Atten ATM3500A User Manual

ATTEN.EU

®

ATM3500A

6.5 Digit Digital Multimeter

User’s Manual

ATM3500A DMM

User’s Manual

2

Printed date: 11/2011

Version: 1.05

Table of Contents

1

General Information

This section contains general information about ATTEN.EU ATM3500A

Multimeter. The information is shown below:

Feature Overview

Warranty Information

Safety Information

Symbols and Terms

Specifications

Inspection

Options and Accessories

If you have any questions after reading this information, please

contact your local service representative.

1.1 Feature Overview

ATM3500A is a 6.5 digit digital multimeter. It has 0.0015% 24-hour

basic DC voltage accuracy at 10V range and 0.002% 24-hour basic

resistance accuracy at 10kΩ range. At 6.5 digit, the multimeter

delivers 50 triggered RDGS/sec via remote interface. At the fast 4.5

digit, it reads over 2000 RDGS/sec into its internal buffer. ATM3500A

provides wide measurement ranges:

3

Note: The 24-hour measurement is subject to calibration accuracy.※

DC voltage: 0.1V, 1V, 10V, 100V & 1000V.

AC voltage: 0.1V, 1V, 10V, 100V & 750V.

DC current: 10mA, 100mA, 1A & 3A.

AC current: 1A & 3A.

2 & 4-wire resistance: 100Ω, 1KΩ, 10KΩ, 100KΩ, 1MΩ, 10MΩ &

100MΩ.

Frequency: From 3Hz to 300kHz.

Period measurement.

Diode measurement.

Continuity measurement for resistance.

Thermocouple temperature & RTD measurements.

Some additional capabilities of ATM3500A include:

Full math functions – dB, dBm, MX+B, ratio, %, Max/Min, null &

limits.

Optional multipoint scanner card – For internal scanning options

including M3500–opt01 (a 10-channel) & M3500-opt09 (a 20-

channel) general-purpose cards.

USB and GPIB/RS-232 (Optional) remote control interfaces.

Through Microsoft Office Word & Excel for remotely storing and

recalling the measured values.

Through M3500 AP software for simulating the real operation on PC.

4

1.2 Warranty Information

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

1.

Warranty: ATTEN.EU CORP. guarantees that this product meets

its published specifications at the time of shipment from the factory.

Under proper installation it should work as expected.

2.

Warranty Period: This equipment is warranted against defects in

material and manufacturing for a period of one year from the date

of shipment. During the warranty period, ATTEN.EU is responsible

for necessary repairs as long as the product can be proved to be

defective.

For warranty service or repair this product must be returned to a

service facility designated by ATTEN.EU. Please contact your local

service representative.

3.

Excluded Items: This warranty does not include consumptive

parts such as fuses, buttons and relays. Neither does this warranty

cover defects caused by improper installation, improper or

insufficient maintenance, unauthorized modification, improper

operation, ignorance of environmental specifications or improper

software or interfacing.

4. Remarks:

No other warranty is expressed or implied, except for the above

mentioned.

The remedies provided herein are the buyer’s sole and exclusive

remedies. ATTEN.EU shall not be liable for any direct, indirect,

special, incidental or consequential damages.

5

Limitation of warranty

1. Our warranties do not cover any damage resulting from

unauthorized modification or misuse.

2.

Unless mentioned elsewhere in this document, our warranty does

not apply to fuses, probes, and problems arising from normal wear

or your abnormal operations.

3.

Our warranties do not apply on any direct, incidental, special, or

consequential damages.

4.

The above warranties are exclusive and no other warranty is

expressed or implied. ATTEN.EU disclaims any implied warranties of

MERCHANTABILITY, SATISFACTORY QUALITY, and FITNESS for any

particular reasons.

1.3 Precaution of Operation

Please carefully read the manual before operating this device.

This manual is for reference only. Please consult your local service

representative for further assistance.

The contents of this manual may be amended by the manufacturer

without notice.

Never dismantle the equipment by any unauthorized personnel, or

equipment may be damaged.

The equipment has been strictly tested for quality before delivery

from our factory. However, this equipment must not be used in

dangerous situations where damage may result.

This product should be placed in a safe area in case of

6

unpredictable personnel use.

The rear protective conduct terminal needs to be connected to the

actual earth ground or electric shock may occur.

The patent and related documents for the equipment belong to

ATTEN.EU CORP. and they aren’t allowed to be used by others

without permission.

1.4 Upkeep of ATM3500A

Although ATM3500A multimeter is very durable and weather

resistant, care should be taken not to expose it to severe impact or

pressure.

Keep ATM3500A far from water and damp environment.

Calibration will be taken every year. Please contact with your local

service representative for more information.

If the incorrect display or abnormal beeps occurred you should stop

using the equipment at once.

Do not use the Meter around explosive gas or inflammable vapor.

Wipe the surface of ATM3500A multimeter with a piece of dry and

clean cloth.

1.5 Safety Information

Caution! Please read through the following safety information

before using the product.

To avoid possible electric shock or personal injury, please read and

follow these guidelines carefully:

Follow the guidelines in this manual and DO NOT use the Meter if

the case is damaged. Check the Meter case and terminals, and

7

make sure all the devices are in the proper positions.

Do not apply excessive voltage to the Multimeter. Apply voltage

within the rated range only.

Use caution when measuring voltages above 30 V RMS, 42 V peak,

or 60 V DC. These voltages pose an electric shock hazard.

When using the probes, always keep your fingers behind the finger

guards.

Always connect the common test leads (black) before connecting

the live test leads (red), and disconnect the live test leads (red)

before disconnecting the common test leads (black). This will

reduce the chance of an electric shock.

Disconnect circuit power and discharge all high-voltage capacitors

before testing resistance, continuity, diodes or capacitance.

If you need to open the Meter case or replace any parts, read the

instruction in this manual first. You must be a qualified personnel to

perform this action.

When replacing fuses, use only the same type and same rating as

specified.

Do not try to operate the Meter if it is damaged. Disconnect the

power from the equipment and consult the local service

representative. Return the product to ATTEN.EU service department

if necessary.

1.6 Symbols and Terms

This symbol indicates hazards that may cause damages to the

instrument or even result in personal injury.

This symbol indicates high voltage may be present. Use extra

caution before taking any action.

This symbol indicates the frame or chassis terminal presented

need to be connected to the actual earth ground.

8

This symbol indicates “Protective Conductor Terminal”.

This symbol indicates earth (ground) terminal.

This symbol indicates this product complies with the essential

requirements or the applicable European laws or directives

with respect to safety, health, environment and consumer

protections.

Note: Full ATM3500A specifications are included in Appendix A.

1.7 Inspection

Your product package is supplied with the following items:

One ATM3500A Multimeter unit. (224mm x 113mm x 373mm,

approx. 4.3 Kg)

One power line cord.

One USB cable.

Standard Test Leads

1

One CD (including this electronic User's Manual and software

applications).

Optional accessories as you ordered. (Refer to the section 1.8

“Accessories”)

1.

The ATM3500A is provided with a Standard Test lead set, described

below.

Test Lead Ratings:

IEC 61010-031 CAT III

9

Operating Voltage: 1000V DC

Current: 10 Ampers

UL/CE Rated

Material:

Probe Body: Outer Insulation-Santoprene Rubber.

Banana Plug: Body Brass, Nickel Plated Spring Beryllium Copper, Nickel

Plated.

Insulation: Polypropylene Resin Flasme Retardant Grade 2038.

Others

If any part of the Test Lead Set is damaged, please do not use and replace

with a new set.

Warning: If you use the Test Lead Set which is not qualified by※

ATTEN.EU Corp., the protection of the Test Lead Set could be

impaired. In addition, please don’t use a damaged Test Lead Set

against the instrument break or personal injury.

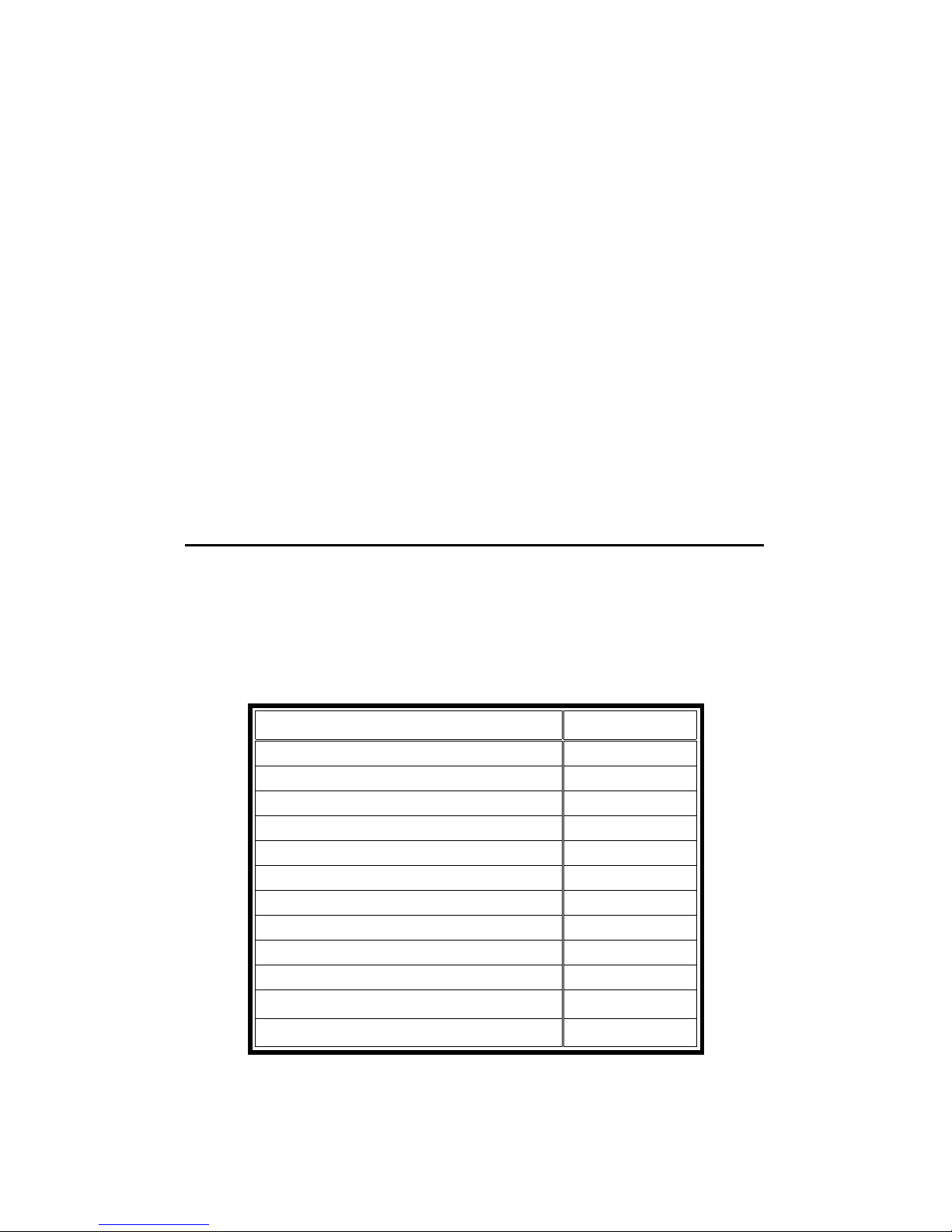

1.8 Accessories

The following accessories are available from ATTEN.EU for use with the

Model ATM3500A. Please refer to the following Table 1-1.

Table 1-1

Part Name Part Number

10-Channel Multi-point Scanner Card M3500-opt01

Thermocouple adapter M3500-opt02

Adapters (Banana to BNC Adapter) M3500-opt03

GPIB Card M3500-opt04

RTD Probe Adapter M3500-opt05

RS232 Adapter M3500-opt06

Kelvin Probe M3500-opt07

4-Wire Test Leads M3500-opt08

20-Channel Multi-point Scanner Card M3500-opt09

Shorting Plug M3500-opt10

K Type Thermocouple Lead M3500-opt11

10-Channel TC-Scanner Card M3500-opt12

10

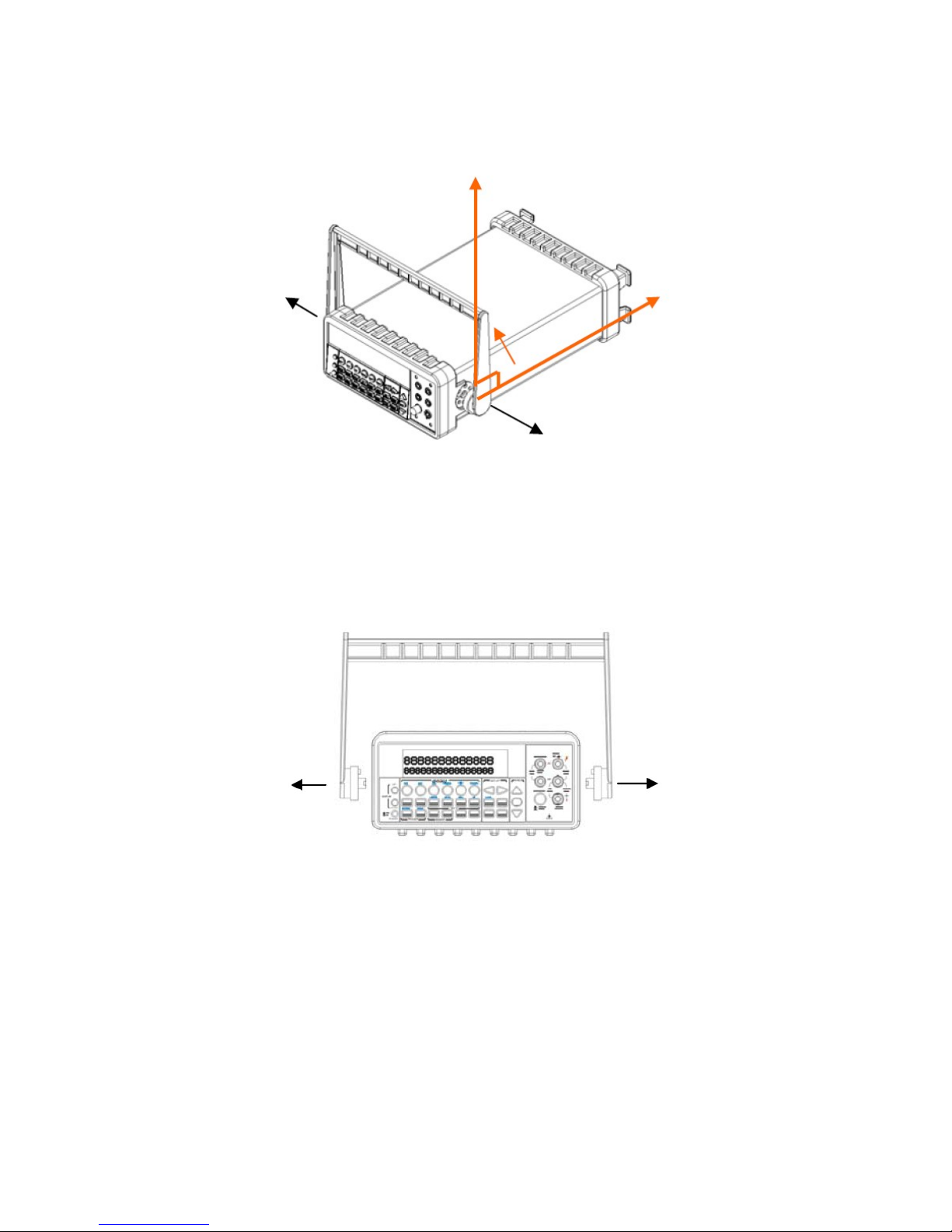

1.9 ATM3500A’s Dimension

Please get the dimension’s information in the following different ways.

1.

The dimension without the handle and the front & Rear Bumpers is

in the following Picture 1. (LxWxD - 213.6x88.6x370 mm)

2.

The dimension with the handle and the front & Rear Bumpers is in

the following Picture 2. (LxWxD - 255x113x373 mm)

3.

The dimension with the front & Rear Bumpers, but without the

handle is in the following Picture 3. (LxWxD - 224x113x373 mm)

11

1

2

3

2

Overview

This chapter will give you an overview of ATM3500A’s basic features

and guide you through the basics of ATM3500A digital multimeter. You

will become familiar with those features after reading this chapter.

2.1 Setting up Your ATM3500A Digital

Multimeter

You may want to check if your multimeter is ready for measurement.

In fact, all of the ATTEN.EU products are inspected perfectly before

being shipped to our customers. If you find any damaged or missing

parts, please contact your local service representative immediately and

do not attempt to operate the damaged product. If having any doubt

of your products, you are encouraged to contact the local service

representative.

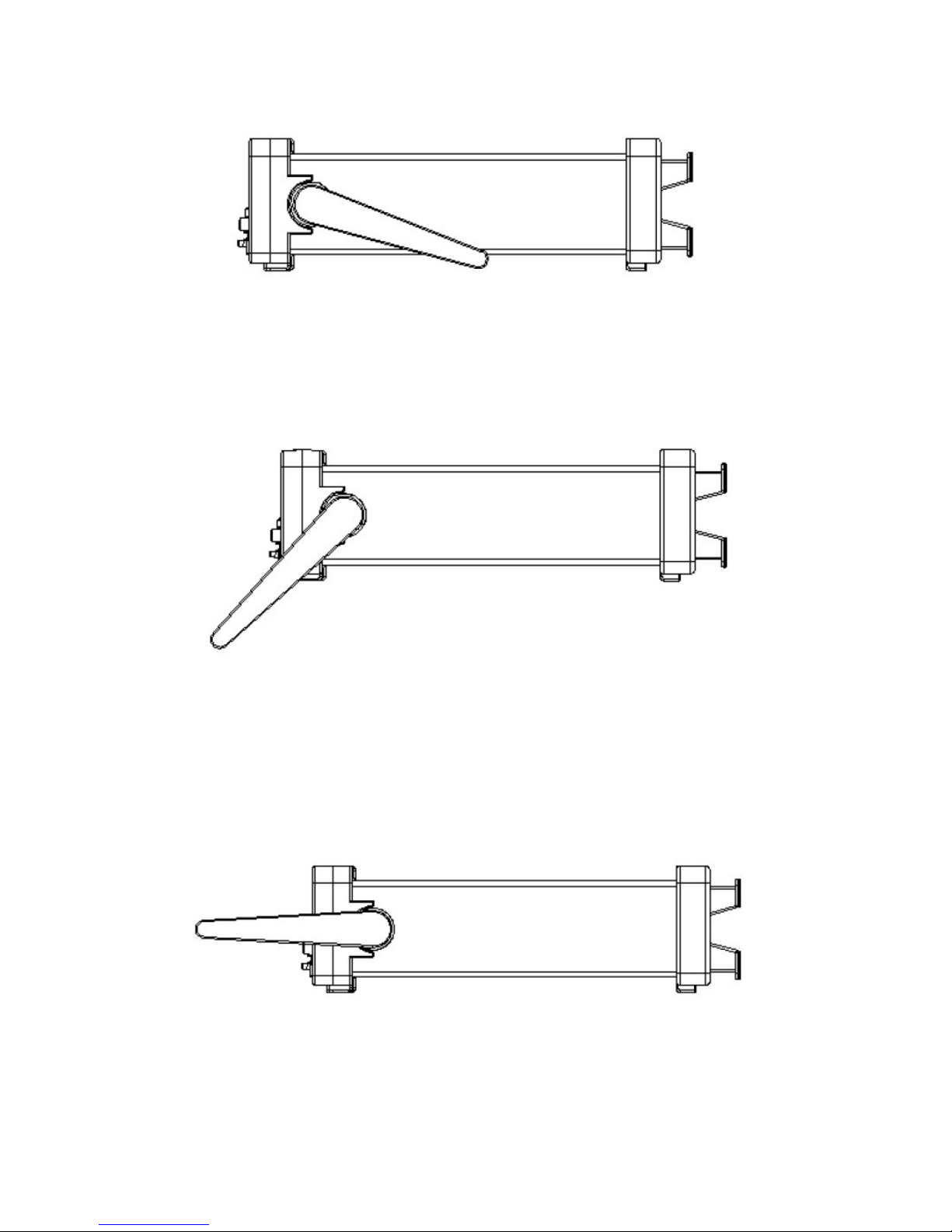

2.1.1 To adjust the handle

You may adjust the carrying handle to suit your needs. The following

figures show you how to adjust the handle.

I. Taking off the handle from the Multimeter

【

Step 1】(Turn up the handle)

Pull slightly outward on both sides of the handle and slowly rotate it up

as shown in Figure 1-1.

12

Figure 1-1

【

Step 2】(Pull out the handle)

When the handle is turned up to 90° with the multimeter please pull

out the handle from the multimeter as shown in Figure 1-2.

Figure 1-2

Ⅱ

. Adjusting the position for your convenience

Here are some referable positions for your reference.

【

Position 1

】

The default position is for packing as shown in Figure 1-3

。

13

Figure 1-3

【

Position 2

】

The adjusted position is for operation as shown in Figure 1-4

。

Figure 1-4

【

Position 3

】

The carrying position is with the handle as shown in Figure 1-5

。

Figure 1-5

14

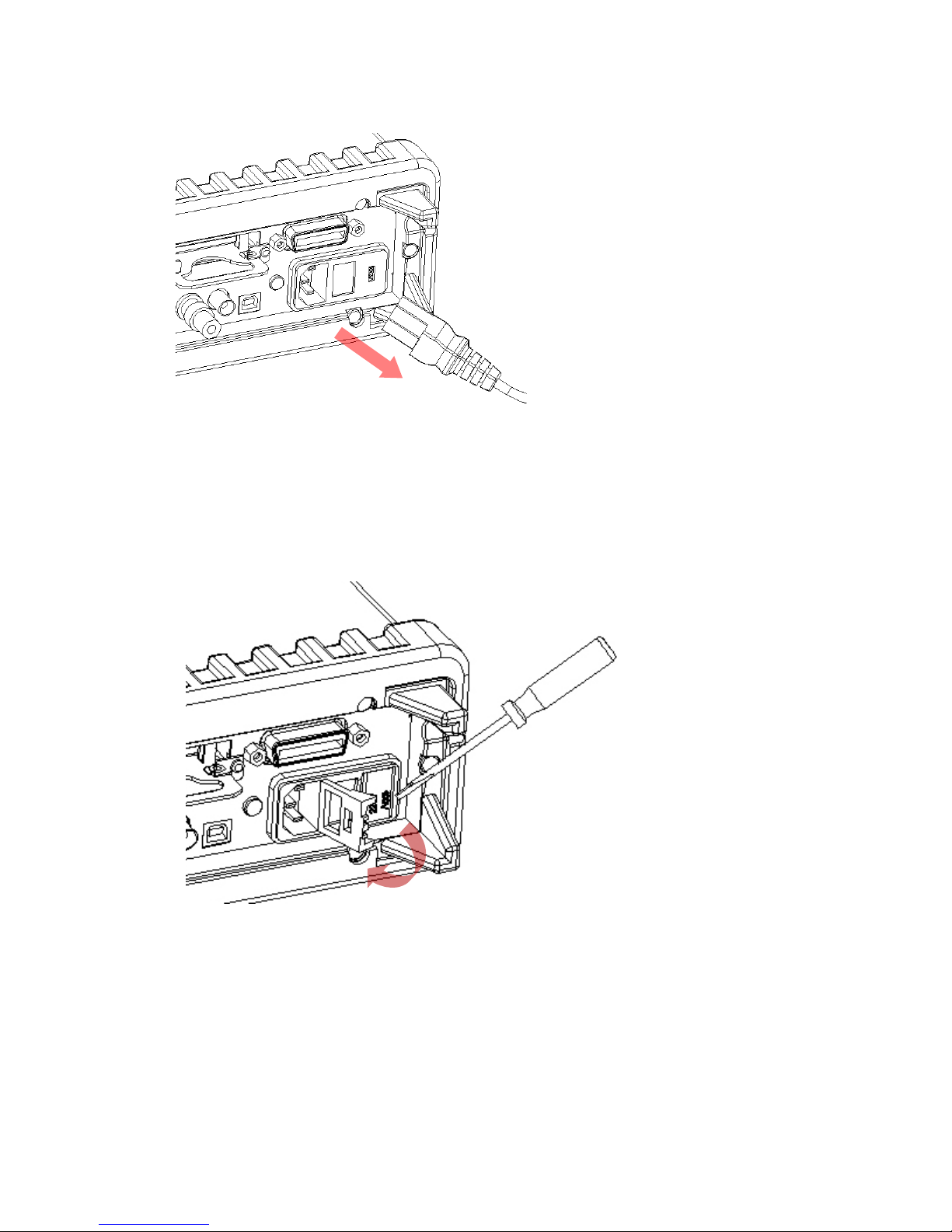

2.1.2 To connect the power

Check the power-line voltage on the rear panel to see if voltage setting

is correct for your area. Change the setting if it is not correct or the

fuse is broken. Please follow the steps below.

2.1.2.1 To convert the voltage

Warning! In some areas, the power supplied voltage is 240V or

120V; in others, the power supplied voltage is 220 V or 100 V. Please

refer to your local power supplied voltage to see if you have the right

setting.

Warning! Before changing the setting, make sure the multimeter

is disconnected from the AC power. An incorrect voltage setting may

cause severe damage to your instrument.

Warning! The power cord supplied with ATM3500A contains a

separate ground wire for use with grounded outlets. When proper

connections are made, instrument chassis is connected to power line

ground through the ground wire in the power cord. Failure to use a

grounded outlet may result in personal injury or death due to electric

shock.

Suppose your condition is in AC 100V and you want to convert the

voltage to the 220V. Follow these steps to change the voltage setting.

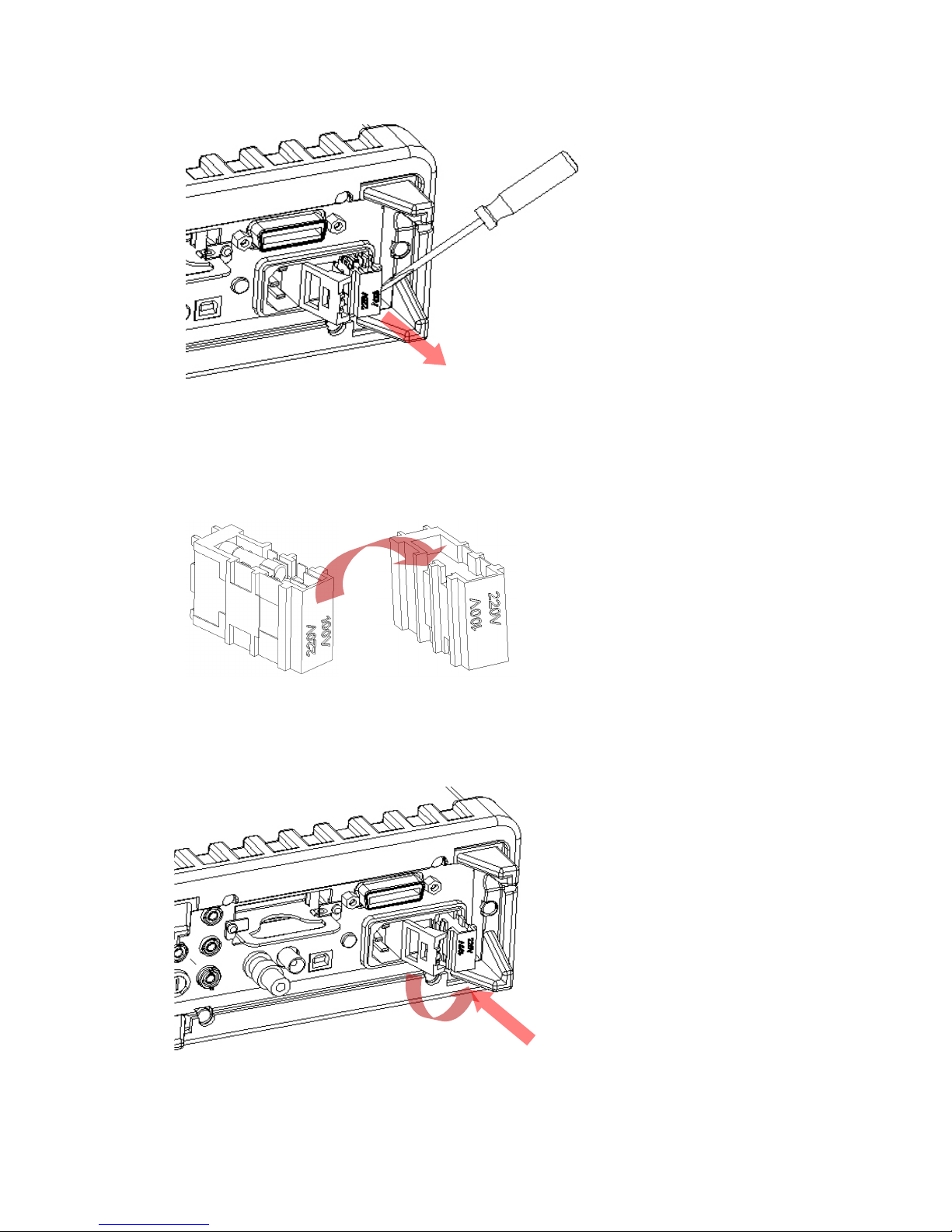

【

Step 1

】

Verify that the meter is disconnected as shown in Figure 2-1.

15

Figure 2-1

【

Step 2

】

Open the voltage setting selector cap as shown in Figure 2-2. (You

might need a screwdriver to do so.)

Figure 2-2

【

Step 3

】

Remove the red voltage setting selector from the right middle seam as

shown in Figure 2-3. (You might need a screwdriver to do so.)

16

Figure 2-3

【

Step 4

】

Turn it over to 220V position as shown in Figure 2-4.

Figure 2-4

【

Step 5

】

Insert the voltage setting selector back into the socket and close the

cap as shown in Figure 2-5.

Figure 2-5

17

2.1.2.2 To change the fuse

Warning! Before replacing the power-line fuse, make sure the

multimeter is disconnected from the AC power. You must be a qualified

personnel to perform this action.

Warning! For continued protection against fire or instrument

damage, only replace fuse with the same type and rating. If the

instrument repeatedly blows fuses, locate and correct the cause of the

trouble before replacing the fuse.

Verify that the power-line fuse is good. Replace the fuse if it is

damaged. Use only the same type and same rating fuse noted on the

rear panel. Please follow the steps below to change the fuse.

【

Step 1

】

Verify that the meter is disconnected as shown in Figure 2-6.

Figure 2-6

18

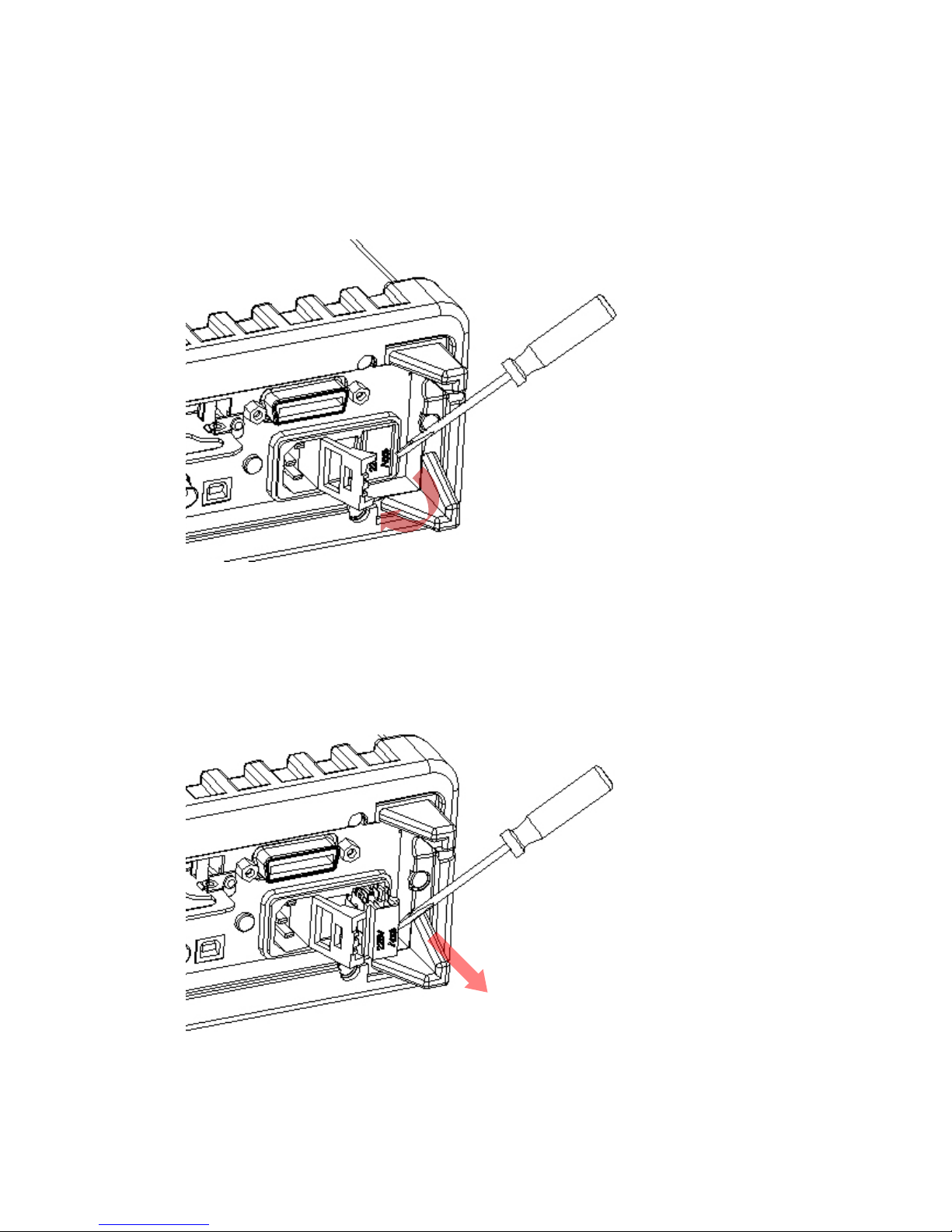

【

Step 2

】

Open the voltage setting selector cap as shown in Figure 2-7. (You

might need a screwdriver to do so.)

Figure 2-7

【

Step 3

】

Remove the red voltage setting selector from the right middle seam as

shown in Figure 2-8. (You might need a screwdriver to do so.)

Figure 2-8

19

【

Step 4

】

Remove the broken fuse from the selector as shown in Figure 2-9.

Figure 2-9

【

Step 5

】

Replace with the new fuse as shown in Figure 2-10.

Figure 2-10

【

Step 6

】

Insert the voltage setting selector back into the socket and close the

cap as shown in Figure 2-11.

Figure 2-11

20

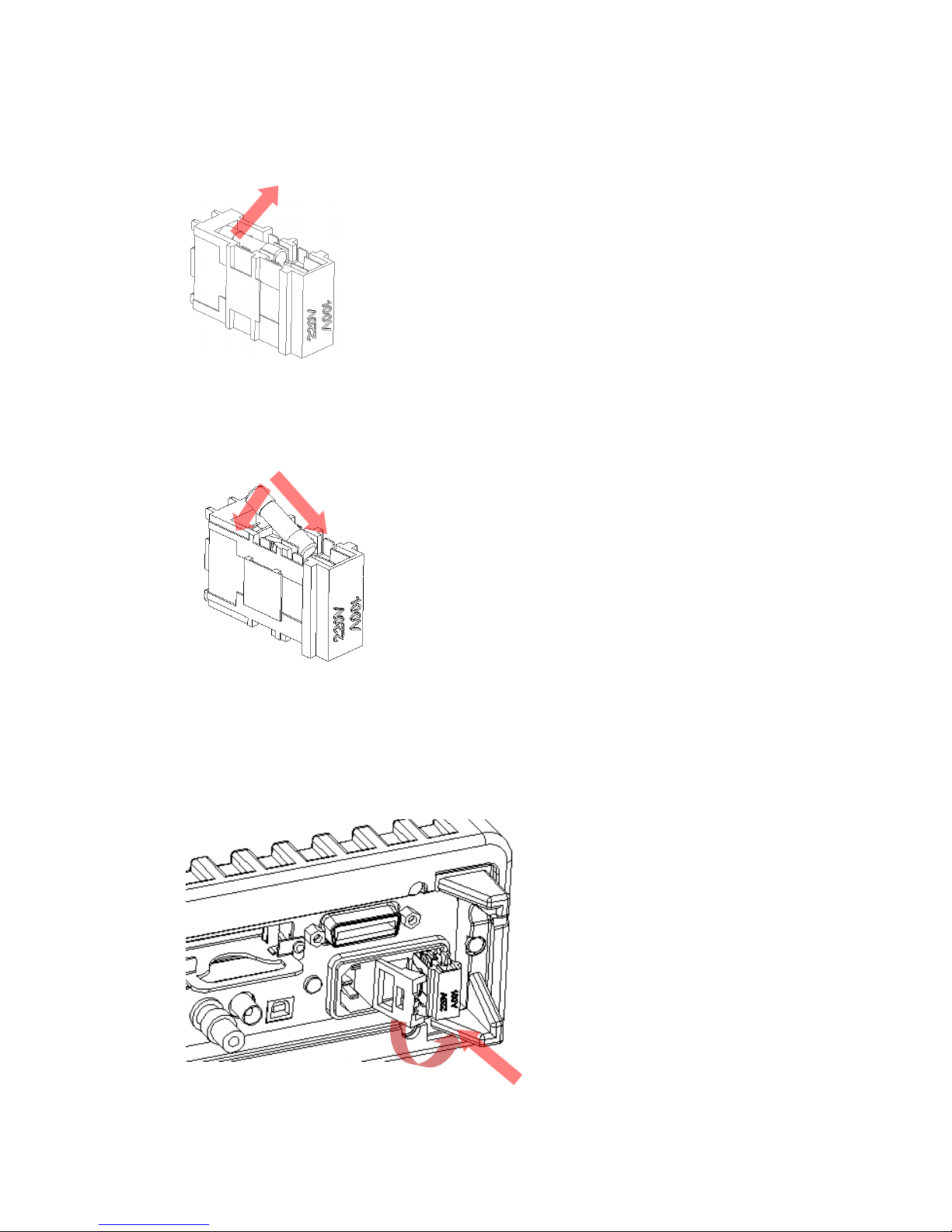

【

Step 7

】

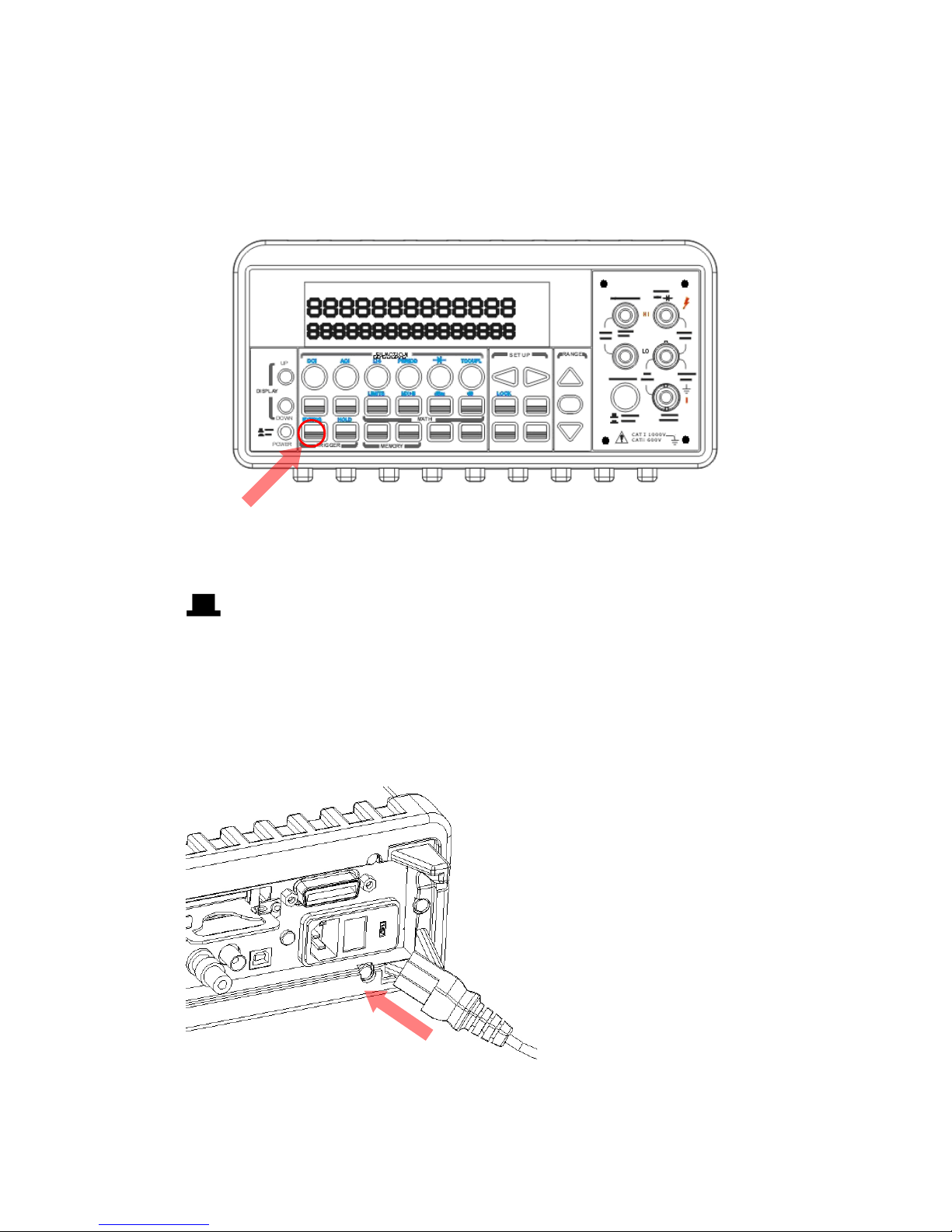

Make sure the power switch on the front panel is in “Power OFF”

condition before plugging as shown in Figure 2-12.

Figure 2-12

Power switch:

“POWER OFF”

【

Step 8

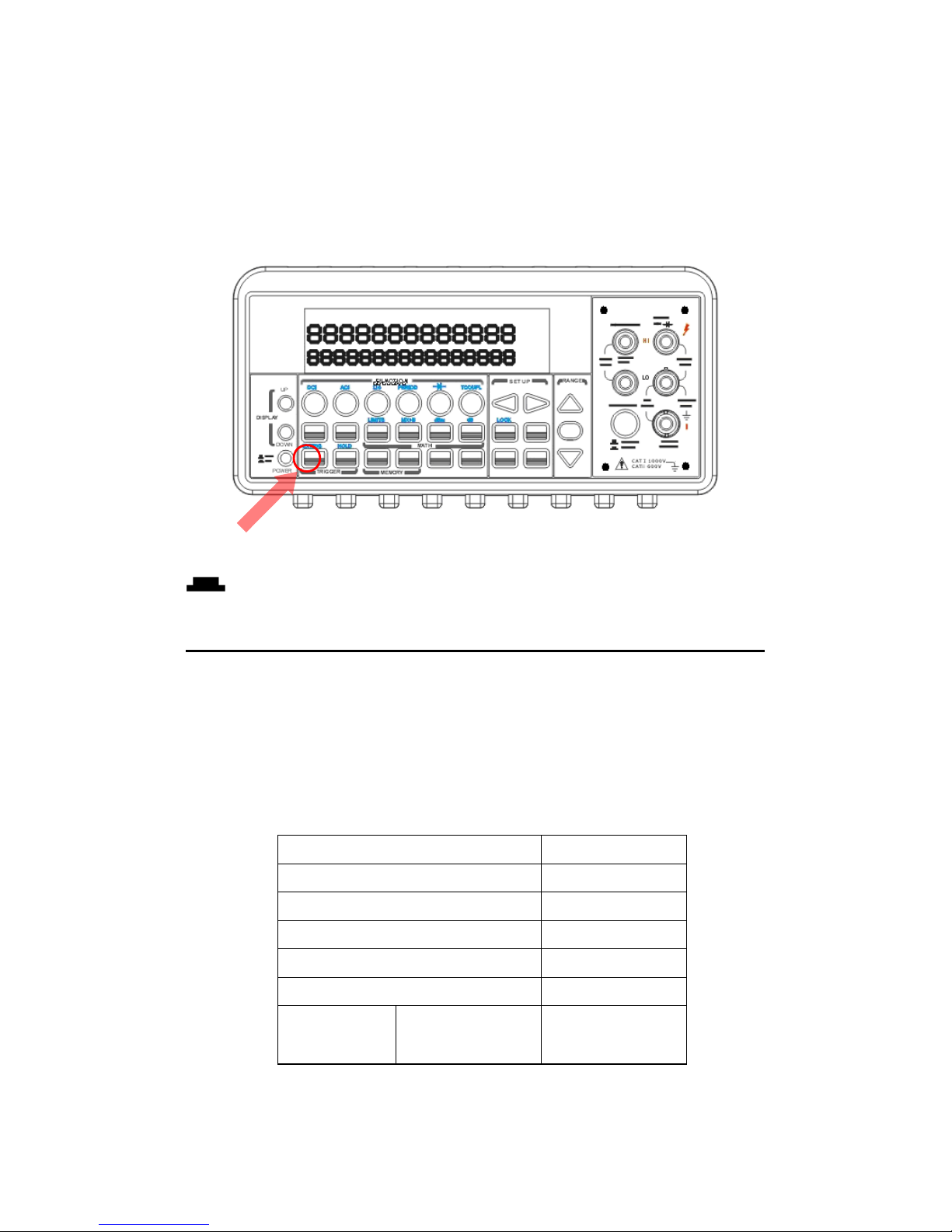

】

After finishing the above procedures, you can plug in your power cord

as shown in Figure 2-13.

Figure 2-13

21

【

Step 9

】

Press on the power switch on the front panel for activating ATM3500A

as shown in Figure 2-14.

Figure 2-14

Power switch:

- “POWER ON”

2.1.3 Factory Default When Power-ON

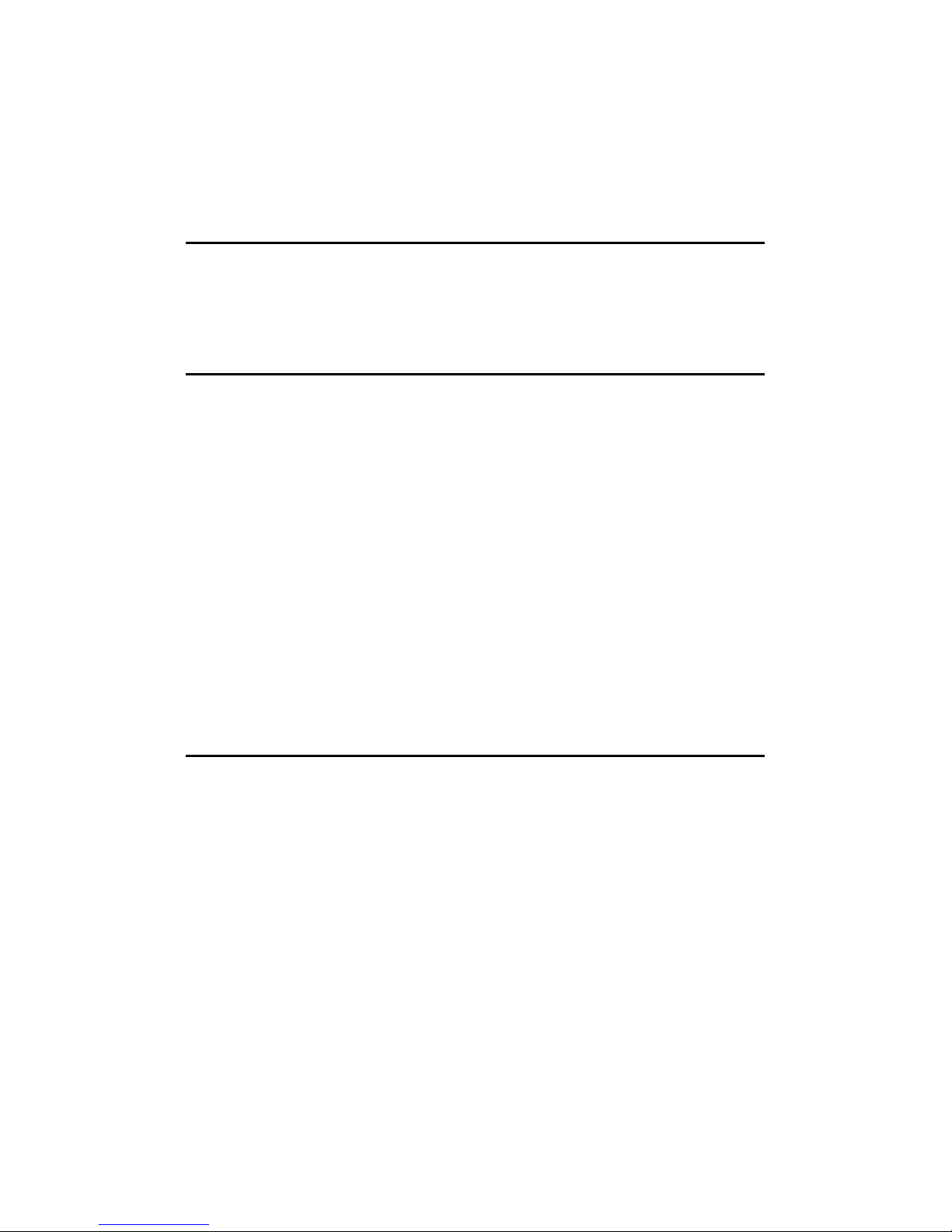

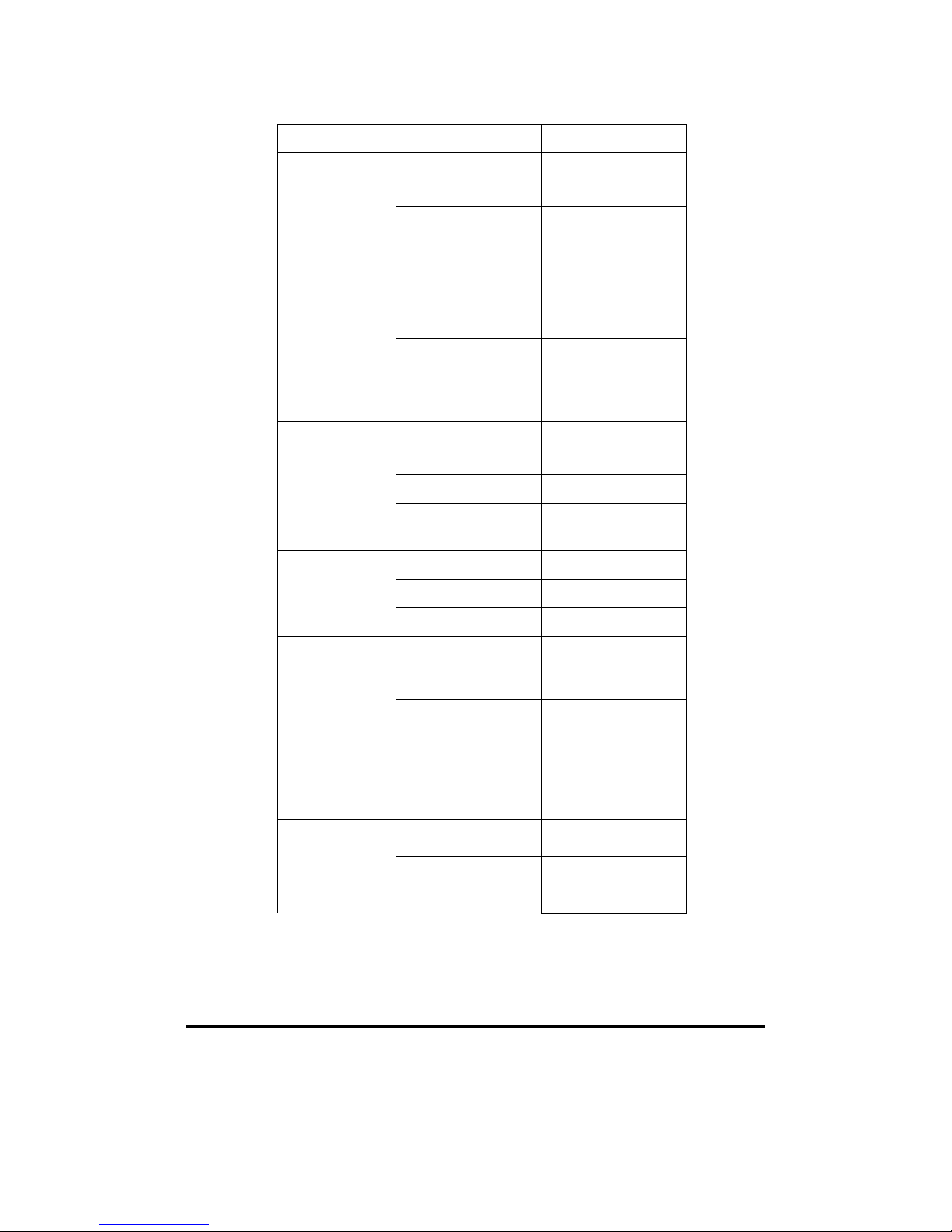

Table 2-1 shows the factory default of ATM3500A.

Table 2-1

Function Default

Function DCV

Autozero On

Frequency and Period Source AC Voltage

Output Format ASCII

Ratio Off

AC

Bandwidth

Input

Frequency

20Hz

22

Function Default

Voltage AC Digits 5.5

DC digits Slow 5.5

(1 PLC)

Range Auto

Current AC Digits 5.5

DC Digits Slow 5.5

(1 PLC)

Range Auto

Frequency

and Period

Digits 5.5

Range AUTO

Rate Medium

(100ms)

Diode Test Digits 5.5

Range 1mA

Rate 0.1 PLC

Resistance

(2-wire)

Digits Slow 5.5

(1 PLC)

Range Auto

Temperature Digits Slow 6.5

(10 PLC)

Thermocouple Universal Type

Triggers Source Immediate

Delay Auto

Input Resistance 10MΩ

2.2 Features

23

Resolution: 6.5 digits.

5*7 dot matrix VFD, dual displays with 3-color annunciators.

11 standard measurement functions & 8 math functions.

4 front ground terminal are connected to Chassis.

Stability, Accuracy and Speed (2000RDGS/Sec at 4.5 Digit, 60

RDGS/Sec at 6.5 Digit in 60 Hz)

Multi-Points Scanner Card: Up to 20 Channels. (Optional)

RTD probe Adapter (optional) convenient to use.

Built-in USB and GPIB/RS-232 (Optional) Interfaces.

Easy & Free PC applications.

2.3 ATM3500A Function Introduction

To become familiar with the ATM3500A DMM, ATTEN.EU will provide

you the brief introduction of the basic ATM3500A DMM operations.

There are three major parts of ATM3500A: (2.3.1) the front panel,

(2.3.2) the display, and (2.3.3) the rear panel.

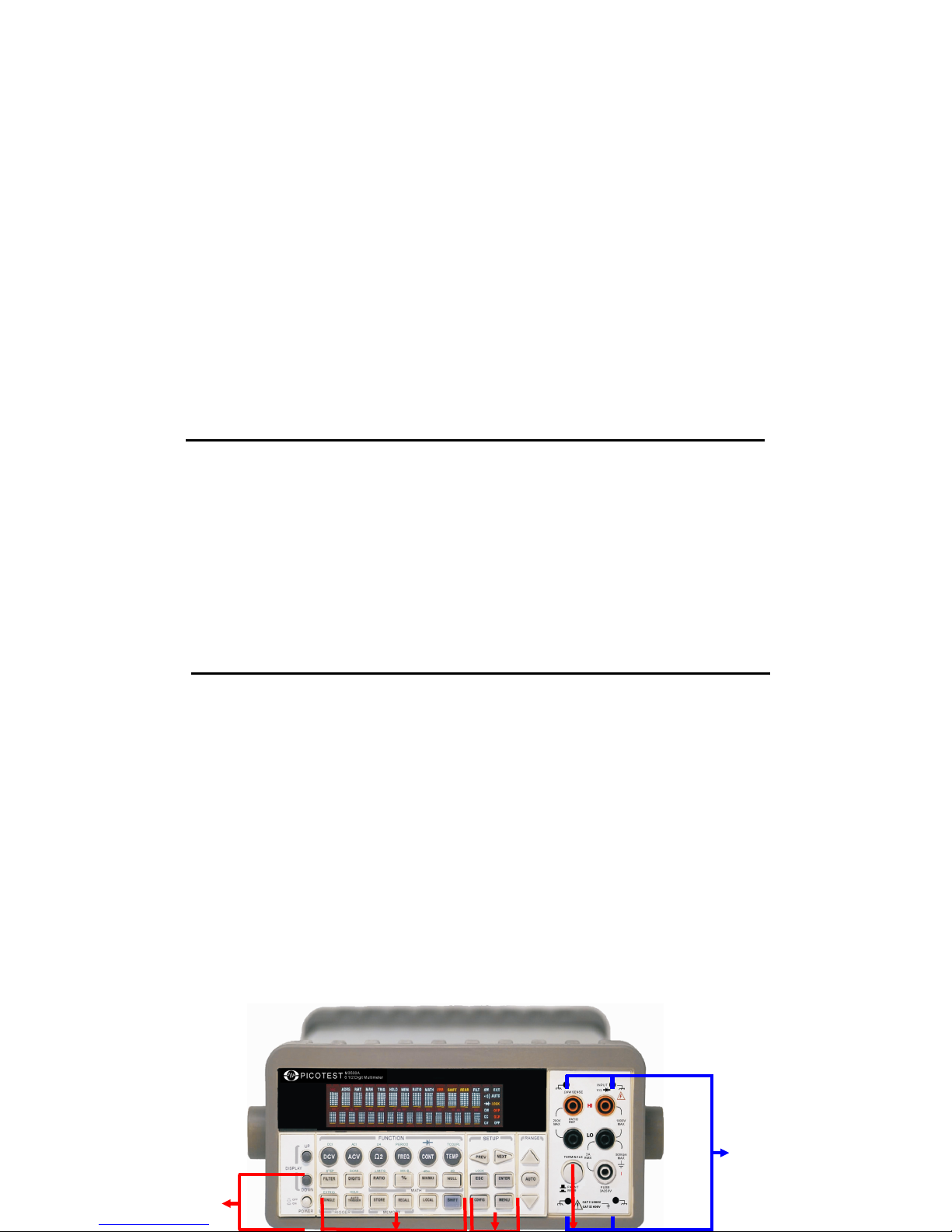

2.3.1 The Front Panel

There are different buttons and terminals on the front panel. They are

divided into the following groups: (DISPLAY & POWER), (FUNCTION,

MATH, TRIGGER, MEMORY, SETUP, RANGE, INPUT TERMINALS), and

(FILTER, DIGITS, LOCAL, and SHIFT) as shown in Figure 2-15.

24

1

2 3 4 5

Figure 2-15

1. Power & Display:

Power: Activates ATM3500A DMM.

Display: Shows model, version & condition by pressing round PREV

& NEXT buttons.

2.1.

First row without SHIFT button:

DCV: Selects DC voltage measurement.

ACV: Selects AC voltage measurement.

Ω2: Selects 2-wire resistance measurement.

FREQ: Selects frequency measurement.

CONT: Selects the continuity test.

TEMP: Selects RTD temperature measurement.

2.2.

First row with SHIFT button:

DCI: Selects DC current measurement.

25

6

7

ACI: Selects AC current measurement.

Ω4: Selects 4-wire resistance measurement.

PERIOD: Selects period measurement.

: Selects diode testing.

TCOUPL: Selects thermocouple temperature measurement.

2.3.

Second row without SHIFT button:

FILTER: Enable or disable the digital filter.

DIGITS: Changes resolution.

RATIO: Enables the dcv:dcv ratio function.

%: Calculates the ratio to a target value in percentage.

MIN/MAX: Captures the minimum or maximum readings from the

measurement.

NULL: Activates the offset function in order to get the real

measured reading.

2.4.

Second row with SHIFT button:

STEP: Scans from a channel to the next channel in delayed action

when using the scanner card.

SCAN: Enables scanning function when using the scanner card.

LIMITS: Used for Setting upper and lower limit values for readings.

MX+B: Used for calculating slope. X is the normal display reading.

M and B are constants defined by user for scale factor and offset.

26

dBm: Used for displaying voltage measurement in dBm power unit.

dB: Used for displaying voltage measurement in decibel unit.

2.5.

Third row without SHIFT button:

SINGLE: Manually triggers the multimeter to make measurements.

AUTO TRIGGER: Instructs the multimeter to make measurements

continuously.

STORE: Stores a specified number of subsequent readings.

RECALL: Displays stored readings and buffer statistics. Use ◁▷ or

△▽ searching buttons to toggle between reading number and

reading.

LOCAL: Cancels USB or GPIB remote mode.

SHIFT (in blue): Used for accompanying other button with upper

print in blue and converting function.

2.6.

Third row with SHIFT button:

EXTRIG: Selects external triggers as the trigger source via BNC port

on the rear panel.

HOLD: Holds reading.

3.1.

The first row in SETUP section

◁▷: Scrolls through buffer, conceals or reveals the digits while

measuring.

27

3.2.

The second row in SETUP section:

ESC: Cancels selection, moving back to measurement display.

ENTER: Accepts selection, moving to next choice or back to

measurement display.

LOCK: Presses SHIFT then ESC button to prevent unpredictable

operation on the panel. In order to release lock condition, please

press ESC again.

3.3.

The third row in SETUP section:

CONFIG: Offers setting or adjusting function, relating some front

panel buttons.

MENU: Offers setting or adjusting function, not relating other front

panel buttons.

4. RANGE:

: Moves to higher range.△

: Moves to lower range.▽

AUTO: Enables or disables auto-range.

5.

Terminals: Selects input signal connections on front or rear

panel.

6. Inserted Connections & Fuse Device:

4 Chassis Ground Connections: Separate environmental noises.

HI & LO: Used for all measurements, except DC and AC current.

(Maximum input voltage: 1000V for voltage measurements. 200V

for 4-wire measurement)

28

LO & I: Used for making DC and AC current measurements.

Front Fuse: Secures your Meter against damage of strong current

pulse. (Maximum current: 3A, 250V)

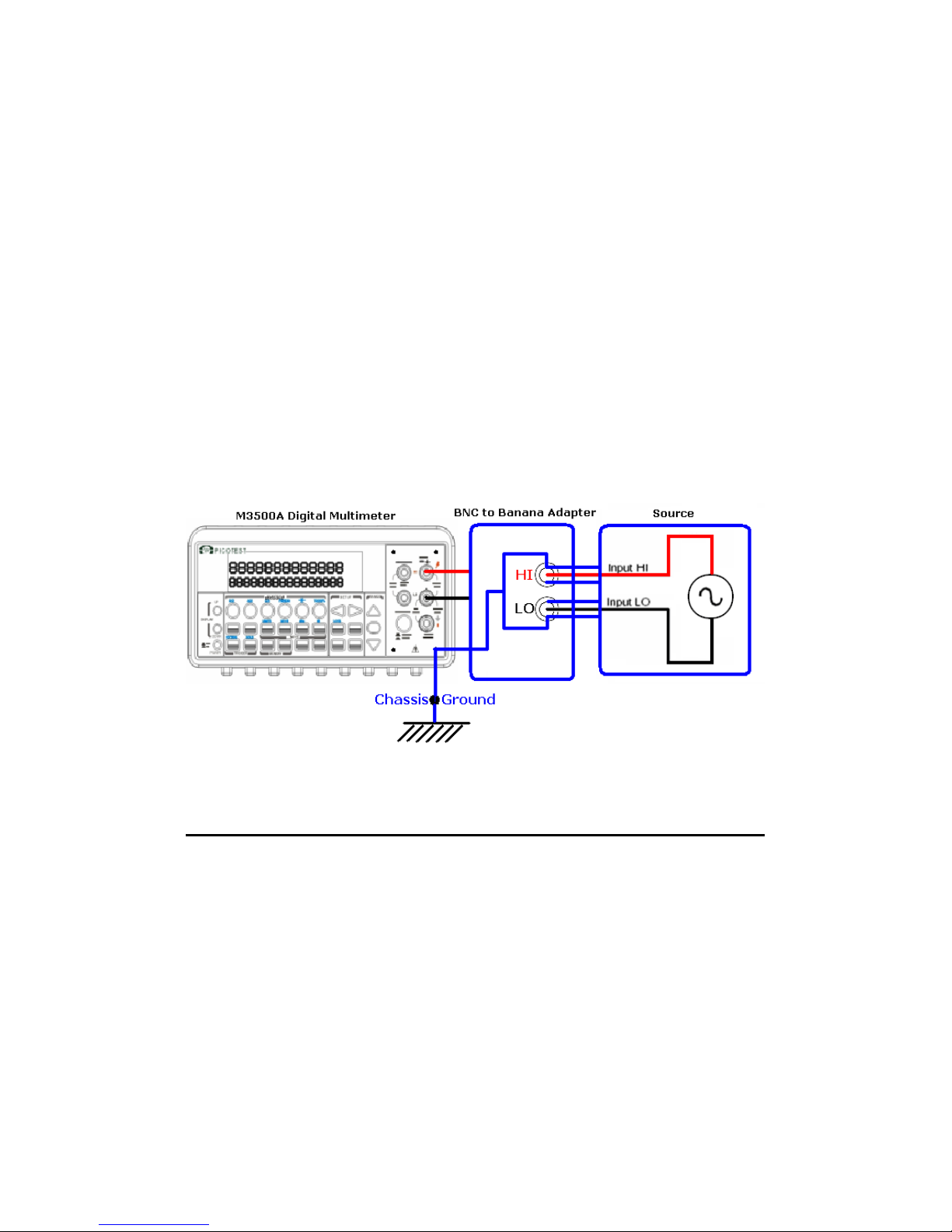

7.

Chassis Ground Terminal:

The chassis ground terminal is used for shielding the noise from

the nature, especially when you want to get a very small signal via

the application of a BNC-to-Banana Adapter. Please refer to the

Figure 2-16.

Figure 2-16

2.3.2 The Display

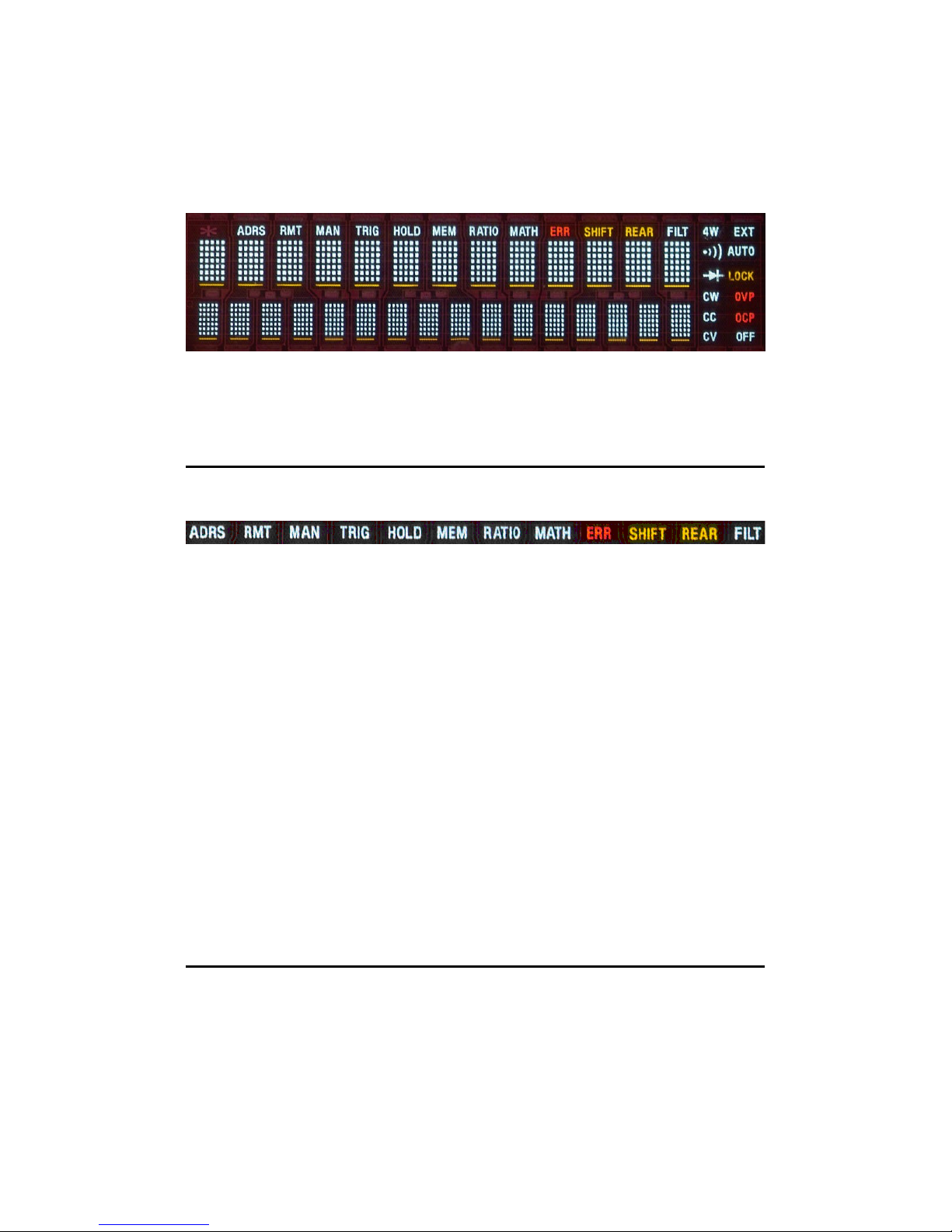

ATM3500A has a 5x7 dot matrix, dual-display with three-color (White,

Red and Yellow) annunciators for a better view. There are two rows in

the dual-display screen. The upper row displays readings and units. A

maximum 13 characters are allowed for upper row dot-matrix display.

The lower row displays range of the measurements, condition or

information about an ongoing configuration. A maximum 16 characters

are allowed for lower row dot-matrix display. There are additional

29

annunciators at upper side and right side of the display screen for

indicating the state or the condition of an ongoing measurement. They

are explained individually in the following sections.

Figure 2-17

2.3.2.1 Annunciators at Upper Side

Figure 2-18

ADRS: Indicates the multimeter is controlled via GPIB Interface.

RMT (REMOTE): Indicates the remote state. (USB Interface)

MAN: Indicates the manual range is taken.

TRIG: Shows the single triggering is enabled.

HOLD: Indicates reading hold function is enabled.

MEM: Indicates the using of internal memory.

RATIO: Indicates the dcv:dcv ratio operation.

MATH: Indicates the “MATH” operation is taken.

ERR: Error occurs.

SHIFT: Indicates SHIFT button is pressed.

REAR: The rear panel input terminal is selected for the

measurement.

FILT: The digital filter is started.

2.3.2.2 Annunciators at Right Side

4W: Indicates 4 –wire mode is selected for resistance

30

Upper Row Display

Lower Row Display

Loading...

Loading...