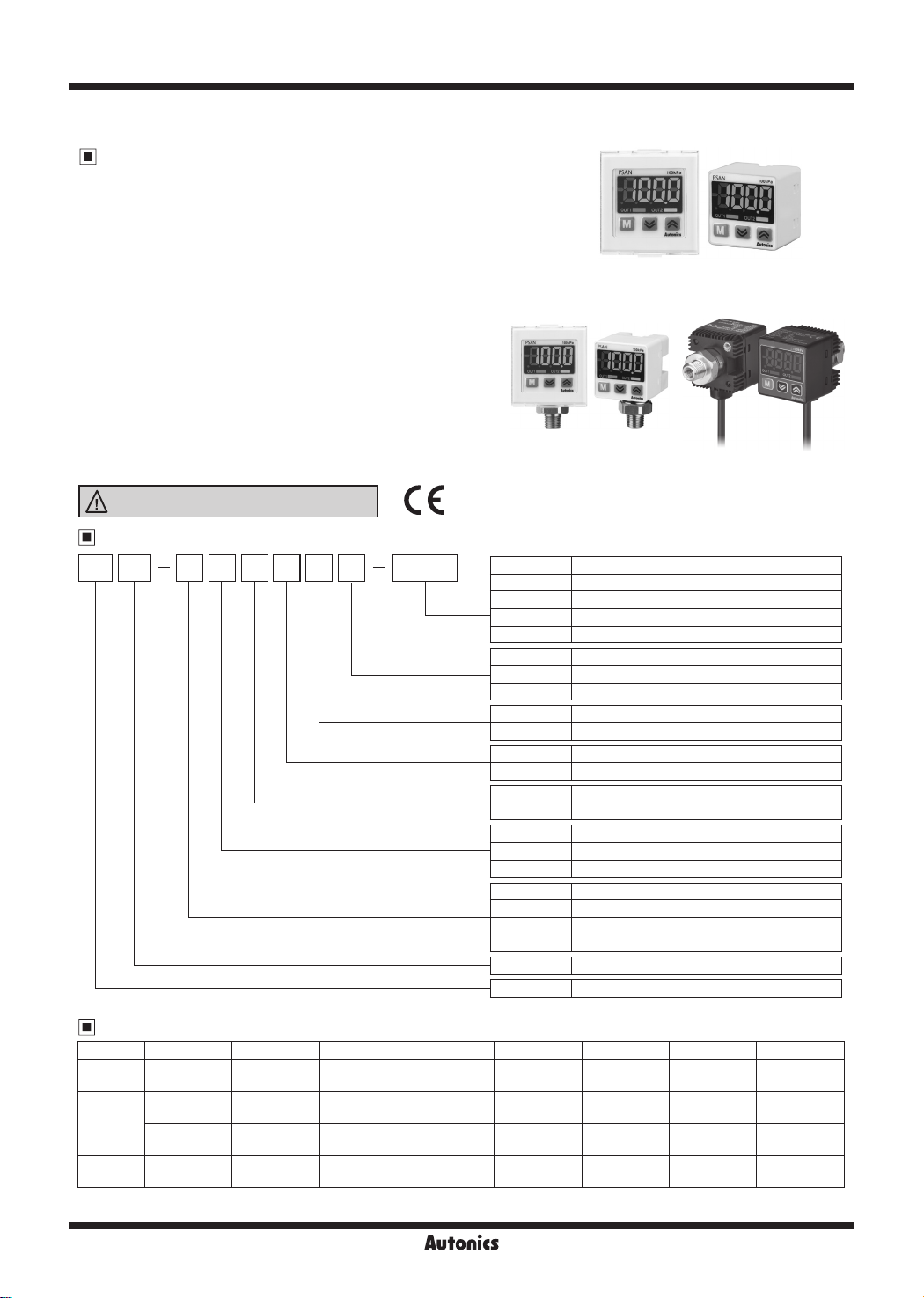

PSAN Series

Compact, Digital Display Pressure Sensors

Features

● Pressure measurement of any gas, liquid or oil

(※except substances which may corrode stainless steel 316L)

● Auto shift function

: with change in the original pressure, the external input adjusts the

determined level to match the change in pressure

(only available in models with auto shift/hold function)

● High display resolutions - negative pressure: 0.1kPa

- standard pressure: 0.1kPa, 1kPa

- compound pressure: 0.1kPa

●

Hold function: hold current display value or control output

● Forced output control mode for device testing and

maintenance

● One-touch connector type for easy wiring and maintenance

● Analog output: voltage (1-5VDC), current (DC4-20mA)

● Zero-point adjustment function,

peak value monitoring function, chattering prevention function

Please read “Safety Considerations”

in the instruction manual before using.

(connector type) (cable type)

Ordering Information

PS AN V 01 C P V Rc1/8

Pressure

port

Option input/output

Control output

Cable

Pressure range

Pressure type

Applicable fluid

Appearance

Item

※

1: In case of using M5 port, use PSO-Z01 (M5 Gender) together.

R1/8 Standard (fluid type), Option (pneumatic type)

Rc1/8 Standard (pneumatic type)

※

NPT1/8 Option

1

7/16-20UNF Option (fluid type)

9/16-18UNF Option (fluid type)

V Voltage (1-5VDC) output

A Current (DC4-20mA) output

H Hold/Auto shift input

No mark NPN open collector output

P PNP open collector output

C Connector type

No mark Cable type

01 100kPa

1 1,000kPa

No mark Standard pressure

V Negative pressure

C Compound pressure

No mark Pneumatic type (gas)/rear port type

D Pneumatic type (gas)/bottom port type

L Fluid type (gas, liquid, oil)/bottom port type

B Fluid type (gas, liquid, oil)/rear port type

AN Regular square New type (30×30mm)

PS Pressure Sensor

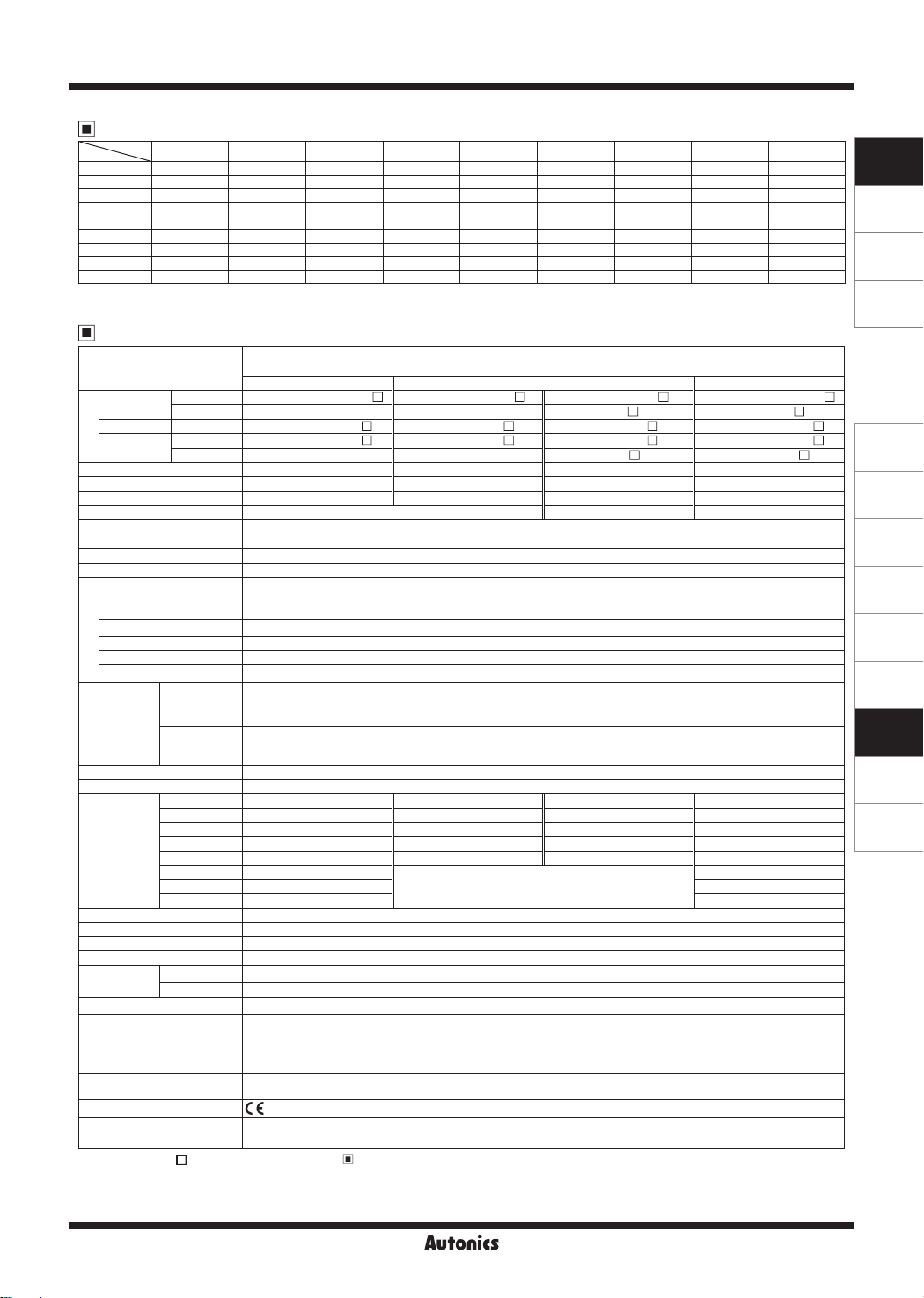

Pressure and Max. Pressure Display Range

Type MPa kPa kgf/cm² bar psi mmHg inHg mmH₂O

Negative

pressure

Standard

pressure

Compound

pressure

※

( ) is max. pressure display range.

※

For using a unit

-

0 to 0.100

(-0.005 to 0.110)

0 to 1.000

(-0.050 to 1.100)

-

mmH

G-22

0.0 to -101.3

(5.0 to -101.3)

0.0 to 100.0

(-5.0 to 110.0)

0 to 1000

(-101.3 to 1100)

-101.3 to 100.0

(-101.3 to 110.0)

, multiply display value by 100.

₂O

0.000 to -1.033

(0.051 to -1.033)

0.000 to 1.020

(-0.051 to 1.122)

0.00 to 10.20

(-0.51 to 11.22)

-1.034 to 1.020

(-1.034 to 1.122)

0.000 to -1.013

(0.050 to -1.013)

0.000 to 1.000

(-0.050 to 1.100)

0.00 to 10.00

(-0.50 to 11.00)

-1.013 to 1.000

(-1.013 to 1.100)

0.00 to -14.70

(0.74 to -14.70)

0.00 to 14.50

(-0.72 to 15.96)

0.0 to 145.0

(-7.2 to 159.6)

-14.70 to 14.50

(-14.70 to 15.96)

0 to -760

(38.0 to -760.0)

- - -

- - -

-760 to 750

(-760.0 to 824.0)

Pneumatic type

Fluid type

0.0 to -29.9

(1.50 to -29.90)

-29.9 to 29.5

(-29.88 to 32.58)

PSAN-

0.0 to -103.3

(5.1 to -103.3)

-103.4 to 102.0

(-103.4 to 112.2)

B

Compact, Digital Display Pressure Sensor

-|Transparent setting guide|-

-|Transparent setting guide|-

Pressure Conversion Chart

to

from

1Pa 1 0.001 0.000001 0.000010197 0.007501 0.101972 0.000145038 0.00001 0.0002953

1kPa 1000 1 0.001 0.010197 7.500617 101.971626 0.145038 0.01 0.2953

1MPa 1000000 1000 1 10.197162 7500.61683 101971.626 145.038243 10 295.299875

1kgf/cm

1mmHg 133.322368 0.133322 0.000133 0.001359 1 13.595099 0.019337 0.001333 0.039370

1mmH

1psi 6894.733 6.89473 0.006895 0.070307 51.714752 703.0167161 1 0.068947 2.036014

1bar 100000 100 0.100000 1.019716 750.062 10197.1626 14.503824 1 29.529988

1inHg 3386.388 3.386388 0.003386 0.034532 25.40022 345.315507 0.491156 0.033864 1

Pa kPa MPa kgf/cm

2

98066.5 98.0665 0.098067 1 735.55924 10000.0005 14.223393 0.980665 28.959025

O 9.80665 0.009807 0.000099 0.073556 1 0.00142 0.000098 0.002896

2

E.g.) For calculating 760mmHg to kPa

: According to above chart, 1mmHg is 0.133322kPa, therefore 760mmHg will be 760×0.133322kPa=101.32472kPa.

Specifications

Gauge pressure(In case of uid type, negative pressure, compound pressure, 1,000kPa/standard

Pressure type

Voltage

1

output

※

Current output

Hold/Auto

Model

shift input

Connector PSAN-(L/D)V01C(P)V-

Cable

Connector PSAN-(L)V01C(P)A-

Connector PSAN-(L)V01C(P)H-

Cable

Rated pressure range 0.0 to -101.3kPa 0.0 to 100.0kPa 0 to 1,000kPa -101.3 to 100.0kPa

Display pressure range 5.0 to -101.3kPa -5.0 to 110.0kPa -101.3 to 1,100kPa -101.3 to 110.0kPa

Min. display unit 0.1kPa 0.1kPa 1kPa 0.1kPa

Max. pressure range 2 times of rated pressure 1.5 times of rated pressure 2 times of rated pressure

Applied uid

Power supply 12V-24VDCᜡ ±10% (ripple P-P: Max. 10%)

Current consumption Max. 50mA (current output: max. 75mA)

Control output

※

Hysteresis

Repeat error ±0.2%F.S. ± Min. display interval

Response time

2

Protection circuit Output short over current protection circuit

Analog output

※

3

Voltage output

Current output

Display digit 4½-digit

Display method 7-segment LED Display

MPa

kPa 0.1 0.1 1 0.1

kgf/cm

Min. display

interval

bar 0.001 0.001 0.01 0.001

psi 0.01 0.01 0.1 0.02

mmHg 0.4

inHg 0.02 0.03

mmH₂O 0.1 0.1

Display accuracy 0 to 50℃: max. ±0.5% F.S., -10 to 0℃: max. ±1% F.S.

Insulation resistance Over 50MΩ (at 500VDC megger)

Dielectric strengtht 1000VAC 50/60Hz for 1 minute

Vibration 1.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Environment

Ambient temp. -10 to 50℃, storage: -20 to 60

Ambient humi. 30 to 80%RH, storage: 30 to 80%RH

Protection structure Connector type: IP40 (IEC standard), Cable type: IP65 (IEC standard)

Material

Cable

Approval

※

4

Weight

※

1: For ' (L)', ' (P)', '

※

2: In hysteresis output mode, detection dierence is variable.

※

3: It is allowed to select one analog output type only.

※

4: The weight includes packaging. The weight in parenthesis in for unit only.

※

The unit is sealed structure. It is based on atmospheric pressure 101.3kPa.

5:

' of model name, please refer to '

pressure are sealed gauge pressure

Negative pressure Standard pressure Compound pressure

- -

- -

• Pneumatic type - Air, Non-corrosive gas

• Fluid type - Air, Non-corrosive gas and fluid that do not corrode Stainless steel 316L

NPN or PNP open collector output

• Load voltage: max. 30VDCᜡ • Load current: max. 100mA

• Residual voltage - NPN: max. 1VDCᜡ, PNP: max. 2VDC

Min. display interval

Selectable 2.5ms, 5ms, 100ms, 500ms, 1000ms

• Output voltage: 1-5VDCᜡ ±2% F.S. • Linear: Within ±1% F.S. • Output impedance: 1kΩ

• Zero point: Max. 1VDCᜡ ±2% F.S. • Span: Max. 4VDCᜡ ±2% F.S. •

• Resolution: Automatically changed to 1/1000 or 1/2000 by display unit

• Output current: DC4-20mA ±2% • Linear: Max. ±1% F.S. • Zero-point: Max. DC4mA ±2% F.S.

• Span: Max. DC16mA ±2% F.S. •

• Resolution: Automatically changed to 1/1000 or 1/2000 by display unit

-

2

0.001 0.001 0.01 0.001

• Pneumatic - Rear port type - Front, Rear case: Polycarbonate, Pressure port: Nickel Plated Brass

• Pneumatic - Bottom port type - Front case: Polycarbonate Rear case: Polybutylene Terephthalate + Glass

• Fluid type - Front case: Polycarbonate, Rear case: Polyamide 6, Pressure port: Stainless steel 316L

Ø4mm, 5-wire, 2m (connector type), 3m (cable type),

AWG24, Core diameter: 0.08mm, Number of cores: 40, Insulator out diameter: Ø1mm

• Pneumatic type - Rear port type: Approx. 165g (approx. 80g) • Pneumatic type - Bottom port type: Approx. 170g (approx. 85g)

• Fluid type - Connector type: Approx. 173g (approx. 88g) • Fluid type - Cable type: Approx. 167g (approx. 90g)

Ordering Information'.

2

mmHg mmH2O psi bar inHg

5

※

)

PSAN-(L/D)01C(P)V- PSAN-(L/D)1C(P)V- PSAN-(L/D)C01C(P)V-

PSAN-B1(P)V- PSAN-BC01(P)VPSAN-(L)01C(P)A- PSAN-(L)1C(P)A- PSAN-(L)C01C(P)APSAN-(L)01C(P)H- PSAN-(L)1C(P)H- PSAN-(L)C01C(P)H-

PSAN-B1(P)H- PSAN-BC01 (P)H-

Response time

: 70ms

0.001 0.001

Response time

: 50ms

-

0.8

-

℃

Fiber 15%, Pressure port: Nickel Plated Brass

※

F.S.: Rated pressure.

※

There may be ±1-digit error in hysteresis by pressure unit calculation error.

※

Environment resistance is rated at no freezing or condensation.

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

(C)

LiDAR

(D)

Door/Area

Sensors

(E)

Vision

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

G-23

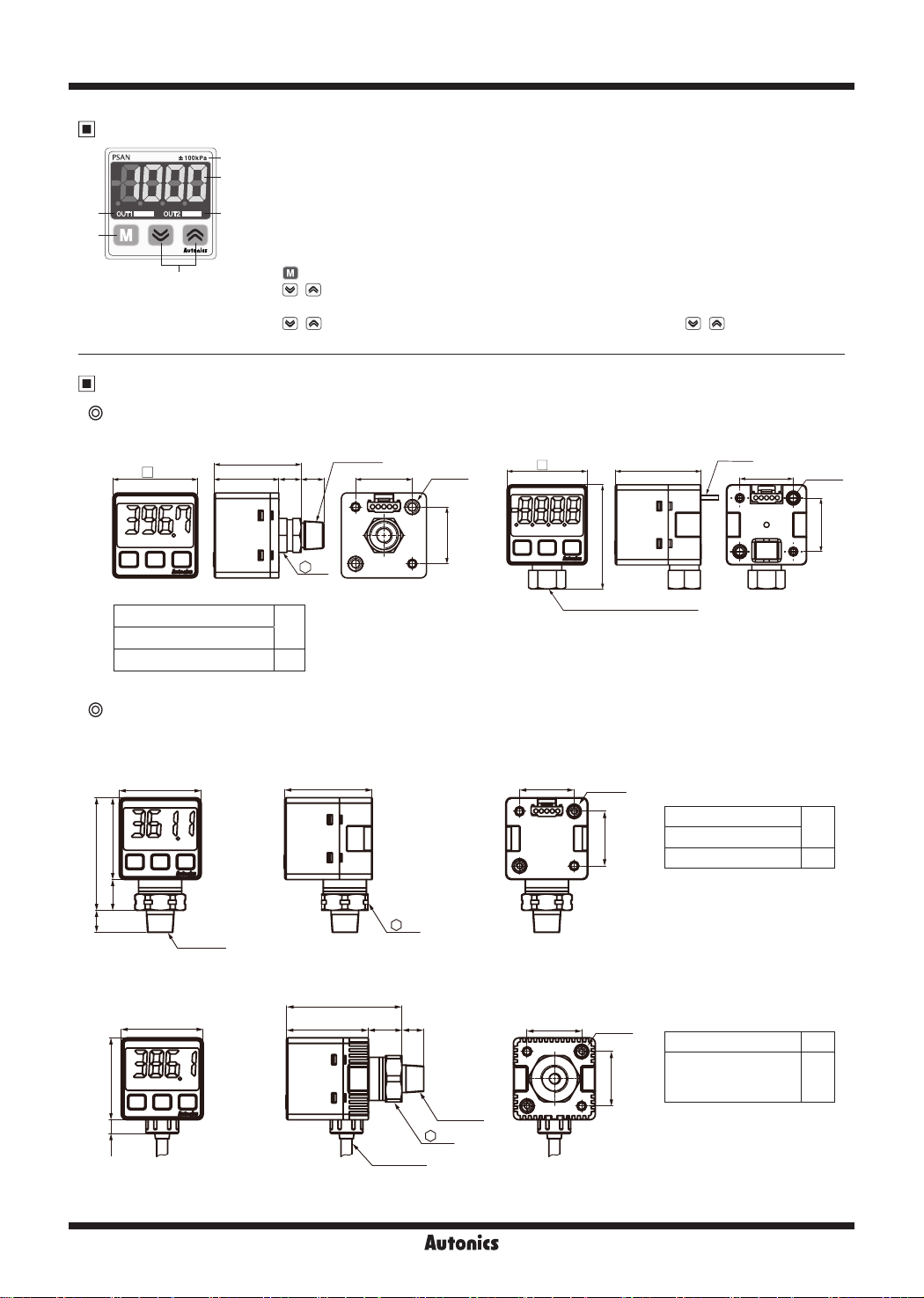

PSAN Series

Unit Description

1. Range of rated pressure

1

2

3

5

4

6

Dimensions

Pneumatic type

1. Rear port type 2. Bottom port type

30

: It is possible to change the pressure unit in Pressure sensor.

Please attach component label which is t for specic indication unit.

2. 4-digit LED display (Red)

: Used to indicate measured pressure value, setting value and error message.

3. Output1 indicator (Red): Output1 is ON, LED will be ON.

4. Output2 indicator (Green): Output2 is ON, LED will be ON.

5.

key: Used to enter into Preset/Parameter setting mode and to save Setting mode.

,

6.

key: Used to set parameter and preset, peak value check mode, function setting or

output operation mode.

+

key : Used for zero point adjustment function by pressing + keys over 1 sec

simultaneously in RUN mode.

Inside

※

1

30.7

22.8 7.9 A

M5 Tap

20 2-M3

30

32

Cable

20

(unit: mm)

2-M3

※

A

Rc1/8 model (standard)

NPT1/8 model

R1/8 model

Fluid type

1. Connector type

30

30

41.3

11.3

A

2. Cable type

30

5.1

Inside

M5 Tap

30

20

12

※

1: Only for R1/8 and NPT1/8 models

39

Rc1/8(Standard), NPT1/8

20

0

8

32

12.3 B

Ø4, 3m

17

Inside

M5 Tap

17

※

1

※

42.3

30

20

2-M3

20

20

2

2-M3

20

※

A

R1/8 model (standard)

NPT1/8 model

7/16-20UNF model

※

1: Only for R1/8 model,

NPT1/8 model

※

B

R1/8 model (standard)

9/16-18UNF model

(metal gasket sealing

method)

※

2: Only for R1/8 model

8

11

8

15.4

G-24

Compact, Digital Display Pressure Sensor

-|Transparent setting guide|-

-|Transparent setting guide|-

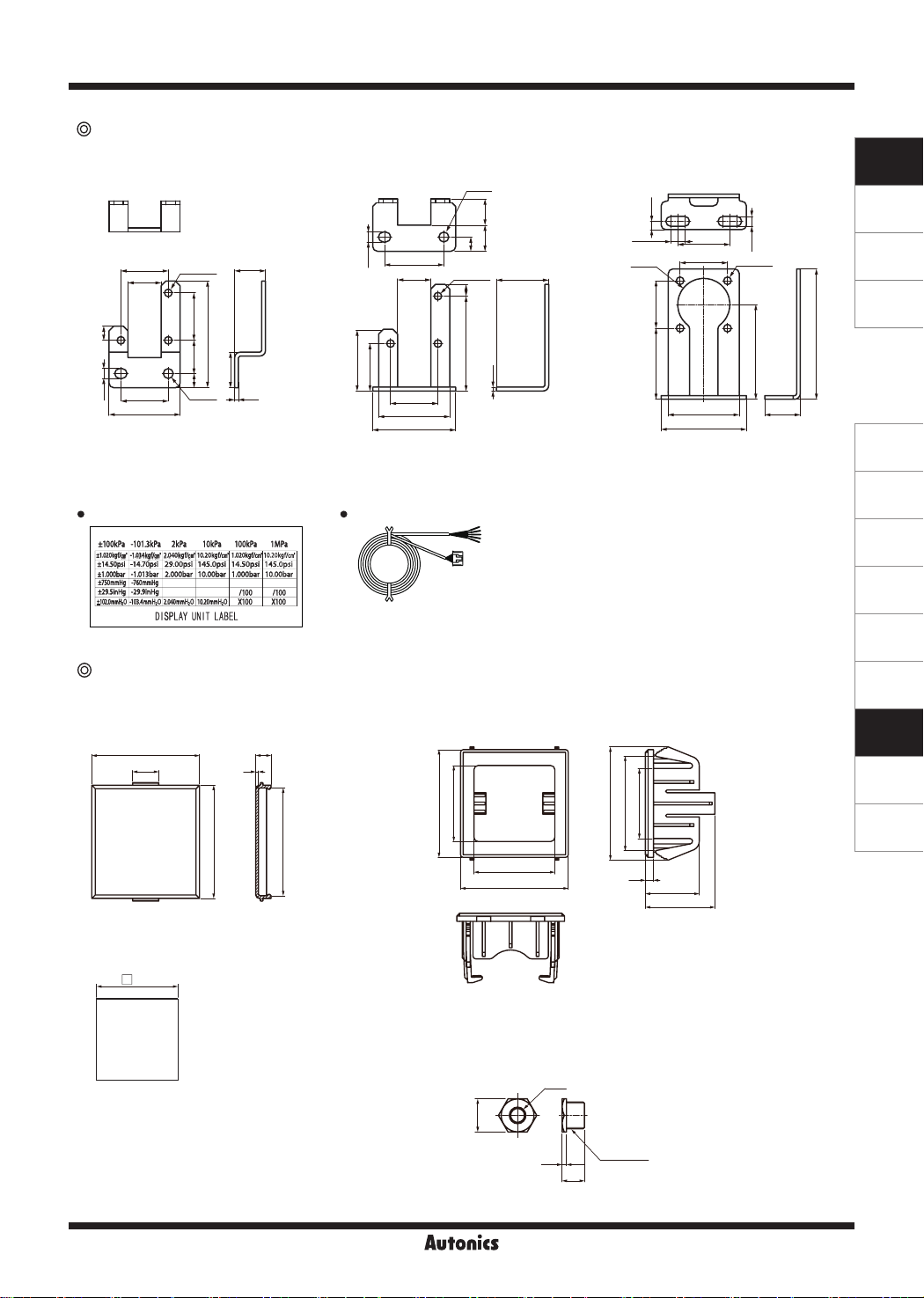

Accessory

● Bracket A ● Bracket C ● Bracket B

Ø4.2

1111

6

25

20

3-Ø3.2

14

6

Ø4.2

20

4.2

30

※

Bracket A/B:

Bracket C:

Pressure unit label Connector cable (PSO-C01)

Pneumatic type, fluid type (

Fluid type (

20

45

14

6

13

15

1.6

cable type)

4.2

14

26

20

20

30

35

connector type)

3-Ø3.2

5

40

1.6

※

Sold separately

● Front cover (PSO-P01)

40

9.7

42

5.7

1

40

● Panel bracket (PSO-B02/B03)

40

28.2

3.5

5.8

22

Ø22

20

30

Ø4mm, 5-wire, 2m

( AWG24, core diameter: 0.08mm,

number of cores: 40,

insulator diameter: Ø1mm)

423526

30

40

3

20

25.8

22

20

30

36

4.2

4-Ø3.2

40

(unit: mm)

55

15

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

(C)

LiDAR

(D)

Door/Area

Sensors

(E)

Vision

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

● Panel cut-out

+0.5

36

0

(panel thickness 0.8 to 3.5mm)

※

PSO-B02 (white): Pneumatic type, Fluid type (connector type)

PSO-B03 (black): Fluid type (cable type)

● M5 gender (PSO-Z01)

M5

12

R1/8 or

1.6

NPT1/8

8.1

G-25

PSAN Series

Control Output Diagram

Voltage (1-5VDC) output type (PSAN-

Current (DC4-20mA) output type (PSAN-

V-

A-

● NPN open collector output type ● PNP open collector output type

(Brown) +V

(Black) OUT1

Over current

protection

circuit

Over current

protection

circuit

Main circuit

1kΩ

※

In case of analog voltage output type models short-circuit protection is not embodied. (

Do not connect of power source or capacitive load directly.

※

Be careful with input impedance of connecting devices when using analog voltage output type models.

※

Be careful with voltage drop due to cable resistance when extending sensor cable.

(White) OUT2

(Orange) Analog output

voltage/current

(Blue) 0V

Hold/Auto shift input (PSAN-

Load

Load

12-24VDC

H-

)

● NPN open collector output type ● PNP open collector output type

(Brown) +V

Load

Load

12-24VDC

Over current

protection

circuit

Over current

protection

circuit

Main circuit

(Black) OUT1

(White) OUT2

(Orange) Hold/

Auto shift input

(Blue) 0V

Over current

protection

circuit

Over current

protection

circuit

Main circuit

1kΩ

Over current

protection

circuit

Over current

protection

circuit

Main circuit

)

)

(Brown) +V

(Black) OUT1

(White) OUT2

(Orange) Analog output

voltage/current

(Blue)0V

: For voltage output type only.)

(Brown) +V

(Black) OUT1

(White) OUT2

(Orange) Hold/

Auto shift input

(Blue) 0V

12-24VDC

Load

Load

12-24VDC

Load

Load

If short-circuit the control output terminal or supply current over the rated specication, control signal is abnormal due to the current

※

protection circuit

Analog Output Characteristic

● Analog output voltage and current

- Pressure characteristic

Output

PSAN-01 PSAN-01

voltage

(V)

6

5

4

3

2

1

0

20 40 60 80 100

Pressure (kPa)

24

20

16

12

8

4

0

Output

current

(mA)

● Analog output voltage and current

- Linear characteristic

Output

6

voltage

(V)

5

4

3

2

1

0

20 40

±1% F.S.

60 80 100

Pressure (kPa)

Output

24

current

20

16

12

8

4

0

Setting

Press key

over 3sec

RUN mode

Press

over 3sec

Press

keys over 1sec

key

+

Parameter

setting

Preset value

setting

Forced output

control mode

setting

Peak hold

Zero-point

adjustment

Pressure

unit setting

Detection level 1 setting (out1) Detection level 2 setting (out2)

Output operation

mode setting

Output

type setting

Response

time setting

Analog output scale and

Hold/Auto Shift input setting

The forced output control mode is applied by pressing key after selecting forced output control mode

[

] in output operation mode [

fOUT

control mode' '

High peak

value check

Output operation mode'

Low peak

value check

] parameter. For more detailed information, refer to '● Forced output

OUtM

Auto shift input setting

(In case of Hold/Auto shift input type model)

Zero-point adjustment

(mA)

Full

scale

Key lock

setting

G-26

Compact, Digital Display Pressure Sensor

-|Transparent setting guide|-

-|Transparent setting guide|-

Zero Point Adjustment

1 2

SENSORS

CONTROLLERS

Press

over 1sec

※

1. In state of atmospheric pressure during RUN mode,

press key and key at the same time for over

1sec.

2. When the zero-point adjustment is complete, it will

)0

display

※

Please execute zero-point adjustment regularly.

and return to RUN mode automatically.

ERR1

will ash while you execute zero

point adjustment in the condition that external

pressure exists.

Please execute zero-point adjustment again in

state of atmospheric pressure without external

pressure.

Parameter Setting

1. It is able to set pressure unit, display resolution, output operation mode, output type, Response time, analog output

scale, Hold/Auto shift and key lock setting in parameter setting mode.

2. If the key lock is set (lock1 or lock2), unlock the key lock before setting parameters. (Refer to Key Lock setting below.)

RUN mode

Press

key over

3sec

Press key

over 3sec

UNIT

OUtM

Pressure unit

setting

Output operation

mode setting

UNIT

and previously set unit will flash in turn every 0.5 sec

or key to select the unit.

Press

(Press

key for 1 sec to save selected unit and move to next mode.)

● Negative pressure, compound pressure:

2

(kPa)

(kgf/cm

(bar)

)

(psi)

(mmHg)

● Standard pressure:

MPA KPA PSIKGF BAR

2

(kPa) (MPa)

OUtM

and previously set output operation mode will f lash in turn every 0.5 sec

Press

or key to select output operation mode.

(Press

key for 1 sec to save selected output operation mode and move to next mode.)

(kgf/cm

(bar)

)

(psi)

H2OKPA INHGKGF MMHGBAR PSI

(mmH

(inHg)

※

For using mm

multiply display value

by 100.

O)

2

unit,

H

₂O

MOTION DEVICES

SOFTWARE

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

(C)

LiDAR

(D)

Door/Area

Sensors

(E)

Vision

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

HYsM WIN HY-W AUTO fOUT

NoNC

NoNC

Output setting

and previously set output operation mode will f lash in turn every 0.5 sec

Press

or key to select output type.

(Press key for 1 sec to save selected output t ype and move to next mode.)

1O2O 1O2C 1C2O 1C2C

SPD

SPD

Response time

setting

and previously set output operation mode will f lash in turn every 0.5 sec

or key to select

Press

(Press key for 1 sec to save selected

@5 %0 100 500 1000

Response time

Response time

.

and move to next mode.)

(unit: ms)

G-27

PSAN Series

Voltage (1-5VDC) output type

(PSAN-

※

1

A-1V A-04 D-IN

※

2

A-5V A-20 ShOT

1V scale setting

5V scale setting

※

A-1V

1:

Press

Setting range: Min. rated pressure ≤ [

(Press key for 1 sec to save selected pressure value as a scale value for 1V and 4mA and move to next mode.)

※

A-5V

2:

Press

Setting range:[

(Press key for 1 sec to save selected pressure value as a scale value for 5V and 20mA and move to next mode.)

※

D-IN

3:

(Press key for 1 sec to save selected function and move to next mode.)

● Select external input function ● Select the control output for Auto shift function

V- )

※

※

(voltage output)/

or key to set analog output scale value for 1V and 4mA.

(voltage output)/

, Key to set analog output scale value for 5V and 20mA.

A-1V, A-04

and previously set control function will flash in turn every 0.5 sec Press

HOLD SHFT

LOCK

LOCK

Key Lock

will flash in turn with previous setting parameter. Press

(Press key for 1 sec to save selected lock setting. Then, it will return to pressure unit setting mode.)

Current (DC4-20mA) output type

(PSAN-

1

2

A-04

A-20

4mA scale setting

20mA scale setting

(current output)and previously set pressure value will flash in turn every 0.5 sec

A-1V, A-04

(current output) and previously set pressure value will flash in turn every 0.5 sec

]+10% of rated pressure ≤ [

A- )

※

] ≤ 90% of rated pressure

A-20

A-SV

,

OUT1 ALLOUT2

※

Refer to '

in ' Functions' for more details

Hold/Auto shift input setting'

Hold/Auto shift input type

(PSAN-

3

] ≤ Max. rated pressure

, key to select key lock setting.

Select external input function

Select the control output for

Auto shift function

, key to select external function.

H- )

OFFLOC1 LOC2

※

When pressing

there is no additional key operation within 60 sec while setting, current set value is not valid and previous set value will remain.

※

All settings are saved regardless of power failure. Make sure that this unit has a limited write life cycle (100,000 times).

key for 3 sec in the middle of parameter setting, current setting value will be saved and it will return to RUN mode. If

Preset Setting

Hysteresis mode [

RUN mode

Press or Key

to select

setting value.

※

ST1

setting range : Min. display pressure <

※

HYS1

setting range : Min. display pressure ≤

※

ST2

setting range : Min. display pressure

※

HYS2

setting range : Min. display pressure ≤

]

HYsMHYsM

and previously

ST1

set value will flash in

turn every 0.5 sec

ST1

HYS1

set value will flash in

turn every 0.5 sec

Press or key

HYS1

to select

setting value.

ST1

≤ Max. display pressure

HYS1

ST1

<

ST2

<

Max. display pressure

≤

HYS2

ST2

<

and previously

and previously

ST2

set value will flash in

turn every 0.5 sec

Press or key

ST2

to select

setting value.

and previously

HYS2

set value will flash in

turn every 0.5 sec

Press or key

HYS2

to select

setting value.

RUN mode

G-28

Compact, Digital Display Pressure Sensor

-|Transparent setting guide|-

-|Transparent setting guide|-

Window comparison output mode [

and previously

RUN mode

※

LO-1

setting range: Min. display pressure ≤

※

HI-1

setting range

※

LO-2

setting range: Min. display pressure ≤

※

HI-2

setting range

※

The minimum display interval for hysteresis is fixed to 1.

LO-1

set value will flash in

turn every 0.5 sec

Press

to select

setting value.

:

+ (3

LO-1

×min. display interval

:

+ (3

LO-2

×min. display interval

or Key

LO-1

Press or Key

to select

setting value.

LO-1

LO-2

]

WINWIN

and previously

HI-1

set value will flash in

turn every 0.5 sec

HI-1

≤

Max. display pressure

) ≤

≤

HI-1

≤

Max. display pressure

) ≤

Max. display pressure

≤

HI-2

Max. display pressure

Hysteresis-Window comparison output mode [

RUN mode

and previously

ST1

set value will flash in

turn every 0.5 sec

and previously

HYS1

set value will flash in

turn every 0.5 sec

LO-2

set value will flash in

turn every 0.5 sec

Press or Key

LO-2

to select

setting value.

- (3

×min. display interval

- (3

×min. display interval

]

HY-WHY-W

and previously

LOW

set value will flash in

turn every 0.5 sec

and previously

and previously

HI-2

set value will flash in

turn every 0.5 sec

Press or Key

HI-2

to select

setting value.

)

)

and previously

HIGH

set value will flash in

turn every 0.5 sec

RUN mode

RUN mode

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

(C)

LiDAR

(D)

Door/Area

Sensors

(E)

Vision

Sensors

Press

or Key

ST1

to select

setting value.

※

ST1

setting range : Min. display pressure

※

HYS1

setting range : Min. display pressure ≤

※

LOW

setting range : Min. display pressure ≤

※

HIGH

setting range : Low value + (3×min. display interval) ≤

※

In case

HYS1

ST1

and

have the same setting values, it will have the minimum display unit as a hysteresis.

Automatic sensitivity setting mode [

Press

Key

and previously

RUN mode

※

setting range : Min. display pressure

ST1

※

setting range :

ST2

※

If certain detection level difference is not ensured, or setting conditions are not met,

setting mode. Check all setting conditions and set proper setting values.

ST2

ST1

set value will flash in

turn every 0.5 sec

Press

or Key

ST1

to select

setting value.

+ 1% of rated pressure

ST1

Press or Key

to select

setting value.

ST1

<

HYS1

LOW

HYS1

≤ Max. display pressure

ST1

<

≤ Max. display pressure - (3×min. display interval)

HIGH

AUTOAUTO

]

Press

Key

and previously

ST2

set value will flash in

turn every 0.5 sec

Press or Key

ST2

to select

setting value.

≤ Max. display pressure - 1% of rated pressure

<

ST1

≤ Max. display pressure

<

ST2

Press or Key

to select

setting value.

≤ Max. display pressure

Press or Key

to select

setting value.

LOW

Press

Key

and previously

SET

set value will flash in

turn every 0.5 sec

Sensitivity will be automatically

Press

value between

SET

SET

message will flash three times and return to

ERR3

Press or Key

HIGH

to select

setting value.

RUN mode

or key to fine-adjust the setting

ST1

ST2

and

.

+

ST2

ST1

=

2

SET

.

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

G-29

PSAN Series

Forced output control mode [

If forced output control mode

is selected, pressure value is

displayed only.

(No output will be provided.)

Control output 1 ON Control output 1 OFF

Control output 2 ON Control output 2 OFF

※

When there is no additional key operation within 60 sec while

setting, it returns to Run mode (Except for force output mode).

Previously set values remain.

※

In case of changing output operation mode, no preset values

will be initialized. Instead, previous output operation settings will

become the preset values.

※

When using the forced output function, Hold/Auto shift function is

not available to use in Hold/Auto shift model.

※

When changing pressure display unit, resolution, and Hold Auto

shift input function, preset values will be initialized as shown on

the next table. (When changing pressure display unit, preset

value will be automatically switched to changed pressure unit.)

]

fOUTfOUT

Present pressure value and

fOUT

will flash in turn every 0.5 sec

● Factory default

Negative

Output

pressure

mode

0.0 to -101.3

ST1

:-50.0

HYS1

ST2

HYS2

LO-1

HI-1

LO-2

HI-2

ST1

HYS1

LOW

HIGH

ST1

ST2

SET

:0.0

:-50.0

:0.0

:0.0

:-50.0

:0.0

:-50.0

:-50.0

:0.0

:0.0

:-50.0

:0.0

:-50.0

:-25.0

HYS.M

WIN

HY-W

AUTO

Standard

pressure

0.0 to 100.0

ST1

:50.0

HYS1

:0.0

ST2

:50.0

HYS2

:0.0

LO-1

:0.0

HI-1

:50.0

LO-2

:0.0

HI-2

:50.0

ST1

:50.0

HYS1

:0.0

LOW

:0.0

HIGH

:50.0

ST1

:0.0

ST2

:50.0

SET

:25.0

Standard

pressure

0 to 1,000

ST1

:500

HYS1

:0

ST2

:500

HYS2

:0

LO-1

:0

HI-1

:500

LO-2

:0

HI-2

:500

ST1

:500

HYS1

:0

LOW

:500

HIGH

:0

ST1

:0

ST2

:500

SET

:250

(unit: kPa)

Compound

pressure

-101.3 to 100.0

ST1

:50.0

HYS1

:-50.0

ST2

:50.0

HYS2

:-50.0

LO-1

:-50.0

HI-1

:50.0

LO-2

:-50.0

HI-2

:50.0

ST1

:50.0

HYS1

:-50.0

LOW

:-50.0

HIGH

:50.0

ST1

:-50.0

ST2

:50.0

SET

:0.0

High Peak/Low Peak Function and Auto Shift Reference Pressure Check/Change

It will return to RUN

mode after previously

set Auto shift reference

pressure is removed.

Auto shift reference

pressure value will

flash every 0.5 sec

or key

Press

to select set value

Key

Press

for over 3 sec

RUN mode

※

1: Displayed only when

※

If there is no Auto shift input, "0" will be displayed. (Refer to '

D-IN

is set to

Retained maximum

pressure value will

flash every 0.5 sec

HHHH

"

" will flash if retained

maximum pressure value

is above the upper limit of

rated pressure.

(For negative pressure type,

LLLL

"

" will flash)

SHFT

(PSAN-

G-30

+

Press

keys over 1sec

Remove the

retained minimum

pressure value.

LLLL

"

minimum pressure value

exceeds low-limit of rated

pressure.

( For negative pressure type,

HHHH

"

H- models only)

High Peak / Low Peak Hold' in ' Functions' for more details.)

Press

+ keys over 1sec

Press

keys over 1sec

Remove the

retained minimum

pressure value.

Retained minimum

pressure value will

flash every 0.5 sec

" will flash if retained

" will flash)

+

※

1

Compact, Digital Display Pressure Sensor

-|Transparent setting guide|-

-|Transparent setting guide|-

Output Operation Mode

1. Hysteresis mode [

It is able to set certain value for pressure detection level

ST1, ST2

[

OUT1 N.O.

ST1/ HYS1

OUT1 N.C.

ST1/ HYS1

OUT2 N.O.

ST2/ HYS2

OUT2 N.C.

ST2/ HYS2

] and hysteresis [

h

ST2

HYS2

h

ST1

HYS1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

] 2. Window comparison output mode [

HYsMHYsM

HYS1, HYS2

].

Time

Time

Time

Time

Time

①

It is able to set the range for high [

] limit of pressure detection level when it is required

LO-2

HI-1, HI-2

to detect pressure at a certain range.

②

Detection hysteresis is fixed to min. display range.

Pressure

OUT1 N.O.

LO-1/ HI-1

OUT1 N.C.

LO-1/ HI-1

OUT2 N.O.

LO-2/ HI-2

OUT2 N.C.

LO-2/ HI-2

HI-2

LO-2

HI-1

LO-1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

※

1

※

1

※

1

※

1

※

: Min. display range

1

], low [

Time

Time

Time

Time

Time

WINWIN

LO-1

]

,

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

Time

Time

Time

Time

Time

HY-WHY-W

LOW

]

4. Automatic sensitivity setting mode [

①

This function is to set pressure detection level to the

proper position automatically. It is set by applied

,

OUtN

pressure from two positions [

②

Detection hysteresis is fixed to min. display range.

③

The pressure detection level[

following calculation.

Pressure

ST2

SET

ST1

SET

SET

ON

OFF

ON

OFF

ON

OFF

ON

OFF

fOUT

OUT1 N.O.

OUT1 N.C.

OUT2 N.O.

ST1/ ST2

OUT2 N.C.

ST1/ ST2

' is changed to '

※

1

SET

ST1+ST2

= (

※

1

※

1

', forced output control mode is

3. Hysteresis-window comparison output mode [

①

It is available to set hysteresis mode and window

comparison output mode when both hysteresis mode

ST1, ST2

[

HIGH

②

Detection hysteresis is fixed to min. display range.

OUT1 N.O.

ST1/ HYS1

OUT1 N.C.

ST1/ HYS1

OUT2 N.O.

LOW/ HIGH

OUT2 N.C.

LOW/ HIGH

5. Forced output control mode [

①

Used to display pressure with forcibly holding comparing output OFF regardless of setting value.

②

In parameter setting, if output operation mode setting '

] and window comparison output mode [

] are necessary.

Pressure

HIGH

LOW

ST1

HYS1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

※

1

※

1

※

1

fOUTfOUT

: Min. display range

]

operated.

③

Output 1, 2 can be ON/OFF manually by pressing

Present pressure value

Display

will be displayed.

Displays PV and forced

output mode alternatively

, key while the forced output control mode is applied.

Present pressure value

will be displayed.

ST1, ST2

SET

SET

)/2

=

AUTOAUTO

].

] is shown in the

+ )

(

2

※

: Min. display range

1

Time

Time

Time

Time

Time

]

(C)

LiDAR

(D)

Door/Area

Sensors

(E)

Vision

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

Output 1

Output 2

ON

OFF

ON

OFF

Time

Time

G-31

PSAN Series

Functions

Pressure unit change

PSAN-V01C (P) and PSAN-C01C (P) has 7 kinds of

pressure unit, PSAN-01C (P) and PSAN-1C (P) has

5 kinds of pressure unit. Please select the proper unit for

application.

• PSAN-V01C (P), PSAN-C01C (P)

: kPa, kgf/cm², bar, psi, mmHg, inHg, mmH2O

• PSAN-01C (P), PSAN-1C (P) : MPa, kPa, kgf/cm², bar, psi

※

When using mmH

Output mode change

There are 5 kinds of control output mode in order to realize

the various pressure detection.

• Hysteresis mode [

When needed to change hysteresis for detecting pressure.

• Window comparison output mode [

When needed to detect pressure in certain area.

• Hysteresis - Window comparison output mode [

When both hysteresis mode and window comparison

output mode are required.

• Automatic sensitivity setting mode [

When needed to set detection sensitivity automatically at

proper position.

• Forced output control mode [

When needed to display pressure with remaining

comparison output OFF regardless of setting value.

Control output change

Type of control output for Out1 and Out2 can be able to

set Normally Open or Normally Closed.

※

Note that Normally Open and Normally Closed provide

opposite output.

OUT1 output OUT2 output Parameter setting value

Normally Open Normally Open

Normally Open Normally Closed

Normally Closed Normally Open

Normally Closed Normally Closed

Response time change

(chattering prevention)

It can prevent chattering of control output by changing

Response time

(2.5ms, 5ms, 100ms, 500ms, 1000ms) and if the

time

is getting longer, the detection will be more stable by

increasing the number.

Analog output scale setting

• Analog voltage output scale setting

The scale function for analog output voltage (1-5VDC) is

not fixed to the rated pressure range. It can be changed for

User's application. Analog output voltage range will be fixed

to 1-5VDC within the pressure range from pressure point of

1VDC output [

A-SV

[

].

• Analog current output scale setting

The scale for analog output Current (DC4-20mA) is not

fixed to the rated pressure range. It can be changed for

User's application. Analog output voltage will be fixed to

DC4-20mA within the rated pressure range from pressure

point of 4mA output [

A-20

output [

G-32

O unit, multiply display value by 100.

2

]

HYsMHYsM

WINWIN

]

fOUTfOUT

1O2O

1O2C

1C2O

1C2C

. It is able to set 5 kinds of

A-1V

] to pressure point of 5VDC output

A-04

] to pressure point of 20mA

].

]

HY-WHY-W

]

AUTOAUTO

Response time

Response

Hold/Auto shift input setting

• Hold

A function to hold present pressure value and control

output at the time of hold signal input.

※

Present pressure value and Hold message will ash in

turn every 0.5 sec while Hold function is set. Make sure

that Hold function is not able to execute while forced

output mode is executed.

Control output timing chart

▶

When Hold signal is applied in Hysteresis mode, refer to

"

Control output diagram".

Pressure

E.g.)

]

OUT1 N.O.

ST1/ HYS1

OUT1 N.C.

ST1/ HYS1

OUT2 N.O.

ST2/ HYS2

OUT2 N.C.

ST2/ HYS2

HOLD

signal line

(Yellow)

OUT1 N.O.

ST1/ HYS1

OUT1 N.C.

ST1/ HYS1

OUT2 N.O.

ST2/ HYS2

OUT2 N.C.

ST2/ HYS2

※

[

] and present pressure value will ash in turn

HOLD

every 0.5 sec while Hold signal is applied.

• Auto shift

A function to use the measured pressure at the moment of

auto shift input as a reference pressure in order to correct

the set point values of control output when initial pressure

changes.

※

Reference pressure is xed to atmospheric pressure

(0.0kPa) when Auto shift function is not used.

※

ShIN

(Auto shift compensation value) will be reset to 0

when changing control output or preset values.

※

Auto shift function will not be executed if "

LLLL

"

•

•

" error occurs or if forced output mode is set.

: Reference pressure change through setting.

ShOT

: Changed reference will be applied to control output

OUT1

1 only.

•

: Changed reference will be applied to control output

OUT2

2 only.

•

: Changed reference will be applied to both control

ALL

output 1 and control output 2.

ST2

HYS2

ST1

HYS1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

High

Low

ON

OFF

ON

OFF

ON

OFF

ON

OFF

h

h

Flashing

in turn every

0.5 sec

HHHH

Time

Time

Time

Time

Time

Time

Time

Time

Time

" or

When

there

is no

HOLD

input

signal

When

there is

HOLD

input

signal

Compact, Digital Display Pressure Sensor

-|Transparent setting guide|-

-|Transparent setting guide|-

When Auto shift is used

▶

When Auto shift input signal remains at low level more than

1ms, the measured pressure at this point will be saved as

a reference value to make correct judgment regardless of

pressure changes. Corrected preset pressure value will be

applied after 7.5ms.

Measured reference pressure value will be saved in [

Flashing twice when

input Auto shift signal

Auto shift

input

Switch

output

response

※

When Auto shift function is used, the possible set

Min. 1ms

Min. 7.5ms

(Switch output

when Auto shift signal is input)

Response time

Preset point value will be

corrected by Auto shift input.

pressure range will be wider than rated set pressure

range.

※

The possible set pressure range for Auto shift type

models.

Pressure

type

Vacuum

pressure

Vacuum

pressure

Compound

pressure

※

If the set point value corrected by auto shift input

Set pressure range

-101.3kPa to 5.0kPa -101.3kPa to 101.3kPa

-5.0kPa to 110.0kPa -110.0kPa to 110.0kPa

-50.0kPa to 1100kPa -1100kPa to 1100kPa

-101.3kPa to 110.0kPa -101.3kPa to 110.0kPa

Possible set pressure range

for Auto shift type models

exceeds set pressure range,an error message will flash

three times and corrected value is not saved.

-HH-

→[

] displayed when the set point value corrected by

Auto shift input is above the upper limit of set pressure

range.

-LL-

→ [

] displayed when the set point value corrected

by Auto shift input is below the lower limit of set pressure

range.

Example of Auto shift

▶

< When Auto shift is not used >

Increase of primary

Pressure

ST1

HYS1

OUT

OFF

Normal primary

h

ON

pressure

Drop of primary

pressure

pressure

ShIN

Time

Time

Time

Time

Time

< When Auto shift is used >

Increase of primary

Pressure

ST1

HYS1

Normal primary

pressure

Drop of primary

pressure

pressure

].

ON

OUT

OFF

Auto shift input

Reference pressure =

Atmospheric pressure

(0.0kPa)

Correction set value:

Correction set value:

※

ShIN

Reference pressure ≤

Atmospheric pressure

is the reference pressure set by Auto shift input.

(0.0kPa)

=

ST1

HYS1

Auto shift input

Reference pressure ≥

Atmospheric pressure

ST1+ ShIN

=

+

HYS1

ShIN

Key lock

The key lock function prevents key operations so that

conditions set in each mode.

•

: All keys are locked; therefore it is not available to

LOC1

change parameter settings, preset value, zero adjustment,

High/Low peak check, and

data initialization. (Lock

ShIN

setting change is available)

•

: Partially locked status; therefore it is not available

LOC2

to change parameter settings only (Lock setting change is

available). Other settings are still available.

•

: All of the setting is available, all keys are unlocked. to

OFF

set detection sensitivity automatically at proper position.

Zero-point adjustment

The key lock function prevents key operations so that

conditions set in each mode.

The zero-point adjustment function forcibly sets the

pressure value to "zero" when the pressure port is opened

to atmospheric pressure. When the zero adjustment is

applied, analog output [Voltage or Current] is changed by

this function.

(Press

+ keys over 1 sec in RUN mode.)

High peak / Low peak hold

This function is to diagnosis malfunction of the system

caused by parasitic pressure or to check through memorizing

the max./min. pressure occurred from the system.

Error

Description Troubleshooting

display

When external pressure is

input while adjusting zero

ERR1

point

When overload is applied

ERR2

on control output

When setting condition is

not met in Auto sensitivity

ERR3

setting mode

When applied pressure

exceeds Low-limit of

LLLL

display pressure range

When applied pressure

exceeds High-limit of

HHHH

display pressure range

-HH-

Auto shift correction error

-LL_

-HO_

Try again after removing

external pressure

Remove overload

Check setting conditions

and set proper setting

values

Apply pressure within

display pressure range

Set the corrected setting

value within setting

pressure range.

(0.0kPa)

Time

Time

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

(C)

LiDAR

(D)

Door/Area

Sensors

(E)

Vision

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

G-33

PSAN Series

Installation Proper Usage

1. Pressure port is divided as standard and option

specication. Therefore, be sure that to use commercially

available one touch tting.

2. Please connect it by using spanner (pneumatic type

12mm, uid type 17mm) at the metal part in order not to

overload on the body when connecting one touch tting.

12mm

Spanner

<Pneumatic type>

<Fluid type>

17mm

Spanner

Caution

PSAN Series is for sensing of non corrosive gas.

Do not use this product at corrosive gas or ammable

gas, etc.

• Please using this unit within the range of specification, if

applying pressure is larger than specification, it may not

be working properly due to damage.

• After supplying power, it takes 3 sec to work.

• When using switching mode power supply, frame ground

(F.G.) terminal of power supply should be grounded.

Caution

The tightening torque of one touch tting should be

max.10N.m. If not, it may cause mechanical problem.

3. Two dierent brackets are provided for pneumatic type

and three dierent brackets are provided for uid type.

Select proper one with considering your application

environments.

4. At rst, please unscrew hexagon wrench bolt and

assemble the bracket on this unit by xing hexagon the

wrench bolt.

Connector type Connector type Cable type

Bracket B

Hexagon wrench blot

(M3×6)

Bracket A

Caution

Spring washer

Bracket C

In this case, tightening torque of hexagon wrench

should be max. 3N.m. If not, it may cause mechanical

problem.

5. Panel bracket (PSO-B02/B03) and front cover

(PSO- P01) are sold separately. Please see the pictures

for installation.

Switching

Mode

Power

Supply

+

-

F.G.

• It may cause malfunction by noise, when wiring with

power line or high voltage line.

• Do not insert any sharp or pointed object into pressure

port. It may cause mechanical problem due to sensor

damage.

• Do not use this unit with flammable gas, because this is

not an explosion proof structure.

• Be sure that this unit should not be contacted directly with

water, oil, thinner, etc.

• Wiring must be done with power off.

Panel bracket

(PSO-B02/B03)

Front cover

(PSO-P01)

Mounting panel

(panel thickness: 0.8 to 3.5mm)

※

Do not pull the cable with a tensile strength of 30N or

over.

G-34

Body (PSAN)

Loading...

Loading...