Page 1

DIGITAL AUDIO/COMPACT DISC CHANGER

SP-11CDS

10 DISC AUTO CHANGER

COMPACT DISC AUDIO CHANGER SYSTEM

MODEL SP-11CDS

10-DISC CD CHANGER

INSTALLATION MANUAL

Page 2

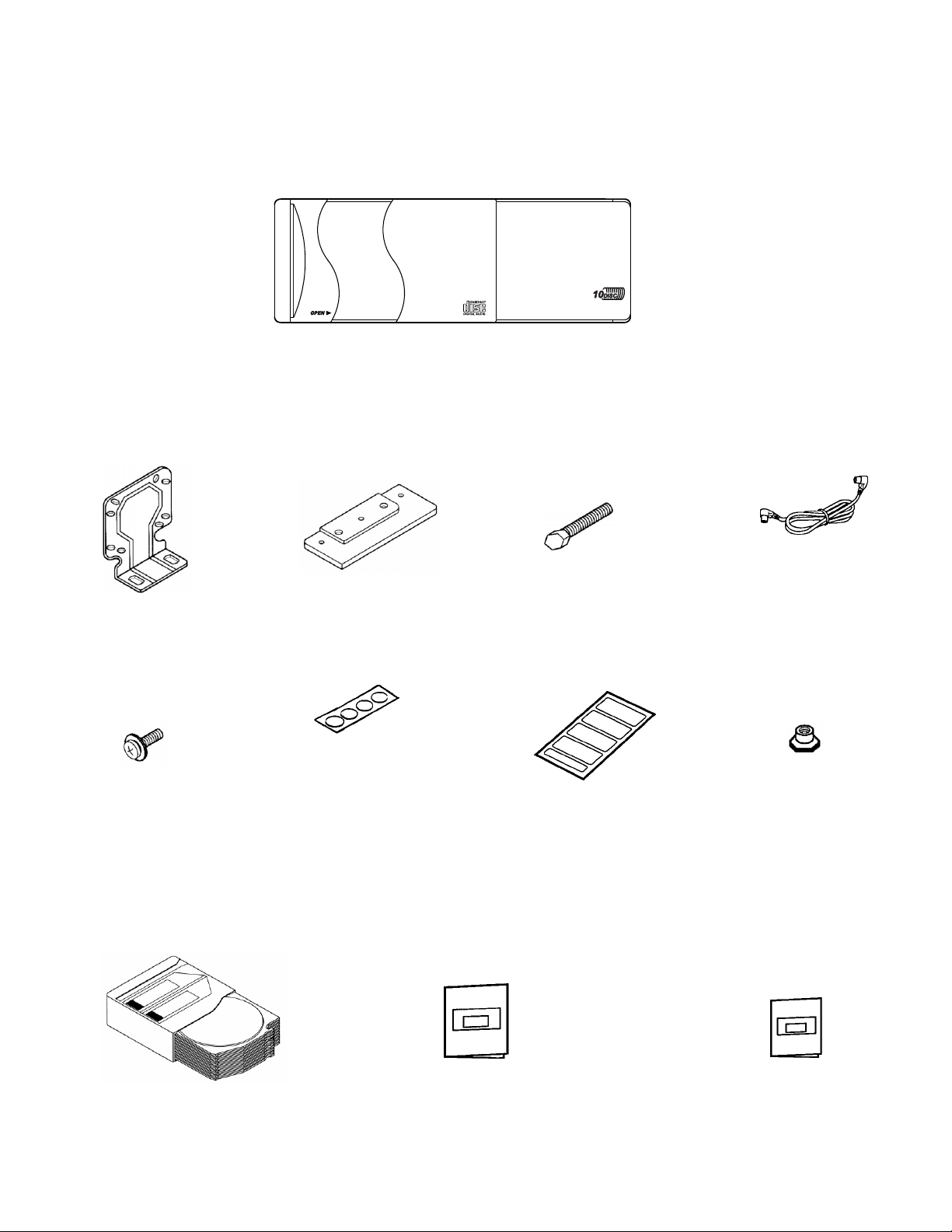

PACKING LIST

MAIN UNIT

Changer

INST ALLATION P ARTS

Bracket

2 pcs

Stud Bracket

2 pcs

DIGITAL AUDIO/COMPACT DISC CHANGER

SP-11CDS

10 DISC AUTO CHANGER

COMPACT DISC AUDIO CHANGER SYSTEM

Hexagonal Bolt

(M6 x 15)

4 pcs.

5 Meter Din Cable

1 pc.

Machine Screw

(M4x 10)

4 pcs.

Screw Hole Cover Labels

OTHER ACCESSORIES

CD Magazine (P/N SP11M)

1 pc.

1 pc.

Installation Manual

1 pc.

Index seal sheet

1 pc.

Hexagonal Nut

(M6)

4 pcs.

Owner's Manual

1 pc.

2

Page 3

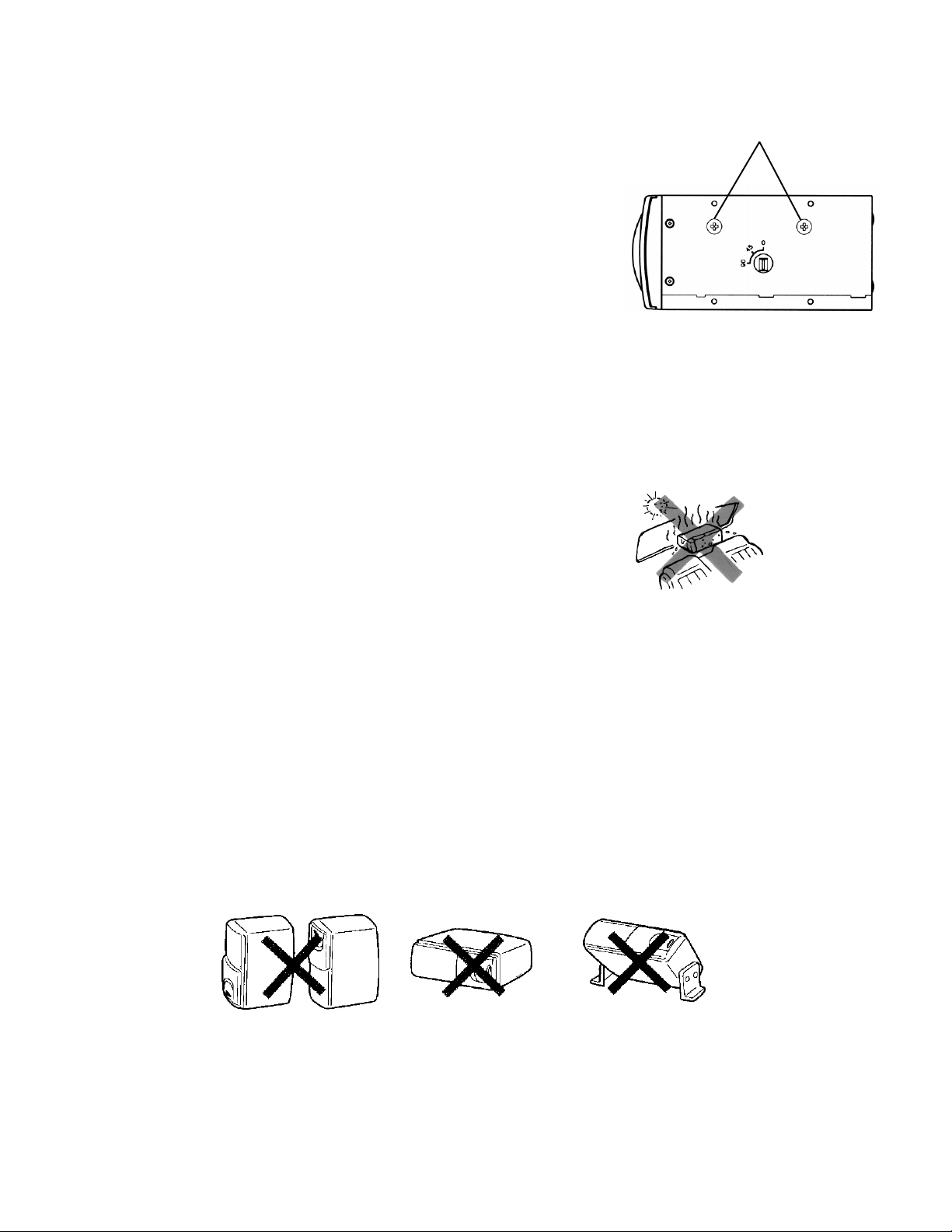

BEFORE INSTALLING THE UNIT

Transport Lock Screws

The mechanism in the CD changer is "locked" into place during shipment by the

transport screws. Be sure to remove the screws prior to installation.

l Caution l

After removing the transport lock screws, place a piece of masking tape over

each screw hole. The tape will keep out dust , which could cause the unit

to malfunction.

TRANSIT BOL TS

(2 RIGHT SIDE, 1 LEFT SIDE)

Installation and Wiring Precautions

To prevent a short-circuit,

1

l Be sure to turn off the ignition and remove the negative (-) battery cable, prior to installation.

l Connect power wires last.

Note

If the changer is to be installed in a car that is equipped with an on-board drive or navigation computer, do not disconnect

the battery cable. If the cable is disconnected, the computer memory may be lost. Under these conditions, use extra

caution during installation, to prevent a short circuit.

Do not install the unit in the following locations.

2

l Locations exposed to direct sunlight.

l Where hot air is discharged from the car heater.

l In areas subject to extreme temperatures.

Incorrect installation can cause the sound to "skip" when playing a disc.

3

Mount the unit firmly in place, using the supplied brackets and screws.

Be careful not to damage the car wiring.

4

l Be sure to use the supplied screws.

5

l Be careful not to snag any wires when tightening screws.

l Do not use any of the screws that are part of the brake or steering system, to install the unit.

l This unit cannot be installed on either side or up-side down. Installation in such positions will cause the mechanism

6

to malfunction.

3

Page 4

INSTALLATION

The unit can be installed horizontally, vertically or at a 45° angle. The position of the built-in anti-vibration springs (left and right side), must

correspond to the mounting position chosen. If the springs are not set correctly for the type of installation chosen, the anti-vibration

compensation will not be effective and vibration may cause the disc to skip.

CAUTION

After setting the built-in anti-vibration springs, place masking tape over the holes. The tape will keep out dust, which could cause the

unit to malfunction.

HORIZONTAL INSTALLATION

Set the 2 anti-vibration springs to

position "0".

ANTI-VIBRA TION SPRINGS POSITION

VERTICAL INSTALLAITON

Set the 2 anti-vibration springs to

position "90".

45° ANGLE INSTALLATION

Set the 2 anti-vibration springs to

position "45°".

PROCEDURE FOR HORIZONTAL INSTALLATION W/O STUDS

1

Attach a bracket to each side of the unit, using the machine

screws with integral flat and lock washers (M4 x 10).

In the horizontal position, use bracket mounting holes 1 and

1' as shown at the right.

Set anti-vibration springs to position "0" as shown above.

NOTE: Use masking tape to cover un-

used mounting holes on sides of

unit.

2

Determine unit mounting location, and drill four mounting

holes.

Never mount the unit near the fuel tank.

3

Secure the unit in place, using four self-tapping screws

(M5 x 12).

Use RTV (silicone sealer) on screw threads and around

the holes to prevent moisture intrusion.

1

2

3

BRACKET

(Left Side)

1

2

3

MACHINE SCREW WITH FLAT

AND LOCK WASHERS (M4 x 10)

DRILL HOLES 4MM IN DIAMETER

SELF-TAPPING SCREWS

(M5 x 12)

BRACKET

(Right Side)

4

Page 5

PROCEDURE FOR VERTICAL INSTALLATION W/O STUDS

Note

If the anti-vibration spring position has been changed and verified for vertical mounting (as shown on page 4), start with step 2.

Attach bracket to each side of the unit, using machine

1

Set the 2 anti-vibration springs to position "90".

2

screws with integral flat and lock washers. (M4 x 10).

In the vertical position, use holes 2 and 2' as shown

at left.

NOTE: Use masking tape to cover unused

mounting holes on sides of unit.

BRACKET

(Left Side)

Determine the mounting location, and drill four mounting

3

holes.

Never mount the unit near the fuel tank.

MACHINE SCREWS

w/WASHERS (M4x10)

Mount the unit in place, using four self-tapping screws

4

(M5 x 12).

Use RTV (silicone sealer) on screw threads and around

the holes to prevent moisture intrusion.

BRACKET

(Left Side)

SELF-TAPPING

SCREWS (M5 x 12)

BRACKET

(Right Side)

DRILL HOLES 4MM IN DIAMETER

BRACKET

(Right Side)

5

Page 6

PROCEDURE FOR 45° ANGLE INSTALLATION W/O STUDS

Note

If the anti-vibration spring position has been changed and verified for 45° angle mounting (as shown on page 4), start with step 2.

Set the 2 anti-vibration springs to position "45°".

1

Attach bracket to each side of the unit, using the machine

2

screws with flat and lock washers (M4x 10).

In the 45 position, use holes 1 and 3' as shown at left.

NOTE: Use masking tape to cover unused

mounting holes on sides of unit.

BRACKET

(Left Side)

MACHINE SCREW WITH FLAT

AND LOCK WASHERS (M4 x 10)

BRACKET

(Right Side)

Determine the mounting location, and drill four mounting

3

holes.

Never mount the unit near the fuel tank.

DRILL HOLES 4MM IN DIAMETER

Mount the unit in place, using four self-tapping screws

4

(M5 x 12).

Use RTV (silicone sealer) on screw threads and around

the holes to prevent moisture intrusion.

SELF-TAPPING SCREWS

(M5 x 12)

BRACKET

(Left Side)

BRACKET

(Right Side)

6

Page 7

PROCEDURE FOR CHANGER INST ALLATION USING MOUNTING

STUDS

Note:

Make sure the anti-vibration spring position has been changed and verified for the proper angle mounting (as shown on page 4).

1 Determine mounting location. If unit is to be installed onto mounting studs located under carpet, lift carpet to expose metal chassis

and mark position of each stud as shown below in detail A and B.

2 Insert two hexagonal mounting bolts through underside of each bracket (detail A) and mount stud bracket in position using two

self-tapping screws into metal chassis. Hex bolt heads should be flush with underside of stud bracket.

3 Replace carpet over bracket studs (detail B), mark position of stud end of each bolt, and cut holes in carpet so bolts protrude through

carpet.

4 Proceed with unit mounting by positioning unit mounting brackets over protruding hex bolts as shown in details C, D and E. Secure

mounting brackets to bolts using hex lock nuts.

5 If mounting studs are to be located directly on mounting surface with no carpet in between, mount changer directly on studs as

illustrated below in details A, C, D and E.

STUD BRACKET MOUNTING

ARRANGEMENT

(Detail A)

SELF-TAPPING SCREWS

(M5 x 12)

HEX BOLT (M6 x 15)

VERTICAL INSTALLATION

WITH STUD BRACKET

(Detail C)

STUD BRACKET

HEX NUT (M6)

SUSPENDED INSTALLATION

WITH STUD BRACKET

(Detail D)

STUD BRACKET

STUD BRACKET MOUNTING

UNDER A CARPET

(Detail B)

CARPET

STUD BRACKET

CHASSIS

HORIZONT AL INST ALLA TION

WITH STUD BRACKET

(Detail E)

HEX NUT (M6)

STUD BRACKET

CHANGER MOUNTING

BRACKET

CHANGER MOUNTING

BRACKET

HEX NUT (M6)

CHANGER MOUNTING

BRACKET

STUD BRACKET

7

Page 8

VEHICLE WIRING

Mating 8-pin DIN socket on rear of

compatible radio chassis (see note 1 below).

Car Stereo with

CD Changer Controls

DIN cable (8-pin)

NOTE: 1. Check with your Audiovox car audio dealer to be

sure your stereo is directly compatible with this

CD changer.

2. Wiring instructions for use with FM Modulator/

Commander Systems are included with the

CDC-MC1, CDC-MCR2, P-MC3 and P-MCR4

accessories.

CD changer

© 2000 AUDIOVOX CORP., HAUPPAUGE, NY Printed in China

128-5777A

Loading...

Loading...