AutoFry MTI-40 E General Manual

A Patented Product of

MTI Form DB

-

0002 Rev.

3/97

Model MTI-40 E

Operator's Manual

E167653

Motion Technology, Inc.

6 Huron Drive

Natick, MA 01760

Telephone: (508) 653-0082

Technical Support: 888-664-6640

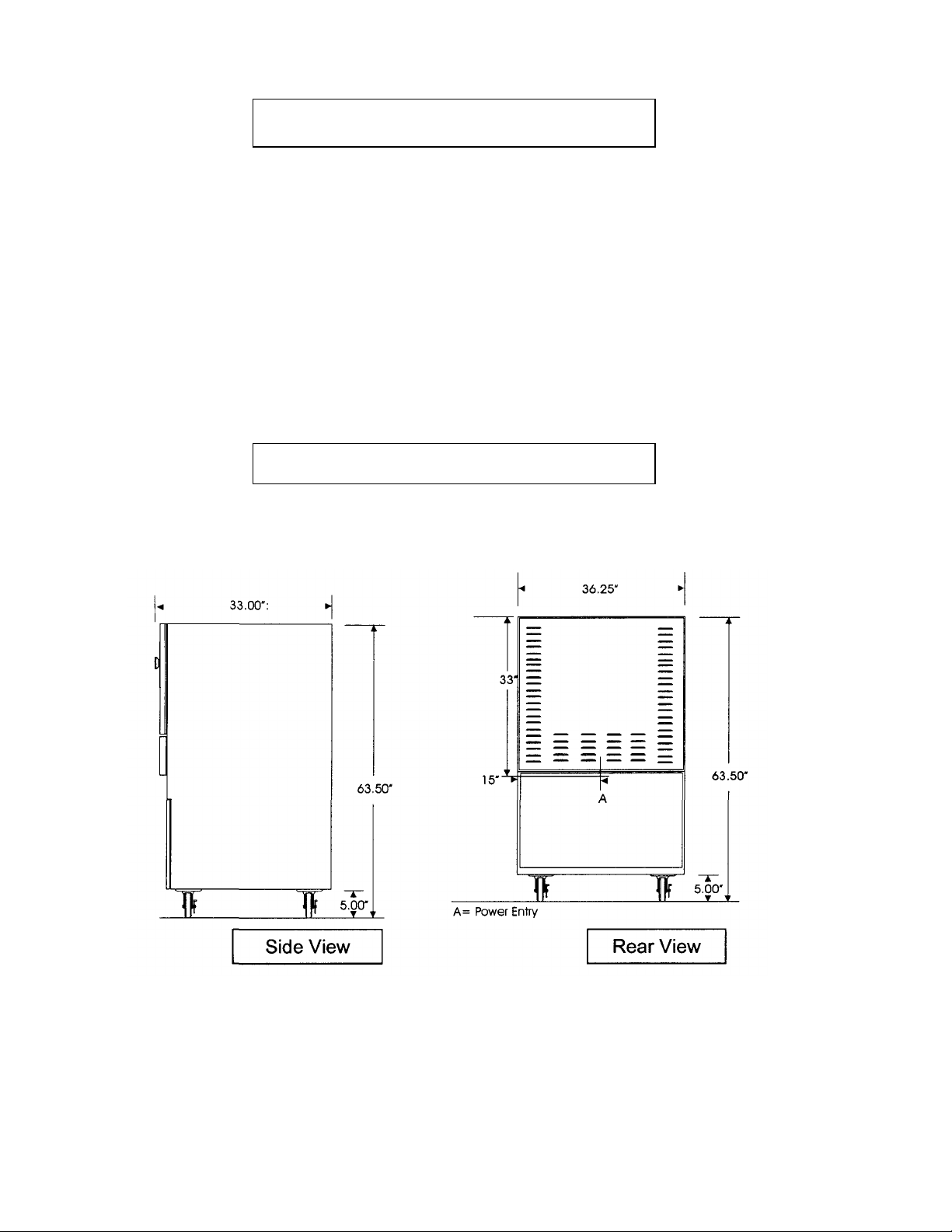

AUTOFRY Model MTI-40E Installation and Operations Manual

Specifications:

(Check ID Tag for Specific Ratings)

AUTOFRY Model MTI-40E

240-Volt Single Phase Grounded

12,000 Watts

50 Amps

Hard-Wire Only

240-Volt Three Phase Grounded (4 wire)

12,000 Watts

29 Amps

6'-00" Power Cord with NEMA 15-50 Plug

Back

Clearances:

Sides

3"

Front

1"

240-Volt Single Phase Grounded

16,000 Watts

67 Amps.

Hard-Wire Only

240-Volt Three Phase Grounded (4 wire)

16,000 Watts

39 Amps 6'-00" Power Cord with NEMA 15-50 Plug

Top

36" 30" Min.

Physical Specifications:

304 Stainless Steel Construction

Shipping Weight: 400 LBS (aprox)

Dimensions: L=32", W=36", H=63 V2" AUTOFRY Model MTI-40E

UL File #E167654

REV 001 1/99

1

AUTOFRY Model MTI-40E Installation and Operations Manual

Table of Contents:

Initial Inspection 3

Installation Instructions 4

Selecting Location 4

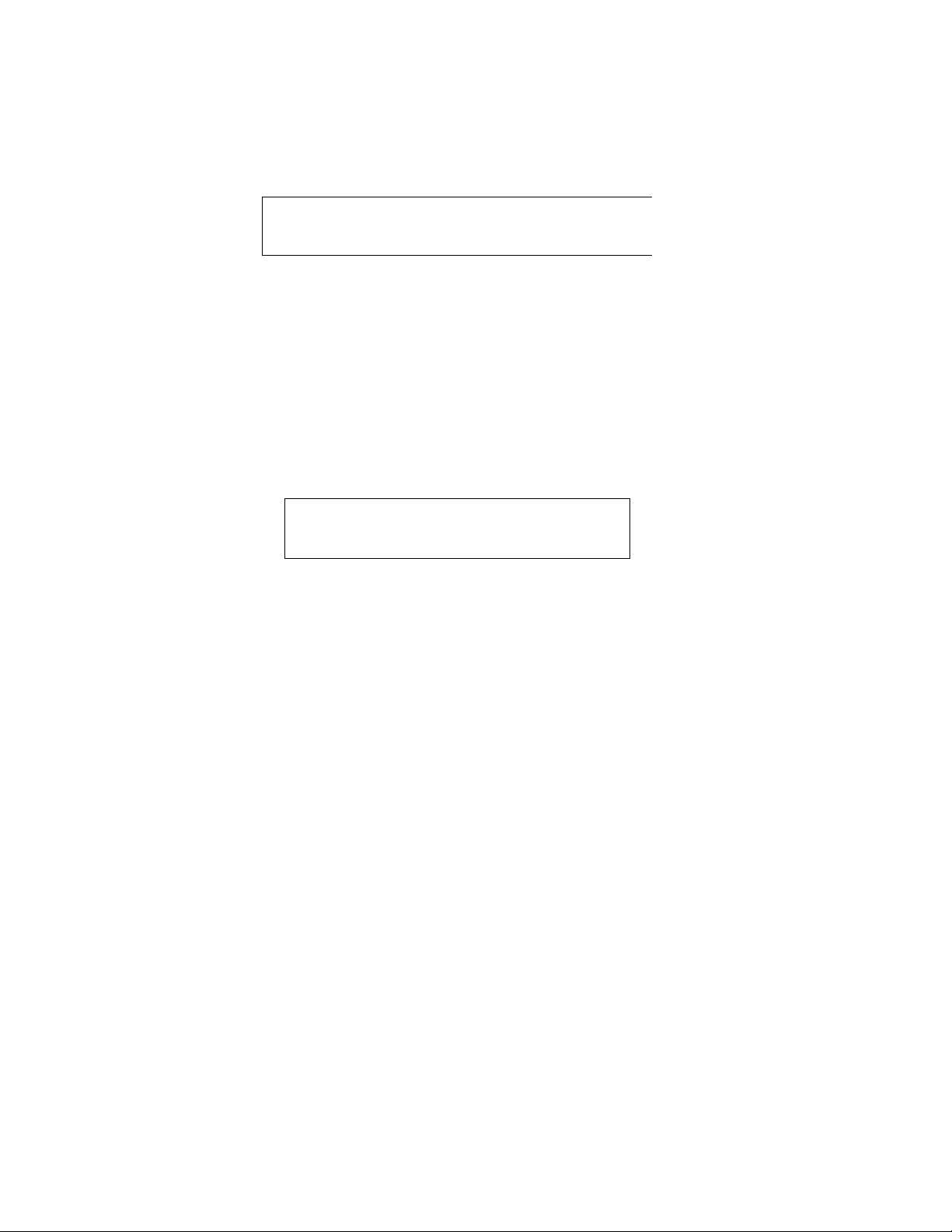

MTI-40 Over-View 5

Inspect Components 6

Install Charcoal Filter 7

Sft Error 7

Install Oil Filtration System 8

Basket Installation 9

Add Liquid Shortening and Fry Compound 10

Install Food Service Baskets 11

Starting the AUTOFRY

During Start-up 12

Start-up Hints 12

A08, A07 & Limit Thermostats 12

Begain Cooking 13

During Cooking 13

AUTOFRY Shut-off

Additional Keypad Functions 15

Count Button 15

Stand-by Button 16

Repeat Cook Time 16

Maximum Cook Time 16

Programming Cook Times 17

Recommended Cleaning Schedule 20

Daily Cleaning 21

Weekly Cleaning 22

Quarterly Cleaning 23

Charcoal Filter Maintenance 24

Grease Baffle Maintenance 24

Semi-Annual Maintenance 25

Maintenance Log 27

Oil Filtration System Instructions 28-34

12

14

MTI Form DB-0002 REV. 3/97 UL

File #E167654

2

AUTOFRY Model MTI-40E Installation and Operations Manual

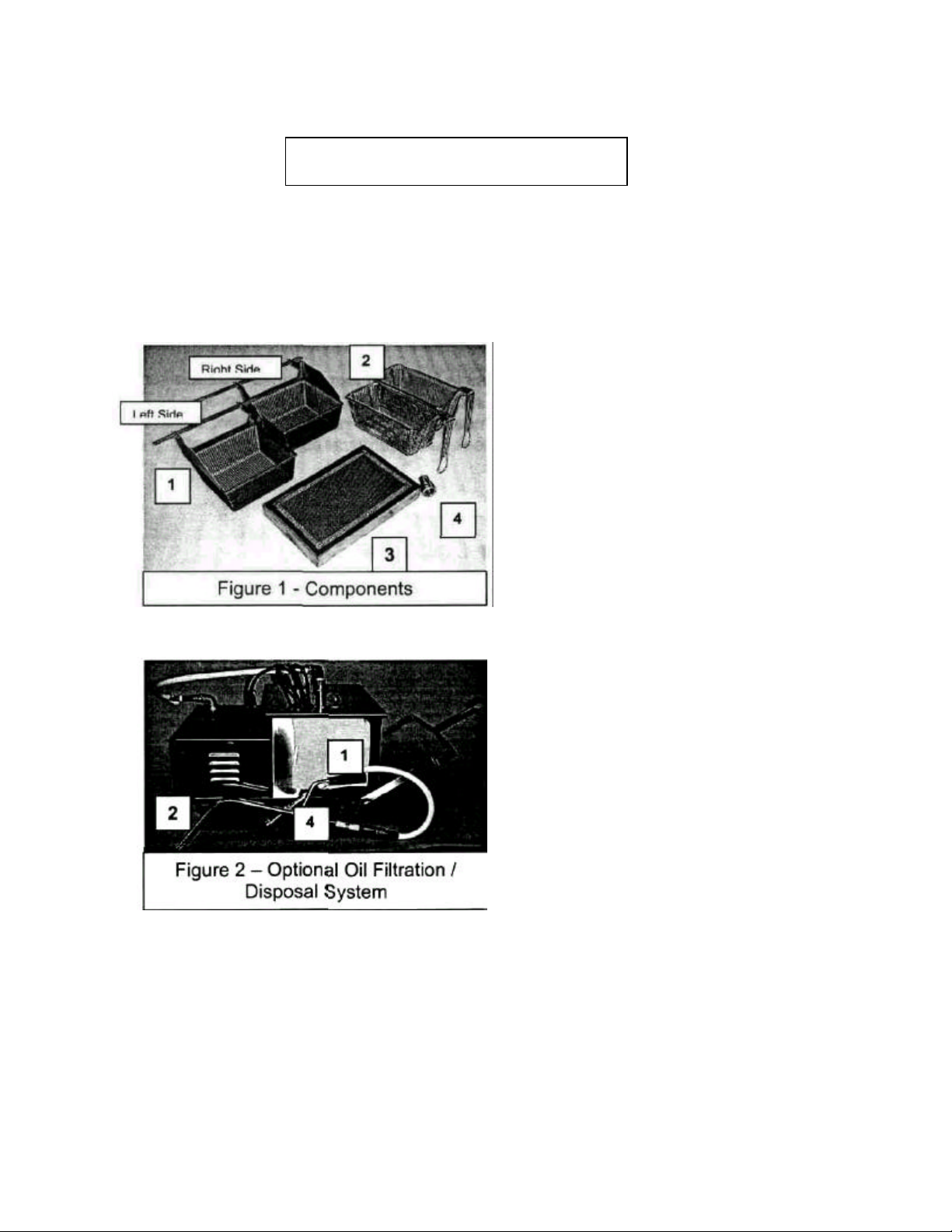

Initial Inspection

The AUTOFRY Model MTI-40E has been packaged to withstand rugged travel;

however, in the event of damage you must notify the shipping company.

• Remove and save all packaging materials

• Inspect for the following components.

1. Two wire food baskets

• One left side

• One right side

2. Two food service baskets

3. Charcoal filter

4. Male quick-disconnect

• (Gas Models Only)

Consult the operator's manual for

component installation.

• The optional Oil Filtration /

Disposal System and its

components include the

following.

1. Oil Pan

2. Trolley

3. Filter foot and carbon pads (not

shown)

4. Discharge Hose and Wand

Installation and operating

instructions are supplied separately

MTI Form DB-0002 REV. 3/97 UL

File #E167654

3

AUTOFRY Model MTI-40E Installation and Operations Manual

Installation Instructions:

Licensed trades-man in accordance with all local and national codes must install

electrical service. Motion Technology, Inc. will not assume responsibility for any

injuries or equipment malfunctions resulting from non-conforming installations.

Motion Technology, Inc. is not responsible for Local requirements that additional

equipment and/or appliances may be required for a food preparation area in a

store, which may include but not be limited to Type II Hood, Vent Fan, Grease

Interceptors and Additional Sinks. Check with your local building or health

departments for specific requirements.

Selecting a Location

The location of the AUTOFRY must be level.

Adequate space must be provided so that the AUTOFRY can be moved forward

for service without interference.

Adequate exhaust or replacement air ventilation must be supplied (200 cfm) if not

already provided by other means.

MTI Form DB-0002 REV. 3/97 UL

File #E167654

4

AUTOFRY Model MTI-40E Installation and Operations Manual

MTI Form DB-0002 REV. 3/97 UL

File #E167654

5

AUTOFRY Model MTI-40E Installation and Operations Manual

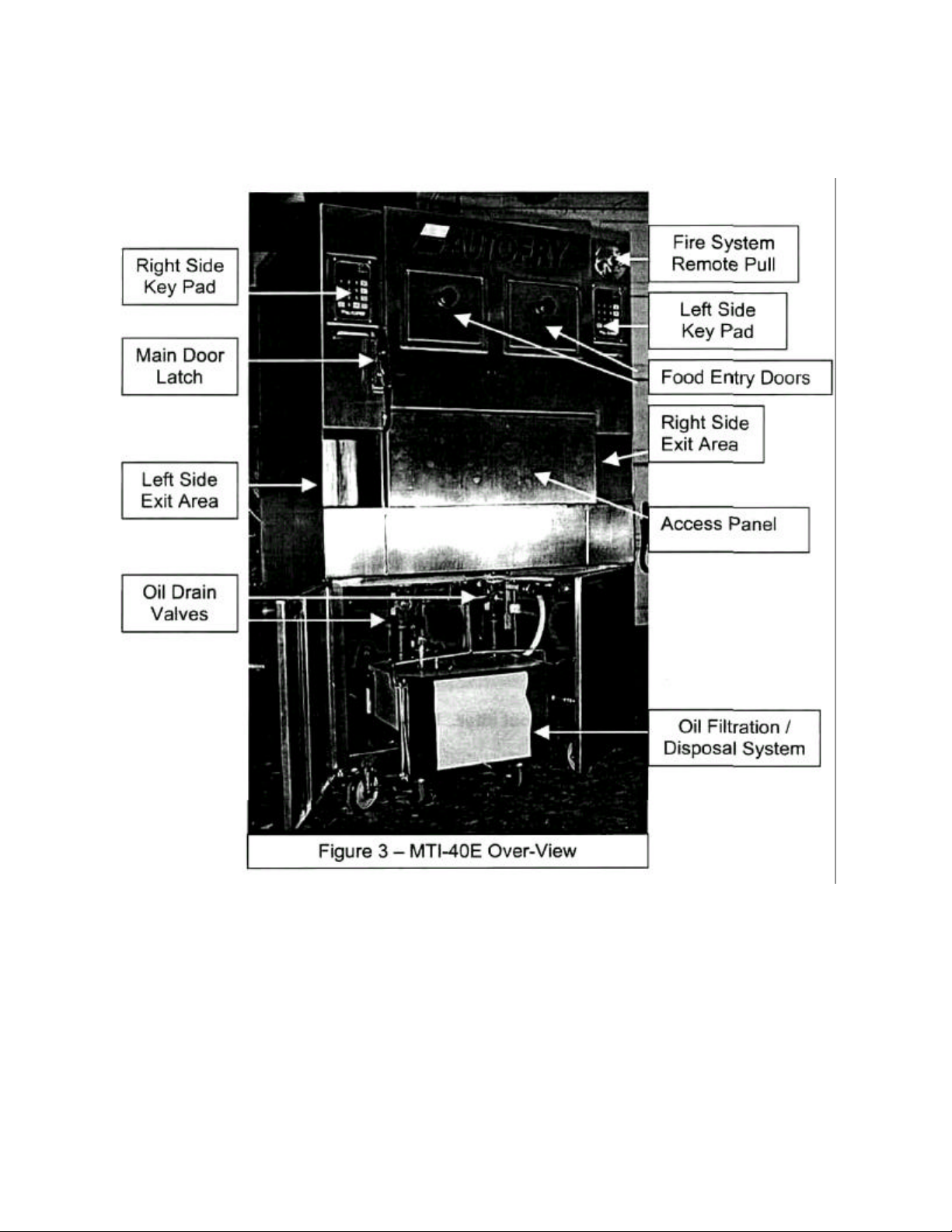

Inspect and Install Components

1. The following components have been supplied with the AUTOFRY (See

Figure 4).

• Two wire food baskets.

• Two food service baskets

• The charcoal filter.

• The round fryer brush.

Wash the two wire food baskets

and the two food service baskets

in warm soapy water followed by a

clear water rinse

CAUTION

Never soak the charcoal filter. Wipe down the exterior surfaces

with a damp cloth.

MTI Form DB-0002 REV. 3/97 UL

File #E167654

6

7

AUTOFRY Model MTI-40E Installation and Operations Manual

2. Install charcoal filter (See Figure 5A & 5B).

• Loosen and remove the two black plastic knobs securing the filter cover plate

by rotating them counter-clockwise.

• Remove the charcoal filter from its plastic bag.

• Insert the charcoal filter into the tracks above the grease baffle.

• Re-install the filter cover plate.

Important Notes:

The AUTOFRY is equipped with a series of safeties. If any of the filters or

filter cover plate are not installed or installed incorrectly the AUTOFRY will

display Sft at the keypad. All filter components must be installed in order for

the AUTOFRYto operate.

The charcoal filter must be maintained on a regular basis in order for the

AUTOFRY to maintain its listing as a Ventless Cooking Appliance. Filter

maintenance and regular cleaning is an important part of your regular

maintenance. Consult the cleaning and maintenance section of this manual for

the frequency of filter changing.

MTI Form DB-0002 REV. 3/97 UL

File #E167654

CAUTION

There is risk of burns

8

AUTOFRY Model MTI-40E Installation and Operations Manual

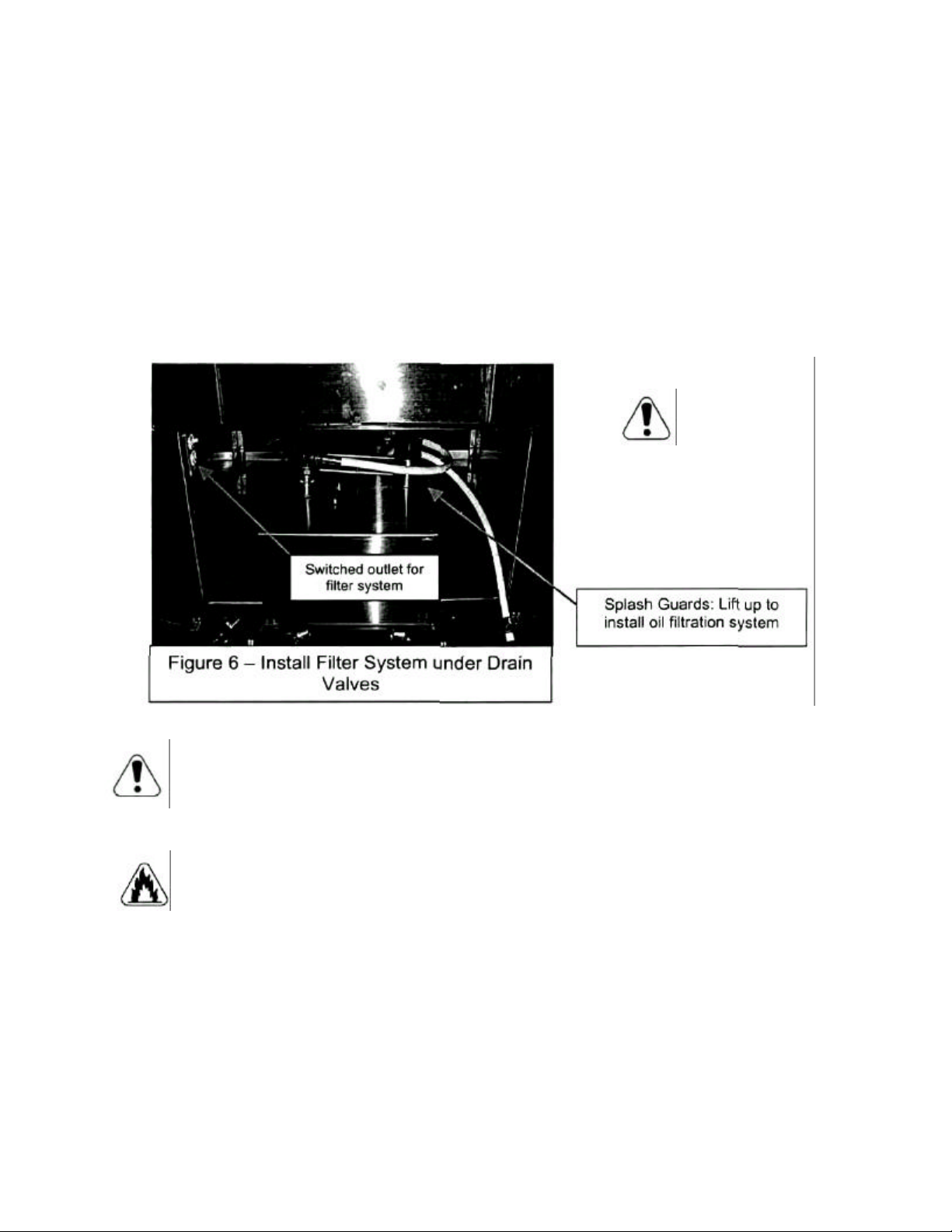

3. Open the lower cabinet doors and install the oil filtration system

(See Figure 6).

• Ensure that both the oil vat drain valves are in the closed position (See

figure 6).

• Ensure that the ON/OFF switch is in the OFF position.

• Plug the filtration system into the switched outlet.

• Roll the oil filtration system into position under the drain valves by lifting

the two splashguards up. The splashguards will fit through the two round

cutouts in the filtration cover.

from hot oil. Always

wear protective clothing

and eye-wear when hot

oil is present

CAUTION

Do not press the ON key until all interior components have been installed

and oil has been added.

RISK OF FIRE

There is risk of fire due to low oil or no oil situation. Ensure there is oil in both oil

vats prior to pressing the ON keys.

MTI Form DB-0002 REV. 3/97 UL

File #E167654

AUTOFRY Model MTI-40E Installation and Operations Manual

9

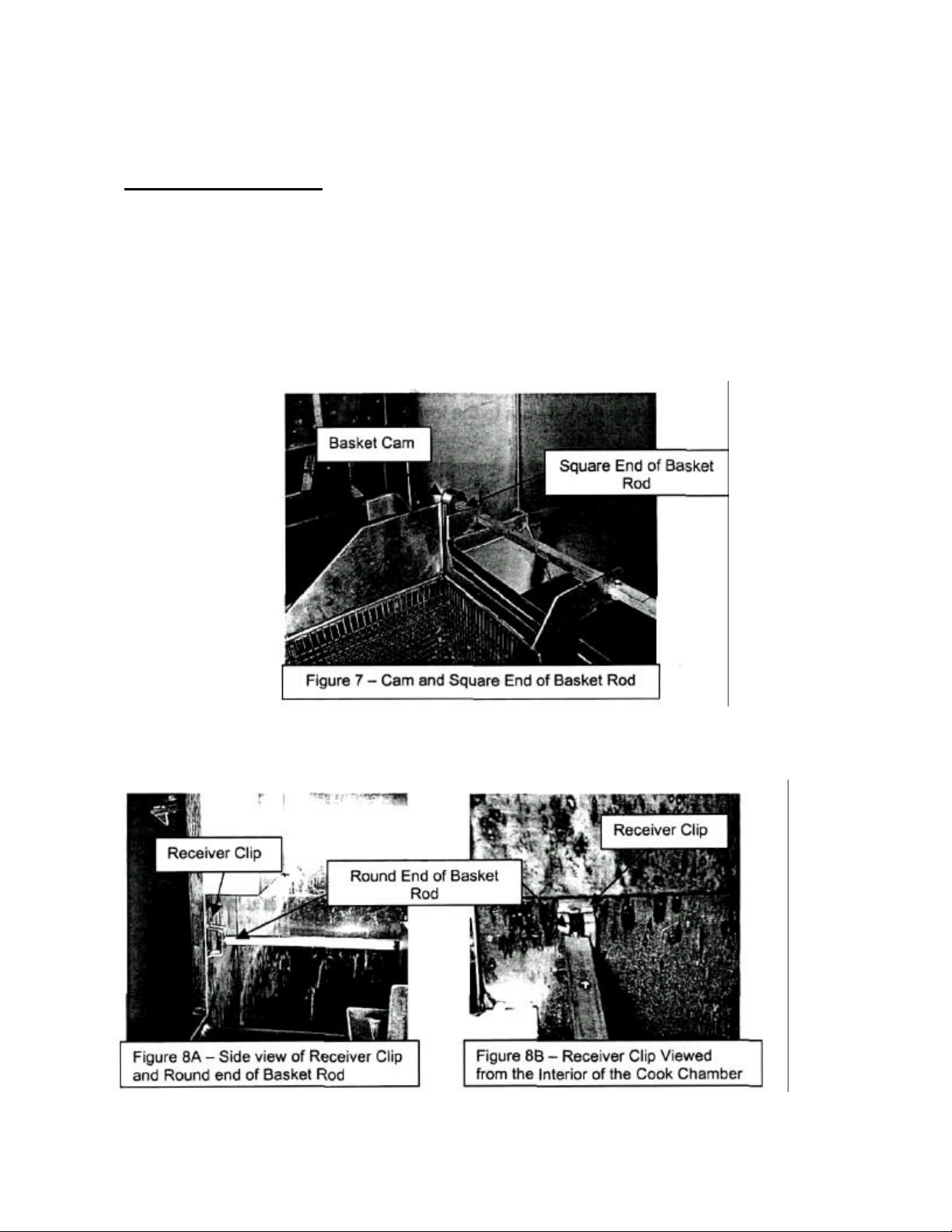

Basket Installations

There are two wire food baskets, one for the left side oil vat and one for the

right side oil vat. When installed the wire food baskets will sit level in the oil

vat.

1. Install the square end of the basket rod into the slot in the basket cam

(SeeFigure 7).

2. Lower the round end of the basket rod into the receiver clip located just

inside the cook chamber (See Figure 8A & 8B).

MTI Form DB-0002 REV. 3/97 UL

File #E167654

AUTOFRY Model MTI-40E Installation and Operations Manual

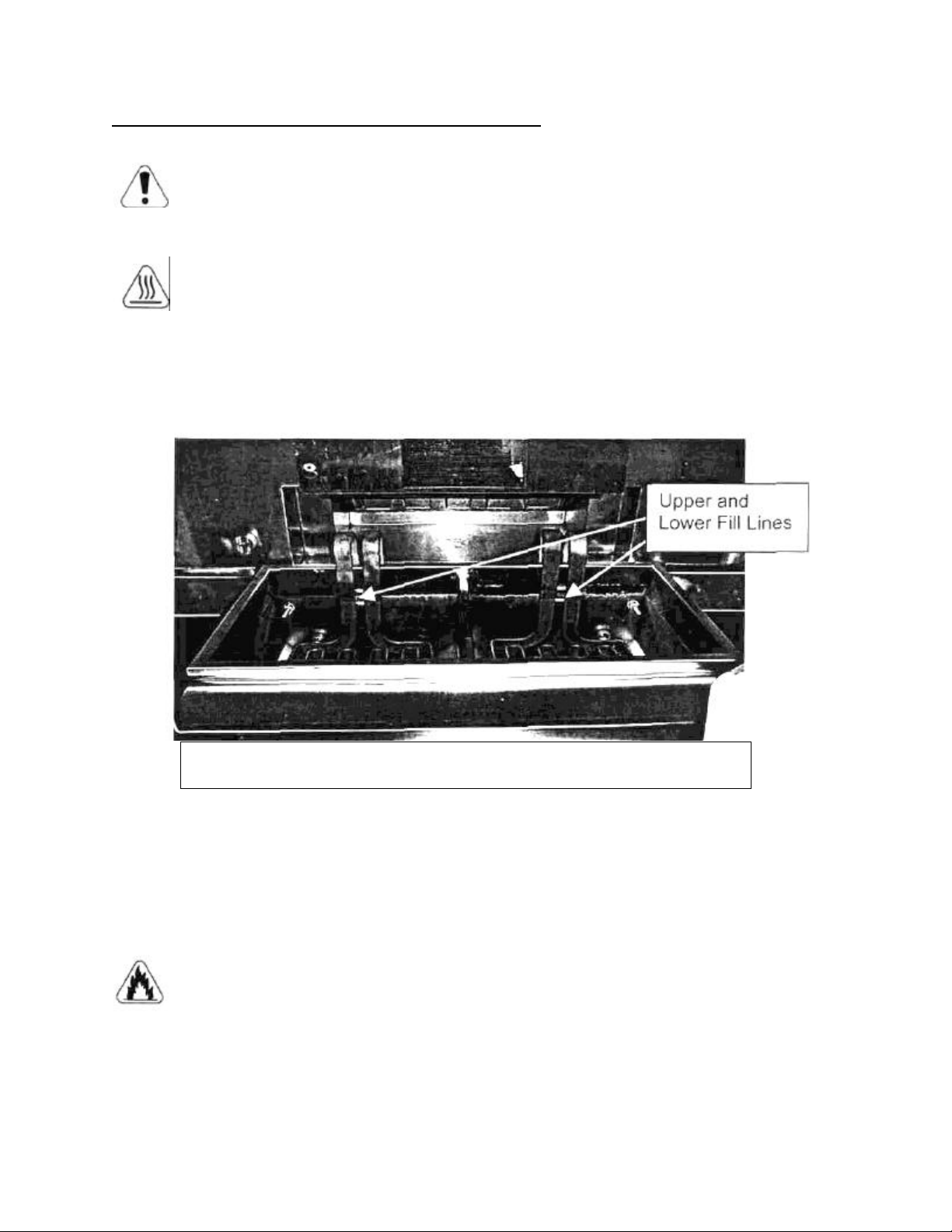

Add Liquid Shortening and Fry Compound

CAUTION

Never use solid shortening as it will solidify in the oil return lines

and cause damage to the basket lift motors. The AUTOFRY Model

MTI-40E has been designed to operate at peak performance with the use of liquid

vegetable shortening.

CAUTION

There is risk of burns from hot oil; always keep the main door locked. Always wear

protective clothing and eye protection when hot oil is present.

1. With the oil drain valves in the closed position and the oil filtration or oil drain

pan in place fill the oil vats to the lower fill line (1 1/2" below the center vat divider).

Figure 9—Add Liquid Shortening and Fry Compound.

2. Add one 2 oz. package of Fry Compound to each vat.

• Fry Compound will allow you to cook at a lower temperature and will extend

the life of your shortening as well as enhance the appearance and taste of your

product.

• To order additional Fry Compound call 1-800-332-9565 and order part

number FC 25-2.

RISK OF FIRE

There is risk of fire due to a low oil condition. Always ensure that there is oil in the oil vats

before pressing the ON keys.

MTI Form DB-0002 REV. 3/97 UL File #E167654 10

AUTOFRY Model MTI-40E Installation and Operations Manual

Install Food Service Baskets

There are two food service baskets that will be installed into the food exit areas at

the front of the AUTOFRY (See Figures 10A & 10B). To install these baskets slide

them into the exit area then lift the baskets up and hang them on the lip at the back of

the exit area.

MTI Form DB-0002 REV. 3/97 UL

File #E167654

11

Loading...

Loading...