Page 1

Multi-turn actuators

SA/SAR 07.2 – 16.2 / SAEx/SAREx 07.2 – 16.2

SAV/SARV 07.2 – 16.2 / SAVEx/SARVEx 07.2 – 16.2

with actuator controls

AC 01.2/ACExC 01.2

ACV 01.2/ACVExC 01.2

SFC version

Functional safetyManual

Page 2

Multi-turn actuators

Table of contents SA .2 with AC(V) 01.2/AC(V)ExC 01.2

NOTICE for use!

This document is only valid with the latest operation instructions attached to the device, the attached manual,

the attached declaration of incorporation as well as the respectively pertaining technical and electrical data sheets.

They are understood as reference documents.

Purpose of the document:

The present documents informs about the actions required for using the device in safety-related systems in

accordance with IEC 61508 or IEC 61511.

Reference documents:

●

exida report no. AUMA 10-12-035 R005E

●

Operation instructions (Assembly, operation, commissioning) for actuator

●

Manual (Operation and setting) actuator controls AC 01.2/ACExC 01.2

●

Manual (Operation and setting) actuator controls ACV 01.2/ACVExC 01.2

●

Manual (Device integration Fieldbus) AC 01.2/ACExC 01.2 / ACV 01.2/ACVExC 01.2

Reference documents are available on the Internet at: http://www.auma.com.

Table of contents Page

104. Safety instrumented systems and safety functions...........................................................

115. Installation, commissioning and operation.........................................................................

115.1. Installation

115.2. Commissioning

115.3. Operation

115.4. Lifetime

125.5. Decommissioning

41. Terminology............................................................................................................................

41.1. Abbreviations and concepts

62. Application and validity.........................................................................................................

62.1. Range of application

62.2. Standards

62.3. Valid device types

73. Architecture, configuration and applications......................................................................

73.1. Architecture (actuator sizing)

73.2. Configuration (setting)

73.3. Protection against uncontrolled operation (self-locking/brake)

83.4. Operation mode (low/high demand mode)

83.5. Further notes and indications on architecture

93.6. Applications (environmental conditions)

136. Tests and maintenance..........................................................................................................

136.1. Safety equipment: check

136.2. Proof test (verification of safe actuator function)

136.2.1. Preliminary tests

136.2.2. Review and validation of the “Safe end position signal” safety function

146.2.3. Checking the collective fault signal

146.3. Partial Valve Stroke Test (PVST)

146.4. Maintenance

2

Page 3

Multi-turn actuators

SA .2 with AC(V) 01.2/AC(V)ExC 01.2 Table of contents

157. Safety-related figures.............................................................................................................

157.1. Determination of the safety-related figures

168. SIL Declaration of Conformity (example).............................................................................

21Index........................................................................................................................................

22Addresses...............................................................................................................................

3

Page 4

Multi-turn actuators

Terminology SA .2 with AC(V) 01.2/AC(V)ExC 01.2

1. Terminology

●

Information sources

1.1. Abbreviations and concepts

IEC 61508-4, Functional safety of electrical/electronic/programmable electronic

safety-related systems – Part 4: Definitions and abbreviations

●

IEC 61511-1, Functional safety - Safety instrumented systems for the process

industry sector – Part 1: Fr amework, definitions, system, hardware and softw are

requirements

To evaluate safety functions, the lambda values or the PFD value (Probability of

Dangerous Failure on Demand) and the SFF value (Safe Failure Fraction) are the

main requirements. Further figures are required to assess the individual components.

These figures are explained in the table below.

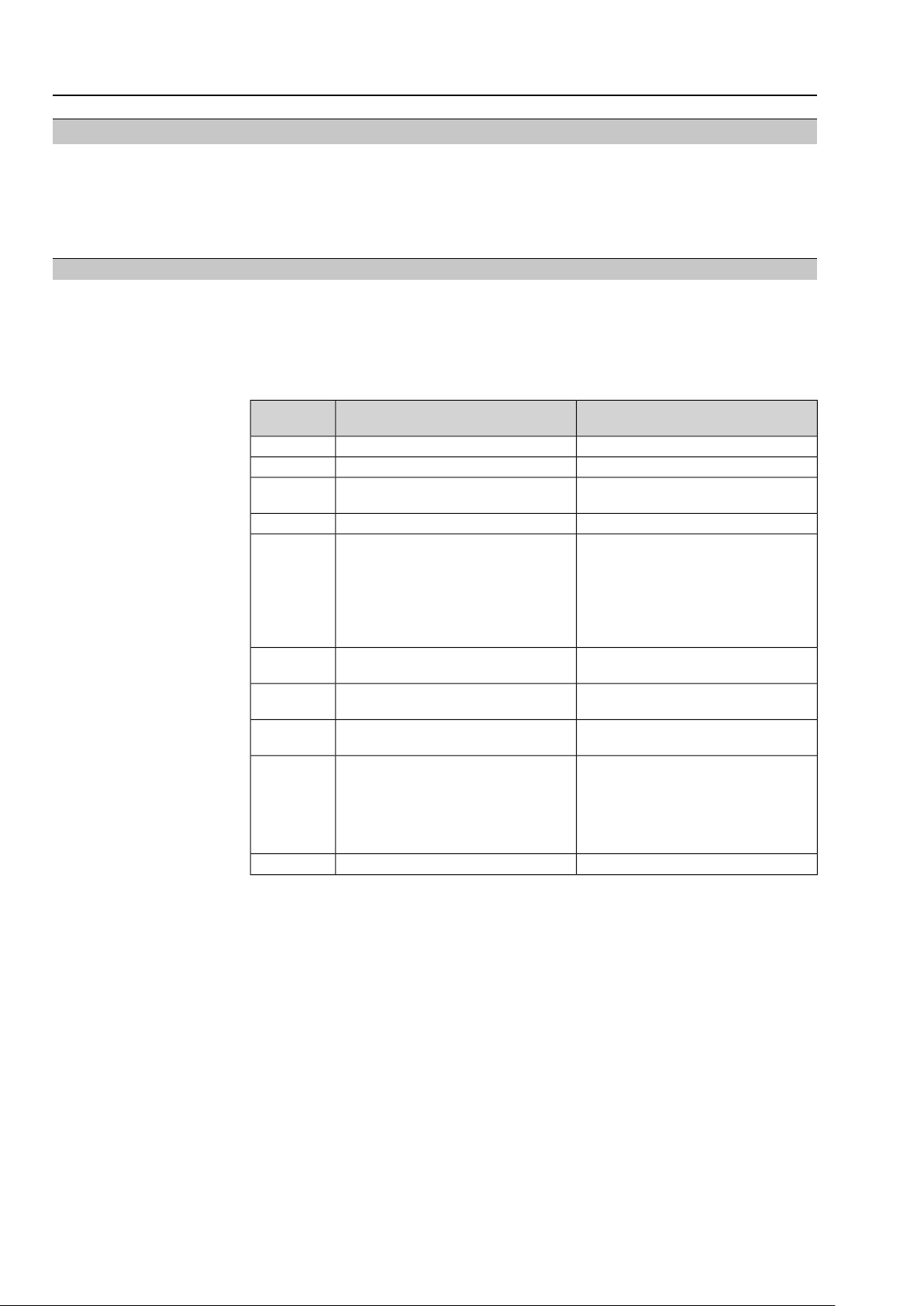

Table 1: Abbreviations of safety figures

ation

S

D

DU

DD

PFD

proof

avg

Lambda Dangerous Undetectedλ

Diagnostic CoverageDC

Mean Time Between FailuresMTBF

Safe Failure FractionSFF

Aver age Probability of dangerous Failure on Demand

Hardware Failure ToleranceHFT

DescriptionFull expressionAbbrevi-

Number of safe failuresLambda Safeλ

Number of dangerous failuresLambda Dangerousλ

Number of undetected dangerous fail-

ures

Number of detected dangerous failuresLambda Dangerous Detectedλ

Diagnostic Coverage - ratio between

the failure rate of dangerous failures

detected by diagnostic tests and total

rate of dangerous failures of the component or subsystem.The diagnostic

coverage does not include any f ailures

detected during proof tests.

Mean time between the occurence of

two subsequent failures

Fraction of safe failures as well as of

detectable dangerous failures

Average probability of dangerous failures on demand of a safety function.

Ability of a functional unit to execute a

required function while faults or deviations are present. HFT = n means that

the function can still be safely ex ecuted

for up to n faults occurring at the same

time.

Interval for proof testProof test intervalT

Safety function

Safety instrumented

function (SIF)

Safety instrumented

system (SIS)

Safety-related system

4

Safety Integrity Level

SIL

The international standard IEC 61508 defines 4 levels (SIL 1 through SIL 4).

Function to be implemented by a safety-related system for risk reduction with the

objective to achieve or maintain a safe state for the plant/equipment with respect to

a specific dangerous event.

Function with specified safety integrity level (SIL) to achieve functional safety.

Safety instrumented system for executing a single or several safety instrumented

functions. An SIS consists of sensor(s), logic system and actuator(s).

A safety-related system includes all factors (hardware, software, human factors)

necessary to implement one or several safety functions. Consequently failures of

safety function would result in a significant increase in saf ety risks for people and/or

the environment.

A safety-related system can comprise stand-alone systems dedicated to perform a

particular safety function or can be integrated into a plant.

Page 5

Multi-turn actuators

SA .2 with AC(V) 01.2/AC(V)ExC 01.2 Terminology

Proof test

MTTR (Mean Time To

Restoration)

MRT (Mean Repair Time)

Device type (type A and

type B)

Periodic test performed to detect dangerous hidden f ailures in a safety-related system

so that, if necessary, a repair can restore the system to an "as new" condition or as

close as practical to this condition.

Mean time to restoration once a failure has occurred. Indicates the expected mean

time to achieve restoration of the system. It is therefore an important parameter for

system availability.The time for detecting the failure, planning tasks as well as

operating resources is also included. It should be reduced to a minimum.

Mean repair time indicates the mean time required to repair a system.The MRT is

crucial when defining the reliability and availability of a system.The MRT should

preferably be small.

Actuator controls can be regarded as type A devices if all of the follo wing conditions

are met for all components required to achieve the safety instrumented function:

●

The failure modes for all constituent components involved are well defined

●

The behaviour under fault conditions can be completely determined.

●

There is sufficient dependable failure data from the field to show that the claimed

rates of failure are met (confidence level min. 70 %).

Actuator controls shall be regarded as type B devices if one or sev eral of the follo wing

conditions are met:

●

The failure of at least one constituent component is not well defined.

●

The fault behaviour is not completely known.

●

There is insufficient dependable failure data to support claims for rates of f ailure

for detected and undetected dangerous failures.

PTC (Proof Test Cover-

age)

Proof test coverage describes the fraction of f ailures which can be detected by means

of a proof test.

5

Page 6

Multi-turn actuators

Application and validity SA .2 with AC(V) 01.2/AC(V)ExC 01.2

2. Application and validity

2.1. Range of application

AUMA actuators and actuator controls with the safety functions mentioned in this

manual are intended for operation of industrial valves and are suitable for use in

safety instrumented systems in accordance with IEC 61508 or IEC 61511.

2.2. Standards

Both actuators and actuator controls meet the following requirements:

For safety functions “Safe end position fieedback”: IEC 61508-2:2010

The safety figures of the devices described meet the requirements of IEC 61508 in

the respective SIL level with regard to failure rates and architecture requirements.

However, this does not imply that all further requirements of IEC 61508 are met.

2.3. Valid device types

The data on functional safety contained in this manual applies to the device types

indicated.

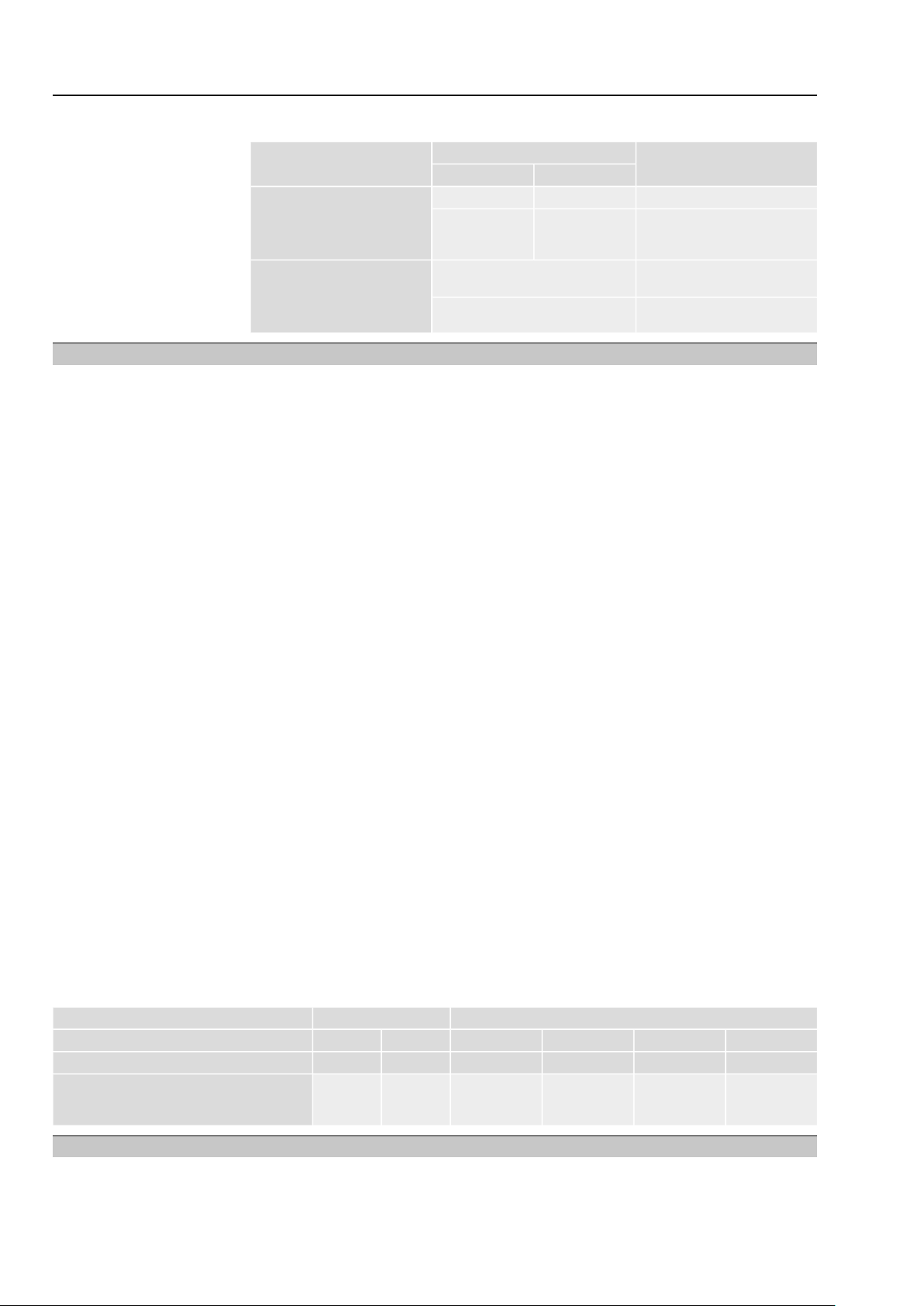

Table 2: Overview on suitable device types

Type

Actuator

SA 07.2 – SA 16.2

SAR 07.2 – SAR 16.2

in SFC version

SAEx 07.2 – SAEx 16.2

SAREx 07.2 – SAREx 16.2

in SFC version

SAV/SARV 07.2 – 16.2

SAVEx/SAR VEx 07.2 – 16.2

in SFC version

Information

Type

Actuator controls

in SFC version

in SFC version

in SFC version

Power supply

Any supplyAC 01.2

S2 - 30 min

S4 - 25 %

S4 - 50 %

Any supplyACExC 01.2

S2 - 30 min

S4 - 25 %

S4 - 50 %

Any supplyACV/ACVExC 01.2

S2 - 30 min

S4 - 25 %

S4 - 50 %

ControlType of dutyMotor

Safe end position feedbackS2 - 15 min

Safe end position feedbackS2 - 15 min

Safe end position feedbackS2 - 15 min

Hardware, software and configuration of actuator and actuator controls must not be

modified without prior written consent by AUMA. Unauthorised modification may

have a negative impact on both safety figures and SIL capability of the products.

In applications with requirements on functional safety, only AUMA actuator controls

and actuators in SFC or SIL version may be used. SFC stands for “Safety Figure

Calculated”.This designation identifies AUMA products for which saf ety figures were

calculated on the basis of FMEDA from field data and generic data (for detailed information refer to <Determination of the figures>).

AUMA actuator controls and actuators in SFC v ersion can among others be identified

from the letters "SFC" following the type designation on the name plate.

Figure 1: Example of name plate with “SFC” marking

6

Page 7

Multi-turn actuators

SA .2 with AC(V) 01.2/AC(V)ExC 01.2 Architecture, configuration and applications

3. Architecture, configuration and applications

3.1. Architecture (actuator sizing)

For actuator architecture (actuator sizing) the maximum torques, run torques and

operating times are taken into consideration.

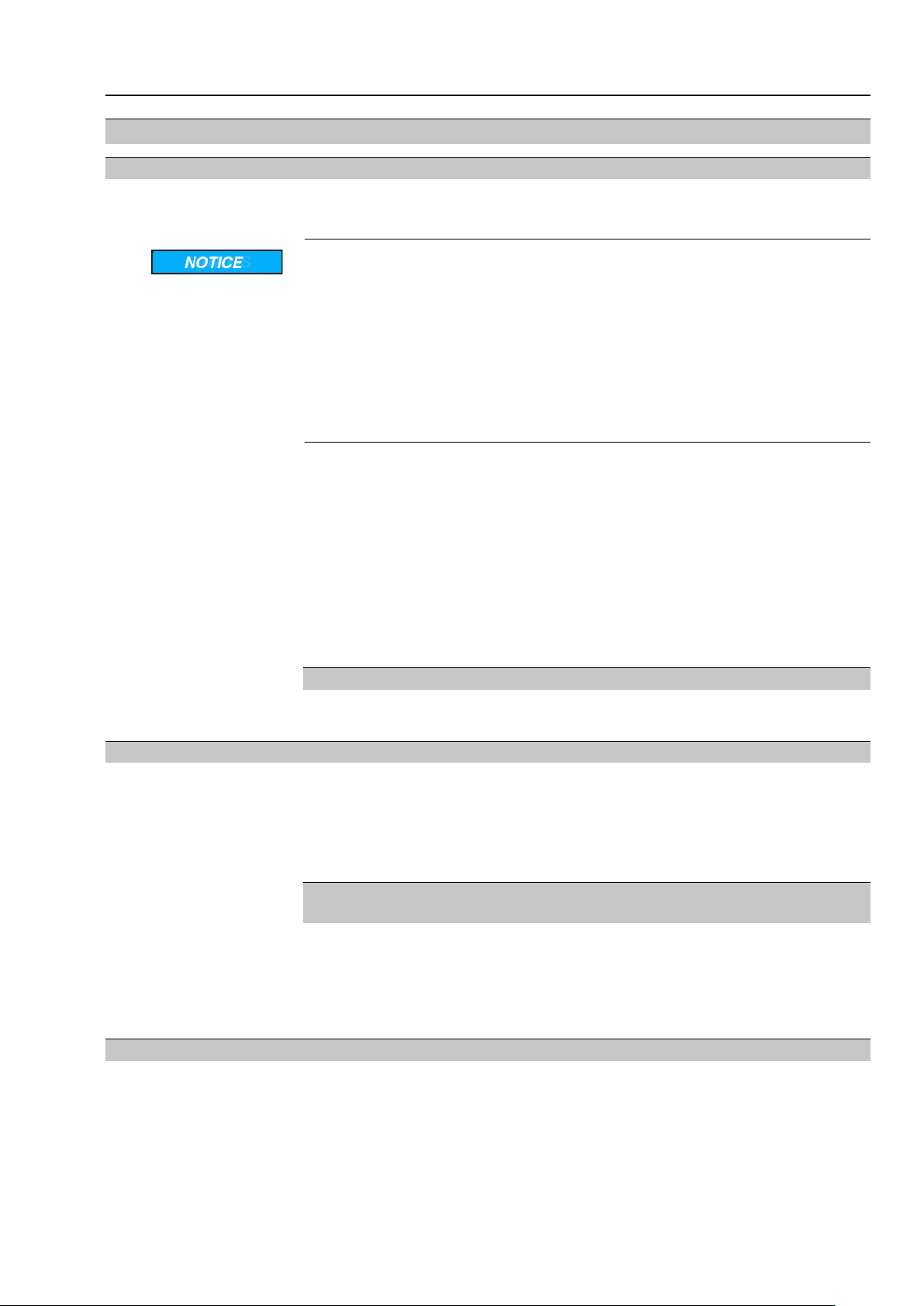

Incorrect actuator architecture can lead to device damage within the safetyrelated system!

Possib le consequences can be valve damage , motor overheating, contactor jamming,

defective thyristors, heating up or damage to cables.

→

The actuator technical data must imperatively be observed when selecting the

actuator.

→

Sufficient reserves have to be provided to ensure that actuators are capab le of

reliably opening or closing the valve even in the event of an accident or undervoltage.

Information

For the “Safe end position feedback” safety function, heed that signalling is made

via mechanical switches. Since these elements have an unav oidab le h ysteresis , the

actuator slightly leaves the end position before the end position signal is deleted.

Consequently, there is a marginal range of actuator positions to the safety position,

for which the end position is still signalled although the actuator has already left the

end position during operation from safety position. If the range in question is approached from the opposite direction, this limitation does not apply. In general this

range is relatively small. However, for unfavourable configurations (low number of

turns per stroke), this range can amount to more than 10 % of the total stroke.

Should, within the framework of unfa v ourab le conditions, the eff ect described abov e

represent an unacceptable limitation for the saf ety function, we recommend ev aluating

both limit and torque switches for the end position feedback.

Power supply

Information

The plant operator is responsible for power supply.

3.2. Configuration (setting)

Configuration (setting) of the safety-related functions is performed as described in

the operation instructions or in the present manual (functional safety).

Information

An exact setting of torque and end position switches f or the end positions is imperatively required to ensure correct function of “Safe end position feedback”. For setting

details related to the respective switches, please refer to operation instructions.

Configuration of reaction monitoring diagnostics and Partial V alve Str oke T est

(PVST)

Depending on the type of diagnostics required, the reaction monitoring or Partial

Valve Stroke Test configurations have to be checked and adapted, if required.

For detailed configuration options on reaction monitoring as well as detailed

information on the Partial Valve Stroke Test (PVST), refer to Manual (Operation and

setting) AUMATIC AC 01.2.

3.3. Protection against uncontrolled operation (self-locking/brake)

For self-locking AUMA actuators, it can be assumed that a load up to maximum

torque will not result in uncontrolled valve operation from standstill due to v alve torque

load. Consequently, in these cases, further protection against uncontrolled operation

is not imperatively required. Howe ver , certain applications may require activ e position

locking, for e xample b y using a brake .There are user-specific standards demanding

this type of protection.Therefore, each project must be subject to individual verification

if any further protection is required. In any case, this protection is required for

actuators without self-locking.

7

Page 8

Multi-turn actuators

Architecture, configuration and applications SA .2 with AC(V) 01.2/AC(V)ExC 01.2

Table 3: Overview self-locking for AUMA actuators (at the time of printing of this document)

Self-lockingOutput speedType

60 Hz50 Hz

Self-locking≤ 108 rpm≤ 90 rpmSA 07.2 – SA 16.2

SAR 07.2 – SAR 16.2

SAEx 07.2 – SAEx 16.2

SAREx 07.2 – SAREx 16.2

SAV 07.2 – SAV 16.2

SARV 07.2 – SARV 16.2

SAVEx 07.2 – SAVEx 16.2

SARVEx 07.2 – SARVEx 16.2

and 12 – 120 1/min

NOT self-locking≥ 150 rpm≥ 125 rpm

Self-lockingSpeed range variants 6 – 60 1/min

NOT self-lockingSpeed range variant 24 – 240 1/min

3.4. Operation mode (low/high demand mode)

The safety functions of the actuators supplied by AUMA are suitable for the low

demand mode and may only be used in this operation mode. If a non-safety

instrumented function of basic process control system is executed via the same

actuator in addition to the safety function, note that while considering the sum of

non-safety instrumented function, required tests and safety function, the defined

number of maximum permissible cycles1) for the respective actuator as well as the

maximum number of starts2) may not be exceeded during deplo yment of the actuator

within a safety instrumented system.

Only the “safe end position feedback” safety function can be operated beyond

the limitations mentioned above under certain conditions even in operation mode

with high demand rate, provided the following requirements and limitations are

heeded:

●

When considering the sum consisting of non-safety instrumented function, required tests and safety function, the number of maximum cycles of the actuator

end position switches as well as the maximum number of starts during actuator

deployment are not exceeded in a safety instrumented system.

●

When considering the sum consisting of non-safety instrumented function, required tests and safety function, the number of maximum cycles f or the respective actuator as well as the maximum number of permissible cycles1) or starts

are not exceeded, if appropriate scaling rules are applied.

●

Lubrication is checked at regular intervals and the lubricant changed if required,

however, at least every 10 years.

●

Every 20,000 cycles1) or starts2) (whatever occurs earlier), the crown wheel and

the worm wheel are checked for wear and replaced if required.

●

The end user makes sure that a test rate (PVST) is achieved for the “Saf e end

position feedback” safety function, complying with the demand r ate to be expected according to the applicable standards for the respective application.

●

All requirements in accordance with the “Technical data for switches” (Y004.619)

data sheet are respected. In particular , the permissible minimum and maximum

currents and voltages.

●

The number of cycles1) as well as the number of cycles of each limit and torque

switch do not exceed the values stipulated in the table below:

2)

Table 4:

switch as well as cycles according to EN 157142:2010

3.5. Further notes and indications on architecture

HFT is 0.

Only flanges of F07 or FA 07 sizes or larger may be used for valve attachment.

1) Definition of “cycles” according to EN 15714-2:2010

2) Definition of “starts” according to DIN EN 15714-2:2010

8

Class C (Modulation)Classes A and B

GoldGoldSilverSilverGoldSilverContact material

50 V/400 mA30 V/30 mA250 V AC/5 A30 V/30 mAMaximum electrical load

< 20,000< 100,000< 20,000< 100,000< 20,000< 20,000Number of permissible cycles of end position

Page 9

Multi-turn actuators

SA .2 with AC(V) 01.2/AC(V)ExC 01.2 Architecture, configuration and applications

For “safe end position feedback”, the actuator can be considered as type A device.

Safety figures

The safety figures relevant for the product supplied as well as potential further

restrictions are indicated on the declaration of incorporation.The declaration of

incorporation is specific for each order and directly supplied with the order.

3.6. Applications (environmental conditions)

When specifying and using the actuators within safety instrumented systems, make

sure that the permissible service conditions and the EMC requirements by the

peripheral devices are met. Service conditions are indicated in the technical data

sheets:

●

Enclosure protection

●

Corrosion protection

●

Ambient temperature

●

Vibration resistance

If the actual ambient temperatures exceed an av erage of +40 °C , the lambda v alues

have to be incremented by a safety factor. For an average temperature of +60 °C,

this factor is specified to 2.5.

For environmental test, actuator and actuator controls were subjected to the f ollowing

standards:

●

Dry heat: EN 60068-2-2

●

Damp heat: EN 60068-2-30

●

Cold: EN 60068-2-1

●

Vibration test: IEC 60068-2-6

●

Induced seismic vibration (earthquake): IEC 68-3-3

●

Enclosure protection test IP68: EN 60529

●

Salt spray test: EN ISO 12944-6

●

Immunity requirements: EN 61326-3-1

●

Emission: EN 61000-6-4

3)

3) Thyristor version only

9

Page 10

Multi-turn actuators

Safety instrumented systems and safety functions SA .2 with AC(V) 01.2/AC(V)ExC 01.2

4. Safety instrumented systems and safety functions

In calculating the safety figures of the actuator, the following safety functions are

taken into account:

●

Safe end position feedback

An end position signal directly wired to the actuator is available.The safety

function is the correct signal whether the actuator is in the requested actuator

end position or not. Only the signal via this signal comm unication path is safety

related. End position feedback via I/O interface relay or a positioner (RWG,

MWG, potentiometer, ...) or via a fieldbus interface does not represent a safe

end position feedback.

4)

4) Please note that safety figures only include the components of the actuator . Further components (e.g.

integrity of external controls, gearboxes , valve shaft, other valve components....) are not considered with

the AUMA safety figures related to this product

Page 11

Multi-turn actuators

SA .2 with AC(V) 01.2/AC(V)ExC 01.2 Installation, commissioning and operation

5. Installation, commissioning and operation

Information

5.1. Installation

Installation and commissioning have to be documented by means of an assembly

report and an inspection certificate. Installation and commissioning may only be

performed by authorised personnel who have been trained on functional safety.

General installation tasks (assembly, electrical connection) have to be performed

according to the operation instructions pertaining to the device and the enclosed

order-specific wiring diagram.

Figure 2:Wiring diagram example with safe end position feedback

[1] Limit switches for safe end position feedback

Information

5.2. Commissioning

5.3. Operation

Installation and commissioning must be recorded and a final installation and

commissioning report must be issued.

When connecting actuator controls to safety PLC and a functional control system,

make sure that the inputs and outputs used have separate potentials. Imperatively

avoid one common f or inputs and outputs when connecting to circuit of safety system

and basic process control system. Particular attention to comply with these

requirements has to be paid when selecting the input for the ESD signal, the inputs

and outputs of PVST and for fault signals (and possibly other feedback signals).

Valve position indication is made via potentiometer or 4 – 20 mA signals. However,

this is not part of the determination of safety figures.

The operation instructions pertaining to the device must be observed for general

commissioning.

After commissioning, the safe actuator function must be verified.

Regular maintenance and device checks in the T

intervals as defined by the

proof

plant operator are the basis for safe operation.

The operation instructions pertaining to the device must be observed for operation.

The plant operator is responsible for power supply.

Once a fault occurs, the system has to be checked immediately and the installation

has to be put in a safe state, if required.

5.4. Lifetime

Actuator lifetime is described in the technical data sheets or the operation instructions.

Safety-related figures are valid for the cycles or modulating steps defined in the

technical data specifications and for typical periods of up to 10 years (the criterion

achieved first is valid). After this period, the probability of failure increases.

11

Page 12

Multi-turn actuators

Installation, commissioning and operation SA .2 with AC(V) 01.2/AC(V)ExC 01.2

Extending this period is basically feasible in many cases “provided both manuf acturer

and operator introduce respective actions” in compliance with footnote N3 of NOTE

3 of the German version of IEC 61508-2:2010 7.4.9.5 b).This is the responsibility

of the operator who will have to take appropriate and suitable measures. Please

contact us if you need support in identifying suitable measures.

5.5. Decommissioning

When decommissioning an actuator with safety functions, the following must be

observed:

●

Impact of decommissioning on relevant de vices, equipment or other w ork must

be evaluated.

●

Safety and warning instructions contained in the actuator operation instructions

must be met.

●

Decommissioning must be carried out exclusively b y suitably qualified personnel.

●

Decommissioning must be recorded in compliance with regular requirements.

12

Page 13

Multi-turn actuators

SA .2 with AC(V) 01.2/AC(V)ExC 01.2 Tests and maintenance

6. Tests and maintenance

Test and maintenance tasks may only be performed by authorised personnel who

have been trained on functional safety.

Test and maintenance equipment has to be calibrated.

Information

Any test/maintenance must be recorded in a test/maintenance report.

Impact of testing/maintenance on relevant devices, equipment or other work must

be evaluated.

6.1. Safety equipment: check

All safety functions within a safety equipment m ust be checked f or perfect functionality

and safety at appropriate intervals.The intervals for saf ety equipment checks are to

be defined by the plant operator.

The plant operator has to establish a safety schedule for the entire safety lifecycle

of the SIS to avoid systematic faults. Policies and strategies for achieving safety as

well as different activities during the safety life cycle should be defined.

6.2. Proof test (verification of safe actuator function)

The proof test serves the purpose to verify the safety-related functions of the actuator

and actuator controls.

Proof tests shall reveal dangerous f aults which might remain undetected until a safety

function is started and consequently result in a potential danger.

For checking the safety-related function, the output of safe end position feedback is

appropriately checked.

Information All installed and used safety functions within the actuator must be checked and all

test steps performed in compliance with the pertaining checklists.

Intervals:

A proof test interval describes the time between two proof tests. Functionality must

be checked at appropriate intervals.The intervals are to be defined by the plant

operator.

In any case, the safety-related functions must be checked after commissioning and

following any maintenance w ork or repair as well as during the T

in safety assessment.

intervals defined

proof

6.2.1. Preliminary tests

The actuator system has to be subjected to a visual inspection first.The system

should be checked for outside damage and corrosion. Furthermore, the electrical

and mechanical connections should be checked and the actuator inspected for

unusual noises while operating the actuator at least a complete trav el from CLOSED

to OPEN and back.

6.2.2. Review and validation of the “Safe end position signal” safety function Test sequence (check-

list)

1. Operate actuator to end position OPEN – Is the end position OPEN signalled

via Safe end position signal?

2. Unseat actuator out of end position OPEN – Is the safe end position signal

OPEN cancelled?

3. Operate actuator again to end position OPEN – Is the end position OPEN signalled again via Safe end position signal?

4. Operate actuator to end position CLOSED – Is the end position CLOSED signalled via Safe end position signal?

5. Unseat actuator out of end position CLOSED – Is the safe end position signal

CLOSED cancelled?

6. Operate actuator again to end position CLOSED – Is the end position CLOSED

signalled again via Safe end position signal?

13

Page 14

Multi-turn actuators

Tests and maintenance SA .2 with AC(V) 01.2/AC(V)ExC 01.2

7. During the complete procedure, no fault signal at collective fault signal output

contact K1?

6.2.3. Checking the collective fault signal Configuration

Test procedure

Test sequence

This check is applicable for all safety functions.

Checking if collective fault signal correctly indicates the fault.

●

Separately check collective fault signal (K1) by simulating a fault.

- Does the output contact react to the simulated fault?

- Does the output contact react to the cancellation of the simulated fault?

●

Cancel the fault simulation after checking is complete.

6.3. Partial Valve Stroke Test (PVST)

— Option —

During the Partial Valve Stroke Test (PVST), the function of the valve is tested by

means of partial OPENING or CLOSING within a defined period of time without

interrupting the process. After successful testing, actuator controls operate the

actuator to its initial position.

PVST is used to test the function of actuator controls and actuators not operated on

a regular basis and can therefore not use reaction monitoring for diagnostics.

Diagnostic via PVST should be performed at least 10 times more often than the proof

test.

Monitoring and assessment of PVST must be ensured by the logic unit of the safety

instrumented system. For this, the collective fault signal must be assessed.

Safety function for safe end position feedback:

●

Actuator movement can be requested via any input.

●

Assessment whether the safety function signals as desired has to be performed

at the end position switches wired directly to the customer connection.

●

The actuator must be in one of the following positions:

- In one of both end positions prior to starting the test run.

The test run is performed out of the end position and back to this end position.

- At a sufficient distance from both end positions prior to starting the test

run.

The test run is performed into an end position and out of this end position.

In both cases, the travel distance must be sufficient to allow for full tripping of the

end position switch. It must be checked whether the end position switch signals the

expected position both at the beginning, during and at the end of the test.

●

Furthermore, test run monitoring must be dynamic.This means a dynamic test

whether the signal change corresponds to the expected value.

Information

If the PVST is only executed in one of both end positions , only the s witch of this end

position is tested for correct function. If both end position switches (OPEN/CLOSE)

are safety relevant, a full stroke test can be performed, for example.

6.4. Maintenance

14

Maintenance and service tasks may only be performed by authorised personnel who

have been trained on functional safety (refer to chapter 5).

Once maintenance and service tasks have been finished, the functional test must

be completed by a validating process of the safety function including at least the

tests described in the <Safety equipment: check> and <Proof test (verification of

safe actuator function)> chapters.

In case a fault is detected during maintenance, this must be reported to AUMA Riester

GmbH & Co. KG.

Page 15

Multi-turn actuators

SA .2 with AC(V) 01.2/AC(V)ExC 01.2 Safety-related figures

7. Safety-related figures

7.1. Determination of the safety-related figures

●

The calculation of the safety figures is based on the indicated safety functions .

Hardware assessments are based on Failure Modes, Effects and Diagnostic

Analysis (FMEDA). FMEDA is a step to assess functional device safety in

compliance with IEC 61508. On the basis of FMEDA, the failure rates and the

fraction of safe failures of a device are determined.

●

Experience data and data taken from the exida database for mechanical components is used to calculate mechanical failure rates.The electronic failure

rates as base failure rates are taken from the SIEMENS Standard SN 29500.

●

In compliance with table 2 of IEC 61508-1, the average target PFD value for

systems with low demand mode are:

-

SIL 1 safety functions:≥ 10-2 to < 10

-

SIL 2 safety functions:≥ 10-3 to < 10

-

SIL 3 safety functions:≥ 10-4 to < 10

Since actuators only represent a part of the overall safety function, the actuator

PFD value should not account for more than 25 % of the permissible total v alue

(PFD

-

●

Safe end position feedback via end position switches directly wired via the

) of a safety function.This results in the following values:

avg

Actuator PFD for SIL 1 applications:≲ 2.50E-02

customer input can be classified as type A components with hardware fault

tolerance of 0.The SFF for the type A subsystem should be <60 % according

to table 2 of IEC 61508-2 for SIL 1 (subsystems with a hardware f ault tolerance

of 0).The SFF for the type A subsystem should be between 60 % and <90 %

according to table 2 of IEC 61508-2 for SIL 2 (subsystems with a hardware f ault

tolerance of 0).

●

The calculation of the PFD values is based on the following assumptions:

- MRT = 72 hours

- Td = 730 hours = time interval PVST

- MTTR = MRT + Td = 802 hours.

-1

-2

-3

The PFD values specified in the declarations of incorporation and in this safety

manual are only examples and subject to certain assumptions e.g. on T

proof

, MTTR,

… The PFD calculation should always be performed individually for each system

using the parameters and conditions applicable for the respective system.The λ

DU

and λDD values should be used as input.When observing the proof test procedures

indicated in this safety manual, we recommend calculation using proof test cov erage

(PTC) of 90 %.5).

As previously mentioned in the architecture section, safeguarding po wer supply and

resulting calculations are the responsibility of the plant operator.

The plant operator is responsible for eliminating faults within the MTTR, otherwise

the data of the quantitative results is no longer valid.

The safety figures mentioned in this safety manual and in the declarations of

incorporation are only valid if all the conditions stipulated in this safety

manual and in the declarations of incorporation and the mentioned activities

are respected. At the same time, the restrictions regarding the validity and

standard conformity stipulated in the declarations of incorporation must be

heeded.

5) For the example calculations within this manual and the declarations of incorporation, different PTC

values were sometimes used as calculation basis.

15

Page 16

Multi-turn actuators

SIL Declaration of Conformity (example) SA .2 with AC(V) 01.2/AC(V)ExC 01.2

8. SIL Declaration of Conformity (example)

16

Page 17

Multi-turn actuators

SA .2 with AC(V) 01.2/AC(V)ExC 01.2 SIL Declaration of Conformity (example)

17

Page 18

Multi-turn actuators

SIL Declaration of Conformity (example) SA .2 with AC(V) 01.2/AC(V)ExC 01.2

18

Page 19

Multi-turn actuators

SA .2 with AC(V) 01.2/AC(V)ExC 01.2

19

Page 20

Multi-turn actuators

SA .2 with AC(V) 01.2/AC(V)ExC 01.2

20

Page 21

Multi-turn actuators

SA .2 with AC(V) 01.2/AC(V)ExC 01.2 Index

S

Index

A

Actuator sizing 7

Ambient conditions 9

Architecture 7

B

Brake 7

Safe failure fraction (SFF) 4

Safety function 4

Safety functions 10

Safety instrumented function

(SIF)

Safety instrumented system

(SIS)

Safety-related system 4

Self-locking 7

C

Commissioning 11

Configuration 7

Service conditions 9

Setting 7

SFF 4

SIL 4

D

Standards 6

DC 4

Declaration of Conformity 16

Decommissioning 12

Device types 6

T

Tests 13

T proof 4

Diagnostic coverage (DC) 4

F

Figures, safety-related 15

4

4

H

HFT 4

I

Installation 11

Interval for proof test 4

L

Lambda values 4

Lifetime 11

Low Demand Mode 15

M

Maintenance 14

Mean Time Between F ailures

(MTBF)

MRT (Mean Repair Time) 5

MTBF 4

MTTR (Mean Time To Restoration)

O

Operation 11

Operation mode 8

P

Partial Valve Stroke Test

14

(PVST)

PFD 4

PFD for actuator 15

Power supply 7

Probability of failure 4, 11

Proof test 5, 13, 13

4

5

R

Range of application 6

21

Page 22

AUMA worldwide

Europe

AUMA Riester GmbH & Co. KG

Location Muellheim

DE 79373 Muellheim

Tel +49 7631 809 - 0

info@auma.com

www.auma.com

Location Ostfildern-Nellingen

DE 73747 Ostfildern

Tel +49 711 34803 - 0

riester@auma.com

Service-Center Bayern

DE 85386 Eching

Tel +49 81 65 9017- 0

Service.SCB@auma.com

Service-Center Köln

DE 50858 Köln

Tel +49 2234 2037 - 900

Service@sck.auma.com

Service Center Magdeburg

DE 39167 Niederndodeleben

Tel +49 39204 759 - 0

Service@scm.auma.com

AUMA-Armaturenantriebe Ges.m.b.H.

AT 2512 Tribuswinkel

Tel +43 2252 82540

office@auma.at

www.auma.at

AUMA BENELUX B.V. B. A.

BE 8800 Roeselare

Tel +32 51 24 24 80

office@auma.be

www.auma.nl

ProStream Group Ltd.

BG 1632 Sofia

Tel +359 2 9179-337

valtchev@prostream.bg

www.prostream.bg

OOO “Dunkan-Privod”

BY 220004 Minsk

Tel +375 29 6945574

belarus@auma.ru

www.zatvor.by

AUMA (Schweiz) AG

CH 8965 Berikon

Tel +41 566 400945

RettichP.ch@auma.com

AUMA Servopohony spol. s.r.o.

CZ 250 01 Brandýs n.L.-St.Boleslav

Tel +420 326 396 993

auma-s@auma.cz

www.auma.cz

IBEROPLAN S.A.

ES 28027 Madrid

Tel +34 91 3717130

iberoplan@iberoplan.com

AUMA Finland Oy

FI 02230 Espoo

Tel +358 9 5840 22

auma@auma.fi

www.auma.fi

AUMA France S.A.R.L.

FR 95157 Taverny Cedex

Tel +33 1 39327272

info@auma.fr

www.auma.fr

AUMA ACTUATORS Ltd.

GB Clevedon, North Somerset BS21 6TH

Tel +44 1275 871141

mail@auma.co.uk

www.auma.co.uk

D. G. Bellos & Co. O.E.

GR 13673 Acharnai, Athens

Tel +30 210 2409485

info@dgbellos.gr

APIS CENTAR d. o. o.

HR 10437 Bestovje

Tel +385 1 6531 485

auma@apis-centar.com

www.apis-centar.com

Fabo Kereskedelmi és Szolgáltató Kft.

HU 8800 Nagykanizsa

Tel +36 93/324-666

auma@fabo.hu

www.fabo.hu

Falkinn HF

IS 108 Reykjavik

Tel +00354 540 7000

os@falkinn.is

www.falkinn.is

AUMA ITALIANA S.r.l. a socio unico

IT 20023 Cerro Maggiore (MI)

Tel +39 0331 51351

info@auma.it

www.auma.it

AUMA BENELUX B.V.

LU Leiden (NL)

Tel +31 71 581 40 40

office@auma.nl

NB Engineering Services

MT ZBR 08 Zabbar

Tel + 356 2169 2647

nikibel@onvol.net

AUMA BENELUX B.V.

NL 2314 XT Leiden

Tel +31 71 581 40 40

office@auma.nl

www.auma.nl

SIGUM A. S.

NO 1338 Sandvika

Tel +47 67572600

post@sifag.no

AUMA Polska Sp. z o.o.

PL 41-219 Sosnowiec

Tel +48 32 783 52 00

biuro@auma.com.pl

www.auma.com.pl

AUMA-LUSA Representative Office, Lda.

PT 2730-033 Barcarena

Tel +351 211 307 100

geral@aumalusa.pt

SAUTECH

RO 011783 Bucuresti

Tel +40 372 303982

office@sautech.ro

OOO PRIWODY AUMA

RU 141402 Khimki, Moscow region

Tel +7 495 221 64 28

aumarussia@auma.ru

www.auma.ru

OOO PRIWODY AUMA

RU 125362 Moscow

Tel +7 495 787 78 21

aumarussia@auma.ru

www.auma.ru

AUMA Scandinavia AB

SE 20039 Malmö

Tel +46 40 311550

info.scandinavia@auma.com

www.auma.se

ELSO-b, s.r.o.

SK 94901 Nitra

Tel +421 905/336-926

office@elsob.sk

www.elsob.sk

Auma Endüstri Kontrol Sistemleri Limited

Sirketi

TR 06810 Ankara

Tel +90 312 217 32 88

info@auma.com.tr

AUMA Technology Automations Ltd

UA 02099 Kiev

Tel +38 044 586-53-03

auma-tech@aumatech.com.ua

Africa

Solution Technique Contrôle Commande

DZ Bir Mourad Rais, Algiers

Tel +213 21 56 42 09/18

stcco@wissal.dz

A.T.E.C.

EG Cairo

Tel +20 2 23599680 - 23590861

contactus@atec-eg.com

SAMIREG

MA 203000 Casablanca

Tel +212 5 22 40 09 65

samireg@menara.ma

MANZ INCORPORATED LTD.

NG Port Harcourt

Tel +234-84-462741

mail@manzincorporated.com

www.manzincorporated.com

AUMA South Africa (Pty) Ltd.

ZA 1560 Springs

Tel +27 11 3632880

aumasa@mweb.co.za

22

Page 23

AUMA worldwide

America

AUMA Argentina Rep.Office

AR Buenos Aires

Tel +54 11 4737 9026

contacto@aumaargentina.com.ar

AUMA Automação do Brazil ltda.

BR Sao Paulo

Tel +55 11 4612-3477

contato@auma-br.com

TROY-ONTOR Inc.

CA L4N 8X1 Barrie, Ontario

Tel +1 705 721-8246

troy-ontor@troy-ontor.ca

AUMA Chile Representative Office

CL 7870163 Santiago

Tel +56 2 2821 4108

claudio.bizama@auma.com

B & C Biosciences Ltda.

CO Bogotá D.C.

Tel +57 1 349 0475

proyectos@bycenlinea.com

www.bycenlinea.com

AUMA Región Andina & Centroamérica

EC Quito

Tel +593 2 245 4614

auma@auma-ac.com

www.auma.com

Corsusa International S.A.C.

PE Miraflores - Lima

Tel +511444-1200 / 0044 / 2321

corsusa@corsusa.com

www.corsusa.com

Control Technologies Limited

TT Marabella,Trinidad,W.I.

Tel + 1 868 658 1744/5011

www.ctltech.com

AUMA Actuators (China) Co., Ltd.

CN 215499 Taicang

Tel +86 512 3302 6900

mailbox@auma-china.com

www.auma-china.com

PERFECT CONTROLS Ltd.

HK Tsuen Wan, Kowloon

Tel +852 2493 7726

joeip@perfectcontrols.com.hk

PT. Carakamas Inti Alam

ID 11460 Jakarta

Tel +62 215607952-55

auma-jkt@indo.net.id

AUMA INDIA PRIVATE LIMITED.

IN 560 058 Bangalore

Tel +91 80 2839 4656

info@auma.co.in

www.auma.co.in

ITG - Iranians Torque Generator

IR 13998-34411 Teheran

+982144545654

info@itg-co.ir

Trans-Jordan Electro Mechanical Supplies

JO 11133 Amman

Tel +962 - 6 - 5332020

Info@transjordan.net

AUMA JAPAN Co., Ltd.

JP 211-0016 Kawasaki-shi, Kanagawa

Tel +81-(0)44-863-8371

mailbox@auma.co.jp

www.auma.co.jp

DW Controls Co., Ltd.

KR 153-702 Gasan-dong, GeumChun-Gu,,

Seoul

Tel +82 2 2624 3400

import@actuatorbank.com

www.actuatorbank.com

FLOWTORK TECHNOLOGIES

CORPORATION

PH 1550 Mandaluyong City

Tel +63 2 532 4058

flowtork@pldtdsl.net

M & C Group of Companies

PK 54000 Cavalry Ground, Lahore Cantt

Tel +92 42 3665 0542, +92 42 3668 0118

sales@mcss.com.pk

www.mcss.com.pk

Petrogulf W.L.L

QA Doha

Tel +974 44350151

pgulf@qatar.net.qa

AUMA Saudi Arabia Support Office

SA 31952 Al Khobar

Tel + 966 5 5359 6025

Vinod.Fernandes@auma.com

AUMA ACTUATORS (Singapore) Pte Ltd.

SG 569551 Singapore

Tel +65 6 4818750

sales@auma.com.sg

www.auma.com.sg

NETWORK ENGINEERING

SY Homs

+963 31 231 571

eyad3@scs-net.org

Sunny Valves and Intertrade Corp. Ltd.

TH 10120 Yannawa, Bangkok

Tel +66 2 2400656

mainbox@sunnyvalves.co.th

www.sunnyvalves.co.th

Top Advance Enterprises Ltd.

TW Jhonghe City,Taipei Hsien (235)

Tel +886 2 2225 1718

support@auma-taiwan.com.tw

www.auma-taiwan.com.tw

AUMA ACTUATORS INC.

US PA 15317 Canonsburg

Tel +1 724-743-2862

mailbox@auma-usa.com

www.auma-usa.com

Suplibarca

VE Maracaibo, Estado, Zulia

Tel +58 261 7 555 667

suplibarca@intercable.net.ve

Asia

AUMA Actuators UAE Support Office

AE 287 Abu Dhabi

Tel +971 26338688

Nagaraj.Shetty@auma.com

AUMA Actuators Middle East

BH 152 68 Salmabad

Tel +97 3 17896585

salesme@auma.com

Mikuni (B) Sdn. Bhd.

BN KA1189 Kuala Belait

Tel + 673 3331269 / 3331272

mikuni@brunet.bn

Al-Arfaj Engineering Co WLL

KW 22004 Salmiyah

Tel +965-24817448

info@arfajengg.com

www.arfajengg.com

TOO “Armaturny Center”

KZ 060005 Atyrau

Tel +7 7122 454 602

armacentre@bk.ru

Network Engineering

LB 4501 7401 JBEIL, Beirut

Tel +961 9 944080

nabil.ibrahim@networkenglb.com

www.networkenglb.com

AUMA Malaysia Office

MY 70300 Seremban, Negeri Sembilan

Tel +606 633 1988

sales@auma.com.my

Mustafa Sultan Science & Industry Co LLC

OM Ruwi

Tel +968 24 636036

r-negi@mustafasultan.com

AUMA Vietnam Hanoi RO

VN Hanoi

+84 4 37822115

chiennguyen@auma.com.vn

Australia

BARRON GJM Pty. Ltd.

AU NSW 1570 Artarmon

Tel +61 2 8437 4300

info@barron.com.au

www.barron.com.au

23

Page 24

AUMA Riester GmbH & Co. KG

P.O. Box 1362

DE 79373 Muellheim

Tel +49 7631 809 - 0

Fax +49 7631 809 - 1250

info@auma.com

www.auma.com

For detailed information on AUMA products, refer to the Internet: www.auma.com

Y006.646/003/en/2.19

Loading...

Loading...