Page 1

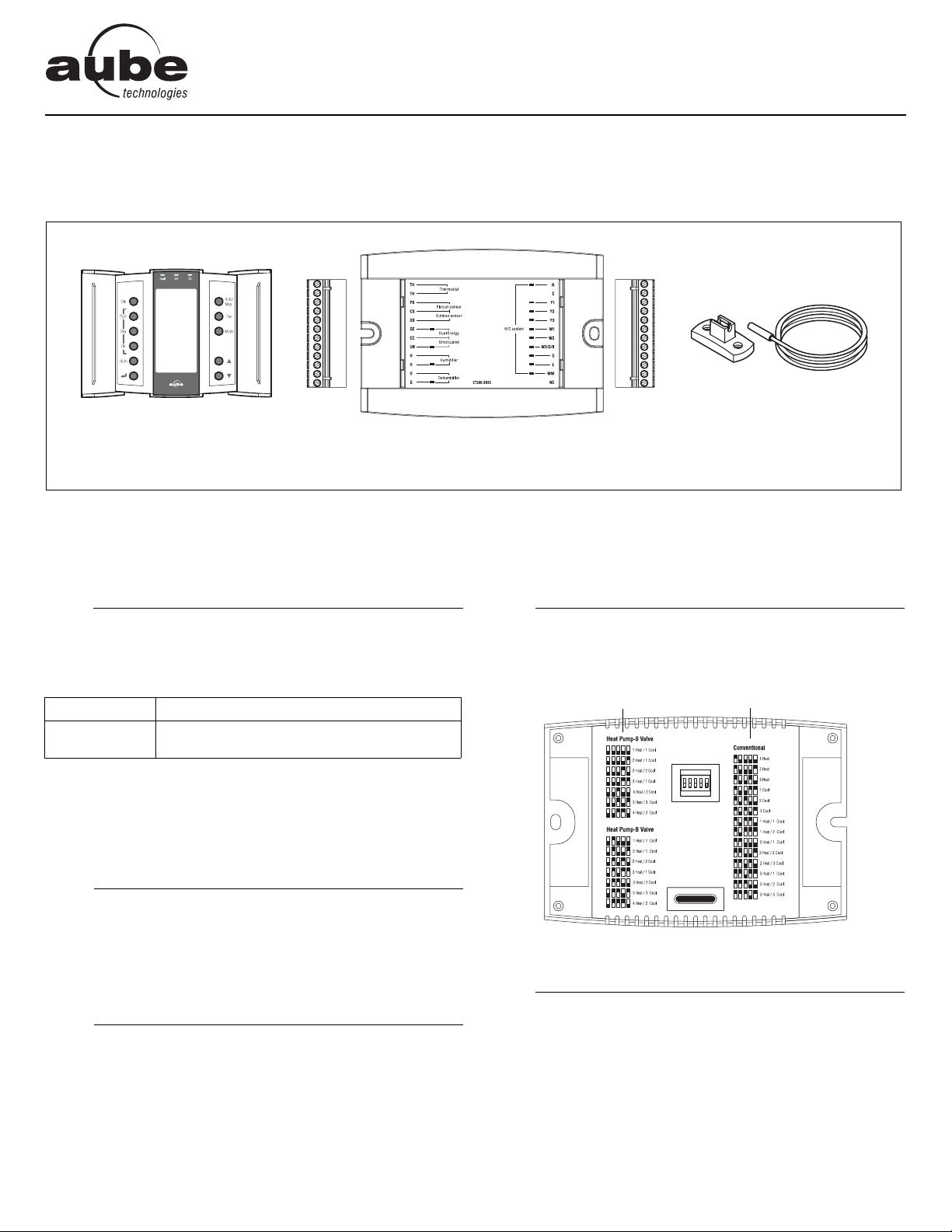

TH146-P-U

Installation Guide

Programmable H/C Controller

Removable

Connector *

TH146-P User Console

* To remove a connector from the control module, pry with a screwdriver.

CT280-3H3C Control Module

1. Introduction

1.1

The TH146-P-U programmable controller can be used with any of

the following heating/cooling systems:

Applications

Heat pump

HVAC

1H1C, 2H1C, 2H2C, 3H1C, 3H2C, 3H3C, 4H2C

1H, 2H, 3H, 1C, 2C, 3C, 1H1C, 1H2C, 2H1C, 2H2C,

2H3C, 3H1C, 3H2C, 3H3C

Removable

Connector *

AC144-03 Outdoor

Temp erature Sensor

2. Installation

2.1

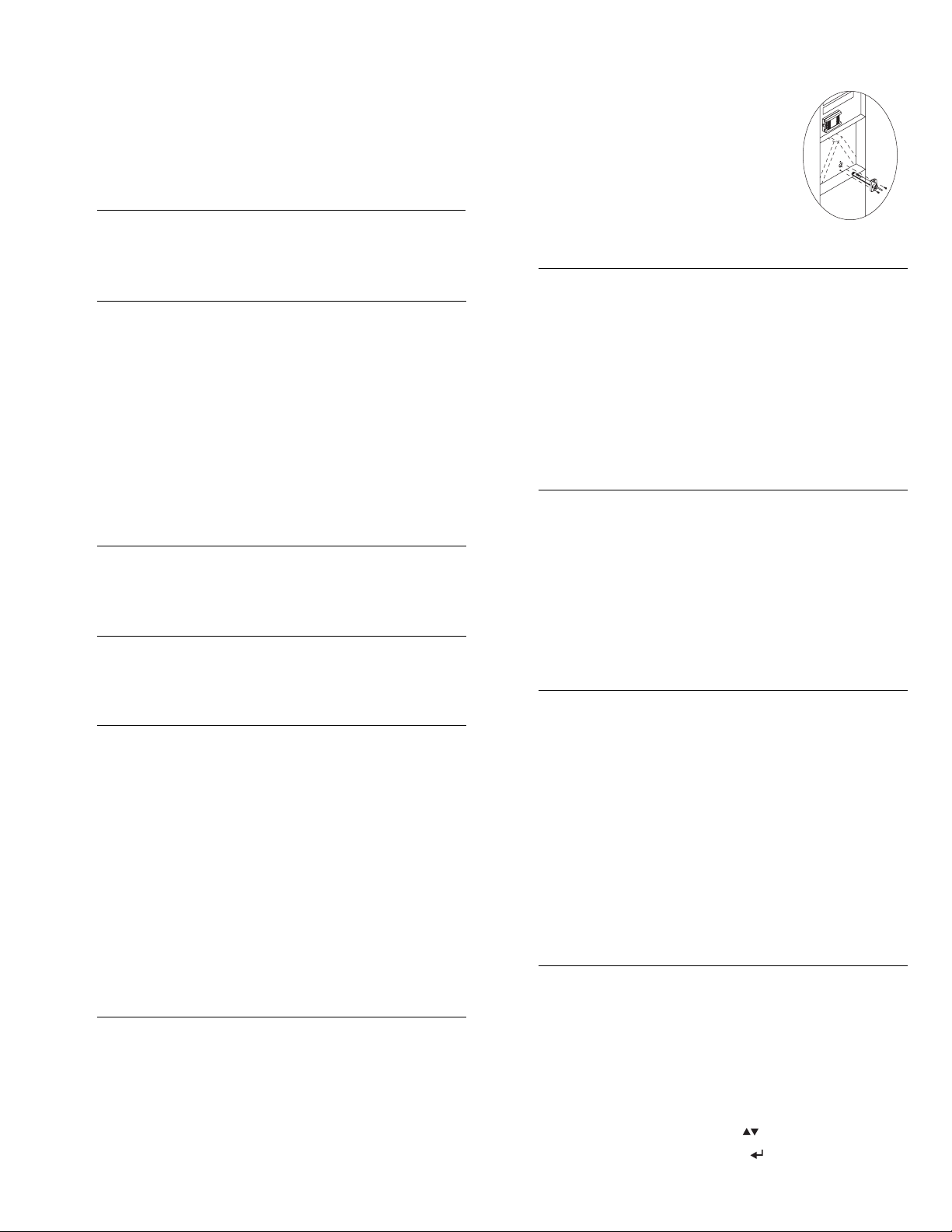

Configure the control module according to your type of heating/cooling system using DIP switches on the back of the module.

Control Module (CT280-3H3C)

Heat pump

HVAC

The following devices can be connected to the controller:

air recirculation fan

humidifier

dehumidifier or air exchanger

dual-register meter (dual energy)

remote control device (for the unoccupied mode)

1.2

• CT280-3H3C control module

• TH146-P console with two wall anchors and mounting screws

• AC144-03 outdoor temperature sensor (3 m or 10 ft) with mount-

1.3

• RC845 relay (see section 2.4)

• AC146-410 plenum temperature sensor (see section 2.8)

• CT241 telephone controller (see section 2.10)

TH146-P-U 400-280-010-B 5/24/07 1/12

Supplied Parts

ing clip (see section 2.7)

Accessories

Install the control module near the heating/cooling system, away

from any heat source.

2.2

Install the console in a central location. Avoid locations with air

drafts (e.g., top of staircase or air outlet) or stagnant air (behind a

door). Do not install the console on a wall hiding air ducts nor

expose it to direct sunlight.

NOTE: If this controller replaces an old thermostat, any two of the

wires that were connected to the thermostat can be used to connect

the user console to the control module. The maximum wiring length

is 30 m (100 ft).

User Console (TH146-P)

Page 2

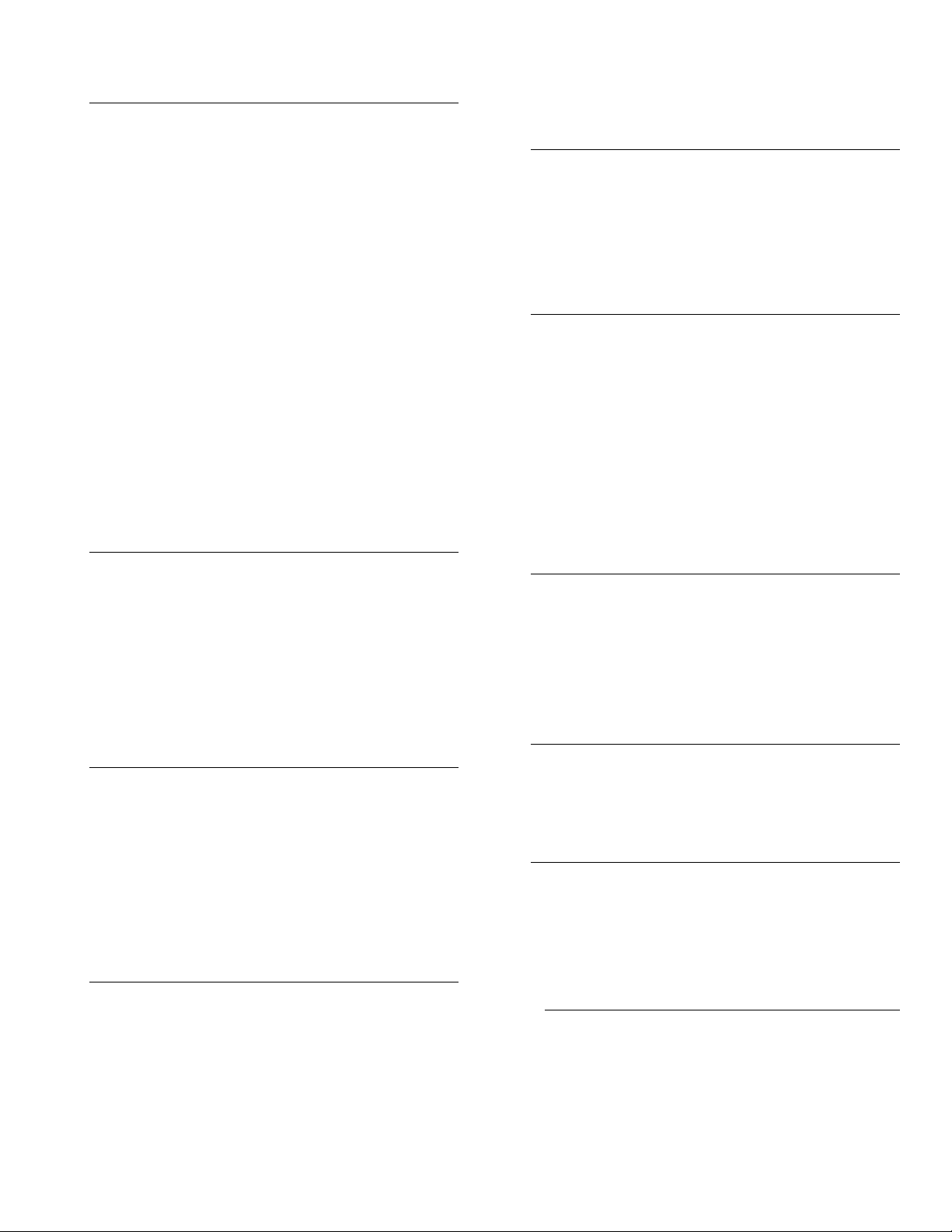

n Choose a location about 1.5 m (5 ft) above the floor on an

inside wall.

o Loosen the captive screw under the console.

p Detach the console from its base by pulling the bottom section.

q Secure the base using th e w all an cho rs an d screw s.

r Connect the console to controller terminals TH and TH (no

polarity).

2.3

The terminals used to connect the heating/cooling system depend

on the type of system. See the appropriate wiring table on page 4.

Heating/Cooling System

needed if the heat pump is not connected to the controller

terminal WW.)

Install the sensor on the side of the plenum and

position it such that its aperture faces the air

flow.

Connect the sensor to controller terminals PS

and CS (no polarity). For more information,

refer to the instructions provided with the sensor.

NOTE: The maximum wiring length is 30 m

(100 ft).

2.9

Dual-energy Input

2.4

If you have an add-on installation, you might need an RC845 relay

to connect the furnace (auxiliary heating) and its fan to the controller. Install the relay near the control module and connect the wires

as follows:

• relay terminals W, G and C to controller terminals W1, G and C.

• relay terminals T and T to the appropriate furnace terminals: T

NOTE: Refer to the relay’s installation instructions for more details.

If you have a 3H1C or 4H2C heat pump, a second RC845 relay

might be required to connect the second auxiliary heat.

2.5

Connect the humidifier in series with the power supply between

controller terminals H and H (dry contact).

2.6

Connect the dehumidifier or air exchanger in series with the power

supply between controller terminals D and D (dry contact).

2.7

The outdoor sensor is required for the following:

When installing the sensor, observe the following guidelines:

Install the sensor using its mounting clip and connect it to controller

terminals OS and CS (no polarity).

NOTE: The maximum wiring length is 30 m (100 ft).

RC845 Relay

and T (oil); TH and TH (gas); R and W (electric).

Humidifier

Dehumidifier / Air Exchanger

Outdoor Sensor (AC144-03)

• outdoor temperature display

• balance points (heat pumps only, see section 4.2)

• defrost point (heat pumps only, see section 4.3)

• automatic humidity control (see section 7.2)

• use of an air exchanger (see section 4.10)

• Avoid locations where the sensor can be covered with snow

or exposed to direct sunlight.

• Avoid air outlets and concealed chimneys or stove pipes.

NOTE: The dual-energy input can be used only with a heat pump

equipped with auxiliary heat.

The dual-energy input can be connected to the dual-register meter

equipped with a normally open (NO) dry contact. Connect the controller terminals DE and CC to the meter terminals (yellow and red

wires).

The contact closes when the outdoor temperature drops below the

temperature setting on the meter. When the contact is closed, the

heat pump is disabled and only the auxiliary heat can be used.

2.10

To use the unoccu pied mode, the controller requires a remote control device such as Aube’s CT241 telephone controller equipped

with a normally open (NO) dry contact placed between terminals UN

and CC of the controller. The unoccupied mode is activated when

the contact closes. (See section 6.4.)

Unoccupied Mode Input

3. Configuration

3.1

To access the configuration switches, loosen the captive screw

under the console and separate the console from its base by pulling

the bottom section.

3.1.1 Access Mode (SW1-1)

INST: Installer mode. Gives access to all configuration parameters.

USER: User mode. Gives access to configuration parameters 1 to 4

only.

3.1.2 Keypad Lock (SW1-2)

I: The keypad is locked. Settings cannot be changed.

O: The keypad is unlocked.

3.2

Configuration Switches

NOTE: In installer mode, the short-cycle protection is disabled

and the interstage delay is reduced to 1 minute.

Software Configuration

n Place the console in Installer mode (INST) using the SW1-1

2.8

The plenum sensor is required for the following:

Plenum Sensor (AC146-410)

• low temperature limit inside the plenum (HVAC only)

• high temperature limit inside the plenum (HVAC only)

• fan limit if gas heating is used (HVAC only)

• high pressure protection during defrost cycle (This protection

is generally needed for add-on installations only. It is not

switch on the back of the console.

o Press the Mode button for 3 seconds to access the configura-

tion menu (see page 8). The first menu item (parameter) is displayed.

p To view another menu item, briefly press the Mode button.

q To modify a parameter, press either button.

r To exit the configuration menu, press .

s Return the console to User mode (USER).

TH146-P-U 400-280-010-B 5/24/07 2/12

Page 3

4. Principles of Operation

4.1

With automatic heating/cooling mode changeover, there’s no need to adjust

the controller at every change of season or weather condition. The controller

switches automatically between heating mode and cooling mode to maintain

the desired temperature.

Manual Mode

When the controller is in manual mode, the heating/cooling mode

changeover occurs as follows:

• The controller switches to cool ing mode when the indoor temperature

• The controller switches the heating mode when the indoor temperature

Automatic Mode

When the controller is in automatic mode, it follows the programmed schedule. Two temperature settings (heating setpoint and cooling setpoint) are

programmed for each period of the schedule. The heating/cooling mode

changeover occurs as follows:

• When the controller is in heating mode, the indoor temperature is main-

• When the controller is in cooling mode, the indoor temperature is main-

4.2

Balance Points are used to disable the heat pump or the auxiliary heating

when the outdoor temperature is below or above a set temperature.

• When the outdoor temperature is below the Balance Point Low

• When the outdoor temperature is above the Balance Point High (bP H),

NOTE: Balance Points cannot be used if the AC144-03 outdoor temperature

sensor is not connected to the controller.

4.3

The auxiliary heat is activated during defrost except under the following conditions:

• When the outdoor temperature is above the defrost point (see page 8,

• When the plenum temperature is above 40°C (104°F). The auxiliary

NOTE: The auxiliary heat’s short-cycle protection is disabled during defrost.

4.4

Automatic Heating/Cooling Changeover

is higher than the setpoint by more than 1.5°C (2.5°F) for 15 minutes.

is lower than the setpoint by more than 1.5°C (2.5°F) for 15 minutes.

tained at the heating setpoint. However, if the temperature rises and

remains above the cooling setpoint for 15 minutes, the controller will

switch to cooling mode.

tained at the cooling setpoint. However, if the temperature drops and

remains below the heating setpoint for 15 minutes, the controller will

switch to heating mode.

Balance Points (heat pumps only)

(bP L), the heat pump is disabled and only auxiliary heating can be

used (see page 8, item 5).

the auxiliary heat is disabled and only the heat pump can be used (see

page 8, item 6).

Heating During Defrost (heat pumps only)

item 7). Note: This condition will not apply if the AC144-03 outdoor sen-

sor is not connected to the controller.

heat is re-activated when the plenum temperature drops below 32°C

(90°F). Note: This condition will not apply if the AC146-410 plenum

sensor is not connected to the controller.

Types of Heat Pump Installations

• New Installation: In this type of installation, as there is not already a

furnace, the auxiliary heat source is installed at the same time as the

heat pump. In this type of installation, the indoor coils are located

upstream of the auxiliary heat. When the controller is configured for a

new installation, the heat pump and the auxiliary heat can operate

simultaneously.

4.5

Interstage Delay is the time allocated for the temperature to return to an

acceptable value when it deviates too far from the setpoint. If this time has

elapsed, the next heating or cooling stage is activated. The heating or cooling stage will be deactivated when the temperature returns to an acceptable

value. The Interstage Delay is fixed at 4 minutes if the controller is configured for an HVAC system and is user-adjustable if it is configured for a heat

pump (see page 8, item 9).

4.6

Low Temperature Limit (LLMT) and High Temperature Limit (HLMT) are

used to keep the plenum from becoming too cold or too hot. During cooling,

if the plenum temperature is lower than LLMT, a cooling stage is deactivated

starting with the one that was last activated. If, after a while, the temperature

is still too low, another cooling stage is deactivated and so on. Likewise, during heating, if the plenum temperature is higher than HLMT, a heating stage

is deactivated starting with the one that was last activated. If, after a while,

the temperature is still too high, another heating stage is deactivated and so

on. (see page 8, items 10 and 11.)

WARNING: LLMT and HLMT can be used in parallel with an UL353approved device but they do not replace such device.

NOTE: LLMT and HLMT cannot be used if the plenum temperature sensor is

not connected to the controller.

4.7

When Smart Fan is enabled (see page 8, item 15), the fan operates as follows:

• During periods 2 and 4 of automatic mode and during the unoccupied

• The fan operates continuously the rest of the time.

NOTE: For Smart Fan to work, set the fan to On (see section 5.3).

4.8

If a humidifier and a dehumidifier are both connected to the controller, the

controller will automatically switch between the two devices to maintain the

desired humidity level. The changeover occurs when the humidity deviates

from the setpoint by more than 3% for 30 minutes.

4.9

Dehumidification by droop is a method of dehumidification without using a

dehumidifier. This method is possible only if your system has a cooling

stage. When this feature is enabled (see page 8, item 18), if the humidity

level is too high, the temperature is temporarily lowered below the setpoint

to reduce the indoor humidity level.

NOTE: Dehumidification by droop can cause overcooling.

Interstage Delay

Low and High Temperature Limits

Smart Fan

mode (i.e., when you are away from home or sleeping), the fan operates only when heating or cooling is activated.

Automatic Humidification / Dehumidification Changeover

Dehumidification by Droop

The controller can be configured for either of the following types of heat

pump installations (see page 8, item 8).

• Add-on Installation: This type of installation is performed when adding

a heat pump to an existing furnace. When the heat pump is installed,

the furnace becomes the auxiliary heat source. In this type of installation, the indoor coils are usually installed downstream of the auxiliary

heat source. When the controller is configured for an add-on installation, the heat pump is disabled during auxiliary heating to prevent overpressure.

TH146-P-U 400-280-010-B 5/24/07 3/12

4.10

Dehumidification using an air exchanger will not be efficient if the outdoor

temperature is too high. When an air exchanger is used, the controller will

disable dehumidification if the outdoor temperature is NOT lower than the

indoor temperature by more than 5°C (9°F). When this occurs, the message

HIGH TEMP is displayed.

Dehumidification by Air Exchanger

Page 4

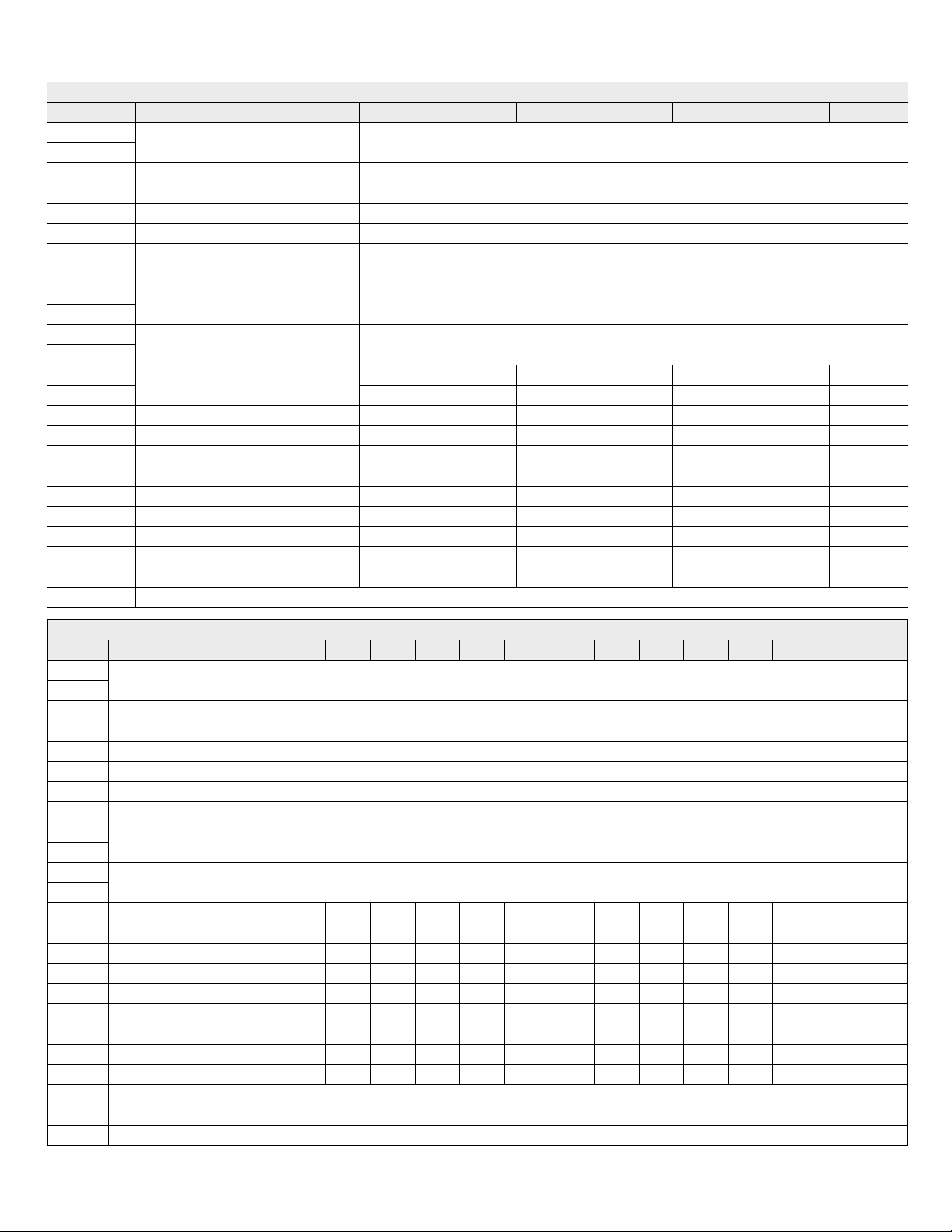

Wiring Tables

Heat Pump

Terminal Device 1H1C 2H1C 3H1C 2H2C 3H2C 4H2C 3H3C

TH

TH

PS Plenum sensor Connect the plenum sensor between the PS and CS terminals (no polarity)

CS Common S Common terminal for the plenum sensor and the outdoor sensor

OS Outdoor sensor Connect the outdoor sensor between the CS and OS terminals (no polarity)

DE Dual Energy Connect the dual-register meter between the DE and CC terminals (no polarity)

CC Common C Common terminal for the dual-energy meter and the unoccupied mode input

UN Unoccupied mode input Connect a dry contact between the UN and CC terminals (no polarity)

H

H

D

D

Dehumidifier (24 Vac / 1 A) Connect the dehumidifier between the D terminals (dry contact)

R

C

Y1 Compressor 1 (24 Vac / 1 A)

Y2 Compressor 2 (24 Vac / 1 A)

Y3 Compressor 3 (24 Vac / 1 A)

W1 Auxiliary heat 1 (24 Vac / 1 A)

W2 Auxiliary heat 2 (24 Vac / 1 A)

W3/O/B Reversing valve (24 Vac / 1 A)

G Fan (24 Vac / 1A)

L Fault (24 Vac / 5 mA)

WW Defrost (24 Vac / 5 mA)

NC Not used

Console Connect the console between the TH terminals (no polarity)

Humidifier (24 Vac / 1 A) Connect the humidifier between the H terminals (dry contact)

Power (24 Vac)

√√√√√√√

√√√√√√√

√√√√√√√

√√√√

√√ √√

√√

√√√√√√√

√√√√√√√

√√√√√√√

√√√√√√√

√

HVAC

Terminal Device 1H 2H 3H 1C 2C 3C 1H1C 1H2C 2H1C 2H2C 2H3C 3H1C 3H2C 3H3C

TH

TH

Console Connect the console sensor between the TH terminals (no polarity)

PS Plenum sensor Connect the plenum sensor betw een the PS and CS terminals (no polarity)

CS Common S Common terminal for both plenum sensor and outdoor sensor

OS Outdoor sensor Connect the outdoor sensor between the OS and CS terminals (no polarity)

DE Not used

CC Common C Common terminal for the unoccupied mode input

UN Unoccupied mode input Connect a dry contact between UN and R terminals (no polarity)

H

H

D

D

R

C √√√√√√√√√√√√√√

Humidifier (24 Vac / 1 A) Connect the humidifier between the H terminals (dry contact)

Dehumidifier (24 Vac / 1 A) Connect the dehumidifier between the D terminals (dry contact)

Power (24 Vac)

√√√√√√√√√√√√√√

Y1 Cooling unit 1 (24 Vac / 1 A) √√√√√√√√√√√

Y2 Cooling unit 2 (24 Vac / 1 A) √√√√√√√

Y3 Cooling unit 3 (24 Vac / 1 A) √√√

W1 Heating unit 1 (24 Vac / 1 A) √√√ √√√√√√√√

W2 Heating unit 2 (24 Vac / 1 A) √√ √√√√√√

W3/O/B Heating unit 3 (24 Vac / 1 A) √ √√√

G Fan (24 Vac / 1 A) √√√√√√√√√√√√√√

L Not used

WW Not used

NC Not used

TH146-P-U 400-280-010-B 5/24/07 4/12

Page 5

Wiring Diagram: 2H1C Heat Pump — New Installation

AC146-410

AC144-03

Dual Energy

CT241

Humidifier

Dehumidifier

Compressor

Auxiliary Heat

Reversing Valve

Fan

Fault

Defrost

TH146-P-U 400-280-010-B 5/24/07 5/12

Page 6

Wiring Diagram: 3H2C Heat Pump — Add-on Installation

AC146-410

AC144-03

Dual Energy

CT241

Humidifier

Dehumidifier

Compressor 1

Compressor 2

Reversing Valve

Fault

Defrost

Furnace

Fan Limit

TH146-P-U 400-280-010-B 5/24/07 6/12

Page 7

Wiring Diagram: 3H2C HVAC

AC146-410

AC144-03

CT241

Humidifier

Dehumidifier

Cooling Unit 1

Cooling Unit 2

Heating Unit 1

Heating Unit 2

Heating Unit 3

Fan

TH146-P-U 400-280-010-B 5/24/07 7/12

Page 8

Configuration Menu

Item HP HVAC Parameters Display Options Default Description

1 √√ Time format 12 Hr / 24 Hr 24 Hr Select the time display format.

• On: Heating or cooling starts in advance (as determined by the controller) so that the desired temperature is attained at the set times.

2 √√ Early Start On / OF OF

3 √√

4 √√ Temperature format °C / °F °C Select the temperature display format.

5 √ Balance point low

6 √ Balance point high

7 √ Defrost point

8 √ Installation type Ad / nr Ad

9 √

10 √ Low temperature limit

11 √ High temperature limit

12 √√ Cycles per hour 2 to 6 4

13 √ Heat type GA / EL EL

14 √ Fan limit

15 √√ Smart Fan On / OF OF

16 √√Temperature setback

17 √√

18 √√ Dehumidifier type Co / AE / dr Co

19 √√

Note: Only items 1 to 4 are available when the controller is placed in user mode (SW1-1 switch).

Automatic daylight

savings adjustment

Auxiliary

interstage delay

Humidifier

operating mode

Minimum air

exchange time

OF / 1 / 2 OF

-30 to 10°C

(-22 to 50°F)

-5 to 30°C

(23 to 86°F)

-10 to 15°C

(14 to 59°F)

5 to 90 min. 30 min. Set the interstage delay for the auxiliary stage (see section 4.5).

-10 to 20°C

(14 to 68°F)

30 to 90°C

(86 to 194°F)

38 to 90°C

(100 to 194°F)

0 to 9°C

(0 to 16°F)

Co / HE / Fn Fn

0 - 60 min. 0

-10°C

(14°F)

5°C

(41°F)

10°C

(50°F)

5°C

(41°F)

70°C

(158°F)

80°C

(176°F)

0°C

(0°F)

• OF (Off): Heating or cooling starts at the set times.

NOTE: Early Start applies for periods 1 and 3 (P1 and P3) only. When this

feature is enabled, heating or cooling will st art i n advance o f the set time for

P1 and P3 but will start at the set time for P2 and P4.

• OF (Off): The function is deactivated.

• 1 : The controller switches to daylight savings time on the f irst Sunday o f

April and to normal time on the last Sunday of October.

• 2 : The controller switches to daylight savings time on the second Sunday of March and to normal time on the first Sunday of November.

Set the bP L limit (see section 4.2).

NOTE: Lower bP L below its minimum (- -) if you do not wish to use this

function.

Set the bP H limit (see section 4.2).

NOTE: Raise bP H above its maximum (- -) if you do not wish to use this

function.

Set the defrost point temperature (see section 4.3).

NOTE: Raise the defrost point above its maximum (- -) if you do not wish to

use this function.

Set according to the type of heat pump installation (see section 4.4).

• Ad (add-on): Use this setting when the indoor coils are located downstream of the auxiliary heat source. This is generally the case for add-on

installations.

• nr (normal): Select this setting when the indoor coils are located

upstream of the auxiliary heat source. This is generally the case for new

installations.

Set the low temperature limit of the plenum (see section 4.6).

NOTE: This function is not used if you lower LLMT below its minimum

(- -) or if the plenum temperature sensor is not connected to the controller.

Set the high temperature limit of the plenum (see section 4.6).

NOTE: This function is not used if you raise HLMT above its maximum (- -)

or if the plenum temperature sensor is not connected to the controller.

Select the number of heating/cooling cycles per hour. For optimal heating

control, use the setting that matches your system as follows: 3=20 min (hot

water, 90%+ high-ef ficiency furnace), 4=15 min (gas or oil), 5=12 min (gas

or oil), 6=10 min (electric).

This setting determines the fan operation in automatic mode when the system is in heating mode (see section 5.3).

• EL (electric heating): The fan starts and stops at the same time as heating.

• GA (gas or oil heating): The fan starts when the temperature inside the

plenum rises above the Fan Limit (see item 14) and stop s when th e temperature drops 12°C below the Fan Limit. NOTE: The fan will not start if

the plenum temperature sensor is not connected to the controller.

This parameter is available only when gas heating is selected (see it em 13).

WARNING: FLMT can be used in parallel with an UL353-approved device

but they do not replace such device.

NOTE: The fan will not start if you raise FLMT above its maximum (--).

• On: Smart Fan is On (see section 4.7).

• OF: Smart Fan is Off.

Set the amount of temperature setback when the controller is placed in

Unoccupied mode (see section 6.4).

• Co (conventional): The humidifier wi ll operate if the humi dity is too low. If

the fan is not already On, it will turn On at the same time as the humidifier.

• HE (heat): The humidifier can operate only when heating is activated.

• Fn (fan): The humidifier can operate as long as the fan is running,

whether heating is activated or not.

NOTE: The humidifier is disabled when cooling is activated.

Set according to the type of dehumidifier used.

• Co (conventional): Select this setting when using a dehumidifier (except

an air exchanger) or when you do not wish to dehumidify.

• AE (air exchanger): Select this setting when using an air exchanger (see

section 4.10).

• dr (droop): Select this setting to dehumidify by droop (see section 4.9).

This parameter is available only if the controller is configured for using an

air exchanger (see item 18). Use it to set the minimum air exchange time

(see section 8.3).

TH146-P-U 400-280-010-B 5/24/07 8/12

Page 9

TH146-P-U

User’s Guide

Programmable H/C Controller

Time and day setting

Programming

Program day selection

Program clear

Humidity setting

Return

5. General Setting

5.1

n Press Clk. The hour display flashes.

o Set the hour using .

p Press Clk. The minute display flashes.

q Set the minutes using .

r Press Clk. The day display flashes.

s Set the day using .

t Press to return to the normal display.

5.2

n Press Clk for 3 seconds to display the year.

o Set the year using .

p Press Clk to display the mont h.

q Set the month using .

r Press Clk to display the date.

s Set the date using .

t Press to return to the normal display.

Clock and Day Setting

Date Setting

Indicator LEDs

Temperature

adjustment

mode selection

Fan operating

mode selection

System operating

mode selection

Up/Down buttons

Indicator LEDs

FAULT: System fault

EH: Emergency heat mode

DE: Dual energy

Backlight

The screen is lit for 12 seconds

when any button is pressed.

However, the screen remains li t

while you are configuring the

controller.

Day

Clock

Indoor temperature

Indoor humidity

Outdoor temperature

6. Temperature Setting

6.1

The controller normally displays the measured indoor temperature.

To view the setpoint, press one of the buttons. The setpoint and

the symbol will be displayed for the next 5 seconds.

6.2

Press Mode to place the system in one of the following modes:

Display

Appears when the

temperature setpoint

is displayed

Heating is On

Auxiliary heating is On

Temperature adjustment

mode (appears when the

system is in automatic

mode, disappears when it

is in manual mode)

System Operating Mode

Indoor temperature

Cooling is On

System operating mode

Fan operating mode (appears when the fan is in

continuous mode, disappears when it is in automatic mode)

5.3

Press the Fan button to select the fan operating mode.

• In automatic mode, the fan runs only when heating or cooling is

• In continuous mode, the fan runs continuously and the sym-

TH146-P-U 400-280-010-B 5/24/07 9/12

Fan Operating Mode

activated. NOTE: For gas-operated HV AC systems, there might

be a delay before the fan starts or stops when heating is activated or deactivated.

bol is displayed. NOTE: if Smart Fan is enabled, when the controller is in periods 2 and 4 of automatic mode and in

unoccupied mode, the fan will run only when heati ng or cooling

is activated. The fan will run continuously the rest of the time

HEAT

COOL

AUTO

OFF

EHEAT

The system is in heating mode.

The system is in cooling mode.

The system is in automatic changeover mode. (The system

switches between heating mode and cooling mode to maintain the desired temperature.)

The system is off.

The system is in emergency heat mode. Only auxiliary heat-

ing is used when there is a call for heat. (This mode applies

only when the controller is connected to a heat pump

equipped with auxiliary heating).

Page 10

6.3

6.3.1 Manual Adjustment

Use this mode to set the temperature manually. To place the controller in this mode, press Auto/Man so that disappears from the

screen. Set the temperature using the buttons.

NOTE: If the controller is in automatic heat/cool changeover (see

section 6.2), the setpoint is automatically redu ced or raised by 1°C

(1.8°F) when the controller switches to heating mode or to cooling

mode respectively. For example, if the setpoint is 24°C (75°F) in

heating mode, it will become 25°C (77°F) in co oling mode and will

return to 24°C (75°F) when the controller switches back to heating

mode.

6.3.2 Automatic Adjustment

Use this mode if you want the controller to adjust the temperature

according to the programmed schedule. To place the controller in

this mode, press Auto/Man so that appears on the screen.

Pre-programmed Schedule

The following schedule has been programmed at the factory. Two

temperature settings are programmed for each period of the schedule: a heating setpoint and a cooling setpoint.

Temperature Adjustment

Pre-programmed Schedule MO TU WE TH FR SA SU

P1

P2

P3

P4

Heating 21°C (70°F)

Cooling 25.5°C (78°F)

Heating 16.5°C (62°F)

Cooling 29.5°C (85°F)

Heating 21°C (70°F)

Cooling 25.5°C (78°F)

Heating 16.5°C (62°F)

Cooling 28°C (82°F)

6:00 a.m.

8:00 a.m. --

6:00 p.m. --

10:00 p.m.

point is 22°C (72°F) and you set the heating setpoint to 23°C (73°F),

the cooling setpoint will automatically become 24°C (75°F). However, if you raise the heating setpoint to 21°C (70°F), the cooling

setpoint will remain at 22°C (72°F). The same principle applies

when you set the cooling temperature.

• Press to exit.

The following diagram shows how to navigate the programming

menu.

MO TU

6:00 6:00

P1

Heat

21 25.5 21 25.5

P2

Heat

16.5 29.5 16.5 29.5

Temporary Bypass

When you modify the temperature setpoint while the control ler is in

automatic mode, the new temperature is used for the next 2 hours.

The icon flashes during the bypass. After the bypass, the temperature set for the current period is used.

Pgm

Mode

8:00 8:00

Mode

Cool Heat

Pgm

Pgm

Cool

Day

Day

Heat

Mode

Mode

Pgm

Cool

Pgm

Pgm

Cool

Modifying the Schedule

You can program up to 4 periods per day. To program a period, you

need to set the start time, the heating setpoint and the cooling setpoint. The program can be different for each day of the week.

• Press Pgm to enter the programming mode. The setti ngs for

Monday, Period 1 (P1) appear.

• To select a day to program, press Day until the day is displayed. Press for 3 seconds to select all 7 days.

NOTE: If you select all 7 days, the settings of the displayed

period will be copied to all 7 days. For example, if you select all

7 days while period 1 is displayed, they will all now have the

same settings for period 1. If you display period 2 while all 7

days are selected, they will all now have the same settings for

period 2.

• To set the start time of a period, press Pgm until the period

number (P1 to P4) is displayed and the time display flashes.

Then press the buttons. The time changes in increments of

15 minutes.

NOTE: To skip a period, display the period and press Clr. For

example, in the pre-programmed schedule, periods 2 and 3

have been skipped for Saturday and Sunday.

• To set the temperatures for a period, press Pgm until the period

number (P1 to P4) is displayed and the temperature display

flashes. If necessary, press Mode to display the heating set-

point or the cooling setpoint. Press the buttons to set the

temperature.

NOTE: The cooling setpoint is always higher than the heating setpoint by a minimum of 1°C (1.8°F). For example, if the cooling set-

6.4

Y ou can place the controller in the unoccupied mode using a remote

control device such as Aube’s CT241 telephone controller. In this

mode, the temperature is lowered in heating mode or raised in cooling mode (see page 8, item 16). The message UNOC appears during

the unoccupied mode.

NOTE: Automatic changeover is disabled during the unoccupied

mode.

Temporary Bypass

In the unoccupied mode, only the buttons work. When you

adjust the temperature during this mode, the new temperature will

be used for the next 2 hours, after which the controller will return to

the previous setpoint. The message UNOC flashes during the bypass.

Unoccupied Mode

TH146-P-U 400-280-010-B 5/24/07 10/12

Page 11

7. Humidity Setting

7.1

Display

Appears when

dehumidification is

disabled because the

outdoor temperature

is too high

Appears when the

humidity setpoint

is displayed

Humidity level

8.2

To deactivate the air exchange mode:

Manual Deactivation

n Press the Hum button until one of the following appears on the

screen.

AUTO: The air exchanger is in humidity control mode (automatic adjustment).

MAN: The air exchanger is in humidity control mode (manual

adjustment).

OFF: The air exchanger is Off.

o Press the button to return to normal display.

Humidifier is On

Dehumidifier is On

7.2

Manual Adjustment

The humidity level is set by the user (5 to 60%).

Humidity Adjustment

Humidity control mode

(auto, manual, off or

air exchange)

n Press the Hum button until MAN appears on the screen.

8.3

If the controller is configured for a minimum air exchange time every

hour and that minimum has not already been attained by the end of

the hour, the air exchanger will be activated regardless of the indoor

humidity level (see page 8, item 19). Let’s say the minimum time is

set to 10 minutes. If the air exchanger has operated for 7 minutes

during a particular hour, it will automatically be activated for another

3 minutes by the end of that hour.

Minimum Air Exchange Time

9. Technical Specifications

o Press one of the buttons to adjust the humidity level.

p Press the button.

Automatic Adjustment

The humidity level is set by the controller based on the outdoor temperature to prevent ice formation or condensation on the windows

while providing enough humidity for your comfort. However, the user

can apply an offset (-9 to 9%). For example, the user can enter a

negative offset if there is ice formation or condensation on the windows.

n Press the Hum button until AUTO appears on the screen. The

humidity level set by the controller is also displayed.

o Press one of the buttons to enter or change the offset.

CT280-3H3C CONTROL MODULE

Power supply: 24 VAC

Current consumption: 150 mA

Maximum load per output: 1 A @ 24 VAC

Short cycle protection: 2 minutes

Control cycles: 2 to 6 per hour

Operating temperature: 0°C to 50°C (32°F to 122°F)

Storage temperatur e : -20°C to 50°C (-4°F to 122°F)

Humidity conditions: 0 to 95%, non-condensing

Dimensions: 95 x 137 x 30 (3.8 x 5.4 x 1.2 in.)

p Press the button.

Off

To turn off the humidity control:

n Press the Hum button until OFF appears on the screen.

o Press the button to save and exit the programming.

8. Air Exchange Duration Setting

8.1

If an air exchanger is connected to the controller, it can be used in

either of the following modes:

In air exchange mode, the air exchanger is activated to circulate air

between indoors and outdoors regardless of the indoor humidity

level). To activate the air exchange mode:

Manual Activation

• Humidity control mode (see section 7.2)

• Air exchange mode (see below).

TH146-P USER CONSOLE

Temperature setpoint range

Heating mode: 5°C to 30°C (40°F to 86°F)

Cooling mode: 15°C to 40°C (59°F to 104°F)

Humidity setpoint range: 5 to 60%

Indoor temperature display range: 0°C to 70°C (32°F to 158°F)

Outdoor temp. display range: -50°C to 70°C (-58°F to 158°F)

Temperature display resolution: 0.5°C (1°F)

Program protection: non-volatile memory

Operating temperature: 0°C to 50°C (32°F to 122°F)

Storage temperatur e : -20°C to 50°C (-4°F to 122°F)

Humidity conditions: 0 to 95%, non-condensing

Dimensions: 79 x 79 x 24 mm (3.1 x 3.1 x 1 in.)

n Press the Hum button until AIR appears on the screen.

o Set the duration you want the air exchanger to operate using

the buttons. Select 10 - 90 minutes for a specific duration

or On for an indefinite length of time.

p Press the button.

TH146-P-U 400-280-010-B 5/24/07 11/12

Page 12

10.Warranty

Aube warrants this product, excluding battery, to be free from

defects in the workmanship or materials, under normal use and

service, for a period of three (3) years from the date of purchase by

the consumer. If at any time during the warranty period the product

is determined to be defective or malfunctions, Aube shall repair or

replace it (at Aube's option).

If the product is defective,

(i) return it, with a bill of sale or other dated proof of purchase, to

the place from which you purchased it, or

(ii) contact Aube. Aube will make the determination whether the

product should be returned, or whether a replacement product

can be sent to you.

This warranty does not cover removal or reinstallation costs. This

warranty shall not apply if it is shown by Aube that the defect or

malfunction was caused by damage which occurred while the

product was in the possession of a consumer.

Aube's sole responsibility shall be to repair or replace the product

within the terms stated above. AUBE SHALL NOT BE LIABLE FOR

ANY LOSS OR DAMAGE OF ANY KIND, INCLUDING ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING,

DIRECTLY OR INDIRECTLY, FROM ANY BREACH OF ANY

WARRANTY, EXPRESS OR IMPLIED, OR ANY OTHER FAILURE

OF THIS PRODUCT. Some provinces and states do not allow the

exclusion or limitation of incidental or consequential damages, so

this limitation may not apply to you.

THIS WARRANTY IS THE ONLY EXPRESS WARRANTY AUBE

MAKES ON THIS PRODUCT. THE DURATION OF ANY IMPLIED

WARRANTIES, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, IS HEREBY LIMITED TO THE THREE-YEAR

DURATION OF THIS WARRANTY. Some provinces and states do

not allow limitations on how long an implied warranty lasts, so the

above limitation may not apply to you.

This warranty gives you specific legal rights, and you may have

other rights which vary by province or state.

11.Support

If you have any questions about the product installation or

operation, or concerning the warranty, contact us at the address

shown below.

705 Montrichard

Saint-Jean-sur-Richelieu, Quebec

J2X 5K8

Canada

Tel: (450) 358-4600

Toll-free: 1-800-831-AUBE

Fax: (450) 358-4650

Email: aube.service@honeywell.com

For more information on our products, visit us at:

www.aubetech.com

NERGY STAR

As an E

has determined that this product meets the

E

NERGY STAR guidelines for energy efficiency.

10, rue Ampère

95500 Gonesse

France

Tel: 33 (0) 1 34 07 99 00

Fax: 33 (0) 1 34 07 99 19

Email: advaube@comintes.com

®

partner, Aube Technologies

TH146-P-U 400-280-010-B 5/24/07 12/12

Loading...

Loading...