EZ ZoneEZ Zone

EZ Zone

EZ ZoneEZ Zone

+

FAN

COOL 1

COOL 2

HEAT1

HEAT2

BYPASSOPEN

MODE

FRI

M

+

+

COOL

YORK

03:48P

OCCUPIED

Meridian

ALARMS

4-08-96

NO

0

2

1

5

4

8

7

0

*

BYPASSCLOSE

COMMUNICATION

ALARM

A = ALL ZONES

B = EACH ZONE

A

C = HVACUNIT/CLEAR

3

B

D = ALARMS

6

C

# = STEP/ENTER

9

= DECIMAL

D

*

#

+

+

COOL

YORK

03:48PM

OCCUPIED

Meridian

ALARMS

NO

04-08-96

2

1

5

4

8

7

0

*

MODE

3

6

9

#

FRI

A

B

C

D

FAN

COOL 1

COOL 2

HEAT1

HEAT2

BYPASSOPEN

BYPASSCLOSE

COMMUNICATION

ALARM

A = ALL ZONES

B = EACH ZONE

C = HVACUNIT/CLEAR

D = ALARMS

# = STEP/ENTER

= DECIMAL

*

+

TT

oo

T

o

TT

oo

+

UpgUpg

Upg

UpgUpg

rr

adeade

r

ade

rr

adeade

+

AA

uto-Zoneuto-Zone

A

uto-Zone

AA

uto-Zoneuto-Zone

Auto-Zone Plus

OCCUPIED

09/20/00 03:38PM WED

NO ALARMS

M

3

2

6

1

5

9

4

7

Dec.

*

C

8

inus

M

0

u

n

e

r

lea

MANAGER

SYSTEM

Esc

Enter

rm

la

A

tio

a

ic

n

u

m

m

o

rrid

C

e

v

O

WATTMASTER CONTROLS INC.

n

e

GuideGuide

Guide

GuideGuide

8500 NW River Park Drive • Parkville , MO 64152

PH: (816) 505-1100 • FX: (816) 505-1101 • E-mail: mail@wattmaster.com

Visit our website at www.wattmaster.com

Form: WM-AEZ-UG-01C Copyright 2000 WattMaster Controls, Inc.

Auto-Zone & System Manager are registered trademarks of WattMaster Controls, Inc.

EZ Zone is a registered trademark of York International Corp.

WattMaster Controls assumes no responsibility for errors, or omissions.

This document is subject to change without notice. All rights reserved.

Table of Contents

Introduction ........................................................................................................................................ 4

EZ Zone Upgrade Overview .............................................................................................................. 5

Component Descriptions .................................................................................................................... 6

Upgrade Package Selection ................................................................................................................ 7

Example #1 - EZ Zone Stand Alone To AZ Basic ..................................................................... 8 & 9

Example #2 - EZ Zone Stand Alone To AZ Plus ................................................................... 10 & 11

Example #3 - Networked EZ Zone To AZ Plus ..................................................................... 12 & 13

Optional Controllers And Accessories................................................................................... 14 & 15

EZ Zone Wiring ................................................................................................................................ 16

Auto-Zone Basic Wiring .................................................................................................................. 17

Auto-Zone Plus Wiring .................................................................................................................... 18

Auto-Zone Plus Address Switches................................................................................................... 19

HVAC Staging Connections ............................................................................................................. 20

Sensor Connections .......................................................................................................................... 21

Bypass Damper Connections ........................................................................................................... 22

Honeywell Economizer Actuators ................................................................................................... 23

System Manager Installation ........................................................................................................... 24

CommLink II Installation ................................................................................................................ 25

Modem Linc Central EPROM Replacement ................................................................................ 26

Master Interface EPROM Replacement ........................................................................................ 27

Zone Controller EPROM Replacement.......................................................................................... 28

EPROM Installation Procedures..................................................................................................... 29

Ribbon Cable Installation ................................................................................................................ 30

Upgrade Parts List Summary .......................................................................................................... 31

Additional Information .................................................................................................................... 32

Table of Figures

Figure 1: Existing EZ Zone Master Controller Wiring ................................................................ 16

Figure 2: New Auto-Zone Basic Controller Wiring ...................................................................... 17

Figure 3: Existing Auto-Zone Plus Controller Wiring .................................................................. 18

Figure 4: New Auto-Zone Plus Address Switch Setting ................................................................ 19

Figure 5: Existing EZ Zone HVAC Wiring .................................................................................... 20

Figure 6: New Auto-Zone HVAC Wiring ....................................................................................... 20

Figure 7: Existing EZ Zone Master Controller Sensor Wiring .................................................... 21

Figure 8: New AZ Zone Manager Sensor Wiring.......................................................................... 21

Figure 9: Existing EZ Zone Bypass Damper Wiring .................................................................... 22

Figure 10: New Auto-Zone Bypass Damper Wiring...................................................................... 22

Figure 11: Honeywell Economizer Actuators Wiring Information.............................................. 23

Figure 12: System Manager Wiring................................................................................................24

Figure 13: CommLink II Wiring ..................................................................................................... 25

Figure 14: EZ Zone Modem Linc Central EPROM Location ...................................................... 26

Figure 15: EZ Zone Master Interface Board EPROM Location ................................................. 27

Figure 16: EZ Zone Zone Controller EPROM Location .............................................................. 28

Figure 17: EPROM Removal & Installation .................................................................................. 29

Figure 18: 3 Connector Ribbon Cable Installation ....................................................................... 30

EZ Zone/Auto-Zone

Introduction

+

YORK

OCCUPIED

Meridian COOL MODE

NO ALARMS

04-08-96 03:48PM FRI

1

4

7

*

The Auto-Zone Controls System was created from the

+

FAN

COOL 1

COOL 2

HEAT1

HEAT2

BYPASSOPEN

BYPASSCLOSE

COMMUNICATION

ALARM

A = ALL ZONES

B = EACH ZONE

A

C=HVACUNIT/CLEAR

3

B

D = ALARMS

2

6

C

# = STEP/ENTER

5

9

= DECIMAL

D

*

8

#

0

+

original EZ Zone Control System concept by redesigning, enhancing and expanding the original systems capabilities under the new Auto-Zone Controls System

name.

WattMaster’s Auto-Zone Control Systems have continued in the York EZ Zone tradition of keeping the controls simple to install and use while enhancing the system to make it more applicable and in line with the needs

of the current marketplace. In addition to offering an

excellent control system for zoning applications, the

Auto-Zone Control System has been expanded to allow control of multiple single zone constant volume

units and other devices such as lighting, exhaust fans,

and unit heaters.

+

The York International Corporation’s EZ Zone Controls

System was first introduced in the early nineties. The

EZ Zone Controls System was designed for York, by

WattMaster Controls, as a simple zone control system

for York’s line of commercial unitary roof top and split

system HVAC units. Since its original design and introduction, the York EZ Zone Control System has

changed very little.

Auto-Zone Plus

OCCUPIED

09/20/00 03:38PM WED

NO ALARMS

3

2

6

1

5

9

4

8

Minus

7

0

Dec.

*

Upgrading your EZ Zone system to the Auto-Zone Controls system allows you and your customer to take advantage of the many improvements that have been made

in the Auto-Zone Controls system without having to

replace all the EZ Zone system components that are

installed on your job.

This guide is intended to provide you with simple

instructions on upgrading an existing EZ Zone system

to an Auto-Zone Control System.

MANAGER

Alarm

Menu

Clear

SYSTEM

Esc

Enter

T

A

W

Communication

R

E

T

S

A

M

T

Override

O

C

.

C

IN

S

L

O

R

T

N

4 Upgrade

EZ Zone Upgrade Overview

EZ Zone/Auto-Zone

The basic steps required to upgrade your EZ

Zone system to an Auto-Zone system are:

z Determine what EZ Zone components

are currently installed on the system.

z Replace the existing EZ-Zone Master

Controller board with an Auto-Zone

Zone Manager controller board

z Replace the existing EZ Zone

EPROM’s in each Zone Controller

with a new Auto-Zone EPROM.

z Install return air and outside air

temperature sensors

EZ Zone to Auto-Zone upgrade allows you to

retain:

z All existing wiring

z Master Controller enclosure with

keypad and display

z Existing supply air and static pressure

sensors

z Existing bypass damper

After upgrading your system from EZ Zone to

Auto-Zone, you will be able to take advantage

of many new enhancements including:

Damper actuators can be programmed

z

for direct or reverse operation

z Full modulating economizer control

capability including optional wetbulb

economizer control

z Outside air temperature sensor provides

lockout function for both heating and

cooling. When converted to Auto-Zone

Plus system only one outside air sensor

is required for the entire system

z Contact closure input for dirty filter

status

z Global and individual zone override

modes

z Zones can be set for voting or

nonvoting status

z Room sensor slide can be programmed

± 0° F to ± 5° F adjustment

from setpoint

z All Zone Dampers

z * All Zone Controllers

z Room sensors

z Staging delays, minimum off times,

and changeover intervals are

programmable

z Sensor offset calibration to correct

sensor errors due to poor location

z * Modem Link Central

z * All Master Interface Boards

z ZoneView enhanced graphical computer

front end software available when

CommLink and a PC are used

z All Fan Terminal Controllers

z System Manager operator interface

* These controllers can be retained but they will re-

quire an EPROM chip upgrade to be compatible

with the Auto-Zone System.

allows all controllers to be accessed from

one central location

Upgrade 5

EZ Zone/Auto-Zone

Component Descriptions

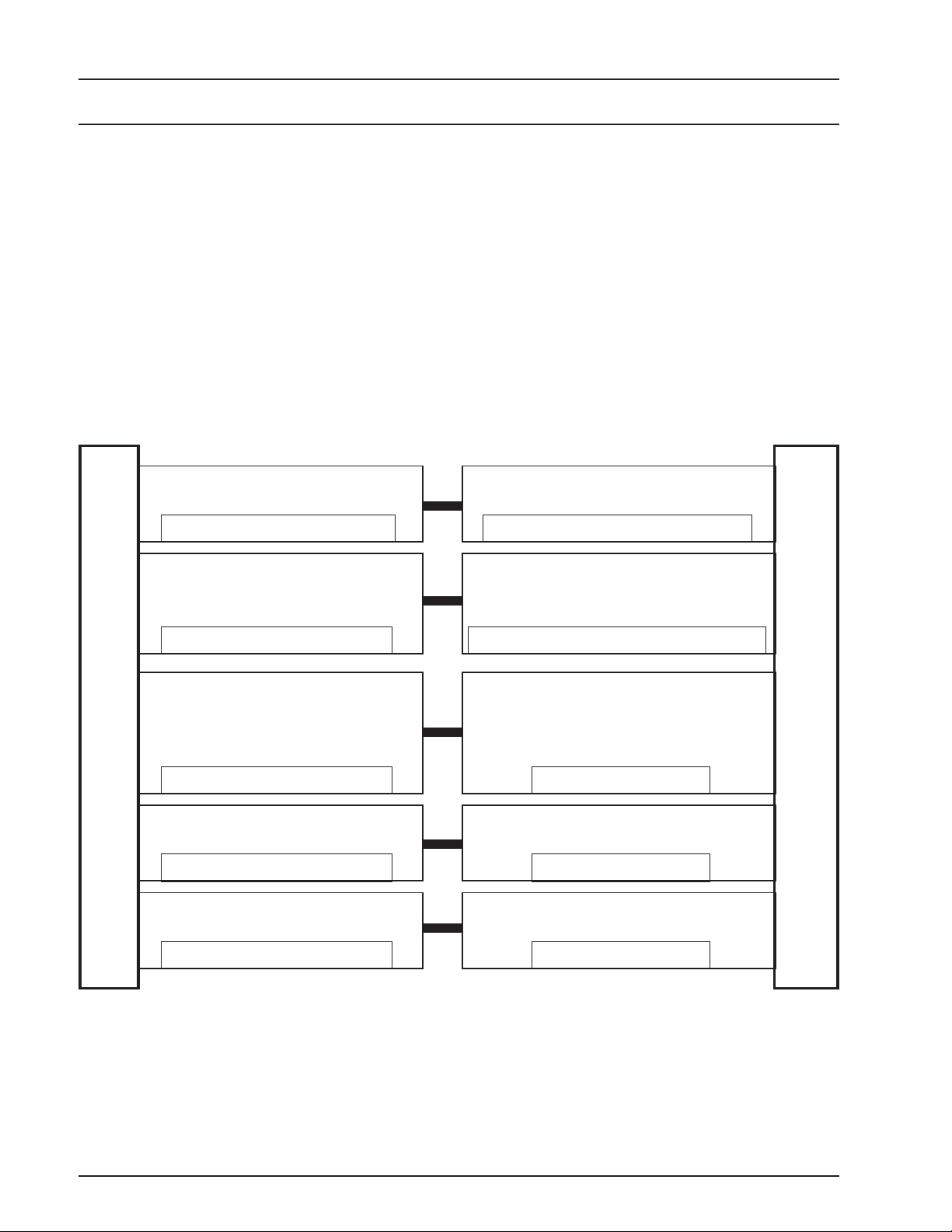

The general architecture of the EZ Zone and the AutoZone Systems are very similar making the upgrade process relatively easy.

There are some changes in the component descriptions

between the EZ Zone system and the Auto-Zone system. It is important to understand these differences

before you begin the upgrade process.

Master Controller Zone Manager

Must Be Replaced Improved Hardware & Software

Fan Terminal

Controller

Many of these components look similar, however, in

some cases they do not function in an identical fashion.

Having the wrong component installed can cause improper system operation.

The chart below depicts the difference in descriptions

for the various comparable system components in the

EZ Zone and Auto-Zone Systems.

Relay Expansion

Board

Replacement Not Required

Master Interface Board

EPROM Replacement Required

EZ Zone Components

Modem Linc Central CommLink II

EPROM Replacement Required

Zone Controller Zone Controller

EPROM Replacement Required

Same As Existing Fan Terminal Controller

MiniLink

Communications

Interface

Improved Software

Auto-Zone Components

Improved Software

Improved Software

6 Upgrade

Upgrade Package Selection

EZ Zone/Auto-Zone

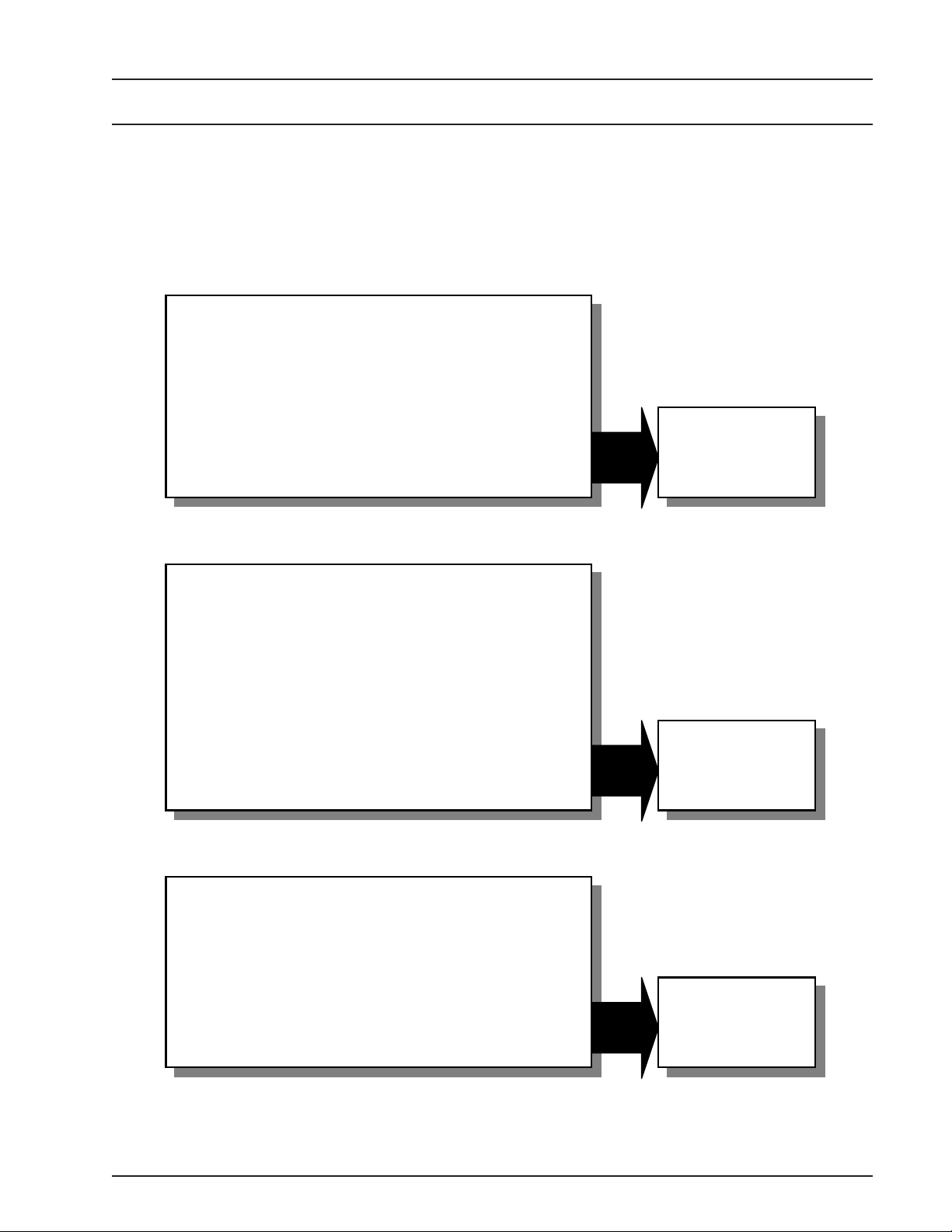

There are basically 3 possible EZ Zone to Auto-Zone

upgrade scenarios you may encounter. We have outlined these below to assist you in deciding which option is best for your application.

Upgrade A Simple EZ Zone Stand Alone

System(s) To The Auto-Zone Basic System

•

Each Existing Master Controller Has It’s Own Display

And Keypad And Is Treated As A Separate System

•

No Communications Cable Between Existing Master

Controllers

•

No Central Display Or Computer Interface Is Desired

Upgrade A Simple EZ Zone Stand Alone

System(s) To The Auto-Zone Plus System

Please see the Auto-Zone upgrade selection chart below to help determine which example best fits your

needs.

See Example #1

On

Pages 8 & 9

•

Two Or More Existing Master Controllers On The Job.

•

No Communications Cable Between Existing Master

Controllers

•

The Customer Wants To Connect The Master

Controllers So That They Are Part Of A Networked

System And/Or Install Constant Volume Unit

Controllers Or Other Controller Boards On Their

System

Upgrade A Networked EZ Zone System To

The Auto-Zone Plus System

•

Two Or More Existing Master Controllers That Are

Networked Together With A Modem Linc Central

•

The Customer May Want To Add Constant Volume

Unit Controllers Or Other Controller Boards To Their

System

See Example #2

On

Pages 10 & 11

See Example #3

On

Pages 12 & 13

Upgrade 7

EZ Zone/Auto-Zone

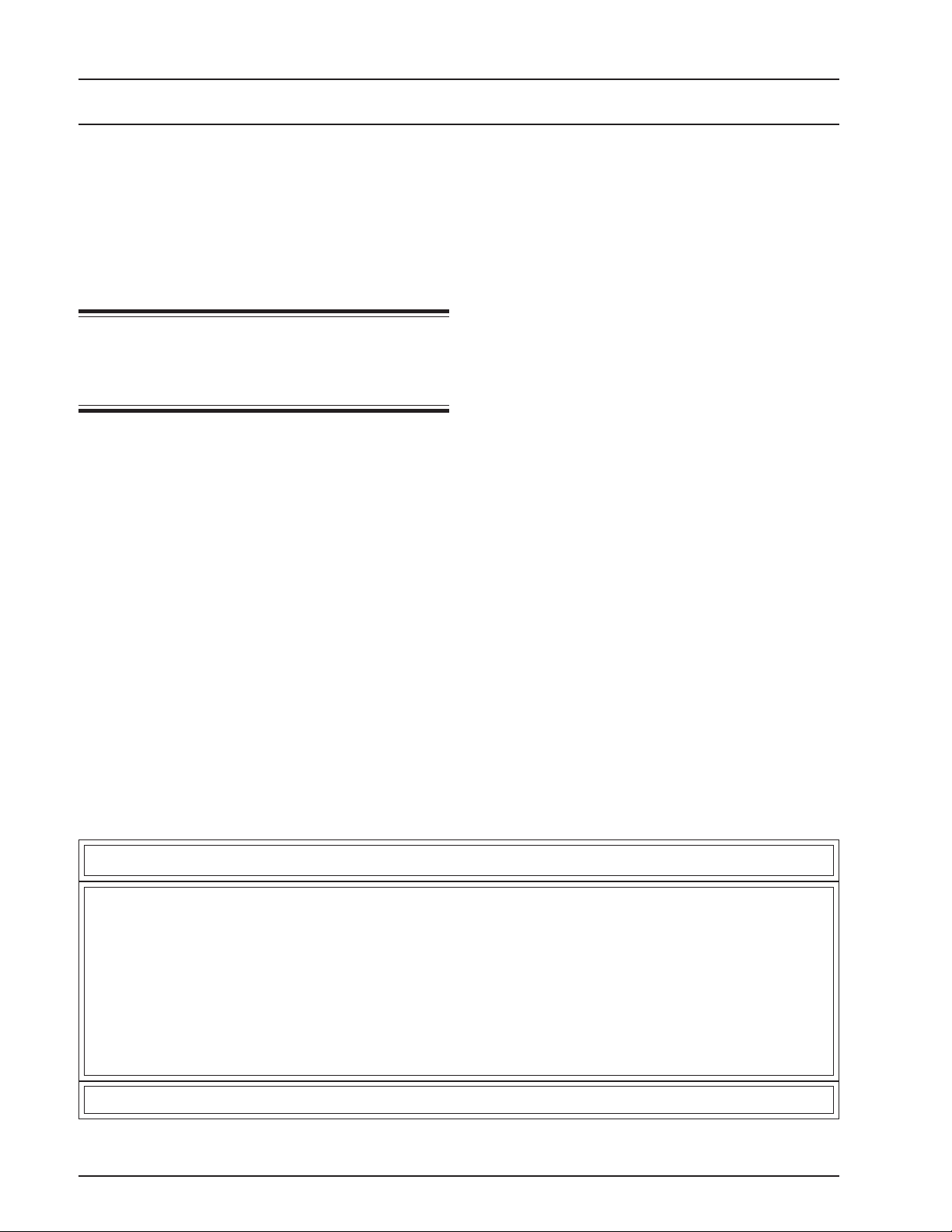

Example #1:

Your project has a single EZ Zone Master Panel and

it’s associated Zone Controllers. This is a typical EZ

Zone system. The upgrade will essentially convert this

to an Auto-Zone Basic System. Please see the required

upgrade components to be ordered in the list below.

To upgrade your existing EZ Zone System to the AutoZone Basic System the following procedure will be required.

Warning: All removal and installation procedures

must be done with the power to the controllers

turned off. Failure to do so can cause severe damage to the controller boards.

1) All power and input/output wiring will need to be

disconnected from the board. Remove the enclosure

cover and disconnect the keypad & display cable by

unplugging the cable connector at the board connection.

2) The new Return Air Sensor should be installed in

the return air stream in a location upstream of the point

that the bypass duct connects to the return duct.

3) Install the new Outdoor Air Sensor in a location on

the exterior of the building that provides shade and pro-

tection from the weather. See the mounting instructions

included with the sensor for detailed mounting instructions.

4) Remove the existing EZ Zone Master Controller

Board from the EZ Zone enclosure. This will require

the removal of 4 screws securing the board to the enclosure base.

5) Install the new Zone Manager board onto the existing enclosure base. The new board installation requires

6 plastic standoffs be inserted between the back of the

new board and the existing standoffs. Secure the board

to 4 of the threaded standoffs (one in each corner of the

board) with the mounting screws provided.

6) Connect the input, output and power wiring per the

Auto-Zone Basic wiring diagram (See Figure 2 on page

17). Connect the keypad display connector of the existing EZ Zone enclosure cover to the new Auto-Zone Zone

Manager board and secure the existing enclosure cover

to the enclosure base with the existing screws.

7) Remove and replace each EPROM on all the existing EZ-Zone Zone Controllers. See Figures 16 & 17 on

pages 28 & 29 for detailed EPROM Replacement information.

Note: When ordering be sure to specify Fahrenheit or Celsius operation for your system

To Upgrade To The AZ Basic System Order the Following:

(1) (OE751) EZ Zone to Auto-Zone Basic Upgrade Kit

(Includes: Zone Manager Board w/ Mounting Screws, Plastic Standoff Kit for Zone Manager,

Return Air Sensor, Upgrade Label, Installation Instructions.

(1) (OE250) Outside Air Sensor

(X) (OE752) EPROM (Replaces EZ Zone, Zone Controller EPROM) (One Required Per Controller)

For optional components list and information see pages 14 & 15 of this manual.

8 Upgrade

EZ Zone Stand Alone to AZ Basic

COMM

LINK

II

Existing System

To HVAC Unit

Master

Controller

Control Panel

+

YORK

EZ-ZONE COOL MODE

OCCUPIED

NO ALARMS

04-08-96 03:48PM FRI

2

1

5

4

8

7

0

*

+

+

FAN

1

COOL

2

OOL

C

®

HEAT1

2

EN

HEAT

OP

SE

BYPASS

TION

BYPASSCLO

UNICA

MM

CO

ARM

AL

ALLZONES

=

ZONE

A

EACH

=

B

UNIT/CLEAR

AC

=HV

A

C

ARMS

3

AL

=

B

D

6

C

#= STEP/ENTER

9

DECIMAL

=

D

*

#

+

Supply

Air Temp

Sensor

Bypass Air

Damper

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

EZ Zone/Auto-Zone

#16

Static

Pressure

Sensor

Upgraded System

Telephone Line

(Required For

Remote Link)

1

2

4

3

5

7

6

S

y

c

h

r

o

n

o

u

s

D

a

t

a

L

in

k

SIG

DET

RDY

SND

REC

PWR

C

O

NTR

O

Remote Link

(Optional)

CommLink II

Single Loop

(Optional)

Outside

Air Temp

Sensor

LS

C

O

M

M

L

IN

K

I

I

L

O

C

O

O

M

P

M

O

D

P

E

M

WCLI

AT

T

M

A

S

T

E

R

O

N

T

R

O

S,N

C

Zone Manager

+

8

*

0

To HVAC Unit

Control Panel

FA

O

C

O

C

®

E

H

E

H

Y

E

B

D

I

O

R

M

F

L

M

Y

O

P

B

O

8

C

4

:

D

E

3

YOR K

E

N

0

I

S

O

O

P

M

C

Z

6

U

R

9

C

A

Z

C

L

E

8

O

A

0

A

-

L

O

4

A

N

0

L

A

=

A

A

E

=

B

A

V

H

=

A

C

L

3

A

=

B

D

2

E

6

T

S

1

=

C

#

5

C

9

E

D

4

=

D

*

8

#

7

0

*

9

#

Computer

(Optional - By Others)

Supply

+

N

1

L

O

2

L

O

1

T

A

2

T

A

N

E

P

O

S

S

A

E

P

S

O

L

C

S

N

S

A

IO

P

T

A

IC

N

U

M

M

M

R

S

E

N

O

Z

L

E

N

O

R

Z

A

H

E

L

C

/C

IT

N

U

C

S

M

R

A

R

E

T

N

E

/

P

L

A

M

I

+

Air Temp

Sensor

Return

Air Temp

Sensor

Bypass Air

Damper

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

#16

+

Static

Pressure

Sensor

Upgrade 9

EZ Zone/Auto-Zone

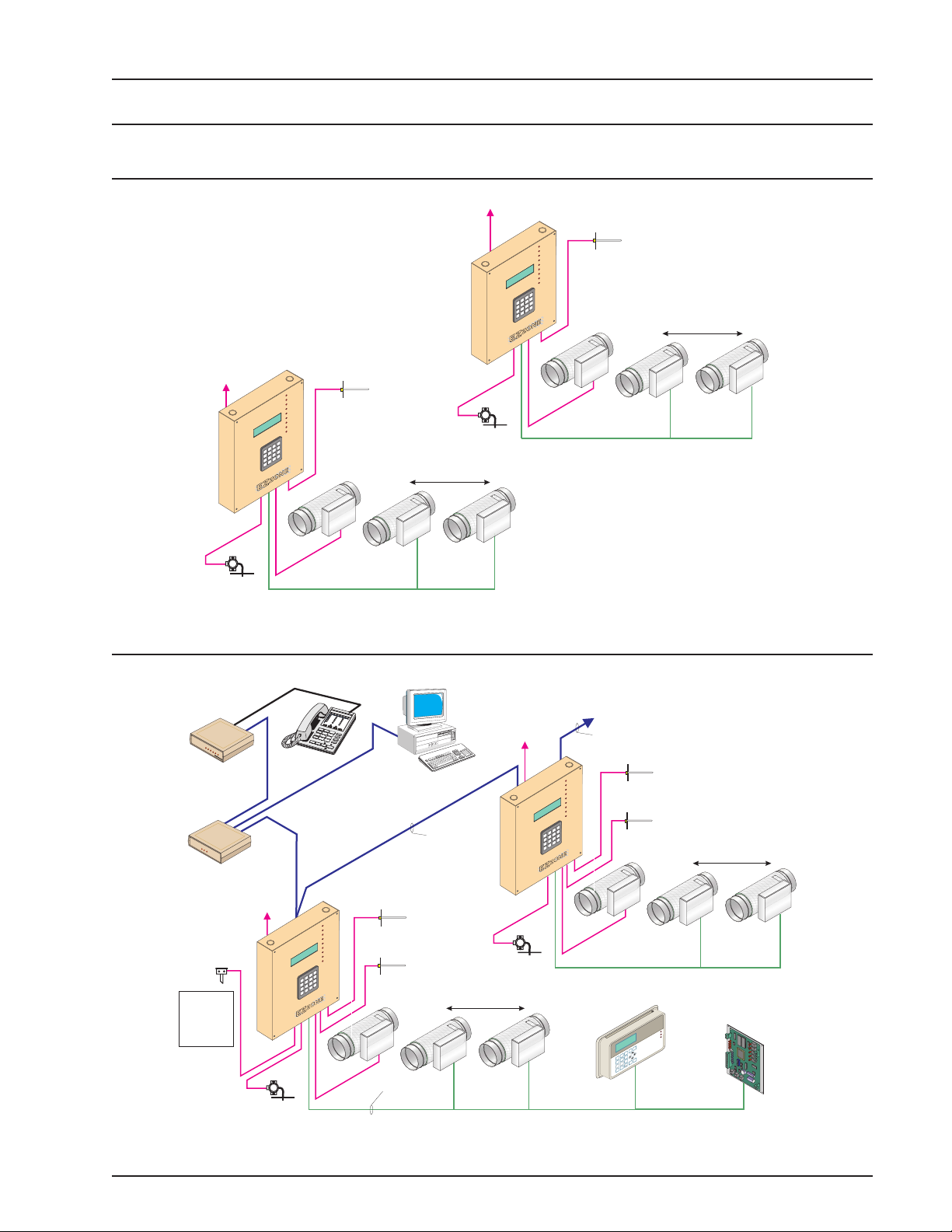

Example #2:

Your project has multiple EZ Zone Master Panels and

their associated Zone Controllers. This upgrade will

convert this to an Auto-Zone Plus System.

To upgrade your existing EZ Zone System to the AutoZone Plus System the following procedures will be

required.

Warning: All removal and installation procedures

must be done with the power to the controllers

turned off. Failure to do so can cause severe damage to the controller boards.

1) All power and input/output wiring will need to be

disconnected from the existing Master Controller board.

Disconnect the keypad & display cable from the board

by unplugging its connector from the board and the display on the existing enclosure cover.

2) The new Return Air Sensor should be installed in

the return air stream in a location upstream of the point

that the bypass duct connects to the return duct.

3) Install the new Outdoor Air Sensor in a location on

the exterior of the building that provides shade and

protection from the weather. Only one OA sensor is

required for the entire system. See the mounting instructions included with the sensor for detailed mounting

instructions.

4) Connect the CommLink to the network communica-

tions loop and wire in 24VAC power (See Figure 13 on

page 25).

5) Remove the existing EZ Zone Master Controller

Board from the EZ Zone enclosure. This will require

the removal of 4 screws securing the board to the enclosure base.

6) Install the new Zone Manager board onto the existing enclosure base. The MiniLink should then be

mounted to the Zone Manager board using the standoffs and screws included with the MiniLink. The new

Zone Manager board installation requires 6 plastic

standoffs be inserted between the back of the new board

and the existing standoffs. Secure the board to 4 of the

threaded standoffs (one in each corner of the board)

with the screws that were included with the new Zone

Manager board.

7) Connect the input, output and power wiring per the

Auto-Zone Plus wiring diagram (See Figure 3 on page

18). Connect the new 3 Connector Ribbon Cable keypad display connector to the existing EZ Zone enclosure cover and to the new Auto-Zone Zone Manager

board (See Figure 18 on page 30). Secure the existing

enclosure cover to the enclosure base with the existing

screws.

8) Remove and replace each EPROM on all the existing EZ-Zone Zone Controllers. See Figures 16 & 17 on

pages 28 & 29 for detailed EPROM Replacement information.

Note: When ordering be sure to specify Fahrenheit or Celsius operation for your system

To Upgrade To The Auto-Zone Plus System Order the Following:

(X) (OE753) EZ Zone to Auto-Zone Plus Upgrade Kit (One Required Per Existing Master Controller)

(Includes: Zone Manager Board w/ Mounting Screws, Plastic Standoff Kit for Zone Manager,

MiniLink w/ Mounting Hardware, Return Air Sensor, 3 Way Display/Keypad Connector cable,

Upgrade Label, Installation Instructions).

(1) (OE361-04-CLMA) CommLink II Kit (Includes: Cables, Power Supply, Installation Instructions)

(1) (OE250) Outside Air Sensor (Only One Required For Entire System)

(X) (OE752) EPROM (Replaces EZ Zone, Zone Controller EPROM) (One Required Per Controller)

(1) (OE392-01-AZSYSM) System Manager (Not Required if Using Optional Computer)

For optional components list and information see pages 14 & 15 of this manual.

10 Upgrade

EZ Zone Stand Alone to AZ Plus

C

COMM

LINK

II

MANAGER

Existing System

To HVA

Unit

To HVAC Unit

Control Panel

+

+

YOR K

EZ-ZONE

OCCUPIED

NO

04-08-96

1

4

7

*

Controller

®

FRI

COOL MODE

03:48PM

ALARMS

A

3

B

2

6

C

5

9

D

8

#

0

Master

N

FA

1

L

O

O

C

2

L

O

O

C

1

T

A

E

H

2

T

A

N

E

E

H

P

O

S

S

A

E

P

S

Y

O

B

L

C

S

S

O

A

I

P

T

Y

A

B

C

I

N

U

M

M

O

C

M

R

A

L

S

A

E

N

O

Z

L

L

E

A

N

=

O

Z

A

H

E

L

C

C

A

/

E

T

I

=

N

B

U

C

A

V

H

=

S

C

M

R

A

L

R

A

E

T

=

N

D

E

/

P

E

T

S

=

L

A

#

IM

C

E

D

=

*

Control Panel

Supply

+

N

R

A

+

Air Temp

Sensor

Bypass Air

Damper

Static

Pressure

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

Sensor

+

+

#16

YOR K

EZ-ZONE

OCCUPIED

NO

04-08-96

1

4

7

*

Master

Controller

®

MODE

FRI

COOL

03:48PM

ALARMS

A

3

B

2

6

C

5

9

D

8

#

0

Supply

+

N

FA

1

L

O

O

C

2

L

O

O

C

1

T

A

E

H

2

T

A

N

E

E

H

P

O

S

S

A

E

P

S

Y

O

B

L

C

S

N

S

A

IO

P

T

Y

A

B

IC

N

U

M

M

O

C

M

R

A

L

S

A

E

N

O

Z

L

L

E

A

N

=

O

R

Z

A

A

H

E

L

C

C

A

/

E

IT

=

N

B

U

C

A

V

H

=

S

C

M

R

A

L

R

A

E

T

=

N

D

/E

P

E

T

S

=

L

A

#

IM

C

E

D

=

*

+

Air Temp

Sensor

Bypass Air

Damper

EZ Zone/Auto-Zone

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

#16

Static

Pressure

Sensor

Upgraded System

Telephone Line

(Required For Remote Link)

To Other Zone Managers

1

2

4

3

5

7

6

S

y

c

h

r

o

n

o

u

s

D

a

t

a

L

i

n

k

SIG

DET

RDY

SND

REC

PWR

CO

N

TR

O

L

S

Remote Link

(Optional)

8

9

*

0

#

Computer

(Optional - By Others)

Supply

Air Temp

Sensor

Return

Air Temp

Sensor

Network Loop

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

C

O

M

M

L

I

N

K

I

I

L

O

C

O

O

M

P

M

O

D

P

E

M

WCLI

AT

T

M

A

S

T

E

R

O

N

T

R

O

S,N

C

CommLink II

Multiple Loop

To HVAC Unit

Control Panel

Zone Manager

Outside

Air Temp

Sensor

Only One OA

Sensor Is

Required

For Entire

System

+

+

YOR K

OCCUPIED

Meridian

ALARMS

NO

04-08-96

1

4

7

*

+

N

FA

1

L

O

O

C

2

L

O

O

C

1

T

A

E

H

2

T

A

N

E

E

H

P

O

S

S

E

A

P

S

Y

O

B

L

C

S

MODE

N

FRI

S

O

A

I

P

T

Y

A

B

IC

COOL

N

U

M

M

03:48PM

O

C

M

R

A

L

S

A

E

N

O

Z

L

L

E

A

N

=

O

R

Z

A

A

H

E

L

C

A

/C

E

IT

=

N

B

U

C

A

V

H

=

S

A

C

M

R

A

L

3

R

A

E

T

=

B

N

D

2

/E

P

E

6

T

S

=

L

C

A

#

5

M

I

C

9

E

D

=

D

*

8

#

0

Bypass Air

+

Damper

To HVAC Unit

Control Panel

Zone Manager

Pressure

Sensor

+

+

Static

YOR K

04-

#16

MODE

FRI

COOL

03:48PM

OCCUPIED

Meridian

ALARMS

08-96

NO

A

3

B

2

6

1

C

5

9

4

D

8

#

7

0

*

Local Loop

Static

Pressure

Sensor

(Up to 30 Allowed On System)

Network Loop

Supply

Air Temp

+

N

FA

1

L

O

O

C

2

L

O

O

C

1

T

A

E

H

2

T

A

N

E

E

H

P

O

S

S

E

A

P

S

Y

O

B

L

C

S

N

S

A

IO

P

T

Y

A

B

IC

N

U

M

M

O

C

M

R

A

L

S

A

E

N

O

Z

L

L

E

A

N

=

O

R

Z

A

A

H

E

L

C

A

/C

E

T

I

=

N

B

U

C

A

V

H

=

S

C

M

R

A

L

R

A

E

T

=

N

D

/E

P

E

T

S

=

L

A

#

IM

C

E

D

=

*

+

(Optional If Computer Front End Used)

Sensor

Return

Air Temp

Sensor

Bypass Air

Damper

System

Manager

s

lu

ED

P

SYSTEM

W

e

n

o

-Z

S

uto

A

RM

LA

OCCUPIED

01/01/9703:38PM

NOA

c

s

E

u

en

M

3

2

6

1

r

e

t

n

E

5

r

9

a

le

4

C

s

8

u

in

M

7

0

.

c

e

D

*

ER

ANAG

M

rm

a

Al

n

tio

a

ic

n

u

m

e

m

d

o

ri

C

er

v

O

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

Other Controllers

(Optional - Up to 13 On Each Loop))

#16

Upgrade 11

EZ Zone/Auto-Zone

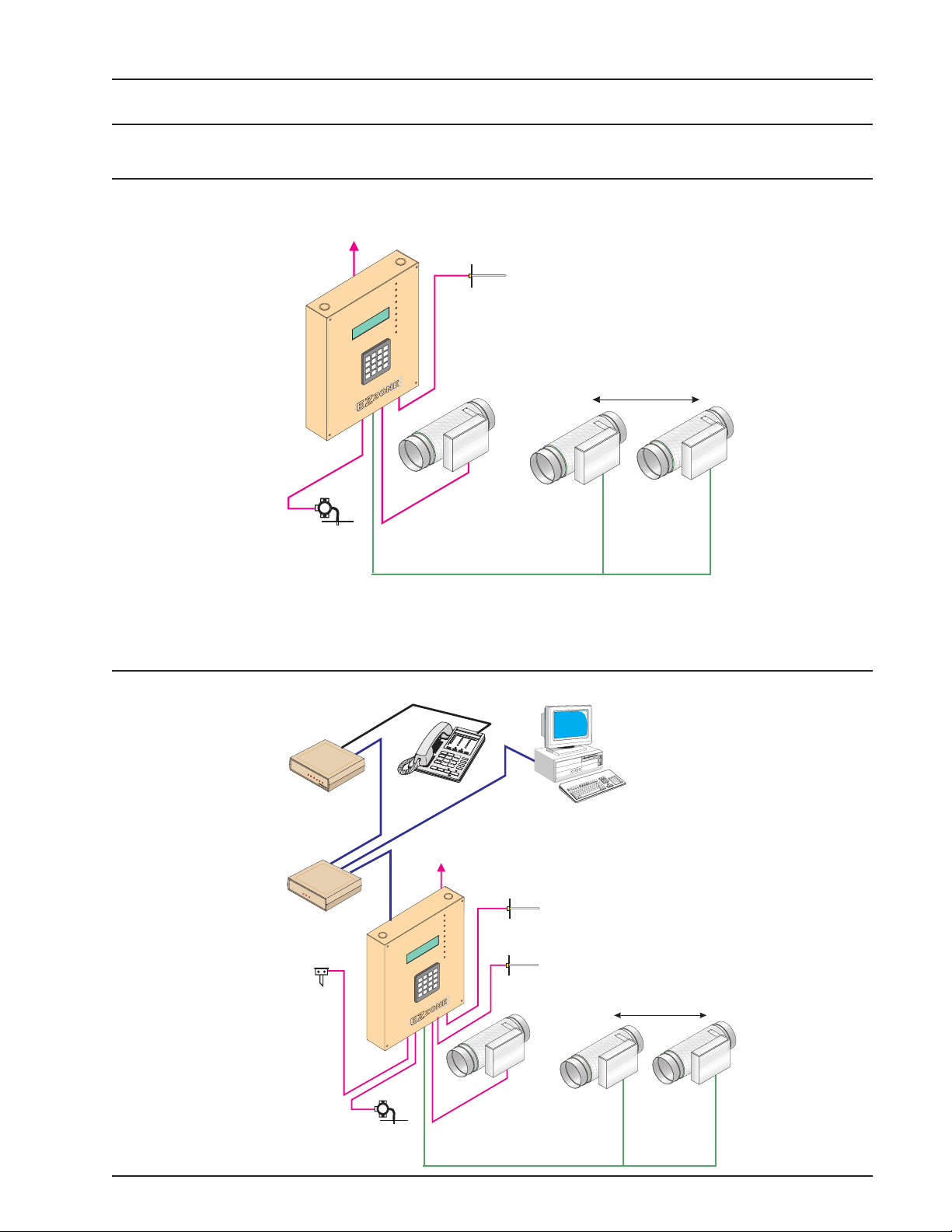

Example #3:

Your project has a Networked EZ Zone System that you

want to convert to the Auto-Zone Plus system. Please

see the required upgrade components list below for the

necessary parts to be ordered.

To upgrade your existing Networked EZ Zone System

to the Auto-Zone Plus System the following procedures

will be required.

Warning: All removal and installation procedures

must be done with the power to the controllers

turned off. Failure to do so can cause severe damage to the controller boards.

1) All power and input/output wiring will need to be

disconnected from the existing Master Controller board.

Disconnect the keypad & display cable from the board

by unplugging its connector from the board.

2) The new Return Air Sensor should be installed in

the return air stream in a location upstream of the point

that the bypass duct connects to the return duct.

3) Install the new Outdoor Air Sensor in a location on

the exterior of the building that provides shade and

protection from the weather. Only one OA sensor is

required for the entire system. See the mounting instructions included with the sensor for detailed mounting

instructions.

& 27 for detailed EPROM installation instructions.

5) Remove the existing EZ Zone Master Controller

Board from the EZ Zone enclosure. This will require

the removal of 4 screws securing the board to the enclosure base. Remove the existing Master Interface

Board from the old Master Controller board. Remove

the old EPROM from the Master Interface board and

install the new MiniLink upgrade EPROM to the Master Interface board. See Figures 15 & 17 on pages 26 &

27 for detailed EPROM installation instructions.

6) Install the upgraded Master Interface board to the

new Zone Manager board using the existing mounting

hardware. Install the new Zone Manager board onto the

existing enclosure base. The new Zone Manager board

installation requires 6 plastic standoffs be inserted between the back of the new board and the existing standoffs. Secure the board to 4 of the threaded standoffs

(one in each corner of the board) with the screws that

were included with the new Zone Manager board.

7) Connect the input, output and power wiring per the

Auto-Zone Plus wiring diagram (See Figure 3 on page

18). Connect the existing 3 Connector Ribbon Cable

keypad display connector to the existing EZ Zone enclosure cover and to the new Auto-Zone Zone Manager

board (See Figure 18 on page 30). Secure the existing

enclosure cover to the enclosure base with the existing

screws.

4) Take the cover off of the Modem Link Central, remove the old EPROM and replace with the new

CommLink EPROM. See Figures 14 & 17 on pages 25

Note: When ordering be sure to specify Fahrenheit or Celsius operation for your system

To Upgrade To The Auto-Zone Plus System Order the Following:

(X) (OE751) EZ Zone to AZ Basic Upgrade Kit (One Required Per Existing Master Controller)

(Includes: Zone Manager Board w/ Mounting Screws, Plastic Standoff Kit for Zone Manager,

Return Air Sensor, Upgrade Label, Installation Instructions)

(1) (OE755) Modem Link Central to CommLink II Upgrade Kit

(Includes: ComLink EPROM Upgrade Chip, Upgrade Label)

(1) (OE754) Master Interface Board to MiniLink Upgrade Kit

(Includes: MiniLink EPROM Upgrade Chip, Upgrade Label)

(1) OE250 Outside Air Sensor (Only One Required Per System)

(X) (OE752) EPROM (Replaces EZ Zone, Zone Controller EPROM) (One Required Per Controller)

(1) (OE392-01-AZSYSM) System Manager (Not Required if Using Optional Computer)

For optional components list and information see pages 14 & 15 of this manual.

8) Remove and replace each EPROM on all the existing EZ-Zone Zone Controllers. See Figures 16 & 17 on

pages 28 & 29 for detailed EPROM Replacement information.

12 Upgrade

Networked EZ Zone To AZ Plus

COMM

LINK

II

Teleph

COMM

LINK

II

Existing System

oneLine

24VAC

Modem

(Optional)

C

O

M

M

L

IN

K

II

L

O

C

O

O

M

P

M

O

D

P

E

M

WCLI

ATT

MA

S

T

E

RON

TR

O

S,N

24VAC

C

Modem Link Central

To HVAC Unit

Control Panel

Master

Controller

Master

Controller

To HVAC Unit

Control Panel

+

YOR K

M

4

0

+

Static

Pressure

Sensor

#16

O

M

L

M

O

P

O

8

C

4

:

D

n

3

E

a

0

I

i

S

P

d

M

6

U

i

R

9

C

r

A

C

e

L

8

O

A

0

O

N

3

2

6

1

5

9

4

8

#

7

0

*

1

2

4

3

5

7

6

8

9

*

0

#

Computer

(Optional)

Network Loop

Supply

Air Temp

+

N

FA

1

L

O

O

C

2

L

O

O

C

1

T

A

E

H

2

T

A

N

E

E

H

P

O

S

S

A

E

P

S

Y

O

E

B

L

D

I

C

O

R

S

M

N

F

S

O

A

I

L

P

M

T

O

Y

A

P

O

B

C

8

I

C

+

4

N

U

:

D

n

YOR K

M

3

E

a

M

0

I

i

S

O

P

d

M

C

6

U

i

R

9

C

r

A

C

e

L

M

8

O

M

A

R

0

A

-

L

O

4

S

A

N

0

E

N

O

Z

L

L

E

A

N

=

O

R

Z

A

A

H

E

L

C

C

A

/

E

T

I

=

N

B

U

C

A

V

H

=

S

A

C

M

R

A

L

3

R

A

E

T

=

B

N

D

E

2

/

P

E

6

T

S

1

=

L

C

#

A

5

M

I

C

9

E

D

4

=

D

*

8

#

7

0

*

+

+

Sensor

Bypass Air

Damper

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

To Other Master Controllers

(Up to 30 Allowed On System)

Network Loop

+

N

FA

1

L

O

O

C

2

L

O

O

C

1

T

A

E

H

2

T

A

N

E

E

H

P

O

S

S

A

E

P

S

Y

O

E

B

L

D

I

C

R

S

N

F

S

O

A

I

P

T

Y

A

B

C

I

N

U

M

M

O

C

M

R

A

L

S

A

E

N

O

Z

L

L

E

A

N

=

O

R

Z

A

A

H

E

L

C

C

A

/

E

T

I

=

N

B

U

C

A

V

H

=

S

A

C

M

R

A

L

R

A

E

T

=

B

N

D

E

/

P

E

T

S

=

L

C

#

A

M

I

C

E

D

=

D

*

+

Supply

Air Temp

Sensor

Bypass Air

Damper

EZ Zone/Auto-Zone

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

#16

Static

Pressure

Sensor

Upgraded System

Telephone Line

Local Loop

24VAC

Zone

Manager

To HVAC Unit

Control Panel

+

YOR K

r

e

M

0

4

0

+

Static

Pressure

Sensor

#16

E

D

I

O

R

M

F

L

M

O

P

O

8

C

4

:

D

n

3

E

a

0

I

i

S

P

d

M

6

U

i

R

9

C

A

C

L

8

O

A

O

N

A

B

A

C

3

B

D

2

6

1

C

#

5

9

4

D

*

8

#

7

0

*

1

2

4

3

5

7

6

8

9

*

0

#

Modem

(Optional)

C

O

M

M

L

IN

K

II

L

O

C

O

O

M

P

M

O

D

P

E

M

WCLI

ATTMASTER ON

TRO

S,NC

Upgraded

Modem Link Central

To HVAC Unit

Control Panel

Zone

Manager

Outside

Air Temp

Sensor

Only One OA

Sensor Is

Required

For Entire

System

24VAC

+

N

FA

1

L

O

O

C

2

L

O

O

C

1

T

A

E

H

2

T

A

N

E

E

H

P

O

S

S

E

A

P

S

Y

O

E

B

L

D

I

C

O

R

S

M

N

F

S

A

IO

L

P

M

T

O

Y

A

P

O

B

8

IC

C

+

+

YOR K

a

i

d

6

i

9

r

C

e

8

O

M

0

O

4

N

0

1

4

7

N

4

U

:

D

n

M

3

E

M

0

I

S

O

P

M

C

U

R

C

A

L

M

A

R

A

L

S

A

E

N

O

Z

L

L

E

A

N

=

O

R

Z

A

A

H

E

L

C

A

/C

E

IT

=

N

B

U

C

A

V

H

=

S

A

C

M

R

A

L

3

R

A

E

T

=

B

N

D

2

/E

P

E

6

T

S

=

L

C

A

#

5

M

I

C

9

E

D

=

D

*

8

#

0

*

Bypass Air

+

Damper

Supply

Air Temp

Sensor

Return

Air Temp

Sensor

Computer

(Optional)

Network Loop

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

Local Loop

Static

Pressure

Sensor

To OtherZone Managers

(Up to 30 Allowed On System)

Network Loop

Supply

Air Temp

+

N

FA

1

L

O

O

C

2

L

O

O

C

1

T

A

E

H

2

T

A

N

E

E

H

P

O

S

S

E

A

P

S

Y

O

B

L

C

S

N

S

A

IO

P

T

Y

A

B

IC

N

U

M

M

O

C

M

R

A

L

S

A

E

N

O

Z

L

L

E

A

N

=

O

R

Z

A

H

E

L

C

A

/C

E

IT

=

N

U

C

A

V

H

=

S

M

R

A

L

R

A

E

T

=

N

/E

P

E

T

S

=

L

A

IM

C

E

D

=

+

(Optional If Computer Front End Used)

Sensor

Return

Air Temp

Sensor

Bypass Air

Damper

System

Manager

s

D

lu

E

P

SYSTEM

W

e

n

M

o

8P

-Z

D

to

IE

3:3

S

u

0

P

A

M

U

7

R

C

/9

A

C

L

O

A

/01

O

01

N

c

s

E

u

n

e

M

3

2

6

1

Enter

5

r

9

a

e

l

4

C

s

8

u

n

i

M

7

0

.

c

e

D

*

MANAGER

m

r

a

l

A

n

o

i

t

a

ic

n

u

m

e

m

d

i

o

r

r

C

e

v

O

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

Other Controllers

(Optional - Up to 13 On Each Loop))

#16

Upgrade 13

EZ Zone/Auto-Zone

Optional Controllers and Accessories

In addition to the standard Zone Manager and Zone

Controllers, WattMaster offers many other controllers

and accessories to enhance your new Auto-Zone System. Optional Controllers that are available for use with

the Auto-Zone Plus system include the CV, CV-C, GPC,

Optimal Start Scheduler, Lighting Panel Controller and

Wetbulb Module. These controllers are not available

for use with the Auto-Zone Basic System. To utilize

any of the optional controllers you must upgrade your

system to the Auto-Zone Plus configuration. Accesso-

CV Controller

The CV Controller provides control of single zone constant volume rooftop or split system HVAC equipment.

CV controllers have four configurable relay outputs for

heating/cooling staging, a 0-10VDC output for economizer control, on board time clock for scheduling/night

setback functions and built in alarming features.

The CV Controller can be used with the Auto Zone

CV-C Controller

ries that are available for use with either the Auto-Zone

Plus or Basic System include the CommLink II Communications Interface, Remote Link, Room Sensors,

Round Zone Dampers and Rectangular Zone Dampers.

WattMaster also offers Communication Cable that is

color coded and labeled for the network communications loop and local communications loop.

Following are brief descriptions of the optional controllers and accessories that are available.

Plus System only. The CV can be programmed and

monitored from the either the System Manager or from

a personal computer which has the ZoneView Computer front end software installed. Up to 13 CV controllers can be installed on each local communications

loop of your Auto-Zone Plus system.

The CV-C Controller is a field configurable constant

volume unit controller that provides additional features

which are not available with the standard CV controller. CV-C controllers can be configured for applications

requiring CO2/IAQ economizer control, modulating HW

and CW control valves and dehumidification. The CVC relay outputs can be expanded via a plug-in expansion board for use in applications requiring additional

heating/cooling staging control.

GPC Controller

The GPC (General Purpose Controller) is a very versa-

tile controller that can be used for a variety of control

applications that are outside the function of our standard HVAC unit controllers. Each GPC controller has

(5) Universal Inputs that can accept contact closures,

thermistor temperature sensors, or 4-20mA/2-10VDC

signals. The controller has (5) digital outputs for on/off

control and (1) 0-10VDC analog output to modulate a

valve or damper. These inputs and outputs can be configured in a variety of ways using And/Or logic functions, time schedules, setpoints, etc. to perform many

different tasks.

The CV-C Controller can be used with the Auto-Zone

Plus System only. The System Manager cannot be used

to program or monitor the CV-C controller. CV-C controllers require that a personal computer which has the

ZoneView computer front end software installed be used

for all programming and monitoring. Up to 13 CV-C

controllers can be installed on each local communications loop of your Auto-Zone Plus system.

The GPC can be used for many applications including,

but not limited to:

• Control of Unit Heaters

• Control of Boilers

• Control of Exhaust Fans

• Monitoring of Temperature

• Monitoring of Humidity

• Monitoring of Status Contacts

The GPC Controller can be used with the Auto-Zone

Plus System only. The System Manager cannot be used

to program or monitor the GPC controller. GPC controllers require that a personal computer which has the

ZoneView computer front end software installed be used

for all programming and monitoring.

14 Upgrade

Lighting Panel Controller

EZ Zone/Auto-Zone

Adds building lighting control capability to the AutoZone System. The Lighting Panel Controller provides

up to (7) Independent time schedules and light levels

for control of up to (7) lighting circuits. The Lighting

Panel Controller relay outputs can be set for on/off relay or pulsed relay control depending on the lighting

system control contactor requirements. Pushbutton override is available for each lighting circuit by connecting

a momentary pushbutton to the Lighting Panel Controller board.

Optimal Start Scheduler

Provides expanded scheduling capabilities beyond those

incorporated with the standard Auto-Zone controllers.

The Optimal Start Scheduler provides for optimal

Start/Stop and up to (7) independent schedules with 2

Start/Stop events per day and (14) Start/Stop holiday

events per schedule.

Wetbulb Module

Provides wetbulb temperature monitoring for control

of all economizer equipped units on the Auto-Zone

system. The Wetbulb Module includes an Outside Air

Humidity Sensor for measuring outside air relative

humidity and utilizes the installed Outdoor Air Sensor

on the Auto-Zone System to calculate the wetbulb

temperature. This temperature is used by the economizer

control portion of the unit controller to provide accurate

The Lighting Panel Controller can be used with the Auto

Zone Plus System only. The System Manager cannot

be used to program or monitor the Lighting Panel Controller. Light Panel Controllers require that a personal

computer which has the ZoneView computer front end

software installed be used for all programming and

monitoring.

The Optimal Start Scheduler can be used with the Auto

Zone Plus System only. The System Manager cannot

be used to program or monitor the Optimal Start Scheduler Controller. This controller requires that a personal

computer which has the ZoneView computer front end

software installed be used for all programming and

monitoring.

economizer operation. The Wetbulb Module can be used

with the Auto-Zone Basic and Plus Zone Systems. The

Wetbulb Module can be monitored and programmed

from either the System Manager or from a personal

computer which has the ZoneView computer front end

software installed.

Accessories

WattMaster offers a complete line of accessories for

your Auto-Zone system. For part ordering information

and a complete list of accessories please see the AutoZone Product List Pricing manual and the Auto-Zone

• Remote Link - 14,400 baud modem for

remote access to any Auto-Zone system

• CommLink II - Required to connect the

Auto Zone Basic system to a personal

computer

• Round Air Dampers - Air damper with a

Zone Controller and actuator mounted in a

control enclosure. Available in pressure

dependent and pressure independent models.

Available in round duct sizes of 6”, 8”, 10”,

12”, 14” and 16” diameter.

Upgrade 15

Replacement Parts List Pricing Catalogs. Following is

a brief list of some of the accessories that are offered

for the Auto-Zone system.

• Rectangular Air Dampers - Rectangular,

aluminum frame opposed blade dampers.

Available in rectangular duct sizes from 8” x

8” to 24” x 36” in 2” increments of height and

width

• Rectangular Air Damper Kit - Zone

Controller and actuator mounted in a control

enclosure for use with Rectangular Air

Dampers

• ZoneView Computer Front End Software

Free when ordered with an EZ Zone to AutoZone upgrade

EZ Zone/Auto-Zone

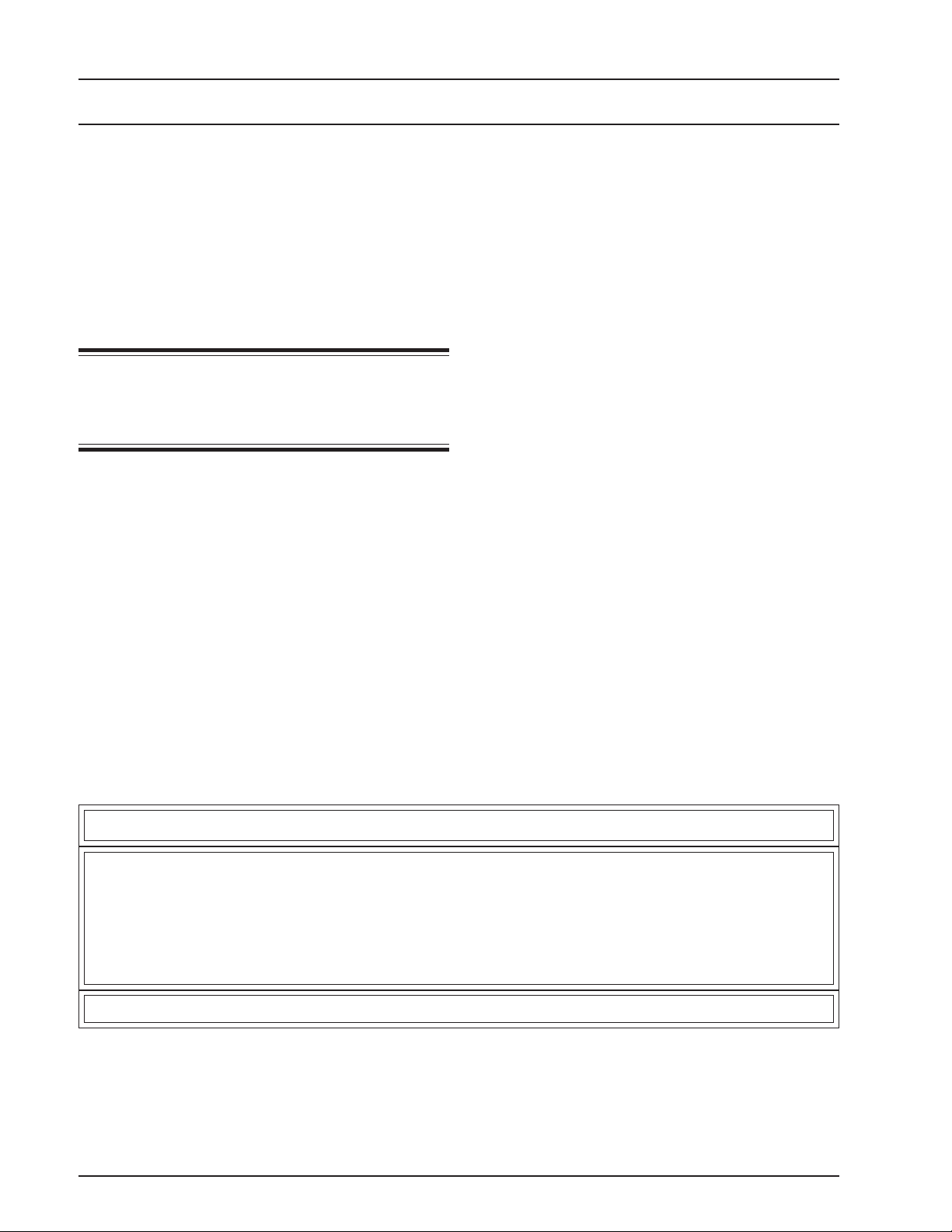

EZ Zone Wiring

The wiring diagram below depicts a typical existing

EZ Zone Master Controller wiring. This diagram is

shown for reference only. It’s intent is to show the difference between the EZ Zone system wiring and the

Bypass Air Damper

Actuator

90

75

60

45

Master Controller Board

Auto-Zone system wiring. All wiring should be connected per the specific Auto-Zone system wiring diagrams on the following pages.

Splice As

Required

Red

Blk

Grn

LO HI

Static

Pressure

Sensor

Static

Pick-up

Supply Air

Temp Sensor

Actuator Wiring

Interface

Feedback (BK)

Gnd (WH)

Open (YL)

Close (GR)

R

G

Y1

Y2

W1

HVAC Unit

W2

24VAC Only

Line

Voltage

24VAC

GND

RS-485

Communication cable

to Zone Controllers

Figure 1: Existing EZ Zone Master Controller Wiring

16 Upgrade

Auto-Zone Basic Wiring

EZ Zone/Auto-Zone

Figure 2 below depicts the wiring schematic that should

be used for the Auto-Zone Basic System upgrade as

described in Example 1 on pages 8 and 9 of this manual.

Bypass Air Damper

Actuator

90

75

60

45

24VAC

POWER

TB2

GND

Actuator Wiring

Interface

Feedback (BK)

Gnd (WH)

Open (YL)

Close (GR)

Y1

Y2

W1

HVAC Unit

W2

R

G

+

+

REC

FDBK

GND

OPEN

CLOSE

FAN

COOL1

COOL2

HEAT1

HEAT2

V3

V4

V5

V6

24VAC Only

Line

Voltage

24VAC

GND

See Note 1 &2

Notes:

1.)24 VAC Must Be Connected So

That All Ground Wires Remain

Common.

2.)All Wiring To Be In Accordance With

Local And National Electrical Codes

and Specifications.

NE5090

BYPASS

OPEN

BYPASS

CLOSE

G

FAN

Y1

COOL 1

Y2

COOL 2

W1

HEAT 1

W2

HEAT 2

Address Switch Must Always Be Set

To Address 0 on Zone Manager Board

Splice As

Required

LO HI

Static

Pressure

Sensor

Zone Manager

+

+

32BNET

16

8

As Shown

3.)All Communication Wiring To Be 18

Ga. Minimum, 2 Conductor Twisted

Pair With Shield. Belden #82760 Or

Equivalent.

+

5.11V

ADJUST

Auto-Zone COOL MODE

06/11/95 03:48PM FRI

OCCUPIED

NO ALARM(S)

LCD DISPLAY

&

KEYPAD

1 2 3BA

4 5 6

0*#D

D

D

D

D

D

D

D

D

18

20

22

24

1

19

21

23

7

MADE IN U.S.A.

C1992

RockerDown

SW

1

4

>

ADD

OFF

1

4

2

B

32

8

N

1

6

ET

RS-485

Communications To Zone

Controllers

These Switches Must Be

In The OFF Position

As Shown

RockerDown

>

ADD

OFF

1

2

Be sure to pay strict attention to all warnings and cautions listed on the schematic.

Supply Air Temp.

Sensor

Return Air Temp.

Sensor

Outdoor Air Temp.

Auxiliary Inputs

( Dry Contacts )

Aux3

Aux2

Forced

Filter

Occupied

Alarm

Mode

Warning:

See Figure 11 in this manual for

important wiring instructions

regarding Honeywell

Economizer Actuators

Economizer Actuator

WARNING!

Use Extreme Care When Wiring

Economizer Actuators

Never Connect Or Disconnect

Wiring With Power Applied!

Never Apply Power If The

Gnd ( 1 Com ) Terminal On The

Actuator Is Not Connected.

Belimo Actuator Wiring Shown.

Consult Factory For Other

Models Of Economizer Actuators.

Some Actuators Require Isolation

Transformers In Order To Prevent

Damage To The Controller Board.

Sensor

Aux1

Economizer

Disable

5U

4Y2

3Y1

2+

1 COM

BELIMO

AF24-SR

133 IN-LB

C987

Static

Pick-up

Grn

Red

Blk

SEN

TB12

PRESSURE

SO

R

JA

GND

+5V

SIG

C

K

PJ1

ANALOG

INPUTS

+12V

+

+

SAT

RAT

OAT

AUX1

+

AUX2

AUX3

GND

GND

+

EXHAUST

CONTACTS

N.O.

RIBBON

CABLE

ANALOG

OUTPUTS

A1

A2

G

TB2

EXP

BUSS

P1

R5

C

R6

C

1

+

2

To Relief / Exhaust Fans

COMM

T

75176

SH

RS-485

COMM DRIVER

R

Local Loop

Zone Manager

Address Switch

ADD

1

2

4

8

16

32

B

NET

4.)For Individual Component Wiring See

Specific Component Wiring Diagram.

5.)It Is Recommended That All

Controllers Address Switches Are

Set Before Installation.

Figure 2: New Auto-Zone Basic Controller Wiring

Upgrade 17

EZ Zone/Auto-Zone

Auto-Zone Plus Wiring

Figure 3 below depicts the wiring schematic that should

be used for the Auto-Zone Plus System upgrade as described in Example 2 on pages 10 and 11 of this manual.

This schematic is also used for wiring of Example 3 on

Bypass Air Damper

Actuator

90

75

60

45

Actuator Wiring

Interface

Network Loop RS-485

19200 Baud

To Other Zone

Managers and/or

CommLink on

System

R

G

Y1

Y2

W1

HVAC Unit

W2

24VAC Only

Line

Voltage

24VAC

GND

See Note 1 &2

Notes:

1.)24 VAC Must Be Connected So

That All Ground Wires Remain

Common.

2.)All Wiring To Be In Accordance With

Local And National Electrical Codes

and Specifications.

3.)All Communication Wiring To Be 18

Ga. Minimum, 2 Conductor Twisted

Pair With Shield. Belden #82760 Or

Equivalent.

24VAC

GND

2

IC

EXP

PORT

+

REC

T

SHIELD

R

T

SHIELD

R

PWR

+

FDBK

GND

OPEN

CLOSE

V3

V4

R

FAN

COOL1

COOL2

HEAT1

HEAT2

NE5090

K1

OPEN

K2

CLOSE

T

SH

R

NETWORK

T

SH

R

Splice As

Required

LO HI

Zone Manager

V

R

3

7824

D

U

25

14

+

1

2

4

8

16

32

LOOP

LOCAL

LOOP

Local Loop

4.)Only One Outside Air Sensor Is

Required Per System. It May Be

Connected To Any CV Controller Or

Zone Manager On The System. If A

Wetbulb Module Controller Is Used The

OA Sensor Must Be Connected To The

Wetbulb Module.

5.)For Individual Component Wiring See

Specific Component Wiring Diagram.

V

R

2

C

C

7812

27

26

R

+

+

40

5.11V

ADJUST

MINILINK

SW

1

C

ADD

16

2

4

B

A

8

pages 12 & 13 of this manual. Be sure to pay strict attention to all warnings and cautions listed on the schematic.

Supply Air Temp.

Sensor

Static

Pressure

Sensor

Static

Pick-up

Red

Grn

Blk

S

E

P

N

R

S

E

O

S

R

GND

+5V

SIG

SU

JA

R

C

E

K

PJ1

D1

D2

D3

D4

RS-485

Communications To Zone

Controllers, CV Controllers

And/Or System Manager

ANALOG

R7

INPUTS

R8

+12V

+

+

SAT

R9

R10

RAT

OAT

AUX1

+

AUX2

AUX3

GND

GND

+

EXHAUST

CONTACTS

ANALOG

OUTPUTS

A1

A2

G

COMM

SH

N.O.

To Relief / Exhaust Fans

TB2

T

R

TB3

Return Air Temp.

Sensor

Outdoor Air Temp.

Sensor

(See Note 4)

Auxiliary Inputs

( Dry Contacts )

Aux1

Economizer

Disable

Aux2

Filter

Alarm

Aux3

Forced

Occupied

Mode

WARNING!

Use Extreme Care When Wiring

Economizer Actuators

Never Connect Or Disconnect

Wiring With Power Applied!

Never Apply Power If The

Gnd ( 1 Com ) Terminal On The

Actuator Is Not Connected.

Belimo Actuator Wiring Shown

Consult Factory For Other

Models Of Economizer Actuators

Some Actuators Require Isolation

Transformers In Order To Prevent

Damage To The Controller Board.

Economizer Actuator

5U

BELIMO

4Y2

AF24-SR

3Y1

133 IN-LB

2+

1 COM

Warning:

See Figure 11 in this manual for

important wiring instructions

regarding Honeywell economizer

actuators

Figure 3: Existing Auto-Zone Plus Controller Wiring

18 Upgrade

16

32

8

4

2

1

Caution!

The MiniLinks Must Have Address Switches Set Between 1

And 30 (Up To 30 MiniLinks (Mounted on Zone Managers)

Are Allowed Per Auto-Zone Plus System). The MiniLinks

Should Be Addressed In Consecutive Order Starting With

Address #1. Address #1 Must Be Present On The Loop For

The System To Function.

Address Switch Shown Is

Set For Address 1

Address Switch Must Always Be Set

To Address 17 on Zone Manager Board

As Shown

Address Switch Shown Is

Set For Address 4

Zone Manager

Address Switch

MiniLink

Address Switch

These Switches Must Be

In The OFF Position

As Shown

These Switches Must Be

In The OFF Position

As Shown

Caution:

The Power To The Zone Manager Must Be

Removed And Reconnected After Changing The

MiniLink Or Zone Manager Address Switch Settings

In Order For Any Changes To Take Effect.

Caution:

Disconnect All Communication Loop Wiring From

The Zone Manger Before Removing Power.

Reconnect Power And Then Reconnect

Communication Loop Wiring To Zone Manager.

ADD

ADD

ADD

1

2

4

8

16

32

B

NET

ADD

All Zone Managers On System Must Be

Addressed As 17

Network Switch As ShownMust Be ON

The Address For Each MiniLink

Must Be Unique To The Other MiniLinks

On The Network Loop. Loop #1 MiniLink

Should Be Addressed As #1

Loop #2 MiniLink Should Be Addressed

As #2 Etc..

ADD

ADD

ADD

32

3232BBNET

NET

16

16

16

8

8

8

4

4

4

1

1

1

2

2

2

OFF >

OFF

>

OFF

>

RockerDown

RockerDown

RockerDown

HEAT2

HEAT1

COOL2

COOL1

FAN

R

LOCAL

LOOP

T

SH

R

TB3

COMM

T

SH

R

MINILINK

V4

V3

CLOSE

OPEN

FDBK

GND

OPEN

K1

NETWORK

LOOP

SH

R

T

CLOSE

K2

ANALOG

OUTPUTS

A2

G

TB2

A1

Zone Manager Board

(Under MiniLink Board)

MiniLink Address Switch Setting

Zone Manager Address Switch Setting

MiniLink Board

(Mounted On Top Of Zone Manager Board)

Auto-Zone Plus Address Switches

EZ Zone/Auto-Zone

The Auto-Zone Plus Zone Manager has two different

address switches. One is located on the main Zone

Manager board and one is located on the MiniLink board

that is located on the top of the Zone Manager board.

The Zone Manager board address should always be set

to address 17 on an Auto-Zone Plus system. The

MiniLink board should be addressed with a unique number for each Zone Manager on the system. It is recommended that you start with address 1 and address each

Zone Manager consecutively. See Figure 4 below for

detailed information.

Figure 4: New Auto-Zone Plus Address Switch Setting

Upgrade 19

EZ Zone/Auto-Zone

HVAC Staging Connections

Figure5 below shows the EZ Zone Master Controller

wiring. Figure 6 below depicts the wiring schematic

that should be used for wiring of all Auto-Zone Zone

Managers boards. As can be seen below, the Auto-Zone

24VAC-R

Fan-G

Cool - Y1

Cool - Y2

Heat - W1

Heat - W2

OUT1

FAN

OUT2

COOL1

OUT3

COOL2

OUT4

HEAT1

OUT5

HEAT2

Zone Manager wiring is much simpler than the EZ Zone

Master Controller wiring. Be sure to pay strict attention to all warnings and cautions listed on the schematic.

The EZ Zone Master Controller relay outputs consist

of a series of five double pole

terminal blocks. Wire jumpers between terminal blocks

are required to the common

of each relay.

Figure 5: Existing EZ Zone HVAC Wiring

24 VAC -R

Fan-G

Cool - Y1

Cool - Y2

Heat - W1

Heat - W2

R

FAN

COOL1

COOL2

HEAT1

HEAT2

The Auto-Zone Zone Manager wiring has been simplified. There is only one terminal block with connections

clearly marked for ease of installation. Jumpers are no

longer required since the

commons are tied together

within the circuit board.

Figure 6: New Auto-Zone HVAC Wiring

20 Upgrade

Sensor Connections

C4

Splice As

Required

Red

Grn

Blk

PRESSURE

To Bypass

Actuator Feedback

SENSOR

TB12

SIG

ANALOG

+5V

GND

INPUTS

+V

+V

1

2

3

4

5

6

7

8

G

G

Figure 7: Existing EZ Zone Master Controller Sensor Wiring

LO HI

Supply Air

Sensor

Static

Pressure

Sensor

Static

Pick-up

The EZ Zone Master Controller sensor connections are located on the right side of the board.

Only a supply air temperature sensor and the

bypass actuator feedback are connected here.

EZ Zone/Auto-Zone

Splice As

D2

D3

D4

D5

D6

D8

PJ1

Required

SE

PR

N

ESSU

SO

R

JAC

R

E

+5V

SIG

K

R7

R8

C

4

+

R9

R10

TB1

GND

ANALOG

INPUTS

+12V

+

SAT

RAT

OAT

AUX1

+

AUX2

AUX3

GND

GND

+

EXHAUST

CONTACTS

TB3

N.O.

LO HI

Static

Pressure

Sensor

Static

Pick-up

Supply Air Temp.

Sensor

Return Air Temp.

Sensor

Outdoor Air Temp.

Sensor

The Auto-Zone Zone Manager includes terminals for connecting the following sensors:

• Supply Air Temperature

• Return Air Temperature

• Outside Air Temperature

The terminals are marked SAT, RAT, and OAT

for ease of wiring. Auxiliary input terminals

AUX1, AUX2 and AUX3 are used for Economizer Disable, Dirty Filter Alarm and Forced

Occupied Mode. Bypass damper feedback has

TB4

ANALOG

OUTPUTS

A1

A2

G

TB5

been relocated (see next page).

Figure 8: New AZ Zone Manager Sensor Wiring

Upgrade 21

EZ Zone/Auto-Zone

Bypass Damper Connections

PRESSURE

SENSOR

Actuator Wiring

Interface

Feedback

Gnd

Open

Close

24 VAC

OUT6

OUT7

BYPASS

OPEN

BYPASS

CLOSE

SIG

+5V

GND

Figure 9: Existing EZ Zone Bypass Damper Wiring

NE5090

K1

OPEN

K2

CLOSE

V3

V4

NETWORK

T

SH

R

Actuator Interface

Wiring

Feedback (Bk)

Ground (Wh)

Open (Yl)

Close (Gr)

REC

FDBK

GND

OPEN

CLOSE

TB12

ANALOG

INPUTS

+V

+V

1

2

3

4

5

6

7

8

G

G

The EZ Zone Master Controller has two double pole

terminal blocks for the bypass actuator connections.

These terminal blocks must

be tied together by an external jumper. In addition, the

feedback connection from the

actuator must be terminated

on the other side of the controller .

The Auto-Zone Zone Manager wiring has been simplified. There is only one terminal block with connections

clearly marked for ease of

installation. The actuator

“feedback” connection is

now terminated at the same

location as all the connections. Jumpers are no longer

required since the commons

are tied together within the

circuit board.

Figure 10: New Auto-Zone Bypass Damper Wiring

22 Upgrade

Honeywell Economizer Actuators

EZ Zone/Auto-Zone

When the HVAC units that are being upgraded to

the Auto-Zone system are equipped with either the

Honeywell M7415 or M7405 economizer actuators, an interface module and a isolation transformer

are required in order to connect and use the economizer outputs on the Auto-Zone system. The interface module converts the Honeywell actuator from

0-5VDC operation to 0-10VDC operation. An isolation transformer is also required for this installation to prevent voltage feedback to the control system. The OE266-01 Actuator Interface Module kit

Honeywell M7415 Actuator

Without Interface Module

M7415A1014

025-26250

TR

TR1

T

T1

P

P1

SENSOR

24VAC

MIN

POSN

is available from WattMaster. This kit includes both

the MS000204 Interface Module and a 24VAC Isolation Transformer.

Warning: Both the interface module and a 24VAC

isolation transformer must be installed as shown

below when connecting to the Honeywell M7415

or M7405 actuator. Failure to install these components as shown can result in serious damage to

the Auto-Zone controller board.

Honeywell M7415 Actuator With

Q769C1007 (WM # MS000204)

Interface Module Installed

7415A1014

M

Place Interface Module On

Terminals P1 and P

24VAC

SENSOR

025-26250

TR

TR1

T

T1

Installing MS000204 Interface Module To Honeywell M7415 Or 7405 Actuator

ANALOG

INPUTS

+12V

SAT

RAT

OAT

AUX1

AUX2

AUX3

GND

GND

EXHAUST

CONTACTS

N.O.

ANALOG

OUTPUTS

A1

A2

G

TB2

Zone Manager

A1

G

24 VAC - Isolation Transformer

Q769C1007 Interface Module

+

-

(WM # WP000019)