Auto Start AS-6850TW-FM, PS-7850TW-FM, EX-6850TW-FM, NS-5050TW-FM, CS-695i Installation Manual

...Page 1

TWOWAYLCDAUTOMATIC/MANUALTRANSMISSION

REMOTESTARTERWITHFULLALARMSYSTEM

ANDVIRTUALTACHSYSTEM

(ASPRG1000COMPATIBLE)

Doc#: 091106 Rev: 2.1 © 2009 -CC- Canada

Installation Guide

AS-6850TW-FM, PS-7850TW-FM, EX-6850TW-FM

NS-5050TW-FM, CS-695i, CS-6850TW-FM

Notice

The manufacturer will accept no responsibility for any electrical damage resulting from improper installation of

the product, be that either damage to the vehicle itself or to the unit. This unit must be installed by a certified

technician using all safety devices supplied. Please note that this guide has been written for properly trained

technicians: a certain level of skills and knowledge is therefore assumed. Please review the Installation Guide

carefully before beginning any work.

Warning

Before installing the unit, if installing on a vehicle with a manual tr ansmission, test that the OEM Door Switch

contacts of the vehicle work well, and that the Parking Brake system operates properly. If installing on a vehicle

with an automatic transmission, test that the vehicle does not start when the gearshift lever is in the “Drive”

position. If it starts in gear, install a manual transmission remote starter system instead.

Page 2

P. 2 Installation Guide

Table of Contents

Introduction .................................................................... 3

Included in the Package ............................................... 3

Installation Tools ........................................................... 3

Installation Points to Remember ................................. 3

Installation Order ........................................................... 4

A basic introduction to the Relay ................................ 6

Clutch Bypass ............................................................. 9

Harness Description .................................................... 10

6-Pin Main Ignition Harnes ........................................ 11

5-Pin Secondary Harness ......................................... 11

12-Pin Accessories Harness ..................................... 12

5-Pin Harness............................................................ 14

Auxiliary Relay ............................................................. 15

Fifth Relay Output ..................................................... 15

Manual or Automatic Transmission .......................... 15

Transmitter Programming Procedure ....................... 16

Entering Programming Mode ..................................... 17

The Programming Assistance Button (a.k.a. PAB) ... 17

Entering Programming Options ................................. 18

Programming Options ............................................... 18

Virtual Tach System .................................................... 20

Optional Time Delay Adjustment in Virtual Tach

System ...................................................................... 20

Tach Learning .............................................................. 21

Tach jumper settings ................................................. 21

Multi-speed Tach Programming Procedure .............. 21

Auto Tach Programming Procedure ......................... 21

Siren/Horn Timing Adjustment .................................. 21

Setting the unit into Ready Mode .............................. 22

Arming and disarming of the System ........................ 23

Installation-programmable Features .......................... 23

Ignition-Controlled Door Locks .................................. 23

Secure Lock ............................................................... 24

AUX 3 output ............................................................. 24

AUX 2 ......................................................................... 24

“Home Valet

TM

” Mode ................................................ 24

Safe Start ................................................................... 25

Engine Run Time ....................................................... 25

Idle Mode ................................................................... 25

Turbo Mode ............................................................... 26

Vehicle Type – Gas Or Diesel ................................... 26

Siren Chirps ............................................................... 26

Arming ........................................................................ 27

Ignition monitoring (Siren or Horn mode) .................. 27

Shock Sense and Warn-away Sense ........................ 27

Ignition valet: .............................................................. 27

Relock ........................................................................ 27

Bypass ....................................................................... 28

Multi-car Operation .................................................... 28

Intrusion Codes via LED light ..................................... 28

Diagnostics via parking lights .................................... 29

Diagnostic table for shutdown. .................................. 29

Diagnostic table for start failure. ................................ 29

Parking lights flash summary table ........................... 29

Resetting the module to default features .................. 30

Closing Up .................................................................... 30

Testing ........................................................................... 30

Troubleshooting Poor Transmitting Range .............. 31

Troubleshooting Q & A ................................................ 31

Page 3

Installation Guide P. 3

Introduction

This guide contains all the information relevant a nd necessary for the ins tallation of the al arm and

remote starter system. Most of the features of this product are explained in the user guide.

Therefore, if you need detailed information about a feature of the produ ct, we recommend that you

refer to the user guide.

IncludedinthePackage

Please review the Installation Guide before beginning the installation, particularly the Wiring

Schematic and the Programming Options.

It is very important that you familiarize yourself with the programming and the operation of the

system, even if you have already installed a similar system in the past. There are many great

features that may be overlooked if the man ual is not read; this would prevent you from ma ximizing

the potential of the Module.

Prior to the installation, make sure that all the hardware components required to install the system

are in the box.

The following is a list of components included in the kit:

1- Control unit 1- Plug in dual shock sensor

1- 2 WAY LCD 6 button remote 1- Siren

1- 1 WAY 5 button remote 1- Parts bag

1- Antenna and interconnect cable 1- User and quick guide

1- Harness Kit

InstallationTools

Here is a list of basic tools and supplies you will need to test and install safely.

• Digital Multi Meter (DMM), Computer s afe logic probe, Fused jump er wire, Neon 'trou ble' light

that is carpet safe, Fender protector, Carpet protector

• Soldering Iron, solder, electrical tape, wire tie straps, split loom, diodes, resistors, relays

• Wire cutters, Wire strippers, Wire crimpers, Needle Nose Pliers

• Sharp knife, Panel poppers, Various Screw drivers

• Socket set, Wrench set, Drill with Drill Bits, Coat hanger (for fishing wires through the fire

wall)

InstallationPointstoRemember

• On vehicles with a manual transmission, always ensure that all door pins are monitored by the remote

starter.

• Make sure that the Parking brake and Door switch contacts work properly.

• When working on a vehicle, always leave a window open.

• Never leave the keys in the car. Leave them on a workbench with a window rolled down.

Page 4

P. 4 Installation Guide

• If possible, remove courtesy light fuse to prevent battery drain.

• The Programming Assistance Button (a.k.a. PAB): The PAB is mounted on the side of the unit. This

push button mimics the hood-pin switch in order to avoid having to get out of the vehicle and pressing the

hood-pin switch. The PAB will work only when the hood is up.

• Inspect vehicle for any body damage or electrical problems.

• Always solder and tape all connections.

• Keep the transceiver away from other types of antennas (GPS/OnStar®).

• Never install the control unit where it could interfere with normal operation or obstruct service technicians.

• Always use a grommet when running wires into the engine compartment.

• Never run wires through bare or sharp metal.

• Do not disconnect the battery on vehicles equipped with air bags and anti-theft radios.

• Never ground the control unit to the steering column.

• Make sure that all electrical switches and controls operate properly.

• Verify that the vehicle starts and idles properly.

• Make sure that all safety equipment is installed: the valet button (if installed), the hood switch, and the

warning label.

Example:

Wiring a clutch bypass and a transponder module to the ground out when running wire: At the

junction point, where Ground Out when running “splits” and goes to each device, a diode is inserted on

each of those lines.

Multiple or separate door pin connections:

When joining all door pins together to the door pin input wire of the module, each wire must be isolated

with a diode to prevent feedback.

N.B.: The above examples reflect common situations where diodes are used to isolate. Please note that

there are numerous other scenarios where diode isolation is required.

• Always make sure that any external relays or modules added to the Remote Starter module are properly

fused and diode isolated.

• When testing the Shock Sensor, never test on glass with an opened hand, and never hit glass hard

enough to break it. When testing on metal or plastic, make sure the testing does not result in damage to

the vehicle (i.e.: dents, broken glass, damaged trims, etc.).

• Vehicles equipped with daytime running lights may not allow the installer to view certain programming

results since the daytime running lights do not turn OFF with the IGN off (Note: The Parking Light output

relay in the module gives two “clicks” per flash, 1 “click” for ON and 1 “click” for OFF).

1. Parking Light flashes referred to in this manual refer to the Parking Light output of the module

INDUSTRY CANADA USER NOTICE:

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2)

this device must accept any interference, including interference that may cause undesired operation of

the device.

To reduce potential radio interference to other users, the antenna type and its gain should be so chosen

that the equivalent isotropically radiated power (EIRP) is not more than that required for successful

communication.

NOTE: The manufacturer is not responsible for any radio or TV interference caused by unauthorized

modifications to this equipment. Such modifications could void the user's authority to operate the

equipment.

InstallationOrder

The following is a suggested order for the Installation procedure. It is intended as a guide for novices, to help

make the process of installing a remote starter module easier. Time is wasted by rewiring the module when

mistakes are made. Also, the neatness of the installation is lessened every time the module is taken down and

the wiring is “corrected”.

Page 5

Installation Guide P. 5

• Visit www.autostart.ca to obtain a copy of your vehicle’s tech sheet (wire colors and locations)

• Before you get started, make sure the vehicle starts and idles properly with the Ignition key, and that the

electrical system is not compromised in any way.

• After deciding what options are to be added to the basic installation, you can start by looking for the wires

that will be needed.

• Remember to be careful when removing the panels that are covering the wires you are searching for.

• Once all of the wires have been found, they should be tested to verify that they are the correct ones

needed for the installation.

• When all the wires have been tested and found, they can be stripped to expose the wire (over one inch of

insulation should be removed).

• It is always better to strip more than you need. A common way cold solder joints happen is when not

enough insulation is stripped off the vehicle's wire, so during the soldering process the insulation from the wire

melts and flows into the connection instead of the solder.

• Decide where the module is going to be mounted. It is ALWAYS mounted inside the passenger

compartment, and NEVER in the engine bay. Under the driver's side of the dash there is usually enough room

for the module to fit. Once the location has been decided, proceed to the next step.

• Mount the antenna and run the cable to the location where the module is going to be mounted. The

antenna will get the best range when it is high up in the vehicle, and not obstructed by metal. The most

common choice is the center of the windshield at the top, behind the rear view mirror, and at least one inch

below the tint strip. Another location should be used if there is another antenna in this location, compass, or

other device that may interfere with the range of the start module.

• In the engine compartment, mount the hood pin, in a suitable location. Search along the firewall for an

OEM grommet you run the wires through. If you cannot find an OEM grommet to use, you will have to drill a

hole. The hole must be big enough for all of your wires to fit through. To be safe drill the hole out a little bigger

so the wires will have ample room. We recommend using an aftermarket grommet whenever you drill a hole

through the firewall. This will protect the wires from rubbing against the bare metal and possibly shorting out. If

you are installing an alarm / starter combo module, mount the siren in the engine compartment at this time.

• The next step is to pre-wire the module. This is done on your work bench, and not in the vehicle. Connect

any external modules and relays that may be needed for you install. Tape or tie-strap wires that are going to be

routed to the same areas of the vehicle. This will keep things neat when the module is in the vehicle. The fuses

on the power wires should be removed during the pre-wire stage. The fuses will not be put back in until the

powering stage of the installation.

• Connect all the necessary accessories to the module before mounting it in the vehicle. Use tie-straps to

secure it to the vehicle. Make sure the module and harnessing do not interfere with any moving parts, and do

not obstruct access to diagnostic ports, or fuse boxes. It should be up in the dash, high enough that it won't get

kicked by accident.

• Once the module is secured, route the wires to the previously stripped wires they correspond to (leave the

engine compartment wires for last). Tie strap them up as you go, so they do not interfere with anything else.

• When all of the passenger compartment wires are ran to their locations, you can route the engine

compartment wires through the firewall.

• With the engine compartment wires out the way, you can begin making the connections in the passenger

compartment. Strip about an inch of wire past where the connection is going to be made. This extra bit of wire

is wrapped around the exposed OEM wire to secure in place while you are soldering.

• When all of the wires have been connected, solder the connections. When the solder has cooled, the

connections are then individually taped up, to isolate them.

• Return to the engine bay and route the tach and hood pin wire to their corresponding connections.

• Solder the engine compartment wire once the connections are made. When the solder has cooled, the

connections are then individually taped up, to isolate them.

• Use your DMM to verify that your ground location is good before grounding the module.

• The last step before programming is to power up the module. Replace the power fuses on the power wire

fuse holders. The module will click twice to confirm the power-up.

Page 6

P. 6 Installation Guide

AbasicintroductiontotheRelay

What is a relay?

A relay is a switching device that responds to a small current or voltage change by activating switches or other

devices in an electric circuit such as an electromagnetic switch, remote controlled switch, a switching device.

Why are relays used?

Relays can have several purposes in remote car starter installations. They are mainly used for isolation,

inversion, interruption, strengthening current, and for powering multiple wires from one source safely.

How does a relay work?

The basic relay consists of a coil and a set of contacts. The most common relay mechanism is the

electromagnetic mechanism. When voltage is applied to the coil, current passes through the wire and creates a

magnetic field. This magnetic field pulls the contacts together and holds them until the current flow in the coil

has stopped.

Relays come in all varieties and types, but for the applications that concern us, we will concentrate on the

single pole double throw (SPDT) 12 volts relay.

Naming Convention

Usually the relay’s manufacturer will include an electrical diagram on the relay displaying the role of each

terminal and how they interact with each other.

These terminal numbers are standard, and can be used with any SPDT relay.

85 & 86: The coil. These inputs energize the coil when one is +12 volts, and the other is negative. They are

usually non-polarized, so it does not matter which one is positive (+) or negative (-).

87: Normally Open (N/O). When the coil is energized, 87 is connected to 30.

87A: Normally Closed (N/C). When the coil is at rest, 87A is connected to 30.

30: Common. When the relay is at rest, 30 is connected to 87A, when the coil is energized, it is then moved

and makes contact with 87. (Note: in a SPDT relay, 30 can never be connected to 87 and 87A at the same

time, 30 is connected to either 87 or 87A)

What happens?

When there is no voltage across the coil (terminals 85 and 86), the relay's movable contact arm (connected to

terminal 30) is held, by spring tension, against terminal 87A (normally closed circuit).

When 12 volts is applied to the coil (terminals 85 and 86), the arm (connected to terminal 30) is pulled by the

electromagnet (coil) so that it physically connects to terminal 87 (normally open circuit).

When 12 volts is applied to the coil (terminals 85 and 86), the arm (connected to terminal 30) is pulled by the

electromagnet (coil) so that it physically connects to terminal 87 (normally open circuit).

Remember, there is no polarity on a relay’s coil. This means that you may apply positive from the battery to

either terminal 85 or 86, and then ground the other terminal to activate the relay. In other words, you may use

either a positive or negative trigger to energize the relay.

Keep in mind, when the relay is energized, if the positive or the ground connection on the coil is broken, the

arm switches the connection between 30 back from 87 to 87a.

Quenching Diodes

It was said earlier that a relay energizes itself by applying positive from the battery to either 85 or 86 and

grounding the other terminal. This is not absolutely true, some relays are “polarized” if they have a quenching/

suppression diode (A diode installed between the coil terminals 85 and 86, could be internal or external).

To activate the coil on this type of relay, make sure that the +12 volts trigger is on the same terminal of the

relay as the anode (+ or non striped side) side of the quenching/suppression diode, and that the negative

trigger is on the same terminal of the relay as the cathode (- or striped side) of the quenching/ suppression

diode.

When a relay’s coil is energized, a magnetic field is created and energy is stored in the coil. When power is

removed from the coil, the magnetic field collapses. This causes a reverse voltage to be generated and can

sometimes reach 200 volts. A quenching diode absorbs this reverse voltage spike.

Page 7

Installation Guide P. 7

A closer look at a relay

Now that you know what the main inscriptions are on the relay, take a look on the side, and you will see another

inscription: 12 VDC, 40/ 30 A.

12 VDC: This indicates the coil voltage rating. For an automotive relay, it's usually 12 volts DC.

40/ 30 A: This indicates the current carrying capability of the contacts 30, 87, & 87A.

40: Indicates that the normally closed circuit (30 and 87a) can safely handle a maximum of 40 amps of current.

30: Indicates that the normally open circuit (30 and 87) can safely handle a maximum of 30 amps of current.

Examples: The following examples demonstrate some of the most common uses for relays: isolation,

inversion, interruption, strengthening current, and for powering multiple wires from one source safely.

Powering multiple wires from one source safely

Example: Powering a second ignition

Problem: You need to power multiple ignition wires to remote start the vehicle, but your module only has one

ignition output available.

Solution: You will need to add a second ignition relay to power the second-ignition wire. (Jumping ignition 1

to ignition 2 is never recommended ⎯Always use a relay. The vehicle circuits are isolated for a reason;

the wiring of the remote star module should reflect this .)

The Relay Connections

85: Connects in parallel to the ignition 1 output from the remote start module. This becomes the positive side of

the coil.

86: Connects to the Ground Out When Running wire from the remote start module. This becomes the

negative side of the coil.

87: Connected to a fused +12 volts source, that is capable of supplying power for the vehicle's second ignition

wire. This becomes the source of power for the 2

nd

ignition wire.

87A: NO CONNECTION. This terminal is not used in this application.

30: Connects to the vehicle's second ignition wire. This becomes the output of the 2

nd

ignition relay.

Comments: The relay is only energized when the vehicle is running by remote start. When started with the key,

the relay is not energized and the integrity of the stock system has been preserved.

Isolation:

Example: Isolating a parking light output

Problem: Some vehicle circuits need to be isolated from feedback. In some cases, when a vehicle is remote

started, feed back occurs on a circuit, and powers another device or switch, that was not intended to be

powered during the remote starts.

The following example will be a positive (+) park light circuit that feeds back and activates the windshield wipers

during remote starts.

Solution: When power is applied to the OEM parking light wire it back feeds through the park light switch, and

activates the wipers. Where the connection was made from the start module’s park light output, and the

vehicle's park light circuit, the OEM park light wire is cut to isolate the park light switch and the actual parking

lights. A relay is added to the park light circuit so that power from the remote start module is only sent to the

parking lights and not the parking light switch.

The Relay Connections

85: Connects to the +12 volt park light output from the remote start module. This becomes the positive side of

the coil.

86: Connects to a negative source (where the remote start module is grounded). This becomes the negative

side of the coil.

87: Connects to the +12 volt park light output from the remote start module. This becomes the power supply for

the vehicle's park lights.

The OEM park light wire is cut. The side that is still connected to the switch becomes the “switch side”. The side

that is still connected to the parking lights becomes “parking lights side”.

Page 8

P. 8 Installation Guide

87A: Connects to the “switch side” of the cut OEM park light wire.

30: Connects to the “park light side” of the cut OEM park light wire.

Comments: When the relay is at rest, the OEM park light wire is connected (through 87A & 30) and allowed to

operate normally. When the remote start module powers the park lights, the OEM park light wire is opened, and

power from the remote start module is sent only to the actual parking lights ( from 87 through 30).

Inversion:

Example: Activating a positive trunk release switch

Problem: The vehicle's power trunk release switch is activated by a positive (+) pulse, and the remote start

module's trunk output is negative (-).

Solution: A relay is used to invert the negative signal from the start module to a positive signal before it is sent

to the OEM switch.

The Relay Connections

85: Connects to the start module's trunk release output wire. This becomes the negative side of the coil.

86: Connects to a fused +12 volts source. This becomes the positive side of the coil.

87: Connects to a fused +12 volts source. This becomes the supply for the positive trunk release.

87A: No connection. This terminal is not used in this application.

30: Connects to the OEM trunk wire in the vehicle.

Comments: At rest, the trunk switch is allowed to operate normally. When the trunk button is pressed, the

negative trunk output from the remote start module triggers the relay. When the relay is activated, +12 volts

from 87 is sent through 30, and the OEM trunk switch is activated, by the positive pulse.

Interruption:

Example: Creating a starter disable relay to prevent unauthorized starting of the vehicle.

Problem: The OEM starter circuit needs to be disabled only when theft is attempted.

Solution: A relay is used to interrupt the OEM starter wire. There is an output on the remote start module

especially for this purpose (starter disable output).

The Relay Connections

85: Connects to the starter disable output wire from the remote start module. This becomes the negative trigger

for the coil.

86: Connects to the vehicle's ignition wire. This becomes the positive trigger for the coil.

87: No connection. This terminal is not used in this application.

The vehicle's OEM start wire is cut. The side of the wire that is still connected to the ignition switch becomes

the “key side” of the starter wire. The side of the wire that is still connected to the starter motor becomes the

“starter side” of the of the starter wire.

87A: Connects to the “key side” of the cut OEM starter wire.

30: Connects to the “starter side” of the cut OEM start wire.

Comments: At rest the relay is not active, and +12 volts on the starter wire passes through the relay (through

87A & 30) normally. The starter disable output wire on the remote start module is activated when the LOCK

button is pressed on the remote control.

When a theft attempt happens, and the thief powers the ignition circuit (to hot-wire the vehicle), and the starter

disable was armed (by the LOCK button on the remote), the starter disable relay

activates. The OEM start

wire is now open, (does not make connection) because 30 is no longer connected to 87A, and the vehicle is

unable to start.

Strengthening Current:

Example: Strengthening an output

Problem: A vehicle has a negative (-) trigger trunk release wire. The module has a negative trunk release

output wire. The remote start module is unable to supply the necessary current to activate the vehicle's trunk

release wire.

Solution: A relay is used to provide the necessary negative current to active the vehicle's trunk release wire.

Page 9

Installation Guide P. 9

The Relay Connections

85: Connects to the start module's trunk release wire output. This becomes the negative trigger for the coil.

86: Connects to a fused +12 volt source.

87: Connects to a negative source (where the remote start module is grounded). This becomes the supply for

activating the vehicle's trunk release wire.

87A: No connection. This terminal is not used in this application.

30: Connects to the vehicle's trunk release wire.

Comments: At rest the relay is not active and the vehicle's trunk release switch is allowed to operate normally.

When the trunk release button is pressed, the start module's trunk release output activates the relay. The

ground signal is sent from 87 through 30 to the vehicle's trunk release wire activating the switch and opening

the trunk.

ClutchBypass

In order to remote start a manual transmission vehicle, the clutch switch must be bypassed. Clutch safety

switch circuits can take many forms. Listed below are the most common ones. When testing to determine the

type of clutch circuit, it is recommended to use a computer safe logic probe. Some vehicles may also have a

separate or combined switch on the clutch pedal for cruise control. Usually a cruise control switch reacts the

moment you touch the pedal, where as a clutch switch reacts only when the pedal is near the floor. Once the

circuit type has been determined, you must recreate what happens electrically at the switch, with the remote

start module, to bypass the clutch during remote starts. Relays are often used to accomplish this. Always use

the Ground Out When Running (G.O.) as the negative trigger on your clutch bypass relays, as it is only active

during remote starts. NEVER permanently bypass a clutch switch. Do not attempt this if you are unfamiliar

with the use of relays, and diode isolation.

Before any Hot Wiring attempts:

Test and record the way each wire tests in the following positions:

With out the pedal pressed:

• Test the wires with the Ignition OFF

• Test the wires with the Ignition ON

• Test the wires with the Key in the start position

With the pedal pressed:

• Test the wires with the Ignition OFF

• Test the wires with the Ignition ON

• Test the wires with the Key in the start position

With this information for every wire at the switch, determining what type of clutch switching system you have will

be easy.

Direct Feed:

The simplest type of system to test and bypass is the “Direct Feed” system. This circuit simply interrupts the

+12v signal starter wire from the ignition switch to the starter solenoid. There are 2 wires in this circuit, the “key

side” wire which goes from the clutch pedal to the Ignition switch, and the “solenoid side” which goes from the

clutch switch to the starter motor. When the key is turned to the start position without pressing the pedal, you

will test 12v only on one of the wires at the clutch switch, this is the key side. When the pedal is pressed down,

and the key is in the crank position, the other wire will also read 12 volts; this is the solenoid side wire. To

confirm you have a direct feed clutch switch, hot wire the “solenoid side” wire with a fused +12 volts and the

starter motor will crank. Connect the starter output from the remote starter to solenoid side wire.

Note: In the next two systems a Relay in the vehicle interrupts the start wire between the Ignition switch and

the starter motor. With the key in the start position, and the clutch pedal pressed, the relay energizes and

allows the start signal to reach the starter motor. In these systems a wires from the clutch triggers the relay,

when the pedal is pressed. There will be another wire at the clutch switch that supplies the signal to the trigger

wire (either positive or negative, depending on the system)

Negative:

In a Negative system, when the clutch is pressed; a negative signal is sent to the relay, the relay energizes,

when the Key is turned to the start position the 12volts from the start wire is allowed to pass through the relay

and to starter motor. One of the wires at the clutch will test as negative, this is the supply wire. The relay's

negative trigger wire will only show negative when the pedal is pressed (some vehicle's also require the Ignition

Page 10

P. 10 Installation Guide

system to be powered). To confirm you have a Negative system, hot wire the negative trigger wire by jumping it

to a ground source with your fused test jumper. You should now be able to turn the key to the start position and

engage the start motor without pressing in the clutch pedal. If there is nothing else connected to the Ground

Out When Running (G.O.) wire from the remote start module, the G.O. wire should be strong enough to trigger

the vehicle's clutch relay. If there are other devices or modules connected to the G.O. Wire, a relay (and

diodes) may have to be added to strengthen the negative current going to the clutch bypass.

Positive:

Very similar to the negative system, except that the vehicle's clutch relay is trigger by 12 volts, instead of a

negative signal. In a Positive system, when the clutch is pressed; a positive (12 volts) signal is sent to the relay,

the relay energizes, when the Key is turned to the start position the 12 volts from the start wire is allowed to

pass through the relay and to starter motor. One of the wires at the clutch will test as 12 volts, this is the supply

wire. The relay's positive trigger wire will only show positive when the pedal is pressed (some vehicle's also

require the Ignition system to be powered). To confirm you have Positive system, hot wire the positive trigger

wire by jumping it to a 12 volt source with your fused test jumper. You should now be able to turn the key to the

start position and engage the start motor, without pressing in the clutch pedal. A relay is needed to send 12

volts to the trigger wire from the start module during start attempts.

Normally Closed (N/C):

Note: There are different types of this system used by various vehicle manufacturers; the following is used to

illustrate how these systems work in general.

A Relay is also used in these types of systems to interrupt the starter wire. In the previous two examples, the

clutch was bypassed by engaging the clutch relay; with this system you bypass the clutch by preventing the

clutch relay from engaging. When the Ignition Key is turned to the start position the relay energizes and

interrupts the start wire, when the pedal is not pressed. When the Ignition key is turned to the start position, and

the pedal is pressed, the relay does not energize, and the start signal reaches the starter motor.

In a N/C system the supply wire is connected to the relay's trigger wire at rest (pedal not pressed). When the

pedal is pressed, the connection is broken between the supply wire and the relay's trigger wire (this disengages

the relay).

To verify that you have a N/C system, disconnect the clutch switch and the vehicle should start without the

clutch pedal being pressed. When you test the trigger wire with your logic probe, the trigger wire will test as 12

volts or negative when the pedal is not pressed, it should read as an open circuit ( or Float) when the pedal is

pressed,

Please note:

Your probe may also show feed back from the other end of the circuit. The Polarity of the Trigger wire does not

matter in this system, since all you need to do in order to bypass it is to use a relay to interrupt it during remote

starts.

HarnessDescription

When connecting the Module, it is important to make sure the conn ector with the Ground wire is

connected first before making the 12-volt c onnections. Should the unit be powered before being

grounded, there could be s erious damage to internal components of the unit. Be careful not to

power up a Module before it is properly grounded. To avoid any ac cident , it is rec ommend ed to

pull out the fuses from their sockets before the i nstallation, and to put them back during the very

last steps.

Page 11

Installation Guide P. 11

6PinMainIgnitionHarnes

Wire Description

A

RED

+12 V

Battery

Connect to the largest 12 V supply wire at the Ignition harnes s. Ensur e

that the OEM power wire is fused for more than 30 A.

NOTE: certain new vehicles have no suitable 12 volts source at the

IGNITION switch (the 12 Volt wire is too small to suppl y the necessary

current). In this case, the fuse box , o r the B+ connec tion on the b attery

is recommended.

B

PURPLE (+)

30 A

starter

output

Connect to the Starter wire of the vehicle (at the IGNITION switch).

The source wire should have +12 V with the Ignition Key in the

CRANK position only.

C

RED

+12 V

Battery

Connect to the largest 12 V supply wire at the Ignition harnes s. Ensur e

that the OEM power wire is fused for more than 30 A.

NOTE: certain new vehicles have no suitable 12 volts source at the

IGNITION switch (the 12 Volt wire is too small to suppl y the necessary

current). In this case, the fuse box , o r the B+ connec tion on the b attery

is recommended.

D

YELLOW (+)

30 A

Ignition

output

Connect to Ignition wire of the vehicle. The source wire s hould have

+12 V with the Ignition Key in the I GNITION ON (RUN) and CRANK

positions.

Warning! Some vehicles have more than one IGN wire at the

IGNITION switch for powering the heater blower motor. Use the 5th

relay (pin F) and extra relays to power up any extra IGN. wires if

necessary. DO NOT JUMP WIRES at the IGNITION switch, this will

compromise the OEM electrical system.

E

ORANGE (+)

30 A

Accessories

output

This wire is for powering the heater blower motor. It is us ually classed

as an ACC. (no power in the CRANK position.) if it tests as an

IGNITION (power in the crank pos.) then power it as an IGNITION (5th

relay, or extra relay).

Warning! Some vehicles have more than one ACC wire at the

IGNITION switch for powering the heater blower motor. Use the 5th

relay (pin F) and extra relays to power up any extra ACC. wires if

necessary. DO NOT JUMP WIRES at the IGNITION switch; this will

compromise the OEM electrical system.

F

GREEN (+)

30 A

5th relay

output

This high-current output can be used to power a 2nd IGNITION or a

2nd ACCESSORY or a 2nd STARTER WIRE. See jumper settings in

5th relay section later in the guide for correct output position (page-15).

Additional IGNITIONS, ACCESSORIES, or STARTER WIRES must

use external relays. DO NOT JUMP WIRES at the IGNITION switch ,

this will compromise the OEM electrical system.

5PinSecondaryHarness

Wire Description

1

BLACK (–)

Chassis

ground

input

This wire must be connected to bare, unpainted metal (the Chassis or

true Body ground). It is preferable to use a factory ground bolt rather

than a self-tapping screw. Screws tend to get loos e or rusted over time

and can cause erratic problems.

Page 12

P. 12 Installation Guide

Wire Description

2

PURPLE

(AC)

TACH

input

This wire tells the Module if the Engine is running or n ot. It requires at

least 1.8 volts (AC) and 1.5 Hz (or faster) at idle. Common Tach

references are: the negative sid e of an injector, the negat ive side of an

Ignition Coil, Camshaft sensor, Crankshaft sensor or the Engi ne Control

Module (ECM).

NOTE: A Tach signal that is too low will cause the Module to “over

crank” and a Tach signal t hat is too high will cause th e Mo dul e to “under

crank”.

3

GRAY (–)

Hood

Switch

input

Connect this wire to the Hood Pin-switch supplied. This input will disable

or shut down the Remote Starter when the Hood is opened. It is als o

used for programming and therefore it is essential that it is installed.

4

ORANGE

(+) Brake

Switch

input

This wire must be connected to the Brake Lig ht switch of the vehicle.

The wire should be +12 V only while the Brake Pedal is pressed. This

input will shut down the Remote Starter if the Brake Pedal is pressed. I t

is also used for programming and therefore it is essential that it is

installed.

5

YELLOW

(+)

+12 V

Parking

Light

output

This wire provides a +12 V output (15 A max.) and must be connecte d

to the Parking Light wire that tests +12 V when the Parking lights are

ON.

NOTE: Ensure that the voltage does not vary when the dimmer control

switch is turned up or down. If this is the case, selected the wrong wire.

There is also a negative Parking L ight output. Only one of these two

different outputs needs to be connected.

12PinAccessoriesHarness

Wire Description

1

BLUE (–)

AUX 3

(Trunk)

output

500 mA negative output. This output can be used to control Trunk

release (1-sec. pulse) or can be set to operate as a constant ou tput as

long as the

button is pressed and held. (For Sunroof or Window

close).

Note: AUX 3 (TRUNK) operates only when Ignition is OFF or when the

vehicle is running under remote control.

2

BROWN (–)

Lock

output

Programmable 500 mA, 7/10sec., 4sec or 1/10sec. negative output.

3

GREEN (–)

Unlock

output

Programmable 500 mA, 7/10sec., 4sec., double 1/4 sec. pulse or

1/10sec negative output.

4

WHITE /

BROWN

(–)

Arm output

500 mA ground output when the button is pressed. This output is

activated 500 ms before the LOCK pulse and deactivated at the s ame

time as the LOCK pulse ends.

Note: The system will also give an ARM/REARM pulse on this wire

when it shuts down the vehicle after a remote start.

5

WHITE /

GREEN

(–)

Disarm

output

500 mA ground output when the button is pres sed. This wire is f or

disarming OEM Alarm systems.

Note: System will also give a DISARM pulse before remote start.

Page 13

Installation Guide P. 13

Wire Description

6

BLUE /

WHITE

(+)

Positive

Door input

This input should be used in vehicles that use a positive-switching

Dome Light circuit. Connect to a Dome Light wire testing +12 V with a

Door open.

CAUTION! You can only use ei ther the NEGATIVE DOOR INPUT or

the POSITIVE DOOR INPUT wire. It is essential that the Module be

connected in such a way as to allow each one of the Doors to be

detected by the remote starter.

7

WHITE /

ORANGE

(–)

Starter Kill

output

The unit is equipped with a selectab le passive- or active-arming Starter

Kill circuit that will immobilize the vehicle when the system is armed.

This wire will provide a constant 500-mA negative output when the

system is armed (locked by remote) or if remote started. This wire

should be connected to a Single Pole Double-Throw Relay (This wire

will connect to Pin 85, on the Relay, and Pin 86 wi ll be connec ted to the

Ignition wire).

A second benefit of the Starter Kill is the Anti-Grind feature. When the

vehicle has been remote started the Anti-Grind prevents the starter

motor from re-engaging when the ignition key is insert ed in the Ignition

switch and accidentally turned to the CRANK pos ition (The Starter Kill

output becomes active during remote starts).

8

ORANGE

(–) Parking

Brake

input

This input is for manual transmission vehicle ONLY. It is used in the

Ready Mode sequence and must be connected. The Parking Brake

input must be given a ground signal (-) when the Parking Brakes are

applied.

9

PURPLE

(+) Siren

output

+12 V Siren output. Connect to the positive side of the Siren.

10

WHITE (–)

Ground

out when

running

This wire provides a constant 500 mA negative output while the veh icle

is remote started. The output becomes active 1.5sec before Ignition,

and becomes inactive when the Mo dule shuts down. The output can be

used to activate external relays, bypass kits, etc.

CAUTION! If multiple relays or modules are connec ted to the Ground

Out wire, ensure that they are all diode isolated in order to avoid

feedback and damaging the vehicle.

11

GRAY (–)

Negative

Door input

This input should be used in vehicles that use a negative-switching

Dome Light circuit. Connect to a wire that tests ground with a door

open.

CAUTION! You can only use ei ther the NEGATIVE DOOR INPUT or

the POSITIVE DOOR INPUT wire. It is essential that the Module be

connected in such a way as to allow each one of the Doors to be

detected by the remote starter.

Page 14

P. 14 Installation Guide

Wire Description

12

YELLOW

(+)

Glow-plug

input

This positive input will monitor the Gl ow Plu g L igh t in Di es el M od e: it will

wait until the Glow Plug Light goes out to crank th e Engine. Connect to

the side of the Glow Plug Light that becomes positive when the Light is

on.

Note: In Diesel Mode there is an 18-sec. crank timing delay (or

approximately 25-sec. if t he run time is set to 30 min.): if the Glow Plug

Light is still on after the delay expires, the module will proceed t o start

the Engine.

(Also known as the “wait-to-start light”.) The purpose of the Glowplug circuit on diesel vehicles is to pre-heat the Combustion Chamber

before the vehicle is started.

When a Remote Starter is inst alled on a diesel vehicle, the Gl ow- plug

section of the Ignition circuit must be activ ated and allowed to operate

before the vehicle is remote-started. For that purpose, the Glow-plug

input wire of the module must be c onnected to the Glow-plug indicator

light of the vehicle. The module will only ac cept positiv e Glow-plug input

signals, if the signal is negative, use a relay to invert it s polarity . A diode

must be added between the negative Glow-plug trig ger on the relay and

the negative Glow-plug wire of the car. This is to prevent feedback

effects on the Glow-plug indicator light on the instrument cluster: the

light on the dash would come on b ecause of t he feedback , even though

the circuit is off.

When the user remote-starts the vehicle:

The module will power up the Ignition circuit and wait to engage the

Starter Motor while the Glow-plug indicator light is still on.

The module will engage the Starter Motor as soon as the Glow-plug

light (+) goes out.

Minimum waiting time is 4 seconds.

Maximum waiting time is 30 seconds (approximately).

If no Glow-plug wire is found on th e vehicle, the Glow-plu g input on the

module may be “timed out”. The mo dule will power up the Ignition and

Glow-plug circuits and simply wait for the time-out before starting.

Keeping the Glow-plug input wire of the modu le unconnected will hold

the ignition on for the preprogrammed delay.

Warning! Please program the tach before connecting the glow-plug

input to the vehicle.

5PinHarness

Wire Description

1

GRAY /

LIGHT BLUE

(–)

Trunk input

This input should be used in vehicle s with negative switching trunk pin

circuit. Connect to the Trunk light wi re that tests ground when the trunk

is open.

2

WHITE/

PURPLE

(–)

Horn output

500 mA negative Horn output.

Page 15

Installation Guide P. 15

3

BLACK /

GREEN

(–)

AUX 2 output

500 mA programmable negative output.

4

BLACK/

BROWN

(–)

Priority door

output only

Gives a negative pulse on the second press of the button.

5

YELLOW

(–)

Parking

Light output

500 mA negative Parking Light output

Note: Ensure that the voltage does not vary when the dimmer contro l

switch is turned up or down. If this is the case, you have selected the

wrong wire.

WARNING! There is also a positive Parking Light out put. Only one of

these two outputs needs to be connected.

AuxiliaryRelay

FifthRelayOutput

Remote car starters of this series are

equipped with an on-board highcurrent programmable 5

th

relay that

can be used to power a second

ignition, accessory or crank wire. The

unit uses 3 sets of pins; each set

corresponds to a specific function of

the output. In order to activate one of

the three possible functions, y ou must

place the jumper (supplied) on one of

the three sets of pins and connec t the

14 AWG wire to the second

IGN. / ACC. /

CRANK

wire of the vehicle.

Caution!

Only one set of pins can be used at one ti me. Using more than one jumper may result in s erious

damage to the vehicle.

The relay output rating on this unit is 25A at most. Defective OEM solenoid switches can

sometimes draw up to 50 or 60a, c ausing the 30A fuse to blow. Alway s verify your circuit with an

appropriate measuring device.

ManualorAutomaticTransmission

This module may be installed on vehic les with manual or automatic transmissions. It is originally

configured for manual transmis sions

. If the vehicle you are working on is auto matic , it is ma ndatory

to make a few quick and easy modi fications before the unit is connected. In the event th at the

Page 16

P. 16 Installation Guide

configuration requires changes afterwards, a complete reset will be necess ary before those

changes become effective.

To install this unit in a vehicle with a manual transmission:

1. Make sure the Yellow loop on the PC board is connected.

2. Connect the Orange handbrake wire located on the 12-pin harness to the vehicle

handbrake switch.

3. Connect the Blue/White (+) door input OR

the Grey (-) door input wire located on the

12-pin harness to the vehicle do or pin wire, which monitors all the doors of the vehicle

(only use 1 of the 2 door trigger inputs).

4. Make sure the Purple TACH wire is plugged in – the TACH wire MUST be hooked up

when the module is set for a manual transmission.

5. Make all your regular connections.

6. Power up the unit by first insertin g the 5-pin connector, then the 6-pin connector and

finally the 12-pin connector. The park ing lights will flash 4 times t o confirm that the unit

is in manual mode.

7. When learning the transmitter, the parking ligh ts will flash 5 times quickly, confirming

that the module is set to manual mode.

8. Upon the first successful remote start, the system will lock the transmission

settings to manual mode.

To install this unit in a vehicle with an automatic transmission:

1. Cut the loop on the pc board (Yellow wire).

2. Make sure the Orange handbrake wire is not

connected to any of the vehicle circuits.

3. Make all the regular connections.

4. Power up the unit. The parking lights will flash 4 times.

5. When learning the first transmitter, the parking lights will flash 5 times quickly.

6. Upon the first successful remote start once the yellow loop has been cut, the

system will lock the transmission settings to automatic mode.

Note1: When learning the first transmitter after the unit is RESET, the parking lights will flash

5 times quickly followed by 2 slow flashes confirming that the module is set to automatic

mode.

Note2: If upon pressing the

button, the parking lights give 3 slow flashes, make sure that

the Orange handbrake wire is not connected and that the yellow loop is cut and isolated.

TransmitterProgrammingProcedure

1. Enter programming mode (page-17) - the parking lights will stay on for up to 20

seconds.

2. Before the lights go out, turn the ignition key to the Ignition On (Run) position and

immediately to the OFF position.

3. Press and hold the

button and keep it down until the siren chirps twice.

4. The transmitter has been stored in memory.

Note: When finishing the programming operation of the LCD transmitter, make sure that the

message “LRN-OK” is displayed on the screen. In order to re-program the same transmitter, you

will need to press the FUNCTION button immediately after h earing 3 beeps from the remote. The

same “LRN-OK” message will then be displayed again, to confirm that the re-programming

operation was successful.

Page 17

Installation Guide P. 17

Each unit can store 4 remotes in its memory. To program a transmitter on the second vehicle for

multi-car operation, you must press t he

button (instead of or ) in step 3 of the transmitter

programming procedure:

EnteringProgrammingMode

This allows the installer to program the unit. Once the system is in programming mode, the installer

will have up to 20 seconds to select one of the sub-menus. If the installer fails to select a sub-menu

before the 20-second delay, the system will exit programming mode.

Using the Hood Pin

• Press and hold the hood pin for 4 seconds.

• Release the hood pin.

The parking lights will turn ON.

• While the parking lights are ON, press the hood pin once more and

release immediately.

The parking lights will turn ON and stay ON for 20 seconds.

• You now have 20 seconds to select one of the sub-menus.

Note: To exit programming mode, close the hood.

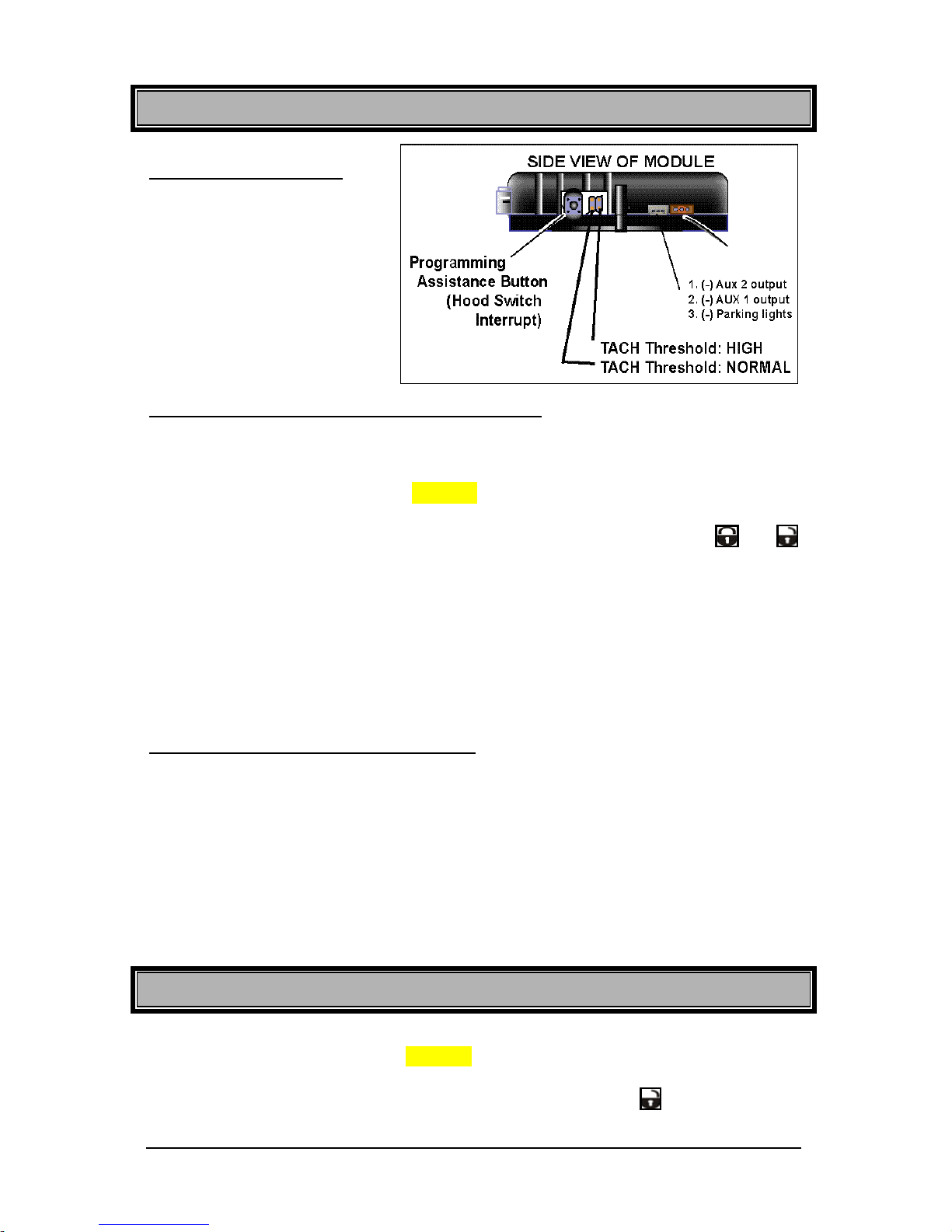

TheProgrammingAssistanceButton(a.k.a.PAB)

The PAB is located on the

side of the module. This

push button mimics the

hood-pin switch in order to

avoid having to get out of

the vehicle and pressing

the hood-pin switch. The

PAB will work only when

the hood is up.

Sub-menus:

a) Transmitter Programming

b) Programming Options

c) Honk Horn/Siren Timing Adjustment

d) Tach Programming

Note: For vehicles that require the ignition to be turned ON to activate the brake, follow these

steps:

a. After flashing the hood, turn the ignition ON; The parking lights will turn OFF

b. After 4 seconds the parking lights will turn ON and then press the brake.

Page 18

P. 18 Installation Guide

EnteringProgrammingOptions

1) Enter programming mode (page-17) ⎯ the parking lights will stay on for up to 20 seconds.

2) Before the lights go out, press and hold the brake pedal and then press one of the following

buttons:

i)

------------------------------------------------ ----------- to access mode 1;

ii)

-------------------------------------------- --------------- to access mode 2;

iii)

---------------------------------------------- -------------- to access mode 3;

iv)

------------------------------------------------------------- to access mode 4.

3) The siren will chirp once, twice, three or four times to confirm entry into a mode.

4) Release the brake pedal.

5) Once the desired mode has been selected, the unit will fall (by default) into function #1 of that

mode; you can now select the option you want in function 1. Once this option has been

chosen, the parking lights will flash one, two, three or four times to confirm your chosen

option. You can not jump over the Function! The unit will move on to fu nc tion 2 of the

mode selected, and so on.

i)

----------------------------------------------------------- for Option 1,

ii)

------------------------------------------------------------ for Option 2,

iii)

------------------------------------------------------------ for Option 3;

iv) -------------------------------------------------------------- for Option 4.

ProgrammingOptions

MODE 1

*indicates default setting

FUNCTION1 – Ignition-Controlled Door locks

OPTION 1* Ignition Lock DISABLED

OPTION 2 Ignition Lock ENABLED

OPTION 3 Ignition UNLOCK ONLY

OPTION 4 Ignition LOCK ONLY

FUNCTION 2 – Secure Lock

OPTION 1* Secure Lock DISABLED

OPTION 2 Standard Secure lock ENABLED

OPTION 3 Smart secure lock ENABLED

FUNCTION 3 – Door Locks Pulse Timing

OPTION 1* 7/10 Second Lock/Unlock pulses.

OPTION 2 4 Seconds Lock/Unlock pulses

OPTION 3 7/10 Seconds Lock pulse and two ¼ second unlock pulses

OPTION 4 1/10 Second Lock/Unlock pulses.

FUNCTION 4 – AUX 3 Programming

OPTION 1* Constant while the TRUNK button is pressed, disarm and passive rearm after 30s

OPTION 2 1-sec. Trunk output with disarm/ rearm while Ignition is OFF.

FUNCTION 5 – AUX 2 Programming

OPTION 1* Car finder

OPTION 2 Toggle ON/OFF with a 30-sec. time out

OPTION 3 Constant output

Page 19

Installation Guide P. 19

MODE 2 *indicates default setting

FUNCTION 1 – Home valet

OPTION 1 Home Valet TM enabled

OPTION 2* Home Valet TM disabled

FUNCTION 2 – Safe Start

OPTION 1 Safe Start enabled

OPTION 2* Safe Start disabled

OPTION 3 “Swap Start” –enhanced safe start mode with extended safety:

FUNCTION 3 – Engine Run Time

OPTION 1 Run time - 3 minute in Gas mode / 8 minutes Diesel mode.

OPTION 2* Run time - 15 minute in Gas mode / 20 minutes Diesel mode

OPTION 3 Run time - 25 minute in Gas mode / 30 minutes Diesel mode.

FUNCTION 4 – Idle Mode & Turbo Mode (auto) / Turbo Mode (manual)

OPTION 1 Idle mode & Turbo mode DISABLED (auto)/ Turbo Mode DISABLED (manual)

OPTION 2* Idle mode & Turbo mode ENABLED (auto)/ Turbo Mode DISABLED (manual)

OPTION 3 Idle mode & Turbo mode ENABLED (auto)/ Turbo Mode ENABLED (manual)

FUNCTION 5 – Engine Type and Cold Weather Mode

OPTION 1 Diesel Engine Mode and 20-minute run time in Cold Weather Mode with 30sec delay

OPTION 2* Gasoline Engine Mode and 3-minute run time in Cold Weather Mode

OPTION 3 Diesel Engine Mode and 8-minute run time in Cold Weather Mode with 18sec delay

OPTION 4 Diesel Engine Mode and 8-minute run time in Cold Weather Mode with 7sec delay

MODE 3 *indicates default setting

FUNCTION 1 – Siren Chirps

OPTION 1 Warning Chirps only; Lock Confirmation if the Lock button is press 2nd time

OPTION 2* Chirps enabled

OPTION 3 Chirps enabled with Open-Zone notification.

OPTION 4 Chirps disabled with Lock confirmation if the Lock button is press 2nd time.

FUNCTION 2 – Arming

OPTION 1 Active Arming

OPTION 2* Passive Arming (30 sec.) / (*two-stage disarm)

OPTION 3 Passive Arming (30 sec.) / (*single stage disarm)

OPTION 4 Active Arming with Disarmed Notification.

FUNCTION 3 – Ignition Monitoring: Siren Mode / Horn Mode

OPTION 1 Siren mode: with Ignition Monitoring – DISABLED.

OPTION 2* Siren mode with Ignition Monitoring – ENABLED.

OPTION 3 Horn mode with Ignition Monitoring – DISABLED.

OPTION 4 Horn mode with Ignition Monitoring – ENABLED.

FUNCTION 4 – Shock Sense / Warn Away

OPTION 1 Shock Sense - Ignored / Warn away – ignored

OPTION 2* Shock Sense - monitored / Warn away – monitored

OPTION 3 Shock Sense - Monitored / Warn away – ignored

OPTION 4 Shock Sense - Ignored / Warn away – monitored

FUNCTION 5 – Ignition Valet

OPTION 1 Ignition Valet – DISABLED

OPTION 2* Ignition Valet - ENABLED

Page 20

P. 20 Installation Guide

MODE 4 *indicates default setting

FUNCTION 1 – Relock

OPTION 1 Disabled

OPTION 2* Enabled – Relocks all doors 30 seconds after unlocking if neither doors nor trunk are

opened.

FUNCTION 2 – Pager (Pager sold separately)

OPTION 1 Pager ENABLED

OPTION 2* Pager DISABLED

FUNCTION 3 – Ready Mode Option

OPTION 1 Enabled by handbrake

OPTION 2* Enabled by remote

FUNCTION 4 – Bypass

OPTION 1 ADS

OPTION 2* Xpresskit

OPTION 3 Fortin

FUNCTION 5 – Bypass Type

OPTION 1 One Way communication

OPTION 2* Two Way communication ( For Xpresskit bypass ONLY)

VirtualTachSystem

Virtual Tach System combines the l atest microcontroller technol ogy and a complex algorithm tha t

took years to develop. VTS is able to effectively monitor the engine starting seque nce and release

the starter at the right time without physically connecting the tach wire to the remote st arter. The

VTS constantly monitors the data and readjusts itself automatically in order to maximize its

capability to start the engine properly in any weather or deteriorating battery condition

Note: Virtual Tach System is only available in automatic transmission.

OptionalTimeDelayAdjustmentinVirtualTachSystem

Follow these steps to program crank time adjustment, if needed:

1. Enter programming mode (page-17) ⎯ the parking lights wil l stay on for up to 20

seconds.

2. Before the lights go out, press and hold the brake pedal and press the and

buttons simultaneously ⎯ Siren will chirps 4 times. Do not release the brake pedal.

3. Press the butto n if you wish to inc rease the time d elay or the button if you want

to decrease it. The time delay will be increased or decreased by 5 0ms. and the park ing

lights will flash once if the is pressed or twice if the button is pressed.

4. Press the

button to save the settings you have entered. The p arking lights will flas h

5 times.

5. Release the brake pedal – the time delay programming is now complete.

Page 21

Installation Guide P. 21

TachLearning

Tachjumpersettings

Some new vehicles have a higher

TACH voltage threshold, which

would fall out of the normal TACH

trigger circuit of the remote car

starter. Changing the jumper to

TACH Threshold HIGH will allow

the module to properly detect the

TACH signal.

MultispeedTachProgrammingProcedure

The system is designed to read a wide range of Tach signals produced by newer Ignition

systems. Note that you should go through the Tach programming procedure every time a new

Unit is installed.

1. Enter programming mode (page-17) ⎯ the parking lights will stay on for up to 20

seconds.

2. Before the lights go out, press and hold the brake pedal and press the and

buttons simultaneously ⎯ the siren will chirp 4 times.

3. Release the brake pedal.

4. Start up the engine and allow the vehicle to reach regular engine idle speed.

5. Once the engine is running at normal idle speed, press the brake pedal and keep it

down until you hear the siren chirps 2 times.

6. Release the brake pedal ⎯the tach programming is now complete.

Note: If another Tach programming is required, simply repeat the “Multi Speed Tach

learning”.

AutoTachProgrammingProcedure

This process can be carried out instead of the conventional Tach Programming Procedure.

1. Make sure all the connections are done properly and that the Module has been

powered-up.

2. With the Hood up (Ground on the Hood Pin line), start the vehicle using the key.

3. Start up the engine and allow the vehicle to reach regular engine idle speed.

4. Once the engine is running at normal idle speed, press the brake pedal and keep it

down until you hear the siren chirps 2 times.

5. Turn the Ignition OFF. At this point, the Tach setting has been programmed.

Note: The “Auto tach programming” can on ly be carried out once unless the system is reset.

Siren/HornTimingAdjustment

Follow these steps to adjust siren/horn pulse timing:

1) Enter programming mode (page-17) - the parking lights will stay on for up to 20

seconds.

2) Press and hold the brake pedal, then simultaneously press the

and START buttons

⎯ the siren will chirp 5 times.

Page 22

P. 22 Installation Guide

3) Release the brake pedal.

4) To change the timing:

a) To increase the pulse by 3 ms, press the

button.

b) To decrease the pulse by 3 ms, press the

button.

c) To increase the pulse by 10 ms, press the button.

d) To decrease the pulse by 10 ms, press the

button.

5) To save the new settings: press

and . The siren/horn will chirp 3 times to

indicate that the settings have been successfully saved.

SettingtheunitintoReadyMode

If the vehicle has a manual transm ission you must read the followi ng indications. The unit must

first be set to Ready Mode in order to start the vehicle by remote. If t he unit is not set to Ready

Mode, it cannot remote start the vehicle.

Please note that Ready Mode can be enabled by the remote or the handbrake, depending on th e

option that was selected. Therefore , you must follow the appropriate procedure between the two

described below in order to set the vehicle into Ready Mode.

Once the system is set to Ready Mode, the vehicle can be remote started and stopped at any time.

The system will exit Ready Mode if a door, the hood or the trunk is opened, if the brake pedal is

pressed, if the parking brak e is disengaged or if the ignition key is turned to the

IGNITION ON (RUN)

position.

To set the system to Ready Mode:

If Ready Mode is enabled by remote If Ready Mode is enabled by handbrake

1. Ensure that all the doors, hood and trunk are closed. Make sure that the gear selector

is in the neutral position.

2. With the engine already running, apply

the parking brake once and release

the brake pedal.

2. With the engine already running, apply

the parking brake twice within 10sec.

Make sure to release the brake pedal.

The parking lights will flash 3 times

quickly and remain lit.

Skip to step 4.

3. Within 20 sec. of engaging the parking

brake, press and hold , or

on the transmitter.

The parking lights will flash 3 times

quickly and remain lit.

-

4. Remove the key: the engine will continue running.

5. Exit the vehicle and close all doors, hood and trunk.

6. Press for approx. 1 second either:

• to lock the doors and shut down the engine;

• to unlock the doors and shut down the engine;

• to shut down the engine without affecting the doors.

7. The icon will appear on your screen.

Page 23

Installation Guide P. 23

ArminganddisarmingoftheSystem

The Alarm can be configured by the installer either to Passive Mode (so as to arm a utomatically)

or Active Mode (so as to require the user’s intervention for arming). By default, the R emote Car

Starter is configured to Passive Mo de

1) Passive mode:

a) To arm the alarm, press the

button on the transmitter, OR

i) In Passive Mode, the alarm will automatically arm 30sec once the last door is

closed.

ii) The LED on the antenna will flash quickly during the countdown preceding the

activation of the system.

iii) Once the activation countdown ex pires, the siren will chirp once and the LED will

flash slowly to indicate that the alarm is now armed.

b) To disarm the alarm, press the

button on the transmitter.

i) The LED on the antenna will flash quickly during the countdown preceding the

activation of the system.

ii) The alarm w ill automatically rearm itself after 30s ec if no door is left opened and

the ignition is not turned ON.

2) Active Mode:

a) To arm the alarm, press the

button on the transmitter.

i) The siren will chirp once.

ii) The LED on the antenna will flash slowly.

b) To disarm the Alarm, press the

button on the transmitter.

i) The siren will chirp twice.

ii) The LED on the antenna will remain OFF.

InstallationprogrammableFeatures

The following features can be programmed according to the needs of the installation and the

requirements of the user:

IgnitionControlledDoorLocks

1. Ignition Lock disabled: turns OFF the Ignition Lock feature.

2. Ignition Lock enabled: locks all Doors when the key is in the ON position an d the user

presses the Brake Pedal. Similarly, when the Ignition key is turned to the OFF

position, the Doors will unlock.

3. Ignition Lock Only: the system will only lock all Doors when the Ignition Key is turned

to the IGNITION ON (RUN) position and Brake Pedal is pressed.

4. Ignition Unlock Only: the system will unlock all Doors when the Key is turned to the

OFF position, provided the Ignition K ey was in the IGNITION ON (RUN) position and the

Brake Pedal was pressed at least once.

Page 24

P. 24 Installation Guide

SecureLock

This feature allows the module t o control certain OEM fact ory alarm systems witho ut requiring the

use of other wires for disarming the OEM alarm. (Namely, this feature is designed for OEM

systems that use the factory lock wire to arm the alarm and the unlock wire to disarm it.)

1) Standard Secure Lock disabled: By default, the unit will send a disarm pulse before IGN,

an arm pulse once the car is remote started and an arm pulse 4 sec after the engine shuts

down.

Note: No lock pulse or unlock pulse is sent at any moment of the remote start sequence.

2) Standard Secure Lock: If this Option is selected,

at remote start, the module will send an

unlock/disarm pulse (disarming the factory Alarm)

before start-up, lock pulse when the

engine is running, and lock/arm pulse 4 seconds after it shuts down the engine.

Note: The unit DOES NOT send an arm pulse while the engine is under remote start.

3) Smart Secure Lock:If the vehicle was previously locked with the remote starter transmitter,

at remote start the module will send an unlock/disarm pulse before start-up, lock pulse when

the engine is running, and lock/arm pulse 4 seconds after it shuts down the engine.

If the vehicle is initially unlocked, the unit will not send a lock pulse, arm pulse, unlock

pulse or a disarm pulse at any moment of the remote start sequence.

Note: The unit DOES NOT send an arm pulse while the engine is under remote start.

AUX3output

This 500 mA negative AUX 3 output (trunk output) can be used for many different applic atio ns. The

output can be programmed to give a 1-sec. or to giv e a c ontinu ous out put as long as the

button

is held down.

OPTION 1

Constant output: Pressing and holding the

button for more than 5 se conds

will send a disarm pulse and a nega tive pulse to the tr unk wire as long a s the

button is held down (maximum of 15 sec.). A rearm pulse is sent after 30sec.

(passive mode).

OPTION 2

1-sec. trunk pulse: Pressing the

butt on for 5sec will send a disarm pulse, a

1sec negative trunk pulse and a rearm pulse after 30 sec. (passive arm).

AUX2

Note: This 500 mA negative Aux 2 output can be used for many different applications

OPTION 1

Car Finder. The siren will sound once each t ime the

and are pr ess

simultaneously

.

OPTION 2

Toggle ON/OFF for a maximum of 30sec. Press and releas e to select

L-01 and then press the

button to activate AUX-2.

OPTION 3

AUX-2 constant output (15sec). Press and releas e to select L-01 and

then press and hold the

button to activate AUX-2.

“HomeValetTM”Mode

If configured at installation, this feat ure will remotely set the vehicle to a no-remote-start mod e: if

the vehicle is parked indoors there is no danger of it s tarting accidentally by remote contr ol. If the

vehicle has a manual transmission, it should be set into ready mode before activating the Home

Valet™.

Note: Once the Home Valet Mode is activated, the vehicle will not start by rem ote, but the

alarm functions will remain active.

Page 25

Installation Guide P. 25

To take the system into home valet mode:

1. Press the or button.

2. Within 3 seconds, press the

and buttons simultaneously

3. The transmitter will beep once and the

icon will display.

To take the system out of home valet mode:

• Turn the ignition key to the IGNITION ON (RUN) position.

The system will warn you if someone attempts to start your vehicle while it stands in home valet

mode. The parking lights will: Turn ON then OFF; then, flash twice, pause; then, flash twice again.

SafeStart

This feature will eliminate accidental remote starts, e.g. when children are playing with the

transmitter.

1. Safe start enabled: If this feature is enabl ed, the user must press the

button twice within

3 seconds to remote-start the vehicle.

2. Swap start: If this feature is enabled;

a. Press and release

to select L-01.

b. Press

to remote start the vehicle.

The AUX 2 output can be activated by pressing the button.

EngineRunTime

On a gas engine, the Remote Car Starter can be programmed to run the engine for 3, 15, or

25 minutes (15 minutes by default). On a diesel engine, the Remote Car Starter can be

programmed to run the engine for 8, 20, or 30 minutes (20 minutes by default).

IdleMode

Convenience feature: Idle Mode allows you to keep the engine running and the doors

locked while you stop, for example, at a convenience store or for a short delivery.

This feature allows you to let the remote start er take over control of the vehicle (i.e. no Key in the

Ignition Switch) while the engine is running.

If your vehicle has an automatic transmission, proceed as follows to set the system to Idle Mode:

1. With the engine running, make sure to release the brake pedal and press the

, or

button on the transmitter until the parking lights come ON.

2. Remove the ignition key from the ignition switch.

The engine will continue running.

3. Exit the vehicle and close all doors, hood and trunk.

4. Press the

button to lock the doors, to arm the starter kill and to arm the alarm.

If your vehicle has a manual transmission, I dle Mode can be activated through the same routine

as that used for Ready Mode (page-22); at the last step, the button is pressed inste ad of the

other buttons. This will lock the doors, arm the system and leave the engine running.

Note1: The engine will continue running until the user re-ent ers th e v eh ic le or until the expiration of

the engine run time.

Note2: If the pre-programmed run-time expires or if the user shuts down the engine by remote

control, the vehicle will enter Ready Mode.

Page 26

P. 26 Installation Guide

Caution!!! Do not leave children or pets unattended in a vehicle standing in Idle Mode.

TurboMode

If Turbo Mode is configured at installation, it will allow a turbocharger to idle down after the user

leaves the vehicle: the unit will take over the vehicle and keep it running for 60 seconds (or until it

is shut down by remote control), then shut down the engine.

If your vehicle has an automatic transmission, proceed as follows to set the system to Turbo

Mode:

1. With the engine running, make sure to release the brake pedal and press the , or

button on the transmitter until the parking lights come ON.

2. Remove the ignition key from the ignition switch.

The engine will continue running.

3. Exit the vehicle and close all doors, hood and trunk.

4. Press the

button; this will lock the doors, arm the system alarm and confirm tha t the

vehicle is in Turbo Mode.

5. The engine will shut down after 60 seconds.

If your vehicle has a manual transmission, follow all steps of the Ready Mode routine (page-22)

to activate Turbo Mode. At the last step,

• Press to lock the doors and have the engine shut down after 60 seconds;

The parking lights will flash 3 times and remain lit.

The alarm and starter kill will be armed.

• Press