Atwood APC45, APC32, APC55, APC75 Installation, Operation And Maintenance Manual

LITERATURE NUMBER MPD 39065

CONVERTER/CHARGER

9

APC MODELS: 32, 45, 55 & 75 AMP

ENGLISH •Installation •Operation •Maintenance

Effective 2/04/08

SAFETY ALERT SYMBOLS

Safety Symbols alerting you to potential personal safety hazards. Obey all safety

messages following these symbols.

WARNING CAUTION

avoid possible avoid possible

injury or death injury and/or property damage

FOR YOUR SAFETY READ ALL INSTRUCTIONS

BEFORE INSTALLATION AND OPERATION

INSTALLATION MUST COMPLY WITH ALL APPLICABLE STANDARDS AND CODES.

Installer: Provide these instructions to the consumer.

Consumer: Keep documents for future reference.

The Converter/Charger is designed to convert 120 VAC to

12 VDC. This allows operation of 12 VDC devices while being

connected to shore power; using power from a generator; or

using power from on board storage batteries. It also provides

exceptionally clean low voltage power for charging on board

batteries. This Converter/Charger is a ‘switch mode’ type

supply. Its high frequency electronic design is maintenance

free with superior performance.

The APC Series offers a wide range of power - 32,45, 55 and

75 amp models - in a compact design weighing just six

pounds. Atwood technology maintains safe, cool, reliable

converter/charging operation, ensuring the performance of

electrical systems with sophisticated controls. The

thermostatically controlled cooling fan also reduces noise and

increases warm weather performance. The APC’s circuitry

includes over-temperature and over-current protection,

safeguarding against power supply damage. External fuses

provide “reversed battery” protection, preventing damage from

cross-wiring.

APC filtered power provides smooth, optimum DC appliance

operation and the full output rating is available for battery

charging.

COMMON FEATURES

• Regulated output voltage ensures against erratic charging and

damage to amenities.

• Over current protection prevents battery damage caused by overcharging.

• Short circuit protection prevents damage to power supply.

• Reverse battery hook-up protection prevents power supply damage

due to cross-wiring.

• Fan cooled prevents unit from over-heating.

• 100% burn-in tested ensures stringent quality assurance.

• 2-year limited warranty.

• ETL listed to UL 458.

INSTALLATION

1. DISCONNECT POWER. Disconnect the RV battery POS (+) wire

at the battery before connecting the Converter/Charger.

WARNING

PERSONAL INJURY/PRODUCT DAMAGE

• Never store electrical devices in a compartment where

flammable liquids are stored.

• Do not mount the unit in a compartment designed for the

storage of batteries or flammable liquids (such as gasoline).

2. LOCATION. Mounting location may be on any interior (out of

direct weather) surface. Location chosen must be

accessible after installation. When mounted inside a

cabinet, the cabinet must be vented and large enough to

allow dissipation of heated air. Make sure that there is a

minimum of 1” (one inch) free air space from sides and back

of the unit so that cooling air can move through the unit

properly.

AVOID foreign contaminants such as dirt, metal particles or

moisture.

3. MOUNTING. Flanges with holes are provided for ease of

mounting using standard fasteners. Surface must support

the converter’s weight (6 lbs) during vehicle operation.

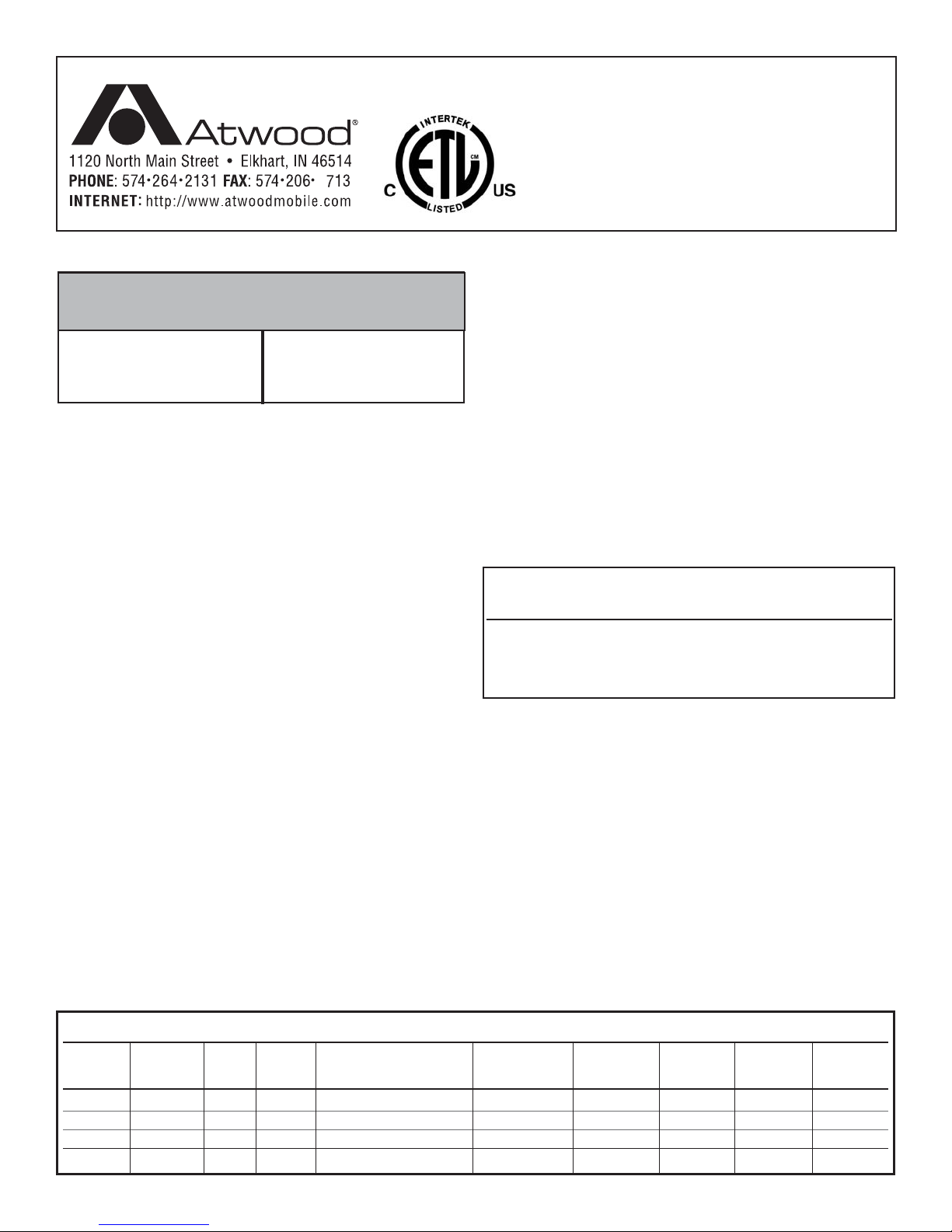

SPECIFICATIONS FOR CONVERTERS

PART EXTERNAL INPUT OUTPUT INPUT OUTPUT INPUT

NO

. MODEL LBS. AMPS DIM. IN INCHES VOLTAGE VOLTAGE CURRENT CURRENT FREQ.

35411 APC32 6 32 10.36 x 7.75 x 3.5 105-130 13.6 7 32 58 to 62

35412 APC45 6 45 10.36 x 7.75 x 3.5 105-130 13.6 10 45 58 to 62

35413 APC55 6 55 10.36 x 7.75 x 3.5 110-130 13.6 13 55 58 to 62

35414 APC75 6 75 10.36 x 7.75 x 3.5 110-130 13.6 15 75 58 to 62

AC DC AMPS AMPS HZ

1

4. ELECTRICAL REQUIREMENTS. A 120 VAC receptacle needs to

be located within 36 inches of the converter to supply

power. Electrical consideration should also be given to

mounting near the locations of the RV batteries and the

12-volt distribution panel to minimize wiring lengths.

5. ELECTRICAL CONNECTIONS. Be sure to tighten all connections

securely. A loose connection can quickly cause terminals

and wires to overheat. Review unit labels for recommended

terminal torque values.

A. 12 VDC: It is important to use the correct wire gauge for

the specific model selected. As an example the APC-32

is a 32 amp Converter/Charger which would require a 10

AWG wire.

• An 8 AWG copper wire minimum must be connected

from the vehicle chassis to the chassis lug.

• The terminal marked “-” is for the system 12 VDC

negative connection.

• The terminal marked “+” is for the 12 VDC system

positive connection.

• The APC series Converter/Charger is current limiting

by design and therefore the output wiring does not

require overcurrent protection. However, all electrical

connections need to comply with the appropriate

NEC code.

B. 120 VAC Connections: Using the power cord on the

Converter/Charger, connect to the 120 VAC receptacle.

6. TEST. Energize the Converter circuit. To test for proper

output power, use a multimeter and measure output voltage

from the positive and negative terminals with no load on the

converter (All DC fuses must be removed.) The voltage

should read 13.6 +/-0.2VDC. Replace fuses and turn on a

load to about 2/3 of the rated capacity of the converter.

Recheck voltage, which should remain approximately the

same as at no load.

7. BATTERY. Connect the positive terminal to a known good

battery. With the converter energized, measure the voltage

at the converter and at the battery. The voltage should be

about the same in both locations. As with any battery it is

important that the fluid level be checked on a regular basis.

When continuously connected to any charging source all

batteries will “Gas” and lose some fluid.

8. HI-POT TESTING. (RV Manufacturing Facilities Only) Do not Hi-

Pot DC wiring with the Converter/Charger connected to the

RV wiring.

TROUBLESHOOTING

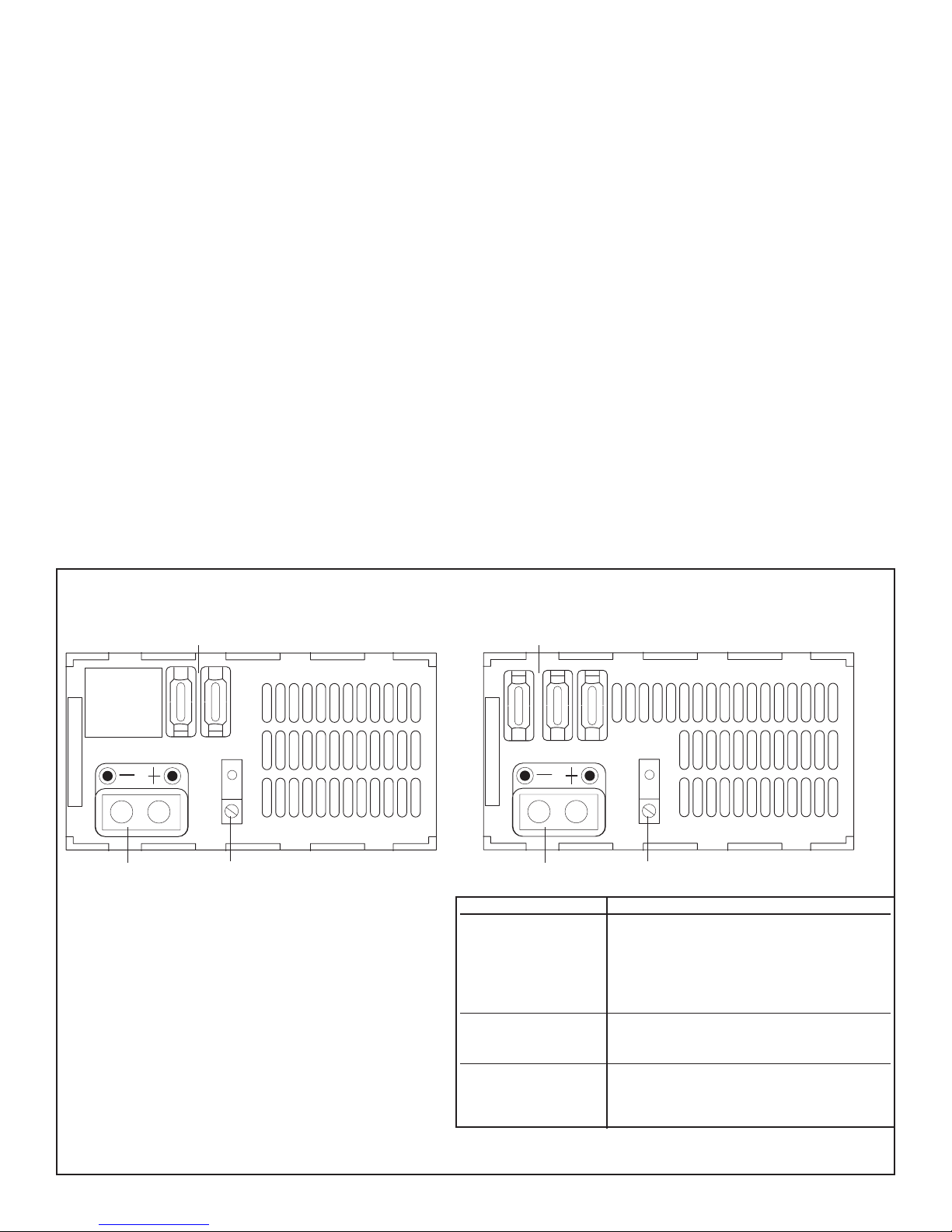

MODELS: APC 32, 45 & 55 MODELS: APC 75

Reverse Battery Protection Fuses

Serial # Code Date

Output Terminals

Before replacing converter perform the following

checks:

1. Disconnect the AC power from the coach.

2. Disconnect the wire from the “Positive Output

Terminal”.

3. Re-connect the AC power.

4. Using the voltmeter read the DC voltage at the

terminals on the converter.

• If the reading is greater than 13.4 VDC, but less

than 13.8 VDC the converter is operating properly.

Earth Ground/Chassis Lug

Reverse Battery Protection Fuses

Serial # Code Date

Output Terminals

PROBLEM SOLUTION

No 12 VDC Output • 120 VAC not connected to coach.

Converter cycles • Fan air flow inadequate.

on and off • Internal converter failure.

Low Output • Load excessive for rating of converter.

Earth Ground/Chassis Lug

• Converter circuit breaker in OFF position.

• Reverse battery fuses blown.

• Internal converter failure.

• Shorted output.

• Battery has bad cells.

• Internal converter failure.

2

Loading...

Loading...