DRW170936AB

Autonics

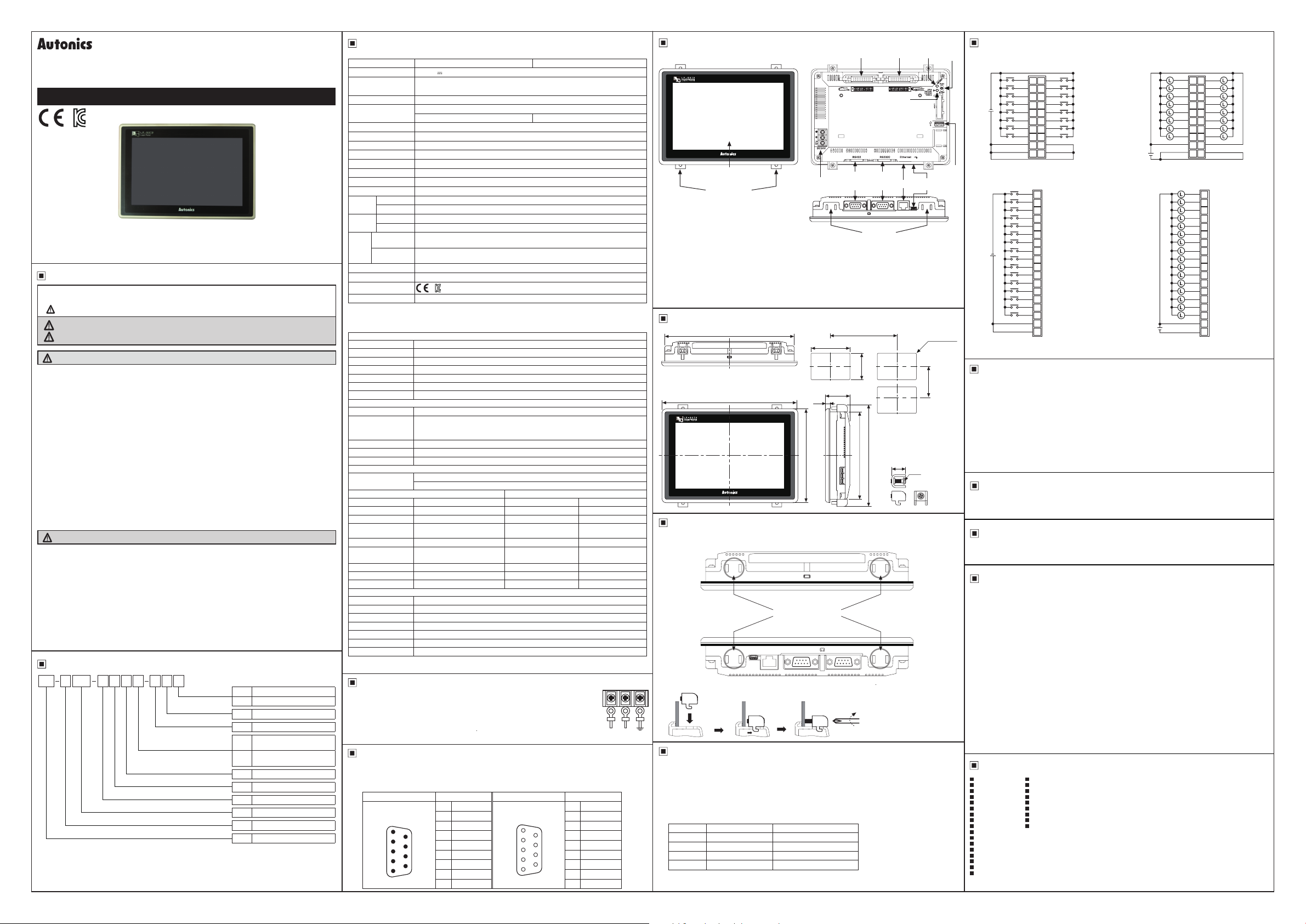

7 inch TFT Color LCD type Logic Panel

LP-S070

I N S T R U C T I O N M A N U A L

Please read the following safety considerations before use.

Safety Considerations

Please observe all safety considerations for safe and proper product operation to avoid

※

L_

hazards.

001

■

A -------71

symbol represents caution due to special circumstances in which hazards may occur.

※

Warning

Caution

1~

Warning

1. Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment,

ships, vehicles, railways, aircraft, combustion apparatus, safety

equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in re, personal injury, or economic loss.

2. Use the unit within the rated specications.

Failure to follow this instruction may result in shortening the life cycle of the product or re.

3. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in re.

4. Check 'Power Wiring', 'Serial Interface', and 'Input/Output Wiring' before wiring.

Failure to follow this instruction may result in re.

5. In preparation for product damage, communication error, or malfunction, install external

emergency stop circuit, forward/reverse interlock circuit, limit switch, emergency stop

switch, or other protection circuit.

Failure to follow this instruction may result in re, personal injury, or economic loss.

6. Since Lithium battery is embedded in the product, do not disassemble or burn the unit.

Failure to follow this instruction may result in re.

7. Do not disassemble or modify the unit.

Failure to follow this instruction may result in re.

8. Please contact to us for battery replacement.

Caution

1. Do not use the unit in the place where ammable/explosive/corrosive gas, humidity,

direct sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in re or explosion.

2. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in electric shock or re.

3. When connecting the power input, use AWG 23 cable or over and tighten the

terminal screw with a tightening torque of 0.5 to 0.8N.m.

Failure to follow this instruction may result in re or malfunction due to contact failure.

4. Keep metal chip, dust, and wire residue from owing into the unit.

Failure to follow this instruction may result in re or product damage.

5. Do not push over 2 point at the same time.

Failure to follow this instruction may result in malfunction.

Ordering Information

LP

S T 9 D 6 C 5 R

Item

The above specications are subject to change and some models may be discontinued without

※

notice.

Be sure to follow cautions written in the instruction manual, user manual and the technical

※

descriptions (catalog, homepage).

Thank you for choosing our Autonics product.

______

Failure to follow these instructions may result in serious injury or death.

Failure to follow these instructions may result in personal injury or product damage.

070

Series

Screen size

Color

Display unit

-

ll

Interface

Power supply

I/O connector

I/O composition

Module

L__

R Ribbon cable connector

T Terminal block connector

5 IN: 16 point, OUT: 16 point

C All-in-one type

~~~~~

RS232C, RS422,USB HOST

6

USB DEVICE, Ethernet

RS232C(2),USB HOST

7

USB DEVICE, Ethernet

D 24VDC

9 16,777,216 color

T TFT Color LCD

070 7 inch

S S series

LP Logic Panel

I

Specications

00

General specications

◎

Model LP-S070-T9D6-C5R(T) LP-S070-T9D7-C5R(T)

Power supply 24VDC

Allowable voltage

range

Power consumption Max. 7 2W

Serial interface

USB interface Each of USB Host, USB Device (version 1.1)

Ethernet interface EEE802.3(U), 10/100Base-T

Real-time controller RTC embedded

Battery life cycle 3 years at 25

Insulated resistance Over 100MΩ (at 500VDC megger)

Ground 3rd grounding (max. 100Ω)

Noise immunity ±0.5kV the squre wave noise (pulse width: 1㎲) by the noise simulator

Withstanding voltage 500VAC 50/60Hz for 1 minute

Mechanical

Vibration

Malfunction

Mechnical 300m/s² (approx. 30G) in each X,Y,Z direction for 3 times

Shock

Malfunction 100m/s² (approx. 10G) in each X,Y,Z direction for 3 times

Ambient

temperature

Environ

ment

Ambient

humidity

Protection structure P65 (front panel, IEC standard)

Accessory Fixing bracket: 4pcs, battery (included)

Approval

t=~==E~===========~L-------7

※1

Weight

※

1: The weight includes packaging. The weight in parenthesis is for unit only.

~~~±(

※

Environment resistance is rated at no freezing or condensation.

Performance specications

◎

Display performance

.

LCD type TFT Color LCD

Resolution 800×480 dot

Display area 152.4mm×91.44mm

Color 16,777,216 color

LCD view angle Within each 60°/45°/60°/60°of top/bottom/left/right

Backlight White LED

Brightness Adjustable by software

Graphic drawing performance

Language

Text

Graphic drawing memory

Number of user screen

Touch switch Analog touch

Interface type

Communnication

interface

Input Output

Input point 16 point Out point 16 point

Insulation method Photo coupler insulation Power supply 24VDC

Rated input voltage 24VDC Insulation method

Input resistance

I

Voltage range 19.2-28.8VDC

Input resistance

Response time 1ms

Common method 16 point/1 COM Common method 16 point/1 COM

Acceptable wire 0.3 to 0.7mm

Control performance

Command Basic command: 28, application command: 233

Program capacity 8K step

Processing time Average: approx. 2㎲/basic command, application command

I/O control type

Computer control mode

Device range Refer to 'LP-S070 user manual'

Special function Positioning function

※

※

● For power supply, use the wire of which cross section is at least 0.75mm² and use the

● Use round terminal with at least 3mm of internal diameter and less than 6mm of

●Do not apply power before power line connection.

●Check power polarity.

●Tighten the terminal screw with 0 5 to 0.8N

Loo

●Ground resistance should be less than 100Ω and ground it separately.

1

※

1: Supported language can be added.

2: Please refer to 'LP-S070 user manual' for more special function.

Power Wiring

wire of which cross section is at least 1.25mm² for grounding.

external diameter.

------11'_11;71111

90 to 110% of power supply

asynchronous method: each port of RS232C, RS422

Each port of RS232C, RS422 Two ports of RS232C

℃

0.75mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 1 hour

0.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 10 min

0 to 50℃, storage: -20 to 60

35 to 85% RH, storage: 35 to 85%RH

Approx. 699g (approx. 510g)

~

(

~===========

Korean, English

•Vector font •6×8, 8×8 ASC II character, high quality view of number

•8×16 ASCII character, 16×16 regional characters

(1 to 8times bigger for width, 0.5 to 5 times for height)

16MB

500 pages

LP-S070-T9D6-C5R(T): each port of RS232C, RS422, USB Host, USB Device, Ethernet

I

LP-S070-T9D7-C5R(T): two ports of RS232C, USB Host, USB Device, Ethernet

I

Contact X0 to X5: approx. 10mA

Contact X6 to XF: approx. 4mA

Contact X0 to X5: 2 2

Contact X6 to XF: 5.6

2

Batch processing

Repeated-doubling method, interrupt processing

㏀

㏀

2

※

m torque.

℃

Photocoupler insulation

Rated load voltage 24VDC

Allowable load voltage range

Max. load current

Max. voltage falling when ON

Acceptable wire 0 3 to 0.7mm

19.2-28 8VDC

0.1A/1 point,

1 6A/1COM

Max. 0.2VDC

2

+

24VDC

--+

Serial Interface

● All devices connectable into LP-S070 including PC, PLC, serial printer, barcode reader, and dedicated

connectors can be connected in to both RS232C and RS422 ports.

●Device must be set for the port in system setting for LP-S070. For details, please refer to 'LP-S070 user manual'.

●For connecting external device such as PLC, refer to 'GP, LP user manual for communication'.

Port Pin Port Pin

RS232C

RS232C-A

RS232C-B

5

•

4

•

3

•

2

•

1

•

D-Sub 9-pin Male

•

•

•

•

1 Non-Used RS422 1 TXD+

2 RXD 2 RXD+

3 TXD 3 Non-Used

9

4 DTR 4 Non-Used

5 SG 5 SG

8

6 DSR 6 TXD-

7

7 Non-Used 7 RXD-

6

8 Non-Used 8 Non-Used

9 Non-Used 9 Non-Used

0

1

2

3

4

5

D-Sub 9-pin Female

6

0

0

7

0

0

8

0

0

9

0

0

Unit Description Input/Output Wiring

LCD Screen

(2 slots is in upper side, 2 slot is in lower side)

●Ethernet port: For connecting LAN cable and hub, use direct cable, and for connecting PC directly, use cross

●USB Device: When setting USB Device mode to HID mode in serial setting, it is for uploading/downloading

●USB Host:

Fixing bracket

cable.

GP Editor, SmartStudio project. When setting to Storage mode, it is for transferring/coping data

between PC and LP-S070 with recognition as a storage device by PC.

For details, please refer to 'LP-S070 user manual'.

It is for transferring/coping data between USB storage device and LP-S070 and upgrading

firmware.

Power terminal

block

Input

terminal

RS422

or

RS232C-A

Program

status LED

RS232C

or

RS232C-B

Mounting slot

for bracket

terminal

Dimensions

I

C

I

185

194

I

L----

1

186

6.5

134

Min. 240

1.1

0

1.0

0

126

35

Panel thickness: max.

※

Fixing bracket

125

145 8

Output

Ethernet

15

M4

Power

LED

USB

Device

(unit: mm)

Max. 4-R3

Min. 175

Run/Stop

1. LP-S070-T9D6(7)-C5R

Switch

●Input wiring (source type)

X0

8

0

X1

9

1

X2

A

2

X3

B

3

X4

C

COM1

COM3

COM1

COM2

4

X5

D

5

X6

E

6

X7

F

7

+

+

+

+

X0

0

X1

1

X2

2

X3

3

X4

4

X5

5

X6

6

X7

7

X8

8

X9

9

XA

A

XB

B

XC

C

XD

D

XE

E

XF

F

+

+

24VDC

USB

2. LP-S070-T9D6(7)-C5T

Host

●Input wiring (source type)

24VDC

※Check the pin number of the case before wiring.

Manual

For the detail information and instructions, please refer to user manual and user manual for communication,

and be sure to follow cautions written in the technical descriptions (catalog, homepage).

● GP Editor user manual

It describes how to write screen data, and is about related usage of LP HMI function.

4mm

● SmartStudio user manual, SmartStudio programming manual, LP series command manual

It contains install method and usage, commands, etc of SmartStudio.

● GP, LP user manual for communication

It describes connection for external devices such as PLC.

● LP-S070 user manual

It describes general information on the installation and usage of LP-S070 and system contents.

Cable (sold separately)

00

Communication cables connectable into external devices such as PLC are sold separately.

Please refer to "GP, LP user manual for communication" for communication cable.

Installation

1. Set LP-S070 in panel.

2. Set xing brackets in 4 slots (2 slots is in upper side, 2 slots is in lower side).

Upper side

(~

Lower side

'

3. Tighten xing bracket with M4 screw driver and tightening torque is 0 3 to 0.5N

LJ~~-~==-j~

Software

00

● GP Editor

GP Editor is for editing shape, arrangement, default of tag data which is displayed on LP-S070

screen.

● SmartStudio

SmartStudio is for writing program and debugging to LP-S070.

For GP Editor, SmartStudio software, computer specification is as below.

※

Operating system: Windows XP/7/8/10 (SmartStudio does not support Window XP.)

Item Minimum specication Recommended specication

CPU Pentium4 or above Pentium Dual Core

Memory 512MB 1GB

Hard disk 1GB (available space) 5GB (available space)

Resolution 1024

I

● Firmware

Please refer to 'LP-S070 user manual', 'GP Editor user manual', and 'SmartStudio user manual'.

fu&ir•~~~

https://manualmachine.com/

~

~t~

768 1280×1024

×

I I

~

Mounting slot

for bracket

n

~~

~·==~-~~j\

~-·~--1-

9 ~

-

m.

M4 Screw driver

I

Battery Replacement

Please contact our service center to replace LP-S070 battery.

t may cause an explosion or a re when using improper battery.

Cautions during Use

00

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. 24VDC power supply should be insulated and limited voltage/current or Class 2, SELV power supply

device.

3. Install a power switch or circuit breaker in the easily accessible place for supplying or disconnecting

the power.

4. Operate the product after supplying power to the product, input/output equipment, and load.

If operate product before supplying power, it may result in output error or malfunction.

5. Keep away from high voltage lines or power lines to prevent inductive noise.

Do not use near the equipment which generates strong magnetic force or high frequency noise.

6. Make a required space around the unit for radiation of heat, and do not block ventilation openings.

7. Do not push the touch panel with a hard and sharp object or push the panel with excessive force.

It may result in fire or malfunction.

When skin is smeared with liquid crystal from the broken LCD, rinse with running water for over 15

minutes.

If it gets into the eyes, rinse eyes with running water for over 15 minutes and contact a doctor.

8. This unit may be used in the following environments.

Indoors (in the environment condition rated in 'Specifications')

①

Altitude max. 2,000m

②

Pollution degree 2

③

------~

Installation category II

④

Major Products

00

Photoelectric Sensors Temperature Controllers

■ ■

Fiber Optic Sensors Temperature/Humidity Transducers

■ ■

Door Sensors SSRs/Power Controllers

■ ■

Door Side Sensors Counters

■ ■

Area Sensors Timers

■ ■

Proximity Sensors Panel Meters

■ ■

Pressure Sensors Tachometer/Pulse (Rate)Meters

■ ■

Rotary Encoders Display Units

■ ■

Connector/Sockets Sensor Controllers

Switching Mode Power Supplies

■

Control Switches/Lamps/Buzzers

■

I/O Terminal Blocks & Cables

■

Stepper Motors/Drivers/Motion Controllers

■

Graphic/Logic Panels

■

Field Network Devices

■

Laser Marking System (Fiber, Co₂, Nd:yag)

■

Laser Welding/Cutting System

■

■ ■

X8

X9

XA

XB

XC

XD

XE

XF

COM2

COM4

●Output wiring (sync type)

●Output wiring (sync type)

24VDC

24VDC

Y0

Y8

8

0

Y1

Y9

9

1

Y2

YA

A

2

Y3

YB

B

3

Y4

YC

C

4

Y5

YD

D

5

Y6

YE

E

6

Y7

YF

F

7

+

+

-

-

Y0

0

Y1

1

Y2

2

Y3

3

Y4

4

Y5

5

Y6

6

Y7

7

Y8

8

Y9

9

YA

A

YB

B

XC

C

XD

D

YE

E

YF

F

+

-

DRW170936AB

Loading...

Loading...