DRW190188AC

Autonics

100mm Hybrid Recorder

KRN100 SERIES

I N S T R U C T I O N M A N U A L

Please read the following safety considerations before use.

Safety Considerations

Please observe all safety considerations for safe and proper product operation to avoid hazards.

※

symbol represents caution due to special circumstances in which hazards may occur.

※

Failure to follow these instructions may result in serious injury or death.

Warning

Caution

Failure to follow these instructions may result in personal injury or product damage.

Warning

1. Fail-safe device must be installed when using the unit with machinery that may cause serious injury or substantial

economic loss. (e.g. nuclear power control, medical equipment, ships, vehicles, railways, aircraft, combustion

apparatus, safety equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in personal injury, economic loss or re.

2. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in re or electric shock.

3. Check ‘Connections’ before wiring.

Failure to follow this instruction may result in re.

4. Do not touch the product during operation or for a certain period of time after stopping.

Failure to follow this instruction may result in burn or re.

5. Do not use the unit in the place where ammable/explosive/corrosive gas, high humidity, direct sunlight, radiant heat,

vibration, impact, or salinity may be present.

Failure to follow this instruction may result in explosion or re.

6. Install on the device panel or DIN rail, and ground to the F.G. terminal separately.

When connecting the F.G. terminal, use AWG16 (1.25mm

Failure to follow this instruction may result in re or electric shock.

7. Do not disassemble or modify the unit.

Failure to follow this instruction may result in re or electric shock.

8. Since Lithium battery is embedded in the product, do not disassemble or burn the unit.

Failure to follow this instruction may result in re.

Caution

1. Use the unit within the rated specications.

Failure to follow this instruction may result in re or product damage.

2. Use a dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in re or electric shock.

3. Keep the product away from metal chip, dust, and wire residue which ow into the unit.

Failure to follow this instruction may result in re or product damage.

4. When connecting the power input or measurement input, use AWG20 (0.50mm²) cable or over and tighten the terminal

screw with a tightening torque of 0.74 to 0.9N.m.

Failure to follow this instruction may result in re or malfunction due to contact failure.

5. Do not use the load beyond rated switching capacity contact.

Failure to follow this instruction may result in re, relay broken, contact melt, insulation failure or contact failure.

6. Do not disassemble or assemble input/output card, when power is supplied.

Failure to follow this instruction may result in product damage.

7. Use the transmitter output terminals only as the power for the transmitter.

Failure to follow this instruction may result in product damage.

8. When connecting the temperature sensor(TC, RTD) or analogue input (voltage, current) as input to the universal

input card, set the jumper pin to the correct place for the connected input method.

If the jumper pin is placed improperly, it may result in product damage or malfunc ion.

Specications

Series KRN100

Power voltage 100-240VAC

Allowable voltage range 85 to 110% of rated voltage

Power consumption Max. 55VA

LCD type STN Graphic LCD

Screen

Input channels 2 / 4 / 6 / 8 / 10 / 12-channel (2-channel/card)

Universal input Temperature sensor (RTD, thermocouple), analog (voltage, current)

Sampling cycle

Recording speed in graph mode 10, 20, 40, 60, 120, 240mm/H

Recording speed accuracy F.S. ±0.5%

Storage cycle 1 to 3600 seconds (storage interval time to inner log le is 1 seconds)

Inner memory 512MB

USB memory

Dielectric voltage 2500VAC 50/60Hz for 1 minute (power terminal and case) ※Excepts USB Device and Ethernet

Vibration strength

(for convey and storage) and

operating vibration

Insulated resistance Over 20MΩ (at 500VDC megger)

Noise immunity ±2kV the square wave noise (pulse width 1㎲) by the noise simulator

Time accuracy Within ±2 min/year (enables to use up to 2100 year)

Mechanism

Protection IP40 (front panel, IEC Standard)

Recording paper 113mm×9m

Environment

Approval

Weight

※

※

※

Resolution 320×120 Pixel

Adjusting brightness 4-level (OFF/Min/Standard/Max)

Backlight White LED, 2-level (Temp/Always)

※

1

Ink cartridge

I

Ink dry time Max. 15 minutes

I

Ambient temperature 0 to 50℃, storage : -20 to 60℃ (without ink cartridge)

I

Ambient humidity 35 to 85% RH, storage : 35 to 85% RH

I

※

2

1: USB memory is included in the box. If you use USB memory you purchased separately, it could not be recognized.

2: The weight includes packaging. The weight in parentheses is for unit only.

Environment resistance is rated at no freezing or condensation.

Dimensions

144

□

● Panel cut-out

Min.175

Min.175

※

Use a steel plate which is 2 to 8mm thickness.

※

The above specications are subject to change and some models may be discontinued without notice.

※

Be sure to follow cautions written in the instruction manual and the technical descriptions (catalog, website).

Thank you for choosing our Autonics product.

2

) or over.

50/60Hz

~

1 to 4-channel: 25ms/125ms/250ms, 5 to 12-channel: 125ms/250ms

(inner sampling cycle is operation unit time for average movement lter and alarm output function.)

※

Min. sampling cycle for TC-R, U, S, T sensor is 50ms.

Recognizes max. 32GB, enables to use cable up to 1.5m

Vibration strength: 10 to 60Hz 4.9m/s

Opera ing vibration: 10 to 60Hz 1m/s2 (each X, Y, Z axis for 10 minutes)

Enables to normal print with going and returning printing max. 5 times within 7 days after

opening he unit

2

(each X, Y, Z axis for 1 hour)

cm

Approx. 2.4 to 2.7kg (approx. 1.7 to 2.0kg)

137

□

le'-

~

I D D

, C

a1,1,4121

El

El El

11

El

El El

This rear side dimension is with

installed I/O cards to every slot.

138

18.6

168

~

llJI'"

137

1.0

0

138

1.0

0

~

※

(unit: mm)

~

"'"'""'"

El El

El El

,

El

El

•

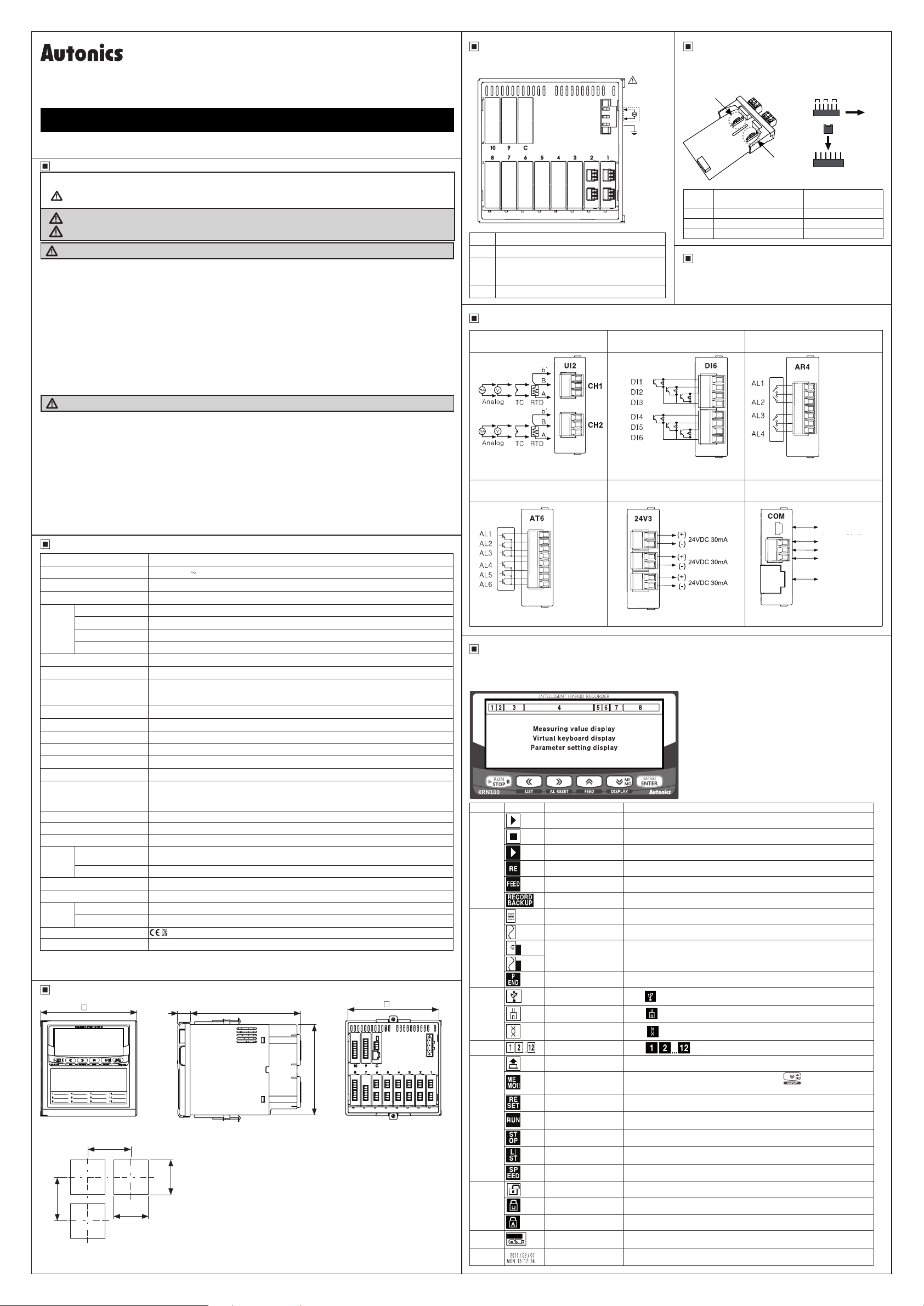

Connections

This gure is he rear side of KRN100-04000-00-0S.

nnno

ooooomo~;

~:

7.-

10

9 C

8 7 6 S 4 3

2 1

SOURCE

100-240VAC

50/60Hz, 55VA

F.G.

Input Type Setting

Before setting the parameters, set the jumper pin channel 1/2 of

universal input card (KRN-UI2) depending on input specification

as below figure.

Ch1 Jumper

Ch2 Jumper

② ①

③

Terminal

direction

[]I []I

Jumper

[]I []I

n

Slot Description

1 to 6 Connects universal input card(KRN-UI2).

Connects digital input card(KRN-DI6), alarm output

7 to 10

card(KRN-AR4, KRN-AT6), transmitter power output

card(KRN-24V3).

C Connects communication output card(KRN-COM).

I I

l/O Card

Universal input card

[KRN-UI2]

Ul2

b'

-

CCC~

+

Analog

-

CCC~

+

Analog

※

Each channel is isolated and dielectric

strength is 500V.

AL1

AL2

AL3

AL4

AL5

AL6

※

AL1,2,3 and AL4,5,6 are isolated.

TC RTD

TC RTD

Alarm output card

[KRN-AT6(transistor output)]

Inner

AT6

Alarm Output

NPN Open

Collector

12-24VDC/

30mA Max.

RESISTIVE

LOAD

[I

[I

CH1

CH2

※Each 24V output

Screen Layout and Status Display

Screen layout is divided as two; upper screen for status display, lower screen for measuring value display, virtual keyboard display,

parameter setting display.

Upper screen displays recorder status and informa ion of recorder as icon.

INTELLIGENT

HYBRID

RECORDER

[I]211

3

Measuring value display

Virtual keyboard display

Parameter setting display

Section Icon Name Description

[f]

~

1

IJ

II

E

!Im

-

~

[2]

2

~

[2a

Ml

Ct]

3

[illi]

[]]

4 Alarm ON icon

mm

~

HI

5

~

m

m

m

~

~

6

7

8

lml

1"11

ffll

2011/02/07

MON

Record start icon Marks if for starting recording measuring value of recordable channels.

Record stop icon Stops recording measuring value.

List record icon Flashes during list recording.

Reservation record icon Flashes during reserva ion recording.

FEED icon Flashes during feeding recording paper.

Backup data print icon Flashes during backup data printing.

Digital mode icon Marks it for digital record mode.

Graph mode icon Marks it for graph record mode.

Record memory status

icon

No recording paper icon Marks it for no recording paper. Please replace new recording paper.

USB

communication icon

Ethernet communication

icon

RS485 communica ion

icon

...

~

Digital input(DI) icon Marks the below icon according to input function setting during digital input (DI).

Digital input(DI)memo icon

Digital input(DI)alarm reset icon

Digital input(DI)start record icon

Digital input(DI)stop record icon

Digital input(DI)LIST output icon

Digital input(DI)record speed icon

Unlock icon Marks it for unlock status.

User(general user)

lock icon

Administrator lock icon Marks it for administrator and general user lock status.

Inner and external (USB)

memory capacity icon

Date/Time display

15:

17

34

1

®11

Digital input card

[KRN-DI6]

DI1

DI2

DI3

DI4

DI5

DI6

Transmitter power output card

[KRN-24V3]

24V3

\~j

(+)

(-)

(+)

(-)

is isolated individually.

11

s 1

Marks it storage capacity of record memory in digital mode or graph mode.

Marks icon during Modbus RTU communication using USB.

n

Marks

Marks icon during Modbus RTU communication using RS485.

Marks channel icon which alarm occurs.

Marks it when digital memo of digital input or front is input in recording

status.

Marks it when alarm reset signal of digital input (DI) is input.

Marks it when start record signal of digital input (DI) is input.

Marks it when stop record signal of digital input (DI) is input.

Marks it when LIST output signal of digital input (DI) is input.

Marks it when changing record speed signal of digital input (DI) is input.

Marks it for user (general user) lock status.

Displays data capacity of internal memory as bar graph.

Displays current date and time. In summer time season, (S) mark is also

displayed at front of year.

icon during Modbus TCP communication using Ethernet.

11!!1

1:1

Dfl

...

lE

Input

pin

specication

0 to 20mA, 4 to 20mA Enables only 4 to 20mA

①

TC, RTD, ±60mV, ±200mV Enables

②

±2V, 1 to 5V, ±5V, -1 to 10V Disables

③

Input break alarm

User Manual

For the detail informa ion and instructions, please refer to user

manual and user manual for communication.

Alarm output card

[KRN-AR4(relay output)]

D16

AL1

AL2

AL3

AL4

24VDC 30mA

24VDC 30mA

24VDC 30mA

AR4

Inner

Alarm Output

Relay Contact

250VAC 3A 1a

RESISTIVE LOAD

Communication output card

[KRN-COM]

USB 2 0

(Mini B type)

RS485 A(+)

RS485 B(-)

RS485 S.G

10/100 Base-T

RJ45(Ethernet)

@

~

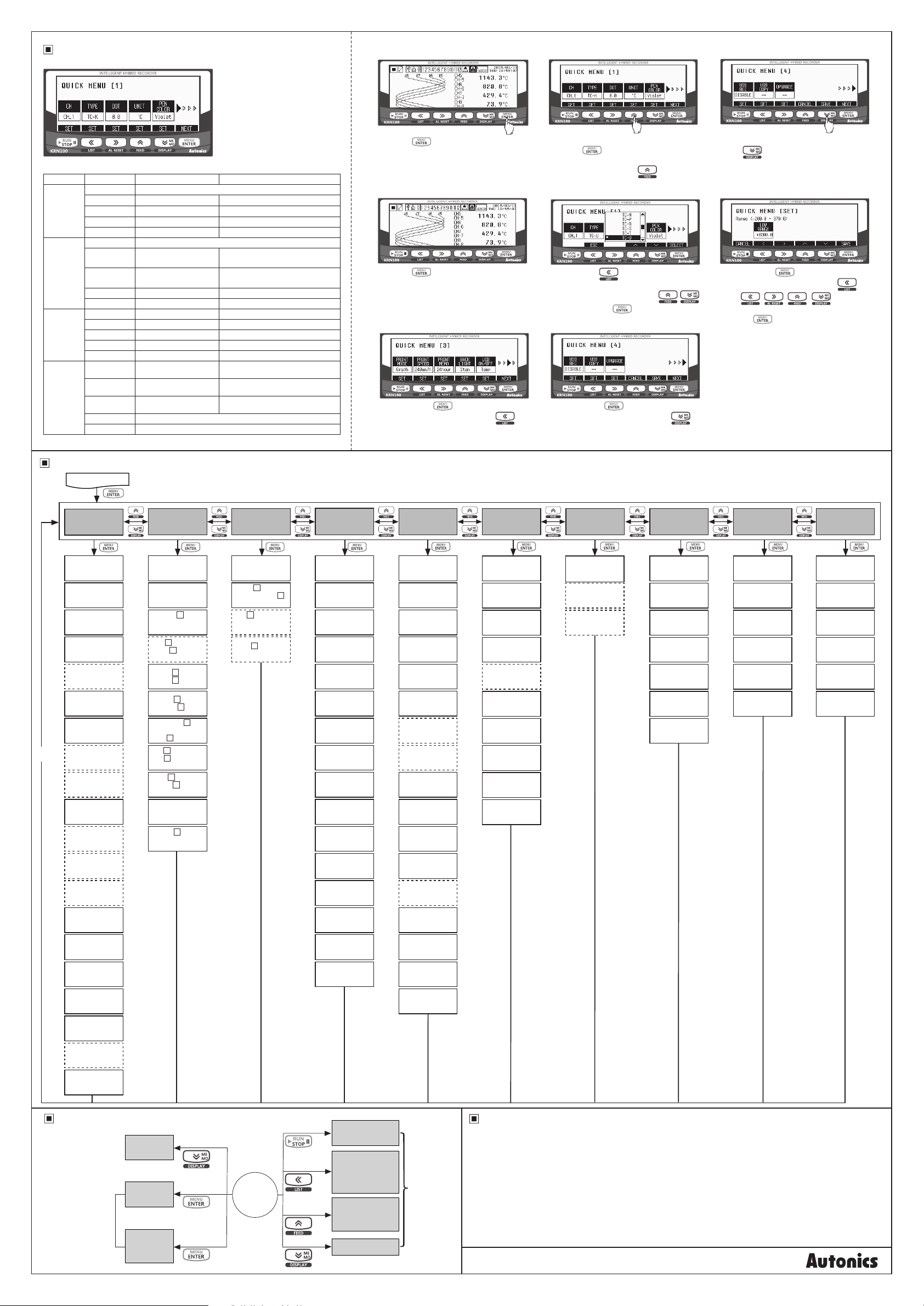

QUICK MENU

QUICK MENU consists of usually used parameters for quickly parameter setting.

QUI

CK

HENU

[1 l

2) QUICK MENU Setting

① ② ③

=~•=====•-~9=-THU

2015/03/1

19:5510

3

°C

UU I CK

~~~~~~~le~I►

------

►

:~":-11■

INTELLIGENT HYBRID RECORDER

[1

l

HENU

«

■

»•~

·

~~

~~

~

-

Eri

':flu

R

OU I CK

HENU

[4]

1) Parameters of QUICK MENU

Page Parameter Description Linked parameters

QUICK

MENU [1]

QUICK

MENU [2]

QUICK

MENU [3]

QUICK

MENU [4]

※

Refer to “KRN100 user manual”.

CH Select channel for the QUICK MENU[1] setting.

TYPE Input type [INPUT SETUP]-[Input Type]

DOT Decimal point [INPUT SETUP]-[Range/Scale Point]

UNIT Display/Temperature unit [INPUT SETUP]-[Display/Temp Unit]

PEN COLOR Pen color [INPUT SETUP]-[Pen Color]

CH Select channel for the QUICK MENU[2] setting.

LOW RANGE

HIGH RANGE

LOW SCALE Low-limit scale value [INPUT SETUP]-[Low Scale]

HIGH SCALE High-limit scale value [INPUT SETUP]-[High Scale]

PRINT MODE Record mode [RECORD SETUP]-[Record Mode]

PRINT SPEED Standard record speed [RECORD SETUP]-[Standard Speed]

PRINT MEMO Digital memo period [RECORD SETUP]-[Memo Period]

BACK LIGHT LCD backlight [SYSTEM SETUP]-[Backlight]

LCD ON/OFF

USB REC Memory save

USB COPY Call USB COPY window

UPGRADE Call upgrade window

CANCEL Cancel the settings

SAVE Save the setting of QUICK MENU[1] to [4].

Low-limit input value or

graph scale value

High-limit input value or

graph scale value

LCD backlight On/O

[INPUT SETUP]-[Low Range] or

[INPUT SETUP]-[Low Graph Scale]

[INPUT SETUP]-[High Range] or

[INPUT SETUP]-[High Graph Scale]

[SYSTEM SETUP]-[Backlight On/O]

[FILE/MEMORY SETUP][USB LogData Save]

[FILE/MEMORY SETUP][USB Memory Copy/Move]

[USER/INFORMATION SETUP][Firmware Upgrade]

Press the key once in RUN mode and it

enters to QUICK MENU.

QUICK MENU consists of usually used

parameters for quickly parameter setting.

Set the keys following the each parameter. Press

the NEXT(

E.g ) When changing the temperature unit (℃→℉)

of CH1, press the SET(

) key and it moves to next page.

) key.

After completing the set ing, press the

SAVE(

the settings. It returns to RUN mode.

ᆞE.g.) In case of CH1, recording as input type=TC-U, low-limit input value=300, standrad record speed= 240mm/h

① ② ③

④ ⑤

~cc,c=~=

Press the key in RUN mode to enter

QUICK MENU.

UU

I CK HENU

!!!!!~1

►:

y~~

..

.

------

"

Press the NEXT( ) key once and it moves

to QUICK MENU [3]. Press the SET(

and set standard record speed [PRINT SPEED]

as 240mm/h.

=-"ce

INTELLIGENT

HYBRID

[3]

~!~~~

» • A

«

■

r:a;;;i[1

~

201'5/03/1

~~-•~~TI-IU 19:'5'5:0

43. 3°C

RECORDER.

~ ~►~

■

~=~

• E~i"EUR

CD

-

) key

T

C-N

~

TC-P

TC-R

TC-S

--►>

~

> >

,

)

TC-T

Press the SET(

and below screen is displayed. Set input type

[TYPE] as TC-U by pressing SET(

keys and press the

OU I CK

Press the NEXT(

to QUICK MENU [4]. Press the SAVE(

key to save the set ings of QUICK MENU [1] to

[4] and it returns to RUN mode.

) key at QUICK MENU [1]

CD

-

key.

HENU

[41

) key once and it moves

OU I CK

Range

Press he NEXT(

to QUICK MENU [2]. Press the SET(

)

using

low-limit input range [LOW RANGE] as 300 and

press the

) key at QUICK MENU[4] and save

HENU

[SETJ

(-200. 0 N 370.

0)

~t'!

«

»

) key once and it moves

CD

-

, ,

MENU

key.

ENTER

,

keys to set

) key

Parameters

RUN mode

INPUT SETUP

(input setting)

Select UI Card

(universal input

card select )

Input Set Copy

(input parameter

LCD/Paper Record

(display and record

measuring value)

Pen Color

(record color)

Record Zone

(record zone)

------------

Tag Name

(channel name)

Input Type

specications)

OK,

Range/Scale Point

Cancel

(decimal point)

' '

·------------·

·------------·

Display/Temp Unit

' '

' '

(display/temp.

' '

High/Low Range

& Graph Scale

(high/low input v alue

and graph scale)

I I

·------------·

Low Scale/

' '

High Scale

(high/low scale value)

Special Func

(special function)

·------------·

------------

Two Unit

(display vacuum,

static pressure)

------------

Ref Channel

(reference

channel)

Input Bias

(error correction)

(gradient

adjustment)

Record Method

(data storage

Filter Type

(input digital lter)

Filter Counter

(number of digital

·------------·

Burnout Action

(display setting

for break)

I I

copy)

(input

unit)

Span

method)

lters)

I

3 sec.

ALARM SETUP

(alarm setting)

Select UI Channel

(universal input

Alarm Set Copy

(copy alarm

Alarm type

(alarm operation

Alarm Ref Channel

(alarm reference

------------

Alarm Option

(alarm

Alarm Value

(alarm

(alarm hysteresis)

Alarm ON/OFF Delay

(alarm output ON/ OFF

Alarm Alarm No

(alarm

alarm number)

Selection Alarm Card

(Alarm output card

Alarm- Status

(relay and transistor

I

select)

parameter)

□

mode)

□

□

channel)

□

option)

□

□

SV)

□

Alarm

□

Hysteresis

□

□

□

delay time)

□

output

□

select)

□

output method

※

Dot parameters may or may not appear, depending on the other parameter setting.

COMMUNICATION

SETUP

(com. setting)

Modbus Address

(com. address)

RS485 Port

(RS485 com. use)

Baud Rate

(com. speed)

Parity Bit

(com. parity bit)

Stop Bit

(com. stop bit)

Termination Set

(terminating

resistance)

Response Wait Time

(com. response

waiting time)

Protocol

(com. protocol)

RS485 Com/Write

(RS485 com.

write)

Ethernet Port

(Ethernet com.

use)

IP Address

(IP address)

Subnet Mask

(subnet mask)

Default Gateway

(default gateway)

Ethernet Com

Write

(Ethernet com. write)

USB Device Port

(USB com. use )

USB Com Write

(USB com. write)

I I

RECORD SETUP

(record setting)

Record Mode

(record mode)

Digital Print type

(1 line record CH during

numeric recording)

Standard Speed

(standard record

speed)

Option Speed

(option record

speed)

Memo Period

(digital memo

cycle)

Divide Zone

(record zone

division)

Standard Period

(standard record

cycle)

Option Period

(option record

cycle)

------------

Listing Language

(language for list

printing)

Alarm Speed

(alarm record

speed)

Power On Status

(record status

when power ON)

Run Status

(list printing at

start recording)

List Out Option

(list record option

------------

Zone Dot Line

Distance

(dot line for zone division)

CH Print Distance

(record interval for

each channel graph

Start Line Print

(start line when

starting record)

Range Print Time

(input range

record period)

I

I

SYSTEM SETUP

(system setting)

(summer time period)

------------

(sampling cycle)

(LCD backlight ON

I

(digital input card

·------------·

·------------·

(operation status)

I

DIGITAL INPUT

SETUP

(digital input setting)

Select DI Card

select )

DI- Type

(digital input

select)

DI- Reset No

(reset alarm

number)

DI- Status

□

Device Name

(device name)

Date/Time

(date/time)

Date Type

(date type)

Summer Time

(summer time)

Summer Time

Period

Alarm Sound

(alarm sound)

Sampling Rate

Log Speed

(save cycle)

Backlight

(LCD backlight

brightness)

Baklight On/O

method)

(reservation setting)

(reservation record)

Reservation Period

·------------·

·------------·

Reservation Time

I

RESERVATION

SETUP

Reservation

Type

(reservation

record period)

(reservation

record time)

FILE/MEMORY

SETUP

(le/memory setting)

Load Set File

(parameter setting

le open)

Save Set File

(parameter setting

le save)

Memory Status

(memory capacity)

Memory Clear

(memory delete)

USB LogData

Save

(USB save function)

Memory Save Option

(memory save

option)

USB Memory

Copy/Move

(data move/copy)

I I

USER/INFORMATION

SETUP

(user/info. setting)

Password

(password mode)

Login Admin

(admin. log in)

Change Admin

Password

(password change by admin.)

User Lock

(user authority

change)

Information

(system info.

check)

Firmware Upgrade

(rmware

upgrade)

l'--------r-----1

RECORD BACKUP

DATA

backup data record setting

Record Backup

(backup data

record)

Backup Data List

(backup data list)

Start Date and Time

(start time for data

save)

End Date and

Time

(end time for data save)

Backup Print Mode

(backup data print

mode)

Selection Print Mode

(backup data recording

mode setting)

l'-------r-----'

Usually used

parameters of

parameter setting group

are reorganize as

QUICK MENU.

Each parameter setting

is linked.

Operation

Trend graph

→ Bar graph

→ Digital number

Screen

display

QUICK

MENU

Parameter

setting

group

3 sec.

RUN mode

3 sec.

3 sec.

3 sec.

Start/Stop

recording

Parameter

setting

information

output

Manual feed

(when stop

recording)

Digital memo

Special

function for

record

Cautions during Use

00

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. Install a surge absorber at each end of inductive load coil when controlling high-capacity power relay or inductive

load (e.g. magnet).

3. Check the polarity of the terminals before wiring the temperature sensor.

For RTD temperature sensor, wire it as 3-wire type, using cables in same thickness and length.

For thermocouple (CT) temperature sensor, use the designated compensation wire for extending wire.

4. Keep away from high voltage lines or power lines to prevent inductive noise.

In case installing power line and input signal line closely, use line lter or varistor at power line and shielded wire

at input signal line.

Do not use near the equipment which generates strong magnetic force or high frequency noise.

5. This unit may be used in the following environments.

①Indoors (in the environment condition rated in 'Specications') ②Altitude max. 2,000m

③Pollution degree 2 ④Installation category II

Autonics

Loading...

Loading...