Page 1

Design, Installation

Basic System

and Operations Manual

Revision 02C

Page 2

Page 3

Auto-Zone

Basic

Design, Installation & Operations Manual

Section 1..............................................................................System Overview

Section 2...................................................................Installation and Wiring

Section 3....................................................................................Programming

Section 4........................................................Start-Up and Troubleshooting

This document is subject to change without notice.

WattMaster Controls, Inc. assumes no responsibility

for errors, or omissions herein.

Auto-Zone Basic Installation & Operations Manual - Form WM-AZB-IO-02C

Auto-Zone is a registered trademark of WattMaster Controls, Inc.

Copyright 2009 WattMaster Controls, Inc.

All rights reserved.

Page 4

Page 5

Section 1

Table of Contents

Conventions .....................................................................1

General Information.........................................................3

Description of System Components.................................................................................3

Design Considerations.....................................................5

Zone Diversity .................................................................................................................5

Cooling - Partial Load Conditions ...................................................................................5

Heating - Partial Load Conditions ...................................................................................7

Override Conditions.........................................................................................................7

Building Pressurization....................................................................................................7

Design Guide....................................................................8

Step #1 - Zoning ..............................................................................................................8

Step #2 - Sizing the Central Unit ...................................................................................10

Step #3 - Duct Design Considerations...........................................................................10

Step #4 - Room Air Motion/Diffuser Selection.............................................................11

Step #5 - Bypass Damper Sizing ...................................................................................11

Step #6 - Sizing Zone Dampers .....................................................................................13

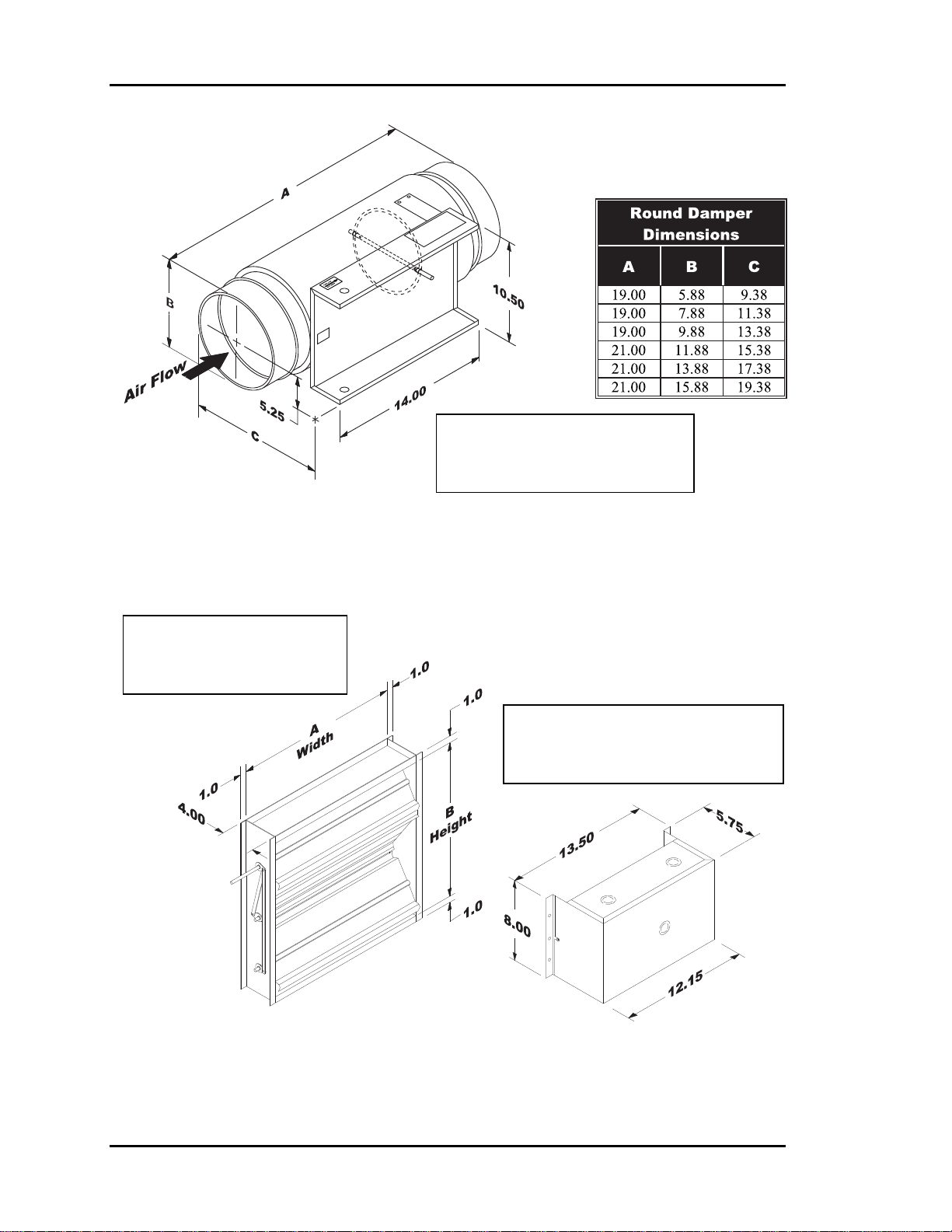

Round Dampers .............................................................................................................15

Rectangular Dampers.....................................................................................................15

Pressure Independent Zone Dampers ............................................................................16

Auxiliary Heat Control Options......................................17

Relay Expansion Board .................................................................................................18

Table of Figures & Tables

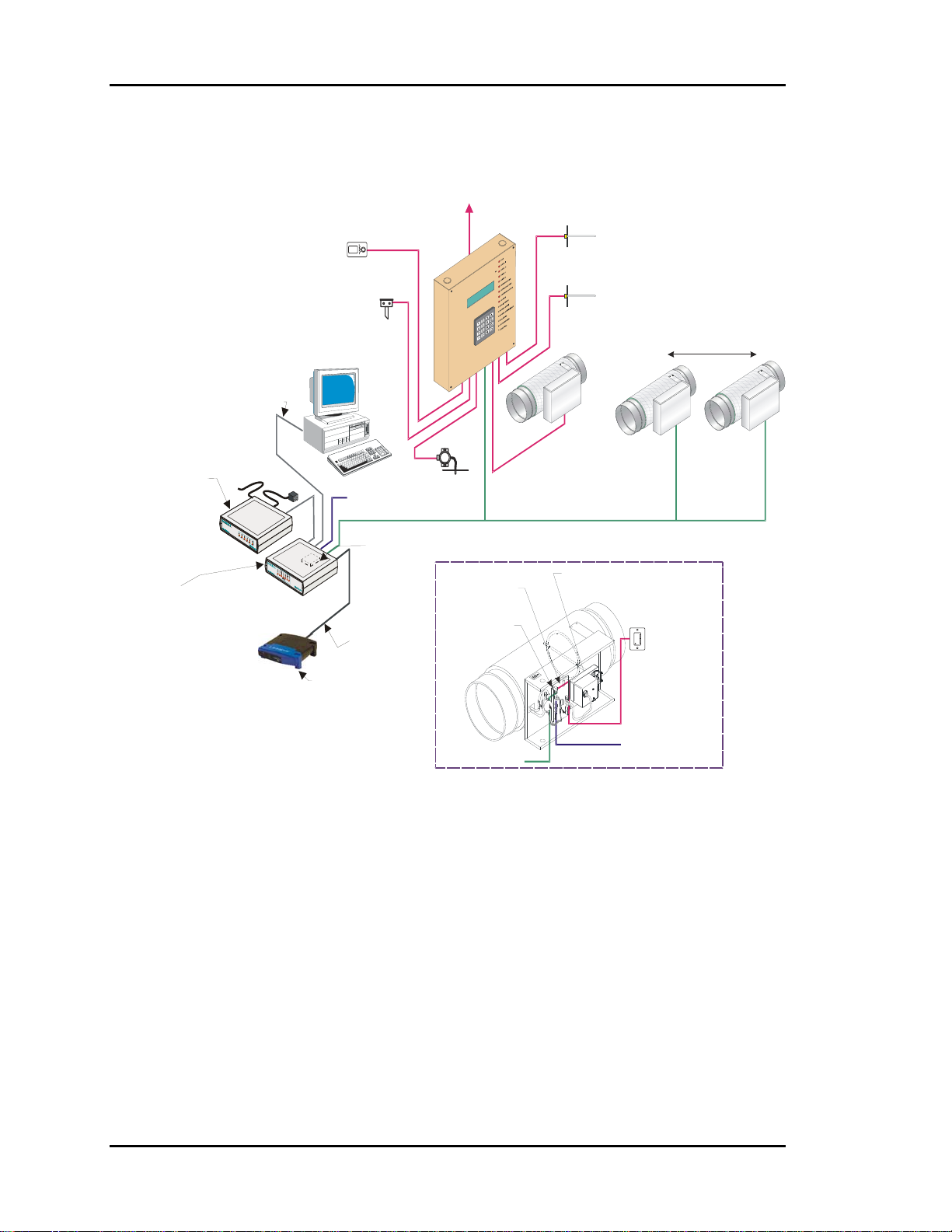

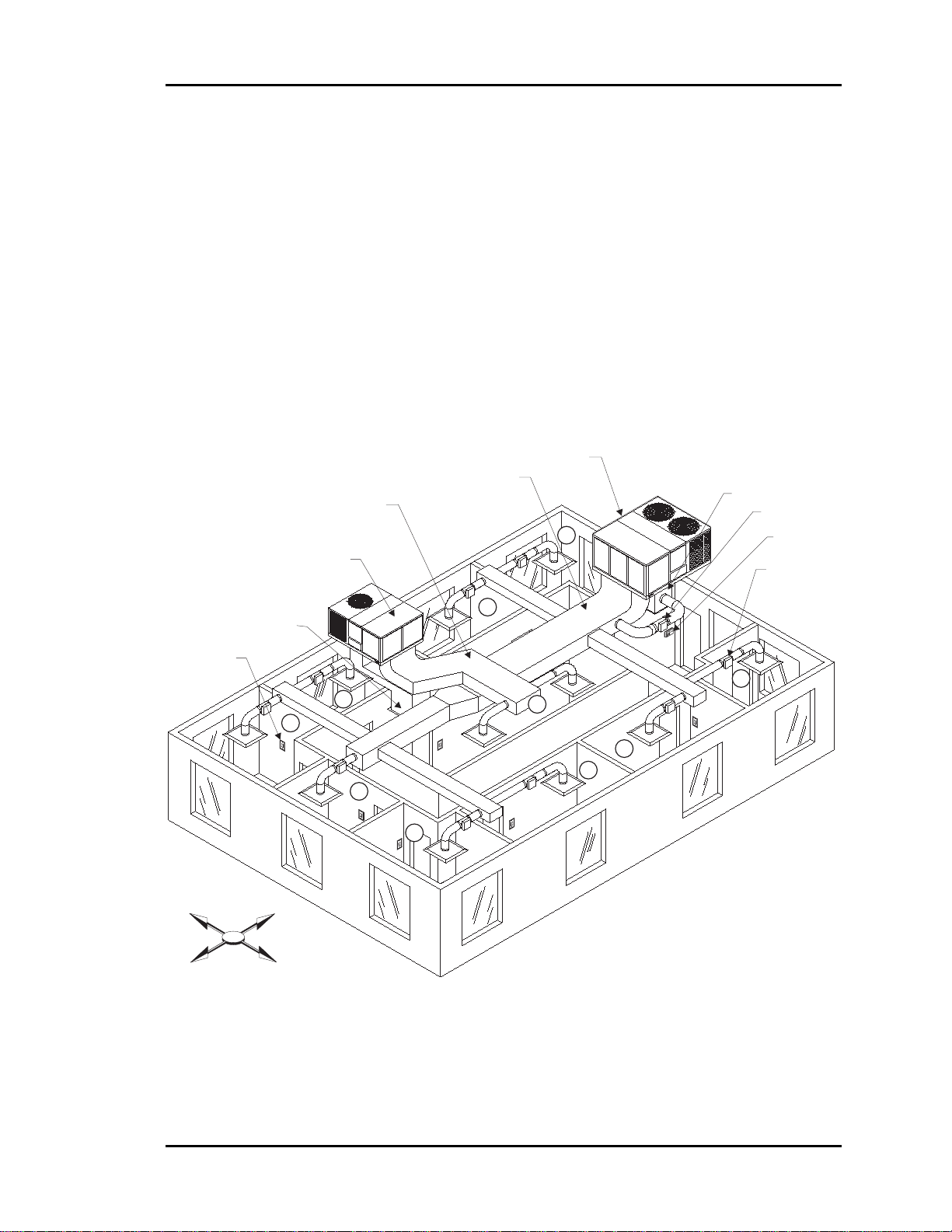

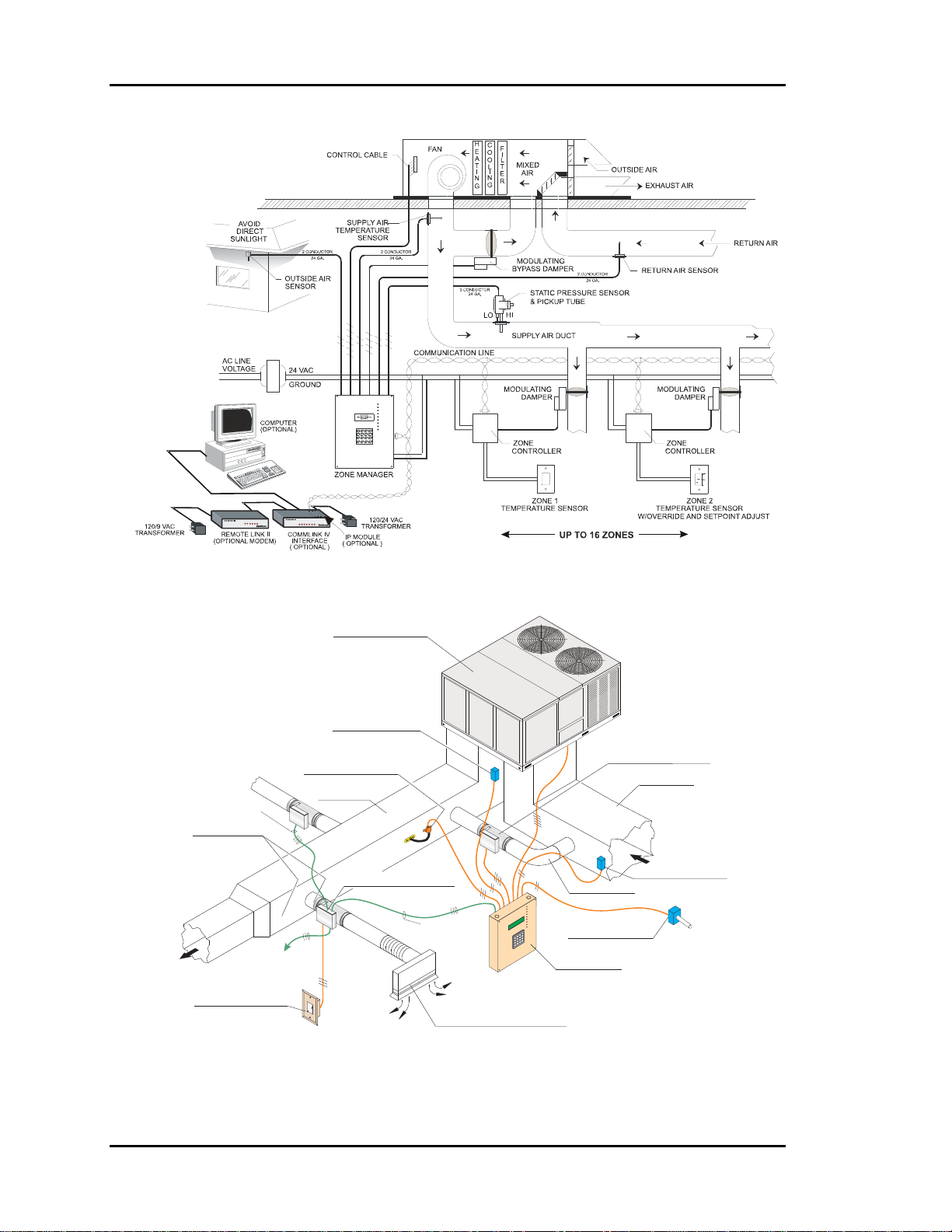

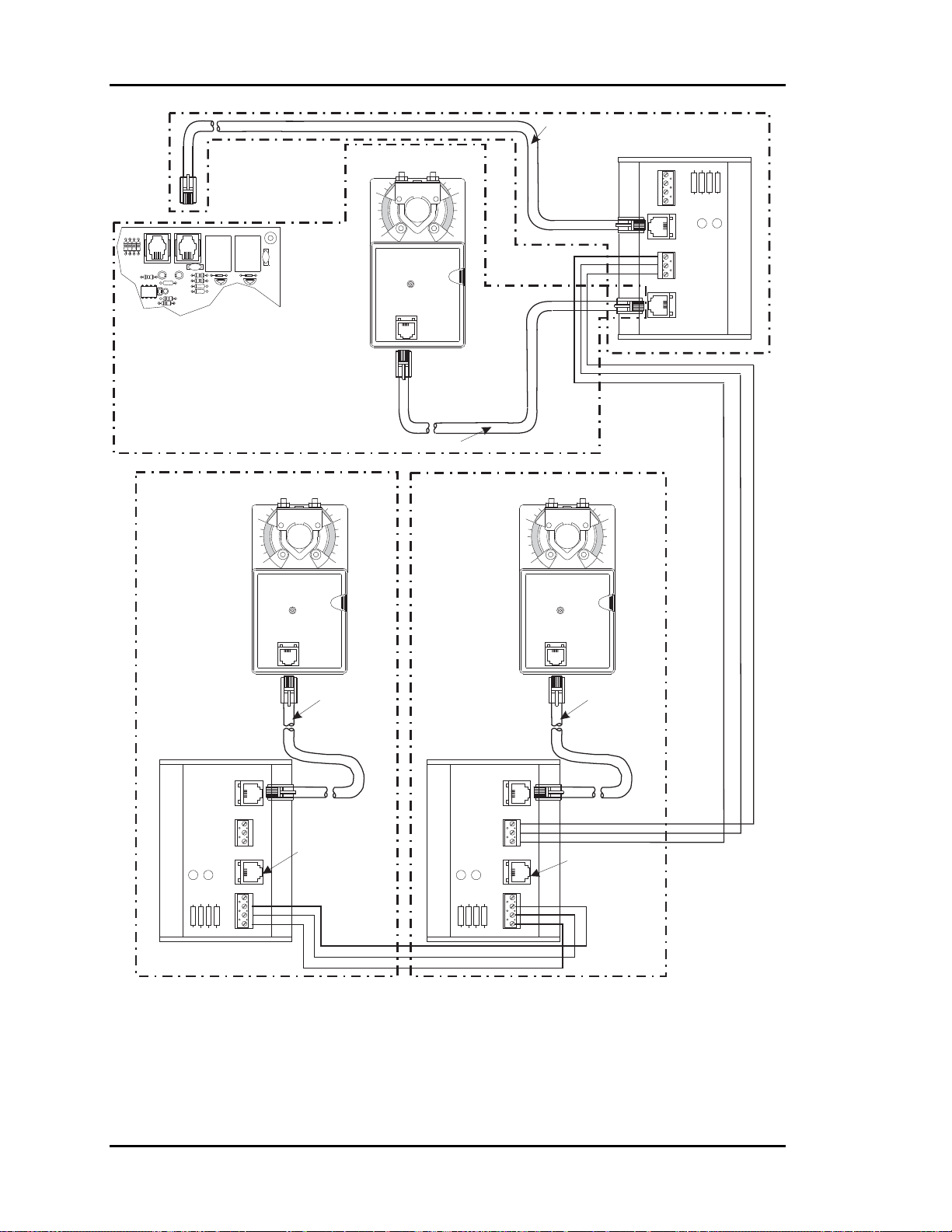

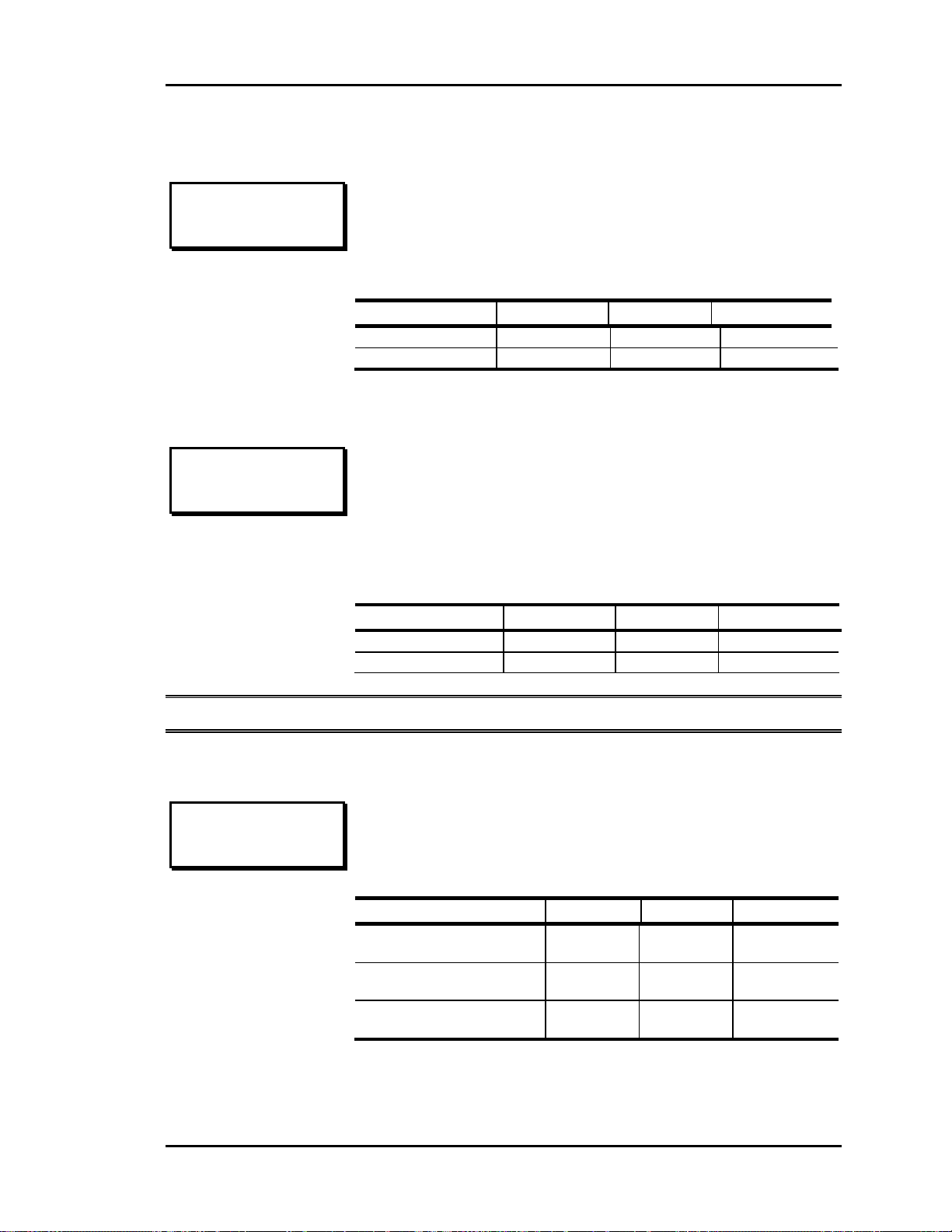

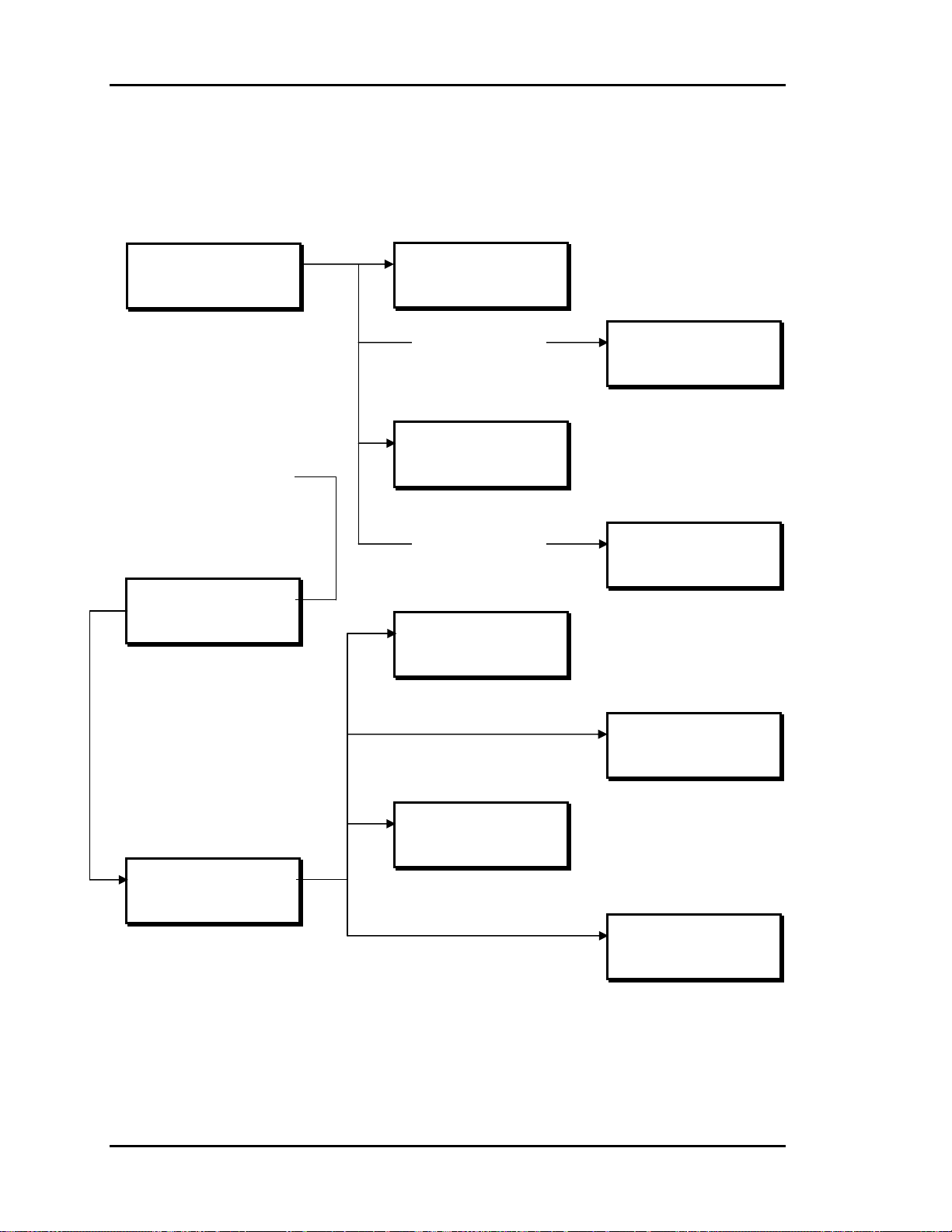

Figure 1-1: Auto-Zone Basic Control System...............................................................2

Figure 1-2: Control Zones Affected by the Outdoor Load ............................................9

Figure 1-3: Locating the Static Pressure Sensor for Bypass Damper Control ............12

Figure 1-4: Round Damper Dimensions......................................................................14

Figure 1-5: Rectangular Damper & Kit Dimensions...................................................14

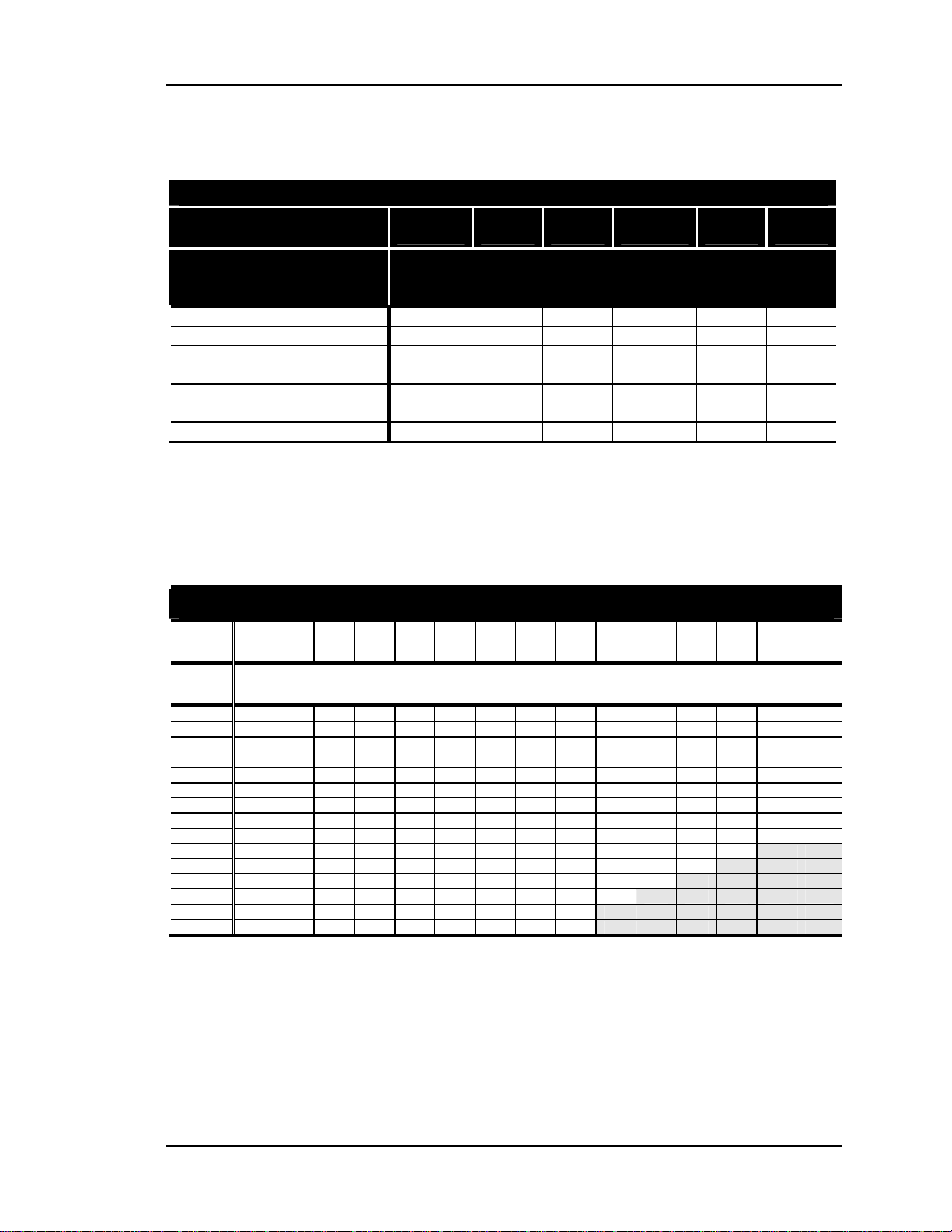

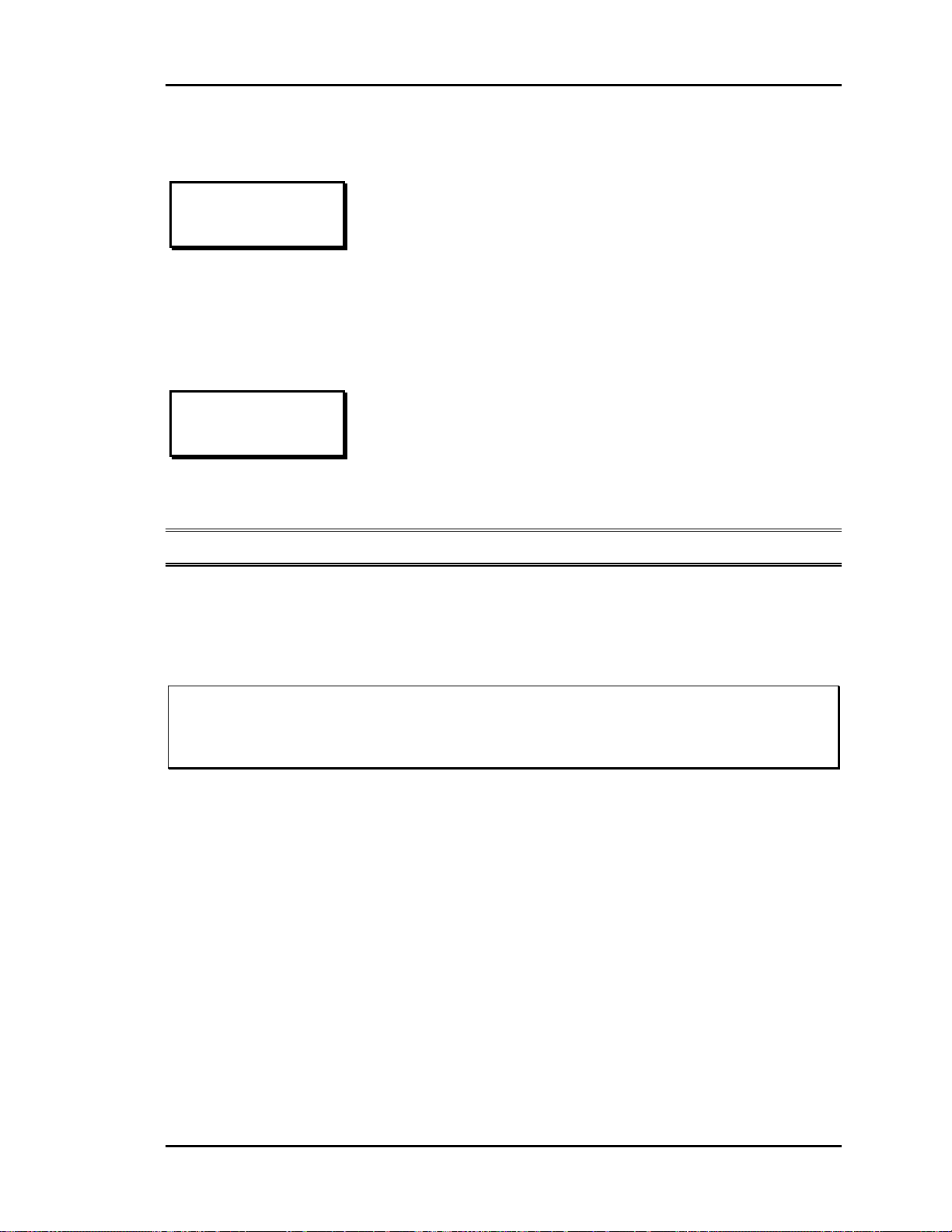

Table 1-1: Round Air Damper Selection .....................................................................15

Table 1-2: Rectangular Damper Selection...................................................................15

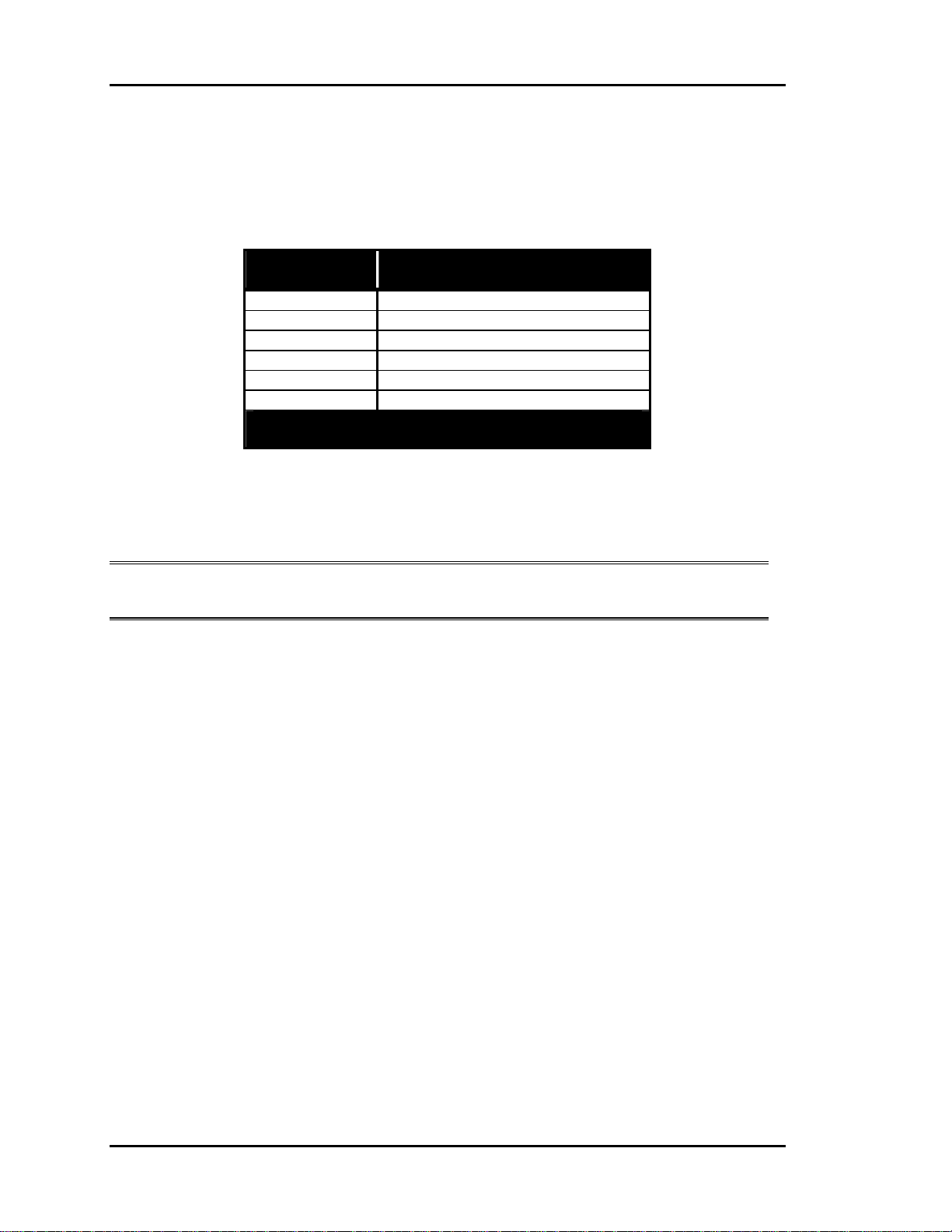

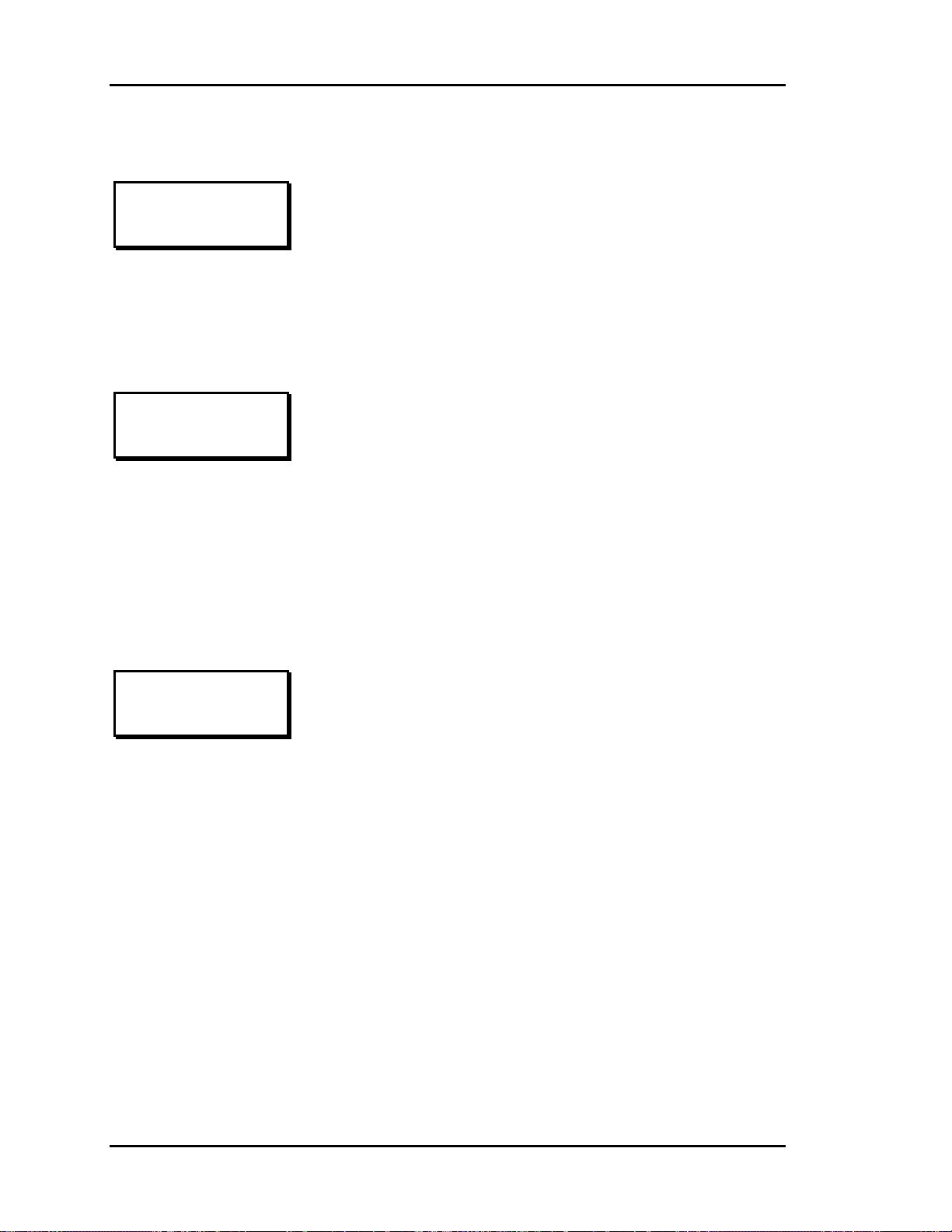

Table 1-3: Pressure Independent Flow Factors............................................................16

Design Guide

Page 6

Page 7

Auto-Zone Basic

Section 1

Conventions

This document uses the following definitions throughout as a guide to the user in

determining the nature of information presented:

Note: Additional information which may be helpful

Tip: Suggestion to make installation, set-up, and troubleshooting easier.

Caution: Items which may cause the equipment not to function correctly, but will

not otherwise damage components.

Warning: Errors which can result in damage to equipment and void warranties.

Design Guide 1-1

Page 8

Section 1

A

V

Auto-Zone Basic

To HVAC Unit

Control Panel

Supply

ir Temp

Sensor

Optional Remote Li nk II

Connects to CommLink IV

And Provides Alarm Call-Outs

A Second Remote Link Is Required

If Connection To Job Site

Is Desired From Remote Computer

Remote Link II

(Optional)

CommLink IV

The CommLink IV Is

Required For All Systems.

The IP Module, Remote

Link II, And Computer Are

Optional On All Systems.

All Computers Requ ire

Installation of Prism

Graphical User Interface

Software

USB Cable To Computer

Phone Cable To

Telephone

Wall Outlet Jack

CommLink IV

Single Loop

Economizer

(Actuator By Others)

Outside

Air Temp

Sensor

Computer

(Optional)

24VAC

Ethernet Cable To Router

Ethernet Router

(By Others)

When IP Module

Option Is Used

RS-485

9600 Baud

Optional IP Module

Installs Into CommLink IV

And Provides

LAN And Internet

Communications

With The Control System

Static

Pressure

Sensor

Zone Controller

elocity Sensor

(Optional)

Return

Air Temp

Sensor

Bypass Air

Damper

Typical Zone

Damper Actuator

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

Room Sensor

with Optional

Override & Adj.

#16

RS-485

Comm Loop

24 VAC

Figure 1-1: Auto-Zone Basic Control System

1-2 Design Guide

Page 9

Auto-Zone Basic

Section 1

General Information

The primary application of the Auto-Zone Basic Control System is to provide multiple

controlled comfort zones from a single zone, unitary heating and air-conditioning

package unit. It can also be applied to existing installations for improved comfort to

multiple zones currently controlled by a single thermostat.

Description of System Components

A typical Auto-Zone Basic Control System is comprised of the following four basic

components.

Zone Manager

The Zone Manager is a microprocessor-based controller which monitors up to 16 zones

in the system. The zone manager then controls the HVAC unit to satisfy the requirements

of each individual zone while maintaining efficient operation and comfort. The zone

manager is also responsible for controlling duct static pressure.

In the Auto-Zone Basic version, the Zone Manager has a display and a keypad. The 4line by 20-character display is backlighted, making it easier to read in low light

environments.

Bypass Damper

The bypass damper controls proper duct static pressure to insure proper airflow. The

damper is modulated by the Zone Manager based on a signal received from the static

pressure sensor connected to the main duct.

Zone Controller

The Zone Controller monitors space temperature and allocates proper airflow to the

assigned zone to achieve desired comfort and ventilation levels. If supply air temperature

will benefit the local zone temperature setpoint, the zone damper modulates to reduce or

increase airflow as needed. If supply air will not benefit the local zone, the controller will

direct the damper actuator to a minimum position and wait for a change in supply air

temperature.

Design Guide 1-3

Page 10

Section 1

Auto-Zone Basic

Zone Sensor

The patented zone sensor is a flush, wall-mounted design. A special plate on the face of

the sensor accurately senses space conditions. As a result of its unique design, the zone

sensor rejects the influence of internal wall temperature effects. The sensor comes in four

different configurations:

• Sensor only

• Sensor w/push-button override (override is fixed at 2 hours)

• Sensor w/setpoint adjustment

• Sensor w/override & setpoint adjustment

Any combination of these sensor configurations can be used with the system.

1-4 Design Guide

Page 11

Auto-Zone Basic

Section 1

Design Considerations

Consider the following items when designing a system using Auto-Zone.

Zone Diversity

The Auto-Zone Basic Control System is designed to improve tenant comfort by

dynamically re-balancing the air distribution when used with a typical constant volume

rooftop heating/cooling unit. If zones with extremely different load conditions are

serviced by a single rooftop unit, the result will be poor control and excessive wear due

to cycling of the equipment.

It is especially important to avoid mixing interior zones (which require cooling all year)

with exterior zones (which may require constant heat during winter months). If you must

mix zones under these conditions, consider using either VAV boxes with heat or separate

baseboard heat on exterior zones. Auto-Zone Basic Control Systems offer a variety of

methods to control additional zone heat to help you avoid problems.

Cooling - Partial Load Conditions

The engineer must be aware of several potential problems when applying the Auto-Zone

Basic Control System during cold weather operation.

Low Ambient Temperature Lockout

During very cold weather it is common for mechanical systems to have “low temp

lockouts” which protect equipment from damage if operated under these conditions.

Auto-Zone also provides user programmed lockouts for protection purposes, although

mechanical safeties should always be used as the final stage of protection.

If the rooftop unit services interior zones with thermal loads which require cooling when

outside temperatures are below the safe operating limits for your equipment, you should

seriously consider installing an economizer on your rooftop unit. The Auto-Zone control

system is designed to take advantage of an economizer if it is installed. The use of an

economizer will save money on utilities and provide comfort under conditions when it is

not possible to operate the mechanical cooling system.

Low Supply Air Temperatures

Under lightly loaded conditions much of the supply air may be bypassed back into the

return airside of the system. This bypassing will result in the lowering of the supply air

Design Guide 1-5

Page 12

Section 1

temperature, which may result in the supply air temperature reaching the low temp safety

limit. If the supply air low temp safety limit is exceeded, the control system will “cut-off”

the mechanical cooling to protect it from damage. Excessive cycling of the mechanical

system will result if this condition persists. Comfort may also suffer if the system cannot

run long enough to satisfy cooling demands.

A number of things can be done to reduce this problem. Some of these things depend

upon the type of installation.

• Avoid oversizing the unit. Do your load calculations carefully. Since Auto-Zone

directs the heating or cooling to the zones which require it, you may find that you can

use a smaller unit in many cases. Oversizing is the number one cause of excessive

low supply air temperature cycling.

• Increase your cooling minimum airflow or damper position settings to allow more air

during cooling operation. Be careful to avoid settings which are so high you cause

over cooling of the spaces. Find a compromise position.

• Bypass the air into the plenum instead of into the return air intake. Be careful if you

use this method since you may get “dumping” of cold air from your return air grilles.

This method works best with plenum returns. Do not use this method with ducted

returns unless you have carefully considered the consequences.

• Increase your static pressure setpoint to help reduce the amount of air being bypassed.

Be aware of increased noise levels and the cost of operation if you use excessive

static pressures.

Auto-Zone Basic

Warning: If the fan system has the capability of producing static pressures

which could damage ductwork, you must provide a manual reset high

pressure limit switch to cut-off the fan system in the event of high

duct static. Do not use your Auto-Zone Basic Control System as a

safety device!

• Use an Economizer. Although this is not a cure-all, it greatly improves operation

during cool weather when cooling loads are minimal. Using an Economizer also

improves ventilation and lowers operating costs, both of which are significant.

1-6 Design Guide

Page 13

Auto-Zone Basic

Section 1

Heating - Partial Load Conditions

Heating difficulties are less common than cooling difficulties. They are similar in nature,

however, and the cures are generally the same.

• Increase the Heating minimum setpoints on as many zones as possible.

• Increase the static pressure setting as high as is practical. Increasing static pressure

does not help if you are using pressure independent operation.

• Bypass to plenum instead of the return air intake if acceptable.

• Do not oversize your equipment.

• Use auxiliary heat in either your VAV boxes or baseboard.

Auto-Zone has a number of auxiliary heat control options which provide solutions to

most problems. Refer to the Auxiliary Heat Control Options topic near the end of this

section.

Override Conditions

After-hours overrides can produce aggravated partial load conditions in both the heating

and cooling modes. The problem is most commonly caused by a single zone being

overridden for after-hours use. This causes the rooftop equipment to operate for only one

zone. The Auto-Zone Basic Control System offers an improved solution to this common

problem by allowing a single override to trigger a group of zones via a “global” override.

This allows the system to operate with sufficient load to reduce cycling caused by light

load conditions.

Building Pressurization

If you are using an economizer, building pressurization must be addressed. Failure to

properly handle building pressurization may result in doors remaining open when the

economizer is operating. Pressurization problems can render economizer operation

useless. The following suggestions will help to avoid potential problems.

• Use powered exhaust when the system uses ducted returns. The return duct pressure

drop will cause most barometric relief dampers to function poorly or not at all. AutoZone has the ability to control a powered exhaust whenever the economizer is

operating.

• Use a separate building pressure control which operates a relief fan or dampers.

Design Guide 1-7

Page 14

Section 1

Auto-Zone Basic

Design Guide

There are six basic steps to designing an Auto-Zone Basic Control System:

1. Zoning

2. Sizing the Central Unit

3. Duct Design Considerations

4. Room Air Motion / Diffuser Selection

5. Bypass Damper Sizing

6. Sizing Zone Dampers

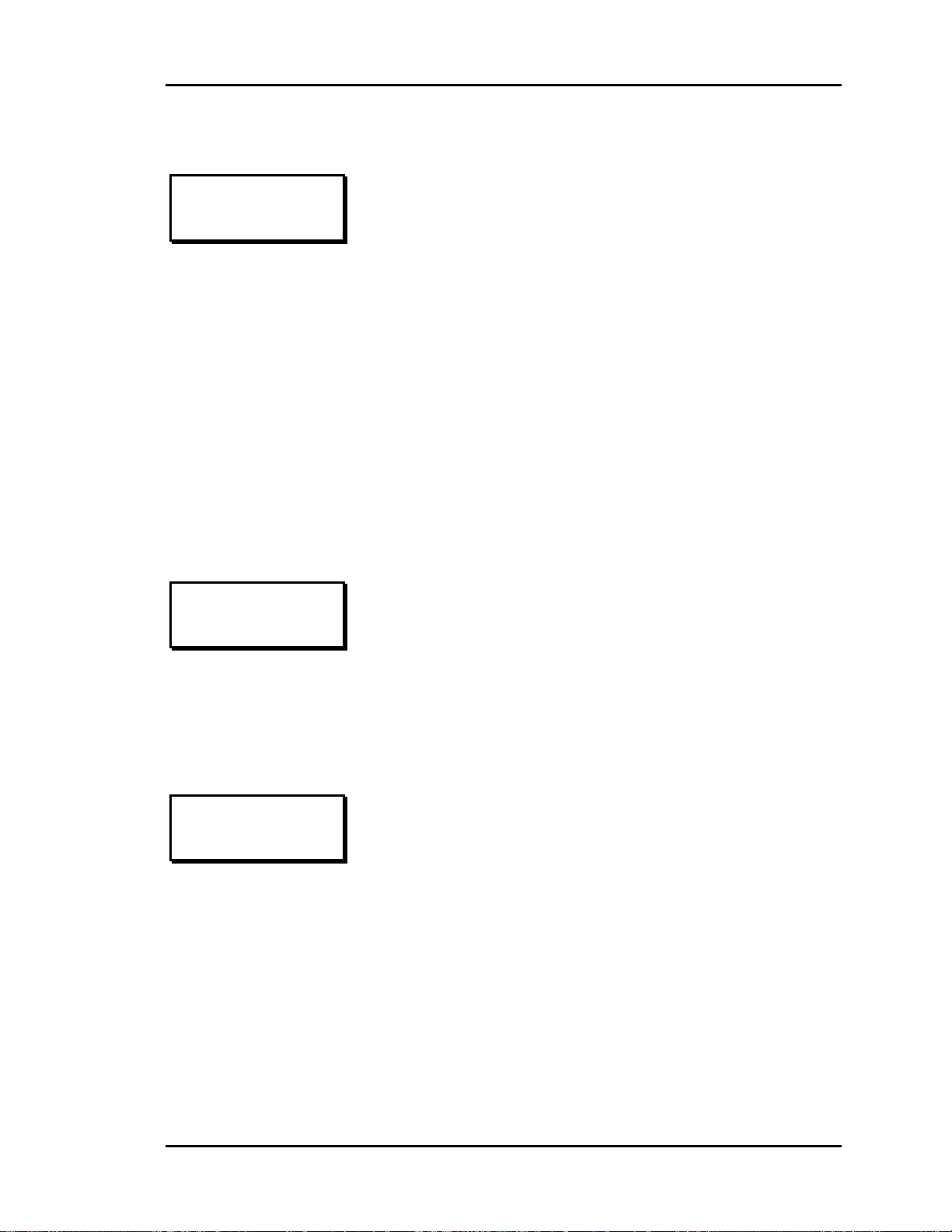

Step #1 - Zoning

Determine the number of zones. A single air handler unit can have no more than 16

zones. If the number of zones exceeds 16, then more than one Zone Manager will be

required. Consider using the Auto-Zone Plus system if more than one Zone Manager is

required.

The primary precaution to be taken in applying the Auto-Zone Basic Control System is to

select the zoning so that no zone will be at maximum (design) heating (or cooling) load

when any other zone requires the opposite temperature air to satisfy its load. For

example, depending on the wall, ceiling, floor material, and location within the building

(e.g. top or middle floor), a typical floor of a building usually has a minimum of 9

distinct temperature or control zones that are affected uniquely by the outdoor load.

These zones are depicted in Figure 1-2.

Depending on the size of the building and partition layout, some of these zones may

overlap or be insignificant from a zoning standpoint. For example, Zone 10 could be

multiple conference or computer rooms where additional zoning would be required, or it

could be as small as a corridor where no zoning is required. Similarly, zones 4 and 5

could have no external windows and no partitions between them and could be considered

a single zone. Zone 3 could be divided into multiple offices with full partitions between

them, thus requiring separate Zone Controllers because of different internal loads, but the

same external load.

Generally, the greater the number of individual Zone Controllers there are, the greater the

comfort. The designer will have to look at the specific building, balancing the costs of

multiple zones with the added comfort possible with multiple zones, to match the owner's

requirements.

1-8 Design Guide

Page 15

Auto-Zone Basic

Section 1

It is important to recognize that there are purely internal zones, such as Zone 10, which

may contain separate offices/conference/computer rooms. These internal zones could

easily have high cooling requirements while external zones (1, 2, 3, etc.) could be at or

near design heating load. This is a misapplication of the Auto-Zone Basic or Plus (or any

heating/cooling changeover) system. The interior zones with cooling-only loads should

be served with a separate air-conditioning unit (that could be zoned between multiple

rooms with a similar load profile). Supplemental heat could be added to the perimeter

zones and controlled with the auxiliary heat control board from the Zone Controller.

System performance will generally be compromised and frequent changeover from the

heating to the cooling mode will occur during the heating season if purely internal zones

are combined on the same air-conditioning unit serving perimeter zones.

Zoned HVAC Unit

Supply Air Duct

Supply Air Duct

9

Constant Volume HVAC Unit

Return Air Plenum

Bypass Damper

System Manager

Round Zone Damper

(Typical)

Room Sensor

(Typical)

W

S

Return Air Plenum

N

E

8

ER

G

ANA

M

rm

la

A

EM

n

tio

a

ic

n

s

mu

D

u

e

l

m

d

E

i

o

r

P

SYST

r

C

e

W

v

e

O

n

M

o

P

Z

8

-

D

3

o

:

t

E

3

I

u

S

0

P

A

M

7

U

9

R

C

/

A

1

C

L

0

/

O

A

1

0

.

O

C

N

I

N

c

S

s

L

E

O

R

T

N

O

u

C

n

R

e

E

T

M

S

A

M

T

T

A

W

3

2

6

1

r

e

t

n

E

5

r

9

a

e

l

4

C

s

8

u

n

i

M

7

0

.

c

e

D

*

1

7

6

W

A

R

W

A

R

M

N

O

E

R

M

R

A

L

C

O

V

O

R

O

L

E

R

M

N

O

E

R

M

R

A

L

C

O

V

O

R

O

L

E

R

10

W

A

R

M

N

O

E

R

M

R

A

L

C

O

V

O

R

O

L

E

R

2

3

5

W

A

R

M

N

O

E

R

M

R

A

L

C

O

V

O

R

O

L

E

R

4

W

A

R

M

N

O

E

R

M

R

A

L

C

O

V

O

R

O

L

E

R

W

A

R

M

N

O

E

R

M

R

A

L

C

O

V

O

R

O

L

E

R

Figure 1-2: Control Zones Affected by the Outdoor Load

Design Guide 1-9

Page 16

Section 1

Auto-Zone Basic

Step #2 - Sizing the Central Unit

Because the zones are controlled with variable air volume, it is unlikely that all zones

will be at design load at the same time. The zoning allows for the diversity of loads to be

taken into account and will often provide better comfort with a smaller HVAC unit.

In sizing the system, the individual zone loads should be calculated using any dependable

load estimating program. Because of diversity, the central unit should be selected for the

instantaneous peak load, not the sum of the peak loads, as would be done with a constant

volume single zone system. Consider the following when sizing the central unit.

• Size the peak cooling load based on the month and hour of the greatest total

building/system load.

• Heating should be sized for the lowest design temperature with an additional margin

for morning "pickup." This margin is generally recommended to be 20 to 25 percent

of base design.

Step #3 - Duct Design Considerations

The Auto-Zone Basic Control System uses a typical low pressure duct design. To reduce

noise problems, duct pressures should not exceed 1 inch W.C.

Primary trunk ducts should not be "undersized." This is especially true for "pressure

dependent" systems. Pressure dependent refers to the typical Auto-Zone Zone Controller

without the airflow sensor. With larger trunk ducts, it is easier to assure relatively constant

pressure to each zone. Runs should be as short as possible and the trunk duct system kept

as symmetrical as possible to facilitate system balancing. Wherever possible, run the trunk

ducts above corridors and locate the zone dampers above corridors to reduce the noise in

the space and facilitate service of the units. Trunk ducts should be sized for no more than

0.1 inch W.C. drop per 100 feet and a maximum duct velocity of 2000 FPM.

Note: For pressure independent terminal units with velocity sensors and

conventional "VAV" boxes properly selected for "quiet" operation, this 2000

FPM rule can be exceeded by up to 50 percent. The designer, however, should

be very experienced in VAV system design before considering modification

of this general rule.

Typical VAV systems with pressure independent terminals use the static regain method

for sizing ducts. The typical Auto-Zone Basic Control System is a low-pressure, pressure

dependent system that utilizes conventional unitary air-conditioning units. These systems

should use the equal-friction method of sizing the ducts and use the maximum loss of 0.1

inch per 100 feet as described above.

1-10 Design Guide

Page 17

Auto-Zone Basic

Section 1

Step #4 - Room Air Motion/Diffuser

Selection

Air motion is a consideration for occupant comfort. The selection of diffusers for an

Auto-Zone Basic Control System requires more care than a constant volume system due

to varying flow of air into the zones. Slot diffusers are recommended due to their superior

performance at low airflows. Because the zone airflow is variable volume, lower cost

round or rectangular diffusers that were satisfactory for constant volume may prove

unsatisfactory with an Auto-Zone Basic Control System. These diffusers may result in

"dumping" of the cold air at low flows in the cooling mode and insufficient room air

motion at low air flows in the heating mode. Although high air motion in the heating

mode can be undesirable, a slot diffuser with a high induction ratio generally helps to

reduce room air "stratification" when the heating comes from a ceiling diffuser. Linear

slot diffusers should be properly selected for the airflow and "throw" suited to the

specific installation or zone.

Additional factors to consider in diffuser selection are sound level and throw at design

flow. Generally, multiple diffusers will result in lower sound levels in the space, but this

must be balanced with the additional hardware and installation costs. It is commonly

recommended that slot diffusers be located near the perimeter or outside wall with the

airflow directed into the room. Consult your diffuser supplier or catalog for proper

diffuser sizing and location.

Series fan boxes may be used instead of zone dampers where higher induction rates are

desirable. If the heat loss on perimeter walls is high, such as large areas of glass, the use

of Series Fan Boxes may be indicated to maintain higher induction rates to offset

“downdrafts.” If the heat loss is greater than 275 BTUH/LINEAR FOOT, you should use

high quality slot diffusers next to the outer wall with the airflow directed inward to

counteract downdrafts during heating. Serious downdraft problems occur when heat

losses exceed 400 BTUH/LINEAR FOOT. In such case, both high induction diffusers

and series fan boxes are recommended.

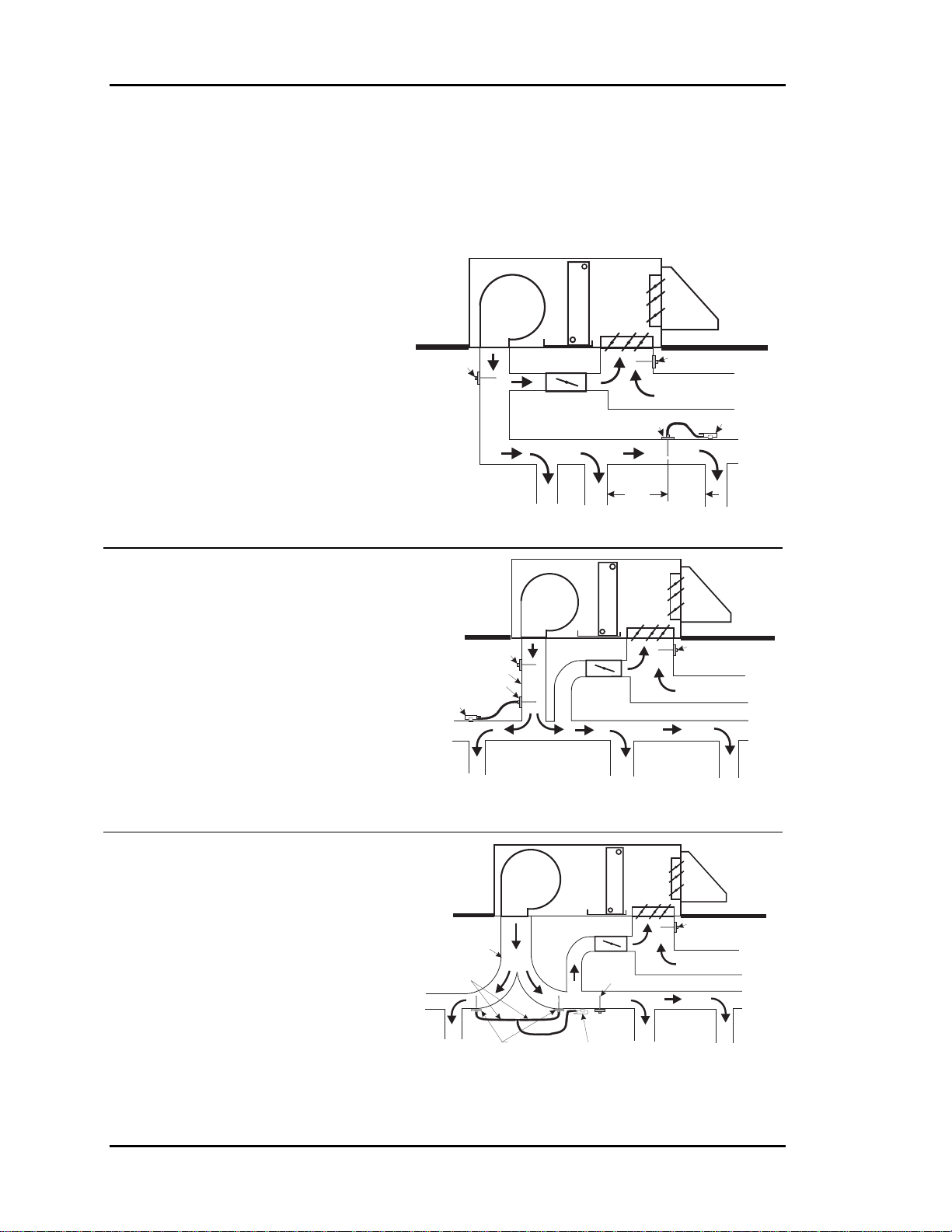

Step #5 - Bypass Damper Sizing

Using a load calculation program, the bypass damper should be sized to give you the

maximum CFM of air to be bypassed, typically 60 to 70 percent of the HVAC units rated

capacity. Bypass Dampers can either be round or rectangular depending on building or

job requirements. Use the appropriate round or rectangular damper selection table to

determine the correct damper size for your application. To size the damper, select a

damper from the table based on calculated bypass CFM and a maximum velocity

between 1750-2250 FPM. When determining the bypass duct size, be sure to take into

account any transition fittings and associated pressure drops. (See Table 1-1: Round

Damper Selection or Table 1-2: Rectangular Damper Selection.)

Design Guide 1-11

Page 18

Section 1

Auto-Zone Basic

If space limitations or total airflow requires it, multiple bypass dampers can be controlled

in parallel. For proper control of the Bypass Damper, the static pressure sensor location is

very important. Refer to Figure 1-3: Locating the Static Pressure Sensor for Bypass

Damper Control below for proper mounting locations.

Preferred Location

If the trunk ducts are properly sized

for minimum pressure drop, the

Fan

location of the static pickup probe is

not particularly critical. It should

ideally be located at right angles to

the airflow in a straight section of the

supply duct approximately ⅔ the

distance of the total length of the

supply duct. Also, the probe should

SA Sensor

Bypass Damper

SPPickup

Supply Air Duct

RASensor

Return Air Duct

SP Sensor

be located not less than 3 duct

diameters downstream and 2 duct

diameters upstream of any elbow or

3D

Min.2DMin.

takeoff.

Less Than Ideal, But

Acceptable

Since the "ideal" location is often

Fan

difficult to find in an installation, a

location in the main trunk where

the tip is not in a "negative

pressure area" (e.g. just

downstream of the inside curve of

Supply Air Duct

SP Sensor

SA Sensor

SPPickup

Bypass Damper

RASensor

Return Air Duct

an elbow) or an area where the

tube opening is directly impacted

by the velocity of the supply air is

acceptable.

Least Desirable, But

Acceptable

If the supply duct comes directly

from the unit and immediately

splits in opposite directions, the

pressure pickup should be located

ahead of the split or as close to it

Supply Air Duct

TubingToBeEqual

LengthAnd Size

Fan

Bypass Damper

SA Sensor

RASensor

Return Air Duct

as possible, even if the bypass

damper(s) are located downstream

of the split.

SPPickups

SP Sensor

Figure 1-3: Locating the Static Pressure Sensor for Bypass Damper Control

1-12 Design Guide

Page 19

Auto-Zone Basic

Section 1

Step #6 – Sizing Zone Dampers

Use a load program to determine the peak load for each zone. These calculations will be

used in selecting the appropriate zone damper sizes.

A round damper or rectangular damper can be selected depending on the building or job

requirements. If the job requires pressure independent damper control, the damper

selected must be a round damper. Rectangular dampers are not available for pressure

independent control. Please see Table: 1-1 for round damper selection. Please see Table:

1-2 for rectangular damper selection.

Using the maximum acceptable velocity for a branch duct (typically 1000-1500 FPM for

minimal noise), find the smallest damper that will deliver the required CFM as

determined by the load program.

Go to either the Round Damper Selection table (Table: 1-1) or the Rectangular Damper

Selection table (Table: 1-2) depending on your requirements to select the dampers.

Locate the branch velocity used in the duct design program on the left hand column of

either damper sizing chart (Table: 1-1 or Table: 1-2). Move across the chart and find the

damper which will provide the acceptable CFM to meet each zone’s airflow

requirements.

Note: Compare the damper size selected against the duct size to determine if the

next size up or down will provide acceptable performance without requiring a

transition fitting.

Up to two additional dampers may be slaved together for larger zones. See zone wiring

diagram for details. This should be reserved for situations when it is not practical to use a

single large damper.

Design Guide 1-13

Page 20

Section 1

Note: Dimensions Are

Identical For Round Zone,

Bypass & Slave Dampers

Auto-Zone Basic

Figure 1-4: Round Damper Dimensions

Note: See Table 1-2 for

Available “A” x “B”

Rectangular Damper Sizes

Note: Dimensions Are Identical

For Rectangular Zone, Bypass &

Slave Dampers

Figure 1-5: Rectangular Damper & Kit Dimensions

1-14 Design Guide

Page 21

Auto-Zone Basic

Section 1

Round Dampers

Round Air Damper Selection

Air Damper Round Duct Size

( Area Ft2 )

Velocity Through Round Air

Damper

(FPM)

750 - Zone

1000 - Zone

1250 - Zone

1500 - Zone

1750 - Bypass Only

2000 - Bypass Only

2250 - Bypass Only

Table 1-1: Round Air Damper Selection

6”

(0.188)

(0.338)

141 254 399 577 788 1031

188 338 532 769 1050 1375

235 423 665 961 1313 1718

282 507 798 1154 1575 2062

329 592 931 1346 1838 2405

376 676 1064 1538 2100 2749

423 761 1197 1730 2363 3094

8”

10”

(0.532)

12”

(0.769)

14”

(1.050)

Volume Through Round Air Damper

(CFM)

16”

(1.375)

Rectangular Dampers

Rectangular Damper Selection

Damper

Height

(B)

Damper

Width

(A)

8”

10”

12”

14”

16”

18”

20”

22”

24”

26”

28”

30”

32”

34”

36”

Table 1-2: Rectangular Damper Selection

Notes: 1.) Zone Dampers Should Be Sized Based On The Required Zone CFM. The Table Above Is

8” 10” 12” 14” 16” 18” 20” 22” 24” 26” 28” 30” 32” 34” 36”

Airflow Through Rectangular Damper

CFM @ 1000 FPM Velocity

410 530 640 740 850 970 1080 1190 1300 1410 1520 1630 1740 1850 1970

510 590 690 800 910 1030 1150 1260 1380 1500 1610 1730 1840 2000 2080

560 650 730 850 970 1090 1210 1330 1460 1580 1700 1820 1940 2060 2190

660 770 880 1030 1180 1330 1480 1630 1760 1910 2060 2210 2360 2510 2640

750 890 1030 1200 1370 1540 1710 1880 2060 2230 2400 2570 2740 2910 3090

770 980 1180 1380 1580 1780 1980 2180 2350 2550 2750 2950 3150 3350 3540

850 1090 1330 1550 1770 1990 2210 2430 2650 2870 3090 3310 3530 3750 3990

930 1210 1480 1730 1980 2230 2480 2730 2950 3200 3450 3700 3950 4200 4440

950 1290 1630 1900 2170 2440 2710 2980 3250 3520 3790 4060 4330 4600 4880

990 1390 1780 2080 2380 2680 2980 3280 3550 3850 4150 4450 4750

1070 1500 1930 2250 2570 2890 3210 3530 3850 4170 4500 4820

1020 1550 2080 2430 2780 3130 3480 3830 4150 4500 4850

1090 1660 2230 2600 2970 3340 3710 4080 4450 4820

1150 1770 2380 2780 3180 3580 3980 4370 4750 NA NA NA NA NA NA

1060 1790 2520 2670 3090 3510 3930 4350 5040

NA NA NA NA NA

NA NA NA NA NA NA

NA NA NA

NA NA NA NA

Calculated Based On 1000 FPM Velocity Through The Rectangular Damper. Zone Damper

Recommended Velocity Is 1000 – 1500 FPM. Select 1000 FPM or Less for Quiet Operation. For Other

Velocities, Use The Following Multipliers To Obtain The Correct CFM: 500 FPM = 0.5, 750 FPM =

0.75, 1250 FPM = 1.25, 1500 FPM = 1.5, 2000 FPM = 2.0, 2250 FPM = 2.25.

2.) Bypass Dampers Should Be Selected for 60% to 70% of the HVAC Units Rated CFM Capacity.

Recommended Bypass Damper Velocity is 1750 – 2250 FPM.

NA NA

Design Guide 1-15

Page 22

Section 1

Auto-Zone Basic

Pressure Independent Zone Dampers

Pressure Independent operation is only available for round zone dampers. Use the chart

below to set the calibration of the zone damper after installation.

Damper

Size

6” 474

8” 950

10” 1417

12” 2120

14” 2908

16” 3700

Flow Probe “K” Factor =

CFM @ 1” Velocity Pressure

Table 1-3: Pressure Independent Flow Factors

Flow Probe

“K” Factor

Note: K Factors are programmed for each zone so that the correct CFM will be

calculated for the different size air valves.

1-16 Design Guide

Page 23

Auto-Zone Basic

Section 1

Auxiliary Heat Control

Options

The Auto-Zone Basic Control System offers you a variety of methods to deal with zone

heating requirements. When deciding how to handle zone heating requirements, you

should consider the following:

• Does the rooftop unit have heat?

• Are you using fan-powered boxes?

• Is auxiliary heat used such as baseboard or radiant ceiling panels?

If the zone has some type of heat, you must consider how the heat is to be used. Typical

questions that should be asked:

Q: Should the zone heat be used as a first stage where it will become active before a

heating demand is created at the rooftop unit?

A: This mode is useful if you expect to have both heating and cooling demands at the

same time. The zone will use its own heat and allow the rooftop unit to continue to

provide cooling for other zones. This mode is also useful if the rooftop unit does not

have any heating capabilities.

Q: Is the zone heat only to be used as a second stage where it will be activated only if

the rooftop unit cannot maintain the space temperature such as during very cold

weather?

A: In this mode of operation the rooftop will examine the heating and cooling demands

and try to satisfy all of the zones by switching between heating and cooling as

required. The zone heat will only be activated if the zone temperature falls below a

selected limit.

Q: Should the zone heat be locked out if the rooftop unit is supplying warm air?

A: In many instances, it is desirable to use the rooftop heating whenever possible and

only use zone heat when the rooftop unit is in cooling or vent mode. This often

provides the most cost-effective operation since zone heat is typically electric. This

mode of operation will lockout zone heat if the rooftop is delivering heated air.

Design Guide 1-17

Page 24

Section 1

Auto-Zone Basic

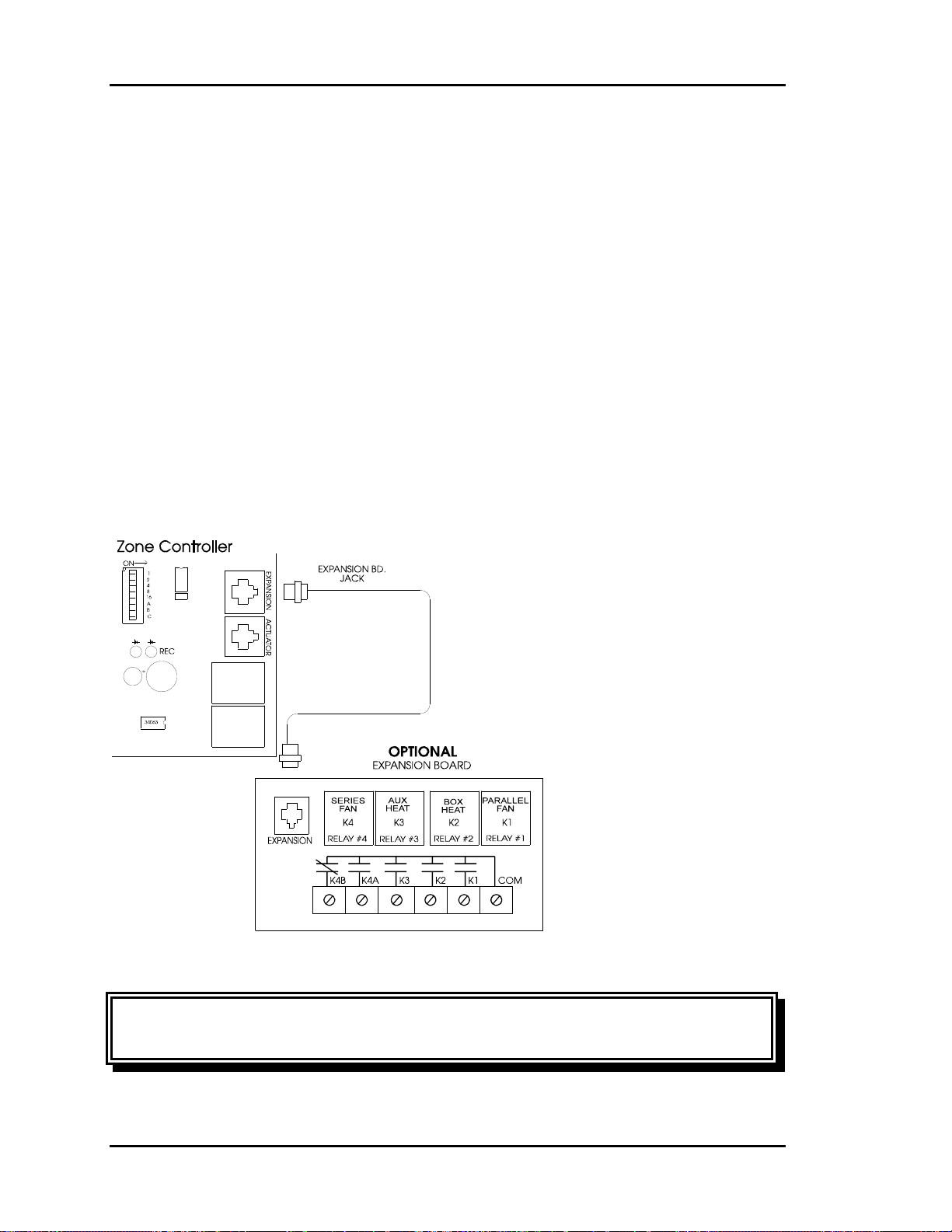

Relay Expansion Board

The following describes the operation of each of the relays on the optional relay

expansion board. You can choose the appropriate relays for any given application.

Relay #1 - Parallel Fan

If the Zone is in cooling mode or vent mode, the parallel fan can activate any time the

zone temperature drops 0.5°F below the heating setpoint. It de-activates when the

temperature rises above the heating setpoint. The space temperature must be below the

AUX HEAT setpoint in the occupied mode before the Parallel Fan relay can be

energized.

Relay #2 - Box Heat

If the zone is in cooling mode or vent mode, the box heat can activate any time the zone

temperature drops 1.5°F below the heating setpoint. It de-activates when the temperature

rises to within 1.0°F of the heating setpoint. Box heat is not allowed to activate in the

heating mode when there is hot air being supplied by the air handling unit. This output

was intended to allow zone re-heat while the Zone Manager is satisfying cooling

demands in other zones. The space temperature must be below the AUX HEAT setpoint

in the occupied mode before the Box Heat relay can be energized.

Relay #3 - Aux Heat

In the occupied mode, the aux heat can activate any time the zone temperature is 0.5°F

below the aux heat setpoint. It de-activates when the temperature rises 0.5°F above the

aux heat setpoint. In the unoccupied mode, the aux heat uses the unoccupied heating

setpoint with the same deadband values mentioned above. This prevents the zone from

maintaining the same aux heat setpoint at night that it does during the daytime.

This output was intended to allow zone heating to augment the normal heating mode and

also to allow a zone an attempt to satisfy its own heating needs before creating a heating

demand at the Zone Manager.

Relay #4 - Series Fan

The series fan runs any time the main fan is running. This includes occupied and

unoccupied modes. The fan can only start running when the zone damper is closed, so it

determines that the damper is closed before starting the fan.

1-18 Design Guide

Page 25

Auto-Zone Basic

Index

Section 1

1 inch W.C. ......................................... 10

After-Hours

Overrides........................................... 7

Air

Bypassing.......................................... 6

Air Motion .......................................... 11

Auto-Zone Plus System ........................ 8

AUX HEAT

Setpoint ........................................... 18

Auxiliary Heat

Control Board ................................... 9

Control Options............................... 17

Recommendation .............................. 7

Barometric

Relief Dampers ................................. 7

Baseboard

Heat................................................. 17

Basic System

Design Guide .................................... 8

Diagram............................................. 2

Boards

Relay Expansion ............................. 18

Box Heat ............................................. 18

Building Pressurization......................... 7

Building Zones

Diagram............................................. 9

Bypass

Air ..................................................... 6

Plenum .............................................. 7

Return Air Intake .............................. 7

Bypass Damper

Overview........................................... 3

Sizing .......................................... 8, 11

Bypass Duct Size ................................ 11

Ceiling Diffuser .................................. 11

Central Unit

Sizing .......................................... 8, 10

CFM

Correct ............................................ 16

Maximum........................................ 11

Comfort............................................... 11

Cooling

Partial Load Conditions .................... 5

Cooling Load

Maximum.......................................... 8

Dampers

Slaved.............................................. 13

Design

Duct............................................. 8, 10

Room Air Motion.............................. 8

Zoning............................................... 8

Design Guide ........................................ 8

Diagrams

Basic System..................................... 2

Diffusers

Ceiling............................................. 11

High Induction ............................ 11

Selection...................................... 8, 11

Slot .................................................. 11

Dimensions

Rectangular Damper ....................... 14

Round Damper ................................ 14

Duct Design ........................................ 10

Considerations .................................. 8

Duct Static

High................................................... 6

Duct Static Pressure .............................. 3

Ducted Returns ..................................... 6

Ducts

Undersizing..................................... 10

Ductwork

Damaging.......................................... 6

Economizer

Benefits Of........................................ 6

Recommendation .............................. 5

Equipment

Oversizing......................................... 7

Exhaust

Powered............................................. 7

Exterior Zones....................................... 5

Global Override .................................... 7

Design Guide 1-19

Page 26

Section 1

Auto-Zone Basic

Heat

Auxiliary ........................................... 7

Baseboard........................................ 17

Supplemental..................................... 9

Heating

Auxiliary ......................................... 17

Difficulties ........................................ 7

Partial Load Conditions .................... 7

Radiant Ceiling Panels.................... 17

Heating Load

Maximum.......................................... 8

Heating Minimum Setpoints................. 7

High Induction Diffusers .................... 11

High Pressure Switch

Manual Reset .................................... 6

Induction Ratio

High................................................. 11

Interior Zones........................................ 5

K Factors............................................. 16

Linear Slot Diffusers........................... 11

Load .................................................... 10

Diversity.......................................... 10

Load Calculation

Program........................................... 11

Load Estimating

Program........................................... 10

Lockout

Low Temp......................................... 5

Low Ambient Termperature Lockout ... 5

Low Supply Air Temperatures.............. 5

Low Temp Lockout............................... 5

Manual Reset

High Pressure Switch........................ 6

Maximum

CFM ................................................ 11

Cooling Load .................................... 8

Duct Velocity.................................. 10

Heating Load..................................... 8

Mechanical Safeties .............................. 5

Mutliple Zones...................................... 8

Negative Pressure Area....................... 12

Noise Levels ......................................... 6

Noise Problems ................................... 10

Operation

Quiet................................................ 10

Override

After-Hours....................................... 7

Conditions......................................... 7

Global................................................ 7

Oversizing

Equipment......................................... 7

Unit ................................................... 6

Overview

Auto-Zone System ............................ 3

Bypass Damper ................................. 3

Zone Controller................................. 3

Zone Manager ................................... 3

Zone Sensor ...................................... 4

Parallel Fan ......................................... 18

Partial Load Conditions ........................ 5

Aggravated........................................ 7

Heating.............................................. 7

Plenum Returns..................................... 6

Powered Exhaust................................... 7

Pressure Dependent............................. 10

Pressure Independent

Flow Factors ................................... 16

Zone Dampers................................. 16

Pressurization

Building ............................................ 7

Problems

Noise ............................................... 10

Program

Load Calculation............................. 11

Load Estimating.............................. 10

Quiet Operation................................... 10

Radiant Ceiling Panels........................ 17

Rectangular Damper

Dimensions ..................................... 14

Selection.......................................... 15

Relay Expansion Board ...................... 18

Relief Dampers

Barometric......................................... 7

Returns

Ducted............................................... 6

Plenum .............................................. 6

Room Air Motion................................ 11

Design ............................................... 8

Round Air Damper

Dimensions ..................................... 14

1-20 Design Guide

Page 27

Auto-Zone Basic

Section 1

Selection.......................................... 15

Safeties.................................................. 5

Selection

Diffuser ....................................... 8, 11

Rectangular Damper ....................... 15

Room Air Motion............................ 11

Round Air Damper.......................... 15

Series Fan............................................ 18

Boxes............................................... 11

Setpoints

AUX HEAT .................................... 18

Heating Minimum............................. 7

Static Pressure................................... 6

Sizing

Bypass Damper ........................... 8, 11

Central Unit................................. 8, 10

Zone Dampers............................. 8, 13

Slaved

Dampers .......................................... 13

Slot Diffusers ...................................... 11

Linear .............................................. 11

Static Pickup Probe............................. 12

Static Pressure

Setpoint ............................................. 6

Setting ............................................... 7

Static Pressure Sensor........................... 3

Location .......................................... 12

Stratification........................................ 11

Supplemental

Heat................................................... 9

System

Design Guide .................................... 8

Overview........................................... 3

Performance ...................................... 9

Temperatures

Low Supply Air................................. 5

Temperature Lockout

Low Ambient .................................... 5

Undersizing

Ducts ............................................... 10

Units

Oversizing......................................... 6

Velocity

Maximum Acceptable..................... 13

Zone

Comfort............................................. 8

Design ............................................... 5

Diversity............................................ 5

Zone Controller

Overview........................................... 3

Zone Dampers

Pressure Independent ...................... 16

Sizing .......................................... 8, 13

Zone Heating

Auxiliary ......................................... 17

Zone Manager

Overview........................................... 3

Units Per ........................................... 8

Zone Sensor

Overview........................................... 4

Zones

Divided.............................................. 8

Exterior ............................................. 5

External............................................. 9

Interior .............................................. 5

Internal .............................................. 9

Multiple............................................. 8

Number Of ........................................ 8

Overlapping ...................................... 8

Perimeter........................................... 9

Zoning

Design ............................................... 8

Design Guide 1-21

Page 28

Section 1

Auto-Zone Basic

1-22 Design Guide

Page 29

Section 2

Table of Contents

Tips Before Beginning Installation..................................1

Zone Manager ..................................................................3

Communications Loop .....................................................8

Communications Loop Wiring Overview........................................................................9

Bypass Dampers ............................................................10

Zone Dampers................................................................13

Zone Controllers ............................................................14

Room Sensors ................................................................................................................21

Supply Air Temperature Sensor ....................................................................................23

Return Air Temperature Sensor.....................................................................................24

Outside Air Temperature Sensor ...................................................................................25

Duct Static Pressure Sensor ...........................................................................................26

Auxiliary Relay Board for Zone Controllers...................28

Zone Controller Auxiliary Relay Board Operation .......................................................29

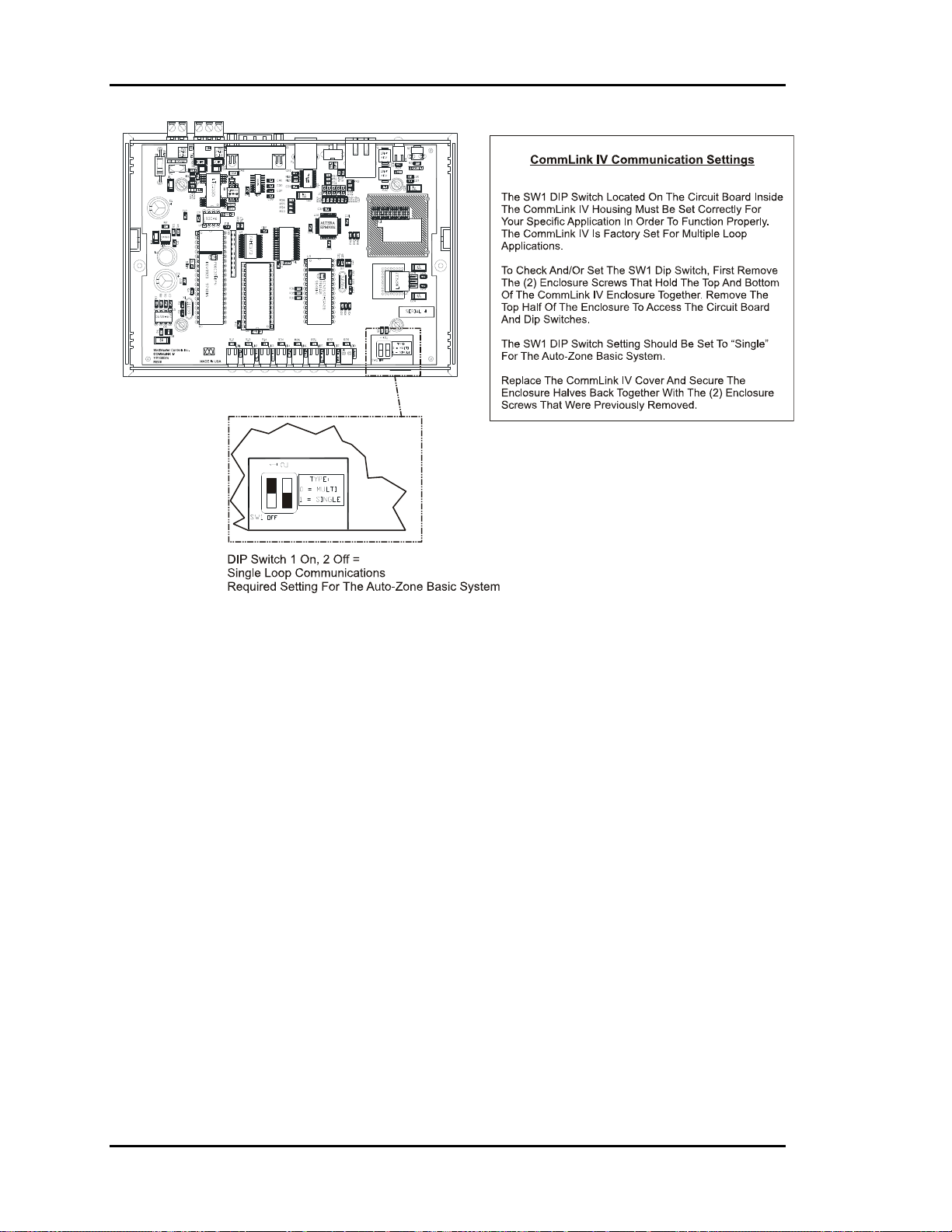

CommLink IV Interface..................................................30

Basic System Worksheet................................................................................................33

Installation and Wiring

Page 30

Section 2

Table of Figures

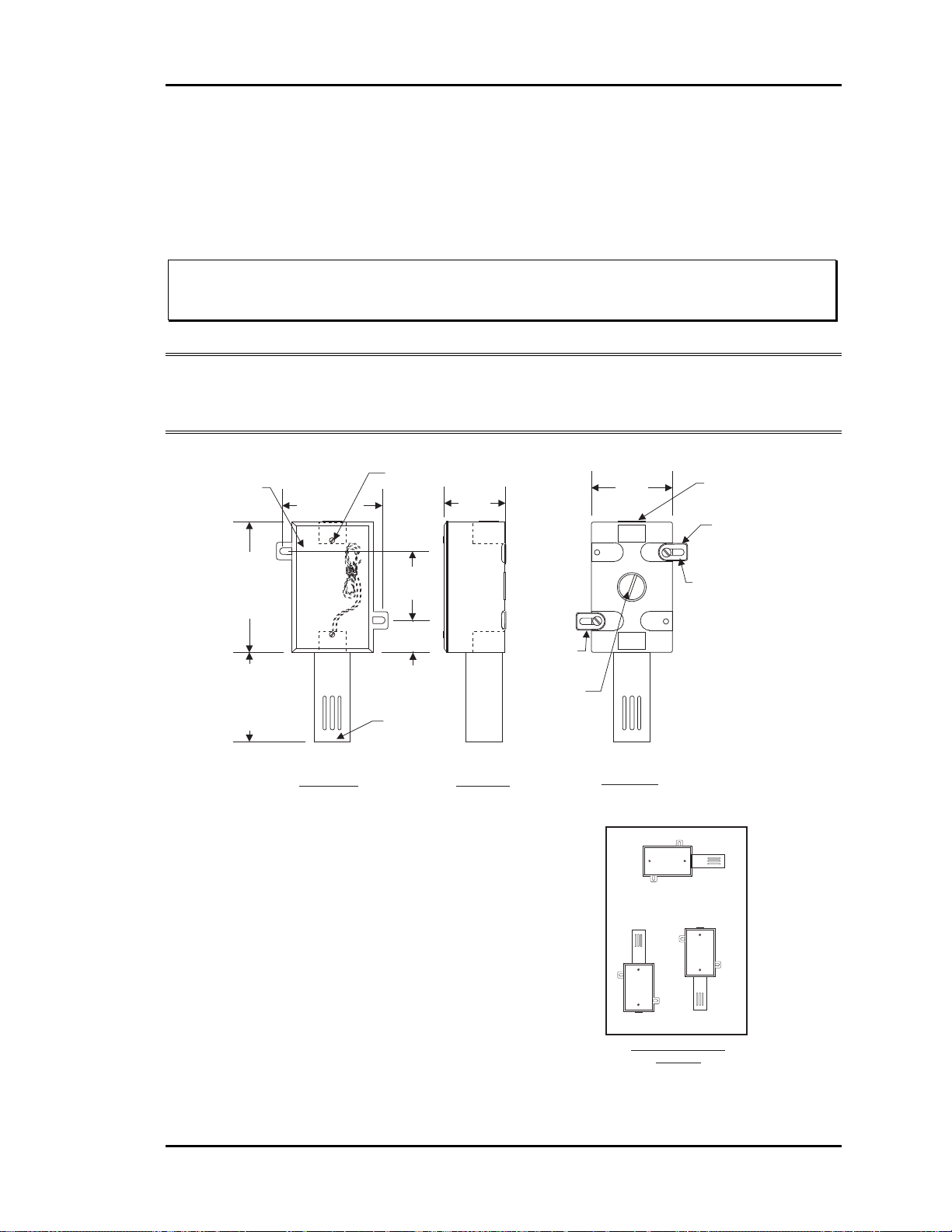

Figure 2-1: System Overview........................................................................................2

Figure 2-2: Typical System Component Locations.......................................................2

Figure 2-3: Zone Manager Dimensions ........................................................................3

Figure 2-4: Zone Manager Component Locations.........................................................4

Figure 2-5: Zone Manager Wiring.................................................................................5

Figure 2-6: Zone Manager Address Switch Setting ......................................................7

Figure 2-7: Communication Loop Wiring, Daisy-Chain Configuration .......................9

Figure 2-8: Round and Rectangular Bypass Dampers.................................................10

Figure 2-9: Bypass Damper Wiring.............................................................................12

Figure 2-10: Round and Rectangular Zone Dampers .................................................13

Figure 2-11: Zone Controller Components.................................................................15

Figure 2-12: Zone Controller Wiring..........................................................................17

Figure 2-13: Zone Controller Address Switch Settings..............................................19

Figure 2-14: Slaved Zone Controller Wiring..............................................................20

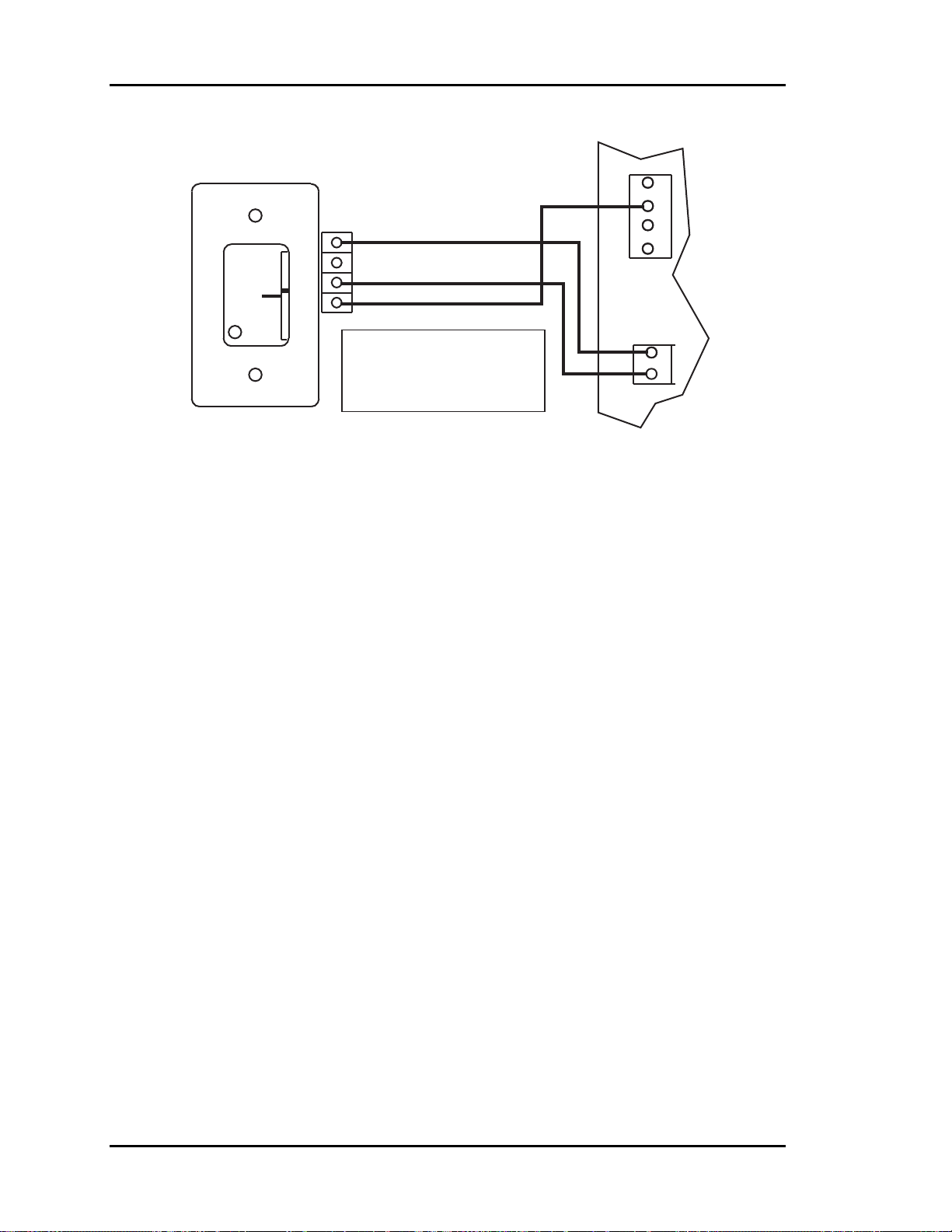

Figure 2-15: Room Sensor Installation .......................................................................21

Figure 2-16: Room Sensor Wiring..............................................................................22

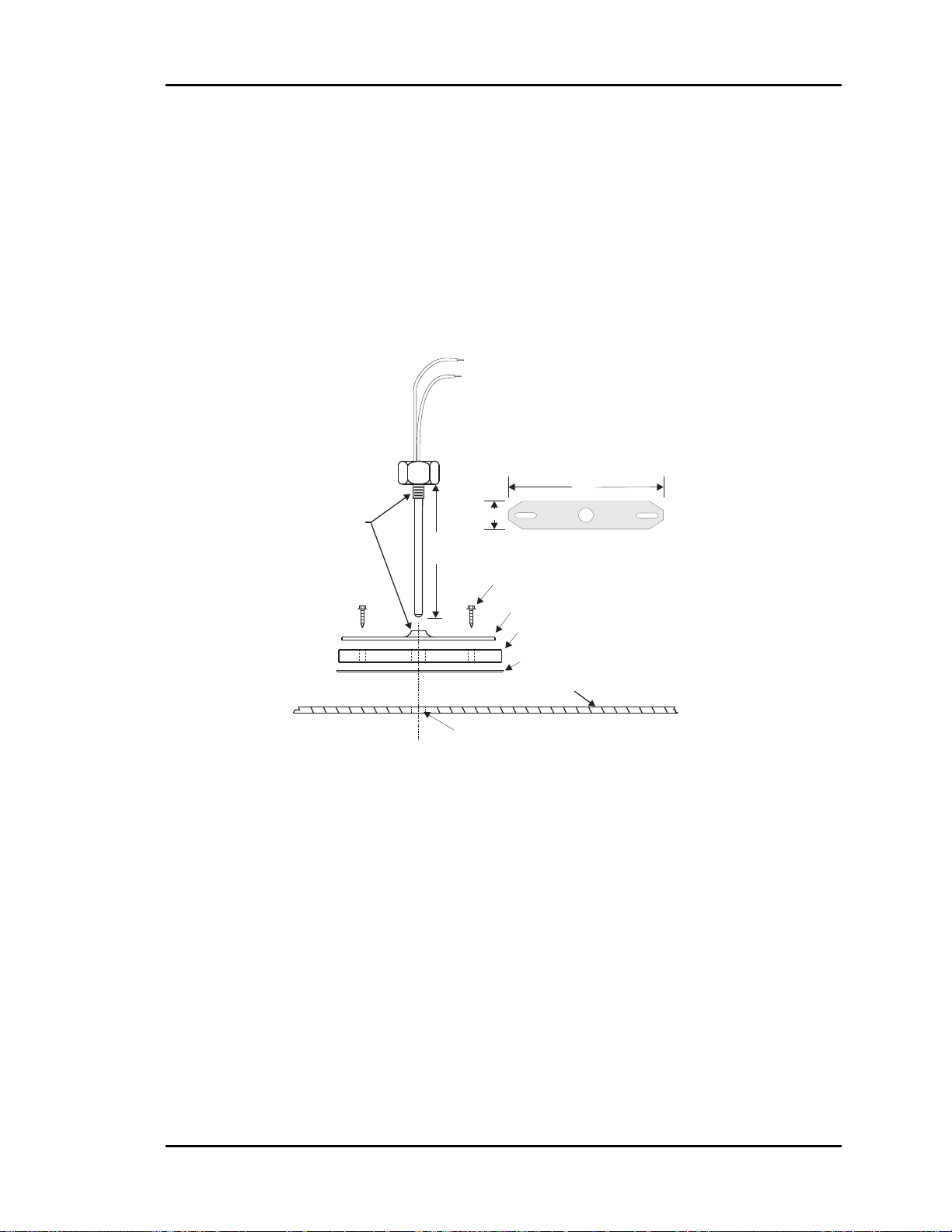

Figure 2-17: Supply or Return Air Sensor Dimensions and Installation ....................23

Figure 2-18: Outside Air Temperature Sensor Dimensions and Installation..............25

Figure 2-19: Duct Static Pressure Sensor Dimensions and Installation .....................26

Figure 2-20: Static Pressure Sensor Wiring................................................................27

Figure 2-21: Auxiliary Relay Board Layout...............................................................28

Figure 2-22: CommLink IV Interface Communication Wiring..................................30

Figure 2-23: CommLink IV Interface Connections....................................................31

Figure 2-24: CommLink IVJumper Switch Settings ..................................................32

Installation and Wiring

Page 31

Auto-Zone Basic

Section 2

Tips Before Beginning

Installation

Take a few moments to review the following before beginning installation of the

Auto-Zone Basic Control System.

• Familiarize yourself with all system components and review all documentation.

Pay special attention to “Cautions” and “Warnings” since these may keep you

from experiencing unnecessary problems.

Before installing zone dampers, be sure to tag each damper with its appropriate location.

It is also best to set the zone controller address switches before mounting in drop ceilings.

Use the Basic System Worksheet found in the back of this section or in the Basic Submittal Package to list all zone locations and Zone Manager configurations. This will assist

you greatly when setting up the system.

• Be sure to install all wiring according to local, state, and national codes.

• Pay close attention to communication wiring since the most common mistakes are

made in this area. Polarity is the most important rule. Make notes on your wiring diagrams as to which color wire you will be using on each terminal.

• When in doubt - ask! Contact your local Auto-Zone distributor if you have any ques-

tions. The only dumb questions are the ones you don’t ask.

• Remember - each electronic device contains only one puff of smoke. If you release it,

you have voided the warranty! So please be careful and pay attention.

Installation and Wiring

2-1

Page 32

Section 2

Auto-Zone Basic

Figure 2-1: System Overview

Typical HVAC Unit

(Packaged or Split System)

Supply Temp Sensor

(Ahead of Bypass Takeoff)

Static Pressure Pickup

(2/3 Of The Way Down Main Duct)

LOCAL COMM LOOP

TWISTED PAIR

WITH SHIELD TO

ZONE CONTROLLER

Above Corridor

( Preferred Location )

Supply Duct

Zone Damper and Control

LOCAL COMM LOOP

TWISTED PAIR WITH

SHIELD TO OTHER

ZONE CONTROLLERS

Zone Sensor

(4-1/2' to 5'; Shoulder Height)

W

A

R

M

N

O

E

R

M

R

A

L

C

O

O

V

R

O

L

E

R

( Over Corridor for Easy Service )

LOCAL COMM LOOP

TWISTED PAIR

WITH SHIELD TO

ZONE CONTROLLER

+

N

FA

1

L

O

O

C

2

L

O

O

C

®

1

T

A

E

H

2

T

A

N

E

E

H

P

O

S

S

E

A

P

S

Y

O

B

L

C

S

N

S

A

IO

P

T

Y

A

B

C

I

+

N

U

M

M

O

C

M

R

A

L

S

A

E

N

O

Z

L

L

E

A

N

=

O

R

Z

A

A

H

E

L

C

A

/C

E

T

I

=

N

B

U

C

A

V

H

=

S

A

C

M

R

A

L

3

R

A

E

T

=

B

N

D

E

2

/

P

E

6

T

S

1

=

L

C

A

#

5

M

I

C

9

E

D

4

=

D

*

8

#

7

0

*

+

+

Diffuser at Perimeter Wall

(Direct Airflow Inward Towards Center of Area)

Bypass Damper

( Locate Where Easily Accessible )

Return Temp Sensor

Duct to Return

(Preferred)

Outdoor Air Sensor

(Mount Away From Direct Sunlight))

(Avoid Mixed Air Area)

Zone Manager

Return Duct

Figure 2-2: Typical System Component Locations

2-2

Installation and Wiring

Page 33

Auto-Zone Basic

Section 2

Zone Manager

The Zone Manager may be installed in any convenient, protected location. Observe the

recommended environmental limitations for the Zone Manager (see Technical Data section of product data sheet) when choosing a location. The unit should be mounted with

the display at eye level for easy viewing.

When installing the Zone Manager with display and keypad, you must remove the cover.

Use care not to damage the display while handling and protect the display from physical

damage while removed.

The ribbon cable should be unplugged from the display board which is mounted inside

the front cover. The ribbon cable is keyed to prevent a reverse connection.

Warning: Always remove power before connecting or disconnecting the ribbon

cable which joins the display and keypad to the Zone Manager. Failure to observe this precaution may result in damage to the display or

Zone Manager.

The Zone Manager may be mounted without removing the controller from the enclosure

or mounting plate. The unit is mounted by four (4) screws in the corners. Select the correct screws or other fasteners for the type of mounting material being utilized.

Please see Figure 2-3, Figure 2-4, Figure 2-5, and Figure 2-6 for Zone Manager dimen-

sions, components, wiring, and addressing information.

3.00

Display

11.50

9.25

FRI

Mode

03:48PM

+

08-08-01

Cool

OCCUPIED

ALARMS

NO

1

4

7

*

A

3

B

2

6

C

5

9

D

8

#

0

+

N

FA

1

L

O

O

C

2

L

O

O

C

1

T

EA

H

2

T

EA

H

PEN

O

S

AS

SE

YP

B

LO

C

N

SS

A

TIO

YP

A

B

IC

N

U

M

M

O

C

RM

LA

S

A

NE

ZO

LL

E

A

N

=

ZO

A

AR

H

C

EA

=

B

UNIT/CLE

C

A

V

H

=

S

C

M

R

ALA

TER

=

D

/EN

STEP

=

L

A

#

IM

EC

D

=

*

+

Keypad

+

Figure 2-3: Zone Manager Dimensions

Installation and Wiring

2-3

Page 34

Section 2

Auto-Zone Basic

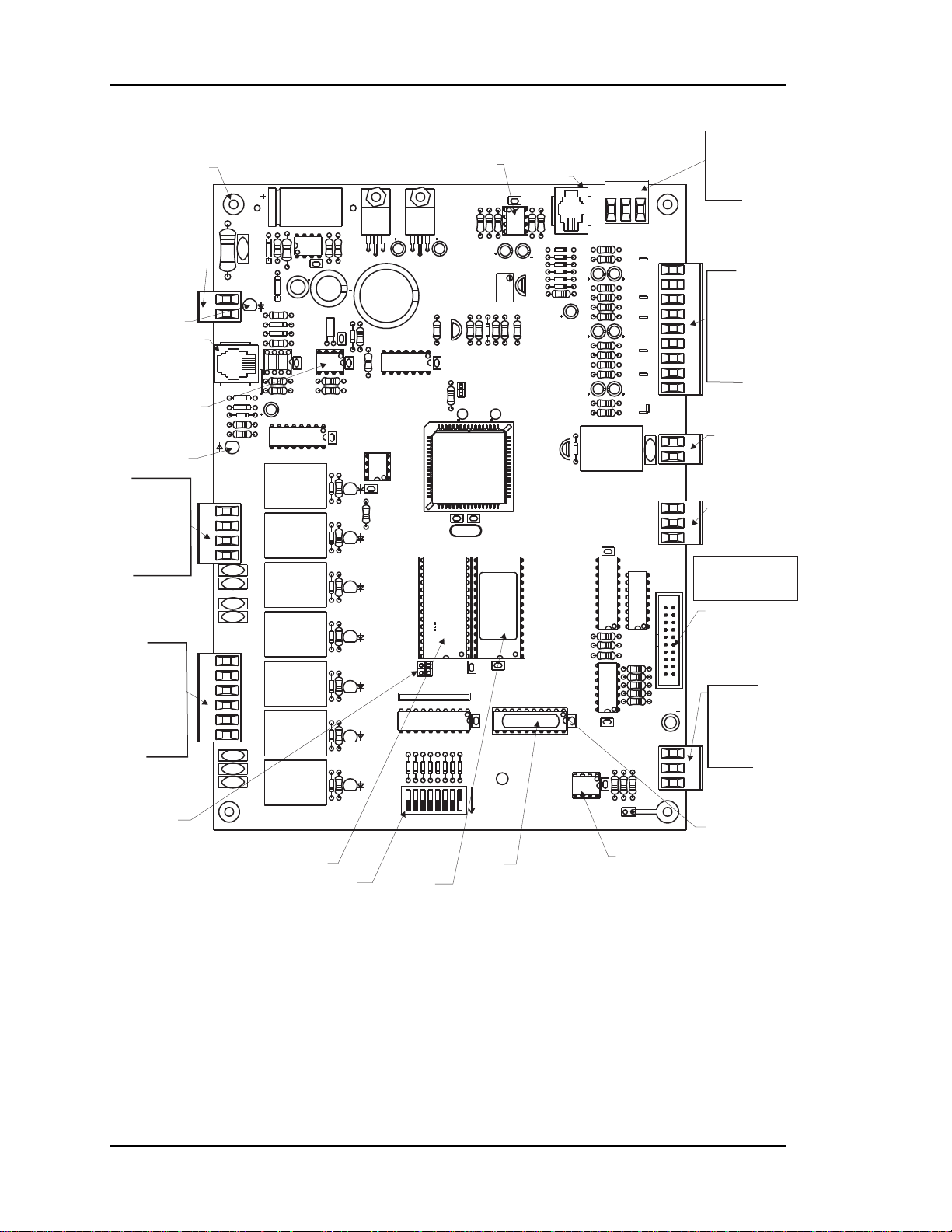

Mounting Holes

Typ. Of 4

24 VAC

Power Input

Power LED

Not Used

Real Time

Clock Chip

Comm

LED

Bypass

Damper

Connections

FDBK

GND

Open

Close

HVAC Unit

Connections

(R) Common

Fan

Cool 1

Cool 2

Heat 1

Heat 2

RAM Size

Select

Jumper

24VAC

GND

I2CEXP PORT

D13

D14

D15

R39

R40

BYPASSPDAMPER

TB7

R10

C1

D1

V1

U2

C6

R7

D7

POWER

TB2

REC

FDBK

GND

OPEN

CLOSE

V3

V4

V5

V6

R

FAN

COOL1

COOL2

HEAT1

HEAT2

V7

V8

V9

L1

R18

D9

D11

R26

CX3

U3

R32

R34

C17

U6

K2

K4K3

K5

K7K6

K8

RAM

Chip

Address Switch

(Set To 0 Without

CommLink. Set to 17

With CommLink)

Static Pressure

Real Time

Clock Chip

R2

R1

VR1

R9

C9

D12

Y1

R25

C12

SC1

CX4

R29

R33

R35

CX6

U7

OPEN

CX7

D17

R41

R42

CLOSE

D18

R43

FAN

R44

D19

COOL1

R46

D20

COOL2

D21

R52

HEAT1

D22

R56

HEAT2

D31

R57

VR2

C2

C3

5.11V

ADJUST

Q1

R20

D10

R22

R21

CX5

J01

U5

EWDOG

R36

C18

U8

C21 C20

32K

8K

JO2

U13

D23

D24

D26

D25

D27

SW1

NET

B

32

16

X2

RAM

U10

CX10

RN2

1

CX13

D29

D30

D28

MADE IN U.S.A.

ADD

284

1

PAL

EPROM

Chip

Chip

Sensor - Optional

Modular Connection

Input

CX1

R5

R4

R3

U1

D2

D3

C4 C5

D4

D5

D6

D8

R15

VR3

R13

R23

R24

R61

C19

5.11V

ADJ

YS101722

Rev. 2

EPROM

U11

CX11

1992

SENSOR JACK

PRESSURE

PJ1

R11

R12

C7

R14

R16

R17

C11

R19

C13

R27

R28

R30

R31

C15

R37

R38

Q2

D16

CX9

U9

R45

R47

R48

U12

U14

CX14

CX12

CX15

U15

RS-485

COMM DRIVER

+5V

PU1

C8

PU2

PU3

C14

PU4

PU5

ECONOMIZER

R58

R59

SIG

C16

PU6

EXH/RELIEF

RN1

R49

R55

R60

TB1

GND

ANALOG

INPUTS

+12V

SAT

RAT

OAT

AUX1

AUX2

AUX3

GND

GND

V2

ANALOG

OUTPUTS

GND

C22

T

SH

R

RS-485

Communications

Driver Chip

TB3

EXHAUST

CONTACTS

N.O.

TB4

TB5

Note:

EXP

Keypad & Display

BUSS

Not Shown

P1

COMM

TB8

Static Pressure

Sensor Inputs

+5V

SIG

GND

Analog Inputs

SAT

RAT

OAT

AUX1

AUX2

AUX3

GND

Binary Output

Relief/Exhaust

Fans

Analog Output

0-10 VDC

Economizer

Display &

Keypad

Ribbon Cable

Connector

RS-485

Communications

Loop Connection

T

SH

R

Typical

Pin 1

Indicator

Figure 2-4: Zone Manager Component Locations

2-4

Installation and Wiring

Page 35

Auto-Zone Basic

Section 2

Bypass

Air Damper

Actuator

Bypass & Slave

Interface Card

BYPASSAND

SLAVEINTERFACE

YS101824

OPEN

CLOSE

FROM ZONE

LD2

LD1

W1

HVAC Unit

W2

24VAC Only

Line

Voltage

TO ACTUATOR

PJ1

TB2

CONTROLLER

PJ2

TB1

R

G

Y1

Y2

GND

OPEN

CLOSE

FDBK

GND

OPEN

CLOSE

24VAC

GND

See Note 1 &2

Splice As

Required

10

Basic Zone Manager

+

NE5090

BYPASS

OPEN

BYPASS

CLOSE

G

FAN

Y1

COOL 1

Y2

COOL 2

W1

HEAT 1

W2

HEAT 2

+

LCD DISPLAY

KEYPAD

1 2 3BA

4 5 6

0*#D

D

D

D

D

D

D

D

24

22

20

18

19

23

21

SW

1

16

B

4

2

NET

32

8

Communications To Zone

Notes:

1.)24 VAC Must Be Connected So

That All Ground Wires Remain

Common.

2.)All Wiring To Be In Accordance With

Local And National Electrical Codes

and Specifications.

3.)All Communication Wiring To Be 18

Ga. Minimum, 2 Conductor Twisted

Pair With Shield. Belden #82760 Or

Equivalent.

24VAC

GND

+

POWER

TB2

+

REC

FDBK

GND

OPEN

CLOSE

FAN

COOL1

COOL2

HEAT1

HEAT2

V3

V4

V5

V6

LO HI

+

5.11V

ADJUST

&

D

17

MADE IN U.S.A.

C 1992

RockerDown

>

ADD

OFF

1

RS-485

Controllers

Static

Pressure

Sensor

C987

Pick-up

SEN

SO

R

JA

C

K

PJ1

75176

RS-485

COMM DRIVER

Static

PRESSURE

+5V

+

Red

Blk

SIG

RIBBON

CABLE

Grn

TB12

GND

ANALOG

INPUTS

+12V

+

SAT

RAT

OAT

AUX1

+

AUX2

AUX3

GND

GND

+

EXHAUST

CONTACTS

N.O.

ANALOG

OUTPUTS

A1

A2

G

EXP

BUSS

R5

R6

C

2

COMM

T

SH

R

Local Loop

TB2

P1

C

1

+

To Relief / Exhaust Fans

RS-485

Communications

To CommLink

When Used

Suppy Air Temp.

Sensor

Return Air Temp.

Sensor

Outdoor Air Temp.

Auxiliary Inputs

( Dry Contacts )

Aux3

Aux2

Forced

Filter

Occupied

Alarm

Mode

Economizer Actuator

Use Extreme Care When Wiring

Economizer Actuators

Never Connect Or Disconnect

Wiring With Power Applied!

Never Apply Power If The

Gnd ( 1 Com ) Terminal On The

Actuator Is Not Connected.

Belimo Actuator Wiring Shown.

Consult Factory For Other

Models Of Economizer Actuators.

Some Actuators Require Isolation

Transformers In Order To Prevent

Damage To The Controller Board.

Sensor

(See Note 4)

Aux1

Economizer

Disable

5U

BELIMO

4Y2

AF24-SR

3Y1

133 IN-LB

2+

1 COM

WARNING!

Figure 2-5: Zone Manager Wiring

Warning: Use extreme care not to damage any of the electronic components

while mounting the enclosure. Mark the holes and then remove the

Zone Manager before drilling. Do not allow metal shavings

to fall onto the circuit boards.

Installation and Wiring

2-5

Page 36

Section 2

The Zone Manager requires the following electrical connections:

18-Gauge minimum unless otherwise noted.

-24VAC Supply Voltage........................................................................... 2 Conductors

-Communications Loop ...................................... 2 Conductor twisted pair with shield

(Belden #82760 or equivalent)

-Supply Air Temperature Sensor........................................ (24 ga. Min.) 2 Conductors

-Return Air Temperature Sensor ........................................(24 ga. Min.) 2 Conductors

-Outside Air Temperature Sensor.......................................(24 ga. Min.) 2 Conductors

-Supply Static Pressure Sensor ...........................................(24 ga. Min.) 3 Conductors

-Bypass Damper........................................................................................ 4 Conductors

-HVAC Unit Control Wiring.....................................................................R - Common

G - Fan

Y1 - Cool 1

Y2 - Cool 2

W1 - Heat 1

W2 - Heat 2

Tip: After making all electrical connections, you should unplug all terminal blocks

on the Zone Manager until you are ready to begin the checkout procedure. This

may help to prevent damage if wiring errors occur elsewhere in the system during installation or start-up.

Auto-Zone Basic

2-6

Installation and Wiring

Page 37

Auto-Zone Basic

BYPASSPDAMPER

FDBK

GND

OPEN

CLOSE

V3

K4K3

V4

V5

V6

K5

TB7

R

FAN

COOL1

COOL2

HEAT1

K7K6

HEAT2

V7

V8

K8

V9

CLOSE

D18

R43

R44

D19

COOL1

R46

D20

COOL2

D21

R52

HEAT1

D22

R56

HEAT2

R57

D31

Section 2

RAM

EPROM

FAN

U10

32K

8K

JO2

RN2

U13

D23

D24

D26

D25

D29

D28

D27

SW1

NET

32

B

16

U11

CX10

CX11

1

CX13

D30

MADEIN U.S.A.

1992

ADD

284

1

U14

U9

R45

R47

R48

U12

CX14

U15

RS-485

COMMDRIVER

CX9

RN1

R49

P1

R55

C22

CX12

CX15

COMM

T

R58

R59

R60

SH

R

TB8

RS-485

Communications

To CommLink

When Used

Local Loop

RS-485

9600 Baud

RS-485

Communications To Zone

Controllers

All Comm Loop Wiring Is

Straight Thru

T

T

SH

R

T

SH

SH

R

R

T

SH

R

These Switches Must Be

In The OFF Position

As Shown

RockerDown

>

Notes:

1.)AllCommunication Wiring To Be

2 Conductor Twisted Pair With

Shield. Use Belden #82760 Or

Equivalent.

2.)It Is Recommended That All

Controllers Address Switches Are

Set Before Installation.

3.)Power To The Zone Manager Must Be

Cycled Before Address Switch

Changes Will Take Affect.

3232BBNET

16

4

8

Address Switch Must Be Set

To Address 0 on Zone Manager Board

As Shown

Basic System Without CommLink

NET

16

4

8

Address Switch Must Be Set

To Address 17 on Zone Manager

Board When CommLink Is Used

ADD

OFF

1

2

These Switches Must Be

In The OFF Position

As Shown

RockerDown

>

ADD

OFF

1

2

Basic System With CommLink

Figure 2-6: Zone Manager Address Switch Setting

NET

NET

B

B

Zone Manager

Address Switch

ADD

2

4

8

16

32

Zone Manager

Address Switch

ADD

2

4

8

16

32

1

1

Caution: Your Auto-Zone Basic Control System will not work properly unless

you set the Address switch correctly. Remember, you must power

down the Zone Manager after changing the address switch in order for

the change to take effect.

Installation and Wiring

2-7

Page 38

Section 2

Auto-Zone Basic

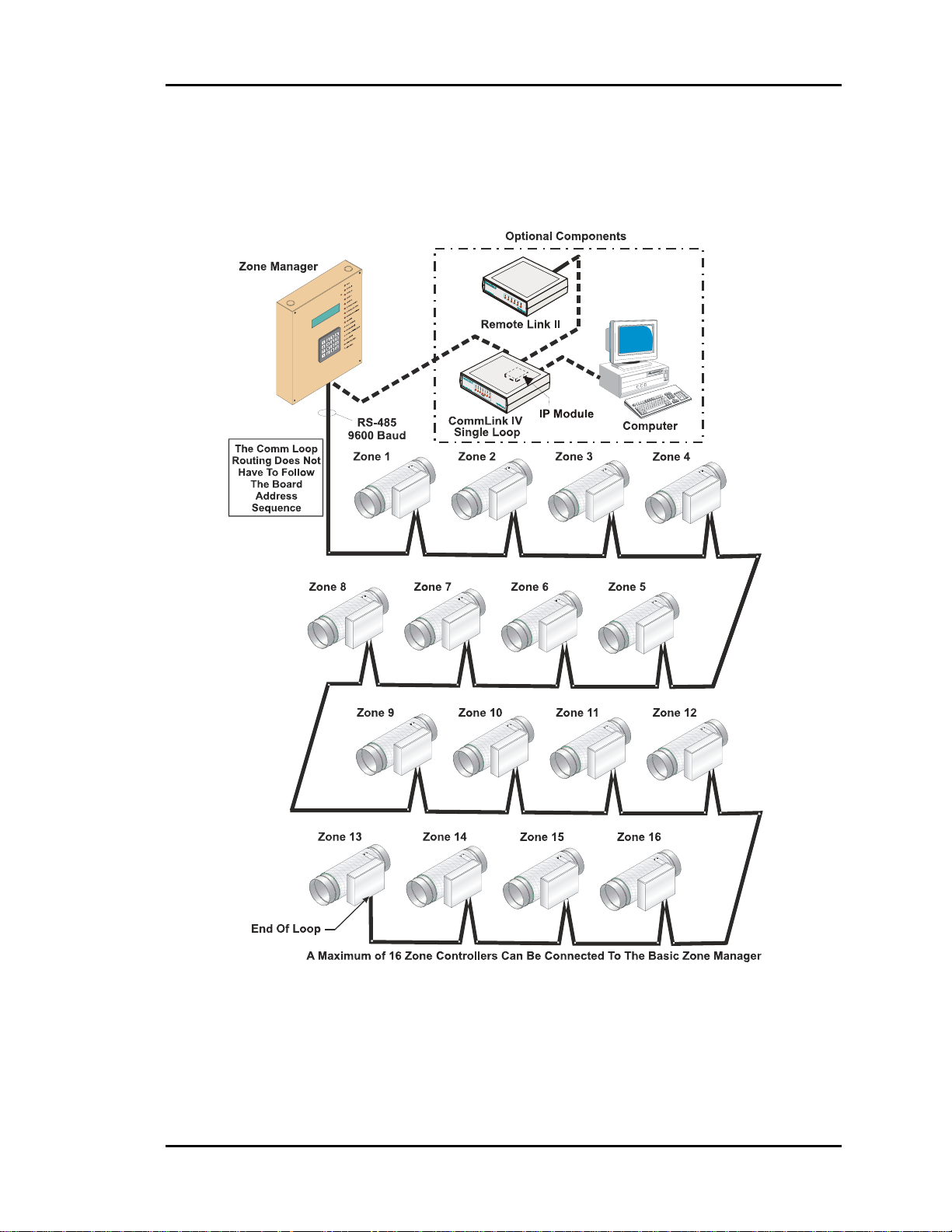

Communications Loop

The communications network is a two-wire shielded RS-485 loop. The loop is best con-

nected in a daisy chain configuration, meaning the loop is connected from one controller

to another. It is not necessary to sequentially address the zone controllers in relation to

their location on the loop. Cable must be Belden No. 82760 or equivalent.

Tip: Incorrect wiring of the communications loop is the most common mistake made

during installation. Before beginning installation, write down the wire color

used on each terminal connection and consistently maintain that color code. It is

recommended that a continuous wire run be made between devices. Any time a

splice is made in the cable, you increase your chance of problems.

Caution: Make sure when you are inserting wires into the terminal blocks that

strands of wire do not stick out and touch the next terminal. This could

cause a short or erratic operation.

Note: The loop does not have to follow the controller address sequence.

Caution: If comm loop is not installed in conduit, be careful to position the cable

away from high noise devices like fluorescent lights, transformers,

VFDs, etc. Conduit is not required for comm loop wiring unless required by local codes.

2-8

Installation and Wiring

Page 39

Auto-Zone Basic

Section 2

Communications Loop Wiring Overview

The daisy chain is the best method for running a communications loop since there is only

one starting point and one ending point. See Figure 2-7.

Figure 2-7: Communication Loop Wiring, Daisy-Chain Configuration

Even though the daisy chain configuration is preferred, the star configuration can also be

used. If required, a combination of the two can also be used. Remember, the best comm

loop wiring is the one which utilizes the minimum number of ends while using the shortest wiring path. See Figure 2-6 and Figure 2-13 for controller addressing information.

Installation and Wiring

2-9

Page 40

Section 2

Auto-Zone Basic

Bypass Dampers

The Bypass Damper can be either round or rectangular. The Round Bypass Damper is

supplied with the Damper Actuator and Bypass Wiring Interface Board factory mounted

in a sheet metal enclosure attached to a Round Air Damper assembly. This Round Bypass

Damper Package is field connected to the appropriate size round duct. Rectangular Bypass Dampers mount directly in the rectangular ductwork using flanged connections field