AT&T MERLIN LEGEND Communications System Release 2.0 Maintenance And Troubleshooting Manual

Page 1

AT&T 555-620-143

Issue 1

October 1992

AT&T

TM

MERLIN LEGEND

Communications System

Release 2.0

Maintenance and Troubleshooting

Page 2

Copyright © 1992 AT&T

All Rights Reserved

Printed in U.S.A.

AT&T 555-620-143

Issue 1

October 1992

Notice

Every effort was made to ensure that the information in this book was complete and

accurate at the time of printing. However, information is subject to change.

Federal Communications Commission (FCC)

Electromagnetic Interference Information

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his own expense.

Canadian Department of Communications (DOC)

Interference Information

This digital apparatus does not exceed the Class A limits for radio noise emissions set

out in the radio interference regulations of the Canadian Department of Communications.

Le Présent Appareil Numérique n’émet pas de bruits radioélectriques dépassant Ies

Iimites applicable aux appareils numériques de la class A prescribes clans Ie Réglement

sur Ie brouillage radioélectrique édicté par Ie ministére des Communications du Canada.

Trademarks

Magic On Hold and Megacom are registered trademarks, and MERLIN LEGEND,

MLX-10, MLX-10D, MLX-20L, and MLX-28D are trademarks of AT&T in the U.S. and other

countries.

Phillips is a registered trademark of the Phillips Screw Company.

UNIX is a registered trademark of UNIX System Laboratories, Inc.

Support Telephone Number

AT&T provides a toll-free customer Helpline (1-800-628-2888) 24 hours a day

(U.S.A. only). Call the Helpline, or your authorized dealer, if you need assistance when

installing, programming, or using the system.

Page 3

Contents

1

2

About This Book

■

Intended Audience

■

Conventions

■

Product Safety Labels

■

Related Documents

■

How to Comment on This Document

Introduction to System Maintenance

■ Equipment

■ Maintenance Strategy

■ Unit Loads

Error Logs, the Access Log, and System

1

1

2

3

3

5

1-1

1-1

1-15

1-25

3

Inventory

■

Error Logs

■

Access Log for Maintenance and System Programming

■

System Inventory

Telephone Problems

■

Telephone Troubleshooting

■

Fixing Telephone Problems

■

MLX Telephone Tests

2-1

2-1

2-21

2-22

3-1

3-2

3-3

3-9

Contents i

Page 4

Contents

4

5

A

Control Unit Problems

Power Supply Problems

■

Processor Problems

■

■

Module Problems

■

100D Module Problems

■

Carrier Problems

■

Checking System Status and Slot Status

Central Office Problems

■ Trunk Errors

■ Checking Ports

System Numbering Forms

4-1

4-2

4-13

4-22

4-51

4-62

4-64

5-1

5-1

5-7

A-1

B

ii

Contents

■

Form 2a, System Numbering—Station Jacks

■

Form 2b, System Numbering—Digital Adjuncts

■

Form 2c, System Numbering—Trunk Jacks

■

Form 2d, System Numbering—Special Renumbers

Unit Load Calculation Worksheet

■ Unit Load Worksheet

A-2

A-4

A-5

A-6

B-1

B-2

Page 5

Contents

GL Glossary

I

Index

GL-1

l-1

Contents iii

Page 6

Contents

iv

Contents

Page 7

Figures

4

1

Introduction to System Maintenance

Figure 1-1.

Figure 1-2.

Figure 1-3.

Figure 1-4.

Figure 1-5. Remote Modem Setup

Figure 1-6.

Removing the Control Unit Housing

Installing the Control Unit Housing

Setting up the MLX-20L Telephone

Setting up the PC

Maintenance Strategy

Control Unit Problems

Figure 4-1.

Figure 4-2.

Figure 4-3.

Figure 4-4.

Figure 4-5.

Figure 4-6.

Power Supply Interlocking Post

Replacing a Ring Generator

Replacing an Auxiliary Power Unit

Module Test Process

551 T1 CSU Connection

ESF T1 CSU, DTE Loopback Switch (on Front

Panel)

1-4

1-6

1-8

1-10

1-11

1-20

4-4

4-6

4-10

4-23

4-53

4-54

A

System Numbering Forms

Figure A-1.

Figure A-2.

Figure A-3.

Figure A-4.

Form 2a, System Numbering—Station Jacks

Form 2b, System Numbering-Digital Adjuncts

Form 2c, System Numbering—Trunk Jacks

Form 2d, System Numbering—Special

Renumbers

A-2

A-4

A-5

A-6

Contents v

Page 8

vi

Contents

Page 9

Tables

1

2

3

4

Introduction to System Maintenance

Table 1-1.

Transient/Permanent Error Thresholds

Error Logs, the Access Log, and System

Inventory

Table 2-1.

Error Codes

Telephone Problems

Table 3-1.

Table 3-2.

Control

Table 4-1.

Table 4-2.

Table 4-3.

Table 4-4.

Troubleshooting Telephone Problems

MLX Telephone Display Buttons

Unit Problems

Internal Loopback Test Errors

Board Controller Test Errors

B-Channel Loopback Errors

CSU Loopback Test Errors

1-22

3-2

3-11

4-38

4-43

4-47

4-56

5

Central Office Problems

Table 5-1.

Troubleshooting Trunk Symptoms

5-2

Contents

vii

Page 10

viii

Contents

Page 11

CUSTOMER WARNING

This manual is designed for use

only.

hands-on instructor-led course covering installation and

maintenance for this product. Installation or maintenance of this

product by anyone other than a qualified service technician may

void the warranty.

inside this product.

Technician qualification includes completion of an AT&T

Hazardous electrical voltages are present

The exclamation point in an equilateral triangle is

intended to alert the user to the presence of

important operating and maintenance (servicing)

instructions in the literature accompanying the

product.

by qualified service technicians

IMPORTANT SAFETY INSTRUCTIONS

When installing telephone equipment, always follow basic safety precautions

to reduce the risk of fire, electrical shock, and injury to persons, including:

Read and understand all instructions.

Follow all warnings and instructions marked on or packed with the

product.

Never install telephone wiring during a lightning storm.

Never install a telephone jack in a wet location unless the jack is

specifically designed for wet locations.

Never touch uninsulated telephone wires or terminals unless the

telephone wiring has been disconnected at the network interface.

Use caution when installing or modifying telephone lines.

ix

Page 12

Use only AT&T-manufactured MERLIN LEGEND™ Communications

System circuit modules, carrier assemblies, and power units in the

MERLIN LEGEND Communications System (51 1A) control unit.

Use only AT&T-recommended/approved MERLIN LEGEND

Communications System accessories.

If equipment connected to the analog station modules (008, 408,

408 GS/LS) or to the MLX telephone modules (008 MLX, 408 GS/LSMLX) is to be used for in-range out-of-building (IROB) applications,

IROB protectors are required.

Do not install this product near water, for example, in a wet basement

location.

Do not overload wall outlets, as this can result in the risk of fire or

electrical shock.

The MERLIN LEGEND Communications System is equipped with a

three-wire grounding-type plug with a third (grounding) pin. This plug

will fit only into a grounding-type power outlet. This is a safety feature.

If you are unable to insert the plug into the outlet, contact an electrician

to replace the obsolete outlet. Do not defeat the safety purpose of the

grounding plug.

The MERLIN LEGEND Communications System requires a

supplementary ground.

Do not attach the power supply cord to building surfaces. Do not allow

anything to rest on the power cord. Do not locate this product where

the cord will be abused by persons walking on it.

Slots and openings in the module housings are provided for ventilation.

To protect this equipment from overheating, do not block these

openings.

Never push objects of any kind into this product through module

openings or expansion slots, as they may touch dangerous voltage

points or short out parts, which could result in a risk of fire or electrical

shock. Never spill liquid of any kind on this product.

Unplug the product from the wall outlet before cleaning. Use a damp

cloth for cleaning. Do not use cleaners or aerosol cleaners.

x

Page 13

Customer Support Information

Support Telephone Number

In the U.S.A. only,

24 hours a day. Call the Helpline, or your authorized dealer, if you need assistance

when installing, programming, or using your system.

Outside the U. S.A., if you need assistance when installing, programming, or using

your system, contact your authorized AT&T dealer.

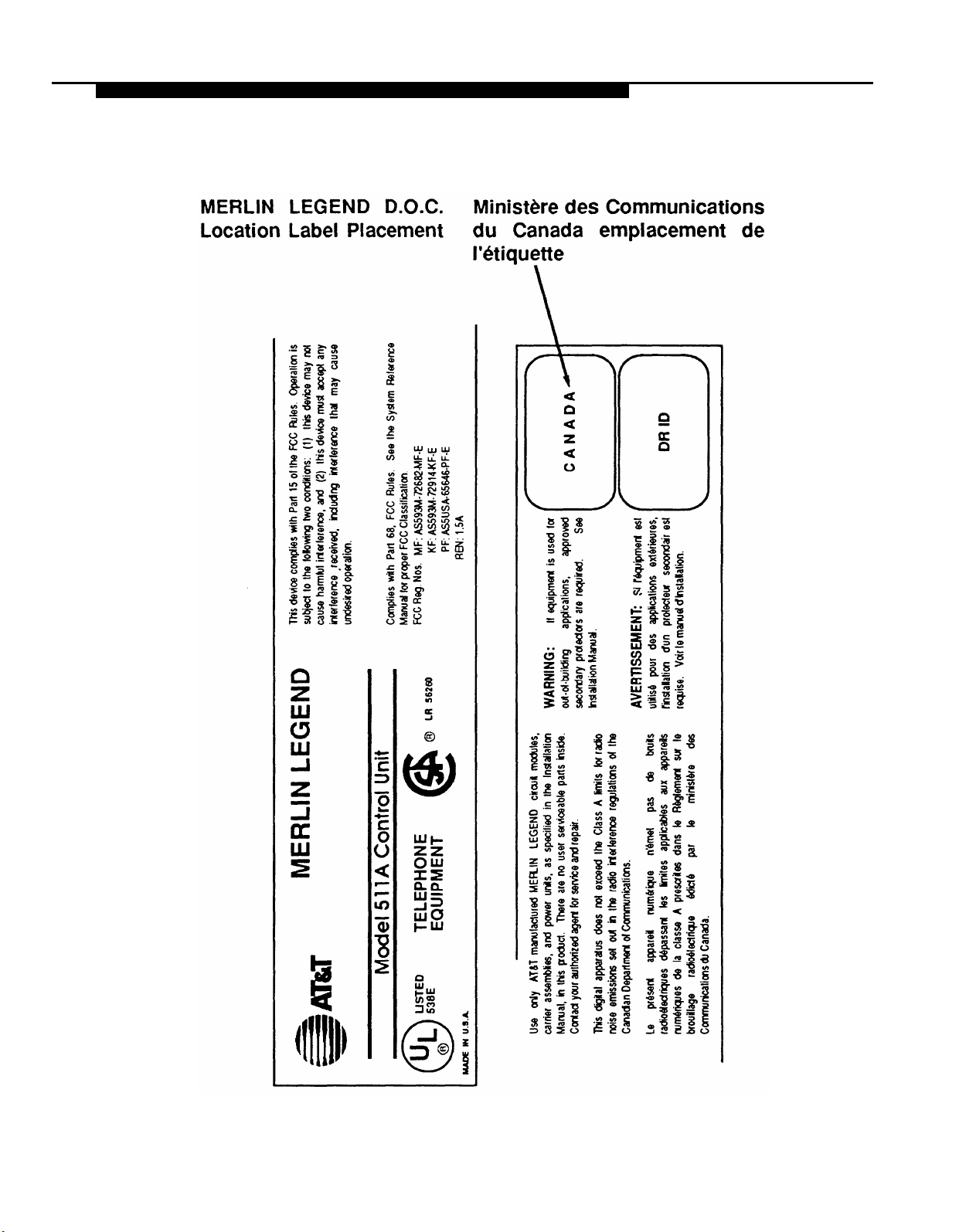

Federal Communications Commission (FCC)

Electromagnetic Interference Information

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference,

in which case the user will be required to correct the interference at his own expense.

Canadian Department of Communications (DOC)

Interference Information

This digital apparatus does not exceed the Class A limits for radio noise emissions set

out in the radio interference regulations of the Canadian Department of

Communications.

AT&T provides a toll-free customer Helpline ( 1 -800-628-2888)

Le Présent Appareil Numérique n’émet pas de bruits radioelectriques depassant Ies

Iimites applicable aux appareils numériques de la class A prescribes clans Ie

reglement sur Ie brouillage radioelectrique edicté par Ie ministère des Communications

du Canada.

Customer Support Information

xi

Page 14

Customer Support Information

FCC Notification and Repair Information

This equipment is registered with the FCC in accordance with Part 68 of its rules. In

compliance with those rules, you are advised of the following:

Means of Connection. Connection of this equipment to the telephone network

shall be through a standard network interface jack: USOC RJ11C, RJ14C,

RJ21X. Connection to E&M tie trunks requires a USOC RJ2GX. Connection to

off-premises stations requires a USOC RJ11C or RJ14C. Connection to 1.544Mbps digital facilities must be through a USOC RJ48C or RJ48X. Connection

to DID requires a USOC RJ11C, RJ14C, or RJ21X. These USOCs must be

ordered from your telephone company.

This equipment may not be used with party lines or coin telephone lines.

Notification to the Telephone Companies. Before connecting this

equipment, you or your equipment supplier must notify your local telephone

company’s business office of the following:

The telephone number(s) you will be using with this equipment.

The appropriate registration number and ringer equivalence number

(REN), which can be found on the back or bottom of the control unit,

as follows:

If this equipment is to be used as Key System, report the number

AS593M-72914-KF-E.

If the system provides both manual and automatic selection of

incoming/outgoing access to the network, report the number

AS593M-72682-MF-E.

If there are no directly terminated trunks, or if the only directly

terminated facilities are personal lines, report the number

AS5USA-65646-PF-E.

The REN for all three systems is 1.5A.

For tie line connection, the facility interface code (FIC) is TL31M and

the service order code (SOC) is 9.0F.

For connection to off-premises stations, the FIC is OL13C and the

SOC is 9.0F.

For equipment to be connected to 1.544-Mbps digital service, the FIC

is 04DU9-B for D4 framing format or 04DU9-C for extended framing

format, and the SOC is 6.0P.

For equipment to be connected to DID facilities, the FIC is 02RV2-T

and the SOC is 9.0F.

The quantities and USOC numbers of the jacks required.

For each jack, the sequence in which lines are to be connected: the

line types, the FIC, and the REN by position when applicable.

You must also notify your local telephone company if and when this equipment

is permanently disconnected from the line(s).

The REN is used to determine the number of devices that may be connected to

the telephone line. Excessive RENs on the line may result in the devices not

xii

Customer Support Information

Page 15

Customer Support Information

ringing in response to an incoming call. In most, but not all, areas the sum of

the RENs should not exceed five (5.0). To be certain of the number of devices

that may be connected to the line, as determined by the total RENs, contact the

telephone company to determine the maximum REN for the calling area.

Installation and Operational Procedures

The manuals for your system contain information about installation and operational

procedures.

Repair Instructions. If you experience trouble because your equipment is

malfunctioning, the FCC requires that the equipment not be used and that it be

disconnected from the network until the problem has been corrected. Repairs

to this equipment can be made only by the manufacturers, their authorized

agents, or others who may be authorized by the FCC. In the event repairs are

needed on this equipment, contact your authorized AT&T dealer or, in the

U.S.A. only,

1-800-628-2888.

Rights of the Local Telephone Company. If this equipment causes harm to

the telephone network, the local telephone company may discontinue your

service temporarily. If possible, they will notify you in advance. But if advance

notice is not practical, you will be notified as soon as possible. You will also be

informed of your right to file a complaint with the FCC.

Your local telephone company may make changes in its facilities, equipment,

operations, or procedures that affect the proper functioning of this equipment.

If they do, you will be notified in advance to give you an opportunity to maintain

uninterrupted telephone service.

Hearing Aid Compatibility. The custom telephone sets for this system are

compatible with inductively coupled hearing aids as prescribed by the FCC.

Automatic Dialers.

MAKING TEST CALLS TO EMERGENCY NUMBERS:

Direct Inward Dialing (DID).

This equipment returns answer supervision signals to the Public

a.

Switched Telephone Network when:

(1)

(2)

(3)

(4)

contact the National Service Assistance Center (NSAC) at

WHEN PROGRAMMING EMERGENCY NUMBERS AND/OR

Remain on the line and briefly explain to the dispatcher the reason for

the call.

Perform such activities in off-peak hours, such as early morning or late

evening.

answered by the called station

answered by the attendant

routed to a recorded announcement that can be administered

by the customer premises equipment user

routed to a dial prompt

Customer Support Information

xiii

Page 16

Customer Support Information

This equipment returns answer supervision on all DID calls forwarded

b.

back to the Public Switched Telephone Network. Permissible

exceptions are when:

(1)

(2)

(3)

Allowing this equipment to be operated in such a manner as not to provide

proper answer supervision signaling is in violation of Part 68 rules.

DOC Notification and Repair Information

NOTICE: The Canadian Department of Communications (DOC) label identifies certified

equipment. This certification means that the equipment meets certain

telecommunications network protective, operational, and safety requirements. The

DOC does not guarantee the equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to connect it

to the facilities of the local telecommunications company. The equipment must also be

installed using an acceptable method of connection. In some cases, the company’s

inside wiring for single-line individual service may be extended by means of a certified

connector assembly (telephone extension cord). The customer should be aware that

compliance with the above conditions may not prevent degradation of service in some

situations.

a call is unanswered

a busy tone is received

a reorder tone is received

Repairs to certified equipment should be made by an authorized Canadian

maintenance facility designated by the supplier. Any repairs or alterations made by

the user to this equipment, or any equipment malfunctions, may give the

telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of

the power utility, telephone lines, and internal metallic water pipe system, if present,

are connected. This precaution may be particularly important in rural areas.

CAUTION: Users should not attempt to make such connections themselves, but should

contact the appropriate electrical inspection authority or electrician, as appropriate.

To prevent overloading, the Load Number (LN) assigned to each terminal device

denotes the percentage of the total load to be connected to a telephone loop used by

the device. The termination on a loop may consist of any combination of devices

subject only to the requirement that the total of the Load Numbers of all the devices

does not exceed 100.

DOC Certification No.: 230 4095A

CSA Certification No.: LR 56260

Load No.: 6

xiv

Customer Support Information

Page 17

Customer Support Information

Renseignements sur la notification du ministère des Communications du Canada et

la réparation

AVIS: L’étiquette du ministère des Communications du Canada identifie Ie materiel

homologué. Cette étiquette certifie que Ie materiel est conforme à certaines normes de

protection, d’exploitation et de sécurité des réseaux de telecommunications. Le

Ministère n’assure toutefois pas que Ie matériel fonctionnera à la satisfaction de

I’utilisateur.

Avant d’installer ce matériel, I’utilisateur doit s’assurer qu’il est permis de Ie raccorder

aux installations de I’entreprise locale de telecommunication. Le matériel doit

également être installé en suivant une méthode acceptée de raccordement. Dans

certains cas, Ies fils intérieurs de I’enterprise utilises pour un service individual à Iigne

unique peuvent être prolongés au moyen d’un dispositif homologué de raccordement

(cordon prolongateur téléphonique interne).

L’abonné ne doit pas oublier qu’il est possible que la conformity aux conditions

énoncées ci-dessus n’empêchent pas la degradation du service clans certaines

situations. Actuellement, Ies entreprises de telecommunication ne permettent pas que

I’on raccorde Ieur matériel à des jacks d’abonné, sauf clans Ies cas précis prévus pas

Ies tarifs particuliers de ces entreprises.

Les reparations de materiel homologué doivent être effectuées par un centre

d’entretien canadien autorisé désigné par Ie fournisseur. La compagnie de

telecommunications peut demander à I’utilisateur de débrancher un appareil a la suite

de reparations ou de modifications effectuées par I’utilisateur ou à cause de mauvais

fonctionnement.

Pour sa propre protection, I’utilisateur doit s’assurer que tous Ies fils de mise à la terre

de la source d’énergie électrique, des lignes téléphoniques et des canalisations d’eau

métalliques, s’il y en a, sent raccordés ensemble. Cette précaution est

particulièrement importance clans Ies régions rurales.

AVERTISSEMENT: L’utilisateur ne doit pas tenter de faire ces raccordements luimême; il doit avoir recours à un service d’inspection des installations éctriques, ou à

un electrician, selon Ie cas.

L’indite de charge (IC) assigné à chaque dispositif terminal indique, pour éviter toute

surcharge, Ie pourcentage de la charge totale qui peut être raccordée à un circuit

téléphonique bouclé utilisé par ce dispositif. La terminaison du circuit bouclé peut être

constitute de n’importe quelle combinaison de dispositifs, pourvu que la somme des

indices de charge de I’ensemble des dispositifs ne dépasse pas 100.

No d’homologation: 230 4095A

Node certification: CSA LR 56260

L’indite de charge: 6

Customer Support Information

XV

Page 18

Customer Support Information

xvi

Customer Service Information

Page 19

Customer Support Information

Security of Your System—Preventing Toll Fraud

As a customer of a new telephone system, you should be aware that there exists an

increasing problem of telephone toll fraud. Telephone toll fraud can occur in many

forms, despite the numerous efforts of telephone companies and telephone equipment

manufacturers to control it. Some individuals use electronic devices to prevent or

falsify records of these calls. Others charge calls to someone else’s number by

illegally using lost or stolen calling cards, billing innocent parties, clipping on to

someone else’s line, and breaking into someone else’s telephone equipment physically

or electronically. In certain instances, unauthorized individuals make connections to

the telephone network through the use of remote access features.

The Remote Access feature of your system, if you choose to use it, permits offpremises callers to access the system from a remote telephone by using an 800

number or a 7- or 10-digit telephone number. The system returns an

acknowledgement signaling the user to key in his or her authorization code, which is

selected and administered by the system manager. After the authorization code is

accepted, the system returns dial tone to the user. If you do not program specific

egress restrictions, the user will be able to place any call normally dialed from a

telephone associated with the system. Such an off-premises network call is originated

at, and will be billed from the system location.

The Remote Access feature, as designed, helps the customer, through proper

administration, to minimize the ability of unauthorized persons to gain access to the

network. Most commonly, phone numbers and codes are compromised when

overheard in a public location, through theft of a wallet or purse containing access

information, or through carelessness (writing codes on a piece of paper and improperly

discarding it). Additionally, hackers may use a computer to dial an access code and

then publish the information to other hackers. Enormous charges can be run up

quickly. It is the customer’s responsibility to take the appropriate steps to properly

implement the features, evaluate and administer the various restriction levels, protect

access codes, and distribute access codes only to individuals who have been fully

advised of the sensitive nature of the access information.

Common carriers are required by law to collect their tariffed charges. While these

charges are fraudulent charges made by persons with criminal intent, applicable tariffs

state that the customer of record is responsible for payment of all long-distance or

other network charges. AT&T cannot be responsible for such charges and will not

make any allowance or give any credit for charges that result from unauthorized

access.

Customer Support Information

xvii

Page 20

Customer Support Information

To minimize the risk of unauthorized access to your communications system:

Use a nonpublished Remote Access number.

Assign authorization codes randomly to users on a need-to-have basis,

keeping a log of ALL authorized users and assigning one code to one person.

Use random sequence authorization codes, which are less likely to be easily

broken.

Deactivate all unassigned codes promptly.

Ensure that Remote Access users are aware of their responsibility to keep the

telephone number and any authorization codes secure.

When possible, restrict the off-network capability of off-premises callers, via

use of Call Restrictions and Disallowed List capabilities.

When possible, block out-of-hours calling.

Frequently monitor system call detail reports for quicker detection of any

unauthorized or abnormal calling patterns.

Limit Remote Call Forward to persons on a need-to-have basis.

Limited Warranty and Limitation of Liability

AT&T warrants to you, the customer, that your MERLIN LEGEND Communications

System will be in good working order on the date AT&T or its authorized reseller

delivers or installs the system, whichever is later (“Warranty Date”). If you notify AT&T

or its authorized reseller within one year of the Warranty Date that your system is not in

good working order, AT&T will without charge to you repair or replace, at its option, the

system components that are not in good working order. Repair or replacement parts

may be new or refurbished and will be provided on an exchange basis. If AT&T

determines that your system cannot be repaired or replaced, AT&T will remove the

system and, at your option, refund the purchase price of your system, or apply the

purchase price towards the purchase of another AT&T system.

If you purchased your system directly from AT&T, AT&T will perform warranty repair in

accordance with the terms and conditions of the specific type of AT&T maintenance

coverage you selected. If you purchased your system from an AT&T-authorized

reseller, contact your reseller for the details of the maintenance plan applicable to your

system.

This AT&T limited warranty covers damage to the system caused by power surges,

including power surges due to lightning.

The following will not be deemed to impair the good working order of the system, and

AT&T will not be responsible under the limited warranty for damages resulting from

xviii

Customer Support Information

Page 21

Customer Support Information

failure to follow AT&T’s installation, operation, or maintenance instructions

unauthorized system modification, movement, or alteration

unauthorized use of common carrier communication services accessed

through the system

abuse, misuse, or negligent acts or omissions of the customer and persons

under the customer’s control

acts of third parties and acts of God

AT&T’S OBLIGATION TO REPAIR, REPLACE, OR REFUND AS SET FORTH ABOVE IS

YOUR EXCLUSIVE REMEDY.

EXCEPT AS SPECIFICALLY SET FORTH ABOVE, AT&T, ITS AFFILIATES, SUPPLIERS,

AND AUTHORIZED RESELLERS MAKE NO WARRANTIES, EXPRESS OR IMPLIED,

AND SPECIFICALLY DISCLAIM ANY WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

Limitation of Liability

EXCEPT FOR PERSONAL INJURY, DIRECT DAMAGES TO TANGIBLE PERSONAL

PROPERTY PROXIMATELY CAUSED BY AT&T, AND LIABILITY OTHERWISE

EXPRESSLY ASSUMED IN A WRITTEN AGREEMENT SIGNED BY AT&T, THE

LIABILlTY OF AT&T, ITS AFFILIATES, SUPPLIERS, AND AUTHORIZED RESELLERS

FOR ANY CLAlMS, LOSSES, DAMAGES, OR EXPENSES FROM ANY CAUSE

WHATSOEVER (INCLUDING ACTS OR OMISSIONS OF THIRD PARTIES),

REGARDLESS OF THE FORM OF ACTION, WHETHER IN CONTRACT, TORT OR

OTHERWISE, SHALL NOT EXCEED AN AMOUNT EQUAL TO THE LESSER OF THE

DIRECT DAMAGES PROVEN OR THE PURCHASE PRICE OF THE SYSTEM. IN NO

EVENT SHALL AT&T OR ITS AFFILIATES, SUPPLIERS, OR AUTHORIZED RESELLERS

BE LIABLE FOR INCIDENTAL, RELIANCE, CONSEQUENTLY, OR ANY OTHER

INDIRECT LOSS OR DAMAGE (INCLUDING LOST PROFITS OR REVENUES)

INCURRED IN CONNECTION WITH THE SYSTEM. THIS LIMITATION OF LIABILITY

SHALL SURVIVE FAILURE OF THE EXCLUSIVE REMEDY SET FORTH IN THE LIMITED

WARRANTY ABOVE.

Voice Mail Systems

Your Voice Mail system permits callers to leave verbal messages for system users or

gain access to the back-up position in an emergency as well as create and distribute

voice messages among system users.

The Voice Mail system, through proper administration, can help you reduce the risk of

unauthorized persons gaining access to the network. However, phone numbers and

authorization codes can be compromised when overheard in a public location, are lost

through theft of a wallet or purse containing access information, or through

carelessness (writing codes on a piece of paper and improperly discarding them).

Customer Support Information

xix

Page 22

Customer Support Information

Additionally, hackers may use a computer to dial an access code and then publish the

information to other hackers. Substantial charges can accumulate quickly. It is your

responsibility to take appropriate steps to implement the features properly, evaluate

and administer the various restriction levels, protect and carefully distribute access

codes.

Under applicable tariffs, you will be responsible for payment of toll charges. AT&T

cannot be responsible for such charges and will not make any allowance or give any

credit resulting from unauthorized access.

To reduce the risk of unauthorized access through your Voice Mail system, please

observe the following procedures:

Employees who have voice mailboxes should be required to use the

passwords to protect their mailboxes.

Have them use random sequence passwords.

Impress upon them the importance of keeping their passwords a

secret.

Encourage them to change their passwords regularly.

The administrator should remove any unneeded voice mailboxes from the

system immediately.

AUDIX Voice Power™ has the ability to limit transfers to subscribers only. You

are strongly urged to limit transfers in this manner.

Use the PBX or Key system administration capability to do the following:

Block direct access to outgoing lines and force the use of account

codes/authorization codes.

Disallow trunk-to-trunk transfer unless required.

Assign toll restriction levels to all AUDIX Voice Power ports.

If you do not need to use the Outcalling feature, completely restrict the

outward calling capability of the AUDIX Voice Power ports.

Monitor SMDR reports or Call Accounting System reports for outgoing calls that

might be originated by AUDIX Voice Power ports.

Remote Administration and Maintenance

The Remote Administration and Maintenance feature of your telecommunications

system, if you choose to use it, permits users to change the system features and

capabilities from a remote location.

The Remote Administration and Maintenance feature, through proper administration,

can help you reduce the risk of unauthorized persons gaining access to the network.

However, telephone numbers and authorization codes can be compromised when

overheard in a public location, are lost through theft of a wallet or purse containing

access information, or through carelessness (writing codes on a piece of paper and

xx

Customer Support Information

Page 23

Customer Support Information

improperly discarding them). Additionally, hackers may use a computer to dial an

access code and then publish the information to other hackers. Substantial charges

can accumulate quickly. It is your responsibility to take appropriate steps to implement

the features properly, evaluate and administer the various restriction levels, and protect

and carefully distribute access codes.

Under applicable tariffs, you will be responsible for payment of toll charges. AT&T

cannot be responsible for such charges and will not make any allowance or give any

credit resulting from unauthorized access.

To reduce the risk of unauthorized access through Remote Administration and

Maintenance, please observe the following procedures:

The System Administration and Maintenance capability of a PBX or Key system

is protected by a password.

Change the default password immediately.

Continue to change the password regularly.

Only give the password to people who need it and impress upon them

the need to keep it secret.

If anyone who knows the password leaves the company, change the

password immediately.

If you have a special telephone line connected to your PBX or Key system for

Remote Administration and Maintenance, you should do one of the following:

Unplug the line when it is not being

Install a switch

Keep the Remote Administration and Maintenance telephone number

secret. Only give it to people who need to know it, and impress upon

them the need to keep it a secret. Do not write the telephone number

on the PBX or Key system, the connecting equipment, or anywhere

else in the system room.

If your Remote Administration and Maintenance feature requires that someone

in your office transfer the caller to the Remote Administration and Maintenance

extension, you should impress upon your employees the importance of only

transferring authorized individuals to that extension.

in the line to turn it off when it is not being used.

used.

Customer Support Information

xxi

Page 24

About This Book

The Maintenance and Troubleshooting guide provides information and

guidelines to assist you in resolving problems with the MERLIN LEGEND™

Release 2.0 Communications System.

Intended Audience

This book is intended for the qualified field technicians who respond to

customer trouble reports.

Intended Audience

1

Page 25

About This Book

Conventions

The following typographical conventions are used in this book:

Bold type is

Press

Italic type is used for emphasis and as a substitute for information for

which you must supply a specific value.

Dial feature code; dial

Constant width

screens or on a PC screen,

Select

Bold constant width

exactly as shown.

Type

Keys on the PC are shown in boxes.

Press [ F7 ].

When two keys are to be pressed at the same time, the keys are

connected by a hyphen.

used for telephone buttons.

Drop

Sys Program.

install ; dial

to delete the current entry.

✱

ext. no.

type is used for information on telephone display

type indicates information that you enter

#55.

2 Conventions

Press [ Alt ] - [ P ] .

Page 26

About This Book

Product Safety Labels

Throughout these documents, hazardous situations are indicated by an

exclamation point inside a triangle and the word “caution” or “warning.”

WARNING:

Warning indicates the presence of a hazard that could cause death

or severe personal injury if the hazard is not avoided.

CAUTION:

Caution indicates the presence of a hazard that could cause minor

personal injury or property damage if the hazard is not avoided.

Related Documents

The books listed below comprise the entire MERLIN LEGEND Release 2.0

Communications System family of documentation. These documents are

listed by their abbreviated titles. For example, MERLIN LEGEND Release 2.0

Communications System Maintenance and Troubleshooting is referred to as

Maintenance and Troubleshooting.

Within the continental United States, these documents can be ordered from

the AT&T Customer Information Center (CIC) by calling 1-800-432-6600.

NOTE:

For any application that runs on the MERLIN LEGEND Communications

System, you can also order documentation from the CIC. If you do not

know the exact title or number, they can provide you with a list of all

documentation for each application.

Related Documents 3

Page 27

About This Book

Document No.

555-620-114

555-620-110

555-620-115

555-620-116

555-620-111

555-620-112

555-620-113

555-620-122

555-620-123

555-620-150

555-620-152

555-620-124

555-620-125

555-620-151

555-620-120

555-620-121

555-620-128

555-620-126

555-620-127

Title

System Documents

System Overview

Feature Reference

Equipment and Operations Reference

Pocket Reference

System Programming

System Planning

System Planning Forms

Telephone User Support

MLX-10D™, MLX-28D™, and MLX-20L™

Display Telephones User’s Guide

MLX-10D, MLX-28D, and MLX-20L

Display Telephones Quick Reference

MLX-10D Telephone Tray Cards (6 cards)

MLX-28D and MLX-20L Telephone Tray Cards (5 cards)

MLX-10™ Non-Display Telephone User’s Guide

MLX-10 Non-Display Telephone Quick Reference

MLX-10 (non-display) Telephone Tray Cards (6 cards)

Analog Multiline Telephones User’s Guide

Analog Multiline Telephones Quick Reference

ML C-5 Cordless Telephone Quick Reference

Single-Line Telephones User’s Guide

Single-Line Telephones Quick Reference

555-620-134

555-620-135

555-620-132

555-620-133

555-620-136

555-620-137

555-620-130

555-620-131

555-620-129

4

Related Documents

System Operator Support

MLX Direct-Line Consoles Operator’s Guide

MLX Direct-Line Consoles Quick Reference

Analog Direct-Line Consoles Operator’s Guide

Analog Direct-Line Consoles Quick Reference

MLX Queued Call Console Operator’s Guide

MLX Queued Call Console Quick Reference

Miscellaneous User Support

Calling Group Supervisor’s Guide

Calling Group Supervisor’s Quick Reference

Data User’s Guide

Page 28

About This Book

Document No.

555-620-140

555-620-141

555-620-142 System Programming & Maintenance (SPM)

555-620-143

555-620-144

Title

Documentation for Qualified Technicians

Installation, Programming, & Maintenance (lP&M) Binder

(consists of 555-620-141,555-620-142, 555-620-143,

and 555-620-144)

Installation

Maintenance and Troubleshooting

Programming Summary

How to Comment on This Document

We welcome your comments, both good and bad, Please use the feedback

form on the next page to let us know how we can continue to serve you.

If the feedback form is not included in this section, write directly to the

following address:

A. Sherwood

AT&T

99 Jefferson Road

Room 2A25

Parsippany, NJ 07054

How to Comment on This Document

5

Page 29

Introduction to System Maintenance

The purpose of maintenance is to detect, report, and clear problems quickly

with minimum disruption of service. The system attempts to isolate each

problem to a single replaceable unit whenever possible by running automatic

tests. Errors that cannot be automatically corrected are usually recorded in

error logs. Most of your troubleshooting will rely on checking these error logs

and interpreting them using Table 2-1, “Error Codes,” in Chapter 2.

Equipment

To perform maintenance, you need a maintenance terminal and some

additional tools, all of which are defined below.

Maintenance Terminal

Whether you perform maintenance on-site or remotely, you will need a

maintenance terminal:

■

For on-site maintenance, use one of the following:

— MLX-20L console

— PC with System Programming and Maintenance (SPM)

Equipment 1-1

Page 30

Introduction to System Maintenance

NOTE:

The PC can be a DOS PC or a Master Controller

(MCII+ or MCIII)

A 355 AF adapter and D8W-87 cord is required to

connect the PC to the control unit

■

For remote maintenance, use a DOS PC with SPM.

NOTE:

On-site maintenance is preferred; remote maintenance overrides on-site

maintenance and programming, except when on-site backup or restore is

in progress.

See “On-Site Maintenance” or “Remote Maintenance” later in this section for

details.

Tools

In addition to setting up the maintenance terminal, you should have the

following tools:

EIA breakout box

digital voltmeter (KS-20599 or equivalent)

110O/66-type punch down tool

Dracon TS21 or equivalent touch-tone test telephone

assorted flathead screwdrivers

assorted Phillips®-head screwdrivers

long-nosed pliers

1-2 Equipment

Page 31

Introduction to System Maintenance

regular pliers

wrist grounding strap

CAUTION:

Electrostatic discharge can destroy or severely damage the

integrated circuits in the power supply, processor, and

modules. Should you ever need to open a module and

handle the circuit board, use the wrist strap to connect your

wrist to a suitable ground first.

replacement parts recommended by your technical support

organization

Removing the Control Unit Housing

Disconnect AC power from each auxiliary power unit at the wall outlet.

1.

Disconnect AC power from each carrier by disconnecting the power

2.

cord at the wall outlet.

Remove the housing (see Figure 1-1):

3.

If the existing control unit is a MERLIN II Communications System,

remove the housing as follows.

Remove the front housing from each carrier by pulling the

a.

bottom-front towards you. When it releases, remove it by lifting

up as shown in Figure 1-1.

b.

Remove the top from each carrier in the system by pushing it

straight up from the front.

If the existing control unit is a MERLIN LEGEND Communications

System, remove the housing as follows.

a.

From both sides of the control unit, pry the clips from the

housing, using a screwdriver if difficult to reach.

Equipment 1-3

Page 32

Introduction to System Maintenance

b.

When the clips are freed from the housing, carefully pull the

housing towards you.

NOTE:

If the system has more than one carrier, make sure you hold

the housing only from the basic carrier side. Otherwise, the

housing may disassemble.

Communications System

MERLIN II

MERLIN LEGEND

Communications System

Figure 1-1. Removing the Control Unit Housing

1-4 Equipment

Page 33

Introduction to System Maintenance

Installing the Control Unit Housing

When you have completed maintenance and troubleshooting, install the

control unit housing as follows:

If the housing is not already assembled, assemble it as follows:

1.

a.

Lay the front panel(s) face down.

b.

If more than one carrier is being housed, connect the front

panels together by lining up the arrows and then sliding the

panels until the semicircles form a complete circle.

Connect the side panels to the front panel(s) similarly.

c.

Line up the wire clips that are attached to the carrier with the recesses

2.

on the outside of the side panels. See Figure 1-2.

NOTE:

If the wire clips are not already attached to both sides of the control

unit, see “Installing the Housing Clips” in Chapter 2 of

the

Installation guide.

Push the panels back until the clips hook over the tabs and rest in the

3.

recesses.

Equipment 1-5

Page 34

Introduction to System Maintenance

Figure 1-2. Installing the Control Unit Housing

1-6 Equipment

Page 35

Introduction to System Maintenance

On-Site Maintenance

You can do on-site maintenance with an MLX-20L console or a PC with SPM

software. See the System Programming & Maintenance (SPM) guide for

details. If you are in the UNIX® environment, see the documentation for

Integrated Solution Ill (IS-III) as well.

Setting up the MLX-20L Maintenance Terminal

Connect the MLX-20L console to the control unit by plugging one end

1.

of the D8W-87 cord into one of the first five jacks on the leftmost MLX

module.

NOTE:

Only the following modules qualify:

■ 008 MLX

■

408 GS/LS-MLX

The first MLX jack (the lowest telephone jack) is the default. See

Figure 1-3.

If the first MLX jack is being used for the attendant console (the

customer receptionist or operator), use one of the other jacks. If one of

these five jacks is already being used for system programming or

maintenance, use that jack. Only one jack at a time can be used for

system programming or maintenance.

Plug the other end of the D8W-87 cord into the

2.

LINE

jack underneath

the MLX-20L console.

Equipment 1-7

Page 36

Introduction to System Maintenance

Alternate

MLX-20L

Jacks

(the first five)

Default

008 MLX

Line Jack

408 GS/LS-MLX

Underneath the MLX-20L Console

Figure 1-3. Setting up the MLX-20L Telephone

Default

Line Jack

1-8

Equipment

Page 37

Introduction to System Maintenance

MLX-20L Failure

If the MLX-20L console does not work, troubleshoot it as follows:

Replace the MLX-20L console with one that is known to be working (if

1.

available).

If the failure persists, or if a working MLX-20L console is not available,

2.

connect the original MLX-20L console directly into the appropriate MLX

jack on the control unit using a cord that is known to be working,

If the trouble clears, replace the original D8W-87 cord.

3.

If not, use the PC as your maintenance terminal and then troubleshoot

leftmost MLX module.

the

For

details, see “Module Problems” in Chapter 4.

Equipment 1-9

Page 38

Introduction to System Maintenance

Setting up the PC

Plug your laptop or PC into the SPM jack on the processor as shown in

Figure 1-4.

Figure 1-4.

1-10

Setting up the PC

Equipment

Page 39

Introduction to System Maintenance

Remote Maintenance

Remote maintenance allows you to do everything as if you were on-site,

including checking error logs, checking system status, and restarting the

system.

Figure 1-5. Remote Modem Setup

Equipment

1-11

Page 40

Introduction to System Maintenance

As shown in Figure 1-5, you need the following equipment to perform remote

maintenance:

1. DOS PC with SPM

2. Tip/ring telephone

3. 1200-bps modem

Connect the equipment as follows:

1. Connect the PC and modem using EIA-232-D cable.

NOTE:

If the modem is a circuit board in the PC, this connection is already

established.

2. Connect the modem to a T/R trunk jack using a D8W cord.

3. Connect the modem to a T/R telephone using a D8W cord.

When this equipment is set up, you can perform remote maintenance by

dialing the remote processor’s built-in 1200-bps modem. You can dial the

modem directly or call the system attendant and request to be transferred to

the modem. Both procedures are explained in this section.

Considerations

Remote maintenance overrides on-site maintenance and

programming, except when on-site backup or restore is in progress.

Whenever you do remote maintenance, notify the customer

administrator in advance.

You can perform remote maintenance and programming only from a

If

DOS PC, not from the UNIX environment.

you are running SPM under

IS-III, you cannot perform remote maintenance.

Line noise can cause the SPM screen to display

When this happens during remote maintenance,

unpredictable results.

hang up and redial.

1-12

Equipment

Page 41

Introduction to System Maintenance

NOTE:

Under applicable tariffs, the customer is responsible for any charges

incurred through the remote use of system facilities. Precautions should

be taken to prevent unauthorized use of the system’s outside lines by

remote callers, also called toll fraud, See “Customer Support Information”

at the beginning of this guide for more information on security.

Dialing the Attendant

If you do not know the remote access trunk number, dial the number for the

customer’s system as indicated in this procedure:

1.

Start SPM, press any key when the welcome message appears, and

enter the command to put the modem in originate mode (this command

varies depending on the type of modem used).

2.

Pick up the handset on the tip/ring telephone and dial the customer’s

system attendant (the listed directory number for the customer’s

system).

When the call is answered, explain what you are doing and ask for any

3.

passwords you may need; then ask the attendant to transfer you to the

modem by pressing

Transfer

and then dialing ✱ 10.

NOTE:

If the password is not known, check the System Information

Report or ask to speak with the system administrator.

You can change the password without knowing the old

password only when you are on-site and connected to the

SPM jack on the processor.

4.

When you hear the modem tone, hang up.

If nothing appears on the SPM screen, press [ Enter ] .

5.

Equipment

1-13

Page 42

Introduction to System Maintenance

6.

When the

press

Password:

[ Enter ]

).

prompt appears, type the password (do not

The SPM Main menu appears. You are ready to proceed with remote

maintenance.

Dialing the Modem Directly

To dial the modem directly, do the following:

Start SPM, press any key when the welcome message appears, and

1.

enter the command to put the modem in originate mode (this command

varies depending on the type of modem used).

Pick up the handset on the tip/ring telephone and dial the remote

2.

access trunk number.

This is possible only when a trunk is programmed as a dedicated

trunk

for remote access to the built-in modem.

You will hear ringing, followed by dial tone.

3.

If the dial tone begins with three short tones followed by a steady one,

dial the access barrier code on the tip/ring telephone. Otherwise, go to

the next step.

NOTE:

If you do not know the remote access barrier code, contact

the customer’s system administrator, or check Form 3a,

Incoming Trunks—Remote Access.

You can change the access barrier code without knowing

the old one only when you are on-site and connected to the

SPM jack on the processor.

4.

When you hear the dial tone, dial

✱

10

to connect to the modem on the

remote system.

1-14

Equipment

Page 43

Introduction to System Maintenance

5.

When you hear the modem tone, hang up.

6.

If nothing appears on the SPM screen, press

7.

When the

password (do not press

NOTE:

Password:

prompt appears in the SPM window, type the

[ Enter ]

[ Enter ].

).

If you do not know the password,

Information Report or ask to speak with the system

administrator.

You can change the password without knowing the old

password only when you are on-site and connected to the

SPM jack on the processor.

The SPM Main menu appears. You

maintenance.

check the System

are ready to proceed with remote

Maintenance Strategy

The strategy presented in this section is only a guideline, not a fixed

procedure. As you become more experienced with the maintenance and

troubleshooting of the system, you will most likely develop your own strategy.

Rely on this strategy as a guideline whenever you are uncertain as to how to

proceed.

Trouble Reports

Trouble is reported in two ways:

User-reported problems

System alarms (permanent errors)

Maintenance Strategy

1-15

Page 44

Introduction to System Maintenance

Automatic Tests

The system performs ongoing maintenance automatically by running tests that

do the following:

monitor the status of equipment

audit operations consistency

detect hardware malfunctions

The tests check hardware and software that are in service without disrupting

normal service. Any errors detected are registered in the error logs. Errors

are corrected automatically whenever possible.

Alarms

If the automatic tests indicate serious error conditions, the system generates

an alarm. Depending on how the system is programmed, the alarm is

indicated in one of the following ways:

an LED for a line or feature button on an operator console or other

designated telephone turns on

the LED on the processor turns on

the status display indicates alarm status (this is true for both

maintenance terminals—the MLX-20L console and a PC running SPM)

a supplemental alert, if installed, is activated (bell, chime, or strobe)

If an LED is programmed to indicate the alarm, the LED stays on until the error

is cleared. When the system indicates an alarm, check the permanent error

logs.

Clearing Alarms

Alarms are cleared automatically when the error condition no longer exists.

To clear an alarm manually, select

Drop

on the MLX-20L console or

[ ALT ] - [ P ] on a PC.

1-16

Maintenance Strategy

Page 45

Introduction to System Maintenance

System Restarts

Depending on the severity and duration of a problem, you may need

to restart

the system. Some errors cause the system to restart automatically.

Every restart causes an error log entry, and each type of restart has its own

error code.

There are three types of system restarts, all of which occur automatically:

Warm start (you cannot select this from the maintenance menu)

Cold start (select Restart to do this manually)

Frigid start (select System Erase to do this manually)

Warm Start

A loss of power for less than 250 ms can cause a warm start.

Effect on service:

Calls in progress are not dropped, but calls in the process

of being connected may be dropped.

NOTE:

Power interruptions of less than 100 ms usually do not affect the

system.

Warm starts can cause telephones to ring inexplicably. To stop

the ringing, call the telephone.

Restart (Cold Start)

If you need to restart the system, Restart (a cold start) is recommended.

Effect on service:

As with System Erase (a frigid start), all calls are dropped.

Restart saves the system programming, whereas System Erase does not.

Maintenance Strategy

1-17

Page 46

Introduction to System Maintenance

To perform a cold start, select

Menu → SysProgram → Exit → System → Restart → Yes

NOTE:

A cold start occurs automatically after a power interrupt of more

than one second.

A cold start does not blank out the screen on an MLX-20L

telephone until the cold start is completed.

A cold start can cause telephones with the Station Status feature to

lose their toll restrictions.

For more information on the Restart procedure, see the System

Programming guide.

For more information on Restart, see “Processor Problems” in Chapter 4.

Restart

as follows:

System Erase (Frigid Start)

CAUTION:

All system programming will be erased.

When you perform a System Erase (frigid start), all calls are dropped,

and the system configuration information is erased. All system

memory must be reinitialized, including system programming. Then

the entire system must be rebooted.

To perform a frigid start, select System Erase as follows:

Menu → Maintenance → Slot → Type 00 → Demand Test → System

Erase

(Line 5, left button) twice → Yes

1-18 Maintenance Strategy

Page 47

Introduction to System Maintenance

NOTE:

System Erase

is not displayed on the MLX-20L status display.

To select System Erase, press the left button on Line 5 twice.

After a System Erase or frigid start, the default printer is the PC

printer, not the Station Message Detail Recording (SMDR) printer.

If you want printouts on-site from the SMDR printer, make sure you

change the option.

To change the printer option, see the System Programming &

P

Maintenance (SPM) guide for information on the

rint Opts

option on the SPM Main Menu.

For more information on System Erase, see “Processor Problems” in

Chapter 4.

Isolating the Trouble

Any problem can be isolated to one of the following areas:

Telephone

Control unit

Central office

NOTE:

If you change the jack assignment of any telephone, be sure to record the

extension jack change on Form 2a, System Numbering—Station Jacks.

See Appendix A for details.

Figure 1-6 diagrams the entire maintenance strategy. Refer to this figure and

the text that follows whenever you need guidance in troubleshooting.

Maintenance Strategy

1-19

Page 48

Introduction to System Maintenance

AT&T-authorized personnel

1a

Troubleshoot telephone

1a

2a

Problem gone;

verify that errors

do not recur

2a

3

4

5

6

7

8

User or

reports a probIem

(Chapter 3)

Problem persists

Check error logs

(Chapter 2)

Error

Troubleshoot errors

(Table 2-1, “Error Codes”)

Troubleshoot

Troubleshoot

Troubleshoot

power supply

(Chapter 4)

processor

(Chapter 4)

Troubleshoot

(Chapter 4)

Troubleshoot

(Chapter 4)

Troubleshoot

(Chapter 5)

(Chapter 5)

Inconclusive

Can’t access error logs

Corrective action per Table 2-1

Power supply OK; problem persists

Processor OK; problem persists

Modules OK; problem persists

Carrier OK; problem persists

trunks

Trunks OK; problem persists

central office

Phone

problem

All

other

problems

first (if indicated)

(if indicated)

modules

carrier

One or more alarms turn on:

Discuss problem

with the source

1a

Maintenance or programming

accessed just before

error(s) occurred

Check Access Log

2c (Chapter 2)

Problem persists

1b

Inconclusive

Errors

❑

Attendant Alarm LED

❑

Processor LED

❑

Supplemental alert

❑

Status display

Check

permanent errors

in error logs

1b (Chapter 2)

Can’t access

error logs

Troubleshoot

2b

Troubleshoot

2b

Troubleshoot

2b

Escalate to NSAC

or AT&T-authorized dealer

2b

or AT&T-authorized dealer

9

power supply

(Chapter 4)

Problem persists

processor

(Chapter 4)

Problem persists

carrier

(Chapter 4)

Problem persists

Escalate to NSAC

Figure 1-6. Maintenance

1-20 Maintenance Strategy

Strategy

Page 49

Introduction to System Maintenance

Step 1a: Check Telephone Problems

If the customer reported a telephone problem, do the following, which

Chapter 3 describes in more detail:

1.

Discuss the problem with the user who reported the problem.

2.

Run the appropriate test to verify the complaint.

3.

Replace the telephone with one that is known to be working properly.

If this does not resolve the problem, replace the telephone wiring.

4.

5.

If the problem persists, proceed to Step 2a.

Step lb: Check Permanent Errors

If a system alarm turns on (see the top-right of Figure 1-6), begin

troubleshooting by checking the permanent errors in the error logs.

Step 2a: Check the Error Logs

For an unresolved telephone problem or any other problem, check the error

logs. The problem is now isolated to the control unit or central office.

1.

Check the permanent errors first; these are the most serious.

2.

Check transient errors only if they remain after clearing all permanent

errors.

Transient errors are less serious. Some transient errors become

permanent if they occur a certain number of times, as shown in Table

1-1. The

Threshold

column indicates the number of occurrences at

which a transient error becomes permanent.

3.

Check the last 10 errors whenever you want to see the 10 most recently

recorded errors—both permanent and transient.

Maintenance Strategy

1-21

Page 50

Introduction to System Maintenance

NOTE:

As you are checking the error logs, see Table 2-1, “Error Codes,” in

Chapter 2 for detailed descriptions of each problem.

Table 1-1. Transient/Permanent Error Thresholds

Error

Code

7402

7403

7404

8403

840B

840C

840D

Step 2b: Trouble Accessing the Error Logs

If you cannot access the error logs, or if the system is inoperable,

troubleshoot the system until the problem is resolved:

Error

Description

LOOP BIT CONTROL NOT SET

NO LOOP CURRENT

STUCK RINGING

NO EXTERNAL RELEASE

NO LOOP CURRENT

STUCK RINGING

INCORRECT FIRMWARE STATE

Transient/Permanent

Threshold

4

4

2

2

4

2

2

1-22

1.

Check the power supply LED:

a.

Is the power switch turned on?

b.

Is the power cord connected to an AC wall outlet (that is not

controlled by a wall switch)?

If the LED is off and you are sure that the power is connected and

turned on, see “Power Supply Problems” in Chapter 4.

2.

If you still cannot access the error logs after checking the power

supply, see “Processor Problems” in Chapter 4.

Maintenance Strategy

Page 51

Introduction to System Maintenance

If you still cannot access the error logs after checking the processor,

3.

see “Carrier Problems” in Chapter 4.

4.

If you still cannot access the error logs, escalate the problem to your

technical support organization. See “Escalating the Problem” in

Chapter 2

for details.

Step 2c: Check

the Access Log for Maintenance and System

Programming

At any time during the maintenance process, you may want to check the

access log for maintenance and system programming. This log indicates the

last 20 times that maintenance or system programming was accessed. If you

find that someone accessed maintenance or system programming shortly

before the problem originated, that person may be able to help you isolate the

trouble by providing additional information.

Once you receive that information, use any maintenance or system

programming feature that may lead to the root of the problem.

See “Access Log for Maintenance and System Programming”

in Chapter 2 for

additional information.

See the System Programming guide for information on system

programming

and Inspect.

Step 3: Check the Power Supply

If the error logs indicate the power supply, resolve this problem before

continuing.

See “Power Supply Problems” in Chapter 4.

Step 4: Check the Processor

If the error logs indicate the processor, do the following:

1.

Back up the system programming using SPM (see the System

Programming & Maintenance (SPM) guide

Troubleshoot the processor as described under “Processor Problems”

2.

in Chapter 4.

Maintenance Strategy

1-23

Page 52

Introduction to System Maintenance

Step 5: Check the Modules

If the error logs indicate any modules, see “Module Problems” in Chapter 4.

Step 6: Check the Control Unit Carrier

The last possible cause withln the control unit is the carrier. If the carrier is

damaged, it must be replaced.

See “Carrier Problems” in Chapter 4.

Step 7: Check the Trunks

Troubleshoot the trunks that are connected to the control unit. See Chapter 5.

Step 8: Check the Central Office

If the error logs indicate the central office, and you have resolved all other

possible causes, troubleshoot as follows (see Chapter 5 for details):

1. Call the central office and ask them to check the problem at their end.

If they indicate that the problem is in the central office,

duplicate the original problem after they fix it.

If the problem persists, repeat this process until the problem

clears.

If they indicate that the problem is not in the central office,

escalate the problem as described in Step 9.

Step 9: Escalate

Escalate any remaining problems to your technical support organization.

See “Escalating the Problem,

access the System Inventory screen, which contains information that your

technical support organization may request (the hardware vintage, software

vintage, and ROM ID for each module).

“ in Chapter 2. This section explains how to

1-24

Maintenance Strategy

Page 53

Introduction to System Maintenance

Unit Loads

A unit load is a measure of power (1,9 watts) used to determine the electrical

load that the following components have on each carrier’s power supply:

telephones and adjuncts

Only the telephones and adjuncts that connect to the analog and

digital ports on the control unit require unit load calculation. Do not

include any equipment with its own power supply (for example, an

answering machine) in the unit load calculation.

direct-inward dial (DID) modules

Checking Unit Loads

In the event of maintenance or equipment changes, recalculate the unit loads

for each carrier resulting in a different configuration.

Use the worksheet in Appendix B.

General Rule:

equally across the carriers, you will prevent unnecessary drain on any one

carrier.

Also, depending on the system’s mode, the rules vary. The next two sections

provide the rules for calculating unit loads in various modes.

Unit Loads for the Hybrid/PBX Mode

The power supply (model 391 Al) generally supports six modules of any type

in a Hybrid/PBX system.

However, if both of the following conditions are true, the unit loads on a carrier

can exceed the 54-unit maximum:

all six carrier slots are occupied by MLX telephone or analog multiline

telephone modules

If you can distribute the DID modules and telephone modules

the carrier has more than 45 telephones installed (MLX-20L telephones

and/or 34-button analog multiline telephones)

Unit Loads

1-25

Page 54

Introduction to System Maintenance

Unit Loads for Key or Behind Switch Mode

In a Key or Behind Switch system with four or fewer modules, no calculation is

needed. The power supply (model 391A1) generally supports four modules

of any type in Key or Behind Switch mode.

Auxiliary Power Units

The power supply provides 54 unit loads to each carrier. If the unit load

requirement for a carrier exceeds 54, an auxiliary power unit is needed to

allow that carrier to support an additional 27 unit loads.

NOTE:

Running the system with more than 54 unit loads per carrier may not

appear to do harm. However, this can cause the system to malfunction,

creating “no trouble found” situations.

An auxiliary power unit redirects the power requirements from the last two

slots on the carrier. Any station connected to the modules in the last two slots

receives power from the auxiliary power unit instead of from the power supply.

If an auxiliary power unit is required, complete instructions are provided in the

Installation guide.

1-26

Unit Loads

Page 55

Error Logs, the Access Log, and System Inventory

As described under “Maintenance Strategy” in Chapter 1, much of your

troubleshooting will rely on the error logs and the Access Log for maintenance

and system programming. Both of these maintenance features are described

here in detail. This chapter also explains how to access the System inventory

screen, which you may need when escalating unresolvable problems to your

technical support organization.

Error Logs

Whenever an error occurs, the system records it in the error logs, which are

stored in battery-backed-up RAM. These errors indicate problems that span

the entire system including the control unit, telephones, adjuncts, and network

interface.

Error Logs 2-1

Page 56

Error Logs, the Access Log, and System Inventory

Checking the Error Logs

Print the errors immediately after exiting the error logs. This will help you

determine if your work has resolved each problem.

To print the errors, follow this procedure:

System Programming → More → Print → More → (twice) → Error Log

See the System Programming guide for additional information on printing.

Quick Reference

Menu → Maintenance → System → Error Log → Last 10

Permanent

or

Transient

Procedure: Check the Error Logs

Step

1

2

Display

Maintenance

Make a selection

System

slot

Port

Exit

System:

Make a selection

Status

Error Log

Inventory

Access Log

Exit

Enter

Instructions

Select System.

>

Select

Error Log.

or

2-2

Error Logs

Page 57

Error Logs, the Access Log, and System Inventory

Step

3

System Error Log:

Make a selection

Last 10

Permanent

Transient

(most recent alarm)

Exit

Display

Instructions

Depending on your purpose, select Last

10,

Permanent,

or

Transient.

If you are not sure which selection to make,

see ’’Step 2a: Check the Error Logs” in

Chapter 1 under “Maintenance Strategy."

Once you make your selection, continue

with one of the following subsections:

“Checking Permanent Errors”

“Checking Transient Errors”

“Checking the Last 10 Errors”

NOTE:

The most recent alarm message. stays on the System Error Log screen

until it is replaced by another one. The screen does not update the most

recent alarm while displayed; to see any updates, you need to exit this

screen and re-enter.

Error Logs

2-3

Page 58

Error Logs, the Access Log, and System Inventory

Checking Permanent Errors

(continued from “Procedure: Check the Error Logs” )

Step

4

Permanent Errors:

xxxxxxxxxxxxxxxxxxxxxxxx

Slot xx Port xx

First

Last

Code

Exit

Display

Count xxx

mm/dd/yy hh:mm

mm/dd/yy hh:mm

xxxx

Instructions

This screen appears when you select

>

Permanent.

Line 2 provides a brief description of the

error code identified on Line 6. For more

information on any error code, see

Table 2-1.

Line 3 indicates the slot and port where the

error was detected, followed by the

number of times it was detected.

Lines 4 and 5 indicate the error’s first and

last occurrences.

More

Drop

allows you to page through the permanent errors.

(

[ Alt ] - [ P ]

on a PC) deletes an error log entry.

NOTE:

Depending on which entry that you delete, you might clear an alarm. See

“Alarms” under “Maintenance Strategy” in Chapter 1 for additional

information on alarms.

2-4

Error Logs

Page 59

Error Logs, the Access Log, and System Inventory

Checking Transient Errors

(continued from “Procedure: Check the Error Logs” )

Step

4

More

Drop

Display

Instructions

This screen appears when you select

Transient Errors:

xxxxxxxxxxxxxxxxxxxxxxxx

Slot xx Port xx

First

Last

Code

Exit

mm/dd/yy hh:mm

mm/dd/yy hh:mm

xxxx

Count xxx

>

Transient.

Line 2 provides a brief description of the

error code identified on Line 6. For more

information on any error code, see

Table 2-1.

Line 3 indicates the slot and port where the

error was detected, followed by the

number of times it was detected.

Lines 4 and 5 indicate the error’s first and

last occurrences.

allows you to page through the transient errors.

(

[ Alt ] - [ P ]

on a PC) deletes an error log entry.

Error Logs

2-5

Page 60

Error Logs, the Access Log, and System Inventory

Checking

(continued

Step

4

Last 10 System Errors: >

xxxxxxxxxxxxxxxxxxxxxxxx

Slot xx Port xx

Last

Code

Exit

the Last 10 Errors

from “Procedure: Check the Error Logs” )

Display

Instructions

This

screen appears when you select

10.

Line

2 provides a brief description of the

mm/dd/yy hh:mm

xxxx

error code identified on Line 6. For more

information on any error

Table 2-1.

Line 3 indicates the slot

error was detected.

Line 5 indicate the error’s last occurrence.

More

allows you to page through the last 10 errors.

NOTE:

You cannot delete an error log entry from this screen.

Last

code, see

and port where the

2-6

Error Logs

Page 61

Error Logs, the Access Log, and System Inventory

Interpreting Error Codes

Table 2-1 explains how to interpret each error from the error logs. For

additional information on how to use the error logs, read this entire chapter

and see “Maintenance Strategy” in Chapter 1.

Table 2-1. Error Codes

Error

Code

Description

Action

0001

0002

0003

0004

0006

TIMEOUT COLD START:

System programming is okay.

POWER UP WARM START:

System programming is okay.

SOFTWARE COLD START:

System programming is okay.

SOFTWARE WARM START: