Page 1

ST7000 Installation

Page 2

Autohelm

Autohelm

AutohelmAutohelm

®®®®

Page 3

Page 4

Contents

1. System Description

1.1.1 Course Computer 3 4.1 Recommended Settings 34

1.1.2 Control Unit 3 4.2 Calibration Mode 34

1.1.3 Fluxgate Compass 3 4.3 Adjusting Calibrati on 35

1.1.4 Rudder Reference Transducer 4 4.4 Display Contrast Adjust m ent 37

1.1.5 Auxiliary Alarm 4 4.5 Permanent Watch Alarm 38

1.1.6 Masthead Transducer 4 4.6 Recorded Calibration Setti ngs 38

1.1.7 Type CR Interface Unit 5 4.7 Rudder and Rate Gain Tables 38

1.2 Drive Systems 6

1.2.1 Rotary Drive 6

1.2.2 Linear Drive 7 5.1 Automatic Deviat i on C orrection 39

1.2.3 Hydraulic Drive 8 5.2 First Sea Trials 39

1.2.4 Constant Running Power Pack 9 5.3 Response Control 39

1.2.5 Sterndrive 11 5.4 Automatic Trim Cont rol 40

5.5 Rudder Gain Adjustment

2. Installation

2.1.1 Course Computer 12 5.6 Rudder Gain adjustment

2.1.2 Control Unit 13 (High Speed Planing Craft ) 41

2.1.3 Fluxgate Compass 13 5.7 Manual overide

2.1.4 Rudder Reference Transducer 14 (Sterndrive Actuators only) 41

2.1.5 Auxiliary Alarm 15 5.8 Rate Gain Adjustment 41

2.1.6 Masthead Transducer 16 5.9 Compass Alignment 42

2.2 Drive Systems 16

2.2.1 Rotary Drive 16

2.2.2 Linear Drive 18 6.1 Functional Test 43

2.2.3 Hydraulic Drive 19 6.2 Operating Hints 43

2.2.4 Stern Drive 22

2.3 Cabling and Power Supplies 26

2.3.1 Signal Cabling 26

2.3.2 Connection to other SeaTalk Uni t s 27

2.3.3 NMEA Input 28

2.3.4 D.C. Power Supplies and Drive Uni t 28

2.3.5 Type CR Installat i ons 30

2.3.6 Stern Drive Actuator 31

3. Functional Test

3.1 Switch On 32

3.2 Rudder Angle Sense 32

3.3 Mechanical Test (Manual Steering) 32

3.4 Rudder Angle Alignment 32

3.5 Operating Sense 32

3.6 Rudder Deadband 32

3.7 Mechanical Test (Autopil ot St eering) 32

3.8 Mechanical Test – Sterndrive

(Autopilot steering)

3.9 Rudder Angle Limit 33

4. Calibration

2

5. Initial Sea Trials

12 (Displacement craft) 40

6. Track Control

7. Windvane Control (Sail Only)

32

33

34

39

43

45

Page 5

1

Page 6

1. System Description

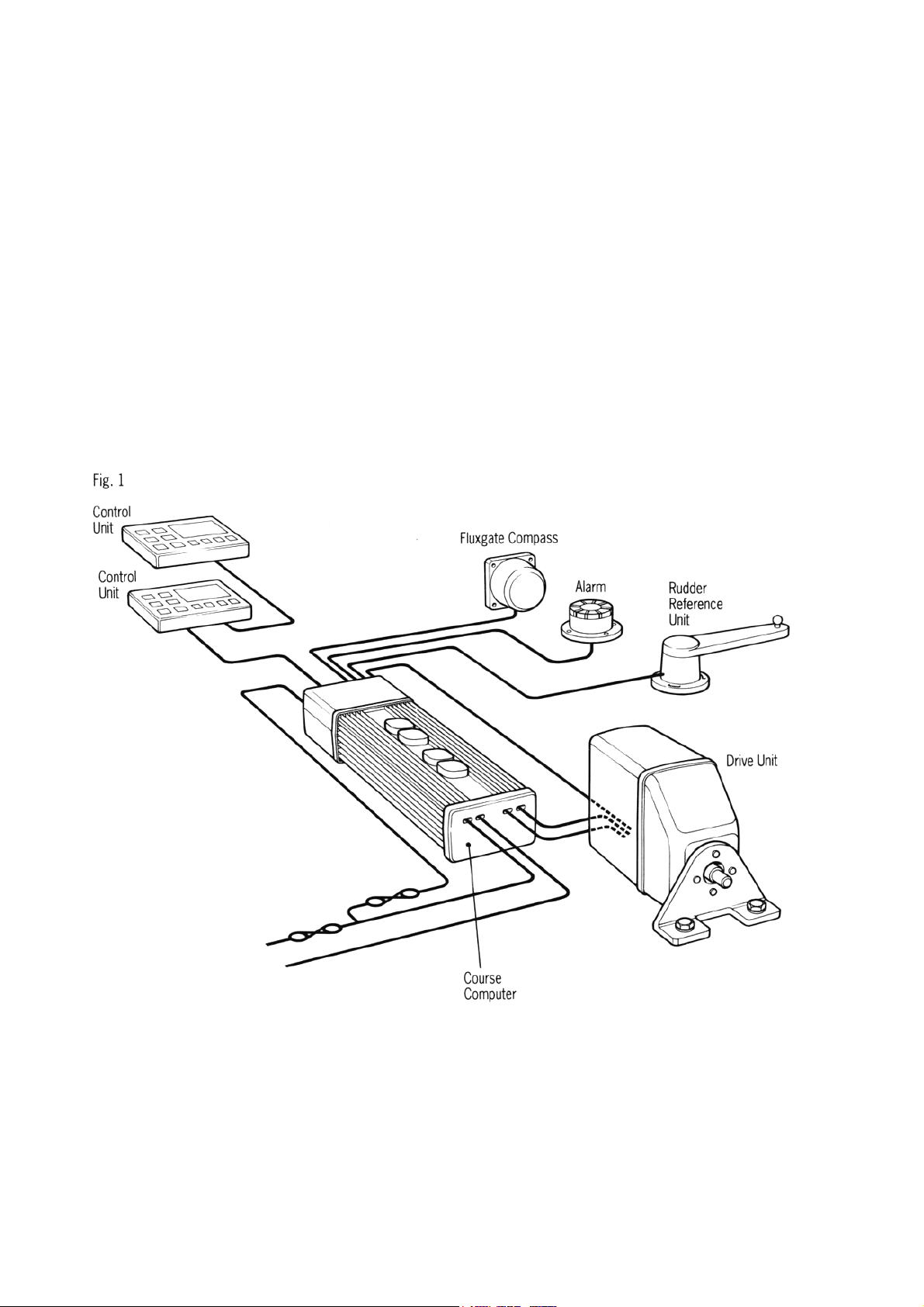

A

The ST7000 is a modular automatic pilot system

that can be built up to match the individual

requirements of all types of vessels. A range of

high efficiency rotary, linear, and hydraulic rudder

drive units are available to match all types of

steering systems.

The ST7000 is SeaTalk compatible providing full

data sharing with Autohelm range of SeaTalk

instruments.

The contr ol unit has a built in interface which will

accept navigation and wind angle data to

0180/0183 format.

fully comprehensive installation is shown below.

The most basic installation would consist only of a

central course computer, drive unit, fluxgate

compass, rudder reference unit and a single

control unit.

2

Page 7

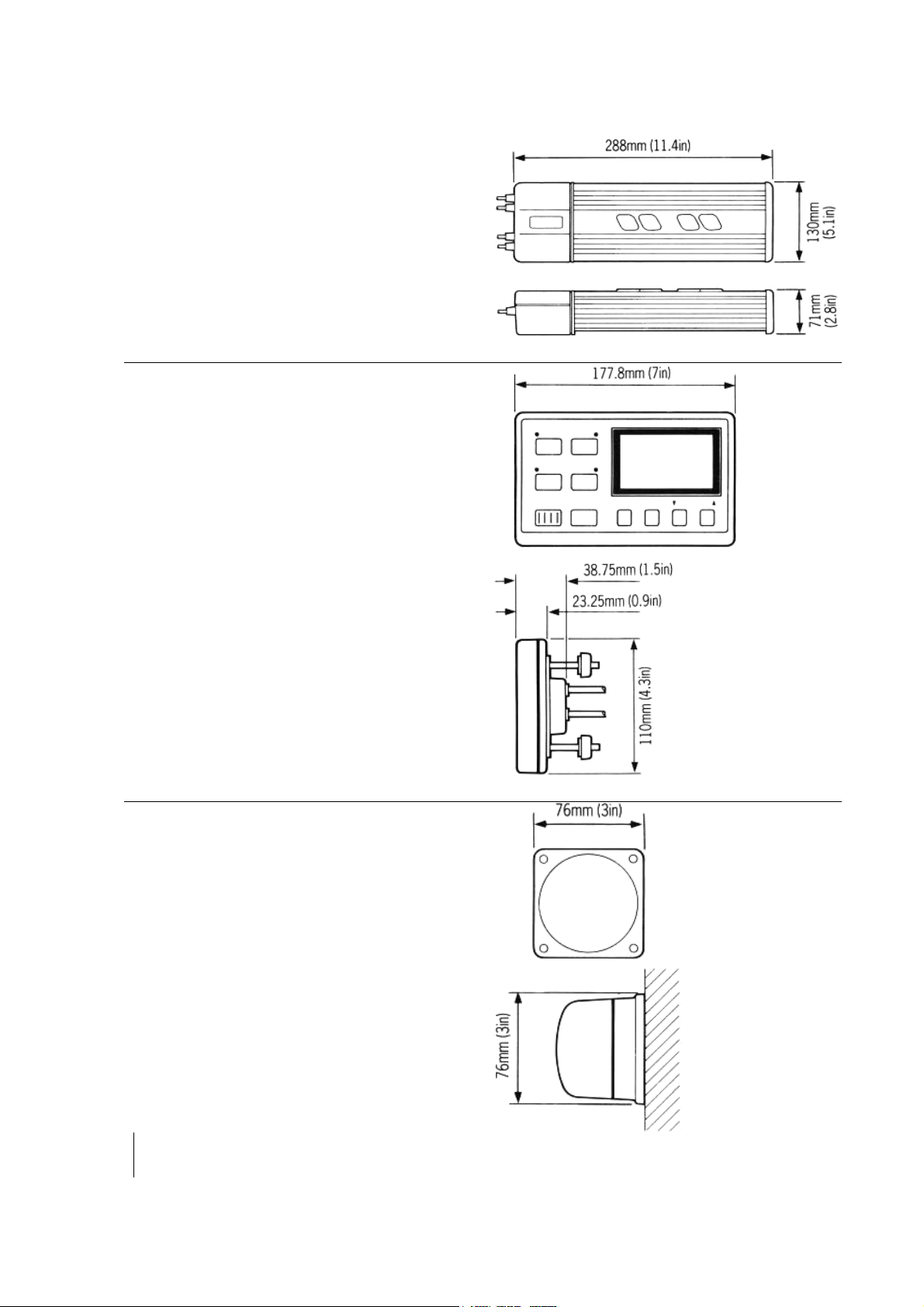

1.1.1 Course Computer

(Cat. No. Z083-12V Cat . No. Z084-24V)

The course computer houses the microprocessor,

electronic control circuitry and power amplifier for

the drive unit. The course computer is splash

proof only and must be mounted in a dry and

protected position. The course computer is

available for operation with 12V and 24V power

supply.

1.1.2 Control Unit (Cat. No. Z082)

The control unit is designed for above or below

deck mounting. The control unit accepts NMEA

0183 navigation and wind angle data input .

1.1.3 Fluxgate Compass (Cat. No. Z130)

The fluxgate compass has been especially

developed for marine application. The compass

contains a gimbal mechanism to permit accurate

readings with pitch and roll movements up to +35

deg. The compass is bulkhead mounted below

decks and connects directly to the course

computer.

The fluxgate compass may be mounted above

deck on steel vessels however autopilot

performance may be degraded due to the

increased motion.

3

Page 8

1.1.4 Rudder Reference Transducer

(Cat. No. Z131)

The rudder reference transducer provides the

course computer with a precise rudder position. It

is mounted on a suitable base adjacent to the

rudder stock. The interconnecting cable connects

directly to the course computer connector unit.

1.1.5 Auxiliary Ala r m

The autopilot is provided with an automatic off

course alarm system which sounds from all

control units and provides sufficient audible

warning under most conditions. In cases where a

high pow er ala rm is n eces sar y, an au xiliary alar m

can be fitted. The auxiliary alarm is connected to

the main connector unit via a t wo core cable.

(Cat. No. Z035)

1.1.6 Masthead Transducer (Sail Only)

(Cat. No. Z080)

If the installation does not include an Autohelm

ST50 Wind Instrument the masthead transducer

can be connected directly to the course computer

to supply wind angle information.

4

Page 9

1.1.7 Type CR Interface Unit

(Cat. No. Z085)

A standard ST7000 course computer can be

connected to the solenoids on a constant running

hydraulic power pack using the Type CR Interface

Unit. The unit also provides connections to

energise a solenoid operated bypass valve if

required.

5

Page 10

1.2 Drive Systems

The ST7000 offers a choice of Mechanical or

Hydraulic Drive Units. All ves sels with hydraulic

steering will require a hydraulic drive unit (see

section 1.2.3).

Mechanical steering systems may be driven with

either a rotary or linear drive unit. If space permit s

the linear drive unit provides the simplest

installation by connecting directly to the rudder

stock tiller arm. It may also be used to power

steer the vessel if steering li nkage f ai l ure occurs.

1.2.1 Rotary Drive Units

The Autohelm Rotary Drive Units provide smooth

powerful steering commands with virtually silent

operation.

A rugged electric motor drives a precision

epicyclic gearbox v ia a high tensile belt drive. An

electronic clutch is totally fail-safe yet transmits

high torque loads with no slippage.

The drive units can be mounted in any attitude

simplifying installation.

6

Page 11

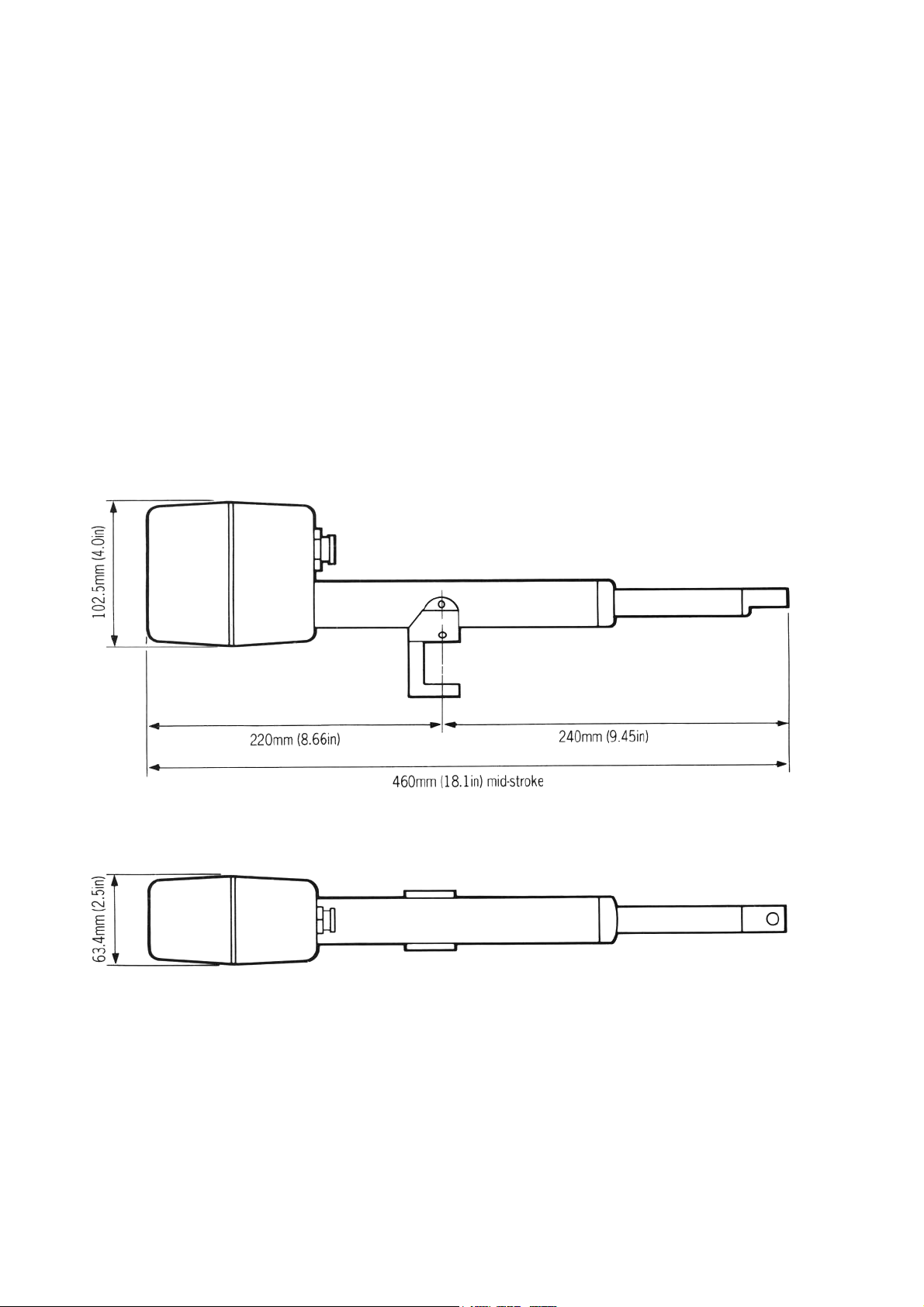

1.2.2 Linear Drive Units

The Autohelm Linear Drive Units are of

outstanding design which features powerful thrust,

fast hard overtimes and near silent operation.

When backdriven the movement is smooth with

minimal backdrive force. Using a hi gh tensile belt

drive and epicyclic reduction gearbox the powerful

electric motor is controlled by an electronic failsafe clutch.

The design is highly efficient and provides high

performance for minim um current consumpt i on.

Supply Voltage 12 volts 12 volts(24V opt i onal ) 12 volt s(24V opt i onal )

Peak Thrust 295Kg(650lb) 480Kg(1050lb) 480Kg(1050lb)

Maximum Stroke Speed 28mm/sec(1.1

Maximum Stroke 300mm(12in) 300mm(12in) 400mm(16in)

Overall length at Mid

Stroke 'A'

Tiller Arm Length 'B'

(+35deg Rudder)

Maximum Rudder Torque 735Nm(6500lb in) 1190Nm(10,500lb in) 1660Nm(14,700lb in)

Power Consumption

(typical average)

Suitable for vessels up to 14m(45ft) LOA 17m(55ft)LOA 18m(60ft)LOA

Maximum displacement 11800Kg(26000lbs) 20000Kg(44000lbs) 25000Kg(55000lbs)

Type 1 Type 2S Type 2L

in/sec)

700mm(27.5in) 700mm(27.5in) 850mm(33.5in)

250mm(10in) 250mm(10in) 350mm(14in)

1.5 - 3 amps 2.75 - 6 amps 2.75 - 6 amps

A tiller arm of adequate strength must be used to

transfer drive from the drive unit to the rudder

shaft. Both Edson and Whitlock Marine provide

suitable standard tillers.

28mm/sec(1.1 in/sec) 28mm/sec(1.1 in/sec

Page 12

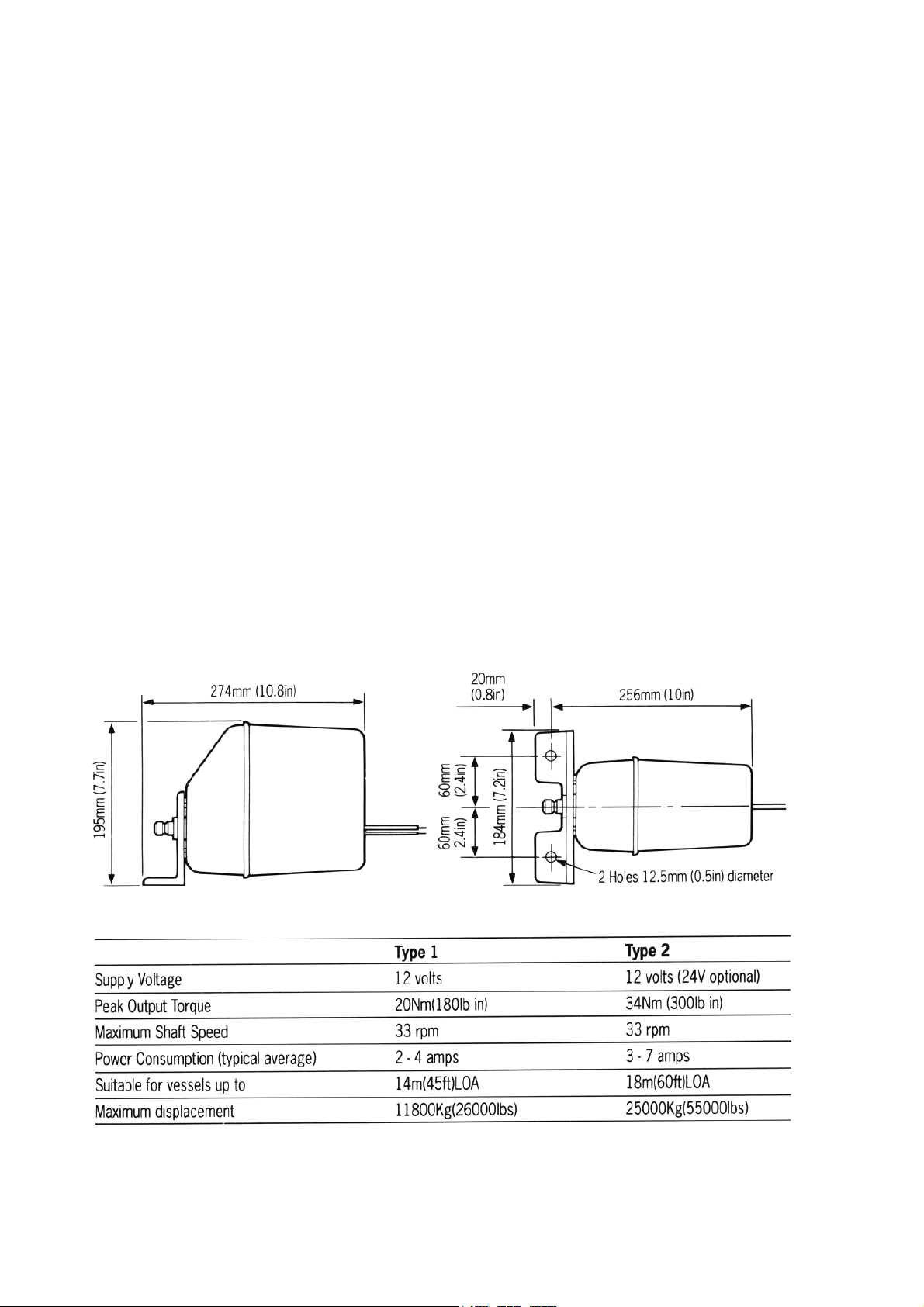

1.2.3 Hydraulic Drive Units

Two reversing hydraulic drive units are available

depending on the size of the vessel and the

displacement of the ram.

The vessel size and displacement

recommendations given below apply to directly

driven steering systems. When a power steering

system is fitted the vessel size and displacement

recommendations can be ignored.

Type 1 and Type 2

The hydraulic drive unit consists of a precision

gear pump with integral check valve block driven

by a continuously rated servo motor. The pump

drive motor is connected directly to the course

computer which also regulates peak pump

pressure.

7

Supply Voltage 12 volts 12 volts (24V optional)

Regulated Peak Pressure 50 bar (750 psi) 55 bar (900 psi)

Flow Control Integral Pilot Check Valve Integral Pilot Check Val ve I ntegral

Peak Flow Rate (unloaded) I 1 00cc/min (67in3/min) 1700cc/min (103in3/min)

Minimum Ram Capacit y 100cc (6in3) 200cc (12in3)

Maximum Ram Capacity 230cc (14in3) 400cc (24in3)

Ram Type Single or Double Ended Single or Double Ended

Power Consumption (typical

average)

Overall Length 'A' 190mm (7.5in) 216mm (8.5in)

Maximum Vessel size 13m (42ft) 18m (60ft)

Maximum Vessel Displacement 118OOKg (26000lbs) 24OOOKg (55000lbs)

Type 1 Type 2

2 - 4 amps 4 - 8 amps

Page 13

8

Page 14

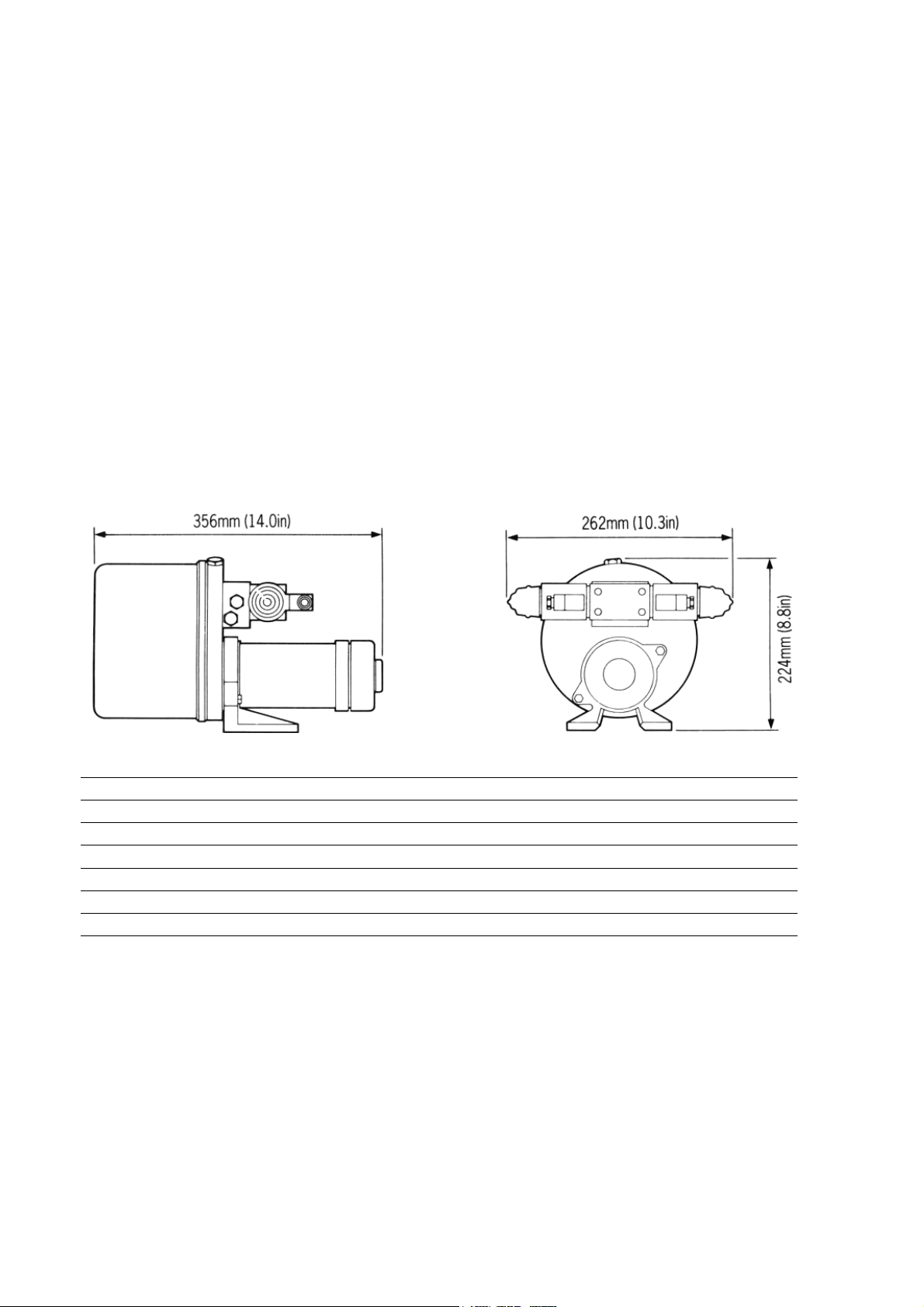

1.2.4 Constant Running Power Pack

When steering loads require a ram capacity

above 400cc (24in3) the Autohelm Constant

Running Power pack provides the ideal autopilot

drive system .

Hydraulic fluid is provided from a self contained

reservoir and flow to the steering ram is controlled

by integral solenoid operated valves.

For the most rugged and demanding steering

applications the Autohelm Constant Running

Power pack is the optimum solution.

Used with a solenoid operated bypass valve and

separate hydraulic ram this system is

recommended for heavy duty applications on

large mechanically steered vessels.

Supply Voltage 12 volts (24V opt i onal ) 12 volts (24V optional )

Regulated Peak Pressure 50 bar (750 psi) 50 bar (750 psi)

Peak Flow Rate (unloaded) 3000cc/min (180in3/min) 4500cc/min (270in3/min)

Minimum Ram Capacit y 400cc (24in3) 750cc (46in3)

Maximum Ram Capacity 750cc (46in3) 1500cc (92in3)

Ram Type Single or Double Ended Single or Double Ended

Type CR1 Type CR2

9

Page 15

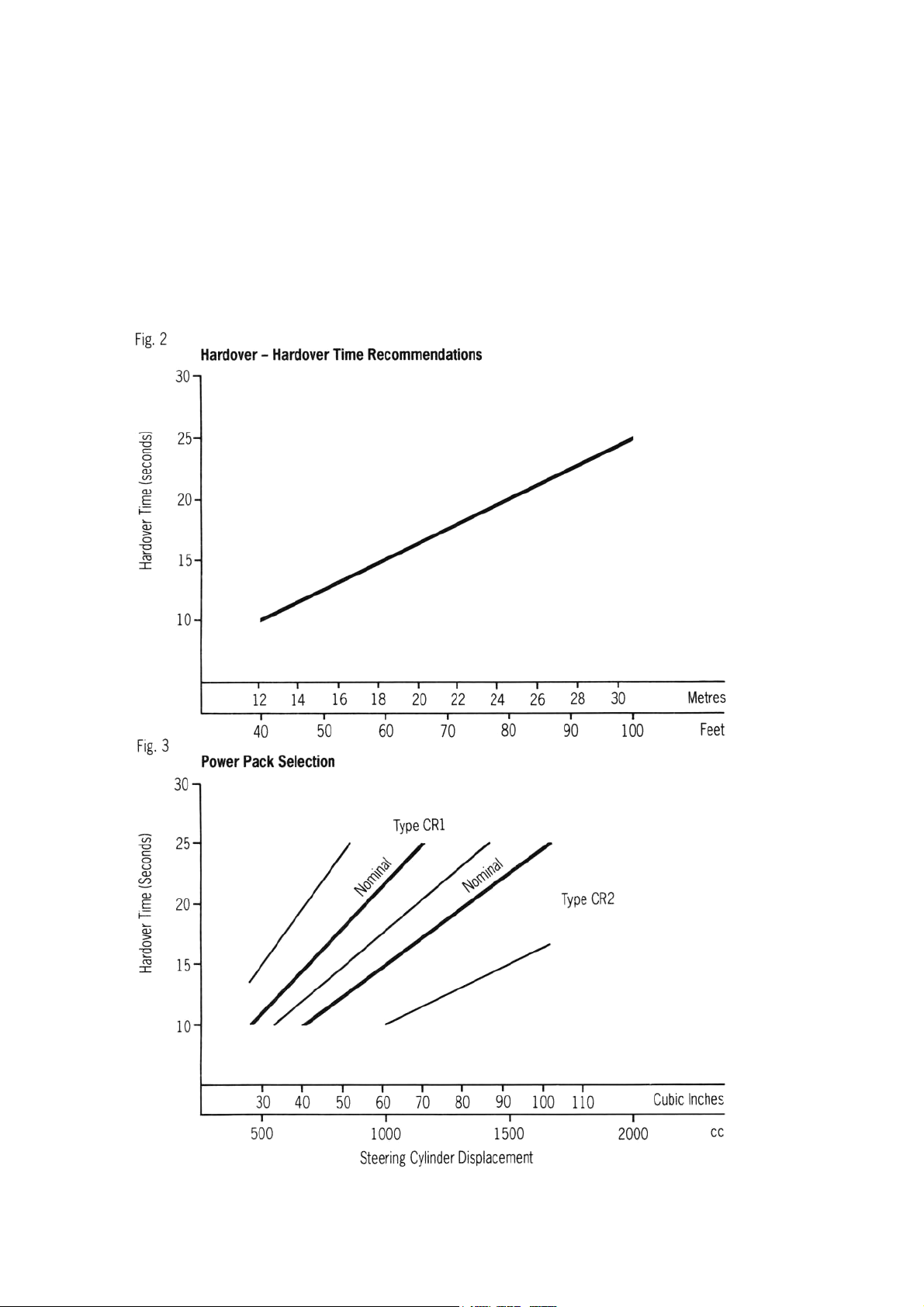

Power Pack Selection (Constant Running)

Hydraulic power pack selection depends on the

vessels overall length and the displacement of the

steering cylinder.

Using figure 2 establish the target hardover time

for your vessel. This is combined with the

steering cylinder displacement in figure 3 to select

the appropriate hydraulic power pack.

Note: If power packs other than the Autohelm

models are used with the ST7000 the following

solenoid specifications must complyPull in Voltage - less than 8V (16v for 24v

systems)

Drop out Voltage - great er t han 2V

Operating Current - less than 5A

The Solenoid Voltage must be the same as the

course computer.

10

Page 16

1.2.5 Sterndrive

The Sterndrive Actuator must only be used on

sterndrives with cable operated power assisted

steering.

The drive unit operates the power steering valve

identically to the steering cable. A clutch

disengages the drive unit to allow manual steering

when the autopilot is di sengaged.

Two installation kits are available to allow

connection to different engine manufacturers

equipment.

Specifications

Description Size

Hardover/Hardover

time (unloaded)

Stroke 190mm(7.5in)

Power

Consumption(Typical

average)

Maximum Thrust 150 Kgf (330lbs)

8.8 secs

1.5 - 3 amps

Cat. No. Manufacturer

D129 V ol vo Penta

D137 Mercruiser/OMC/Yamaha

11

Page 17

2. Installation

2.1.1 Course Computer

Mounting Posit i on - B el ow Deck

The course computer should be positioned in a

dry protected area of the vessel free from high

operating temperatures and excessive vibration. It

can be mounted in any attitude. Care must be

taken to allow at least 150mm (6in) clearance all

round to aid heat dissipation from the power

amplifier in the unit. Do not mount in the engine

room.

Do not position the course computer so that it will:

• Receive any direct water splash/spray (from

Bilge/Hatch et c).

Be liable to physical damage from heavy

•

items.

• Be covered by other

equipment or onboard gear.

Be close to major sources of

•

transmitted energy

(Generators/SSB radios,

Aerial Cables etc).

Mounting Instructions

• Remove Terminal box li d (Fi g. 4).

• Unscrew two internal thumb retaining nuts

(Fig. 4).

• Unplug termi nal box and mounting spine.

• Position terminal box and mounting spine in

correct location, mark off and pilot drill for the

5 self-tapping screws supplied (Fig. 5).

• Screw terminal box and mounting spine into

place.

• Plug course computer unit to terminal box.

Retighten thumb retaining screws.

The course computer is now ready for wiring

(see 2.3).

12

Page 18

2.1.2 Control Unit

The control units must be mounted close to the

steering stations and are designed for above or

below deck installation.

Position them where they are:-

• Reasonably well protected from physical

damage.

• At l east 230m m (9i n) f rom a compass.

• At least 500mm (20in) from radio receiving

equipment.

• Accessible from behind to secure in place and

run cables.

Note: The back cover is designed to breath

through a duct in the cable boss to prevent

moisture accumulation. Direct exposure of the

rear of the control unit t o water must be avoided.

Mounting Procedure (Fig. 6)

The mounting surface must be smooth and flat.

Use the template provided to mark the centres of

the two fixing holes and central boss.

Note: Adjacent instruments should have a 6mm

(1/4in) separation to allow room for the protective

covers.

• Drill to 4mm (5/32in) diameter.

• Use 50mm (2in) diameter cutter to drill the

hole for the central boss 1.

• Screw the two fixing studs 2 into the back

cover.

Pass the cable tails through the central hole and

secure the instrument with the thumb nuts

provided 3. (A sealing gasket 4 is already

attached to the back cover).

2.1.3 Fluxgate Compass

The fluxgate compass may be attached to a

convenient vertical surface using the self tapping

screws provided (Fig. 7).

Correct positioning of the fluxgate is crucial if

ultimate perf orm ance f rom the autopilot inst al l at i on

is to be achieved. The fluxgate should ideally be

positioned as near as possible to the pitch and roll

centre of the vessel in order to gimbal disturbance

(Fig. 8).

13

Page 19

large iron masses, such as the engine and other

magnetic devices which may cause deviation and

reduce the sensitivity of the sensor. If any doubt

exists over magnetic suitability of the chosen site,

the position may be surveyed using a simple hand

bearing compass. The hand bearing compass

should be fixed in the chosen position and the

vessel swung through 360 deg. Relative

differences in reading between the hand bearing

compass and the vessel's main steering compass

should ideally not exceed 10 deg. on any heading.

Installation Precautions

Correct installation of the course computer and

fluxgate compass is vital to the successful

performance of the ST 7000.

2.1.4 Rudder Reference Transducer

The rudder reference unit must be mounted on a

suitable base adjacent to the rudder stock (Fig.9)

using the self tapping screws provided. The base

height must ensure correct vertical alignment of

the rudder reference unit arm and tiller arm. If it is

more convenient, the rudder reference unit may

be mounted upside down (logo downwards), but if

this is done, the red and green wires must be

reversed in the connector unit.

It is very important to ensure that the fluxgate is

positioned at least 0.8m (2ft 6in) away from the

vessel's steering compass in order to avoid

deviation of both compasses. The fluxgate must

also be positioned as far away as possible from

14

The rudder reference unit has a built in spring to

remove any free play in the linkage to the tiller.

This gives very precise rudder position.

Page 20

The rudder reference arm movement is limited to

± 60 deg. Care must be taken during installation

to ensure the rudder reference arm is opposite the

cable entry when the rudder is amidships. Failure

to do this could result in damage if the rudder

reference arm is driven onto its end stops by the

steering system (Fig . 10).

Control Dimensions

It is important to ensure that the dimensions set

out in Fig. 11 are within the limits set and the tiller

arm and rudder reference arm are parallel to each

other.

With the rudder amidships, the rudder reference

arm should be opposite the cable entry and at 90

deg. to the connecting bar. Minor adjustment can

be made by slackening off the 3 securing screws

and rotating the transducer body.

The tiller pin must be positioned within the limits

shown in Fig. 11. Ideally dimension A should be

140mm (5.5in). However, changing this within the

limits shown will not degrade the autopilot

performance but will slightly alter the scaling of the

rudder angle display on the control unit. The tiller

pin is secured to the tiller arm using the self

tapping screws provided,

Cut the studding X (Fig. 11) to length and screw

on the lock nuts Y (Fig. 11) and ball pin sockets.

The sockets can then be pressed onto the pins.

Move the rudder from side to side to ensure the

linkage is free from any obstruction at all rudder

angles.

2.1.5 Auxiliary Alarm

The auxiliary alarm unit is waterproof and may

therefore be mounted in any position. The alarm

unit is supplied with a terminal block to connect a

two core interconnection cable to the course

computer. A 22mm (7m/8in) hole should be bored

through the mounting panel/deck to pass through

the two way connector block and interconnecting

cable (Fig. 12).

Finally, the alarm unit should be screwed into

position using the four self tapping screws

provided. A foam seal on the alarm mounting

flange will ensure a watertight joint to the

mounting surface.

15

Page 21

2.1.6 Masthead Transducer (Sail only)

Installation (Fig. 13)

• With the threaded end of the mounting block I

facing forward, mark the position for the 2 self

tapping screws.

• Drill the holes using the 4.0mm (5/32in) drill bit

supplied.

• Attach the mounting block using sealing

compound.

• Tighten t he l ocking ring 3 very securely.

Cabling

• Cut the cable with sufficient length to route

from the mounting block to the below deck

junction box.

• Feed the cable (30m (100 ft) supplied) down

the mast. If the mast is deck stepped the

cable should be passed through the deck and

sealed using a proprietary gland fitting.

• Connect the cable to the junction box supplied

close to its entry to the vessel to allow mast

unstepping.

• Route the remainder of the cable back to the

course computer connector box and connect

to AUX 1 terminal.

Note: Do not connect the yellow core. This

should be cut back and insulated.

2.2 Drive Systems

2.2.1 Rotary Drive Unit

The rotary drive unit is coupled to the steering

mechanism by a chain drive. Most steering gear

manufacturers supply special autopilot drive

attachments and many include this facility as

standard.

Having selected the position for attachment of the

autopilot drive chain it is necessary to determine

the chain reduction ratio. Count the number of

turns of the steering gears' shaft (this is the driven

sprocket) when the rudder is driven from hardover

to hardover. Use Fig. 14 to determine the

sprocket sizes required.

These reduction ratios will provide good steering

performance for most vessels with approximately

10 second and 14 second Hardover-Hardover

times for the Type I and Type 2 drive units

respectively. If the vessel is thought to have

unusual steering characteristics, Raymarine's

Product Support Department or one of our

authorised representatives should be contacted

for advice.

Standard 3/8" or 1/2" pitch chain is recommended

for the chain drive and the drive sprocket ideally

should not have less than 15 teeth. Bore and

keyway dimensions for the drive unit sprocket are

detailed in Fig. 15. It is essential that these bore

and keyway dimensions are strictly adhered to.

All sprockets must be keyed and grub screwed to

their shaft and fi nal ly secured wit h 'Loct i t e'.

16

Page 22

rotated through 90 deg. to provide a more

convenient mounting position if required (Fig. 17).

In some cases, it may be necessary to fabricate a

special frame to mount the drive unit., It should be

noted that chain tension can exceed 230Kgs

(500lbs) and thus an extremely rigid mounting

structure is vital to maintain good chain alignment.

Installation failures can occur in this area and it is

desirable to 'over engineer' the drive unit

mounting. All fastenings should be secured by

lock washers.

Provision must also be made for chain adjustment

which is most easily achieved by removable

shims placed under the mounting foot or by

elongated clearance holes in the mounting frame

as illustrated in Figs. 16 and 17.

The drive unit is mounted by bolting to a

substantial frame member (Fig. 16). The

mounting foot is secured to the drive unit by four

equally spaced caphead screws and may be

17

Page 23

Both sprockets must be accurately aligned to run

in the same plane and correct alignment must be

carefully checked by means of a straight edge.

The gearbox may be mounted in any convenient

attitude. In addition, the drive sprocket may face

any direction since steering sense can be

corrected when the installation is complete by

reversing the polarity of the drive motor

connection (see section 3.3). Finally, the chain

should be tensioned until it is just tight and

contributes negligible lost motion to the drive

system. Total lost motion between the driven

sprocket attached to the steering system and the

rudder stock should not exceed 2% of total

movement under any circumstances. If lost

motion exceeds this level it must be corrected,

otherwise steering performance will be impaired.

Having completed the drive unit installation, turn

the steering wheel from hardover to hardover and

check that the chain and sprockets driving the

actuator move freely and in alignm ent .

2.2.2 Linear Drive Unit (Fig. 18)

The linear drive unit couples directly to t he

rudder stock at the tiller arm radius given below—

Drive Unit Tiller Radius (B)

Type 1 (Z039) 250mm (10in)

Type 2S (Z058,Z059) 250mm (10in)

Type 2L (Z029, Z032) 360mm (14in)

It is preferable to couple the linear drive unit to the

rudder stock via an independent tiller arm

(Edson and Whitlock offer a standard fitting). In

certain cases, however, it may be possible to

couple the pushrod to the same tiller arm or

rudder quadrant employed by the main steering

linkage. It is important to note that the linear drive

system can exert a thrust of over 50OKgs

(1000lbs). If any doubt exists about the strength

of the existing tiller arm or rudder quadrant the

steering gear manufacturer must be consult ed.

When siting the linear drive unit, the following

points should be noted:-

• The drive unit mounting bracket may be

attached to any horizontal or vertical surface.

If necessary the drive unit may be mounted

upside down.

• The ball end fitting will allow up to 5 deg.

misalignment between the pushrod and tiller

arm plane of rotation. Accurate angular

alignment is extremely important and under

no circumstances should the above limit be

exceeded.

• The drive unit must be at right angles to the

tiller arm when the tiller is amidships (Fig. 18).

18

Page 24

The mounting bracket should be bolted to a

substantial frame number. Always over engineer

to ensure reliability and maintenance of correct

alignment.

Installation

The pushrod ball end must be attached to the tiller

arm using the fixing bolt supplied with its flange

positioned between the ball end and the tiller arm

(Fig. 19). It is vitally important that the lock

washer supplied is used and that the nut is fully

tightened.

The mounting bracket should be attached with

four stainless steel M10 bolts with locknuts or lock

washers.

Having installed the drive unit turn the steering

wheel from hardover to hardover and check that:-

• no part of the drive unit fouls the vessels'

structure.

• the mechanical limit stop on the vessels'

steering system is reached before the

actuator reaches its mechanical limi t .

• angular movement of the ball end fitt i ng i s less

that 5 deg.

2.2.3 Hydraulic Drive Units

General Guide-lines

The hydraulic drive unit should be mounted clear

of spray and the possibility of immersion in water.

It should be located as near as possible to the

hydraulic steering cylinder. It is important to bolt

the hydraulic drive unit securely to a substantial

member to avoid any possibility of vibration that

could damage the inter-connecting p@pework.

There are three basic types of hydraulic steering

system, these are illustrated in Fig. 20. Typical

connection points for the drive unit are shown in

each case. In all cases it is strongly

recommended that the steering gear manuf act urer

be consulted.

Minimisation of hydraulic fluid loss during

connection of the drive unit will help to reduce the

time and effort required later to bleed the system

of trapped air. Absolute cleanliness is essential

since even the smallest particle of foreign matter

could interfere with the correct function of

precision ch eck va lves in the steering system.

19

Page 25

When the installation has been completed the

hydraulic pump may be operated by switching the

control unit to Auto and operating the + 10 deg.

and - 10 deg course change buttons. Greater

motor movements will be obtained if the rudder

gain is set to maximum.

The hydraulic steering system should be bled

according to the manufacturer's instructions. From

time to time during the bleeding process the drive

unit should be run in both directions to clear

trapped air from the pump and interconnecting

pipe work.

If the air is left in the system the steering will feel

spongy particularly when the wheel is rotated to

the hardover position. Trapped air will severely

impair correct operation of the autopilot and the

steering system and mu st be rem o ved.

During the installation of the system it has not

been necessary to keep track of the connection

sense to the hydraulic steering circuit since

operating sense of the autopilot can be corrected

if necessary by reversing the polarity of the pump

drive motor connections.

Type 1 and Type 2 Installation

The pump should be mounted on a suitable

horizontal surface

All ports are tapped 1/4in B.S.P. Three 1/4in

B.S.P. to 1/4in N.P.T. adaptors are included to

convert to N.P.T. where required (Fig. 21). The

sealing washers supplied should be placed

between the fitting and the pump (Fig. 22).

Type CR Installation

The hydraulic power pack (Fig. 23) should be

bolted to a suitable horizontal surf ace. The service

ports are tapped to 1/4in B.S.P. and the reservoir

port is tapped to 3/8 B.S.P. Three N.P.T. adaptors

are included for conversion to N.P.T. where

required.

20

Page 26

Bypass Valve (Cat. No. Z079) (Fi g. 25)

If the autopilot operated hydraulic cylinder is

independent of the manual steering system a

solenoid operated bypass valve should be fitted to

allow the cylinder to backdrive when manual

steering. The bypass v alve should be connected

to the 'bypass' connector on the Type CR

Interface Unit.

The bypass valve Fig. 24 should be fitted between

the autopilot steering cylinder ports and will

normally be de-energised to allow the cylinder to

backdrive. When the autopilot is engaged, the

valve is energised by the Type CR Interface to

allow the autopilot steering cylinder to drive the

rudder. If the steering cylinder is unbalanced

(single ended) the reservoir connection must be

connected to the reservoir

below the oil level (Fig. 25) to enable excess oil to

be returned and made up to the reservoir.

Note

• The bypass valve voltage must be matched to

the course computer supply voltage i.e. 12V

or 24V.

• If the bypass valve is used on systems with a

reversing gear pump (i.e. without the type CR

Interface Unit) a 5 amp relay should be used

to energise the bypass valve. The relay

should have a 12V coil, taking less than

500ma and be driven by the clutch output on

the course computer connector unit.

21

Page 27

2.2.4 Stern Drive Actuator

The drive unit can be fitt ed t o power assisted st ern

drive systems made by Volvo Penta, Mercruiser,

OMC and Yamaha. A different installation kit is

required for each manufacturer

Volvo Penta Installation

(Using D129 Kit, Fig. 26)

The stern drive actuator should be connected to

the centre hole on the tiller arm. On twin engine

installations this is the position used to connect

the engine tie bar to link the two tiller arms.

Installation

• Push the mounting bracket behind the

steering cable sliding the location pins either

side (top and bottom) of the Volvo power

steering block (Fig. 27).

• Ensuring that the bracket clamp is correctly

orientated (larger diameter towards engine)

place the bracket clamp between the valve

block and cable clamp nut and attach with the

four hexagonal bolts supplied. Tighten the

four bolts evenly until the bracket is securely

located (Fig. 27).

22

Page 28

• Uncouple the engine tie bar from the outdrive

tiller arm by bending back the lock tabs and

removing the cotter pin. This should be

replaced with the multi-engine adaptor pin,

ensuring that it is secured properly with a split

pin* (Fig.28) (on single engine installation, fit

the single engine adaptor pin in the vacant

middle hole in the tiller arm).

• Attach the drive unit to the bracket using the

long cotter pin and split pin provided. The

small spring clip can then be used to attach

the drive unit to t he adapt or pi n (Fi g. 28).

• Slowly turn the steering system from hard

over to hard over. It is most important that

the drive unit and the adaptor pin bracket

do not touch any part of the engine or

steering system.

23

Page 29

Mercruiser Installation

(Using DI 37 Kit) (A l so OMC &Yamaha)

The drive unit should be mounted onto the tiller

end block and the pushrod connected to the cable

end sheath via a custom mounting bracket. The

first stage of installation is to fit the custom

bracket:-

Mercruiser Bracket Mounting Kit (D137)

Installation

• Remove locating pin attaching cable rod to

tiller end block and slide the drive unit 'C'

bracket over the end block.

• Secure by pushing the supplied clevis pin

upwards through the drive unit 'C' bracket,

end block and cable rod end.

• Secure the assembly by inserting the split pin

through the drive 'C' bracket (Fig.30).

• With the helm turned hard to port, assemble

the adaptor pin bracket and bracket clamp

onto the cable end sheath using the 2 socket

head bolts provided. This should be

positioned 165mm (6.5in) from the drive unit

'C' bracket clevis pin. Make sure the adaptor

pin bracket points upwards. (See Figs. 30, 31

& 32).

• Position the drive unit pushrod over the top of

the adaptor pin and secure with the spring clip

(Figs. 30 & 32).

Slowly turn the steering system from hard over to

hard over. It is most important that the drive

unit and the adaptor pin bracket do not touch

any part of the engine or steering system.

24

Page 30

Mounting in a Restricted Area

If an obstruction prevents installation of the drive

unit as supplied, the main body can be rotated

relative to the mounting bracket as follows (Fig.

33):

• Remove the 2 fixing screws and gently slide

the cover forwards, ensuring that the four

cables do not pull from the plus inside the

cover.

• Slacken off the lock nut and rotate the main

body as required

• Retighten the lock nut securely and make

sure that the lock nut is no more than one turn

from the start of the thread.

• Replace the cover taking care not to trap any

cables.

Using the steering wheel move from hard over to

hard over and check that no part of the drive unit

touches any part of the vessel/fit tings.

Cable Connection

• Plug in the power cable supplied with the

drive unit making sure that the connector is

locked in place by turning the locking ring

clockwise.

• Route the cable back to the course computer.

Secure the cable close to the drive unit but

allowing sufficient free length to accommodate

the drive unit movement.

• Once again using the steering wheel to -move

the rudder from hard over to hard over and

check that the cable does not catch on any

part of the vessel/fi t tings.

25

Page 31

2.3 Cabling and Power Supplies

2.3.1 Signal Cabling System Components

Cable connections for all components are shown

schematically in Fig. 1. All components, other than

the Actuator motor, connect to the course

computer connector unit where they are

permanently wired to connector blocks mounted

on a central printed circuit board (Fig. 34).The 6m

(20ft) cable with the 3 pin connector at one end is

used to connect the first control unit to the course

computer. Additional units are connected using

SeaTalk cable either to the first control unit (see

2.3.2) or to the second SeaTalk connector block

(BUS 2) on the connector unit .

26

Page 32

Where additional cables have to be brought into

the connector unit, the blanking discs (Fig. 35)

should be pressed out and replaced with the

rubber grommets supplied.

After cutting the interconnecting cable to length

(Fig. 36), it may be passed through the inserted

rubber grommet and prepared for connection to

the relevant connector block (Fig. 34).

Each connector block is clearly identified on the

printed circuit board and each wire position is

identified by coloured dots which match the

individual wire colours. The cable screen should

be connected to terminals identified by a white

dot.

Each peripheral unit is supplied with 6m (20ft) of

interconnecting cable. Additional cabling can be

supplied in 12m (40ft) cut l engt hs as f oll ows: Cat. No. Used On

D086 Alarm and Clutch

(Two core unscreened)

M083 (Complete reel) Fluxgate Compass

D088

(Four core screened)

M085 (complete reel)

The total length of interconnecting cable to the

fluxgate should not exceed 20m (60ft). If it is

necessary to exceed the above maximum length

recommendation, please consult Raymarine's

Product Support Department for specific advice.

In general the length of interconnecting cables

should be kept to an absolute minimum to reduce

the possibility of interference by other electronic

equipment.

All cables should be run at least 1 m (3ft) from

existing cables carrying radio frequency or pulsed

signals, and should be clamped at 0.5m (1.5ft)

intervals.

2.3.2 Connection to other SeaTalk Units

All Autopilot Control Units and SeaTalk

instruments receive both power and information

from the SeaTalk bus (Fig. 37). Each instrument

has two SeaTalk connectors (3 pin) on short 1

50mm (6in) tails to allow adjacent units to simply

plug together.

Separated units are connected using the SeaTalk

Extension cable (Cat. No D131). This is supplied

with a SeaTalk connector fitted to each end and

with a junction box to rejoin the cable if it is cut to

ease routing or for shortening.

27

Page 33

If preferred, any 2 core screen cable which has

the following specification may be used in the

place of the SeaTalk cable.

Screen 0.5mm2

2 Cores 0.5mm2

28

Minimum Copper Area

2.3.4 D.C. Power Supplies and Drive

Unit connections.

The ST7000 requires two D.C. power supplies,

one, a heavy duty supply (which connects via

spade connectors to the end of the course

computer) and secondly a light duty supply (which

connects into the course computer connector

box). Flexible connection tails fitted with insulated

spade connectors are supplied with the course

computer to connect the heavy duty power supply

(Blue and Brown) and drive unit motor

connections (Red and Black).

All four flexible wire tails are pre-connected to a

four-way heavy duty terminal block for Connection

to the main power cabling. Similarly, the drive unit

is supplied with flexible tails for the motor power

connection (Red and Black).

Before commencing power cabling, all

interconnecting terminal block should be screwed

into a position where they will remain dry and

protected. When planning the position of me

course computer (ref.2.1.1), it is important to

reduce the overall length of heavy power cable

between the drive unit and the vessel's central

power distribution panel t o a m i ni m um .

Excessive lengths will generate losses in the

cable and will reduce system performance. In

addition, the cable length between the course

computer and drive unit must be less than 5m (I

6ft).

Having sited the course computer, measure the

total cable length between the drive unit and the

vessel's central distribution panel and select the

appropriate cable size from the table below

depending on the drive unit used.

Type 1 Drive Units

Total

Cable

Length

Up to 7m 50/0.25 2.5mm2 14 AWG

Up to 10M 56/0.3 4.0mm2 12 AWG

Up to 16m 84/0.3 6.0mm2 10 AWG

Cable

Type

Copper

Area

Cable

Gauge

Page 34

Type 2 Drive Units

Total

Cable

Cable

Type

Copper

Area

Cable

Gauge

Length

Up to 7m 56/0.3 4.0mm2 12 AWG

Up to 10m 84/0.3 6.0mm2 10 AWG

Up to 16m 84/0.4 10.0mm2 7 AWG

The two power supplies must be led separately

from the main distribution panel and protected by

circuit breaker as shown in Fig.39. A separate 5

amp fuse must be fitted in the electronic power

supply cable.

When connecting the power supplies to the main

distribution panel and to the course computer

spade connectors, it is essential that the polarit y is

correct (Brown positive, Blue negative) for the

autopilot to operat e.

Electronic Power Supply

Total

Cable

Cable

Type

Copper

Area

Cable

Gauge

Length

Up to 7m 32/0.2 1.0mm2 18 AWG

Up to 10m 30/0.25 1.5mm2 16 AWG

29

Page 35

2.3.5 Type CR Installations (Fig.40)

The Type CR Interface (Cat. No Z085) must be

used on all installations with constant running

hydraulic power packs. The power supply is led to

the course computer using the Interface Unit

which has connections for the power pack

solenoid valves, and the bypass valve if one is

required.

The Type CR Interface Unit may also be

connected to alternative constant running

hydraulic powe r p acks p ro vi d i n g:-

• The solenoid coils require less than 10 amps

•

The response time of the solenoid valve is less

than 80 milliseconds.

The operating voltage of the solenoid coils is the

•

same as the course computer supply

It is important to minimise the overall cable length

between the solenoid valves and the vessel's

power distribution panel.

Having sited the course computer use the

following table to select the appropriate cable.

Course Computer Power Supply

Cable Length,

Power Supply

to Course

Computer

Up to 7m 50/0.25 2.5mm2 12 AWG

Up to 10m 56/0.3 4.0mm2 10 AWG

The supply cable must be protected by a fuse or

current overload trip switch as shown in Fig.40.

Cable

Type

Copper

Area

Cable

Gauge

30

Page 36

Solenoid Valve Power Supply

Cable Length,

Course

computer to

Power Pack

Up to 7m 50/0.25 2.5mm2 12 AWG

Up to 12m 56/0.3 4.0mm2 10 AWG

Up to 17m 84/0.3 6.0mm2 8 AWG

The solenoid valve connectors can only accept

cable up to 2.5mm2 copper area. If larger cable is

required a 0.5m tail of 2.5mm2 cable should be

used to wire to the connectors.

Hydraulic Power Pack Motor

The power supply to the motor of the constant

running hydraulic power pack should be

connected to the vessel's central distribution

panel using cable selected from the following

table.

Cable

Length

Up to 5m 84/0.3 6mm2 8 AWG

Up to 8m 84/0.4 10mm2 7 AWG

Cable

Type

Cable

Type

Copper

Area

Copper

Area

Cable

Gauge

Cable

Gauge

An isolator switch and circuit breaker (Fig 40)

should be installed to supply power to the

complete system. The lighter power supply leads

for the electronic power supply and solenoid drive

amplifier should be independently fused (see Fig.

40).

2.3.6 Sterndrive Installations

The stern drive actuator is supplied with 6m (20ft)

of 4 core cable.

The blue and brown cores are fitted with spade

connectors (Fig. 41) and should be connected to

'motor 1' and 'motor 2' course computer spade

connectors. The remaining two cores (red and

black) drive the actuator clutch and should be

connected into the connector box.

31

Page 37

3. Functional Test

The following functional test and set up

procedures must be carried out before sea trials

are attempted.

3.1 Switch on

Switch on the electrical supply from the main

panel. All control units will emit a short beep tone

and display 'ST7000'. Within 2 seconds Standby

will be dis pla y ed to in dic a te the c o mpu ter is a c tive

and the autopilot is in Standby mode.

3.2 Rudder Angle Sense

Moving the wheel to produce a turn to starboard

should move the rudder angle display to the ri ght :-

If the display moves in the opposite direction the

red and green wires of the rudder reference

transducer should be reversed.

3.3 Mechanical Test (Manual Steering)

The steering system and drive unit/rudder

reference unit should be carefully inspected and

the following points checked using the steering

wheel to drive the vessel's steering from hardover

to hardover.

• The steering system reaches the Rudder End

Stops before the Drive Actuator reaches its

end stops (Linear/Stern Dri ve).

• No part of the Autopilot Drive System fouls

any part of the steering system or vessel's

structure through full t ravel (al l dri ves),

• The mechanical alignment of the drive unit is

as specified in this manual (Linear/Stern

Drive).

• The mechanical alignment of the Rudder

Reference Unit is as specified in this manual

(all drives).

32

• All connecting wires are secured clear of the

bilge and cannot foul any part of the steering

system. Any connectors are tightly secured

(all drives).

• All securing bolts are fully tightened and

mechanical locking arrangements as

specified are in place (all drives).

3.4 Rudder Angle Alignment

With the rudder amidships, check that the rudder

angle display reads zero. Any misalignment must

be removed by rotating the rudder reference

transducer within the slots in the body.

3.5 Operating Sense

The operating sense of the autopilot can be

checked as follows:-

• Push Auto.

• Push + 10 which should move the rudder a

few degrees to produce a turn to starboard. If

the rudder moves hardover to port the motor

connections between the course computer

and drive unit should be reversed.

3.6 Rudder Deadband

The factory preset rudder deadband level (see 4-

1) will provide stable rudder positioning on most

steering systems. On some steering systems

where a rotary or hydraulic drive unit is sited a

long way from the rudder, slight instability may

occur. This can be removed by increasing the

'damping' level (see 4.3). Any increase should be

minimised as it will reduce the autopilots course

keeping accuracy.

3.7 Mechanical Test (Autopilot Steeri ng)

Rotary/Linear/Hydraulic Drives

Warning: When the steering system is being

moved manually or under drive from the autopilot

do not touch any part of the system. The forces

exerted are considerable and could cause injury.

• Push Auto.

• Push the + 10 button repeatedly to drive the

rudder hardover onto end stops (Note: May

require increasing the rudder limit (see 4.3)).

• Ensure the drive unit mounting shows no sign

of movement.

Page 38

• For hydraulic systems ensure there is no

seepage of hydraulic fluid and that the

steering ram moves smoothly.

• Repeat using the - 10 button to drive the

rudder hardover to the opposite end stop.

Current Limit and Cutout

When the rudder is driven onto end stops drive

will be cut out after a few seconds. This is normal.

Drive will only be restored if the rudder moves

away from the end stop or if drive is required in

the opposite direction.

3.8 Mechani cal Test - S tern Drive (Autopilot

Steering)

It is recommended that the 'Auto Release' facility

is used when the Autohelm mechanical stern drive

actuator is installed. This is selected and tested as

follows:

• Select 'Auto Release' in calibration mode (see

4.3)

• Select 'Auto Release '1’ (ON).

• Exit calibration mode. Manually drive the

steering hardover to starboard.

• With the vessel's engines running engage

Auto and with repeated presses of the - 10

button drive the steering to the opposite lock

(Port).

• The autopilot should drive the steering onto

the end stops, sound an alarm whilst

displaying the Release message and then

revert to Standby.

• Re-engage the autopilot (Auto) and repeat the

above driving the steering hard to starboard

using the + 10 button.

• The autopilot should again drive onto the

endstop, alarm/display Release and return to

standby.

Note: If the ST7000 sounds the alarm and

displays 'Release' before reaching the opposite

lock carefully check the vessel's steering system

for any stiffness or mechanical jam m i ng.

If the condition persists set the 'Auto Release'

function to "off" and contact the Product Support

Department at Raymari ne f o r f urther advice.

Warning

• The 'Auto Release' function should always be

set to "off" if using any drive unit other than a

stern drive actuator.

• Auto Rel ease is not avail abl e in dri ve level 4.

3.9 Rudder Angle Limit (All Drive Units)

Having checked the correct functioning of the

drive unit and the appropriate End Stop

Cutout/Auto Release function the programmable

rudder angle unit should be set.

The rudder angle limit sets the maximum angle to

which the autopilot will move the rudder. This

should be set to just less than the vessel's

mechanical limit stop to avoid putting the steering

system under unnecessary load.

Using the rudder angle display record maximum

rudder angle in both directions and set up the

rudder angle limit in calibration mode (see 4.3) to

5 degrees less than the minimum angle recorded.

33

Page 39

4. Calibration

4.1 Recommended Settings

As supplied the ST7000 can be switched on and

tested safely without any adjustments to the

factory calibration settings.

The table below lists the suggested settings for

sailing and power displacement and planing

power vessels. These will provide good

performance for initial sea trials can be fine-tuned

later to optim i se perf orm ance.

Vessel Type

Rudder

Gain(level)

Rate Gain(level) 2 1

Rudder Angle

Limit (degrees) 30 30

Turn Rate Limit

(degrees/sec)

Cruise

Speed(knots)

Off Course Alarm

(degrees)

Trim Level 1 1

Auto Adapt off On

Drive Type 3 3 4

Rudder

Position

Deadband

(level) See

3.8

Auto

Release

Displacement Planing

Factory preset Set to

5 2

20 5

8 25

20 20

Autopilot Drive Unit Type

Mechanical

Drive

Factory Set to Set to

preset

1 1 1

off on off

Stern

Drive

Hydraulic

Drive

4.2 Selecting and Exiting from Calibration

Mode

To select calibration mode:-

• Push Standby

• Push and hold down for 2 seconds, Track and

• Repeat push and hold down for 2 seconds,

To exit calibration mode at any point.

a) Saving any changes made:

• Push and hold down for 2 seconds, Track

b) ignoring any changes made: Push Standby.

Display together.

Track and Display together to enter

calibration mode.

and Display together.

34

Page 40

4.3 Adjusting Calibration

In calibration mode, the display button is used to

scroll through the menu. The displayed value is

adjusted using the Response buttons (hold button

down for fast scroll).

• Rudder Angle Limit, 15 to 40 deg. (see 3.4).

• Rate of Turn Limit, 5 to 20 deg./sec

• Rudder Gain, le vels 1 t o 9 (see 5. 5 & 5.6)

• Rate Gain, levels 1 to 9 (see 5.8) (Counter

Rudder)

• Cruise Speed, for Track mode operation, 4 to

60 knots

35

Page 41

• Off-Course A larm , 15 to 40 deg. Angle

• Autom atic Trim (see 5.4).

• Manual Steering Lever Type

• Autopilot Drive Unit Type

• Remote Control Identif i er (For Future Use)

36

• Rudder Position Deadband (levels 1 to 9),

(See 3.6)

Page 42

• Northerly/Southerly Heading Instability

• Auto Rel ease (see 3.8 & 5.7)

Select Hemisphere

0 (OFF)

N (North)

S (South)

Enter Local Latit ude using Response Keys.

A typical display in the Northern Hemisphere

would be:

and in the Southern Hemi sphere

OFF

1 = ON

The Auto Release facility is designed to provide

Emergency Manual Override when used with the

Autohelm Stern Drive Actuator.

For all other Drive Systems Auto Release must be

selected "O F F".

4.4 Display Contrast Adjustment

The LCD Contrast can be adjusted to suit a wide

range of control unit viewing angl es.

• Push display and track toget her m om ent ari l y.

• Push response ▲ to increase contrast (suits

viewing from below).

• Push response ▼ to decrease contrast (suits

viewing from above).

Adjust the display fo r opt i m um viewi ng.

• Push display and track together momentarily

to store selection and return to previous

operating mode.

37

Page 43

If the 'CAL' display reappears at any stage during

calibration mode please press Display to advance

to the next menu level

4.5 Permanent Watch Alarm (SFIA)

If the permanent watch alarm is required, please

contact Raymarine's Product Support Department

or authorised dealer for detail s.

4.6 Recording Calibration Settings

Having fine-tuned the calibration settings during

initial sea tria ls, recor d them in the following tab le

for future reference.

Rudder Gain 6 0.55

Rate Gain 7 0. 67

Rudder Limit 8 0.82

Turn Limit 9 1.0

Cruise Speed

Off Course

Automatic Trim

Manual Type

Drive

Damping

Auto Adapt

Auto Release

Once calibration has been carried out, further

adjustment can be made at any ti me.

38

Setting

4.7 Rudder and Rate Gain Tables

• Rudder Gain

Level Value

1 0.1

2 0.14

3 0.19

4 0.25

5 0.35

6 0.47

7 0.65

8 0.88

9 1.2

• Rate Gain (Seconds)

Level Value

1 0.2

2 0.24

3 0.3

4 0.37

5 0.45

Page 44

5. Initial Sea Trials

Initial sea trials should be carried out in calm

conditions with plenty of sea room. As the vessel

will be constantly changing heading it is very

important to m ain t ai n a constant l ook out .

Before sea trials:-

• Carry out the functional test (section 3) to verify

that the autopilot is operating correctly and

that you are familiar with all of its controls.

• If a planing vessel, check that the rudder gain

is set to 2 and turn rate limit to 5 degrees as

recommended in section 4.1. The lower turn

rate limit is very important for safety at planing

speeds where large course changes can

otherwise produce violent turns.

• If the system has a hydraulic drive unit set up

the drive type to 4 (see 4.1).

• Read the Operati ng M anual .

5.1 Automatic Deviation Correction

The ST7000 will correct the fluxgate compass for

any deviating magnetic fields. This should be

carried out in calm conditions preferably in flat

water.

• To select compass adjust Push and hold

Standby for 1 second.

• Keeping boat speed below 2 knots, turn the

vessel slowly so that it takes at least 3

minutes to complete 360 deg. Keep turning

until the display changes to show the amount

of deviation the aut opi lot has corrected:-

Note: If the amount exceeds 15 deg., it is

recommended the fluxgate should be re-sit ed.

• Use the course change buttons to adjust the

displayed heading until it agrees with the

steering compass or a known transit bearing.

Note: 000˚ is alwa ys follow ed by off. Th is will

suppress the display of compass and

automatic headings on the control unit.

• To exit compass adjust and store the

compass settings push and hold Standby for

1 second.

• To exit compass adjust without saving any

new settings push Standby momentarily.

5.2 First Sea Trials

• Hold the course steady for 5 to 10 seconds.

• Press Auto t o l ock onto the current heading.

• In calm conditions a perfectly constant

heading will be maintained.

• Alter course to port and starboard in multiple

increments of 1 and 10 degrees from any

control unit. Course changes should be

prompt and without any sign of overshooti ng.

• Press Standby to disengage the autopilot for

return to hand steering.

5.3 Response Control

There are three response levels to provide tighter

than normal course keeping when restricted sea

room requires. Select each level in turn and

observe the autopilot activit y.

Level 1 - Automatic Sea State Control This

provides the optimum compromise between

power consumption and course keeping accuracy

and is suitable for most sit uations.

The automatic sea state control can be observed

during the sea trial.

When the autopilot is initially engaged in Auto

mode the autopilot will respond to all pitch and roll

movements.

During the first minute of operation, it will be

noticed that repetitive movements of the vessel

are gradually neglected until finally the autopilot

will respond only to true variations in course.

39

Page 45

To ensure precise course adjustments the sea

state control is automatically reset whenever a 10

deg. course change is selected.

Level 2 - Automati c S ea S tate Inhibit

Where increased course keeping accuracy is

required the automatic sea state control can be

inhibited by moving to response level 2.

Autopilot activity and therefore power

consumption will be increased.

Level 3 - Automati c S ea S tate Inhibit

- Counter Rudder

Where maximum course keeping accuracy is

required move to response level 3. This

introduces counter rudder (rate) to increase @e

natural damping of the vessel. On power craft

level 3 is useful at slow speed where the natural

damping of the vessel is reduced. Autopilot

activity and therefore power consumption will be

at a maximum.

The minimum response level necessary to

achieve the desired course keeping should be

used to reduce power consumption and autopilot

wear and tear.

5.4 Automatic Trim Control

The ST7000 automatically corrects for trim. No

adjustment of t he pil ot is necessary.

After each course change the Automatic Trim is

cancelled and the ST7000 will re-establish the

correct trim for the new heading. It should be

noted that if a large course change is keyed in

(greater than 60 deg.) the autopilot will not

assume the final selected course immediately.

The vessel will come to within say 10 deg. of the

desired course and will only settle onto course

when the Automatic Trim has been full

established. This may take up to two mi nut es.

It is recommended the following procedure is

adopted for large course changes.

• Note required new headi ng.

• Select Stand by and steer manually.

• Bring vessel onto new heading.

• Select Auto and let vessel sett le onto course.

• Bring to final course with 1 deg. course

change increments.

40

It is sound seamanship to make major course

changes only whilst steering manually. In this way

any obstructions or other vessels may be cleared

properly and due account taken of the changed

wind and sea conditions on the new heading prior

to engaging the autopilot.

Important Note

If the automatic trim control is switched off (see

section 4.3), regular checks on the vessels

heading should be made as changes in standing

helm will change the course steered by the

autopilot.

5.5 Rudder Gain Adjustment

(Displacement Craft)

The rudder gain level recommended in Section

4.1 will provide stable control for initial se a trials.

However, vessels can vary widely in their

response to the helm, and further adjustment to

the rudder gain may improve the autopilots

steering characteristics. Setting up rudder gain

should be carried out with Response level 1.

An excessively high rudder control setting results

in oversteer which can be recognised by the

vessel swinging from side to side of the automatic

heading accompanied by excessive rudder

movement. In addition, distinct overshoot will be

observed when the course is changed. This

condition can be correc ted by reducing the rudder

setting.

Similarly, an insufficient rudder control setting

results in understeer which gives sluggish

steering performance and is particularly apparent

when changing course. This is corrected by

increasing the rudder setting. These tendencies

are most easily recognised in calm sea conditions

where wave action does not mask basic steering

performance. The rudder control setting is not

over critical and should be set to the lowest set t i ng

consistent with accurate course keeping. This will

minimise actuator movements and hence reduce

power consumption and wear and tear generally.

Typically if at cruising speed a course change of

40 deg. results in an overshoot of between 2 and

5 deg., the rudder gain is correctly adjust ed.

Page 46

5.6 Rudder Gain Adjustment

(High Speed Planing Craf t )

It is particularly important that the Rudder Gain is

correctly set on high speed craft. Incorrect

adjustment will lead to poor steering performance

and is a dangerous condition at high speed.

Adjust as follows:

Optimum Setting

• Set to Rudder Gain for optimum steering

performance at the vessels normal cruising

speed.

• Push and hold down both Response keys

together for 1 second to gain access to

Rudder Gain, Adjust either side of the

calibrated setting to provide optimum autopilot

steering.

Auto Adapt

It is recommended that for high speed craft the

Auto Adapt facility is selected. This a utomatically

reduces the effects of Northerly/Southerly heading

instability.

This feature is selected in calibration by entering

the vessel's operating latitude (see 4.3). When

selected it automatically adjusts the Rudder Gain

depending on heading removing the need for

manual adjustment.

Warning: If Auto Adapt is not selected manual

adjustment of rudder gain is normally required

when going from Northerly to Southerly headings

or vice versa. Failure to do so can lead to poor

course keeping.

Adjustment with Speed

• Due to the significant differences in dynamic

stability between planing and non-planing

conditions most high speed craft require

Rudder Gain adjustment when going from

planing to displacement speeds or vice versa.

The required adjustment can be achieved

automatically or manuall y.

• When the ST7000 is used with the speed

input from an Autohelm ST50 SPEED or

TRIDATA instrument the Rudder Gain is

automatically adjusted with boat speed. After

setting the gain at planing speed no further

manual adjustment should be required.

• If no ST50 speed input is available manual

adjustment should be carried out to the

Rudder Gain setting via the Response keys

(see 'optimum setti ng') adj usti ng as f ol l ows:

• Speed decreases from planing to

displacement

- increase gain by 1 or 2 levels.

• Speed increases from displacement to

planing

- decrease gain by 1 or 2 levels.

Warning: The manual gain adjustment must be

made after reduc ing from planing to displacement

speed and before increasing from displacement

to planing speed.

5.7 Manual Override

(Sterndrive Actuat ors only)

Manual override is selected during calibration

using the Auto Release option. It must only be

used on installations fitted with the stern drive

actuator. When it has been selected, the ST7000

can be overridden to allow hand steering by

turning the steering wheel. This will return the

ST7000 to Standby and sound the control unit

buzzer for 10 seconds. There is a slight delay

before the ST7000 will return to Standby.

Excessive force is not required and will not

reduce this delay.

With the ST7000 in Auto and clear of obstruction

turn the steering wheel to observe the manual

override. Repeat two or three times until you are

confident with its operation.

The manual override is intended for

emergency use only. The ST7000 should

normally be disengaged by pushing the

Standby button on the control unit.

5.8 Rate Gain Adjustment

(Counter Rudder)

Counter rudder increases the natural yaw

damping of the vessel and at the expense of

increased autopilot activity, will generally provide

improved course keeping accuracy.

41

Page 47

5.9 Compass Alignment

If it is necessary to change Compass Alignment

without carrying out the Automatic Deviation

Correction proceed as follows:-

• Push and hold Standby for 1 second to

select compass adjust mode.

• Push Display once to bypass Automatic

Deviation Correction

• Use the course change buttons to adjust the

heading displayed

• To exit compass adjust and store the new

setting push and hold Standby for 1 second

• To exit compass adjust without saving the

new setting push Standby momentarily

• To confirm the alignment procedure has been

correctly carried out, switch off power, switch

back on and check displayed heading.

Repeat the alignment procedure if incorrect.

42

Page 48

6. Track Control

Track control allows the ST7000 to maintain track

between two waypoints entered on a GPS, Decca,

Loran or satellite Navigation System. The

Navigation System must have a suitable autopilot

output which at minimum transmits cross track

error to one of the following formats.

NMEA 0180 – Simple Format

NMEA 0183 – XTE

XTR

APA

APB

RMB

If the navigation system transmits the correct

NMEA 0183 sentences (shown below), the

autopilot will receive and display bearing to

waypoint, distance to waypoint and waypoint

number.

NMEA 0183 Sentence Headers

Bearing to

Waypoint

APB WDR APB

BPI WDC APA

BWR BPI BPI

BWC BWR BWR

BER BWC WDR

BEC BER BWC

RMB BEC WDC

RMB RMB

BOD

WCV

BER

BEC

Distance to

Waypoint

Waypoint

Number

6.1 Functional Test

Before attempting sea trials confirm that the

control unit is receiving navigation data by using

the Display to bring it up on t he cont rol uni t LCD.

Note: If the data is not being received it is

impossible to sel e ct Track Mode.

6.2 Operating Hints

Basic Principles

The control unit accepts cross track error data

from the Navigation System and computes course

changes to maintain the desired track. It is

primarily designed to keep a vessel on track,

automatically compensating for tidal streams and

leeway.

To obtain best performance in the track following

mode the track should be manually acquired by

steering the vessel to within 0.1nm of track and

then bringing the heading to within 5 deg. Of the

bearing to the next waypoint before pressing the

Track button.

Under most conditions the Track control will hold

the track to withi n 0. 05nm (300ft) or better.

The autopilot takes account of vessel speed when

computing course changes to ensure optimum

performance over a wide range of vessel speeds.

If an Autohelm ST50 Speed or Tridata instrument

is connected to control unit will use measured

speed, otherwise the cruise speed entered during

calibration will be used.

43

Page 49

Waypoint Advance

If your navigation receiver transmits valid

waypoint number and bearing to waypoint NMEA

headers (see table) it is possible to advance from

one waypoint to the next by simply pressing the

Track button.

As the vessel passes the target waypoint the

navigation receiver should select, manually or

automatically, the next target waypoint. The

ST7000 will detect and display the bearing to the

new waypoint whilst sounding an alarm to indicate

waypoint arrival.

Note: While the waypoint advance alarm is

sounding, track control is stopped and the ST7000

will maintain the current heading,

Once it is considered safe to turn onto the new

track press the Track button once. This will cancel

the waypoint arrival alarm and steer the boat

towards the next waypoint.

Limitations

Although there is no need to fully understand the

details of the track keeping algorithm, it is very

important to understand its limitat i ons to obt ai n t he

best performance from the Track control. The

most significant of these limitations is imposed if

NMEA 0180 cross track error data is transmitted

by the Radio Navigation Receiver. This data is

restricted to +0.30nm, which means that even if

the vessel were 5 miles to starboard of track, the

transmitted data would still be 0.30nm,

Attempts to engage Track control beyond the

0.30nm limit will lead to excessive overs hoots and

can result in the vessel circling. For this reason

the alarm code is displayed (see operating

handbook) whenever the cross track error

exceeds 0.30nm The requirement to remain within

0.30nm of track also limits the maximum allowable

angular error between the track course and the

vessel's heading. If the angular error is too great,

the Track control will be unable to cancel it within

the 0.30nm limit leading to the problems outlined

above.

The NMEA 0183 format transmits cross track

error data up to 9.99nm and enables the Track

control to operate with larger cross track errors.

However, the alarm code will still be

44

displayed in case there are navigational hazards

close to the intended track.

Low Speed Operation

Operating the 'rack control at low speeds requires

more care as the effect of t i dal st ream s is f ar m ore

significant than at higher speeds. In general

terms, providing the tidal flow is less than 35% of

the vessel speed no noticeable difference will

occur, in the performance of the Track control.

However, extra care should be taken to ensure

that the vessel is as close as possible to track,

and that the direction made good over the ground

is as close as possible to the direction of the next

waypoint before engaging Track control. Under

these circumstances positive positional checks at

regular intervals are vital especially if navigational

hazards are close.

Dodges

Full control remains available from all control units

when the autopilot is in Track control. Dodges are

accomplished by simply selecting the desired

course change on the Autohelm keypad. Once the

hazard has been avoided the course change

selected for the dodge manoeuvre should be

cancelled by selecting an equal course change in

the opposite direction. Provided the vessel

remains within 0.1nm of track there is no need to

steer back t owa rd s the track.

Safety

Passage making in Track control removes the

chores of compensation for wind and ti dal drift and

will aid precise navigation. It is most important

however to maintain an accurate log with regular

plots and to verify the computed position read

from the Radio Navigation Receiver with a dead

reckoned position from recording the average

course steered and the distance logged. In open

water such plots should be at least hourly and

more frequent in confined waters or when

potential hazards are near.

Local variations in radio signal quality and

changes in the tidal stream will produce deviations

from the desired track. When setti ng

Page 50

up waypoints, remember that deviations will

occur, and thoroughly check along each track and

to 0.5nm each side to ensure that there are no

hazards within the zone. Always confirm the

position given by the Radio Navigation Receiver

using an easily identifiable fixed object at the start

of a passage to check and enable compensation

to be made for fixed positional errors.

The use of Radio Navigation control will enable

accurate track keeping even in complex

navigational situations. It cannot remove the

responsibility of the skipper to ensure the safety of

his vessel at all times by careful navigation and

frequent positi on checks.

7. Windvane Control (Sail Only)

Windvane Control allows the ST7000 to maintain

an apparent wind angle, There are two methods of

supplying the ST7000 with wi nd angl e:-

• Using the NMEA 0183 output from another

manufacturers instrument system and

connecting it to the S T 7000 control uni t .

Note. The NMEA 0183 output must transmit VWR

(Relative wind bearing).

• Using an Autohelm ST50 wind instrument

connected using the SeaTalk bus.

The ST7000 uses Wind Trim to eliminate the

effects of turbulence and short term wind

variations and provide smooth precise

performance under windvane with minimum

power consumption. Wind Trim uses the fluxgate

compass as the primary heading reference, and

as changes in the apparent wind angle occur the

compass heading is adjusted to maintain the

original apparent wind angle.

Operating Hints

Wind Trim adjusts the compass course over a

minute period, providing optimum response for

offshore conditions where genuine shifts in wind

direction occur gradually. In gusty and unsteady

inshore conditions it is best to sail a few degrees

further off the wind so that changes in apparent

wind direction can be tolerated.

It is also important to ensure that the amount of

standing helm is minimised by careful sail trim and

positioning of the m ai nsheet traveller.

It is recommended that the headsail and mainsail

are reefed a littl e early rat her than too late.

45

Page 51

46

Page 52

47

Page 53

48

44321/5

Page 54

Page 55

Raymarine Ltd.

Anchorage Park

Portsmouth

Hampshire

PO3 5TD

UK

Tel +44 23 9269 3611

Fax +44 23 9269 4642

www.raymarine.com

Loading...

Loading...