Page 1

Hardware Installation Manual

AudioCodes MediaPack Analog Gateway Series

MP-1288

High-Density Analog Media Gateway

Version x.y

Page 2

Notice

MP-1288 | Hardware Installation Manual

Notice

Information contained in this document is believed to be accurate and reliable at the time

of printing. However, due to ongoing product improvements and revisions, AudioCodes

cannot guarantee accuracy of printed material after the Date Published nor can it accept

responsibility for errors or omissions. Updates to this document can be downloaded from

https://www.audiocodes.com/library/technical-documents.

This document is subject to change without notice.

Date Published: July-14-2020

WEEE EU Directive

Pursuant to the WEEE EU Directive, electronic and electrical waste must not be disposed of

with unsorted waste. Please contact your local recycling authority for disposal of this product.

Customer Support

Customer technical support and services are provided by AudioCodes or by an authorized

AudioCodes Service Partner. For more information on how to buy technical support for

AudioCodes products and for contact information, please visit our website at

https://www.audiocodes.com/services-support/maintenance-and-support.

Documentation Feedback

AudioCodes continually strives to produce high quality documentation. If you have any

comments (suggestions or errors) regarding this document, please fill out the Documentation

Feedback form on our website at https://online.audiocodes.com/documentation-feedback.

Stay in the Loop with AudioCodes

Notes and Warnings

Read and adhere to all warning statements in this document before installing the

device.

This device is considered as IPX0 non-water ingress protected and therefore, must be

installed only indoors.

- ii -

Page 3

Notice

MP-1288 | Hardware Installation Manual

The Ethernet port interface cabling must be shielded and routed only indoors.

The device must be connected to a grounded power outlet.

Routing of FXS telephony cables: Routing FXS telephony cables outdoors can be done

only in conjunction with a three-electrode Gas Discharge Tube (GDT) rated at 350V

located at the entry point of the two-wire into the building, and properly grounded. When

done correctly, the installation will meet ITU-T K.21 requirements.

Caution Electrical Shock: Do not open or disassemble this device. The device

carries high voltage and contact with internal components may expose you to electrical

shock and bodily harm.

The device must be installed and serviced only by qualified service personnel.

The device must be installed only in restricted access locations that are compliant with

ETS 300 253 guidelines where equipotential bonding has been implemented.

Disconnect the device from the mains and Telephone Network Voltage (TNV) before

servicing.

For AC powered models, use only the AC power cord that is supplied with the device to

connect to the power source.

Related Documentation

Document Name

SBC-Gateway Series Release Notes for Latest Release Versions

SBC-Gateway Series Release Notes for Long Term Support Versions

MP-1288 Media Gateway User's Manual

- iii -

Page 4

Notice

MP-1288 | Hardware Installation Manual

Document Revision Record

LTRT Description

28020 Initial document release.

28021 Cable anchor clip for power cord; adding FXS blade procedure (removing

connector covers).

28022 Physical dimensions updated; warning bulletin for 19-inch rack cabinet.

28023 AC power cable warning (Japanese).

28024 REN 3 update.

28025 Lifeline activation only upon power outage; FXS off-hook current.

28026 Fan tray section and air filter replacement section updated.

28027 Off-hook loop current and ring voltage updated regarding ports.

28028 Power surge warning updated.

28029 Air filter replacement statement.

28030 Logo updated.

28031 DC power supply added; package items updated; airflow illustration added.

28032 Note removed from environmental specifications.

28033 Off-hook loop current updated.

28034 Duration of press for reset to defaults; trademarks.

28035 Power Supply module hardware revisions note bulletin.

- iv -

Page 5

Content

MP-1288 | Hardware Installation Manual

Table of Contents

1 Introduction 1

2 Unpacking the Device 2

3 Physical Description 3

Physical Dimensions and Operating Environment 3

Front Panel Description 3

LED Descriptions 4

SYS LED 4

TEL LED 4

PWR LED 5

FAN LED 5

Fan Tray 6

Rear Panel Description 7

CPU Module 8

FXS Blades 9

Power Supply Module 12

AC Power Supply Module 12

DC Power Supply Module 13

LED Descriptions 14

Ethernet LEDs 14

STAT LED 14

FXS LEDs 14

Power Supply LED 16

4 19-Inch Rack Mounting 17

5 Cabling the Device 19

Grounding and Surge Protection 19

Connecting Ethernet Interfaces 21

Connecting FXS Interfaces 22

Connecting FXS Interfaces using AudioCodes FXS Patch Panel 24

Connecting FXS Interfaces using Centronics Cable 28

Connecting FXS Interfaces Directly to an MDF 29

Connecting the FXS Analog Lifeline 30

Connecting the Serial Interface to a Computer 32

Connecting to Power 34

AC Power Supply 34

DC Power Supply 36

6 Hardware Maintenance 39

Preventing Electrostatic Discharge Damage 39

Replacing the Fan Tray Module 39

Replacing the Air Filter 41

Replacing FXS Blades 43

- v -

Page 6

Content

MP-1288 | Hardware Installation Manual

Adding an FXS Blade 46

Replacing the CPU Module 49

50

Replacing Power Supply Modules 51

- vi -

Page 7

CHAPTER1 Introduction

1 Introduction

This document provides a hardware description of AudioCodes MP- 1288 Analog Media

Gateway (hereafter referred to as device) and step-by-step procedures for mounting and

cabling the device.

The device supports the following:

■ Up to 288 FXS ports, 72 FXS ports per FXS blade (can house up to four FXS blades)

■ Two 100/1000 Base-T Gigabit Ethernet ports

■ Fan Tray module

■ 1+1 AC or DC Power Supply modules

Hardware configurations may change without notice. Currently available hardware

configurations are listed in AudioCodes Price Book. For available hardware

configurations, contact your AudioCodes sales representative.

MP-1288 | Hardware Installation Manual

- 1 -

Page 8

CHAPTER2 Unpacking the Device

2 Unpacking the Device

Follow the procedure below for unpacking the carton in which the device is shipped.

➢ To unpack the device:

1. Open the carton and remove packing materials.

2. Remove the chassis from the carton.

3. Check that there is no equipment damage.

4. Ensure that in addition to the chassis, the package contains the following items:

● 2 x front-mounting brackets for 19-inch rack mounting

● 1 x RJ-45 to DB-9 serial cable adapter for serial communication

● For AC-powered models: 2 x AC power cords

MP-1288 | Hardware Installation Manual

● For DC-powered models: 2 x DC terminal blocks

● 1 x grounding lug

5. Check, retain and process any documents.

If there are any damaged or missing items, notify your AudioCodes sales representative.

- 2 -

Page 9

CHAPTER3 Physical Description

3 Physical Description

This section provides a physical description of the device.

Physical Dimensions and Operating Environment

The device's physical dimensions and operating environment are listed in the following table:

Table 3-1: Physical Dimensions and Operating Environment

MP-1288 | Hardware Installation Manual

Physical

Specification

Dimensions (H x W xD)3U high, 19-inch rack wide

132.5 x 438 x 482.5 mm (5.22 x 17.24 x 19 inches)

Weight 21 kg (46.3 lbs.) for fully-populated chassis

Environmental

■ Operational: 0 to 40°C (41 to 104°F)

■ Storage: -40 to 70°C (-40 to 158°F)

■ Humidity: 5 to 90% non-condensing

■ Over-voltage protection and surge immunity: ITU-T K.21 (basic)

compliant

Description

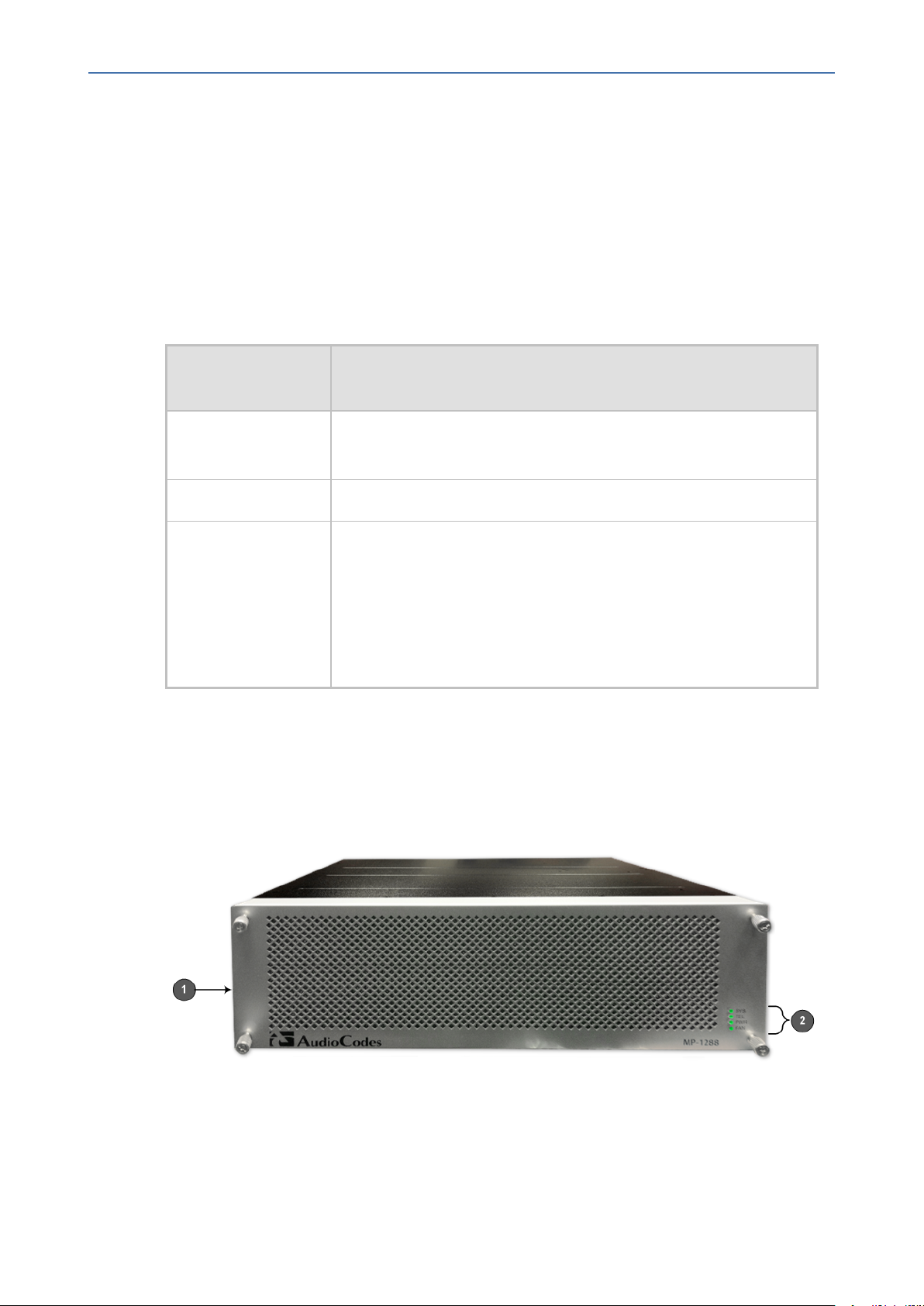

Front Panel Description

The device's front panel is shown in the following figure and described in the subsequent table.

Figure 3-1: Front Panel

- 3 -

Page 10

CHAPTER3 Physical Description

MP-1288 | Hardware Installation Manual

Table 3-2: Front Panel Description

Item

#

1 -

Label Description

Fan Tray cover. For more information, see Fan Tray on

page6.

2 SYS / TEL / PWR /

FAN

Front-panel LEDs. For more information, see LED

Descriptions below.

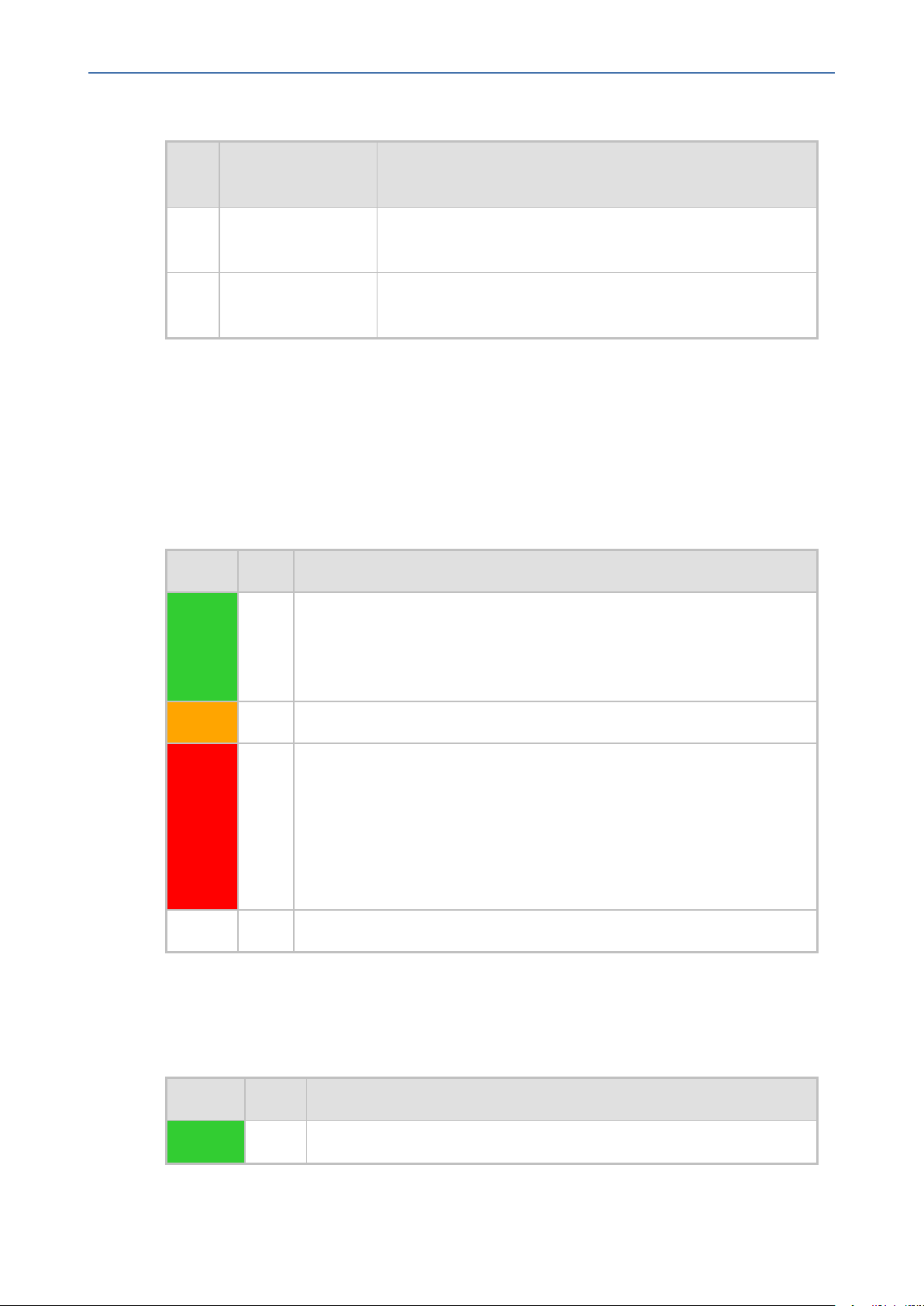

LED Descriptions

This section describes the LEDs on the front panel of the chassis.

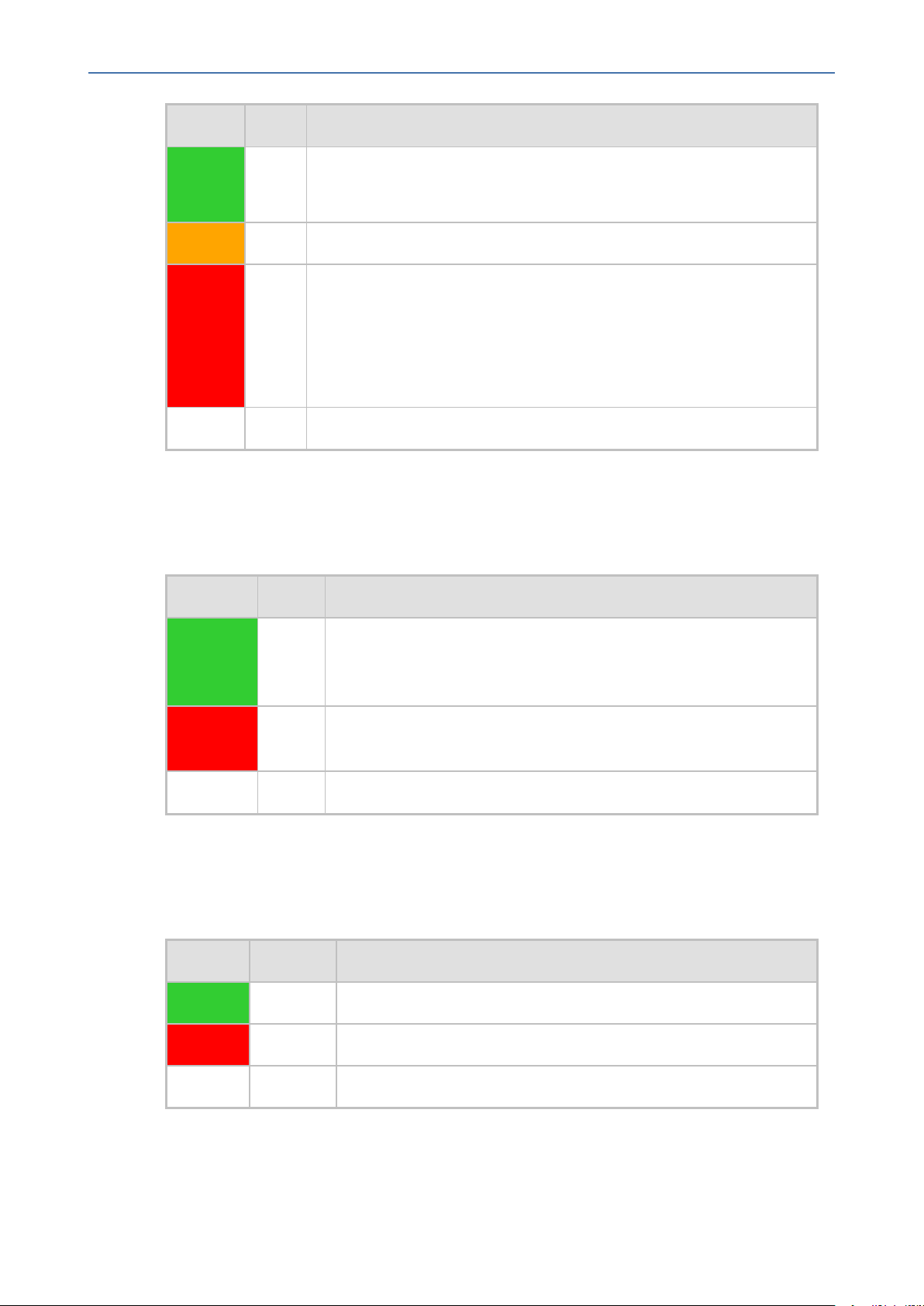

SYS LED

The SYS LED indicates the device's operating status, as described in the following table.

Table 3-3: SYS LED Description

Color State Description

Green On LED lit as a result of one of the following:

■ Device is operating normally

■ During first stage of boot up when device is powered on

Orange On Chassis is approaching high temperature threshold, but not yet critical

Red On LED lit as a result of one of the following:

■ Fault detected in CPU module

■ Incompatible or faulty software version (.cmp file) detected during

boot up

■ Approaching critical high temperature threshold

Off No power

TEL LED

The TEL LED indicates the status of the FXS blades, as described in the following table.

Table 3-4: TEL LED Description

Color State Description

Green On LED lit as a result of one of the following:

- 4 -

Page 11

CHAPTER3 Physical Description

Color State Description

Orange On At least one DSP hasreached the high temperature threshold.

Red On LED lit as a result of one of the following:

MP-1288 | Hardware Installation Manual

■ During booting up phase

■ During normal operation, indicating normal FXS blade operation

■ During initial phase of power-up

■ Failure detected in at least one FXS blade

■ No FXS blades detected in the chassis

-

Off

No power.

PWR LED

The PWR LED indicates the power status, as described in the following table.

Table 3-5: PWR LED Description

Color State Description

Green On Chassis receiving power and Power Supply modules are functioning

normally. If the device is configured to use only one Power Supply

module, the LED is lit if at least one of them is operating normally.

Red On One of the Power Supply modules is faulty (if device is configured to

use two Power Supply modules).

-

Off No power received by the device.

FAN LED

The FAN LED indicates the status of the Fan Tray module, as described in the following table.

Table 3-6: FAN LED Description

Color State Description

Green On

Red On

- Off

Fans are functioning normally.

At least one fan in the Fan Tray module is faulty.

No power.

- 5 -

Page 12

CHAPTER3 Physical Description

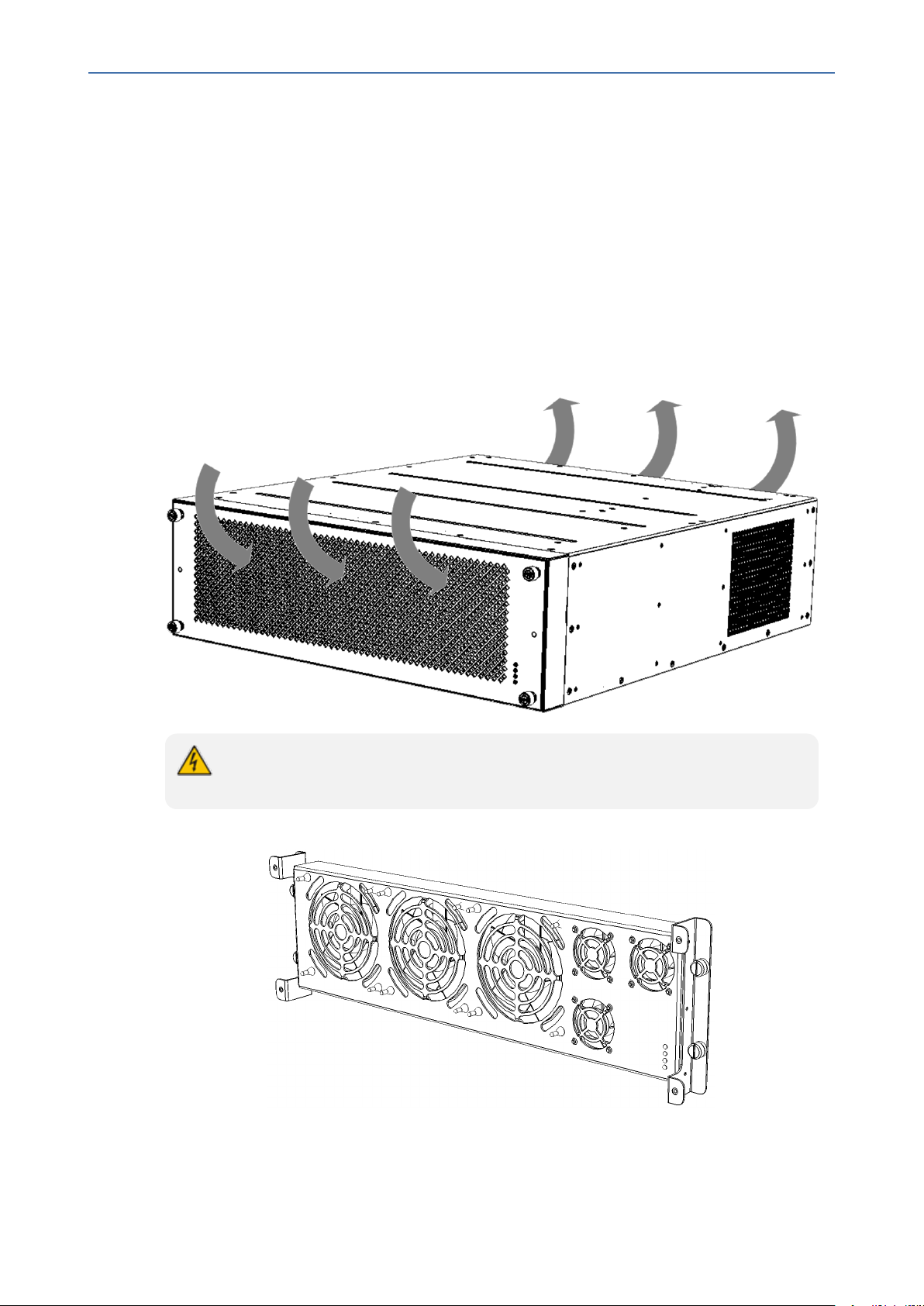

Fan Tray

The device provides a Fan Tray module, located on the front panel, which is concealed by a fan

tray cover. The Fan Tray module contains six individual fans which cool the device's internal

components to maintain an acceptable operating temperature inside the chassis.

The Fan Tray module draws air in from the outside through the perforated fan tray cover on

the front panel (see following figure). A replaceable air filter, located inside the fan tray cover,

removes dust particles from the sucked in air. The incoming air passes through the chassis,

cooling the internal components and then exits the chassis through the vents on the rear

panel (see following figure).

MP-1288 | Hardware Installation Manual

Figure 3-2: Airflow Directions through Chassis

When installing the chassis, make sure there is sufficient front- and rear-side clearance

for proper airflow into and out of the chassis.

Figure 3-3: Fan Tray Module

- 6 -

Page 13

CHAPTER3 Physical Description

The Fan Tray provides a LED indicating the operating status of the Fan Tray module. For more

information, see FAN LED on page5.

During system operation, the inner ambient temperature is continuously monitored. Upon

excessive temperature conditions, an SNMP Temperature Alarm is generated

(acBoardTemperatureAlarm). Upon a speed degradation or full stop of any fan, an SNMP Fan

Alarm (acFanTrayAlarm) is generated.

MP-1288 | Hardware Installation Manual

Figure 3-4: Fan Tray Cover

The Fan Tray module is hot-swappable, allowing you to replace it even when the device is

powered on. The Fan Tray module, fan tray cover, and air filter are available as fieldreplaceable units (FRU). For replacing the Fan Tray module, see Replacing the Fan Tray Module

on page39. For replacing the air filter, see Replacing the Air Filter on page41.

For replacing the Fan Tray module or any of its components, perform only the

instructions as described in Replacing the Fan Tray Module on page39.

Rear Panel Description

The device's rear panel is shown in the following figure and described in the subsequent table.

Figure 3-5: Rear Panel Description

The figure above is used only as an example. The number of installed FXS blades, and number

and type of Power Supply modules (AC or DC) depend on your ordered hardware

configuration.

- 7 -

Page 14

CHAPTER3 Physical Description

Item # Label Description

1 CPU CPU module providing the central processing unit and

MP-1288 | Hardware Installation Manual

Table 3-7: Rear Panel Description

various network port interfaces. For more information,

see CPU Module below.

2 PS1 / PS2

Power Supply modules. For more information, see Power

Supply Module on page12.

3 Blades: S1 / S2 /

S3 / S4

FXS blades providing FXS port interfaces. For more

information, see FXS Blades on the next page.

FXS Ports:FXS 1-

24 / FXS 25-48 /

FXS 49-72

4 Protective grounding for connecting a grounding lug for

chassis ground connection for ESD-preventive equipment

or a grounding wire.

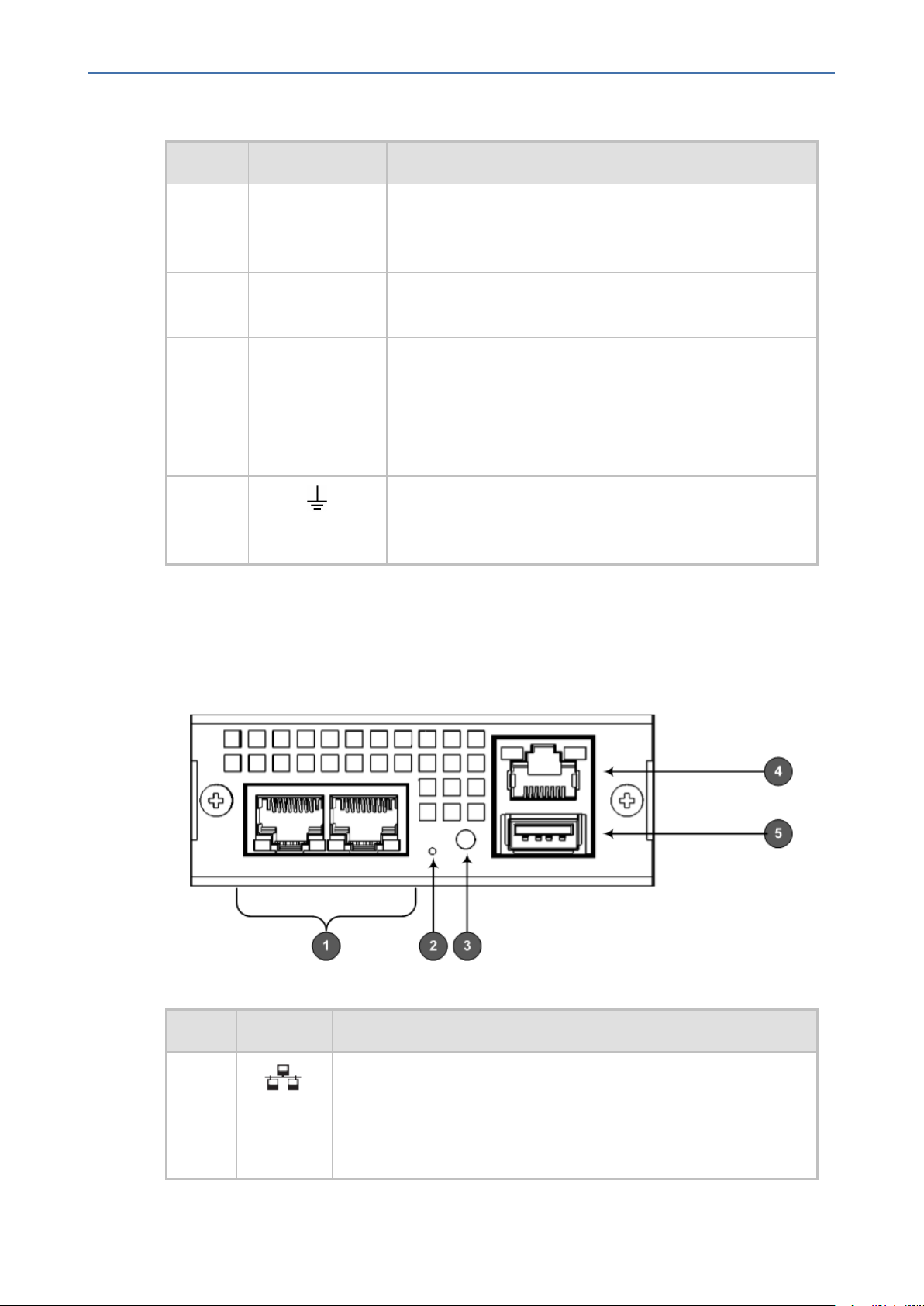

CPU Module

The CPU module provides the central processing unit and port interfaces, as shown in the

following figure and described in the subsequent table.

Figure 3-6: CPU Module

Table 3-8: CPU Module Description

Item # Label Description

1 Two 100/1000Base-T (Gigabit) Ethernet ports (RJ-45) for connecting

to the IP network.

The ports support the following features:

■ 1+1 Ethernet port redundancy

- 8 -

Page 15

CHAPTER3 Physical Description

Item # Label Description

MP-1288 | Hardware Installation Manual

■ Half- and full-duplex modes

■ Auto-negotiation

■ Straight or crossover cable detection

The ports provide LEDs to indicate Ethernet status. For more

information, see Ethernet LEDs on page14.

2

Reset pinhole button for resetting the device and restoring

factory defaults:

■ To reset the device: Using a paper clip or any other similar

pointed object, press and hold down the button for at least 2

seconds (but no more than 10 seconds).

■ To restore the device to factory defaults: Using a paper clip or

any other similar pointed object, press and hold down the

button for at least 15 seconds (but no more than 30 seconds).

3 STAT LED indicating the status of the CPU module. For more

information, see STAT LED on page14.

4 |O|O| RJ-45 port for RS-232 serial communication.

5 USB Type-A port which can be used, for example, for various

storage capabilities to an external USB hard drive or flash disk (disk

on key).

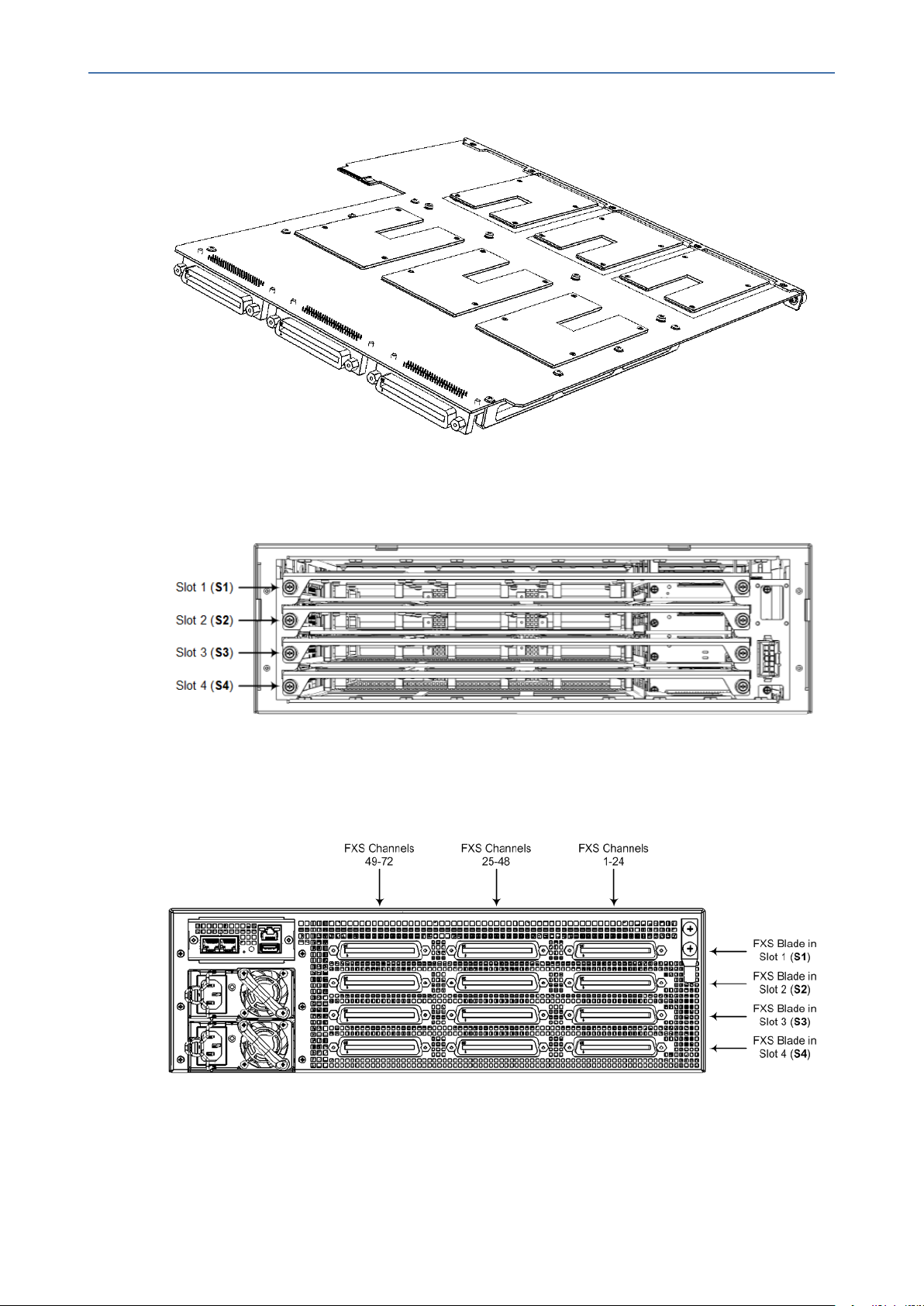

FXS Blades

The FXS blade (referred to as Module in the device's management interfaces) provides the FXS

port interfaces. Each blade provides three FXS port connectors - 50-pin Telco connector

(Centronics type). Each connector provides 24 FXS interfaces and therefore, each blade

provides up to 72 FXS interfaces (3 x 24 FXS). The device can be housed with up to four FXS

blades thereby, supporting up to 288 FXS port interfaces (4 blades x 72 FXS). The FXS blades are

available as spare parts. For replacing FXS blades, see Replacing the Fan Tray Module on

page39.

Each FXS blade provides a LED on the front and rear panel, as described in FXS LEDs on

page14.

- 9 -

Page 16

CHAPTER3 Physical Description

Figure 3-7: FXS Blade Showing Three FXS Telco Connectors

The chassis slot assignment for the FXS blades is shown in the following figure (front panel).

Note that the slot labels (S1, S2, S3 and S4) are located on the rear panel.

MP-1288 | Hardware Installation Manual

Figure 3-8: Chassis Slot Assignment for FXS Blades (Front Panel)

The FXS channel (port) number range of each FXS connector on an FXS blade is indicated by

the labels (FXS 1-24, FXS 25-48, and FXS 49-72) located on the rear panel above the FXS blades,

as shown in the following figure:

Figure 3-9: FXS Blades and FXS Channels per FXS Connector (Rear Panel)

The following table lists the specifications of the device's FXS ports.

- 10 -

Page 17

CHAPTER3 Physical Description

Specification Description

MP-1288 | Hardware Installation Manual

Table 3-9: FXS Port Specifications

Analog

Lifeline

(PSTN

Fallback)

Interface

Type

FXS

Signaling

Formats

FXS Loop

Impedance

Off-hook

Loop

Current

The FXS blade supports analog lifeline (PSTN Fallback). For more

information, see Connecting the FXS Analog Lifeline on page30.

FXS connection via 50-pin CHAMP connector

In-band signaling DTMF (TIA 464B)

Up to 1500 ohm (including phone impedance)

■ 25 mA (maximum) on all ports

■ 35 mA (maximum) on the first (1) and last (24) ports per FXS connector.

In other words, it applies to up to six ports per FXS Blade. This applies

to emergency / elevator phones.

Ring Voltage

(Sine)

■ 54 Vrms

■ 80 Vrms on six ports per FXS Blade (for emergency / elevator phones)

Note:

■ Balanced ringing only.

■ Simultaneous ringing of 288 phones (72 per FXS Blade given REN 3

load)

Ring

25-100 Hz

Frequency

Maximum

Ringer Equivalency Number (REN) 3

Ringer Load

Caller ID Bellcore GR-30-CORE Type 1 using Bell 202 FSK modulation, ETSI Type 1,

NTT, Denmark, India, Brazil, British and DTMF ETSI CID (ETS 300-659-1)

Polarity

Immediate or smooth to prevent erroneous ringing

Reversal /

Wink

Metering 12/16 KHz sinusoidal bursts; generation on FXS

- 11 -

Page 18

CHAPTER3 Physical Description

Specification Description

Tones

MP-1288 | Hardware Installation Manual

Distinctive

Ringing

Message

Waiting

Indication

(MWI)

By frequency (15-100 Hz) and cadence patterns

DC voltage generation (TIA/EIA-464-B); V23 FSK data; Stutter dial tone

Power Supply Module

The device can be powered from an AC or a DC power source. The type of power depends on

your ordered hardware configuration.

AC Power Supply Module

For the AC- powered model, the device provides two AC Power Supply modules for load

sharing and power redundancy. The power source is a standard electrical outlet providing AC

power.

Power surge protection, caused for example from lightning, is also supported. For more

information, see Grounding and Surge Protection on page19.

The Power Supply module is available as a spare part. The Power Supply modules are hotswappable and therefore, if only one needs to be replaced, it can be done while the device is

receiving power from the working Power Supply module. For replacing Power Supply modules,

see on page50.

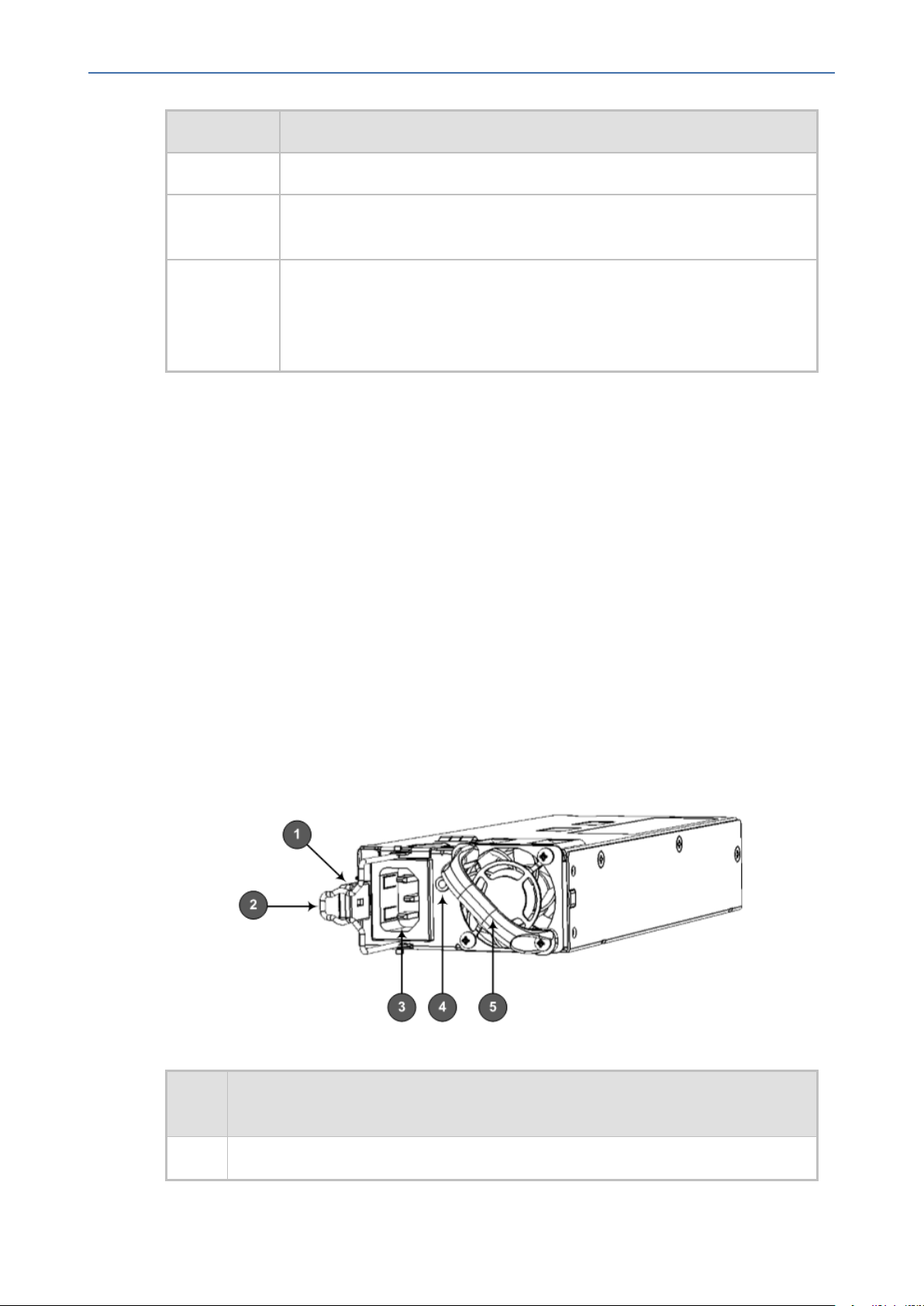

Figure 3-10: AC Power Supply Module

Table 3-10: AC Power Supply Module Description

Item

#

Description

1 Release latch for releasing and securing module from / to chassis slot.

- 12 -

Page 19

CHAPTER3 Physical Description

MP-1288 | Hardware Installation Manual

Item

#

Description

2 Power cord anchor clip.

3 3-Prong power inlet.

4

LED for indicating power status. For more information, see Power Supply LED on

page16.

5 Handle for extracting and installing module.

The two Power Supply modules installed in the chassis must be of the same hardware

revision. For more information, see the note in on page50.

DC Power Supply Module

For the DC- powered model, the device provides two DC Power Supply modules for load

sharing and power redundancy.

Power surge protection, caused for example from lightning, is also supported. For more

information, see Grounding and Surge Protection on page19.

The Power Supply module is available as a spare part. The Power Supply modules are hotswappable and therefore, if only one needs to be replaced, it can be done while the device is

receiving power from the working Power Supply module. For replacing Power Supply modules,

see on page50.

Figure 3-11: DC Power Supply Module

Table 3-11: DC Power Supply Module Description

Item # Description

1 Release latch for releasing and securing module from / to chassis slot.

2 DC power inlet.

3 Handle for extracting and installing module.

- 13 -

Page 20

CHAPTER3 Physical Description

LED Descriptions

This section describes the LEDs on the rear panel of the chassis.

Ethernet LEDs

Each Ethernet port on the CPU module provides a LED (located on its left) which indicates

network connectivity status, as described in the following table.

Color State Description

Green On Ethernet link established.

MP-1288 | Hardware Installation Manual

Table 3-12: Ethernet LEDs Description

Flashing Data is being received or transmitted.

-

Off No Ethernet link.

STAT LED

The STAT LED on the CPU module indicates the operating status of the CPU module, as

described in the following table.

Table 3-13: STAT LED Description

Color State Description

Green On LED is lit because of one of the following:

■ Device is operating normally

■ During first stage of boot up when device is powered on

Orange On Chassis is approaching high-temperature threshold, but not yet critical

Red On LED is lit because of one of the following:

■ Fault detected in CPU module

■ Incompatible or faulty software version (.cmp file) detected during

boot up

■ Approaching critical high-temperature threshold

-

Off

No power.

FXS LEDs

Each FXS blade provides two LEDs that indicate the status of the FXS blade, as described in the

following table. Both LEDs indicate the same status information. One LED is located on its front

- 14 -

Page 21

CHAPTER3 Physical Description

panel and the other LED on its rear panel to the left of the left-most FXS port (labeled FXS 49-

72), as shown in the following figures:

Figure 3-12: FXS LED Location on Front Panel per FXS Blade

Figure 3-13: FXS LED Location on Rear Panel per FXS Blade

MP-1288 | Hardware Installation Manual

Table 3-14: FXS LEDs Description

Color State Description

Green On FXS blade initialization completed and is functioning normally.

Orange On Some (less than a third) FXS ports are out of service.

Red On FXS blade initialization has not completed or a failure detected in the

FXS blade due to any of the following:

■ Multiple FXS ports (more than a third) are out of service

■ DSP failure

-

Off No power.

- 15 -

Page 22

CHAPTER3 Physical Description

Power Supply LED

The Power Supply module, located on the chassis rear panel, provides a LED which indicates

the operating status of the module, as described in the following table.

Color State Description

Green On Connected to power source, chassis receiving power, and

Amber Flashing Connected to power source, but chassis not receiving power or

MP-1288 | Hardware Installation Manual

Table 3-15: Power Supply Module LED Description

Power Supply module's fan operating normally.

fault detected in Power Supply module's fan.

If the chassis houses two Power Supply modules, but only one

of them is connected to the power source, the LED on the

Power Supply module that is not connected flashes amber.

-

Off No power received from power source.

- 16 -

Page 23

CHAPTER4 19-Inch Rack Mounting

4 19-Inch Rack Mounting

The device is designed to be mounted in a standard 19-inch rack. This is done by attaching it to

the rack's posts using front-mounting brackets (supplied).

At least two people are required to mount the device in the 19-inch rack.

Avertissements: Au moins deux personnes sont nécessaires pour monter l’appareil

dans le bâti 19 pouces.

A fully-populated chassis weighs up to 21 kg (46.3 lbs.). The 19-inch rack cabinet must

be able to withstand this weight.

Rack Mount Safety Instructions: When installing the chassis in a rack, adhere the

following safety instructions:

● Elevated Operating Temperature: If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may be

greater than room ambient temperature. Therefore, consideration should be given

to installing the equipment in an environment compatible with the maximum

ambient temperature (Tma) of 40°C (104°F).

● Reduced Air Flow: Installation of the equipment in a rack should be such that the

amount of air flow required for safe operation on the equipment is not

compromised.

● Mechanical Loading: Mounting of the equipment in the rack should be such that a

hazardous condition is not achieved due to uneven mechanical loading.

● Circuit Overloading: Consideration should be given to the connection of the

equipment to the supply circuit and the effect that overloading of the circuits might

have on over-current protection and supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern.

● Reliable Earthing: Reliable earthing of rack-mounted equipment should be

maintained. Particular attention should be given to supply connections other than

direct connections to the branch circuit (e.g., use of power strips.)

MP-1288 | Hardware Installation Manual

➢ To mount the device in a 19-inch rack:

1. Attach the two front-mounting brackets (supplied) to both sides of the chassis, as shown

in the following figure. Each bracket is secured to the chassis using 9 screws (supplied).

- 17 -

Page 24

CHAPTER4 19-Inch Rack Mounting

Figure 4-1: Attaching Mounting Brackets to Chassis

2. With two people, lift the chassis into the rack from the front of the rack.

3. Hold the chassis for support while the second person positions the chassis in the rack so

that the front-mounting brackets are flush against the front-rack posts and that the holes

of the front-mounting brackets aligned with the holes on the front-rack post, as shown in

the following figure:

MP-1288 | Hardware Installation Manual

Figure 4-2: Front-Mounting Brackets Flush and Aligned with Front Rack Posts

4. Hold the chassis in position while the second person secures the two front-mounting

brackets to the front posts, by finger-tightening 19-inch rack bolts (not supplied) to the

rack posts. Each mounting bracket is secured to the rack by two bolts.

Make sure that the left and right front-mounting brackets are attached to the rack posts

at the same level so that the chassis is supported in a horizontal position.

5. Tighten the bolts on the front-mounting brackets.

- 18 -

Page 25

CHAPTER5 Cabling the Device

5 Cabling the Device

This section describes how to cable the device:

■ Connecting to earth / ground – see Grounding and Surge Protection below

■ Connecting to the LAN – see Connecting Ethernet Interfaces on page21

■ Connecting the FXS interfaces – see Connecting FXS Interfaces on page22

■ Connecting the FXS lifeline – see Connecting the FXS Analog Lifeline on page30

■ Connecting to a PC for serial communication – see Connecting the Serial Interface to a

Computer on page32

■ Connecting to power – see Connecting to Power on page34

Grounding and Surge Protection

MP-1288 | Hardware Installation Manual

The following procedure describes how to ground the device.

Grounding and Power Surge Protection:

● The device must be installed only in telecommunication sites / centers in

compliance with ETS 300-253 requirements "Earthing and Bonding of

Telecommunication Equipment in Telecommunication Centers".

● Prior to installation, earth loop impedance test must be performed by a certified

electrician to ensure grounding suitability at the power outlet intended to feed the

unit. It is essential that the impedance will be kept below 0.5 ohms!

● Proper grounding is crucial to ensure the effectiveness of the lightning protection,

connect the device permanently to ground (as described in the procedure below).

The device's grounding screw must be connected to the equipotential grounding

bus bar located in the Telecommunication rack or installation site, using a wire of 6

mm2surface wire. If the device is installed in a rack with other equipment, the rack

must be connected to the equipotential grounding bus bar of the

Telecommunication room, using a stranded cable with surface area of 25 mm2.

The length of this cable must be as short as possible (no longer than 3 meters).

Protective Earthing:

● The equipment is classified as Class I EN 60950 and UL 60950 and must be

earthed at all times (using an equipment-earthing conductor).

● Finland: "Laite on liltettava suojamaadoituskoskettimilla varustettuun

pistorasiaan."

● Norway: "Apparatet rna tilkoples jordet stikkontakt."

● Sweden: "Apparaten skall anslutas till jordat uttag."

➢ To connect the chassis to an earth ground:

1. Prepare an adequate length (maximum 20 mm or 0.8 in.) of stranded grounding wire (16

AWG minimum size) for the ground connection, as shown in the following figure:

- 19 -

Page 26

CHAPTER5 Cabling the Device

2. Using a Philips-head screwdriver, remove the two screws and their spring washers for

attaching the grounding lug, located on the chassis' rear panel as shown in the following

figure:

MP-1288 | Hardware Installation Manual

Figure 5-1: Stripped Grounding Wire

Figure 5-2: Removing Screws and Washers

3. Insert one end of the grounding wire into the grounding lug (supplied), as shown in the

following figure, and then use a crimping tool (not supplied) to secure the wire to the

grounding lug:

Figure 5-3: Attaching Grounding Wire to Grounding Lug

4. Attach the grounding lug (supplied) to the chassis using the two screws.

5. Attach the grounding lug to the chassis, as shown in the following figure. Make sure that

the spring washers are located between screw head and lug.

Figure 5-4: Attaching Grounding Lug to Chassis

- 20 -

Page 27

CHAPTER5 Cabling the Device

6. Connect the other end of the grounding wire to the building protective earth. This should

be in accordance with the regulations enforced in the country in which the device is

installed.

Connecting Ethernet Interfaces

The device provides two 100/1000Base-T Gigabit Ethernet ports (RJ-45) for connecting to the IP

network (e.g., LAN). The ports support half- and full-duplex modes, auto-negotiation, and

straight or crossover cable detection.

The ports can operate as a pair (Ethernet Group) to provide 1+1 port redundancy, where one

port serves as the active port while the other as standby. When the active port fails, the device

switches to the standby port.

The cabling specifications and procedure for connecting the device to the LAN is as follows:

■ Cable: Straight-through, Category (Cat) 5/5e/6 cable

■ Connector: Standard RJ-45

MP-1288 | Hardware Installation Manual

■ Connector Pinouts:

Table 5-1: RJ-45 Connector Pinouts for Ethernet Ports

Pin Signal Name

1 Ethernet signal pair

2

3 Ethernet signal pair

6

4 Ethernet signal pair

5

7 Ethernet signal pair

8

Shield Chassis ground

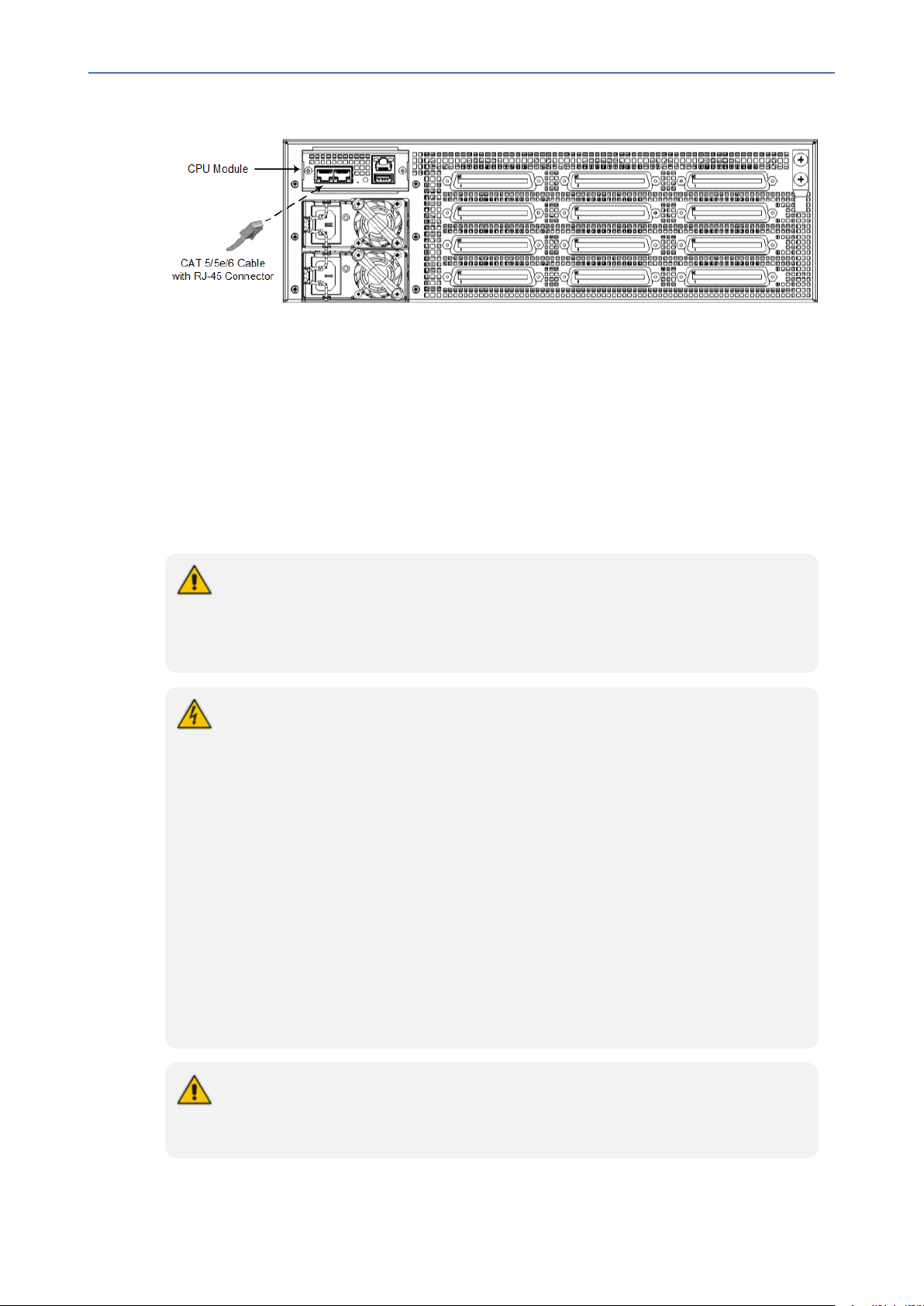

➢ To connect the Ethernet interfaces:

1. Connect the RJ-45 connector, at one end of a straight-through Cat 5e or Cat 6 cable, to

one of the Ethernet ports (labeled ) on the CPU module located on the chassis' rear

panel, as shown in the following figure:

- 21 -

Page 28

CHAPTER5 Cabling the Device

2. Connect the other end of the cable to your network.

3. For 1+1 Ethernet port redundancy, repeat steps 1 through 2 for the standby port. Make

sure that you connect each port to a different network (but in the same subnet).

Connecting FXS Interfaces

The device interfaces with the FXS analog telephone equipment (e.g., fax machines, modems,

or telephones) through the 50-pin Telco connectors provided on the FXS blades. For more

information on the FXS blades, see FXS Blades on page9.

MP-1288 | Hardware Installation Manual

Figure 5-5: Connecting the LAN Ports

Safety Notice:

● Make sure that the FXS ports are connected to the appropriate, external devices;

otherwise, damage to the device may occur.

● FXS ports are considered TNV-2.

FXS Outdoor Cabling and Power Surge Protection:

● The device includes an integrated secondary surge protection, but does not include

primary telecom protection! When the FXS telephone lines are routed outside the

building, additional protection - usually a 350V three-electrode Gas Discharge Tube

(GDT) as described in ITU-T K.44 - must be provided at the entry point of the

telecom wires into the building (usually on the main distribution frame / MDF), in

conjunction with proper grounding. The center pin of the GDT (MDF grounding bar)

must be connected to the equipotential grounding bus bar of the

Telecommunication room.

● Failing to install primary surge protectors and failing to comply with the grounding

instructions or any other installation instructions, may cause permanent damage to

the device!

● The device complies with protection levels as required by EN 55024/EN 300386.

Higher levels of surges may cause damage to the device.

● To protect against electrical shock and fire, use a minimum of 26-AWG wire size to

connect the FXS ports.

To configure the current (mA) that the device supplies to the FXS ports in off-hook

state, use the EnhancedFXSLineCurrent parameter. Configuration is applicable only to

the first and last ports (e.g., 1 and 24) on each FXS connector. For more information,

- 22 -

Page 29

CHAPTER5 Cabling the Device

refer to the User's Manual.

The FXS cabling specifications include the following:

■ Cable: You can use any of the following cables:

● AudioCodes orderable FXS Patch Panel (see Connecting FXS Interfaces using

AudioCodes FXS Patch Panel on the next page)

● AudioCodes orderable Centronics cable connector (10 m) to open leads, which needs

to be connected to a distribution panel (see Connecting FXS Interfaces using

Centronics Cable on page28)

● Third-party, main distribution frame (MDF) connector (see Connecting FXS Interfaces

Directly to an MDF on page29)

■ Connector Type: 50-pin Telco

MP-1288 | Hardware Installation Manual

Figure 5-6: 50-pin Telco Connector

■ Connector Pinouts:

Table 5-2: 50-pin Telco Connector Pinouts

FXS Phone Channel

(Ports)

Connector Pins

1 1/26

2 2/27

3 3/28

4 4/29

5 5/30

6 6/31

7 7/32

8 8/33

9 9/34

- 23 -

Page 30

CHAPTER5 Cabling the Device

MP-1288 | Hardware Installation Manual

FXS Phone Channel

(Ports)

Connector Pins

10 10/35

11 11/36

12 12/37

13 13/38

14 14/39

15 15/40

16 16/41

17 17/42

18 18/43

19 19/44

20 20/45

21 21/46

22 22/47

23 23/48

24 24/49

25 for Analog Lifeline 25/50

For analog Lifeline cabling, see Connecting the FXS Analog

Lifeline on page30.

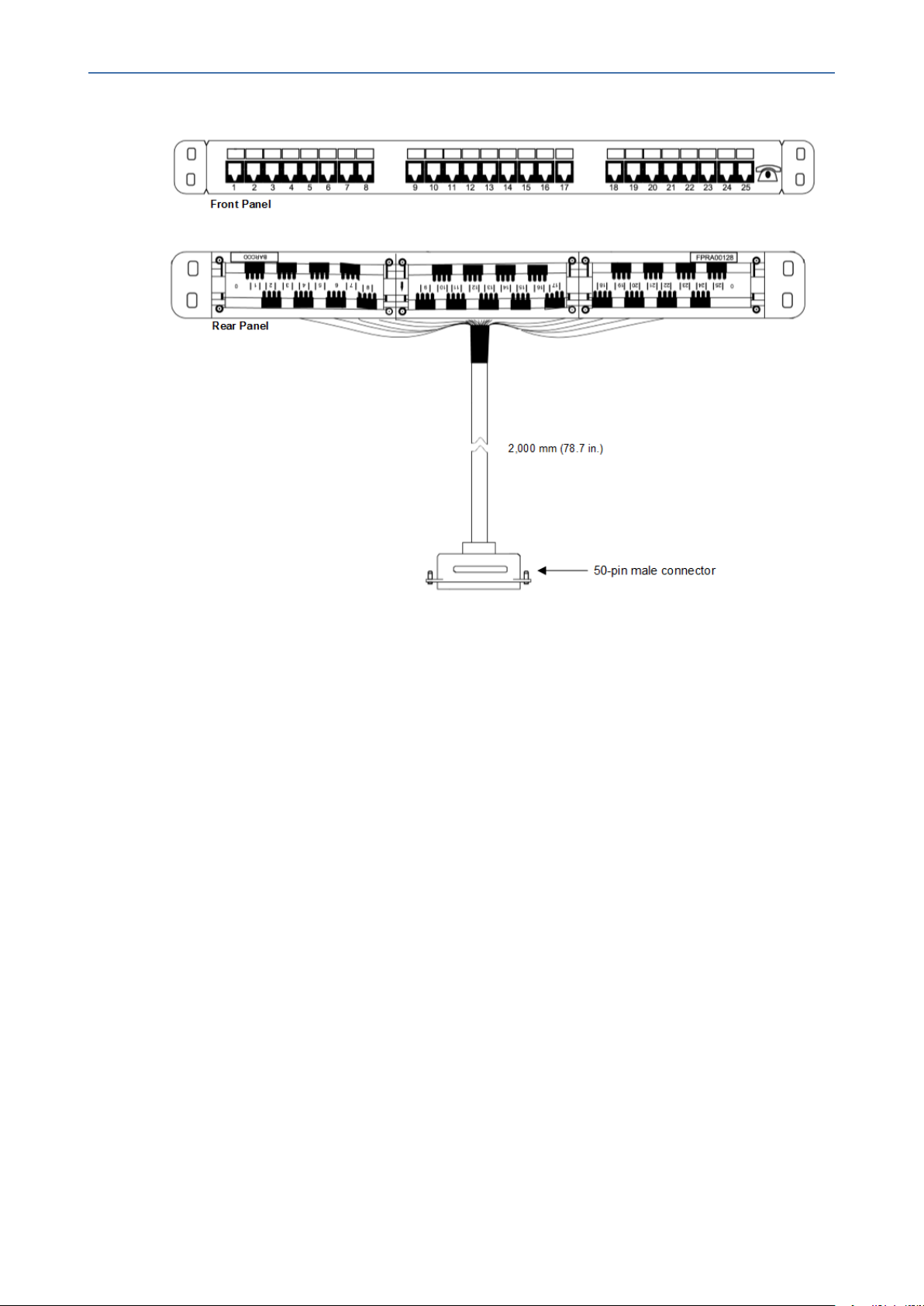

Connecting FXS Interfaces using AudioCodes FXS Patch Panel

You can purchase AudioCodes' FXS Patch Panel (shown in the following figure) to connect the

FXS interfaces to FXS equipment. The patch panel can be mounted in a 19-inch rack using

integrated mounting brackets and provides a 2-meter (78.7 in.) extension cable with a 50-pin

male connector for connection to the FXS port on the FXS blade. All incoming wires from the

50-pin Telco connector are terminated to the back of the patch panel. The FXS endpoints (e.g.

telephones) can be plugged into the corresponding RJ-11 jacks on the front of the patch panel.

- 24 -

Page 31

CHAPTER5 Cabling the Device

MP-1288 | Hardware Installation Manual

Figure 5-7: Orderable FXS Patch Panel

➢ To connect the FXS interfaces using the FXS Patch Panel:

1. Mount the Patch Panel in a 19-inch rack, using the integrated mounting brackets located

on either side of the Patch Panel. Use four 19-inch rack bolts (not supplied) to securely

attach the brackets to the front-rack posts. Make sure that the left and right mounting

brackets are attached to the rack posts at the same level so that the patch panel is

supported in a horizontal position.

- 25 -

Page 32

CHAPTER5 Cabling the Device

MP-1288 | Hardware Installation Manual

Figure 5-8: Mounting Patch Panel in Rack

2. Connect the Patch Panel's 50-pin male connector to one of the FXS blade's 50-pin female

Telco connectors located on the chassis' rear panel, and secure the connector with the

two captive screws located on either side of the connector, using a flat-head screwdriver:

Figure 5-9: Connecting 50-Pin Telco Connector to Port on FXS Blade

3. Connect your analog equipment to the Patch Panel, by plugging the RJ-11 connectors into

the RJ-11 sockets on the Patch Panel's front panel:

- 26 -

Page 33

CHAPTER5 Cabling the Device

Figure 5-10: Connecting Analog Equipment to FXS Patch Panel

For outdoor FXS cabling installations, you must install additional power surge protection as

illustrated in the following figure. For indoor FXS cabling installations, there is no need for

primary lightning protection usage.

Figure 5-11: Connecting FXS Interfaces using FXS Patch Panel

MP-1288 | Hardware Installation Manual

- 27 -

Page 34

CHAPTER5 Cabling the Device

Connecting FXS Interfaces using Centronics Cable

You can purchase AudioCodes' Centronics-type cable connector, as shown in the following

figure, to connect the FXS interfaces to FXS equipment. The 10-meter cable (32.8 ft.) provides a

50-pin male Telco connector on one end and open leads on the other end, which need to be

connected to your patch panel or distribution frame.

MP-1288 | Hardware Installation Manual

Figure 5-12: Orderable Centronics Cable and Pinouts

➢ To connect the FXS interfaces using the Centronics cable:

1. Connect the 50-pin male connector on end of the cable to one of the FXS blade's 50-pin

female Telco connectors located on the chassis' rear panel, and secure the connector with

the two captive screws located on either side of the connector, using a Philips screwdriver:

Figure 5-13: Connecting 50-Pin Telco Connector to Port on FXS Blade

- 28 -

Page 35

CHAPTER5 Cabling the Device

2. Terminate the wires on the other end of the cable to your patch panel or distribution

frame. The wires are grouped in pairs with labels indicating the FXS channels. Make sure

that you connect the wires according to the correct port channels as labelled on the wires.

3. Connect your analog equipment to your patch panel or distribution frame, by plugging

their RJ-11 connectors into the RJ-11 sockets on the patch panel or distribution frame.

Connecting FXS Interfaces Directly to an MDF

If you are using your own third-party MDF, perform the following instructions.

To reduce noise interference, use a twisted pair Octopus cable that is terminated on a

metal-hooded 50-pin Telco connector.

➢ To connect FXS interfaces directly to an MDF:

1. Wire the 50-pin Telco connectors according to the pinouts in Connecting FXS Interfaces on

page22.

MP-1288 | Hardware Installation Manual

2. Connect the wire-pairs at the other end of the cable to a 50-pin male Telco connector (not

supplied).

3. Attach the male connector to one of the FXS blade's 50-pin female Telco connectors,

located on the chassis' rear panel.

4. Attach each pair of wires from a 25-pair Octopus cable (not supplied) to its corresponding

socket on the MDF.

5. Connect the telephone lines from the MDF to the analog equipment, by inserting each RJ-

11 connector on the 2-wire line cords to the RJ-11 sockets on the front of the MDF:

- 29 -

Page 36

CHAPTER5 Cabling the Device

Figure 5-14: Connecting FXS Interfaces Directly to MDF

MP-1288 | Hardware Installation Manual

Connecting the FXS Analog Lifeline

The device supports PSTN Fallback (analog Lifeline), whereby it automatically connects an FXS

port (Lifeline extension or phone) to the PSTN / PBX upon a power outage. This enables the

phone to make and receive calls to and from the PSTN respectively, instead of the IP network.

Each FXS blade supports up to three FXS Lifelines, one per FXS connector. For each connector,

the first channel provides the connection to the Lifeline extension and the last channel is the

- 30 -

Page 37

CHAPTER5 Cabling the Device

Lifeline interface providing the connection to the PSTN / PBX. For example, for FXS connector

labeled FXS 1-24, channel 1 is the Lifeline extension and channel 25 is the Lifeline interface for

the PSTN / PBX.

The cable specifications for the FXS Lifeline include the following:

■ Cable: For optional cable types, see Connecting FXS Interfaces on page22.

■ Connector Type: 50-pin Telco

■ Connector Pinouts:

Table 5-3: 50-pin Telco Connector Pinouts for FXS Lifeline

MP-1288 | Hardware Installation Manual

Figure 5-15: 50-pin Telco Connector for FXS Lifeline

Telco

Connector

Description

Pins

1/26 Connects to FXS Lifeline extension

25/50 Connects to PSTN / PBX (Lifeline interface)

For all the connector's pinouts, see Connecting FXS Interfaces on page22.

➢ To cable FXS Lifeline per FXS connector:

1. See Connecting FXS Interfaces on page22 for connecting the 50-pin Telco connector to the

FXS blade and for connecting it to a distributional panel.

2. Once you have performed Step 1, connect the lifeline as follows:

● Connect Port #1 to the FXS extension (e.g., telephone).

● Connect Port #25 to the PSTN / PBX (Lifeline interface).

- 31 -

Page 38

CHAPTER5 Cabling the Device

Connecting the Serial Interface to a Computer

The RS-232 interface port is used to access the command line interface ( CLI) for serial

communication.

MP-1288 | Hardware Installation Manual

Figure 5-16: Cabling FXS Lifeline

The device provides an RS-232 serial interface port on its rear panel. The RS-232 interface port

is used to access the device's command line interface (CLI).

■ Port Type: RJ-45

■ Cable: RJ-45 to DB-9 female cable adapter (supplied)

Figure 5-17: RJ-45 to DB-9 Female Cable Adapter

■ Connector Pinouts:

Table 5-4: RJ-45 to DB-9 Serial Cable Connector Pinouts

RJ-45 DB-9 Female

Pin Signal Pin Signal

1 Internally used 8 Not

used

2 Ground (GND) 6 Ground

(GND)

3 Transmit Data (TXD) 2 Receive

Data

(RXD)

4 Internally used 5 Not

- 32 -

Page 39

CHAPTER5 Cabling the Device

5 Internally used 5 Not

6 Receive Data (RXD) 3 Transmit

7 Ground (GND) 4 Ground

8 Internally used 7 Not

MP-1288 | Hardware Installation Manual

RJ-45 DB-9 Female

used

used

Data

(TXD)

(GND)

used

➢ To connect the serial interface port to a computer:

1. Connect the RJ-45 connector, at one end of the cable, to the device's serial port (labeled

|0|0|), located on the CPU module on the rear panel.

Figure 5-18: Connecting Serial Interface

2. Connect the DB-9 connector, at the other end of the cable, to a COM RS-232

communication port on your PC.

The RS-232 port is not intended for permanent connection.

- 33 -

Page 40

CHAPTER5 Cabling the Device

Connecting to Power

The device can be powered from an AC or a DC power source, depending on ordered hardware

configuration.

AC Power Supply

The device provides two hot-swappable Power Supply modules for load-sharing and power

redundancy in case of failure in one of the modules. To replace a faulty power supply module,

see Replacing the Fan Tray Module on page39.

The device receives power from a standard alternating current (AC) electrical outlet. The

connection is made using the supplied AC power cord.

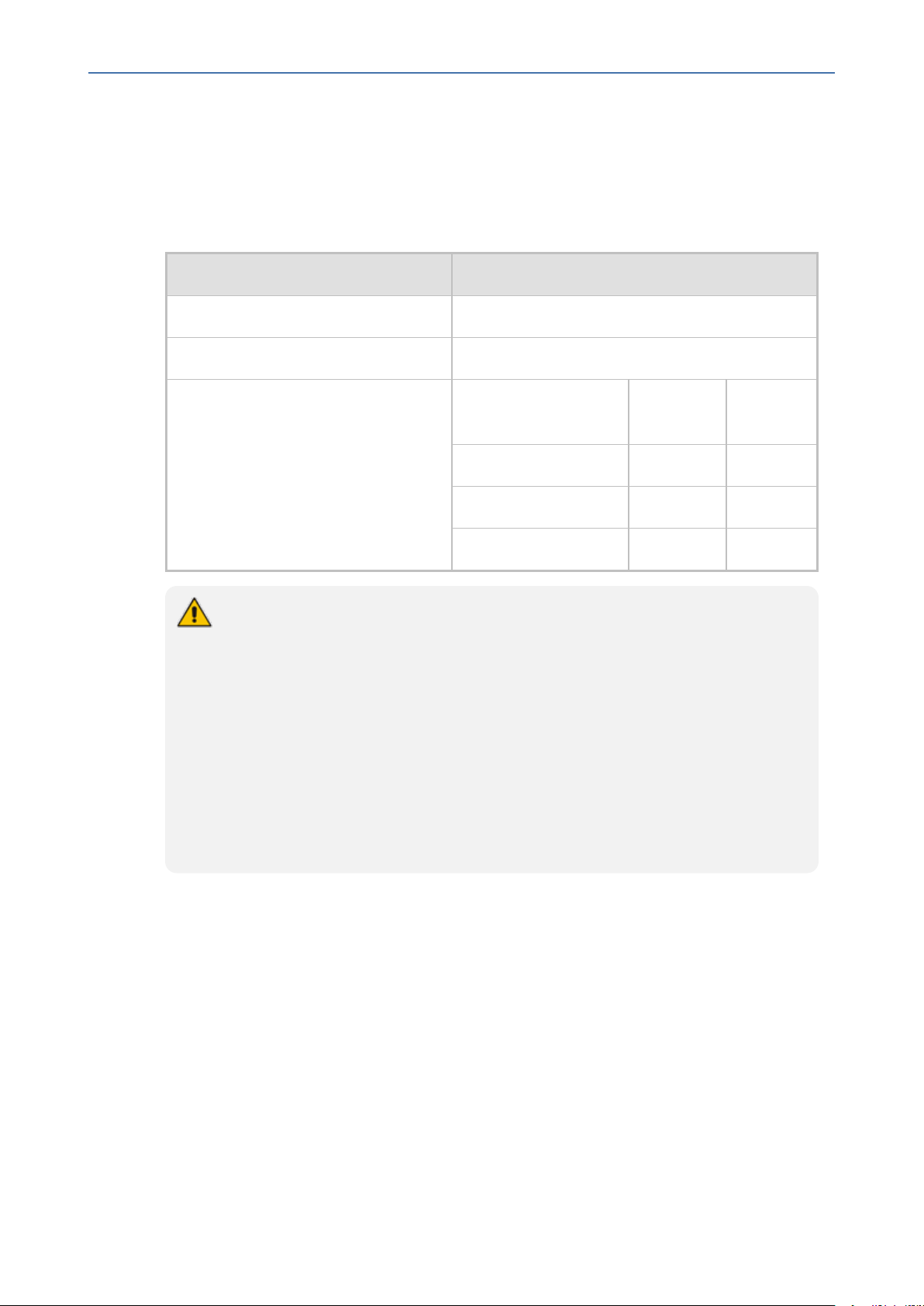

Physical Specification Value

MP-1288 | Hardware Installation Manual

Table 5-5: AC Power Specifications

Input Voltage Dual universal AC power supply 100-240V

AC Input Frequency 50/60 Hz

Max. AC Input Current 10 A

Max. Power Consumption FXS Interfaces Short Haul

(W)

Long Haul

(W)

288 450 950

216 400 770

144 350 600

If you are using both Power Supply modules, connect each one to a different AC power

supply source. The two AC power sources must have the same ground potential.

ご注 意

本 製 品 に 添 付 の 電 源 ケー ブ ル は、 MP- 1288

に専 用 設 計 されているため、汎 用 性 がありません. 本 電 源 ケーブルを他の機器 に使 用

されないよう、ご注 意ください.

➢ To connect the device to power:

1. Swing the cable anchor clip, located over the power inlet of the Power Supply module,

sideways, away from the power inlet to provide space for the power plug.

- 34 -

Page 41

CHAPTER5 Cabling the Device

Figure 5-19: Swinging Cable Anchor Clip away from Power Inlet

2. Plug the female end of the AC power cord (supplied) into the power inlet.

MP-1288 | Hardware Installation Manual

Figure 5-20: Connecting to Power

3. Secure the power cord to the power inlet by providing strain relief, using the cable anchor

clip. Slide the cable anchor clip sideways, towards the power inlet and then push the

power cord into the cable anchor clip, as shown in the following figure. This protects the

plug from accidentally being pulled out.

Figure 5-21: Strain Relief for Power Cord using Cable Anchor Clip

Strain relief for the power cord using the cable anchor clip is not mandatory.

4. Connect the male end of the power cord to a standard AC electrical outlet.

5. If you are using both Power Supply modules, repeat steps 1 through 3 for connecting the

second Power Supply module, but using the power socket associated with the second

Power Supply module and connecting this to a different supply circuit.

6. Turn on the power at the power source (if required).

7. Check that the LED on each Power Supply module (front panel) is lit green, indicating that

the device is receiving power. For more information on the power LED, see Power Supply

LED on page16.

- 35 -

Page 42

CHAPTER5 Cabling the Device

DC Power Supply

The device houses two hot-swappable Power Supply modules, providing 1+1 load-sharing and

power redundancy in case of a Power Supply module failure.

Physical Specification Value

Input Ratings Dual universal power supply 40-60 VDC, 32A max

Connection to DC Mains Supply Molex terminal block (supplied)

MP-1288 | Hardware Installation Manual

Table 5-6: DC Power Specifications

Max. Power Consumption

FXS Interfaces Short Haul

(W)

288 450 950

216 400 770

144 350 600

DC Power Safety Notice:

● Connect the device to a safety extra-low voltage (SELV) source that is sufficiently

isolated from the mains.

● The device must be permanently connected to earth (ground), as described in

Grounding and Surge Protection on page19.

● Connection of the device to the DC mains power must be done only by a certified

electrician and in accordance with local national electrical regulations.

● Both Power Supply modules must be connected. Ensure that you connect each

one to a different DC power supply source.

● The two DC power sources must have the same ground potential.

● If a failure occurs in any one of the Power Supply modules, replace the module

immediately.

Long Haul

(W)

The device is shipped with a DC terminal block plug for each Power Supply module. You need

to connect two 6-AWG power leads (one for positive and one for negative) to this terminal

block.

➢ To connect to a DC power supply:

1. Disconnect your DC wires from your DC power source.

2. Using a wire-stripping tool, strip the ends of the two wires (6-AWG) to a length that is

sufficient for inserting into the supplied terminal block. Make sure that you do not strip

too much of the insulation so that wire is not exposed when it exits the terminal block plug

after it has been secured to the terminal block.

- 36 -

Page 43

CHAPTER5 Cabling the Device

3. Identify the polarity (negative and positive) of the two DC power feed wires. Polarity of

power feed wires are typically color-coded, where red is positive (RTN) and black is

negative (-48VDC).

4. Insert the exposed wire of one of the two DC-input power source wires into the correct

opening (according to polarity) on the terminal block plug (supplied), as shown in the

following figure. Make sure that only wire with insulation exits the terminal block.

5. Using a Philips or flat-head screwdriver, tighten the captive screw located above the

installed wire lead to secure the wire to the terminal block.

6. Repeat steps 1 through 5 for the second wire.

Figure 5-22: Wiring DC Power Leads to Terminal Block

MP-1288 | Hardware Installation Manual

7. Make sure that no wire strands are left outside the connector and that all strands have

been clamped under the terminal block screw.

8. Gently try and pull the wires from the terminal block. Only if the wires remain secured to

the terminal block may you continue to the next step; otherwise, if the wires become free,

repeat Step 5 to secure the wires to the terminal block.

9. Insert the DC terminal block plug into the DC inlet of the Power Supply module located on

the device's rear panel. The following figure shows the completed wiring of the terminal

block.

- 37 -

Page 44

CHAPTER5 Cabling the Device

10. Connect the DC power leads to a 48-VDC power source.

MP-1288 | Hardware Installation Manual

Figure 5-23: Wired DC Power Supply Modules

- 38 -

Page 45

CHAPTER6 Hardware Maintenance

6 Hardware Maintenance

The device is designed as a modular chassis and allows you to order any module as a Field

Replacement Unit (FRU). This section describes the procedures for replacing modules.

Ensure that all unoccupied module chassis slots are covered with blank panels. This

allows optimal internal airflow pressure within the chassis.

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) due to improper handling of the device's modules and

components can cause irreversible damage to the equipment. Therefore, adhere to the

following guidelines for preventing ESD:

■ When handling modules, always wear a grounded ESD wrist strap or ankle strap at a

grounded work area to prevent ESD. Connect the equipment end of the strap to the

chassis' ground lug.

MP-1288 | Hardware Installation Manual

■ To prevent static electrical damage to the module, do not touch the electrical components

of the module. Instead, hold the module only on the edges where no electrical

components are located.

■ Make sure that the modules are securely installed in the chassis.

➢ To attach an ESD wrist strap to the chassis:

1. Attach the ESD wrist strap to your body (typically, the wrist) so that it is in direct contact

with your skin.

2. Attach the other end of the wrist strap (e.g., an alligator clip) to the grounding lug located

on the rear panel of the chassis. To attach a grounding lug, see Grounding and Surge

Protection on page19.

Replacing the Fan Tray Module

The following procedure describes how to replace the Fan Tray module.

● DO NOT operate the device without the Fan Tray module.

● Before replacing a failed Fan Tray module, make sure that you have the

replacement Fan Tray module on hand so that you can replace the module

immediately.

● When removing the Fan Tray module, the fan blades may still be rotating at high

speeds (even if you power off the device). Therefore, partially extract the module

from the chassis and then wait a few seconds to allow the fan blades to stop, prior

to extracting the module entirely from the chassis.

Avertissements:

- 39 -

Page 46

CHAPTER6 Hardware Maintenance

● N’opérez pas l’appareil sans module de Caisse de ventilateur ! Avant de remplacer

le module de Caisse de ventilateur, assurez-vous que vous avez le module de

remplacement en main.

● Avant de retirer le module de Caisse de ventilateur et une fois l’appareil mis hors

tension, les lames risquent de continuer à tourner à grande vitesse. Aussi,

patientez quelques secondes pour permettre aux lames de s’arrêter, avant

d’extraire le module du châssis.

➢ To replace the Fan Tray module:

1. Remove the Fan Tray module:

a. On the front panel, loosen the four Philips-head, spring-loaded captive screws located

in each corner of the Fan Tray cover, using a flat-head or Philips screwdriver:

Figure 6-1: Location of Screws on Fan Tray Cover

MP-1288 | Hardware Installation Manual

b. Remove the Fan Tray cover:

Figure 6-2: Removing Fan Tray Cover

c. Loosen the four flat-head, spring-loaded captive screws securing the Fan Tray module

to the chassis, using a flat-head screwdriver.

- 40 -

Page 47

CHAPTER6 Hardware Maintenance

Figure 6-3: Location of Screws on Fan Tray Module

d. Grip the handle of the Fan Tray module where you removed the screws in the

previous step, and then gently but firmly pull the module away from the chassis so

that it disconnects from the connector providing it with power:

Figure 6-4: Location of Handles and Removing Fan Tray Module

MP-1288 | Hardware Installation Manual

2. Install the new Fan Tray module:

a. Orientate the Fan Tray module as shown in the previous figure.

b. Grip the handles on the Fan Tray module, and then gently attach the module to the

front panel, making sure that it has engaged with the chassis backplane.

c. Secure the Fan Tray module to the chassis by tightening the four flat-head, spring-

loaded captive screws on the front panel of the module. You can use a flat-head

screwdriver.

d. Orientate the Fan Tray cover as shown in Step 1 above and then place it over the Fan

Tray module so that the screws are flush with screw holes on the handles of the Fan

Tray module. Secure the cover by tightening the four Philips-head, spring-loaded

captive screws located in each corner of the cover.

Replacing the Air Filter

The air filter is intended to prevent dust and other airborne particles from entering the chassis

and adversely affecting its components. To maintain proper operation of the device, you must

periodically replace the air filter. The frequency of replacing the air filter depends on the

cleanness at the installation site. In installation rooms with extra-building openings (exposed

to dust and/or air particles), you may need to replace the air filter once every 3 months. In

cleaner rooms (e.g., no extra-building openings), you may need to replace the air filter once

- 41 -

Page 48

CHAPTER6 Hardware Maintenance

every 6 months. In air-purified (conditioned) rooms, air filter replacement can be done

annually. It's the user's responsibility to determine the cleanness level and the air filter

replacement frequency.

● The device's components may be damaged due to a dirty or blocked air filter.

● Replace the air filter only with an air filter purchased from AudioCodes.

● Before removing the air filter, make sure that you have the replacement air filter on

hand so that you can replace it immediately.

The air filter is hot-swappable.

➢ To replace the air filter:

1. On the front panel, remove the Fan Tray cover, by loosening the four Philips-head, spring-

loaded captive screws located in each corner of the cover and then gently pulling the cover

away from the chassis:

MP-1288 | Hardware Installation Manual

Figure 6-5: Removing Fan Tray Cover on Front Panel

2. Remove the air filter cover, located on the inside of the Fan Tray cover, by removing the

two flat-head, spring-loaded captive screws located on either side of the air filter cover,

using a flathead screwdriver:

Figure 6-6: Removing Air Filter Cover from Fan Tray Cover

3. Pull out the exposed air filter from the enclosure of the air filter cover and dispose of it:

- 42 -

Page 49

CHAPTER6 Hardware Maintenance

Figure 6-7: Removing Air Filter from Air Filter Cover

4. Insert the new filter into the enclosure of the air filter cover.

5. Attach the air filter cover back on the Fan Tray cover by using the two spring-loaded

captive screws (see the figure in Step 2).

6. Attach the Fan Tray cover to the chassis (see the figure in Step 1).

MP-1288 | Hardware Installation Manual

Replacing FXS Blades

The following procedure describes how to replace an FXS blade.

Power off the device when removing or installing FXS blades.

➢ To replace an FXS blade:

1. Remove the faulty FXS blade:

a. Identify the faulty FXS blade by the color of its LED, located on the rear panel as

described in FXS LEDs on page14.

b. Power down the device, by disconnecting the power cord from the power source, and

then unplugging the power cord from the power inlet on the Power Supply module.

c. On the rear panel, disconnect the FXS cables from the 50-pin FXS ports on the FXS

blade. This is done by removing the captive screws, located on either side of the Telco

connector, from the blade's hex-standoff screws, using a flathead screwdriver:

- 43 -

Page 50

CHAPTER6 Hardware Maintenance

Figure 6-8: Removing 50-Pin Telco Connector

d. On the rear panel, remove all the hex-standoff screws securing the FXS blade to the

chassis, using a 3/16-in. hex-head nut driver. Each FXS port has two hex-standoff

screws (7 mm) on either side and therefore, you need to remove all six screws:

MP-1288 | Hardware Installation Manual

Figure 6-9: Removing Hex Standoff Screws on Rear Panel (Example FXS Blade S4)

e. On the front panel, remove the Fan Tray cover and Fan Tray module, as described in

Replacing the Fan Tray Module on page39.

f. On the front panel, loosen the two Philips-head, spring-loaded captive screws located

on either side of the FXS blade:

- 44 -

Page 51

CHAPTER6 Hardware Maintenance

Figure 6-10: Loosening Screws on FXS Blade on Front Panel

g. Gently pull the FXS blade out of the chassis slot:

MP-1288 | Hardware Installation Manual

Figure 6-11: Removing FXS Blade from Chassis Slot on Front Panel

2. Install the new FXS blade:

a. Hold the blade on the front where the captive screws are located, making sure that

you do not touch the blades electrical components.

b. On the chassis front panel, orientate the FXS blade as shown in the previous figure.

c. Gently slide the blade into the slot, keeping the left side of the blade aligned with the

left guiding rail located above the captive screw socket, and ensuring that the notch

on the underside of the blade is aligned to the left of the inner guiding rule, as shown

in the following figure. Slide the FXS blade into the slot until it has engaged with the

chassis backplane:

- 45 -

Page 52

CHAPTER6 Hardware Maintenance

Figure 6-12: Slot's Guiding Rails for FXS Blade

d. On the rear panel, secure the FXS blade to the chassis by inserting the hex-standoff

screws (see the figure in Step 1.d for location of screws), using a 3/16-in. hex-head nut

driver. Do not tighten the screws.

MP-1288 | Hardware Installation Manual

e. On the front panel, secure the FXS blade to the chassis, by tightening the two Philips-

head, captive screws on the front panel of the blade. You can use a Phillips or flathead

screwdriver.

f. On the rear panel, insert the hex-standoff screws on the FXS blade, using a 3/16-in.

hex-head nut driver.

g. On the rear panel, connect the 50-pin Telco connector cables to the FXS ports of the

new FXS blade.

h. On the front panel, re-install the Fan Tray module and Fan Tray cover, as described in

Replacing the Fan Tray Module on page39.

i. Re-connect the chassis to the power source.

Adding an FXS Blade

The following procedure describes how to add an FXS blade.

Power off the device before adding an FXS blade.

➢ To add an FXS blade:

1. Power down the device, by disconnecting the power cord from the power source, and

then unplugging the power cord from the power inlet on the Power Supply module.

2. On the rear panel, remove all three metal plates covering the slot openings for the three

50-Pin Telco connectors. To do this, insert a flat-head screwdriver into the hole of the

metal plate and carefully pry the plate off by moving the screwdriver downwards:

- 46 -

Page 53

CHAPTER6 Hardware Maintenance

Figure 6-13: Inserting Screwdriver into Cover Plate Hole

MP-1288 | Hardware Installation Manual

Figure 6-14: Removing Cover Plates

3. On the front panel, remove the Fan Tray cover and Fan Tray module, as described in

Replacing the Fan Tray Module on page39.

4. Hold the blade on its front where the captive screws are located, making sure that you do

not touch the blades electrical components.

5. On the chassis front panel, orientate the FXS blade as shown in the figure in Step 1.g in

Replacing FXS Blades on page43, and then gently slide the blade into the slot, keeping the

left side of the blade aligned with the left guiding rail located above the captive screw

socket, and ensuring that the notch on the underside of the blade is aligned to the left of

- 47 -

Page 54

CHAPTER6 Hardware Maintenance

the inner guiding rule, as shown in the following figure. Slide the FXS blade into the slot

until it has engaged with the chassis backplane:

Figure 6-15: Slot's Guiding Rails for FXS Blade

MP-1288 | Hardware Installation Manual

6. On the rear panel, secure the FXS blade to the chassis by inserting the hex-standoff

screws, using a 3/16-in. hex-head nut driver. Do not tighten the screws:

Figure 6-16: Securing FXS Blade to Chassis

7. On the front panel, secure the FXS blade to the chassis, by tightening the two Philips-head,

captive screws on the front panel of the blade. You can use a Phillips or flathead

screwdriver:

- 48 -

Page 55

CHAPTER6 Hardware Maintenance

Figure 6-17: Tightening Captive Screws of FXS Blade on Front Panel

8. On the rear panel, tighten the hex-standoff screws on each Telco connector of the FXS

blade, using a 3/16-in. hex-head nut driver.

MP-1288 | Hardware Installation Manual

9. On the front panel, re-install the Fan Tray module and Fan Tray cover, as described in

Replacing the Fan Tray Module on page39.

Replacing the CPU Module

The following procedure describes how to replace the CPU module.

Power off the device before replacing the CPU module.

➢ To replace the CPU module:

1. Power off the device.

2. Remove the faulty CPU module:

a. Power down the device by disconnecting the power cord from the power source, and

then unplugging the power cord from the power inlet on the power supply module. If

your device is installed with two power Supply modules, disconnect both of them

from the power source.

b. Remove all cables connected to the ports on the CPU module.

c. Remove the two Philips screws on both sides of the module that secure the module to

the chassis, using a Philips screwdriver.

d. Hold the front part of the module with one hand and place your other hand under the

module to support it. Gently pull the module out of the slot, keeping it at a 90-degree

angle to the backplane.

- 49 -

Page 56

CHAPTER6 Hardware Maintenance

Figure 6-18: Removing CPU Module on Rear Panel

3. Install the new CPU module:

a. Hold the front part of the module with one hand and place your other hand under the

module to support it.

b. Orientate the module as shown above and align the module with the guiding rails in

the chassis slot.

MP-1288 | Hardware Installation Manual

c. Gently slide the module into the slot until it has engaged with the chassis backplane.

d. Secure the module to the chassis, by tightening the two Philips screws on the module.

You can use a Phillips or flathead screwdriver.

e. Attach the network cables to the module.

f. Power up the device.

- 50 -

Page 57

CHAPTER6 Hardware Maintenance

Replacing Power Supply Modules

The following procedure describes how to replace a Power Supply module. The Power Supply

modules are hot-swappable. Therefore, if you are replacing only one module, you can leave

the second module connected to the power source.

The two Power Supply modules installed in the chassis must be of the same hardware

revision. You can identify the hardware revisions by the location (top or middle) of the

power LED on the front panel, as shown below:

MP-1288 | Hardware Installation Manual

➢ To replace a Power Supply module:

1. Remove the faulty Power Supply module:

a. Disconnect the Power Supply module from the power source.

◆ For AC Power: Disconnect the one end of the power cord from the power source,

by pulling the power plug out of the electrical wall outlet. Remove the plug at the

other end of the power cord from the power inlet on the Power Supply module.

◆ For DC Power: Disconnect the DC power feed cables from your DC power source.

Remove the DC terminal block from the Power Supply module.

b. While pressing inwards (sideways and to the right) on the release latch of the Power

Supply module, grip the handle of the module and gently pull the module halfway out

of the chassis slot:

- 51 -

Page 58

CHAPTER6 Hardware Maintenance

MP-1288 | Hardware Installation Manual

Figure 6-19: Handle and Release Latch on Power Supply Module (Example using AC Module)

c. Place your other hand under the Power Supply module for support and then slide it

completely out of the chassis. Avoid touching the top of the module; it may be hot

from being in the chassis:

Figure 6-20: Removing Power Supply Module from Chassis (Example using AC Module)

2. Install the new Power Supply module:

a. Grip the handle on the Power Supply module with one hand while supporting it

underneath with the other hand.

b. Orientate the Power Supply module as shown in the previous figure and align it with

the chassis slot from which you removed the faulty module.

c. Gently insert the Power Supply module into the slot until it has engaged fully with the

chassis backplane and a "click" sound heard when the release latch of the module

locks it into the slot.

d. Connect the Power Supply module to the power source.

- 52 -

Page 59

CHAPTER6 Hardware Maintenance

MP-1288 | Hardware Installation Manual

This page is intentionally left blank.

- 53 -

Page 60

International Headquarters

1 Hayarden Street,

Airport City

Lod 7019900, Israel

Tel: +972-3-976-4000

Fax: +972-3-976-4040

AudioCodes Inc.

200 Cottontail Lane

Suite A101E

Somerset NJ 08873

Tel: +1-732-469-0880

Fax: +1-732-469-2298

Contact us: https://www.audiocodes.com/corporate/offices-worldwide

Website: https://www.audiocodes.com/

Documentation Feedback: https://online.audiocodes.com/documentation-

feedback

©2020 AudioCodes Ltd. All ri ghts reserved. AudioCodes, AC, HD VoIP, HD VoIP Sounds Better, IPmedia, Mediant, MediaPack, What’s Inside Matters, OSN, SmartTAP, User Management Pack, VMAS,

VoIPerfect, VoIPerfectHD, Your Gateway T o VoIP, 3GX, VocaNom, AudioCodes One Voice, AudioCodes

Meeting Insights, AudioCodes Room E xperience and CloudBond are trademarks or registered trademarks of AudioCodes Limited. All other products or trademarks are property of thei r respective owners. Product speci fications are subject to change without notice.

Document #: LTRT-28035

Loading...

Loading...