Page 1

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

1

/25

G150XG03 V4

(V

) Preliminary Specifications

( ) Final Specifications

Module 1

5 Inc

h Color TFT-LCD

Model Name G150XG03 V4

Customer Date

Checked &

Approved by

Note: This Specification is subject to change

without notice.

Approved by Date

Vito Huang 2011/6/13

Prepared by

Wennie Lee

2011/6/13 __

General Display Business Division /

AU Optronics corporation

Page 2

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4

Contents

1. Operating Precautions.....................................................................................4

2. General Description.............................

2.1 Display Characteristics...........................................................................................................5

2.2 Optical Characteristics ...........................................................................................................6

3. Functional Block Diagram ...............................................................................9

4. Absolute Maximum Ratings ..........................................................................10

4.1 Absolute Ratings of TFT LCD Module .................................................................................10

4.2 Absolute Ratings of Environment ........................................................................................10

5. Electrical Characteristics ..............................................................................11

5.1 TFT LCD Module.................................................................................................................. 11

5.2 Backlight Unit........................................................................................................................13

6. Signal Characteristic .....................................................................................14

6.1 Pixel Format Image ..............................................................................................................14

............................................................5

6.2 Scanning Direction ...............................................................................................................14

6.3 Signal Description ................................................................................................................15

6.4 The Input Data Format .........................................................................................................16

6.5 Interface Timing ....................................................................................................................17

6.6 Power ON/OFF Sequence ...................................................................................................18

7. Connector & Pin Assignment........................................................................19

7.1 TFT LCD Module: LVDS Connector.....................................................................................19

7.2 Backlight Unit: LED Driver Connector .................................................................................20

7.3 LED Connector Pin Assignment ..........................................................................................21

9. Mechanical Characteristics ...........................................................................23

9.1 LCM Outline Dimension (Front View) ..................................................................................23

9.2 LCM Outline Dimension (Rear View)...................................................................................23

10. Label and Packaging....................................................................................24

10.1 Shipping Label (on the rear side of TFT-LCD display) ......................................................24

10.2 Carton Package .................................................................................................................24

11 Safety.............................................................................................................25

11.1 Sharp Edge Requirements.................................................................................................25

11.2 Materials .............................................................................................................................25

11.3 Capacitors...........................................................................................................................25

11.4 National Test Lab Requirement..........................................................................................25

G150XG03 V4 rev. 0.1

2

/25

Page 3

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

3

/25

G150XG03 V4

Record of Revision

Version and Date Page

Old description New Description

0.0 2011/6/8 All First Edition

0.1 2011/6/13 21

H208K-P06N-02B or compatible 3808K-F05N-02R or compatible

3808K-F06N-02R H208K-P05N-02B or compatible

Page 4

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4

1. Operating Precautions

1) Since front polarizer is easily damaged, please be cautious and not to scratch it.

2) Be sure to turn off power supply when inserting or disconnecting from input connector.

3) Wipe

spots.

4) When the panel surface is soiled, wipe it with absorbent cotton or soft cloth.

5) Since the panel is made of glass, it may be broken or cracked if dropped or bumped on

hard surface.

6) Since CMOS LSI is used in this module, take care of static electricity and insure human

earth when handling.

7) Do not open nor modify the module assembly.

8) Do not press the reflector sheet at the back of the module to any direction.

9) In case if a module has to be put back into the packing container slot after it was taken

off water drop immediately. Long contact with water may cause discoloration or

out from the container, do not press the center of the CCFL Reflector edge. Instead,

press at the far ends of the CFL Reflector edge softly. Otherwise the TFT Module may

be damaged.

10) At the insertion or removal of the Signal Interface Connector, be sure not to rotate nor

tilt the Interface Connector of the TFT Module.

11) TFT-LCD Module is not allowed to be twisted & bent even force is added on module in a

very short time. Please design your display product well to avoid external force applying

to module by end-user directly.

12) Small amount of materials without flammability grade are used in the TFT-LCD module.

The TFT-LCD module should be supplied by power complied with requirements of

Limited Power Source (IEC60950 or UL1950), or be applied exemption.

13) Severe temperature condition may result in different luminance, response time.

14) Continuous operating TFT-LCD Module under high temperature environment may

accelerate LED light bar exhaustion and reduce luminance dramatically.

15) The data on this specification sheet is applicable when TFT-LCD module is placed in

landscape position.

16) Continuous displaying fixed pattern may induce image sticking. It’s recommended to

use screen saver or moving content periodically if fixed pattern is displayed on the

screen.

G150XG03 V4 rev. 0.1

4

/25

Page 5

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

5

/25

G150XG03 V4

2. General Description

G150XG03 V4 is a Color Active Matrix Liquid Crystal Display composed of a TFT-LCD display, a

driver circuit, and a backlight system. The screen format is intended to support XGA (1024(H) x

768(V)) screen and 16.2M (RGB 8-bits) or 262k colors (RGB 6-bits). All

input signals are LVDS

interface compatible. All design rules of this module can correspond to PSWG standard.

G150XG03 V4 is designed for industrial display applications.

2.1 Display Characteristics

T

he f

ollowing items are characteristics summary on the table under 25

condition:

Items Unit Specifications

Screen Diagonal [inch] 15

Active Area [mm] 304.128(H) x 228.096(V)

Pixels H x V 1024x3(RGB) x 768

Pixel Pitch [mm] 0.297 x 0.297

Pixel Arrangement R.G.B. Vertical Stripe

Display Mode TN, Normally White

Nominal Input Voltage VDD [Volt] 3.3 typ.

Typical Power Consumption [Watt] 6.46 (64 Gray Bar Pattern)

Weight [Grams] 1000g (max.)

Physical Size [mm] 326.5(H)x 253.5(V) x 12.0(D) (max.)

Electrical Interface 1 channel LVDS

Surface Treatment Anti-glare, Hardness 3H

Support Color 16.2M / 262K colors

Temperature Range

Operating

Storage (Non-Operating)

[℃]

[℃]

-

30 to +85

-30 to +85

RoHS Compliance RoHS Compliance

Page 6

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

6

/25

G150XG03 V4

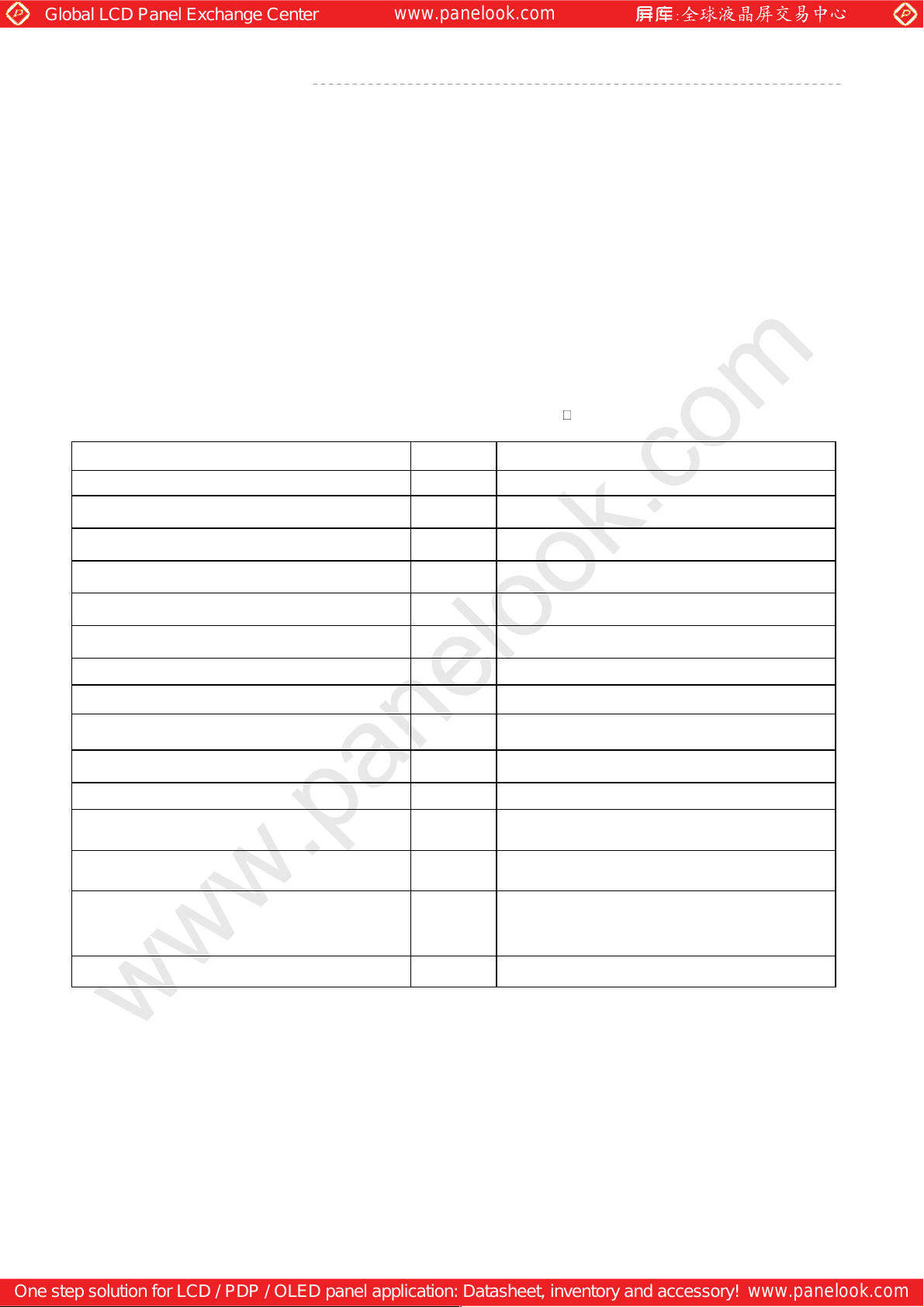

2.2 Optical Characteristics

The optical characteristics are measured under stable conditions at 25 (Room Temperature):

Item Unit Conditions Min. Typ.

Max. Note

White Luminance

[cd/m2]

200 250 - 1

Uniformity

%

9 Points

75 80 - 1, 2, 3

Contrast Ratio

400 700 - 4

Cross talk

%

- 1.2 1.5 5

[msec]

Rising

-

5.7

[msec]

Falling

- 2.3

Response Time

[msec]

Raising + Falling

- 8

6

[degree]

[degree]

Horizontal (Right)

CR = 10 (Left)

70

70

80

80

-

-

Viewing Angle

[degree]

[degree]

Vertical (Upper)

CR = 10 (Lower)

60

50

70

60

-

-

7

Red x

TBD TBD TBD

Red y

TBD TBD TBD

Green x

TBD TBD TBD

Green y

TBD TBD TBD

Blue x

TBD TBD TBD

Blue y

TBD TBD TBD

White x

0.263

0.313

0.363

Color / Chromaticity

Coordinates

(CIE 1931)

White y

0

.279

0.329

0.379

Color Gamut %

60

65 -

Note 1: Measurement method

Equipment Pattern Generator, Power Supply, Digital Voltmeter, Luminance meter (SR_3 or equivalent)

Aperture

1

w

i

t

h50

cmv

i

ew

i

ng

di

s

t

ance

Test Point Center

Environment < 1 lux

LCD Module

SR_3 or

equivalent

Measuring distance

Module Driving Equipment

Page 7

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

7

/25

G150XG03 V4

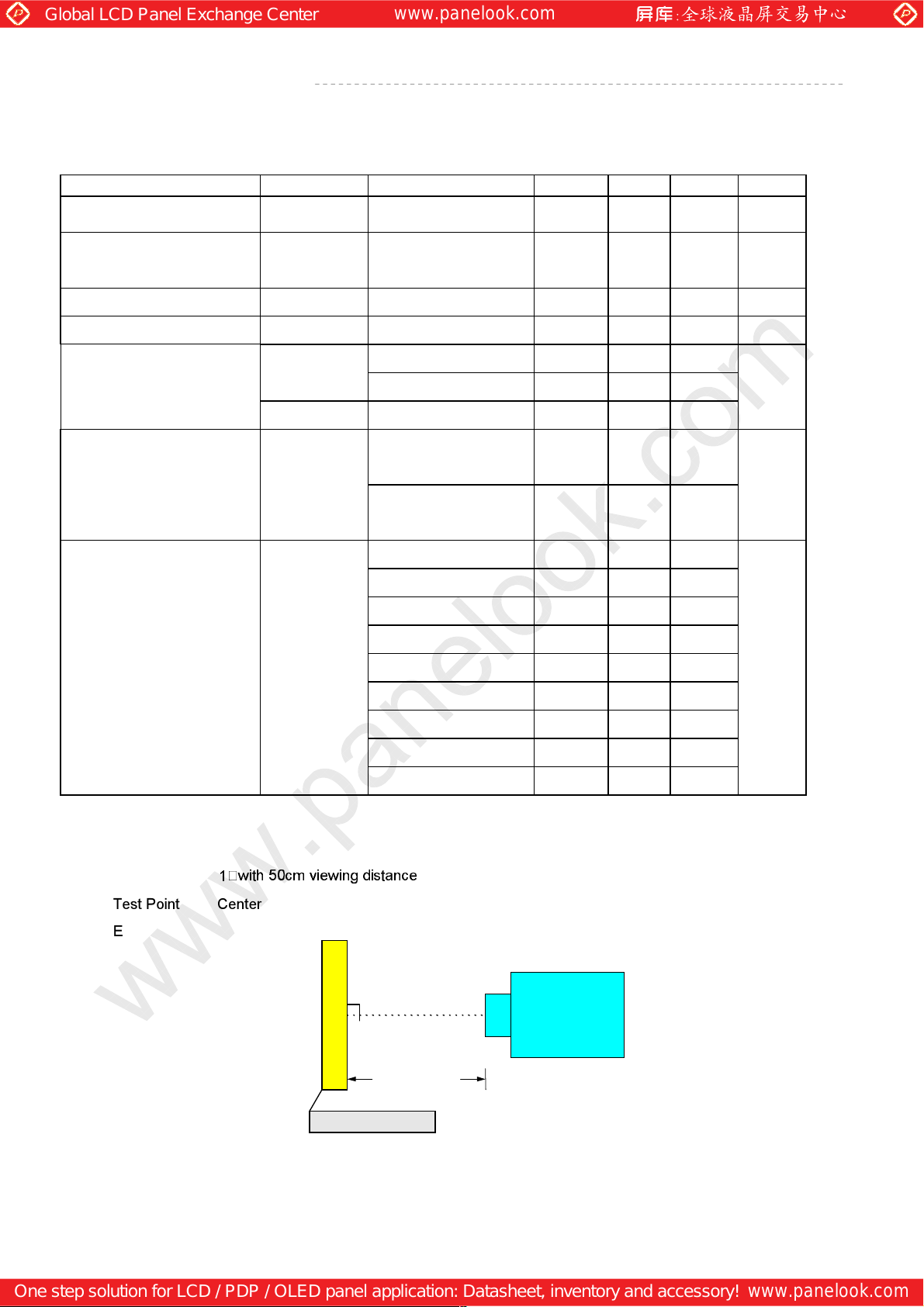

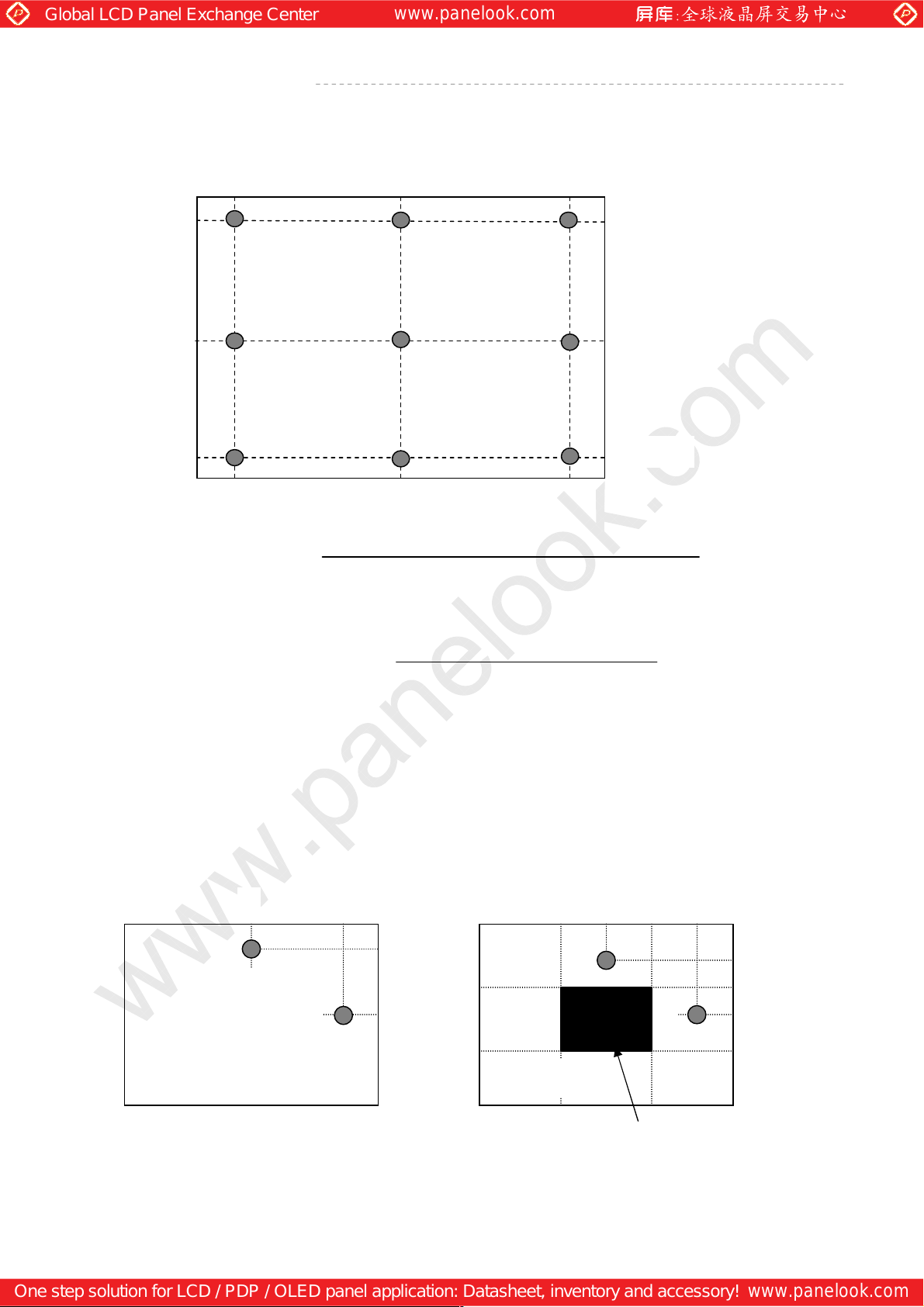

Note 2: Definition of 9 points position (Display active area : 304.128(H) x 228.096(V))

Note 3: The luminance uniformity of 9 points is defined by dividing the minimum luminance values by the maximum test

point luminance

Note 4: Definition of contrast ratio (CR):

N

ote 5: Definition of cross talk (CT)

CT = | YB – YA | / YA × 100 (%)

Where

YA = Luminance of measured location without gray leve

l 0 pattern (cd/m2)

YB = Luminance of measured location with gray level 0

pattern (cd/m2)

Minimum

Brightnes

s of

nine

poin

ts

δ

W9

=

Maximum

Brightness of

nine

points

Contrast ratio (CR)=

Brightness on the “White” state

Brightness on the “Black” state

50 %

90 %

90 %

50 %

10 %

10 %

1/2

1/2

1/6

1/6

A

B

1/2

1/2

1/6

1/6

2/3 1/3

1/3

2/3

A’

B’

184 gray level

Page 8

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

8

/25

G150XG03 V4

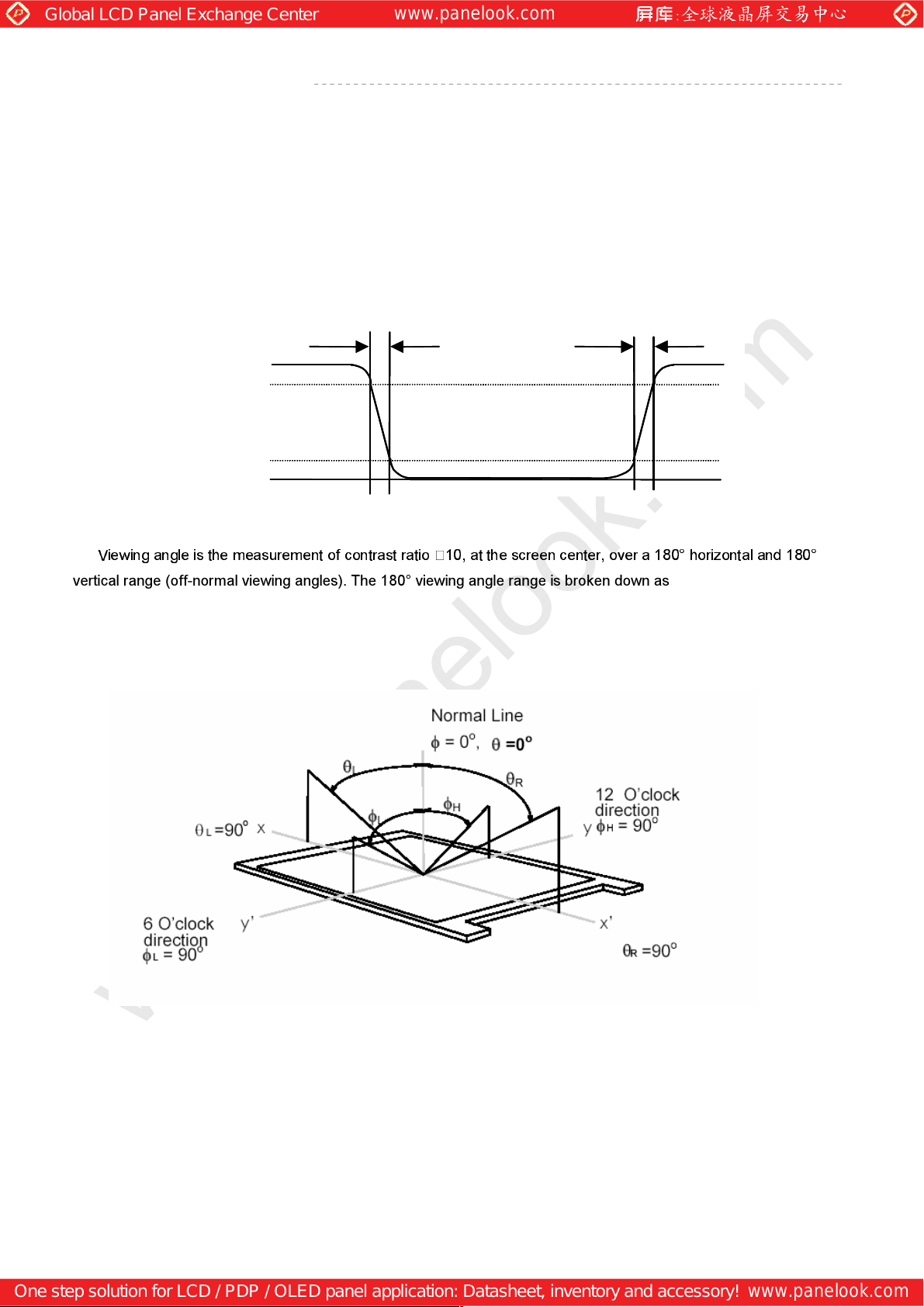

Note 6: Definition of response time:

The output signals of photo detector are measured when the input signals are changed from “White” to “Black”

(falling time) and from “Black” to “White” (rising time), respectively. The response time interval is between 10% and

90% of amplitudes. Please refer to the figure as below.

Note 7: Definition of viewing angle

V

i

ew

i

ngang

l

e

i

s

t

h

emeasuremen

t

o

f

con

t

ras

t

ra

t

i

o

#

10

,

a

tt

h

escreencen

t

er

,

overa

180°h

or

i

zon

t

a

l

an

d180°

vertical range (off-normal viewing angles). The 180° viewing angle range is broken down as below: 90° (θ) horizontal

left and right, and 90° (Φ) vertical high (up) and low (down). The measurement direction is typically perpendicular to the

display surface with the screen rotated to its center to develop the desired

measurement viewing angle.

100

90

10

0

%

Optical

response

White

Black

White

Tf

Tr

90

10

0

Optical

response

White

Black

White

Tr

Page 9

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

9

/25

G150XG03 V4

3. Functional Block Diagram

The following diagram shows the functional block of the

15 inch color TFT/LCD module:

Page 10

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

1

0/25

G150XG03 V4

4. Absolute Maximum Ratings

4.1 Absolute Ratings of TFT LCD Module

It

em Symbol Min Max Unit

Logic/LCD Drive

Voltage

Vin -

0.3 +

3.6 [Volt]

4.2 Absolute Ratings of Environment

Item Symbol Min Max Unit

Operating Temperature

TOP -30 +85 [oC]

Operation Humidity HOP 8 90 [%RH]

Storage Temperature

TST -30 +85 [oC]

Storage Humidity HST

8 90

[%RH]

Note: Maximum Wet-Bulb should be 39

,

an

d

nocon

d

ensa

t

i

on

.

Page 11

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

5. Electrical Characteristics

5.1 TFT LCD Module

5.1.1 Power Specification

S

ymbol Parameter Min Typ

VDD

IDD

Irush

PDD

Logic/LCD Drive

Voltage

VDD Current

LCD Inrush Current

VDD Power

Note 1: Measurement condition:

(High to Low)

Control

Signal

+3.3V

3.0 3.3 3.6 [Volt]

-

- -

-

R1

47K

R2

Max Units Remark

550 660 [mA]

3 [A]

1.9 2.2 [Watt]

Q3

AO6402

D6

D5

D2 S

D1

D2SD1D5

G

G

D6

Q3

AO6402

F1

10%

±

64 Gray Bar Pattern

(VDD=3.3V, at 60Hz)

Note 1

64 Gray Bar Pattern

(VDD=3.3V, at 60Hz)

C1

1uF/16V

G150XG03 V4

VDD

VCC

(LCD Module Input)

SW1

SW MAG-SPST

1 2

+12.0V

C2

1uF/25V

1K

R2

1K

VR1

C3

0.01uF/25V

47K

90%

3.3V

10%

0V

470 us

VDD rising time

64 Gray pattern

G150XG03 V4 rev. 0.1

1

1/25

Page 12

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

1

2/25

G150XG03 V4

5.1.2 Signal Electrical Characteristics

Input signals shall be low or Hi-Z state when VDD is off.

Note: LVDS Signal Waveform.

Symbol Item Min. Typ. Max. Unit Remark

VTH

Differential Input High Threshold - - 100

[mV]

VCM=1.2V

VTL

Differential Input Low Threshold -100

- -

[mV]

VCM=1.2V

|VID| Input Differential Voltage

100 400 600

[mV]

VICM

Differential Input Common Mode Voltage

1.1 1.45

[V]

VTH/VTL=±100mV

Page 13

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4

5.2 Backlight Unit

5.2.1 Parameter guideline for LED

(R

o

Following characteristics are measured under stable cond

ition using a LED driving board at 25

Symbol Parameter Min Typ Max

Vcc Input Voltage 10.8 12 12.6 Volt

Ivcc Input Curent - 0.38 - A 100% Dimming

PLED Power Consumption - 4.56 - Watt 100% Dimming

FPWM PWM Dimming Frequency 200 - 20k Hz

Swing Voltage 4.5 5 5.5

Dimming Duty Cycle 5 - 100 %

Vanalog Analog Dimming Voltage 2.0 5 5.5 5V, 100% Brightness

IF LED Forward Current - 80 84 mA Ta = 25oC

Operating Life 50000 - - Hrs Ta = 25oC

7

om Temperature).

Unit

Remark

Note 1: Ta means ambient temperature of TFT-LCD module.

Note 2: If G150XG03 V4 module is driven at high ambient temperature & humidity condition. The operating life will be

reduced.

Note 3: Operating life means brightness goes down to 50% initial brightness. Min. operating life time is estimated data.

G150XG03 V4 rev. 0.1

1

3/25

Page 14

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

1

4/25

G150XG03 V4

6. Signal Characteristic

6.1 Pixel Format Image

Following figure shows the relationship between inpu

t signal and LCD pixel format.

6.2 Scanning Direction

T

he following figures show the image seen from the front view. The arrow indicates the direction of scan.

Fig. 1 Normal scan (Pin4, REV = Low or NC) Fig. 2 Reverse scan (Pin4, REV = High)

Page 15

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4

6.3 Signal Description

The module using a pair of LVDS receiver SN75LVDS82(Texas Instruments) or compatible. LVDS is a differential

signal technology for LCD interface and high speed data transfer device. Transmitter shall be SN75LVDS83(negative

edge sampling) or compatible

transmits even pixels.

3804-F20N-06R (E&T) / MSB240420E(STM)

Pin No. Symbol Description

1 VDD Power Supply, 3.3V (typical)

2 VDD Power Supply, 3.3V (typical)

3 VSS Ground

4 REV Reverse Scan selection *.Note1

5 Rin1- - LVDS differential data input (R0-R5, G0)

6 Rin1+ + LVDS differential data input (R0-R5, G0)

7 VSS Ground

8 Rin2- - LVDS differential data input (G1-G5, B0-B1)

. The first LVDS port(RxOxxx) transmits odd pixels while the second LVDS port(RxExxx)

9 Rin2+ + LVDS differential data input (G1-G5, B0-B1)

10 VSS Ground

11 Rin3- - LVDS differential data input (B2-B5, HS, VS, DE)

12 Rin3+ + LVDS differential data input (B2-B5, HS, VS, DE)

13 VSS Ground

14 ClkIN- - LVDS differential clock input

15 ClkIN+ + LVDS differential clock input

16 GND Ground

17 Rin4- - LVDS differential data input (R6-R7, G6-G7,B6-B7) *Note2

18 Rin4+ - LVDS differential data input (R6-R7, G6-G7,B6-B7) *Note2

19 VSS Ground

20 SEL68 Selection for 6 bits/8bits LVDS data input *Note1,3

Note 1: Input signals shall be in low status when VDD is off.

Note 2: If only the 6 bits mode is needed, pin 17 and pin 18 are suggested to be floated. (In this situation, 8 bits

mode will be disable permanently)

Note 3: High stands for “3.3V”, Low stands for “GND”, NC stands for “No Connection”.

G150XG03 V4 rev. 0.1

1

5/25

Page 16

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

6.4 The Input Data Format

6.4.1 SEL68

SEL68 = ”High” or “NC” for 6 bits LVDS Input

RxCLKIN

IN1

Rx

N2

RxI

RxIN3

SEL68 = “Low” for 8 bits LVDS Input

RxCLKIN

xIN1

R

IN2

Rx

RxIN3

G0 R5 R4 R3 R2 R1 R0

B

1 B0 G5 G

DE VS HS B5 B4 B3 B2

G0 R5 R4 R3 R2 R1 R0

B

1 B0 G5 G

DE VS HS B5 B4 B3 B2

G150XG03 V4

4 G3 G2 G1

4 G3 G2 G1

RxIN4

RSV B7 B6 G7 G6 R7 R6

Note1: Please follow PSWG.

Note2:

R/G/B data 7:MSB, R/G/B data 0:LSB

ignal Name Description Remark

S

R7

R6

R5

R4

R3

R2

R1

R0

G7

G6

G5

G4

G3

G2

G1

G0

B7

B6

B5

B4

B3

B2

B1

B0

Red Data 7

Red Data 6

Red Data 5

Red Data 4

Red Data 3

Red Data 2

Red Data 1

Red Data 0

Green Data 7

Green Data 6

Green Data 5

Green Data 4

Green Data 3

Green Data 2

Green Data 1

Green Data 0

Blue Data 7

Blue Data 6

Blue Data 5

Blue Data 4

Blue Data 3

Blue Data 2

Blue Data 1

Blue Data 0

Red-pixel Data

For 8Bits LVDS input

MSB: R7 ; LSB: R0

For 6Bits LVDS input

MSB: R5 ; LSB: R0

Green-pixel Data

For 8Bits LVDS input

MSB: G7 ; LSB: G0

For 6Bits LVDS input

MSB: G5 ; LSB: G0

Blue-pixel Data

For 8Bits LVDS input

MSB: B7 ; LSB: B0

For 6Bits LVDS input

MSB: B5 ; LSB: B0

RxCLKIN LVDS Data Clock

DE Data Enable Signal When the signal is high, the pixel data

shall be valid to be displayed.

VS Vertical Synchronous Signal

HS Horizontal Synchronous Signal

Note: Output signals from any system shall be low or Hi-Z state when VDD is off.

G150XG03 V4 rev. 0.1

1

6/25

Page 17

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

1

7/25

G150XG03 V4

6.5 Interface Timing

6.5.1 Timing Characteristics

Signal Parameter Symbol Min. Typ. Max. Unit

Clock Timing Clock frequency 1/ T

Clock

50 65 81

MHz

Period T

V

776 806 900

Active T

VD

768 768 768

Vsync Timing

Vertical

Section

Blanking

T

VB

8 38 132

T

Line

Period T

H

1054 1344 2048

Active T

HD

1024 1024 1024

Hsync Timing

Horizontal

Section

Blanking

T

HB

30 320 1024

T

Clock

Frame Rate F

50 60 75

Hz

Note: DE mode only.

Note : Typical value refer to VESA STANDARD

6.5.2 Input Timing Diagram

DOTCLK

DE

T

H

T

HB

T

HD

DE

T

V

T

VB

T

VD

Input Timing Definition ( DE Mode)

T

CLOCK

Input

Data

Pixel1Pixel2Pixel3Pixel

N-1

Pixel

N

Invaild

Data

Invaild

Data

Pixel

1

Page 18

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

1

8/25

G150XG03 V4

6.6 Power ON/OFF Sequence

VDD power and LED on/off sequence is as below. Interface signals are also shown in the chart. Signals from any system shall be Hi-Z state or low

level when VDD is off.

Power ON/OFF sequence timing

The above on/off sequence should be applied to avoid abnormal function in the display. Please make sure to turn off

the power when you plug the cable into the input connector or pull the cable out of the connector.

90%

10%

90%

10%

10%

90%

90%

90%

90%

10%

10%

10%

T T

T

T T

T T

T1

T T

T1 T1 T1

VDD

Signal

VLED

Back light dimming

Back light

10%

10%

90%

90%

Page 19

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

1

9/25

G150XG03 V4

7. Connector & Pin Assignment

Physical interface is described as for the connector on module. These connectors are capable of accommodating

the following signals and will be following components.

7.1 TFT LCD Module: LVDS Connector

Connector Name / Designation Signal Connector

Manufacturer E&T or compatible

Connector Model Number 3804-F20N-06R / MSB240420E

Adaptable Plug HRS DF14-20S-1.25C

Pin# Signal Name Pin# Signal Name

1

VDD

2 VDD

3

VSS

4 REV

5

Rin1-

6

Rin1+

7

VSS

8 Rin2-

9

Rin2+

10 VSS

11

Rin3-

12 Rin3+

13

VSS

14

ClkIN-

15

ClkIN+

16 GND

17

Rin4-

18 Rin4+

19

VSS

20 SEL68

Page 20

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

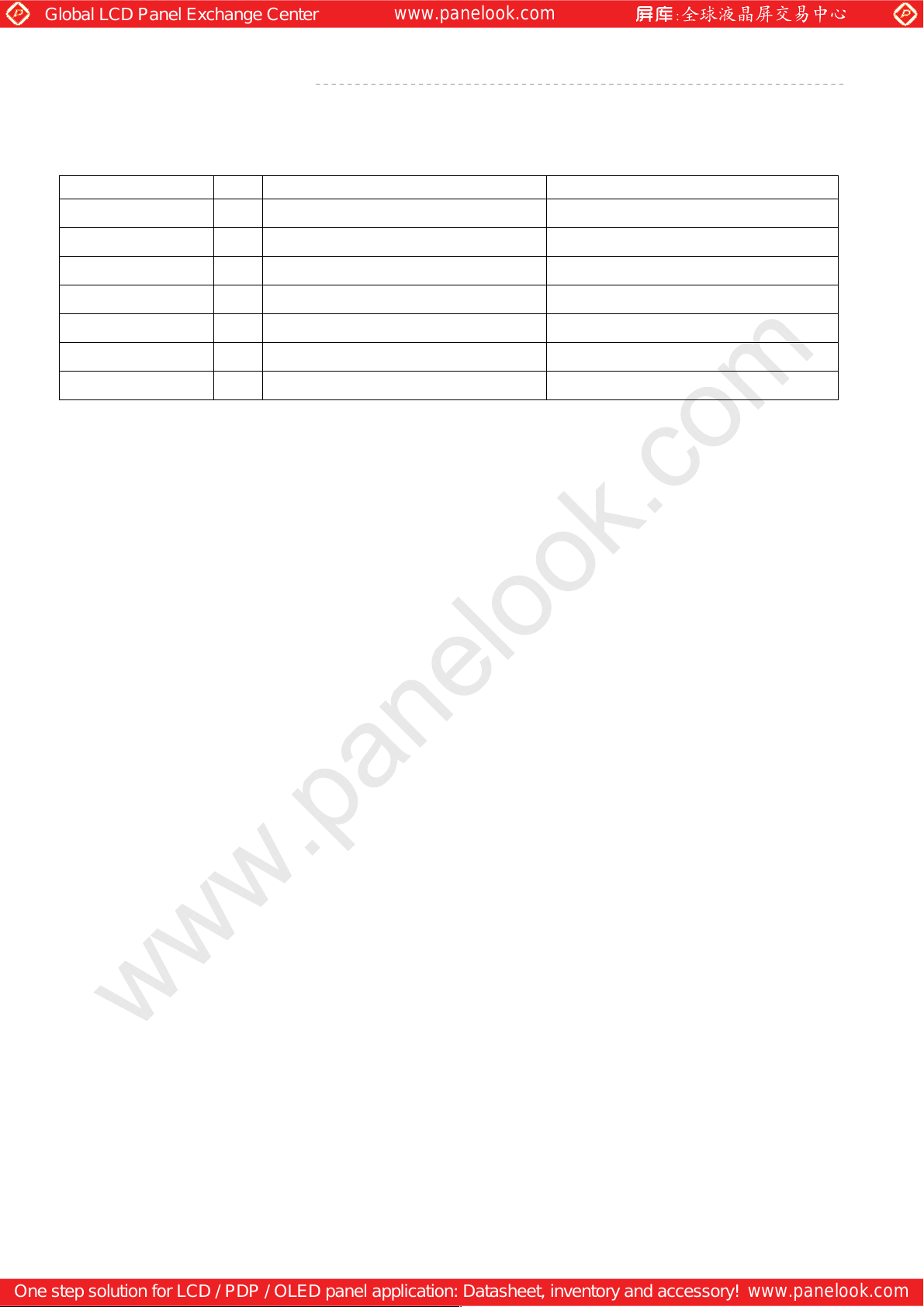

8. Reliability Test Criteria

Items

Temperature

Humidity Bias

High Temperature

Operation

Low Temperature

Operation

Hot Storage

Cold Storage

Thermal Shock

Test

Shock Test

(Non-Operating)

Vibration Test

(Non-Operating)

Required Condition Note

50℃/80%,300 hours

85℃,300 hours

-30℃,300 hours

85℃,300 hours

-30℃,300 hours

-20℃

50G,20ms,Half-sine wave,( ±X, ±Y, ±Z)

1.5G, (10~200Hz, P-P)

30 mins/axis (X, Y, Z)

G150XG03 V4

30

i

60

30

i

m

/

C

n

,

/

100

m

n

,

l

cyc

es

On/off test

ESD

On/10 sec, Off/10 sec, 30,000 cycles

Contact Discharge: ± 8KV, 150pF(330Ω ) 1sec, 8 points, 25 times/ point

Note 1

Air Discharge: ± 15KV, 150pF(330Ω ) 1sec, 8 points, 25 times/ point

Note1: According to EN61000-4-2, ESD class B: Some performance degradation allowed. No data lost

. Self-recoverable. No hardware failures.

G150XG03 V4 rev. 0.1

2/25

2

Page 21

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

2

1/25

G150XG03 V4

7.2 Backlight Unit: LED Driver Connector

Connector Name / Designation LED Driver Connector

Manufacturer ENTERY or compatible

Connector Model Number 3808K-F05N-02R or compatible

Mating Model Number H208K-P05N-02B or compatible

7.3 LED Connector Pin Assignment

Pin# Symbol Signal Name

1 Vcc 12V

2 GND GND

3 Enable 5V-On / 0V-Off

4 Dimming PWM Dimming or Analog Dimming

5 NC NC

Page 22

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

2

0/25

G150XG03 V4

7.1.1 Connector Illustration

Page 23

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

2

3/25

G150XG03 V4

9. Mechanical Characteristics

9.1 LCM Outline Dimension (Front View)

9.2 LCM Outline Dimension (Rear View)

Page 24

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

G150XG03 V4 rev. 0.1

2

4/25

G150XG03 V4

10. Label and Packaging

10.1 Shipping Label (on the rear side of TFT-LCD display)

10.2 Carton Package

G150XG03 V4

Page 25

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

11 Safety

11.1 Sharp Edge Requirements

There will be no sharp edges or comers on the display assembly that could cause injury.

11.2 Materials

11.2.1 Toxicity

There will be no carcinogenic materials used anywhere in the display module. If toxic materials are used,

they will be reviewed and approved by the responsible AUO toxicologist.

11.2.2 Flammability

All components including electrical components that do not meet the flammability grade UL94-V1 in the

module will complete the flammability rating exception approval process.

The printed circuit board will be made from material rated 94-V1 or better. The actual UL flammability

rating will be printed on the printed circuit board.

G150XG03 V4

11.3 Capacitors

If any polarized capacitors are used in the display asse

being inserted backwards.

mbly, provisions will be made to keep them from

11.4 National Test Lab Requirement

The display module will satisfy all requirements for compliance to:

UL 1950, First Edition U.S.A. Information Technology Equipment

G150XG03 V4 rev. 0.1

5/25

2

Loading...

Loading...