Page 1

Part-turn gearboxes

Worm gearboxes

GS 50.3 – GS 250.3

for flange types FA

Operation instructions

Page 2

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

Scope of these instructions:

These operation instructions are valid for worm gearboxes of the type range

GS 50.3 – GS 125.3 with primary reduction gearings VZ 2.3 – VZ 4.3. and GS

160.3 – GS 250.3 with primary reduction gearings GZ 160.3 – GZ 250.3.

Table of contents Page

1. Safety instructions 3

1.1 Range of application 3

1.2 Maintenance 3

1.3 Warnings and notes 3

2. Technical data 4

3. Transport, storage and packaging 7

3.1 Transport 7

3.2 Storage 7

3.3 Packaging 7

4. Fitting the handwheel 7

5. Mounting positions of the different versions 8

6. Mounting multi-turn actuators SA/SAR 9

7. Mounting to valve 11

8. Setting the end stops for manual operation 12

8.1 Worm gearboxes on butterfly valves 12

8.2 Worm gearboxes on ball valves 13

9. Setting the end stops with mounted multi-turn electric actuator 13

9.1 Worm gearboxes on butterfly valves 13

9.2 Worm gearboxes on ball valves 14

10. Changing the swing angle 16

10.1 Changing the swing angle for sizes GS 50.3 – GS 125.3 (option)16

10.2 Changing the swing angle for sizes GS 160.3 – GS 250.3 17

11. Enclosure protection IP 68 18

12. Maintenance 19

12.1 General notes 19

12.2 Grease change for worm gearboxes GS 50.3 – GS 125.3 and primary reduction gearing

VZ 2.3 – VZ 4.3 20

12.2.1 Worm gearboxes 20

12.2.2 Primary reduction gearing 20

12.3 Grease change for worm gearboxes GS 160.3 – GS 250.3 and primary reduction gearing

GZ 160.3 – GZ 250.3 21

12.3.1 Worm gearboxes 21

12.3.2 Single-stage reductions gearings GZ 160.3 – GZ 250.3 (reduction ratios 4:1 and 8:1) 21

12.3.3 Double-stage primary reduction gearing GZ 200.3 – GZ 250.3 (reduction ratio 16:1) 22

12.4 After maintenance 22

13. Disposal and recycling 23

14. Service 23

15. Spare parts list worm gearboxes GS 50.3 – GS 125.3 and reduction gearing

VZ 2.3 – VZ 4.3 24

16. Spare parts list worm gearboxes GS 160.3 – GS 250.3 26

17. Spare parts list reduction gearings GZ 160.3 – GZ 250.3 (reduction ratios 4:1, 8:1 and 16:1) 28

Index 31

Addresses of AUMA offices and representatives 32

2

Page 3

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

1. Safety instructions

1.1 Range of application AUMA worm gearboxes GS 50.3 – GS 250.3 are used for the operation of valves

(e.g. butterfly valves and ball valves).

They are designed for manual operation as well as motor operation in conjunction

with electric actuators.

For other applications, please consult us. The manufacturer is not liable for any

possible damage resulting from use in other than the designated applications.

Such risk lies entirely with the user.

Observance of these operation instructions is considered as part of the gearboxes’

designated use.

1.2 Maintenance The maintenance instructions (refer to page 19) must be observed, otherwise a

safe operation of the worm gearbox is no longer guaranteed.

1.3 Warnings and notes Non-observance of the warnings and notes may lead to serious injuries or

damage. Qualified personnel must be thoroughly familiar with all warnings and

notes in these operation instructions.

Correct transport, proper storage, mounting and installation, as well as careful

commissioning are essential to ensure a trouble-free and safe operation.

The following references draw special attention to safety-relevant procedures in

these operation instructions. Each is marked by the appropriate pictograph.

This pictograph means: Note!

“Note” marks activities or procedures which have major influence on the correct

operation. Non-observance of these notes may lead to consequential damage.

This pictograph means: Warning!

“Warning” marks activities or procedures which, if not carried out correctly, can

affect the safety of persons or material.

3

Page 4

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

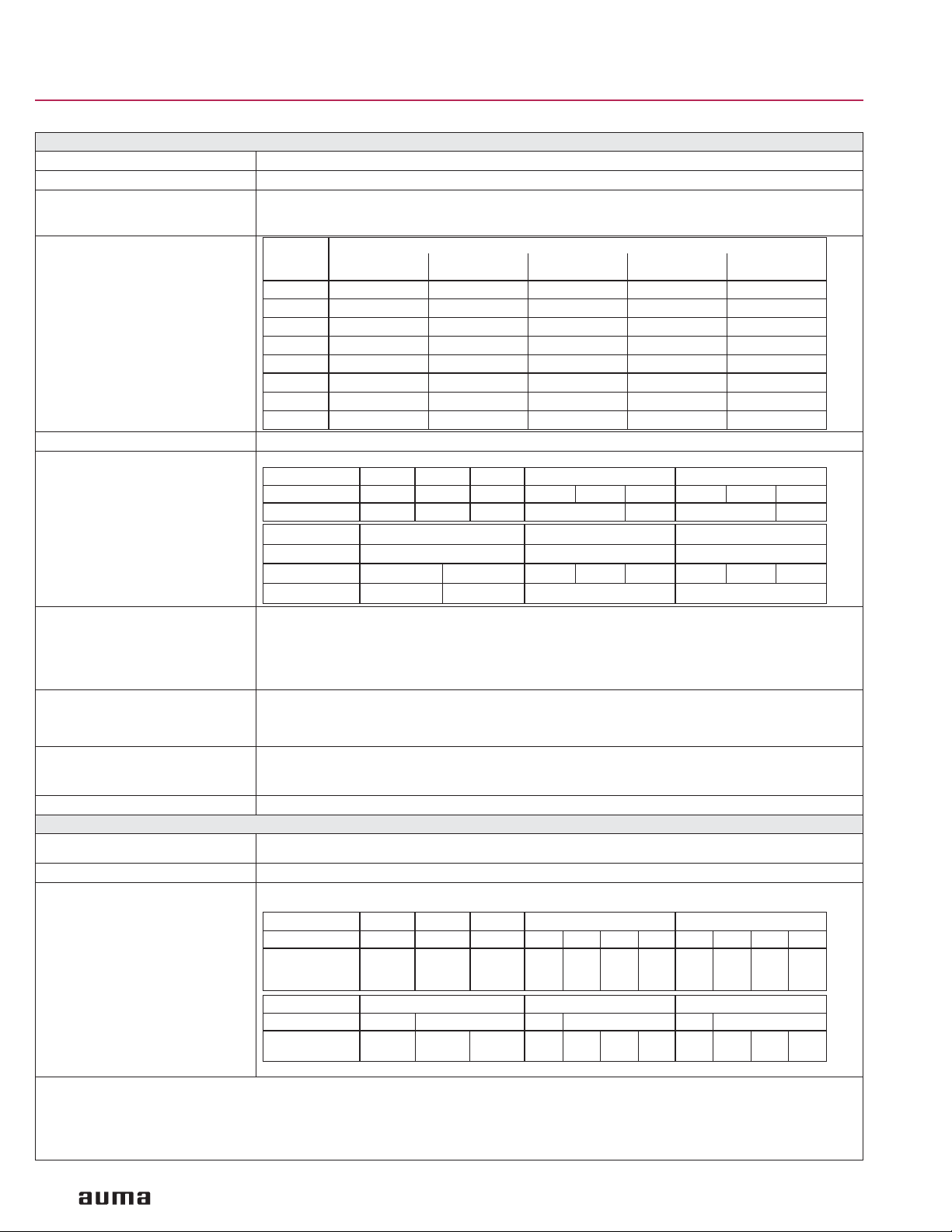

2. Technical data

Features and functions

Version Standard: clockwise rotation RR, counterclockwise rotation LL, option: RL or LR

Housing material Standard: cast iron (GJL-250), Option: spheroidal cast iron (GJS-400-15)

Self-locking The gearboxes are self-locking when at stand-still under normal service conditions; strong

Output torques

End stops Positive for both end positions by traveling nut, sensitive adjustment

Strength of end stop Guaranteed strength of end stop (in ft lbs.) for input side operation

Swing angle

GS 50.3 – GS 125.3

Swing angle

GS 160.3 – GS 250.3

Mechanical position indicator Standard: Pointer cover for continuous position indication

Input shaft Cylindrical with parallel key according to DIN 6885.1

Operation

Motor operation With electric multi-turn actuator, directly or through primary reduction gearing VZ/GZ

Type of duty According to actuator

Manual operation

1) With worm wheel made of spheroidal cast iron

2) Requires worm wheel made of bronze

3) Special sizing is required

4) For gas applications with sealed pointer cover, an air vent in the pointer cover or venting grooves in the valve mounting flange must be provided

5) Handwheel sizes shown reflect general industrial selection criteria. For information on gearbox/handwheel selection in accordance with AWWA Standard C504, please

refer to separate selection list/chart.

5)

vibrations may cancel the self-locking effect. While in motion, safe breaking is not guaranteed. If

this is required, a separate brake must be used.

Type Output torques

100 % 140 % 175 %

max. ft lbs. max. ft lbs. max. ft lbs. max. ft lbs. max. ft lbs.

GS 50.3

GS 63.3

GS 80.3

GS 100.3

GS 125.3

GS 160.3

GS 200.3

GS 250.3

Type

Reduction gearing – – – VZ 2.3 VZ 3.3 VZ 4.3 VZ 2.3 VZ 3.3 VZ 4.3

ft lbs. 185 330 330 370 185 370 185

Type

Reduction gearing GZ 160.3 GZ 200.3 GZ 250.3

Reduction ratio 4:1 8:1 4:1 8:1 16:1 4:1 8:1 16:1

ft lbs. 370 330 370 370

184 258 – 369 92

369 516 – 738 184

738 1,033 – 1,475 369

1,475 2,065 – 2,950 738

2,950 4,130 – 5,900 1,475

5,900 8,298 10,326 – 2,950

11,801 16,595 20,652 – 5,900

23,602 32,822 41,303 – 16,000

GS 50.3 GS 63.3 GS 80.3 GS 100.3 GS 125.3

GS 160.3 GS 200.3 GS 250.3

1)

200 %

1)

Modulating torque

2)

Standard: Fixed swing angle up to max. 100°; set in the factory to 92° unless ordered otherwise.

Options: Adjustable in steps of:

10°– 35°, 35° – 60°, 60° – 80°, 80° – 100°, 100° – 125°, 125° – 150°,

150° – 170°, 170° – 190°

For version with worm wheel made of bronze: swing angle > 190°,

Multi-turn version without end stops, version GSD

3)

Standard: Adjustable 80° – 100°; set in the factory to 92° unless ordered otherwise.

Options: Adjustable in steps of: 20° – 40°, 40° – 60°, 60° – 80°,

‘ Multi-turn version without end stops, version GSD

For version with worm wheel made of bronze: swing angle

3)

Options: Sealed pointer cover for horizontal outdoor installation

> 100°,

4)

Protection cover for buried service instead of pointer cover

Flanges for mounting of actuator, refer also to separate technical data sheets.

Via handwheel, directly or through primary reduction gearing VZ/GZ

Available handwheel diameters, selection according to the max. output torque:

Type

Reduction gearing – – – – VZ 2.3 VZ 3.3 VZ 4.3 – VZ 2.3 VZ 3.3 VZ 4.3

Handwheel Ø

mm

Type

Reduction gearing – GZ 160.3 – GZ 200.3 – GZ 250.3

Handwheel Ø

mm

GS 50.3 GS 63.3 GS 80.3 GS 100.3 GS 125.3

160

200

250

630

800

250

315

GS 160.3 GS 200.3 GS 250.3

400 315 – 500

315

400

400

500

315

315

400

630

250

400

315

400 315 – 800

500

630

800

400

500

400

500

500

630

315

400

400

25.4 mm correspond to 1 inch

4

Page 5

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

Primary reduction gearing

Primary reduction gearing Planetary gear with various reduction ratios for reducing the input torques

Valve attachment

Valve attachment Dimensions according to SP 101

Standard: GS 50.3 – GS 125.3: without spigot

Options: GS 50.3 – GS 125.3: with spigot

Splined coupling for connection

Standard: without bore or pilot bore from GS 160.3

to the valve shaft

Options: Machined with bore and keyway, square bore or bore with two-flats

Service conditions

Enclosure protection according

to EN 60 529

6)

Standard: IP 68-3, dust and water tight up to max. 3 m head of water

Options

Corrosion protection Standard: KN Suitable for installation in industrial units, in water or power plants

Options: KS Suitable for installation in occasionally or permanently aggressive

Paint Standard: GS 50.3 – GS 125.3: Two-component iron-mica combination

Color Standard: Grey (DB 702, similar to RAL 9007)

Option: Other colors on request

Ambient temperature Standard: – 20 °F to + 175 °F/ – 25 °C to + 80 °C

Options: – 40 °F to + 140 °F/ – 40 °C to + 60 °C (low temperature), version L

Lifetime Open-close duty: The lifetime is based on a load profile typical for part-turn valves

GS 160.3 – GS 250.3: without spigot

GS 160.3 – GS 250.3: with spigot

Worm gearbox can be repositioned 4 x 90° on coupling

7)

: IP 68-6, dust and water tight up to max. 6 m head of water

IP 68-10, dust and water tight up to max. 10 m head of water

IP 68-20, dust and water tight up to max. 20 m head of water

with a low pollutant concentration

atmosphere with a moderate pollutant concentration

(e.g. in wastewater treatment plants, chemical industry)

KX Suitable for installation in extremely aggressive atmosphere

with high humidity and high pollutant concentration

GS 160.3 – GS 250.3: Two-component iron-mica combination

– 75 °F to + 140 °F/ – 60 °C to + 60 °C (extreme low temperature), version EL

+ 32 °F to + 250 °F/ – 0 °C to + 120 °C (high temperature), version H

Type Operating cycles (OPEN - CLOSE - OPEN)

100 % 140 % 175 %

GS 50.3 15,000 5,000 – 1,000

GS 63.3 15,000 5,000 – 1,000

GS 80.3 15,000 5,000 – 1,000

GS 100.3 15,000 5,000 – 1,000

GS 125.3 15,000 5,000 – 1,000

GS 160.3 15,000 5,000 1,000 –

GS 200.3 15,000 5,000 1,000 –

GS 250.3 10,000 3000 750 –

Modulating duty: min. 2.5 million operations

6) Refer to section enclosure protection IP 68

7) Not available for GS 50.3

8) With worm wheel made of spheroidal cast iron

9) The lifetime for modulating duty depends on the load and the number of starts. A high starting frequency will rarely improve the modulating accuracy. To reach the

longest possible maintenance and fault-free operation time, the number of starts per hour chosen should be as low as permissible for the process

for swivel movements of 90° (max. 100°)

and a maximum output torque of

8)

8)

200 %

9)

5

Page 6

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

Accessories

Valve position indicators Valve position indicator WSG for the signalization of intermediate and end positions for precise

Limit switching Limit switching WSH for manually operated valves. For the signalization of intermediate and

Further information

Reference documents Product description Worm gearboxes GS 50.3 – GS 250.3 /GS 315 – GS 500

Lever gearboxes See separate documents

and low-backlash feedback for swing angles ranging from 82° – 98°

(refer to separate data sheet)

Valve position indicator WGD for signalization of intermediate and end positions for swing

angles

> 180° (refer to separate data sheet)

end positions (refer to separate data sheet)

Dimension sheets GS 50.3 – GS 125.3, GS 160.3 – GS 250.3

Technical data GS 50.3 – GS 125.3, GS 160.3 – GS 250.3

Technical data SA, SAR, WSG, WGD, WSH

6

Page 7

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

3. Transport, storage and packaging

3.1 Transport

3.2 Storage

3.3 Packaging Our products are protected by special packaging for the transport ex works. The

.

Transport to place of installation in sturdy packing.

.

If mounted together with actuator:

Attach ropes or hooks for the purpose of lifting by hoist only to the gearbox and

not to the actuator.

.

If eyebolts are supplied with the gearbox, they should be used to lift the gearbox

only and not the valve

.

Store in well-ventilated, dry room.

.

Protect against floor dampness by storage on a shelf or on a

wooden pallet.

.

Cover to protect against dust and dirt.

.

Apply suitable corrosion protection agent to bare surfaces.

In case worm gearboxes are to be stored for a long period

(more than 6 months), the following points must be observed additionally:

.

Prior to storage: Protect bare surfaces, in particular the output drive parts and

mounting surface, with long-term corrosion protection agent.

.

Check for corrosion approximately every 6 months. If first signs of corrosion

show, apply new corrosion protection.

packaging consists of environmentally friendly materials which can easily be

separated and recycled.

For the disposal of the packaging material, we recommend recycling and collection

centers.

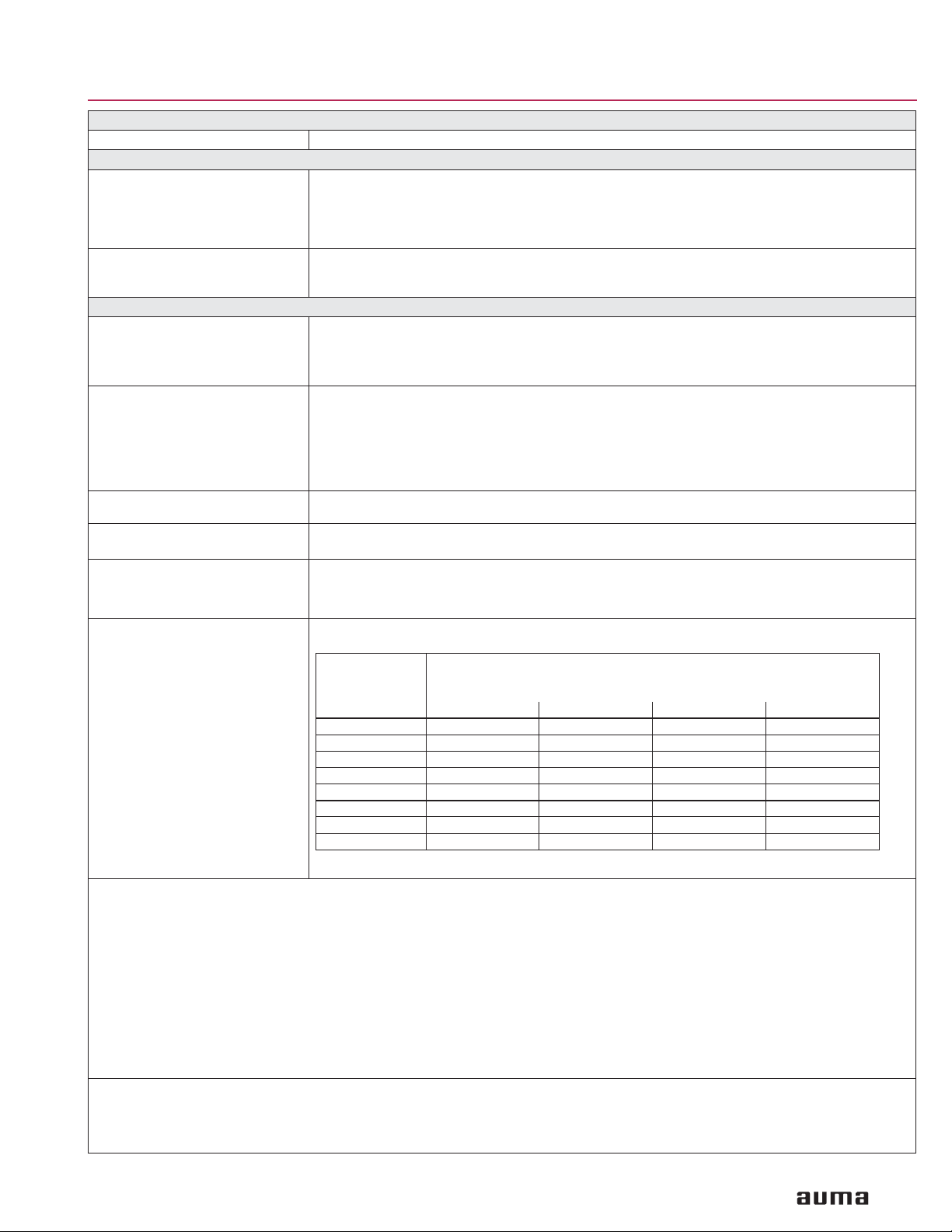

4. Fitting the handwheel For worm gearboxes designed for manual operation the handwheel may be

supplied separately. Fitting is done on site according to figure A.

Figure A: Handwheel

Ball handle

(option)

Circlip

Worm shaft

gearbox

Spacer

(may be required)

Spacer

(may be required)

Circlip

Handwheel

7

Page 8

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

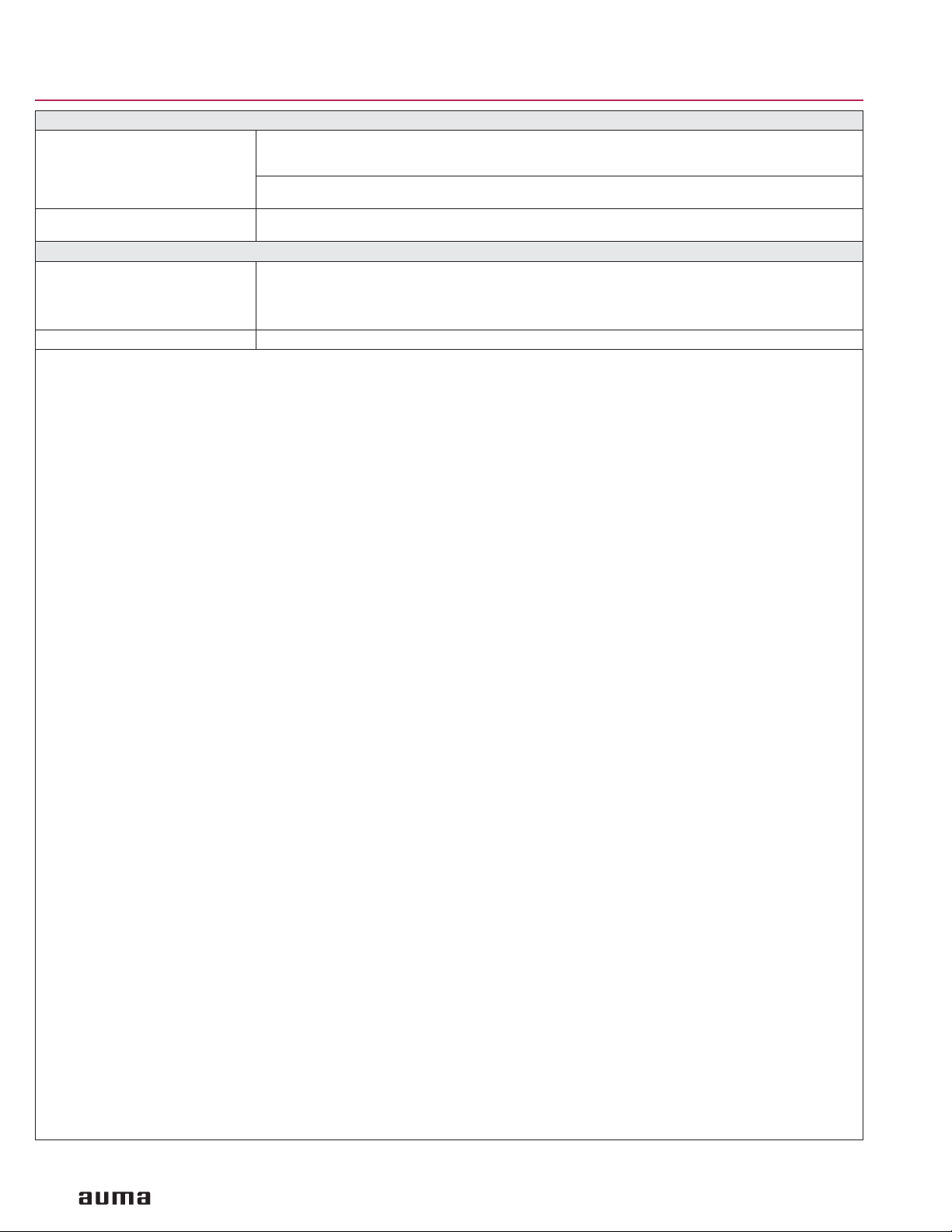

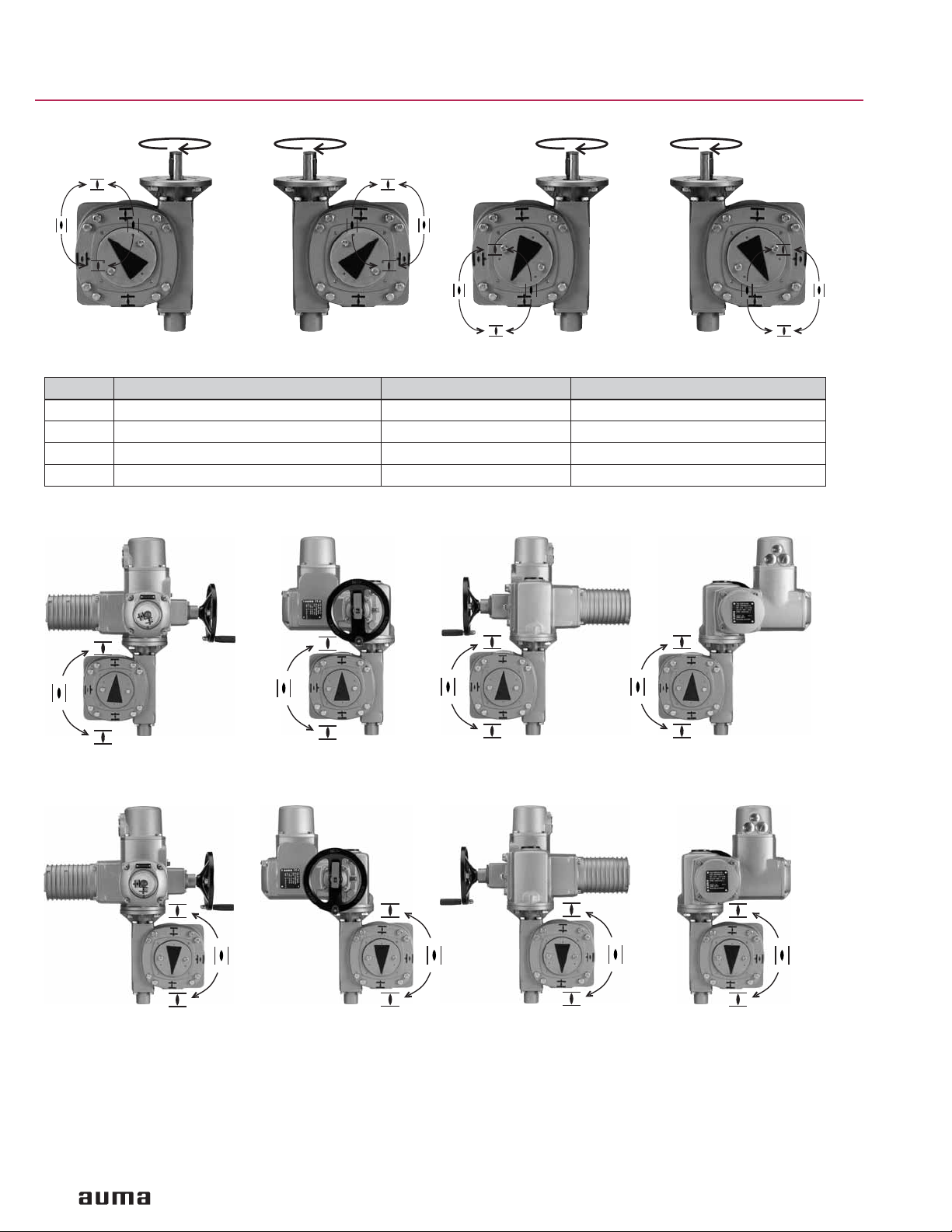

5. Mounting positions of the different versions

RR LL RL LR

Description of the 4 versions (viewed at the pointer cover):

Code Direction of rotation at input shaft Position of worm shaft Direction of rotation at output drive

RR

LL

RL

LR

clockwise

clockwise

clockwise

clockwise

Right side

Left side

Right side

Left side

Mounting positions of AUMA multi-turn actuator with AUMA worm gearbox (please indicate when ordering)

GS versions RR / RL

clockwise

counterclockwise

counterclockwise

clockwise

RR

RL

RR

RL

A

B

RR

RL

C

RR

RL

D

GS versions LL / LR

LL

LR

A

B C

LL

LR

LL

LR

D

LL

LR

Mounting positions can easily be changed at a later date.

Limitation: For SA/SAR 14.1/14.5 with GS 125.3, mounting position “C” in version RR/RL and “A” in version LL/LR is

only possible for a handwheel diameter up to 12.4 ”.

Up to size GS 125.3, the actuator-gearbox combination is delivered in the ordered mounting position. For packing

reasons, actuator and gearbox is delivered separately from size GS 160.3.

8

Page 9

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

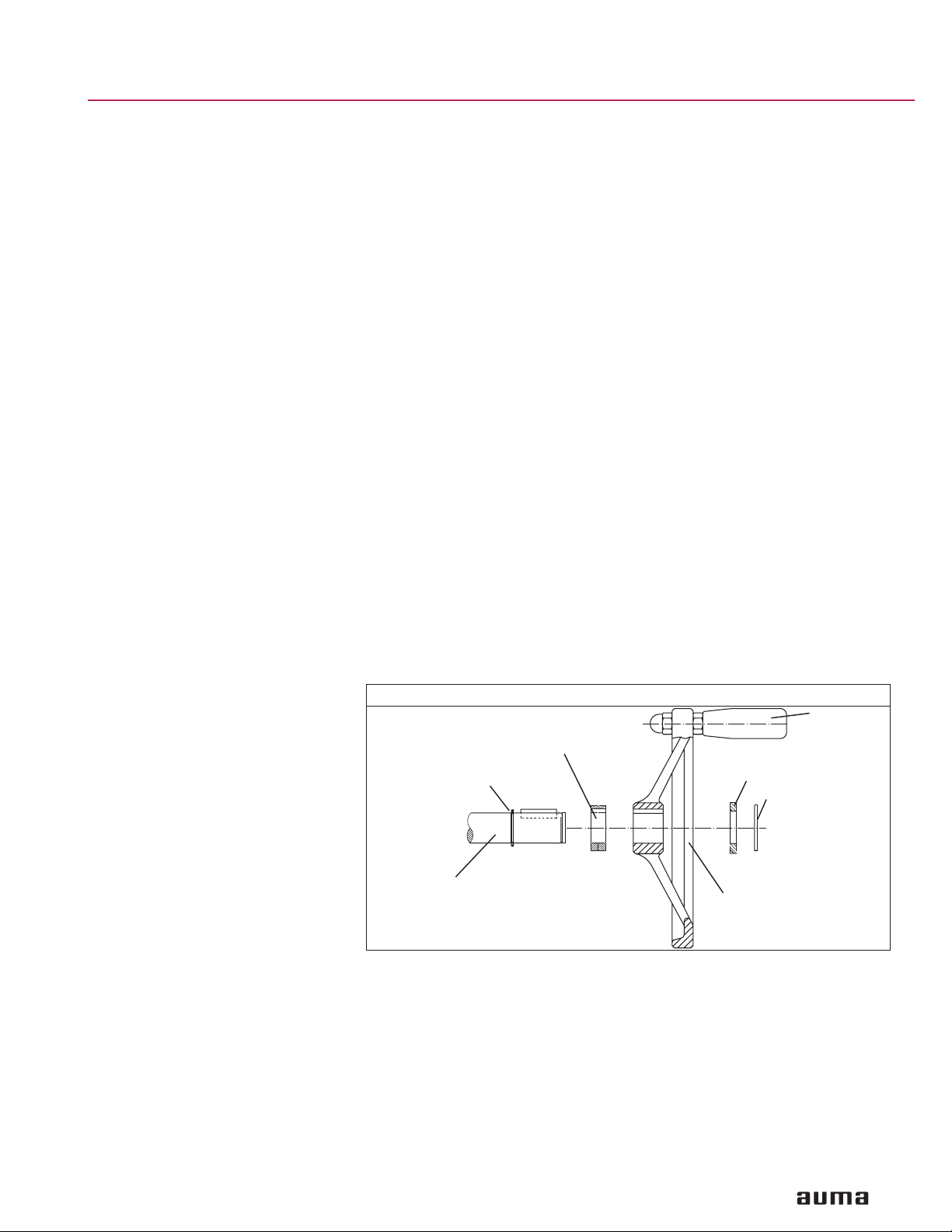

6. Mounting multi-turn actuators SA/SAR

When gearboxes and multi-turn actuators are supplied together, the mounting has

been done in the factory up to gearbox size GS 125.3. For sizes GS 160.3 and

larger, the mounting of gearboxes is performed as follows.

In case flange for actuator is not attached to gearbox or

reduction gearing:

.

Thoroughly degrease the mounting faces of the gearbox or reduction gearing as

well as the flange for actuator.

.

For GS 100.3 – GS 250.3:

Insert pin in the corresponding groove of the bearing cover.

.

Fit flange for actuator and fasten with bolts and lock washers.

.

Fasten bolts crosswise with a torque according to table 2.

Figure B: Mounting multi-turn actuator to worm gearbox

Flange for actuator

Bearing flange

Flange for actuator

Primary

reduction

gearing

Bearing flange

Mounting the multi-turn actuator:

.

Thoroughly degrease the faces of the flange for actuator at the gearbox or

reduction gearing as well as the actuator’s bearing flange.

.

Place the multi-turn actuator on the worm gearbox or reduction gearing. The

multi-turn actuator can be mounted on the valve at every 90°

(see page 8, mounting positions).

.

Ensure that the spigot mates uniformly in the recess and that the mounting faces

are in complete contact.

.

Fasten actuator with bolts and lock washers (see table 1) at the flange of the

worm gearbox.

.

Fasten bolts crosswise with a torque according to table 2.

Do not attach ropes or hooks for the purpose of lifting the actuator

by hoist to the handwheel. If multi-turn actuator is mounted on

gearbox, attach ropes or hooks for the purpose of lifting by hoist

to gearbox and not to multi-turn actuator.

9

Page 10

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

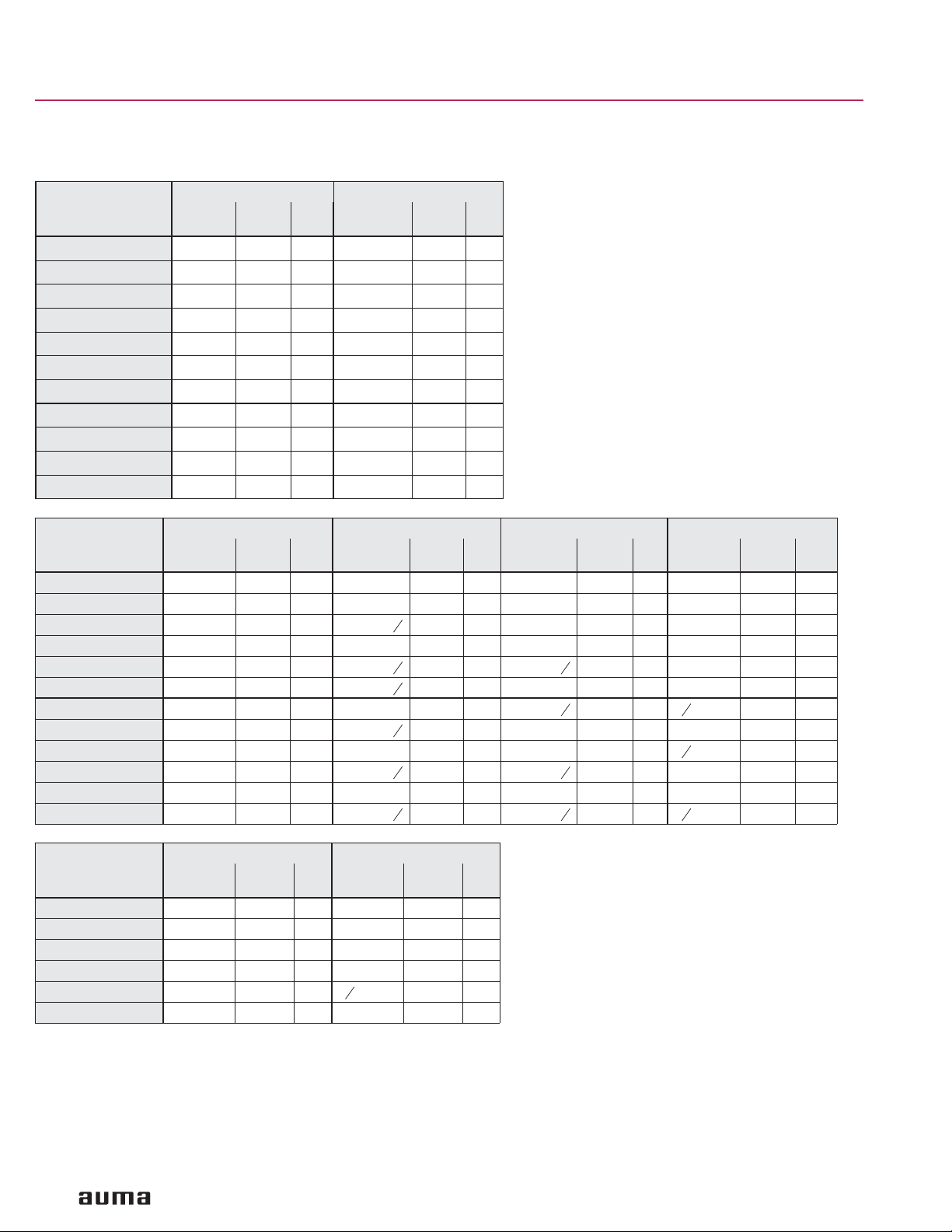

Table 1: Bolts for mounting AUMA actuators to worm gearboxes/ primary reduction gearing

(strength class min. 8.8)

Worm gearbox/

primary

reduction gearing

GS 50.3

GS 63.3

GS 80.3

GS 100.3

GS 100.3/VZ

GS 125.3

GS 125.3/VZ

GS 160.3

GS 160.3/GZ

GS 200.3

GS 200.3/GZ

SA(R) 07.1-FA10 SA(R) 07.5-FA10

Bolt

(UNC)

Lock

washer

Qty.

Bolt

(UNC)

washer

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

Lock

Qty.

Worm gearbox/

primary

reduction gearing

GS 63.3

GS 80.3

GS 100.3

GS 100.3/VZ

GS 125.3

GS 125.3/VZ

GS 160.3

GS 160.3/GZ

GS 200.3

GS 200.3/GZ

GS 250.3

GS 250.3/GZ

Worm gearbox/

primary

reduction gearing

GS 160.3

GS 160.3/GZ

GS 200.3

GS 200.3/GZ

GS 250.3

GS 250.3/GZ

SA(R) 10.1-FA10 SA(R) 14.1-FA14 SA(R) 14.5-FA14 SA(R) 16.1-FA16

Bolt

(UNC)

Lock

washer

Qty.

Bolt

(UNC)

Lock

washer

Qty.

Bolt

(UNC)

Lock

washer

Qty.

Bolt

(UNC)

washer

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

5/8-11x1

1

2

5/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

3/8-16x1 3/8 4

5/8-11x1

5/8-11x1

5/8-11x1

5/8-11x1

5/8-11x1

1

2

1

2

1

2

1

2

1

2

5/8 4

5/8 4

5/8 4

5/8 4

5/8 4

5/8-11x1

5/8-11x1

5/8-11x1

5/8-11x1

1

2

1

2

1

2

1

2

5/8 4

5/8 4

5/8 4

5/8 4

3

-10x2

4

3

-10x2

4

3

-10x2

4

SA(R) 25.1-FA25 SA(R) 30.1-FA30

Bolt

(UNC)

Lock

washer

Qty.

Bolt

(UNC)

Lock

washer

Qty.

5/8-11x2 5/8 8

3

5/8-11x2 5/8 8

-10x2

4

3/4 8

Lock

3/4 4

3/4 4

3/4 4

Qty.

10

Page 11

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

7. Mounting to valve AUMA worm gearboxes GS and primary reduction gearings VZ/GZ can be

operated in any mounting position.

.

For butterfly valves, the recommended mounting position is end position

CLOSED

(Prior to mounting, bring the gearbox to the mechanical end stop CLOSED by

turning the handwheel clockwise).

.

For ball valves, the recommended mounting position is end position OPEN

(Prior to mounting, bring the gearbox to the mechanical end stop OPEN by

turning the handwheel counterclockwise).

.

Alternatively, the limit stop housing can be turned up to the end position of the

respective valve.

.

Thoroughly degrease mounting faces of gearbox and valve.

.

Place coupling sleeve onto valve shaft and secure (refer to figure C, detail A or B),

ensure that dimensions X, Y, and Z are observed (refer to table 2).

.

Apply non-acidic grease at splines of coupling.

.

Mount gearbox on valve. Ensure that the spigot (if provided) mates uniformly in the

recess and that the mounting faces are in complete contact.

.

Fasten gearbox with bolts (quality min. 8.8) and lock washers.

.

Fasten bolts crosswise with a torque according to table 2.

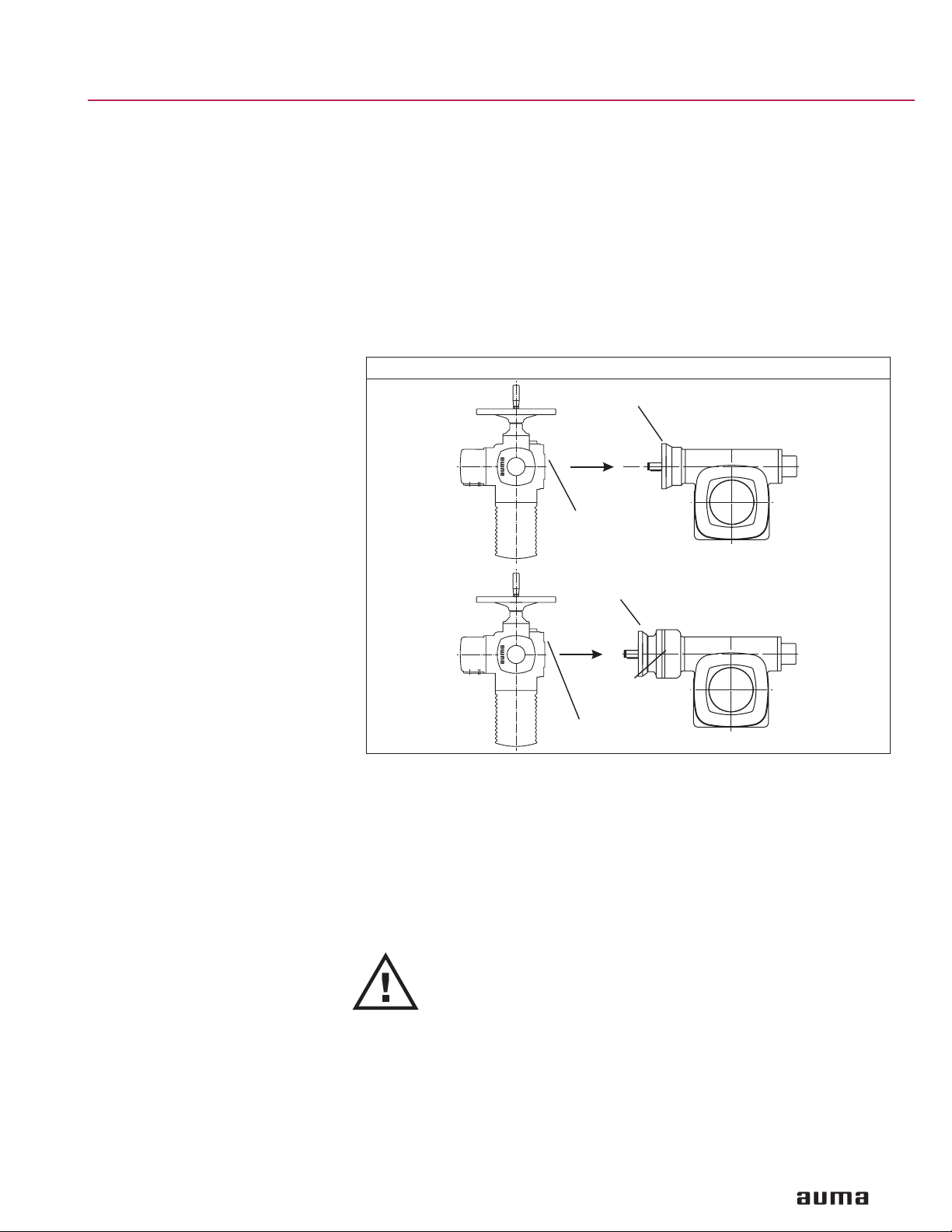

Figure C

A

B

Coupling

Grub screw

X

Valve

Table 2: Standard dry fastening torques for bolts

Gearbox Dimensions Bolts Strength class

Flange type X

GS 50.3-FA10

GS 63.3-FA10

GS 63.3-FA12

GS 80.3-FA14

GS 100.3-FA14

GS 100.3-FA16

GS 125.3-FA16

GS 125.3-FA25

GS 160.3-FA25

GS 160.3-FA30

GS 200.3-FA30

GS 200.3-FA35

GS 250.3-FA35

GS 250.3-FA40

Y max Z max Qty. x threads

max

14 5 61 4 x

718 73 4 x

10 13 76 4 x

23 5 88 4 x

22 13 123 4 x

22 8 123 4 x

17 35 126 4 x

17 27 126 8 x

15 11 130 8 x

30 0 140 8 x

19 19 160 8 x

44 0 190 8 x 1 - 8 590

8 8 220 8 x 1 - 8 590

13 0 230 8 x 1

(UNC)

Z

Y

Fastening torque T

3

- 16 33

8

3

- 16 33

8

1

- 13 78

2

5

- 11 155

8

5

- 11 155

8

3

- 10 257

4

3

- 10 257

4

5

- 11 155

8

5

- 11 155

8

3

- 10 255

4

3

- 10 255

4

1

- 7 1,200

4

Grade 5

[Ft lbs.]

A

Note:

Experience showed that it is very difficult to fasten bolts or nuts of 1-8 UNC or

larger with the defined torques. The worm gearbox may be moved radially against

the valve flange by accident.

To improve adhesion between valve and gearbox, we recommend to apply

Loctite 243 (or similar products) on mounting faces.

11

Page 12

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

0

8. Setting the end stops for manual operation

If worm gearboxes GS are supplied on a valve the end stops are

already set by the valve manufacturer.

8.1 Worm gearboxes on butterfly valves

Setting end position CLOSED

Tabl e 3

Gearbox End stops fas-

GS 50.3

GS 63.3

GS 80.3

GS 100.3

GS 125.3

GS 160.3

GS 200.3

GS 250.3

Conversion factor: 1 Nm corresponds to 0.74 ft lbs.

.

Remove all bolts (03) at limit stop housing (figures D, E).

.

Turn valve manually to end position CLOSED.

.

In case limit stop housing (10) has not yet rotated, turn it clockwise up to the

stop.

.

If the holes of limit stop housing (10) do not align with the threads of the housing

(1), take off the limit stop housing (10) and replace it in the required position.

.

Fasten bolts (03) with lock washers (04).

.

Fasten bolts crosswise with a torque according to table 3.

Material Protective cap

tened with

bolts (03)

M 8 A2-80 24

M 8 A2-80 24

M 8 A2-80 24

M 12 A2-80 82

M 12 A2-80 82

M 10 A2-80 M 6 A2-80 48

M 12 A2-80 M 6 A2-80 82

M 16 A2-80 M 6 A2-80 200

Figure D: End stop up to GS 125.3

fastened with

bolts (054)

Figure E: End stop from GS 160.3

Material Fastening torque

[Nm]

T

A

03/04

10

.

If the position of the pointer cover does not correspond to the symbol CLOSED,

slightly loosen the screws of the pointer cover. Turn the pointer cover to the

CLOSED symbol and fasten the screws again.

Setting end position OPEN The end stop need not be set since the required swing angle has been set in the

factory.

If the swing angle does not match, refer to section 10.

1

03/04

1

1

12

Page 13

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

8.2 Worm gearboxes on ball valves

In case end stops require adjustment, set end position OPEN first.

If the exact end position of the valve cannot be seen through a

position marking at the valve shaft, the setting may have to be

done with the valve removed.

Setting end position OPEN

Setting end position

CLOSED

9. Setting the end stops with mounted multi-turn electric actuator

.

Remove all bolts (03) at limit stop housing (10) (figures D, E).

.

Turn valve manually to end position OPEN.

.

In case limit stop housing (10) has not yet rotated, turn it counterclockwise up to

the stop.

.

If the holes of limit stop housing (10) do not align with the threads of the housing

(1), take off the limit stop housing (10) and replace it in the required position.

.

Fasten bolts crosswise with a torque according to table 3.

.

If the position of the pointer cover does not correspond to the symbol OPEN,

slightly loosen the screws of the pointer cover. Turn the pointer cover to the

OPEN symbol and fasten the screws again.

The end stop need not be set since the required swing angle has been set in the

factory.

If the swing angle does not match, refer to section 10.

.

If worm gearboxes GS and multi-turn actuators are supplied on a

valve, the end stops as well as limit and torque switching should

already have been set by the valve manufacturer.

.

If the limit and torque switching have not yet been set, they have

to be set according to the operation instructions SA/SAR and the

specifications of the valve manufacturer.

.

The valve manufacturer states whether the valve should be limit

or torque seated.

9.1 Worm gearboxes on butterfly valves

Setting end position CLOSED.Remove all bolts (03) at limit stop housing (figures D, E).

.

Determine the overrun of the multi-turn actuator for both directions, i. e. how much

does the valve move after the motor has been switched off?

.

Change actuator to manual drive and move the valve manually to end position

CLOSED.

.

In case limit stop housing (10) has not yet rotated, turn it clockwise up to the

stop.

.

Turn limit stop housing (10) back counterclockwise by ½ turn. This ensures that

the mechanical end stop is not reached in electric operation and thus the valve

can close tightly, provided that torque seating has been specified.

.

If the fixing holes of limit stop housing (10) do not align with the threads of the

housing (1), take off the limit stop housing (10) and replace it in required

position.

.

Fasten bolts (03) with lock washers (04).

.

Fasten bolts crosswise with a torque according to table 3.

.

If the position of the pointer cover does not correspond to the symbol CLOSED,

slightly loosen the screws of the pointer cover. Turn the pointer cover to the

CLOSED symbol and fasten the screws again.

13

Page 14

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

0

0

Limit seating in end position CLOSED

.

Turn back the valve from the end position by an amount equal to the overrun.

.

Set limit switching according to the operation instructions SA/SAR.

.

Check torque switching for end position CLOSED according to the operation

instructions SA/SAR, and, if necessary, set to the required value.

Torque seating in end position CLOSED

.

Turn handwheel counterclockwise by approx. 4 – 6 turns.

.

Set limit switching for the end position CLOSED according to the operation

instructions SA/SAR (for actuator indication).

.

Check torque switching for end position CLOSED or set to the required value.

Setting end position OPEN The end stop need not be set since the required swing angle has been set in the

factory.

.

Move gearbox to the end stop in position OPEN.

The last part of the travel has to be made manually.

.

To turn the valve back manually from the end position by an amount equal to the

overrun, proceed as follows:

For actuators mounted directly:

by approx. 4 to 6 turns at the handwheel.

With mounted primary reduction gearing VZ/GZ:

by approx. 10 to 15 turns at the handwheel, according to the reduction ratio of

the primary reduction gearing.

.

Set limit switching in actuator for the end position OPEN according to the

operation instructions SA/SAR.

If the swing angle does not match, refer to section 10.

9.2 Worm gearboxes on ball valves

.

Figure F: End stop up to GS 125.3

03/04

1

In case end stops require adjustment, set end position OPEN first.

If the exact end position of the valve cannot be seen through a

position marking at the valve shaft, the setting may have to be

done with the valve removed.

Determine overrun of the actuator for both directions, i. e. how much does the valve

move after the motor has been switched off?

1

Figure G: End stop from GS 160.3

03/04

1

1

14

Page 15

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

Setting end position OPEN.Remove all bolts (03) at limit stop housing (10) (figures F, G).

Switching off in end position

OPEN

Setting end position

CLOSED

.

Change to manual drive and move the valve manually to end position OPEN.

.

In case limit stop housing (10) has not yet rotated, turn it counterclockwise up to

the stop.

.

Turn limit stop housing (10) back by ½ turn clockwise. This ensures that the

mechanical end stop is not reached in electric operation.

.

If the holes of limit stop housing (10) do not correspond to the threads of the

housing (1), take off the limit stop housing (10) and replace it in the required

position.

.

Fasten bolts (03) with lock washers (04).

.

Fasten bolts crosswise with a torque according to table 3.

.

If the position of the pointer cover does not align with the symbol OPEN, slightly

loosen the screws of the pointer cover. Turn the pointer cover to the OPEN

symbol and fasten the screws again.

.

Turn back the valve from the end position by an amount equal to the overrun.

.

Set limit switching according to the operation instructions SA/SAR.

The end stop need not be set since the required swing angle has been set in the

factory.

.

Move gearbox to the end stop in position CLOSED.

The last part of the travel has to be made manually.

.

To turn the valve back manually from the end position by an amount equal to the

overrun, proceed as follows:

For actuators mounted directly:

by approx. 4 to 6 turns at the handwheel.

With mounted primary reduction gearing VZ/GZ:

by approx. 10 to 15 turns at the handwheel, according to the reduction ratio of

the primary reduction gearing.

.

Set limit switching in actuator for the end position CLOSED according to the

operation instructions SA/SAR.

If the swing angle does not match, refer to section 10.

15

Page 16

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

10. Changing the swing angle

10.1 Changing the swing angle for sizes GS 50.3 – GS 125.3 (option)

The adjustment is made in end position OPEN.

Optional for size GS 50.3 – GS 125.3

Standard for size GS 160.3 – GS 250.3

Accuracy:

GS 50.3 – GS 125.3: 0.6°

GS 160.3 – GS 250.3: 0.11° to 0.14°

.

Unscrew protective cap (16) at limit stop housing (10) (figure H).

.

Remove roll pin (020) with appropriate tool (available from AUMA).

Increasing the swing angle

.

Turn end stop nut (15) back counterclockwise.

When turning back the end stop nut (015), make sure the roll pin

(020) can still be tapped in within the oblong hole.

.

Move valve into the desired end position.

.

Turn end stop nut (15) clockwise until it is tight up to the stop nut (7).

Reducing the swing angle

.

Move valve into the desired end position.

.

Turn end stop nut (15) clockwise until it is tight up to the stop nut (7).

The end stop nut (15) must entirely cover the roll pin (020).

Figure H: End stop up to GS 125.3

020 15 10 716 08

.

Tap in roll pin (020) with tool. If slot in end stop nut (15) does not align with the

hole in the worm shaft, turn end stop nut (15) slightly counterclockwise until it is

in alignment, then tap in roll pin.

.

Check O-ring (08) and replace, if damaged.

.

Replace protective cap (16).

.

If gearbox is mounted to a multi-turn actuator, set limit switching again for the

end position OPEN according to the operation instructions SA/SAR. Allow for

overrun.

Figure J: End stop from GS 160.3

082/083

058

03/04

34 1516

055

10 7056054

16

Page 17

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

10.2 Changing the swing angle for sizes GS 160.3 – GS 250.3

.

Remove all bolts (054) and pull off protective cap (16)

(figure J).

.

Remove screw (082) with washer (058) and setting ring (34).

Increasing the swing angle

.

Turn end stop nut (15) back counterclockwise.

.

Move valve into the desired end position.

.

Turn end stop nut (15) clockwise until it is tight up to the stop nut (7).

Reducing the swing angle

.

Move valve into the desired end position.

.

Turn end stop nut (15) clockwise until it is tight up to the stop nut (7).

.

Place setting ring (34), secure with washer (058) and screw (082).

.

Check O-ring (056) and replace, if damaged.

.

Place protective cap (16), fasten bolts (054) with lock washers (055).

.

Fasten bolts crosswise with a torque according to table 3.

.

If gearbox is mounted to a multi-turn actuator, set limit switching again for the

end position OPEN according to the operation instructions SA/SAR. Allow for

overrun.

17

Page 18

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

11. Enclosure protection IP 68

Definition According to EN 60 529, the conditions for meeting the requirements of enclosure

protection IP 68 (requirements exceed those of IP 67) are to be agreed between

manufacturer and user. AUMA worm gearboxes and primary reduction gearings in

enclosure protection IP 68 meet the following requirements according to AUMA:

.

IP 68-3, submersible in water up to 3 m head of water

.

IP 68-6, submersible in water up to 6 m head of water

.

IP 68-10, submersible in water up to 10 m head of water

.

IP 68-20, submersible in water up to 20 m head of water

For size GS 50.3, only enclosure protection IP 68-3 is available.

If submersed in other media, additional measures for corrosion protection may be

necessary; please consult AUMA. Submersion in aggressive media, e.g. acids or

alkaline solutions, is not permitted.

Review Gearboxes in enclosure protection IP 68-3 were type tested in the factory.

Gearboxes in enclosure protection IP 68-6, IP 68-10 and IP 68-20 undergo a

routine testing for tightness in the factory.

Note:

.

The enclosure protection IP 68 refers to the interior of the gearboxes, but not to

the coupling compartment.

.

If the gearboxes are likely to be repeatedly submersed, a higher corrosion

protection KS or KX is required.

.

For gearboxes intended for buried service we strongly recommend to use the

higher corrosion protection KS or KX.

.

For horizontal outdoor installation of the gearboxes, a sealed pointer cover

should be used.

For gas applications with sealed pointer cover, an air vent in the pointer cover or

venting grooves in the valve mounting flange must be provided.

.

In case of permanent submersion of the gearboxes or for buried service, a

protection cover must be fitted instead of a pointer cover. This will be taken into

account in the factory if indicated on the purchase order. Subsequent exchange

of the pointer cover for the protection cover is possible.

.

Use suitable sealing material between valve flange and gearbox.

.

Water can enter into the coupling compartment along the valve shaft. This would

lead to corrosion of hub and coupling. Therefore a suitable anticorrosive (or

sticky grease) must be applied to the hub and coupling of the gearbox before

mounting.

.

With corrosion protection KX, the hub and coupling are provided with a high

quality corrosion protection as standard.

18

Page 19

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

12. Maintenance

12.1 General notes After commissioning, check worm gearbox for damage to paint finish.

Do a thorough touch-up to prevent corrosion.

Original paint in small quantities can be supplied by AUMA.

AUMA worm gearboxes require only very little maintenance.

To ensure that the worm gearbox is always ready to operate,

gearboxes operated less than 10 times per year,

.

Approximately six months after commissioning and every year after check bolts

between multi-turn actuator, worm gearbox, and valve for tightness. If required,

tighten applying the torques given in table 2 (page 11).

.

Perform a test run every six months.

.

Perform a visual inspection for grease leakage on each gearbox every

2 years.

.

Carry out a detailed functional test for each gearbox every 5 years. Record the

results for future reference.

.

For gearboxes permanently exposed to ambient temperatures above

104 °F, maintenance must be performed at shorter intervals.

Seals:

Seals made of elastomeric materials are subject to ageing. The theoretical usable

lifetime of the seals made of NBR is 13.5 years from the date of manufacture.

These figures are based on an average ambient temperature of 104 °F. Seal kits

may be obtained from AUMA.

the following measures:

we recommend for

Grease:

A grease and seal change is recommended after the following operation time:

.

if operated seldom after 10 – 12 years

.

if operated frequently, after 6 – 8 years

.

in modulating duty after 4 – 6 years

.

Only original AUMA grease must be used.

.

For the grease type, refer to the name plate.

.

Lubricants should not be mixed.

Table 4: Grease quantities for worm gearboxes and primary reduction gearings

GS

Qty dm³

Weight1)g

Primary

reduction

gearing

Quantity dm³

Weight1)g

1) for ρ = approx. 900 g/dm3; conversion factor: 1 oz corresponds to 28.35 g

The removed lubricant and the cleaning agent used must be

disposed of according to the relevant regulations.

50.3 63.3 80.3 100.3 125.3 160.3 200.3 250.3

0.1 0.3 0.4 1.0 1.3 3.3 6.6 12.2

90 270 360 900 1,170 3,000 6,000 11,000

VZ GZ

2.3 3.3 4.3 160.3 200.3 250.3

4:1/8:1 16:1 4:1/8:1 16:1

0.35 0.35 0.35 1.0 1.5 2.0 2.2 2.8

320 320 320 900 1,400 1,800 2,000 2,250

19

Page 20

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

12.2 Grease change for worm gearboxes GS 50.3 – GS 125.3 and primary reduction gearing VZ 2.3 – VZ 4.3

.

For gearboxes with multi-turn actuator: Remove multi-turn actuator.

.

Remove gearbox from the valve:

During this time, the valve/pipeline must not be under pressure!

12.2.1 Worm gearboxes Refer to spare parts list GS 50.3 – GS 125.3, page 24.

Grease type, see name plate; grease quantities, see page 19, table 4.

.

Mark position of the gearbox on the valve, loosen connecting bolts to the valve

and remove the worm gearbox.

.

Remove fastening bolts with lock washers from the housing cover (518.0) and

take off housing cover.

.

Remove bolts with lock washers from the bearing cover (522.0). Lift worm wheel

carefully from the housing. For this, the worm shaft must be pulled from the

bearings and tilted slightly in the worm channel.

.

Remove old grease completely from the housing and the individual parts and

clean gear housing. For this purpose, a suitable cleaning agent should be used.

.

Clean mounting faces at housing and housing cover (518.0). Replace O-rings at

the worm wheel (010, 011) by new ones.

.

Re-insert worm wheel carefully and bring worm shaft into correct position, fasten

bearing cover (522.0) at housing with bolts and lock washers.

.

Fill with new grease.

.

Place housing cover (518.0) on housing, while ensuring the proper position of

the O-rings (010, 011) at the worm wheel. Place bolts with lock washers and

fasten them evenly crosswise.

– Thoroughly degrease mounting faces at mounting flange.

– Apply non-acidic grease at splines of coupling

– Mount worm gearbox to valve, ensure correct position,

observe mark made in previous step

– Fasten with bolts of minimum quality 8.8 using lock washers, fasten bolts

crosswise to the appropriate torque according to table 2, page 11.

.

Gearbox without primary reduction gearing: Continue with section “After

maintenance”.

.

Gearbox with reduction gearings VZ 2.3 – VZ 4.3: Perform grease change at the

reduction gearing according to the following subsection.

12.2.2 Primary reduction gearing Refer to spare parts list VZ 2.3 – VZ 4.3., page 24.

Grease type, see name plate; grease quantities, see page 19, table 4.

.

Remove bolts with lock washers from housing cover (020.0) and pull off housing

cover (020.0) with the complete input drive shaft (021.0).

.

Take off plate with internal teeth (045.0) and planet carrier (022.0) with the

planet wheels.

.

Remove old grease completely from the housing and the individual parts and

clean them. For this purpose, a suitable cleaning agent should be used.

.

Clean mounting faces at housing (019.0), housing cover (020.0) and plate with

internal teeth (045.0). Replace O-rings by new ones.

.

Insert planet carrier (022.0) with planet wheels.

.

Fill with new grease.

.

Place plate with internal teeth (045.0) and insert the input drive shaft (021.0)

completely. Screw in bolts with lock washers and fasten them evenly crosswise to

the appropriate torque according to table 2, page 11.

.

Continue with section “After maintenance”, page 22.

20

Page 21

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

12.3 Grease change for worm gearboxes GS 160.3 – GS 250.3 and primary reduction gearing GZ 160.3 – GZ 250.3

.

For gearboxes with multi-turn actuator: Remove multi-turn actuator.

.

Remove gearbox from the valve:

During this time, the valve/pipeline must not be under pressure!

12.3.1 Worm gearboxes Refer to spare parts list GS 160.3 – GS 250.3, page 26.

Grease type, see name plate; grease quantities, see page 19, table 4.

Tools: Lock nut tool, can be obtained from AUMA.

.

Mark position of the gearbox on the valve, loosen connecting bolts to the valve

and remove the worm gearbox.

.

Remove bolts with lock washers from the housing cover (518.0) and take off

housing cover.

.

Remove bolts with lock washers from the bearing cover (522.0). Take off bearing

lock nut (537.0) by loosening the grub screw. Remove protective cap (536.0), pull

off snap ring from end nut (526.0). Remove end stop (523.0). Lift worm wheel

carefully from the housing. For this, the worm shaft must be pulled from the

bearings and tilted slightly in the worm channel.

Pull out worm shaft from housing in direction of the input shaft.

.

Remove old grease completely from the housing and the individual parts and

clean gear-housing. For this purpose, a suitable cleaning agent should be used.

.

Clean mounting faces at housing and housing cover (518.0). Replace O-rings at

the worm wheel (010, 011) by new ones.

.

Re-insert worm wheel carefully and bring worm shaft into correct position. Screw

in bearing lock nut (537.0) and secure with grub screw. Fasten bearing cover

(522.0) at the housing with bolts and lock nuts.

.

Fill with new grease.

.

Place housing cover (518.0) on housing, while ensuring the proper position of

the O-rings (010, 011) at the worm wheel. Place bolts with lock washers and

fasten them evenly crosswise.

– Thoroughly degrease mounting faces at mounting flange and valve.

– Apply non-acidic grease at splines of coupling.

– Mount worm gearbox to valve, ensure correct position, observe mark.

– Fasten with bolts of minimum quality 8.8 using lock washers, fasten bolts

crosswise to the appropriate torque according to table 2, page 11.

.

Gearbox without primary reduction gearing: Continue with section “After

maintenance”.

.

Gearbox with reduction gearings GZ 160.3 – GZ 250.3: Perform grease change

at the reduction gearing according to the following sections.

12.3.2 Single-stage reductions gearings GZ 160.3 – GZ 250.3 (reduction ratios 4:1 and 8:1)

Refer to spare parts list GZ 160.3 – GZ 250.3, page 28.

Grease type, see name plate; grease quantities, see page 19, table 4.

.

Remove bolts with lock washers at housing cover (002.0) and pull off housing

cover (002.0) with the input drive shaft (003.0) and the plate with internal teeth).

.

Remove screws from the plate with internal teeth and separate the plate with

internal teeth from the input drive shaft.

.

Remove old grease completely from the housing and the individual parts and

clean them.

.

For this purpose, a suitable cleaning agent should be used.

.

Clean mounting faces at housing (001.0), housing cover (002.0) and plate with

internal teeth. Replace O-rings by new ones.

.

Fill housing cover (002) with new grease.

.

Fix plate with internal teeth (006.0) with screws at housing cover.

21

Page 22

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

.

Fill housing (001.0) with remaining grease and fit the complete housing cover

with input drive shaft (003.0). Screw in bolts with lock washers and fasten them

evenly crosswise to the appropriate torque according to table 2, page 11.

.

Continue with section “After maintenance”, page 22.

12.3.3 Double-stage primary reduction gearing GZ 200.3 – GZ 250.3 (reduction ratio 16:1)

Refer to spare parts list GZ 160.3 – GZ 250.3, page 28.

Grease type, see name plate; grease quantities, see page 19, table 4.

.

Remove bolts with lock washers from housing cover (002.0) and pull off housing

cover with the complete input drive shaft (003.0).

.

Take off screws with lock washers from housing frame (010.0) and remove

housing frame with planet carrier and hollow wheel.

.

Remove screws from the plate with internal teeth and separate the plate with

internal teeth from the input drive shaft (003.0).

.

Remove screws (021) from the second stage of the plate with internal teeth and

separate it from the pinion (011.1).

.

Remove old grease completely from the housing and the individual parts and

clean them. For this purpose, a suitable cleaning agent should be used.

.

Clean mounting faces at housing (001.0), housing frame, housing cover (002.0)

and hollow wheels. Replace O-rings by new ones.

.

Fill housing (001.0) with new grease.

.

Fix second stage of the plate with internal teeth on housing frame (010.0).

.

Replace complete housing frame. Screw in bolts with lock washers and fasten

them evenly crosswise to the appropriate torque according to table 2, page 11.

.

Fill housing frame (010.0) and housing cover (002.0) with the remaining grease.

.

Fix first stage of the plate with internal teeth on the housing cover (002.0).

.

Place complete housing cover with input drive shaft onto housing frame. Screw

in bolts with lock washers and fasten them evenly crosswise to the appropriate

torque according to table 2, page 11.

12.4 After maintenance

.

If applicable, mount multi-turn actuator.

.

Reset the end stops.

.

For gearboxes with multi-turn actuator, check the setting of the limit switching

according to the operation instructions for multi-turn actuators; if required, reset.

.

Perform test run to ensure the proper function.

.

Check worm gearbox for damage to paint finish. Do a thorough touch-up to

prevent corrosion. Original paint in small quantities can be supplied by AUMA.

22

Page 23

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

13. Disposal and recycling

AUMA gearboxes have an extremely long lifetime. However, they have to be

replaced at one point in time.

Our gearboxes have a modular design and may therefore easily be disassembled,

separated and sorted according to materials, i.e.:

.

various metals

.

plastics

.

greases and oils

The following generally applies:

.

Collect greases and oils during disassembly. As a rule, these substances are

hazardous to water and must not be released into the environment.

.

Send disassembled material to a sound disposal or to separate recycling center

according to materials.

.

Observe the local regulations for waste disposal.

14. Service AUMA offers extensive services such as maintenance and inspection for

gearboxes.

The AUMA service department can be reached at:

phone: 724-743-AUMA (2862)

fax: 724-743-4711

email: mailbox@auma-usa.com

www.auma-usa.com or www.auma.com.

23

Page 24

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

15. Spare parts list worm gearboxes GS 50.3 – GS 125.3 and reduction gearing VZ 2.3 – VZ 4.3

512.0

512.0

020.0

522.0

S1(009)

S1(009)

522.0

S1(017)

524.0

S1(011)

521.1

S1(012)

512.0

S1(017)

520.0

526.0

S1(009)

S1(017)

520.0

S1(010)

517.0

519.1

S1(010)

S1(034)

021.0

534.0

520.0

045.0

525.0

022.0

S1(033)

S1(033)

24

019.0

518.0

S1(073)

527.0

S1(009)

523.0

S1(076)

S1(009)

Page 25

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

Note: Please state type and commission no. of the device (see name plate) when ordering spare parts. Only original

AUMA spare parts should be used. Delivered spare parts may slightly vary from the representation

in these instructions.

No. Designation Type

019.0

020.0

021.0

022.0

045.0

512.0

517.0

518.0

519.1

520.0

521.1

522.0

523.0

524.0

525.0

526.0

527.0

534.0

536.0

S1

Housing VZ Sub-assembly

Housing cover VZ Sub-assembly

Input drive shaft VZ Sub-assembly

Planet carrier VZ Sub-assembly

Plate with internal teeth VZ Sub-assembly

Flange for actuator Sub-assembly

Housing Sub-assembly

Housing cover Sub-assembly

Worm wheel Component

Worm shaft Sub-assembly

Travelling nut Component

Bearing cover Sub-assembly

Limit stop housing Sub-assembly

Pointer cover Sub-assembly

Coupling Sub-assembly

End stop nut Sub-assembly

Protection cover Sub-assembly

Input shaft Sub-assembly

Cap Sub-assembly

Seal kit Set

25

Page 26

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

16. Spare parts list worm gearboxes GS 160.3 – GS 250.3

537.0

512.0

520.0

521.1

524.0

S1(011)

518.0

S1(012)

522.0

S1(009)

538.1

526.0

517.0

S1(017)

538.0

26

513.1

S1(009)

S1(056)

S1(073)

527.0

S1(010)

523.0

519.1

536.0

S1(010)

525.0

Page 27

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

Note: Please state type and commission no. of the device (see name plate) when ordering spare parts. Only original

AUMA spare parts should be used.

Delivered spare parts may slightly vary from the representation in these instructions.

No. Designation Type

512.0

513.0

517.0

518.0

519.1

520.0

521.1

522.0

523.0

524.0

525.0

526.0

527.0

536.0

538.0

538.1

S1

Flange for actuator Sub-assembly

Grub screw Component

Housing Sub-assembly

Housing cover Sub-assembly

Worm wheel Component

Worm shaft Sub-assembly

Travelling nut Component

Bearing cover Sub-assembly

Limit stop housing Sub-assembly

Pointer cover Sub-assembly

Coupling Sub-assembly

End stop nut Sub-assembly

Protection cover Sub-assembly

Cap Sub-assembly

Input shaft Sub-assembly

Input shaft Sub-assembly

Seal kit Set

27

Page 28

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

002.0

17. Spare parts list reduction gearings GZ 160.3 – GZ 250.3 (reduction ratios 4:1, 8:1 and 16:1)

GZ 200.1 – GZ 250.1

GZ 160.1 – GZ 250.1

16:1

4:1 / 8:1

S1(004)

S1(009)

001.0

S1(009)

S1(004)

001.0

003.3

006.0

S1(029)

006.0

S1(003)

S1(029)

003.0

003.3

S1(003)

S1(003)

S1(003)

003.0

S1(014)

512.0

002.0

011.1

010.0

GZ 200.1 – GZ 250.1

16:1

S1(009)

S1(004)

001.0

013.0

006.0

S1(029)

S1(003)

S1(029)

S1(014)

512.0

S1(003)

003.0

003.3

S1(014)

512.0

002.0

28

011.1

013.0

010.0

Page 29

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

Note:

Please state type and commission no. of the device (see name plate) when ordering spare parts. Only original AUMA

spare parts should be used. Delivered spare parts may slightly vary from the representation in these instructions.

No. Designation

001.0

002.0

003.0

003.3

006.0

010.0

011.1

013.0

512.0

S1

Housing Sub-assembly

Housing cover Sub-assembly

Housing cover Sub-assembly

Input drive shaft Sub-assembly

Planetary gear Sub-assembly

Housing frame Sub-assembly

Pinion Sub-assembly

Planetary gear 1st stage Sub-assembly

Flange for actuator Sub-assembly

Seal kit Set

29

Page 30

Worm gearboxes GS 50.3 – GS 250.3 Operation instructions

Notes

30

Page 31

Operation instructions Worm gearboxes GS 50.3 – GS 250.3

Index

B

Bolts for mounting actuators 10

C

Changing the swing angle 16

Corrosion protection 7

D

Disposal and recycling 23

E

Enclosure protection IP 68 18

F

Fitting the handwheel 7

H

Handwheel 7

L

Lubricant 19

M

Maintenance 3,19

Manual operation 12

Motor operation 13

Mounting positions 8

Mounting the multi-turn actuators 9

Mounting to valve 11

P

Packaging 7

R

Range of application 3

S

Safety instructions 3

Service support/ Parts 23

Setting the end stop

with mounted

multi-turn actuator 13

Setting the end stops

for manual operation 12

Spare parts list

GS 50.3 - GS 125.3 24,25

GS 160.3 - GS 250.3 26,27

GZ 160.3 - GZ 250.3

(4:1/8:1/16:1) 28,29

Storage 7

T

Technical data 4

Transport 7

31

Page 32

North American Sales and Service:

US Headquarters and Factory:

AUMA Actuators, Inc.

100 Southpointe Blvd.

Canonsburg PA 15317

Tel: 724-743-AUMA (2862)

Fax: 724-743-4711

email: mailbox@auma-usa.com

www.auma-usa.com

Regional Offices:

Northeast (Maryland and New York)

Southeast (South Carolina)

Midwest (Illinois)

Midwest (Kansas)

Houston (Texas)

West Coast (Northern and Southern California)

Representatives and Distributors

Anchorage

Atlanta

Baltimore

Baton Rouge

Birmingham

Boston

Charlotte

Chicago

Cincinatti

Corpus Christi

Dallas

Denver

Detroit

Hawaii

Houston

Indianapolis

Kansas City

Los Angeles

Mexicali (Mexico)

Mexico City

Milwaukee

Minneapolis

Montana

Monterrey (Mexico)

New York

Omaha

Orlando

Philadelphia

Phoenix

Pittsburgh

Rochester

Salt Lake City

San Diego

San Francisco

San Juan

Seattle

St. Louis

Toronto

Tulsa

International Headquarters:

AUMA Riester GmbH & Co. KG

Müllheim/ Germany

www.auma.com

International Sales and Service:

South America:

Argentina

Brazil

Chile

Colombia

Peru

Venezuela

Europe:

Austria

Benelux

Czech Republic

Denmark

Finland

France

Greece

Hungary

Italy

Norway

Poland

Portugal

Russia

Spain

Sweden

Switzerland

Turkey

Ukraine

United Kingdom

Africa

Egypt

South Africa

Asia, Australia

Australia

China

Hong Kong

India

Japan

Korea

Kuwait

Oman

Qatar

Singapore

Taiwan

Thailand

UAE

For the name and phone number of the office

nearest you, call us at 724-743-2862 or visit our

website at www.auma-usa.com/saleserv.htm

2005-06-27

Y003.822/031/us/1.06

Loading...

Loading...