Page 1

AT&T 555-640-140

March 1996

MERLIN LEGEND

Communications

System

Releases 3.1

and 4.0

Installation

®

Page 2

Customer Support Information,

Customer Support Information.

Copyright 1996, AT&T AT&T 555-640-140

All Rights Reserved Issue 1

Printed in U.S.A. March 1996

Notice

Every effort was made to ensure that the information in this book was complete and accurate at the time of printing. However,

information is subject to change.

See Appendix A, “

this binder.

” for important information. It follows

Maintenance and Troubleshooting

in

Your Responsibility for Your System’s Security

Toll fraud is the unauthorized use of your telecommunications system by an unauthorized party, for example, persons other

than your company’s employees, agents, subcontractors, or persons working on your company’s behalf. Note that there may

be a risk of toll fraud associated with your telecommunications system, and if toll fraud occurs, it can result in substantial

additional charges for your telecommunications services.

You and your System Manager are responsible for the security of your system, such as programming and configuring your

equipment to prevent unauthorized use. The System Manager is also responsible for reading all installation, instruction, and

system administration documents provided with this product in order to fully understand the features that can introduce risk of

toll fraud and the steps that can be taken to reduce that risk. AT&T does not warrant that this product is immune from or will

prevent unauthorized use of common-carrier telecommunication services or facilities accessed through or connected to it.

AT&T will not be responsible for any charges that result from such unauthorized use. For important information regarding your

system and toll fraud, see Appendix A, “

”

Federal Communications Commission Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case the user will be required

to correct the interference at his own expense. For further FCC information, see Appendix A, “Customer Support Information.”

Canadian Department of Communications (DOC)

Interference Information

This digital apparatus does not exceed the Class A limits for radio noise emissions set out in the radio interference regulations

of the Canadian Department of Communications.

Le Présent Appareil Numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils

numériques de la class A préscrites dans le reglement sur le brouillage radioélectrique édicté par le ministère des

Communications du Canada.

Trademarks

5ESS, ACCUNET, ACCULINK, CONVERSANT, DEFINITY, Magic On Hold, Megacom, MERLIN, MERLIN II, MERLIN LEGEND,

MERLIN MAIL, MultiQuest, Music on Hold, and Systimax are registered trademarks and 4ESS, AT&T Attendant, AUDIX Voice

Power, FAX Attendant System, HackerTracker, MERLIN Identifier, MERLIN Identifier, MLX-10, MLX-10D, MLX-10DP,

MLX-16DP, MLX-20L, MLX-28D, Page Pac, and PassageWay are trademarks of AT&T in the U.S. and other countries.

Windows is a trademark and Microsoft

ProComm and ProComm Plus are registered trademarks of DataStorm Technologies, Inc.

Supra, StarSet, and Mirage are registered trademarks of Plantronics, Inc.

UNIX is a registered trademark of UNIX System Laboratories, Inc.

PagePac is a registered trademark of DRACON, a division of Harris Corporation.

Okidata is a registered trademark of Okidata Corporation.

® a registered trademark of Microsoft Corporation.

Page 3

Ordering Information

in

Limited Warranty and Limitation of Liability

in Appendix A,

Customer Support Information,

Call: AT&T GBCS Publications Fulfillment Center

Write: AT&T GBCS Publications Fulfillment Center

Order: Document No. AT&T 555-640-140

For more information about AT&T documents, refer to the section entitled, “Related Documents”

Support Telephone Number

In the continental U.S., AT&T provides a toll-free customer helpline 24 hours a day. Call the AT&T Helpline at 1 800 628-2888

or your AT&T authorized dealer if you need assistance when installing, programming, or using your system. Outside the

continental U.S., contact your local AT&T authorized representative.

Voice 1 800 457-1235 International Voice 317 361-5353

Fax 1 800 457-1764 International Fax 317 361-5355

P.O. Box 4100

Crawfordsville, IN 47933

Comcode: 107713737

Issue 1, March 1996

AT&T Corporate Security

Whether or not immediate support is required,

to AT&T Corporate Security at 1 800 821-8235. In addition to recording the incident, AT&T Corporate Security is available for

consultation on security issues, investigation support, referral to law enforcement agencies, and educational programs.

AT&T Fraud Intervention

If you

suspect you are being victimized

Service Assistance Center at 1 800 628-2888.

Warranty

AT&T provides a limited warranty on this product. Refer to “

“

“

About This Book

all

toll fraud incidents involving AT&T products or services

by toll fraud and you need technical support or assistance, call GBCS National

” which follows

Maintenance and Troubleshooting

in this binder.

.”

should be reported

”

Page 4

Contents

About This Book

■

Intended Audience xix

■

How to Use This Book xix

■

Terms and Conventions Used xxi

■

Product Safety Labels xxii

■

Security xxiii

■

Related Documents xxiv

■

How to Comment on This Document xxv

1 Introduction

n

Installation Sequence 1–1

n

System Forms 1–2

n

Programming the System 1–4

n

Upgrading the System 1–5

2 Installing the Control Unit

n

Overview 2–1

n

AC Power and Grounding 2–5

n

Unit Loads 2–16

n

Installing the Basic Carrier 2–17

n

Installing the Power Supply 2–19

n

Installing the Auxiliary Power Unit 2–25

Installation

iii

Page 5

Contents

Installing the Control Unit, Continued

n

Installing Expansion Carriers 2–27

n

Installing the Processor 2–29

n

Installing the Modules 2–32

n

Replacing a Module 2–40

n

Connecting the Control Unit to an AC Outlet 2–43

n

Powering Up the System 2–44

n

Powering Down the System 2–45

3 Installing Telephones and Adjuncts

n

Installing Multi-Function Modules 3–1

n

Installing Adjuncts 3–22

n

Installing Direct Station Selectors 3–43

n

Assembling MLX Telephones 3–48

n

Installing Cordless or Cordless/Wireless Telephones 3–57

n

Connecting Telephones to the Control Unit 3–58

4 Connecting the Control Unit to the Network Interface

n

Wiring 4–2

n

Testing Trunks 4–12

n

Labeling Trunks 4–14

n

Installing the Channel Service Unit 4–15

iv Installation

Page 6

Contents

5 Installing the PC, CAT, or Printer

n

Connecting a PC to the Control Unit 5–1

n

Connecting a CAT to the Control Unit 5–7

n

Connecting a Printer to the Control Unit 5–7

6 Connecting Data Equipment

n

Data Stations 6–1

n

Analog Voice and Modem Data Stations 6–5

n

Modem Data-Only Stations 6–8

n

MLX Voice and Modem Data Stations 6–10

n

MLX Voice and Terminal Adapter Data Stations 6–12

n

Terminal Adapter Data-Only Stations 6–14

n

Video Conferencing Data Stations 6–17

7 Initializing and Testing the System

n

Initializing the System 7–1

n

Setting the Time and Date 7–3

n

Testing the System 7–3

n

Installing the Control Unit’s Housing 7–20

Installation

v

Page 7

Contents

8 Installing Applications

n

Voice Messaging Systems and Touch-Tone

Receivers 8–2

n

Automated Document Delivery System 8–4

n

Call Accounting System 8–5

n

Call Accounting Terminal 8–8

n

Call Management System 8–9

n

CONVERSANT 8–12

n

Integrated Solution III 8–14

n

AT&T Attendant 8–17

n

MERLIN MAIL 8–18

n

MERLIN PFC 8–21

n

PassageWay Direct Connect Solution 8–23

n

System Programming and Maintenance (SPM) 8–25

9 Upgrading the System

n

Backing up System Programming 9–2

n

Removing the Control Unit Housing 9–3

n

Powering Down the System 9–5

n

Upgrading the Control Unit 9–7

n

Modifying the Processor for Key Mode 9–12

n

Completing the Upgrade 9–16

n

Upgrading from the MERLIN II

Communications System 9–16

n

Replacing the Control Unit Housing 9–18

vi Installation

Page 8

Contents

2

4

5

6

2

A System Numbering Forms

Form 2a, System Numbering: Extension Jacks A–

Form 2b, System Numbering:Digital Adjuncts A–

Form 2c, System Numbering: Line/Trunk Jacks A–

Form 2d, System Numbering: Special Renumbers A–

B Unit Load Calculation Worksheet

Unit Load Worksheet B–

Index IN-1

Installation

vii

Page 9

Figures

1. AC Grounding Requirements 2

2. Measuring the AC Outlet Voltages 2

3. Central Office and AC Grounds 2

4. Installing 146A and 147A Protectors 2

5. Marking the Basic Carrier Screw Holes 2

6. Installing a Copper Shield in the Power Supply 2

7. Installing the Ferrite Cores 2

8. Installing an Auxiliary Power Unit 2

9. Connecting the Carriers 2

10. Installing the Processor into the Carrier 2

11. 400EM Module Sample Dip Switch Settings for

12. Line/Trunk and Telephone Jack Locations on

13. Removing Modules from the Carrier 2

1. Multi-Function Module Packing List 3

2. Removing the User Card Tray and Line Cable 3

3. Releasing the Deskstand 3

4. Removing the Deskstand 3

5. Releasing the Module Cover Screw 3

6. Releasing the Module Cover 3

7. Removing the Module Cover 3

8. Removing an MFM Module 3

2 Installing the Control Unit

2–

2–

2–

2–

2–

2–

2–

2–

2–

2–

2–

Signaling Types 1C and 5 2–37

2–

Each Module 2–39

2–

–7

–9

–11

–15

–18

–22

–24

–26

–28

–31

–42

3 Installing Telephones and Adjuncts

3–

viii Installation

3–

3–

3–

3–

3–

3–

3–

–3

–4

–5

–6

–7

–8

–9

–10

Page 10

Figures

9. Installing an MFM Module 3

10. Setting and Adjusting the MFM Jumpers 3

11. Removing the Jack Guard 3

12. Placing the Module Cover into the Locating Slot 3

13. Lowering and Locking the Module Cover 3

14. Replacing and Tightening the Module Cover Srew 3

15. Replacing the Deskstand 3

16. Lowering the Deskstand and Locking into Place 3

17. Replacing the User Card Tray and Line Cable 3

18. Adjusting the Deskstand Height 3

19. Powering Up the Telephone after Installing the

20. Routing the Cord(s) Through the Cord Channel 3

21. Manual and One-Touch Headset Operation 3

22. Single-Zone Paging with PagePac Plus 3

23. Single-Zone Paging with Customer-Supplied

24. Single-Zone Paging with UPAM 3

25. Single-Zone Paging with Background Music and

26. Multizone Paging with Background Music, Magic

27. Installing the Supplemental Alert Adapter 3

28. Connecting One or More DSSs 3

29. Wiring for Auxiliary Power 3

30. Adjusting or Removing the Deskstand 3

31. Connecting the Line Cords 3

32. Removing the Extension Label 3

Installing Telephones and Adjuncts, Continued

3–

3–

3–

3–

3–

3–

3–

3–

3–

3–

3–

MFM 3–21

3–

3–

3–

3–

Amplifier 3–32

3–

3–

Magic on Hold 3–36

3–

on Hold, and Bidirectional Paging (Talk-Back) 3–37

3–

3–

3–

3–

3–

3–

–11

–12

–13

–14

–15

–16

–17

–18

–19

–20

–23

–29

–31

–33

–39

–45

–46

–49

–50

–51

Installation

ix

Page 11

Figures

33. Labeling the Extension 3

34. Removing the Handset Holder 3

35. Rotating the Handset Holder 3

36. Replacing the Extension Label 3

37. Mounting the Backplate 3

38. Routing the Cord Through the Backplate 3

39. Connecting Two Voice Pairs to a Telephone Using

40. Removing the Connecting Block 3

1. RJ21X Network Interface Connector 4

2. RJ21X Wiring Field Hardware 4

3. RJ21X Wiring Field Tools 4

4. Using the D-Impact Tool to Seat the Conductors 4

5. RJ11 and RJ14 Interfaces 4

6. 3150 Front Panel 4

7. 3150 Back Panel 4

Installing Telephones and Adjuncts, Continued

3–

3–

3–

3–

3–

3–

3–

a Bridging Adapter (BR-241-B1) 3–61

3–

4 Connecting the Control Unit to the Network Interface

4–

4–

4–

4–

4–

4–

4–

–52

–53

–53

–54

–55

–56

–63

–5

–6

–7

–8

–10

–17

–17

x Installation

Page 12

Figures

1. Connecting a PC Within 50 ft. (15.2 m) 5

2. Connecting a PC More Than 50 ft. (15.2 m) Away 5

3. Connecting a CAT and Printer on the Same AC

4. Connecting a CAT and Printer on Different AC

5. Connecting a Printer Within 50 ft. (15.2 m) 5

6. Connecting a Printer More Than 50 ft. (15.2 m)

7. Connecting the 248B Adapter and the 2012D

1. Analog Voice and Modem Data Equipment

2. Modem Data-Only Equipment Configuration 6

3. Modem Data and MLX Voice Equipment

4. MLX Voice and Terminal Adapter Data Equipment

5. Terminal Adapter Data-Only Equipment

6. Video Conferencing Configuration 6

5 Installing the PC, CAT, or Printer

5–

6 Connecting Data Equipment

5–

5–

Outlet 5–10

5–

Outlets: Control Unit Connections 5–13

5–

5–

Away 5–19

5–

Transformer 5–20

6–

Configuration 6–7

6–

6–

Configuration 6–10

6–

Configuration 6–13

6–

Configuration 6–16

6–

–3

–6

–16

–9

–19

Installation

xi

Page 13

Figures

1. Ground-Start Button 7

2. Installing the Control Unit Top Cover 7

3. Installing the Control Unit Front Cover 7

1. Removing the Control Unit Housing 9

2. Powering Down the System 9

3. Removing a Module from the Carrier 9

4. Replacing a Module in the Carrier 9

5. Removing the Processor Module Cover 9

6. Removing the Processor Module Circuit Board 9

7. Changing the Key Mode Switch Position to Closed 9

8. Installing the Control Unit Housing 9

2

4

5

6

7 Initializing and Testing the System

7–

9 Upgrading the System

7–

7–

9–

9–

9–

9–

9–

9–

9–

9–

–18

–21

–22

–4

–6

–9

–11

–13

–14

–15

–18

A System Numbering Forms

A–1. Form 2a, System Numbering: Extension Jacks A–

xii Installation

A–2. Form 2b, System Numbering:Digital Adjuncts A–

A–2. Form 2c, System Numbering: Line/Trunk Jacks A–

A–4. Form 2d, System Numbering: Special Renumbers A–

Page 14

Tables

1. Environmental Requirements 2

2. AC Power Requirements 2

3. Heavy Lightning Protection 2

4. Setting the 400EM (Tie Trunk) Module DIP

5. Signaling Formats for the 400EM (Tie Trunk)

1. Unsupported Telephones and Adjuncts 3

2. Single-Line Telephones 3

3. Single-Line Telephones Supported by Release 3.0

1. Network Interfaces 4

2. Central Office Network Interface Codes 4

2 Installing the Control Unit

2–

3 Installing Telephones and Adjuncts

2–

2–

2–

Switches 2–35

2–

Module 2–36

3–

3–

3–

and Later 3–42

–2

–8

–14

–40

–41

4 Connecting the Control Unit to the Network Interface

4–

4–

–2

–3

Installation

xiii

Page 15

Tables

1. AT&T 572 Printer Options 5

2. AT&T 475/476 Printer DIP Switch Settings 5

3. AT&T CAT Printer DIP Switch Settings 5

1. Data Station Configurations 6

2. Terminal Adapter Settings 6

1. TTRs Required by VMS 8

2. MERLIN MAIL Ports Required 8

5 Installing the PC, CAT, or Printer

5–

6 Connecting Data Equipment

8 Installing Applications

5–

5–

6–

6–

8–

8–

–22

–24

–25

–2

–21

–3

–19

xiv Installation

Page 16

Safety

The exclamation point in an equilateral

triangle is intended to alert the user to the

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the product.

IMPORTANT SAFETY INSTRUCTIONS

When installing telephone equipment, always follow basic safety precautions

to reduce the risk of fire, electrical shock, and injury to persons, including:

■

Read and understand all instructions.

■

Follow all warnings and instructions marked on or packed with the

product.

■

Never install telephone wiring during a lightning storm.

■

Never install a telephone jack in a wet location unless the jack is

specifically designed for wet locations.

■

Never touch uninsulated telephone wires or terminals unless the

telephone wiring has been disconnected at the network interface.

■

Use caution when installing or modifying telephone lines.

■

Use only AT&T-manufactured MERLIN LEGEND Communications

System circuit modules, carrier assemblies, and power units in the

MERLIN LEGEND Communications System control unit.

■

Use only AT&T-recommended/approved MERLIN LEGEND

Communications System accessories.

■

If equipment connected to the analog extension modules (008, 408,

408 GS/LS) or to the MLX telephone modules (008 MLX, 408 GS/LSMLX) is to be used for in-range out-of-building (IROB) applications,

IROB protectors are required.

Installation

xv

Page 17

Safety

■

Do not install this product near water, for example, in a wet basement

location.

■

Do not overload wall outlets, as this can result in the risk of fire or

electrical shock.

■

The MERLIN LEGEND Communications System is equipped with a

3-wire grounding-type plug with a third (grounding) pin. This plug will

fit only into a grounding-type power outlet. This is a safety feature. If

you are unable to insert the plug into the outlet, contact an electrician

to replace the obsolete outlet. Do not defeat the safety purpose of the

grounding plug.

■

The MERLIN LEGEND Communications System requires a

supplementary ground.

■

Do not attach the power supply cord to building surfaces. Do not

allow anything to rest on the power cord. Do not locate this product

where the cord will be abused by persons walking on it.

■

Slots and openings in the module housings are provided for

ventilation. To protect this equipment from overheating, do not block

these openings.

■

Never push objects of any kind into this product through module

openings or expansion slots, as they may touch dangerous voltage

points or short out parts, which could result in a risk of fire or electrical

shock. Never spill liquid of any kind on this product.

■

Unplug the product from the wall outlet before cleaning. Use a damp

cloth for cleaning. Do not use cleaners or aerosol cleaners.

■

Auxiliary equipment includes answering machines, alerts, modems,

and fax machines. To connect one of these devices, you must first

have a Multi-Function Module (MFM).

■

Do not operate telephones if chemical gas leakage is suspected in

the area. Use telephones located in some other safe area to report the

trouble.

xvi Installation

Page 18

Safety

!

WARNING:

■

For your personal safety, DO NOT install an MFM yourself.

■

ONLY an authorized technician or dealer representative shall install,

set options, or repair an MFM.

■

To eliminate the risk of personal injury due to electrical shock, DO

NOT attempt to install or remove an MFM from your MLX telephone.

Opening or removing the module cover of your telephone may expose

you to dangerous voltages.

SAVE THESE INSTRUCTIONS

Installation xvii

Page 19

Safety

xviii Installation

Page 20

About This Book

The MERLIN LEGEND Communications System is an advanced digital

switching system that integrates voice and data communications features.

Voice features include traditional telephone features, such as Transfer and

Hold, and advanced features, such as Group Coverage and Park. Data

features allow both voice and data to be transmitted over the same system

wiring.

Intended Audience

This book is intended for qualified field technicians who install and upgrade

the system.

How to Use This Book

Qualified technicians can use this book as a guide to installation and

upgrading procedures. The technician is given specific steps for installing all

units of the control unit, telephones, adjuncts and data equipment.

Installation

xix

Page 21

How to Use This Book

later in this section, provides a complete list of system

Refer to the following documentation for additional information:

■

Equipment and Operations Reference

on system hardware, telephones, and other equipment.

■

Feature Reference

communications system.

■

System Planning

system for installation.

■

System Programming

system features.

■

Users’ guides and Operators’ Guides give procedural instructions for

programming and using telephone features.

“Related Documents,”

documentation together with ordering information.

In the U.S.A. only, AT&T provides a toll-free customer Helpline (1 800 628-

2888) 24 hours a day. Call the Helpline, or your AT&T representative, if you

need assistance when installing, programming, or using your system.

provides detailed information

provides details on the features of the

provides procedures and forms for planning a

gives procedural instructions for programming

xx Installation

Page 22

Terms and Conventions Used

Terms and Conventions Used

In this document, the terms in the following list are used in preference to

other, equally acceptable terms for describing communications systems.

Lines, Trunks and Facilities

Facility

telephone system and the telephone company central office. Technically a

trunk

Communications System to the central office. Technically, a

start facility or a communications path that does not connect two switches

(for example, an intercom line or a Centrex line). However, in actual usage,

the terms

use

refer to

start trunk, Direct Inward Dialing (DID) trunk, and so on. When you talk to

your local telephone company central office, ask them what terms they use

for the specific facilities they connect to your system.

Some older terms have been replaced with newer terms. The following list

shows the old term on the left and the new term on the right:

is a general term that designates a communications path between a

connects a switch to a switch, for example the MERLIN LEGEND

line

is a loop-

line

and

trunk

are often applied interchangeably. In this book, we

line/trunk

and

lines/trunks

digital facilities

to refer to facilities in general. Specifically, we

. We also use terms such as personal line, ground-

trunk module line/trunk module

trunk jack line/trunk jack

station extension

station jack extension jack

analog data station modem data station

digital data station terminal adapter

7500B data station terminal adapter

analog voice and analog data station analog voice and modem data

digital voice and analog data station MLX voice and modem data

analog data only station modem data only station

digital data only station terminal adapter only station

7500B data only station terminal adapter only station

digital voice and digital data station MLX voice and terminal

adapter station

MLX voice and 7500B data station MLX voice and terminal

adapter station

Installation

xxi

Page 23

Product Safety Labels

Typographical Conventions

Certain type fonts and styles act as visual cues to help you rapidly

understand the information presented:

Example Purpose

It is

very

important that you follow

these steps. You

wristband before touching the

connection.

The part of the headset that fits over

one or both ears is called a

headpiece.

If you press the Feature button on an

MLX display telephone, the display

lists telephone features you can

select. A programmed Auto Dial

button gives you instant access to an

inside or outside number.

Choose

screen.

To activate Call Waiting, dial

Ext Prog

must

attach the

from the display

*11

.

Italics indicate emphasis.

Italics also set off special terms.

The names of fixed-feature, factoryimprinted buttons appear in bold. The

names of programmed buttons are

printed as regular text.

Plain constant-width type indicates text

that appears on the telephone display

or personal computer (PC) screen.

Constant-width type in italics indicates

characters you dial at the telephone or

type at the PC.

Product Safety Labels

Throughout these documents, hazardous situations are indicated by an

exclamation point inside a triangle and the word

!

WARNING:

Warning indicates the presence of a hazard that could cause death or

severe personal injury if the hazard is not avoided.

xxii Installation

caution

or

warning

.

Page 24

Security

on the inside front cover of this book and

Security

in Appendix A,

!

CAUTION:

Caution indicates the presence of a hazard that could cause minor

personal injury or property damage if the hazard is not avoided.

Security

Certain features of the system can be protected by passwords to prevent

unauthorized users from abusing the system. You should assign passwords

wherever you can and limit knowledge of such passwords to three or fewer

people.

Nondisplaying authorization codes and telephone numbers provide another

layer of security. For more information, see Appendix A, “Customer Support

Information” following

Throughout this document, toll fraud security hazards are indicated by an

exclamation point inside a triangle and the words Security Alert.

Maintenance and Troubleshooting

.

!

Security Alert:

Security Alert indicates the presence of toll fraud security hazard. Toll

fraud is the unauthorized use of your telecommunications system by an

unauthorized party (e.g., persons other than your company’s

employees, agents, subcontractors, or persons working on your

company’s behalf). Be sure to read “Your Responsibility for Your

System’s Security”

of Your System: Preventing Toll Fraud”

Support Information.”

“

“Customer

Installation xxiii

Page 25

Related Documents

Related Documents

In addition to this book, the documents listed below are part of the

documentation set. Within the continental United States, these documents

can be ordered from the AT&T GBCS Publications Fulfillment Center by

calling 1 800 457-1235.

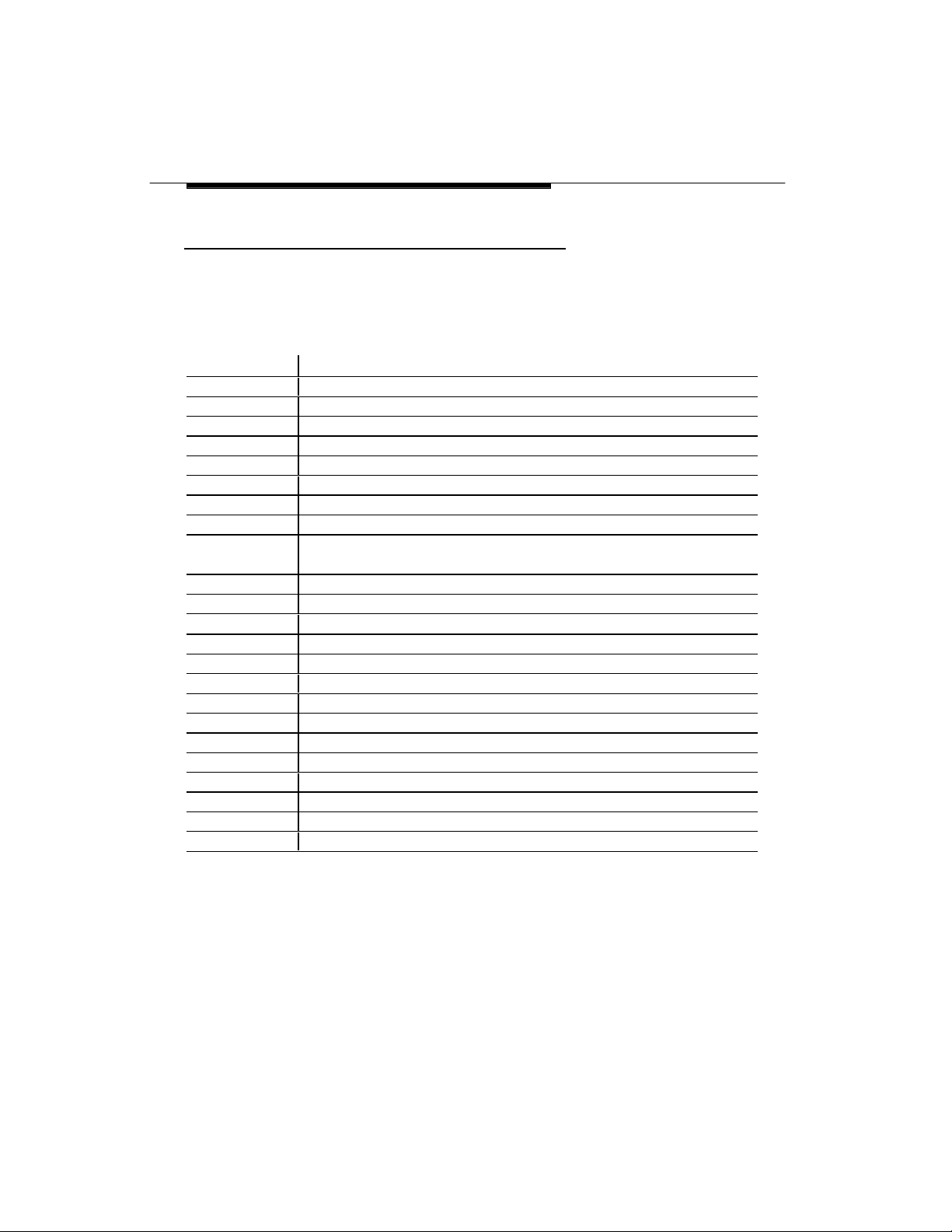

Document No. Title

System Documents

555-640-110

555-640-111

555-640-112

555-640-113

555-640-116

555-640-118

555-640-122

555-630-150

555-630-153

555-640-124

555-630-151

555-640-120

555-640-126

555-640-138

555-640-134

555-640-132

555-640-136

555-640-130

555-640-105

Feature Reference

System Programming

System Planning

System Planning Forms

Pocket Reference

System Manager’s Guide

Telephone User Support

MLX-10D, MLX-10DP, MLX-16DP

MLX-20L

Display Telephones User’s Guide

,

MLX-28D, and

MLX-10D Display Telephone Tray Cards (5 cards)

MLX-28D and MLX-20L Telephone Tray Cards (5 cards)

MLX-10 Nondisplay Telephone User’s Guide

MLX-10 Nondisplay Telephone Tray Cards (6 cards)

Analog Multiline Telephones User’s Guide

Single-Line Telephones User’s Guide

MDC 9000 and MDW 9000 Telephones User's Guide

System Operator Support

MLX Direct-Line Consoles Operator’s Guide

Analog Direct-Line Consoles Operator’s Guide

MLX Queued Call Console Operator’s Guide

Miscellaneous User Support

Calling Group Supervisor’s Guide

Data and Video Reference

xxiv Installation

Page 26

How to Comment on This Document

Document No. Title

Documentation for Qualified Technicians

555-640-140

555-025-600

Installation, Programming & Maintenance (IP&M) Binder

[consists of Installation, System Programming & Maintenance

(SPM), Maintenance & Troubleshooting

Toll Fraud Security

GBCS Products Security Handbook

How to Comment on This Document

We welcome your comments, both good and bad. Please use the feedback

form on the next page to let us know how we can continue to serve you. If the

feedback form is missing, write directly to:

Documentation Manager

AT&T

211 Mount Airy Road

Room 2W226

Basking Ridge, NJ 07920

Installation

xxv

Page 27

How to Comment on This Document

xxvi Installation

Page 28

Introduction

1

1

Installation of the MERLIN LEGEND Communications System involves the

following:

■

Installing the control unit

■

Installing the telephones

■

Connecting system wiring

■

Installing optional equipment

This chapter provides an overview of the installation process, which varies

from customer to customer.

Installation Sequence

The following is a list of the components that the system can include and

shows the order in which you should install them. When installing your

customer’s system, try to adhere to this order as much as possible:

1. Install the control unit (required).

2. Connect power accessories to the control unit (optional).

3. Install the telephones (required) and adjuncts (optional).

4. Connect the telephones to the control unit (required).

Introduction

1–

Page 29

System Forms

5. Connect the control unit to the network interface (required).

6. Connect the channel service unit (CSU) to the 100D module on the

control unit (required only with the 100D module).

7. Connect the printer and PC to the control unit (optional).

8. Connect data equipment to the control unit (optional).

9. Initialize and test the system (required).

10. Install the control unit housing (required).

11. Install applications (optional).

A list of required tools and equipment is given before each installation

procedure.

System Forms

Some of the installation procedures in this guide refer to system forms. These

forms indicate information that is specific to your customer’s system. The

forms you need should be included with the system programming disk or

memory card, which contains all of the programming specifically for your

customer’s system.

If you are upgrading an existing system and do not have the required forms

for your customer’s system, you can load System Programming and

Maintenance (SPM) and print out the required forms.

If you find that you do not have a completed set of system forms for your

customer’s system, contact your technical support organization or the

Customer Service Center (CSC). See the inside front cover for telephone

numbers.

The system forms that you need are specific for each system, and include

some or all of those described in the following sections.

1–2 Introduction

Page 30

Installing

3

System Forms

Installing the Control Unit

■

Form 1, System Planning. Some procedures in Chapter 2, “

the Control Unit,” refer to the Control Unit Diagram, which is printed on

the reverse side of this form.

■

Form 3c, Incoming Trunks: Tie. If you install a 400EM module in the

control unit, use this form to determine the appropriate switch settings

prior to installation.

Installing Telephones (Required) and Adjuncts (Optional)

The following forms indicate the telephones and adjuncts that you must install:

■

Form 2a, System Numbering: Extension Jacks

■

Form 2b, System Numbering: Digital Adjuncts

■

Form 4b, Analog Multiline Telephone

■

Form 4d, MLX Telephone

■

Form 4e, MFM Adjunct: MLX Telephone

■

Form 4f, Tip/Ring Equipment

■

Form 5a, Direct-Line Console (DLC): Analog

■

Form 5b, Direct-Line Console (DLC): Digital

■

Form 5c, MFM Adjunct: DLC

■

Form 5d, Queued Call Console (QCC)

Introduction

1–

Page 31

Programming the System

Connecting the Network Interface

The following forms indicate the trunks that you must connect to the control

unit. Information regarding the channel service unit (CSU) is included on

these forms.

■

Form 2c, System Numbering: Line/Trunk Jacks

■

Form 3a, Incoming Trunks: Remote Access

■

Form 3b, Incoming Trunks: DS1 Connectivity (100D Module)

■

Form 3d, Incoming Trunks: DID

Connecting Data Equipment

The following forms indicate the data equipment you will need to set up data

stations.

■

Data Form 1a, Modem Data Station

■

Data Form1b, 7500B Data Station

■

Data Form 2, Data Hunt Groups

Programming the System

If you have a system programming disk created with SPM or a Translation

memory card, you do not need to program the system. Instead, you can use

the disk or memory card to restore the system; see Chapter 7, “Initializing and

Testing the System,” for instructions. If you did not receive a disk or a memory

card and it is your responsibility to program the system, see

Programming

for instructions.

1–4 Introduction

System

Page 32

Upgrading the System

then Chapter 7,

5

Upgrading the System

If you are upgrading to Release 4.0 from Release 3.1, 3.0, 2.1, 2.0, 1.0, 1.1, or

from the MERLIN

the System,”

instructions.

NOTE:

You cannot retain the programming from the MERLIN ll Communications

System. You must first upgrade the hardware, then reprogram the system.

II Communications System, refer to Chapter 9, “Upgrading

“Initializing and Testing the System,” for upgrade

Introduction

1–

Page 33

Upgrading the System

1–6 Introduction

Page 34

Installing the Control Unit

1

2

If you have not read Chapter 1, “Introduction,” do so before continuing with

this chapter.

Overview

Installing the control unit involves the following procedures:

■

Preparation requirements

■

Installing the backboard

■

Meeting the power and grounding requirements

■

Checking the total unit load

■

Installing the basic carrier

■

Installing any expansion carriers

■

Installing the power supply

■

Installing the processor

■

Installing the line/trunk and extension modules

■

Connecting the control unit to AC power

■

Powering up the system

■

Powering down the system

Installing the Control Unit

2–

Page 35

Overview

The following sections provide detailed instructions for these installation

procedures. Follow the procedures in the order in which they are presented.

Environment

The control unit must be installed on a backboard. The placement of the

backboard, and the control unit on it, requires careful consideration. Make

sure you install the backboard in an area that meets all of the environmental

requirements listed in Table 2–1.

Table 2–1. Environmental Requirements

Operating

Temperatures

Humidity

Airborne

Contamination

Ventilation

Electrical Fields

Heat Dissipation

!

WARNING:

Do not install the control unit outdoors.

40o–104oF (4o–40oC)

Optimal temperature: 60oF (15.6oC)

20%–80%

Do not expose the control unit to moisture, corrosive gases, dust,

chemicals, spray paint, or similar material.

Allow at least 1 in. (2.54 cm) on the right and left sides of the control

unit and 12 in. (30.48 cm) minimum, above and below it, to prevent

overheating.

Do not place the control unit near extreme heat sources (for example:

furnaces, heaters, attics, or direct sunlight).

Do not expose the control unit to devices that generate electrical

currents causing interference (such as arc welders or motors).

Basic carrier: 500 Btu/hr

Basic carrier: with one expansion carrier 1000 Btu/hr

Basic carrier: with two expansion carriers 1500 Btu/hr

2–2 Installing the Control Unit

Page 36

Overview

Basic carrier: 14 in. wide by 23 in. high by 12 in. deep

Basic carrier and one expansion carrier: 25 in. wide by 23 in. high

3

Electrical Noise/Radio-Frequency Interference

In most cases, electrical noise is introduced to the system through trunk or

telephone cables. However, electromagnetic fields near the control unit can

also cause noise in the system. Therefore, you should

unit and cable runs in areas where a high electromagnetic field strength

exists.

Radio transmitters (AM and FM), television stations, induction heaters, motors

(with commutators) of 0.25 horsepower (200 watts) or greater, and similar

equipment are leading causes of radio-frequency interference (RFI). Small

tools with universal motors are generally not a problem when they operate on

separate power lines. Motors without commutators generally do not cause

interference.

Field strengths below 1.0 volt per meter are unlikely to cause interference. To

estimate the field strength produced by radio transmitters, divide the square

root (√) of the emitted power, in kilowatts, (÷) by the distance from the antenna

in kilometers which equals (=) the field strength in volts per meter.

not

place the control

Example: √49,000 kw

This yields the approximate field strength in volts per meter and is relatively

accurate for distances greater than about half a wavelength (492 ft., or 150 m,

for a frequency of 1000 Hz). If the result exceeds 1.0 volt per meter, you may

have to install shielded cables and or Z200A filters. See Appendix A,

“Customer Support Information,” following

for FCC Part 15 radio frequency regulations.

= 7,000 ÷ 10 km (6.2 miles) = 0.7 volts per meter

Control Unit Requirements

■

Dimensions

—

—

by 12 in. deep

Maintenance and Troubleshooting

Installing the Control Unit

2–

,

Page 37

Overview

Basic carrier and two expansion carriers: 37 in. wide by 23 in. high

Within 5 ft. (152 cm) of an AC power outlet that is

not

switch-

Within 25 ft. (762 cm) of the network interface, or use an Off-

Within 1000 cable ft. (305 m) of telephones, or use an OPRE (for

¾-inch plywood

Check with the local building code enforcement agency to see

—

■

Location

by 12 in. deep

—

controlled

—

Premises Range Extender (OPRE)

—

!

basic telephones)

CAUTION:

The AC outlet for the control unit cannot be switch-controlled. Plugging

the control unit into such an outlet invites accidental disconnection of

the system.

Hardware Preassembly Process

If an installation is to be preassembled, wired, programmed, and tested on

the new lightweight plastic backboard, see “Installing the Backboard.”

Backboard Requirements

The backboard should be wide enough to accommodate the carrier and up to

two additional carriers, assuming that system growth is anticipated. There

should be enough room on each side of the control unit for the necessary

wiring fields.

To accommodate the maximum control unit size, make sure the backboard

meets the following requirements:

■

Material

—

—

whether fire-retardant material is required.

2–4 Installing the Control Unit

Page 38

AC Power and Grounding

Make sure that the material meets local building codes.

With Systimax wiring: 7 ft. wide by 4 ft. high

Without Systimax wiring: 6 ft. wide by 3 ft. high

5

—

■

Dimensions

—

—

Installing the Backboard

When you are certain that the backboard meets the requirements indicated

above, or is the new lightweight plastic material backboard with

preassembled equipment in place, attach the backboard to the wall.

Use the following mounting hardware:

■

For a wood mounting surface, use wood screws.

■

For brick, cinderblock, or concrete, use masonry anchors.

■

For plaster or plasterboard, use toggle bolts.

■

For sheet metal, use sheet-metal screws and attach them to the

structural members.

NOTE:

The mounting hardware should resist a combined pullout force of at least 650

pounds (295 kilograms).

AC Power and Grounding

Proper power and grounding are essential for the system to run correctly and

safely.

!

CAUTION:

If any of the following requirements are not met, the customer must

contact a licensed electrician. Do not install the system until all

requirements are met.

Installing the Control Unit 2–

Page 39

Approved Grounds,

later in

1).

includes complete installation instructions.

below,

AC Power and Grounding

Verify that all of the following power and grounding requirements are met:

■

The load center of appropriate current rating must be equipped with

circuit breaker(s) labeled

■

Each breaker must protect one dedicated quad AC outlet or two

120 V AC, 15 amps

.

dedicated duplex AC outlets.

■

All AC outlets must connect to the same load center and the ground

wire must connect to the single-point ground bar on the first AC outlet

(see Figure 2–1).

■

One outlet must have an attached ground bar connected by a #6 AWG

copper wire to an approved ground (see “

this chapter, for a description of approved grounds). This ground bar

is the system’s single-point ground (see Figure 2–

■

To prevent someone from accidentally shutting off the power,

connect the control unit to a switch-controlled outlet.

■ The AC outlet should be within 5 ft. (152 cm) of the control unit.

■

Each carrier requires one AC outlet receptacle.

■

Auxiliary equipment requires additional AC outlets.

■

If a printer or PC is installed on the system, it must be plugged into the

same AC branch as the power supply of the basic carrier.

”

do not

If the printer or PC is 50 ft. (15 m) or more from the control unit, or is

plugged into a different AC circuit, Asynchronous Data Units (ADUs)

must be installed as well. Chapter 5, “Installing the PC, CAT, or

Printer,”

■

The AC power requirements indicated in “AC Outlet Tests,”

must be met.

2–6 Installing the Control Unit

Page 40

AC Power and Grounding

1. AC Grounding Requirements

7

From AC

Load Center

(2 separately

fused 15 A

circuits)

HUBBELL

Receptacles

(5262 15 A

or equivalent)

Ground Wire

#14 AWG

4" Box (RACO 230

or equivalent)

Figure 2–

Single-Point

!

CAUTION:

Ground

Ground Bar Mounted

on a 4" Box (Square

"D" PK9GTA or

approved equivalent)

Approved

Building Ground

#12 or #14 AWG Copper

Wire to Each Power Supply

Grounding Screw

4" Cover

(RACO 807

or equivalent)

Ground Wire

#6 AWG Copper

The AC outlet for the control unit cannot be switch-controlled. Plugging

the control unit into such an outlet invites accidental disconnection of

the system. The AC outlet must be properly wired as described in “AC

Outlet Tests.”

Installing the Control Unit 2–

Page 41

AC Power and Grounding

Table 2–2. AC Power Requirements

Parameter Value

Nominal voltage 117 V AC

Voltage range 110–125 V AC

Frequency 60 Hz +/– 5%

Maximum current 3 amps per power supply

Power consumption 225 watts per power supply

AC Outlet Tests

If the AC outlet tests indicate that any of the power requirements in Table 2–2

are not met, your customer must contact a licensed electrician.

the system until all requirements are met.

If the AC outlet tests reveal any of the following conditions, they must be

corrected before you install the system:

■

Open ground

■

Hot and neutral reversed

■

Open hot

■

Open neutral

■

Hot and ground reversed

Do not

install

!

WARNING:

Hazardous voltages are present during the following tests. Follow all

instructions carefully when working with AC power line voltages.

2–8 Installing the Control Unit

Page 42

AC Power and Grounding

2. Measuring the AC Outlet Voltages

9

Using an Ideal 61-035 Circuit Tester (or Equivalent)

1 Plug the circuit tester into the outlet that you want to test.

If the circuit is properly grounded, the yellow and white lights on the tester

turn on.

2 Unplug the circuit tester.

Using a Volt-Ohm Milliammeter (VOM)

1 Set the VOM to the lowest scale on which you can read 130 V AC.

2 Measure the AC outlet voltages. See Figure 2–2.

■

Phase to ground should be 110 to 125 V AC.

■

Neutral to ground should be less than 1 V AC.

■

Phase to neutral should be 110 to 125 V AC.

110 - 125

Volts AC

Figure 2–

!

Neutral

Less than

1.0 Volt AC

Phase

(HOT)

Ground

110 - 125

Volts AC

WARNING:

If the voltage readings do not measure the values required, the AC

outlet is improperly wired—do not install the system. Advise the

customer to have a licensed electrician correct the problem.

Installing the Control Unit 2–

Page 43

1 and 2

3 show this connection.

AC Power and Grounding

Grounding Requirements

Proper grounding of the installation site safeguards the system by protecting it

from the following:

■

Lightning

■

Power surges

■

Power crosses on central office trunks

■

Electrostatic discharge (ESD)

When installing the control unit, make sure you meet the following grounding

requirements:

■

The control unit, the central office trunk protector, and the AC power

service panel should be as close to each other as possible.

■

Because equipment can be located throughout a building, the

National Electrical Code requires that the ground point for the central

office trunk protector be bonded to the AC power ground as shown in

Figure 2–3.

■

The AC outlet and the single-point ground bar must be properly

grounded as shown in Figure 2–1 and Figure 2–3.

■

Each power supply in the control unit must be connected to the singlepoint ground bar by a #12 AWG or a #14 AWG solid copper wire.

Figures 2–

This wire run should be as short as possible, preferably within 5 ft.

(152 cm), not to exceed 10 ft. (305 cm). See “Approved Grounds,”

later in this chapter, for more information.

■

The AC outlet must be connected to the 147A protector with #12 AWG

or a #14 AWG solid copper wire.

–

2–10 Installing the Control Unit

Page 44

AC Power and Grounding

3. Central Office and AC Grounds

To Central

Office or

Serving

Facility

CO

Lines

#12 or #14

AWG

Ground

Wire

CO

Line

Protector

Earth

Ground

Network

Interface

Coupled Bonding

Conductor (optional)

Power

)

(

Supply

CAUTION

TURN OFF

POWER BEFORE

INSERTING OR

REMOVING

MODULES

Plug

#6 AWG

Ground

Wire

Power

Ground

Bond

Wire

Processor

Outlet

Rod

DIW or

25-Pair Cable

AC

Single -

Point

Ground

Bar

Shield

Ground

CO

Wiring

Field

B

W

GND (Green)

Commercial

Power

Power

Service

D2R

Cords

Figure 2–

Installing the Control Unit 2–11

Page 45

AC Power and Grounding

Other local metal underground systems or structures, such as

Rod and pipe electrodes, a 5/8-in. (1.58-cm) solid rod or ¼-in.

Plate electrode, a minimum of 2 square ft. (61 square cm) of

!

WARNING:

Improper ground can cause equipment failures, service outages, and

electrical shock. Verify that the AC power uses an approved ground for

its primary ground, that all voltage-limiting devices are grounded to an

approved ground, and that the ground is one of the approved grounds

listed below.

Approved Grounds

Approved grounds are listed below, in order of preference:

■

Building Steel. The most preferred ground.

■

Acceptable Water Pipe. Must be a metal,

underground water pipe at least ½ in. (1.27 cm) in diameter, and in

direct contact with the earth for at least 10 ft. (3 m).

It must be electrically continuous so that the protector ground is

uninterrupted. (Check for insulated joints, plastic pipe, and plastic

water meters that might interrupt electrical continuity.)

A metallic underground water pipe must be supplemented by the

metal frame of the building, a concrete-encased ground, or a ground

ring. If these grounds are not available, the water pipe ground can be

supplemented by one of the following types of grounds:

not plastic or vinyl

,

—

tanks and piping systems,

—

(0.63-cm) conduit or pipe electrode driven to a minimum depth of

8 ft. (244 cm)

—

metallic surface exposed to the exterior soil

2–12 Installing the Control Unit

but not gas pipes

Page 46

AC Power and Grounding

At least 20 ft. (6.1 m) of one or more steel reinforcing rods, each at

20 ft. (6.1 m) of bare copper conductor not smaller than #4 AWG,

This electrode must be located within and near the bottom of a

Ground ring, consisting of at least 20 ft. (6.1 m) of bare copper

this is a safety

■

Concrete-Encased Ground. Must be an electrode, consisting of one

of the following:

—

least ½ in. (1.27 cm) in diameter

—

encased in 2 in. (5 cm) of concrete

—

concrete foundation or footing that is in direct contact with the

earth.

—

conductor (not smaller than #2 AWG) encircling the building. The

ground ring must be in direct contact with the earth and buried at

least 2.5 ft. (77 cm) below the earth’s surface.

!

WARNING:

Do not use a metal underground gas piping system—

risk.

Central Office Trunk Protection

The telephone company is responsible for providing the following protection

of central office (co) trunks at the entrance to the site:

■

Carbon blocks or gas discharge tubes connected to an approved

ground

■

Adequate bonding of the central office trunk protector ground and the

power company ground

!

CAUTION:

Check these requirements with a simple, visual inspection. If you cannot

verify that the central office grounding requirements are met, contact the

central office. Do not connect the control unit to the central office trunks

until you are certain that these requirements are met.

Installing the Control Unit 2–13

Page 47

AC Power and Grounding

Heavy Lightning Protection

For most surges, adequate protection is provided by meeting the previously

listed requirements. Additional protection is required when the customer is

located in a heavy lightning area.

Connect a 147A protector to the system to limit surges from the AC lines and

up to four CO trunks.

For systems with more than four CO trunks, do the following:

■

Connect a 146A protector to the 147A protector, providing protection

for an additional four trunks.

■ Connect up to three (maximum) 146A protectors to a 147A protector,

allowing a maximum of 16 trunks on one 147A protector.

■

For more than 16 trunks, add another 147A protector and continue

adding 146A protectors as needed. See Table 2–3 for various

configurations and Figure 2–4 for a typical 147A protector installation.

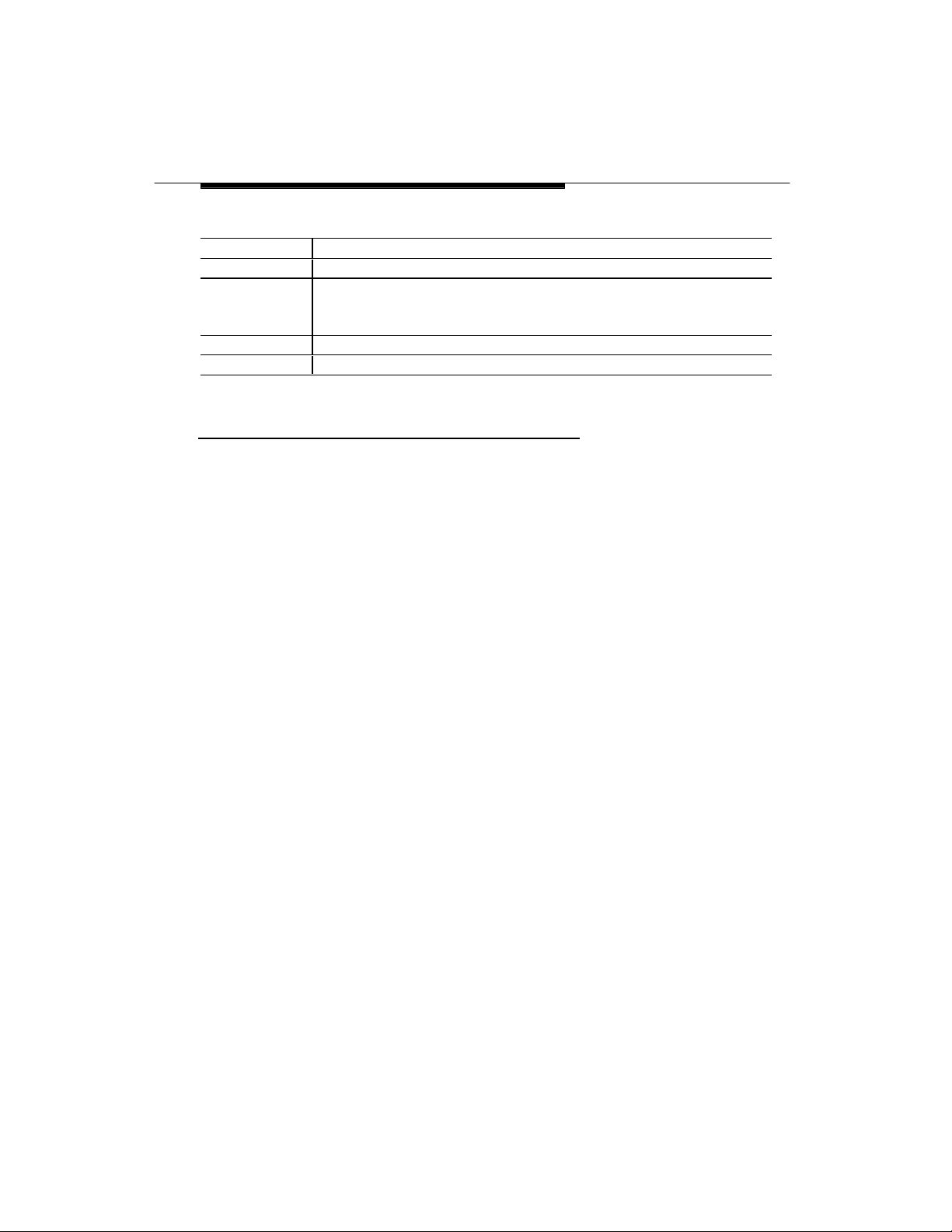

Table 2–3. Heavy Lightning Protection

Number of CO Trunks Required Protectors

1–4 147A

5–8 147A and a 146A

9–12 147A and two 146As

13–16 147A and three 146As

17–20 Second 147A

21–24 Second 147A and one 146A

NOTES:

1. When you use the second 147A, you can connect the 146As in any

combination, up to a maximum of three 146As per 147A.

2. For detailed installation instructions, see the documentation packaged with

the protectors.

2–14 Installing the Control Unit

Page 48

AC Power and Grounding

4. Installing 146A and 147A Protectors

CONTROL UNIT

TEL CO LINE

CONTROL UNIT

TEL CO LINE

CONTROL UNIT

TEL CO LINE

CONTROL UNIT

TEL CO LINE

To Central

Office

Cross-Connect

Field

Status

Indicator

Ground

Connection

AC Surge/Suppressor

Protector

AC

Outlet

To

Control

Unit

147A Protector

Light

Strap

AC

146A

Protector

Ground

Strap

8 MLX (Digital) Telephones

008 MLX

408

PROCESSOR

POWER

CAUTION

ON

OFF

Turn off

power before

inserting or

removing

modules

AG INPUT

FR

GND

#12 or #14

AWG Ground Wire

To Power Supply

Module

44GS or LS Outside Lines/

408 GS/LS

012

8 Analog Telephones (ATL)

Control Unit

Figure 2–

Connect telecommunications

equipment only to these outlets.

Maximum load 12.5A

Installing the Control Unit 2–15

Page 49

Unit Loads

Unit Load Calculation Worksheet.

Unit Loads

A unit load is a measure of power (1.9 watts) that you use to determine the

electrical load that the components listed below place on the control unit’s

power supply.

Only the telephones and adjuncts that connect to the analog and digital

extension jacks (ports) on the control unit require unit load calculation. When

calculating unit load, do not include any equipment with its own power supply.

Checking Unit Loads

In the event of maintenance or equipment changes, recalculate the unit loads

for each carrier where there is a new configuration. Use the worksheet in

Appendix B, “

As a general rule, if you can distribute the 800 DID modules and telephone

modules equally across the carriers, you prevent unnecessary drain on any

one carrier. However, the rule varies depending on the system’s mode. The

next two sections provide the rules for calculating unit loads in various modes.

■

Telephones and adjuncts

■

800 DID modules

”

Unit Loads for Hybrid/PBX Mode

Older power supplies (models 391A1 or 391A2) generally supports six

modules of any type in Hybrid/PBX mode, without requiring an upgrade to a

newer power suppy (model 391A3). If the following conditions are true,

however, the unit loads on a carrier can exceed the 54-unit maximum and,

therefore, require a newer power suppy (model 391A3):

■

All six carrier slots are occupied by MLX telephone or analog multiline

telephone modules.

■

The carrier has a total of more than 45 MLX-20L telephones or

34-button analog multiline telephones installed.

2–16 Installing the Control Unit

Page 50

Installing the Basic Carrier

Unit Loads for Key or Behind Switch Mode

In a Key or Behind Switch system with four or fewer modules, no calculation is

needed. The older power supplies (models 391A1 or 391A2) generally

supports four modules of any type. With more than four modules, a newer

power suppy (model 391A3) may be needed.

Installing the Basic Carrier

Continue with this procedure only if you have met all of the requirements

discussed earlier in this chapter.

NOTE:

When you mount the basic carrier onto the backboard, leave 29 in. (73.66 cm)

of backboard to the right. This allows you to easily install and remove the

control unit cover, and also allows enough room for system expansion to the

right for the total length of up to three carriers.

Installing the Control Unit

2–17

Page 51

Installing the Basic Carrier

5. Marking the Basic Carrier Screw Holes

To install the basic carrier, follow the steps below:

1 Mark the screw-hole locations on the backboard, using the basic carrier

or the template supplied with the plastic preassembled backboard as a

guide. See Figure 2–5.

Make sure the carrier is level before marking the holes.

2 Drill a pilot hole in the center of each of the four screw-hole marks.

3 Anchor the screws approximately halfway into the backboard.

4 Position the carrier on the screws and slide the carrier to the left.

5 Tighten the screws.

Mounting Surface

Figure 2–

2–18 Installing the Control Unit

Mounting

Screw

Backboard

Basic

Carrier

Page 52

Installing the Power Supply

later in this chapter. Failure to comply with this procedure

Installing a Copper Shield,

later

Installing the Power Supply

!

WARNING:

Do not attach any cables or power cords to the power supply until it is

installed in the carrier.

Do not power up the control unit until all of the modules and power

equipment are installed. Once they are installed, refer to “Powering Up

the System,”

can result in shock hazard and or damage to the equipment.

If you are upgrading an older system and a ring generator is specified in

the system forms (Control Unit Diagram), install it in the power supply

before putting the power supply in the carrier. The procedure is detailed

in

Maintenance and Troubleshooting.

For expansion carriers with older power supply modules only, a copper

shield must be installed on the power supply before installing it in the

carrier. The procedure is explained in “

in this chapter.

”

Before touching leads, connectors, pins, and other components, use a

properly grounded wrist strap, to prevent damage from electrostatic

discharge (ESD).

Remove the protective cover from the gold-finger connector (on the

back of the power supply) before inserting it into the carrier.

Installing the Control Unit 2–19

Page 53

Installing the Power Supply

Installing the power supply can involve as many as four procedures,

depending on the system configuration. The procedures are:

■

Turning off all power to the control unit

■

Installing a copper shield [for older power supply modules (391A1,

391A2, 391B1) only]

■

Installing the ferrite cores

NOTE:

It is not necessary to install ring generators in a new system with new 012

(apparatus code 517G13 or later) modules or new 008 (apparatus code

517D28 or later letter). If you are upgrading or using older modules, see

Maintenance and Troubleshooting

.

Turning Off the Power

1 Turn off

2 Disconnect

each

power supply.

all

power cords and auxiliary units.

Installing a Copper Shield

The added power supply in each expansion carrier can cause excessive

noise in the module occupying the next slot. To eliminate this noise, a copper

foil shield is installed over the power supply. These shields and their labels

are packaged in the power unit shielding kit included with the expansion

carrier.

NOTE:

The 391A3 and 391B2 power supply modules do not require copper

shielding. Perform this procedure for older power supply modules (391A1,

391A2, and 391B1) only.

2–20 Installing the Control Unit

Page 54

Installing the Power Supply

To install a copper shield, follow the steps below. Refer to Figure 2–6

throughout the procedure.

1 Make sure all power is off.

2 Place the power supply on a flat surface with the right side up (as viewed

from the front edge).

3 Wipe the module free of any dust or dirt.

4 Peel the backing paper from the smaller copper-foil shield to expose the

adhesive.

Check the positioning of the foil shields before sticking them to the side of the

module. Once in place, the foil is difficult to remove.

5 Position the foil on the upper part of the module and work out any air

bubbles as you press the foil firmly in place.

6 Peel the backing paper from the larger copper-foil shield to expose its

adhesive.

7 Position the foil on the lower part of the module.

a The shields

b They should

must

meet.

not

overlap or have

any space

between them.

Installing the Control Unit

2–21

Page 55

Installing the Power Supply

6. Installing a Copper Shield in the Power Supply

CAUTION

TURN OFF

POWER BEFORE

INSERTING OR

REMOVING

MODULES

Upper Copper

Foil Shield

Lower Copper

Foil Shield

Power Unit

Information

Label

UL Label

or

CSA Label

Figure 2–

8 Tuck the foil shield tightly along the ledge (or crease) of the housing and

work out any air bubbles as you press the foil firmly in place.

9 With the copper-foil shield in place, put the power unit information label

on the lower piece of foil.

10 Attach the UL or CSA label on the power supply below the copper-foil

shield.

2–22 Installing the Control Unit

Page 56

Installing the Power Supply

Installing the Power Supply Module in the Carrier

1 Lower the power supply module hook onto the rod on top of the carrier.

2 Make sure the connector on the module mates properly with the

connector on the carrier.

3 Push the module into the carrier until it locks into place.

Installing the Ferrite Cores

At this point, the power supply should have been installed in the carrier, but

there should be no cables or power cords attached to the power supply

module.

NOTE:

If you are upgrading a system, unplug the AC power cord and remove the

ground wire attached to the grounding screw on the front of the power supply.

Follow these steps to install the ferrite cores:

1 Feed the AC power and ground wire through the wire manager (refer to

Figure 2–7).

2 Open the ferrite cores by unsnapping the plastic case.

3 Attach a ferrite core around the AC power cord and the ground wire by

snapping the plastic case shut.

4 Attach the second ferrite core adjacent to the first ferrite core by

repeating Steps 2 and 3.

5 Slide the ferrite cores between the wire manager and the power supply

module (refer to Figure 2–7).

6 Attach the ground wire to the grounding screw on the power supply

module.

7 Check that the other end of the ground wire is connected to the terminals

of the single-point ground bar on the AC outlet box.

Installing the Control Unit

2–23

Page 57

Installing the Power Supply

7. Installing the Ferrite Cores

!

CAUTION:

Do not connect the power cord until the entire control unit is assembled.

AC Power Cord

POWER SUPPLY MODULE

Figure 2–

2–24 Installing the Control Unit

Ground Wire

Attach

Ferrite Cores

(Open Position)

CAUTION

TURN OFF

POWER BEFORE

INSERTING OR

REMOVING

MODULES

On/Off Power Indicator (Green LED)

-48 VDC Auxiliary Power Input Jack

On/Off Switch

AC Power Input

Grounding Screw

Wire Manager

Feed AC Power Cord and

Ground Wire through

Wire Manager

Page 58

Installing the Auxiliary Power Unit

Powering Up the System

Installing the Auxiliary Power Unit

The Control Unit Diagram on the back of Form 1, System Planning, indicates

whether an auxiliary power unit is required for the carrier that you are

installing.

NOTE:

Use the 9024 auxiliary power unit for new installations. You can continue to

use a previously installed 335A auxiliary power unit, as long as no new

telephones or modules are added to the carrier.

To install an auxiliary power unit, follow the steps below. Refer to Figure 2–8

throughout this procedure.

1 Turn off the switch on the power supply.

2 Mount the auxiliary power unit on a surface (preferably the backboard)

within 2 ft. (61 cm) of the control unit.

3 Plug the power unit line cord into the AUX POWER INPUT jack on the

power supply.

4 Plug the other end of the line cord into the AUX POWER jack on the

auxiliary power unit.

!

CAUTION:

Do not plug the power supply or the auxiliary power unit into the AC

outlet until you are ready to turn on the system, as described in

“

If the system is backed up by an Uninterruptible Power Supply (UPS),

connect the auxiliary power to the UPS.

Do not attach the power cord(s) to any building surfaces.

Use only the power unit line cord supplied with the auxiliary power unit.

An incorrect cord will damage the power supply and may damage

modules.

” later in this chapter.

Installing the Control Unit 2–25

Page 59

Installing the Auxiliary Power Unit

8. Installing an Auxiliary Power Unit

Auxiliary

Power

Unit

AC

INPUT

AUX Power Unit

AC Power Cord

AUX

POWER

AC

Outlet

-48 VDC

Auxiliary

-48 VDC

Power Cord

Power

Input

AC

Input

Ground

Wire

Processor

Ferrite

Cores

Control Unit

AC Power Cord

Figure 2–

2–26 Installing the Control Unit

Page 60

Installing Expansion Carriers

Upgrading

in Chapter 9 before continuing.

Installing Expansion Carriers

1 Locate the breakaway plastic tab on the right side of the previously

2 Align the connector of the expansion carrier with the card extender on

3 Mark the screw-hole locations on the backboard, using the expansion

4 Disconnect the expansion carrier connector from the previously mounted

5 Drill a pilot hole in the center of each of the four screw-hole marks.

If you are adding an expansion carrier to an existing system, see “

the Control Unit”

If you are to install one or more expansion carriers, follow the steps below to

mount each one. Refer to Figure 2–9 and Figure 2–5 throughout the procedure.

mounted carrier. Using a flat-blade screwdriver, gently pry the tab open

to expose the card extender.

the previously mounted carrier and slide the connector onto the

extender.

carrier or the template that comes with the preassembled plastic

backboard as a guide.

Make sure the carrier is level before marking the holes.

carrier and put the expansion carrier aside.

6 Anchor the screws approximately halfway into the backboard.

7 If housing clips are to be installed on the housing and this is the last

carrier in the control unit, place the housing clips around the right-hand

molding for the screws on the back of the carrier.

If not, go to Step 8.

8 Position the expansion carrier on the screws and slide it to the left, to

reconnect the expansion carrier card extender to the previous carrier’s

connector.

9 Make sure the connection is secure.

10 Make sure the carrier is level and that the housing clips extend as far as

possible from the right side of the carrier.

11 Tighten the screws.

Installing the Control Unit

2–27

Page 61

Installing Expansion Carriers

9. Connecting the Carriers

BASIC CARRIER EXPANSION CARRIER

BASIC CARRIER EXPANSION CARRIER

CONNECTOR

CARD

EXTENDER

(under the

breakaway tab)

BACKBOARD

BACKBOARD

Figure 2–

2–28 Installing the Control Unit

Page 62

Installing the Processor

Form 1, System Planning, indicates Permanent Key mode.

Form 2c, System Numbering: Line/Trunk Jacks, indicates no GS

Installing the Processor

Installing the processor includes the following procedures:

■

If

both

of the following conditions are true, follow the procedures in

Chapter 9, “Modifying the Processor for Key Mode.”

—

NOTES:

—

(ground-start) trunks in the Incoming Trunk Type column.

■

Insert the processor into the carrier as indicated in “Installing the

Processor in the Carrier,” later in this chapter.

1. If the system is programmed for Permanent Key mode, check the switch

setting. Refer to Chapter 9, “Modifying the Processor for Key Mode” for

detailed procedures. If the switch is set to Permanent Key-only operation,

all trunks revert to loop-start. If the switch is not set, any programmed

designation for ground-start trunks is retained.

The ground-start pool never has trunks assigned to it automatically, but

must be programmed after the ground-start ports are designated. Groundstart trunks are assigned to the ground-start pool on initialization, except in

a system switched for Permanent Key mode operation. (In Release 1.0,

ground-start and loop-start trunks automatically defaulted to loop-start.)

2. Beginning with Release 3.0, the feature module required for Release 2.1

and earlier is no longer needed. The Release 3.0 processor module

contains a PCMCIA memory card interface capable of accommodating a

4-MB memory card. This card is used to install or upgrade system

software and perform firmware upgrades on circuit modules. It can be

used to backup and restore system programming,

Installing the Control Unit

2–29

Page 63

Installing the Processor

!

CAUTION:

Before touching leads, connectors, pins, and other components when

handling the circuit board, use a properly grounded wrist strap to

prevent damage from electrostatic discharge (ESD).

Installing the Processor in the Carrier

To install the processor in the carrier, follow the steps below. Refer to Figure

2–10.

1 Remove the protective cover from the gold-finger connector on the back

of the processor.

2 Lower the hook on top of the processor module onto the rod on top of

the carrier in Slot 0, the first slot next to the power supply.

3 Make sure that the connector on the module mates properly with the

connector on the carrier as you swing the processor down into place.

!

CAUTION:

To avoid damage, do not force the module. If the module does not insert

easily, press the bottom rear locking tab, remove the module, and

inspect the module and carrier for damage or obstruction. The bottomrear locking tab is shown in Figure 2–10. This tab is used on all

modules.

If there is no damage and no obstruction, reinsert the module.

A damaged carrier or module must be replaced.

4 Push firmly until the processor snaps into place.

The processor should be securely attached to the carrier and locked in place

by the locking tab on the bottom rear of the processor.

2–30 Installing the Control Unit

Page 64

Installing the Processor

10. Installing the Processor into the Carrier

2

1

3

Figure 2–

Installing the Control Unit 2–31

Page 65

Installing the Modules

Installing the Modules

!

CAUTION:

Use a properly grounded wrist strap to prevent damage from

electrostatic discharge (ESD) when installing the modules, and avoid

touching leads, connectors pins, and other components.

Guidelines

Follow these guidelines when you install modules, as indicated on the Control

Unit Diagram of Form 1, System Planning:

■

Do not leave empty slots between modules. The system ignores

modules installed beyond any empty slot.

■

If a phantom module (a programmed empty slot) is indicated on the

Control Unit Diagram, make sure the slot remains empty and do not

install any modules to the right of it. The system ignores any modules

installed to the right of a programmed empty slot.

■

Make sure you install each module in its assigned slot. If you install a

module in the wrong slot, the system will not function properly.

■

Be sure to place all 012 modules and all 008 OPT modules without

built-in ring generators in carriers with modules that have ring

generators so that the modules without ring generators can be

supported.

NOTE:

All 016 modules and some 012 modules (apparatus code 517G13

or later) have built-in ring generators.

■