ATX UCrypt IP to Analog 2, IP2Agen2 Installation & Operation Manual

UCrypt

®

IP2Agen2

Patent Pending

UCrypt® IP to Analog 2nd Generation

Installation & Operation Manual

General Guide Notes

Document ANW1154 UCrypt IP to Analog - 2nd Generation

Installation & Operation Manual

Release Date August 15 2017

Firmware Version

Some features described in this manual require the latest rmware to be installed on the hardware platform. Check with ATX

Networks Technical Support for the latest release of rmware. The rmware version installed on your Device may be found in

the UI on the System tab. At the time of publication of this manual the most current released rmware versions are:

Ubuntu OS Release 12.04

Firmware Release 16188

Organization of This Manual

This manual is generally organized based on the main interface tabs with individual chapters dedicated to describing the

congurable features. Further chapters outline activities related to installation and the UI operation and conguration.

Cross Reference Usage

Hyperlinks are used throughout the guide to assist the reader in nding related information if the reader is viewing the PDF

le directly. Hyperlinks may be identied by their blue text. Most links are to related pages within the document, but some may

reference outside documents if the reader needs that additional information. The Table of Contents is entirely hyperlinked and

bookmarks are available but the bookmark feature must be turned on in your Reader application.

Symbol Usage

Throughout the manual, some symbols are used to call the readers attention to an important point. The following symbols are

in use:

WARNING: This symbol usage will call the reader’s attention to an important operation feature of

the equipment which may be safety related or may cause a service outage.

NOTE: This symbol indicates that there is helpful related information available in this note or

elsewhere in the guide.

Although every effort has been taken to ensure the accuracy of this document it may be necessary, without notice, to make amendments or correct omissions.

Specications subject to change without notice.

* Any use of the UCrypt® product, directly or indirectly, for the decryption and unauthorized reproduction of content that constitutes or may constitute copyright infringement or otherwise infringes on the

proprietary rights of any third party is expressly prohibited. No user of UCrypt shall use UCrypt for any purpose or in any manner which, directly or indirectly, violates the law, violates the proprietary rights of

any other party, or aids in any unlawful act or undertaking including, without limitation, laws governing data privacy, international data transmission, and export of technology or data. Any multiple systems

operator or other similar party (“MSO”) will use the UCrypt product in strict compliance with all applicable laws and in compliance with any agreement in effect between the MSO and a content provider.

In no event shall ATX Networks Corp. or any of its afliates be liable to an MSO, any end user of the UCrypt product, or any other third party, for any claims arising out of or related to any use or misuse

of the UCrypt product in contravention of this disclaimer. It is the express obligation of an MSO to convey this disclaimer to any other end user of the UCrypt product.

MDU Solutions® and UCrypt® are registered trademarks of ATX in the United States and/or other countries. Products or features contained herein may be covered by one or more U.S. or foreign

patents. Other non-ATX product and company names mentioned in this document are the property of their respective companies.

TABLE OF CONTENTS

GENERAL GUIDE NOTES ....................................................II

1. SAFETY ............................................................. 1-1

2. OVERVIEW ........................................................... 2-1

2.2 Chapter Contents ................................................. 2-1

2.3 Front Panels ..................................................... 2-1

2.4 Controls & Indicators .............................................. 2-1

2.5 Rear Panels ..................................................... 2-2

2.6 Switch & Firewall Port Openings ..................................... 2-3

3. INSTALLATION ........................................................ 3-1

3.1 Chapter Contents ................................................. 3-1

3.2 Preparation for Installation .......................................... 3-1

3.3 Precautions ...................................................... 3-1

3.4 General Mechanical ............................................... 3-2

3.5 General Electrical ................................................. 3-3

3.6 General Environment .............................................. 3-3

3.7 Gigabit Ethernet Ports ............................................. 3-3

3.8 Install the 1RU Device ............................................. 3-4

3.9 Install the 2RU Device ............................................. 3-8

3.10 Equipment Safety Grounding ........................................ 3-9

3.11 AC Power Supplies ............................................... 3-10

3.12 DC Power Supplies ................................................3-11

3.13 Power Supply Redundancy .........................................3-11

4. STARTUP ............................................................ 4-1

4.1 Chapter Contents ................................................. 4-1

4.2 Congure Your Computer ........................................... 4-1

4.3 Device Connections ............................................... 4-1

4.4 Use a Browser to Login ............................................ 4-2

4.5 Principle UI Features .............................................. 4-3

4.6 Congure Network Settings ......................................... 4-4

4.7 Select Analog Channel Plan ......................................... 4-4

4.8 Setup Analog Channels ............................................ 4-4

4.9 Add an Input Stream ............................................... 4-4

5. CHANNELS TAB ...................................................... 5-1

5.1 Chapter Contents ................................................. 5-1

5.2 Publishing Changes ............................................... 5-1

5.3 Status Icons Explained ............................................. 5-1

5.4 Reset Conguration ............................................... 5-2

5.5 Expand and Enable Resources ...................................... 5-2

5.6 Mass Conguration ................................................ 5-3

5.7 Add an Input Stream ............................................... 5-4

5.8 Congure Redundancy Failover ...................................... 5-7

MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual iii

5.9 Manually Activate the Backup Stream ................................. 5-9

5.10 Setup the Output Analog Channels .................................. 5-10

5.11 Decryption .......................................................5-11

6. SYSTEM TAB ......................................................... 6-1

6.1 Chapter Contents ................................................. 6-1

6.2 Network Conguration ............................................. 6-2

6.3 Ethernet Interface Bonding ..........................................6-11

6.4 User Conguration ............................................... 6-14

6.5 Location ....................................................... 6-15

6.6 Current Date .................................................... 6-16

6.7 Power ......................................................... 6-17

6.8 Firmware ....................................................... 6-17

6.9 Monitoring/Alerts ................................................. 6-18

6.10 EAS ........................................................... 6-18

6.11 Conguration Backup ............................................. 6-19

6.12 Diagnostics ..................................................... 6-21

6.13 Debugging ..................................................... 6-21

7. RF SETTINGS ......................................................... 7-1

7.1 Chapter Contents ................................................. 7-1

7.2 About RF Settings Page ............................................ 7-1

7.3 Select Active Channel Plan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.4 Download a Channel Plan .......................................... 7-3

7.5 Upload a Custom Channel Plan ...................................... 7-4

7.6 Set Carriers to CW Mode ........................................... 7-5

8. SERVICE & SUPPORT .................................................. 8-1

8.1 Contact ATX Networks ............................................. 8-1

8.2 Warranty Information .............................................. 8-1

iv MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual

SAFETY

1. Safety

WARNING! FAILURE TO FOLLOW THE SAFETY PRECAUTIONS LISTED BELOW MAY RESULT IN PROPERTY DAMAGE

OR PERSONAL INJURY. PLEASE READ AND COMPLY WITH THE FOLLOWING:

SAFETY GROUND: The connection to earth of the supplementary grounding conductor shall be in compliance with the

appropriate rules for terminating bonding jumpers in Part V of Article 250 of the National Electrical Code, ANSI/NFPA 70, and

Section 10 of Part I of the Canadian Electrical Code, Part I, CSA C22.1.

WATER AND MOISTURE: Care should be taken to prevent entry of splashed or dripping water, other liquids, and physical

objects through enclosure openings.

DAMAGE: Do not operate the device if damage to any components is suspected.

POWER SOURCES: Only connect the unit to a power supply of the type and capacity specied in the operating instructions

or as marked on the device.

NOTE: a) For 115 VAC operation, use the power cord supplied for operation from a 115 VAC source.

b) For 230 VAC operation, use the power cord supplied for operation from a 230 VAC source.

CHAPTER 1: SAFETY

GROUNDING OR POLARIZATION: Electrical grounding and polarization means must not be defeated.

POWER CORD PROTECTION: Care must be taken during installation to route or arrange the power supply cord to prevent

and avoid the possibility of damage to the cord by external objects. Pay particular attention to the exit point from the device

and plug.

POWER SUPPLY CORD ROUTING: The power supply cord shall not be attached to the building surface, nor run through

walls, ceilings, oors and similar openings in the building structure.

SERVICE: Do not attempt to service the device beyond procedures provided in the operating instructions. All other servicing

should be referred to qualied service personnel.

MODIFICATIONS: Modications should not be made to the device or any of its components for applications other than those

specied in the operating instructions.

SAFETY CODES AND REGULATIONS: The device should be installed and operated in compliance with all applicable local

safety by-laws, codes and regulations.

MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual 1-1

CHAPTER 1: SAFETY

This page intentionally left blank.

1-2 MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual

OVERVIEW

2. Overview

The UCrypt IP to Analog Version 2, referred to as Device in this manual, is built in either a 1RU chassis for up to 20 analog

channels or a 2RU chassis for up to 60 analog channels. Each device can ingest MPEG-2, H.264, SD or HD, SPTS and MPTS

IP multicast video streams with redundancy and output in either NTSC or PAL analog formats.

2.2 Chapter Contents

• “Front Panels”

• “Controls & Indicators”

• “Rear Panels”

• “Switch & Firewall Port Openings”

2.3 Front Panels

The front panel of each Device, shown in Figure 2-1 and Figure 2-2, contains a set of controls and indicators to show the

status of important operation parameters and allow some control over the device. These control panels are explained further

in the next section.

CHAPTER 2: OVERVIEW

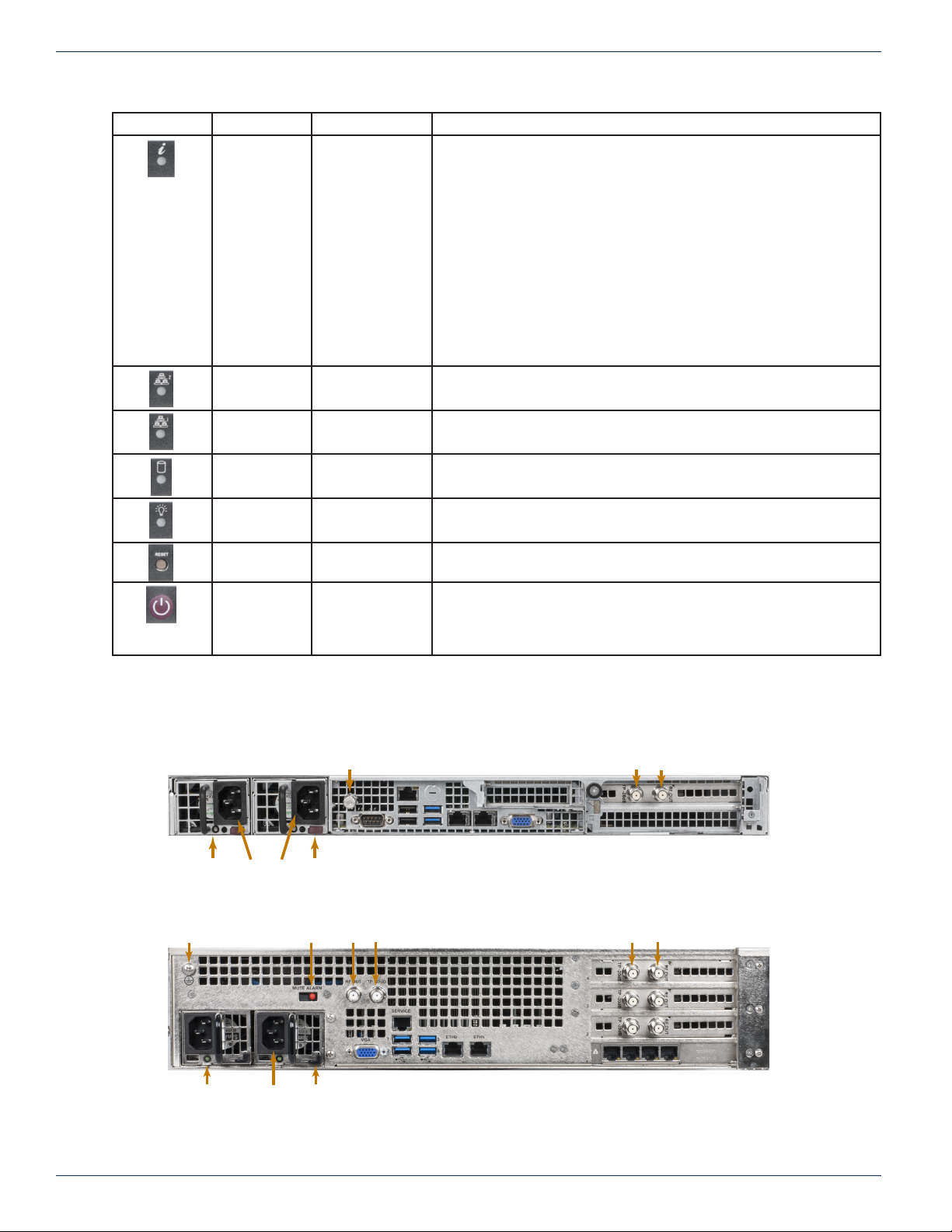

2.4 Controls & Indicators

The products are designed to be plug and play and will be in a powered on state when the power cord is plugged in. There

may be instances where it is desired to reboot or power down the devices manually and recessed switches to enable that are

located on the front panel, a detailed view of which is shown in Figure 2-3 (1RU) and Figure 2-4 (2RU). Indicator lights are

provided to allow monitoring of errors and alarms and have a slightly different appearance but the same functionality on 1RU

and 2RU devices . See Table 2.4a for functional descriptions of all front panel controls and indicators.

Figure 2-3: 1RU Controls & Indicators

Table 2.4a: Front Panel Controls and Indicators

1RU Symbol 2RU Label Function Description

N/A UID Recessed Button Universal Identier: A switch that will turn on the adjacent “U” light.

Figure 2-1: UCrypt 1RU Front Panel

Figure 2-2: UCrypt 2RU Front Panel

Figure 2-4: 2RU Controls & Indicators

This switch exists only on the 2RU model.

MDU Solutions® – UCrypt® IP to Analog V2 – Installation & Operation Manual 2-1

CHAPTER 2: OVERVIEW

1RU Symbol 2RU Label Function Description

U Indicator LED

Blue

Universal Information LED: The Universal Information BLUE LED is

used to indicate fan failure, power failure, overheat condition, or to

identify the unit within a large rack installation. This may be activated

by the IPMI or front panel button.

State Indication:

• Fast Blinking Red (1 per sec) - Fan Failure

• Solid Red - CPU Overheated

• Slow Blinking Red (1 per 4 sec) - Power Failure

• Solid Blue - Local UID Button Depressed

• Blinking Blue - IPMI Activated UID

Note: Deactivating the UID LED must be performed in the same way it

was activated. (If the UID LED was activated via IPMI, you can only turn

the LED off via IPMI and not with the UID button.)

ETH1 Indicator LED

Indicates network activity on eth1 network port.

Green

ETH0 Indicator LED

Indicates network activity on eth0 network port.

Green

HDD Indicator LED

Indicates SSD/HDD drive activity when ashing.

Green

PWR Indicator LED

Green

Indicates power is being supplied to the system’s power supply units.

This LED should be illuminated when the system is operating.

RST Recessed Button Reset Switch. Used to warm reboot the Device. Functionally equal to a

reset button on a computer.

PWR Recessed Button Power Switch. This is the main soft power switch and is used to apply

or remove power to the Device. Activating this switch effectively turns

the unit off but keeps standby power supplied to the system. You must

unplug the system before servicing. Press again to power up.

2.5 Rear Panels

The rear panel connections are shown here. Some ports that are unlabeled are not used in this model of Device.

AC Power

Indicator

Safety Ground

AC Power

Indicators

AC Power

Input

Power Supply Alarm Mute

AC Power

Input

Module Release

Latch

Safety Ground

Module Release

Latch

Combined

RF Output

eth1

eth0

192.168.0.23

Management

Multicast Input

Figure 2-5: 1RU Rear Panel

Test Point

eth1

eth0

192.168.0.23

Management

Multicast input

Figure 2-6: 2RU Rear Panel

Channel Group

RF Outputs

eth5 eth4 eth3 eth2

Multicast input

RF Output-20 dB Test Point

Channel Group

Test Points

2-2 MDU Solutions® – UCrypt® IP to Analog V2 – Installation & Operation Manual

2.6 Switch & Firewall Port Openings

Any Management Switch used between IP2A Devices and the Management Computer will require the following ports to be

opened both Inbound and Outbound.

NOTE: Failure to open these ports may result in communications problems between the

management computer and IP2A Devices.

Table 2.6a: Ports to Open on Switch

Port Number Transport Protocol

80 TCP HTTP

443 TCP HTTPS

CHAPTER 2: OVERVIEW

•

MDU Solutions® – UCrypt® IP to Analog V2 – Installation & Operation Manual 2-3

CHAPTER 2: OVERVIEW

This page intentionally left blank.

2-4 MDU Solutions® – UCrypt® IP to Analog V2 – Installation & Operation Manual

INSTALLATION

3. Installation

This chapter provides a guide to get your Device installed in a rack and connected safely.

3.1 Chapter Contents

• “Preparation for Installation”

• “Precautions”

• “General Mechanical”

• “General Electrical”

• “General Environment”

• “Gigabit Ethernet Ports”

• “Install the 1RU Device”

• “Install the 2RU Device”

• “Equipment Safety Grounding”

• “AC Power Supplies”

• “DC Power Supplies”

• “Power Supply Redundancy”

CHAPTER 3: INSTALLATION

3.2 Preparation for Installation

Carefully unpack the equipment from the shipping box. If the box or equipment is damaged, notify the freight company to make

a damage claim. If you suspect that there is a problem with the equipment that may preclude safe operation, do not install or

operate it. Contact ATX Networks immediately for instructions.

WARNING: This equipment is intended for installation in a RESTRICTED ACCESS LOCATION

only.

WARNING: This equipment is NOT for use in a computer room as dened in the Standard for

Protection of Electronic Computer/Data Processing Equipment, ANSI/NFPA 75.

WARNING: This equipment is intended for use in a xed position and should be installed securely

before operation is initiated.

3.3 Precautions

3.3.1 Electrical Precautions

Basic electrical safety precautions should be followed to protect yourself from harm and the Device chassis from damage:

• Be aware of the locations of the power on/off switch on the chassis as well as the room’s emergency power-off switch,

disconnection switch or electrical outlet. If an electrical accident occurs, you can then quickly remove power from the

system.

• Power should always be disconnected from the system when servicing. When disconnecting power, you should rst

power down the operating system rst and then unplug the power cords. The unit has more than one power supply

cord. Disconnect two power supply cords before servicing to avoid electrical shock.

• When working around exposed electrical circuits, another person who is familiar with the power-off controls should

be nearby to switch off the power if necessary.

• Use only one hand when working with powered-on electrical equipment. This is to avoid making a complete circuit,

which will cause electrical shock. Use extreme caution when using metal tools, which can easily damage any electrical

components or circuit boards they come into contact with.

• Do not use mats designed to decrease static electrical discharge as protection from electrical shock. Instead, use

rubber mats that have been specically designed as electrical insulators.

MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual 3-1

CHAPTER 3: INSTALLATION

• The power supply power cords must include a grounding pin and must be plugged into grounded electrical outlets.

• Remove any jewelry or metal objects from your body, which are excellent metal conductors that can create short

circuits and harm you if they come into contact with printed circuit boards or areas where power is present.

• This product may be connected to an IT power system. In all cases, make sure that the unit is also reliably connected

to Earth (ground).

3.3.2 General Precautions

WARNING: The RF connections provided with this equipment are not intended for direct connection

to any outside telecommunications network or outside cable distribution plant.

WARNING: When the equipment is lifted by the front handles, always use both front handles for

security. Never lift this equipment using only a single front handle due to the weight of the equipment.

• The Devices weighs up to approximately 30 lbs (13.5kg). When lifting the system, two people should lift slowly with

their feet spread out to distribute the weight. Always keep your back straight and lift with your legs.

• While working on the system, do not wear loose clothing such as neckties and unbuttoned shirt sleeves, which can

come into contact with electrical circuits or be pulled into a cooling fan.

• After accessing the inside of the Device, close the chassis back up and secure it to the rack unit with the retention

screws and ensure that all connections have been made.

3.3.3 Chassis Precautions

• Determine the placement of each component in the rack before you install the rails.

• Install the heaviest components on the bottom of the rack rst, and then work up.

• Use a regulating uninterruptible power supply (UPS) to protect the Device from power surges, voltage spikes and to

keep your system operating in case of a power failure.

• Allow any power supply modules to cool before touching them.

3.3.4 Rack Precautions

• Ensure that the leveling jacks on the bottom of the rack are fully extended to the oor with the full weight of the rack

resting on them.

• In single rack installation, stabilizers should be attached to the rack. In multiple rack installations, the racks should

be coupled together.

• Mechanical Loading - Mounting of the equipment in the rack should be such that a hazardous condition is not

achieved due to uneven mechanical loading.

3.4 General Mechanical

• The equipment will require 1RU or 2RU of vertical rack space depending on the model being installed and may

be mounted directly above or below other equipment without providing space between, however, 1RU space is

recommended to be maintained from other equipment which generates signicant heat.

• Leave enough clearance in front of the rack to enable you to work on the chassis (~25 inches) and approximately 30

inches of clearance in the back of the rack to allow for sufcient airow and ease of servicing.

NOTE: More general information about equipment abient temperature requirements may be found

in this document from ATX Networks: http://www.atxnetworks.com/pdf/ANW1066_MDU_UCrypt_

Environment_Temp_Considerations_InfoSheet.pdf

• Rear support of the unit is mandatory and rails for attachment to rear supports are provided. Do not use the unit

chassis to support other equipment. Alternately, if rear support rails are unavailable or impractical, install the unit on

a well supported shelf.

3-2 MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual

3.5 General Electrical

• Consideration should be given to the connection of the equipment to the mains power and the effect that any

possible overloading of circuits might have on over current protection and supply wiring. Appropriate consideration of

equipment nameplate ratings of all connected equipment should be used when addressing this concern.

• Reliable earthing of rack-mounted equipment should be maintained in addition to any grounding conductor provided

in the power cord. Particular attention should be given to supply connections other than direct connections to the

branch circuit (e.g. use of power strips).

3.6 General Environment

• Be sure to maintain freedom of air movement around equipment to ensure safe operation.

• Installation of the equipment in enclosed racks is not recommended due to possibility of restricted air ow.

• Installation of the equipment in a rack should be such that the amount of air ow required for safe operation of the

equipment is not compromised.

• The equipment is designed to operate to specication in an ambient temperature of +0°C to +40°C (+35°F to +104°F),

however, normal room temperature is recommended to ensure long term operation of the equipment.

• If equipment is installed in a closed or multi-unit rack assembly, the operating ambient temperature of the rack

environment may be greater than room ambient. Therefore, consideration should be given to installing the equipment

in an environment compatible with the maximum ambient temperature (Tma) of +40°C (+104°F).

CHAPTER 3: INSTALLATION

3.7 Gigabit Ethernet Ports

The input ports are auto MDI-MDIx and intended to be connected to a network distribution switch using straight through wired

Cat5e or better quality cable. The rear panel Management Interface port allows connection to a notebook or desktop PC for

managing and conguring the system. The port may be connected to directly, or in the case of a headend with many devices to

manage, may be connected to a management network (recommended) or the distribution switch containing the video stream

content. It is possible to set up virtual ports for a VLAN. Connections should be made with Cat5e or better network cables.

The GigE management port is auto MDI-MDIx and may be connected to a switch or router with a straight through wired cable.

MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual 3-3

CHAPTER 3: INSTALLATION

3.8 Install the 1RU Device

This section provides information on installing the 1RU Device chassis in a rack unit with the rails provided. There are a variety

of rack units on the market, which may mean that the assembly procedure will differ slightly from the instructions provided. You

should also refer to the installation instructions or adapt these instructions to suit the rack unit you are using.

WARNING: The illustrations in Figure 3-4 and Figure 3-5 are for general guidance purposes only.

Always install the Device chassis to the bottom of the rack rst to avoid the rack becoming top

heavy.

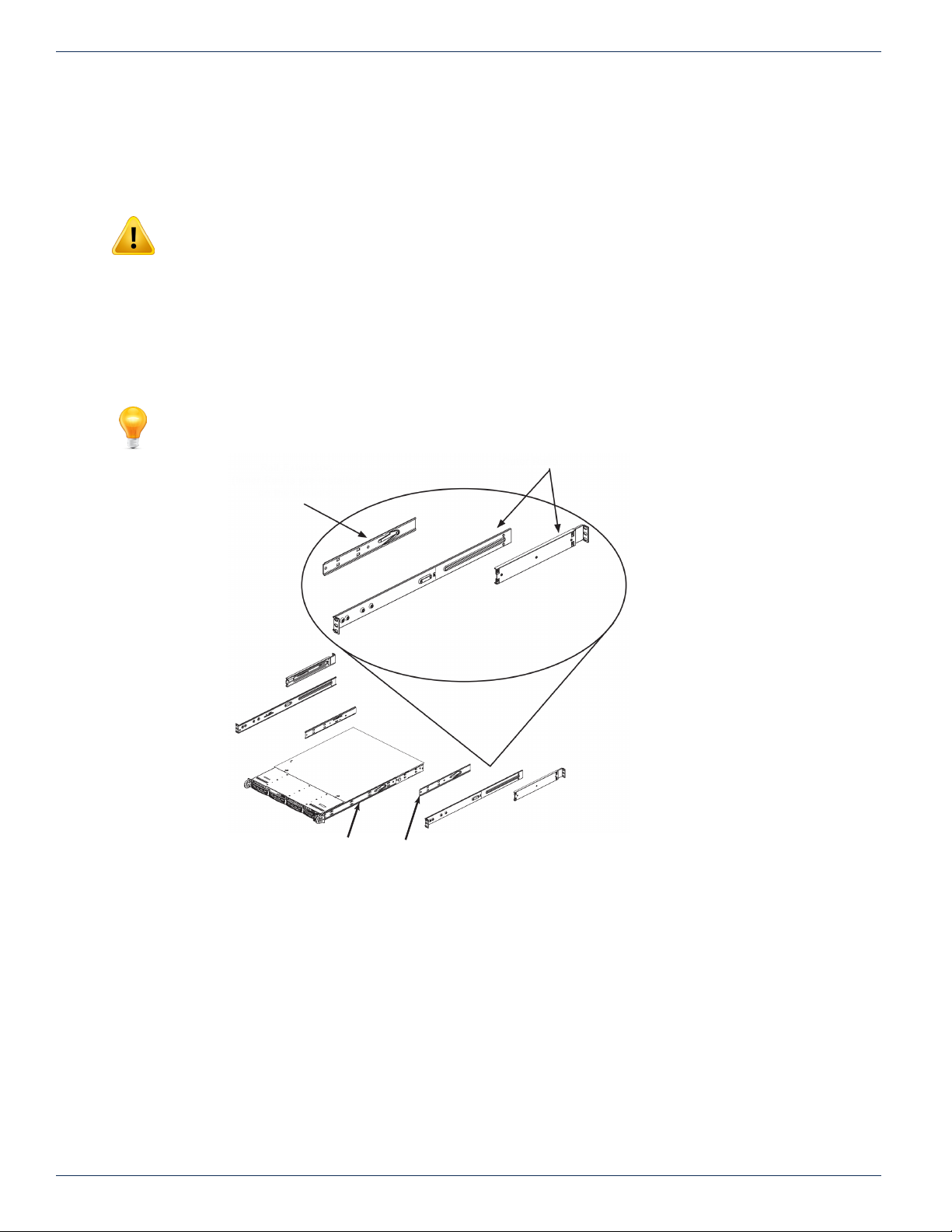

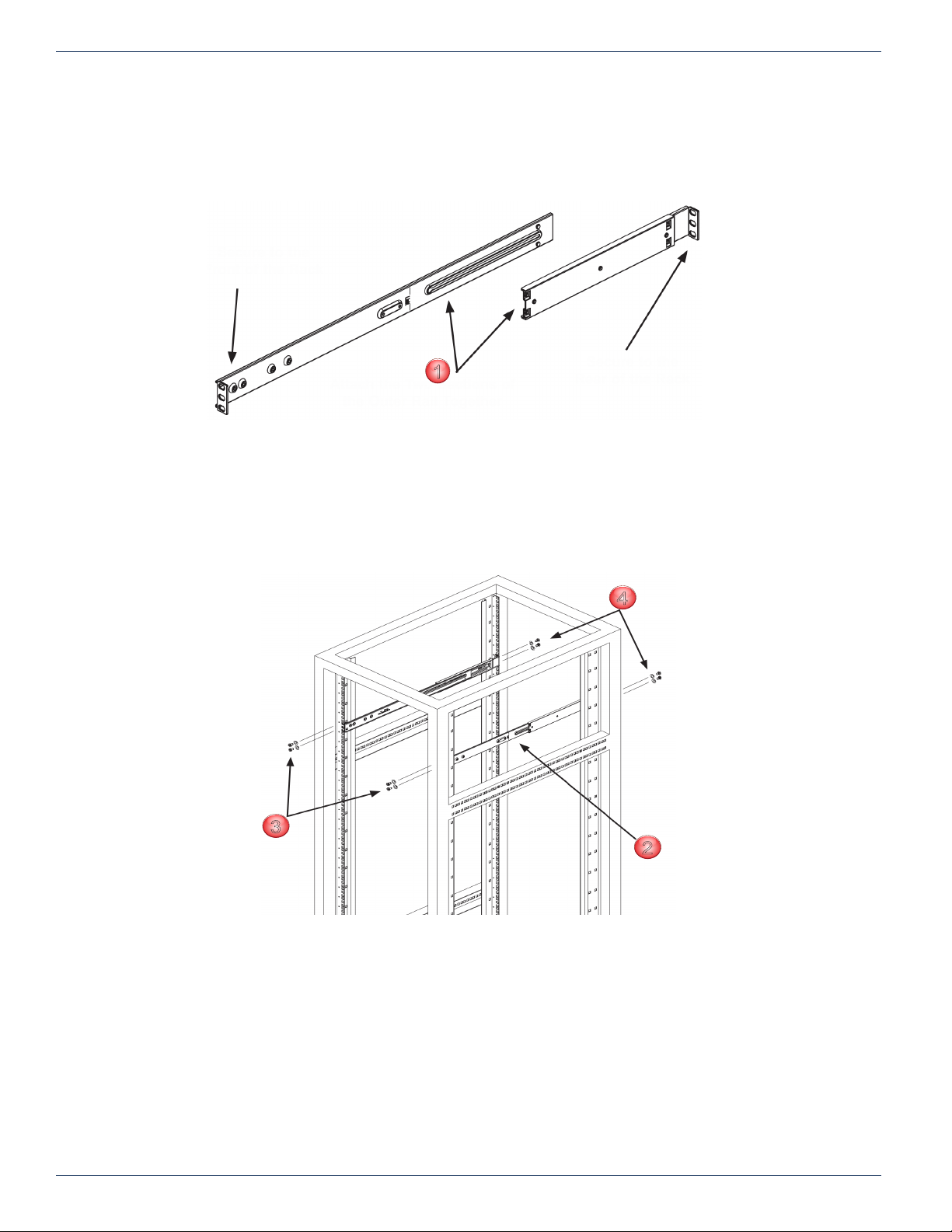

3.8.1 Identifying the Rack Rail Sections

The 1RU Device chassis includes two rail assemblies in the rack mounting kit. Each assembly consists of two sections: An

inner chassis rail secured to the chassis (front part is factory installed, extension is eld installed), an outer rail that secures

to the rack, and an outer rail extension that secures directly to the rear vertical support, Figure 3-1. Each of these assemblies

are designed for mounting universally on the left or right side of the chassis.

NOTE: This rail will t a rack between 26” and 33.5” deep.

(Inner rail is factory-assembled

on the chassis)

Inner rail factory installed

Figure 3-1: Identifying Rack Rail Sections

Outer RailsInner Rail Extension

Inner Rail extension

3-4 MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual

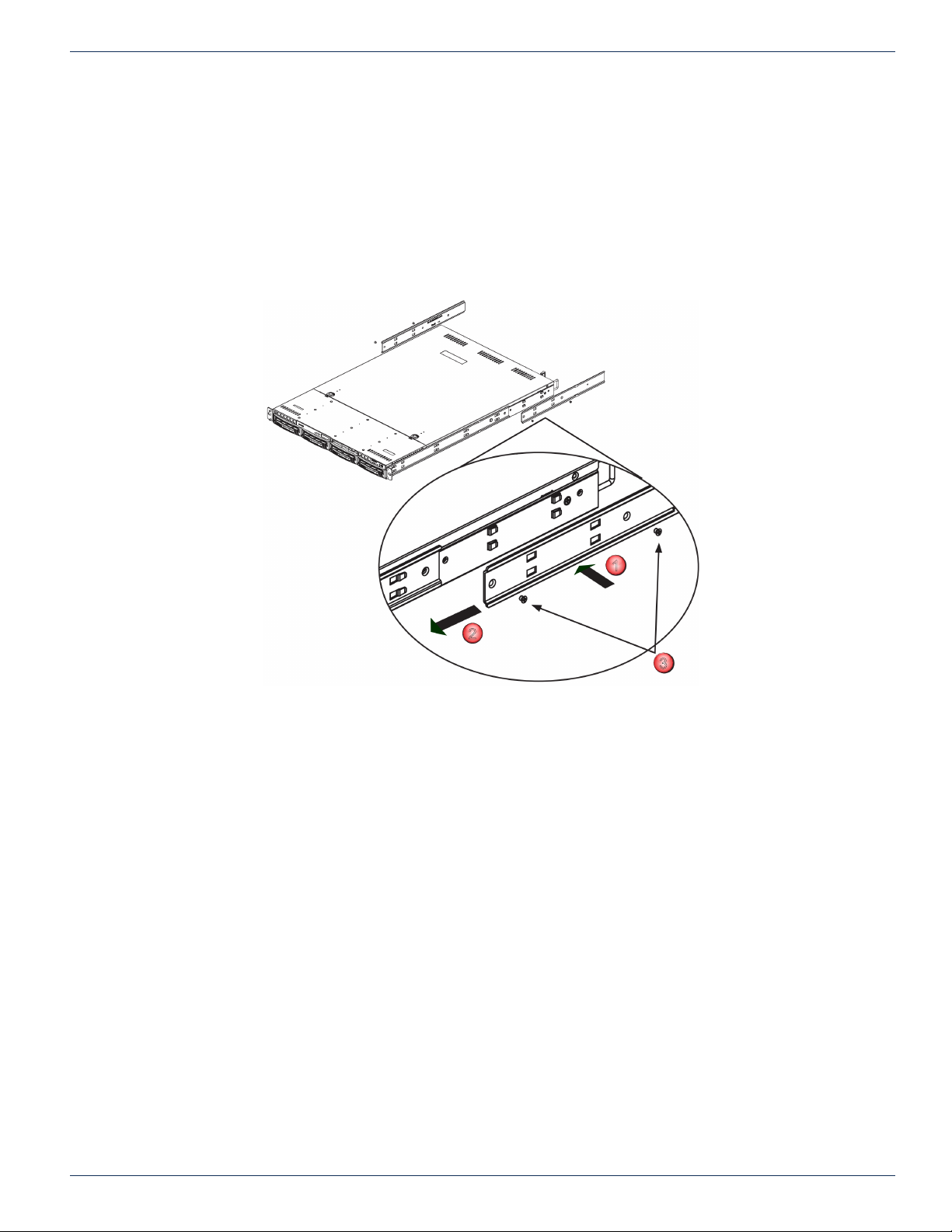

3.8.2 Install Inner Rail Extensions

1

2

3

The chassis includes a set of inner rails which are in two sections: inner rails and inner rail extensions. The inner rails are

pre-attached and do not interfere with normal use of the chassis if you decide not to use a server rack. Attach the inner rail

extension to help support the rear of the chassis within the rack.

1. Place the inner rail extensions on the side of the chassis aligning the hooks of the chassis with the inner rail extension

holes, Figure 3-2. Make sure the inner rail extension faces “outward” just like the pre-attached inner rail.

2. Slide the extension toward the front of the chassis latching it onto the hooks.

3. Secure the rail extension with 2 screws as illustrated.

4. Repeat steps 1-3 for the other inner rail extension.

CHAPTER 3: INSTALLATION

Figure 3-2: Identifying Rack Rail Sections

MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual 3-5

CHAPTER 3: INSTALLATION

1

2

3

4

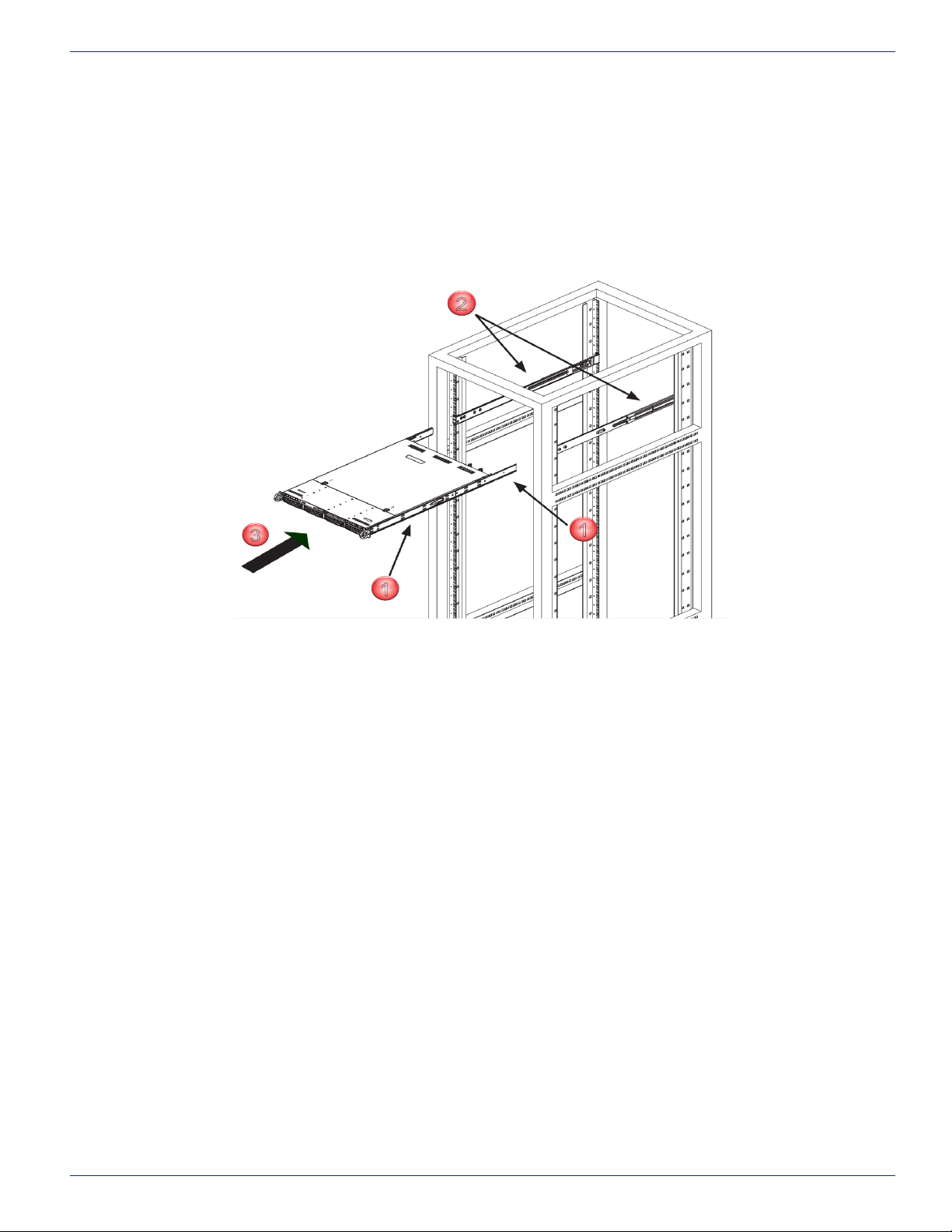

3.8.3 Install the Outer Rails in the Rack

1. Attach the longer section of the outer rail to the outside of the shorter section of the outer rail, Figure 3-3. You must

align the pins with the slides. Both ends of the outer rail must face the same direction in order to be secured to the

rack.

Secure to rack front rails

Attach the 2 sections tegether

Secure to the rear rack support rails

Figure 3-3: Install Rail Sections

2. Adjust both sections of the outer rail to the proper length so that the rail ts snugly within the rack, Figure 3-4.

3. Secure the longer section of the outer rail to the of the front rack rails with two 10-32 rack screws.

4. Secure the shorter section to the rear rack rails with two 10-32 rack screws.

5. Repeat steps 1-4 for the remaining outer rail.

Figure 3-4: Install Outer Rails to Rack

3-6 MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual

3.8.4 Mount the Chassis

Inner rails

Inner Rail

extensions

Outer rails and extensions

1

2

3

1

1. Conrm that the inner rails and rail extensions have been installed on the chassis, Figure 3-5.

2. Conrm that the outer rails and extensions are installed on the rack.

3. Line up the chassis rails with the front of the outer rack rails, then slide the chassis rails into the rack rails, keeping the

pressure even on both sides (you may have to depress the locking tabs when inserting). When the Device has been

pushed completely into the rack, you should hear the locking tabs “click” into the locked position.

4. Insert and tighten the screws that hold the front of the Device to the rack if desired.

CHAPTER 3: INSTALLATION

Figure 3-5: Install Chassis to Rack

MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual 3-7

CHAPTER 3: INSTALLATION

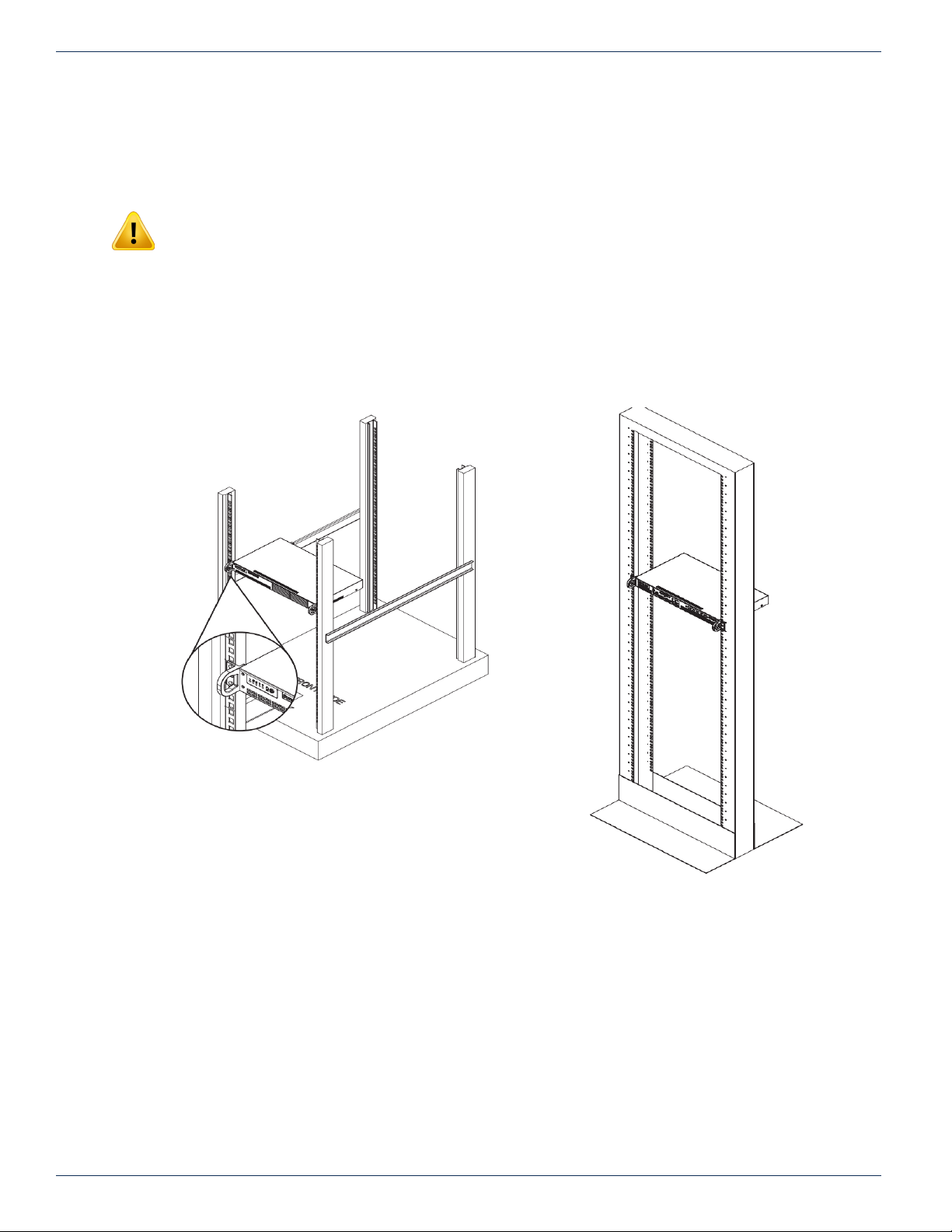

3.9 Install the 2RU Device

This section provides information on installing the Device chassis in a rack unit with the rails provided. There are a variety of

rack units on the market, which may mean that the assembly procedure will differ slightly from the instructions provided. You

should also refer to the installation instructions or adapt these instructions to suit the rack unit you are using.

NOTE: The illustrations in Figure 3-6 and Figure 3-7 are for general guidance purposes only.

Always install the Device chassis to the bottom of the rack rst to avoid the rack becoming top

heavy.

3.9.1 Mount the Chassis

1. Conrm that you have the four mounting screws required to mount the chassis into a rack.

2. Align the thru holes of the chassis with the thru holes of the rack.

3. Insert the mounting screws into the thru holes in the front of the chassis and through the thru holes in the rack as

shown in Figure 3-6 and Figure 3-7.

Figure 3-6: Install Chassis to Standard Rack

Figure 3-7: Install Chassis to Telco Rack

3-8 MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual

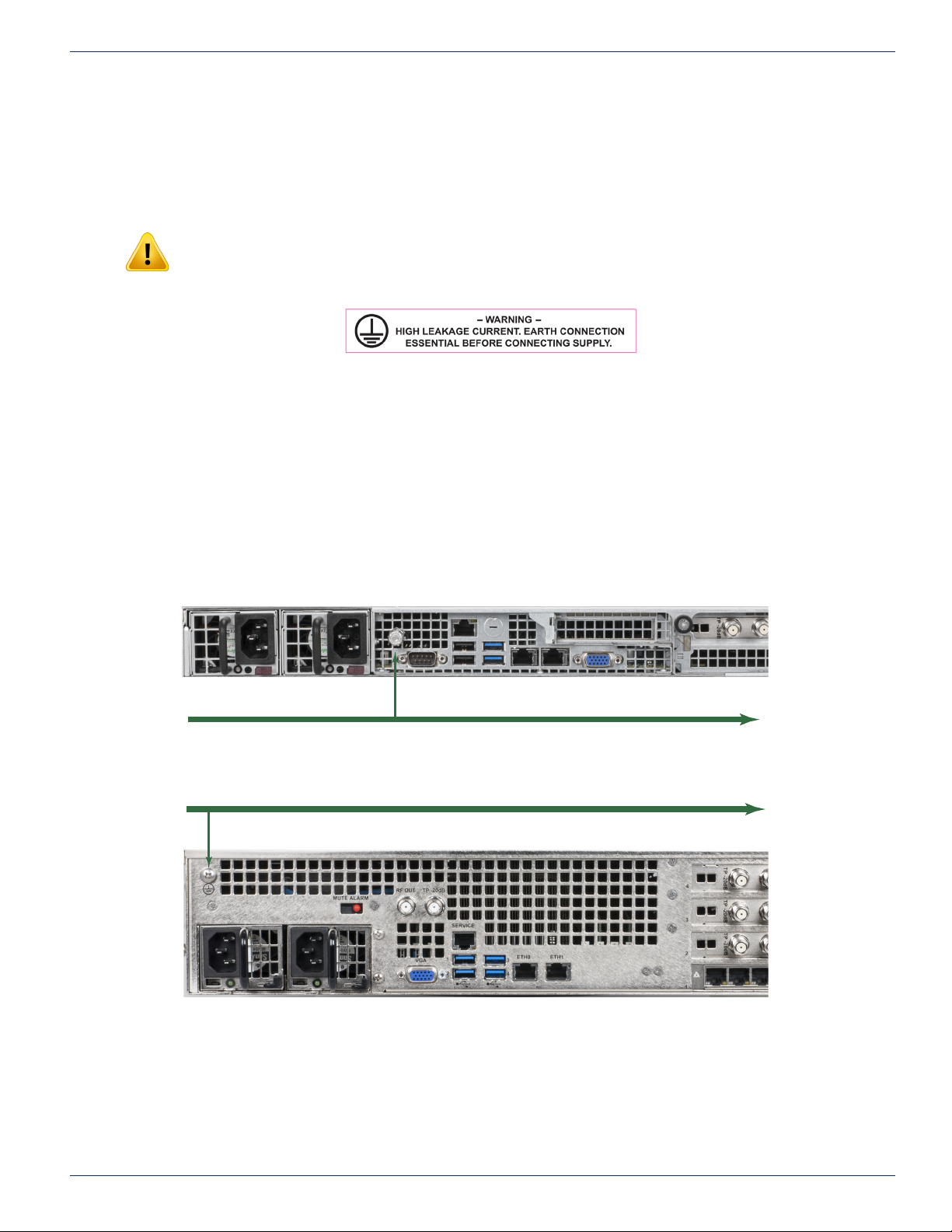

3.10 Equipment Safety Grounding

Reliable earthing of rack-mounted equipment should be maintained. Particular attention should be given to supply connections

other than direct connections to the branch circuit (e.g. use of power strips). The following guidelines are provided to clarify

the requirements for the installation to meet UL, CUL and CB standards. The use of the words “Ground” and “Earth” as well as

“Grounding” and “Earthing” may be used interchangeably and in this context, have the same meaning.

WARNING: To comply with standards it is imperative that the chassis be connected to a

permanent building ground before connecting any power supply conductors due to high leakage

currents present in redundant power supply congurations. A warning label, shown in Figure 3-10,

is attached to all affected products.

Figure 3-10: Leakage Current Warning Label

The Device housing and power supplies must be connected to a permanent building ground in a manner that will ensure that

the exposed metal parts are constantly connected to ground through independent means even when the power supply cord

or wires may be disconnected temporarily. A ground connection screw terminal is provided on the rear panel to conveniently

effect such a connection.

CHAPTER 3: INSTALLATION

3.10.1 Ground Connection

The supplementary equipment grounding conductor is to be installed between the rear panel ground screw and earth, that

is, in addition to the equipment ground conductor in the power supply cord or wires. The screw terminals provided for this

connection are located on the rear panel as illustrated in Figure 3-8 and Figure 3-9.

Safety Ground Lug

Safety Ground Lug

Rack Ground Buss

Figure 3-8: 1RU Safety Ground Connection

Rack Ground Buss To building electrical ground system

To building electrical ground system

Figure 3-9: 2RU Safety Ground Connection

3.10.2 Ground Conductor Size

The supplementary equipment grounding conductor may not be smaller in size than the branch-circuit supply conductors

or a minimum #14 AWG. The supplementary equipment grounding conductor is to be connected at the rear panel terminal

provided, and connected to earth in a manner that will retain the earth connection when the power supply cord is unplugged.

The connection to earth of the supplementary grounding conductor shall be in compliance with the appropriate rules for

MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual 3-9

CHAPTER 3: INSTALLATION

terminating bonding jumpers in Part V of Article 250 of the National Electrical Code, ANSI/NFPA 70, and Section 10 of Part I

of the Canadian Electrical Code, Part I, CSA C22.1.

3.10.3 Ground Conductor Termination

Termination of the supplementary equipment grounding conductor may be made to building steel, to a metal electrical raceway

system, or to any grounded item that is permanently and reliably connected to the electrical service equipment earth.

3.10.4 Ground Conductor Type

Bare, covered or insulated grounding conductors are acceptable. A covered or insulated grounding conductor shall have a

continuous outer nish that is either green, or green with one or more yellow stripes.

3.11 AC Power Supplies

Both the redundant and non-redundant AC power supplies are auto-sensing switching type power supply systems which may

be operated on input voltages from 115 VAC to 230 VAC. There is no need to congure the power supplies to operate on any

voltage in this range.

3.11.1 AC Power Cord Protection

Measures must be taken during installation to route or arrange the power supply cords or wires to prevent physical damage

and to avoid the possibility of future damage occurring. The cords shall be installed and routed such that, throughout it’s

length, the cord and it’s points of connection are not strained in any way.

3.11.2 AC Power Cord Attachment

The unit AC power supply cords shall not be attached to a building surface, bundled with audio, video or RF coaxial cables,

nor run through walls, ceilings, oors and similar openings in the building structure.

3.11.3 Provision of Electrical AC Power Outlet

An AC electrical power outlet of appropriate type and rating shall be provided near the location where the unit is installed

and easily accessible such that the provided power supply cords may be routed in an appropriate manner, without the use of

extension cords, between the receptacle and the chassis. Alternately, the chassis shall be installed in close proximity to an

existing AC electrical outlet such that the requirements of this paragraph are achieved.

3.11.4 IEC C13 Power Input Cord for AC

The AC power input receptacle is a standard IEC C14 socket connector similar to that commonly used on computers and

monitors. The power cords provided with the IP2A product is a North American conguration with a NEMA 5-15 grounded

plug for 115 VAC. If it is necessary to operate the product on 230 VAC, the installer must obtain IEC C13 cords with a NEMA

6-15 grounded plug for use in North America. This may be obtained at time of order from ATX Networks or locally. If shipped

outside of North America, the Device will be supplied with an IEC C13 cord set appropriate for the locale to which it is shipped.

3.11.5 AC Input Power Requirements

When installing the equipment, it is the responsibility of the installer to determine that sufcient capacity is available in the

electrical circuit feeding the unit to avoid overloading the supply circuit. The AC model will require power to be supplied from a

properly grounded AC outlet. The installer shall determine that the AC power outlet, its wiring and receptacle is in compliance

with local and/or national electrical codes as applicable. The AC input power requirement is constant over the range of input

voltages. At higher input voltages, the current consumption is lower than it is at lower voltages where the input current is higher.

3-10 MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual

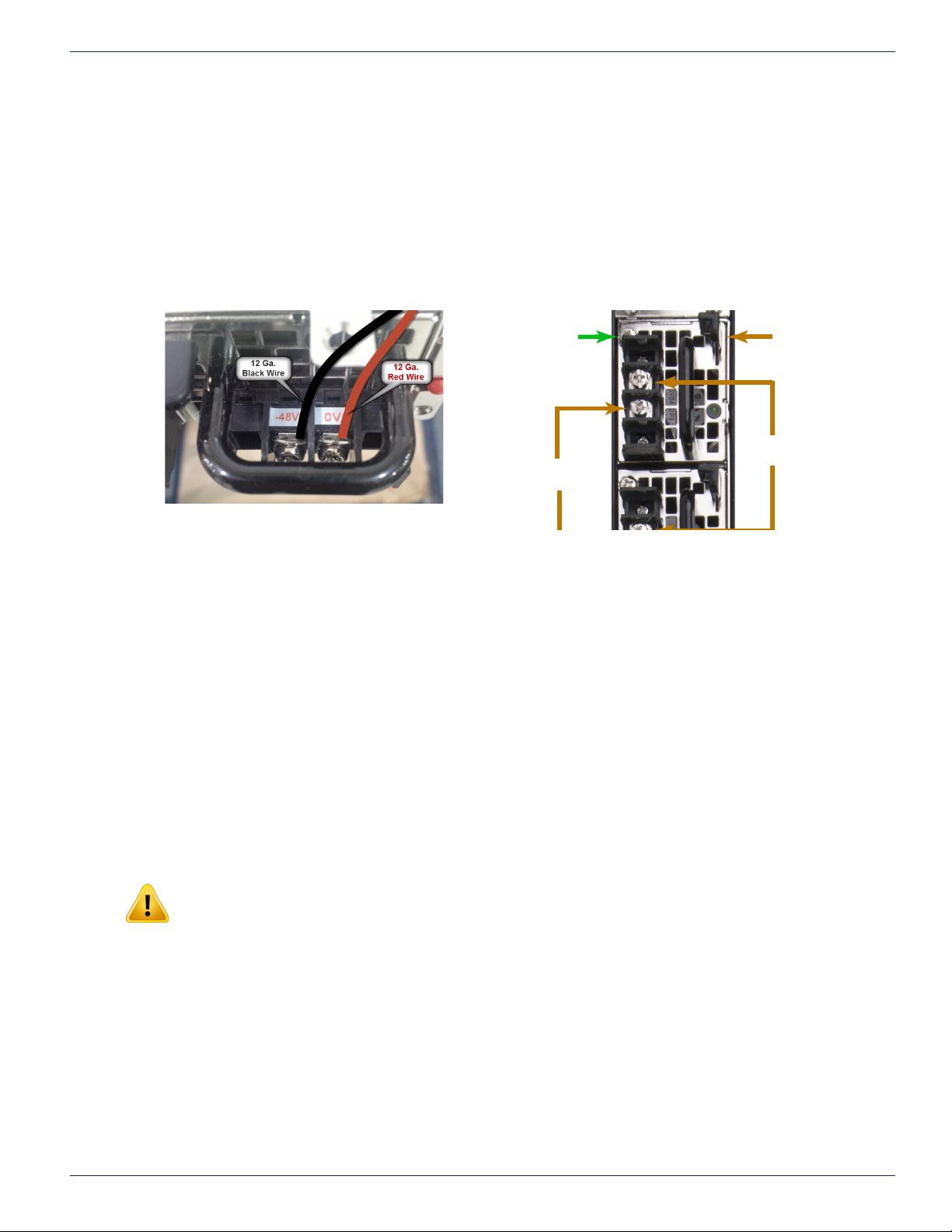

3.12 DC Power Supplies

3.12.1 DC Power Supply Connections

The optional redundant DC switching type power supply system is intended to operate on nominal -48 VDC power systems

but functions between -40 and -57.2 VDC. A pair of insulated #12 AWG DC power wires must be eld installed for each of the

two modules using permanent wiring methods. Wire insulation colors must be different for each of the two conductors clearly

indicating the polarity of the voltage. It is recommended that stranded conductors be used for DC power and that RED wire be

used for the 0V conductor and BLACK for the -48V conductor. Crimped on style Ring or Spade terminals may be used and it

is also permissible to strip the wire 8mm, twist the stranded conductors tightly and clamp the wire in the provided wire clamp

as illustrated in Figure 3-11.

CHAPTER 3: INSTALLATION

Figure 3-11: DC Power Module Connections

3.12.2 DC Disconnect and Fusing

Each DC power module should be externally fused or otherwise adequately protected at no more that 20 Amperes and

must be provided with it’s own external readily accessible disconnect device. Each disconnect must be prominently labeled

indicating the units being powered and with adequate instructions for the removal of all power from the unit being serviced.

The disconnect must be turned off for BOTH power modules before removing supply wires from the module terminal blocks

when replacing a power supply module or otherwise servicing the unit.

3.13 Power Supply Redundancy

For the redundant power supplies, either power module on its own can provide the required power safely if one fails. To retain

the redundancy feature, replace a failed power module as soon as possible. A power module failure or the failure of the supply

current or protection fuse will be indicated by an audible alarm within the encoder power modules and the green power status

LED on the power module will be extinguished. Silence the audible alarm with the red rear panel Alarm Reset switch adjacent

to the power supply modules, Figure 3-12.

Safety

Ground

0 Volts In

Figure 3-12: Redundant DC Power Supply

Latch

-48 Volts In

3.13.1 Redundant Power Module Replacement

AC Version

WARNING: The power cords for BOTH power modules must be disconnected before attempting

to remove the power modules or otherwise servicing the unit.

Power module failure will be indicated by the alarm being sounded and the green status light on the module will no longer be

lit. This power module may be replaced by rst disconnecting the AC power cord from the IEC input socket of BOTH power

modules, then release the module by pressing to the left on the thumb latch at the bottom of each module. Extract the module

and replace with an identical replacement module only.

MDU Solutions® – UCrypt® IP to Analog 2nd Generation – Installation & Operation Manual 3-11

Loading...

Loading...