Page 1

AT&T

AT&T System 25

Installation and

Maintenance Manual

555-540-103

B

November 1995

Page 2

©1989 AT&T

All Rights Reserved

Printed in USA

TO ORDER COPIES OF THIS DOCUMENT REFER TO DOCUMENT NUMBER

555-540-103

Contact: Your AT&T sales representative, or

Call: 800-432-6600, Monday through Friday between 7:30 am

and 6:00 pm EST, or

In Canada call: 800-255-1242

Write: AT&T Customer Information

2855 North Franklin Road

P.O. Box 19901

Indianapolis, Indiana 42619

Every effort was made to ensure that

complete and accurate at the time of

subject to change. This document will

changes.

Center

the information in this document was

printing.

However, this information is

be reissued periodically to incorporate

Installation and Maintenance Manual

Prepared by System 25

Document Development Group and the

AT&T Documentation

Management Organization

Page 3

DANGER

Do not open the fan assembly or remove rear cabinet cover before

unplugging the cabinet from the electrical outlet. Wait at least five

minutes after unplugging the power cord before removing the rear

cover or power supply. The AT&T System 25 cabinets are not user

serviceable. Some voltages inside the cabinets are hazardous.

This equipment is to be serviced only by qualified technicians.

CUSTOMER WARNING

The Installation and Maintenance Manual is designed for use by

qualified service technicians only. Technician qualification includes

completion of an AT&T hands-on instructor-led course covering

installation and maintenance for this product. The use of these

documents by anyone else might void the warranty. Hazardous

electrical voltages are present inside this product.

SERVICE TECHNICIAN WARNING

1. Never install telephone wiring during a lightning storm.

2. Never install telephone jacks in wet locations unless the

is specifically designed for wet locations.

3. Never touch uninsulated telephone wires or terminals un

jack

less the

telephone line has been disconnected at the network interface.

4. Use caution when installing or modifying telephone lines.

a

Page 4

THE FOLLOWING SYMBOLS AND PICTOGRAPHS

APPEAR ON THE EQUIPMENT

SYMBOL

The exclamation point

within an equilateral

triangle is intended

to alert the user to

the presence of

important operating

and maintenance

(servicing) instructions

ELECTRICAL SHOCK

Warns of the danger

of electrical shock

from hazardous voltages

present within the

control unit

Warns of the risk of

fire if the air filter

is not in place

b

Page 5

FCC NOTIFICATION AND REPAIR INFORMATION

AT&T SYSTEM 25

This telephone equipment is registered with the Federal Communications

Commission (FCC) in accordance with Part 68 of its Rules. In compliance with

the Rules, be advised of the following:

MEANS OF CONNECTION

Connection of this telephone equipment to

the nationwide telecommunications

network shall be through a standard network interface USOC RJ21X jack.

Connection to private line network channels requires USOC RJ2GX jack for tie

lines or USOC RJ21X jack for off-premises station lines. Connection to T1

facilities requires USOC RJ48X or RJ48C jack. These can be ordered from your

telephone company.

NOTIFICATION TO THE TELEPHONE COMPANY

If the system is to be connected to off-premises stations (OPSs), you must notify

the telephone company of the OPS class of service, OL13C, and the service

order code, 9. OF. For R3 systems, the Analog service order code is 9.0Y, the

Digital service order code is 6.0Y.

Upon the request of the telephone company, inform them of the following:

— The Public Switched Network “lines” and the Private “lines” to which

you will connect the telephone equipment.

— For private line connections, provide the facility interface code, TL31M

for tie lines. You must also specify the service order code, 9.0F or 9.0Y

for R3 systems.

Customer instructions will advise the customer to provide the telephone

company with the registration number (either -MF or -KF, depending on

the application of the system) and the ringer equivalency number (REN)

from the label on the equipment. In addition, customer will be advised

c

Page 6

that certification in writing may be required when an existing

multifunction system is being reconfigured as a Key system, if the

customer desires the lower rate.

— For Digital connections with D4 Framing Format provide the Facility

interface code 041DU9-B, for digital connections with Extended Framing

Format, provide the Facility interface code 04DU9-C. You must also

specify the service order code, 6.0Y.

— The quantities and USOC numbers of the jacks required.

— For each jack, provide the sequence in which lines are to be connected;

the type lines and the facility interface code and the ringer equivalence

number by position, when applicable.

This telephone equipment should not be used on coin telephone lines.

Connection to party line service is subject to state tariffs.

REPAIR INSTRUCTIONS

If you experience trouble with this telephone equipment, contact the AT&T

Business Customer Service Center on 1-800-242-2121. The telephone company

may ask that you disconnect this equipment from the network until the problem

has been corrected or until you are sure that this equipment is not

malfunctioning.

System 25 troubles that must be escalated to a higher level of maintenance

should be referred to the National Service Assistance Center on 1-800-628-2888.

RIGHTS OF THE TELEPHONE COMPANY

If your telephone equipment causes harm to the telephone network, the

telephone company may discontinue your service temporarily. If possible, they

will notify you in advance. But if advance notice isn’t practical, you will be notified

as soon as possible. You will be informed of your right to file a complaint with the

FCC.

d

Page 7

Your telephone company may make changes in its facilities, equipment,

operations, or procedures that could affect the proper functioning of your

equipment. If they do, you will be notified in advance to give you an opportunity

to maintain uninterrupted telephone service.

HEARING AID COMPATIBILITY

The voice terminals described in this manual are compatible with inductively

coupled hearing aids as prescribed by the FCC.

FCC INFORMATION

FCC REGISTRATlON lNFORMATlON

Registration Number

AS593M-71565-MF-E

Ringer Equivalence

0.5A

Network Interface

RJ21X, RJ2GX or RJ48X

PRIVATE LINE SERVICE

Service Order Code

● Analog

9.0F

● Analog (R3)

9.0Y

●

Digital (R3)

I

6.0Y

Facility Interface Code

●

Tie Lines

TL31 M

● Off-Premises Stations

OL13C

● Digital D4 Framing

04DU9-B

●

Digital ESF

04DU9-C

November 1995

Page 8

FCC WARNING STATEMENT

Federal Communicatlons Commission (FCC) Rules require that you be notified of

the following:

This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

interference to radio communications.

It has been tested and found to comply with the limits for a Class A computing

device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to

provide reasonable protection against such interference when operated in a

commercial environment.

Operation of this equipment in a residential area is likely to cause interference

in which case the user at his or her own expense will be required to take

whatever measures may be required to correct the interference.

SECURITY OF YOUR SYSTEM-PREVENTING TOLL FRAUD

As a customer of a new telephone system, you should be aware that there exists

an increasing problem of telephone toll fraud. Telephone toll fraud can occur in

many forms, despite the numerous efforts of telephone companies and telephone

equipment manufacturers to control it. Some individuals use electronic devices

to prevent or falsify records of these calls. Others charge calls to someone else’s

number by illegally using lost or stolen calling cards, billing incorrect parties,

clipping on to someone else’s line, and breaking into someone else’s telephone

equipment physically or electronically. In certain instances, unauthorized

individuals make connections to the telephone network through the use of remote

access features.

The Remote Access feature of your system, if you chose to utilize it, permits offpremises callers to access the system from a remote telephone by using an 800

number or a 7- or 10- digit telephone number. The system returns an

acknowledgement signaling the user to key in his or her authorization code,

which is selected and administered by the system manager. After the

authorization code is accepted, the system returns dial tone to the user. If you do

not program specific egress restrictions, the user will be able to place any call

Page 9

normally dialed from a telephone associated with the system. Such an offpremises network call is originated at, and will be billed from, the system location.

The Remote Access feature, as designed, helps the customer, through proper

administration, to minimize the ability of unauthorized persons to gain access to

the network. Most commonly, phone numbers and codes are compromised

when overheard in a public location, through theft of a wallet or purse containing

access information, or through carelessness (writing codes on a piece of paper

and improperly discarding it). Additionally, hackers may use a computer to “dial”

an access code and then publish the information to other hackers. Enormous

charges can be run up quickly. It is the customer’s responsibility to take the

appropriate steps to properly implement the features, evaluate and administer the

various restriction levels, protect access codes, and distribute access codes only

to individuals who have been fully advised of the sensitive nature of the access

information.

Common carriers are required by law to collect their tariffed charges. While

these charges are fraudulent charges made by persons with criminal intent,

applicable tariffs state that the customer of record is responsible for payment of

all long-distance or other network charges. AT&T cannot be responsible for such

charges and will not make any allowance or give any credit for charges that result

from unauthorized access.

To minimize the risk of unauthorized access to your communications system:

● Use a nonpublished Remote Access number.

● Assign authorization codes randomly to users on a “need-to-have”

basis, keeping a log of ALL authorized users and assigning one code

per person.

● Use random sequence authorization codes, which are less likely to be

broken.

● Deactivate all unassigned codes promptly.

● Ensure that Remote Access users are aware of their responsibility to

keep the telephone numbers and any authorization codes secure.

● When possible, restrict the off-network capability of off-premises callers,

via use of Call Restrictions and Disallowed List capabilities.

Page 10

● When possible, block out-of-hours calling.

● Frequently monitor system call detail reports for quicker detection of any

unauthorized or abnormal calling patterns.

● Limit Remote Call Forward to persons on a “need-to-know” basis.

Page 11

Contents

INTRODUCTION

FCC PRECAUTIONS

INSTALLATION

TOOLS AND TEST EQUIPMENT

CROSS-CONNECT EQUIPMENT DESCRIPTION

Trunk Access Equipment

700A-110-BI -25 or 700A-66-B1-25 Cut-Down Jack

108 Emergency Transfer Unit (ETU)

Station Interconnect Panel (SIP)

617A Panel

Adapters

Fanning Strip

Cables

Splitter Cables

Octopus Cables

853B Adapter Cable

DS1 Connector Cables

Cable Labels

Symbols Used in Figures

PREINSTALLATION REQUIREMENTS

Table and Backboard

Network Interface

AC Power

Grounding

Lightning Protection

Secondary Protection

Building Wiring

INSTALL SYSTEM CABINETS

Position Cabinet(s)

Check Cabinet Contents

Required Circuit Pack Positions

Label Connectors on Back Cover

Install 4A Retainer Clips

Connect Cabinet

1-1

1-2

2-1

2-2

2-3

2-4

2-4

2-4

2-6

2-6

2-8

2-10

2-11

2-11

2-12

2-12

2-12

2-13

2-15

2-16

2-16

2-16

2-18

2-18

2-19

2-21

2-22

2-23

2-23

2-23

2-28

2-28

2-29

2-30

Page 12

TDM Bus Connections.

Ground Wire Connections.

POWER UP AND INITIALIZE SYSTEM

Connect Power

Connect Administration Equipment

Cold Start the System

Check Performance of Cabinet Components

Report Problems

Initialize System

INSTALL CROSS-CONNECT EQUIPMENT

Install TAE, 617A Panels, and Fanning Strips

Mount 858A orZ210A2 Adapters

INSTALL MODULAR BULK POWER SUPPLY

(Optional)

INSTALL EQUIPMENT ROOM TRUNK CABLING

Connect Network Interfaces to TAE Blocks

Connect Cabinets to TAE Blocks

Connect Ground Start, Loop Start, and DID Trunks

Connect Tie Trunks

Install DS1

Connect S25 to Another On Premises PBX

Off Premises Metallic (Cable) Connections

Off Premises Non Metallic Connections

Install Customer Service Unit (CSU)

Line Compensation/Equalization

Connect Coupled Bonding Conductor (CBC)

INSTALL EQUIPMENT ROOM STATION CABLING

Connect Building Wiring to SIP

Modular Plug Termination

4-Pair Cable Terminations

Connect Cabinets to SIP

Prepare Carrier Loading Labels

Modify Octopus Cables if Required

Make SIP Connection for CPU/Memory

Make SIP Connections to Cabinet for 7300H Series

Terminals

Make SIP Connections to Cabinet for MET Sets

Make SIP Connections to Cabinet for Single-Line Sets

2-30

2-33

2-33

2-33

2-34

2-35

2-39

2-42

2-43

2-43

2-44

2-47

2-49

2-49

2-49

2-51

2-51

2-52

2-53

2-53

2-56

2-56

2-57

2-58

2-58

2-60

2-62

2-62

2-64

2-66

2-67

2-69

2-71

2-73

2-74

2-74

-ii-

Page 13

Make SIP Connections for Data Terminals and

Computers

Make SIP Connections to Cabinet for ATL Cordless

Telephones

Perform SIP Housekeeping

INSTALL

EMERGENCY TRANSFER UNITS (ETUs)

Make Emergency Transfer Connections

Install Ground-Start Key

INSTALL ATTENDANT

CONSOLE

INSTALL TERMINALS

Label Terminals

Stand-Alone Voice Terminals

Stand-Alone Remotely Powered Voice Terminals

Single-Line and 7300H Series Voice Terminals With

Associated ADUs

ATL Cordless Telephone

Off-Premises Stations (TN742)

Out-of-Building Voice Terminals (TN742)

Out-of-Building Voice Terminals (ZTN79)

Off-Premises—

DS1 lnterface

Stand-Alone Data Terminals

ADU Connections

MADU Connections

INSTALL CUSTOMER’S

SAT

Nonswitched Connection of Equipment Plugged Into

System AC Outlet

Nonswitched Connection of Equipment

On-Premises Digital Switched Connection

Off-Premises Nonswitched Connection

Off-Premises Switched Connection

INSTALL CUSTOMER’S DTU

INSTALL STATION MESSAGE DIGITAL RECORDING

(SMDR) EQUIPMENT

INSTALL STARLAN NETWORK INTERFACE

Shared System 25 Voice/STARLAN NETWORK Data

Connections

Single-Line Voice Terminals

2-75

2-76

2-76

2-77

2-80

2-82

2-83

2-87

2-88

2-90

2-91

2-92

2-94

2-95

2-95

2-96

2-96

2-98

2-98

2-101

2-102

2-102

2-104

2-106

2-109

2-109

2-111

2-111

2-112

2-113

2-113

-III-

Page 14

7300H Series Voice Terminals

INSTALL MUSIC-ON-HOLD INTERFACE

FCC-Registered Music Source Interface

Non-FCC Registered Music Source Interface

INSTALL EXTERNAL ALERTS

INSTALL RECORDED DELAY ANNOUNCEMENT

2-115

2-117

2-117

2-119

2-120

2-121

2-121

2-121

2-122

2-124

2-128

INSTALL DICTATlON SYSTEM INTERFACE

INSTALL PAGING SYSTEM INTERFACE

Direct Connection to TN763 Auxiliary Trunk CP

Connection to TN763 Auxiliary Trunk CP (278A

Adapter Required)

Connection to ZTN76 or ZTN77 CP

SYSTEM TESTS

TEST OUTGOING TRUNKS

TEST DS1 INTERFACE.

TEST INCOMING DID TRUNKS

TEST INCOMING TIE TRUNKS

TEST 7300H SERIES VOICE TERMINALS

TEST SINGLE-LINE VOICE TERMINALS

TEST ATL CORDLESS TELEPHONE

TEST DIAL ACCESS CODES

TEST SYSTEM FEATURES

ARS and SMDR Tests

DGC Test

System Speed Dialing Test

PDC Login Test

Call Coverage Test

TEST ATTENDANT CONSOLE

TEST SELECTOR CONSOLE

3-1

3-1

3-1

3-2

3-2

3-3

3-5

3-6

3-6

3-6

3-6

3-7

3-7

3-8

3-8

3-9

3-9

TEST DATA TERMINAL DIALING FEATURE

3-10

-iv-

Page 15

MAKE POOLED MODEM TEST CALL

. . . .

TEST TRANSFER TO DATA . . . . ... . . .

TEST

EXTERNAL ALERT (NIGHT SERVICE)

TEST

TEST

TEST

TEST

TEST

3-11

3-11

3-12

DICTATION SYSTEM ACCESS

3-13

PAGING INTERFACE

MUSIC-ON HOLD

EMERGENCY TRANSFER

TOUCH-TONE RECEIVERS

3-13

3-14

3-15

3-16

MAINTENANCE

4-1

EQUIPMENT NEEDED

Precautions

GENERAL INFORMATION

System Errors and Alarms

Emergency Transfer

Circuit Pack LEDs

Attendant Console LED

Power Supply

Switches and Test Points

System Administration

Remote Initialization Maintenance (RIM) Service

4-4

4-4

4-4

4-4

4-6

4-6

4-6

4-6

4-6

MAINTENANCE STRATEGY

Total System Failures

Port Problems

Common Control Problems

Staion, Trunk Problems

Antomatic Maintenance Tests

Maintenance Failure

4-9

4-11

4-11

4-12

4-13

4-13

4-13

USING THE DIGITAL TAPE UNIT

Setting Up the DTU

Saving Translations

Verifying Translations

Restoring Translations

4-14

4-14

4-15

4-16

4-18

-v-

Page 16

ROUTINE MAINTENANCE

Reseating and Replacing Circuit Packs

Removing and Restoring Power

Restarting the System

ERROR LOG

Accessing the Error Log From the SAT

ERROR MESSAGES

Clearing System-Detected Troubles

Complete System Failure

Common Control Trouble

Circuit Pack Trouble

Frontplane Ribbon Connector Trouble (Release 1

Only)

Power Supply Trouble

Power Supply Protection

Power Supply Replacement

Fan Assembly Trouble

Overheating Trouble

Backplane and Cabinet Trouble

Emergency Transfer Unit Trouble

CLEARING USER-DETECTED TROUBLES

Administration Equipment Troubles

Time-Keeping Troubles

Voice Terminal and Wiring Troubles

Voice Transmission Troubles

7300H Series Terminal Troubles

Virtual Facilities Troubles

Trunk Troubles

Outgoing Trunk Problems

Incoming Trunk Problems

Error Log Interpretation: Loop-Start Trunks

Error Log Interpretation: Ground-Start Trunks

DID Trunks Troubles

Switched

Loop Attendant Console Troubles

Special Port Circuit Options for Stations and Trunks

Data Line Troubles

Multiple Troubles or Trouble That Cannot Be

Diagnosed

4-20

4-20

4-22

4-23

4-27

4-30

4-32

4-61

4-61

4-61

4-63

4-64

4-64

4-69

4-70

4-71

4-72

4-72

4-80

4-81

4-81

4-82

4-82

4-83

4-84

4-85

4-89

4-89

4-90

4-90

4-91

4-92

4-93

4-99

4-100

4-102

-vi-

Page 17

REFERENCES

ABBREVIATIONS AND ACRONYMS

5-1

6-1

A-1

APPENDIX A: System Wiring

Connector Pin Assignments

System 25 Building Wiring

APPENDIX B: Parts Listing

Tables

A-1

A-1

B-1

APPENDIX C: System Additions or Changes

Evaluate Cabinet Unit Power Load

Add Circuit Pack

Add Cabling

Set Option Switches on TN760B CP

Replace Circuit Pack

Add Cabinet

Add Termina

Add Trunk

Add Trunk—DSl

Interface

Replace Voice-Only Terminal With Voice/Data

Terminal

Add Pooled Modem Circuit Pack

Add

Auxiliary Equipment

APPENDIX D: System Upgrades

APPENDIX E: Administration Codes and Data

Default Dial Code Assignments

C-1

C-1

C-2

C-3

C-5

C-7

C-8

C-10

C-11

C-11

C-12

C-13

C-13

D-1

E-1

E-1

-vii-

Page 18

APPENDIX F: Administration Error Messages

GLOSSARY

INDEX

F-1

G-1

I-1

-viii-

Page 19

Figures

Figure 2-1.

Figure 2-2.

Figure 2-3.

Figure 2-4.

Figure 2-5.

Figure 2-6.

Figure 2-6a.

Figure 2-7.

Figure 2-8.

Figure 2-9.

Figure 2-10.

Figure 2-11.

Figure 2-12.

Figure 2-13.

Figure 2-14.

Figure 2-15.

Figure 2-16.

Figure 2-17.

Figure 2-18.

Figure 2-19.

Figure 2-20.

Figure 2-21.

Figure 2-22.

Figure 2-23.

Figure 2-24.

Figure 2-25.

Figure 2-26.

Figure 2-27.

Figure 2-28.

Figure 2-29.

Figure 2-30.

Figure 2-31.

Figure 2-32.

Figure 2-33.

Figure 2-34.

Figure 2-35.

Figure 2-36.

10 BEAU

617A Panel

SIP Adapters

50A Fanning Strip

Splitter Cables

Octopus Cable

853B Adapter Cable

Cable Labels

Typical System 25 Floor Plan

AC Power Distribution—Multiple Cabinet System

Three-Cabinet System, Front View With Covers

Removed

Position of Shorting Plugs on CPU/Memory Circuit

Pack . . . . . . . . . . . . . . . .

4A Retainer Clip Installation

TDM Bus Terminations (Rear View of 3-Cabinet

System)

Temporary SAT and DTU Connections

Typical System 25 Port Circuit Pack

SIP and TAE Backboard Layout

Alternate SIP and TAE Backboard Layout

Mounting Adapters

Direct Connection (Side by Side)

Direction Connection (Side by Side)

DS1 Connections—1311 to 4310 Feet

DS1 mnnections4311 Feet or More

DS1 Connections–Off Premise Cabling

DS1 Connections-Non Metallic Connections

CSU Connections

Voice and Data Station Records Form (Example

Entered)

Modular Plug Terminations Connected to the SIP

Cut Down Terminations Connected to the SIP

Carrier Loading Label

Standard and Modified Octopus Cables

Mounting Octopus Cable on Fanning Strip

10B Emergency Transfer Unit

Emergency Transfer Unit Connections

Ground Start Key Installation

Attendant Console With DXS Console

Remotely Powered DXS Console Connection

2-5

2-7

2-9

2-10

2-11

2-12

2-12

2-14

2-17

2-21

2-26

2-27

2-29

2-32

2-34

2-42

2-45

2-46

2-48

2-54

2-54

2-55

2-55

2-56

2-57

2-58

2-61

2-63

2-65

2-68

2-70

2-72

2-78

2-79

2-82

2-84

2-86

November 1995

-ix-

Page 20

Figure 2-37.

Figure 2-38.

Figure 2-39.

Figure 2-40.

Figure 2-41.

Figure 2-42.

Figure 2-43.

Figure 2-44.

Figure 2-45.

Figure 2-46.

Figure 2-47.

Figure 2-48.

Figure 2-49.

Figure 2-50.

Figure 2-51.

Figure 2-52.

Figure 2-53.

Figure 2-53a.

Figure 2-54.

Figure 2-55.

Figure 2-55a.

Figure 2-56.

Figure 2-57.

Figure 2-58.

Figure 2-59.

Figure 4-1.

Figure 4-2.

Figure 4-3.

Figure 4-4.

Figure 4-5.

Figure 4-6.

Figure 4-7.

Stand-Alone Voice Terminal Connections 2-90

Stand-Alone Remotely Powered Voice Terminal

Connections

2-91

Single-Line Terminal/ADU Connections 2-93

7300H Series Terminal/ADU Connections 2-94

DS1 to D4 Connections for Off-Premises Stations 2-97

Local Powering of an ADU

2-99

Remote Powering of an ADU (Optional) 2-100

MADU to Host Computer or Terminals Connections 2-101

Nonswitched Connection of Peripheral Equipment

Plugged Into System AC Outlet

2-103

Greater Than 50 Feet and/or Not Sharing Same

AC Outlet

2-105

On-Premises Peripheral Equipment With Switched

Connection to CPU/Memory 2-108

Off-Premises Peripheral Equipment With Direct

Connection to CPU/Memory

2-110

ZTN84 STARLAN Interface CP Connection 2-112

Single-Line Analog Terminal/STARLAN

NETWORK Workstation Connections

2-114

7300H Series Terminal/STARLAN NETWORK

Workstation Connections

2-116

Music Source, FCC Registered

2-118

Music Source, Non-FCC Registered

2-119

Music-on-Hold

2-119a

External Alerts

2-120

Paging System Connection to TN763 Circuit Pack 2-123

Loudspeaker Paging with Background

Music

2-124a

Paging System Connection to TN763 Circuit Pack

(278A Adapter Required)

2-126

278A Adapter Plug Positions for Connecting TN763

Circuit Pack to Paging System

2-127

PagePac 20 System Connection to ZTN76 or

ZTN77 Circuit Pack

2-129

Paging System Connection to ZTN76 or ZTN77 2-131

Response to System 25 Trouble Report

4-10

Clearing Power Supply Troubles (Sheet 1 of 4-47

Clearing CO Trunk Troubles

4-49

Clearing 4-Wire Tie Trunk Troubles (Sheet 1 of 4) 4-50

Clearing STARLAN Interface Troubles

4-54

Clearing Tie Trunk Troubles (Sheet 1 of 5) 4-55

Clearing Paging Equipment Troubles 4-60

-x-

November 1995

Page 21

Figure 4-8.

Figure 4-9.

Figure 4-10.

Figure 4-11.

Figure 4-11.a.

Figure 4-12.

Figure 4-13.

Figure C-1.

Figure C-2.

Figure C-3.

Table 2-A.

Table 2-B.

Table 2-C.

Table 2-D.

Table 2-E.

Table 2-F.

Table 4-A.

Table 4-B.

Table 4-C.

Table 4-D.

Table 4-E.

Table 4-F.

Table A-A.

Table A-B.

Table A-A.

Table A-B.

Table C-A.

Table C-B.

Table E-A.

Table E-B.

AC Power Schematic

4-68

System Cabinet Backplane Wiring Side (Sheet 1

of 2)

4-73

TDM Signal Destinations on Cabinet Backplane 4-75

Power Designations on Cabinet Backplane 4-76

853 Adapter

4-79a

Clearing Virtual Facilities Troubles (Sheet 1 of 3) 4-86

Clearing Switched Loop Attendant Console

Troubles (Sheet 1 of 5)

4-94

Typical System 25 Port Circuit Pack

C-4

Tie Trunk (TN760B) Circuit Pack Option Switches C-5

DS1 Network Interface Connections

C-12

Tables

Tools and Test Equipment Required for

Installation

2-2

Circuit Packs, Their Functions, and Protectors 2-24

Displayed SAT Messages During Cold or Warm

Restart

2-37

Circuit Pack LED Status Indications

2-40

Circuit Pack Versus Terminal Type 2-66

Feature Button Abbreviations and Lables 2-88

Displayed SAT Messages During Cold or Warm

Start 4-25

Power Supply Test Points

4-65

Circuit Pack Voltages—Symptoms

4-66

25-Pair Connector to Backplane Designations 4-78

Station/Trunk/Special Port Circuit Pack Options 4-99

Applicable Actions for Circuit Pack Options 4-

100

25-Pair Connector Pin Assignments

A-2

Building Wiring

A-4

25-Pair Connector Pin Assignments

A-2

Building Wiring

A-4

Unit Loads C-2

TN760B Option Switch Settings and

Administration

C-6

Default Dial Codes

E-1

PORT/PD. Administration, Voice Terminals

(Menu=1/2)

E-2

November 1995

-xi-

Page 22

Table E-C.

Table E-D.

Table E-E.

Table E-F.

Table E-G.

. .

Table E-H.

Table E-1.

Table E-J.

Table E-K.

Table E-L.

Table E-M.

Table E-N.

Table E-0.

Table E-P.

Table E-Q.

Table E-R.

Table E-S.

Table E-T.

Table E-U.

Table E-V.

Table E-W.

Table E-X.

Table E-Y.

Table E-Z.

Table E-AA.

Table E-AB.

Table E-AC.

Table E-AD.

Table E-AE.

Table E-AF.

Table E-AG.

Table E-AH.

Voice Terminal Type Codes

Feature Button Translation (Menu=1/2)

Multiline Voice Terminal Button Defaults

Switched Loop Attendant Console Button

Defaults (Type 310)

Switched Loop Attendant Console Button

Defaults (Type 311)

Direct Trunk Attendant Console Button Defaults

(Cold-Start Defaults)

Direct Trunk Attendant Console Defaults

(Administration-lnstalled Defaults)

MET Set Button Defaults

PORT/PDC Administration, Data Terminals

(Menu=1/2)

Data Port Type Codes

Port Administration, Trunks (Menu=1)

Trunk Type Codes

Trunk Class-of-Service (for all trunks except DID)

Port Administration, Auxiliary Equipment

(Menu=1)

Special Feature Port Type Codes

Port Options

Applicable Options

PDC Administration (Menu=2)

High Density Circuit (Menu=3)

System Administration (Menu=4)

Standard Call Type Defaults

Message-Center-Like Call-Type Defaults (effect

of Action 90)

Floating PDC Administration (Menu=5)

Direct Group Calling (DGC) Administration

(Menu= 6)

Toll Calls Allowed (TCA) List Administration

(Menu= 7)

DGC Announcement Administration

Searches: Action Items (Menu=8)

Board Type—Wildcard Representation

Port/Board Type—Specific Representation

Save/Restore and System Restarts (Menu=9)

RS232 Port Administration (Menu=10)

Automatic Route Selection Administration

(Menu=11)

E-13

E-14

E-17

E-18

E-19

E-20

E-21

E-22

E-23

E-25

E-26

E-28

E-29

E-30

E-32

E-33

E-34

E-35

E-35

E-36

E-42

E-43

E-43

E-44

E-44

E-45

E-46

E-50

E-51

E-54

E-55

E-56

-xii-

November 1995

Page 23

INTRODUCTION

INTRODUCTION

This manual provides procedures and information for installing, and testing the

AT&T System 25 Release 3 and associated equipment. The maintenance

information contained in Section 4 pertains to the AT&T System 25 Release 1,

Versions 1 and 2 (RI VI and R1V2), Release 2, Version 1 (R2V1 ), as well as to

AT&T System 25 Release 3, Version 1,2 and 3 (R3V1, R3V2 and R3V3).

Installation and maintenance procedures for the AT&T System 25 Call

Management System and Integrated Solution are provided in a separate set of

documents for each system.

This manual is intended for use by an installation and/or maintenance technician

dispatched to a System 25 site for an installation or in response to an alarm or a

user trouble report. This technician must have completed the Tier 1 training

course (T-335). Each installed System 25 has a customer-designated System

Administrator.

The technician should work closely with this System

Administrator. The System 25 Administration (555-540-500) and Implementation

(555-540-650) Manuals describe the administrator’s functions.

In the S25 documentation, the terms “voice terminal”, “voice stations”, and

“telephone” are used to describe the same piece of hardware. The S25

documentation also uses the terms ‘Personal Dial Code (PD.)”, and ‘extension

number’ interchangeably.

The remainder of this manual is divided into Sections 2 through 6 and six

appendices:

●

Section 2. Installation-Describes the installation of the cabinet(s)

wiring, and other components. Certain preinstallation requirements

must be met; therefore, read “PREINSTALLATION REQUIREMENTS”

before installing any part of System 25.

●

Section 3. System Test—Describes all the tests necessary to verify

that the system is operating correctly.

●

Section 4. Maintenance — Provides information necessary for

monitoring, testing, and maintaining all releases of AT&T System 25.

November 1995

1-1

Page 24

INTRODUCTION

●

●

●

●

●

●

●

●

Section 5 References-Lists and

describes other related

documentation

Section 6 Abbreviations and Acronyms-Lists and describes

abbreviations and acronyms frequently encountered in System 25

documentation

Appendix A. System Wiring Table–Lists pinouts and wiring used

with System 25

Appendix B. Parts Listing—Lists all related parts of System 25

Appendix C. System Additions and Changes-Describes how to

make additions to an existing system

Appendix D. System Upgrade–Describes how to upgrade an R1V1

R1V2 or R2V1 release of System 25 to an R3 release

Appendix E. System Codes and Data Entries–Lists all default codes

and data entries for administering the system

Appendix F. Administration Tables–Lists all error messages that

can occur when the system is being administered

FCC PRECAUTIONS

Electromagnetic fields radiating from the system cabinets may generate noise in

other communications equipment The technician must be sure that all cabinet

panels and covers are securely in place after performing maintenance

Caution:

Electrostatic discharge can destroy or severely damage

integrated circuits or CPs.

The maintenance technician MUST ALWAYS WEAR A WRIST GROUNDING

STRAP when handling CPs The cord must be attached to the grounding block at

the back of the cabinet or to a front-cover retainer screw Damage to integrated

circuits caused by electrostatic discharge may not be immediately apparent

Caution: The wrist grounding strap must not be clipped to any

cabinet location other than the grounding block.

1-2

November 1995

Page 25

INSTALLATION

INSTALLATION

Installation of a System 25 requires the completion of a number of basic

steps, similar to those required to install any customer switching system.

Assuming that the building (station) wiring is already in place, the

recommended sequence of steps for installation of the system is as follows:

1.

Preinstallation Requirements

2. Install System Cabinets

3. Power Up and Initialize System

4.

Install Cross-Connect Equipment (See Note below.)

5. Install Modular Bulk Power Supply (Optional)

6. Connect Cabinets to

7. Connect Cabinets to

8. Install

9. Install

10.

Install

Trunk Access Equipment

Station Interconnect Panel (SIP)

Customer’s Peripheral Equipment

Terminals

Auxiliary Equipment

11.

Test System

Note:

Step 4 can be done before Steps 2 and 3 if the crossconnect equipment is delivered before the cabinets.

2-1

Page 26

INSTALLATION

TOOLS

AND

TEST EQUIPMENT

Table 2-A lists tools and test equipment required for installing a System 25.

Table 2-A.

Tools and Test Equipment Required for Installation

Tasks Tools Required

Recommended Type

Install

Push Drill

Cross-Connect Screwdriver

8-inch Flat Blade

Field

Carpenter’s Level

30-inch

Rule 30-inch

Chalk Line

11 O-type Punch-down Tool

AT-8762 D-Impact Tool

Adapter

BR866 JC (403608235)

Unpack

Tin Snips

Cabinet

Utility Knife

Adjustable Wrench 6- or 8-inch

Install

Rule

30-inch

Cabinets

Adjustable Wrench

6- or 8-inch

or Add Screwdriver

8-inch Flat Blade

Carriers

Allen Wrench 1/8-inch

Add Voice

Terminals Diagonal Pliers

or Install Screwdriver 8-inch Flat Blade

Auxiliary 11 O-type Punch-down Tool

AT-8762 D-impact Tool

Equipment

Add

Screwdriver 8-inch Flat Blade

Circuit Packs (CPs)

Initialize

System Administration TerminalRS-232C

System

Digital Tape Unit (not RS-232C)

—

Test System*

Test Set Dracon TS21

☛

Used in Section 3 of this manual

2-2

Page 27

INSTALLATION

CROSS-CONNECT EQUIPMENT DESCRIPTION

This section provides a brief description of some of

connect/interconnect equipment. More details on the

can be found in the Reference Manual (555-540-200).

the following:

●

Trunk Access Equipment

700A Jacks

Emergency Transfer Unit

● Station Interconnect Panel

— 617A Panel

Adapters

Fanning Strip

● Cables

— Splitter Cables

— Octopus Cables

— Cable Labels.

the System 25 cross-

System 25 equipment

This section describes

2-3

Page 28

INSTALLATION

Trunk Access Equipment

The trunk access equipment (TAE) consists of 700A-I 10-61-25 or 700A-66B1 -25 (157BF) cut-down jacks, or equivalent, and up to four 10B Emergency

Transfer Units (ETUs). The 10B ETU is shown in Figure 2-1.

700A- 110-M-25 or 700A-66-B1-25 (157BF) Cut-Down Jack

Trunk circuits that appear on the network interfaces are grouped by trunk

type (Direct Inward Dialing [DID], Central Office [CO], or Tie) and punched

down on the 700A jack. One 700A jack is required for each RJ21 X or RJ2GX

network interface. The 700A-1 10-B1-25 jack has a 110-type cut-down field,

and the 700A-66-B1-25 (157BF) has a 66-type cut-down field. It is important

to note that most secondary wiring protectors (sneak current fuses) are

compatible only with the 66-type jack.

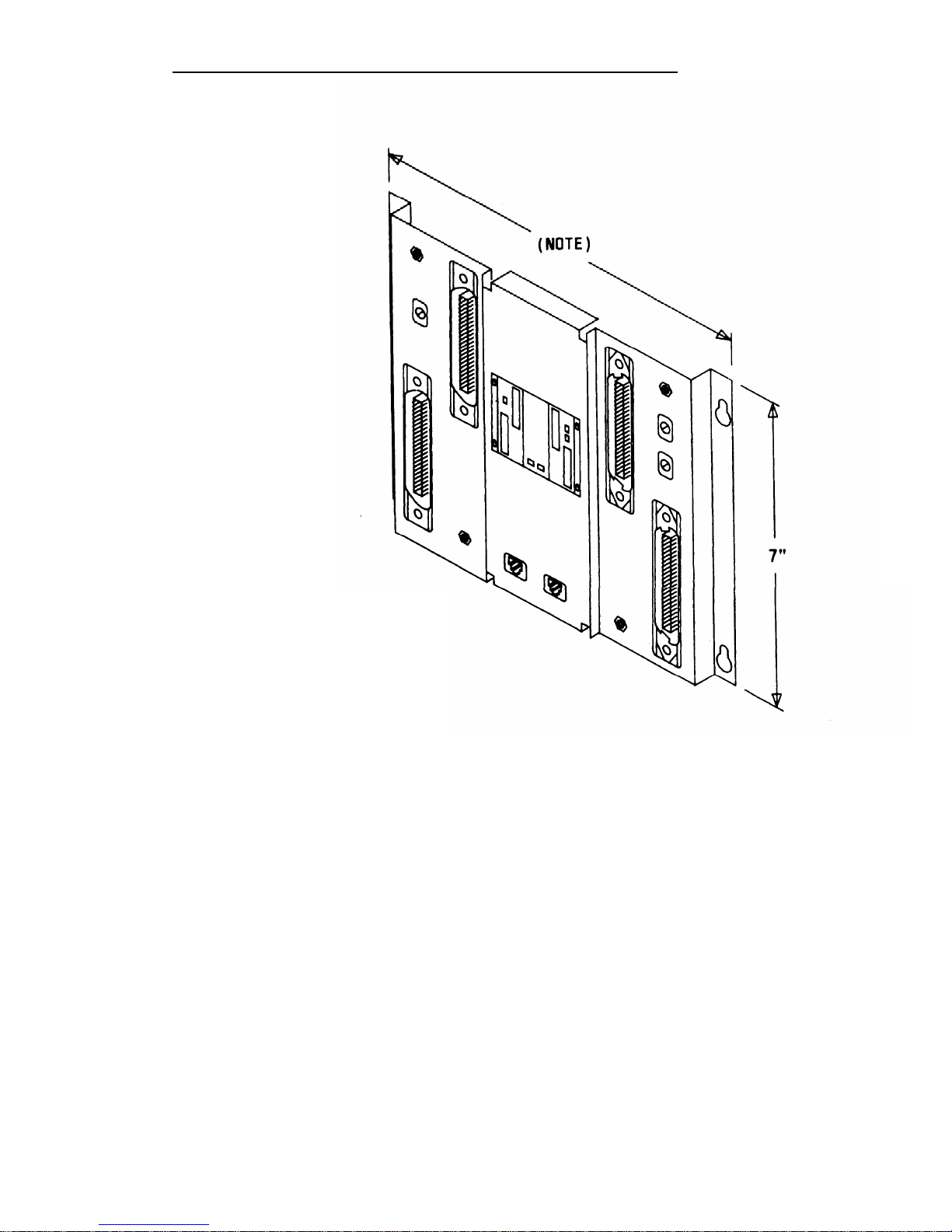

10B Emergency Transfer Unit (ETU)

During a power failure or system outage, each 10B ETU provides contact

closures for bypassing the switch and connecting up to five predesignated

FCC registered single-line voice terminals to telephone company trunks.

Connectorized cables (25-pair) connect the ETU to the 700A jacks, the

system cabinets, and the Station Interconnect Panel. A modular plug-ended

cord (part of octopus cable) connects control power (–48 V dc) from the

system cabinet.

Screw terminals that connect to relay contacts which may be used for an

external alerting device are also provided. The relay contacts close when a

failure occurs. (Any alerting device and associated power unit with a dc

current requirement less than or equal to 0.5 ampere may be used.) The ETU

also controls a DID make-busy contact that connects to the last pair on the

700A jack. For a more detailed drawing of the 10B ETU, see Install

Emergency Transfer Units (ETUs) in this part.

2-4

Page 29

INSTALLATION

NOTE: 9“ WIDE, MOUNTING

CENTERS ARE 8-1/2”

APART, FLANGES

OVERLAPPED

Figure 2-1.

10B ETU

2-5

Page 30

INSTALLATION

Station Interconnect Panel (SIP)

The SIP is the station cross-connect field and consists of the following

equipment:

● 617A Panels

● Adapters

● 50A Fanning Strips.

617A Panel

The 617A Panel is a metal plate with keyslot holes on each side for mounting

on a backboard. (See Figure 2-2.) Each 617A Panel can hold eight 2210A2

or 858A Adapters, each of which can accommodate six connections to the

port circuits in the cabinets.

As many as five 617A Panels may be required

for a maximum size system.

The adapters snap into prepunched holes on

the 617A Panels. (Reattached spacer buttons keep adapters from touching

the metal panels.)

The cable rings located at the top of the 617A Panel route the building wiring

cables to the adapters.

Purse lock clips hold the building wiring cables in

place. The white posts at the bottom of the 617A Panel guide the wiring from

the 50A Fanning Strip to each column of adapters.

Preprinted boxes and numbers on the panel identify modular jacks for

record-keeping purposes.

Letters are marked in the boxes at the top of each

column by the installer.

The letter (A through J) and the corresponding

preprinted row number (1 through 24) identify the port jacks. For example,

Al identifies the modular jack located in column A row 1.

2-6

Page 31

INSTALLATION

MOUNTING CENTERS

WHEN FLANGES ARE

OVERLAPPED

Figure 2-2. 617A Panel

2-7

Page 32

INSTALLATION

Adapters

The adapters shown in Figure 2-3 are used at the SIP.

Z210A2 or 858A Adapters

These adapters connect the building wiring (station runs) to the station port

circuit packs (CPs) located in the system cabinets (through octopus cables).

As many as 40 of these adapters may be required for a maximum size

system, Any combination of the adapters can be used, depending upon the

type of building wiring.

The port side of the adapters consists of six 8-pin

modular jacks. The station side of the adapters is equipped as follows:

● Z210A2—Six 8-pin modular

modular plug-ended D-inside

must be installed at the top

connections for the System

Tape Unit (DTU), etc.

jacks used for terminating 4-pair

wire (DIW). One of these adapters

of column A on the SIP to provide

administration Terminal (SAT), Digital

● 858A—Six 11 O-type 8-pin wiring blocks used for terminating 4-pair

DIW.

WP90851, L1 Y-Adapter

This adapter separates voice and data pairs that are run over

cable for connection through octopus cables to the System

the same 4-pair

25 port circuits.

This adapter plugs into the port side of either of the two adapters described

above. It has a DATA and a VOICE modular jack. The DATA jack connects

to a TN726 Data Line port circuit pack. The VOICE jack connects to a port

circuit on a Tip Ring Line, Analog Line, or ATL Line circuit pack.

2-8

Page 33

INSTALLATION

Z21OA1

ADAPTER

Y-ADAPTER

WP90851,L1

858A

ADAPTER

Figure 2-3.

SIP Adapters

2-9

Page 34

INSTALLATION

Fanning Strip

The 50A Fanning Strip (Figure 2-4) is a metal panel with positions to hold 16

octopus (switch) cables. The bundled portion of the octopus cable is

anchored at the fanning strip. The eight octopus cable cords hang free. One

fanning strip is required for 1-cabinet systems. Two fanning strips are

required for 2- or 3-cabinet systems.

NOTE : 9“ WIDE, 8-1/2”

WHEN FLANGES ARE

OVERLAPPED

MOUNTING CENTERS

Figure 2-4.

50A Fanning Strip

2-10

Page 35

INSTALLATION

Cables

Splitter Cables

The splitter cables (Figure 2-5) connect trunk circuits from the 700A jacks to the

system cabinets or 10B ETU (3:1 only).

3:1 Splitter Cable (WP90929, L1)

This cable connects the twenty-four 1-pair trunk circuits on a 700A jack to three

8-port trunk circuit packs (loop start, ground start, or DID). The connection may

be either director through a

are male.

2:1 Splitter Cable (WP90929, L3)

10B ETU. Al 25-pair ribbon connectors on the cable

This cable connects eight 3-pair tie trunk circuits

trunk circuit packs. All 25-pair connectors on the

on a 700A jack to two 4-port tie

cable are male.

.

3:1 SPLITTER CABLE

WP90929,L1

2:1 SPLITTER CABLE

WP90929,L3

Figure 2-5.

Splitter Cables

Page 36

INSTALLATION

Octopus Cables

Octopus cables (Figure 2-6) connect the station port and CPU/Memory circuit

packs to the SIP adapters. Each cable consists of a 25-pair male connector that

connects to the switch cabinet and eight modular plugs that connect to the SIP

adapters. These cables are provided with all system cabinets.

Figure 2-6.

Octopus Cable

8536 Adapter Cable

The 853B Adapter Cable (104305834) connects two octopus cables to a 16-port

TN746B Analog Line circuit pack. As shown on Figure 2-6a, each cable consists

of one 25-pair male connector (Connector O) and two 25-pair female connectors

(Connectors 1 and 2). The cable length is eight feet.

CONNECTOR 1

CONNECTOR O

CONNECTOR 2

Figure 2-6a. 853B Adapter Cable

DS1

Connector Cables

The following Connector cables are available to connect the DS1 Interface circuit

packs to DS1 digital facilities:

●

H600 307, G2—50-foot long shielded cable equipped with a 50-pin male

connector on one end and unterminated at the other end. The cable

may be cut to length. Shipped loose are a KS23007, L1 15-pin male

2-12

Page 37

INSTALLATION

connector and a KS23146,L3 50-pin male connector.

To connect a DS1 interface circuit pack to a 551-type

Unit (CSU), field terminate the 15-pin plug.

To connect DS1 tie trunks on co-located System 25s,

50-pin male connector (see Figure 2-1 9).

Customer Service

field terminate the

● C6E connector cable (comcode 104307 434)—1 00-foot long shielded

cable equipped with a 50-pin male connector on one end and a 50-pin

female connector on the other end. This cable is used as an

“extension” cable between the DS1 Interface circuit pack and the other

connector cables.

Cable Labels

A set of preprinted labels for identifying the system cabinet cables and ETU

cables are provided (Figure 2-7). The system cable labels are prenumbered to

identify the cabinet (1, 2, 3) and circuit pack slot (1-12, - see NOTE) and are also

color-coded as follows:

Note: Because of the combined CP/Memory board in R2V1 and R3,

ten slots are available in Cabinet 1.

I

Cabinet No.

Color

I

1

Blue

2

Orange

3

Green

The call processor octopus cable labels and ETU cable labels are white. The

use of these labels is discussed in this manual.

2-13

Page 38

INSTALLATION

AT&T

CAR 1

CABLE

LABELS

CAB1 SLOT1

CAB1 SLOT1

CAB1 SLOT2

CAB1 SLOT2

CABl SLOT3

CAB1 SLOT3

CAB1 SLOT4

CAB1 SLOT4

CAB1 SLOT5

CAB1 SLOT5

CAB1 SLOT6

CAB1 SLOT6

CAB1 SLOT7

CAB1 SLOT7

CAB1 SLOT8

CAB1

SLOT8

CABl SLOT9

CAB1

SLOT9

CAB1 SLOT10 CAB1 SLOT10

CAB1 SLOT11 CAB1 SLOT11

CAB1 SLOT12

CAB1 SLOT12

CAB1 SLOT

CAB1 SLOT

CAB1 SLOT

CAB1

SLOT

CAB1 SLOT

CAB1 SLOT

CAB 1

BLUE

CAB 2

- ORANGE

CAB 3 - GREEN

CALL

AT&T

PROCESSOR

OCTOPUS

CABLE

LABELS

SYSTEM

SYSTEM

ADMIN ADMIN

TERM TERM

SMDR SMDR

DIGITAL DIGITAL

TAPE TAPE

UNIT UNIT

REMOTE

REMOTE

MAINT MAINT

ETU1

ETU1

SWITCH(CPU)

SWITCH(CPU)

ETU2

ETU2

SWITCH(CPU)

SWITCH(CPU)

n

WHITE

AT&T

ETU

CABLE LABELS

ETU 1 SIP

ETU 1 SIP

ETU 2 SIP ETU 2 SIP

ETU 3 SIP ETU 3 SIP

ETU 4 SIP

ETU 4 SIP

ETU SIP

ETU SIP

SWITCH(TRUNK) SWITCH(TRUNK)

SWITCH(TRUNK) SWITCH(TRUNK)

SWITCH(TRUNK) SWITCH(TRUNK)

SWITCH(TRUNK) SWITCH(TRUNK)

SWITCH(LINE) SWITCH(LINE)

SWITCH(LINE) SWITCH(LINE)

SWITCH(LINE)

SWITCH(LINE)

SWITCH(LINE)

SWITCH(LINE)

SWITCH SWITCH

SWITCH

SWITCH

ETU 1 CO

ETU 1 CO

ETU 2 CO

ETU 2 CO

ETU 3 CO

ETU 3 CO

ETU 4 CO

ETU 4 CO

ETU CO ETU CO

ETU

CO

ETU CO

Figure 2-7.

Cable Labels

2-14

Page 39

INSTALLATION

Symbols Used in Figures

Modular jacks are shown by the triangle symbol. The 25-pair connectors are

indicated by shaded blocks.

Generally, only one leg of an octopus cable is

shown. Unterminated wiring requiring cut down or other termination does not

show symbolic designations.

The 103A Connecting Block is a typical

modular wall jack that provides cut-down connections for building (station)

wiring and a modular jack for connection to terminal equipment.

2-15

Page 40

INSTALLATION

PREINSTALLATION REQUIREMENTS

The AT&T System 25 Reference Manual (555-540-200) provides a complete

listing of System 25 equipment location requirements. Before installation

begins, check the items described in this section.

Caution: System 25 cross connect hardware must be located in a

restricted access area only.

Table and Backboard

Verify that an equipment table and cross-connect backboard are installed.

(See Figure 2-8 for a sample layout.) The cross-connect backboard is a 48-

inch by 96-inch by 3/4-inch plywood panel, mounted horizontally 30-inches

above the floor and within 5 feet of the location chosen for the cabinets.

If wall space in the equipment room is limited, an alternate layout may be

provided. If more than four 617A Panels are required, this alternate layout

will require more than one 48-inch by 96-inch plywood panel. See Install

Equipment Room Station Cabling for details.

Network Interface

The RJ21X network interface (CO lines) installed by the telephone company

must be located within 25 feet of the system cabinets. In addition to the

RJ21X network interface, an RJ2GX interface is required for tie

lines. For T1

interfaces, RJ48X network interfaces must be provided.

If System 25 is

replacing another system and no additional lines are required, the network

interfaces used with the previous system should already be in place.

The network interfaces should also include a coupled bonding conductor

extended from the building service entrance.

2-16

Page 41

NOTES :

1.

2.

3.

4.

5.

115V AC, 60 Hz, 15 AMP OUTLETS

(HUBBELL 5262 OR EQUIVALENT)

MUST BE LOCATED WITHIN 4 FEET

OF SYSTEM CABINETS.

MULTIPLE CABINET SYSTEMS REQUIRE

TWO QUAD OUTLETS, SINGLE CABINET

SYSTEMS REQUIRE ONE QUAD OUTLET.

ALLOW AT LEAST 24 INCHES OF SPACE

IN FRONT OF CABINETS. TABLE MUST

BE ABLE TO SUPPORT 250 POUNDS.

BACKBOARD IS 3/4 INCHES THICK BY

48 INCHES WIDE BY 96 INCHES LONG

(FOR MAXIMUM SYSTEM).

SYSTEM 25 CABINETS AND BACKBOARD

MUST BE LOCATED IN A RESTRICTED

ACCESS AREA.

RESTRICTED

ACCESS AREA

(NOTE 5)

Figure 2-8.

Typical System 25 Floor Plan

2-17

Page 42

INSTALLATION

AC Power

All cabinets and any locally-connected System 25 peripheral equipment

(System Administration Terminal [SAT], Station Message Detail Recording

[SMDR] device, Digital Tape Unit [DTU]), and Customer Service Unit (CSU)

used for DS1 connections must be plugged into the common ac power outlet.

This outlet must have an associated ground block connected to an approved

building ground, using #6 AWG copper wire. (This ground block is the

system’s single-point ground.)

A 1-cabinet system requires one quad ac outlet. A 2- or 3-cabinet system

requires a second quad outlet and two separately fused 15-ampere circuits.

Additional ac outlets may be needed for auxiliary equipment. All ac outlets

must have the safety ground (green wire) cross-connected to the single-point

ground block on the first quad outlet. (See Figure 2-9.)

Local options may require that surge protectors be used for all peripheral

equipment used with the System 25, including the Customer Service Unit

(CSU).

Grounding

For proper grounding instructions, refer to the AT&T System 25 Electrical

Protection and Exposure Check List (555-500-1 20).

Warning:

Verify that the building ground has been provided by

one of the methods listed below, that ac power uses

approved building ground for its primary ground, and

that all voltage limiting devices are grounded to building

approved ground. Improper ground can result in

equipment failures and service outages from lightning

induced surges on the power lines.

An approved building ground for System 25 may be one of the following,

listed in decreasing order of preference:

1.

Building steel.

2. Acceptable water pipe—

a metal underground water pipe at least 1/2

inch in diameter, in direct contact with the earth for at least 10 feet.

The pipe must be electrically continuous (or made electrically

continuous by bonding around insulated joints, plastic pipe, or plastic

water meters) to the point where the protector ground is connected.

A metallic underground water pipe must be supplemented by the

2-18

Page 43

INSTALLATION

3.

4.

metal frame of the building, a concrete encased ground, or a ground

ring. If these grounds are not available, the water pipe ground can

be supplemented by one of the following types of grounds.

● Metal underground gas piping system—an electrically

continuous metal underground gas piping system that is

uninterrupted with insulating sections or joints and without

an outer nonconductive coating.

● Other local metal underground systems or structures—local

underground structures such as tanks and piping systems.

● Rod and pipe electrodes—

a 5/8-inch (solid rod) or 3/4-inch

(conduit or pipe) electrode driven to a minimum depth of 8

feet.

●

Plate electrode—expose a minimum of 2 square feet of

metallic surface to the exterior soil.

Concrete encased ground

—defined to be an electrode, consisting of

at least 20 feet of one or more steel reinforcing rods at least 1/2 inch

in diameter, or 20 feet of bare copper conductor not smaller than #4

AWG encased in 2 inches of concrete. This electrode must be

located within and near the bottom of a concrete foundation or

footing that is in direct contact with the earth.

Ground ring consisting of at least 20 feet of bare copper conductor

not smaller than

must be in direct

below the earth’s

Lightning Protection

#2 AWG encircling the building. The ground ring

contact with the earth and buried at least 2.5 feet

surface.

System 25’s lightning protection plan involves five distinct but interdependent

items required at every installation:

●

Primary protection in the form of voltage limiters (typically carbon

blocks or gas tubes) on all pairs that leave the building, whether

aerial or buried. These devices bypass surges to approved building

ground and limit potential differences between T/R pairs and building

ground to less than 1500 volts.

2-19

Page 44

INSTALLATION

● A single-point ground (SPG) system in which the green wire ground

(system ground) and the telephone company ground are connected

to approved building ground.

● The coupled bonding conductor must be connected between the

telephone company ground at the building entrance and System 25’s

SPG.

● Surge protection on the ac power to System 25.

For greater than 99 percent of all lightning strikes, the protection outlined

above will do the job.

However, there are a few locations where the

described protection may not be sufficient.

External secondary protection,

located at the trunk access area of the System 25 cross-connect field, can be

employed.

Several commercial units are available.

If 66-type block terminations are

used, a very convenient device is the LP5-230-220 Fused Lightning Protector.

This unit plugs into the 66-block (in place of the shorting bars) and includes

the sneak current fuse. One unit is required per protected pair. A ground

bar is provided with the lightning protection units or can be ordered

separately (Comcode 901-007-120). All lightning protectors located in the

System 25 cross-connect area must be grounded to System 25’s SPG via a

#6AWG copper wire.

In addition, an AC Surge Suppressor (Tll Model 428) may be required. Local

practice should be followed.

The unit plugs directly into one of the quad

outlets and provides a dual outlet to protected equipment. Sufficient units

should be provided to protect all at-powered equipment. Each cabinet in the

system requires a protected outlet, and in addition, a protected outlet is

required for each auxiliary unit, such as the SAT, a tape unit, or a printer.

When a Surge Suppressor is used, all peripheral equipment directly

connected to System 25 must be connected to alternating current via the

Surge Suppressor.

2-20

Page 45

INSTALLATION

Secondary Protection

External secondary protection,

located at the trunk access area of the

System 25 cross-connect field, is required for all trunks and off-premises

lines. Refer to Table 2-B for approved trunk protectors.

FROM AC

LOAD CENTER

(TWO SEPARATELY

FUSED 15 AMP

CIRCUITS)

SINGLE

POINT

GROUND

H

GROUND

I

LOAD

CENTER

II

(GREEN)

(#14 AWG)

I

/

TO CABINET NO. 1

GROUND BAR MOUNTED ‘ GROUND BLOCK (MAX.

ON 4“ BOX (SQUARE D

LENGTH =

20 FT.)

PK9GTA OR APPROVED

EQUIVALENT)

4“ BOX (RACO 230

OR EQUIVALENT)

HUBBELL RECPTS.

( 5262 15 AMP

OR EQUIVALENT)

4“ COVER (RACO 807

OR EQUIVALENT)

APPROVED

BUILDING GROUND

(#6 AWG, COPPER)

Figure 2-9.

AC Power Distribution—Multiple Cabinet System

2-21

Page 46

INSTALLATION

Building Wiring

Building (station) wiring (must be 24 AWG or heavier) from voice and data

terminals to the equipment location should already be in place. System 25

wiring requires that 4-pair circuits be distributed from the equipment location

to each station’s wall jack. The SIP hardware (Figures 2-2 through 2-6),

designed specifically for this purpose, is furnished with each system. Except

in extraordinary circumstances, this cross-connect hardware must be used.

In unusual circumstances where the 617A Panels are not used and some

other cross-connect equipment that does not provide a modular jack interface

to the port circuits is used, separate 4-pair circuits must be run for the voice

and data terminal at the workstation.

All examples and instructions in this

The station wiring terminations in

manual assume

the equipment

that a SIP is used.

area should have been

labeled to indicate the room location and jack number of the other end of the

line. When SIP connections are made, the connection information should be

entered on the Voice and Data Station Records Form (see Install Equipment

Room Station Cabling in this part for details).

2-22

Page 47

INSTALLATION

INSTALL SYSTEM CABINETS

Before beginning the cabinet installation, position the cabinet table within 2

feet of the ac power receptacle. Make sure that the cabinets are easily

accessible from both the front and the back.

Position Cabinet(s)

Caution: A fully-equipped cabinet weighs 80 pounds.

1.

2.

3.

4.

Check

Unscrew and remove the upper rear panel of each

unscrew the lower part with the 12 connectors.

cabinet. Do not

Near the center of the backplane, note an address plug in one of the

positions marked 1, 2, or 3 on the black address strip. (Position 4 is

not used.) This indicates the cabinet number for software purposes.

The position of the plug (1, 2, or 3) should agree with the position of

the cabinet (Cabinet 1 on the bottom, etc.).

Use the CAB 1, CAB 2, and CAB 3 labels from the cable label sheets

(Figure 2-7) to label each cabinet.

Position the cabinet label in the

box adjacent to connector 12 on the lower back panel. (The number

may have already been stamped by the factory.)

Stack the cabinets on top of one another on the stand. If there is

more than one cabinet, stack Cabinet 1 on the bottom arid Cabinet 3

on the top. Cabinet 1 contains the CPU/Memory (ZTN129 or

ZTN130 [R3]), and Service (ZTN85 or ZTN131 [R3]) circuit packs

(Figure 2-1 O). Do not replace the upper back panels yet.

Cabinet Contents

Check to make sure that the cabinets have been delivered with the correct

circuit packs (CPs). Table 2-B lists available CPs, their functions, and their

protectors.

If the system has TN760B Tie Trunk CPs, you may also have to

set the option switches on the CPs. See “Set TN760B Option Switches” in

Appendix C for details.

November 1995

2-23

Page 48

INSTALLATION

Table 2-B. Circuit Packs, Their Functions, and Protectors

Approved Secondary

Circuit Pack

Function

Wiring Protector

N/A

ZTN78

Supports single-line voice terminals.

(Must not be used on out-of-building

circuits, )

SCP-1 or 79A

TN742

Supports off-premises, out-ofbuilding, and bridged single-line

voice terminals.

lTW/LlNX343* I ROB

ZTN79

Supports the 7300H Series voice

terminals used with a MERLIN®

system. (Requires local (set) power

for distances beyond 1000 feet.)

ITWILINX343* lROB TN735

Supports MET sets.

N/A

TN726

Supports data terminals and

computers.

N/A

TN758

Contains pooled modems.

SCP-1 , SCP-2, SCP-3, ZTN76

Supports ground start trunks.

or LP5-230-220

SCP-1 , SCP-2, SCP-3,

ZTN77

Supports bop start trunks.

or LP5-230-220

SCP-1 or 79A

TN753

Supports direct inward dialing trunks.

(DID)

SCP 1 or 79A

TN760B

Supports tie trunks.

N/A

TN763

Supports auxiliary equipment.

N/A

ZTN130 (R3)

Call processing/memory.

N/A TN748B Tone Detector.

SCP-1 or 79A

TN767

Provides DS1 Interface.

N/A

ZTN131 (R3)

Provides system clocks, tone

generators, detectors, and DS1

synchronization.

SCP-1 or 79A

TN747E3

Supports ground start or loop start

trunks.

lTW/LlNX343* I ROB

TN762B

Supports hybrid voice terminals.

Must be vintage 4 or later.

*Note: lROB unit ITW341 has been replaced. Use model lTW/LlNX343 only.

2-24

November 1995

Page 49

INSTALLATION

Two fans are located on the left-hand front side of each cabinet. The

cabinet’s power supply is located behind the fans; to the right of the power

supply are up to 12 CPs in individual slots.

Each CP is identified by a label

on the front. See Figure 2-10.

1.

Remove the front cover of each cabinet.

2. Note any obviously bent or otherwise damaged circuit packs.

3. Check the CPs against the customer order. In case of irregularities

or damage, follow established notification procedures.

Danger: The System 25 cabinet contents are not user

serviceable. Some voltages inside the cabinets

are hazardous.

This equipment is to be

serviced only by qualified technicians.

The CPU/Memory (ZTN129 or ZTN130 [R3]) circuit pack has two shorting

plugs that are used for factory tests (see Figure 2-1 1). They should have

been removed at the factory.

If these shorting plugs have been accidentally

left in by the factory, the system may cold start when it should warm start.

Check the CPU/Memory CP; if the plugs are present, remove them. The

shorting plugs are located on the component side of the circuit pack.

2-25

Page 50

INSTALLATION

Figure 2-10.

Three-Cabinet System, Front View With Covers Removed

2-26

Page 51

INSTALLATION

Figure 2-11.

Position of Shorting Plugs on CPU/Memory Circuit Pack

2-27

Page 52

INSTALLATION

Required Circuit Pack Positions

The required CP positions for Cabinet 1 are:

SLOT CP

1

ZTN129 or ZTN130 (R3)

I

2

I

ZTN85 or ZTN131 (R3)

Also, all DID Trunk circuit packs should be installed in Cabinet 1.

There are no other restrictions on CP position in a single-cabinet or

multicabinet system; however, you should refer to the power supply unit load

requirements for the maximum unit loads for each CP type within a single

cabinet.

Caution:

Be careful not to exceed unit load restrictions on each

cabinet.

Label Connectors on Back Cover

Each cabinet has twelve 25-pair receptacles across the bottom of the rear

panel.

These connectors link the CPs inside the cabinet to the Station

Interconnect Panel (SIP) and Trunk Access Equipment (TAE). The connectors

are numbered from 1 to 12 and correspond to the CP slots.

Using a felt-tipped pen, write the CP code for each slot in the box above the

connector number on the lower rear cover.

2-28

Page 53

INSTALLATION

Install 4A Retainer Clips

The 4A retainer clips must be installed on each of the 12 receptacles on the

lower rear panel of the cabinets.

To install a clip, position it and insert the

legs in the cabinet as shown in Figure 2-12.

Figure 2-12.

4A Retainer Clip Installation

2-29

Page 54

INSTALLATION

Connect Cabinets

The Time Division Multiplex (TDM) bus extender cable and the intercabinet

#6 AWG ground wire must be connected between cabinets. The TDM bus

terminates on each side of the cabinet, and the intercabinet #6 AWG ground

wire connects to the ground block at the rear of each cabinet.

Note:

Make certain that the address plug is installed in the rear pin

field of each cabinet (see Figure 2-13).

TDM Bus Connections

One end of the TDM bus is terminated by resistors mounted on the ZTN129

or ZTN130 (R3) CP. This CP is always in slot 1 of Cabinet 1. The other end of

the TDM bus is terminated by a Bus Terminator that plugs into the upper pin

field of the topmost carrier (which may, of course, be the only cabinet). These

connections are shown in Figure 2-13.

Whenever a cabinet is added, the Bus Terminator must be moved to the end

of the bus on the new top cabinet.

This can be either slot 1 or slot 12,

depending on the number of cabinets and how the TDM bus extender cable

is run.

When removing a Bus Terminator and TDM bus extender cable,

to bend the backplane pins.

1.

Verify that the Bus Terminator is in the proper position:

● Slot 12 of Cabinet 1 for 1-cabinet systems

● Slot 1 of Cabinet 2 for 2-cabinet systems

● Slot 12 of Cabinet 3 for 3-cabinet systems.

take care not

2. See Note. For 2- and 3-cabinet systems, install extender cable

between slot 12 of Cabinet 1 and slot 12 of Cabinet 2. For 3-cabinet

systems, install another extender cable between slot 1 of Cabinet 2

and slot 1 of Cabinet 3.

Note:

When properly installed, the light blue stripe on the

extender cable is at the bottom of the cable and the

lettering on the cable (SER=1, for example, is right

2-30

Page 55

INSTALLATION

side up).

3.

Install the upper rear panels.

Route the extender cable between

the slots formed by the upper and lower rear panels.

2-31

Page 56

INSTALLATION

TDM

BUS

TERM

CARD

ADDR

PLUG

TDM B

EXTEN

CABLE

ADD

PLU

PLUG

Figure

~CABINET 3

ON/OFF

.SWITCH

AC POWER

# 6 AWG

BUILDING

GROUND

WIRE

CABINET 2

AC POWER

. #6 AWG

2-13.

TDM Bus Terminations (Rear View of 3-Cabinet System)

2-32

Page 57

INSTALLATION

Ground Wire Connections

The cabinets are connected to the single-point ground with #6 AWG copper

wires.

(Building ground requirements are described in Preinstallation

Requirements in this section.)

Warning:

The cabinet power switches must be set to off.

1.

In 2- or 3-cabinet systems, connect a #6 AWG wire between the

ground blocks of Cabinets 1 and 2 and Cabinets 1 and 3.

2. Connect a #6 AWG wire between the ground block of Cabinet 1 and

the single-point ground. (See Figures 2-9 and 2-1 3.)

POWER UP AND INITIALIZE SYSTEM

Separate power cords for each cabinet must be plugged into the designated

quad outlets.

Peripheral equipment (SAT, SMDR [Station Message Detail

Recording], or CAS [Call Accounting System], DTU and CSU [Customer

Service Unit]) collocated with the switch cabinet(s) must also be plugged into

these ac outlets.

Connect Power

1.

2.

3.

4.

Make sure the rear panel is in place on each cabinet.

Connect the receptacle end of a 3-wire power cord to the plug at the

rear of each cabinet.

Connect the power cord’s plug end to the quad ac outlet for each

cabinet.

Recheck the electrical and ground connections.

Danger: Once power is applied, do not put your hands or

any tools into the cabinet.

2-33

Page 58

INSTALLATION

5.

Starting with Cabinet 2 or 3, turn on the power switch on each

cabinet [Cabinet 1 must be last).

IMPORTANT: If power to Cabinet 1 is not turned

cold start initialization may not occur properly.

6.

Check to be sure that the cabinet fans are rotating.

Connect Administration Equipment

on last, the

Connect the SAT and DTU to their respective modular jacks on an 858A

Adapter at the SIP.

If the SIP has not yet been installed, connect an octopus cable to Cabinet 1,

slot 1. Make temporary connections as shown in Figure 2-14 to the SAT and

Note:

The direct octopus cable connections are only temporary.

All permanent

connections to peripheral and station

LEGEND :

ZTN129 -

cl -

355A ADAPTER -

355AF ADAPTER -

NOTE :

CPU/MEMORY CP

OCTOPUS CABLE ( WP90780 )

RS-232 PLUG TO MODULAR JACK

RS-232 RECEPTACLE TO MODULAR JACK

LEG 1 CONNECTS TO SAT; LEG 3 CONNECTS TO DTU.

Figure 2-14.

Temporary SAT and DTU Connections

2-34

Page 59

INSTALLATION

Cold Start the System

To ensure that the system recognizes the current position of the CPs, you

must cold start the system before beginning initialization. A cold start causes

the system to check all slots for valid CP types and assign default

translations to ail ports (except auxiliary trunk ports).

A limited cold start is available. The limited cold start does not assign default

translations to ports.

The limited cold start is useful if the customer’s dial

plan is significantly different from the System 25 default plan. You do not

have to delete the default codes before you enter the true dial plan. See the

Administration Manual (555-540-500) for a listing of default translations

provided in Release 3 systems.

The time required for a cold start depends on the number of CPs in the

system, but is usually several minutes.

A limited cold start takes about 30

seconds.

Follow these steps to manually start the system from the SAT:

1.

2.

3.

4.

5.

6.

Connect the SAT to the CPU/Memory CP administration port, (leg 1

of the octopus cable).

If the SAT has a selectable baud rate, set it to 1200 baud.

Be sure transmission parity is set to none, with the parity bit set to

space (0).

Turn the terminal on and press the carriage return key once or twice.

On most terminals, this key is <RETURN> or <ENTER>.

After communication with the system is established, a prompt is

displayed:

Enter Password ->

Enter SYSTEM25 and press <RETURN>. The main menu will now

be displayed along with the prompt:

Make one selection from menu ->

Enter 9 (for the SAVE/RESTORE selection) and press <RETURN>.

2-35

Page 60

INSTALLATION

7. The system will respond with:

Action=

8. Enter 20 for a cold start. The system will respond with:

Save/Restore: Action=20 Data=

9. Enter D. The system will complete the word Data followed by the =

sign.

10.

Enter 1 for a cold start or 2 for a limited cold start. The system will

respond with:

Save/Restore: Action=20 Data=1 (or

You are about to initiate a cold start

.

c to continue, any other key to abort

11. Enter c to initiate the cold start.

Data=2)

Typing errors can be erased by pressing the backspace key. Each time you

press the backspace key, one character is erased.

2-36

Page 61

INSTALLATION

Cold and warm starts both display the same type of information on the SAT. This

consists of a listing of the version of the firmware loaded in the CPU/Memory

CP, followed by a configuration listing of all CPs recognized by the system. The

CPU/Memory CP is not in the configuration listing; however, it is located in slot 1

of Cabinet 1.

Table 2-C provides a listing of SAT messages

cool or warm start. The displayed message is

and port translations.

that may be displayed during a

a result of CP occupancy, type,

Table 2-C. Displayed SAT Messages During Cold or Warm Restart

Circuit Pack (CP)

Port Translated

Displayed

in Slot

Message

No Yes

Missing

†

Yes

No

CP Type Listed #

Yes

Yes

CP Type Listed

Yes

Yes (doesn’t match

CP Type Listed*

physical CP)

Yes (Unsupported

Yes or No

Illegal

CP Type)

† Warm restart only.

# Mark indicating that the CP is unused.

* Mark indicating that the CP is mismatched.

November 1995

2-37

Page 62

INSTALLATION

The SAT message for a cold or warm start appears after the system has

performed all self-tests and reading of its configuration. Typical cold start SAT

message is as follows. The example is for a 2-cabinet system.

Typical Release 3 Version 3 Cold Start Message

RESTART

TS ROM pair

1:version 3.5 *

FC ROM pair

1:version 3.13

●

FC ROM pair

2:version 3.13’