atwood 13500, 15000 User Manual

574-206-9713

•Installation •Operation •Maintenan

This air conditioner design has been certified by the Canadian

Standards Association for installation in recreation vehicles.

SERVICE CALLS & QUESTIONS

Location and phone numbers of qualified Service Centers can

be found at our website

866-869-3116 to locate a Service Center.

WARNING

manual is read and understood before

installation. The unit must be installed by a

qualified service technician. Failure to properly

install the unit or attempting to modify it in any

way can be extremely hazardous and may

result in property damage and personal injury

and will void the warranty.

http:/www.atwoodmobile.com

:

It is important that this installation

ce Effective 04/16/2012

or call

BEFORE INSTALLATION

Ensure

that the installation instructions have

properly read and

Installation must conform

regulations or, in the

Standard on Recreational

National Electrical Code NFPA

DO NOT

installation procedure.

This equipment must

refrigeration mechanic to maintain warranty

coverage.

If

please contact Atw

advice.

Atwood will not be held responsible for problems

relating to incorrect or improper installation

methods.

attempt

your installation varies

underst

to

ood.

to

Local wiring codes

absence

modify

only be serviced by a license

ood Mobile Pr

of

local codes,

Vehicles, NFPA 1192.

70.

or

add components

from the method

oducts, LLC

been

and

the

and

to the

d

outlined

for specialt

LITERATURE N U M B E R MPD

Rooftop

Conditioner

Recreational

15000

Air

for

Vehicles

Models

13500

and

15000

GENERAL

INFORMATION

I. PURPOSE

This Atw

for installation on

provide cooling

with 15000 models.

-The

unit which is 99lbs (45Kg).

-The absolute minimum thickness

less than

-The

5 inches (125mm).

-Trimming

depending on

It

according

ood

AirCommand

the roof of a recreational vehicle

with 13500 models and cooling/heating

roof must be capable

1 inch (25mm).

maximum thickness

of the ductwork and/or bolts may be necessary

the roof thickness

is important

that the unit

to the

recommended guidelines.

air conditioning unit

of supporting the weight

of the roof must

of the roof must

is installed properly

not exceed

is designed

to

of the

not be

and

II. ENSURING EFFECTIVE OPERATION

The effectiveness of the

s

everal factors

an Atwood

vehicle is

in all

walls and

(preferably double glazed) and

when closed. Other methods of

-Closing all doors, hatches, windows and blinds

-Position the

and protect

-Turning

-Ensuring

In

periods

to start the air conditioner earlier

improve its ab

e.g. size and heat load

unit

is installed Atw

well insulated

roof, that the wi

vehicle so

the wi

off

appliances

the

vehicle is parked

of extreme

ility

air conditioner is dependent

of the

vehicle. When

ood assumes

with 1 inch (25mm) foam minimum

ndows are

the roof vents are

reducing heat load

if

porch is used,

ndows

from direct

that might

high temperature it

to

cope

with the expected high heat

radiation.

increase

in

a shaded position.

in the

that the

of moderate size

it will

face

the heat

is

morning

on

airtight

include:

the sun

load

recommended

to greatly

load.

III. CONDENSATION

y

In areas

cause “sweating”

humid warm air contacts

this

-Closing all doors, hatches, windows and blinds

ingress

c

higher airflow and reduce

c

of

high humidity, the

or condensation in parts of the unit

occurs please ensure

of

warm humid

Avoid running

onditions. Running

ondensation form.

the

humid air

the

colder air discharge system. If

the following:

air

inside fan on LOW

the

fan on HI fan speed

the tendency to have

within the

or

AUTO

will result

RV

will

as

the

to limit the

in such

in

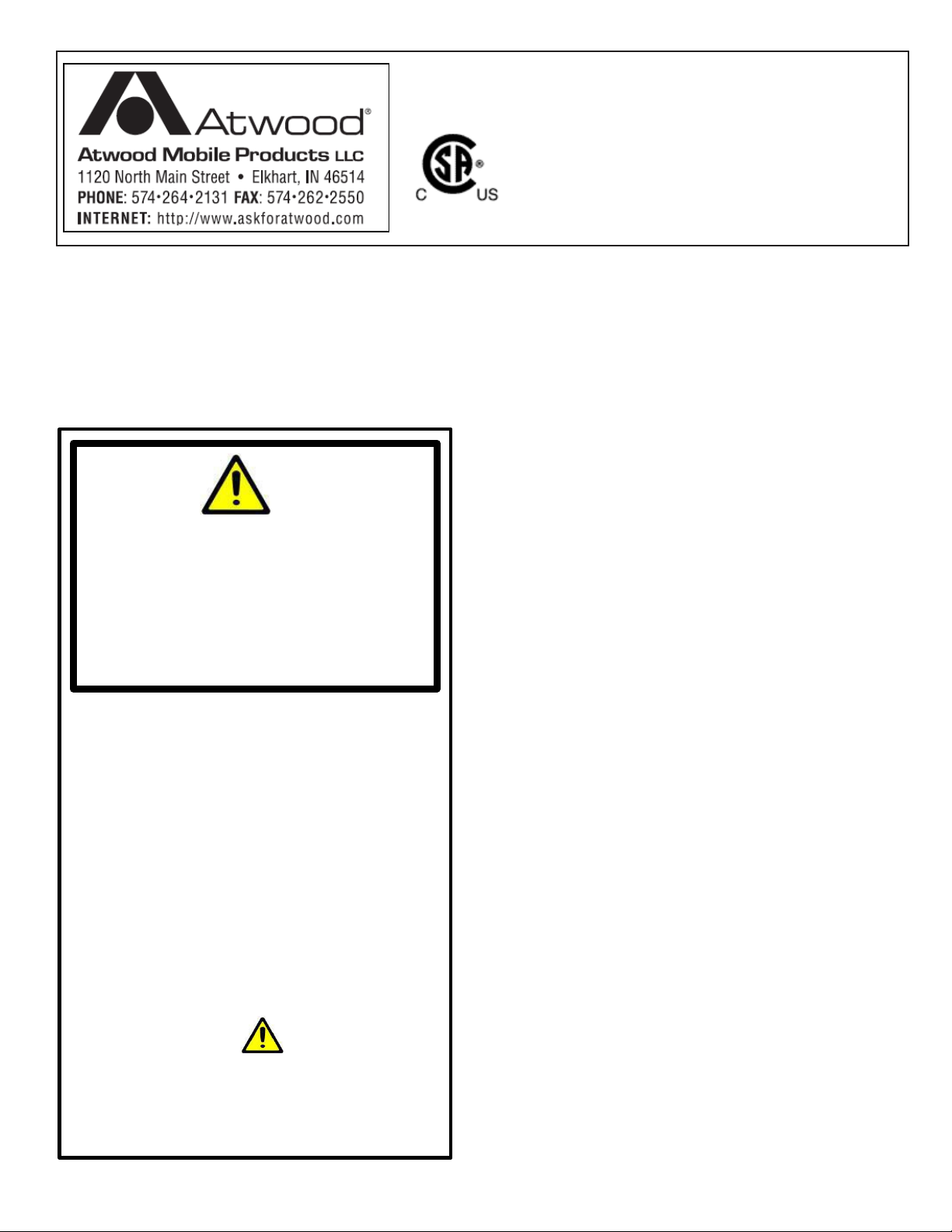

INSTALLATION PARTS LIST

Minimum 1” clearance

Minimum 8” clearance from

MAIN COMPONENTS

1) Atwood

Rooftop

2) Roof Seal Gasket 2 Pcs

3)

Adapter

AirCommand

Air

conditioner

4) Extension

5) Brace Assembly

6) Plenum

7) Plenum Filters

Duct

x2

FITTINGS & FIXTURES

8)

M8 Bolts x 4

9) Hold Down Bars x

10) Plenum Cover Screws x

11) Self Tapping Screws x

4

4

6

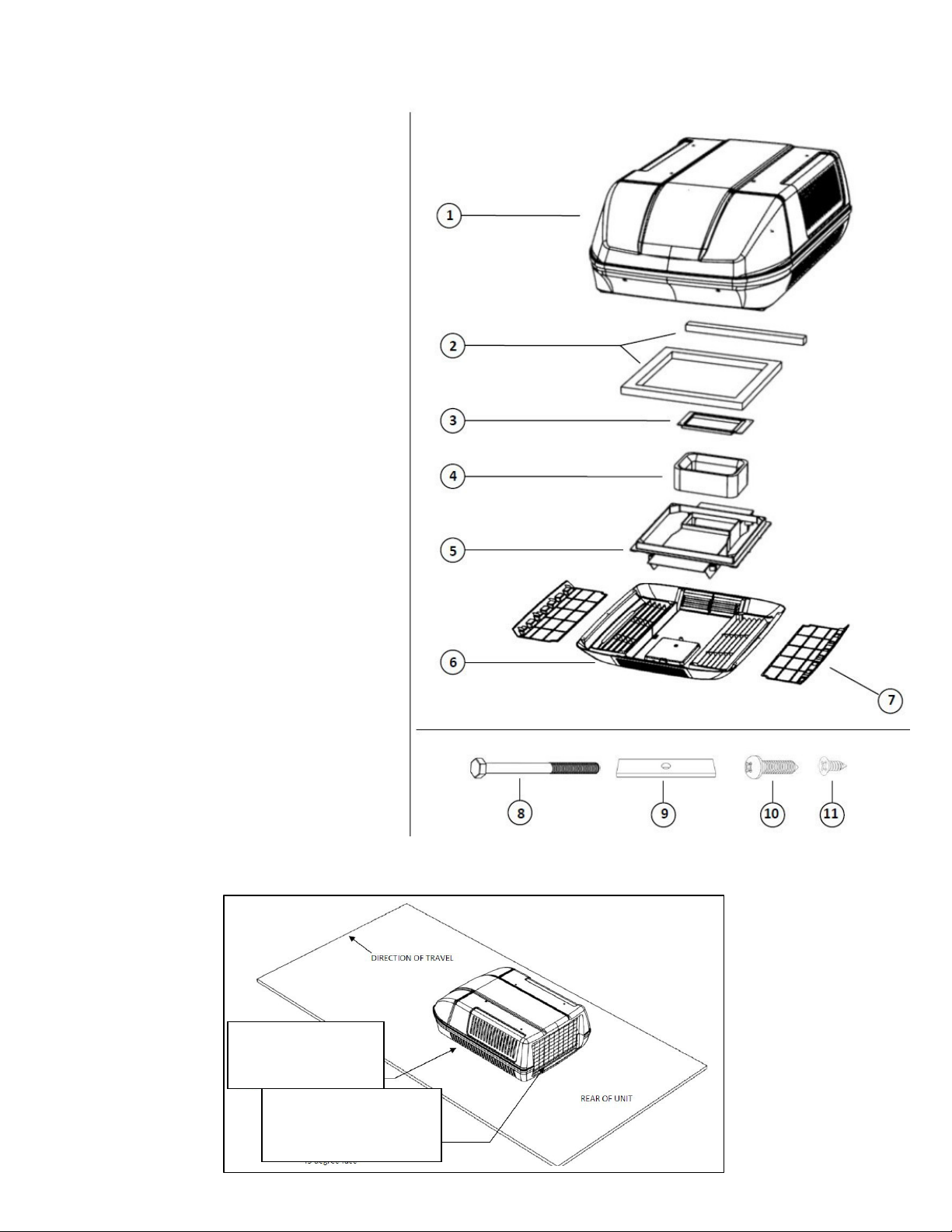

INSTALLATION POSITION

from side grilles to any

obstruction

rear grilles to any vertical face,

4” to any 45 degree face.

Unit Installation (Non-Ducted)

.79 MIN

Before beginning, mark

unit

considering

the

following

out the position

important

of the

requirements:

-

The air conditioner should be situated a

centrally

even

-

The

direction of travel; failure

instruction will result

as possible on

air distribution.

the

vehicle,

front of the unit MUST

to follow this

in

damage

face

to

ensure

the

to the

s

condenser fans.

- If the

vehicle is over 23’

unusually high heat load (see Genera

Operating Information section

expectations a

bout insulation etc.),

would recommend

in length, or

regarding

2 or

more units to cool

has

l

Atwood

effectively.

-

When considering

remember

to

plenum inside

-

Avoid an installation position

bulkhead, cupboard

interfere

with the

the installation positi

check

for

clearance around

the vehicle.

or light fitting could

discharge air

on

where

a

flow from the

plenum.

It is important that the unit is never

more than 5°

from the horizontal and

the rear of the unit should never be

higher than the front.

- Contact Atwood

differs significantly.

if

your installation

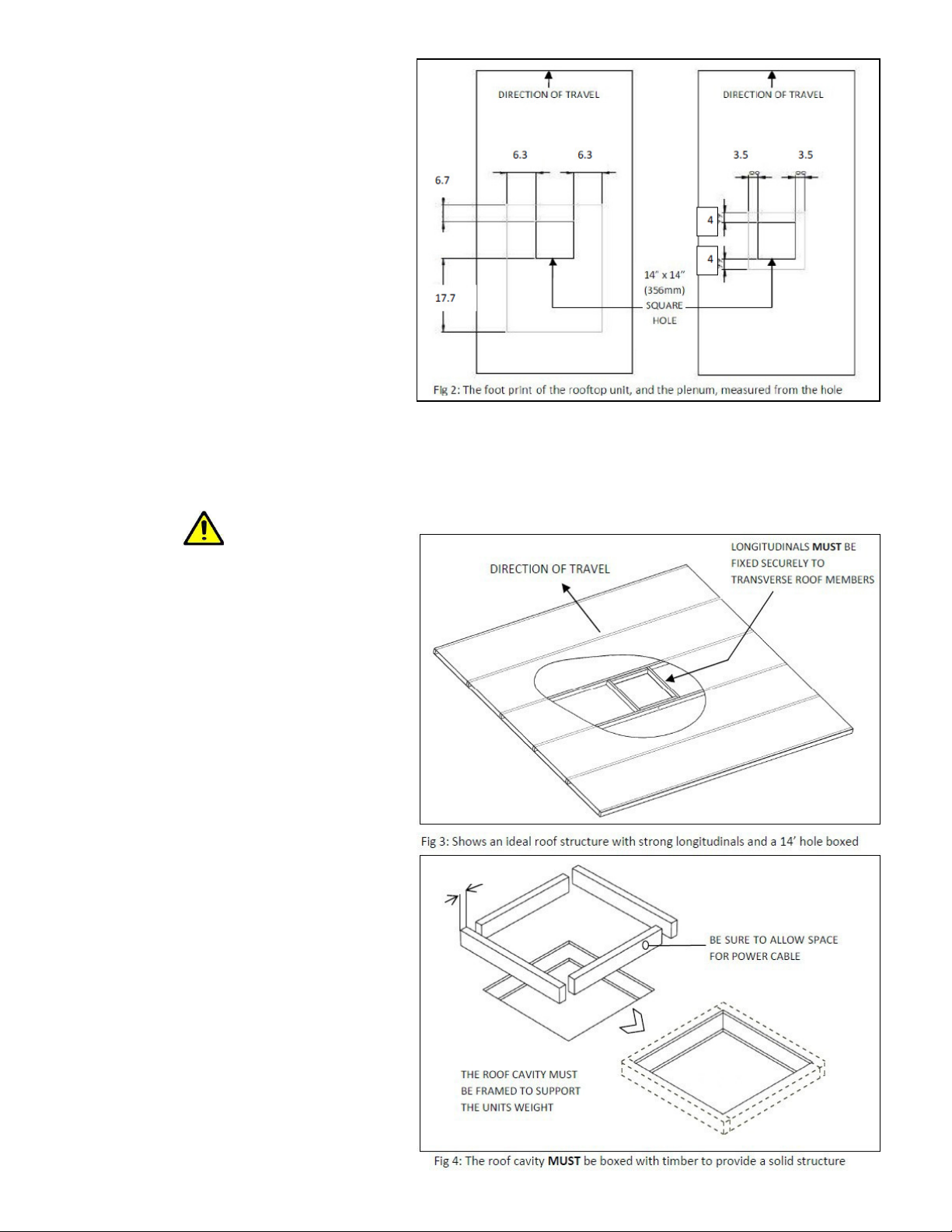

ASSESS ROOF STRENGTH

-

The

roof

members

to support

(45kg)

cause

the weight

without

“pooling” of

Contact your

the

max

load the roof

any

doubt

consider

“H” frame.

- If the roof

does

one must be cut. Cut

the roof

hole as a guide

ceiling. Contact

the best met

-

The square hole

14” x 14”)

3/4 inch

hod

MUST

square timber

strong enough

of the installation bolts. This is also

that

air

in not

(Fig

3 &

4). Remember

wiring.

- Longitudinals MUST

transverse

(see Fig

roof

3).

MUST

be strong enough

of the unit

any

roof deflection that will

water around

RV manufacturer

is able

to

the

use

of an external

not

have an existing hole

from the roof then use

to cut through

your

RV manufacturer

to cut through

in the roof

(356 x

be boxed up

to

provide a structur

to withstand

drawn

the compressi

from the roof cavity

to

leave access

be fixed securely

members

to transfer

99

lbs

the unit.

to

confirm

handle.

If in

the

for

the roof.

356mm,

with minimum

to ensure

for

to the

load

an

the

on

-

The above outline on

ATWOOD

14”

-

The above outline on

the

calculated

unit

square hole (356 x

Plenum located on

from a 14”

e

the left

on

the roof of the

356mm)

the right

the

square hole (356 x

shows

the

vehicle, distances

shows

ceiling inside

minimum clearance required around

shown are calculated from a

the

minimum clearance required

the

vehicle, distances

356mm)

shown

are

the

around

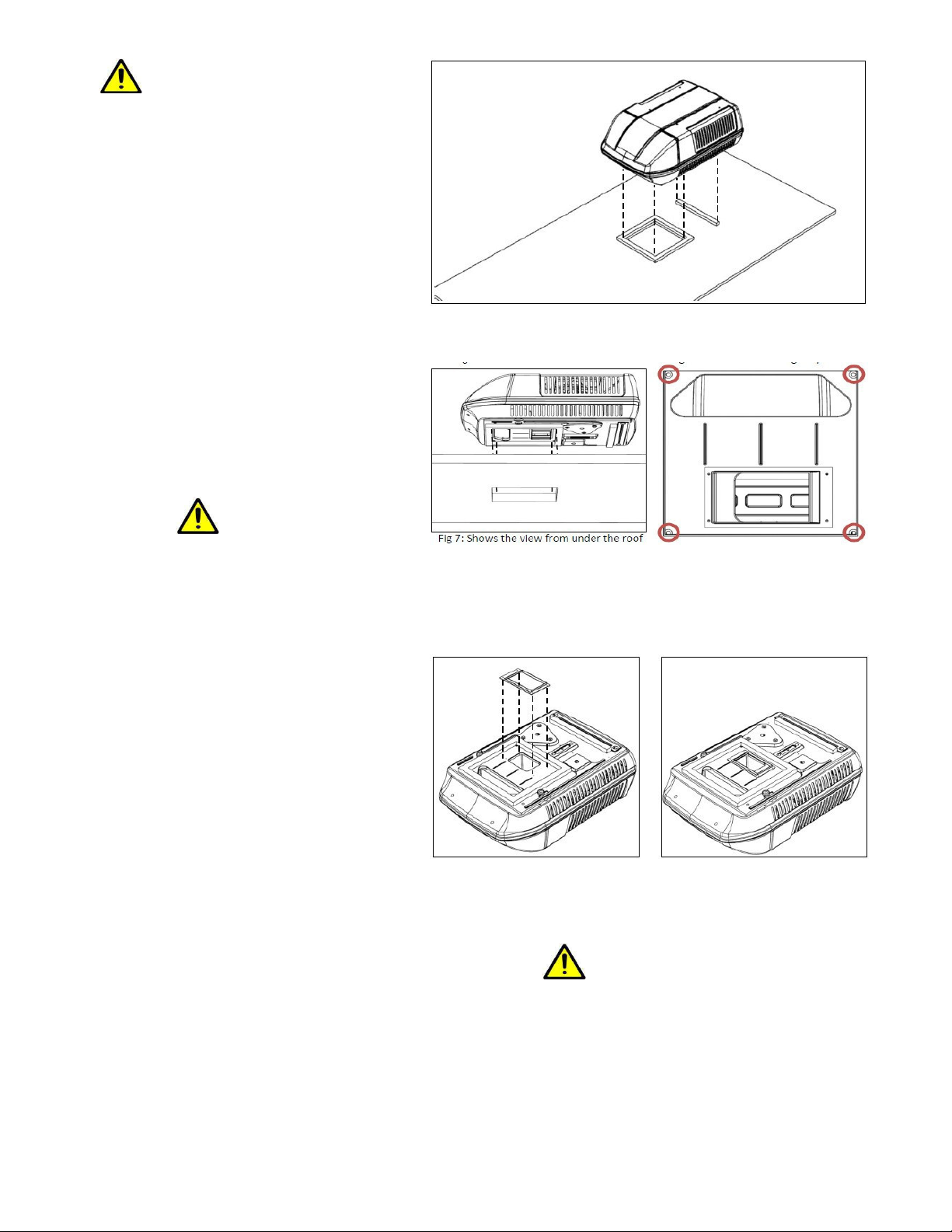

WARNING

There may be electrical wiring located

between the roof and ceiling. Ensure

that power is properly disconnected at

the supply (mains and/or battery).

Failure to do so may result in personal

injury or death

TIP:

Always use crawl boards across

to

avoid

damage

POSITION UNIT ON ROOF

-

Remove

carton.

- Position the unit

the

roof

hole

TIP:

looking through

is on

unit.

the

air conditioner

over

corners

of the

square hole

line up

with the

underneath the

Have one person inside

the

hole while

the roof adjusting the position

from the

the gasket so

corners

air conditioner (Fig

of the

the RV

The unit weights approximately 99

lbs (45kg). Ensure a two person lift or

use a mechanical hoist to avoid the

risk of injury.

-

DO NOT slide

damage

- Four M8 mounting holes on

underneath the

the

corners

the unit

the gasket and result

air conditioner

of the

on the roof, this

square

roof

ATTACH ADAPTER TO UNIT

- Screw adapter to the

the 4

screws provided (this step

done before

but

be careful not to

-

The adapter

to

ensure adapter

and avoid affixing back

the unit

will

underside

is positioned on

damage while

only

fit

one way, be

is positioned correctly

to front.

CONNECT ELECTRICAL

SUPPLY

Installation must conform

and regulations

codes,

the Standard

NFPA 1192.

70.

- Connect

- Note:

Brown (on

Blue (on

Yellow/Green

or, in the

and National Electrical

power supply

unit) to

unit) to White –

(on

unit) to

to

local wiring codes

absence

on Recreational Vehicles,

to

lead

Black

or

Red

Common

Green - Ground

the roof

in the RV

square

the other

of the

in leaks.

the

chassis

will

line up

hole (Fig

of unit with

can also

of local

Code NFPA

from unit

– Hot

that

6).

may

with

7).

be

the roof

fitting)

careful

(Fig

8)

Fig 6- Position the unit over the roof gasket and set down gently.

Position the unit so the 4 mounting holes (circled) line up with the

corners.

Fig 8: Shows positioning of adapter to be attached to underside of unit. Ensure adapter

is mounted the correct way, screw holes will not line up if attached out of phase.

WARNING

Ensure that power is properly disconnected at the supply

(mains and/or battery). Failure to do so may result in

damage to the unit and personal injury or death.

COC-1 Self Contained Power

Connector Installation Instructions

For 2 Wire Cable With Ground Applications

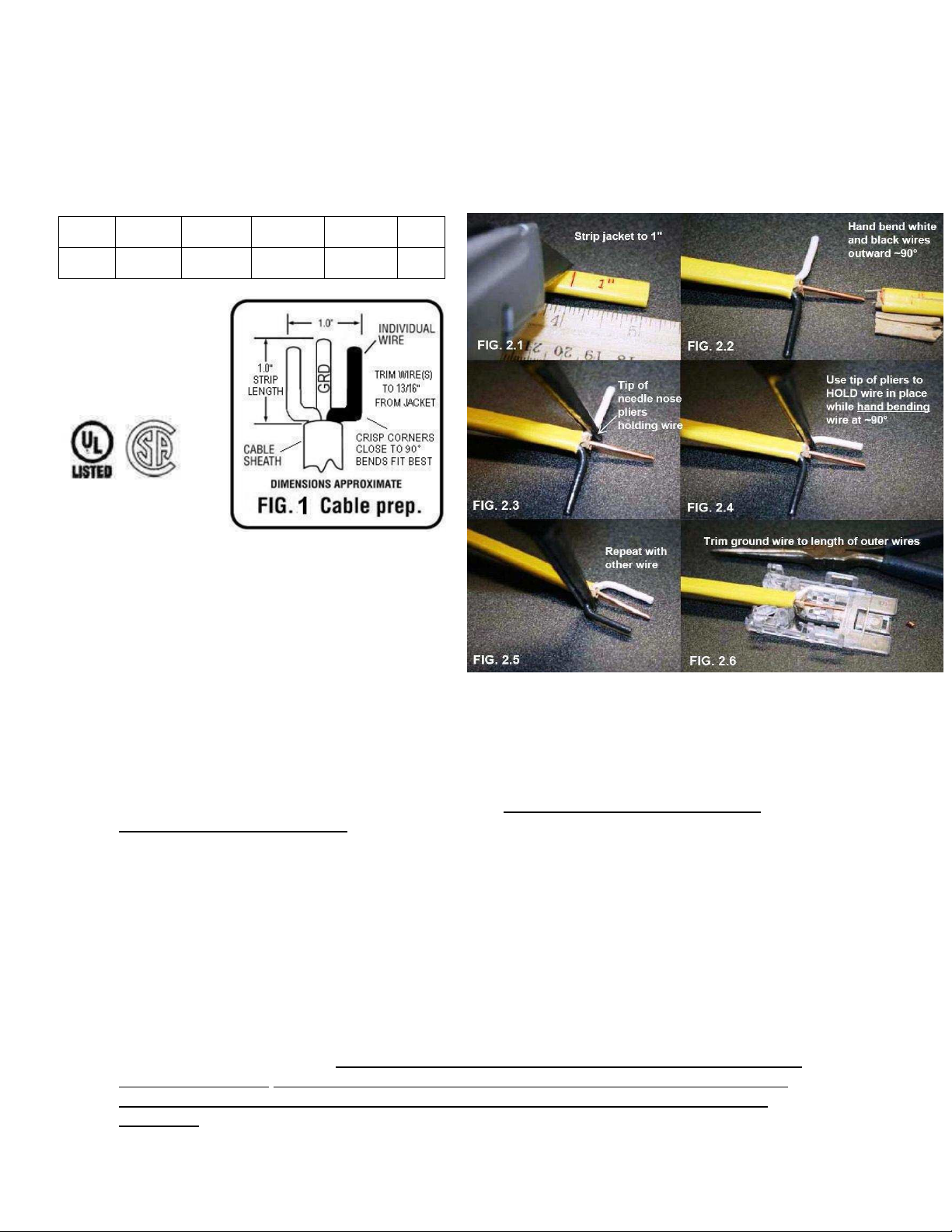

The 2-circuit-with-ground connectors will splice non-metallic-sheathed cable in the following wire ranges and types:

Self Contained Connector

2 Circuit with ground for Solid Wire

Wire Range

AWG

12-14 19045-1000

Order

No.

(COC-1)

-

Optional

Hand Tool

19285-0074

Optional Bench

M

ount Tool

Referenc

e Information

UL File Number: E182087,

CSA File Number: LR18689-C53

NEC Article: 550, 551, and 545

HUD Section: 3280.801

Current:

20A,Voltage:

300V

N/A

Optional Bench

Arbor Press

64006-0200 White

Housing

Color

FIG. 2

Installation Procedure:

1. Carefully strip and prepare the wires to the

hints shown in photographs of Figure 2.

2. Hold the clear strain relief cover with bottom facing upward as shown in Figure 3.

3. Lay wire into locator slots, making sure the black wire is placed into the polarization slot as

shown in Figure 3.

4. Press the cable sheath into the integral strain relief slot as shown in Figure 3. Trimming of

ground wire and possibly others will be necessary. Wires must not extend beyond the

locators as shown in Figure 4!

5. While holding the strain relief cover, position the housing’s hinge posts into the hinge slots

and press down until both lock into place as shown in Figure 4.

6. Close the strain relief cover and housing by hand. Place the connector assembly into Molex

tool (preferred) as shown in Figure 5. Squeeze the tool until the connector bottoms out and

the locking latches engage on both sides. OR alternately, squeeze the top and bottom

closed with tongue and groove pliers as shown in Figure 5.1. Pliers must be a minimum of

10" long. Squeeze

firmly on both sides, squarely across the connector between ribs A and B to ensure wires seat

completely into slots.

7. Inspect the connector to ensure the wires have been properly engaged into the housing

assembly contacts. A properly terminated wire is fully seated into its proper slots with no

significant bow of the cover. If the wires extend past the insulations tops, the wires must be

re-terminated with a

NEW CONNECTOR. Once

cannot be re-used. Failure to comply with this procedure may result in the failure of the

connector.

8. Mating and un-mating the completed connector is illustrated in Figure 6.

configuration

as shown in Figure 1 using helpful

the cover has been closed the connector

Loading...

Loading...