Page 1

Features

•

Carrier Frequency f

•

Typical Data Rate up to 5 kbaud at 125 kHz

•

Suitable for Manchester and Bi-phase Modulation

•

Power Supply from the Car Battery or from 5-V Regulated Voltage

•

Optimized for Car Immobilizer Applications

•

Tuning Capability

•

Microcontroller-compatible Interface

•

Low Power Consumption in Standby Mode

•

Power-supply Output for Microcontroller

100 kHz to 150 kHz

osc

Read/Write

Base Station

Applications

•

Car Immobilizers

•

Animal Identification

•

Access Control

•

Process Control

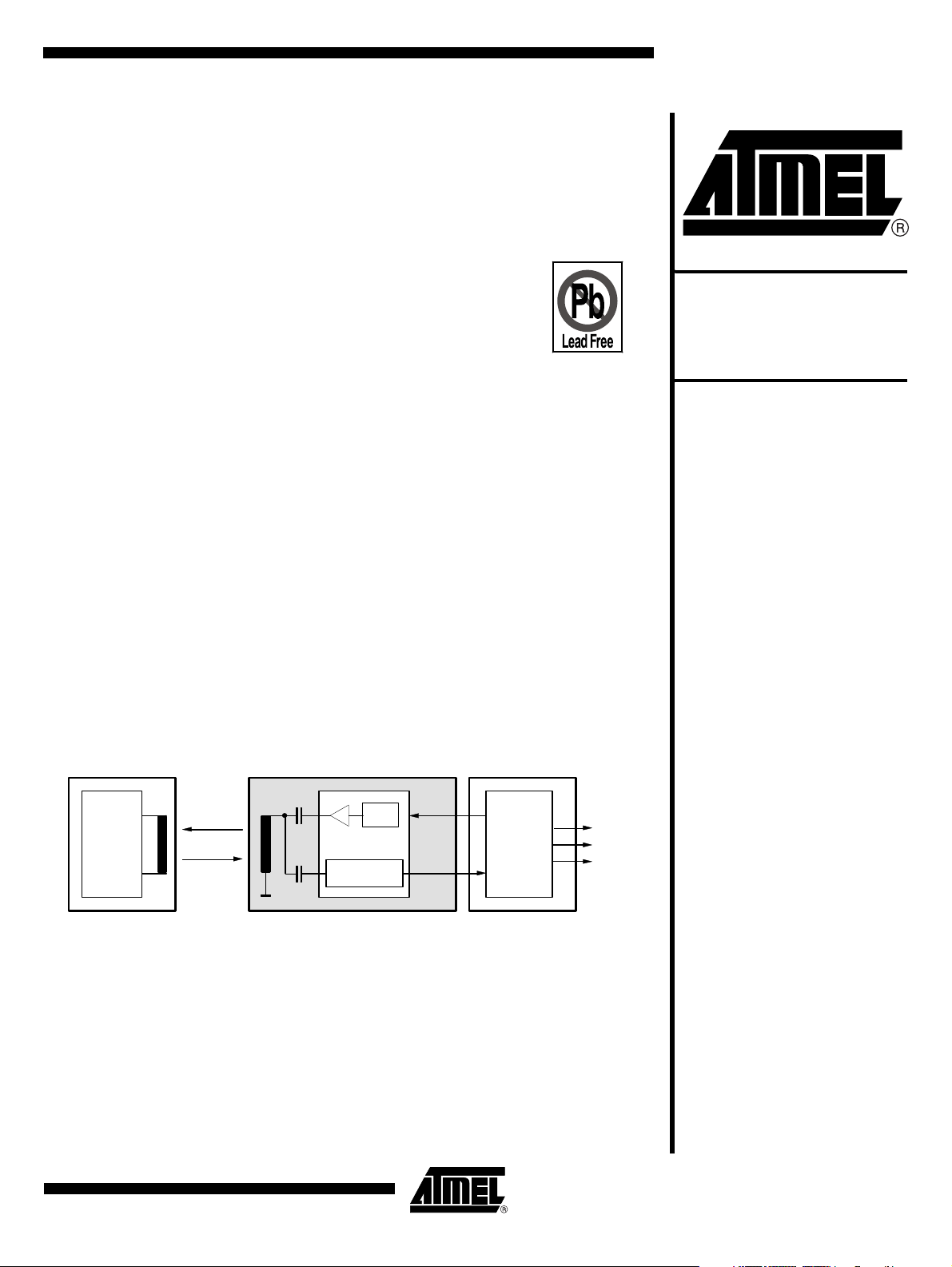

1. Description

The U2270B is an IC for IDIC® read/write base stations in contactless identification

and immobilizer systems.

The IC incorporates the energy-transfer circuit to supply the transponder. It consists of

an on-chip power supply, an oscillator and a coil driver optimized for automotive-specific distances. It also includes all signal-processing circuits which are necessary to

transform the small input signal into a microcontroller-compatible signal.

Figure 1-1. System Block Diagram

Transponder/TAG

Transponder

IC

RF field

typ. 125 kHz

Read/write base station

Osc

U2270B

NF read channel

Carrier

enable

Data

output

MCU

Unlock

System

U2270B

Rev. 4684B–RFID–09/05

Page 2

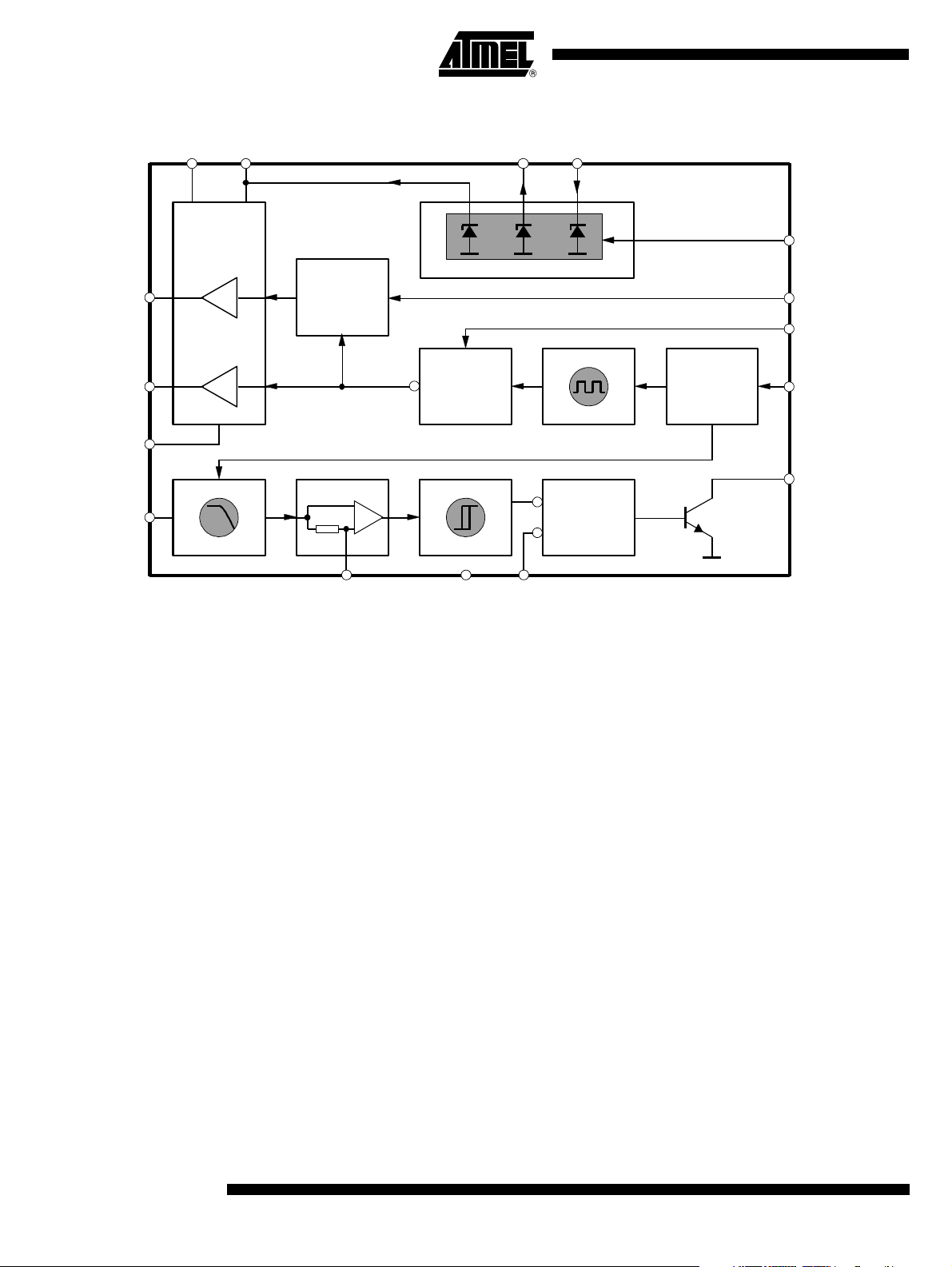

Figure 1-2. Block Diagram

COIL1

COIL2

DGND

Input

DV

Driver

Lowpass filter

V

S

EXT

= 1

Amplifier

Schmitt trigger

HIPASS OEGND

Power supply

&

V

S

V

Batt

Oscillator

Frequency

adjustment

Standby

MS

CFE

RF

Output

&

2

U2270B

4684B–RFID–09/05

Page 3

2. Pin Configuration

Figure 2-1. Pinning

Table 2-1. Pin Description

Pin Symbol Function

1 GND Ground

2 OUTPUT Data output

3 OE Data output enable

4 INPUT Data input

5 MS Mode select coil 1: common mode/differential mode

6 CFE Carrier frequency enable

7 DGND Driver ground

8 COIL2 Coil driver 2

9 COIL1 Coil driver 1

10 VEXT External power supply

11 DVS Driver supply voltage

12 VBatt Battery voltage

13 STANDBY Standby input

14 VS Internal power supply (5V)

15 RF Frequency adjustment

16 HIPASS DC decoupling

GND

OUTPUT

OE

INPUT

MS

CFE

DGND

COIL2

U2270B

1

16

HIPASS

2

15

RF

3

14

VS

4

13

STANDBY

5

12

VBATT

6

11

DVS

7

10

VEXT

8

9

COIL1

4684B–RFID–09/05

3

Page 4

3. Functional Description

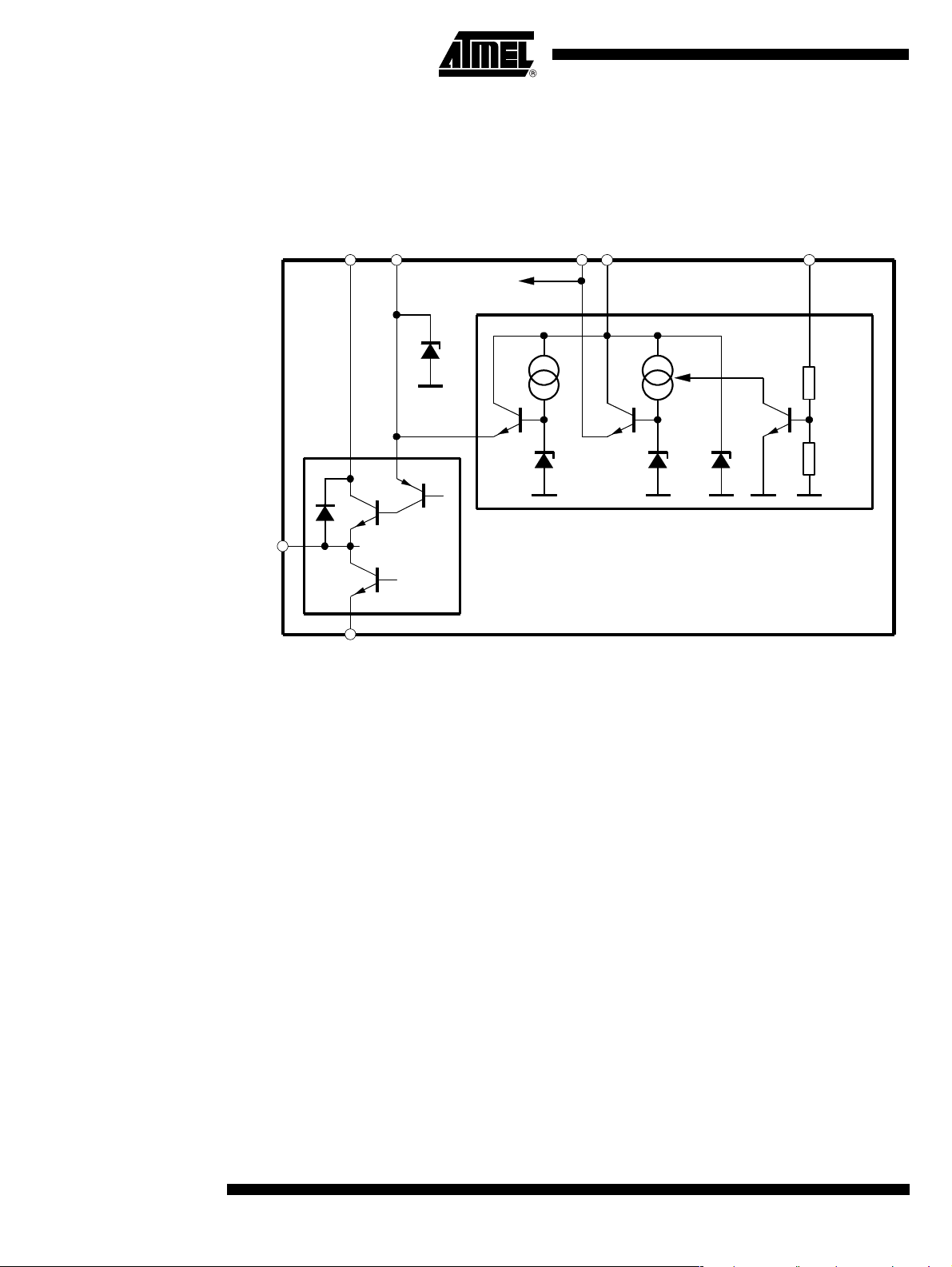

3.1 Power Supply (PS)

Figure 3-1. Equivalent Circuit of Power Supply and Antenna Driver

DV

S

V

EXT

internal supply

9 V

6 V 6 V 18 V

V

S

V

Batt

Standby

25 kΩ

12 kΩ

PS

COILx

DRV

DGND

The U2270B can be operated with one external supply voltage or with two externally-stabilized

supply voltages for an extended driver output voltage or from the 12-V battery voltage of a vehicle. The 12-V supply capability is achieved via the on-chip power supply (see Figure 3-1). The

power supply provides two different output voltages, V

V

is the internal power supply voltage except for the driver circuit. Pin VS is used to connect a

S

block capacitor. V

sumption is very low. V

can be switched off by Standby pin. In standby mode, the chip’s power con-

S

is the supply voltage of the antenna’s pre-driver. This voltage can

EXT

also be used to operate external circuits, like a microcontroller. In conjunction with an external

NPN transistor it also establishes the supply voltage of the antenna coil driver, DVS.

and V

S

EXT

.

4

U2270B

4684B–RFID–09/05

Page 5

3.2 Operation Modes to Power the U2270B

The following section explains the 3 different operation modes to power the U2270B.

3.2.1 One-rail Operation

All internal circuits are operated from one 5-V power rail (see Figure 3-2). In this case, V

and DVS serve as inputs. V

Figure 3-2. One Rail Operation Supply

is not used but should also be connected to that supply rail.

Batt

+5 V (stabilized)

U2270B

, V

S

EXT

3.2.2 Two-rail Operation

In this application, the driver voltage, D

higher voltage than the rest of the circuitry to obtain a higher driver-output swing and thus a

higher magnetic field (see Figure 3-3). V

ages can be as high as 8 V. This operation mode is intended to be used in situations where an

extended communication distance is required.

Figure 3-3. Two Rail Operation Supply

DVSV

DVSV

EXTVSVBatt

, and the pre-driver supply, V

VS

is connected to a 5-V supply, whereas the driver volt-

S

EXTVSVBatt

Standby

Standby

7 to 8 V (stabilized)

5 V (stabilized)

, are operated at a

EXT

3.2.3 Battery-voltage Operation

Using this operation mode, V

3-4). For this mode, an external voltage regulator is not needed. The IC can be switched off via

the Standby pin. V

a microcontroller (even in Standby mode).

Pin V

EXT

and V

4).The maximum current into the pins is determined by the maximum power dissipation and the

maximum junction temperature of the IC.

4684B–RFID–09/05

and V

S

supplies the base of an external NPN transistor and external circuits, like

EXT

are overvoltage protected via internal Zener diodes (see Figure 3-1 on page

Batt

are generated by the internal power supply (see Figure

EXT

5

Page 6

Figure 3-4. Battery Operation

7 to 16 V

DVSV

EXTVSVBatt

Standby

Table 3-1. Characteristics of the Various Operation Modes

Operation Mode External Components Required Supply-voltage Range

One-rail operation

Two-rail operation

1 Voltage regulator

1 Capacitor

2 Voltage regulators

2 Capacitors

5V ±10% ≈ 4V No

5V ±10%

7V to 8V

1 Transistor

2 Capacitors Optional for load

Battery-voltage operation

dump protection:

6V to 16V ≈ 4V Yes

1 Resistor

1 Capacitor

3.3 Oscillator (Osc)

The frequency of the on-chip oscillator is controlled by a current fed into the RF input. An integrated compensation circuit ensures a wide temperature range and a supply-voltageindependent frequency which is selected by a fixed resistor between R

For 125 kHz, a resistor value of 110 kΩ is defined. For other frequencies, use the following

formula:

14375

Ω[]

--------------------- 5–=

f0kHz

[]

Rtk

Driver Output

Standby Mode

Voltage Swing

6V to 7V No

(pin 15) and VS (pin 14).

F

Available

This input can be used to adjust the frequency close to the resonance of the antenna. For more

details refer to the section “Applications” on page 10” and to the application note ANT019.

Figure 3-5. Equivalent Circuit of Pin R

6

U2270B

F

2 kΩ

V

S

R

f

R

F

4684B–RFID–09/05

Page 7

3.4 Filter (LPF)

U2270B

The fully-integrated lowpass filter (4th-order butterworth) removes the remaining carrier signal

and high-frequency disturbances after demodulation. The upper cut-off frequency of the LPF

depends on the selected oscillator frequency. The typical value is f

rates up to f

/25 are possible if Bi-phase or Manchester encoding is used.

Osc

A highpass characteristic results from the capacitive coupling at the input pin 4 as shown in Fig-

ure 3-6. The input voltage swing is limited to 2 V

. For frequency response calculation, the

pp

impedances of the signal source and LPF input (typical 220 kΩ) have to be considered. The rec-

ommended values of the input capacitor for selected data rates are given in the section

“Applications”.

Note: After switching on the carrier, the DC voltage of the coupling capacitor changes rapidly. When the

antenna voltage is stable, the LPF needs approximately 2 ms to recover full sensitivity.

Figure 3-6. Equivalent Circuit of Pin Input

V

+ 0.4 V

Bias

/18. That means that data

Osc

3.5 Amplifier (AMP)

The differential amplifier has a fixed gain, typically 30. The HIPASS pin is used for dc decoupling. The lower cut-off frequency of the decoupling circuit can be calculated as follows:

f

The value of the internal resistor R

Recommended values of C

on page 10.

cut

--------------------------------------------=

2 π C

1

HPRi

R

S

Input

C

IN

V

10 kΩ

Bias

- 0.4 V

210 kΩ

V

Bias

×××

can be assumed to be 2.5 kΩ.

i

for selected data rates can be found in the section “Applications”

HP

4684B–RFID–09/05

7

Page 8

Figure 3-7. Equivalent Circuit of Pin HIPASS

R

R

LPF

V

Ref

+

Schmitt

trigger

3.6 Schmitt Trigger

R

HIPASS

R

i

R

C

HP

The signal is processed by a Schmitt trigger to suppress possible noise and to make the signal

microcontroller compatible. The hysteresis level is 100 mV symmetrically to the DC operation

point. The open-collector output is enabled by a low level at OE (pin 3).

Figure 3-8. Equivalent Circuit of Pin OE

7 µA

OE

8

U2270B

4684B–RFID–09/05

Page 9

3.7 Driver (DRV)

U2270B

The driver supplies the antenna coil with the appropriate energy. The circuit consists of two independent output stages. These output stages can be operated in two different modes. In common

mode, the outputs of the stages are in phase. In this mode, the outputs can be interconnected to

achieve a high-current output capability. Using the differential mode, the output voltages are in

anti-phase. Thus, the antenna coil is driven with a higher voltage. For a specific magnetic field,

the antenna coil impedance is higher for the differential mode. As a higher coil impedance

results in a better system sensitivity, the differential mode should be preferred.

The CFE input is intended to be used for writing data into a read/write or a crypto transponder.

This is achieved by interrupting the RF field with short gaps. The various functions are controlled

by the inputs MS and CFE (refer to the function table). The equivalent circuit of the driver is

shown in Figure 3-1 on page 4.

Figure 3-9. Equivalent Circuit of Pin MS

30 µA

MS

Figure 3-10. Equivalent Circuit of Pin CFE

CFE

30 µA

4684B–RFID–09/05

9

Page 10

3.8 Function Table

4. Applications

CFE MS COIL1 COIL2

Low Low High High

Low High Low High

High Low

High High

OE Output Standby U2270B

Low Enabled Low Standby mode

High Disabled High Active

To achieve the system performance, consider the power-supply environment and the magneticcoupling situation.

The selection of the appropriate power-supply operation mode depends on the quality of supply

voltage. If an unregulated supply voltage in the range of V = 7V to 16V is available, the internal

power supply of the U2270B can be used. In this case, standby mode can be used and an external low-current microcontroller can be supplied.

If a 5-V supply rail is available, it can be used to power the U2270B. In this case, please check

that the voltage is noise-free. An external power transistor is not necessary.

The application depends also on the magnetic-coupling situation. The coupling factor mainly

depends on the transmission distance and the antenna coils. The following table lists the appropriate application for a given coupling factor. The magnetic coupling factor can be determined

using Atmels test transponder coil.

Table 4-1. Magnetic Coupling

Magnetic Coupling Factor Appropriate Application

k > 3% Free-running oscillator

k > 1% Diode feedback

k > 0.5%

k > 0.3%

Diode feedback

plus frequency altering

Diode feedback

plus fine frequency tuning

The maximum transmission distance is also influenced by the accuracy of the antenna’s resonance. Therefore, the recommendations given above are proposals only. A good compromise

for the resonance accuracy of the antenna is a value in the range of f

= 125 kHz ±3%. Further

res

details concerning the adequate application and the antenna design is provided in the section

“Antenna Design Hints”.

10

U2270B

4684B–RFID–09/05

Page 11

U2270B

The application of the U2270B includes the two capacitors CIN and CHP whose values are linearly dependent on the transponder’s data rate. The following table gives the appropriate values

for the most common data rates. The values are valid for Manchester- and Bi-phase-code.

Table 4-2. Recommended Cap Values

Data Rate f = 125 kHz Input Capacitor (CIN) Decoupling Capacitor (CHP)

f/32 = 3.9 kbit/s 680 pF 100 nF

f/64 = 1.95 kbit/s 1.2 nF 220 nF

The following applications are typical examples. The values of C

transponder’s data rate only. The arrangement to fit the magnetic-coupling situation is also independent from other design issues except for one constellation. This constellation, consisting of

diode feedback plus fine frequency tuning together with the two-rail power supply, should be

used if the transmission distance of is d ≈ 10 cm.

4.1 Application 1

Application using few external components. This application is for intense magnetic coupling

only.

Figure 4-1. Application Circuit 1

5 V

47 nF

470 kΩ

1.5 nF

47 µF

1N4148

R

C

IN

1.35 mH

V

Batt

DV

S

INPUT

COIL1

V

EXTVS

U2270B

STANDBY

OUTPUT

110 kΩ

RF

MS

CFE

OE

HIPASS

and CHP correspond to the

IN

V

DD

Micro-

controller

H

C

P

4684B–RFID–09/05

1.2 nF

COIL2

DGND GND

V

SS

11

Page 12

4.2 Application 2

Basic application using diode feedback. This application allows higher communication distances

than application 1

Figure 4-2. Application Circuit 2

75 kΩ

100 kΩ

1.2 nF

1.35 mH

Antenna

1N4148

470 kΩ

4x

1N4148

82 Ω

1.5 nF

43 kΩ

68 kΩ

4.7 nF

C

C

HP

22 mF

22 mF

360 Ω

V

DD

Micro-

controller

V

SS

12 V

GND

BC639

22 µF

V

V

S

RF

COIL 2

EXT

DVSV

Batt

MS

CFE

U2270B

COIL 1

Input

IN

HIPASS

DGND GND

Standby

Output

OE

I/O

12

U2270B

4684B–RFID–09/05

Page 13

4.3 Application 3

This application is comparable to application 2 but alters the operating frequency. This allows

higher antenna resonance tolerances and/or higher communication distances. This application

is preferred if the detecting microcontroller is close to the U2270B as an additional microcontroller signal controls the adequate operating frequency.

Figure 4-3. Application Circuit 3

U2270B

75 kΩ

100 kΩ

1 nF

1.5 mH

Antenna

1N4148

180 pF

100 Ω

BC846

4x 1N4148

82 Ω

470 kΩ

1.5 kΩ

43 kΩ

1.5 nF

4.7 kΩ

68 kΩ

4.7 nF

C

IN

5 V

22 µF

V

S

RF

COIL 2

COIL 1

Input

HIPASS

C

HP

DGND GND

V

EXT

U2270B

DVSV

Standby

Output

Batt

MS

CFE

OE

V

DD

Micro-

controller

V

SS

47 nF

GND

4684B–RFID–09/05

Note: Application examples have not been examined for series use or reliability, and no worst case sce-

narios have been developed. Customers who adapt any of these proposals must carry out their

own testing and be convinced that no negative consequences arise from the proposals.

13

Page 14

5. Absolute Maximum Ratings

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating

only and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

All voltages are referred to GND (Pins 1 and 7)

Parameter Pin Symbol Min. Max. Unit

Operating voltage 12 V

V

Operating voltage 8, 9, 10, 11, 14

Range of input and output

voltages

3, 4, 5, 6, 15 16

2 and 13

S, VEXT, DVS,

1, Coil 2

VIN, V

Output current 10 I

Output current 2 I

Driver output current 8 and 9 I

Power dissipation SO16 P

Junction temperature T

Storage temperature T

Ambient temperature T

Batt

EXT

OUT

Coil

tot

stg

amb

j

OUT

Coil

V

S

–0.3 8 V

–0.3

–0.3

–55 125 °C

–40 105 °C

16 V

VS + 0.3

V

Batt

10 mA

10 mA

200 mA

380 mW

150 °C

V

6. Thermal Resistance

Parameter Symbol Value Unit

Thermal resistance SO16 R

thJA

120 K/W

7. Operating Range

All voltages are referred to GND (Pins 1 and 7)

Parameter Symbol Value Unit

Operating voltage Pin 12 V

Operating voltage Pin 14 V

Operating voltage Pins 10, 11 V

EXT

Batt

S

, DV

S

Carrier frequency 100 to 150 kHz

7 to 16 V

4.5 to 6.3 V

4.5 to 8 V

14

U2270B

4684B–RFID–09/05

Page 15

U2270B

8. Electrical Characteristics

All voltages are referred to GND (Pins 1 and 7)

Parameters Test Conditions Pin Symbol Min. Typ. Max. Unit

Data output

- Collector emitter

= 5 mA 2 V

I

out

CEsat

- Saturation voltage

Data output enable

- Low-level input voltage

- High-level input voltage

3V

il

V

ih

2.4

Data input

- Clamping level low

- Clamping level high

- Input resistance

- Input sensitivity

f = 3 kHz (squarewave)

gain capacitor = 100 nF

V

il

4

V

ih

R

in

S

IN

10

2

3.8

220

Driver polarity mode

- Low-level input voltage

- High-level input voltage

5V

il

V

ih

2.4 0.2

Carrier frequency enable

- Low-level input voltage

- High-level input voltage

6V

il

V

ih

3.0 0.8

10,

Operating current

5-V application without load

connected to the coil driver

11, 12

and

I

S

4.5 9 mA

14

Standby current 12-V application 12 I

V

S

- Supply voltage

- Supply voltage drift

14

dVs/dT

- Output current

Driver output voltage

- One-rail operation

- Battery-voltage operation

V

EXT

- Output voltage

- Supply voltage drift

- Output current

- Standby output current

= ±100 mA

I

L

VS, V

V

Batt

, V

EXT

= 12V

Batt

IC active

standby mode

, DVS = 5V

8, 9 V

10

dV

V

V

EXT

I

I

V

I

DRV

DRV

EXT

EXT

EXT

St

S

S

4.6

1.8

2.9

3.1

4.6

/dT

3.5

0.4

30 70 µA

5.4

4.2

3.5

3.6

4.0

5.4

4.2

Standby input

- Low-level input voltage

- High-level input voltage

Oscillator

- Carrier frequency

Lowpass filter

- Cut-off frequency

13 V

RF resistor = 110 kΩ

(application 2), REM 1

(1)

Carrier freq. = 125 kHz f

il

V

ih

f

0

cut

3.1

121 125 129 kHz

7kHz

Amplifier - Gain CHP = 100 nF 30

Note: 1. REM1: In application 1 where the oscillator operates in free-running mode, the IC must be soldered free from distortion. Oth-

erwise, the oscillator may be out of bounds.

400 mV

0.5 V

V

V

V

kΩ

mV

V

V

V

V

V

6.3

mV/K

mA

4.3

4.7

V

V

V

6.3

mV/K

mA

mA

0.8 V

V

pp

PP

PP

4684B–RFID–09/05

15

Page 16

9. Ordering Information

Extended Type Number Package Remarks

U2270B-MFPY SO16 Tube, Pb-free

U2270B-MFPG3Y SO16 Taped and reeled, Pb-free

10. Package Information

Package SO16

Dimensions in mm

11. Revision History

5.2

10.0

9.85

1.4

0.4

1.27

8.89

16 9

18

0.25

0.10

technical drawings

according to DIN

specificati ons

4.8

3.7

3.8

6.15

5.85

0.2

16

U2270B

Please note that the following page numbers referred to in this section refer to the specific revision

mentioned, not to this document.

Revision No. History

• Put datasheet in a new template

4684B-RFID-09/05

• Pb-free Logo on page 1 added

• New heading rows on Table “Absolute Maximum Ratings” on page 14 added

• Ordering Information on page 16 changed

4684B–RFID–09/05

Page 17

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT

OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Unless specifically provided

otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended, authorized, or warranted for use

as components in applications intended to support or sustain life.

© Atmel Corporation 2005. All rights reserved. Atmel®, logo and combinations thereof, Everywhere You Are® and others, are registered trade-

marks or trademarks of Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

Printed on recycled paper.

4684B–RFID–09/05

Loading...

Loading...