constant volume may prove unsatisfactory

with an Auto-Zone Zoning system. These diffusers may

result in “dumping” of the cold air at low flows in the

cooling mode, and insufficient room air motion at low

air flows in the heating mode. Although high air motion in the heating mode can be undesirable, a slot diffuser with a high induction ratio generally helps to reduce room air “stratification” when the heating comes

from a ceiling diffuser . Linear slot diffusers should be

properly selected for the airflow and “throw” suited to

the specific installation or zone.

Additional factors to consider in diffuser selection is

sound level and throw at design flow. Generally, multiple diffusers will result in lower sound levels in the

space, but this must be balanced with the additional

hardware and installation costs. It is commonly recom-

Auto-Zone Systems 15

Page 16

Zoning Design Guide

Zoning Design Procedures

mended that slot diffusers be located near the perimeter or outside wall with the airflow directed into the

room. Consult your diffuser supplier or catalog for

proper diffuser sizing and location.

Series fan boxes may be used instead of zone dampers

where higher induction rates are desirable. If the heat

loss on perimeter walls is high, such as large areas of

glass, the use of Series Fan Boxes may be indicated to

maintain higher induction rates to offset “downdrafts.”

If the heat loss is greater than 275 BTUH/LINEAR

FOOT, you should use high quality slot diffusers next

to the outer wall with the airflow directed inward to

counteract downdrafts during heating. Serious

downdraft problems occur when heat losses exceed 400

BTUH/linear foot and both high induction diffusers and

series fan boxes are recommended.

Step #5 - Bypass Damper Sizing

The function of the bypass damper is to allow a constant volume air handling unit to be used with variable

volume zone dampers. The bypass damper modulates

on a signal from a duct static pressure sensor to “bypass” air from the supply duct back into the return air

duct. If the duct static pressure exceeds the adjustable

setpoint, then the damper opens to bypass more air, and

if the static pressure drops below the setpoint, it closes

to bypass less air.

Using a load calculation program, the bypass damper

should be sized to give you the maximum CFM of air

to be bypassed, typically 60 to 70 percent of the HVAC

units rated capacity.

T o size the damper, select a damper from the table based

on calculated bypass CFM and a maximum velocity

between 1750-2250 FPM. When determining the bypass duct size, be sure to take into account any transition fittings and associated pressure drops. (See Tables

1-1 & 1-2: Damper Sizing Charts)

Whenever possible, use a single bypass damper and

round duct for the bypass. If space limitations or total

airflow requires it, multiple bypass dampers can be controlled in parallel or a rectangular damper may be used.

For proper control of the Bypass Damper, the static pressure sensor location is very important. Refer to Fig-

ures 1-8 Thru 1-10 for proper sensor installation location information and guidelines.

Figure 1-6: Round Bypass Damper

Figure 1-7: Rectangular Bypass Damper & Kit

16 Auto-Zone Systems

Page 17

Fan

RA Sensor

SA Sensor

Return Air Duct

Supply Air Duct

SP Pickup

Bypass Damper

SP Sensor

Fan

Zoning Design Guide

SA Sensor

Bypass Damper

SP Pickup

Supply Air Duct

RA Sensor

Return Air Duct

SP Sensor

3D

Min.2DMin.

Figure 1-8: Preferred Sensor Location

If the trunk ducts are properly sized for minimum pressure drop, the location of the static pickup probe is not

particularly critical. It should ideally be located at right

angles to the airflow in a straight section of the supply

duct approximately 2/3 the distance of the total length

of the supply duct. Also the probe should be located

not less than 3 duct diameters downstream and 2 duct

diameters upstream of any elbow or takeoff. See Fig-

ure 1-8.

Fan

RA Sensor

Return Air Duct

Supply Air Duct

Tubing To Be Equal

Length And Size

SP Pickups

Bypass Damper

SA Sensor

SP Sensor

Figure 1-10: Least Desirable Sensor Location

If the supply duct comes directly from the unit and im-

mediately splits in opposite directions, the pressure

pickup should be located ahead of the split, or as close

to it as possible, even if the bypass damper(s) are located downstream of the split.

Step #6 - Sizing the Zone Damper

Use a load program to determine the peak load for each

zone. These calculations will be used in selecting the

appropriate zone damper sizes.

Using the maximum acceptable velocity for a branch

duct (typically 1000-1500 FPM for minimal noise), find

the smallest damper that will deliver the required CFM

as determined by the load program.

Locate the branch velocity used in the duct design program on the left hand column of the damper sizing chart

(T able 1-1). Move across the chart and find the damper

which will provide the acceptable CFM to meet your

specific zone requirements.

Note Compare the damper size selected against

Figure 1-9: Acceptable Sensor Location

Since the “ideal” location is often difficult to find in an

installation, a location in the main trunk where the tip

is not in a “negative pressure area” (e.g. just downstream

of the inside curve of an elbow) or an area where the

tube opening is directly impacted by the velocity of the

supply air. See Figure 1-9.

One additional damper may be slaved together for large

zones. See zone wiring diagram for details. This should

be reserved for situations when it is not practical to use

a single large damper . Round zone dampers can be specified to be either pressure dependent or independent.

the duct size to determine if the next size

up or down will provide acceptable

performance without requiring a transition fitting.

Auto-Zone Systems 17

Page 18

Zoning Design Guide

Zoning Design Procedures

Pressure Dependent Dampers

With pressure dependent (PD) dampers, the minimum

and maximum airflow is set based on damper position.

During the final commissioning of the system, each zone

is typically balanced with a flow hood and the min/max

position is fixed either mechanically or the preferred

method, in the controller software. Since this min/max

setting is based only on position, as the static pressure

fluctuates it will cause the actual airflow at the zone

damper to increase or decrease. Therefore the name,

pressure dependent since the airflow is dependent on

the static pressure. Pressure dependent dampers are

available in round or rectangular configurations. See

Figure 1-1 1 for a diagram of a typical pressure dependent zone damper.

dent operation. Pressure independent operation is available for round zone dampers only. Pressure independent rectangular dampers are not available. See Figure

1-12 for a diagram of a typical pressure independent

zone damper.

When pressure independent dampers are used they must

be field calibrated so the CFM of airflow for the minimum and maximum airflow setpoints will be correct.

This should be done by the field technician during the

commissioning portion of the system installation. The

K-factor is the amount of airflow in CFM that the specific damper will produce with 1” W .C. duct static pressure on the damper flow sensor. This K-factor is used

by the controller software to maintain the correct minimum or maximum airflow setpoint regardless of the

static pressure at the flow sensor. The K-factor and the

minimum and maximum damper CFMs can be entered

at the Zone Manager on Basic systems, or using the

System Manager on Auto-Zone Plus systems. K-factors can also be entered using a personal computer with

the ZoneView computer front end software installed.

The K-factors for each damper size are listed in Table

1-1: Round Air Damper Selection. Once the correct Kfactors and minimum and maximum damper CFM

setpoints are entered, the damper will modulate to try

to maintain these CFM airflows during damper operation. If zone dampers or fan terminal units manufactured by others are used, the correct K-factors must be

obtained from the equipment manufacturer.

Figure 1-11: Pressure Dependent Damper

Pressure Independent Dampers

When using pressure independent (PI) dampers this

minimum and maximum is set based on actual CFM of

airflow through the damper. Airflow is measured using

a pickup tube mounted in the zone damper and an electronic air flow sensor. Using this method you always

know the actual airflow through each zone damper instead of just the damper percentage open. The minimum and maximum settings are based on this actual

airflow reading. As the static pressure fluctuates, the

flow sensor reads the variation and automatically repositions the damper to maintain the minimum or maximum flow setpoints. Since the minimum or maximum

airflow is maintained independently of the static pressure available in the duct it is called pressure indepen-

Figure 1-12: Pressure Independent Damper

18 Auto-Zone Systems

Page 19

Zoning Design Guide

Round Damper

Blade Assembly

1/2" Foil Faced

Insulation

AIRF

FLOW

LO

IR

A

W

Bypass & Slave Dampers Zone Dampers

Damper Round Duct Size

CFM @ 1” Velocity Pressure

Air Flow Probe “K” Factor- For Pressure

Independent Applications Only

(Area Ft

2

)

Round Damper

Blade Assembly

Zone Controller

1/2" Foil Faced

Insulation

Actuator

Control Enclosure

(Cover Removed)

Bypass & Slave Interface

Table 1-1: Round Damper Selection Data

6”

(0.188)

474 950 1417 2120 2908 3700

8”

(0.338)

10”

(0.532)

L

F

IR

A

W

12”

(0.769)

W

A

O

I

R

F

L

O

Actuator

Control Enclosure

(Cover Removed)

14”

(1.050)

16”

(1.375)

Velocity Through Zone Damper

FPM

750 - Zone

141

(0.03)

1000 - Zone

188

(0.05)

1250 - Zone

235

(0.07)

1500 - Zone

282

(0.09)

1750 – Bypass Only

329

(0.12)

2000 – Bypass Only

376

(0.15)

2250 – Bypass Only

423

(0.18)

WattMaster reserves the right to change specifications without notice

Rectangular Dampers

Auto-Zone rectangular dampers are high quality aluminum construction with opposed/air foil designed

blades for superior control and have both blade and jamb

seals for tight shut off. The dampers are installed using

a mounting flange. The purpose for the flange mounting is to allow as much unrestricted free space within

the duct as possible.

Many companies utilize slide-in type dampers which

Airflow Through Zone Damper - CFM

inches W.C . With Air Damper Full Open)

(∆P

S

254

(0.02)

338

(0.03)

423

(0.04)

507

(0.06)

592

(0.08)

676

(0.10)

761

(0.13)

399

(0.01)

532

(0.02)

665

(0.03)

798

(0.04)

931

(0.06)

1064

(0.07)

1197

(0.09)

577

(0.02)

769

(0.03)

961

(0.04)

1154

(0.05)

1346

(0.06)

1538

(0.07)

1730

(0.09)

788

(0.01)

1050

(0.02)

1313

(0.03)

1575

0.04)

1838

(0.05)

2100

(0.07)

2363

(0.08)

1031

(0.01)

1375

(0.01)

1718

(0.02)

2062

(0.03)

2405

(0.04)

2749

(0.05)

3094

(0.06)

can cause air flow problems. These slide-in dampers

require that the damper frame be inside the duct. Imagine an 8 x 10 rectangular duct using a slide in damper

with a frame thickness of 1”. The frame alone would

reduce the opening to 6 x 8.

Another possible problem encountered with rectangular dampers is the blade width. Many damper manufacturers supply dampers with 6” or 8” dampers blades.

This can become a major problem, for example, if the

Auto-Zone Systems 19

Page 20

Zoning Design Guide

Zoning Design Procedures

damper has a height of 10”. In this case the damper

would utilize an 8” blade and a 2” blade stop or dam

would be installed across the base of the damper. Taking into consideration the “blade stop” and the frame, a

10 x 10 damper would have a reduced opening of 6 x 8

inside the duct. Many contractors have experienced low

air flow problems on projects only to discover this hidden problem of the dampers actually creating the restriction. Auto-Zone utilizes a variety of blade widths

in order to accommodate the size of the damper instead

of the damper trying to accommodate the size of the

blade.

Table 1-2: Rectangular Damper Selection Data

Rectangular Dampers

Damper

Height

“B”

Damper

Width

“A”

8” 410

10” 510

12” 560

14” 660

16” 750

18” 770

20” 850

22” 930

24” 950

26” 990

28” 1070

30” 1020

32” 1090

34” 1150

36” 1060

8” 10” 12” 14” 16” 18” 20” 22” 24” 26” 28” 30” 32” 34” 36”

Airflow Data with Full Open Damper – CFM @ 1000 FPM Velocity

For airflow CFM at other velocities use these multipliers: 750 FPM = 0.75, 1250 FPM = 1.25, 1500 FPM = 1.5, 2000 = 2.0, 2250 = 2.25

530

640

740

850

(0.16)

(0.10)

(0.07)

(0.05)

(0.04)

590

690

800

910

(0.10)

(0.07)

(0.05)

(0.03)

(0.03)

650

730

850

970

(0.07)

(0.05)

(0.03)

(0.02)

(0.02)

770

880

1030

1180

(0.05)

(0.03)

(0.02)

(0.02)

(0.01)

890

1030

1200

1370

(0.04)

(0.03)

(0.02)

(0.01)

(0.01)

980

1180

1380

1580

(0.03)

(0.03)

(0.01)

(0.01)

(0.01)

1090

1330

1550

1770

(0.03)

(0.02)

(0.01)

(0.01)

(0.01)

1210

1480

1730

1980

(0.02)

(0.01)

(0.01)

(0.01)

(0.01)

1290

1630

1900

2170

(0.02)

(0.01)

(0.01)

(0.02)

(0.01)

(0.01)

(0.01)

(0.01)

(0.01)

1390

(0.01)

1500

(0.01)

1550

(0.01)

1660

(0.01)

1770

(0.01)

1790

(0.01)

(0.01)

1780

2080

(0.01)

(0.01)

1930

2250

(0.01)

2080

2430

(0.01)

2230

2600

(-)

2380

2780

(-)

2520

2670

(-)

WattMaster reserves the right to change specifications without notice

(-)

2380

(-)

2570

(-)

(-)

2780

(-)

(-)

2970

(-)

(-)

3180

(-)

(-)

3090

(-)

(-)

(∆PS - inches W.C. @ 1000 FPM Velocity)

970

(0.03)

1030

(0.02)

1090

(0.01)

1330

(0.01)

1540

(0.01)

1780

(0.01)

1990

(0.01)

2230

2440

2680

2890

3130

3340

3580

3510

1080

(0.03)

1150

(0.02)

1210

(0.01)

1480

(0.01)

1710

(0.01)

1980

(0.01)

2210

2480

(-)

2710

(-)

2980

(-)

3210

(-)

3480

(-)

3710

(-)

3980

(-)

3930

(-)

1190

(0.02)

1260

(0.01)

1330

(0.01)

1630

(0.01)

1880

(0.01)

2180

2430

(-)

2730

(-)

2980

(-)

3280

(-)

3530

(-)

3830

(-)

4080

(-)

4370

(-)

4350

(-)

1300

(0.02)

1380

(0.01)

1460

(0.01)

1760

(0.01)

2060

(-)

2350

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

2650

(-)

2950

(-)

3250

(-)

3550

(-)

3850

(-)

4150

(-)

4450

(-)

4750

(-)

5040

(-)

1410

(0.02)

1500

(0.01)

1580

(0.01)

1910

(0.01)

2230

2550

2870

3200

3520

3850

4170

4500

4820

1520

(0.01)

1610

(0.01)

1700

(0.01)

2060

2400

(-)

2750

(-)

3090

(-)

3450

(-)

3790

(-)

4150

(-)

4500

(-)

4850

(-)

(-)

NA NA NA NA NA NA

NA NA NA NA NA NA

1630

(0.02)

1730

(0.01)

1820

(0.01)

2210

(-)

2570

(-)

2950

(-)

3310

(-)

3700

(-)

4060

(-)

4450

(-)

4820

(-)

(-)

NA NA NA NA NA

1740

(0.01)

1840

(0.01)

1940

2360

(-)

2740

(-)

3150

(-)

3530

(-)

3950

(-)

4330

(-)

4750

(-)

(-)

NA NA NA NA

1850

(0.01)

2000

(0.01)

2060

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

NA NA NA

(-)

2510

(-)

2910

(-)

3350

(-)

3750

(-)

4200

(-)

4600

(-)

NA NA

1970

(0.01)

2080

(0.01)

2190

(-)

2640

(-)

3090

(-)

3540

(-)

3990

(-)

4440

(-)

4880

(-)

20 Auto-Zone Systems

Page 21

Zoning Design Guide

Auxiliary Heat Control Options

The Auto-Zone Zoning system offers the user a variety

of methods to deal with zone heating requirements. In

order to control zone heat, an optional Relay Expansion Board is required. When deciding how to handle

zone heating requirements the user should consider the

following:

• Does the rooftop unit have heat?

• Are you using fan-powered boxes with reheat?

• Is auxiliary heat such as baseboard or radiant

ceiling panels used?

If the zone has some type of heat, the user must consider how the heat is to be used. Typical questions that

should be asked:

Q: Should the zone heat be used as a first stage where

it will become active before a heating demand is

created at the rooftop unit?

A: This mode is useful if you expect to have both

heating and cooling demands at the same time. The

zone will use it’s own heat and allow the rooftop

unit to continue to provide cooling for other zones.

This mode is also useful if the roof top unit does

not have any heating capabilities.

Q: Is the zone heat only to be used as a second stage,

where it will be activated only if the roof top unit

cannot maintain the space temperature, such as

during very cold weather?

A: In this mode of operation the rooftop will examine

the heating and cooling demands and try to satisfy

all of the zones by switching between heating and

cooling as required. The zone heat will only be

activated if the zone temperature falls below a

selected limit.

Relay Expansion Board Outputs

The following describes the operation of each of the

relays on the optional relay expansion board. The user

can choose the appropriate relays for any given application.

Relay #1 - Parallel Fan

If the Zone is in cooling or vent mode, the parallel fan

can activate anytime the zone temperature drops 0.5° F

below the heating setpoint. It deactivates when the temperature rises above the heating setpoint.

Relay #2 - Box Heat

If the zone is in cooling or vent mode then the box heat

can activate anytime the zone temperature drops 1.5° F

below the heating setpoint. It deactivates when the temperature rises to within 1.0° F of the heating setpoint.

Box heat is not allowed to activate in the heating mode

when there is hot air being supplied by the air handling

unit. This output was intended to allow zone reheat

while the Zone Manager is satisfying cooling demands

in other zones.

Relay #3 - Aux. Heat

In the occupied mode, the aux heat can activate anytime the zone temperature is 0.5° F below the aux heat

setpoint. It deactivates when the temperature rises 0.5°

F above the aux heat setpoint. In the unoccupied mode,

the aux heat uses the unoccupied heating setpoint with

the same deadband values mentioned above. This prevents the zone from maintaining the same aux heat

setpoint at night that it does during the daytime. The

Parallel Fan and Box Heat are prevented from coming

on until the aux heat is energized.

This output was intended to allow zone heating to augment the normal heating mode and also to allow a zone

an attempt to satisfy its own heating needs before creating a heating demand at the Zone Manager.

Q: Should the zone heat be locked out if the rooftop

unit is supplying warm air?

A: Many times it is desirable to use the rooftop

heating whenever possible and only use zone heat

when the rooftop unit is in cooling. This mode of

operation will lockout zone heat if the rooftop is

delivering heated air.

Relay #4 - Series Fan

The series fan runs anytime the main fan is running.

This includes occupied and unoccupied modes. The fan

can only start running when the zone damper is closed,

so it determines that the damper is closed before starting the fan.

Auto-Zone Systems 21

Page 22

Zoning Design Guide

System Installation

Mounting Of Controllers

All Auto-Zone Round Dampers or Rectangular Damper

Kits have the required controllers, actuators etc. factory mounted in an indoor rated control enclosure. If

you wish to use another manufacturers dampers for zoning control you must purchase Zone or Bypass Packages from WattMaster. These are furnished without a

mounting enclosure. Most local codes require these

components be mounted in an enclosure. If yours does

not require this it is still strongly recommended that

you do mount them in an enclosure. Components that

are not in an enclosure are in danger of being damaged,

and are susceptible to dirt and moisture contamination.

You may furnish your own enclosure or one is available from WattMaster. The part number for the

WattMaster enclosure is EE000075-01. This is an indoor rated enclosure. If the zone mounting location is

susceptible to water damage, watertight enclosures can

be purchased at any local electrical supply. Mounting

location for the controllers should not violate any local, state or national codes.

device. Possible problems you may encounter using

common transformers to power multiple devices are:

• If polarity is not maintained between devices,

shorting of the transformer will occur resulting

in damage to the electronics.

• When using one transformer to power multiple

devices it is possible to lose most or all of your

system if the transformer fails.

• It is important when powering multiple devices

from one transformer that total VA load and

wiring voltage drops be taken into account for

proper sizing of the transformer and wire.

(See Table 3 on page 23)

It is therefore recommended that in most installations

individual transformers be installed for each device.

This will greatly reduce the possibility of errors and

possible damage to the system.

System Wiring

Wiring requirements for Auto-Zone systems can be broken down into four main categories:

1.) Power Wiring

2.) Communications Wiring

3.) Controller Wiring

4.) Sensor Wiring

Each category should be thoroughly understood and

implemented in order to have a trouble free installation.

Power Wiring

All Auto-Zone devices are powered by 24 VAC. It is

possible to power the system using one or more common transformers or individual transformers for each

Power wiring should always be done in accordance with

any local, state, or national codes.

It is also important to note that THE HVAC UNITS

FACTORY TRANSFORMER SHOULD NEVER

BE USED TO POWER Auto-Zone devices! Normally

transformers on typical HVAC units are sized to only

handle the load of the units factory installed controls.

A separate transformer must be used.

Communication Loops

The Auto-Zone system utilizes two different communications loops. The Basic system uses a 9600 Baud

RS-485 communications loop (Local Loop) only. The

Plus system uses two different communications loops.

It has a 9600 Baud RS-485 communications loop (Local Loop) like the Basic system but also has an RS-485

19200 baud communication loop (Network Loop) that

connects the Zone Managers together and connects the

CommLink II communications interface.

22 Auto-Zone Systems

Page 23

Zoning Design Guide

W attMaster requires that all communication wire be 18

gauge minimum, two wire shielded cable, Belden

#82760 or equivalent. W attMaster offers AZWR series

communications cable for this purpose. The 18 gauge

color coded and labeled wire is available for the local

loop and the network loop communications wiring. The

local loop wire is supplied in 1000 ft. spools and is labeled “Local Loop” with a green candy stripe. The

network loop wire is supplied in 500 ft. spools and is

labeled “Network Loop” with a red candy stripe.

Local Loop Wire

Figure 1-13: WattMaster Communications Wire

The loop is best connected in a daisy chain configuration, meaning the loop is connected from one controller to another. It is not necessary to sequentially address the zone controllers in relation to their location

on the loop.

Even though the daisy chain configuration is preferred,

the star configuration can also be used. If required, a

combination of the two can also be used. Remember,

the best communications loop wiring is the one which

utilizes the minimum number of ends while using the

shortest wiring path.

Communication Wiring terminals on most Auto-Zone

controllers are marked “T”, “R” and “SHLD” (Note:

instead of SHLD the CommLink is marked “G” and

the Basic Zone Manager is marked “SH”). All wiring

should be connected T to T , R to R and SHLD to SHLD

throughout the entire loop system. Communication wire

Network Loop Wire

should be color coded to facilitate error free wiring.

The communication loops will not work if any of the

wires are reversed or otherwise landed incorrectly . Communications loops can be run up to a maximum of approximately 4000 ft. in total length. If your system exceeds this length, please consult the WattMaster factory for more information regarding extended communication loop lengths and solutions.

Caution: Unless the communications loop

is installed in conduit, be careful to

position the cable away from high

noise devices like fluorescent

lights, transformers, VFD’s, etc.

Conduit is not required for communications loop wiring unless

required by local codes.

Tip: Incorrect wiring of the communications

loop is the most common mistake made

during installation. Before beginning

installation, write down the wire color

used on each terminal connection and

consistently maintain that color code. It

is recommended that a continuous wire

run be made between devices. Anytime

a splice is made in the cable you increase

your chance of problems. If a splice must

be made,

should be soldered and wrapped or if

soldering is not possible use butt splice

crimp connectors and wrap tightly with

electrical tape.

Caution: Make sure when you are inserting

Never use wire nuts! Cable

wires into the terminal blocks that

strands of wire do not stick out and

touch the adjacent terminals. If

adjacent wires touch each other or

another terminal, shorting and

subsequent damage to the circuit

board could result

Auto-Zone Systems 23

Page 24

Zoning Design Guide

COMM

LINK

II

COMM

LINK

II

System Installation

Computer

(Optional)

C

O

M

M

LINK

II

L

O

C

O

O

M

P

M

O

D

P

E

M

WCLI

AT

T

M

A

S

T

E

R

O

N

T

R

O

S,N

C

CommLink II

(Optional)

S

y

c

h

r

o

n

o

u

s

D

a

t

a

L

i

n

k

SIG

DET

RDY

SND

REC

PWR

CO

NTROLS

Remote Link

(Optional)

RS485 Loop

24VAC

RS485 Loop

HVAC Unit

Zone Manager

UTO-ZONE

A

AUTOZONE

WEDJANUARY11 2001

OCCUPIED

Zone Controllers Occupy

Addresses 1 through 16.

Zone

Controller #1

RAM

R

R

8K

32K

34

18

FLOW

CX4

CX3

CX8

U4

U3

U

8

RN1

1

M

V

B31920P

74H

S6264L-70P

4.00F

AZ

9936

C

ZO

573N

S

D5

N

C

E

094

C

R

27

CX9

U9

C

C

LM

13

9

C

66

RAM

EPROM

C8

2

C

14

80C55

R22

2

D5

A

V

D

R

P.U.

J

EF

C

R32

10

X

R23

1

P

6W

T'STA

ILIPS

R

-5-1

R24

2

U11

T

M

8

/3

H

52

5

0S

R

=1

P

C

1

0C

94

R

1

50

9

8

9

2

1

S

0

IP

06

IL

FD

CB

C

H

P

P

50

D

15

C

E

X

W

R25

U

5

D

D7

5

O

ADDRE

G

SS

ADD

CX10

9

1

U

3C

6

2

R

4

C

75176

8

6

4

O

S

M

C

U

C

8

W

X

M

10

3

1

6

16

32

LD3

P

C

TOKEN

C

O

5

4

W

R

NET

10

E

R

R26

R

1

R14

0

3

V

1

250

D4

LD

LD

R

F1

2

1

21

R

C

9

6

562

Y

S

R

101

E

REC

SCAN

R

R

R

V

fTimesNew

.2

12

1

10

1

L1

fTimesNew

Roman|b0|i0|

Roman|b0|i0|c0|p18;

c0|p18;OMRON

G5L-114P-PS

24VDC

CONTACT:

MDL

Q

VR1

UL/CSA5A250VAC

D

K

2

1

1

D3

T

C7

fTimesNew

7824

7824C

R

24VAC

fTimesNew

15

Roman|b0|i0|

9936

Roman|b0|i0|c0|p18;

M

64A

c0|p18;OMRON

G5L-114P-PS

MC340

24VDC

CONTACT:

Q

U

R16

D

UL/CSA5A250VAC

3

7

R17

2

K2

GND

R5

R6

R7

P

J1

P

J2

V2

CX1

U

1

TC

U

32K

2V

16L8

R1

R2

R3

CX2

Q

1

B

7

4H

3

19

U

C

C

2

1

20

2

59

PS

C

2

R4

S

IO

N

TO

R

E

XP

A

N

AC

T

U

A

Controller #16

D5

5

62

R

E

V

.

2

24VAC 24VAC

Zone

RAM

R

R

8K

32K

3

1

FLOW

4

8

CX4

CX3

CX1

CX8

U4

U3

U

8

U

RN1

1

TC

1

M

V

B

74

U

S

4.00F

31

AZ

32K

62

H

9

93

92

C

64

ZO

57

6

0P

L-7

2V

3N

S

N

C

0P

E

094

C

R

27

16L8

CX9

U9

R1

C

C

LM

1

9

R2

3

C

66

RAM

EPROM

C

R3

2

8

C

1

80C55

R22

4

CX2

2

D5

AD

VR

Q

P.U.

1

J

E

C1

F

R32

X

0

R23