Page 1

Installation and Operating Handbook

ANALOGUE

Autohelm 1000

Page 2

Page 3

The Autohelm 1000 is a highly developed autopilot

built to operate reliably in exposed marine

conditions. When correctly installed it will soon

ears of

The system has been designed for owner installation

and aided by the following installation guide,

fitting should prove to be a straightforward and

Cockpit and tiller configurations vary widely, and

me cases special attachments may be

necessary to effect the neatest possible

installation. The attachments available and their

applications are fully described and are stocked

are

encouraged to contact our Technical Sales

become a vital crew-member giving many y

invaluable service.

enjoyable job.

thus in so

for immediate supply when required.

In cases where special advice is needed you

Department who will be pleased to assist.

Page 4

INSTALLATION

Page 5

The basic actuator unit is a totally self-

contained

magnetic sensing automatic pilot. The autopilot is

ttachment

point to the yacht's structure. After connection to

the yacht's 12 volt electrical system the unit

Since the autopilot incorporates a magnetic sensing

device, it is advisable to ensure that the yacht's

ituated at least 2'6” (750mm)

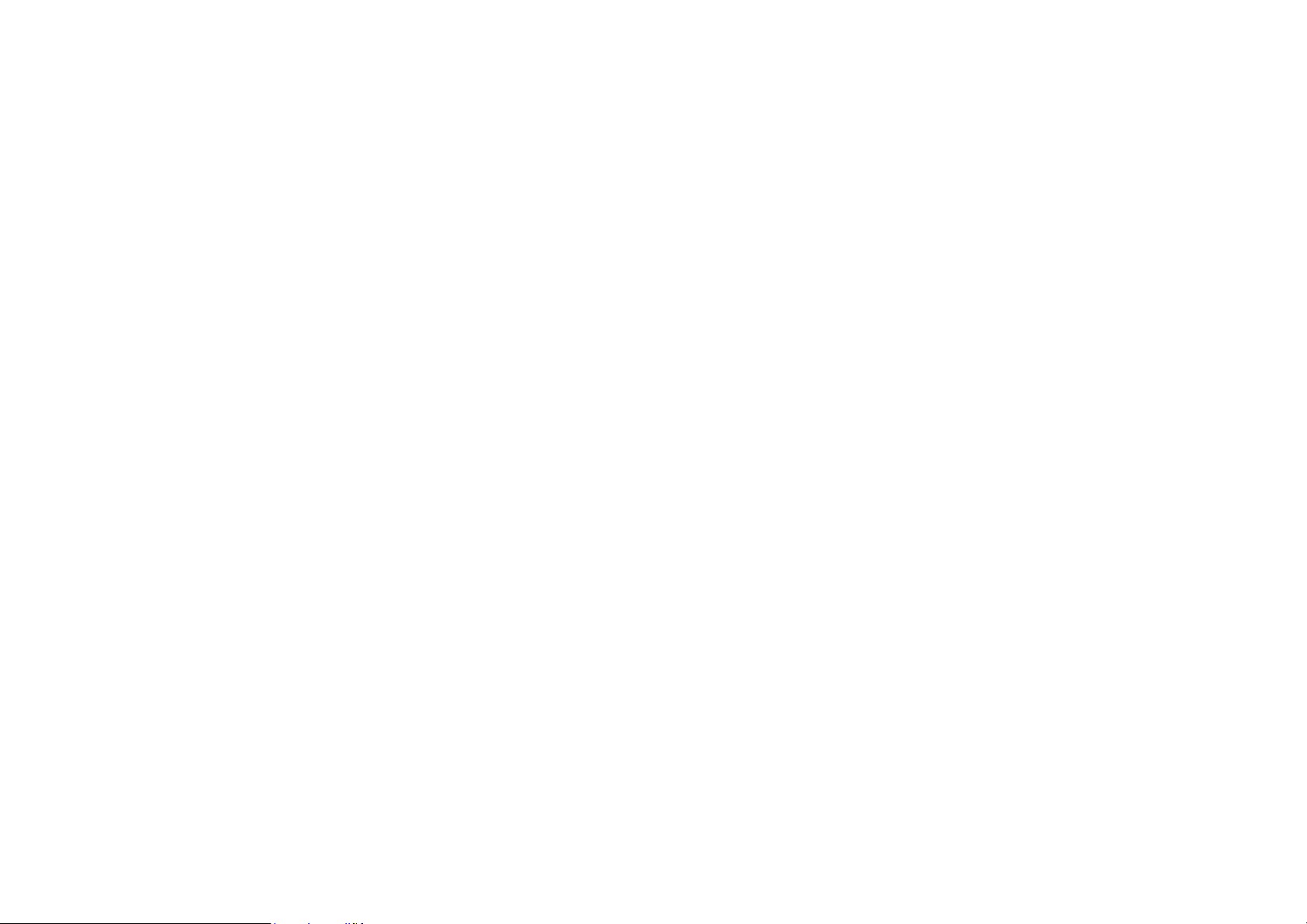

The actuator pushrod attaches to the tiller via a

ended pin situated 18” (460mm) radially

distant from the rudder stock or rudder pintle

osition

ended pin must be positioned at a

radius of l8” (460mm) at 90 degrees to the axis of

rudder rotation as shown on the accompanying

The autopilot slots into the bronze mounting socket

y fixed in

position. The mounting socket should be positioned

of the cockpit centreline

to ensure that port and starboard tiller movements

are equalised. It is also important to ensure that

possible to 90 degrees to the tiller when the

mounted between the tiller and a single a

becomes operational.

steering compass is s

away to avoid deviation.

ball-

centreline.

If the rudder pivot axis is sloping, the p

of the ball-

illustration.

A provided, which should be permanantl

19” (480mm) to starboard

the unit is positioned horizontally and as near as

tiller is centralised.

4

Page 6

Porthand mounting

In certain instances it may be more convenient to

mount the unit on the porthand side. The standard

the tiller and where porthand mounting is required

Porthand systems must be fitted with porthand wind

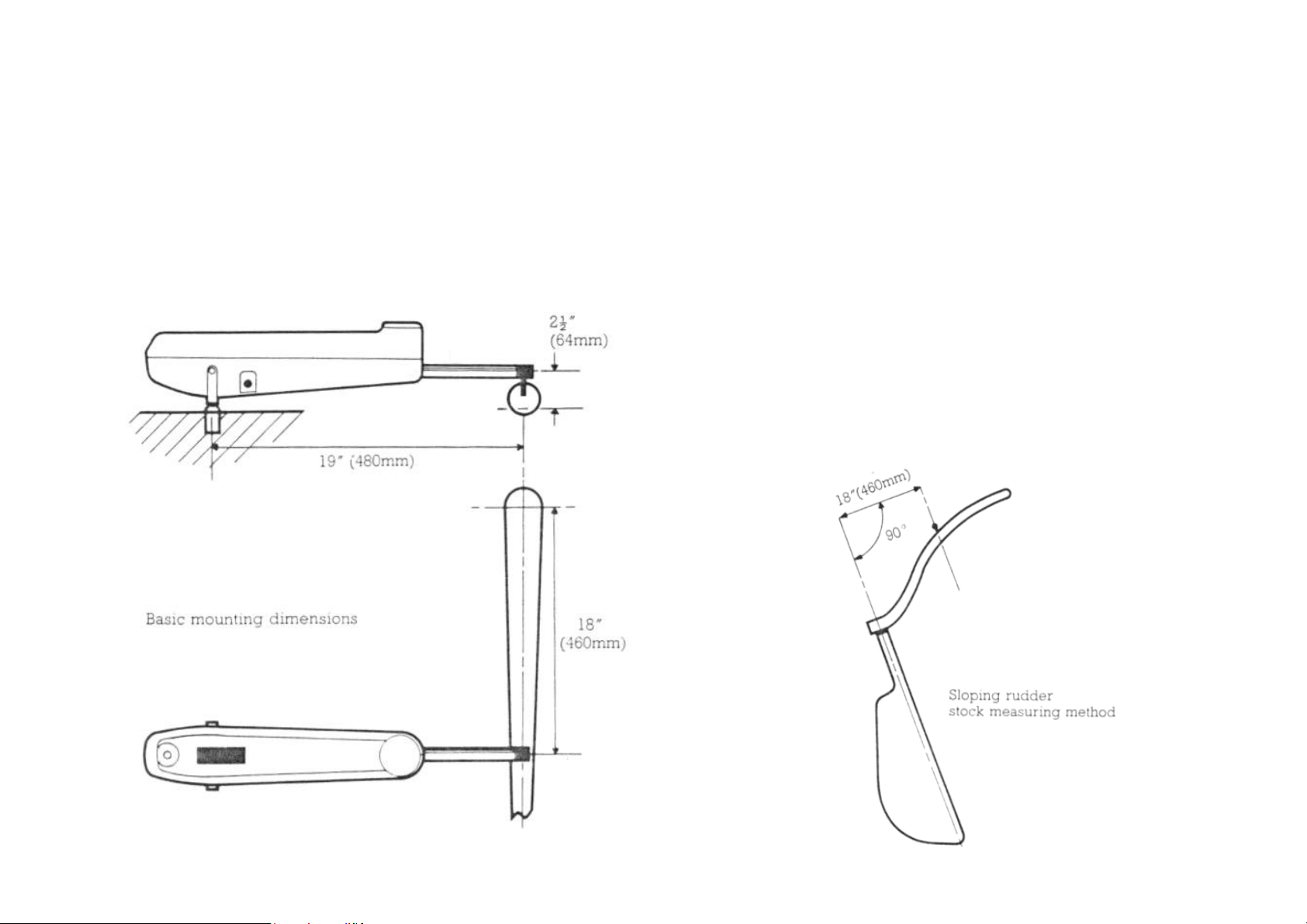

When the tiller is positioned low in the cockpit

able in height, the mounting socket

can be most conveniently positioned on the

starboard cockpit seat. The pushrod is attached to

the tiller via the standard ballpin provided which

is inserted directly into the top of the tiller.

(6mm) drilled hole and securing with a good quality

two pack epoxy adhesive such as Araldite. The

shoulder of the ballpin should be positioned ½”

(12.5mm) above the upper surface of the tiller to

The autopilot mounting socket is installed by

inserting it into a 1.2” (12.5mm) drilled hole and

permanently bonded with Araldite. It is important

to ensure that the mounting socket is securely

,

consists only of a single glass fibre skin of less

thickness than the depth of the socket it will be

necessary to provide reinforcement by bonding a

The autopilot is capable of generating very high

loads and it must be stressed that in all

cases the mounting socket should be very firmly

In some cases it may not be possible to provide a

convenient site for the mounting socket at the

of 19" (480mm). In such

cases the mounting distance can be increased in

increments of 1" (25mm) to a maximum of 6" (l5Omm)

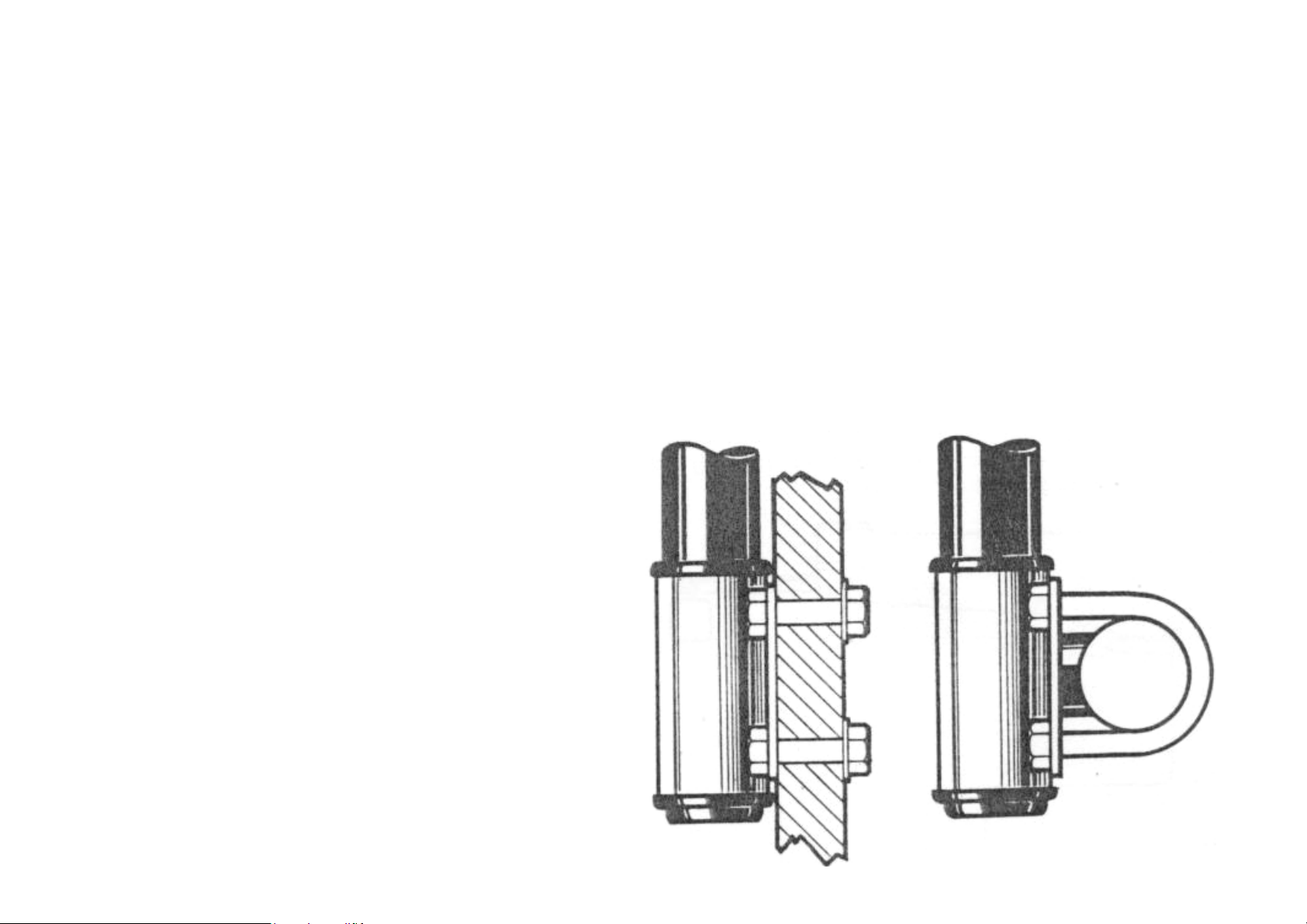

with the use of special pushrod extensions. The

pushrod is extended by first unscrewing the pushrod

hrod extension

into position between the pushrod and the end cap.

This attachment is necessary, for example. When the

cockpit is unusually wide or when it is convenient

Extended pushrods

unit is sensed to operate on the starboard side of

a special porthand system must be ordered.

vane attachments.

Basic installation method

and is adjust

The ballpin is installed by inserting it into a ¼”

avoid fouling when the pushrod is fully retracted.

standard mounting distance

end cap and then screwing the pus

to mount the unit on the cockpit coaming.

installed. If the mounting site, for example

plywood strengthening plate to the underside.

pushrod

bonded into position.

Page 7

5

Page 8

Tiller attachments

er is not adjustable in height or is

positioned appreciably higher than the most

convenient site for the mounting socket. It is

often convenient to lower the ballpin underneath

the tiller. Standard tiller cranks are available in

he ballpin centre in

increments of 1” (25mm) to a maximum of 5” (125mm)

below the underside of the tiller. Since the

pushrod centreline is positioned 2” (62mm) above

the mounting socket, these attachments can cater

ing socket

and the underside of the tiller of up to a maximum

of 7" (190mm). This attachment is particularly

in the case of transom hung rudder

configurations (such as the Folkboat) where the

tiller passes over an extended counter. In such

set

will enable the unit to be neatly mounted directly

The tiller crank attachments are bolted through the

centreline of the tiller, with ¼” (6mm) diameter

nce the bolts through the neutral

bending axis, the bending strength of the tiller

will not be significantly altered. The securing

bolts should be looked into the clearance holes

through the tiller with epoxy adhesive to ensure

When the till

a range of sizes to lower t

for a vertical distance between the mount

useful-

cases a tiller crank of suitable ballpin off-

on the surface of the counter or the rear coaming.

bolts and si

that they do not work loose in operation.

Page 9

6

Page 10

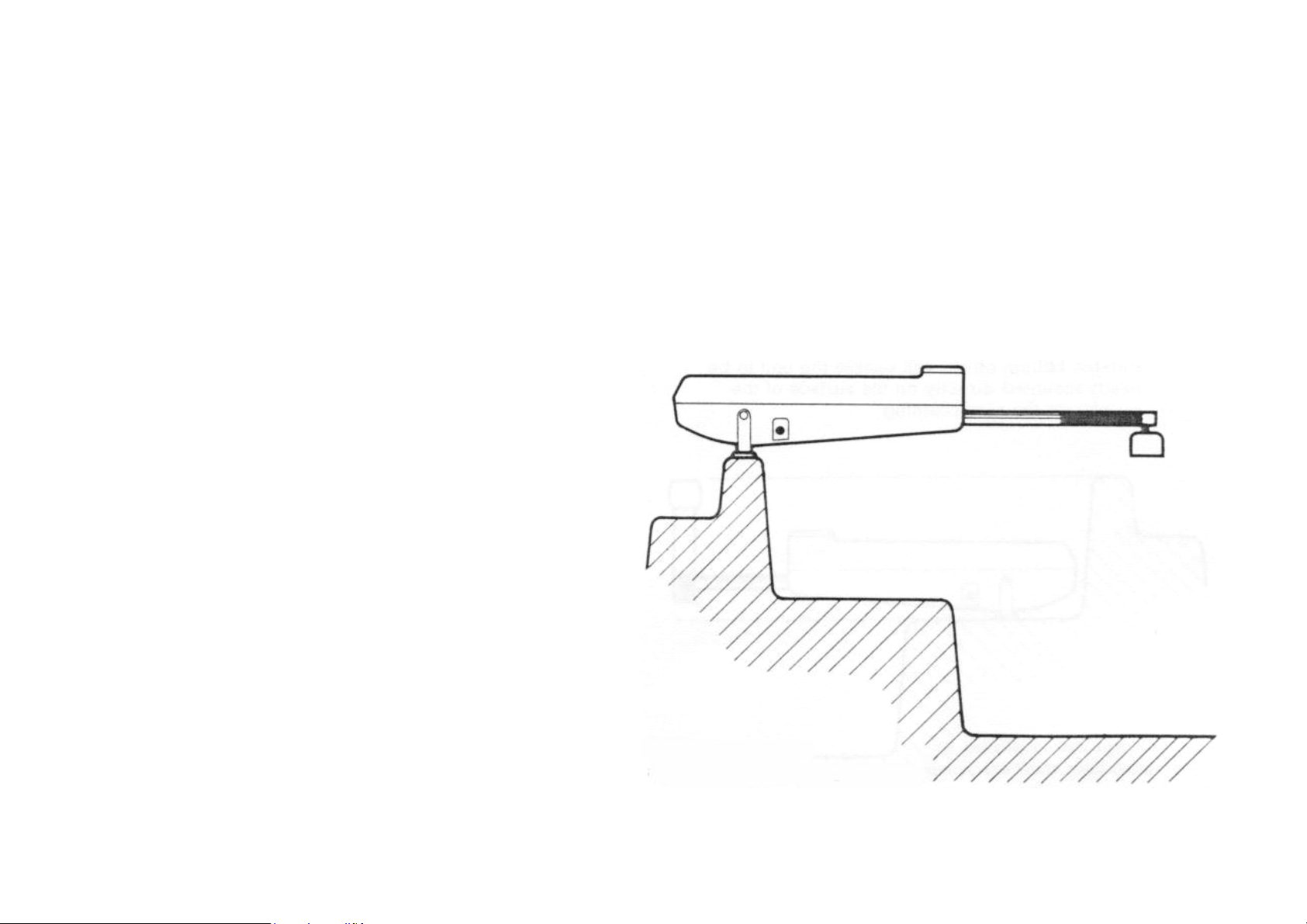

Cantilever mounting

It may sometimes be necessary to attach the

autopilot to a vertical face such as the cockpit

sidewall. In this case, a special cantilever

mounting is available and is particularly

itioned

substantially higher than the level of the cockpit

seat. Full instructions are supplied with each

cantilever mounting kit. The standard cantilever

mounting kit allows the autopilot mounting socket

set by a maximum of 10” (250mm) from the

vertical mounting face. This maximum dimension may

be reduced by cutting the cantilever to length

during installation. The cantilever screws into a

permanently mounted base which is bolted into

position by three ¼” (6mm) stainless steel bolts.

er may be unscrewed from its permanent

mounting base to allow unobstructed working space

In certain cases it may be convenient to raise the

height of the autopilot mounting socket above the

or counter for example. Standard

pedestal assemblies are available to raise the

mounting height from 1½” to 3½" above the mounting

surface in ½" (12.5mm) increments. The pedestal

base is bolted into position by three ¼” (6mm)

he autopilot is not in

use the pedestal may be unscrewed from its base to

convenient when the tiller is pos

Pedestal mounting

cockpit seat

stainless steel bolts. When t

to be off-

The cantilev

when the autopilot is not in use.

allow clear working space when necessary.

Page 11

7

Page 12

The wind vane attachment consists of two basic

the mounting mast which elevates the wind

vane into clear wind and the wind vane transducer

ttaches to the clevis at the head of

the mast by means of the cranked key provided. The

wind vane transducer is electrically connected to

the main autopilot unit by means of the waterproof

jack plug on the end of the interconnecting cable.

ne is not in use and the waterproof

plug is disconnected special care mist be taken to

ensure that the rubber blanking plug attached to

the socket on the main autopilot unit is firmly

pushed into position. If this is not done water

ket and temporarily disable

In very many cases the autopilot can be installed

without the need for special attachments. Where

t easily possible the above standard

attachments will normally provide a neat solution

and avoid the need for structural alterations. In

very rare cases where the standard range of

attachments do not provide a convenient mounting

ssary to consider the use

of purpose made attachments. In the event of

difficulties occurring, our Technical Sales

For trial purposes the actuator power lead may be

's 12 volt battery.

terminal. If the power connections are accidentally

reversed the autopilot will not function but no

at a waterproof plug and socket

is situated adjacent to the unit and the power lead

shortened. A standard 5 amp fuse should be provided

in the power supply circuit to protect the internal

supply cable between the battery and the waterproof

NB The equipment must not be connected to a battery

Use of attachments

this is no

arrangement it may be nece

Department will be pleased to advise.

Wind vane attachment

modules –

head which a

When the wind va

Battery connection

connected directly to the vessel

The brown lead should be connected to the positive

terminal and the blue lead to the negative

damage will result.

It is recommended th

outlet socket.

charger for testing.

could enter the jack soc

the autopilot until the water is dried out.

Page 13

8

Page 14

Similarly when the jack plug is inserted in wet

cockpit conditions, extreme care should be taken to

ensure that the plug is kept dry. Occasional

with Vaseline will

help to minimise problems of water intrusion. Once

the jack plug has been inserted, the connection is

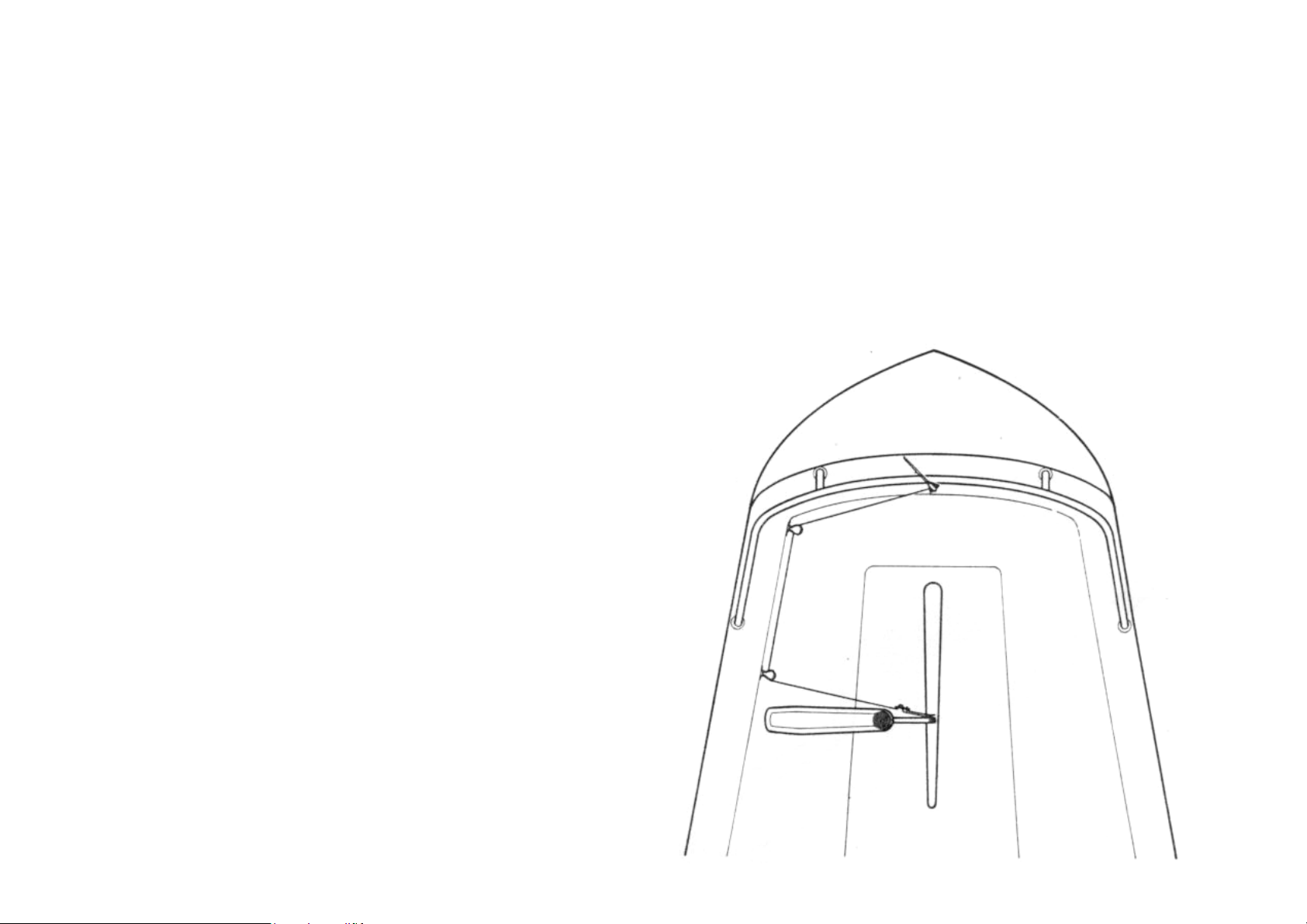

The wind vane transducer mounting mast is normally

clamped centrally to either a vertical or

f the after pulpit using the 'U'

clamps provided. In the event of an after pulpit

not being fitted the mounting flange may be bolted

directly to a suitable vertical face. Care must be

taken to ensure that the wind vane transducer is in

acks and not too close to the

deflected air stream from the mainsail. This is

normally ensured by situating the mounting mast

centrally behind the backstay and by elevating the

wind vane at least 2ft (60cm) above the highest

The autopilot operates on the principle of

mechanical feedback between the sensors and the

rudder to correlate corrective rudder action with

To complete installation of the wind vane

rom

the base of the mounting mast must be connected to

the pushrod. You will see that when the feedback

cord is pulled out of the mounting mast against

spring tension, backlash free rotational movement

are provided for leading the

feedback cord to the tiller. Normally only one

block is necessary to obtain a clear run out but .

occasionally two blocks may be necessary to avoid

obstructions such as the mainsheet. The final

of the actuator

unit as shown so that the final run of the feedback

cord is orientated nearly at right angles to the

tiller. It is important that the final fairlead is

positioned below the centreline of the pushrod so

as a tendency

lubrication of the jack plug

absolutely watertight.

Two small blocks

fairlead should be positioned aft

horizontal rail o

clear wind on both t

deck obstruction.

Feedback linkage

off course error.

attachment, the feedback drive cord emerging f

that the spring tension on the cord h

to pull the pushrod down onto the tiller pin.

of the wind vane transducer results.

Page 15

Feedback Linkage

9

Page 16

Finally, a loop is formed on the end of the

feedback cord after cutting to length and made fast

by means of the plastic adjustor slide provided.

The end of the loop is pos

itioned so that the

feedback cord is just under tension when attached

to the hook on the end of the pushrod in the fully

retracted position. This ensures that the feedback

cord is under tension over the full stroke of the

ver tensioned,

the remaining free scope of movement may not be

sufficient to accommodate the full stroke of the

pushrod and may cause damage to the feedback

mechanism at the full extremity of pushrod travel.

After adjusting the cord tension as described

ove, carefully check that the remaining scope of

feedback cord movement is sufficient to accommodate

After rigging the feedback cord, check that the

wind vane transducer head rotates smoothly over the

d movement. Backlash free vane

head movement is essential to ensure accurate

pushrod. If the feedback cord is o

ab

the full stroke of the pushrod.

full stroke of pushro

steering performance.

Page 17

10

Page 18

Operation

After completing the installation you should carry

out the following functional test to familiarise

f with the system before attempting sea

The autopilot is fitted with a 4 position thumb

operated rotary switch located on the upper case.

when the thumb

clockwise

ining 3 positions of the control

selects compass operation for 'calm' weather

selects compass operation for 'rough' sea

In this position minor yawing motions caused by

ction are neglected. The autopilot will

respond only to changes in mean course, and thus

the duty cycle and power consumption will be

selects wind vane control and enables convenient

e

Hold the unit towards the tiller and rotate the

compass dial until the cardinal point graduations

are approximately aligned with your main steering

raduation

on the compass dial then automatically homes to

Functional test procedure

yoursel

trials.

Operation under compass control

•

compass.

• Switch to calm and note that the north g

The autopilot is switched off

control wheel is in the fully antiposition. The rema

switch provide the following functions.

Calm

conditions.

Rough

conditions.

wave a

substantially reduced.

Vane

transfer of control mode when the wind van

attachment is fitted.

magnetic north.

Main Control Switch

Page 19

11

Page 20

Rotate the compass dial in small increments until

the end of the pushrod remains settled over the

compass dial clockwise to retract the pushrod and

clockwise to extend it. Note that after making

adjustments, it is necessary to release the compass

dial to allow the compass to realign with the

its mooring, you

will see that small variations in heading cause the

unit to apply corrective action to the rudder. Now

and note that the frequency of

ed with a wind vane attachment

the following familiarisation test may be carried

Connect the wind vane jack plug to the main

actuator and attach the feedback cord to the end

Set the wind vane head into its most sensitive

y tilting the head forward until the

vane is almost vertical. Then grip the mounting

mast just above its base and slowly rotate until

the vane feathers into wind. In this position the

ransfer the sensing mode

Note that small variations in wind direction will

now cause the actuator unit to apply corrective

action to the rudder. This is how the Autohelm 1000

ttle further and note

how the tiller takes up a new position to one side.

This is how trim corrections are made for weather

sensitises the wind

ne, and you will note that the frequency of

Preferably, initial trials should be carried out in

reasonably calm conditions and with plenty of sea

ocedure is

Steer onto a fixed heading under engine or sail

Holding the pushrod towards the tiller, rotate

the compass dial until it is approximately

s

Allow the compass to automatically align with the

earth's magnetic field and then adjust the

compass dial further until the end of the pushrod

llow the

tiller pin and clutch onto the tiller. Rotate the

anti-

earth's magnetic field.

If the yacht is swinging about

switch to rough

corrective action is reduced.

Operation under wind vane control

If the system is fitt

out.

•

of the pushrod.

•

position b

vane will flutter evenly between the buffers.

• Switch over to vane to t

to wind vane control.

Rotate the mounting mast a li

or lee helm when under sail.

Finally, tilt the vane head back until the vane is

nearly horizontal. This deva

corrective rudder action is noticeably reduced.

Operation under sail

room.

The following familiarisation pr

recommended.

Compass control

•

and hold the course steady.

•

aligned with the yacht's main steering compas

and switch to calm.

•

is approximately positioned over the tiller pin.

• Clip the pushrod onto the tiller and a

autopilot to take over.

functions when under sail.

Page 21

12

Page 22

After allowing the boat to steady onto an

automatically controlled heading, carry out small

incremental adjustments to the compass dial until

the vessel steadies on to the desired heading.

justment of the compass

The vessel may now be steered onto any other

heading by adjusting the compass dial. If the

autopilot appears to be working continuously due

to sea conditions, switch over to rough. The rate

When the system is fitted with a wind vane

attachment it will in general be easier to set up

under compass control first as described above, and

s under wind vane control are best

carried out when sailing to windward slightly off

When the vessel is sailing steadily under a

magnetically controlled heading, the wind vane

mast should be rotated to feather the vane to

ane and the actuator will then

controlled heading, carry out small rotational

adjustments to the vane mounting mast until you

um

Note that to adjust the yacht's heading you rotate,

the vane stanchion in the same direction as you

would the tiller. You will find also that to trim

your course only very small movements should be

epeat the above procedure broad reaching and

finally running down wind by progressively

slackening the sheets and slowly rotating the

The pushrod is held into engagement with the tiller

erely by the weight of the actuator unit. This

method of engagement is secure and has been adopted

for safety reasons to allow the pushrod to be

easily disengaged when manual override becomes

le when sailing under automatic

pilot control to pay strict attention to sail

balance. Good sail balance is particularly

When a yacht is sailing badly out of balance,

luff

violently to windward. When hand steering, this

tendency is corrected by applying sufficient

weather helm to hold the original course until the

gust subsides. A simple autopilot, however, does

not understand the need for weather helm and will,

ore, allow the yacht to luff to windward

until sufficient helm is applied to achieve a new

•

Note that clockwise ad

dial will alter course to port.

•

of working will then reduce substantially.

Wind vane control

then to switch over to wind vane control.

First trial

the wind

•

applied to the vane stanchion.

• R

vane to bring the vessel onto the new headings.

Disengagement

pin m

necessary.

Operating hints

Sail balance

It is always advisab

wind.

• Switch over to v

respond to variations in wind direction.

• When the vessel has steadied onto a wind-

are satisfied that you are sailing on an optim

course to windward.

essential in gusty conditions and strong winds.

sudden gusts will generally cause it to

theref

state of balance.

Page 23

13

Page 24

Furthermore, it will maintain the luffed heading

for as long as the need for increased weather helm

'persists. Contrary to popular opinio

n a

proportional steering autopilot will not maintain a

constant heading when the yacht's balance changes.

Thus sailing badly out of balance in varying wind

strengths will always give rise to excessive course

ng

the mainsail slightly more than you would when hand

On longer passages when a constant compass course

may be steered for hours on end, variations in wind

strength and direction will almost certainly cause

e reasons given

above, variations in standing helm will cause the

autopilot to steer slightly away from the set

course. In the case of the Autohelm 1000, if 5

degrees of additional weather helm is required as a

the

course steered by the autopilot will

correspondingly change by approximately 20 degrees.

Thus when passage making, if a change in compass

heading is observed, the original course should

trimming sails to obtain

ate of balance. Alternatively,

providing weather helm has not become excessive,

the yacht may be trimmed back on to the original

adjusting the autopilot's compass

ically to

operate at near maximum sensitivity. High vane

sensitivity is essential to ensure optimum

hauled

and usually does not result in excessive actuator

activity. The sensitivity of the vane may be

tilting the entire unit backwards on its

clevis mounting. This has the effect of increasing

the 'dead band' of the vane sensor by allowing up

to a maximum of 15 degrees course variation to

occur before automatic correction is applied. When

ary to sail a very accurate course,

lowering the sensitivity of the vane in this manner

will reduce the number of corrections made and

hence reduce power consumption. In heavy weather or

turbulent wind conditions, the duty cycle of the

sensitising

sensitising the wind vane under

these conditions will not affect the accuracy of

Vane sensitivity adjustment

Normally the wind vane is set almost vert

penetration to windward when sailing close-

wander. This tendency is best overcome by reefi

steering.

changes in helm balance. For the sam

result of rising wind strength, for example,

ideally be restored by rethe original st

heading by resetting.

reduced by

it is not necess

autopilot can usually be lowered by dethe wind vane. De-

the mean course steered.

Page 25

14

Page 26

When the wind vane attachment is not fitted it is

he basic magnetic sensing unit

under both engine and sail. It should be borne in

mind, however, that the compass sensor is

internally gimballed to cope with a maximum angle

of heel of 30 degrees, and will not operate beyond

necessary to lay

slightly off the wind when sailing long passages

hauled to prevent becoming backed by gradual

Wind vane control is always more efficient when

hauled when it will ensure that

age is taken of changing wind

direction to ensure optimum penetration to

windward. In steady wind conditions, wind vane

control will. Usually give best results on all

When the wind is abaft the beam and unsteady in

direction surprisingly large

variations I in apparent wind direction can occur.

Under these conditions compass control generally

When the wind vane attachment is fitted the system

to automatically tack the vessel by

alternately switching over from compass to wind

vane. This is done by setting the vane to control

on the longest tack and the compass sensor on the

other. Tacking is then simply achieved by switching

o the other leaving you free to

As a final caution. it is very easy to relax

keeping, and this temptation must

be avoided however clear the sea ahead may appear

two

just the time it takes to

After use, the Autohelm 1000 system is easily

stowed by unclipping the actuator unit from its

mounting, and removing the vane transducer from its

re system can then be stowed

All moving parts of the system have been lubricated

for life at the factory. Therefore no maintenance

whatsoever will be required. Should a fault

ed in the

original packing case for repair and servicing,

which will be carried out speedily and at a

Selection of transducer

Tacking in enclosed waters

possible to use t

this heel angle. It will also be

closeshifts in wind direction.

sailing closeimmediate advant

other points of sailing.

strength and

improves course keeping accuracy.

can be set up

over from one mode t

handle the sheets.

Watch-keeping

permanent watch-

to be. Remember that a large ship can cover

miles in five minutes brew a cup of coffee!

Stowage

mounting mast. The enti

easily in a small locker.

Maintenance

develop, the entire unit should be return

moderate cost.

Page 27

15

Page 28

Raymarine Ltd.

Anchorage Park

Portsmouth

Hampshire

PO3 5TD

Tel 023 9269 3611

Page 29

Fax 023 9269 4642

www.raymarine.com

Loading...

Loading...