Audi Q7 361, Q7 Service

Serv

ice Training

Audi Q7

Self-study

programme 361

The Audi Q7

In

superior fashion, the Audi Q7 c

ombines

spor

tiness and versatility,

advanced tec

hnology

and

pr

emium-class

luxury.

On the road, it ex

cels with the driving performance

and dy

namics of

a

sports car, while redefi

ning the

possibilities of

its class off-road. A vehicle which

visually display all its qualities and meets its

promise in

tec

hnological

terms, on any road and

under any

conditio

ns.

Audi Q7 – the hi

gh-perf

ormance SUV from the

creator of qua

ttro.

The

very design of the Audi Q7 sets new standards.

Char

acteristic of the typical Audi dynamism are the

swooping cu

rve of the roof

line and the distinctiv

e

rela

tionship between the high wa

istline and narrow

window ar

ea. The

dynamic sweep of the fr

ont se

ction

and

the powerful rear

with the sharply sloping D

-

pillars pr

ovide

a coupe-like profile.

Equally charac

teri

stic elem

ents of the current Audi

styling are the shoulder line and

dyna

mic line which

define the

side section.

361_0

00

Taking the le

ad: With

de

sign & performa

nce

Contents

Intr

oduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

Passenger protection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Running gear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Electric

al system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Air conditioning

system . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Infotainment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

The se

lf-s

tudy programme provides ba

sic informat

ion on the

design

and fu

nction of

new vehicle models,

new vehicle compon

ents or new technologi

es.

The self-study programme is not

intended as a workshop manual.

The spe

cified values only serve for better underst

anding and relate to the so

ftware versions

applicable at the time the SSP was com

piled.

For maintenance

and repair

oper

ations it is

essential

that you refer to the current technical li

terature.

Note

Note

Intr

oduction

In a nutshell

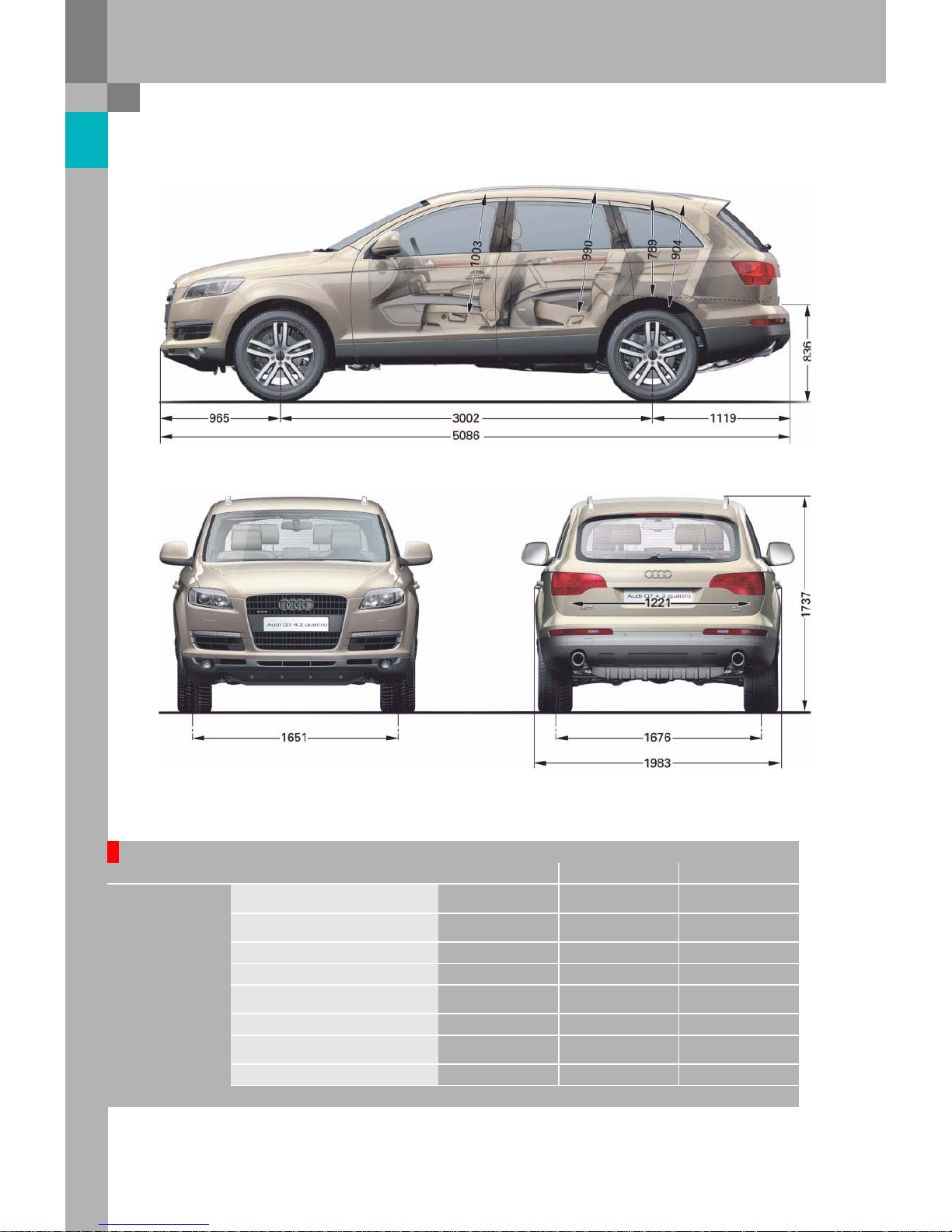

Some Audi Q7 dimensions.

361_045

361_046

5-seater

6/7-seater

Admiss

ible total weight in kg

4.2l FSI

3.0l TDI

Unla

den weight

without dr

iver in kg

4.2l FSI

3.0l TDI

Drag coeffi

cient Cw

0.37

2895

2950

2240

2295

3065

3120

2270

2325

Tank capacity

in

litres 100

Tra

iler weight, braked

(on 12 %

uph

ill

gradient)

in kg

3500 3200

Nose we

ight

in kg 140 130

Combinat

ion weight (12 %) in kg

4.2l FSI

3.0l TDI

Admiss

ible roof

load in kg

100

6495

6550

6365

6420

4

Interior dimensions

361_103

Luggage

compartment volume

775 l

330 l

36

1_105

361

_

104

2035 l

361_10

6

5

Intr

oduction

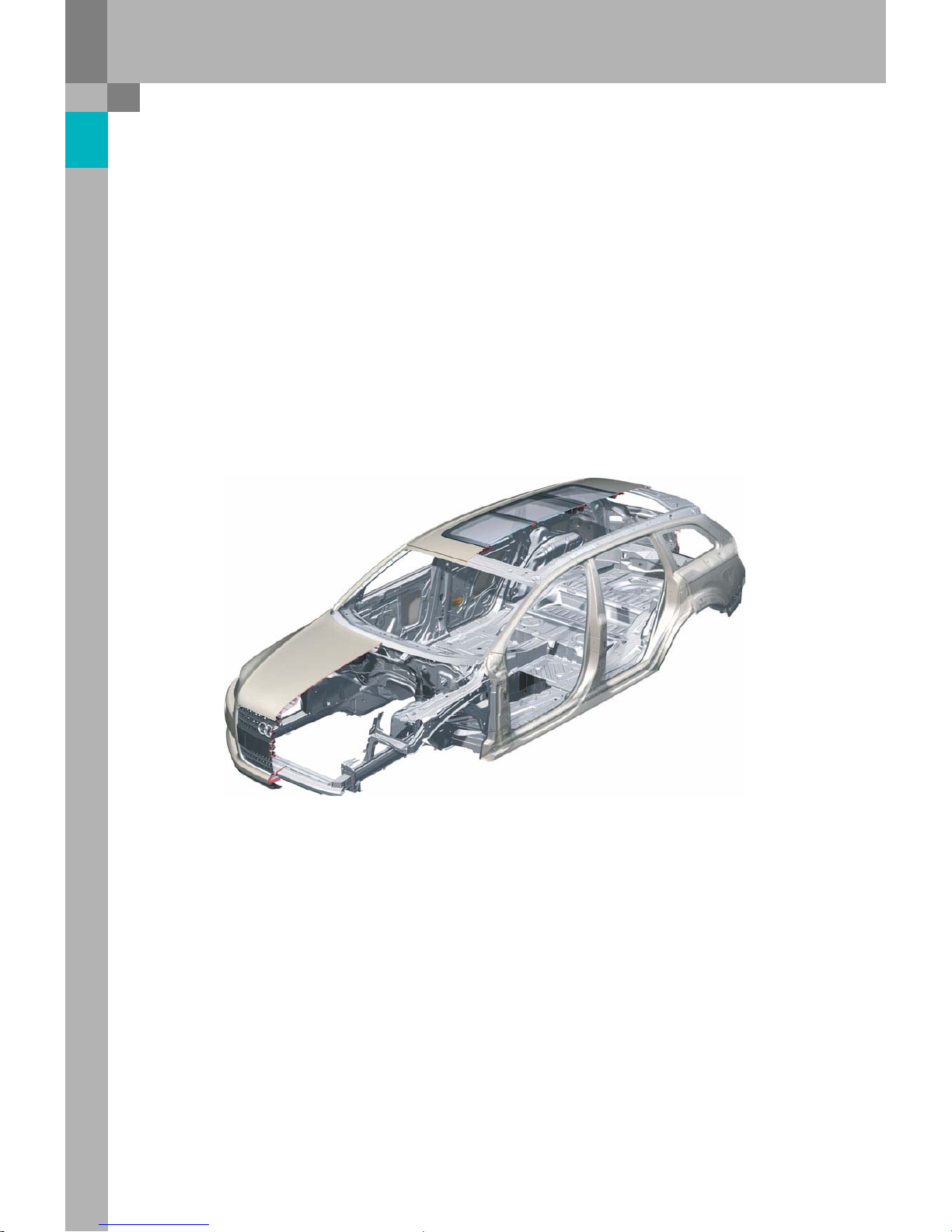

Body

The

body of the Audi Q7 has

been newly developed by Audi and is

not ba

sed on

a predecessor SUV model.

During

the deve

lopment proce

ss, the most signif

icant pr

operties and characteristic

values were initia

lly

defined. For ex

ample:

●

body weight

●

t

orsional and bending values

●

crash

perf

ormance

●

sche

duled development time

●

scope of simulation and protot

ype devel

opment

●

planned insurance ca

teg

ory

Significant features of the Audi Q7 body shell ar

e a

high ov

erall

rigidity as well as optimised local bending and

torsional

va

lues at the body nodes and fo

rce application ar

eas.

Bodys

hell

361_055

The development

●

of an open sky system,

●

an optional third seat row,

●

a

tailgate with integr

ated rear

lights, which wraps

around to the rear side panel,

were furt

her i

mportant features.

The fo

cus was on

combining these elements

with

the typical Audi high quality expressed, for instan

ce,

in the dimens

ional accuracy of the body parts,

the

narrow

gap widths and

surface finish.

The

self-su

pporting, lightwei

ght steel body of

the

Audi Q7 is built in four bodyshell versions:

●

Normal roof

●

Normal roof with three seat rows

●

Panorama roof (open sky system)

●

Panorama roof (open sky system) with thr

ee

seat

rows

The Audi Q7

with thr

ee

seat rows is eq

uipped with

an

additional cross-

piece in the spare wheel well

ar

ea for

attac

hment of the seat belts. On

the

ve

rsions with the panorama roof, the cr

oss-

pieces at

the B and C-pillars are dispensed with. T

heir

function is fulfilled by the open sky mo

dule.

6

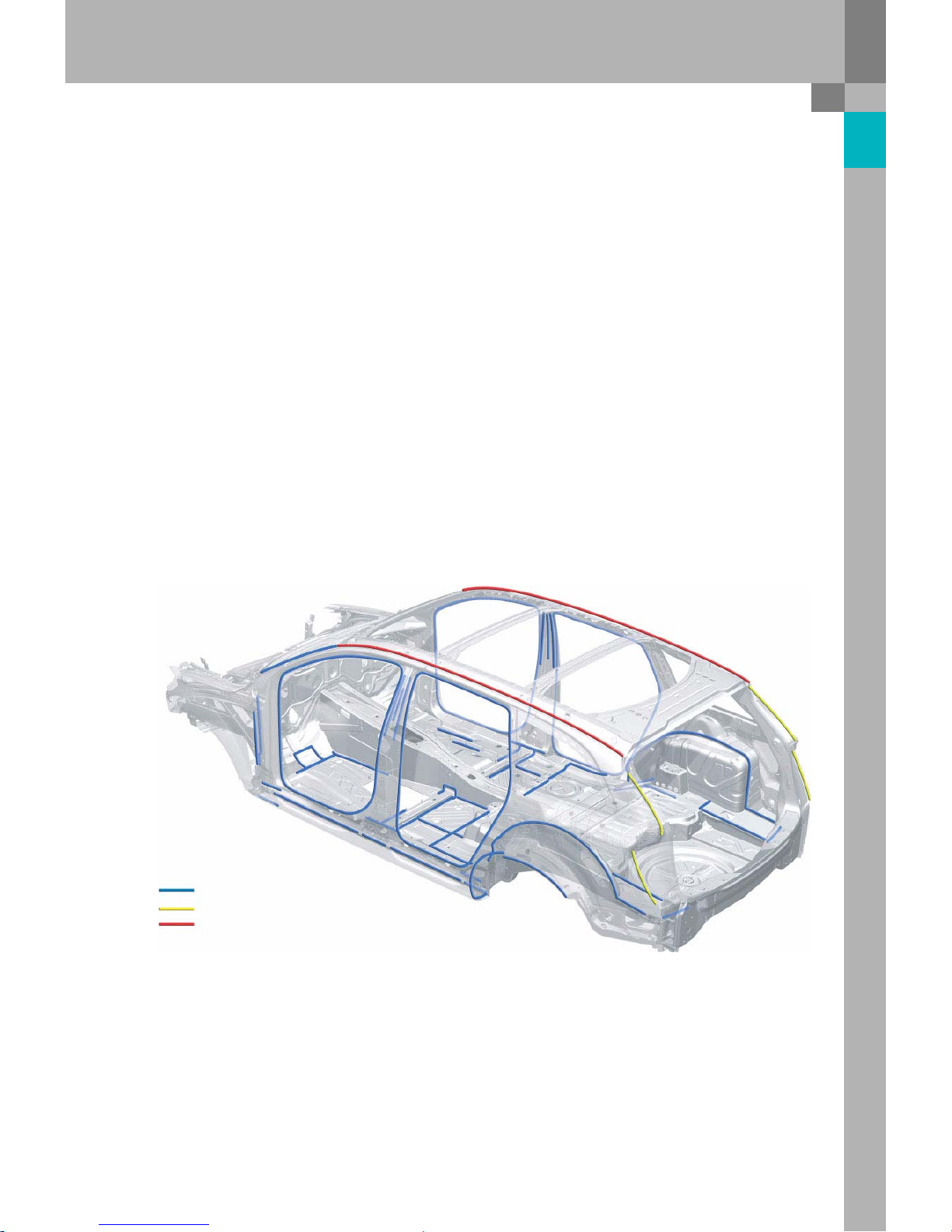

Joining tec

hniq

ues

In

order to

meet the high demands

with regard to

body rigidity, crash safety and optimised pr

oduction

pr

ocesses, the following joining techniques ar

e

employed on the Audi Q7:

–

Spot welding

–

Spot weld bonding

–

MAG welding

–

Laser soldering

–

Pla

smatron soldering

The

joining technique

most frequently employed for

areas subject to

high loads is

spot weld bonding

using

a

structural

adhesive.

The

bonded jo

ints, with

a

length of 79815

mm,

co

mprise

5403

spot welds. The to

tal length of

the

la

ser-soldered

joints (s

eamless joints between roof

and side frame) amou

nts to 4420

mm. As with the

Audi A3 Sportback

and the Audi A6 Avant '05, the

side pa

nel and the rain channel are joined using

plasmatron

soldering. Like la

ser soldering, this

tech

nique

ensures

a hi

gh-q

uality and

a

virtually

invisible seam. The

length of the left and right joints

amounts to 1438

mm. The

length of the MAG

welded jo

ints, used in areas which are inaccessible

using welding tongs, amounts to 15272

mm.

Adhesive

Plasmatron soldering

La

ser soldering

Spot welding (not sh

own)

MAG

welding (not shown)

361_057

7

Body

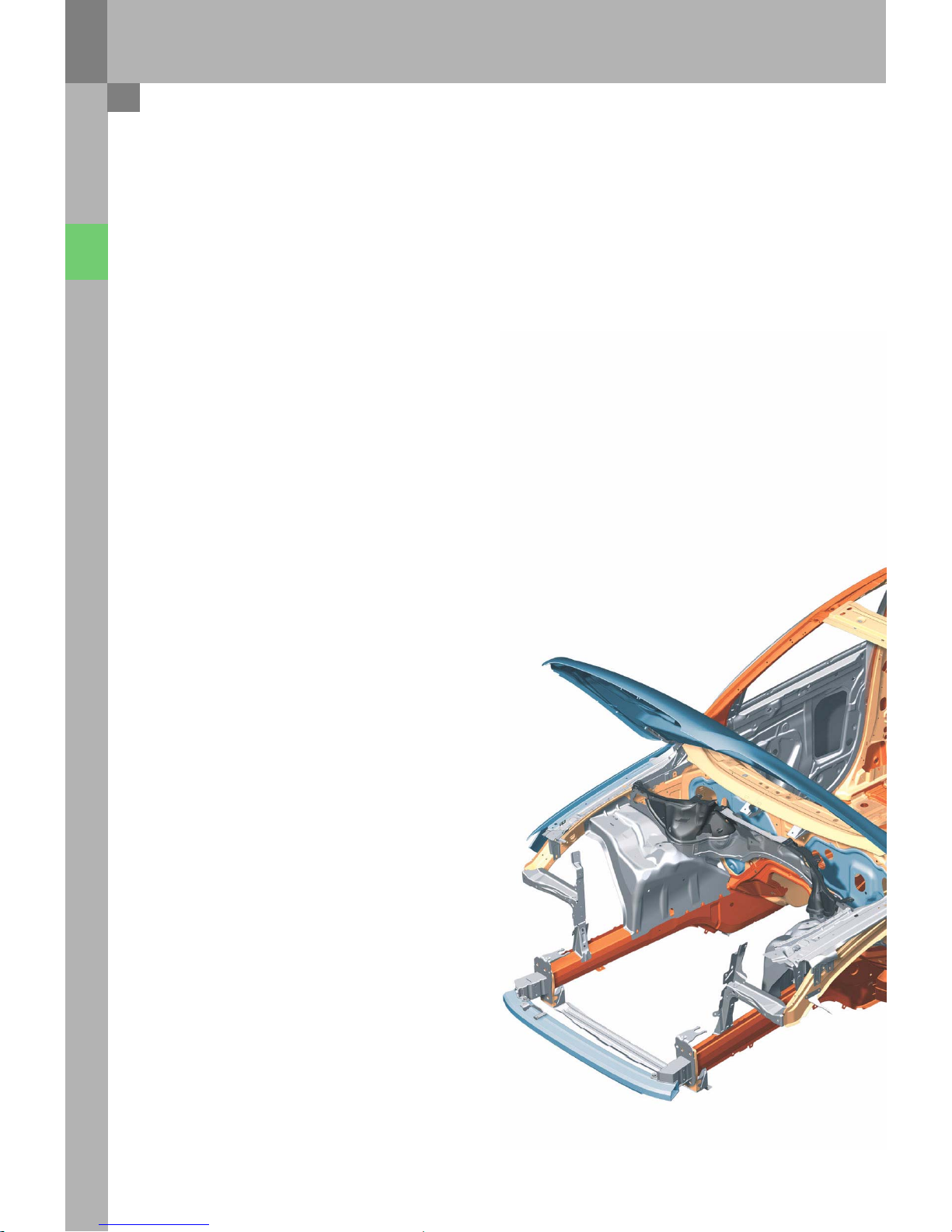

Materials

In

addition to

the joining techniques employed,

selection of the correct materials is vital for

ac

hieving both crash

safety and body rigidity.

Depending on loading and weig

ht, the most

suitable material is

deter

mined for each

component.

The propor

tions of the individual

materials used ar

e

as

follows:

–

Standard steels

36 %

–

High-strength steels

26 %

–

Higher-strength and

super high-strength steels

32

%

–

Aluminium 6%

The

wing panels, bonnet and

tailgate are made of

aluminium, making them some

22

kilogr

ammes

lighter than their

steel counterpar

ts. The

weight was

further reduced through the use of various semifinished pr

oducts*. With ta

ilored ro

lled blan

ks, for

example,

the wall thic

kne

sses can be adapted to

withstand differing component load

ing. Th

e

reinf

orcements for the rear longitudinal members

and the floor

cover pa

nel are made from

tailored

rolled

blanks.

* Semi-f

inished pr

oducts: Pre-processed materials

for the manufacture of parts and components

The

sill tube consists of

a ro

lled section because the

manufacturing tolerances are lo

wer in this case

than for an ex

truded tube, enabling smaller wall

thic

knesses. In order to meet pedestrian pr

otection

requir

ements, plastic parts are used in the ple

num

chamber/bulk

head area.

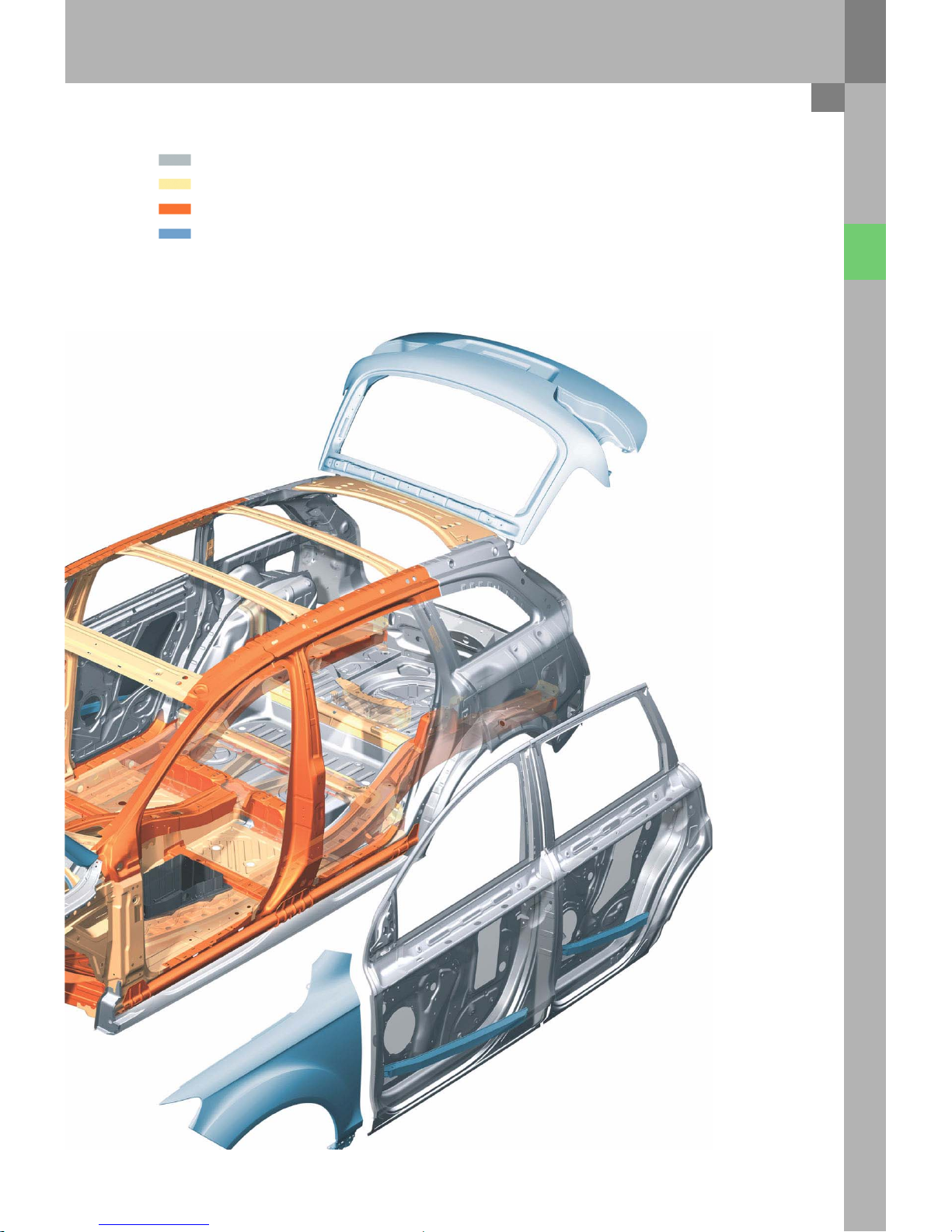

8

Stan

dard steels

High strength

steels

Higher-strength and super high-strength steels

Aluminium

361_0

56

9

Body

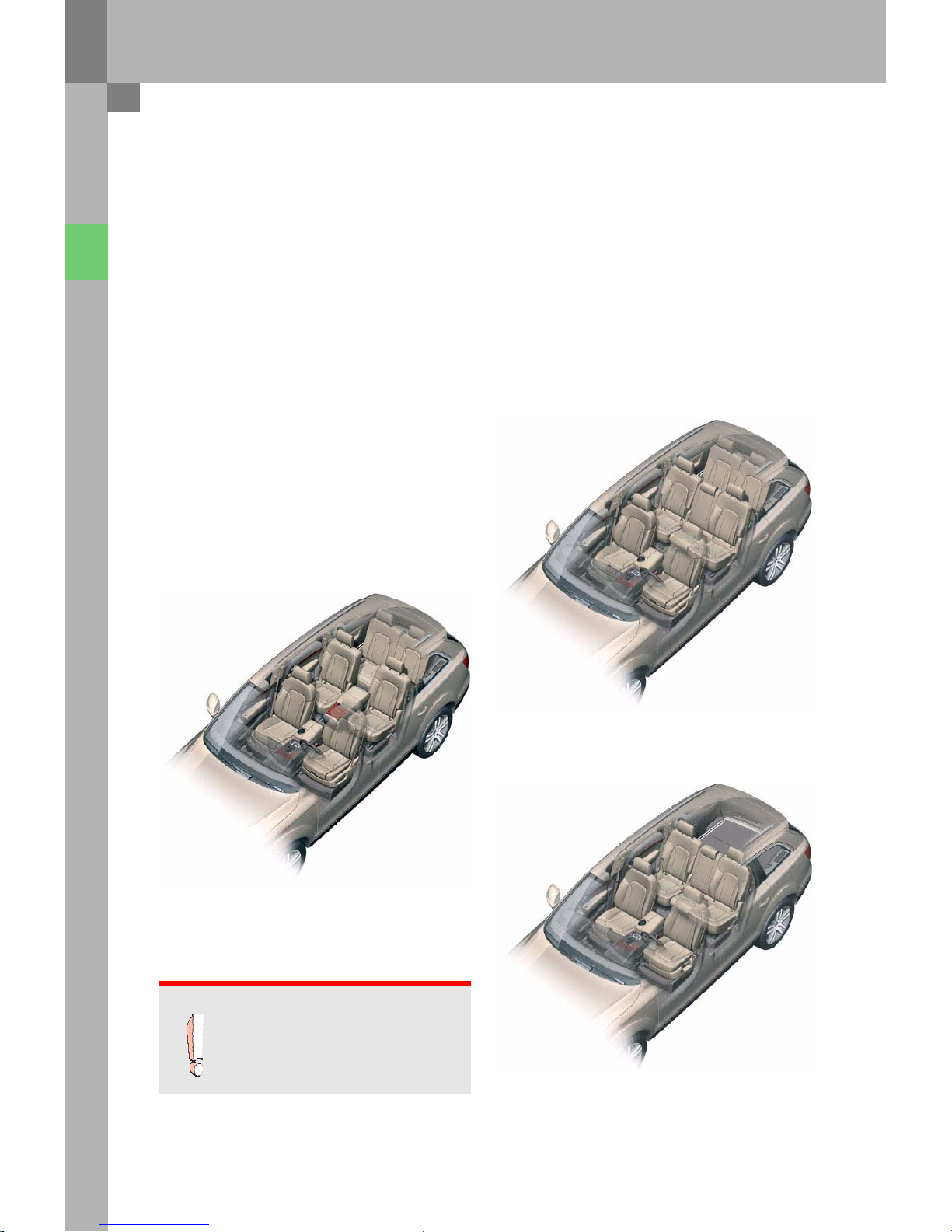

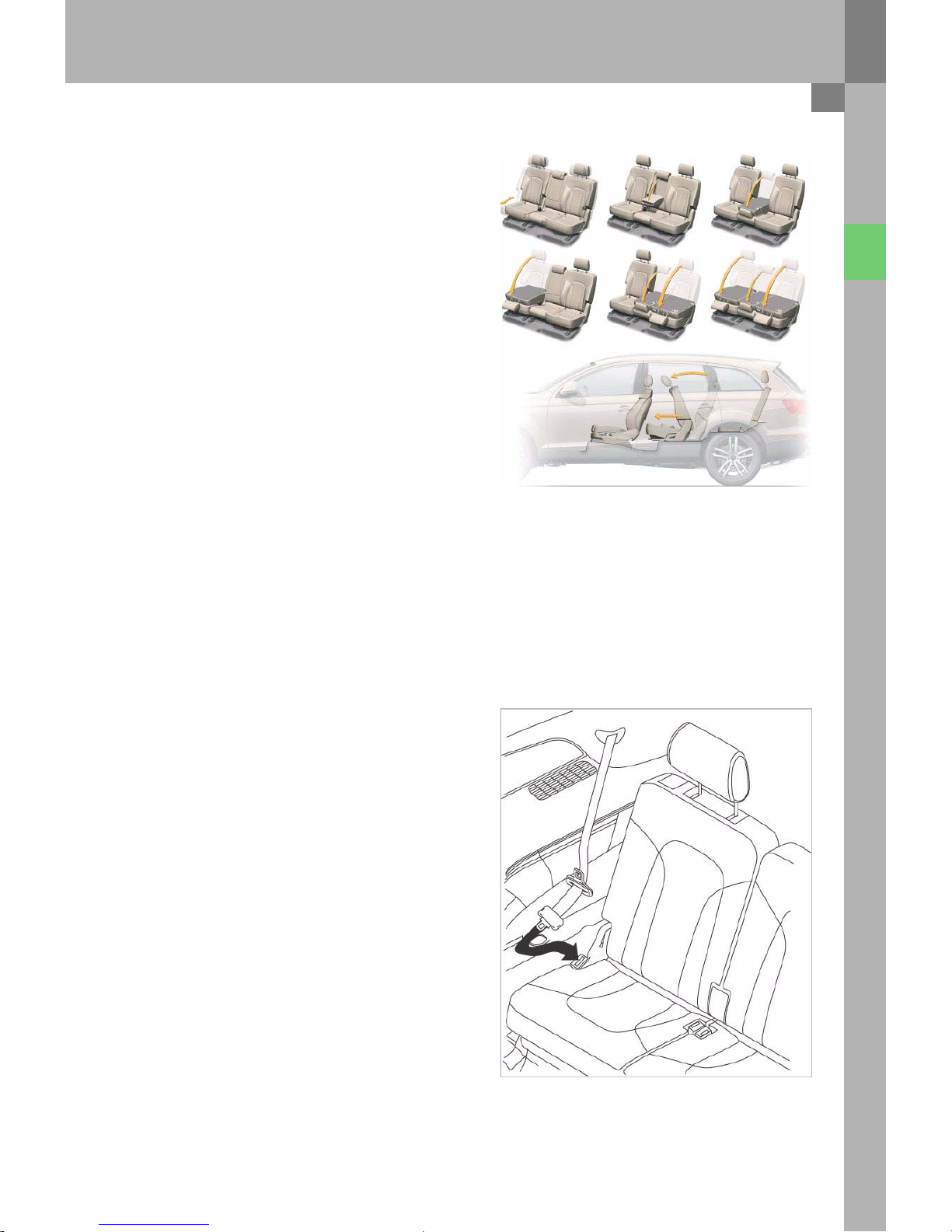

Seat

concept

The Audi Q7 seats up to se

ven occupants. As

standard, the Audi Q7 is eq

uipped with five seats.

The Audi Q7 can optionally be fitted with el

ectrically-adjustable seats for the driver and fr

ont pa

ssenger.

A memory function is also available for the front

seats. The backrests of the driver and front passenger seats

have been ergono

mically designed

such as to reduce to

distance between the occupant's head and the head

restraint. The headrest must be adjusted correctly for

this purpose. The seats in the second seat row can be

individually adjusted long

itu

dinally and offer

occupants the most generous leg room in this

vehicle cla

ss. Wher

e

the Audi Q7 is eq

uipped with

a

third seat row, the

second

seat row features an easy-e

ntry func

tion and

longit

udinal

seat adju

stment. In the 6-

seater equi

pment version, comfort

seats are optionally availa

ble for the

second seat row.

Audi Q7 with seven seats

Audi Q7 with six se

ats

361_050

Audi Q7 with

five se

ats

36

1_052

Note

Please refer to the owner's ma

nual for

inf

ormation on operation of

the

vehicle seats.

361_049

10

The

head restraints of the second seat row do not

pr

event the backrests from fo

lding.

When the head

restraints of the second seat row are lowered, the

backrests do not fully reach

the load floor position.

When folding down the backrests of the third seat

row, the head restraints lower automatically, making

it

ea

sier to fold

down the backrests.

If

the seats in the second and third seat roads are

unoccupied, the head restraints can be lowered by

hand in or

der to impr

ove rearward visi

bility.

The easy-e

ntry func

tion on the second seat row is

operated vi

a a le

ver next to the head restraint. The

backrest folds forwards to

a

certain angle. The seat

base

also moves in the direction of tr

avel. The easy-

en

try function enables the occupants to

enter and

exit the third

seat row.

361_051

Attac

hment of the seat belts to

the seats of the third

sea

t row is ac

hieved via

additional belt buckle

s. Th

e

advantage is that the seatbelts can be removed

from

the seats as requir

ed. The

seat belts ar

e

retracted and the latch plates can be inserted in th

e

D-pillar tr

im. In

this manner,

the seat belts ar

e

pr

otected ag

ainst damage during loading of the

luggage c

ompar

tment

when the backre

sts ar

e

folded down. The central belt bu

ckles ar

e a

ttached

to

the vehicle floor.

Persons above

a

height of

160 cm are prohibited

from

being

seated in the third seat row.

361_044

11

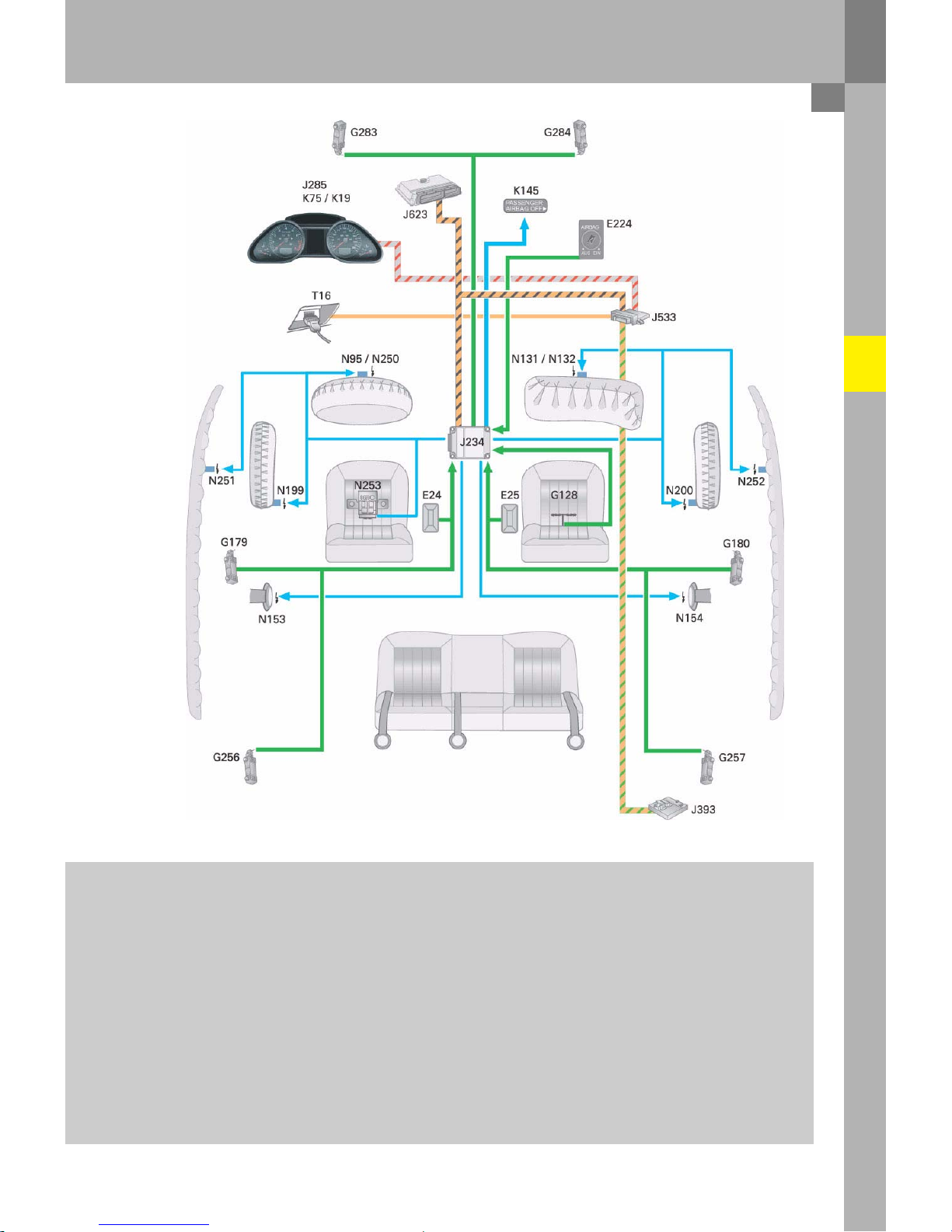

Passenger pr

otection

Passenger pr

otection in the A

udi Q7

Owing to

its wide range of use, the Audi Q7 repr

esen

ted

a

special challenge for the development team:

A high degr

ee of passe

nger protec

tion du

ring both

on-road and off-road oper

ation.

In

meeting these requir

ements, the Audi Q7 fits seamlessly

into

the high safety

level of the current Audi

model

range.

The passenger pr

otection system of the Audi Q7

comprises the following components and systems:

–

Airbag control unit

–

Driver and fr

ont passenger airbag, dual

stage

–

Front side airbags

–

Sideguards (curtain airbags)

–

Crash sensors for front airbag, the so-c

alled upfront sensors for fr

ontal impact detection

–

Crash sensors at the B-pillars for side impact detection

–

Crash sensors at the C-pillars for side impact detection

–

Front belt

tensioners

–

Ba

ttery isolation igniter

–

Switch in fron

t-seat belt buckles

–

Seat occupied sensor in front pa

ssenger seat

Side airbags for

the second seat row and

a key operated

switch for deactivation of the fr

ont passenger airbag

with the corre

sponding warning lamp are also availa

ble as optional equipment.

Owing to

the

va

rious requir

ements and statut

ory regulations placed upon vehicle

manufactur

ers by the

markets, the eq

uipment versions may vary, part

icularly with regard to

the US market.

Key

E24 D

river side belt switch

E25 Front pa

ssenger

side belt switch

E22

4 Key

oper

ated switch to de

activate fr

ont

pa

sse

nger side airbag

G128 Seat occupied sensor, front passenger side

G179 Side airbag crash sensor on driver side

(B-pillar)

G180 Side airbag crash sensor on front pa

ssenger

side (B-pillar)

G256 Rear

side airbag crash sensor on dr

iver side

(C-pi

llar)

G257 Rear side airbag crash sensor on pa

ssenger

side (C-pillar)

12

361_001

G28

3 Front

airbag crash sensor for driver

side

(front end, left)

G28

4 Front airbag crash

sensor for front passenger

side (front end, right)

J234

Airbag control unit

J285

Control unit in dash pa

nel insert

J393

Conven

ience

system central control unit

J533 Data

bus diagnostic interface (g

ateway)

J623

Engine co

ntrol unit

K19 Seat belt

warning

system

warning lamp

K75 A

irbag wa

rning lamp

K1

45 Front passenger side airbag de

activated

warning lamp (PASSENGER AI

RBAG OFF)

N95

Driver side ai

rbag

igniter

N

250 Driver side airbag igni

ter

2

N131 Fr

ont passenger

side airbag igniter

1

N132 Fr

ont passenger

side airbag igniter

2

N153 Driver

seat belt tensioner ig

niter

1

N154 Fr

ont passenger

seat belt

tensioner ig

niter

1

N199 Side airbag

igniter on driver side

N200 Side airbag igniter on front pa

ssenger side

N

251 Driver side curtain airbag igni

ter

N252 Fr

ont passenger

side curtain airbag igniter

N253 Battery

isolat

ion igniter

T16 C

onnector, 16-pin (diag

nostic connection)

13

Passenger pr

otection

Airbag control

unit J234

The

purpose of the electronics integrated in

the airbag control unit is to

detect

vehicle deceleration or

a

cceleration and to evaluate it so as to

detect

a

vehicle

impact. In order to

detect vehicle deceleration or

a

cceleration during an impact, ex

ternal

sensors are used in

addition to

the sensors

instal

led inside the control

unit. The

electronics in the control unit

detect

a crash based al

one on the info

rmation received from

the sensors.

O

nly once all the sensor information has been evaluated by the co

ntrol unit electronics can the electronics

decide when and which safety components should be

activated.

The airbag co

ntrol unit is able to

detect frontal,

side and rear impacts.

A further task of

the airbag control unit is to

activate the relevant restraint systems (belt tensioners or belt

tensio

ners

and airb

ag) depending on the type and se

verity of

the impact as well as signalling the crash to

other vehicle systems.

The

airbag electronics have the following main

ta

sks:

–

Crash detection (front, side, rear)

–

Defined trig

gering of the belt tensione

rs, airbags

and battery isolation igniter

–

Defined triggering of the second fr

ont ai

rbag

stage

–

Eva

luation of all input information

–

Perma

nent monitoring of the complete

airbag

system

–

Independent

power supply via

a ca

pacitor for

a

defined time (approx. 150

ms)

–

Fault display via a failure

warning lamp

–

Storage of fault and crash information

–

Communication of a crash to

the other system

components via the drive CAN or discrete crash

output (conventional wiring)

–

Activation of seat

belt warning system

361_007

For inf

ormation on

which components must be replaced following an accident, please refer to the applicable

W

ork

shop

Manual in ELSA. An airbag co

ntrol unit can o

nly be repl

aced with

the aid of an online-capable VAS

5051

or VAS

5052. The guided fault-finding or guided function

applications must be used for this

purpose. The

airbag control unit must be c

oded and adapted to the re

levant vehicle. If

coding or adaption is not performed

correctly,

this may re

sult in

malfunctions in other vehicle systems,

e.g. the ESP.

14

Data exchange

The

airbag control unit is connected to

the drive CAN.

The airbag

control unit transmits the following inf

ormation

via the dr

ive CAN:

–

Activation of wa

rning lamp K7

5

–

Activation of seat

belt warning system

–

Diagnostic data

–

Crash signal

–

Crash inf

ormation for the control element test

–

ESP data

–

Front passenger airbag activated/deac

tivated status (display in dash panel insert)

The airbag

control unit

evaluates the follow

ing information from the data

bus:

–

Dimming for the fr

ont passenger side airbag de

activated warning lamp (Passenger Airbag Off)

The

information

that a crash has occurred is

used by ot

her control un

its in or

der to u

nlock a locked central

locking system, cut off

the fuel supply,

activate the hazard warning lights

etc.

Ai

rbag warning lamp

K75

Activation of the airbag warning lamp, which is loca

ted in the dash panel insert J285, is

performed via the

CAN bus. In

the absence of a

data message from the airbag control un

it, the warning

lamp is switched on

auto

matically by the dash panel insert.

Rear impact re

cognition

During a rear

impa

ct, the vehicle is strongly a

ccelerated in the direction of trav

el. The crash sensors in the

ai

rbag co

ntrol unit and the crash

sensors G283

and G

284 de

tect this

vehicle acceleration and tr

ansmit

the

rel

evant signals to the airbag electronic

s. Th

e airbag electronics evaluate the information. If

the sensor

sign

als ex

ceed

a

specified

va

lue, the belt tensioners are trig

gered and the battery

isolation igniter is activated.

15

Passenger pr

otection

Seat

belt warning system

The Audi Q7, like the Audi A6 ´

05 for example, features a seat belt warning function for the driver and front

pa

sse

nger.

When the ignition is switched on, the airbag control unit evaluates the info

rmation from

the driver and fr

ont

pa

ssenger belt buckle switches as

well as information from

the fr

ont passenger side seat oc

cupied sensor.

The

airbag control unit de

tects wh

ether the fr

ont passenger

seat is oc

cupied or not ba

sed on the resistance

values of the fr

ont passenger side seat oc

cupied sensor. If

the driver or fr

ont passenger

have not fastened their

seat be

lts, they are aler

ted via the

seat

belt warning sy

stem wa

rning lamp K19 in the dash pa

nel insert and an

a

udible signal.

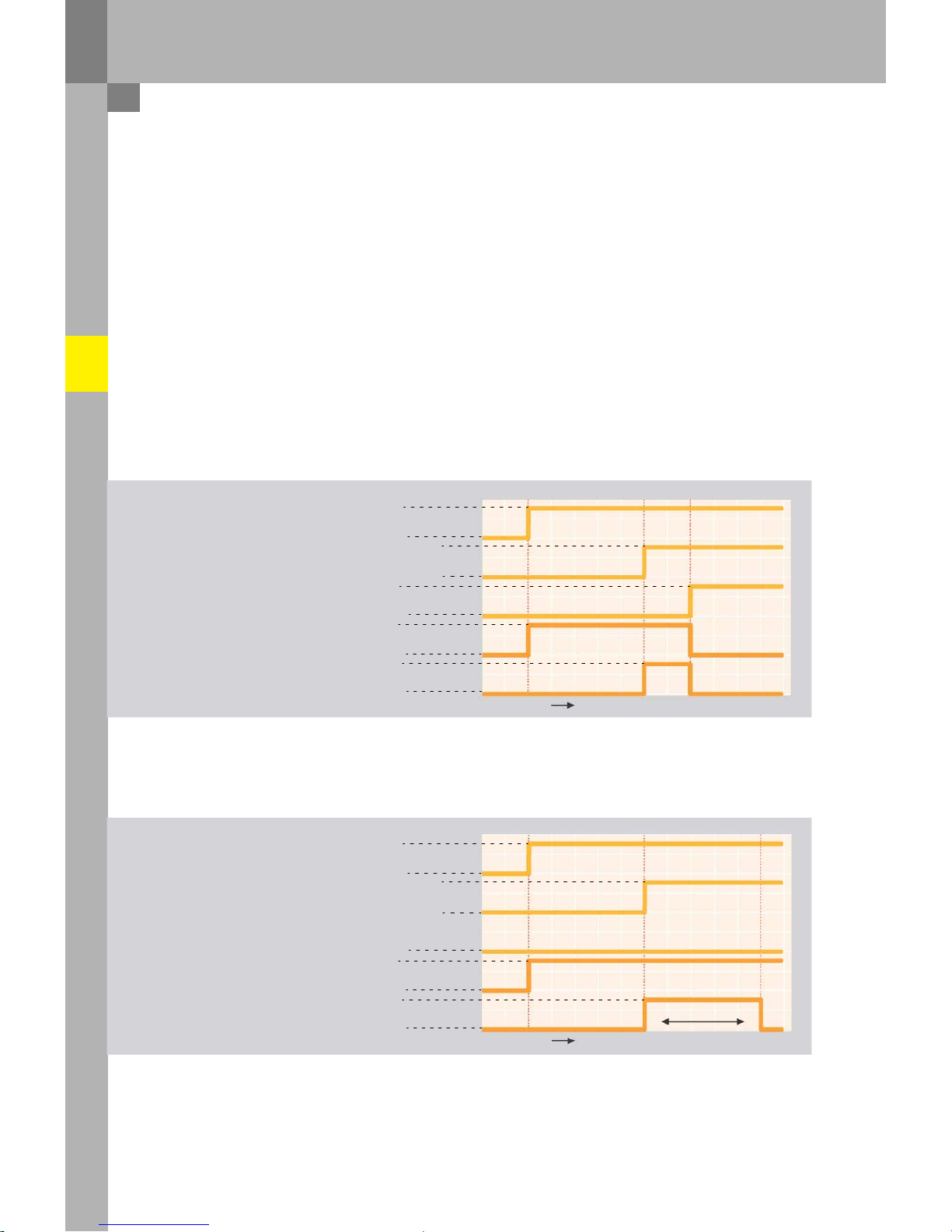

Timing di

agrams for the seat belt

warning system

Visual and audible signals –

seat

belts are fastened

late

Terminal 15

Vehi

cle speed

Fasten

ed

Seat belt warning sy

stem warning lamp

On

Off

v >

10 km/h

v <

10 km/h

Yes

No

On

Aud

ible signal

Off

On

Off

Time

361_016

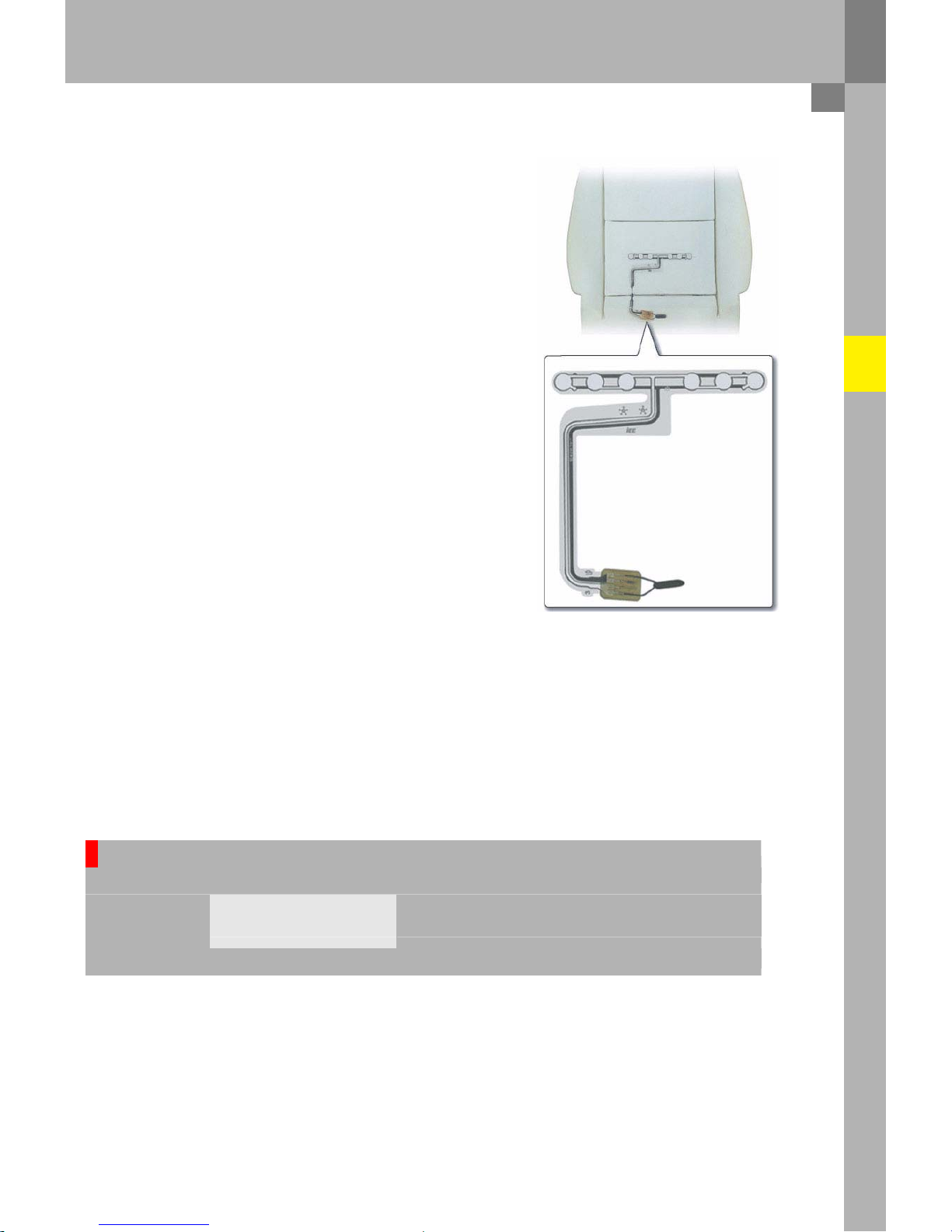

Visual and audible signals –

seat

belts not fastened

Terminal 15

Vehi

cle speed

On

Off

v >

10 km/h

v <

10 km/h

Fasten

ed

No

On

Seat belt warning sy

stem warning lamp

Aud

ible signal

Off

On

Off

Time

min.

90

sec.

361_018

The

warn

ing is re

activa

ted if the seat

belt

sta

tus changes du

ring "termi

nal

15

on".

16

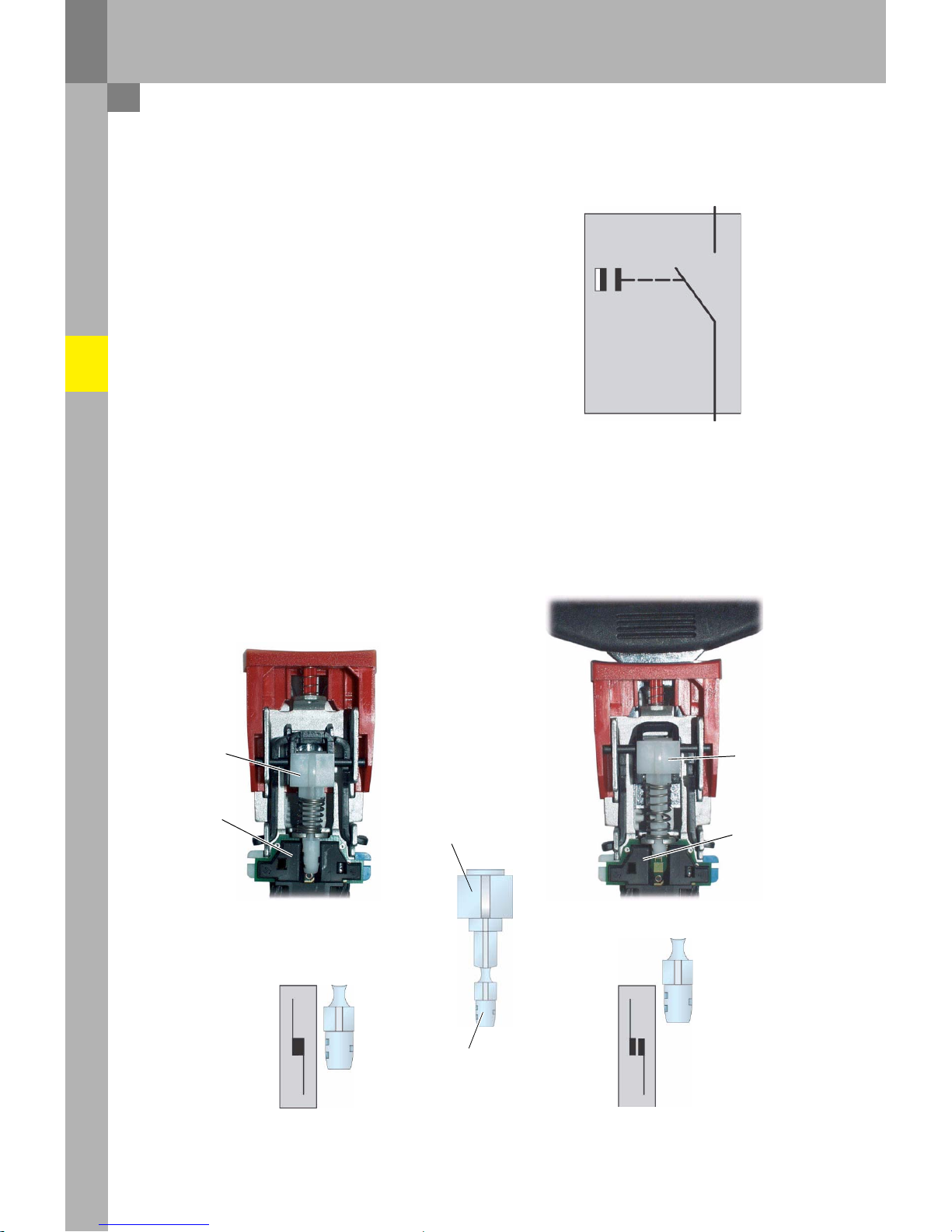

Seat

occupied sensor, fr

ont passenger side G128

The front passenger side seat

occupied sensor

consists of a plastic film

inco

rporating several

individual pr

essure sensors. The front passe

nger

side seat occupied sensor is located in the fr

ont

pa

sse

nger seat, between the seat cover and

padding. The seat occupied sensor ex

tends

across

the rear part of the fr

ont passenger seat and is

positioned such that the relevant ar

ea of the seat

surface is monitored.

Depending on the lo

ad, the resistance

value of the

fr

ont pa

ssenger

side seat occupied sensor is

modified. When the fr

ont passenger seat is

not

occupied, the resistance value of the fr

ont

pa

sse

nger side

seat occupied sensor G128 is high.

As the load incr

eases, the re

sistance value falls.

Above

a load of

appr

ox.

5 kg,

the airbag control unit

detects "seat occu

pied".

The airbag

control unit requires the

information

from

the front pa

ssenger

seat occupied sensor G128

and from the belt buckle switches for

the seat

belt

warning system.

361_017

Resistance va

lue of G1

28

Evaluation

approx. 430 Ohm and high

er

approx. 140 Ohm and lowe

r

Seat not occupied

Seat occu

pied

17

Passenger pr

otection

Belt switch

Driv

er

side belt switch

E24

Fr

ont passenger side belt switch E25

(In the

driver and front passenger side belt buc

kles)

Information as to

whether or not the driver and fr

ont

pa

sse

nger have fastened their seat belts is required

by the "seat belt warning system" function. In order

for the ai

rbag

control unit to receive this informat

ion,

the belt switches

E24 and E25 are integr

ated in th

e

belt buckles for the front

seats.

The

switches fi

tted are r

eed switch

es. The reed

switches

switch from

"switch open" to

"switch

closed" through the action of an external magnetic

field. The magnet

1 in

the so-called spring

thorn is

located near the r

eed switch when

the latch plate is

not in

serted, i.e. the r

eed switch is closed.

When the latch plate is inserted in the belt buckle,

the spring thorn is moved.

The

mag

net

1 in

the spring thorn no l

onger acts

upon the r

eed switch,

i.e. the r

eed switch is open.

Based on the measured re

sistance value, the airbag

control unit recognises wh

ether the seat belt is

fastened or not.

361_019

Spring thorn

Spring

thorn

Reed switch

Spring

thorn

Reed sw

itch

3

61_020

3

61_021

36

1_034

Magnet I

361_041

36

1_040

18

Driv

er seat belt

tensioner igniter 1 - N153

Fr

ont passenger seat belt tensioner

igniter 1 - N154

The front seats of

the Audi Q7 is eq

uipped with the

pr

oven compact tensio

ners. The

belt tensioners

work a

cco

rding to

the "ball

gear" principle

(not

USA)

and are

triggered

electrically by

the airbag control

unit. During a crash, the belt tensio

ners ar

e

activated before the fr

ont airbags. To prevent

excessive loads to the occupants,

the belt r

eels ar

e

eq

uipped with belt force limiters. Above

a

specified

load

level, th

ese force limiters slacken the belt,

allowing the occupant to move forwards into

the

already deployed airbag.

In

the event of

a

side impact with

side ai

rbag

trig

gering, the relevant belt tensioner is also

trig

gered. In the event of a rear

impact, the belt

tensioners are also activated, depending on the

seve

rity of the impact.

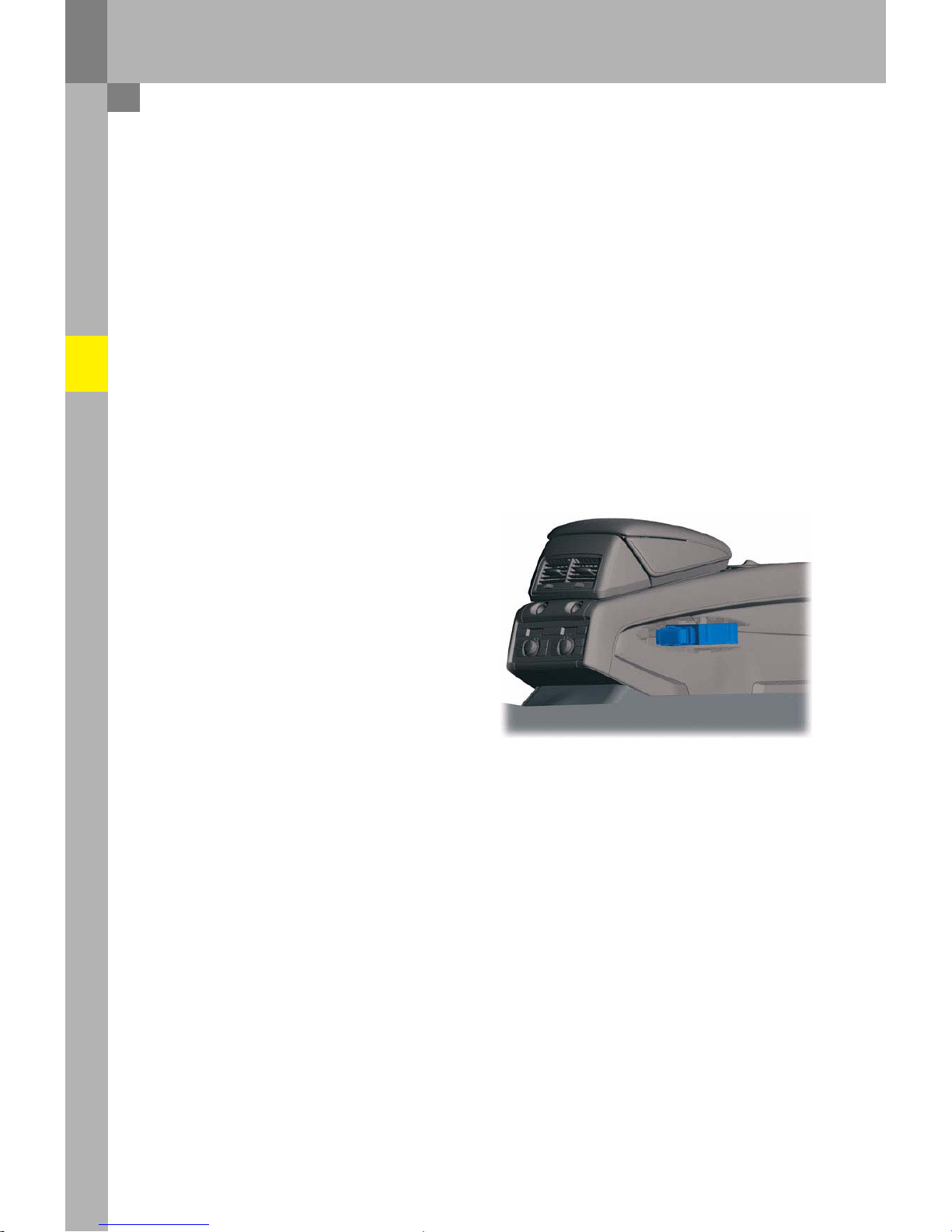

Seat belt

361_053

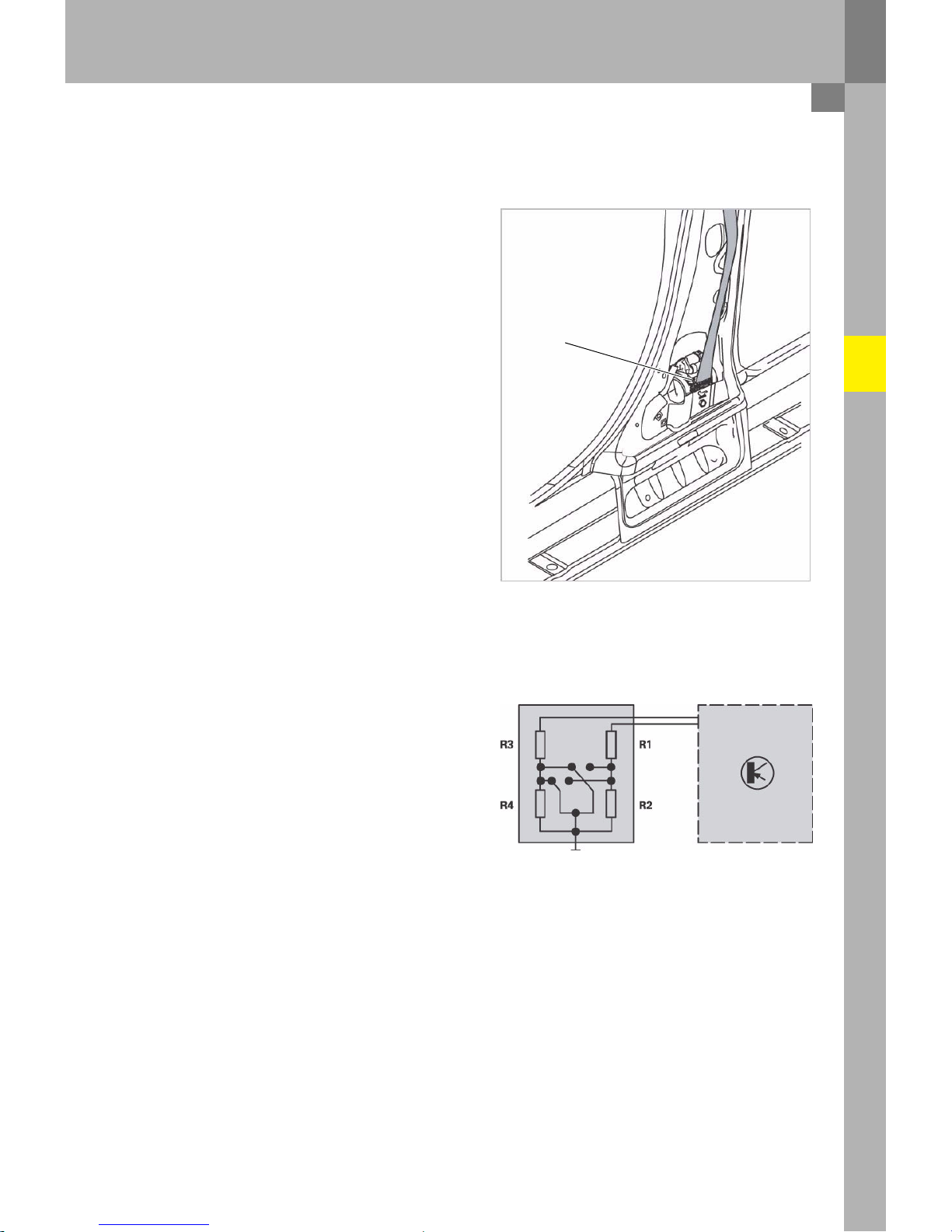

Key oper

ated switch to

deactivate front passenger side

airbag

E224

The

key oper

ated

switch to deactivate fr

ont

pa

sse

nger airbag

E224 and the corre

sponding fr

ont

pa

sse

nger side airbag de

activated warning lamp

K

145 (PASSENGER AIRBAG

OFF) are required in

order to

deactivate the fr

ont passenger airbag. An

illuminated fr

ont passenger side airbag

deac

tivated

warning lamp K145 (P

ASSENGER AIRBAG OFF)

indicates to the

occupants that the front

passenger

airbag is

deac

tiva

ted.

The

control unit unequivocally recognises the

switch position by means of the arra

ngement of

four resist

ors which are connected in-line,

pair

-wise.

If

the airbag

control unit detects

a fa

ulty key

oper

ated switch, a fa

ult me

mory entry is made and

the fr

ont passenger side airbag

deac

tivated warning

lamp K145 (P

ASSENGER AIRBAG OFF)

begins to

flash.

Airbag control unit

J234

361_025

19

Passenger pr

otection

Airbag

The front airbags on the driver and fr

ont passenger sides are eq

uipped with tw

o-stage gas

generators.

Depending on the nature

and severity of the accident, the airbag control unit sets

a

time delay between the

two

ignitions (from approx. 5ms to 30

ms). The loads which the driver and fr

ont passenger are exposed to

during a crash can be reduced by means of a

delayed ignition of the pr

opellant charges.

Both pr

opellant charges are

ignited in all cases. This prevents

a pr

opellant charge from re

maining ac

tive

following

airbag deployme

nt.

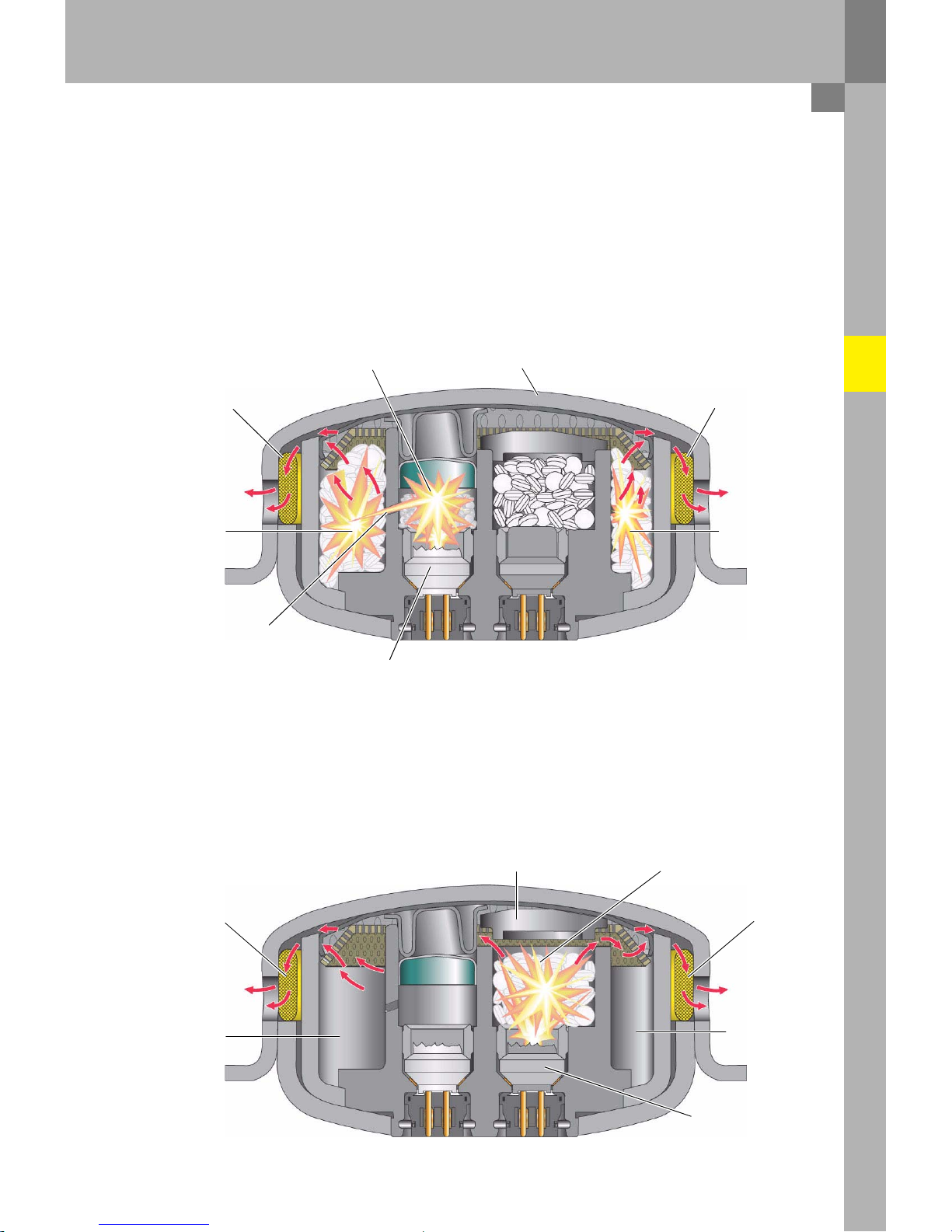

Driv

er

airbag

N95 D

river

side airbag igniter I

N

250 Driver side ai

rbag

igni

ter II

The gas

generator in the driver ai

rbag works

using two

pyr

otec

hnic pr

opellant char

ges.

Priming charge

Housing

Cap

Metal filter

Propellant

charge I

Metal filter

Propellant charge I

Bores

Propellant charge II

Ig

niter I

Ig

niter II

361_014

The

driver's airbag gas generator is flexibly

mounted in

a rubber ring.

This minimises any

vibration at the steering wheel.

The gas generator acts as a vibration damper.

20

Driv

er

side airbag

igniter I - N95

The

electrical

igniter

I,

which is activated by the airbag control unit, igni

tes the priming charge I. This ig

nites the

actual pr

opellant charge I via the bor

es.

When the gas pressure generated thro

ugh co

mbustion of

the

pr

opellant ch

arge I ex

ceeds

a

specified threshold, the housing of the gas ge

nerator becomes def

ormed,

opening up a passage to the airbag via

the me

tal filter. The airbag is deployed.

Priming charge I

Housing

Metal filter

Propellant

charge I

Bores

Metal filter

Propellant charge I

361_015

Ig

niter I

Driv

er

side airbag

igniter II - N250

Following

a

defined delay,

the airbag control unit ener

gises

the second

electrical ig

niter,

which directly igni

tes the

second pr

opellant char

ge. At

a cert

ain pressure, the genera

ted gas

lifts up the cap of the second stage

and flows into

the airbag

via the combustion chamber of

the first stage.

Cap

Propellant ch

arge II

Metal filter

Combustion

chamber

Propellant charge I

Metal filter

Combustion

chamber

Propellant

charge I

Igniter II

361_013

21

Passenger pr

otection

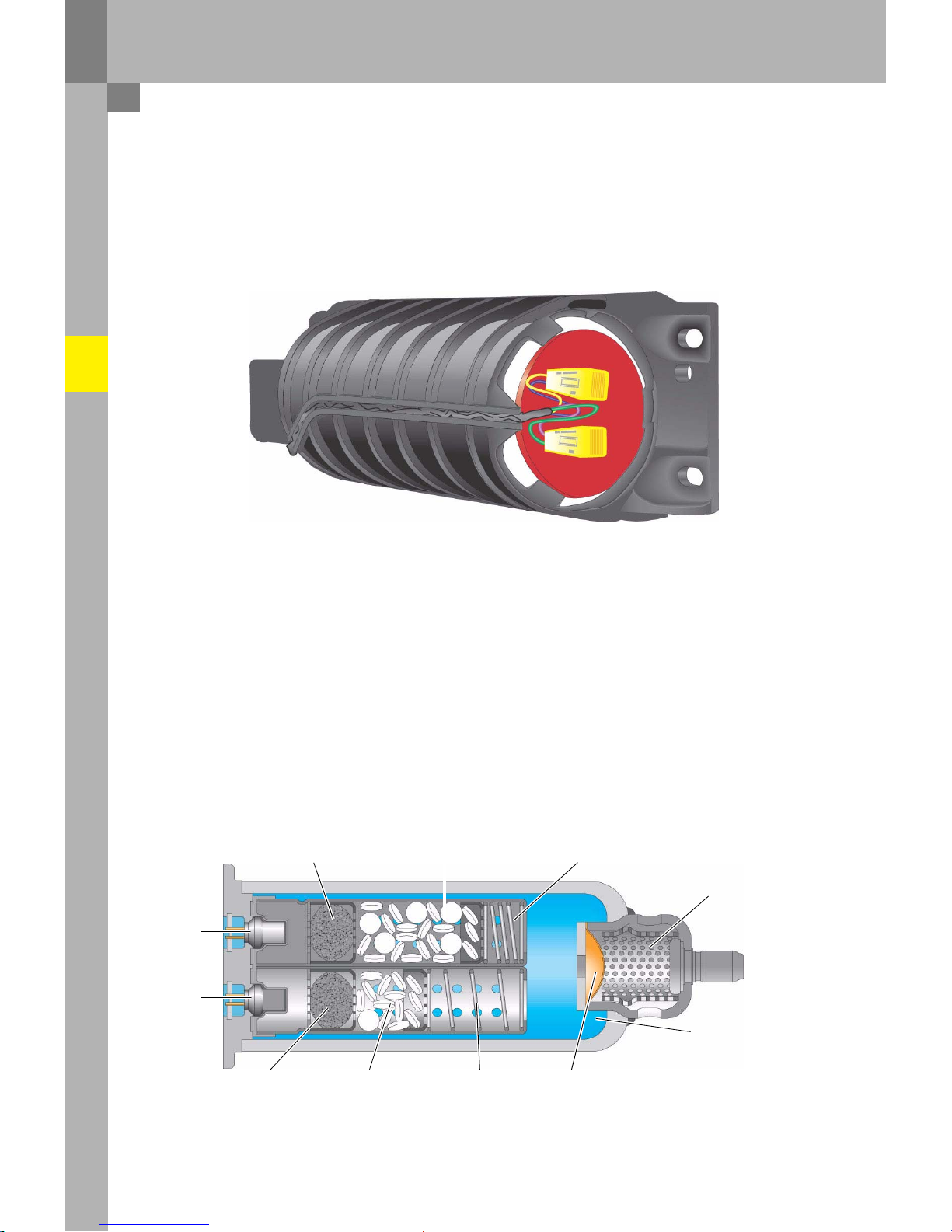

Fr

ont passenger

airbag

N13

1 Front passenger side airbag igniter I

N13

2 Front passenger side airbag igniter II

The front pa

ssenger ai

rbag module h

ousing is made of plastic.

361_008

A two-stage hybrid gas generator is used on the pa

ssenger side. Two pyrotec

hnic propellant char

ges ar

e

contained in

a

compressed gas

cylinder,

which is activated

separately by the airbag

control unit. The

so-c

alled

cold gas in

the compressed gas

cylinder is

under

a pressure of approx.

250

bar and is

a

mixture of ar

gon

(approx. 98 %)

and helium (approx. 2

%). The airbag volume is

approx.

140

litres.

The

coil springs ensure that the propellant charge tablets are held in po

sition

(pretension).

Priming charge I

Propellant ch

arge I

C

oil spring

Filter

Ig

niter I

Ig

niter II

Priming charge II

Propellant charge II Coil spring

Burst disc

Compressed gas

cylinder

G

as: Arg

on, approx.

98 %

helium,

approx.

2 %

Pres

sure:

a

pprox.

250

bar

361_002

22

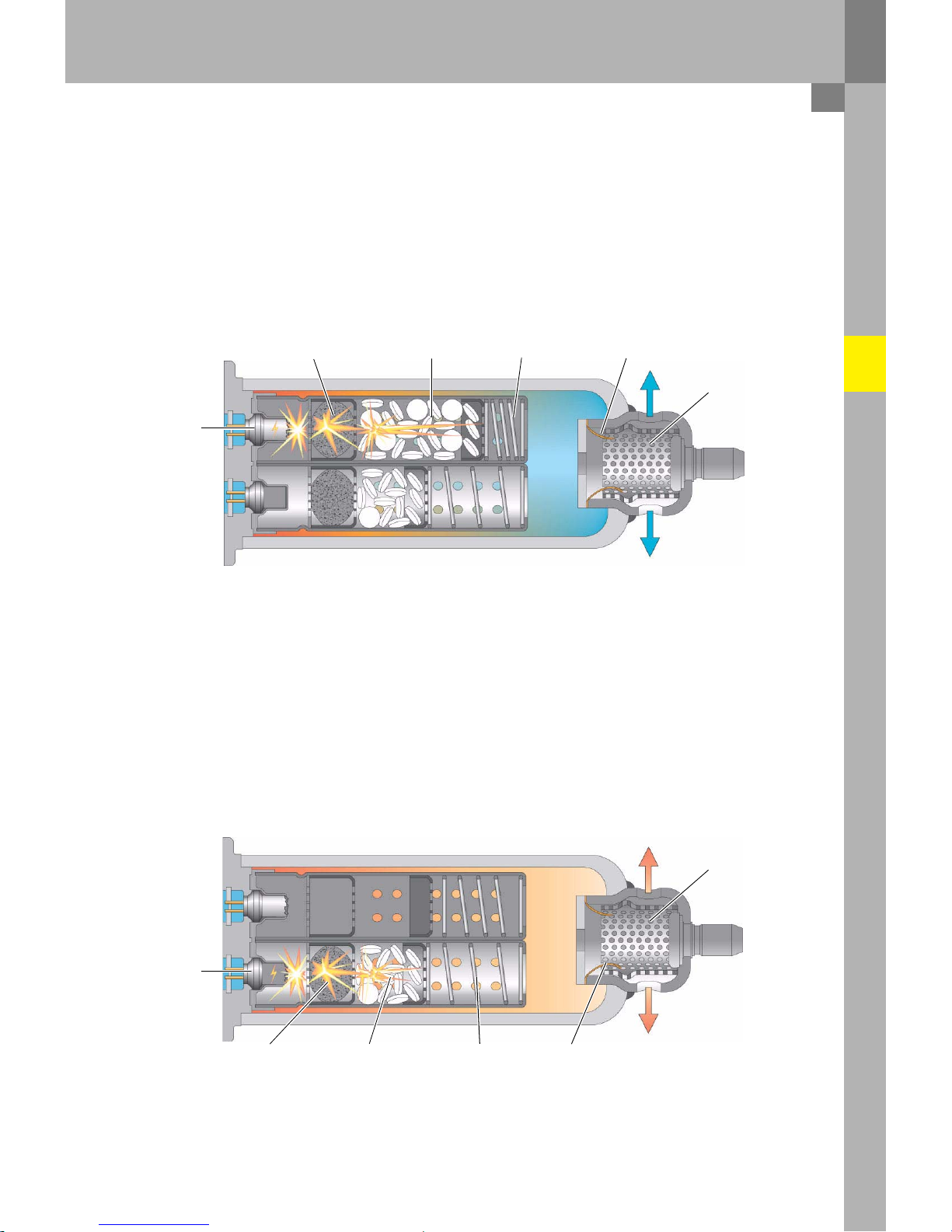

Fr

ont passenger side

airbag

igniter I - N131

The

airbag control unit energizes the igniter I and the priming charge I is ignited. This in turn ignites the

actual pr

opellant charge I. The comb

ustion gas generated increases the pressure in the compressed gas

cylinder until the burst disc breaks at

a pre

determined pr

essure value. The gas

mixture reac

hes the airbag via

the metal filter and it is deployed.

Priming charge I

Propellant ch

arge I C

oil spring

Bu

rst disc

Filter

Ig

niter I

361_003

Fr

ont passenger side

airbag

igniter II - N132

The

oper

ating principle of the second stage is

identical to

that of the first. An additional vo

lume of gas is

supplied to

the airbag through co

mbustion of

the second propellant ch

arge. There is no

further increase in

pr

essure inside the airbag during the

second stage.

Filter

Ig

niter II

Priming charge II

Propellant charge II Coil spring

Burst disc

361_004

23

Loading...

Loading...