DR W 1711 87A B

Specifications

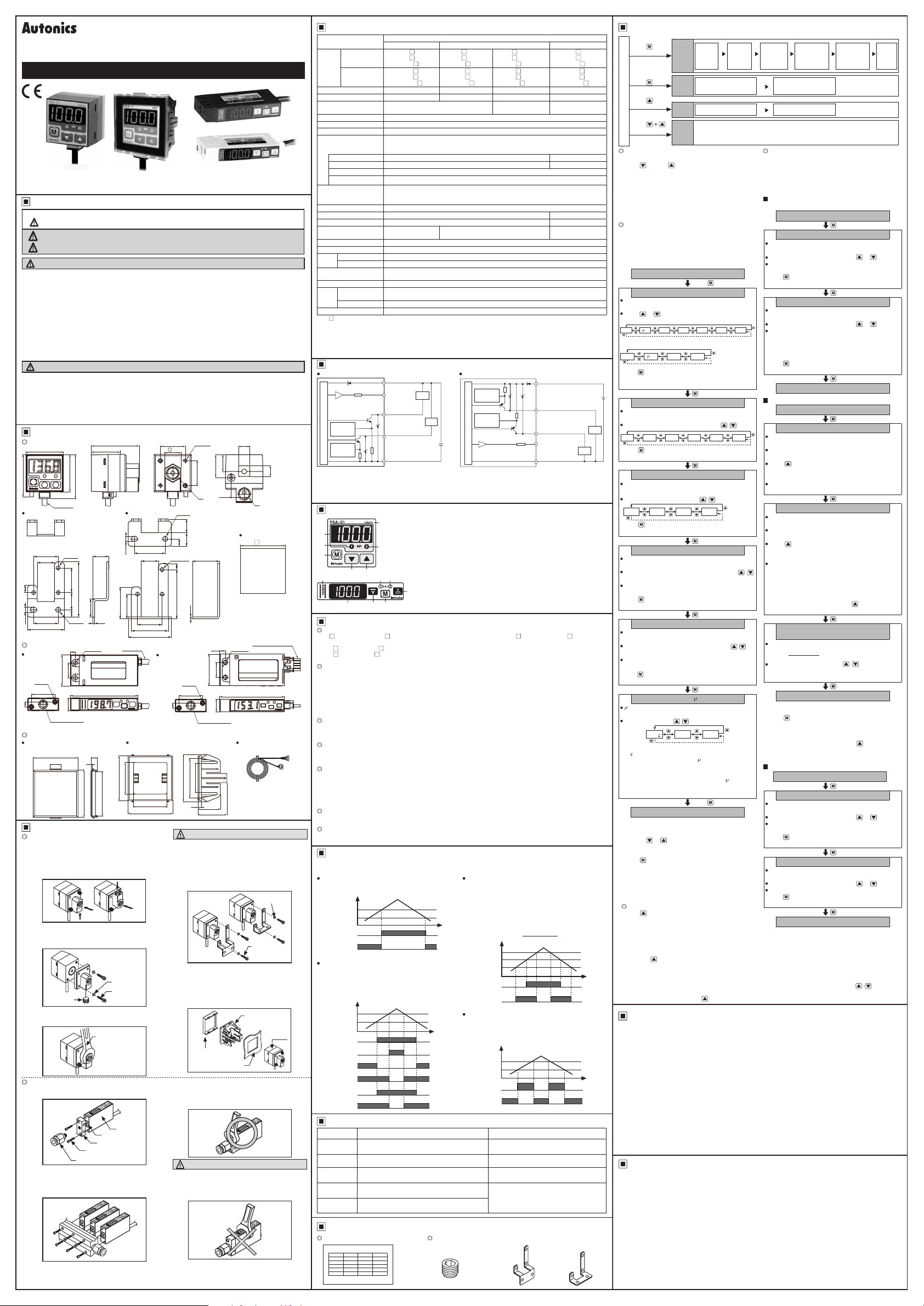

Autonics

DIGITAL PRESSURE SENSOR

PSA/PSB SERIES

I N S T R U C T I O N M A N U A L

PSA PSB

(cable type)

(connector type)

Please read the following safety considerations before use.

Safety Considerations

Please observe all safety considerations for safe and proper product operation to avoid hazards.

※

symbol represents caution due to special circumstances in which hazards may occur.

※

Warning

Caution

Warning

1. Fail-safe device must be installed when using the unit with machinery that may cause serious injury or

substantial economic loss. (e.g. nuclear power control, medical equipment, ships, vehicles, railways,

aircraft, combustion apparatus, safety equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in personal injury, economic loss or re.

2. Do not use the unit in the place where ammable/explosive/corrosive gas, high humidity, direct sunlight,

radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in explosion or re.

3. Install on a device panel or to a pressure port directrly to use.

Failure to follow this instruction may result in re.

4. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in re.

5. Check 'Connections' before wiring.

Failure to follow this instruction may result in re.

6. Do not disassemble or modify the unit.

Failure to follow this instruction may result in re.

Caution

1. Use the unit within the rated specications.

~c======================~~

Failure to follow this instruction may result in re or product damage.

2. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in re.

3. This product is designed to detect the pressure of noncorrosive gas. Do not use for corrosive gas.

Failure to follow this instruction may result in product damage.

4. Keep metal chip, dust, and wire residue from owing into the unit.

Failure to follow this instruction may result in re or product damage.

Dimensions

PSA Series

30

34

~oij!

8,[][]

L.LJ

I h

Bracket A Bracket B

n_______n

20

14

6

20

4.2

30

PSB Series

Cable type

2-M2

19

4

Sold separately

Front cover

(PSA, PSO-P01)

Installation

PSA Series

1. When installing pressure port it is able to bring

pressure from 3 directions by changing the

mounting direction of the pressure port.

2. Standard pressure port is Rc1/8 and option

pressure port is NPT1/8. Use a general one-

touch tting.

3. Please use seal tape at port plug in order to

prevent pressure leak.

4. Please block another two pressure ports not

used with port plug.

Port plug

5. Please connect it by using spanner(13mm) at the

metal part in order not to overload on the body

when connecting one touch tting.

J~

g

PSB Series

1. Pressure port is M5.

t is able to use general one touch tting.

2. It is able to use it without the pressure port

according to environment.

In this case O-Ring between pressure port

and its body should not be taken out in

order to prevent pressure leak.

※

Do not pull the cable with a tensile strength of 30N or over.

※

The above specications are subject to change and some models may be discontinued without notice.

※

Be sure to follow cautions written in the instruction manual and the technical descriptions

(catalog, homepage).

Thank you for choosing our Autonics product.

Failure to follow these instructions may result in serious injury or death.

Failure to follow these instructions may result in personal injury or product damage.

38.5

23

30

35.5

Ø4, 2m

25

4.2

12

10 3

20

14

6

Ø4.2

4

45

42

15

2-Ø3.4

5.7

1

13

26

1.6

Ø4, 2m

54.2

40

40

Spring washer

Hexagon

wrench bolt

13mm Spanner

14

20

20

30

35

Connector type

Mounting bracket

(PSA, PSO-01)

.

~

28.2

~

30

40

3-Ø3.2

25

Pressure port

M5

Tap depth: 5

40

9.7

L

Body

O-Ring

Pressure port

~~

Hexagon wrench bolt

(M2X10)

One touch tting

2-M3

20

13

20

A

Ø4.2

1111

6

3-Ø3.2

22

5

40

1.6

25 5

2-M2

19

4

Pressure port

M5

Tap depth: 5

423526

3

20

25.8

I

Caution

The tightening torque of one touch tting

should be Max. 10N.m.

It may cause mechanical trouble.

6. PSA Series has 2 kinds of brackets so it is able

to install it in two dierent ways.

7. At rst, please unscrew hexagon wrench bolt and

assemble the bracket on this unit by xing the

hexagon wrench bolt.

In this case, tightening torque of hexagon

wrench should be max. 3N.m.

It may cause mechanical trouble.

8. Front cover (PSO-P01) and mounting bracket

(PSO-01) are sold separately.

Please refer to the below pictures for

installation.

Front

cover

(PSO-P01)

p~~~

3. Please connect it by using spanner(10mm)

at pressure port in order not to overload on

the body when connecting one touch tting.

9

13.4

18.4

10.5

※

A: Rc1/8 (standard), NPT1/8 (option)

Panel cut-out

( panel thickness:

0.8 to 3.5mm)

4 5

2-Ø3 2

12

10

Connector cable

(PSB, PSO-C01)

※

Ø4mm, 5-wire, 2m

(AWG24, core diameter:

0.08mm, number of

cores: 40, insulator

diameter: Ø1mm)

Mounting bracket

(PSO-01)

Bracket

panel

I b I

Caution

The tightening torque of one touch tting and

hexagon wrench should be Max. 5N m and

2N m. It may cause mechanical trouble.

Please do not use spanner to install as it may

cause mechanical trouble.

(unit: mm)

8.5

A

0 5

36

0

Connector cable 3m

(Accessory)

52

Spring

washer

Hexagon

wrench bolt

Body

(PSA)

10mm spanner

■

Pressure type

NPN open

collector output

※

1

Model

PNP open

collector output

Rated pressure range 0.0 to -101.3kPa 0.0 to 100.0kPa 0 to 1,000kPa -100.0 to 100.0kPa

Display pressure range 5.0 to -101.3kPa -5.0 to 110.0kPa -50 to 1,100kPa -101.2 to 110.0kPa

Max. pressure range 2 times of rated pressure

Applicable uid Air, Non-corrosive gas

Power supply 12-24VDC ±10%(Ripple P-P: max. 10%)

Current consumption Max. 50mA

Control output

Hysteresis

I

Repeat error ±0.2% F.S. ±1digit ±0.2% F.S.±2digits

I

Response time Selectable 2.5ms, 5ms, 100ms, 500ms

I

Short circuit protection

I

Analog output

Display digit 3½ digit LED

Display method 7 Segment LED

Min. display interval 1digit(psi unit: 2 digits are xed) 2digits

Pressure unit

Display accuracy 0 to 50℃: Max. ±1% F.S., -10 to 0℃: Max. ±2% F.S.

Vibration 1.5mm amplitude at frequency of 10 to 55Hz in each of X, Y, Z directions for 2 hours

Ambient temperature

Environ

I

-ment

Ambient humidity 35 to 85%RH, Storage: 35 to 85%RH

I

Material

Protection IP40(IEC standard)

Cable type

Cable

I

Connector type 5-wire, Length: 3m(AWG 24, insulation diameter: Ø1.4mm)

I

3

※

Weight

※

' is pressure port type. PSA standard: Rc1/8, PSA option: NPT1/8, PSB standard: M5.

1: '

□

※

2: In hysteresis output mode, detection dierence is variable.

※

3: The weight is with packaging and the weight in parentheses is only unit weight.

※

F.S.: Rated pressure.

※

The specication of pressure port for PSA Series is marked on the upper part of the case.

※ForusingmmH2Ounit,multiplydisplayvalueby100.

※

Environment resistance is rated at no freezing or condensation.

h,,,----------~

Input/Output Circuit and Connection Diagram

NPN open collector output type PNP open collector output type

1kΩ

Over current

protection

circuit

Main circuit

Over current

protection

circuit

※

There is no over current protection circuit in analog voltage output type.

Do not connect this unit to power source or capacitive load directly.

※

Please observe input impedance of connected equipment when using analog voltage output.

And be sure with voltage drop by resistance of extended wire.

※

If short-circuit the control output terminal or supply current over the rated specification, control signal is abnormal

due to the current protection circuit

k-------------7

Unit Descriptions

~

1

2

4

6 5

7

1

Functions

Pressure unit change

PS -V01(C)(P) and PS -C01(C)(P) has 7 kinds of pressure unit and PS -01(C)(P) and PS -1(C)(P)

has 4 kinds of pressure unit. Please select the proper unit for application.

• PS -V01(C)(P), PS -C01(C)(P) : kPa, kgf/cm², bar, psi, mmHg, inHg, mmH2O

• PS -01(C)(P), PS -1(C)(P) : kPa, kgf/cm², bar, psi

※

When using mmH2O unit, multiply display value by 100.

Output mode change

There are 6 kinds of control output mode in order to provide the various detection.

Select a mode for your proper application.

• Hysteresis mode[

• Automatic sensitivity setting mode[

proper position.

• Independent 2 output mode[

with one product.

• Window comparison output mode[

Response time change (chattering prevention)

It can prevent chattering of control output by changing response time. t is able to set 4 kinds of

response time (2.5, 5, 100, 500ms) and if the response time is getting longer, the sensing will be more

stable by increasing the number of digital lter.

Analog output scale setting

0

It is not xed the analog output(1-5VDC) scale as the rated pressure range but this is a function to

change properly for user's application. When the position [

for 5VDC output are set, the pressure range of

Key lock

This unit has 2 kinds of key lock function in order to prevent wrong operation.

•

: All keys are locked, it is impossible to change any parameter setting/preset, zero point

LOC

adjustment, peak hold and bottom hold. (enables to change

•

: t is impossible to change parameter setting/preset, zero point adjustment. (Enables to check

PA.L

peak hold and bottom hold, and to change

•

: All of the setting is available, all keys are unlocked.

UNL

Zero point adjustment

This function is to set the display value of pressure at zero when port is opened to atmospheric pressure.

Zero point adjustment aects analog output voltage.

Peak hold and bottom hold function

This function is to diagnosis malfunction of the system caused by parasitic pressure or to check through

memorizing the max /min. pressure that occurred in the system.

Output Operation Mode

※

PSA/PSB Series has 6 kinds of output operation mode, please use proper output operation mode

in accordance with sensing.

Hysteresis mode[

It can be set for pressure sensing level [

sensing dierences [

Pressure

ST1

ST2

ON

OUT1

OFF

ON

OUT2

OFF

Independent 2 output mode[

and

①

ST1

ST2

display pressure range. One is for control, the

other is for alarm or optional control.

②Thesensing

(2 digits for psi unit and compound type)

Pressure

ST2

ST1

ON

OUT1

OFF

F 3

ON

OUT2

OFF

ON

OUT1

OFF

F 4

ON

OUT2

OFF

ON

OUT1

OFF

F 5

ON

OUT2

OFF

Gauge pressure

Negative pressure type

PSA-V01PSB-V01PSB-V01CPSA-V01PPSB-V01PPSB-V01CP-

NPN or PNP open collector output

• Load voltage: Max. 30VDC • Load current: Max. 100mA

• Residual voltage -NPN: Max. 1VDC , PNP: Max. 2VDC

※

2

1digit xed(2digits for psi unit) 2digits xed

Built-in

• Output voltage: 1-5VDC ±2% F.S.

• Zero point: Within 1VDC ±2% F.S.

• Resolution: Approx. 1/200

kPa, kgf/cm

mmHg, mmH2O, inHg

-10 to 50, Storage: -20 to 60℃

• PSA - Case: PC, Pressure port: die-cast (Zn)

• PSB - Case, Pressure port, Cover: IXEF • PSB-C - Case, Pressure port, Cover: IXEF

Ø4mm, 5-wire, Length: 2m(AWG 24, core diameter: 0.08mm, number of cores: 40,

insulation diameter: Ø1mm)

PSA : Approx. 200g(approx. 120g), PSB : Approx. 160g(approx. 70g), PSB-C : Approx. 160g (approx. 70g)

(brown)+V

(orange)

Analog

voltage output

(black)OUT1

(white)OUT2

(blue)0V

1.

3½ digit LED display(red)

7

Displays sensing pressure, every setting value and display error

2. 1 output indicator(red)

3. 2 output indicator(PSA red, PSB green)

3

4. Mode key

5. Up key

3

2

4

6

□ □

□

□

] : When variable hysteresis is required for pressure detection.

F 1

F 3, F 4, F 5

]

F 1

].

ST2

can be set independently within

hysteresis is xed in 1digit.

F 3, F 4, F 5

Standard pressure type

PSA-01-

□

PSB-01-

□

PSB-01C-

□

PSA-01P-

□

PSB-01P-

□

PSB-01CP-

□

2

,bar, psi,

kPa, kgf/cm2, bar, psi

I

※

There may be ±1digit error in hysteresis by pressure unit calculation error.

Load

Load

+

12-24VDC

-

: Enter to parameter or preset setting mode, and save setting value

: Sets the setting value to upper step in preset setting or pressure unit, output

mode, response time, analog output scale, key lock, peak hold value, bottom

hold value display in parameter setting

6. Down key

: Sets setting value to lower step in preset setting or pressure unit,

output mode, response time, analog output scale, key lock, peak hold,

5

bottom hold display in parameter setting.

7. Range of rating pressure

pressure sensor. Please use dierent unit label for your application.

]: When it is required to set detecting sensitivity automatically at

F 2

]: When it is required to detect pressure from two positions

] : When it is required to detect pressure in a certain area.

F 6

to

A 1

KEY

] and

ST1

Time

]

Time

PSA-1-

□

□

□

□

□

□

Over curren

protection

Over curren

protection

Main circuit

:

: Output 1 is ON, LED will be ON

A 1

A 5

mode)

Automatic sensitivity setting mode[

This function is to set pressure sensing level

①

to the proper position automatically. It is set by

received pressure from two positions[

②Thesensing

(2 digits for psi unit and compound type)

The pressure sensing level [

③

the following calculation.

Pressure

OUT1

OUT2

Window comparison output mode[

It is able to set High-limit value[HI], Low limit

①

value [LO] of pressure sensing level in this mode.

The sensing hysteresis is xed to 1digit (2 digits

②

for psi unit and compound type)

Pressure

OUT1

OUT2

□

PSB-1-

□

PSB-1C-

□

PSA-1P-

□

PSB-1P-

□

PSB-1CP-

□

1.5 times of rated

pressure

• Linear: Within ±2% F.S.

• Span: Within 4VDC ±2% F.S.

• Output impedance: 1kΩ

(brown)+V

circuit

circuit

: It is possible to change the pressure unit in

] for 1VDC output and the position [

is to 1-5VDC analog output.

KEY

SET

ST2

SET

ST1

ON

OFF

ON

OFF

HI

LO

ON

OFF

ON

OFF

(black)OUT1

(white)OUT2

(orange)

Analog voltage

1kΩ

output

(blue)0V

: Output 2 is ON, LED will be ON

mode only)

hysteresis is xed in 1digit.

(

+

ST1

ST2

=

2

SET

Error

Error display Description Countermeasures

ER1

b~

ER2

ER3

HHH

LLL

Accessory

~

PSA/PSB (pressure unit label) Only for PSA Series

0

[III

If external pressure applied, when adjusting

Zero point

=======t======

When overloaded on control output Remove overload

When the setting condition is not matched at

automatic sensitivity setting mode

When the applied pressure exceeds the upper

display pressure range up

When the applied pressure exceeds the lower

display pressure range down

±100kPa

-101 3kPa

100kPa 1MPa

± 2 k m

- 4k m 2 k m 2 k m

± 4 s - 4 7 s 4 s 4 s

± a - a a a

±7 mm

7 mm X X

±29 299 X X

± 2 mm

- 4mm

X X

DISPLAY UNIT LABEL

• Port plug • Bracket A • Bracket B

Please try again after external pressure

removing

Set proper setting value after checking

setting condition

Apply pressure within display pressure

range

Compound pressure type

PSA-C01-

□

PSB-C01-

□

PSB-C01C-

□

PSA-C01P-

□

PSB-C01P-

□

PSB-C01CP-

2 times of rated

pressure

I

I

I

I

kPa, kgf/cm2, bar, psi,

mmHg, mmH2O, inHg

I

12-24VDC

□

F 2

ST1, ST2

] is shown in

)

F 6

□

Load

A 5

]

]

Setting

-

Press

key

10

Para-

over 3sec.

key

Press

10

key

Press

I•

RUN mode

over 3sec.

Press

~+~

key over 1sec.

-

Zero point adjustment Preset value setting

0 0

1. In state of atmospheric pressure during RUN mode,

press key and key at the same time for over

1sec.

2. When the zero point adjustment is completed, it will

display

and return to RUN mode automatically.

)0

※

If executing zero point adjustment when external

pressure has been applied,

Please execute zero point again in state of

atmospheric pressure.

※

Please execute zero point adjustment regularly.

Parameter setting

0

1. Set to pressure display unit, output operation

mode, response time(chattering prevention),

analog output scales or key lock.

2. Please set parameter after unlocking key lock

function when key lock function is set.

(please see below key lock setting)

U T

every 0.5 sec.

Press or key to select the unit.

※

Negative pressure, compound pressure:

(kPa)

※

Standard pressure

PA 9F BA PS

cr::

____

(kPa)

( Press

move to the next mode.)

※

For using mm

+

-

UT

by turning o n.(0.5sec.)

Select the output operation mode with , key.

•

Load

Time

F-1 F-6F-2 F-5F-3 F-4

I'

___

( Pre ss key mo mentarily, the resp onse time w ill be

saved, the n move to the nex t mode.)

L__---------,,.~@---

SP

turning on.(0.5sec.)

Select t he respon se time with , key.

•

0¾0.-----:

,.,,

( Pre ss

saved, the n move to the nex t mode.)

A

on.(0.5sec.)

Set the pre ssure which will ou tput 1VDC wi th ,

key.

Set range : Mi n. value of rat ed pressu re ≤ [

(Press

set as 1VDC sc ales, then move to the n ext mode.)

A 5

on.(0.5sec.)

Set the pressure which will output 5VDC by

key.

Set range: [

(Press key momenta rily, the selected p ressure is set

as 5VDC sc ales, then move to the next m ode.

EY

on(0.5sec.)

Select key lock with ,

※

Key lock functions

●

L

]

●

PaL

●

U L

※

When advance to parameter setting mode and preset

setting mode, it displays "Setting item" and "Previous

setting value" by 0.5 sec. turn. This display will stop by

pressing

is untouched for over 1 sec., it will display old value by

0.5sec. turn again.

※

When

return to RUN mode with memorizing on EEPROM.

However, when there is any key is untouched for

60sec., it turns to RUN mode with keeping the previous setting value not current setting value.

※

There is memory protection by EEPROM, but life cycle

].

of EEPROM is 100,000 times.

Peak hold and bottom hold check

0

1. Press

2.

PeH

type is for max. negative pressure) will ash by turning

on (0.5sec.) then display peak hold value.

3.

BoH

type is for min. negative pressure) will ash by turning

on (0.5sec.) then display bottom hold value.

4. If pressing key one time shortly, memorized peak

hold and bottom hold value will be removed then return

to RUN mode.

※

When the peak hold and bottom hold value is over the

max. display pressure value, it displays

opposite, it displays

and bottom hold value by using key.

Display unit [

and previously set unit will flash in turn

9F MMHBAR PS

2

(bar)

(kgf/cm

)

c

________________________________

2

)

(kgf/cm

key momentarily, the unit will be saved, then

@

H₂O

Output operation mode [

and previo us output o perati on mode wi ll flash

cr_

-------------------------------------------------'

Response time [

and the prev ious res ponse tim e will fla sh by

------=-ici4d------:-:;;:-==--,'·'

@5 %0 00 500

___

Iii)

___________________________________

key mom entari ly, the respon se time wi ll be

Analog output scale (1VDC) [

and the prev ious pressure wil l flash by turning

≤ 90% of rate d pressure

key momenta rily, the selected pr essure is

Analog output scale (5VDC) [

and the previous pressure will flash by turning

A 1

[

]≤Max. value of rated pressure

A 5

and the previous key lock will flash by turning

L PaL U L

c5+ciK::jl"

~--c

__

: Disable to change preset value and parameter

value (Enable to change

: Disable to change parameter setting/preset,

zero point adjustment. (Enables to check peak

hold and bottom hold, and to change

: Enable to change preset value and parameter

value(Lock off)

Returns to RUN mode

or key(Display setting value), if any key

key is pressed for 3sec. during setting, it will

key for over 3sec. in RUN mode.

and memorized max. pressure(Negative pressure

and memorized min. pressure(Negative pressure

Display

meter

unit

o►o►o►o►o►o

setting

setting

Preset

Sensing level 1 setting

value

(

ST1, LO

setting

I I

Peak

II

hold

Zero

point

Zero point adjustment

adjust

-ment

I

I

E

RUN mode

Press key over 3 sec.

(psi)

(mmHg)

(bar)

(psi)

unit, multiply display value by 100.

]+10% of rated pressure ≤

Key lock [

EY

key.

:•

__________

!•

___________

Press key over 3 sec.

. Please remove peak hold

LLL

Output

Response

operation

time

mode

setting

setting

)

Peak hold Bottom hold

will be ashing.

]

UNT

(inHg)

I

..

_

OUT

~~

]

SPD

.&:

l•

_

A 1

A 5

]

:

mode only)

EY

HHH

I

I

1. Set the pressure sensing level.

2. Set preset value after unlocking key lock when key

3. Be sure that the setting method is dierent by each

■

H2OPA NH

(mmH

O)

2

]

1

..

1 •

(unit: ms)

]

]

A 1

]

,

~

~

I

~:

)

.

※

※

mode)

EY

. On the

■

※

※

※

Analog

output scale

setting

(1VDC)

Sensing level 2 setting

(

)

ST2, HI

►

I

►

I

lock function is set.

(please refer to the key lock setting)

output operation mode.

When hysteresis mode [

independent 2 output mode [

I

L_

and previous set sensing level 1 flash in 0.5sec.

ST

by turns.

Set the pressure sensing level 1 by or key.

Set range: Min. display pressure <

( Press

saved, then move to the next mode.)

I

L_

and previous set sensing level 2 flash in 0.5sec.

ST2

by turns.

Set the pressure sensing level 2 by or key.

Set range: Hysteresis mode →

( Press

saved, then move to the next mode.)

Automatic sensitivity setting mode [

IL__

and previous set sensing level 1 flash in 0.5sec.

ST

by turns.

Apply the required pressure[ST] within the rated

pressure.

•

Press key shortly one time, current sensing

pressure is set as sensing level 1.

sensing level1 flash by turn (0.5sec.).

Set range: Min. display pressure <

I

and previous set sensing level 2 flash in 0.5sec.

ST2

by turns.

Apply the required pressure[

pressure.

Press key shortly one time, current sensing

pressure is set as sensing level 2.

sensing level1 flash by turn (0.5sec.).

Set range:

※

If differences of between ST and sensing level are

not enough,

setting. Please re-execute the setting for the

ST2

condition.

※

It is possible to set repeatedly by key, the last

setting is set as the sensing level 2.

and sensing level [

ST2

=

SET

Adjust sensing level [

I

adjustment of the sensing level [

(adjustment range: between ST and

When checking the value of sensing level 1, 2 [ST,

] and automatic sensitivity setting value[

ST2

press

Example of the setting in automatic sensitivity setting

mode (to check absorption of component by vacuum

pressure): The state of removed target is ST and the

state of absorbing target is

level [

SET

automatically.

Window comparison output mode [

c-----i

and previous set sensing level 1 flash in 0.5sec.

L

by turns.

Set the pressure sensing level 1 by or key.

Set range: Min. display pressure ≤

( Press

saved, then move to the next mode.)

and previous set sensing level 1 flash in 0.5sec. by

HI

turns.

Set the pressure sensing level 2 by or key.

Set range:

( Pre ss

saved, then move to RUN mode.)

If no key is touched for 60sec., it will return to RUN

mode. [Automatic sensitivity setting mode [

exception)

When changing the display unit, preset value will be

calculated according to the display unit.

Whenever key touched one time, it is

increased(decreased) as 1 digit(2 digits for psi unit

and compound pressure) but it will be continuously

increasing(decreasing) by pressing ( ) key

constantly.

RUN mode

Pressure sensing level 1

___

≤ Max. display pressure

key momentarily, sensing level 1 will be

Pressure sensing level 2

___

Min. display pressure ≤

Independent 2 output mode →

Min. display pressure <

Max. display pressure

key momentarily, sensing level 2 will be

Returns to RUN mode

RUN mode

Pressure sensing level 1

____

-.-1

Max. display pressure-1%of rated pressure

Pressure sensing level 2

+1% of rated pressure ≤

ST

≤Max. display pressure

flashes 3 times then retruns to

E 3

Automatic sensitivity and

ne adjustment

(ST +

)

ST2

2

SET

Returns to RUN mode

key shortly and continuously.

] value is set in the between

RUN mode

Pressure sensing level 1

Max. display pressure

key momentarily, sensing level 1 will be

Pressure detecting level 2

< HI≤ Max. display pressure

L

key momentarily, sensing level 1 will be

Returns to RUN mode

Cautions during Use

1. Follow instructions in 'Cautions during Use'.

Otherwise, It may cause unexpected accidents.

2. 12-24VDC power supply should be insulated and limited voltage/current or Class 2, SELV

power supply device.

3. Use the product, 3 sec after supplying power.

4. When using switching mode power supply

Time

should be grounded.

5. Wire as short as possible and keep away from high voltage lines or power lines, to prevent

inductive noise.

6. This unit may be used in the following environments.

Indoors (in the environment condition rated in 'Specications')

①

Altitude max. 2,000m

②

Pollution degree 2

③

Installation category III

④

1--~

--~

Main Products

■ Photoelectric Sensors ■ Temperature Controllers

■ Fiber Optic Sensors ■ Temperature/Humidity Transducers

■ Door Sensors ■ SSR/Power Controllers

■ Door Side Sensors ■ Counters

■ Area Sensors ■ T

■ Proximity Sensors ■ Panel Meters

■ Pressure Sensors ■ Tachometer/Pulse(Rate) Meters

■ Rotary Encoders ■ Display Units

■ Connector/Sockets ■ Sensor Controllers

■ Graphic/Logic Panels ■ I/O Terminal Blocks & Cables

■ Field Network Devices ■ Stepper Motors/Drivers/Motion Controllers

■ Control Switches/Lamps/Buzzers

■ Switching Mode Power Supplies

■ Laser Marking System(Fiber, CO₂, Nd:YAG)

■ Laser Welding/Cutting System

imers

, frame ground (F.G.) terminal of power supply

Analog

output scale

setting

(5VDC)

Key

lock

setting

I

I

] and

F

F

♦

@

♦

@

] within the rated

ST2

♦

@

] flash in 0.5sec. by turns.

SET

] by , key, when ne

~·

SET

♦

@

. By

ST2

]

3, F 4, F 5

_

•I

ITI

ST

_

[Ti

~

< ST

ST2

≤

ST2

]

F 2

and the set

ST

≤

ST

and the set

ST2

ST2

~

] is required.

)

ST2

SET

key, sensing

and

ST

]

F 6

<

L

F 2

DR W171187A B

I

J

I

I

I

J

I

],

ST2

] is

Loading...

Loading...