Page 1

Page 2

Contents / Introduction

Contents Contents

Introduction

Applications

Type Designation

Multi-turn Actuators

Design Principle

Functions

Open-Close Duty

Regulating Duty

Limit Switching

Torque Switching

Control Equipment

Micro Switches

Reduction Gear Unit

Position Indicators

Intermediate Switch

2

3

4

5

6-7

8

8

8

9

10

11

11

12

12

13

General

Data Sheets

Technical Data Open-Close Duty

Electrical Data Open-Close Duty

Technical Data Regulating Duty

Electrical Data Regulating Duty

Dimension Sheet, Norm

Dimension Sheet, Compact

Dimension Sheet, E-pac

Output Drives

Linear Thrust Unit

Terminal Plan (Norm)

Wiring Diagram (Integral Starter)

Legend - Integral Starter

29

30-31

32-33

34

35

36

37

38

39

40

41

42

43

Manual Operation

Top Bevel Gear Set

Space Heater

Motors

Actuators for Regulating Duty

Actuator Types

Auma Norm Actuators

Auma Integral Starter Actuators

Control Versions

Auma Compact

Auma e-pac

Interface

Valve Attachment

Output Drives

Electrical Connection

Actuator Gearbox Combination

Service Conditions

13

13

13

14-15

16-20

21

21

21

22

22

23

24

24

24

25

26

27

Introduction

In the course of ever increasing demand for

automation in all sectors of industries, electric

actuators for process control and regulation

have become more and more important. For

more than 30 years, Auma concentrates on

design, development and manufacturing of

electric actuators. During this period, Auma

has acquired a know-how in this field that can

hardly be surpassed. Auma today is one of the

leading manufacturers of electric actuators in

the world.

Auma India (Ltd.,) is now a subsidiary of

Auma Werner Riester Gmbh & Co. KG,

Germany manufacturing electric actuators

under brand name . Auma (India) Ltd.,

started its operations in the year 1985 with HQ

and sophisticated manufacturing base at

Bangalore.

Enclosure Protection

Ambient Temperature

Explosion Proof

2

27

27

28

Sales support and after sales service are

provided by network consisting of regional

offices & service centers.

Page 3

Auma multi-turn actuators of the type range SA

can be used wherever the automation of the

valve is required. The adoption to the

requirements of nearly every valve automation

task is possible. This is on account of :

An extermely wide torque range

Various combination possibilities with

Auma Valve Gear boxes. Thereby the torque

range can be further extended and / or the

multiturn actuator can be converted into

part turn, lever or linear actuator.

A large variety of versions, whether for open

or closed loop control, explosion proof

applications, a suitable version is available.

Energy

Power Plants

Air Pollution Control

District Heating

Pipelines

Applications

Water / Waste Water

Water Works

Water Pipelines

Sewage Treatment

Pump Stations

Locks / Dams

Chemical Industry

Petro-chemical

Chemical

Pharmaceutical

Others

Air Conditioning

Steel Mills

Ship Building

Cement Plants

Food Industry

3

Page 4

Type Designation

Actuator

Types

Torque Ratings

Auma

Norm

Auma

Integral Starter

Auma

Flame Proof /

Explosion Proof

3 m kg

6 m kg

12 m kg

15 m kg

25 m kg

30 m kg

50 m kg

60 m kg

100 m kg

OPEN-CLOSE Duty

Regulating Duty

Auma

Compact

Auma

e-pac

Expl. Proof

Norm

Expl. Proof

Compact

OPEN-CLOSE Duty

Regulating Duty

OPEN-CLOSE Duty

Regulating Duty

OPEN-CLOSE Duty

Regulating Duty

OPEN-CLOSE Duty

Regulating Duty

Output Drives

Model : SA

Model : SAR

Model :SA Compact

Model : SAR Compact

Model :SA e-pac

Model : SAR e-pac

Model :SAEx

Model : SAREx

Model :SACEx

Model : SARCEx

A Stem nut

B Plug Sleeve

C Dog Coupling

D Stub Shaft

E Bore with Keyway

Type Designation : Example

Model

Torque Rating

Output Speed

SA A12 22

4 rpm

5.6 rpm

8 rpm

11 rpm

16 rpm

22 rpm

32 rpm

45 rpm

63 rpm

90 rpm

125 rpm

180 rpm

Output Speed in RPM

Output Drive

4

Page 5

Multi-turn Actuator SA3 - SA100

Torque range 3 m kg to 100 m kg

Output speed 4 rpm to 180 rpm

Multi-turn Actuators

Multi-turn Actuator

Integral Starter - Compact

Multi-turn Actuator

Integral Starter - e pac

Multi-turn Actuator

Flame Proof / Explosion Proof

5

Page 6

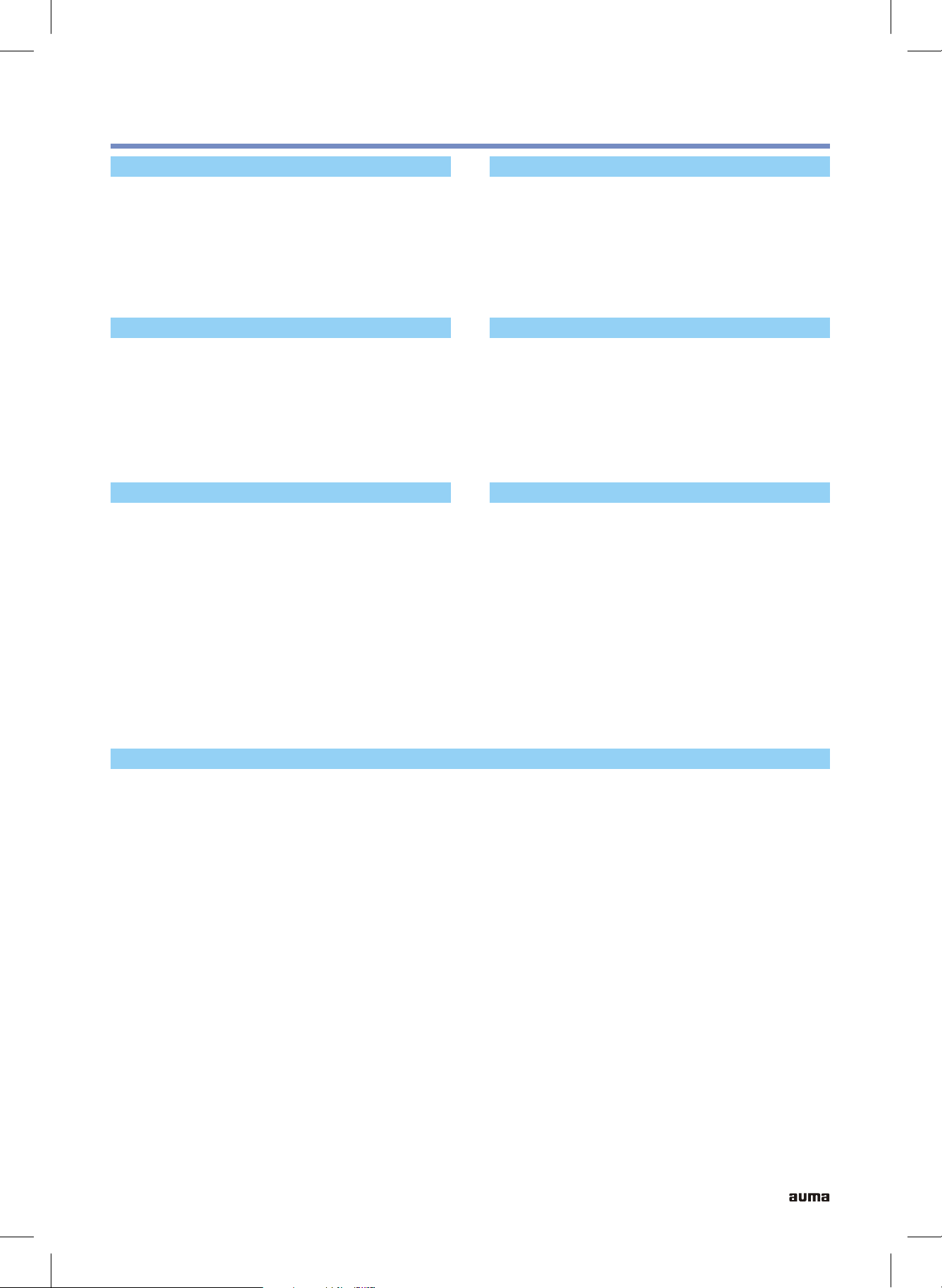

Design Principle

Manual Operation

Motor

Change Gears

Terminal

Compartment

Reduction Gearing

Valve Attachment

Switch Compartment

6

Page 7

Motor Terminal Compartment

Design Principle

Especially high starting torque is frequently

required to unseat valves from end positions.

The motors developed by Auma fulfil this

basic requirement.

Change Gears Valve Attachment

Auma actuators are driven by special

combination of gears which are outside the

grease filled housing & require no lubrication.

If required, output speed can be easily altered

by changing the gear pair and / or motor at

site.

Reduction Gearing Manual Operation

A well proved principle of worm gearing is

used to reduce the motor speed to required

output speed of actuator. Self-locking feature

is achieved by worm gearing upto 90 output

rpm. Worm shaft and output shaft with worm

wheel run in ample sized bearings. The sliding

worm is positioned between two sets of

springs on worm shaft. The worm moves

axially in relation to thrust which is the

measure for torque. Via lever & gears the

torque is transmitted to control unit.

All electrical connections are terminated inside

the terminal compartment. Screw type terminals

are provided for easy connections. Multi-pin

plug-socket connector can be provided for ease

of connections & maintenance.

The mounting flange is according to ISO 5210 /

DIN 3210. Various output drives are available for

for adaption to various types of valves.

For commissioning or in an emergency, actuator

can be operated with hand wheel. When starting

the motor, the manual drive is automatically

disengaged.

Switch Compartment

Depending upon type of valve, the actuator

must be switched off at end positions by limit

switch or torque switch. For this purpose,

independent limit switching or torque

switching devices are provided in the switch

compartment. The switching devices are easily

accessible for any setting at site.

7

Page 8

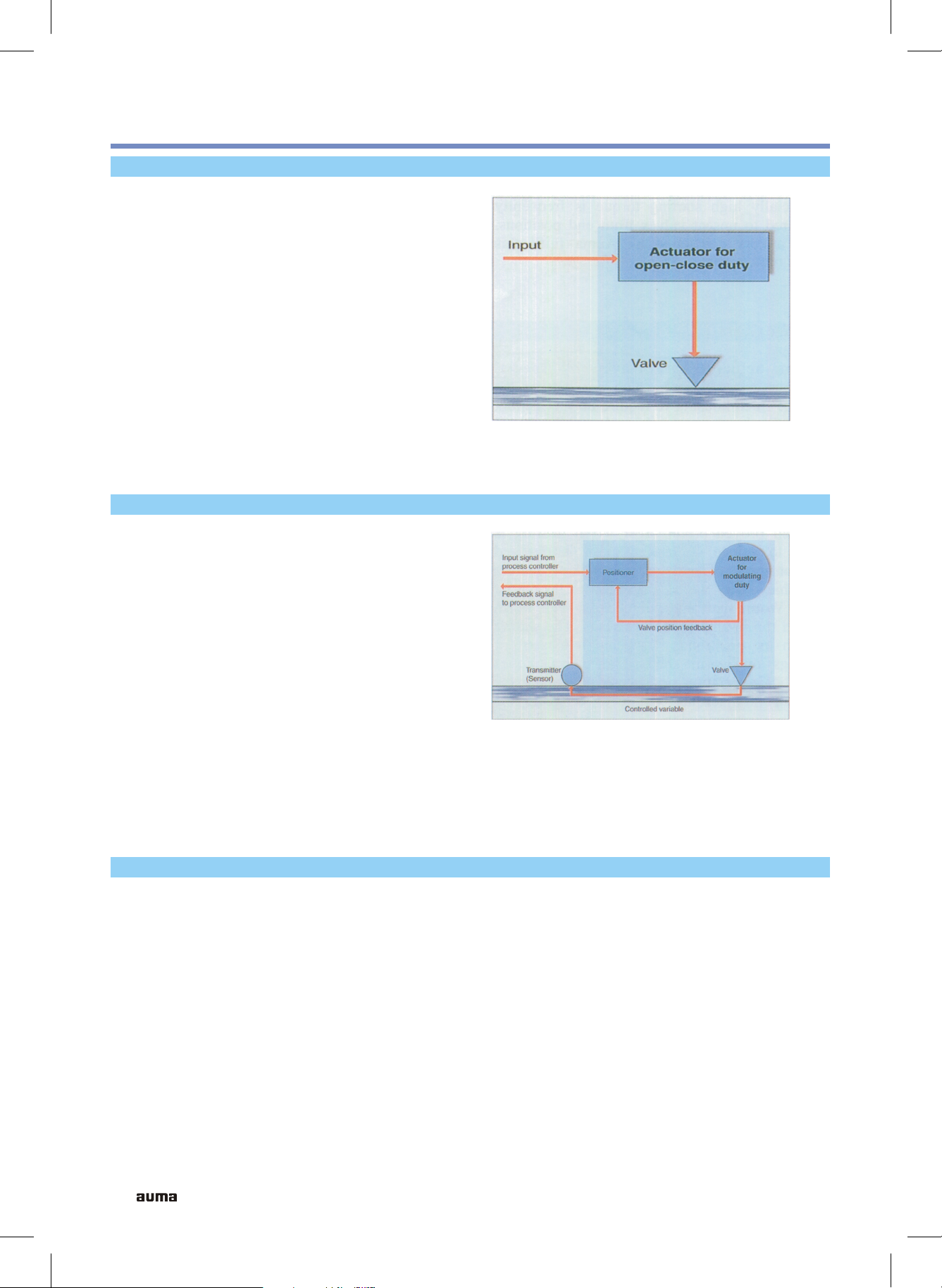

Functions

Open Close Duty

The characteristic feature of this actuator is

open loop. The normal valve positions in

OPEN-CLOSE Duty are end positions OPEN

and CLOSED. After receiving command, the

actuator operates the valve to one of the end

positions or if necessary to a preset

intermediate position. The valves are operated

relatively seldom, the time intervals can span

between a few minutes to several months.

Auma multi-turn actuators type SA for open

close service are rated for short time duty

S2-15min.

Regulating / Modulating Duty

Typical Characteristics of

OPEN-CLOSE DUTY

The characteristic feature of this actuator is

closed loop in which input command signal to

actuator is directly influenced by the flow

through the valve. Regulating / Modulating

duty actuator SAR operates between two set

bands between open-close positions depending

upon actual valve position and feedback signal.

The motors of these actuators are rated for

intermittent duty S4-25%. The mechanical

components and motor are designed to withstand

a large number of operations required for

modulating applications.

Typical Characteristics of

Regulating / Modulating Duty

Pemissible number of starts-stops depends upon

actuator size & speed. The details are available

in Data Sheets.

Short Time and Intermittent Duty IS 12824

Short time Duty S2 Intermittent Duty S4

Operation at constant load during a given

time, less than that required to reach thermal

equilibrium, followed by a rest and deenergized period of sufficient duration to reestablish machine temperatures within 2 C.

o

A sequence of identical duty cycles, each cycle

including a significant period of starting, a period

of operation at constant load and a rest and deenergized period. These periods being too short

to attain thermal equilibrium during one duty

cycle.

The duration of short time is limited to 15, 30

or 60 min.

The relative on time at S4-25% is limited to

25% of the cycle time.

8

Page 9

Limit Switching

Functions

The limit switching enables to switch off the

actuator when reaching defined valve

position, usually end positions. The valve

travel is measured by mechanical counter gear

mechanism which when reaching the set

Two Train Counter Gear

For Two train counter gear, two limit switches,

one for each direction of travel having 1 NO

+ 1 NC or 2 NO + 2 NC contacts are provided.

The number of spindle turns can be set

between 1 and 480 or 1 and 4800.

switching points operate the electrical limit

switches by cams. The setting accuracy is 1/10 of

a turn of actuator output shaft.

In limit switching, two train counter gear and

four train counter gear versions are available :

Four Train Counter Gear

If limit switching is required at two end

positions only, two train counter gear is used.

However, if two additional intermediate

switching positions are desired, Four Train

Counter Gear is required. This limit switching

has 4 counter gears and 4 micro switches. Two

counter gears are used to switch off at end

positions as in Two Train Counter Gear. The

other two are available for setting any desired

intermediate positions between end positions.

After cam actuation, the switches remain

actuated till reaching end of valve travel.

Examples of such application are :

To stop at intermediate position

Sequence control, that is to start

another equipment like pump or bypass

valve actuator after certain travel

of valve.

Two Train Counter Gear

The accuracy of setting is 1/10 of a turn of

actuator output shaft. For four train counter

gear, 4 limit switches of 1 NO + 1 NC or 2 NO

+ 2 NC contacts are provided.

Four Train Counter Gear

9

Page 10

Functions

Torque Switching

The torque switching enables to switch off the

actuator when pre-determined torque is

reached instead of a defined position. The

torque switching works on principle of sliding

worm.

Axial displacement of worm proportional to

thrust is transmitted to torque switches.

Torque switches operate in closing & opening

directions. The required tripping torque can be

easily set on the graduated dial. If limit switch

cut off is selected prior to torque switch, then

torque switch serves as overload protection.

For tight seating of certain valves, the actuator

must be operated to end position CLOSED

with defined force. Such operation can be

carried out by torque seating. Limit seating is

commonly used in the end position OPEN.

Running Indication

Blinker switch is provided in the actuator and

can be used as running indicator.

Torque Switching

When torque seating is used at end position,

limit switches can be used for signalization.

Therefore actuator controls can differentiate

whether actuator was switched off by torque

switch or by limit switch. Micro switches of

torque switching are provided with 1 NO + 1 NC

or 2 NO + 2 NC contacts for both open & close

directions.

10

Page 11

Micro Switches

Control Equipment

With the help of micro switches, mechanical

parameters such as travel & torque are

converted into electrical signals for actuator

control. There are four switches in the basic

version :

One limit switch each for the end

positions OPEN and CLOSE

One torque switch each for the

directions OPEN and CLOSE.

Single and Tandem Micro Switches

Limit and Torque Switches are available in

single or tandem versions.

Limit switches are tripped when an end position

is reached and torque switches are tripped when

the set tripping torque is exceeded.

The micro switches are sealed to enclosure

protection class IP66, as per IS 13947. The micro

switches have double break change over

potential free contacts. The circuit is interrupted

simultaneously at two points. The basic versions

of the switch contacts are of silver. For low

current ratings, micro switches with gold plated

contacts are available.

Switching another circuit also with

different voltage & current

Safety function, to operate with single

switch

Multiplying the available contacts,

example for signalization.

Single Micro Switch

Limit or Torque Switches in tandem version

have additional switching contacts. These

contacts can be wired for following applications :

Micro Switch Ratings

Type of Switch

Limit and

Torque

Type of

Current

AC, cos O = 0.8

Inductive

DC inductive

30 V

DC resistive

Blinker

AC, cos O = 0.8

Inductive

For such applications, a relay is recommended

since there may be small differences in tripping

points of tandem switches.

Rating in Amp at

75 V

8

5

7

7

1

1

Tandem Micro Switch

125 V 250 V

6

0.2

0.5

5

0.1

0.25

4

Approx. Electrical

contact rating

500,000 cycles at

250 V AC, 5A

50,000 cycles at

250 V DC, 0.1A

50,000 cycles at

250 V DC, 0.25A

11

Page 12

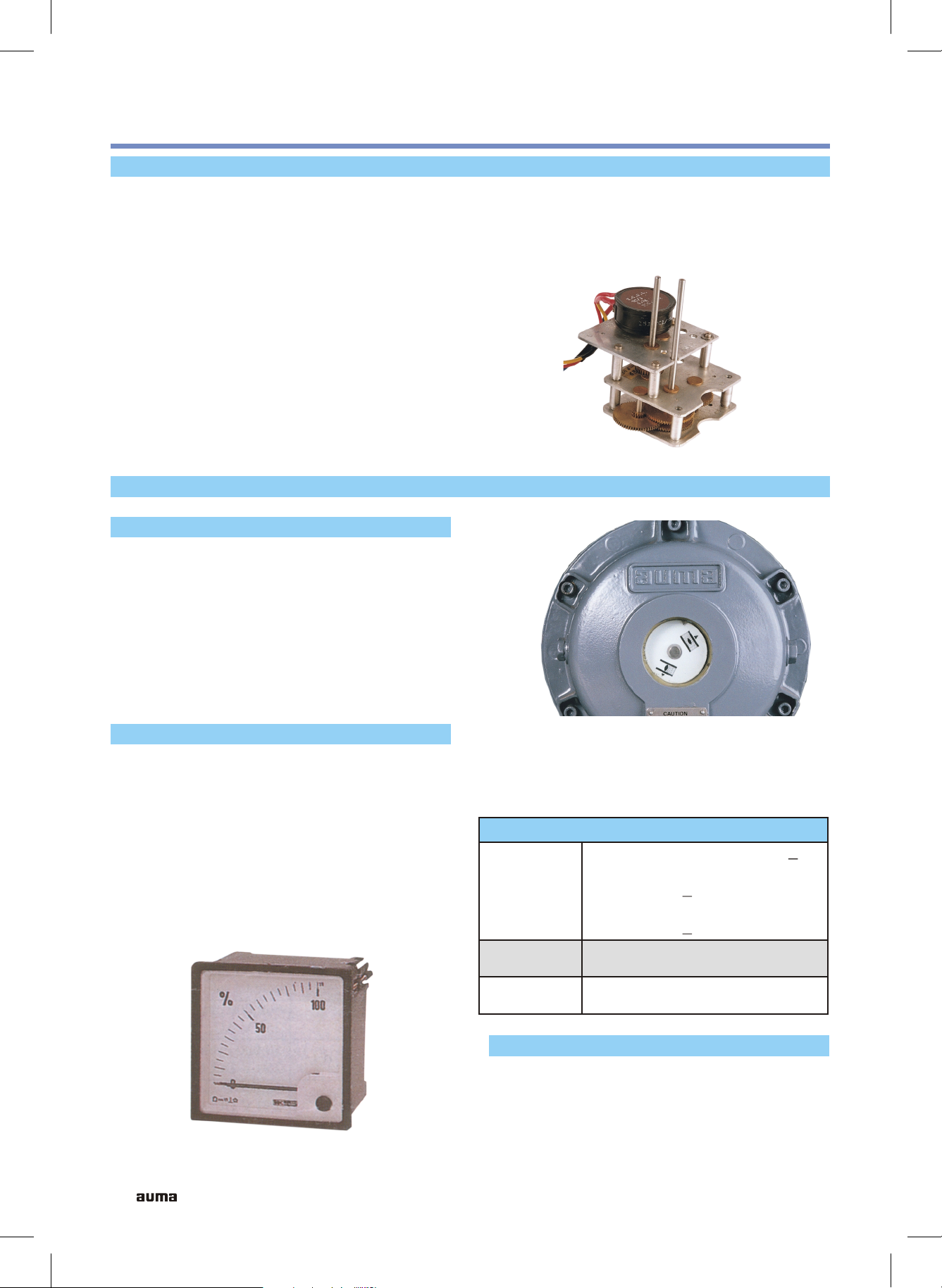

Control Equipment

Reduction Gear Unit

A reduction gear unit (RGU) in the actuator is

used for mechanical position indication,

remote position indication & for operation of

intermediate switches. The output shaft of the

actuator drives final output shaft of RGU

through a series of reduction gears and final

shaft turns by approximately 270 while

o

actuator output shaft performs full number of

turns as set on two train or four train counter

gear unit. The reduction gear ratio needed for

each particular case is fitted at works if the

ratio is known. For this purpose fixed RGU

is supplied. If the ratio needs to be altered

Position Indicators

Mechanical Position Indicator

The position of the valve is indicated

continuously by adjustable discs having

symbols for OPEN and CLOSE. The discs can

be seen through an indicator glass on switch

compartment cover. The open-close discs can

be set to coincide with limit switching. The

mechanical position indicator requires

reduction gear unit for operation.

at site, variable ratio RGU is available which

allows simple modification at site depending

upon number of turns of output shaft for full

stroke of valve.

Reduction Gear Unit (RGU)

Remote Position Indicator

The position of the valve can be transmitted as

a continuous signal for remote indication. A

potentiometer mounted on RGU is used for

this purpose. A power supply unit provides

necessary voltage to the potentiometer. The

potentiometer rotates through 270 for one full

o

stroke of valve & output signal from

potentiometer is proportional to valve travel.

Thus the actual position of the valve can be

Mechanical Position Indicator

read off continuously on position meter

calibrated & mounted on control panel.

Technical Data

Std: 220 ohms, 3W, Linearity + 3%

Optional : 100, 560, 1000 ohms,

Potentiometer

3W, Linearity + 3%

Precision : 200, 500, 1000 ohms,

1W, Linearity + 0.5%

Power

Supply Unit

Position

PS01, input 220V, 50Hz, output

24V DC

0 - 100% in various sizes

Meter

Digital Remote Position Indicator

Actual position display can be provided by

digital remote position indicator, which

displays open position in percentage.

12

Remote Position Indicator

Page 13

Intermediate Switches

With this limit switching, additional switching

points can be set for each direction of rotation.

The switching can be set between 25 and 75%

of valve travel in each direction. The switch

sub assembly consisting of 2 or 4 cam switches

is mounted on output shaft of RGU. Each

micro switch has 1 NO + 1 NC contact.

Manual Operation

For commissioning or in an emergency when

there is no power supply, actuator can be

operated by hand wheel. The manual drive is

engaged by means of a lever. When motor

starts running, the manual drive gets

disengaged immediately & hand wheel does

not rotate during power operation.

Control Equipment

Intermediate Switches

In manual operation, hammer blow can be

effected with hand wheel. The hammer blow

makes it possible to open a jammed or rarely

operated valve.

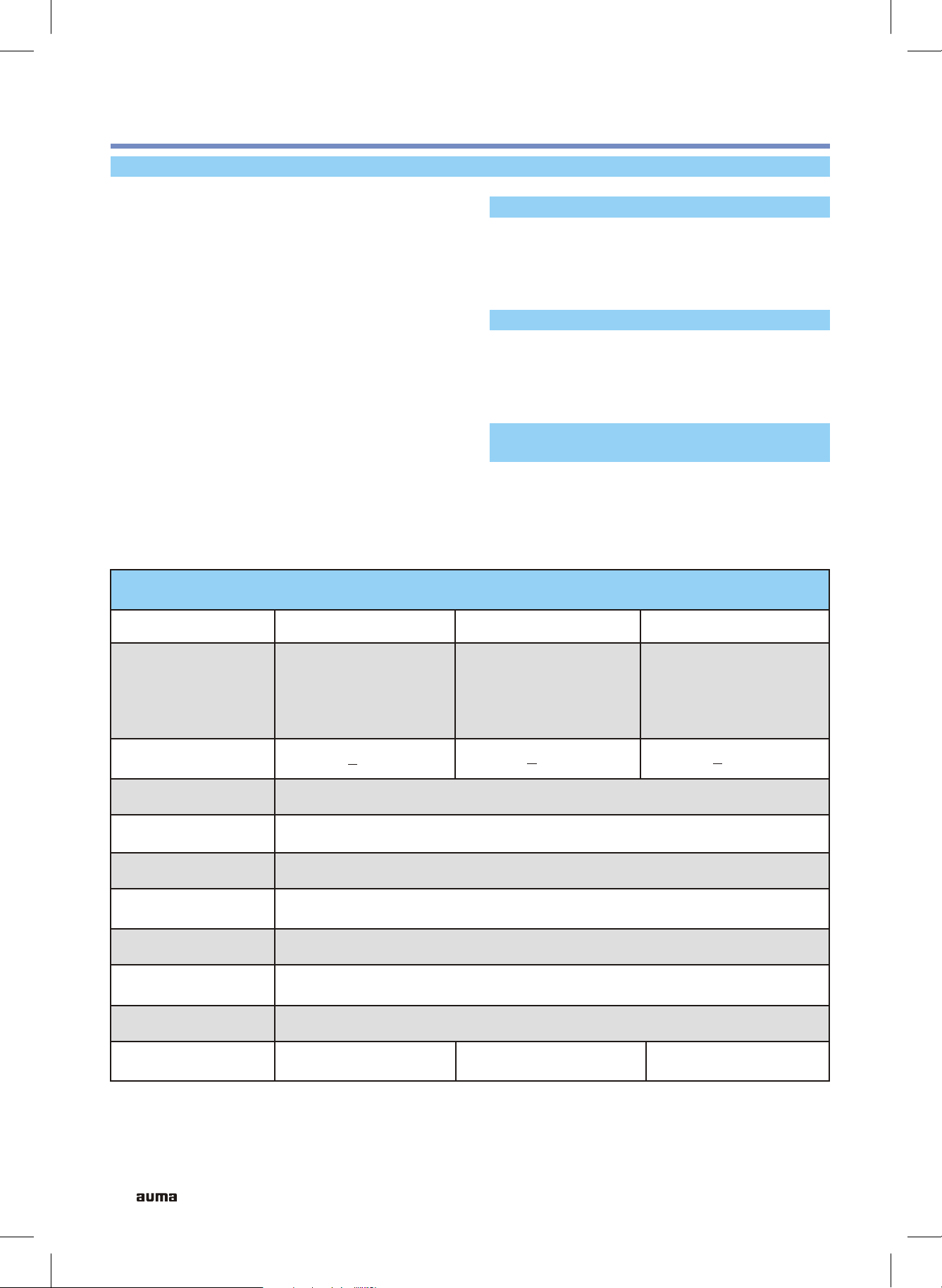

Top Bevel Gear Set

Manual effort on hand wheel can be further

reduced by using a side mounted hand wheel

instead of standard hand wheel. Reduction

ratios available are

SA3 / 6 / 12 / 15

SA25 / 30 / 50 / 60

SA 100

Instead of hand wheel, a chain pulley can be

provided for actuators mounted in inaccessible

zones.

Space Heater

2 : 1

3 : 1

4 : 1

Top Bevel Gear Set

Condensation in the actuator is possible due to

wide fluctuation of the ambient temperature.

The heater integrated in the control unit

prevents the water condensation. The heater is

rated for continuous duty. This may be

continuously energized or when the actuator

is not operating.

Technical Data

Volts, AC

Resistance

ohms

Rating

Watts

230

5K

10 20 10 20

230 110 110

2.7K 1.2K 0.6K

13

Page 14

Control Equipment

Motors

As a standard, Auma multi turn actuators are

equipped with 3 phase induction motors.

Auma motors are class F insulated and

withstand winding temperature upto 140 C.

o

The motors are used for short time duty (S2-15

min or S4-25% as per IS 12824) and provide

approximately three times rated torque for

short duration. The size of the motor is smaller

compared to continuous duty motor S1 of

same output power. This results in reduced

inertia of the rotor and therefore less

overshoot after switching off of motor. Auma

motors are designed for enclosure protection

class IP 68 when mounted on the actuator. All

motor cables are brought to terminal

compartment cover from inside of the actuator

thus avoiding terminal box.

Technical Data

Single Phase AC Motors

Auma actuators can be supplied with single

phase AC motor. The required capacitor is fitted

in the terminal compartment cover.

DC Motors

Auma actuators are also available with DC

motors. These motors operate on 24 V, 110 V or

220 V DC supply.

AC Motors with Other Voltages and

Frequency

Three phase induction motors are available in

wide range of operating voltages from 220 V to

560 V and operating frequency of 50 or 60 Hz.

3 ph AC Motor 1 ph AC Motor DC Motor

50/60 Hz : 220 V, 380 V

50/60 Hz :

400 V, 415 V

Voltages

440 V, 460 V

480 V, 500 V

550 V

Permissible Variation

in Voltage

+ 10%

Mounting C Type Flange, B14, IS 2223

Enclosure Protection IP 67 or IP 68 after mounting

Type of Cooling Surface Cooled

Insulation Class

F Class, IS 325 (max. temp. rise 140 C)

Starting Direct on line

Type of Duty S2-15 min. or S4-25 % IS 12824

Direction of Rotation Clockwise and anticlockwise

220 V - 240 V

110 V - 220 V

220 V

110 V

48 V

24 V

+ 10% + 10%

o

Motor Protection 3 thermo switches 2 thermo switches 4 thermo switches

14

Page 15

Motor Protection

Control Equipment

Motor winding may get overheated if the

actuator is run beyond rated duty or if the

rotor is stalled for considerably longer time or

if too high ambient temperature is

encountered. In order to protect the motor

against over heating, thermo switches are

embedded in the windings of three phase,

single phase AC motors and DC motors. When

integrated into the control circuits, they will

protect the motor against damage due to

excessive winding temperature.

The thermo switches interrupt the control

circuit as soon as winding temperature of

o

140 C is exceeded. After cooling down to a

temperature of approx. 110 C, the actuator can

o

be switched on once again. PTC thermistors

can also be provided for motor protection.

Output Speeds

With large range of available output speeds,

almost every required operating time can be

achieved with Auma actuators.

The actuator output speed is determined by

the motor speed, change gears and reduction

gear ratio of worm / worm wheel.

The output speeds are available from 4 - 180

rpm in geometric progression of 1: 1.4.

During trial run, if found necessary, the

output speed can be easily changed by

Technical Data

AC Voltage

250 V AC

Cos O = 1

250 V AC

Cos O = 0.6

Tripping Temp 140 C

Reset Temp 90 - 110 C

o

o

Switch Rating

2.5 A

1.6 A

Note : The motor protection device must be

integrated into the controls, otherwise warranty

for motor is not valid.

exchanging the change wheels and or motor at

site. The grease filled housing need not be

opened for this purpose. The torque switch

setting & limit switch setting remains the same.

For actuators with output drive A (Stem nut),

max. permissible stem velocity must be

observed:

-

for gate valves max. 500 mm/min

-

for globe valves max. 250 mm/min

For higher velocities it is recommended to use

spring loaded stem nut type AF (special design).

Self Locking

Auma multi turn actuators SA/SAR3 to

SA/SAR100 are self locking (see note below)

with exception of output speeds 125 & 180

rpm. Actuators with 125 & 180 rpm are having

double start worm drive. After torque switch is

tripped, the sliding worm may move back to

initial position by the action of torque

measuring springs. This allows torque switch

to be released. If control system provides

continuous signal, this results in hunting of

motor. This can be avoided by the use of

auxiliary relay.

Note on Self Locking :

Self-locking gearing does not ensure safe

stopping after an operation. If this is required,

separate locking arrangement must be provided.

15

Page 16

Actuators for Regulating Duty

Description of Regulating Duty

Auma actuators of type SAR are suitable for

Regulating duty / Modulating duty. SAR

actuator operates between two set bands in

closed loop and the motor is started, stopped

& reversed at short intervals to correct the

deviation from the set value. SAR actuators

differ from SA actuators in several respects :

- 4 pole motors are used to reduce overshoot

- Worm with high quality finish on flanks for

better efficiency

-

Disc springs on worm shaft are pre

compressed to reduce dead band when

reversing.

While selecting Auma actuators for regulating

duty applications, following points should be

noted :

Principle of Operation

Max. No. of starts-

1200 cycles / hour with motor power upto

0.55 kW & 600 cycles / hour with motor

power above 0.55 kW.

Output speed of actuator max. 45 rpm.

-

-

Torque for regulating duty should not exceed

50% of max. torque of actuator.

-

Max. torque of actuator can be used for

seating & unseating of the valve.

For reversing service, duration of impulse

should be minimum of 50 ms.

-

Electronic position transducer or precision

potentiometer should be used for remote

position indication.

-

The motor should be short time duty

class S4 - 25%.

The SAR actuator basically consists of

control units as explained in following

diagram.

16

SAR

MSAR

MUSAR

Regulating duty actuator

:

Sensor for actuator, i.e.

:

position transmitter at actuator

(potentiometer or inductive

LVDT)

Signal converter for SAR i.e.

:

Electronic position transducer

(RWG 1001/RWG 2002) or

inductive position transmitter

(IWG 1002/ IWG 1003).

CU01

V

M

MU

SE

W

XR

YR

:

Electronic positioner

:

Regulating valve

:

Sensor for regulating valve

:

Signal converter for sensor

:

Setting nominal value

:

Reference input

:

Input value at controller

:

Output value at electronic

positioner

Page 17

Description of Electronic Units

Actuators for Regulating Duty

Sensor for Actuator

A potentiometer is used as sensor for actuator.

Single turn wire wound potentiometer with

4.7 k ohms with linearity of + 0.5 % is available

for this purpose. It is available in single or

tandem version.

Electronic position transducer RWG 1001

This device is a signal converter for the

transformation of resistance value into

proportionate current signal. It can also be

placed in the actuator where the position

determined by the potentiometer is converted

into 4-20 mA current signal.

As position transmitter, preferably a

potentiometer of 4.7 k ohm should be used so

that the reference voltage source is not over

loaded. This device requires 24V DC power

supply regulated within + 15%. Auma power

supply unit PS01 is recommended for this

purpose. RWG 1001 is a 3 wire system and is

having linearity of 0.05 %.

Electronic position transducer RWG 2002

This is basically same as RWG 1001, however

with 2 wire system. The linearity is less than 1%.

Technical Data

Resistance 4.7 k ohms + 0.5 %

Power rating

Angle of rotation

Linearity

3 Watt at 40 C

oo

275 + 5

+ 0.5%

o

RWG 1001

Technical Data - RWG 1001

Configuration 3 Wire

Supply Voltage

Output Current

Input resistance

Displacement of zero

position, max.

Displacement of end

position, max.

Influence of supply

24V DC

min. 18, max. 33V

0-20 mA

(4-20 mA)

150 k ohms

+ 25%

from 50 to 100%

Max. 0.2%

voltage variation

Temp. drift

Linearity not considering

potentiometer

0.2% 10 C

0.05%

o

RWG 2002

Technical Data - RWG 2002

Configuration 2 Wire

Supply Voltage

Output Current

Input resistance

Displacement of zero

24V DC

min. 18, max. 33V

4-20 mA

150 k ohms

+ 25%

position, max.

Displacement of end

position, max.

Influence of supply

from 60 to 100%

Max. 0.15%

voltage variation

Linearity not considering

potentiometer

< 1%

17

Page 18

Actuators for Regulating Duty

Description of Electronic Units

Dual Output Position Transmitter RWG 2002 DG :

It is a signal converter device for the

transformation of resistance value into

proportionate galvanically isolated two current

outputs. This device requires 24 V DC power

supply regulated within + 10%. Auma power

supply unit PS01 is recommended for

this purpose.

Inductive Position Transmitter IWG 1002

When using Auma actuators for regulating duty

with demand of high accuracy, an inductive

position transmitter can be fitted to give precise

read out of position.

Technical Data - RWG 2002 DG

Supply Voltage

Output 1 (Isolated)

Output 2 (Isolated)

Current Drawn

Adjustability of Span

Adjustability of Zero

Change in Output due to

Input Supply Variation

24V DC

+ 10% regulated

0/4-20 mA

0/4-20 mA

100 mA

+ 50%

+ 25%

< 0.2%

Operating Temperature

Range

Linearity Error for both

Outputs

- 20 C to + 80 C

< 1%

oo

The output signal is used as feed back to

electronic positioner or for position indicator.

The system consists of two parts, a linear

variable differential transformer (LVDT) and

an electronic unit. The smallest change of

magnetic core in the measuring coil is

transformed into proportional signal. The

transmitter has no moving contacts. This device

requires 24 V DC power supply regulated

within + 15%. Auma power supply

unit PS01 is recommended for this purpose.

The linearity of the unit is less than 0.3%.

IWG 1002

Technical Data - IWG 1002

Configuration

Supply Voltage

Output Current

Resistance max.

Displacement of zero

position, max.

Displacement of end

position, max.

Temp. drift

Linearity (not

considering LVDT)

2 Wire

24V DC

+ 15% regulated

4-20 mA

600 ohms

+ 25%

60 to 100%

0.4% / 10 C

o

< 0.3%

18

Page 19

Description of Electronic Units

Inductive position transmitter IWG 1003

Actuators for Regulating Duty

IWG 1003 is similar to IWG 1002 however with

3 wire system.

IWG 1003

Electronic Positioner CU01

The electronic positioner CU01 is designed as a

three level positioner for regulating of actuator.

By comparing two input signals (reference

signal W & regulating signal X), the positioner

determines the difference. In case this exceeds a

certain value, the actuator is switched on by

relays. The direction of rotation (opening or

Technical Data - IWG 1003

Configuration

Supply Voltage

Output Current

Resistance max.

Displacement of zero

position, max.

Displacement of end

position, max.

Temp. drift

3 Wire

24V DC

+ 15% regulated

0 / 4-20 mA

600 ohms

+ 25%

60 to 100%

0.4% / 10 C

o

Linearity (not

considering LVDT)

< 0.3%

closing) depends upon the plus or minus sign of

the deviation. Thus the regulating signal

generated by potentiometer or LVDT changes &

when the regulating signal & reference signal

become equal, the actuator stops as long as no

new correction is required.

CU 01

Technical Data

Input WE1 0-20 mA (4-20 mA)

XE2

0-20 mA (4-20 mA)

or 0-Uref

Time delay

Adjustment of zero

0.5-15 secs.

0 - 20%

point

Adjustment of end

position

Sensitivity (dead

60 to 100%

1% - 2.5%

band)

Relay output (max.

resistive load

230V, 10A

19

Page 20

Actuators for Regulating Duty

Description of Electronic Units

Signal Isolator

Auma signal isolators are available in various

versions :

Power supply conditions :

230V AC, 110V AC or 24V DC

Various input signals :

4-20 mA or 1-5 V

Signal Isolator

Power supply unit PS01

Various output signals :

4-20 mA single or dual or 4-20 mA & 1-5V

Isolation is provided between input and output

and between two outputs.

Technical Data

230V AC + 15%

Power Supply

Input

Output

Accuracy

Zero & span

adjustment

110V AC + 15%

24V DC + 1V

4-20 mA

1-5V

4-20 mA single

4-20 mA dual

4-20 mA & 1-5 V

+ 0.1% of output span

+ 2% min. at zero

+ 10% min. at span

This unit gives 24V DC power supply for

regulating system (example : for CU01) & for

remote position indication (example : by a

voltmeter suitably calibrated). There are two

versions available:

Version I : For regulating application with

CU01 :

The output voltage Uo & Uc require no trimming

potentiometer. The voltage Uc is diverted from

voltage Uo, thus Uc can serve as common

reference potential for whole regulating system.

This version is suitable for IWG 1003 or

RWG 1001.

Supply voltage to PS01 is 220V or 110V +

15%, 50 Hz

The maximum output voltage is

Uo = 24V + 1 V DC

Uc = 5.5V + 0.5V DC

Version II : For remote position indication with

potentiometer 220 ohms as position transmitter :

In this two additional potentiometers P1 and P2

are provided for positions zero and maximum.

Version II

Technical Data - PS01

Supply voltage and

frequency

Power drawn

220V or 115V (+ 15%)

50 Hz or 60 Hz

9 VA

20

Version I

Output voltage

max.

Mounting

24V +1V DC

Snap on type for DIN

rail 46277

Page 21

Auma Norm Actuators

This actuator offers a complete actuator type SA

with electric motor, torque switch for open close direction, limit switches for both end

positions & blinker switch for running

indication. The required reversing contactor

should be installed separately & wired to the

motor. For signalization of the switching and to

trip the contactors over micro switches, control

wires are required from actuator terminal

compartment cover to reversing contactor

installed separately.

Auma Integral Starter Actuators

Actuator Types

Auma Norm

The purpose of offering Integral motor controls

for the actuator is to enable the customer to save

high installation costs for external controls.

Actuators with integral controls include control

& switching elements and are supplied

ready for use.

All electrical components such as limit, torque,

thermo switches, all monitoring elements &

position transmitter are integrated into modern

controls.This results in following simplification.

- No extensive wiring in the external control

cabinet

-

Several actuators can be connected to common

supply cable using isolating switch for each

actuator.

-

Actuator signals are processed in the controls,

only feed back to process control system is

necessary.

-

Integral starter housing can be easily

exchanged due to multi pin plug connector

between actuator & integral starter unit.

-

Actuator can be operated from Local or

Remote position by means of selector switch

on the integral starter unit.

Auma Integral Starter

21

Page 22

Actuator Types

Control Versions of Integral Starter Units

Auma Compact

This is a simpler version of Integral Starter Unit

with selector switch & push buttons. The

selector switch has 3 positions :

LOCAL :

The actuator can be operated locally i.e. at the

actuator by push buttons OPEN-OFF-CLOSE.

The running direction is indicated by LEDs.

REMOTE :

The actuator can be operated from remote

control station. The running direction is

indicated by LEDs on the actuator.

OFF :

The actuator cannot be operated with local

controls or from remote.

The selector switch can be locked in any position

with pad lock. The compact unit is completely

wired with reversing contactors and no

additional control box is required.

Auma compact is available as Norm or

Regulating duty actuator. Depending upon Norm

or Regulating duty, following features /

optionals are available :

Reversing contactors

Selector switch

Push buttons & indicating lamps

Thermal overload relay

Power supply unit PS01 for 24 V DC output

Electronic positioner CU01

Electronic position transducer RWG / IWG

Phase discriminator

Signal isolator

DC relay for remote operation

Remote annunciation relay for supply

indication

Multi pin connector can be provided between

actuator and compact and between compact &

terminals for customer connections.

22

Auma Compact

Page 23

Control Versions of Integral Starter Units

Auma e-pac

Actuator Types

The electronic version of Auma India Integral

Starter e-pac incorporates sophisticated

electronic controls with field programming

feature. E-pac is modular in construction and

consists of Power Supply Module, Relay

Module & Programmable Control Module.

Power Supply Module consists of

24 V DC, 150 mA source

Reversing contactors electrically and

mechanically interlocked

Selector switch LOCAL-OFF-REMOTE,

lockable & potential free contacts for localoff & remote

Push buttons OPEN-STOP-CLOSE for

local controls

Single phase supply for space heater 10W

Relay Module consists of

Monitor relay for collective fault

signals (Thermo switch trip, torque switch

trip in mid travel) with potential free contacts

Local status annunciation (Green) & fault

annunciation (Red) by LEDs

Programmable Control Logic Module consists

of

Inching & Non-inching in local mode by dip

switches

Inching & Non-inching in remote mode by dip

switches

Limit switch seating or Torque seating by dip

switches

Wide varieties of versions of e-pac & optional

features make the actuator controls adaptable to

any field situation. Versions & optionals

available are :

Emergency shut down (ESD)

2 wire make-break

Timer board to run the actuator in ON-OFF

steps

Open-Close inhibit

Negative switching

Remote control & local stop

Electronic positioner for regulating duty, with

or without isolator

Single phase protection

Automatic phase correction

Remote annunciation relays

Thermal overload relay

Positioner with PID features

Wall mountable e-pac

For detailed literature, refer separate catalogue.

Auma e-pac

23

Page 24

Interface

Valve Attachment

Valve attachment is according to ISO 5210 or DIN 3210

Flange Sizes

Actuator size

SA/SAR

Max. Torque

Nm

ISO 5210

DIN 3210

3

6

30 60 120 150 250 300 500 600 1000

F10

F10 F10 F10 F14 F14 F14 F14 F16

G0 G0 G0 G0 G3

Output Drives

Various output drive types according to ISO

5210 / DIN 3210 are available in order to

adapt the actuators to different types of valves.

Special sizes can be supplied on request.

Output Drive Type A

Stem nut :

The output drive has stem nut for rising or non

rotating valve stem. The mounting flange

together with stem nut and thrust bearings form

one assembly which is suitable for accepting

thrust loads.

12

15 25 30 50 60 100

G

1

1

1

G

G

2

2

1

G

2

2

Output Drive Type D

Stub Shaft :

The shaft with key engages with bore and

keyway of mating part.

Output Drive Type E

Bore with Keyway :

This type is mainly used for connecting to a gear

box, example Auma Gear Box type GS

(worm / worm wheel) or GK (Bevel gear box).

Output Drive Type B

Plug Sleeve :

Plug sleeve has bore and keyway and is designed

for transmission of torque.

Output Drive Type C

Dog Coupling :

This is similar to type B, however with dog

coupling for torque transmission.

24

Linear Thrust Unit (LTU)

With the linear thrust unit, the rotary movement

of the actuator output shaft is converted into an

axial movement. Thus the multiturn actuator

becomes linear actuator. Different stroke lengths

can be provided.

Technical Data

Linear Thrust

Unit

LTU 6

LTU 12

LTU 25

LTU 50

Tr.

Thread

24 x 5

32 x 6

40 x 7

50 x 8

Max.

thrust

kN

20

35

63

100

Stroke

length

mm

50 & 100

60 & 120

80 & 160

80 & 160

Page 25

Electrical Connection

Terminals

Interface

Screw type terminals are used for electrical

connection as standard. Stud type terminals can

be provided for power connections. Terminals

are DIN rail mountable and are available as

single or double decker versions also.

Plug socket connector

The actuators can also be equipped with plug

socket connectors in two versions.

Electrical Connection for Integral Starter Versions

Between actuator and compact or e-pac :

64 pin connector with 3+1 pins for power

connection or 50 pin circular connector with

6+1 pins for power connection. This simplifies

trouble shooting at site.

From compact or e-pac to customer connections:

Screw type terminals or 64 pin connector with

3+1 pins for power connection or 50 pin circular

connector with 6+1 pins for power connection.

Version I :

32 x 2 = 64 pins for control

3 + 1 = 4 pins for power

Version II :

50 pin circular connector for control

6 + 1 = 7 pins for power

Technical Data

Power

Screw type terminals

Terminals max.

Voltage max.

Current max.

Type of Connection

Cross section max.

Plug socket connector 32 x 2 & 3 + 1

No. of contacts

Voltage max.

Current max.

Type of connections

for customer use

Cross sec. max.

Plug socket connector, circular

No. of contacts

Voltage max.

Current max.

Type of connections

for customer use

3

750 V

34 A -

Scr or stud

4 sq mm

3

750 V

25 A

Screws

6 sq mm

6

(3 used)

750 V

25 A

Screws

Earth

1

-

Scr or

stud

4 sq mm

1

-

-

Screws

6 sq mm

1

-

-

Screws

Screw type terminals

Controls

64

500 V

25 A

Scr

2.5 sq mm

64

Multi-pin Connector

500 V

16 A

Screws

2.5 sq mm

50

250 V

16 A

Circular Connector

Screws

Cross sec. max.

6 sq mm

6 sq mm

2.5 sq mm

25

Page 26

Interface

Threads for Cable Glands

As standard, Auma actuators are supplied with

2 cable glands with British Conduit threads

1

''

1/

1 BSC. The cable glands are directly tightened

4

on the threads provided in cable entry cover. At

the time of despatch, the cable entry opening in

the cable gland is sealed with aluminium shim

& neoprene rubber sheet to prevent ingress of

dust & water.

Stem Protection Tube

3

''

Additional cable glands of sizes , 1'' can be

3/4''

4

provided. For additional protection under

extreme conditions for weather proof & water

proof applications, double compression cable

glands in various sizes can be supplied. NTP &

PG threads can also be provided.

To protect rising valve stem, a protection tube

can be fitted to the hand wheel hub. Internal

threads are provided in the hand wheel hub

Actuator - Gear box Combinations

Combination with Worm Gear boxes

In combination with worm gear box of type

GS40.2 to GS500, a multiturn actuator is

converted into part turn actuator usually for 90

o

movement. This is an ideal solution for large part

turn valves with high torque requirements. The

torque range goes upto 250000 Nm.

Combination with Bevel Gear boxes

By combining multiturn actuators with Bevel

gear boxes GK10.1 to GK35.1, the torque speed

ranges are considerably extended. Output

torques upto 8000 Nm and thrust load upto

820 KN are possible.

as a standard. If protection tube is not required,

the bore of the hand wheel hub is closed with lid.

Combination with Lever Gear boxes

Louvers, dampers or valves which are operated

via lever arrangement require lever gear boxes.

For such application multiturn actuator is

combined with lever operated Gear box type

GF40 to GF315. The torque range goes

upto 63000 Nm.

26

GEAR OPERATORS

Page 27

Enclosure Protection

Service Conditions

Auma actuators conform to enclosure protection

IP67 as per IS 13947 (Part I) : 1993, Appendix C.

Auma actuators are also available with improved

enclosure protection IP68. The definition of

IP67 & IP68 as per standard is as follows :

IP : Ingress Protection

First numeral 6 : Dust tight, prevents ingress

of dust.

Second numeral 7 : Protected against the effects

of immersion. Test is made by completely

immersing the equipment in water so that :

Surface of water is atleast 150 mm above

highest point of equipment.

Ambient Temperature

Type

SA

SAR

Actuator Type

Standard

Multi-turn actuator

Multi-turn

Actuator for

Temp.

Range

-20 to +80 C

-20 to +60 C

o

o

Regulating Duty

SAEx

SAREx

SACEx

SARCEx

Explosion Proof

actuators, standard

compact &

regulating duty

-20 to +40 C

o

The lowest point of equipment is atleast 1 m

below the surface of water

Duration of test is 30 min.

Under above conditions, ingress of water in

harmful quantity shall not be possible.

Second numeral 8 : Test conditions as above,

however no ingress of water is permitted.

Life Time

Auma multi-turn actuators meet the following

requirements of operating cycles at 30 turns per

stroke of close - open - close.

SA3 to SA100

SAR6 to SAR100

15000 Cycles

15000 Cycles

Painting

Type of paint

Standard colour

Primer thickness

Paint thickness

Epoxy

DA grey IS 5

40 microns min.

75 microns min.

Any other type & colour of paint can be provided

on request.

27

Page 28

Service Conditions

Explosion Proof / Flame Proof Actuators

For installation of actuators in potentially

hazardous or explosive areas, special protective

measures are required. These are specified in

Indian Standard IS 2148-1981 ''Specifications

for Flame Proof Enclosures of Electrical

Apparatus''. Auma India actuators developed for

this purpose are suitable for group II gases and in

application other than coal mines. The

enclosures of explosion proof / flame proof

actuators are designed in consideration of

clauses specified in IS 2148-1981 & the

actuators have been tested and certified by

CMRI, Dhanbad.

Necessary approvals from statutory authorities

have been obtained.

Actuator Models

Actual Type Model

Explosion Proof

Norm

Open-Close Duty

Explosion Proof

Norm

Regulating Duty

Explosion Proof

Compact

Open-Close Duty

Explosion Proof

Compact

Regulating Duty

SAEx3/6/12/15

SAEx25/30/50/60

SAEx100

SAREx6/12/15

SAREx25/30/50/60

SAREx100

SACEx3/6/12/15

SACEx25/30/50/60

SACEx100

SARCEx6/12/15

SARCEx25/30/50/60

SARCEx100

For details please refer separate catalogue.

-

SAEx3

SAEx100

SAREx6

- SAREx100

SACEx3

- SACEx100

SARCEx6

SARCEx100

-

28

EN ISO 9001

EN ISO 9001

Certificate : 041005262

Certificate : 041005262

Page 29

Mounting Position Functional Tests

General

Auma actuators also with integral controls can

be operated without restriction in any mounting

position.

Test Certificates

Auma actuators and critical components of

actuators have been tested & guaranteed for

performance. Some of the Type test certificates

available are listed.

Endurance Test as per GDCD Standard

Damp Heat Cycle Test as per IS 9000

Vibration Test as per IS 12075

Noise Test as per IS 12065

Enclosure Protection Test as per IS 13947

Tests on Micro Switches

Motor Performance Tests

After assembly, all actuators are thoroughly

tested and torque switches are calibrated. Final

inspection record is provided to the customer.

29

Page 30

Technical Data

Open-Close duty

Tripping Torque

both directions

Min.Nm

20 26 25 250

20 26 40 250

1)

Max.Nm

30

60

55

30 38 60 250

120

110

50 38 60 250

150

60 52 120 360

250

Actuator Type

Type

SA

3

SA

3

SA

3

SA

3

SA

3

SA

3

SA

3

SA

3

SA

3

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

15

SA

15

SA

15

SA

15

SA

15

SA

15

SA

15

SA

15

SA

15

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

Auma India

Output Speed

1/min

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

2)

11

16

22

32

45

63

90

125

180

4

5.6

8

11

16

22

32

45

63

90

125

180

4

5.6

8

11

16

22

32

45

63

90

125

180

4

5.6

8

11

16

22

32

45

63

4

5.6

8

11

16

22

32

45

63

90

125

180

Valve

Mounting

Flange

Standard

DIN:3210

(Special

ISO:5210)

3)

3)

3)

3)

3)

3)

Stem dia.

Output drive

Type-A

Max. mm Max. kN Min. / Max.

Permissible

Thrust for

Type-A

G0

(F10)

G0

(F10)

G0

(F10)

G0

(F10)

1

G

2

(F14)

Revolutions

for

Full stroke

1-480

or

1-4800

1-480

or

1-4800

1-480

or

1-4800

1-480

or

1-4800

1-480

or

1-4800

SA3-SA100

Hand

wheel

Dia.

Std.

Hand wheel

Ratio

Std. Std.

1:1 2:1

1:1 2:1

1:1 2:1

1:1 2:1

1:1

With bevel

gear set

3:1

Weight

Auma India Norm

With bevel

gear set

Kgs. Kgs.

39 45

39 45

39 45

39 45

72

88

30

220

1) Infinitely adjustable 3) Non self locking

2) At 50 Hz

We reserve the right to alter data according to improvements made. Previous data sheets become invalid with the issue of this data sheet.

3)

3)

Page 31

Technical Data

Open-Close duty

Max.

Nm.

300

1)

Tripping Torque

both directions

Min.

Nm.

100 52 120 360

264

100 52

500

450

100

600

540

1000

Actuator Type

Type

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

Auma India

Output Speed

1/min

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

2)

900

4

5.6

8

11

16

22

32

45

63

90

125

180

4

5.6

8

11

16

22

32

45

63

90

125

180

4

5.6

8

11

16

22

32

45

63

90

125

180

4

5.6

8

11

16

22

32

45

63

90

125

180

3)

3)

3)

3)

3)

3)

3)

3)

Valve

Mounting

Flange

Standard

DIN:3210

(Special

ISO:5210)

1

G

2

(F14)

1

G

2

(F14)

1

G

2

(F14)

G3

(F16)

Stem dia.

Output drive

Type-A

52

65

Permissible

Thrust for

Type-A

Max.

kN

160

160

190

Revolutions

for

Full stroke

Min. / Max.

1-480

or

1-4800

1-480

or

1-4800

1-480

or

1-4800

1-480

or

1-4800

SA3-SA100

Hand

wheel

Dia.

Std.

640

640

800

Hand wheel

Ratio

Std. Std.

1:1

1:1

1:1

1:1

With bevel

gear set

3:1

3:1

3:1

4:1

Weight

Auma India Norm

With bevel

gear set

Kgs.

107

72

75

75

Kgs.

88

92

92

128200

Enclosure : IP67 - IS:13947

Actuators are rated for short time duty S -15min, based on 40 C ambient temperature. The nominal current

2

o

is based on an average load of approximately 35% of max. torque. The max. torque can be utilised for a short

time (e.g. to seat or unseat a valve) and the current can rise to max. value. Refer corresponding column for

current at max. torque in Electrical Data.

1) Infinitely adjustable 2) At 50 Hz 3) Non self locking

We reserve the right to alter data according to improvements made. Previous data sheets become invalid with the issue of this data sheet.

31

Page 32

Torque

Max.

Nm

30

60

55

120

110

150

250

Auma India

Actuator Type

Type

SA

3

SA

3

SA

3

SA

3

SA

3

SA

3

SA

3

SA

3

SA

3

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

6

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

12

SA

15

SA

15

SA

15

SA

15

SA

15

SA

15

SA

15

SA

15

SA

15

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

SA

25

Output Speed

at 50 Hz

1/min

.....

11

.....

16

.....

22

.....

32

.....

45

.....

63

.....

90

.....

125

.....

180

.....

4

.....

5.6

.....

8

.....

11

.....

16

.....

22

.....

32

.....

45

.....

63

.....

90

.....

125

.....

180

.....

4

.....

5.6

.....

8

.....

11

.....

16

.....

22

.....

32

.....

45

.....

63

.....

90

.....

125

.....

180

.....

4

.....

5.6

.....

8

.....

11

.....

16

.....

22

.....

32

.....

45

.....

63

.....

4

.....

5.6

.....

8

.....

11

.....

16

.....

22

.....

32

.....

45

.....

63

.....

90

.....

125

.....

180

Electrical Data

Open-Close duty

Three phase Squirrel cage AC Motor 415V, 50 Hz

Nominal

Output

KW

0.06

0.06

0.06

0.12

0.18

0.18

0.37

0.37

0.37

0.06

0.06

0.06

0.12

0.12

0.12

0.18

0.37

0.37

0.55

0.55

0.55

0.06

0.12

0.12

0.12

0.25

0.25

0.37

0.55

1.1

1.1

1.1

1.1

0.06

0.12

0.12

0.25

0.25

0.37

0.55

1.1

1.1

0.12

0.25

0.55

0.55

0.55

0.55

1.1

1.1

2.2

2.2

2.2

2.2

Speed

1/min

1400

1400

1400

1400

2800

2800

2800

2800

2800

1400

1400

1400

1400

1400

1400

2800

2800

2800

2800

2800

2800

1400

1400

1400

1400

1400

1400

2800

2800

2800

2800

2800

2800

1400

1400

1400

1400

1400

2800

2800

2800

2800

1400

1400

1400

1400

1400

1400

2800

2800

2800

2800

2800

2800

Size

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

90

90

90

90

Nominal

Current

A

0.3

0.3

0.3

0.5

0.6

0.6

1.0

1.0

1.0

0.3

0.3

0.3

0.5

0.5

0.5

0.6

1.0

1.0

1.8

1.8

1.8

0.3

0.5

0.5

0.5

1.4

1.4

1.0

1.8

2.9

2.9

2.9

2.9

0.3

0.5

0.5

1.4

1.4

1.0

1.8

2.9

2.9

0.5

1.4

2.8

2.8

2.8

2.8

2.9

2.9

4.6

4.6

4.6

4.6

Current at

Max. Torque

A

1)

0.30

0.38

0.50

0.62

0.84

1.16

1.62

1.40

2.05

0.25

0.30

0.38

0.45

0.62

0.90

1.18

1.62

2.34

3.08

2.45

3.52

0.38

0.46

0.62

0.90

1.45

1.80

2.42

3.08

4.58

6.50

5.10

7.50

0.45

0.55

0.83

1.36

1.66

2.00

2.75

4.26

5.67

0.65

1.29

1.64

1.92

2.60

3.58

4.75

6.58

8.44

12.5

8.95

13.6

SA3-SA100

Starting

Current

A

1.2

1.2

1.2

2.3

3.3

3.3

5.5

5.5

5.5

1.2

1.2

1.2

2.3

2.3

2.3

3.3

5.5

5.5

9.0

9.0

9.0

1.2

2.3

2.3

2.3

4.6

4.6

5.5

9.0

16.0

16.0

16.0

16.0

1.2

2.3

2.3

4.6

4.6

5.5

9.0

16.0

16.0

2.3

4.6

12.0

12.0

12.0

12.0

16.0

16.0

40.0

40.0

40.0

40.0

Power

Factor

Cos o

0.6

0.6

0.6

0.6

0.7

0.7

0.76

0.76

0.76

0.6

0.6

0.6

0.6

0.6

0.6

0.7

0.76

0.76

0.62

0.62

0.62

0.6

0.6

0.6

0.6

0.5

0.5

0.76

0.62

0.72

0.72

0.72

0.72

0.6

0.6

0.6

0.5

0.5

0.76

0.62

0.72

0.72

0.6

0.5

0.51

0.51

0.51

0.51

0.72

0.72

0.83

0.83

0.83

0.83

Full load

Efficiency

(%)

46

46

46

55

60

60

68

68

68

46

46

46

55

55

55

60

68

68

70

70

70

46

55

55

55

50

50

68

70

72

72

72

72

46

55

55

50

50

68

70

72

72

55

50

60

60

60

60

72

72

80

80

80

80

32

220

1) Current at max. torque. We recommend to select switch gear and cables suitable for those values.

We reserve the right to alter data according to improvements made. Previous data sheets become invalid with the issue of this data sheet.

Page 33

Torque

Max.

Nm

300

264

500

450

600

540

1000

Actuator Type

Type

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

30

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

50

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

60

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

SA

100

Auma India

Output Speed

at 50 Hz

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

1/min

4

5.6

8

11

16

22

32

45

63

90

125

180

4

5.6

8

11

16

22

32

45

63

90

125

180

4

5.6

8

11

16

22

32

45

63

90

125

180

4

5.6

8

11

16

22

32

45

63

90

125

180

Electrical Data

Open-Close duty

Three phase Squirrel cage AC Motor 415V, 50 Hz

Nominal

Output

KW

0.12

0.25

0.55

0.55

0.55

1.1

1.1

1.25

2.2

2.5

2.5

4.0

0.25

0.55

0.55

0.55

1.1

1.1

2.2

2.2

4.0

4.0

5.0

5.0

0.25

0.55

0.55

0.55

1.1

2.2

2.2

4.0

4.0

5.0

5.0

5.0

0.55

0.55

0.75

1.1

2.2

2.2

4.0

4.0

7.5

7.5

7.5

7.5

Speed

1/min

1400

1400

1400

1400

1400

1400

2800

2800

2800

2800

2800

2800

1400

1400

1400

1400

1400

1400

2800

2800

2800

2800

2800

2800

1400

1400

1400

1400

1400

1400

2800

2800

2800

2800

2800

2800

1400

1400

1400

1400

1400

1400

2800

2800

2800

2800

2800

2800

Size

71

71

71

71

71

90

71

90

90

90

90

90

71

71

71

71

90

90

90

90

90

90

112

112

71

71

71

71

90

90

90

90

90

112

112

112

71

71

90

90

90

90

90

90

112

112

112

112

Nominal

Current

A

0.5

1.4

2.8

2.8

2.8

3.7

2.9

2.7

4.6

5.3

5.3

10.2

1.4

2.8

2.8

2.8

3.7

3.7

4.6

4.6

10.2

10.2

9.9

9.9

1.4

2.8

2.8

2.8

3.7

6.9

4.6

10.2

10.2

9.9

9.9

9.9

2.8

2.8

2.0

3.7

6.9

6.9

10.2

10.2

15.6

15.6

15.6

15.6

Current at

Max. Torque

A

1)

0.82

1.39

1.77

2.20

3.08

3.95

5.72

8.65

10.0

15.5

11.5

16.5

1.48

1.95

2.60

3.58

4.80

6.65

8.52

12.5

17.1

26.0

18.2

28.5

1.67

2.2

3.08

5.15

5.75

7.92

10.04

15.05

21.08

31.08

22.5

35.5

2.55

3.85

4.65

6.65

9.06

12.5

17.5

26.0

40.0

60.0

44.6

68.0

SA3-SA100

Starting

Current

A

2.3

4.6

12.0

12.0

12.0

25.0

16.0

22.0

40.0

40.0

40.0

65.0

4.6

12.0

12.0

12.0

25.0

25.0

40.0

40.0

65.0

65.0

80.0

80.0

4.6

12.0

12.0

12.0

25.0

40.0

40.0

65.0

65.0

80.0

80.0

80.0

12.0

12.0

12.0

25.0

40.0

40.0

65.0

65.0

116.0

116.0

116.0

116.0

Power

Factor

Cos o

0.6

0.5

0.51

0.51

0.51

0.58

0.72

0.81

0.83

0.83

0.83

0.7

0.5

0.51

0.51

0.51

0.58

0.58

0.83

0.83

0.7

0.7

0.86

0.86

0.55

0.51

0.51

0.51

0.58

0.63

0.83

0.7

0.7

0.86

0.86

0.86

0.51

0.51

0.72

0.58

0.63

0.63

0.7

0.7

0.78

0.78

0.78

0.78

Full load

Efficiency

(%)

55

50

60

60

60

72

72

79

80

79

79

78

50

60

60

60

72

72

80

80

78

78

88

50

50

60

60

60

72

72

80

78

78

88

88

88

60

60

75

72

72

72

78

78

86

86

86

86

900

Permissible voltage variation : + 10%, Permissible frequency variation : + 5%, Permissible combined variation : 10%

if voltage drops below there will be reduction of nominal output.

Auma motors are provided with 3 thermoswitches one in each winding connected in series to protect windings. Our

warranty is void if those thermoswitches are not connected in control circuit.

Motor data are approximate. Due to usual manufacturing tolerances there may be deviations from the values given.

1) Current at max. torque. We recommend to select switch gear and cables suitable for those values.

We reserve the right to alter data according to improvements made. Previous data sheets become invalid with the issue of this data sheet.

33

Page 34

Tripping

Torque

in both

directions

Max.NmMax.

Min.

Nm

30

60

120

60

150

120

250

150

300

250

500

300

600

500

1000

60

1)

Regu-

lating

Torque

Nm

30

60

75

120

150

250

300

500

Auma India

Actuator Type

Type

6

SAR

6

SAR

6

SAR

6

SAR

6

SAR

6

SAR

6

SAR

6

SAR

12

SAR

12

SAR

12

SAR

12

SAR

12

SAR

12

SAR

12

SAR

12

SAR

15

SAR

15

SAR

15

SAR

15

SAR

15

SAR

15

SAR

15

SAR

25

SAR

25

SAR

25

SAR

25

SAR

25

SAR

25

SAR

25

SAR

25

SAR

30

SAR

30

SAR

30

SAR

30

SAR

30

SAR

30

SAR

30

SAR

30

SAR

50

SAR

50

SAR

50

SAR

50

SAR

50

SAR

50

SAR

50

SAR

50

SAR

60

SAR

60

SAR

60

SAR

60

SAR

60

SAR

60

SAR

100

SAR

100

SAR

100

SAR

100

SAR

100

SAR

100

SAR

Technical Data

Regulating duty

Max.

c/h

Valve

Mounting

Flange

Standard

DIN:3210

(Special

ISO:5210)

G0

(F10)

G0

(F10)

G0

(F10)

1

G

2

(F14)

1

G

2

(F14)

1

G

2

(F14)

1

G

2

(F14)

G3

(F16)

No. of

starts

Output Speed

2)

1/min Max. kNMax. mm

.....

4

.....

5.6

.....

8

.....

11

.....

16

22

32

45

4

5.6

8

11

16

22

32

45

4

5.6

8

11

16

22

32

4

5.6

8

11

16

22

32

45

4

5.6

8

11

16

22

32

45

4

5.6

8

11

16

22

32

45

4

5.6

8

16

22

32

4

5.6

8

11

16