Page 1

$XWR=RQH

Page 2

Page 3

1ed_J_^U3_^db_\CicdU]c

g

)

y

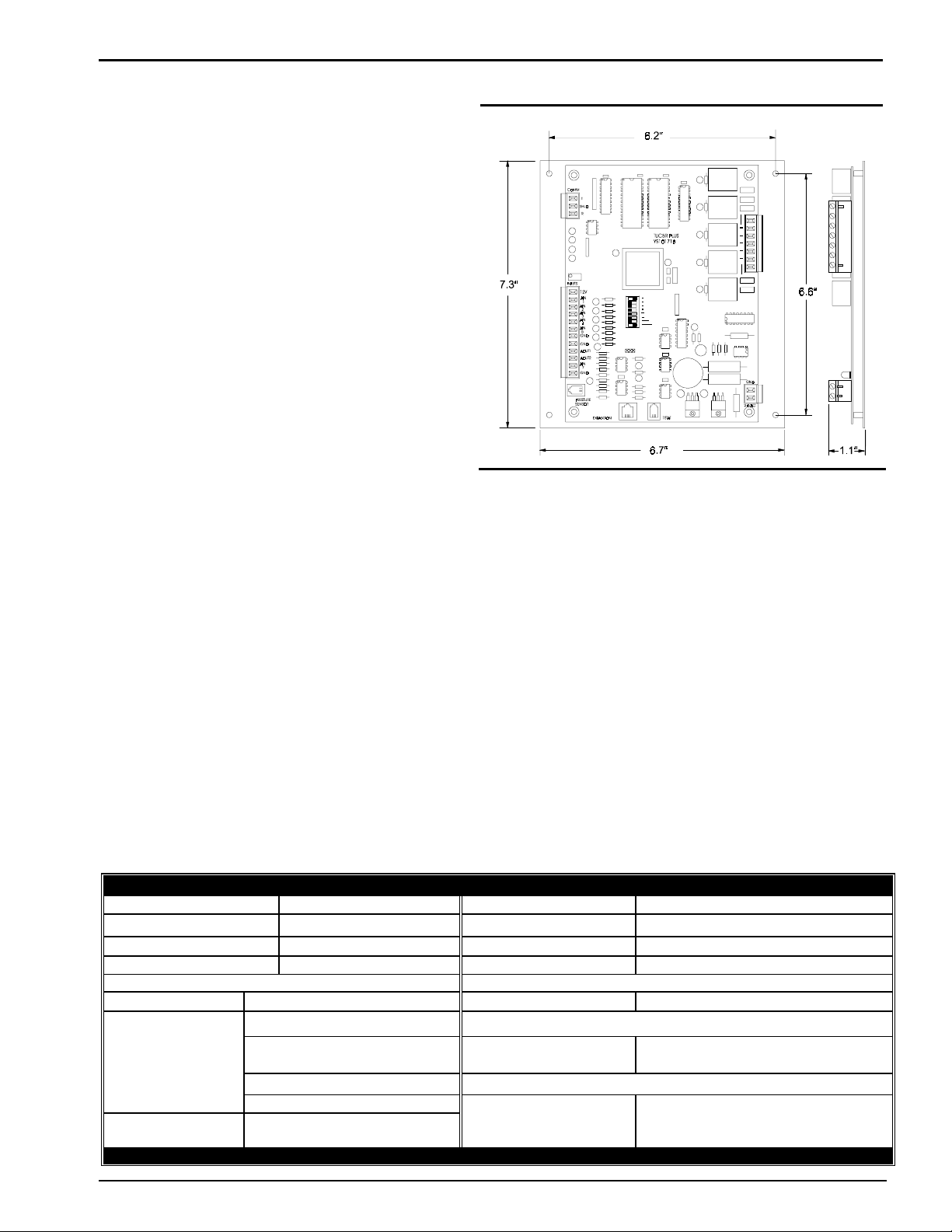

Description

The CV-C Controller is a configurable controller that

allows for user configurable inputs and outputs. CV-C

Controllers also have provisions for mounting a Relay

Expansion Board to provide additional heating or cooling

staging capability.

Analog Inputs

Only Analog Input #1 (Space Temp Sensor Only) and

Analog Input #6 (Airflow Sensor Only) have a specific

function that cannot be changed. All other inputs are user

configurable in one of the following modes:

•

0 - Not Used ( Nothing connected to this input )

•

1 - Slide Offset (Requires Flush Mount Wall

Sensor with this Option)

•

2 - Supply Air Temperature

•

3 - Return Air Temperature

•

4 - Mixed Air Temperature

•

5 - Outdoor Air Temperature (Will broadcast to

ALL other controllers)

•

6 - Humidity Sensor (4-20 ma scaling)

•

7 - Humidity Sensor (0-5 VDC scaling)

•

8 - CO² Sensor (4-20 ma scaling)

•

9 - CO² Sensor (0-5 VDC scaling)

10

•

- Relief Pressure Sensor (Requires 0-5 VDC

±0.3" WG Sensor)

11

•

- Dirty Filter Contact (Normally Open)

12

•

- Alarm Contact (Normally Open)

13

•

- Alarm Contact (Normally Closed)

14

•

- Fan Status Contact (Normally Open)

Analog Outputs

There are two Analog Outputs available on this

controller. They are both user configurable as follows:

•

0 - Not Used (Nothing connected to this

output)

•

1 - Economizer (Requires either Supply Air or

Mixed Air Sensor)

•

2 - Relief Fan VFD Signal (Requires Relief

Pressure Sensor)

•

3 - Chilled Water Valve (Requires Supply

Sensor)

•

4 - Hot Water Valve (Requires Supply Sensor)

•

5 - Humidification/De-Humidification

(Requires Humidity Sensor)

3F33_^db_\\Ub

Relay Outputs

Only Relay Output #1 (Fan On/Off Only) has a specific function

that cannot be changed. All other outputs are user configurable

in one of the following modes:

•

0 - Not Used (Nothing connected to this output )

•

1 - Heating Stage

•

2 - Cooling Stage

•

3 - Humidifier Enable

•

4 - De-Humidifier Enable

•

5 - Scheduled Relay from Internal Schedule

•

6 - Scheduled Relay from External Schedule (Only 1

Available!)

There are a total of 12 relays that can be configured. Four are

found on the Controller itself (R2 - R5) and the remaining eight

(R6 - R13) are found on the Optional Relay Expansion Board that

can be connected to the PJ2 expansion input.

Mounting

The CV-C Controller is provided with an integral backplate for

mounting inside of a control enclosure. An optional factory control

enclosure for the CV-C Controller is available.

Technical Data CV-C Controller

Power 24 Volt AC Weight 1.5 lb.

Power Consumption 12 VA Maximum Network Connection RS-485

Operating Temp

Operating Humidity 90% RH Non-CondensingCommunications RS-485 - 9600 Baud

10°F to 149°F

Inputs: Outputs:

Quantity Available Types Quantity Available Types

Type III-10kohm Sensor

6

1 Modular Phone Jack For

WattMaster reserves the right to change specifications without notice

Form: AZ-CVC-DS-01A-599-0101

Optional Airflow or SP Sensor

0-10 VDC Sensor

0-5 VDC Sensor

4-20mA Sensor

Contact Closure

Binar

Protocol HSI Open Protocol Token Passin

Binary

5 Onboard Relays (2 Amp @ 24 VAC

N.O. Contacts with Suppressors

Analog

2 0-10 Volt DC Out

One Year Warranty

Page

1 of 1

Page 4

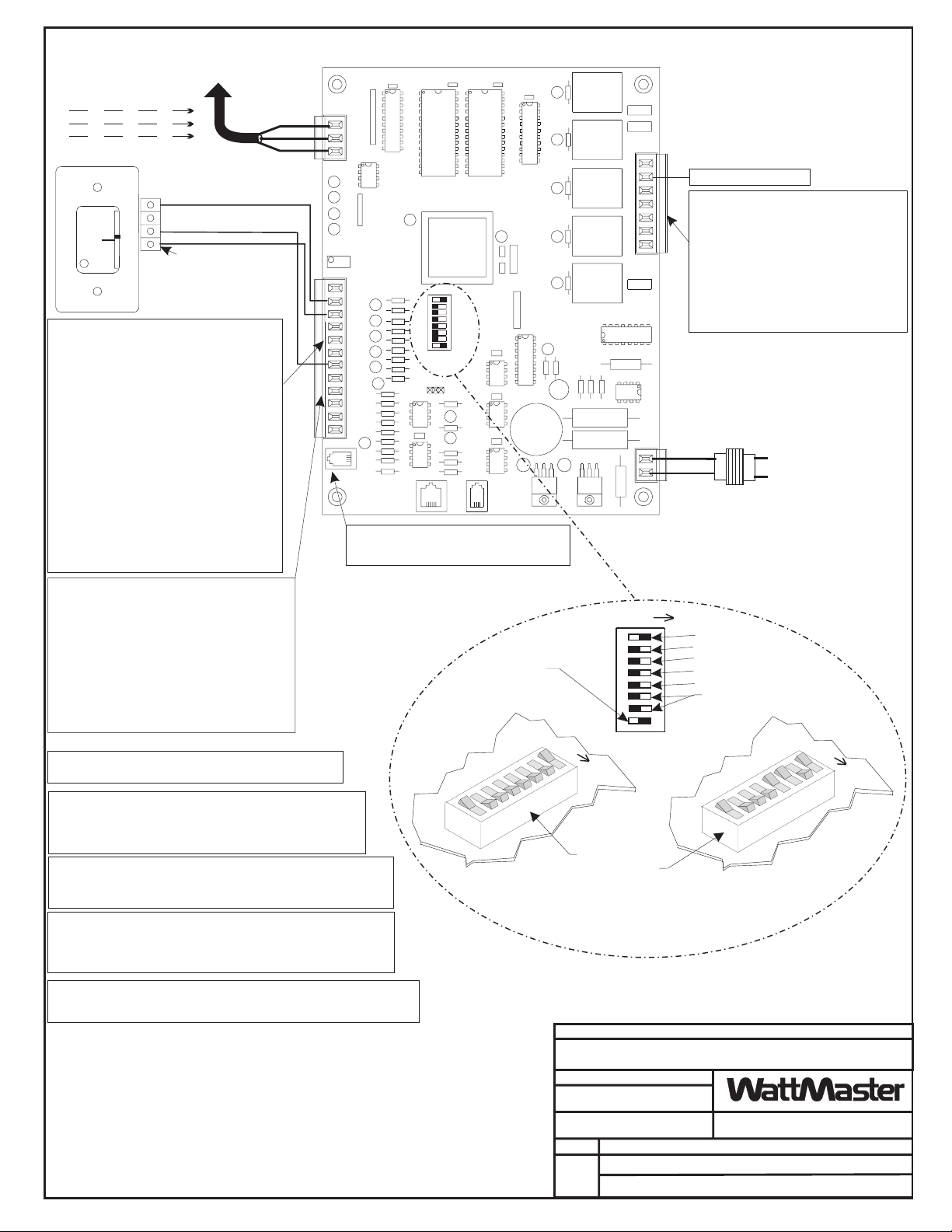

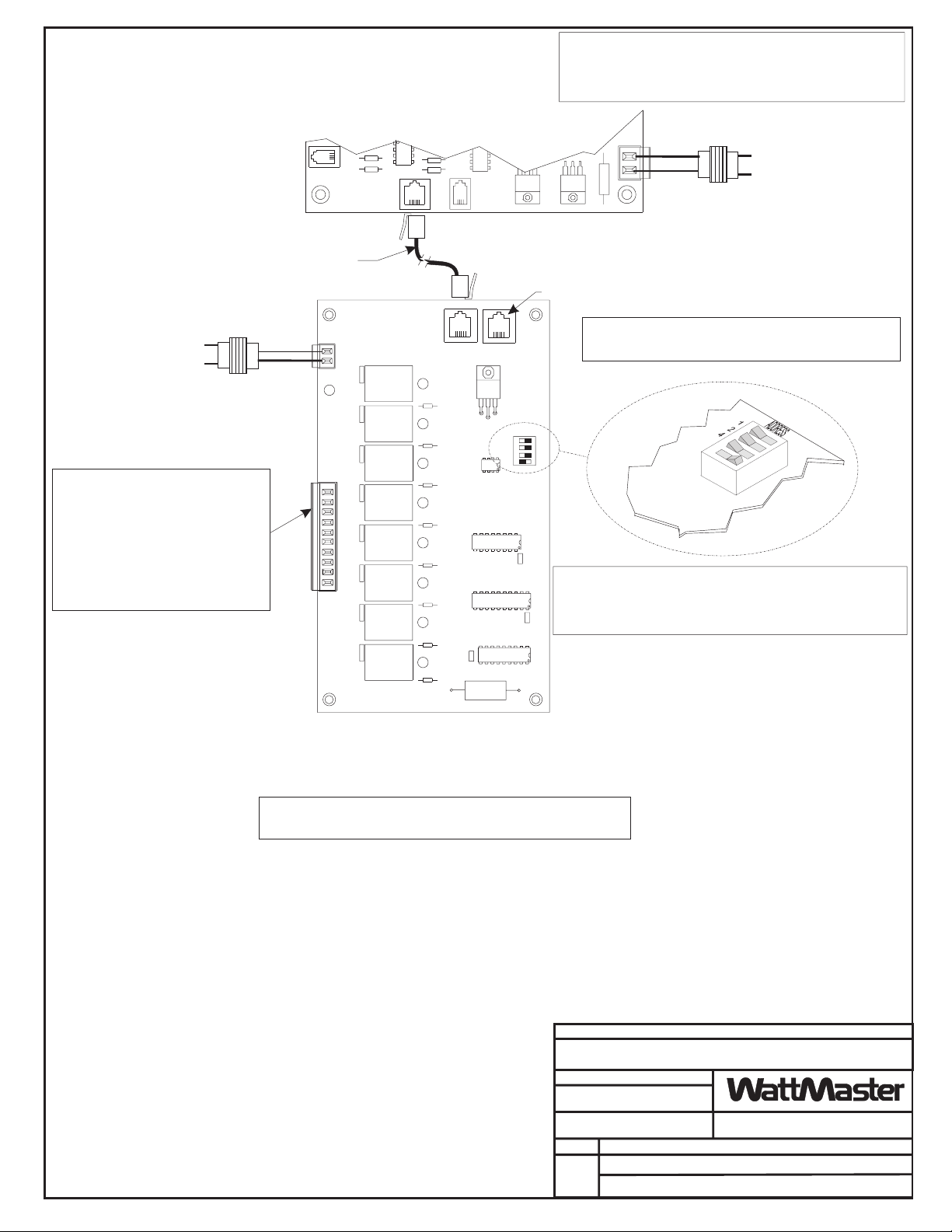

Connect To Next Controller And/Or

All Comm Loop Wiring Is

Straight Thru

T

T

SH

SH

R

SH

R

Room Sensor

W

A

R

M

E

R

NORMAL

C

O

O

OVR

L

E

R

AIN2 Thru AIN5 & AIN7 May Be User

Configured For The Following:

0 - Not Used ( Nothing connected to this input)

1 - Slide Offset

(Requires Flush Mount Wall Sensor)

2 - Supply Air Temperature

3 - Return Air Temperature

4 - Mixed Air Temperature

5 - Outdoor Air Temperature

(Will broadcast to ALL other controllers)

6 - Humidity Sensor (4-20 mA scaling)

7 - Humidity Sensor (0-5 VDC scaling)

8 - CO² Sensor (4-20 mA scaling)

9 - CO² Sensor (0-5 VDC scaling)

10 - Relief Pressure Sensor

(Requires 0-5 VDC ±0.3" WG Sensor)

11 - Dirty Filter Contact (Normally Open)

12 - Alarm Contact (Normally Open)

13 - Alarm Contact (Normally Closed)

14 - Fan Status Contact (Normally Open)

MiniLink On Local Loop

T

T

SH

R

R

TMP

GND

AUX

Connection To

AUX Terminal is Reqd

Only When Sensor

Is Specified With

Slide Adjust Option

Local Loop RS-485

9600 Baud

(See Note 3).

CV- C Controller

COMM

T

SHLD

R

TUC5R PLUS

YS101718

INPUTS

12V

AIN

1

AIN

2

AIN

3

AIN

4

AIN

5

GND

GND

AOUT1

AOUT2

AIN

7

GND

PRESSURE

SENSOR

EXPANSION

AIN6 (Phone Jack) Can Only Be Configured

For An Airflow Sensor And Is Used For

Status or To Verify Fan Operation Only

1

2

4

8

16

32

TOKEN

NETWORK

T'STAT

1-3

M

O

C

R1

R2

R3

R4

R5

4-5

M

O

C

GND

24VAC

R - Fan ON/OFF Only

Relay Outputs R2 Thru R5 May Be User

Configured For The Following:

0 - Not Used (Nothing connected to this

output )

1 - Heating Stage

2 - Cooling Stage

3 - Humidifier Enable

4 - De-Humidifier Enable

5 - Scheduled Relay from Internal Schedule

6 - Scheduled Relay from External Schedule

(Only 1 Available!)

Required VA For Transformer

Each CV-C Controller = 20VA Max.

GND

24VAC

See Note 1

Line Voltage

AOUT1 & AOUT2 May Be User Configured For

The Following:

0 - Not Used (Nothing connected to this output)

1 - Economizer

(Requires Supply or Mixed Air Sensor

2 - Relief Fan VFD Signal

(Requires Relief Pressure Sensor)

3 - Chilled Water Valve

(Requires Supply Sensor)

4 - Hot Water Valve (Requires Supply Sensor)

5 - Humidification / De-Humidification

(Requires Humidity Sensor)

Note: All Temperature Sensors Must Be Thermistor Type III

Which Provide 10K Ohms Resistance @77 Deg. F

Caution!

CV-C Controllers Must Have Address Switches Set Between 1

And 30 When Used With CV or CV-EX Systems. Auto-Zone

Plus Systems Require That The Address Switches Be Set

Between 18 And 30.

Note:

The Power To The CV-C Controller Must Be Removed And

Reconnected After Changing The Address Switch Settings In Order

For Any Changes To Take Effect.

Caution:

Disconnect All Communication Loop Wiring From The CV-C Controller

Before Removing Power From The CV-C Controller. Reconnect Power

And Then Reconnect Communication Loop Wiring.

Note:

Set-up, Programming And Monitoring Of The CV-C Controller Requires The

Use Of A Personal Computer And ZoneView AZ Software.

Notes:

1.)24 VAC Must Be Connected So

That All Ground Wires Remain

Common.

2.)All Wiring To Be In Accordance

3.)AllCommunication Wiring To Be

2 Conductor Twisted Pair With

Shield. Use Belden #82760 Or

Equivalent.

With Local And National Electrical

Codes And Specifications.

This Switch Must Be

In The ON Position

As Shown

ADDRESS

Address Switch Shown Is

Set For Address 1

Must Be Unique To The Other Controllers

ADDRESS ADD

ADD

Controller

Address Switch

Address Switch Shown Is

The Address For Each Controller

On The Local Loop

FILENAME

CVCWIR1.CDR

DATE:

07/08/99

PAGE

1

DESCRIPTION:

CV-C Controller Wiring

1

2

4

8

16

These Switches Should Be

In The OFF Position

As Shown

ADDRESS

Set For Address 13

JOB NAME

CONTROLS

DRAWN BY:

B. CREWS

OE747

ADD

Page 5

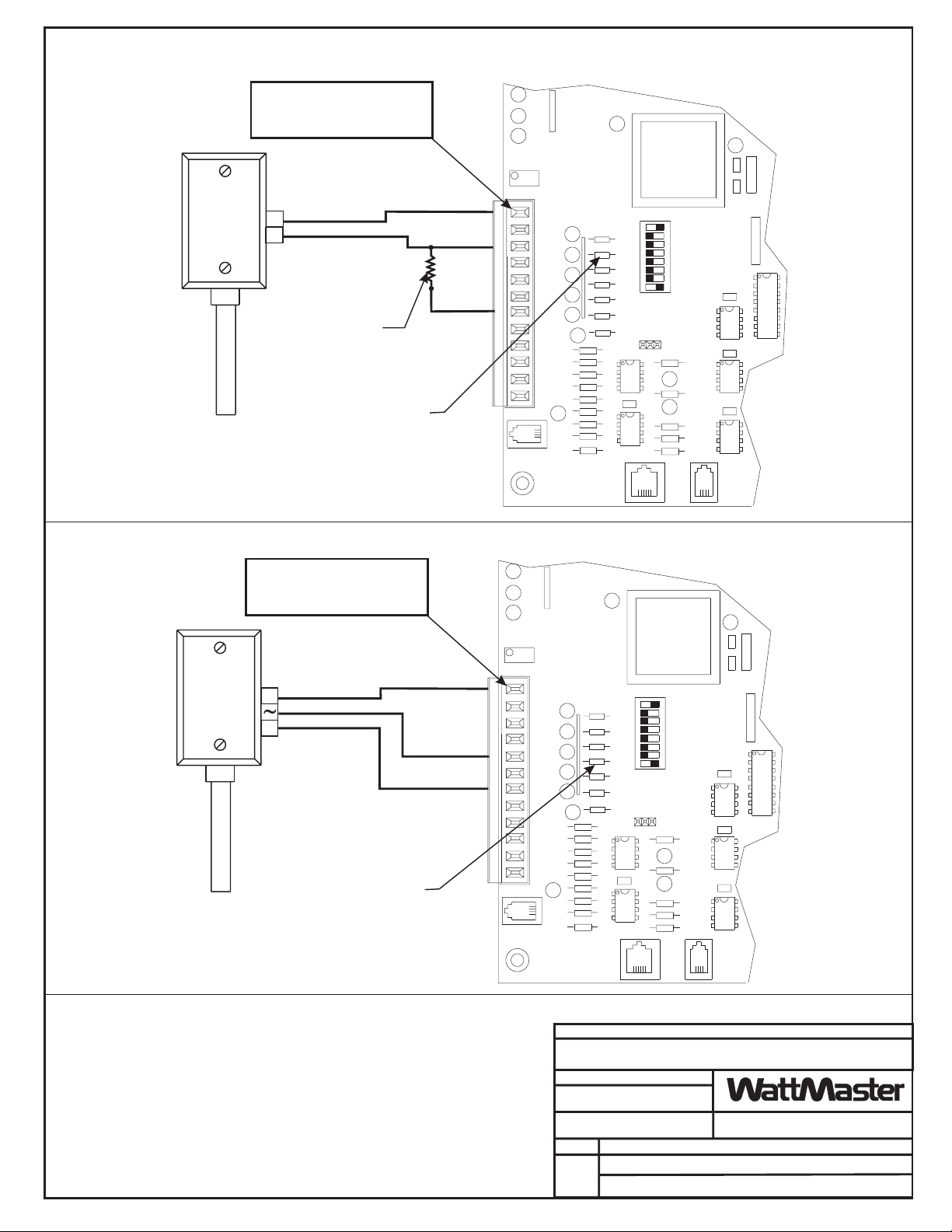

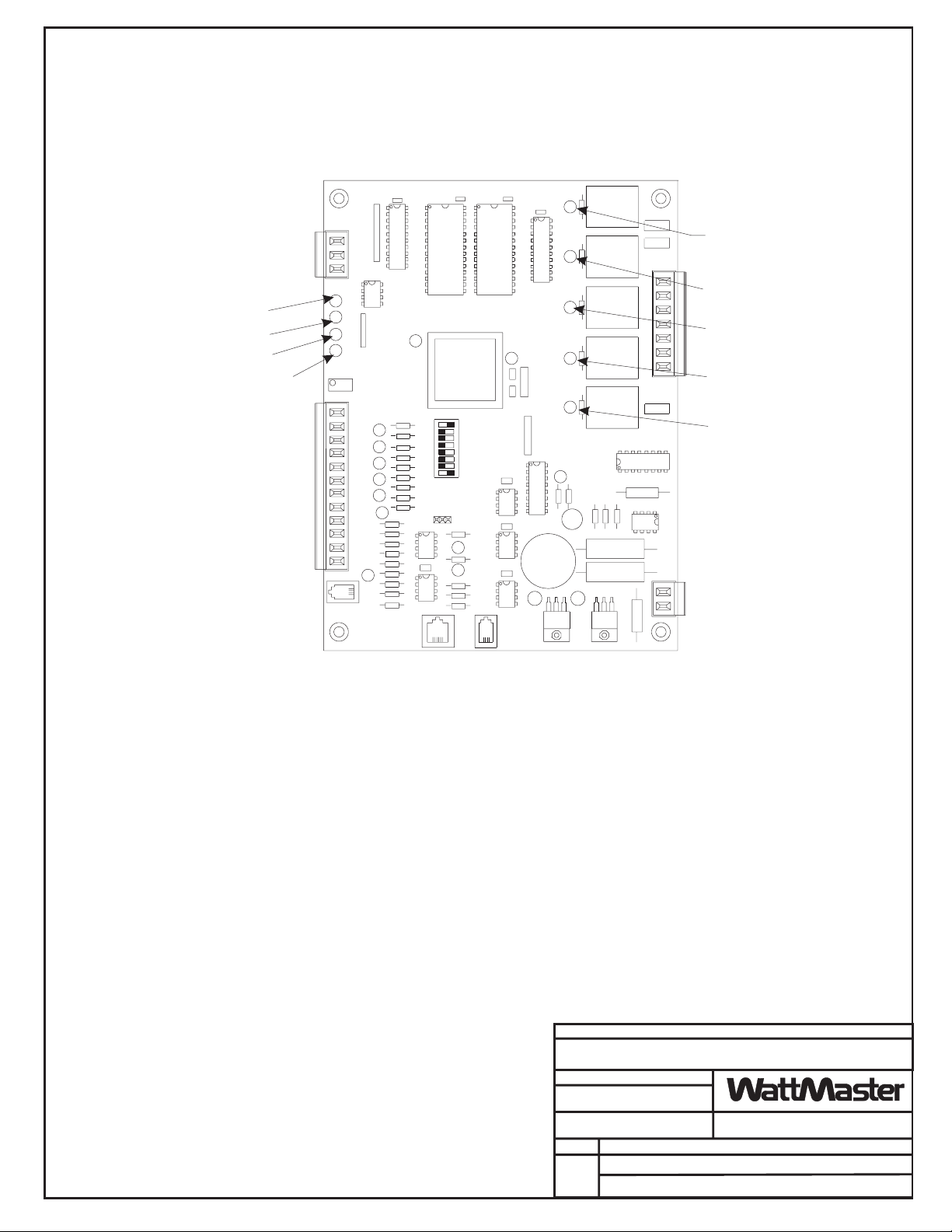

4-20ma

Sensor

Note: Terminal that is Labeled

“12V” on the Terminal Block

has been Electrically Modified

and is Actually 24 Volts

+

-

250 ohm Resistor

Installed Between the

AIN2 Input Terminal

and the GND Terminal

Resistor Must be of 1%

Accuracy or Better

The Pull-up Resistor (PU2),

for the Associated In

Must be Removed When a

4-20ma Sensor is Used

put (AIN2),

4-20ma Sensor Installation

INPUTS

12V

AIN

1

AIN

2

AIN

3

AIN

4

AIN

5

GND

GND

AOUT1

AOUT2

AIN

7

GND

PRESSURE

SENSOR

PU1

PU2

PU3

PU4

PU5

PU7

1

2

4

8

16

32

TOKEN

NETWORK

CV- C Controller

0-5VDC

Sensor

Note: Terminal that is Labeled

“12V” on the Terminal Block

has been Electrically Modified

and is Actually 24 Volts

+

-

The Pull-up Resistor (PU4),

for the Associated In

Must be Removed When a

0-5 VDC Sensor is Used

put (AIN4),

EXPANSION

0-5VDC Sensor Installation

INPUTS

12V

AIN

1

AIN

2

AIN

3

AIN

4

AIN

5

GND

GND

AOUT1

AOUT2

AIN

7

GND

PRESSURE

SENSOR

PU1

PU2

PU3

PU4

PU5

PU7

1

2

4

8

16

32

TOKEN

NETWORK

T'STAT

CV- C Controller

Notes:

1.)24 VAC Must Be Connected So

That All Ground Wires Remain

Common.

2.)All Wiring To Be In Accordance

With Local And National Electrical

Codes And Specifications.

EXPANSION

FILENAME

CVCHUMID1.CDR

DATE:

06/01/00

PAGE

1

CV-C Humidity Sensor Wiring

T'STAT

JOB NAME

CONTROLS

DRAWN BY:

DESCRIPTION:

Auto-Zone

B. CREWS

Page 6

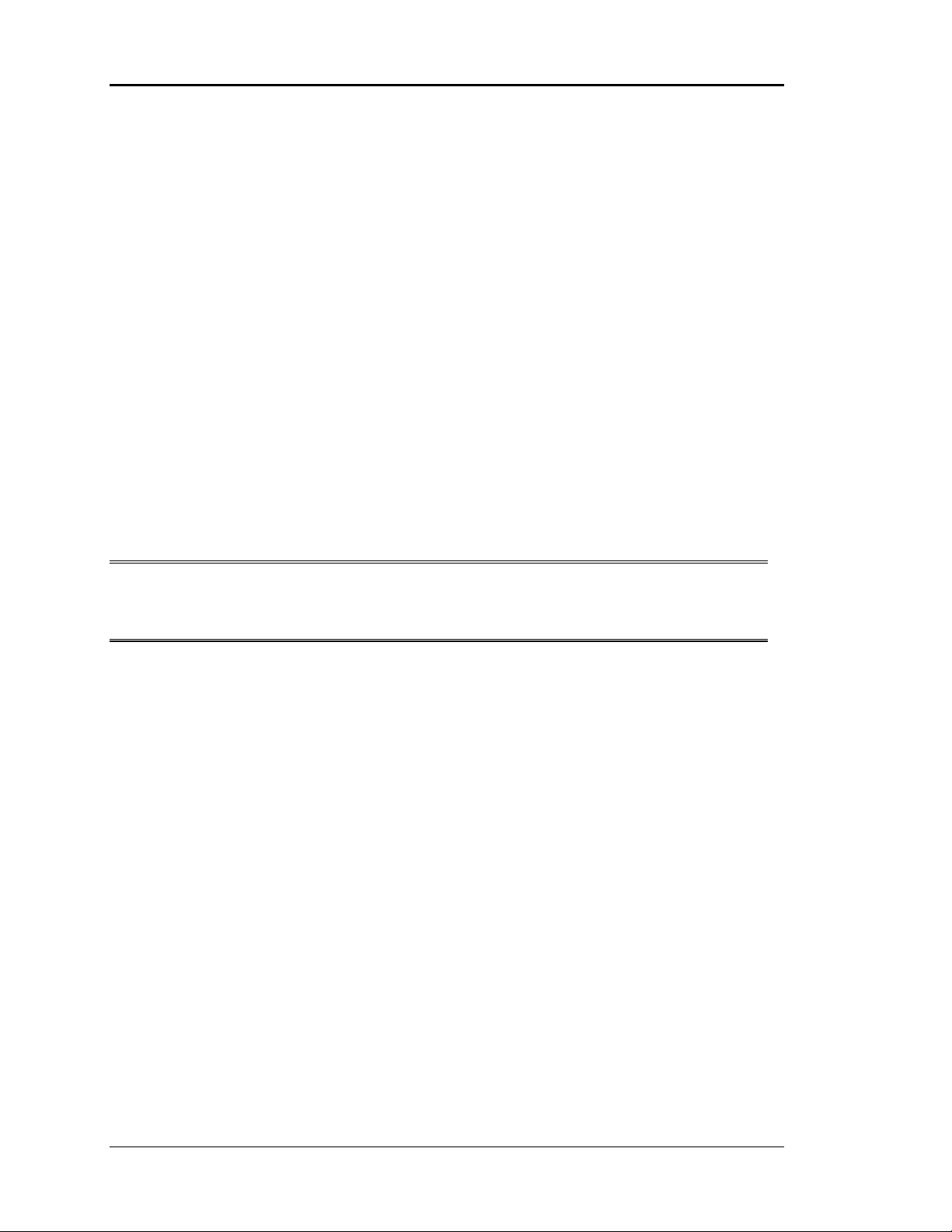

Warning:

If One Transformer Is Used To Power The CV-C Controller And The

Relay Expansion Board, Polarity Must Be Strictly Observed. If The

Polarity Is Reversed, Serious Damage To Both Boards Will Result.

Line Voltage

Required VA For Transformer

Relay Expansion Board = 20VA Max.

See Note 1

Relay Outputs R6 Thru R13 May Be User

Configured For The Following:

0 - Not Used (Nothing connected to this

output )

1 - Heating Stage

2 - Cooling Stage

3 - Humidifier Enable

4 - De-Humidifier Enable

5 - Scheduled Relay from Internal Schedule

6 - Scheduled Relay from External Schedule

(Only 1 Available!)

PRESSURE

SENSOR

EXPANSION

Connect Expansion Board

to CV-C Controller

with Modular Cable

24VAC

GND

24VAC

COM

POWER

N.O. CONTACTS

1-8

RELAY COMMONS 9,10

CV- C Controller

RELAY 1

RELAY 2

RELAY 3

RELAY 4

RELAY 5

RELAY 6

RELAY 7

RELAY 8

T'STAT

IN OUT

EXPANSION PORT

U1

Required VA For Transformer

Each CV-C Controller = 20VA Max.

GND

GND

Line Voltage

24VAC

24VAC

See Note 1

Not Used

Caution!

Relay Expansion Board Must Have Address Switches Set As

Shown Or The Board Will Not Function.

ADDRESS

U3

Caution:

Disconnect The Modular Cable Between The CV-C Controller And The

U4

Relay Expansion Board Before Removing Power From The Relay

Expansion Board. Reconnect Power And Then Reconnect The Modular

Cable Between The CV-C Controller And The Relay Expansion Board.

U5

Notes:

1.)24 VAC Must Be Connected So

That All Ground Wires Remain

Common.

2.)All Wiring To Be In Accordance

With Local And National Electrical

Codes And Specifications.

Relay Expansion Board

Note:

Set-up, Programming And Monitoring Of The CV-C Controller Requires The

Use Of A Personal Computer And ZoneView AZ Software.

FILENAME

CVCWIR1.CDR

DATE:

PAGE

1

JOB NAME

CONTROLS

07/08/99

DRAWN BY:

B. CREWS

DESCRIPTION:

OE351

CV-C Relay Expansion Board Wiring

Page 7

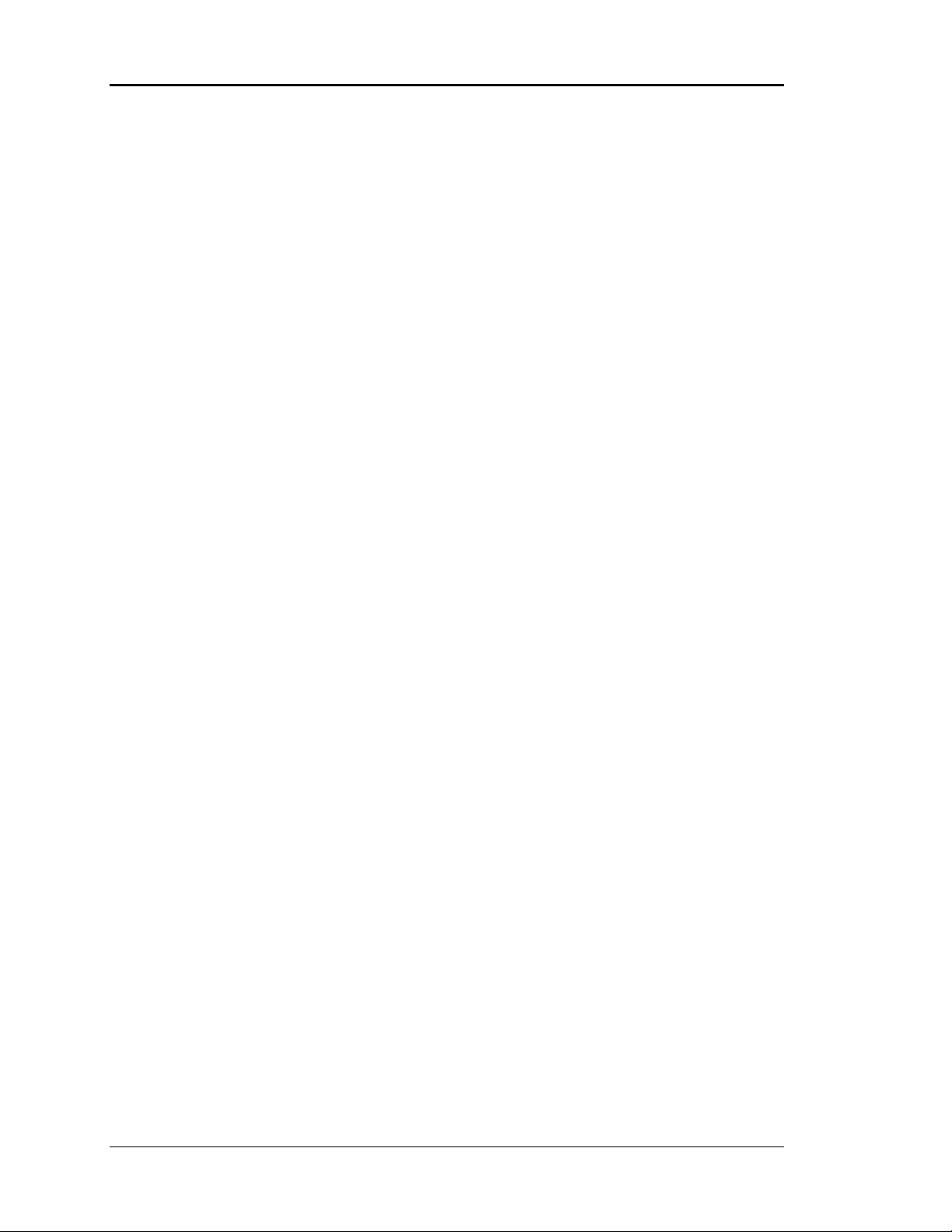

CV-C Controller LED Descriptions

COMMUNICATIONS - LED

POWER - LED

NOT USED

DIAGNOSTIC BLINK CODE - LED

The CV-C Controller uses an on board LED to indicate various diagnostic conditions

during powerup and operation. The CV-C Controller LED is labeled ""COM". Starting

with power up the LED blink codes are as follows:

COMM

INPUTS

T

SHLD

R

12V

AIN

1

AIN

2

AIN

3

AIN

4

AIN

5

GND

GND

AOUT1

AOUT2

AIN

7

GND

PRESSURE

SENSOR

EXPANSION

TUC5R PLUS

YS101718

1

2

4

8

16

32

TOKEN

NETWORK

T'STAT

RELAY #1 ENERGIZED - LED

1-3

M

CO

R1

R2

R3

R4

R5

4-5

M

CO

RELAY #2 ENERGIZED - LED

RELAY #3 ENERGIZED - LED

RELAY #4 ENERGIZED - LED

RELAY #5 ENERGIZED - LED

GND

24VAC

Off for five seconds

SCAN LED blinks the board address (Address 14 = 14 blinks)

Five second pause

Twenty second time delay - LED blinks twenty times

Status code is repeatedly blinked every ten seconds to indicate controller status:

Priority No. of Blinks Status

Lowest 1 Normal Operation

- 2 Override Active

- 3 Bad Zone or Airflow Sensor

- 4 (Not used on CV Units)

Highest 5 Communication Failure

Only the highest priority failure code will be shown. You must correct the highest priority

alarm before other problems will be indicated.

JOB NAME

FILENAME

CVCLED1A.CDR

DATE:

06/01/00

PAGE

DESCRIPTION:

CONTROLS

DRAWN BY:

Auto-Zone

1

LED Descriptions

B. CREWS

Page 8

Page 9

Section 2

Table of Contents

Initialization ................................................................................................................. 1

Operating Summary.................................................................................................... 1

Comm LED Diagnostic Blinks ...................................................................................3

Analog Inputs............................................................................................................... 4

Analog Outputs............................................................................................................5

Relay Outputs ..............................................................................................................5

Pushbutton Override Operation ................................................................................6

HVAC Mode of Operation.......................................................................................... 6

Occupied/Unoccupied Mode of Operation ...............................................................8

Daylight Savings Adjustments ................................................................................... 8

Off Mode of Operation................................................................................................ 9

Vent Mode Operation ................................................................................................. 9

Fan Only Mode Operation ......................................................................................... 9

DX Cooling Operation .............................................................................................. 10

Chilled Water Valve Operation ............................................................................... 13

Step Heating Operation ............................................................................................15

Hot Water Valve Operation ..................................................................................... 18

Fan Control ................................................................................................................ 19

Humidity Control ......................................................................................................20

Humidification ( Relay Enable ).....................................................................................................20

Humidification ( Analog Control ).................................................................................................20

De-Humidification ( Relay Enable )...............................................................................................20

Relief Pressure Control............................................................................................. 21

Economizer Control ..................................................................................................21

Indoor Air Quality..................................................................................................... 23

Scheduled Relays .......................................................................................................23

Fan Status................................................................................................................... 24

Alarm Contact ........................................................................................................... 24

Slide Offset Option .................................................................................................... 24

Dirty Filter Contact ...................................................................................................24

Static Pressure Sensor............................................................................................... 25

Alarm Detection & Reporting .................................................................................. 26

PID Operation............................................................................................................ 28

Page 10

Page 11

Auto-Zone CV-C

Initialization

Initialization

InitializationInitialization

On system powerup LED1 and LED2 are extinguished. After 5 seconds LED2 will blink

out the address of the controller ( Address Switch Setting ). Following this, the LED2

LED will extinguish for another 5 seconds and then begin to blink for a 20 second startup

delay. At the conclusion of this 20 second period, the LED2 LED will begin blinking a

diagnostic code every 10 seconds. This code is described later in this document. The

duration of a powerup initialization sequence is roughly 1 minute plus the user defined

Staggered Start delay described later in this document.

During this initialization period, the controller retrieves all operating setpoints from its

non-volatile EEPROM memory and initializes all outputs to an off condition.

NOTE: All future references to the Constant Volume

Configurable unit in this document use CVC as the

designation.

Section 2

Operating Summary

Operating Summary

Operating SummaryOperating Summary

At all times, after the conclusion of the initialization sequence, the CVC performs a

specific set of operating instructions in the following order: ( a - g Repeat Continuously )

a. Read Analog Inputs for Temperatures, Overrides and Lockout or Reset contact

closures.

b. Check the RS-485 communications port for any new setpoints from the System

Manager and keeps the status updated for the System Manager.

c. If the push-button override is active, it checks the timer to see if the override is

finished.

d. Calculates the current occupied/unoccupied mode from its internal week

scheduling.

e. Calculates what state the output relays and analog output should be set to.

Sequence of Operation 2-1

Page 12

Section 2

f. Updates the diagnostic LED2 blinking.

g. Stores data in the internal trend log if ready for another log.

Auto-Zone CV-C

2-2 Sequence of Operation

Page 13

Auto-Zone CV-C

Comm LED Diagnostic

Comm LED Diagnostic

Comm LED DiagnosticComm LED Diagnostic

Blinks

Blinks

BlinksBlinks

As mentioned earlier, the COMM LED will blink a diagnostic code every 10 seconds

during normal operations. If this LED is off continuously or on continuously, there is a

total failure in the controller and it should be replaced. The diagnostic blinks are

described below in order of priority. The highest priority condition must be corrected

before any lower conditions can be observed and corrected. 1 Blink is the lowest priority

and 5 blinks is the highest priority.

1 Blink Normal operations. No alarm conditions

2 Blinks Pushbutton Override is active during Unoccupied Hours.

3 Blinks Zone Temperature Sensor failure detected.

4 Blinks Not Used in this Controller

5 Blinks RS-485 communications lost

Section 2

Sequence of Operation 2-3

Page 14

Section 2

Analog Inputs

Analog Inputs

Analog InputsAnalog Inputs

Only Analog Input #1 (AIN1) and Analog Input #6 (Airflow Sensor) have a specific

function that cannot be changed. All other inputs are user configurable in one of the

following modes:

0 Not Used ( Nothing connected to this input )

1 Slide Offset ( Requires Flush Mount Wall Sensor with this Option )

2 Supply Air Temperature

3 Return Air Temperature

4 Mixed Air Temperature

5 Outdoor Air Temperature ( Will broadcast to ALL other controllers )

6 Humidity Sensor ( 4-20 ma scaling )

7 Humidity Sensor ( 0-5 vdc scaling )

8 CO² Sensor ( 4-20 ma scaling )

9 CO² Sensor ( 0-5 vdc scaling )

10 Relief Pressure Sensor ( Requires 0-5 vdc ±0.3” WG Sensor )

11 Dirty Filter Contact ( Normally Open )

12 Alarm Contact ( Normally Open )

13 Alarm Contact ( Normally Closed )

14 Fan Status Contact ( Normally Open )

Auto-Zone CV-C

Later in this manual, when it discusses the available options, it will be assumed that you

have installed and configured the correct sensors required for the options you select. If

you haven’t then improper operation will occur.

NOTE: All temperature sensors must be Thermister Type III

which provide 77°F @ 10K Ohms Resistance.

There are a total of 5 programmable Analog Inputs ( AIN2 - AIN5 and AIN7 ).

Analog Input #1 is always configured for a Space Temperature Sensor. This is also the

input that a push-button override would be connected to since the button press

temporarily shorts the thermister sensor to ground to indicate the override request.

Analog Input #6 ( Airflow Sensor ) can be used for status only or to verify fan operation.

No other control outputs can utilize this sensor.

2-4 Sequence of Operation

Page 15

Auto-Zone CV-C

Analog Outputs

Analog Outputs

Analog OutputsAnalog Outputs

There are two Analog Outputs available on this controller. They are both user

configurable as follows:

0 Not Used ( Nothing connected to this output )

1 Economizer ( Requires either Supply Air or Mixed Air Sensor )

2 Relief Fan VFD Signal ( Requires Relief Pressure Sensor )

3 Chilled Water Valve ( Requires Supply Sensor )

4 Hot Water Valve ( Requires Supply Sensor )

5 Humidification / De-Humidification ( Requires Humidity Sensor )

Relay Outputs

Relay Outputs

Relay OutputsRelay Outputs

Section 2

Only Relay Output #1 (R1) has a specific function that cannot be changed. All other

outputs are user configurable in one of the following modes:

0 Not Used ( Nothing connected to this input )

1 Heating Stage

2 Cooling Stage

3 Humidifier Enable

4 De-Humidifier Enable

5 Scheduled Relay from Internal Schedule

6 Scheduled Relay from External Schedule ( Only 1 Available! )

There are a total of 12 additional relays that can be configured. Four are found on the

controller itself (R2 - R5) and the remaining eight are found on an optional relay

expansion board that is connected to the PJ2 Expansion input.

Relay Output #1 is always configured to control the Fan On/Off command.

Sequence of Operation 2-5

Page 16

Section 2

Pushbutton Override

Pushbutton Override

Pushbutton OverridePushbutton Override

Operation

Operation

OperationOperation

This function requires a Space Temperature Sensor that also includes a Push-Button.

During unoccupied hours, the user can force the controller back to occupied operation by

pressing the override button for a period of time between 200 milliseconds and 3 seconds.

This overrides the schedule back to the occupied mode for a user defined period of time.

During Override operations, the user can cancel the override by pressing the override

button for a period of time between 3 seconds and 10 seconds. This removes the override

from the schedule and allows the controller to return to normal unoccupied operations.

If the override button is held for more than 10 seconds, it causes a space sensor failure

alarm. This is due to the fact that the override button actually shorts the space

temperature sensor input to ground. If this input is shorted to ground or left "floating"

with no sensor detected for more than 10 seconds, it is considered a failure.

Auto-Zone CV-C

HVAC Mode of Operation

HVAC Mode of Operation

HVAC Mode of OperationHVAC Mode of Operation

There are five possible modes of operation. These are Cooling Mode, Heating Mode,

Vent Mode, Fan Only Mode and the Off Mode. The HVAC mode of operation is

calculated the same way in both occupied and unoccupied modes of operation.

Off Mode The schedule is off and no overrides are active. There is no heating or

cooling demand in the space. Under these conditions, all outputs will be

off and the analog output will be set to 0.0 vdc.

Vent Mode No heating or cooling demand exists during the occupied mode of

operation. The fan will be on if the CVC is programmed for Constant Fan

operation.

Cool Mode A cooling demand is generated when the space temperature rises half the

amount of the Deadband Setpoint above the currently active Cooling

Setpoint. The space is considered satisfied when it drops that amount

below the Cooling Setpoint.

2-6 Sequence of Operation

Page 17

Auto-Zone CV-C

Heat Mode A heating demand is generated when the space temperature drops half the

amount of the Deadband Setpoint below the currently active Heating

Setpoint. The space is considered satisfied when it rises that amount above

the Heating Setpoint.

Section 2

Fan Only Mode A Fan Only mode cause ALL outputs except for the fan to their inactive

state. It is exactly like the Off Mode except the fan is running. This mode

can be used to temporarily purge the space, etc.

Sequence of Operation 2-7

Page 18

Section 2

Occupied/Unoccupied

Occupied/Unoccupied

Occupied/UnoccupiedOccupied/Unoccupied

Mode of Operation

Mode of Operation

Mode of OperationMode of Operation

Since the CVC contains its own built in Real Time Clock, it can operate from its own

internal scheduling system. This schedule supports a two Start & Stop event per day and

up to 14 Start/Stop Day Holidays. The Holidays all use the same special Holiday

Start/Stop times programmed by the user.

If the current operating mode is unoccupied, the CVC can accept a push-button override

back to the occupied mode. Push-button overrides are not recognized if the current mode

is already occupied. The push-button override duration is user programmed. If the user

wants to extend the current override without reprogramming the Duration, they can reinitialize the existing programmed period by pressing the override button anytime during

the current override. If the current override had been active for 1 hour and 45 minutes and

the user presses the push-button again, the override will reset for another 2 hour period (if

they programmed a 2 hour period), bringing the total override time to 3 hours and 45

minutes. If the user wants to cancel an override before it can time-out, simply hold the

push-button for a period of time between 3 and 10 seconds.

Auto-Zone CV-C

The CVC calculates its current heating and cooling setpoints based on the current mode

of operation. If the command is for unoccupied mode, the CVC adds the unoccupied

setbacks to the occupied heating and cooling setpoints.

Daylight Savings

Daylight Savings

Daylight SavingsDaylight Savings

Adjustments

Adjustments

AdjustmentsAdjustments

Since the CVC system usually contains a System Manager for keypad access to the Status

and Setpoints, the CVC controllers receive a Time Clock broadcast from the System

Manager which keeps all the CVC units synchronized. The System Manager also has the

ability to automatically adjust the time to take the Daylight Savings changes into account.

This is enabled at the System Manager so the effect is automatic at the CVC units. If the

user desires this feature, see Section 3 Setting the Time & Date.

2-8 Sequence of Operation

Page 19

Auto-Zone CV-C

Off Mode of Operation

Off Mode of Operation

Off Mode of OperationOff Mode of Operation

After the schedule goes unoccupied and both heating and cooling demands go away, the

fan stops running, all Relay Outputs are turned off and Analog Output Voltages go to 0.0

vdc. No outputs are allowed to activate in the Off Mode until a heating or cooling

demand occurs. During occupied hours this would be the Vent Mode.

Vent Mode Operation

Vent Mode Operation

Vent Mode OperationVent Mode Operation

During occupied hours when there is no heating or cooling demand, the CVC reverts to a

Vent Mode of operation. The fan is running and the heating and cooling outputs are held

off.

Section 2

See the section titled HVAC Mode of Operation for a graphical representation of how

the Vent Mode is calculated.

Fan Only Mode Operation

Fan Only Mode Operation

Fan Only Mode OperationFan Only Mode Operation

If the user would like to circulate air around the space without causing the heating or

cooling to activate, they can select the Fan Only mode. In this mode all other control

outputs are turned off. All normal scheduled operation is suspended until the Fan Only

mode is canceled. Fan Only mode can be set or cleared from the System Manager or

from the ZoneView front end program on systems equipped for remote communications.

Sequence of Operation 2-9

Page 20

Section 2

DX Cooling Operation

DX Cooling Operation

DX Cooling OperationDX Cooling Operation

If the user has configured the CVC with the DX Cooling option, the following sequence

of operation occurs during a cooling demand.

Once a cooling demand exists (see HVAC Mode of Operation), the following conditions

must be met before any relays can be activated:

a. Make sure any stages of heating are staged off or the hot water valve is

closed.

b. Make sure the Changeover Delay is satisfied. This only applies if the

previous demand was for heating.

c. Check the Outdoor Air Temperature to verify the cooling is enabled to run

due to warm temperatures.

Auto-Zone CV-C

d. If the Economizer option was enabled, the Economizer must be 100%

open if the outside air has enabled it for operation.

e. Check the current Minimum Off Timer to make sure this stage has been

off long enough since the last time it was cycled on and back off.

f. If there is more than 1 stage, check the Staging Delay Time from the

previous stage to be sure it has elapsed before activating the second stage.

g. If we are activating stage #2 or higher, make sure the Space Temperature

Demand is large enough to require the additional stages to activate.

The formula for determining the amount of demand required for each

additional stage is shown below:

Level = ((Deadband / 2) + ((Deadband / 2) * ActiveStages ))

IF Temperature > (Setpoint + Level) THEN its OK to activate another

stage.

( Active Stages refers to the number of compressors currently running. )

Example:

Stage #1 Activates @ 74.5°F - Deactivates @ 73.5°F

Stage #2 Activates @ 75.0°F - Deactivates @ 74.0°F

Stage #3 Activates @ 75.5°F - Deactivates @ 74.5°F

Deadband = 1°F

Setpoint = 74°F

2-10 Sequence of Operation

Page 21

Auto-Zone CV-C

If you have configured the system to control De-Humidification with the DX Cooling

then the compressors are staged on at a rate equal to the Cool Staging Period if the

Humidity reading is above a user defined Humidity Setpoint. This control ignores the

Space Temperature which means it can cause a heating demand in the space. If this

occurs, the cooling remains on to de-humidify the air while the heat runs to warm up the

space. As the humidity drops below the Humidity Setpoint by the Humidity Deadband

value, the compressors can stage off if they have been on at least one minute. If there is

still a cooling demand in the space and the demand requires the currently active cooling

stages to be on, then no staging off will occur until the demand drops low enough to stage

the compressors off.

Ignoring the Humidity Control for the moment, the compressors will stage off if the

following conditions are true.

a. The space temperature has dropped enough to remove a demand for the

currently active stage. ( see previous screen for stage off levels )

b. The outside air has dropped enough to disable the compressors.

Section 2

c. The Supply Air has dropped below 45°F or 7.2°C.

d. Someone has reduced the number of cooling stages to less than what are

currently active.

e. The compressor stage has been on at least one minute.

The staging of compressors always occurs based on both temperature demand and

specific intervals based on whether the unit is staging up or down. There are four timers

that need to be satisfied:

Staging Delay Timer ( User Adjustable )

a.

If a large demand exists when the cooling mode is entered all available

stages would be called for. Only one stage at a time can actually be

activated. The Staging Delay period must be satisfied before each additional

stage is activated.

Minimum Run Timer ( Not Adjustable )

b.

Once a stage has been activated, it must remain for at least one minute

before it is allowed to turn off again. This protects the equipment from short

cycling.

Sequence of Operation 2-11

Page 22

Section 2

Auto-Zone CV-C

c.

d.

The Relay Output assignment always assigns cooling stages starting with those defined

on the TUC-5R+ board and then any additional stages defined on the Relay Expansion

board. The stages are assigned from the lowest relay number up to the highest. If you

defined 6 relays for cooling and two were on the TUC-5R+ board and the remaining four

were on the relay expansion board, then stage #1 would be the lower relay number on the

TUC board and stage #3 would be the lowest relay number on the expansion board.

NOTE: You must take into account the stage assignments

Minimum Off Timer ( User Adjustable )

Once a stage has been turned off, it must remain off for this amount of

time before it can be restarted.

Changeover Delay ( User Adjustable )

If the previous HVAC mode was for heating, the cooling mode is not

allowed to activate any compressors until this delay period has been

satisfied. This period is used to prevent rapid cycling back and forth

between the heating and cooling modes.

when you physically wire the controller and/or

expansion board into your AHU equipment.

2-12 Sequence of Operation

Page 23

Auto-Zone CV-C

Chilled Water Valve

Chilled Water Valve

Chilled Water ValveChilled Water Valve

Operation

Operation

OperationOperation

If the user has configured the CVC with the Chilled Water Valve option, the following

sequence of operation occurs during a cooling demand.

Once a cooling demand exists (see HVAC Mode of Operation), the following conditions

must be met before the valve modulation signal is activated.

a. Make sure any stages of heating are staged off or the hot water valve is

closed.

b. Make sure the Changeover Delay is satisfied. This only applies if the

previous demand was for heating.

Section 2

c. Check the Outdoor Air Temperature to verify the cooling is enabled to run

due to warm temperatures.

d. If the Economizer option was enabled, the Economizer must be 100%

open if the outside air has enabled it for operation.

If you have configured the system to control De-Humidification with the Chilled Water

Valve then the valve will modulate open at a user defined rate if the Humidity reading is

above a user defined Humidity Setpoint. This control ignores the Space Temperature

which means it can cause a heating demand in the space. If this occurs, the cooling

remains on to de-humidify the air while the heat runs to warm up the space. As the

humidity drops below the Humidity Setpoint by the Humidity Deadband value, the valve

can modulate closed. If there is still a cooling demand in the space then the valve will still

modulate to maintain a user defined supply air temperature.

Ignoring the Humidity Control for the moment, the chilled water valve operates as

follows:

a. A cooling demand equal to the Cooling Setpoint plus half the Deadband has

occurred in the space.

b. If the cooling mode is enabled by outside air, then the valve modulates to

maintain a supply temperature, defined by the user, until the demand drops

Sequence of Operation 2-13

Page 24

Section 2

below the cooling setpoint by the same amount it rose above it to start the

demand.

c. Once the cooling demand has been satisfied, the valve will go fully closed

until the next cooling demand or until the Humidity requires the valve to

open.

Once the Chilled Water Valve is enabled for operation, the actual valve position is

calculated using a Proportional, Integral and Derivative (PID) formula. All three formula

constants are user adjustable along with a fourth setpoint for the Integrating Interval.

There are defaults programmed in the code that should not be changed unless the user,

through actual observation, has determined that the valve is hunting or is not operating

quickly enough to maintain a constant Supply Air Temperature.

A later section entitled PID Operation can be refereed to for an actual example of code

that does the valve positioning. This formula applies to both Chilled Water and Hot

Water Valve operations.

Auto-Zone CV-C

2-14 Sequence of Operation

Page 25

Auto-Zone CV-C

Step Heating Operation

Step Heating Operation

Step Heating OperationStep Heating Operation

If the user has configured the CVC with the Step Heating option, the following sequence

of operation occurs during a heating demand.

If the controller was configured for De-Humidification, then any statements concerning

the cooling being off before the heat can activate can be ignored as the cooling is used in

conjunction with the heat to reduce humidity and maintain space temperature.

Once a heating demand exists (see HVAC Mode of Operation), the following conditions

must be met before any relays can be activated:

a. Make sure any stages of cooling are staged off or the chilled water valve is

closed.

b. Make sure the Changeover Delay is satisfied. This only applies if the

previous demand was for cooling.

Section 2

c. Check the Outdoor Air Temperature to verify the heating is enabled to run

due to cool temperatures.

d. If you have Economizer control, the Economizer must be at its minimum

ventilation position.

e. Check the current Minimum Off Timer to make sure this stage has been

off long enough since the last time it was cycled on and back off.

f. If there is more than 1 stage, check the Staging Delay Time from the

previous stage to be sure it has elapsed before activating the second stage.

g. If we are activating stage #2 or higher, make sure the Space Temperature

Demand is large enough to require the additional stages to activate.

The formula for determining the amount of demand required for each

additional stage is shown below:

Level = ((Deadband / 2) + ((Deadband / 2) * ActiveStages ))

IF Temperature < (Setpoint - Level) THEN its OK to activate another

stage.

( Active Stages refers to the number of heating stages currently running. )

Sequence of Operation 2-15

Page 26

Section 2

Auto-Zone CV-C

Example:

Stage #1 Activates @ 71.5°F - Deactivates @ 72.5°F

Stage #2 Activates @ 71.0°F - Deactivates @ 72.0°F

Stage #3 Activates @ 70.5°F - Deactivates @ 71.5°F

Heating can stage off if the following conditions are true.

a. The space temperature has risen enough to remove a demand for the

currently active stage. ( see previous screen for stage off levels )

b. The outside air has risen enough to disable the heating.

c. The Supply Air has risen above 150°F or 65.5°C.

d. Someone has reduced the number of heating stages to less than what are

currently active.

e. The heating stage has been on at least one minute.

Deadband = 1°F

Setpoint = 72°F

The heat staging always occurs based on both temperature demand and specific intervals

based on whether the unit is staging up or down. There are four timers that need to be

satisfied:

Staging Delay Timer ( User Adjustable )

a.

If a large demand exists when the heating mode is entered all available

stages would be called for. Only one stage at a time can actually be

activated. The Staging Delay period must be satisfied before each additional

stage is activated.

b. M

inimum Run Timer ( Not Adjustable )

Once a stage has been activated, it must remain for at least one minute

before it is allowed to turn off again. This protects the equipment from short

cycling.

Minimum Off Timer ( User Adjustable )

c.

2-16 Sequence of Operation

Page 27

Auto-Zone CV-C

Once a stage has been turned off, it must remain off for this amount of time

before it can be restarted.

Changeover Delay ( User Adjustable )

d.

If the previous HVAC mode was for cooling, the heating mode is not

allowed to activate any heat stages until this delay period has been satisfied.

This period is used to prevent rapid cycling back and forth between the

heating and cooling modes.

The Relay Output assignment always assigns heating stages starting with those defined

on the TUC-5R+ board and then any additional stages defined on the Relay Expansion

board. The stages are assigned from the lowest relay number up to the highest. If you

defined 6 relays for heating and two were on the TUC-5R+ board and the remaining four

were on the relay expansion board, then stage #1 would be the lower relay number on the

TUC board and stage #3 would be the lowest relay number on the expansion board.

Section 2

NOTE: You must take into account the stage assignments

when you physically wire the controller and/or

expansion board into your AHU equipment.

Sequence of Operation 2-17

Page 28

Section 2

Hot Water Valve

Hot Water Valve

Hot Water ValveHot Water Valve

Operation

Operation

OperationOperation

If the user has configured the CVC with the Hot Water Valve option, the following

sequence of operation occurs during a cooling demand.

If the controller was configured for De-Humidification, then any statements concerning

the cooling being off before the heat can activate can be ignored as the cooling is used in

conjunction with the heat to reduce humidity and maintain space temperature.

Once a heating demand exists (see HVAC Mode of Operation), the following conditions

must be met before the valve modulation signal is activated.

a. Make sure any stages of cooling are staged off or the chilled water valve is

closed.

Auto-Zone CV-C

b. Make sure the Changeover Delay is satisfied. This only applies if the

previous demand was for cooling.

c. Check the Outdoor Air Temperature to verify the cooling is enabled to run

due to warm temperatures.

d. If you have Economizer control, the Economizer must be at its minimum

ventilation position.

Heating can modulate closed if the following conditions are true.

a. A heating demand equal to the Heating Setpoint plus half the Deadband has

occurred in the space.

b. If the heating mode is enabled by outside air, then the valve modulates to

maintain a supply temperature, defined by the user, until the demand rises

above the cooling setpoint by the same amount it rose above it to start the

demand.

c. Once the heating demand has been satisfied, the valve will go fully closed

until the next heating demand.

2-18 Sequence of Operation

Page 29

Auto-Zone CV-C

Once the Hot Water Valve is enabled for operation, the actual valve position is calculated

using a Proportional, Integral and Derivative (PID) formula. All three formula constants

are user adjustable along with a fourth setpoint for the Integrating Interval. There are

defaults programmed in the code that should not be changed unless the user, through

actual observation, has determined that the valve is hunting or is not operating quickly

enough to maintain a constant Supply Air Temperature.

A later section entitled PID Operation can be referred to for an actual example of code

that does the valve positioning. This formula applies to both Chilled Water and Hot

Water Valve operations.

Fan Control

Fan Control

Fan ControlFan Control

The Fan runs continuously in the occupied mode and cycles on and off with the heating

or cooling in the unoccupied mode unless the user configures it for the Fan Cycle Mode.

In this mode, the Fan will start before any other outputs can be activated. It must have

been off for at least one minute before it can be restarted.

Section 2

Once the fan has been commanded to turn off, it first checks to see if all heating and

cooling stages are off or valves are closed. If everything has been off for at least 30

seconds, the fan is allowed to stop.

If the user has entered the Fan Only force mode, this will be the only active output and all

scheduling or anything else that normally affects the fan will be ignored until the Fan

Only mode is removed.

WARNING: The Fan Only mode does not automatically clear itself. The user must

remove this force command or the fan will never turn off and no

heating or cooling will occur!

Sequence of Operation 2-19

Page 30

Section 2

Humidity Control

Humidity Control

Humidity ControlHumidity Control

If you selected the De-Humidification control using DX Cooling or the Chilled Water

Valve, then that operation is discussed in those sections. This section applies to an Output

Relay that has been assigned to humidity control or an Analog Output that is assigned to

control the humidity level. If an external device will be used to increase or decrease the

humidity but it needs an enable signal from the CVC, then this is the mode to select.

Auto-Zone CV-C

Humidification ( Relay Enable )

As the humidity drops below the user adjustable Humidity Setpoint, the assigned Output

Relay activates. It remains active until the Humidity rises above the setpoint by the user

adjustable Humidity Deadband amount. This operation can occur in both the Occupied

and the Unoccupied mode and the fan will be started if it is not already running.

The only mode that will prevent this Humidification control from occurring is the Fan

Only Mode.

Humidification ( Analog Control )

If you assigned an Analog Output for this mode, the output signal voltage will ramp from

the minimum programmed voltage to the maximum programmed voltage ( 0 to 100% ) as

the Humidity drops below the setpoint. When the humidity level drops below the setpoint

by the Humidity Deadband amount, the output will be at its 100% programmed voltage.

Since the CVC is controlling this voltage signal, this mode requires the fan to be running.

If the voltage signal is greater than 0% the fan is verified to be running or it is started.

The only mode that will prevent this Humidification control from occurring is the Fan

Only Mode.

De-Humidification ( Relay Enable )

If you aren’t using mechanical cooling to control the humidity level, then you can assign

an Enable Relay to activate whenever the Humidity rises above the Humidity Setpoint. It

will remain on until the humidity drops below the setpoint by the Humidity Deadband

amount.

The only mode that will prevent this Humidification control from occurring is the Fan

Only Mode.

No Analog Output Control is available for De-Humidification.

2-20 Sequence of Operation

Page 31

Auto-Zone CV-C

Relief Pressure Control

Relief Pressure Control

Relief Pressure ControlRelief Pressure Control

If you have assigned both a Relief Pressure Sensor on an Analog Input and Relief Fan

control on one of the Analog Outputs, then the following control occurs.

If the Fan is running then the relief fan voltage signal increases as the relief pressure rises

above the Relief Pressure Setpoint by 0.02” WG. The voltage decreases as the pressure

drops below the setpoint by 0.02” WG. this 0.04” WG deadband is not user adjustable.

If the pressure ever exceeds the setpoint by 0.10” WG, the voltage signal will be doubled

in an attempt to reduce building pressure before damage occurs.

The relief fan voltage signal remains at zero volts whenever the main fan is off.

Section 2

Economizer Control

Economizer Control

Economizer ControlEconomizer Control

If you assigned an Analog Output to control an Outside Air Damper ( Economizer ) then

the following sequence occurs.

Assuming that the current HVAC mode is calling for Cooling, the economizer is enabled

for operation when the outside air temperature is below the Enable Setpoint or a Wetbulb

Temperature, received from another controller on the communications loop, is receiving

a value that is below the Enable Setpoint. Whichever value that is being used, the

economizer is enabled when the temperature is 1° below the enable setpoint and is

disabled when the temperature rises 1° above the setpoint.

The economizer is always considered to be the first stage of cooling. If it cannot satisfy

the space temperature with the supply air or mixed air temperature it is providing, then

mechanical cooling will be enabled to operate if the outside air is above the mechanical

cooling lockout setpoint.

The user can select either Supply Air Temperature control or Mixed Air Temperature

control. If the user selects Mixed Air Temperature but then neglects to configure an

Analog Input as a Mixed Air sensor, the controller will default to using the Supply Air

Temperature. If no supply air temperature sensor is provided, then incorrect control will

occur!

Once the economizer is enabled to begin controlling, it checks the outside air temperature

and calculates a starting position to immediately drive to instead of just creeping slowly

open from its programmed minimum position. Once this initial adjustment is made, the

Sequence of Operation 2-21

Page 32

Section 2

economizer watches the movement of the controlling temperature to determine if it

should make any further adjustments. If the temperature is dropping but it is still above

setpoint, the economizer will not open any further unless the temperature stops dropping

and becomes stagnant at a level above the setpoint. The same is true if the temperature is

below the setpoint and rising, no adjustments are made unless the temperature stagnates

as some fixed value.

If the economizer is moving too fast or too slow to maintain stable temperature control,

the user can adjust a Control Rate value between a value of 0.1 and 9.9 with 9.9 being the

fastest control and 0.1 being the slowest control.

As mentioned in the DX Cooling and Chilled Water Valve operations, the economizer

must be fully open before mechanical cooling can occur. On the same hand, if mechanical

cooling has been initiated, the economizer must remain fully open until the mechanical

cooling is removed or the supply air temperature drops below 40°F or 4.4°C. If this

occurs, the economizer closes by 5% every 10 seconds until it is fully closed or the

supply air has recovered enough to allow the economizer to be used again. If the supply

air rises above this low limit protection, the economizer will begin to creep open if it

needs to reduce the supply air or mixed air ( not likely ) downward.

Auto-Zone CV-C

One other test that can occur but is not generally required occurs when the user has

installed a return air sensor. If the outside air is within 5° of the return air temperature

then it can’t really be used for cooling the supply air so the economizer is disabled and

maintained at the user defined minimum position.

2-22 Sequence of Operation

Page 33

Auto-Zone CV-C

Indoor Air Quality

Indoor Air Quality

Indoor Air QualityIndoor Air Quality

If you have configured an Analog Input to read a CO² sensor or to receive the broadcast

of CO² from another unit, this CVC can override the minimum economizer position to

bring in more fresh outside air to relieve the condition.

As the CO² level rises above the user adjustable CO² Setpoint, the Minimum Economizer

position switches over to a user adjustable value of up to 100% and makes sure the

economizer does not close any further than this new value. If the value is less than 100%

and the economizer is opening to control supply or mixed air, the economizer is still free

to modulate between 100% and this new minimum position. The only condition that will

override the minimum is supply air dropping below the 40°F or 4.4°C protection limit.

As the CO² level drops below the CO² Setpoint by the user adjustable Deadband value,

the original Economizer Minimum Position is restored and the economizer is now free to

modulate over its entire range again, or return to minimum if cooling is not required.

Section 2

Scheduled Relays

Scheduled Relays

Scheduled RelaysScheduled Relays

If you define one of the Output Relays to follow the Internal Schedule, then whenever the

Schedule is Occupied the relay will activate. Whenever the schedule goes Unoccupied the

relay de-activates. Push-button overrides will not re-activate this relay. Only the

Occupied mode will activate the relay. Only one relay should be assigned to follow an

external schedule.

If you define one of the Output Relays to follow an External Schedule then the same

conditions apply. That relay will follow the broadcast receipt of the selected schedule.

Only one relay should be assigned to follow an external schedule since there is only one

Schedule Setpoint available. If you assigned more than one relay, they would all follow

the same schedule.

The External Schedule can only be received from an Auto-Zone Optimal Start Scheduler

installed on one of the communications loops in your building. These options require the

ZoneView AZ computer program for programming and monitoring.

Sequence of Operation 2-23

Page 34

Section 2

Fan Status

Fan Status

Fan StatusFan Status

You can configure one of the Analog Inputs to monitor a binary contact closure for proof

of airflow. This is currently a Status Only input and will not affect the operations of the

CVC if no proof of flow is detected.

Alarm Contact

Alarm Contact

Alarm ContactAlarm Contact

If you require a generic type alarm indication on a contact closure, you can configure an

Analog Input for either a Normally Open or a Normally Closed contact. This alarm will

not affect the CVC operation but it will be reported at the ZoneView AZ computer screen

and can be used to generate alarm callouts if all the proper equipment is installed for

remote communications.

Auto-Zone CV-C

Slide Offset Option

Slide Offset Option

Slide Offset OptionSlide Offset Option

If you install Flush Mount Wall Sensors with the optional slide adjustment, you can affect

the current heating and cooling setpoints up or down by a programmable amount. This

can be as much as 5°F above or below the current setpoints or as little as 1°F. The

position of the slide is proportional so that if it is halfway up or down, you affect the

setpoints by half the amount you programmed. If the slide is all the way up or down you

create the maximum effect on the setpoints.

Dirty Filter Contact

Dirty Filter Contact

Dirty Filter ContactDirty Filter Contact

You can configure an Analog Input to monitor for a differential pressure contact closure

in the event the filters become clogged. This contact closure can generate an alarm callout

if desired and if the remote communications options have been installed.

2-24 Sequence of Operation

Page 35

Auto-Zone CV-C

Static Pressure Sensor

Static Pressure Sensor

Static Pressure SensorStatic Pressure Sensor

You can install a Static Pressure Sensor on the fixed Analog Input labeled Pressure

Sensor and be provided automatically with the current static pressure. This is a status

only reading that can be used to verify fan operation if you are viewing this system with

the ZoneView AZ computer program. No setup or programming is required. If the input

detects the sensor, you will see the reading.

Section 2

Sequence of Operation 2-25

Page 36

Section 2

Alarm Detection &

Alarm Detection &

Alarm Detection &Alarm Detection &

Reporting

Reporting

ReportingReporting

The CVC continuously performs self diagnostics during normal operations to determine

if any operating failures have occurred. These failures can be reported to the user in

several ways, depending on the options installed by the user. If you are using the

ZoneView AZ computer software to interface with the unit, you can enable or disable

each alarm condition as desired to prevent nuisance alarms from being reported. This

alarm disabling does not apply to the System Manager alarm polling described below, it

is only from remote alarm callout.

The System Manager continuously polls all installed controllers for alarm conditions. If it

detects any alarm, the ALARM LED on the right side of the front panel illuminates and

latches, even though the alarm may have gone away on the controller. This latching

mechanism allows the user to detect intermittent alarm conditions and begin closer

monitoring of the offending controller to determine what caused the alarm condition.

There is keypad access to retrieve the Loop and Board Addresses of the units in alarm.

Auto-Zone CV-C

On Auto-Zone systems equipped with the Remote Communications option (OE361-04-S)

the ZoneView AZ program can display alarm conditions on each Status Screen as the

user scrolls through the controllers on their system. The CommLink II Communications

Interface can also place a call to a Pager number for on the spot notification of alarm

conditions.

Alarm conditions are not latched in the controller generating the alarm. They can come

and go as the condition is corrected. Alarms are latched at the System Manager so a

record of the alarm is not lost.

Possible Alarm Conditions

Bad Space Sensor

If the space sensor is missing or has been shorted out for more than 10

seconds, an alarm is generated.

2-26 Sequence of Operation

Page 37

Auto-Zone CV-C

Cooling Failure

Anytime the first stage of cooling is activated on CV-C units the Supply

Air has 30 minutes to change by 5°F from its starting condition. If this

does not occur an alarm is generated. This test is not performed if your

system is configured for Chilled Water Valve operation.

Heating Failure

The same conditions apply as listed for Cooling Failure except it looks at

the first stage of heating to test the condition. This test is not performed if

your system is configured for Hot Water Valve operation.

Space Temperature Alarm

If the space temperature is above or below its cooling or heating setpoints

by 5°F for at least 30 minutes, an alarm is generated.

Dirty Filter Alarm

If the Dirty Filter contact closes no operational changes are made but an

alarm is generated.

Section 2

Generic Alarm

If the Normally Open or Normally Closed Generic Alarm input becomes

active and alarm is generated.

NOTE: If you do not required alarm reporting at the System

Manager simply disconnect the RS-485 connector from

the System Manager and force it to Rebuild the Alarm

Map. (See Section 3 Rebuilding Alarm Map)

Sequence of Operation 2-27

Page 38

Section 2

PID Operation

PID Operation

PID OperationPID Operation

The Hot & Chilled Water Valves are controlled via a Proportional, Integral, Derivative (

PID ) loop. This method of control provides accurate temperature control with minimal

adjustments to the valve position. The best method of explaining the PID operation is to

show a simplified form of the formulas incorporated into the controller code.

The following abbreviations will be used in the formula:

TimeSP = Integrating Interval

HotSP = Supply Air Temperature Setpoint

Kp = Proportional Constant

Ki = Integral Constant

Kd = Derivative Constant

P = Proportional Error

I = Integral Error

D = Derivative Error

HWValve = Calculated Valve Position

SupplyAir = Current Supply Air Temperature Reading

Auto-Zone CV-C

IF the TIMER has exceeded the TimeSP THEN

Error = HotSP - SupplyAir

P = ( Error x ( Kp / 100 )) x 100

I = ( Error x ( Ki / 10))

D = ( Error - OldError ) x ( Kd / 10 )

HWValve = P + I + D

OldError = Error “ Save current error for next time “

END ROUTINE

The Error is the difference between the Setpoint and the actual Temperature. The P error

uses a limited amount of this error to create a proportional only valve position. For

example, if the Kp was set to 10 then a 10°C temperature error would cause the P error

to set the valve 100% open.

10° Error = ( 10 x ( 10 / 100)) x 100 = 100%

5° Error = ( 5 x ( 10 / 100)) x 100 = 50%

2-28 Sequence of Operation

Page 39

Auto-Zone CV-C

The Integral ( I ) is added to itself each time through the loop. This prevents the valve

from stopping at a point of equilibrium where the proportional error is not changing,

therefore the valve position would be changing. The amount of effect the Integral can

have is limited by the Ki constant.

The Derivative ( D ) is used to track the rate of change in temperature error from

setpoint. If the last change was small, the derivative would have very little affect since the

( Error - OldError ) subtraction would yield a small value. In this case, the derivative

would not affect on the final valve position calculation.

If the last error was large, indicating the temperature was rapidly moving toward or away

from the setpoint, the valve position calculation could make a large adjustment due to the

proportional error. This could have the affect of causing hunting or overshoot in the

temperature control. To limit the proportional effect during rapid temperature changes,

the derivative becomes the brakes of the system if we are approaching setpoint or the

accelerator if we are moving away from the setpoint. If the temperature error had

increased from the last calculation, the derivative would create a positive value that

would be added to the proportional and integral values to create an even greater valve

position:

Section 2

Accelerator Example:

OldError = 2°

Error = 4°

( Error - OldError ) = 2

P + I + 2 = Increased valve position

Brakes Example:

OldError = 2°

Error = 0°

( Error - OldError ) = -2

P + I + ( -2 ) = No Change in valve position

Since the Proportional Error was also reduced the derivative had the effect of canceling

any change in the valve position until it detects another movement down in the

temperature error. If the effect of remaining unchanged causes the temperature error to

increase again, then the valve position would again increase without ever having

experienced an unneeded or undesired decrease.

If the temperature had continued to drop, then the derivative would add to the

proportional error in an attempt to catch the temperature before it went too far below

setpoint.

Sequence of Operation 2-29

Page 40

Section 2

The Integrating Interval ( TimeSP ) controls how many times per minute the calculations

are made. The default number of times per minute is set to 12

( 60 Seconds / 5.0 Seconds = 12 Times Per Minute ). This allows for a rapid reaction to

changes in temperature. If the default Constants and this TimeSP cause unstable

operation, they can be adjusted to bring the valve positioning under control.

NOTE: It is not possible to recommend which variables to change or how much to

change them without firsthand observation of the valve operation.

It is recommended that the default setpoints be used until you can observe actual heating

control and determine if any changes need to be made. Changes made to the PID

Constants should be made in small increments and one at a time. The results should then

be studied before making any further changes.

Auto-Zone CV-C

2-30 Sequence of Operation

Page 41

Page 42

Form: WM-CVC-SQW-01A Printed in the USA March 2002

All rights reserved Copyright 2002

WattMaster Controls Inc. • 8500 NW River Park Drive • Parkville MO • 64152

Phone (816) 505-1100 www.wattmaster.com Fax (816) 505-1101

Loading...

Loading...