Page 1

DRW170811AB

Autonics

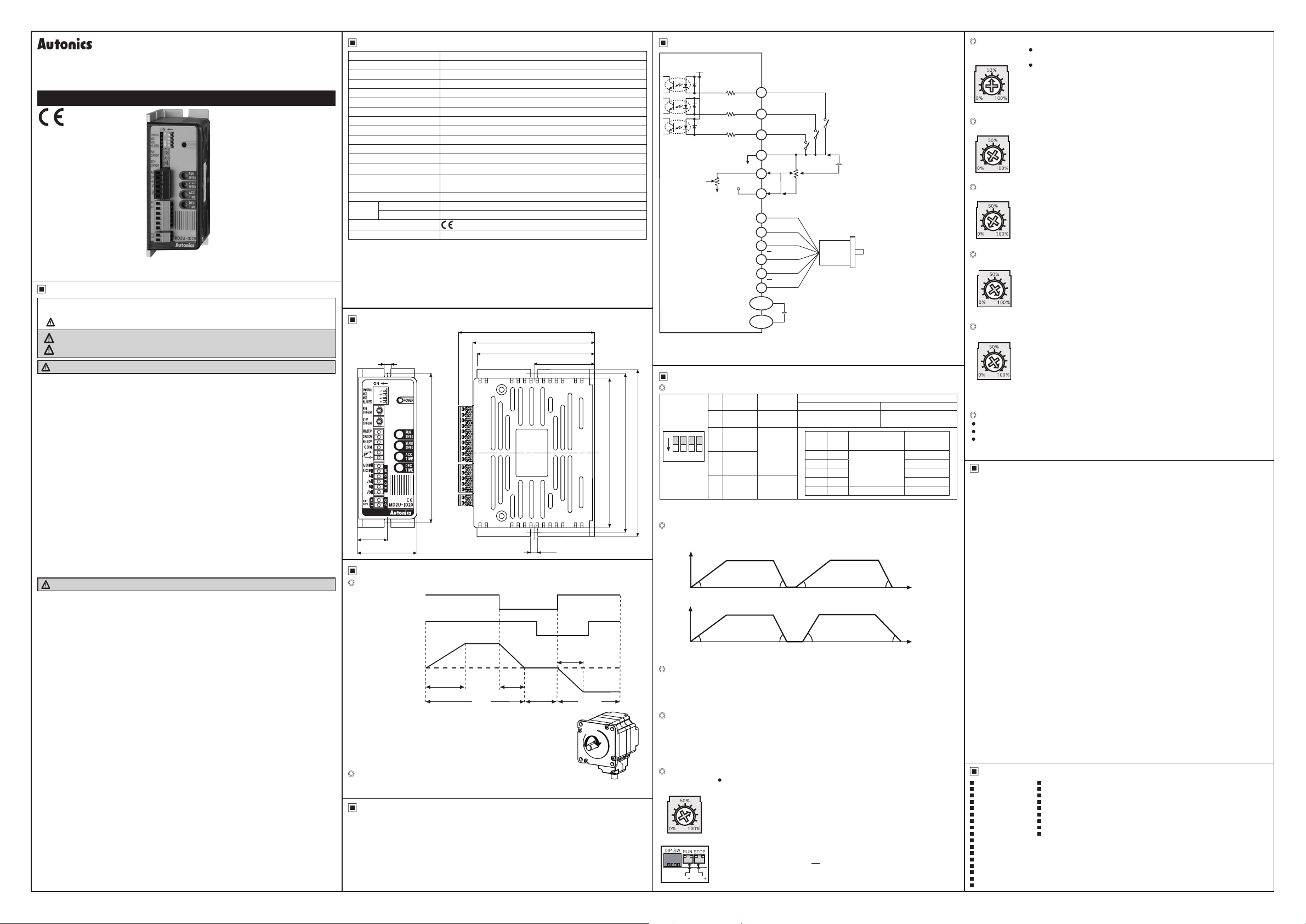

2-Phase Unipolar Intelligent Stepper Motor Driver

MD2U-ID20

I N S T R U C T I O N M A N U A L

Please read the following safety considerations before use.

Safety Considerations

00

Please observe all safety considerations for safe and proper product operation to avoid

※

hazards.

symbol represents caution due to special circumstances in which hazards may occur.

※

Warning

Caution

Ii

Warning

A

1. Fail-safe device must be installed when using the unit with machinery that may

cause serious injury or substantial economic loss. (e.g. nuclear power control,

medical equipment, ships, vehicles, railways, aircraft, combustion apparatus, safety

equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in fire, personal injury, or economic loss.

2. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in fire.

3. Install the unit after considering counter plan against power failure.

Failure to follow this instruction may result in personal injury, or economic loss.

4. Check 'Connections' before wiring.

Failure to follow this instruction may result in re.

5. Do not disassemble or modify the unit.

Failure to follow his instruc ion may result in fire.

6. Install the driver in the housing or ground it.

Failure to follow his instruc ion may result in personal injury, or fire.

7. Do not touch the unit during or after operation for a while.

Failure to follow this instruction may result in burn due to high temperature of the surface.

8. For rotating the motor manually when turning off the power, separate the motor and

the driver.

Power may be supplied to he driver.

9. Emergency stop directly when error occurs.

Failure to follow this instruction may result in re, or personal injury.

Caution

1. When connecting the power input, use AWG 18(0.75mm2) cable or over.

2. Install over-current prevention device (e.g. the current breaker, etc) to connect the

driver with power.

Failure to follow this instruction may result in fire.

3. Check the control input signal before supplying power to the driver

Failure to follow this instruction may result in personal injury or product damage by

unexpected signal.

4. Install a safety device to maintain the vertical position after turn off the power of this

driver.

Failure to follow this instruction may result in personal injury or product damage by releasing

holding torque of the motor.

5. Use the unit within the rated specications.

Failure to follow this instruction may result in fire or product damage.

6. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow his instruc ion may result in fire.

7. Do not use the unit in the place where ammable/explosive/corrosive gas, humidity,

direct sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in re or explosion.

8. The driver may overheat depending on the environment.

Install the unit in the well ventilated place and forced cooling with a cooling fan.

Failure to follow this instruction may result in product damage and degrada ion.

9. Keep metal chip, dust, and wire residue from owing into the unit.

Failure to follow this instruction may result in re or product damage.

10. Use the designated motor only.

Failure to follow this instruction may result in re or product damage.

※

The above specications are subject to change and some models may be discontinued

without notice.

※

Be sure to follow cautions written in the instruction manual and the technical

descriptions (catalog, homepage).

Thank you for choosing our Autonics product.

Failure to follow these instructions may result in serious injury or death.

Failure to follow these instructions may result in personal injury or product damage.

.

Specications I/O Circuit and Connections

Model MD2U-ID20

Power supply

Allowable voltage range 90 to 110% of rating voltage

Max. current consumption

RUN current

STOP current 20 to 70% of RUN current (set by STOP current volume)

RUN method Unipolar constant current drive type

Basic step angle 1.8˚/step

Max. drive speed 1500rpm

Input resistance 3.3kΩ (CW/CCW, RUN/STOP, HOLD OFF)

Insulation resistance

Dielectric streng h 1000VAC 50/60Hz for 1 minute (between all terminals and case)

Noise immunity

Vibration

Shock 300m/s² (approx. 30G) in each X, Y, Z direction for 3 times

Environ-

ment

Approval

Weight

※

1: Since torque characteristics are improved but the driver temperature rises with the 30VDC

power supply, he driver should be installed at the well ventilated environment.

Torque is variable by power supply.

※

2: Based on the ambient temperature 25℃, ambient humidity 55%RH.

※

3: RUN current varies depending on the input RUN frequency, and the max. instantaneous

RUN current varies also.

※

4

: The weight includes packaging. The weight in paren hesis is for unit only.

※

Environment resistance is rated at no freezing or condensation.

Dimensions

1~

1

※

3

※

Ambient temp. 0 to 50℃, storage: -10 to 60℃

Ambient humi. 35 to 85%RH, storage: 35 to 85%RH

4

※

4.5

24-35VDC

2

※

3A

0.5-2A/Phase

Over 200MΩ (at 500VDC megger, between all terminals and case)

±500V the square wave noise (pulse width:1㎲) by the noise simulator

1.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each

X, Y, Z direction for 2 hours

Approx. 303g (approx. 190g)

ᜡ

86

76.5

74

38

(unit: mm)

Inner power (24-35VDC)

V

3.3kΩ

3.3kΩ

3.3kΩ

RUN speed

※

Inner adjuster is correlated to external adjuster control and external voltage control.

1:

Make sure that inner adjuster must be set to maximum in order to set maximum Run

speed using external adjuster and external voltage.

5VDC(Inner)

1

2

3

4

5

6

1

2

3

4

5

6

DC+

Power

DC-

Functions

Function DIP Switch

No. Name Function

SYM/

1

NORMAL

2 MS2

100

20

39 5

4.5

94

100

ON 1 3 42

105

※

1: D=Don't care

※

Reboot the driver after changing function selection switch.

Selection of Symmetry/Asymmetry

※

The function to make the ACC/DEC time of run-speed as asymmetry or symmetry using

DIP switch No. 1.

Speed

(rpm)

3 MS3

H/L

4

SPEED

SYM/

NORMAL

Max. speed

High/Low

speed

Asymmetry (Normal) of accel/deceleration

Time Chart

High Speed mode

RUN/STOP

CW/CCW

Rota ion speed

and direction

(symmetry mode)

※

It accelerates up to RUN speed during ACC time

after RUN signal is ON and decelerates during DEC time

after it is OFF.

※

It is disable to change he direc ion during the signal is ON.

※

It takes 0.5sec for deceleration when DEC time is "0%".

Low speed mode

Max. RUN speed is 150rpm and ACC and DEC time are not available.

It is same with High speed to change RUN/STOP and direction.

Troubleshooting

00

1. When the motor does not rotate

Check the connec ion of controller and driver.

①

2. When motor rotates to the reverse direction

Check the DIR input of

①

DIR input is [ON] for CW, and [OFF] for CCW.

②

3. When operation of motor is unstable

Check whe her driver and motor are connected correctly.

①

Check whe her output current of the driver by current setting is proper for operation of

②

the motor.

ON

OFF

-r-=-

-

ON

OFF

,---_;

'

: : I

ACC time

-------------

he driver.

' '

. . I •

' '

,---~-

' : ' :

: ' :

______J_

DEC

:------.: : : : g

time

' ' '

~

' ' '

~I+---

ACC Time

(same as DEC time)

Motor

stop

' '

---:----_;

'

r-:,:

'

'

CCWCW

CW

I

-----

Speed

(rpm)

※

It is able to set the gradient (acceleration and deceleration time) as ACC/DEC time.

Selection of max. speed (MS2, MS3)

※

The function to select the max. speed of motors.

※

The max. speed of stepper motor is changed by MS2/MS3 and Hi/Low speed.

※

The features of run and vibration are able to change depending on MS2, MS3.

※

Lower the max. speed to run a motor smoothly.

Selection of H/L SPEED

※

H/L SPEED mode selection switch

: Accel/deceleration control is not available in Low speed mode since all sections are

included in Pull-in range.

※

Low speed mode: It is able to drive a motor up to 150rpm of max. drive speed.

※

High speed mode: It is able to drive a motor up to 1500rpm of max. drive speed.

Setting RUN current

RUN

CURRENT

A

V

ACC time and DEC time are repeated as a asymmetrical gure

Symmetry of accel/deceleration

A

V

ACC time and DEC time are repeated as a symmetrical gure

RUN current setting is for the current provided to the motor in running status.

•

When RUN current is increased, RUN torque of the motor is also increased.

※

When RUN current is set too high, the heat of the motor is increased.

※

Set RUN current properly for the load within the rated current range of the

※

motor.

※

RUN current setting range: 0.5 to 2.0A

※

RUN current setting method: Measure he voltage by connecting a

2 0A0.5A

DC voltage meter to both CT+ and CT- terminals while the motor is

running (max. 150rpm).

E.g.) Input voltage (3V) ×

3

Change RUN current only when the motor stops.

CT CT

※

RUN/STOP

CW/CCW

HOLD OFF

COM

※External adjuster control

Inner adjuster control

A-com

B-com

A

A

B

B

+

24-35VDC

-

Switch position

ON OFF

Symmetry Asymmetry

D

\/

D

\

0-5VDC

+

※External voltage control

2kΩ (1 to 3kΩ)

Motor

MS2 MS3 H/L SPEED

ON ON

ON OFF 1350

OFF ON 1000

OFF OFF 500

※

※

1

1

D

D

A

j

D

2

= 2A

(motor excitation current)

※

RUN/STOP signal input

→ [ON]: RUN, [OFF]: STOP

※

Direc ion signal input

→ [ON]: CW, [OFF]: CCW

※

HOLD OFF signal iuput

→ [ON]: HOLD OFF,

[OFF]: HOLD ON

Max. speed

(rpm)

1500

ON: High speed

OFF: Low speed 150

D

\

~

Time (sec)

A

Time (sec)

-

Setting STOP current

STOP

CURRENT

*.

O%

100%

70%

20%

Setting RUN speed

©

RUN SPEED

0% 100%

Setting START speed

©

START SPEED

100%

0%

Setting ACC time

©

ACC TIME

100%

0%

10)

Setting DEC time

DEC TIME

100%

0%

※

ACC Time and DEC Time are declined in proportion to the setting value of START speed.

※

The figures above indicate the factory default for each value.

10)

HOLD OFF function

This signal is for rotating axis of the motor with external force or manual positioning.

•

When hold off signal maintains over 1ms as [H], motor excitation is released.

•

When hold off signal maintains over 1ms as [L], motor excitation is in a normal status.

•

※

Use this func ion only when the motor stops.

※

Refer to I/O Circuit and Connec ions.

STOP current setting is for the current provided to the motor in stopped

•

status, preventing severe heat of the motor.

This func ion is for reducing the heat by variable resistance ratio setting

within 0 to 100% of RUN current setting range (actual setting range: 20 to 70%).

E.g.) In case of RUN current setting value is 2A and STOP current setting

value is 0% (actual setting range: 20%), STOP current is 2A×0.2=0.4A.

※

When STOP current is decreased, STOP torque of the motor is also decreased.

※

When STOP current is set low, the heat of the motor is also low.

※

Change STOP current only when the motor stops.

※

It sets max. RUN speed.

※

Max. RUN speed can be different depending on max. speed setting

(MS2, MS3) and driving mode set ing (Hi/Low speed).

※

Since missing step can occur due to max. input pulse frequency of motors,

consider motor type and its RUN current when setting max. RUN speed.

※

Set the value only when he motor stops.

※

It sets START speed.

※

Max. START speed value is same with RUN speed value.

※

Al hough START speed must be set within max. starting frequency, it is

recommended to set up START speed within 0 to 50% for stable driving.

※

Set the value

※

It sets the acceleration ime from START speed to max. RUN speed.

※

Operates in AT_1 operation mode when ACC time is under 33.3%, AT_2

operation mode when ACC time is under 66.6%, and AT_3 operation

mode when ACC time is over 66.6%.

※

AT_1 is 0.5 sec when RUN speed=100%, START speed=0%.

※

AT_2 is 1 sec when RUN speed=100%, START speed=0%.

※

AT_3 is 2 sec when RUN speed=100%, START speed=0%.

※

Set the value only when he motor stops.

※

It sets the deceleration time from max. RUN speed to STOP.

※Operatesin

operation mode when DEC time is under 66.6%, and DT_3 operation

mode when DEC time is over 66.6%.

※

DT_1 is 0 5 sec when RUN speed=100%, START speed=0%.

※

DT_2 is 1 sec when RUN speed=100%, START speed=0%.

※

DT_3 is 2 sec when RUN speed=100%, START speed=0%.

※

Set the value only when he motor stops.

only when he motor stops.

DT_1 opera ion mode when DEC time is under 33.3%, DT_2

Cautions during Use

1. Follow instructions in 'Cautions during Use'.

Otherwise, It may cause unexpected accidents.

2. 24-35VDC power supply should be insulated and limited voltage/current or Class 2, SELV power

supply device.

3. Re-supply power after min. 1 sec from disconnected power.

4. When the signal input voltage is exceeded the rated voltage, connect additional resistance at the

outside.

5. Set RUN current within the range of motor's rated current depending on the load.

When the rated motor current is over, the heat may be increased and motor may be damaged.

6. If motor stops, switching for STOP current executed by the current down function.

When hold off signal is [H] or current down function is off, the switching does not execute.

7. Use twisted pair (over 0.2mm2) for the signal cable which should be shorter than 2m.

8. The thickness of cable should be same or thicker than the motor cable's when extending the motor

cable.

9. Keep the distance between power cable and signal cable more than 10cm.

10. If the TEST switch is ON, the motor operates immediately and it may be dangerous.

11. Do not change any setting switchs (function, run/stop current, resolution switches) during the

operation or after supplying power.

Failure to follow this instruction may result in malfunction.

12. Motor vibration and noise can occur in specic frequency period

①

Change motor installation method or attach the damper.

②

Use the unit out of the dedicated frequence range when vibration and noise occurs due to

changing motor RUN speed.

13. For using motor, it is recommended to maintenance and inspection regularly.

①

Unwinding bolts and connection parts for the unit installation and load connection

②

Strange sound from ball bearing of the unit

③

Damage and stress of lead cable of the unit

④

Connection error with motor

⑤Inconsistency between the axis of motor output and the center, concentric (eccentric, declination)

of the load, etc.

14. This product does not prepare protection function for a motor.

15. This unit may be used in the following environments.

①

Indoors (in the environment condition rated in 'Specications')

②

Altitude max. 2,000m

③

Pollution degree 2

④

Installation category II

Major Products

00

Photoelectric Sensors Temperature Controllers

■

■ ■

Fiber Optic Sensors Temperature/Humidity Transducers

■ ■

Door Sensors SSRs/Power Controllers

■ ■

Door Side Sensors Counters

■ ■

Area Sensors Timers

■ ■

Proximity Sensors Panel Meters

■ ■

Pressure Sensors Tachometer/Pulse (Rate) Meters

■ ■

Rotary Encoders Display Units

■ ■

Connector/Sockets Sensor Controllers

■ ■

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

■

I/O Terminal Blocks & Cables

■

Stepper Motors/Drivers/Motion Controllers

■

Graphic/Logic Panels

■

Field Network Devices

■

Laser Marking System (Fiber, CO₂, Nd: YAG)

■

Laser Welding/Cutting System

■

DRW170 811AB

Loading...

Loading...