Page 1

ENGINE DRIVEN DRILL

WORKSHOP MANUAL

PAGE 1

ACN 000 583 924

STEP 1

View after removing

handles and LH

Casing Fig. 2

Fig. 2

STEP 2

Lift out clutch drum

and spur gear

assembly

Fig. 3

STEP 3

Lift out spur drive

gear and pinion

assembly

Fig. 4

STEP 5

Lift out main drive

gear assembly

Fig. 6

STEP 4

Lift out pinion and

spiral crown gear

assembly

Fig. 5

Thoroughly

clean all parts

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Remove

all screws

as shown

MANUAL 778

Atom products, including developments of AIRLIFT ® and BLOWMASTER® blowers, blower anti-vibration handle system,

SMARTFAN

®

impellers, and DRILLMASTER® engine powered drills with automatic reverse gear and rotary throttle control, are

extensively protected by many Patents Pending, Patents, Registered Designs, and Registered Shapes and many Trade Marks including

Atom Trade Mark 1,463,4000. Additionally, US Patent No. 8,210,272-B2 tiller construction also covers and protects Atom Lawn

Edger construction.

Registration No. 1470990 is a REGISTERED SHAPE of the Atom Lawn Edger consisting of three dimensional shape of lawn edgers

having a ground engaging wheel supporting a motor or engine and a pair of handles in a wheelbarrow-like configuration.

STEP 1

STEP 2

STEP 3

STEP 4

x11

x11

Fig. 1

Page 2

Atom Engine Drill: Inspect – Clean – Repair – Assemble

PAGE 2

2. Lift Drum and spur gear shaft out of casing. To replace Drum,

hold tightly in gloved hand and spin off clutch nut in left hand

rotation (normal RH thread) with air ratchet Fig. 7.

To reassemble fit clutch hub, drum, washer and screw nut up

fully by hand.

Washer under nut must fit over and around

clutch rib spigot.

! NOTE

Spur gear and shaft replaced as on assembly

as in Fig. 3.

! NOTE

3. To repair drive and pinion gears, remove 6mm screw. Slide

parts off. Replace parts if required. Fig. 8.

To remove pinion hold shaft in vice fitted with soft jaws (use

two pieces aluminium angle) and remove pinion in right

hand rotation (left hand thread). Fig. 9.

4. To replace pinion or spiral crown gear assembly, hold outer

gear diameter in vice with soft jaws and remove nut in left

hand (normal RH thread) rotation. Fig. 10.

5. To replace gears, bearings, clutch dogs, place rear end dog

clutch vertically in a strong vice (Fig. 11) fitted with soft jaws

or use two pieces of aluminium angle.

Remove locking collar, insert 12mm bar through grub screw

hole as shown in Fig. 11. Turn shaft clockwise (LH thread) to

remove clutch dog. Slide off all parts and inspect. Replace as

required. Reverse process to assemble.

6. To remove front gear dog, place shaft in vice (Fig. 12) and

tap counter clockwise (normal RH thread).

Clean all parts before reassembly. To assemble reverse above

procedure. Re-assemble in (reverse) sequence of Fig. 6, 5, 4,

3 and 2. Thoroughly grease all parts and pack about 30cc of

grease in and around all gear teeth. Install 2 casings rubber

gaskets, place top casing on, use 4-5 screws to hold together

then check gears turn smoothly. Complete final assembly.

Fig. 12

Fig. 7

Fig. 9

Fig. 8

Fig. 10

Fig. 11

Tighten nut by holding drum with gloved hand and air ratchet

drive (right hand rotation).

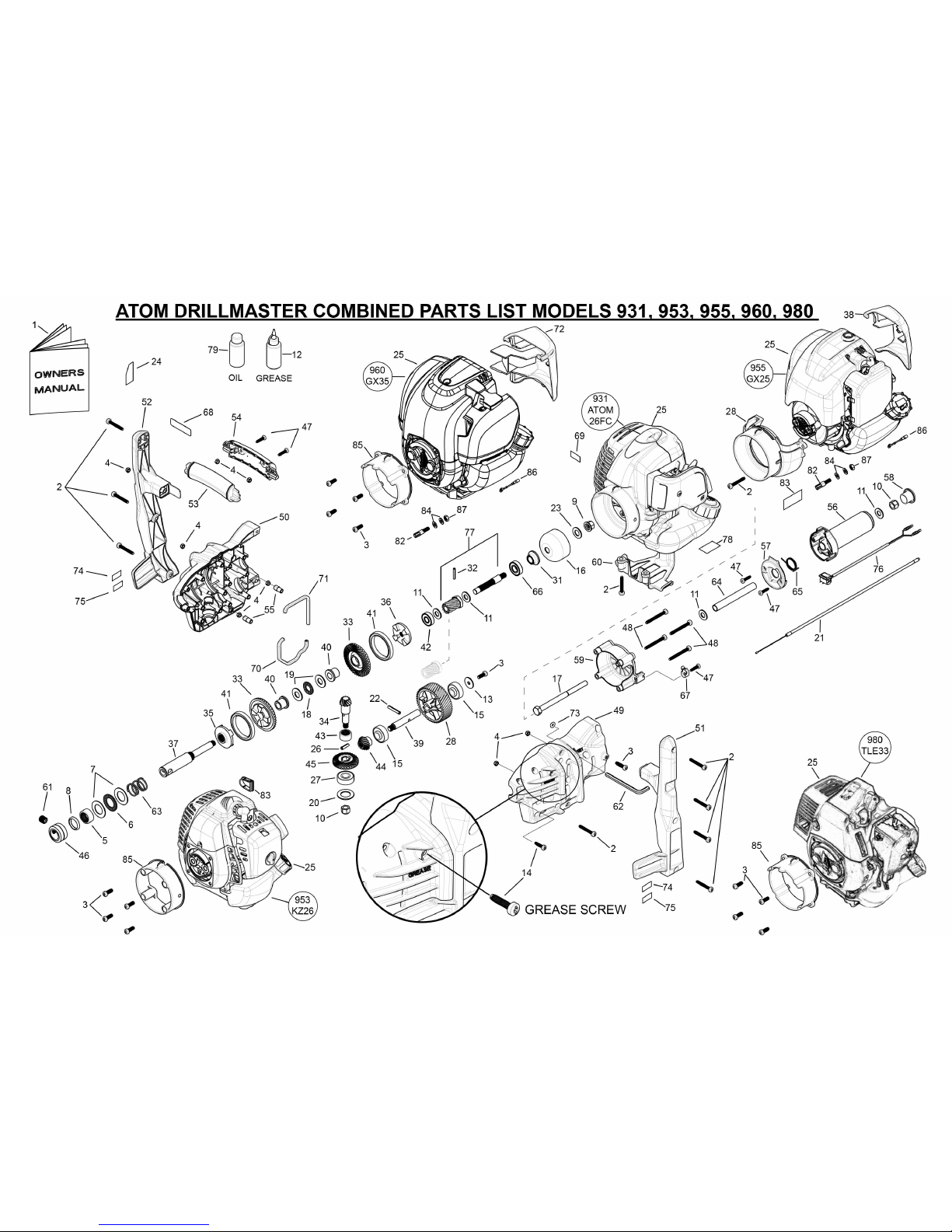

For engine explosions and Parts list, visit

our website: www.atomindustries.com

Go to Find Parts, Order & Service Info page and

enter the engine model number. Refer to Parts List attached.

! NOTE

Atom Industries is a division of Solo Industries Pty Ltd – an Australian owned company that invents, designs and manufactures unique

and outstanding products for local tough and hard Australian conditions with a history of international award winning gold medals,

great backup and service since 1961. Atom has a policy of continuous product improvement and development and reserves the

right to modify the design and appearance of products without notice.

Page 3

Page 4

07-07-14 1

MODEL NO: 931,953,950,960,980

MODEL NO: 931,953,950,960,980MODEL NO: 931,953,950,960,980

MODEL NO: 931,953,950,960,980

Key

Key

Key

Key

Part No

Part No Part No

Part No

Substitute

Substitute Substitute

Substitute

Part No

Part NoPart No

Part No

Description

DescriptionDescription

Description

Key

Key

Key

Key

Part No

Part No Part No

Part No

Substitute

Substitute Substitute

Substitute

Part No

Part NoPart No

Part No

Description

DescriptionDescription

Description

Key

Key

Key

Key

Part No

Part No Part No

Part No

Substitute

Substitute Substitute

Substitute

Part No

Part NoPart No

Part No

Description

DescriptionDescription

Description

1 21775 MANUAL ALL MODELS(PDF) 31

64119 HUB SINTERED

62 64230 KEY ALLEN 6AF x 90

2

40650 SCREW M5 x 36

32

64130 PIN ROLL 4 x 24

63 64231 DR REVERSE SPRING

3

40651 SCREW M6 x 16mm

33 64176 DR CROWN GEAR WITH DOG 64 64232 DR HAN SPACER TUBE

4

40652 NUT NYLOC 5mm

34 64177 DR PINION 65 64233 DR THRO RET SPRING

5

40912 BEAR NEEDLE 20 x 12mm

35 64178 DR FORWARD GEAR DOG 66 64235 BEARING 6001-2RS GRSEALS

6

40914 BEAR THR 20x35x2

36 64179 DR REVERSE GEAR DOG 67 64333WP DR CABLE RETAINER

7

40915 WASHER REAR THRUST

37 64181 DR MAIN SHAFT 68 64335 LABEL WARNING DRILL HANDLE

8

40922 SEAL SHAFT 20 x 26 x 4mm

38 43966RN DEFLECTOR HONDA GX25 69 64337 LABEL

9

43163 NUT FLANGE RH 3/8

39 64183 DR SPUR GEAR SHAFT 70 64347 DR CASING SEAL 1

10

43172 NUT NYLOC 3/8 UNC

40 64184 DR SPACER SINTERED 71 64348 DR CASING SEAL 2

11

43218 WASHER 3/8 FLAT

41 64185 BEAR 6809-2RS 45x58x7 72 43965RN DEFLECTOR HONDA GX35

12

43227 GREASE & DISPENSER

42 64187 BEAR 10x26x8 73 64355 O RING 3 x 11 OD x 5 ID

13

43484 WASHER 22.43 x 5.94 Z/P

43 64188 BEAR NEEDLE 16x22x12 74 64382 LABEL DR HAN LOGO

14

43790 SCREW M5.5 x 22mm

44 64189 DR GEAR BEVEL T15 75 64383 LABEL DR HAN DRILLMASTER

15

43860 BEARING 32 x 10 x 12 + 4mm

45 64190 DR GEAR BEVEL T30 76 64411 DR SWITCH & WIRE

16

44312 DRUM CUP PRO 79x32mm (960,980)

46 64192 DR LOCKING COLLAR 12mm 77 64414 DR SHAFT & GEAR ASSY 12/48 (931)

16

44318 DRUM CLUTCH CUP 54mm (931,953,955)

47 64194 SCREW T20 x 19.50 SELF TAP 77 64415 DR SHAFT & GEAR ASSY 12/33 (953,950)

17

44439 BOLT G.WHEEL AXLE 3/8" x 5"

48 64206 SCREW M5 x 50mm TORX-25 77 64416 DR SHAFT & GEAR ASSY 15/30 (960,980)

18

62964 BEARING NEEDLE 12 x 26 x 2

48 64384 SCREW T20 4 x 50 78 63219 LABEL HOT MOT/OIL

19

62965 WASHER THRUST 12 x 26 x 1.5

48 64385 WASHER 4 x 9 x 1 79 48100 OIL 100ML (HON GX35)

20

62982 WASHER BEARING 32x18x1.6

49 64210GN

64859GN

DR MAIN CAS LH #64859GN 79 48101 OIL 80ML (HON GX25)

21

63263 CABLE THROTTLE (931)

49 64210RN

64859RN

DR MAIN CAS LH #64859RN 80

64859GN

SET ENG DRILL CASING

21 64227 DR THROTTLE CABLE 345+77 50 64211GN 64859GN DR MAIN CAS RH #64859GN 81

64859RN

SET ENG DRILL CASING

22

63275 PIN ROLL 5 x 30

50 64211RN 64859RN DR MAIN CAS RH #64859RN 82

62968

CABLE CONNECTOR M6 x 1.00

23

63277 WASHER 12x22.22x1 (931,953,955)

51 64212WN DR MAIN HANDLE LH 83 62969RN PLUG MUFFLER Z26

23

43116 WASHER 45 x 12 x 2 (960,980)

52 64213WN DR MAIN HANDLE RH 84 63457 WASHER 6.4 x 12.5 x 1.5 ZP

24

63322 LABEL BL WARN SYMBOLS

53 64216WP DR GRIP FRONT W/RUBBER 85 63360RN MOUNT ENGINE Z26

25

48002A ENG HONDA GX35 Model No 765

54 64217WP DR GRIP BACK W/RUBBER 85 63361RN MOUNT ENGINE PRO

25

48004A ENG HONDA GX25 Model No 764

55 64218WP DR NUT RETAINER 86 63355 GROUND WIRE

25

62993A ENG Z26 Model No 763

56 64219WP DR THROTTLE HANDLE (931) 87 63169 NUT M6 X 1mm

25

63405A ENG ATOM 26FCS Model No 767

56 64234WP DR THR HAN W/RUB (953,955,960,980)

26

63440 PIN ROLL 5 x 18

57 64220WP DR THRO HANDLE COV

27

63474 BEARING 32 x 10 x 12

58 64221WP DR THR HANDLE CAP

28

63780 DR HELIC GEAR 48T/12

59 64222WN DR THR MOUNT ATOM

28 64344 DR HELIC GEAR T33/12 (953,955) 59 64224WN DR THR MOUNT GX35

28 64346 DR GEAR HELIC T30/15 (960,980) 59 64225RN DR THR MOUNT Mitsu TLE 33

29

63806RN MOUNT/FAN COWL GX25

60 64226WP DR TANK GUARD A26FC

30 61 64229 SCREW GRUB M12x1.25x13

ATOM PRODUCT: ATOM ENGINE DRILL COMBINED PARTS LIST - ALL MODELS

ATOM PRODUCT: ATOM ENGINE DRILL COMBINED PARTS LIST - ALL MODELSATOM PRODUCT: ATOM ENGINE DRILL COMBINED PARTS LIST - ALL MODELS

ATOM PRODUCT: ATOM ENGINE DRILL COMBINED PARTS LIST - ALL MODELS

Loading...

Loading...