atwood Bolt-on Coupler User Manual

LITERATURE NUMBER

MPD 70055

25,000 LB. BOLT-ON

9

COUPLER & HITCH BALL

ENGLISH, FRANÇAIS (et Canada) •Installation •Operation •Maintenance

Effective 11/21/07

SAFETY ALERT SYMBOLS

Safety Symbols alerting you to potential personal safety hazards. Obey all safety

messages following these symbols.

WARNING CAUTION

avoid possible avoid possible

injury or death injury and/or property damage

FOR YOUR SAFETY READ ALL INSTRUCTIONS

BEFORE INSTALLATION AND OPERATION

Installer: Provide these instructions to the consumer.

Consumer: Keep documents for future reference.

• Safe towing practice requires the proper use of safety chains used

in accordance with instructions provided by the trailer manufacturer.

• Check that the ball has been completely inserted into the coupler ball

socket and the ball clamp (inside the coupler) is closed around the

underside of the tow ball and the handle is in the closed position.

• The loaded weight of the trailer must never exceed the least

capacity marked on the coupler, tow ball, hitch, trailer or vehicle.

• Check coupler, hitch and ball for damage or wear before each use.

Assure all parts operate freely. Replace any component if worn or

damaged.

• Failure to follow warnings and instructions could result in separation of tow vehicle and trailer which can result in death, personal

injury and property damage.

WARNING

INSTALLATION

25,000 LB. BOLT-ON COUPLER

Part No. 75074

Maximum Gross Vehicle Weight: 25,000 lbs.

Ball Size: 2-5/16˝ diameter

Vertical Load Capacity: 5,000 lbs.

The Atwood 25,000 lb. Bolt-on Coupler is designed for use on agricultural, industrial or commercial trailers. The trailer must have a flat vertical surface on the front of the trailer tongue for attaching the coupler

by bolting.

WARNING

PERSONAL INJURY & PRODUCT DAMAGE

•

Know the trailer weight and added load weight. Do not

exceed the 25,000 lbs. GVWR and 5000 lb. tongue weight

capacity indicated on coupler.

• Use a 2-5/16˝ diameter hitch ball only, with the correct tow-

ing capacity.

1. Bolt coupler to trailer frame using four 5/8˝ diameter, Grade 8 bolts,

nuts and lockwashers. Customer must provide this hardware.

2. Tighten bolts to 160 ft. lbs. of torque.

OPERATION

CAUTION

PRODUCT DAMAGE

• Use caution when backing or towing vehicle for hook-up,

damage to coupler may result.

• Avoid sharp turns when towing or backing. Jack-knifing

could bend coupler or create extreme stress or fracture to

the coupler, coupler attachment and trailer frame.

LATCHING INSTRUCTIONS

COUPLING PROCEDURE

1. On level ground place wheel chocks in front and behind wheels,

both sides of the trailer (4 chocks).

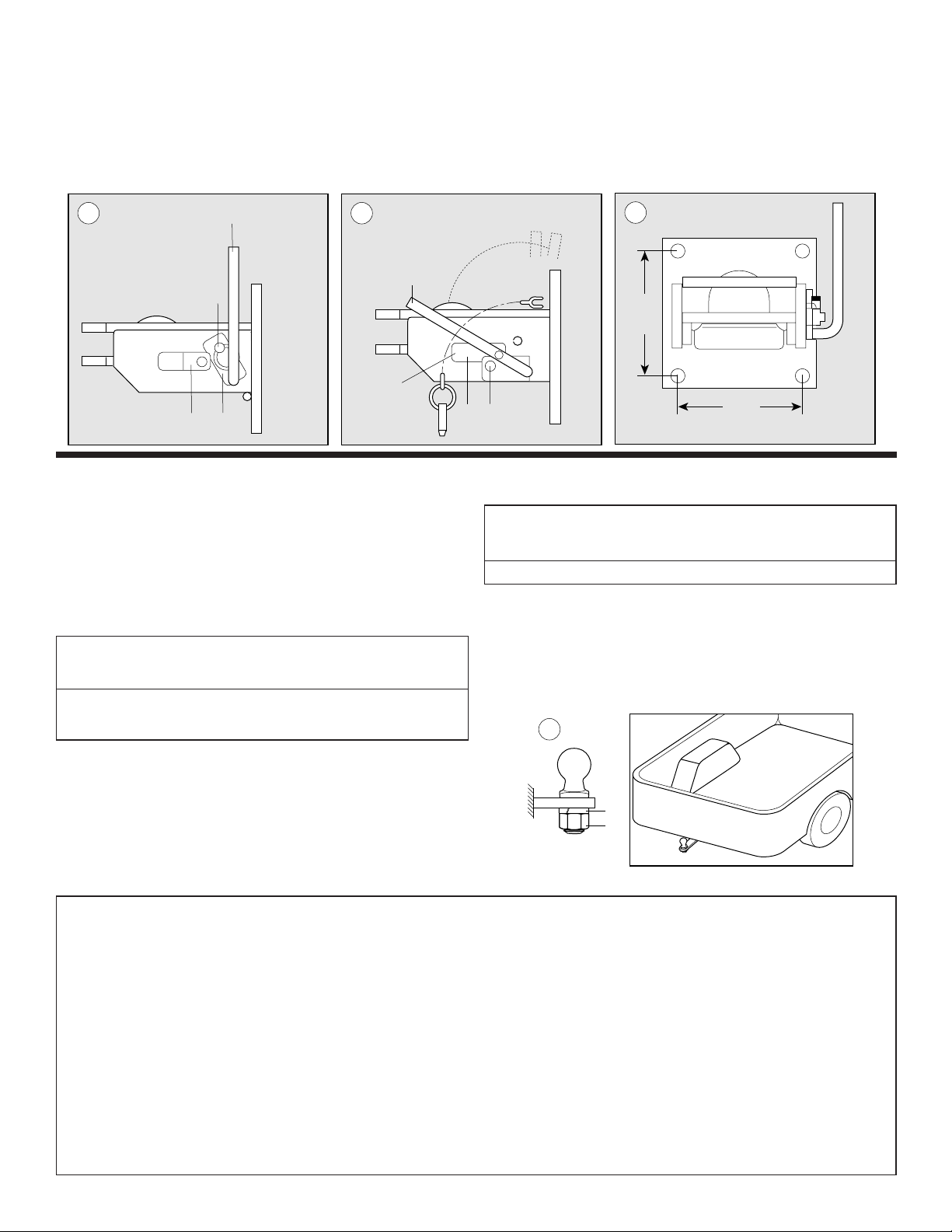

2. ➀ shows coupler handle in a latched position. To open, remove lock

pin ➀-D rotate handle ➀-A counterclockwise a sufficient amount to

allow handle tab ➀-B to clear rivet tab ➀-C, then pull handle away

from coupler and position handle tab under rivet on outside of rivet

tab as in ➁.

3. Adjust trailer jacks until coupler lowers completely down on to hitch

ball.

4. Check to make sure that the handle is in latched position. Place

lock pin ➀-D in holes of tabs ➀-B, pinning the handle in place.

5. Connect power line, breakaway switch line and safety chains

between truck and trailer (see trailer manufacturer’s instructions).

6. Check all lights - stop, turn, tail, and brake lights for proper operation.

7. As an additional check before towing, extend jacks until truck is

raised 3 to 4˝ to verify that coupler is securely attached to ball.

8. Completely retract trailer jacks.

9. Pick up and store wheel chocks.

UNCOUPLING PROCEDURE

1. On level ground place wheel chocks in front and behind wheels,

both sides of the trailer (4 chocks).

2. Lower trailer jacks. If on soft ground, place a support under the jack

feet to prevent trailer from settling.

3. ➀ shows coupler handle in a latched position. To open, remove lock

pin ➀-D rotate handle ➀-A counterclockwise a sufficient amount to

allow handle tab ➀-B to clear rivet tab ➀-C, then pull handle away

from coupler and position handle tab under rivet on outside of rivet

tab as in ➁.

4. Raise trailer until jacks lift coupler completely above the top of ball.

5. Disconnect power line, breakaway switch line and safety chains

between truck and trailer.

6. Drive truck slowly away from under trailer.

1

MAINTENANCE

1 2

3

A

B

C

D

A

BC

4.5"

4.5"

A

B

4

1. Lubricate ball socket and ball clamp with wheel bearing grease.

Clean and lubricate monthly.

2. Check towing hitch, ball and coupler for signs or wear before each

trip. Replace coupler if damaged or worn.

3. Lubricate moving or sliding parts monthly with S.A.E. 30 weight oil.

4. Check the mounting bolts for the proper torque - 160 ft. lbs.

5. Should problems or questions arise, contact your dealer, the trailer

manufacturer or Atwood Service Department 574-264-2131.

6. For Warranty information contact Atwood before having any work

done 574-264-2131.

25,000 LB. HITCH BALL

Part No. 75380

Maximum Gross Vehicle Weight: 25,000 lbs.

Ball Size: 2-5/16˝ diameter

Shank Size 1-1/14˝ - 12 UNF thread

Vertical Load Capacity: 5,000 lbs.

INSTALLATION

WARNING

PERSONAL INJURY & PRODUCT DAMAGE

• The Atwood Ball is intended to be mounted on a drawbar or

hitch platform located at the rear of the tow vehicle.

• Do not weld ball.

1. Ball must be installed in a drawbar having a hole size 1.281˝ diameter and a thickness of 1.00˝ maximum.

2. Attach the drawbar with nut ➃-A and lock washer ➃-B supplied with

ball (see figure 4). Torque nut to 350/450 ft. lbs.

PERSONAL INJURY &/or PROPERTY DAMAGE

• Replace ball if signs of cracking or flat spotting appear.

1. Check monthly that the bolt or nut is tightened to the correct

torque.

2. Lubricate ball monthly with wheel bearing grease.

3. Check monthly for ball wear.

Should problems or questions arise, contact your dealer, the trailer

manufacturer, or Atwood’s Consumer Service Department

574-264-2131.

MAINTENANCE

WARNING

Atwood Hardware Systems & Components Limited Warranty

Atwood Mobile Products warrants to the Original Purchaser of Atwood Hardware Systems & Components that Atwood will replace or repair any hardware

systems and components that are defective in material or workmanship under the following conditions.

1. For two (2) years commencing with the date of purchase, Atwood will

replace or repair any Hardware System & Components that are found to

be defective by Atwood in material or workmanship.

2. In the event of a warranty claim, the Original Purchaser must contact the

Atwood Consumer Service Department, 1120 North Main Street, Elkhart,

IN 46514, Telephone: 574-264-2131. Warranty claim service must be performed as approved by the Atwood Consumer Service Department.

Warranty replacement hardware systems and components or parts will be

furnished freight prepaid. Labor cost to repair or replace will be limited to

the amount of the original purchase price of the systems and components.

The replaced warranty products or parts become the property of Atwood

Mobile Products and must be returned to the Atwood Consumer Service

Department freight prepaid, unless prior arrangements have been made.

3. This limited warranty is valid only when the product is applied, installed,

maintained and operated in accordance with this Atwood Installation,

Maintenance and Operating Manual. Any deviation from these recommended specifications must be approved in writing by Atwood.

4. Any implied warranties are limited to the duration of this limited warranty

as stated above. Atwood does not assume responsibility for consequential

damage or loss, including loss of use of vehicle, loss of time, inconvenience, expense for gasoline, telephone, travel, lodging, loss or damage to

personal properties, or loss of revenues. Some states do not allow limitations on how long an implied warranty lasts or limitations on consequential

damages, so the above limitations may not apply to you. This limited warranty gives you specific legal rights which may vary from state to state.

2

Loading...

Loading...