Page 1

AutoCAD MEP 2010

User's Guide

March 2009

Page 2

©

2009 Autodesk, Inc. All Rights Reserved. Except as otherwise permitted by Autodesk, Inc., this publication, or parts thereof, may not be

reproduced in any form, by any method, for any purpose.

Certain materials included in this publication are reprinted with the permission of the copyright holder.

Trademarks

The following are registered trademarks or trademarks of Autodesk, Inc., in the USA and other countries: 3DEC (design/logo), 3December,

3December.com, 3ds Max, ADI, Alias, Alias (swirl design/logo), AliasStudio, Alias|Wavefront (design/logo), ATC, AUGI, AutoCAD, AutoCAD

Learning Assistance, AutoCAD LT, AutoCAD Simulator, AutoCAD SQL Extension, AutoCAD SQL Interface, Autodesk, Autodesk Envision, Autodesk

Insight, Autodesk Intent, Autodesk Inventor, Autodesk Map, Autodesk MapGuide, Autodesk Streamline, AutoLISP, AutoSnap, AutoSketch,

AutoTrack, Backdraft, Built with ObjectARX (logo), Burn, Buzzsaw, CAiCE, Can You Imagine, Character Studio, Cinestream, Civil 3D, Cleaner,

Cleaner Central, ClearScale, Colour Warper, Combustion, Communication Specification, Constructware, Content Explorer, Create>what's>Next>

(design/logo), Dancing Baby (image), DesignCenter, Design Doctor, Designer's Toolkit, DesignKids, DesignProf, DesignServer, DesignStudio,

Design|Studio (design/logo), Design Web Format, Discreet, DWF, DWG, DWG (logo), DWG Extreme, DWG TrueConvert, DWG TrueView, DXF,

Ecotect, Exposure, Extending the Design Team, Face Robot, FBX, Filmbox, Fire, Flame, Flint, FMDesktop, Freewheel, Frost, GDX Driver, Gmax,

Green Building Studio, Heads-up Design, Heidi, HumanIK, IDEA Server, i-drop, ImageModeler, iMOUT, Incinerator, Inferno, Inventor, Inventor

LT, Kaydara, Kaydara (design/logo), Kynapse, Kynogon, LandXplorer, LocationLogic, Lustre, Matchmover, Maya, Mechanical Desktop, Moonbox,

MotionBuilder, Movimento, Mudbox, NavisWorks, ObjectARX, ObjectDBX, Open Reality, Opticore, Opticore Opus, PolarSnap, PortfolioWall,

Powered with Autodesk Technology, Productstream, ProjectPoint, ProMaterials, RasterDWG, Reactor, RealDWG, Real-time Roto, REALVIZ,

Recognize, Render Queue, Retimer,Reveal, Revit, Showcase, ShowMotion, SketchBook, Smoke, Softimage, Softimage|XSI (design/logo),

SteeringWheels, Stitcher, Stone, StudioTools, Topobase, Toxik, TrustedDWG, ViewCube, Visual, Visual Construction, Visual Drainage, Visual

Landscape, Visual Survey, Visual Toolbox, Visual LISP, Voice Reality, Volo, Vtour, Wire, Wiretap, WiretapCentral, XSI, and XSI (design/logo).

The following are registered trademarks or trademarks of Autodesk Canada Co. in the USA and/or Canada and other countries:

Backburner,Multi-Master Editing, River, and Sparks.

The following are registered trademarks or trademarks of MoldflowCorp. in the USA and/or other countries: Moldflow, MPA, MPA

(design/logo),Moldflow Plastics Advisers, MPI, MPI (design/logo), Moldflow Plastics Insight,MPX, MPX (design/logo), Moldflow Plastics Xpert.

Third Party Software Program Credits

ACIS Copyright© 1989-2001 Spatial Corp. Portions Copyright© 2002 Autodesk, Inc.

Flash ® is a registered trademark of Macromedia, Inc. in the United States and/or other countries.

International CorrectSpell™ Spelling Correction System© 1995 by Lernout & Hauspie Speech Products, N.V. All rights reserved.

InstallShield™ 3.0. Copyright© 1997 InstallShield Software Corporation. All rights reserved.

PANTONE® Colors displayed in the software application or in the user documentation may not match PANTONE-identified standards. Consult

current PANTONE Color Publications for accurate color. PANTONE Color Data and/or Software shall not be copied onto another disk or into

memory unless as part of the execution of this Autodesk software product.

Portions Copyright© 1991-1996 Arthur D. Applegate. All rights reserved.

Portions of this software are based on the work of the Independent JPEG Group.

RAL DESIGN© RAL, Sankt Augustin, 2002

RAL CLASSIC© RAL, Sankt Augustin, 2002

Representation of the RAL Colors is done with the approval of RAL Deutsches Institut für Gütesicherung und Kennzeichnung e.V. (RAL German

Institute for Quality Assurance and Certification, re. Assoc.), D-53757 Sankt Augustin.

Typefaces from the Bitstream® typeface library copyright 1992.

Typefaces from Payne Loving Trust© 1996. All rights reserved.

Printed manual and help produced with Idiom WorldServer™.

WindowBlinds: DirectSkin™ OCX © Stardock

®

AnswerWorks 4.0 ©; 1997-2003 WexTech Systems, Inc. Portions of this software © Vantage-Knexys. All rights reserved.

The Director General of the Geographic Survey Institute has issued the approval for the coordinates exchange numbered TKY2JGD for Japan

Geodetic Datum 2000, also known as technical information No H1-N0.2 of the Geographic Survey Institute, to be installed and used within

this software product (Approval No.: 646 issued by GSI, April 8, 2002).

Portions of this computer program are copyright © 1995-1999 LizardTech, Inc. All rights reserved. MrSID is protected by U.S. Patent No.

5,710,835. Foreign Patents Pending.

Portions of this computer program are Copyright ©; 2000 Earth Resource Mapping, Inc.

OSTN97 © Crown Copyright 1997. All rights reserved.

OSTN02 © Crown copyright 2002. All rights reserved.

OSGM02 © Crown copyright 2002, © Ordnance Survey Ireland, 2002.

FME Objects Engine © 2005 SAFE Software. All rights reserved.

AutoCAD 2009 is produced under a license of data derived from DIC Color Guide® from Dainippon Ink and Chemicals, Inc. Copyright

Dainippon Ink and Chemicals, Inc. All rights reserved.

Government Use

Use, duplication, or disclosure by the U.S. Government is subject to restrictions as set forth in FAR 12.212 (Commercial Computer

Software-Restricted Rights) and DFAR 227.7202 (Rights in Technical Data and Computer Software), as applicable.

©

Page 3

Contents

Chapter 1 New Features in This Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

New Features for Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

New Features for Drawing Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

New Features for Drawing Piping Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

New Features for Drawing Radiant Heating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

New Features for Customizing Catalogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

New Features for Customizing Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

New Features for Building Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2 Moving from AutoCAD to AutoCAD MEP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

AutoCAD to AutoCAD MEP Task Comparisons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Creating Building Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AutoCAD MEP Workspaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Insertion Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Layer Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Modifying Building Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Associative Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Snaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Automating Design Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Domain-Specific Ribbons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Auto Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Interference Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connectivity Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Working With Sizing and Calculation Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sizing Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Circuit Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Plumbing Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pipe Routing Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Solution Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Creating Accurate Construction Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Section Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

iii

Page 4

Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Labeling and Annotation Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Layout Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Project Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Leveraging AutoCAD Knowledge in AutoCAD MEP . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Working with AutoCAD Commands in AutoCAD MEP . . . . . . . . . . . . . . . . . . . . . . . . . . 20

ALIGN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

ARRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

BREAK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CHAMFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

COPY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

EXPLODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

EXTEND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

FILLET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

JOIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

LENGTHEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

MATCHPROP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

MIRROR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

MOVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

OFFSET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

PURGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

ROTATE and ROTATE3D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SCALE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

STRETCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

TRIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Help Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 3 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

About AutoCAD MEP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

AutoCAD MEP Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Intelligent Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Location of Part Catalogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Analysis Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Project Management Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Contacting Autodesk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Tutorials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Courseware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

E-Learning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Discussion Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Updating AutoCAD MEP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

The AutoCAD MEP 2010 Drawing Domain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Workspace Fundamentals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Default Workspaces in AutoCAD MEP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Creating Workspaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Switching Workspaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Workspace Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Workspace Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Displaying the Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Using the Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Locating Commands in the Workspace . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

iv | Contents

Page 5

Static Ribbon Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Contextual Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Application Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Accessing the Application Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Using the Application Menu to Locate Commands . . . . . . . . . . . . . . . . . . . . . 49

Displaying Recently Opened Documents in the Application Menu . . . . . . . . . . . . . 50

Displaying Currently Open Documents in the Application Menu . . . . . . . . . . . . . . 51

Changing the Number of Recent Files and Actions in the Application Menu . . . . . . . . 51

Quick Access Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Context Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

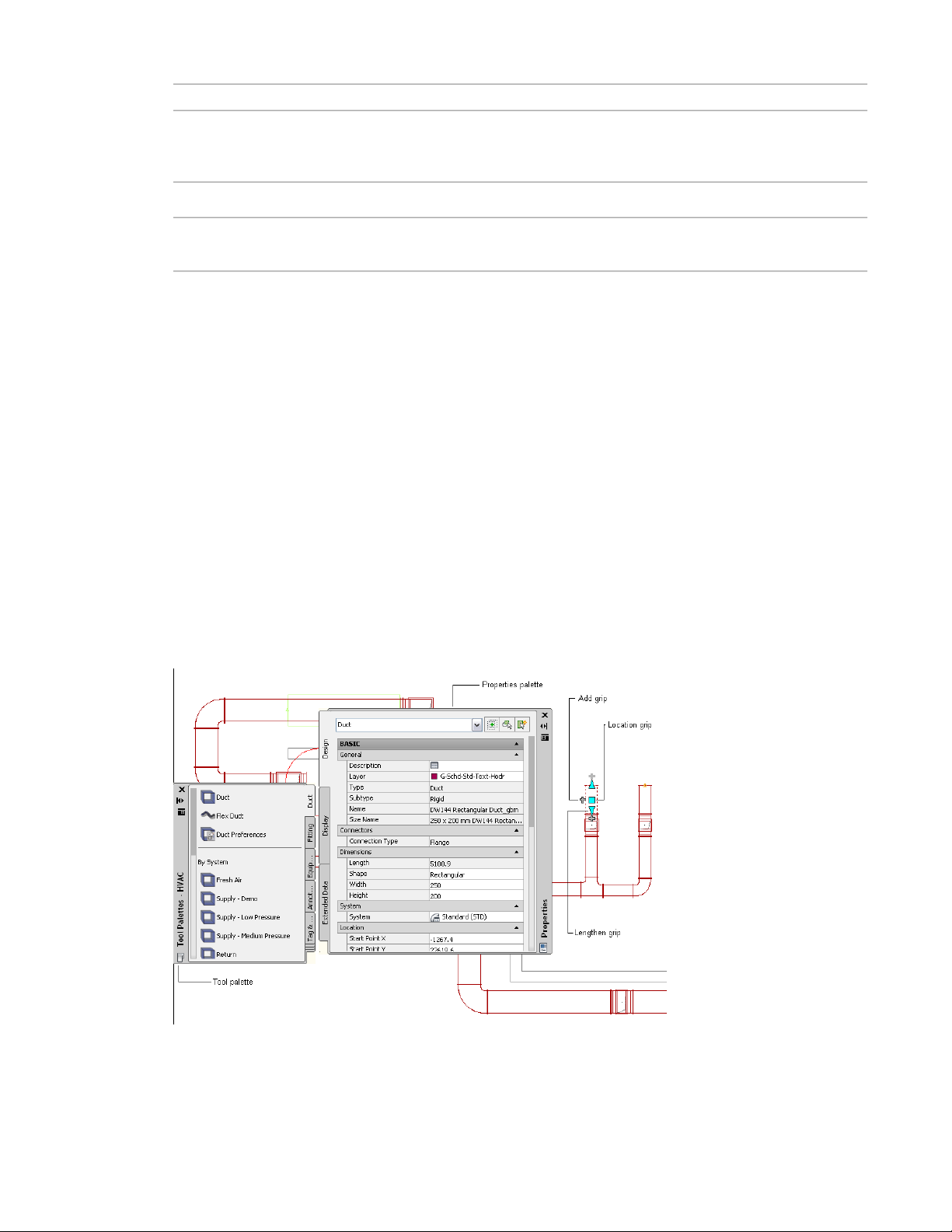

Tool Palettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Properties Palette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Drawing Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Showing and Hiding Commands on the Drawing Status Bar . . . . . . . . . . . . . . . . . 55

Showing and Hiding the Drawing Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . 55

Command Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Application Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Showing and Hiding Commands on the Application Status Bar . . . . . . . . . . . . . . . 58

Project Navigator Palette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Finding Information in AutoCAD MEP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

InfoCenter Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Communication Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

F1 Context Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Tooltips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Command Tooltips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Controlling the Display of Command Tooltips . . . . . . . . . . . . . . . . . . . . . . . . 61

Dialog and Palette Tooltips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Object Rollover Tooltips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Property Palette Tooltips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Thumbnail (Preview) Tooltips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Solution Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Object Grip Tooltips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Working in Model Space and Paper Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Customizing the Display of MEP Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Using Custom Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Chapter 4 Drawing Essentials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Drawing Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

About Layout Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Initialization Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Specifying Part Catalogs and Style-Based Content Locations . . . . . . . . . . . . . . . . . 70

Layout Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Defining System Elevations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Configuring Tooltip Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

AutoCAD MEP Snaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Mechanical, Electrical, and Plumbing Equipment in Building Systems . . . . . . . . . . . . . . . . . 76

Working with Catalog-Based Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

How Catalog Parts are Stored and Referenced . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

How Catalog Parts Are Defined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Part Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Default Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Importing a Building Component into AutoCAD MEP 2010 . . . . . . . . . . . . . . . . . . . . . . . 84

Working with Style-Based Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

How Style-Based Content is Stored and Referenced . . . . . . . . . . . . . . . . . . . . . . . . . 85

Orthographic and Isometric Views of Style-Based Content . . . . . . . . . . . . . . . . . . . . . 86

Working with Tool Palettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Opening the Tool Palette Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Changing the Active Group in the Tool Palette Set . . . . . . . . . . . . . . . . . . . . . . . . . 88

Contents | v

Page 6

Modifying the Appearance of the Tool Palette Set . . . . . . . . . . . . . . . . . . . . . . . . . 89

Docking the Tool Palette Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Hiding the Tool Palette Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Adjusting the Transparency of the Tool Palette Set . . . . . . . . . . . . . . . . . . . . . . 89

Modifying the Appearance of Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Working with the Properties Palette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Opening the Properties Palette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Modifying Object Properties Using the Properties Palette . . . . . . . . . . . . . . . . . . . . . 91

Modifying Display Properties Using the Properties Palette . . . . . . . . . . . . . . . . . . . . . 92

Modifying the Appearance of the Properties Palette . . . . . . . . . . . . . . . . . . . . . . . . 92

Docking the Properties Palette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Hiding the Properties Palette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Adjusting the Transparency of the Properties Palette . . . . . . . . . . . . . . . . . . . . . 92

Working with Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

About System Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Creating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Specifying the Design Rules of a System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Specifying the Rise/Drop Style of a System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Specifying the Display Properties of a System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Attaching Notes and Files to a System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Copying Systems Between Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Purging Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Selecting a Display Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Essentials of Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Object Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Matching Object Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Working with Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Working with Anchors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Attaching Objects with a Curve Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Attaching Objects with a System Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Attaching Objects with a Reference Anchor . . . . . . . . . . . . . . . . . . . . . . . . . 110

Rotating Objects Attached with Curve Anchors . . . . . . . . . . . . . . . . . . . . . . . 110

Releasing Anchored Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Part Anchors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Using the Compass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Customizing the Compass Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

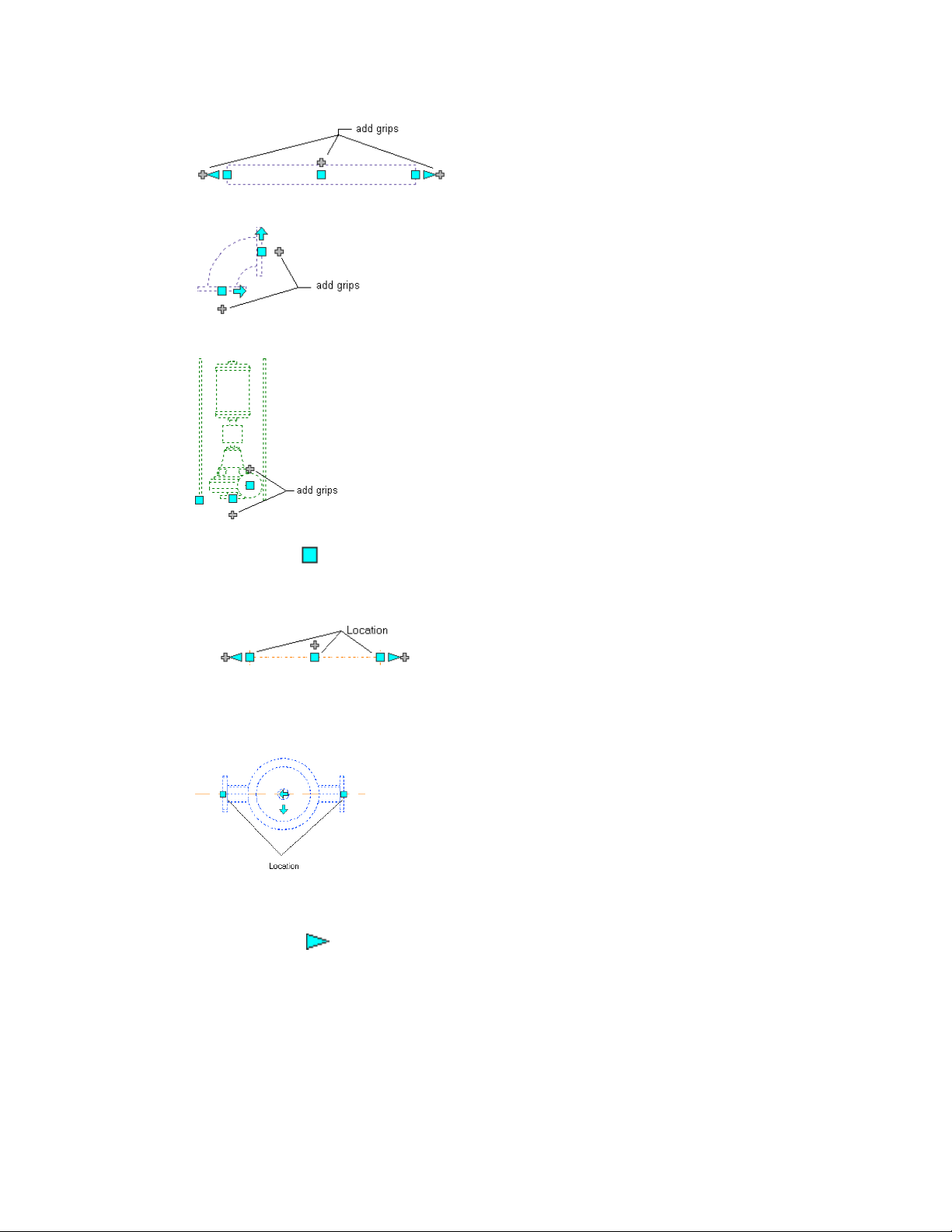

Designing with Dynamic Input and Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Dynamic Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Grip Tooltips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Grip Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Trigger Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Grip Editing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Drafting with Flow Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Selecting Similar Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Selecting MEP Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Regenerating an AutoCAD MEP Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Viewing Part Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Basic Part Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

System Assignments for Parts and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Part Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Part Property Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Part Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Chapter 5 Working with Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Working with Drawing Management Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Establishing Project Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

AutoCAD MEP Layer Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Layer Standards Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Layer Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

vi | Contents

Page 7

Layer Key Styles and Layer Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Layer Standards Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Layer Properties Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Specifying a Layer Standard and a Layer Key Style . . . . . . . . . . . . . . . . . . . . . . . . 134

Accessing Layer Key Styles and Layer Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

AutoCAD MEP Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Display System Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Display Representations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Display Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Display Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Hierarchy of Display Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Managing Display Settings During Project Setup . . . . . . . . . . . . . . . . . . . . . . 141

Configuring Display Settings During Design . . . . . . . . . . . . . . . . . . . . . . . . 143

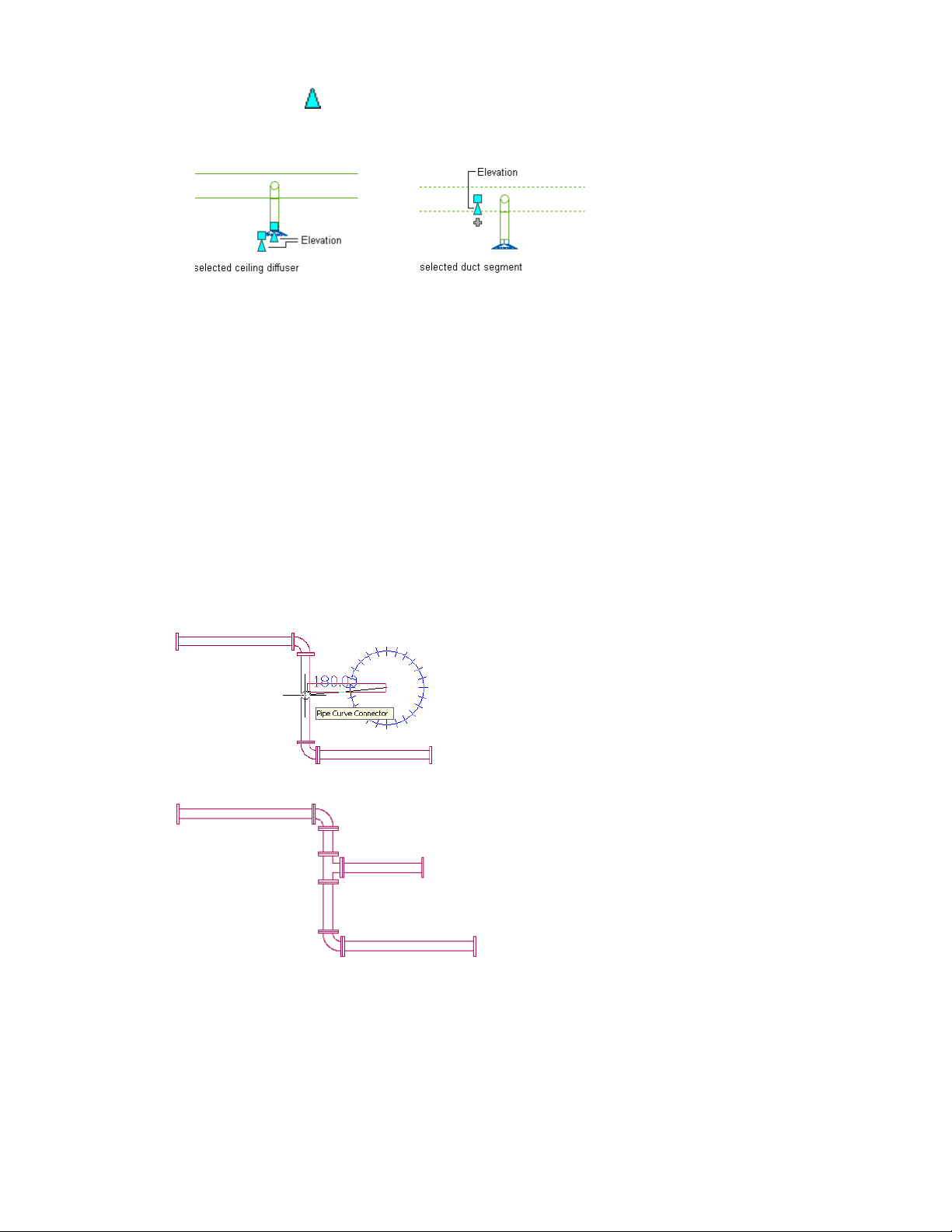

Display of Objects Based on Elevation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Workflow for Displaying Objects Based on Elevation . . . . . . . . . . . . . . . . . . . . 146

Enabling the Elevation-Based Display Components . . . . . . . . . . . . . . . . . . . . . 147

Specifying the Cut Plane and Display Range for a Display Configuration . . . . . . . . . 147

Configuring Elevation-Based Display Components . . . . . . . . . . . . . . . . . . . . . 149

Modifying Elevation-Based Display Components on the Properties Palette . . . . . . . . 149

Overriding the Cut Plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Display of Crossing Objects in 2-Line Plan Views . . . . . . . . . . . . . . . . . . . . . . . . . 151

Configuring the Display of a Gap Between Crossing Objects . . . . . . . . . . . . . . . . 151

Modifying Hidden Lines for Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Display of Center Lines on Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Display of Objects by Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Adding Custom Graphics as a Display Component . . . . . . . . . . . . . . . . . . . . . . . . 155

Troubleshooting Object Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

AutoCAD MEP Templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Default Drawing Templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Creating a Custom Template from a Template or Drawing . . . . . . . . . . . . . . . . . . . . 157

Creating a Custom Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Working with Referenced Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Attaching or Overlaying Xrefs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Reloading Xrefs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Clipping Xrefs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Changing the Display Configurations of Xrefs . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Chapter 6 Drawing HVAC Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

HVAC System Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Mechanical System Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Duct System Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Flow Annotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Flexible Duct Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Auto-layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

HVAC System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Duct Fitting Vanes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Takeoff Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Duct Sizing Methods and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Duct System Snaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Configuring Duct System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Configuring Duct Layout Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Configuring Justification for Duct Insertion . . . . . . . . . . . . . . . . . . . . . . . . . 174

Configuring Sloped Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Breaking Duct at Even Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Adding Lining or Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Adding Labels or Flow Arrows to Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Configuring the Display of Turning Vanes and Flanges . . . . . . . . . . . . . . . . . . . 178

Contents | vii

Page 8

Configuring Flexible Duct Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Specifying Default Parts for Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Configuring Duct Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Configuring Duct System Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Creating a Duct System Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Specifying a Calculation Method for Duct Sizing . . . . . . . . . . . . . . . . . . . . . . 182

Configuring the Display of Ducts and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Using Spaces for Load Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Configuring Space Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Viewing Classification Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Configuring Zone Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Adding Spaces to a Floor Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Adding Engineering Data to Spaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Attaching Property Sets to Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Attaching Spaces to Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Exporting Zones for Load Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Reviewing Spaces and Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Importing Load Analysis Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Using Space and Zone Calculated Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Creating a Duct System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Adding HVAC Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Adding HVAC Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Adding Parts In-Line to Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Configuring Mechanical Parts for Analysis . . . . . . . . . . . . . . . . . . . . . . . . . 196

Adding Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Drawing a Duct Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Adding Duct Using Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Drawing a Vertical Duct Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Drawing 1-Line Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Calculating Duct Sizes for a Duct System . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Adding a Duct Fitting Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Drawing Flexible Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Adding a Parallel Duct Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Offsetting Duct from Existing Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Drawing Sloped Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Using the Elevation Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Connecting Ducts Through Referenced Drawings . . . . . . . . . . . . . . . . . . . . . . 209

Adding a Takeoff to a Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Converting a Line to Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Converting a Polyline to Flexible Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Adding Turning Vanes to Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Creating a Custom Duct Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Using the Part Size Not Found Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Annotating a Duct System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Adding a Label to a Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Adding a Hatching Pattern to Identify a Duct System . . . . . . . . . . . . . . . . . . . . 219

Modifying a Duct System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

About Associative Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Selecting Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Modifying Components Using Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Moving Duct Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Modifying the Elevation of HVAC Parts and Ducts . . . . . . . . . . . . . . . . . . . . . 222

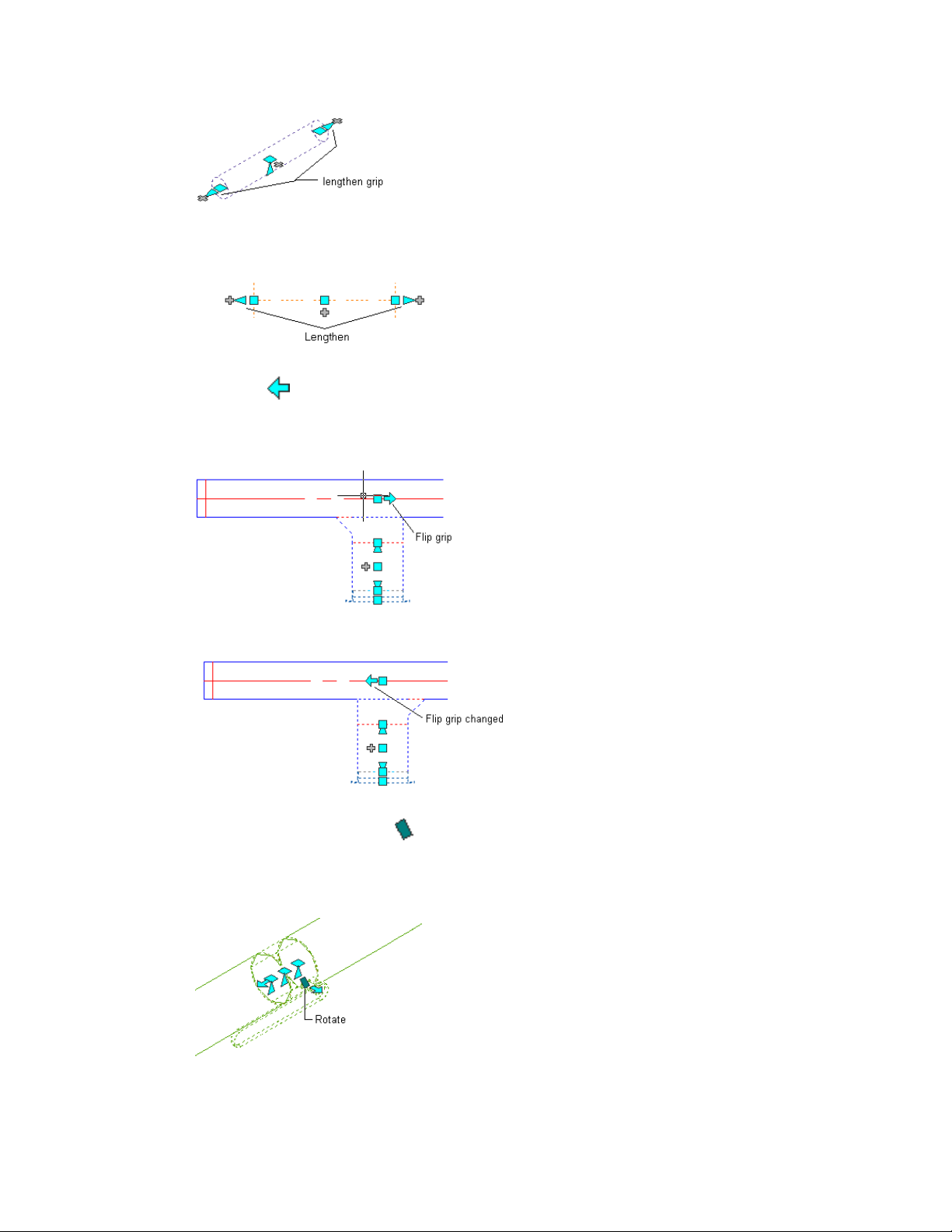

Modifying the Length of Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Rotating Duct Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Modifying HVAC Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Modifying HVAC MvPart Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Modifying HVAC Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Changing a Part to Match Another Part . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Modifying the Flow Value Assigned to a Part . . . . . . . . . . . . . . . . . . . . . . . . 232

Modifying the System Assigned to a Part Connection . . . . . . . . . . . . . . . . . . . 232

viii | Contents

Page 9

Modifying Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Modifying the Size or Shape of a Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Modifying Duct Using AutoCAD Commands . . . . . . . . . . . . . . . . . . . . . . . . 234

Breaking or Merging Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Locking the Size of a Duct or Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Modifying the System Assigned to a Duct . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Modifying a Duct Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Modifying the Layout of Flexible Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Moving an Off-Center Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Modifying a Custom Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Modifying Turning Vanes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Modifying Insulation or Lining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Checking Connectivity in a Duct System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Modifying Annotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Modifying a Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Calculating Duct Sizes Using External Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Specifying ASHRAE Fitting Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Exporting Duct System Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Importing Optimized System Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Resizing a System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Creating Duct System Construction Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Chapter 7 Drawing Piping Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Pipe Systems Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Workflow for Designing a Pipe System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

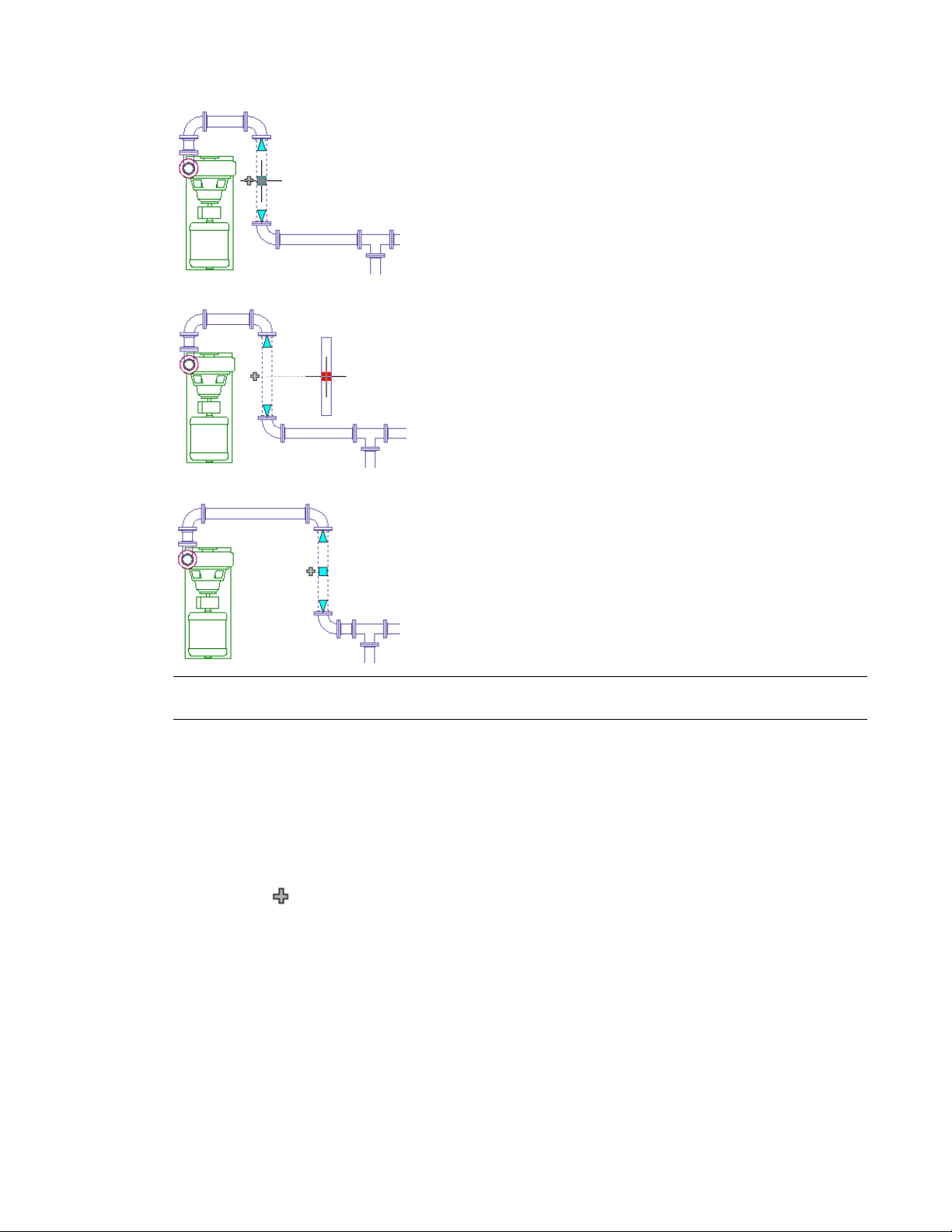

Associative Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Movement of a Pipe Segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Movement of a Pipe MvPart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Routing Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Auto Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Routing Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Sloped Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Pipe System Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Pipe System Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Display Configurations in AutoCAD MEP . . . . . . . . . . . . . . . . . . . . . . . . . . 258

1-Line Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Graphical 1-Line Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

2-Line Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Straight Centerline Display of Elbows . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Placeholder Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Pipe Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

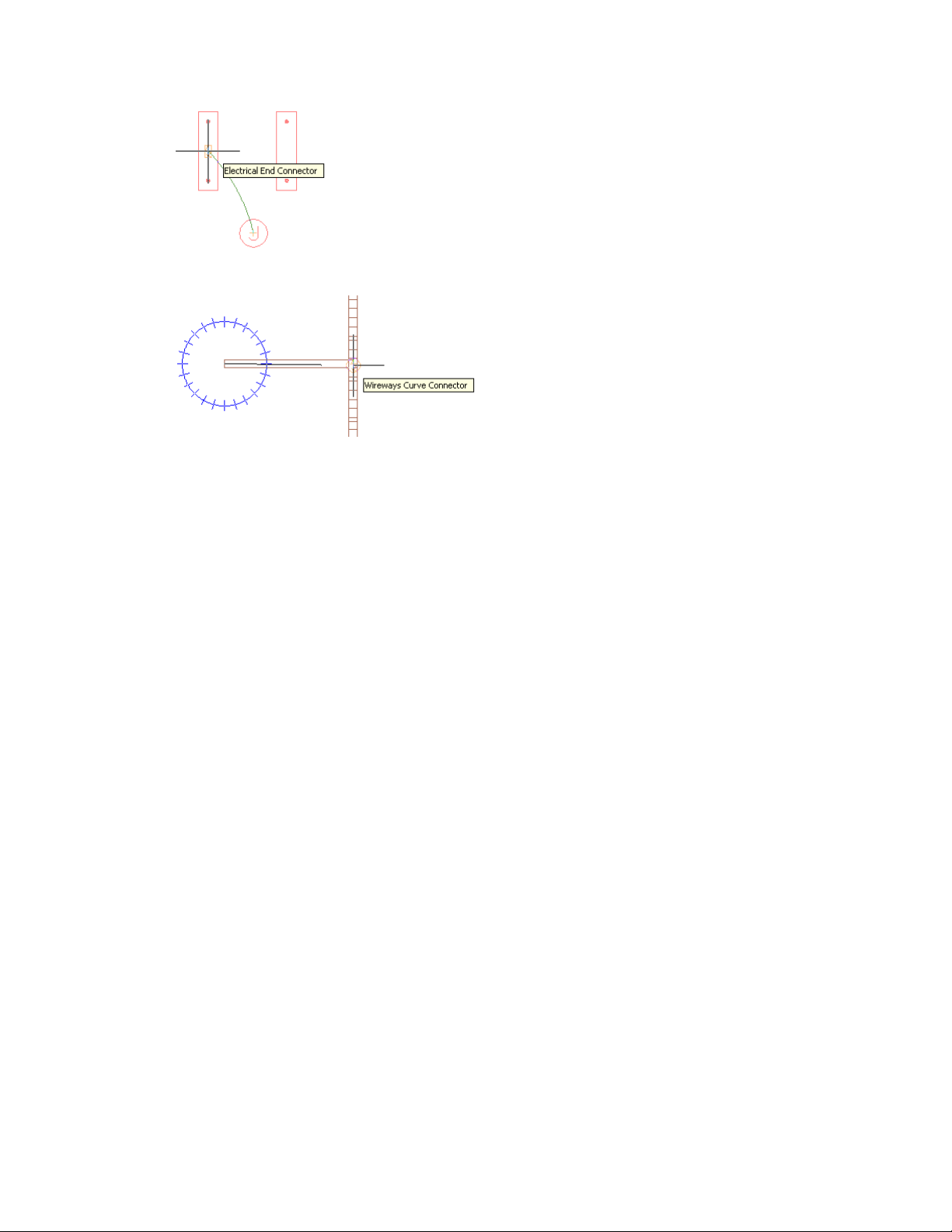

Pipe Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Pipe Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Connector Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Connection Types for Pipe and Pipe Fittings . . . . . . . . . . . . . . . . . . . . . . . . 266

Male-Female Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Pipe Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Pipe Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Pipe Snaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Pipe Elevation Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Pipe Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Configuring Pipe System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Configuring Routing Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Creating or Copying a Routing Preference . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Configuring Properties for a Routing Preference . . . . . . . . . . . . . . . . . . . . . . 280

Configuring Size Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Deleting a Routing Preference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Configuring System Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Creating a System Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Contents | ix

Page 10

Configuring System Definitions for 1-Line, 2-Line, or Single Line Graphics . . . . . . . . 282

Configuring Graphics for Single Line Pipe Display . . . . . . . . . . . . . . . . . . . . . . . . 283

Configuring the Straight Centerline Display of Elbows . . . . . . . . . . . . . . . . . . . . . . 284

Creating a Piping System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Adding Pipe Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Placing a Pipe MvPart in a Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Adding Parts In-Line to Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Adding Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Pipe Properties Palette (Add Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Adding Pipe Using the Tool Palette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Configuring Basic Properties for Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Configuring Pipe Layout Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Configuring Justification for Pipe Insertion . . . . . . . . . . . . . . . . . . . . . . . . . 297

Specifying Cut Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Drawing a Pipe Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Adding Pipe Using Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Manually Specifying Parts During Layout . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Using Routing Solutions to Connect Objects . . . . . . . . . . . . . . . . . . . . . . . . 306

Adding a Pipe Fitting Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Creating a Custom Pipe Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Drawing Sloped Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Drawing a Flexible Pipe Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Viewing Connection Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Adding a Parallel Pipe Run Using Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Offsetting Pipe from Existing Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

Locking Pipe Elevation During Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Adding a Takeoff to a Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Adding Insulation to Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Adding Labels or Flow Arrows to Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Converting a Polyline to Flexible Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Modifying a Piping System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Selecting or Filtering Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Filtering Pipe Objects with Quick Select . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Filtering by Pipe Part Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Modifying Components Using Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Moving Pipe Components Using Location Grips . . . . . . . . . . . . . . . . . . . . . . 320

Modifying the Elevation of Pipe Components . . . . . . . . . . . . . . . . . . . . . . . 320

Rotating Pipe Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Modifying the Length of a Pipe Segment . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Modifying Pipe Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Modifying the Location or Elevation of an MvPart . . . . . . . . . . . . . . . . . . . . . 322

Modifying the Size or Elevation of an MvPart . . . . . . . . . . . . . . . . . . . . . . . . 323

Matching an MvPart of One Type to Another . . . . . . . . . . . . . . . . . . . . . . . . 324

Modifying the K-Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Modifying the System for an MvPart Connector . . . . . . . . . . . . . . . . . . . . . . 324

Modifying Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Pipe Properties Palette (Modify Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Modifying the Routing Preference and Nominal Size . . . . . . . . . . . . . . . . . . . . 328

Modifying the Pipe or Fitting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Modifying Connected Objects Along a Pipe Run . . . . . . . . . . . . . . . . . . . . . . 329

Breaking or Merging Pipe Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Locking the Size of a Pipe or Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Modifying the System Assigned to a Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Modifying a Pipe Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Modifying the Layout of a Flexible Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Modifying Insulation on a Pipe or Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Checking Connectivity in a Pipe System . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Modifying a Label or Flow Arrow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

x | Contents

Page 11

Chapter 8 Drawing Radiant Heating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Radiant Heating Systems Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Creating Radiator Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Using a Calculation Program to Add Radiators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Adding Radiators Using Calculated Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Rules About Updating Existing Radiators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Exporting Drawing Information for Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Designing Radiant Heating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Adding a Radiator MvPart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Modifying a Radiator MvPart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Radiator Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Adding a Radiator Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Modifying a Radiator Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Moving a Radiator Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Connecting MvParts Using Alignment Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Creating Pipe Runs for Radiators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Adding Parallel Pipes to a Radiant Heating System . . . . . . . . . . . . . . . . . . . . . . . . 347

Correcting a Parallel Pipe Routing Conflict . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Connecting Multiple Radiators to Parallel Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Correcting a Radiator Connection Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Chapter 9 Drawing Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

About Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Design Workflow for Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Define System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Design the Electrical System Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

Electrical Project Database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

Circuit Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

Electrical Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Wire Size Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Cable Trays and Conduits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Auto Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Cable Tray and Conduit Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Electrical and Wire Ways Snaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Customizable Electrical Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Control the Appearance and Behavior of Electrical System Designs . . . . . . . . . . . . . . . . . . 363

Creating Electrical System Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

Creating Load Category Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

Configuring Electrical Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

Specifying Voltage Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

Configuring Circuiting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

Specifying an Electrical Project Database File . . . . . . . . . . . . . . . . . . . . . . . . 367

Device Style Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Specifying Design Rules for Device Styles . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Configuring Connectors for Device Styles . . . . . . . . . . . . . . . . . . . . . . . . . . 368

Specifying Classifications for Device Styles . . . . . . . . . . . . . . . . . . . . . . . . . 369

Configuring Styles for Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Specifying Design Rules for Panel Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

Configuring Connectors for Panel Styles . . . . . . . . . . . . . . . . . . . . . . . . . . 372

Configuring Styles for Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Defining Design Specifications for Wire Styles . . . . . . . . . . . . . . . . . . . . . . . 373

Specifying Annotation for Wire Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Configuring Layout Preferences for Cable Tray or Conduit . . . . . . . . . . . . . . . . . . . . 376

Specifying Alignment for Cable Tray or Conduit Insertion . . . . . . . . . . . . . . . . . 376

Contents | xi

Page 12

Specifying the Slope for Cable Tray or Conduit . . . . . . . . . . . . . . . . . . . . . . . 377

Breaking Cable Tray or Conduit at Even Intervals . . . . . . . . . . . . . . . . . . . . . . 378

Specifying Annotation for Cable Tray or Conduit . . . . . . . . . . . . . . . . . . . . . . 379

Specifying Default Parts for Cable Tray or Conduit . . . . . . . . . . . . . . . . . . . . . 379

Configuring Connections for Cable Tray . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Working with Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Using an Electrical Project Database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

How the Electrical Project Database Works . . . . . . . . . . . . . . . . . . . . . . . . . 381

Creating an Electrical Project Database . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

Linking to the Electrical Project Database . . . . . . . . . . . . . . . . . . . . . . . . . . 383

Reloading the Electrical Project Database . . . . . . . . . . . . . . . . . . . . . . . . . . 383

Unlinking From the Electrical Project Database . . . . . . . . . . . . . . . . . . . . . . . 384

Using Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

Creating Circuits Using the Circuit Manager . . . . . . . . . . . . . . . . . . . . . . . . 385

Configuring a Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

Viewing Circuit Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 388

Linking Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

Managing Circuits in a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

Creating Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

Adding Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

Configuring the Electrical Connectors of a Device . . . . . . . . . . . . . . . . . . . . . 395

Example: Aligning a Device to Floor Plan Geometry . . . . . . . . . . . . . . . . . . . . 398

Example: Adding Devices at a Specific Distance Interval . . . . . . . . . . . . . . . . . . 399

Example: Adding a Specific Number of Devices . . . . . . . . . . . . . . . . . . . . . . . 401

Example: Inserting a Device into a Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

Adding Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

Example: Aligning a Panel to Floor Plan Geometry . . . . . . . . . . . . . . . . . . . . . 409

Copying Devices and Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

Example: Copying a Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

Example: Copying a Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

Adding Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

Drawing or Generating Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

Drawing a Home Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 418

Creating a Wire from a Polyline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

Adding Electrical Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

Drawing Cable Trays and Conduits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 420

Drawing a Cable Tray or Conduit Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . 421

Adding a Cable Tray or Conduit Branch . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

Adding Cable Tray or Conduit Fittings Manually . . . . . . . . . . . . . . . . . . . . . . 424

Checking Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

Calculating Wire Sizes Using the Circuit Manager . . . . . . . . . . . . . . . . . . . . . . . . . 425

Viewing Circuit Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

Checking Circuit Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

Generating a Circuit Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

Showing Circuited Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

Showing Connected Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

Viewing Power Totals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

Modifying Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

Modifying Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

Moving Circuits to Manage Demand Load . . . . . . . . . . . . . . . . . . . . . . . . . 429

Modifying Circuit Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

Deleting Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

Modifying Devices and Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

Moving a Device or Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

Modifying Device Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

Modifying Panel Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 439

Modifying Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440

Modifying Wire Layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 441

Modifying Wire Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 441

Moving Tick Marks on Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

xii | Contents

Page 13

Flipping Tick Marks on Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

Modifying Electrical Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

Modifying Cable Trays and Conduits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

Modifying the Layout of a Cable Tray or Conduit Run . . . . . . . . . . . . . . . . . . . 444

Changing the System of a Cable Tray or Conduit Run . . . . . . . . . . . . . . . . . . . 445

Changing the Elevation of a Cable Tray or Conduit Run . . . . . . . . . . . . . . . . . . 445

Modifying the Size of a Cable Tray or Conduit Run . . . . . . . . . . . . . . . . . . . . . 446

Modifying the Length of Cable Tray or Conduit Segments . . . . . . . . . . . . . . . . . 446

Breaking and Merging Cable Tray or Conduit Segments . . . . . . . . . . . . . . . . . . 449

Modifying a Cable Tray or Conduit Fitting . . . . . . . . . . . . . . . . . . . . . . . . . 450

Rotating Cable Tray or Conduit Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . 450

Annotating Electrical System Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

Adding Labels to Wire, Conduit, and Cable Tray . . . . . . . . . . . . . . . . . . . . . . . . . 452

About Panel Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Generating Panel Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

Updating Panel Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 459

Exporting a Panel Schedule to Excel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 459

Creating Panel Schedule Table Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 460

Creating Electrical System Construction Documents . . . . . . . . . . . . . . . . . . . . . . . . . . 461

Chapter 10 Drawing Plumbing Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Plumbing Design Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Plumbing Systems Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

Plumbing Runs and Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

Plumbing System Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

Plumbing Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

Associative Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

Movement of a Plumbing Line Segment . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

Movement of an MvPart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 467

Plumbing Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 469

Grips for Adding to a Plumbing Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 469

Grips for Modifying a Plumbing Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . 470

Rise/Run Angles and Slope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

Fixture Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

Plumbing Line Sizing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

Customizing Plumbing Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

Creating Style-Based Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

Creating Catalog-Based Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

Configuring Plumbing System Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

Creating a Plumbing System Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 478

Specifying the Default Fittings for a Plumbing System Definition . . . . . . . . . . . . . . . . 478

Configuring Fixture Unit Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

Applying a Default Fixture Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

Creating a Fixture Unit Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480

Importing a Fixture Unit Table into a Drawing . . . . . . . . . . . . . . . . . . . . . . . 480

Specifying Plumbing Line Sizing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480

Configuring Styles for Plumbing Lines and Fittings . . . . . . . . . . . . . . . . . . . . . . . . 481

Specifying Annotation for a Plumbing Line Style . . . . . . . . . . . . . . . . . . . . . . 481

Specifying Standard Sizes for a Plumbing Line Style . . . . . . . . . . . . . . . . . . . . 482

Specifying Type and Subtype for a Plumbing Fitting Style . . . . . . . . . . . . . . . . . 482

Connectors for a Plumbing Fitting Style . . . . . . . . . . . . . . . . . . . . . . . . . . . 483

Specifying Plumbing Preferences for Labels and Flow Arrows . . . . . . . . . . . . . . . . . . . 484

Creating Plumbing Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 484

Adding Plumbing Equipment and Fixtures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 485

Adding Plumbing Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

Drawing a Plumbing Run from Equipment or Fixtures . . . . . . . . . . . . . . . . . . . 486

Drawing a Plumbing Run Using Add Grips . . . . . . . . . . . . . . . . . . . . . . . . . 487

Drawing a Plumbing Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 488

Contents | xiii

Page 14

Creating a Plumbing Run from a Polyline . . . . . . . . . . . . . . . . . . . . . . . . . . 488

Connecting Plumbing Lines at Different Elevations . . . . . . . . . . . . . . . . . . . . . . . . 489

Overriding the Default Plumbing Fittings for an Individual Run . . . . . . . . . . . . . . . . . 489

Adding Plumbing Fittings Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 490

Adding an Expansion Loop to a Plumbing Run . . . . . . . . . . . . . . . . . . . . . . . . . . 491

Modifying Plumbing Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 492

Component Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 492

Selecting Connected Branches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 492

Filtering Plumbing Objects by Part Properties . . . . . . . . . . . . . . . . . . . . . . . . 492

Filtering Selections by Part Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 493

Modifying Plumbing Equipment and Fixtures . . . . . . . . . . . . . . . . . . . . . . . . . . . 494

Calculating the Slope of a Plumbing Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 495

Modifying Plumbing Lines and Fittings Using Grips . . . . . . . . . . . . . . . . . . . . . . . 496

Moving Plumbing Lines and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 497

Modifying the Length of Plumbing Lines . . . . . . . . . . . . . . . . . . . . . . . . . . 497

Rotating Plumbing Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 498

Modifying Plumbing Lines and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 498

Modifying the System Assigned to a Plumbing Line or Fitting . . . . . . . . . . . . . . . 498

Reversing the Flow of a Plumbing Run . . . . . . . . . . . . . . . . . . . . . . . . . . . 499

Modifying the Elevation of a Plumbing Line or Fitting . . . . . . . . . . . . . . . . . . . 499

Modifying the Location Coordinates of a Plumbing Line or Fitting . . . . . . . . . . . . 500

Modifying the Nominal Size of a Plumbing Line Segment . . . . . . . . . . . . . . . . . 500

Modifying the Style of a Plumbing Line or Fitting . . . . . . . . . . . . . . . . . . . . . 501

Calculating the Sizes of Supply Plumbing Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501

Sizing Supply Plumbing Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501

Reviewing the Sizing Results for Supply Plumbing Lines . . . . . . . . . . . . . . . . . . . . . 503

Calculations for the Longest Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 503

Calculations at Selected Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . 504

How the Software Performs Calculations to Size Plumbing Lines . . . . . . . . . . . . . . . . . 507

Calculating the Sizes of Sanitary Plumbing Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 508

Overview of Sizing Sanitary Plumbing Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 508

Sanitary Branch Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 509

Sanitary Offset Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 510

Sanitary Stack Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 511

Sizing Sanitary Plumbing Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 511

Sizing Sanitary Plumbing Lines for Multiple Floors . . . . . . . . . . . . . . . . . . . . . . . . 512

Reviewing the Sizing Results for Sanitary Plumbing Lines . . . . . . . . . . . . . . . . . . . . 513

Chapter 11 Drawing Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 517

About Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518

Schematic Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 519

Schematic Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 519

Drawing in Orthographic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 519

Drawing in Isometric Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 520

Customizing Schematic Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 521

Configuring Schematic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 521

Creating Schematic System Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 521

Configuring Styles for Schematic Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 522

Defining Designations for Schematic Line Styles . . . . . . . . . . . . . . . . . . . . . . 522

Specifying Annotation for Schematic Line Styles . . . . . . . . . . . . . . . . . . . . . . 523

Creating a Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 525

Adding Schematic Lines in Orthographic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 525

Adding Schematic Symbols in Orthographic Mode . . . . . . . . . . . . . . . . . . . . . . . . 527

Adding Schematic Lines in Isometric Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 528

Adding Schematic Symbols in Isometric Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 531

Adding Schematic Lines Using Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

Creating a Schematic Line from an AutoCAD Line, Arc, or Polyline . . . . . . . . . . . . . . . 534

Modifying a Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

Associative Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 535

xiv | Contents

Page 15

Selecting Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 535

Modifying the Properties of a Schematic Line . . . . . . . . . . . . . . . . . . . . . . . . . . . 536

Modifying the Properties of a Schematic Symbol . . . . . . . . . . . . . . . . . . . . . . . . . 537

Moving Schematic Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 538

Moving Schematic Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 540

Modifying the Length of Schematic Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 541

Rotating Schematic Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 542

Rotating Orthographic Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 542

Rotating Isometric Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 542

Resizing Schematic Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 544

Resizing by Scale Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 544

Resizing by Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 545

Resizing Using Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 545