Page 1

Models FFG-10 and MTI-10

Operator's Manual

Technical Support: 888-664-6640

MTI Form OP-0010 Rev. 005 5/98

E167653

A Patented Product of

Motion Technology, Inc.

6 Huron Drive

Natick, MA 01760

Telephone: (508) 653-0082

Page 2

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

Table of Contents

Specifications iv

Prepare electrical service 1

Prepare counter top 1

AUTOFRY Installation 2

Unpacking 2

Lea installation 3

Initial cleaning 4

Install charcoal filter 5

Install oil pot 6

Install heater box 6-5

Connect RTD 7

Connect thermocouple 7

Connect heater plug 7

Add liquid shortening 8

Install food exit chute 8

Install wire food basket 9

Power 10

Let's Get Cook/no 11

Starting the AUTOFRY 11

Begin cooking 12

During cooking 12

AUTOFRY shutoff 13

Additional KEYPAD functions 14

The COUNT button 14

The Stand-by button 15

Programming cook times 16

Recommended cleaning schedule 19

Daily cleaning 19

Weekly cleaning 20-21

Quarterly cleaning 22

Charcoal filter 23

Second filter 23

Semi-annual cleaninq and maintenance 24

Safety system test 24-25

Questions and Answers 26-28

Error Codes and Trouble Shooting Guide 29

Maintenance IOG 30-32

Wiring Diagrams 33-34

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 3

AUTOFRY Models FFG-10 and MTI -10 Operator's Manual

Information in this document is subject to change without notice and without incurring any

obligations for the equipment previously or subsequently sold. No part of this document may be

reproduced or trans mitted in any form or by any means, electronic or mechanical, for any

purpose, without the express written permission of Motion Technology, Inc.

NO HOODS?

NO VENTS?

NO PROBLEM!

Is a registered trademark of Motion Technology, Inc.

1999 Motion Technology, Inc. All rights reserved

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 4

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

Table of Figures

Figure 1 Re-set high limit 2

Figure 2 Install legs 3

Figure 3A

Figure 3B Separate food entry chute 4

Figure 4 Filter cover plate 5

Figure 5

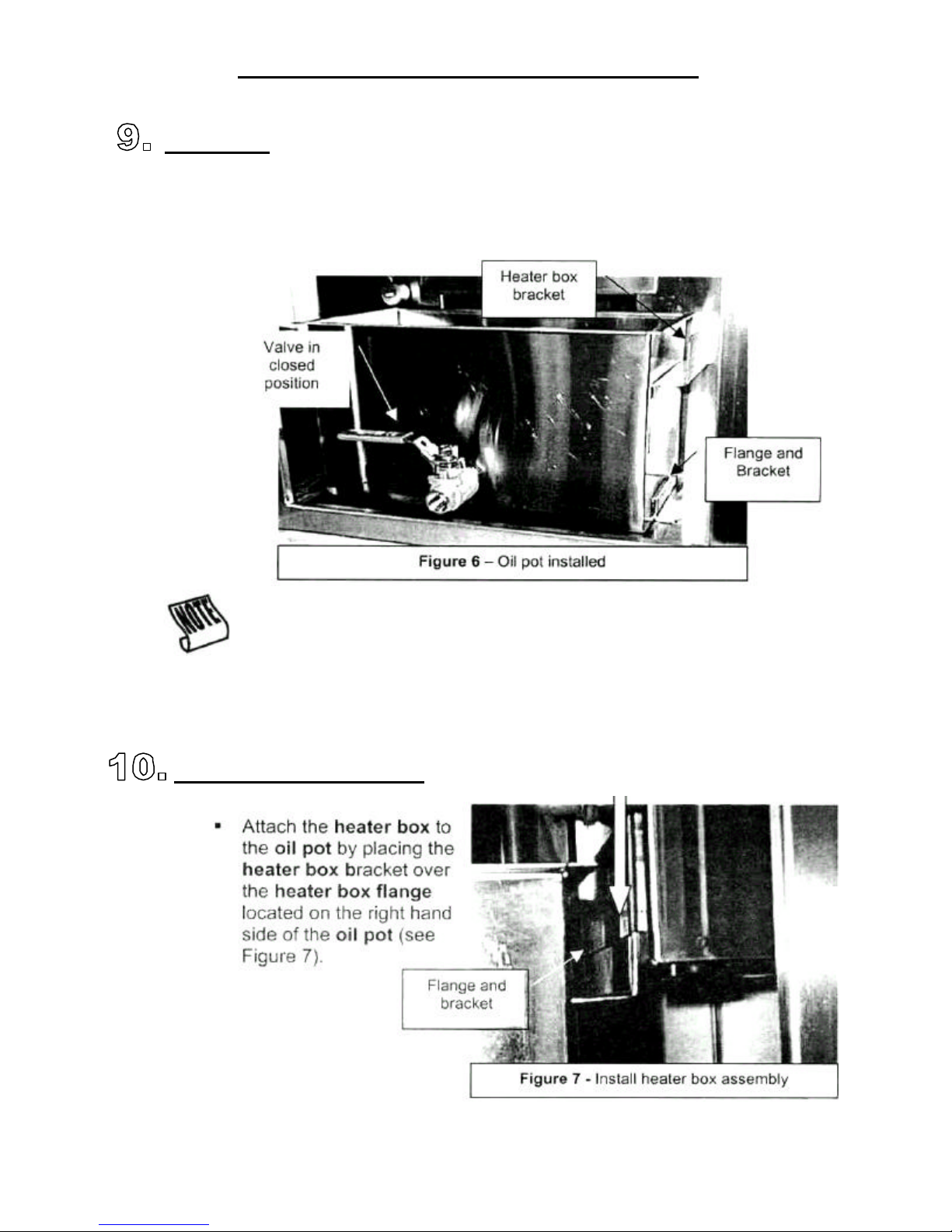

Figure 6 Oil pot installed 6

Figure 7 Install heater box assembly 6

Figure 8A

Figure 8B Thermocouple plug 7

Figure 9 Install food exit chute 8

Figure 10A

Figure 10B Basket rod and receiver clip 9

Figure 11 Completed installation 9

Figure 12A

Figure 12B MTI -10 Fusable link and cable 20

Figure 13A Removable stack cover / fire damper 22

Figure 13B

Remove food entry chute 4

Charcoal filter 5

RTD plug 7

Basket rod and cam 9

FFG-10 Fire actuation cable 20

Fan section 22

MTI FormOP-0010 Rev. 005 5/98 E167654

ii

Page 5

AUTOFRY Models FFG -10 and MTI-10 Operators Manual

Specifications

AUTOFRY Model FF6-10

Electrical Specifications:

208/240 ACV Single Phase Dedicated Grounded Circuit

3750 Watts

18Ampsat208ACV

15.63Ampsat240ACV NEMA 6-20

Plug ETL and NSF Listed BOCA - ES

AUTOFRY Model MTI-10 with RTD

Electrical Specifications:

208 ACV Single Phase Dedicated Grounded Circuit

3750 Watts 18 Amps

NEMA 6-30 Plug UL, cUL and NSF Listed

BOCA - ES

240 ACV Single Phase Dedicated Grounded Circuit

3750 Watts

15.63Amps

NEMA 6-20 Plug

UL, cUL and NSF Listed BOCA - ES

AUTOFRY Model MTI-10 with Thermocouple

Electrical Specifications:

240 ACV Single Phase Dedicated Grounded Circuit

4800 Watts

21Amps

NEMA 6-30 Plug

UL, cUL and NSF Listed BOCA - ES

Physical Specifications for All Models:

Dimensions:

Length 25-1/2" Width 27-1/2" Height 28-3/4"(with 4" legs)

Clearances:

Sides and Back: 2" Top: 24" Min.

Weight: 180Lbs.

Materials: 304 Stainless Steel

Shipping Dimensions: 32" x 32" x 32"

MTI Form OP-0010 Rev. 005 5/98

E167654

iii

Page 6

AUTOFRY Models FFG-10 and MTI -10 Operator's Manual

1

AUTOFRY Models FFG-10 and MTI -10 Set-up and Installation

The AUTOFRY comes from the factory complete with everything you will need to start

cooking with the exception of food and oil. By following these si mple instructions you can

have your AUTOFRY installed and ready to earn profits for you in as little as 30 minutes.

Prepare electrical service.

A licensed electrician in accordance with the National Electrical Code (NEC) and all local

codes must install electrical service. Do not remove or otherwise alter the factory supplied

power cord or plug. Never attach the AUTOFRY to an extension cord. Consult the

Identification Tag for equipment wattage and voltage.

Motion Technology, Inc. will not assume responsibility for any

injuries or equipment malfunctions resulting from non-

conforming electrical installations.

Prepare counter top.

Choose a counter top location that is sturdy, level, easily cleanable and fire resistant.

Stainless steel, fire resistant plastic laminate or solid surface materials are acceptable.

Never use a porous material to prepare food as bacterial contamination could result.

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 7

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

AUTOFRY Installation.

You will need assistance to position and install the AUTOFRY. The approximate

weight of the unit is 180 pounds

Remove and save the packing materials.

Be sure to inspect the AUTOFRY. Your AUTOFRY has left the factory in perfect

condition and has been packaged to withstand rugged travel. However, in the event

that you observe damage to the AUTOFRY, you should contact the carrier

immediately and report any damages. Be sure that you have your signed bill of

lading.

Take out the removable components from inside the AUTOFRY.

• 4 adjustable legs

• " A 36" drain hose

• Food exit chute

• Wire food basket

• * Heater box assembly

• Oil pot

• Oil catch tray

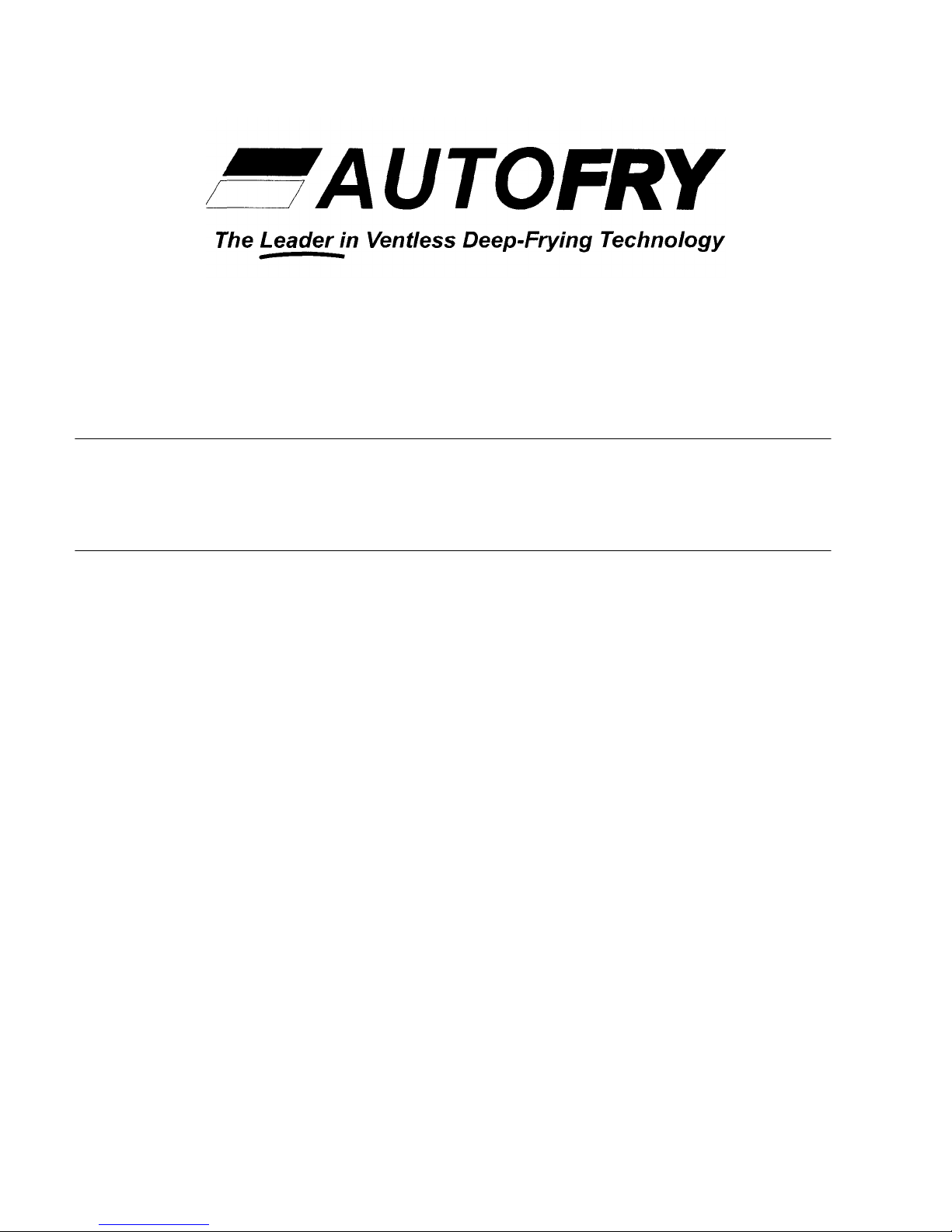

* Check the red high limit re-set button on the bottom of the heater box

assembly by fully depressing it with the eraser end of a pencil. If the limit has been

tripped you will hear a "click" (see Figure 1).

MTI FomnOP-0010 Rev. 005 5/98

E167654

2

Page 8

AUTOFRY Models FFG-10 and MTI -10 Operator's Manual

3

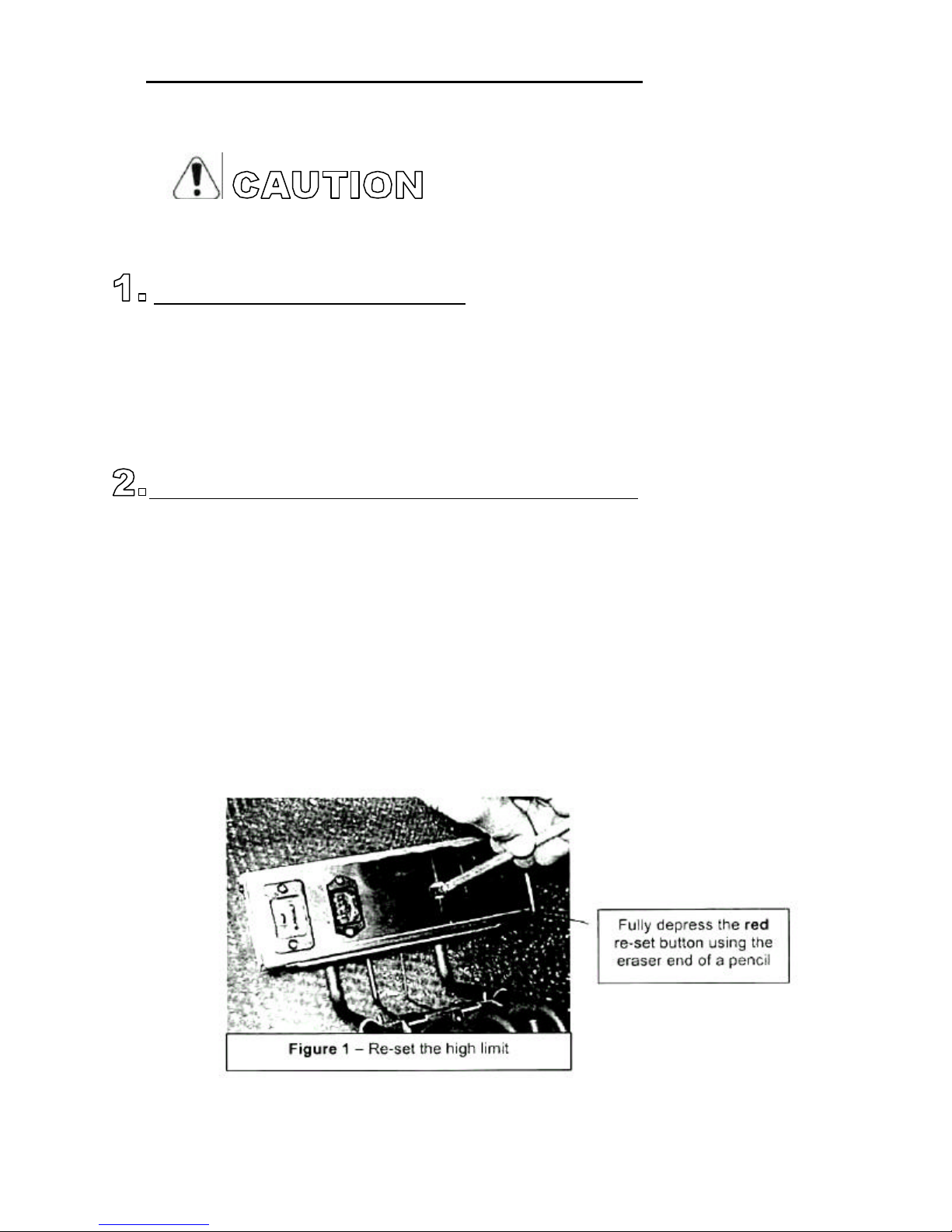

Charcoal filter removal and leg installation.

• With the AUTOFRY still on its shipping pallet, tilt the unit backward and remove the

charcoal filter from the food exit cutout.

• Install two of the adjustable legs by rotating them clockwise to a hand tight fit into

the front two leg plates located on the underside of the AUTOFRY.

• Tilt the AUTOFRY forward and repeat the leg installation for the rear two legs (see

Figure 2).

. Place on counter.

• Carefully place the AUTOFRY on the counter

• Adjust the legs (as needed) to level the AUTOFRY.

• Make sure that nothing is placed on top of the AUTOFRYwhich could obstruct the

exhaust system.

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 9

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

4

Initial Cleaning.

• Wash the oil pot, wire food basket, oil catch tray and food exit chute

in warm soapy water followed with a clear water rinse.

• Remove the food entry chute by turning the food chute knob

counterclockwise (see Figure 3A).

• Separate the two-piece food entry chute and wash in warm soapy

water followed with a clear water rinse (see Figure 3B).

Sanitize parts.

• All parts must be sanitized in a quaternary ammonia or iodine solution at a

temperature of at least 75° F following the manufacturers label instructions.

• Re-assemble and re-install the clean dry parts.

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 10

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

5

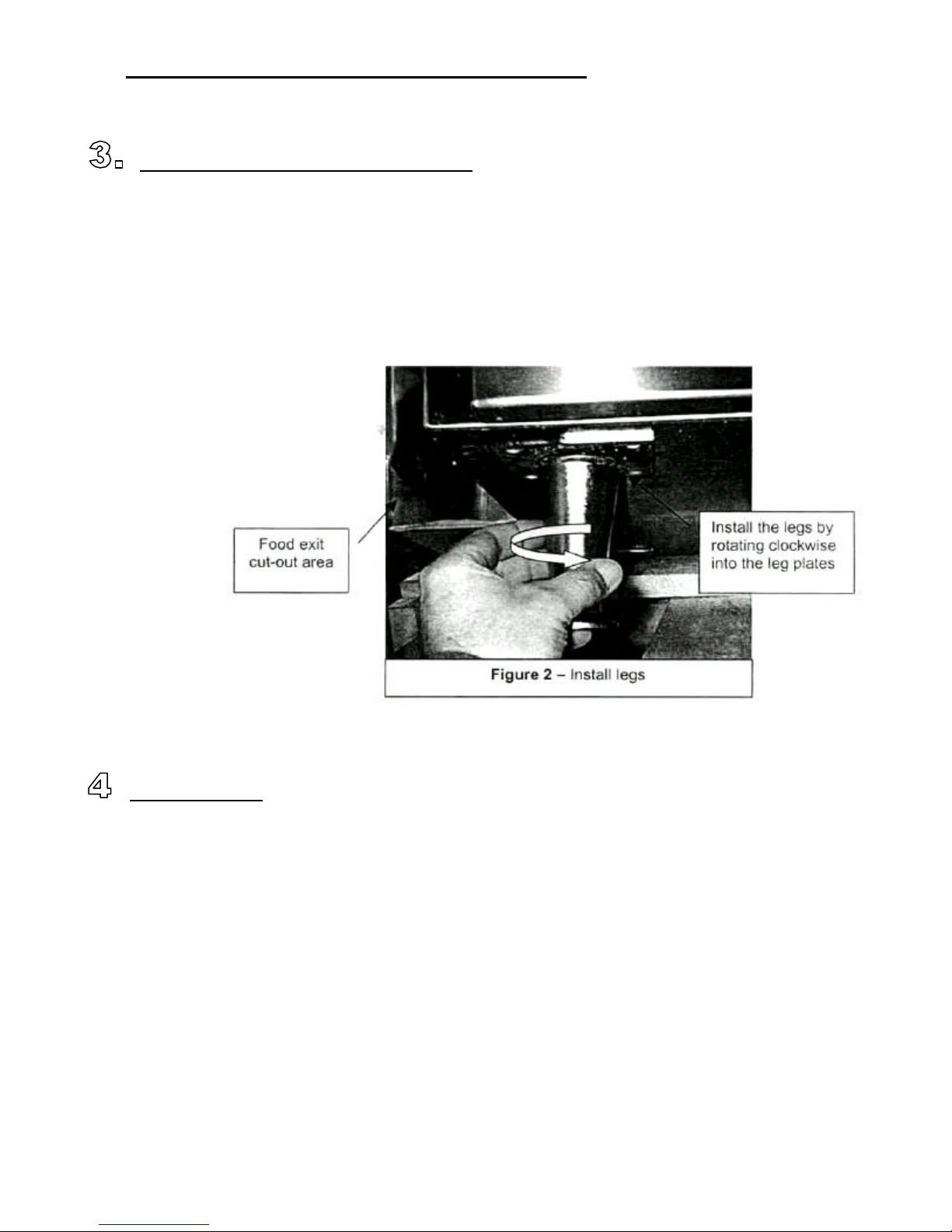

Install Charcoal Filter

• Remove the filter cover plate from the back interior wall of the cooking

chamber by removing the two black plastic knobs securing the cover

plate (see Figure 4).

• Remove the charcoal filter from the plastic bag with the flange facing

down and facing you insert it into the tracks above the second filter (see

Figure 5).

• Re-install the filter cover plate by turn ing the black plastic knobs

clockwise to a hand tight fit. Verify that the word "TOP" on the filter cover

plate is in the upper left-hand corner (see Figure 4).

Both the grease baffle and the second filter have small holes along the one

side of the frame. These drain holes must be facing down in order for the filters to

efficiently drain and clean the air (see Figure 5).

Sanitize interior.

All interior surfaces must be sanitized in a quaternary ammonia or iodine

solution at a temperature of at least 75° F following the manufacturer's label

instructions.

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 11

AUTOFRY Models FFG-10 and MTI -10 Operator's Manual

6

Install oil pot.

• Place the oil pot into the cooking chamber and install the oil pot bracket onto

the oil pot flange mounted on the floor of the cooking chamber. Ensure that

the drain valve is in the closed position (see Figure 6).

Experience has shown that an even light application of Kote® bran soil shield

on the exterior surfaces of the oil pot will prove helpful when it is time to clean

the oil pot. To order call 800-348-2976.

Install the heater box assembly.

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 12

AUTOFRY Models FFG -10 and MTI-10 Operators Manual

7

Connect the RTD or Thermocouple plug.

• The RTD plug will install into the smaller socket on the underside of the

heater box (see Figure 8A).

• The yellow thermocouple plug will install into the yellow socket on the

underside of the of the heater box (see Figure 8B).

It is very important that these plugs are seated firmly into their

respective sockets to prevent inaccurate temperature readings.

Connect the heater plug.

• The heater plug wil l attach to the heater socket on the underside of the

heater box (see figures 8A & 8B).

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 13

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

8

Add liquid shortening (2.5- 2.75 Gallons).

• Making certain that the drain valve is in the closed position (see Figure

6) add liquid shortening to the oil pot. Ensure that the oil level is

approximately 1/2" - 3/4" below the fill line stamped on the interior of the

oil pot.

It is simpler and safer to add cool shortening to the oil pot than it is to remove

hot shortening. Once the AUTOFRY has heated the shortening will expand.

Only after this expansion has finished should the oil level be increased to the

FILL level.

Over filling will result in excessive splashing; never over fill the oil pot.

Under-filling the oil pot will result in under-cooked food product or poor

and erratic temperature readings. Extreme low oil levels could cause

smoking.

NEVER operate the AUTOFRY in a low or no oil condition

Install the food exit chute.

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 14

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

9

Install the wire food basket.

• Insert the square end of the basket rod into the slot in the basket

cam located on the back wall of the cook chamber (see Figure 10A).

• Install the round end of the basket rod into the receiver clip located

just inside the cook chamber and to your left. (see Figure 10B).

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 15

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

10

Power.

• Close and lock the main door of the AUTOFRY.

• Plug the AUTOFRY into the properly rated, single phase, grounded

outlet.

• Pr ess the ON button at the keypad. There may be a 10-12 second

delay prior to display.

• The AUTOFRY will take between 15-20 minutes to reach the ready

temperature. It is important to allow the AUTOFRY to reach the ready

temperature prior to entering food.

You are now ready to start cooking. Please turn to Let's Get Cooking!

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 16

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

11

Let's Get Cooking !

Starting the AUTOFRY

• With the main door closed and locked, press the ON button to begin

heating the oil.

• The O WAIT light will illuminate on the keypad and the exhaust fan will

start to run.

• The current oil temperature will appear on the keypad. This display will

be delayed approximately 12 seconds on the AUTOFRY equipped with

the RTD.

• When the oil temperature reading is between 190°F - 220°F the wire

food basket will complete one test cycle. At this time you may hear the

basket hitting the sidewall of the AUTOFRY. This is a normal condition.

Should the display go blank at this time simply press the ON button to

continue heating the oil.

When the oil temperature at the display reaches 300°F press the OFF

button at the keypad. Unlock and open the main door to check the oil

level. Add oil, if necessary, to fill the oil pot to the "FILL" line.

Close and lock the main door and press the ON button to re-start

the AUTOFRY.

The AUTOFRY equipped with the RTD will allow you to begin cooking at 300° F

however, we recommend that you wait until oil temperature has reached 350°F.

The AUTOFRY equipped with the thermocouple will be ready at 340°F. It takes the

AUTOFRY between 12-20 minutes to heat the oil to 350°F.

Although the heating element is programmed to stop heating at 350°-354°F,

the oil temperature can go as high as 365°F due to the circulation of the oil

in the oil pot. This is a normal condition.

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 17

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

Begin Cooking

Cooking with the AUTOFRY is as simple as 1, 2, 3,1, 2, 3,

1. Enter a cook time by pushing buttons 0-9 on the keypad

For example, to cook for 2 minutes and 30 seconds:

Push 2,3, and 0

The display will read 230

If you enter the wrong time press CLEAR and re-enter your cook

time. Most food products will have recommended cook times

printed on their packaging; use these cook times as a base line

starting point

2. Open the food entry door and place the food product to prepare in the

food chute.

3. Close the food chute and push the START button.

During Cooking

The O READY light has gone out and the O WAIT light will illuminate.

• The display will count down the selected cook time. " The wire food basket

now contains your food product. It will automatically be lowered into the oil

pot.

• At the end of the COOK CYCLE oil temperature replaces time at the

display. The wire food basket will be raised out of the oil pot and drain the

food product for 12 seconds.

• At the conclusion of the DRAIN CYCLE the basket will dispense the food

down the food exit chute. You may hear the sound of the basket hitting the

sidewall. This is a normal condition.

• The DISPENSE CYCLE is repeated once to ensure that all the food has

been emptied from the wire food basket.

• The wire food basket will return to the ready position, the O WAIT light will

go out and the O READY light will illuminate. A quick "beeping" sound will

occur to signal that the AUTOFRY is ready for the next order.

MTIFormOP-0010 Rev. 005 5/98.

E167654

12

Page 18

AUTOFRY Models FFG-10 and MTI -10 Operator's Manual

13

AUTOFRY Shutoff Procedure

Push OFF.

• The keypad display will shut off immediately and the oil will begin to cool.

• The AUTOFRY is safely shut off

The oil will remain hot for a long period. To assu re continuous air cleaning,

the fan will continue to run for about 2 hours or until the oil temperature falls

below 190° F.

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 19

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

14

Additional KEYPAD Functions

The Count Button

The COUNT button tracks equipment cycles and this function can be utilized to

record sales and control inventory.

For the AUTOFRY equipped with an RTD this feature is a cumulative counter

and is not re-settable.

To use COUNT follow this procedure:

Press COUNT to determine the cumulative count of cook cycles

performed by the AUTOFRY.

A display of up to two sets of three numbers will appear on the

keypad:

• From 0-999 total COOK CYCLES, the keypad will display

ONE set of THREE numbers.

examples:

1. 030 = 30 total cook cycles

2. 302 = 302 total cook cycles

3. 999 = 999 total cook cycles

• At 1,000 total cook cycles and up to 6,999 the keypad will

display TWO sets of THREE numbers.

examples:

1. 001 followed by 002 = 1,002 total cook cycles

2. 006 followed by 001 = 6,001 Total cook cycles

• After 6, 999 total cook cycles the counter will return to

000.

For the AUTOFRY utilizing the thermocouple there are two count

features. A re-settable count and a total cumulative count.

To access these count features simply press the COUNT button once to view

the re-settable count. While the count is on the display press the CLEAR

button to clear the count. By pressing the COUNT button twice you can view

the total non resettable count.

MTIFormOP-0010 Rev. 005 5/98

E167654

Page 20

AUTOFRY Models FFG-10 and MTI -10 Operator's Manual

The Stand-By Button

The Button is used during off peak hours to conserve energy and

maximize oil life.

To Activate Stand-By Mode

For all AUTOFRY models, press the

button and the 0 STAND BY

light will illuminate.

The heating element shuts off until the oil temperature drops below 300° F and

then maintains this temperature.

To Exit Stand-By Mode

? For the AUTOFRY with an RTD

Press the button.

? For the AUTOFRY with a thermocouple

Press the CLEAR button

The 0 STAND BY light will go out and the oil will begin to heat up until it reaches

the ready temperature.

Never shut off the AUTOFRY while in the Stand-By mode as the keypad may remain

locked in the Stand-By mode! If this should happen when you

re-start the AUTOFRY simply press the key a second time or press the

CLEAR button.

Repeat Cook Time

Use the following procedure to repeat the last entered cook time:

• Simply press the START and your last cook time will be repeated.

This may be useful if you have a single product menu or multi-product menu

with identical cook times.

Maximum Cook Time

The AUTOFRY equipped with the RTD has a maximum cook time of 10 minutes

and 49 seconds.

The AUTOFRY equipped with thermocouple has maximum cook time of 15 minute

and 59 seconds.

MTI FormOP-0010 Rev. 005 5/98 15

E167654

Page 21

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

16

Programming Cook Times

The AUTOFRY equipped with a thermocouple offers you the ability to program the

1-6 keys for your most common cook times. It is a good idea to write down your six

most commonly used cook times prior to programming the AUTOFRY. Instructions

for programming are as follows,

Entering the programming mode.

1. Press the OFF Button.

2. Simultaneously press the 2 and 0 buttons.

• The display will read P =

3. Press 2 then 2 then 2 then START.

• The display will read 001.

Key # 1

1. Press the 1 key to view or edit the pre-set cook time.

• The display will read 1:00.

2. Press the 2 key to increase the cook time or press the 3 key to decrease the

cook time.

3. Press the 1 key to save the changes.

• The display will return to 001.

If you do not wish to continue re-programming the other 5 buttons simply press the

OFF button. Otherwise, with the display reading 001 follow these instructions:

Key # 2

1. Press the 2 button.

• The display will read 002.

2. Press the 1 button to view or edit the pre-set cook time.

• The display will read 2:00.

3. Press the 2 key to increase the cook time or press the 3 key to decrease the

cook time.

4. Press the 1 button to save the changes.

• The display will return to 002.

If you do not wish to continue re-programming the other 4 buttons simply press the

OFF button. Otherwise, with the display reading 002 follow these instructions:

MTIFormOP-0010 Rev. 005 5/98

E167654

Page 22

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

Programming Cook Times (cont.)

1. Press the 2 button.

• The display will read 003.

2. Press the 1 button to view or edit the pre-set cook time.

• The display will read 3:00.

3. Press the 2 key to increase the cook time or press the 3 key to decrease the cook

time.

4. Press the 1 button to save the changes.

• The display will read 003.

If you do not wish to continue re-programming the other 3 buttons simply press the OFF

button. Otherwise, with the display reading 003 follow these instructions:

1. Press the 2 button.

• The display will read 004.

2. Press the 1 button to view or edit the pre-set cook time.

• The display will read 4:00.

3. Press the 2 key to increase the cook time or press the 3 key to decrease the cook

time.

4. Press the 1 button to save the changes.

• The display will read 004.

If you do not wish to continue re-programming the other 2 buttons simply press the OFF

button. Otherwise, with the display reading 004 follow these instructions:

1. Press the 2 button.

• The display will read 005.

2. Press the 1 button to view or edit the pre-set cook time.

• The display will read 5:00.

3. Press the 2 key to increase the cook time or press the 3 key to decrease the cook

time.

4. Press the 1 button to save the changes.

• The display will read 005.

If you do not wish to continue re-programming the last button simply press the OFF

button. Otherwise, with the display reading 005 follow these instructions:

MTI FormOP-0010 Rev. 005 5/98 17

E167654

Page 23

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

18

Programming Cook Times (cont)

1. Press the 2 button.

• The display will read 006.

2. Press the 1 button to view or edit the pre-set cook time.

• The display will read 6:00.

3. Press the 2 key to increase the cook time or press the 3 key to decrease the

cook time.

4. Press the 1 button to save the changes.

• The display will read 006.

Exit programming mode

To exit the programming mode press the OFF key. You have now pre-

programmed your AUTOFRY for optimum convenience.

Using the pre-programmed times

To use the pre-programmed keys simply press the 1-6 key. The display will show

001-006. Place the selected food into the food entry chute, close the entry chute

door and press the START key. The di splay will count down the pre-programmed

time.

MTIFormOP-0010 Rev. 005 5/98

E167654

Page 24

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

19

Recommended Cleaning Schedule

In order to ensure compliance with State, local and

National health and safety standards regular

maintenance must be performed.

Regular maintenance is extremely important for the health and safety of your

customers.

Proper maintenance is very important in order for your AUTOFRY to continue to operate

without the need for a hood and duct system.

Regular oil changing, as an important part of your regular maintenance, will enhance the

taste of your food product. Oil changing will vary widely depending on the use of the

AUTOFRY. However, the use of a shortening monitor kit is the most accurate means of

determining the status of the oil.

Daily Cleaning

Remove and wash the following in warm soapy water followed by a clear

water rinse:

• The wire food basket

• The food entry chute " The food exit chute

• The filter cover plate

• The grease baffle " The second filter

Thoroughly dry all parts

Remove the charcoal filter and wipe down the exterior surfaces with a clean

damp cloth or paper towels.

Never soak the charcoal filter as permanent damage to the charcoal medium will

result!

MTIFormOP-0010 Rev. 005 5/98

E167654

Next Page

Page 25

AUTOFRY Models FFG-10 and MTI -10 Operator's Manual

20

Daily Cleaning (cont.)

Use extreme caution when cleaning around the fire system actuation cables and

fusible link in the interior cabinet. Accidental discharge of the fire system could

result, (see Figures 12A & 128).

Clean all interior surfaces to bare metal.

Sanitize all part and interior surfaces in a quaternary ammonia or iodine

solution at a room temperature of at least 75° F following the manufacturer's

label instructions.

Polish the exterior surfaces using a commercial grade stainless steel

polish and a soft cloth.

Replace all the clean dry components and add oil or shortening as

needed.

MTIFormOP-0010 Rev. 005 5/98

E167654

Page 26

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

21

Weekly Cleaning

Repeat daily cleaning.

Remove the heater box assembly.

Never immerse the heater box. Permanent damage will

result. Use caution when cleaning around the

temperature probes.

Remove the oil pot.

? Discard the oil or shortening in an environmentally safe manner.

• Clean all surfaces to bare metal

• Re-apply a thin even coating of Kote ® brand soil shield to the exterior

surfaces of the oil pot.

Clean all interior surfaces to bare metal

Use extreme caution when cleaning around the fire

system actuation cables and fusable link in the

interior cabinet. Accidental discharge of the fire

system could result, (see figures 12A & 12B).

Sanitize all part and interior surfaces in a quaternary ammonia or iodine

solution at a room temperature of at least 75° F following the manufacturer's

label instructions.

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 27

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

22

Quarterly Cleaning and Maintenance

Disconnect (un-plug) the AUTOFRY from main power

Perform weekly cleaning routine.

Remove and clean to bare metal the removable stack cover/fire damper and fan

section with a clean dry cloth or absorbent paper towels (see Figure 13Aand 13B).

Re-install the clean dry stack cover / fire damper.

MTIFormOP-0010 Rev. 005 5/98

E167654

Page 28

AUTOFRY Models FFG -10 and MTI-10 operator's Manual

23

Charcoal Filter

VERY IMPORTANT In order for the AUTOFRY to continue to perform as a

ventless cooking appliance the charcoal filter medium or

activated charcoal must be changed a minimum of every three months. This

maintenance is required by your equipment warranty.

While replacing the charcoal medium is easy, there will be some charcoal dust

present. Replacing the charcoal medium should be performed away from your food

preparation areas.

Remove the charcoal filter.

Remove the four screws holding the perforated cover.

• Pour the used charcoal into a suitable container.

• Clean the re-usable housing and perforated screen to bare metal

in warm soapy water followed by a clear water rinse.

• Thorou ghly dry the housing and cover.

Pour the new charcoal into the housing and re-seat the cover and

screws.

Replace the charcoal filter and all the filter components.

All activated carbons do not have the same performance

characteristics. Use replacement charcoal supplied by AUTOFRY

which can be ordered by calling 1-800-348-2976.

Second Filter

The second filter must be replaced a minimum of once every 6 months. Heavy

usage may require that the second filter be changed more frequently; however, if

it appears the second filter can no longer be cleaned effectively then it should be

replaced!

Second filters can be ordered by calling 1-800-348-2976.

MTIFormOP-0010 Rev. 005 5/98

E167654

Page 29

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

24

Semi-Annual Cleaning and Maintenance Fire

Suppression System

An inspection report / insurance certificate of installation will be forwarded to you by

mail shortly after shipment of your AUTOFRY. This document must be filed in a safe

place for future reference.

An inspection of the fire suppression system must be performed every six months

in order to comply with NFPA 96, NFPA 17A and UL 197. A certified fire equipment

maintenance company must perform this inspection.

Consult your fire suppression system manual that has been supplied with this

document for details on the inspection and re-charge instructions.

Safety System Test

The safety system must be tested a minimum of once every six months. A

qualified equipment repair technician following these instructions should

perform this inspection.

This test must be started with a full oil pot of clean cool liquid shortening.

Open the main door of the AUTOFRY and press the ON button.

• The fan will operate for approximately 10-12 seconds then shut off.

• The display will either not come on or it will read Sft.

. Individually remove each of the components listed below.

. Close the main door and press the ON button.

• The fan will operate for approximately 10-12 seconds then shut off.

• The display will either not come on or it will read Sft.

1. The filter cover plate.

2. The grease baffle.

3. The second filter.

4. The charcoal filter.

5. The removable fire damper / stack cover.

MTIFormOP-0010 Rev. 005 5/98

E167654

Page 30

AUTOFRY Models FFG-10 and MTI -10 Operator's Manual

Safety System Test (cont.)

The AUTOFRYis equipped with an airflow switch. To test this switch follow these

instructions.

1. With all the filter components installed and the main door closed press the

ON button at the keypad.

2. Using a flat piece of cardboard or 1/4" plywood completely block the exhaust

flow at the fire damper / stack cover.

• The fan will begin to operate.

It can take upwards of 45 minutes for the air flow switch to react to the

blockage; However, after the air switch has closed, the display will either go

blank or display Sft.

If the oil has heated above 151° F the fan will continue to operate until it cools to

120° F.

Included with this manual is a maintenance log that must be signed and dated

after the completion of the daily, weekly and quarterly maintenance and testing.

Your local or State health and safety inspectors may require this log to be posted in

a conspicuous location.

MTI FormOP-0010 Rev. 005 5/98

E167654

25

Page 31

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

Q:

Can

1

cook more than french fries in my

AUTOFRY

? A: Yes. The

AUTOFRY

can

prepare a wide variety of products. However,

for best results we recommend pre

-

cooked froz

en products.

Q:

How often should

1

change my oil?

A:

That depends on what and how much product you are cooking. Generally

your oil should be changed at least once a week or as often as you deem

necessary to keep your food tast

ing fresh. The use of shortening test

strips will prove useful to determine the oil condition.

Q: 1 hear a "thump" just before and just after the food exits the

AUTOFRY

.

Is there something wrong?

A:

Nothing is wrong with the

A

UTOFRY

.

The sound you are hearing is the

wire food basket contacting the cabinet to ensure full delivery of the

entered food.

Q:

I've entered an order of food and nothing came out?

A:

Here are two of the most common reasons:

1.

The food was entered before the previous cook cycle was completed.

O

READY

the next order.

2. The wire food basket was not installed or not correctly installe

d. Q: I've just cleaned my

AUTOFRY

this

morning and when I turned it on

Sft

A03

A: Did you remember to re

-

install all three filters and the filter cover plate?

The

AUTOFRY

is equipped

with a safety interlock system that will not

allow you to operate it with even one of the three filters not installed.

Check that they are all installed, that the main door is closed and locked

and that there is nothing blocking the air vent

at the top of the

AUTOFRY

. Q:

417

Prb

A02

0

WAIT

A: The temperature sensing plug is not connected to the he

ater box. Ensure

that both plugs are clean and firmly seated into their sockets at the

bottom of the heater box.

26

Questions and Answers

Remember to wait for the

nothing happened or the display reads

I've just cleaned my AUTOFRY and the display reads

the

light is blinking and the fan won't shut off. What is wrong?

MTI FormOP-0010 Rev. 005 5/98

E167654

light to illuminate before entering

or

.

or

or

,

Page 32

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

oil or the charcoal filter is

in need of a change. Occasionally food product

is a "beeping" coming from the

AUTOFRY

.

What should

1

do?

A:

First press the

OFF

button. If the display does not clear un

-

plug the

AUTOFRY

to silence the "beeping" and clear the displa

y. Re

-

plug the

between orders to re

-

heat

the oil. Please wait until the oil temperature is

product in advance of your rush period.

It may be that the

MTI

-10 is just too small for your operation if this is th

e

case please call

AUTOFRY

at 1-800 348 2976

for information on the

Q:

There is a lot of o

il on the inside floor of the

AUTOFRY

.

Is the the oil pot

following items first.

•

Is the drain valve open?

•

Is the oil pot over

-filled?

boil

-

over.

•

Are you entering a se

cond order before the first order has dispensed?

27

Questions and Answers (cont.)

Q:

A:

Q:

My customers are complaining of odor. What's wrong?

Nothing is wrong with the AUTOFRY. It is simply time to change or add

will miss the food basket during entry and end up in the oil pot. If this

does happen it will over-cook and cause excess odor and erratic

temperature readings.

I am in the middle of my lunchtime rush, the display reads A05 and there

AUTOFRY and press the ON button. The A05 is an error message that

simply means the oil temperature has not recovered to 350° F in 16

minutes. Please keep in mind that the AUTOFRY needs some time

at or above 345° F prior to entering food. Alternatively you could prepare

MTI-40 Double Basket AUTOFRY.

An A05 could also be the result of a heater plug that is not connected

loosely connected or grease laden.

A:

is leaking?

Though not impossible it is unlikely that the oil pot is leaking. Check the

• Does your frozen product contain a lot of ice? Excessive ice will cause

• Does your frozen product contain a high level of water?

• Are you over filling the food entry chute?

• Although the AUTOFRY is fully enclosed it is a deep fryer and

splashing of oil is a normal condition.

MTI FormOP-0010 Rev. 005 5/98

E167654

Page 33

AUTOFRY Models FFG -10 and MTI-10 Operator's Manual

Q:

Why does my food come out oily and under

-

cooked?

A:

First, check that you have entered the correct cook time. It may be that

temperature

-

sensing plug

socket

heater box

high limit

(see page

2,

Figure

1). Q:

A04

A:

OFF

display and silence the "beeping".

A04

cause this:

wire

food basket

basket rod

basket cam

receiver

clip.

cook cycle

basket

cook cycle

basket

basket motor

moving parts are subject to malfunction. If this is the case please call

for service.

Q:

A06

A: You

must call our customer service center immediately

at 1-

800-348-2976

Ext.

124.

Q:

A07

A:

OFF

keypad

A07

minutes then plug the

AUTOFRY

back into main power and re

-

start the

A07

Q:

A08

A:

OF

F

A08

the oil temperature fluctuates by

50°

F in a five

-

second period this error

code will be displayed.

28

Questions and Answers (cont.)

the

properly seated in its

Check that the

My keypad is displaying

First press the

button or un-plug the AUTOFRY. This will clear the

, located on the underside of the heater box

has become fouled with oil or is not

at the bottom of the

and the AUTOFRY is "beeping"!

.

is an error message for the basket motor. One of several things can

1. A

is seated correctly into the

2. A power interruption during a

a short

3. Although the

The display on the AUTOFRY reads

that is not properly installed. Ensure that the

and the

. Remove the

then replace the

.

is very durable, it is a moving part. All

.

, enter

The display on the AUTOFRY reads

Begin by pressing the

is a frequency conflict error. Un-plug the AUTOFRY and wait 2-5

unit. If the

reoccurs please call for service.

The display on the AUTOFRY reads

Begin by pressing the

re-start the AUTOFRY.

MTI FormOP-0010 Rev. 005 5/98

E167654

.

button on the

to clear the display.

.

button on the key pad, wait 2-5 minutes then

is a temperature fluctuation error. Anytime

Page 34

AUTOFRY Models FFG-10 and MTI -10 Operator's Manual

10F 10C 12R3

NCC

Fault

/

Condition

Troubleshoot

To clear display and re

-

set

Check plugs

&

sockets. Check

Open or snorted RTD or

probe.

Check condition of all

Un-

plug from supply or press

Thermocouple Probe

cords and connections, (see

OFF

also

A07)

Blank

Blank

Check all safeties, check fan

Display

Display

A03 Sft Open Safety

operation, check fire system

Press OFF

w Fan

Fan On

gauge, check filter

On

Check

/

adjust air flow switch.

Check for broken gears, check

A04 A

04 Basket motor not in

all wire connections, check

Un-

plug from supply or press

positi

on after

10 switches, check switch cam

OFF

seconds

tightness.

Check supply voltage, check

Heater failure to reach

supply breaker, check limit re

Un-

plug from supply or press

A05 A05 A05 A05 set point in

16

Min.

49

set, check voltage at heater

OFF

plug.

Check yellow thermocouple

installation. Check cord

condition. Check connections

A07 Frequency C

onflict/

TC1 on circuit board. Check

Press OFF

Thermocouple short

connections at thermocouple

socket in heater box (yellow

= (+),

red

= (-)

period.

to clear board.

NOTE: AO errors should not be confused with cook times. Error codes do not use a colon cook

times do. The NCC controller can display cook times of

11

minutes as

follows

11

:02 =

A:02,

11

:03 = A:03

11

:04 = A:04,

11

:05 = A:05,

11

:06 = A:06

11

:07 =

A:07

11

:08 = A:08

Error Codes

EPROM DIAGNOSTICS

417

A04

213

A04

A02

Prb

N/A N/A N/A A06 Call Customer Service Call Customer Service Press OFF

A08

Temperature difference

of 50 Deg. In 5 second

Check oil level. Check oil

condition. Un-plug from wall

MTI FormOP-0010 Rev. 005 5/98

E167654

Press OFF and Un-plug from

supply

Loading...

Loading...