查询TS80C51RA2供应商

High Performance 8-bit Microcontrollers

1. Description

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Atmel Wireless & Microcontrollers TS80C51Rx2 is high

performance CMOS ROM, OTP, EPROM and ROMless

versions of the 80C51 CMOS single chip 8-bit

microcontroller.

The TS80C51Rx2 retains all features of the 80C51 with

extended ROM/EPROM capacity (16/32/64Kbytes),256

bytes of internal RAM, a 7-source , 4-level interrupt

system, an on-chip oscilator and three timer/counters.

In addition, the TS80C51Rx2 has a Programmable

Counter Array, an XRAM of 256 or 768 bytes, a

Hardware Watchdog Timer, a more versatile serial

channel that facilitates multiprocessor communication

(EUART) and a X2 speed improvement mechanism.

2. Features

• 80C52 Compatible

• 8051 pin and instruction compatible

• Four 8-bit I/O ports

• Three 16-bit timer/counters

• 256 bytes scratchpad RAM

• High-Speed Architecture

• 40 MHz @ 5V, 30MHz @ 3V

• X2 Speed Improvement capability (6 clocks/

machine cycle)

30 MHz @ 5V, 20 MHz @ 3V (Equivalent to

60 MHz @ 5V, 40 MHz @ 3V)

• Dual Data Pointer

• On-chip ROM/EPROM (16K-bytes, 32K-bytes, 64K-

bytes)

• On-chip eXpanded RAM (XRAM) (256 or 768 bytes)

• Programmable Clock Out and Up/Down Timer/

Counter 2

• Programmable Counter Array with

• High Speed Output,

• Compare / Capture,

• Pulse Width Modulator,

• Watchdog Timer Capabilities

The fully static design of the TS80C51Rx2 allows to

reduce system power consumption by bringing the clock

frequency down to any value, even DC, without loss of

data.

The TS80C51Rx2 has 2 software-selectable modes of

reduced activity for further reduction in power

consumption. In the idle mode the CPU is frozen while

the timers, the serial port and the interrupt system are still

operating. In the power-down mode the RAM is saved

and all other functions are inoperative.

• Hardware Watchdog Timer (One-time enabled with

Reset-Out)

• 2 extra 8-bit I/O ports available on RD2 with high

pin count packages

• Asynchronous port reset

• Interrupt Structure with

• 7 Interrupt sources,

• 4 level priority interrupt system

• Full duplex Enhanced UART

• Framing error detection

• Automatic address recognition

• Low EMI (inhibit ALE)

• Power Control modes

• Idle mode

• Power-down mode

• Power-off Flag

• Once mode (On-chip Emulation)

• Power supply: 4.5-5V, 2.7-5.5V

• Temperature ranges: Commercial (0 to 70

Industrial (-40 to 85oC)

o

C) and

• Packages: PDIL40, PLCC44, VQFP44 1.4, CQPJ44

(window), CDIL40 (window), PLCC68, VQFP64

1.4, JLCC68 (window)

Rev. C - 06 March, 2001 1

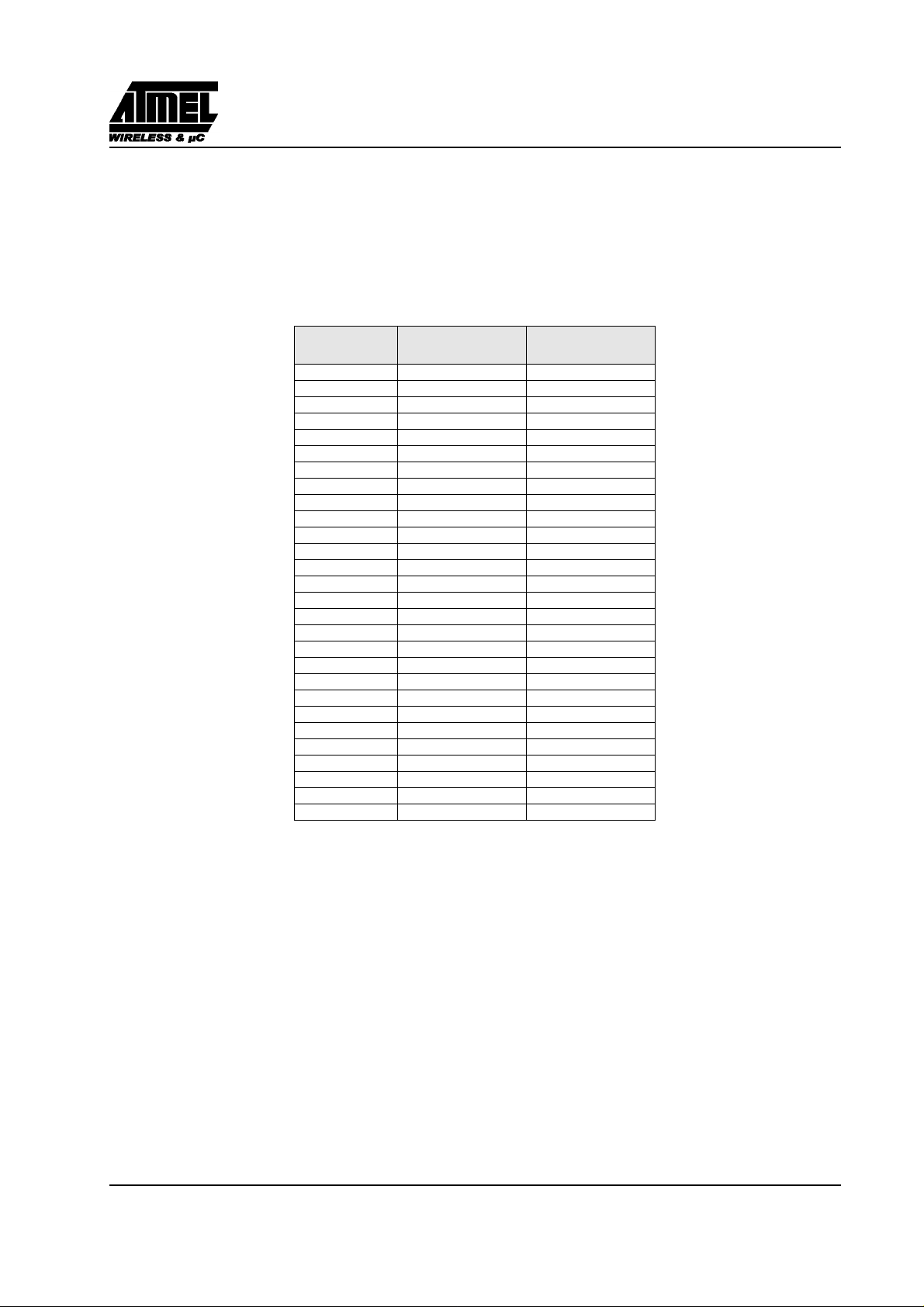

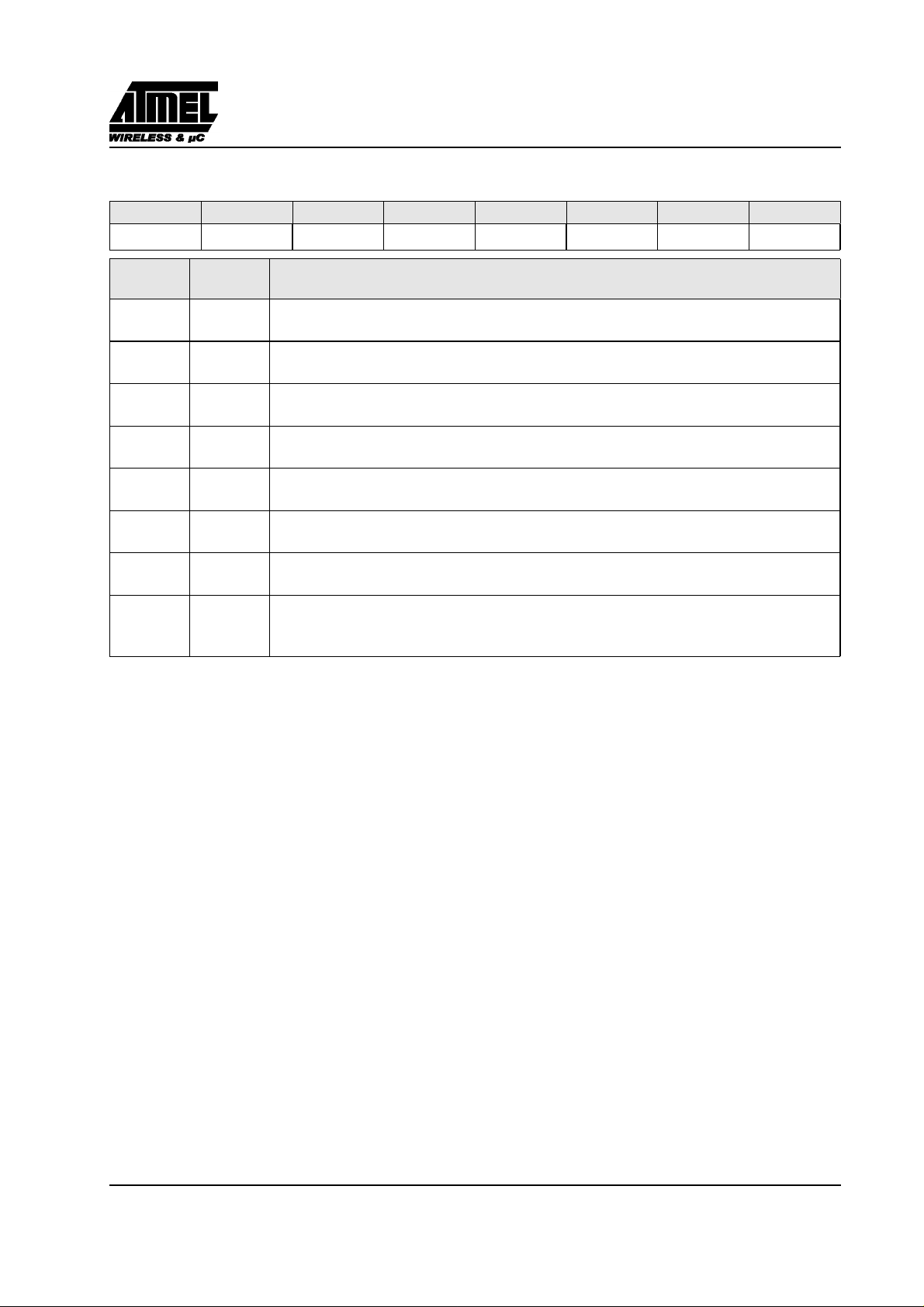

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

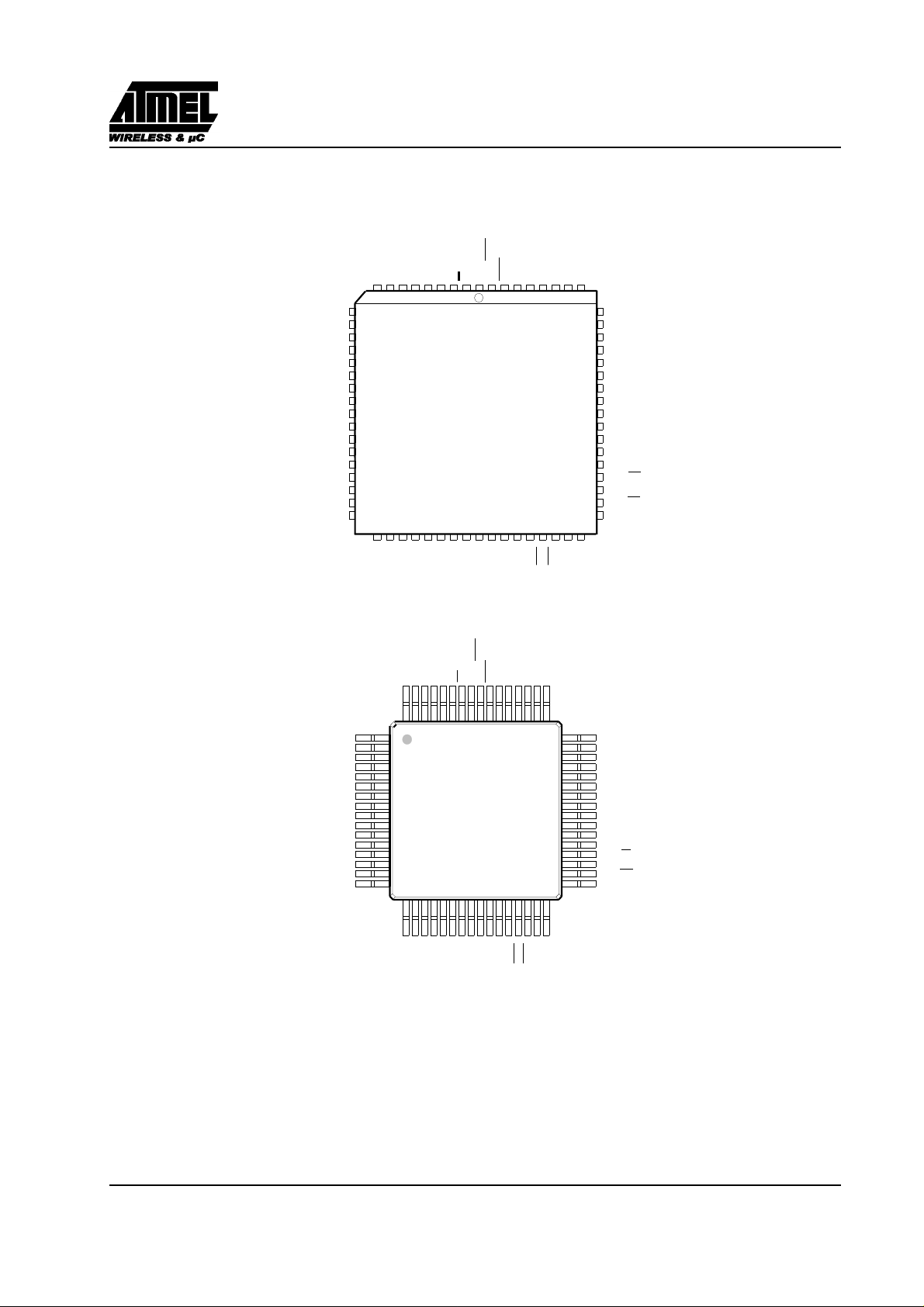

PDIL40

PLCC44

VQFP44 1.4

TS80C51RA2

TS80C51RD2

TS83C51RB2

TS83C51RC2

TS83C51RD2

TS87C51RB2

TS87C51RC2

TS87C51RD2

ROM (bytes) EPROM (bytes) XRAM (bytes)

0

0

16k

32k

64k

0

0

0

0

0

0

0

0

16k

32k

64k

256

768

256

256

768

256

256

768

TOTAL RAM

(bytes)

512

1024

512

512

1024

512

512

1024

I/O

32

32

32

32

32

32

32

32

PLCC68

ROM (bytes) EPROM (bytes) XRAM (bytes)

VQFP64 1.4

TOTAL RAM

(bytes)

TS80C51RD2 0 0 768 1024 48

TS83C51RD2 64k 0 768 1024 48

TS87C51RD2 0 64k 768 1024 48

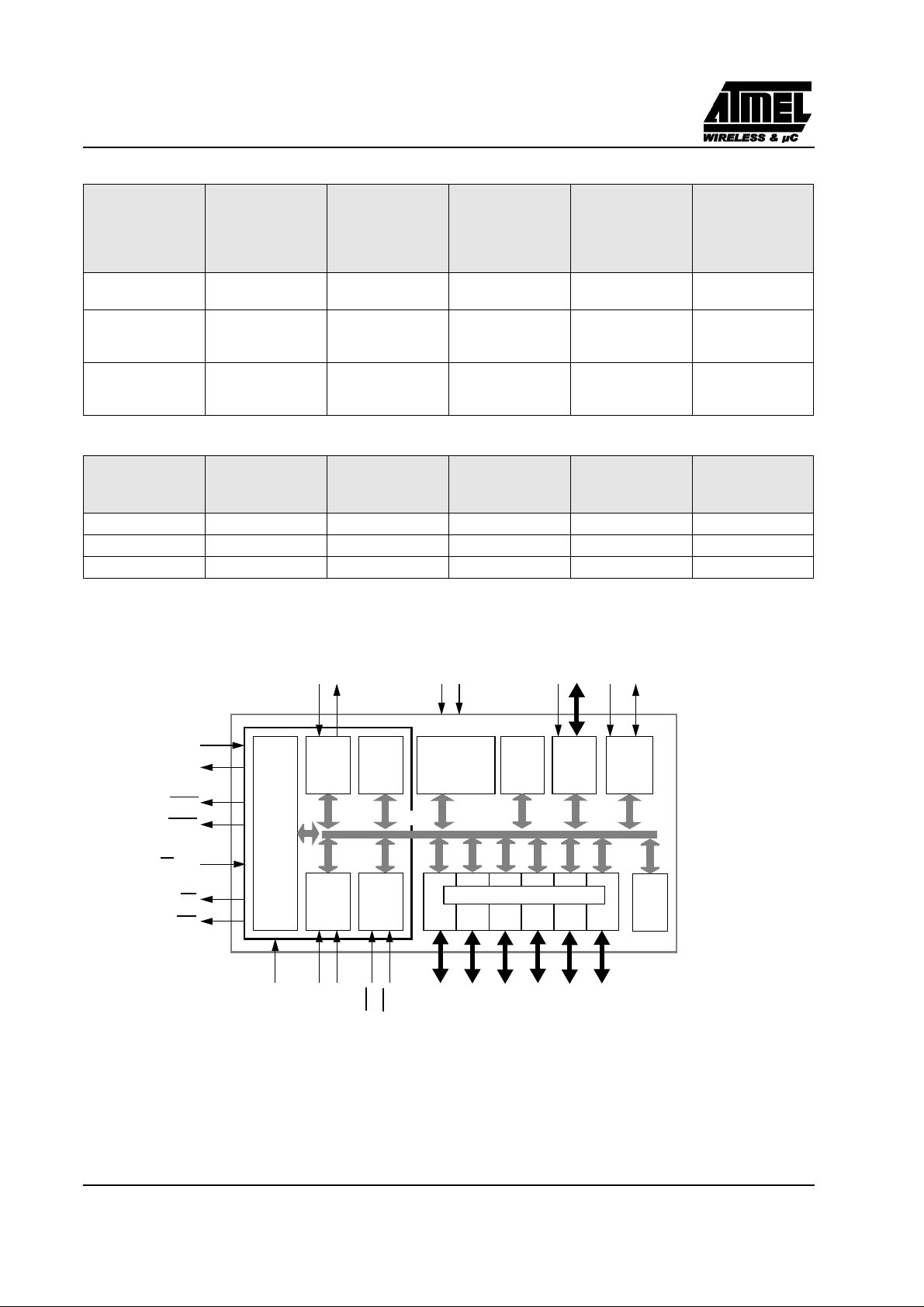

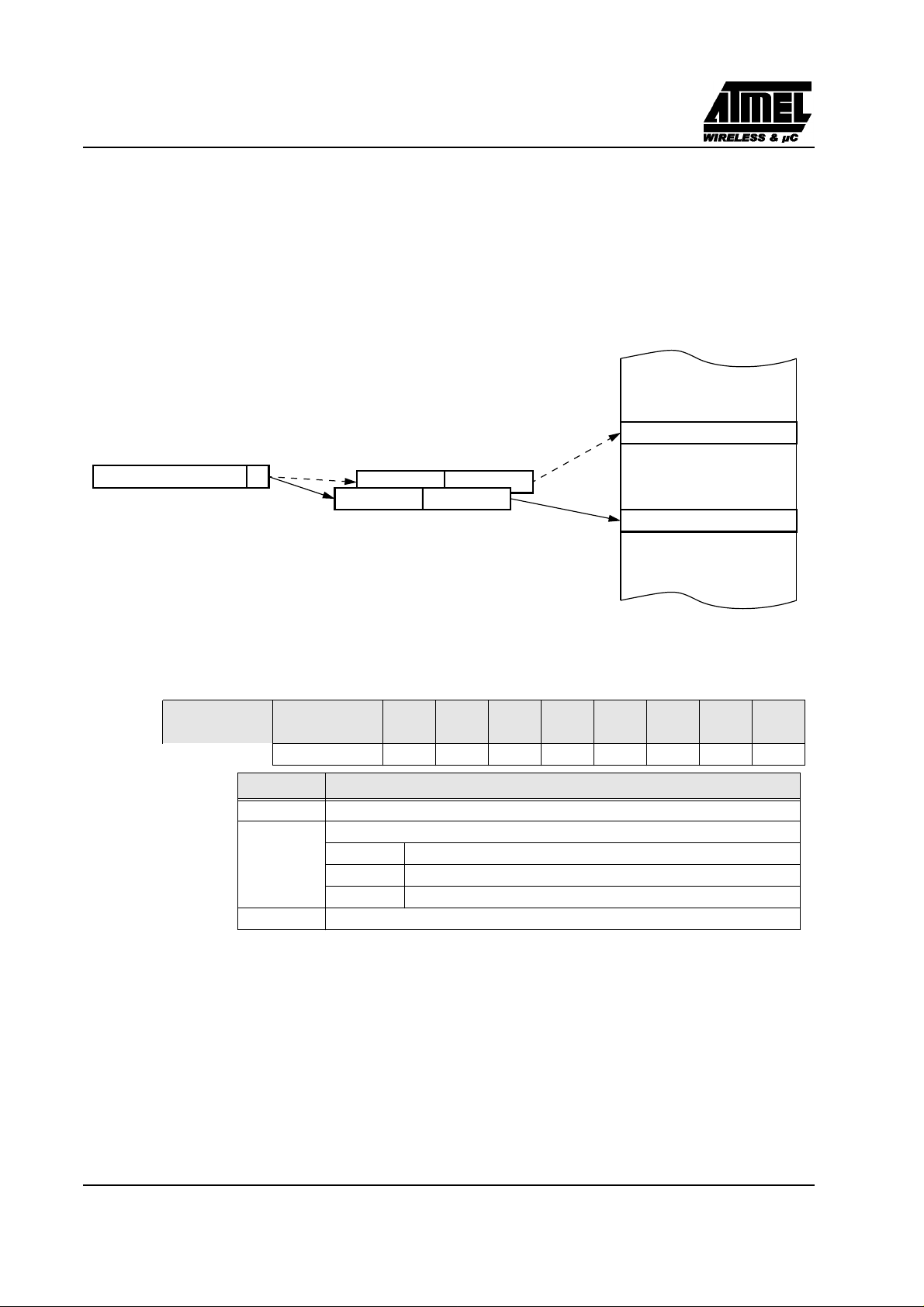

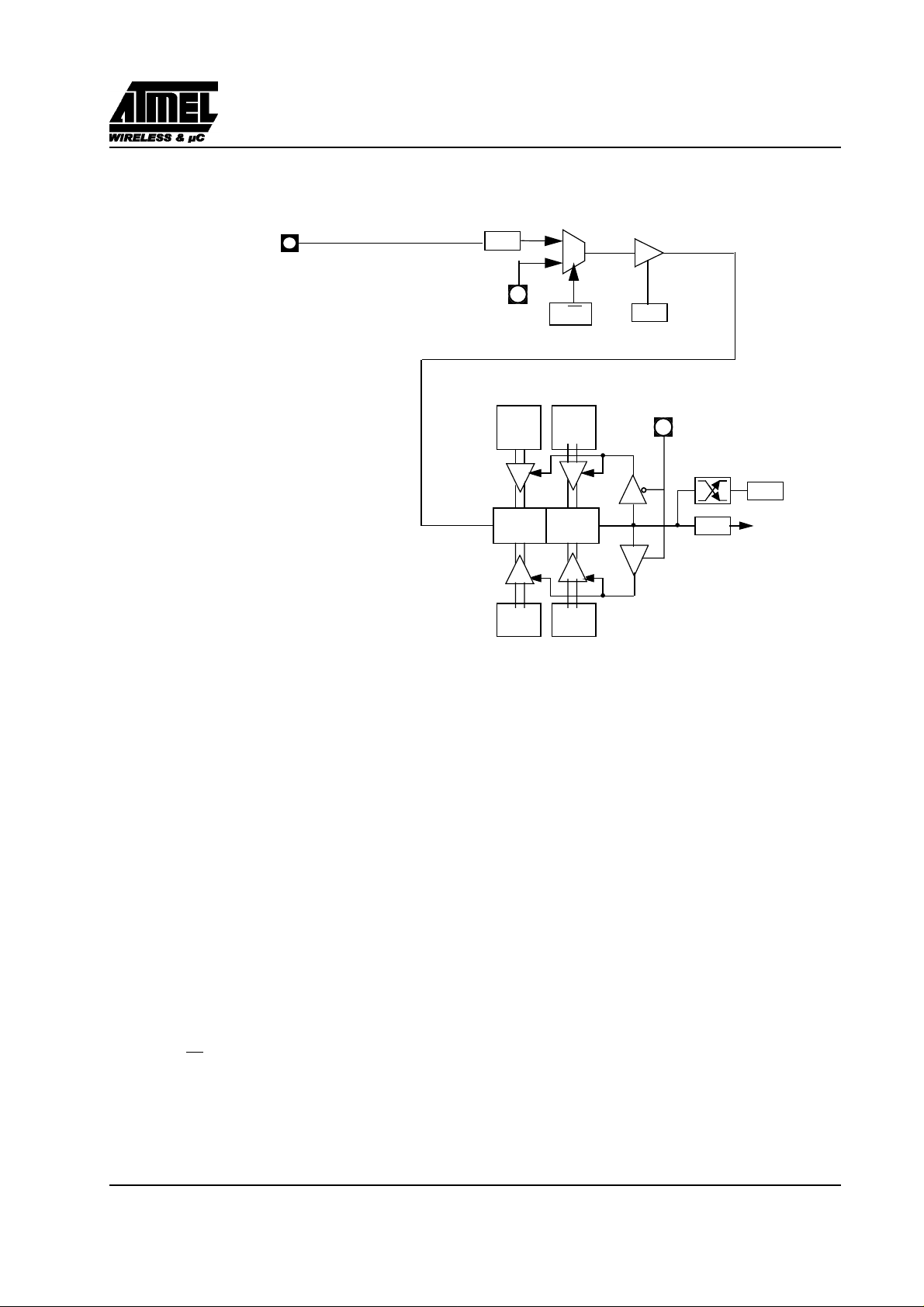

3. Block Diagram

PCA

Port 3

(1)

ECI

PCA

(1)

Port 5Port 4

T2EX

(1) (1)

Timer2

(2)(2)

T2

Watch

Dog

ALE/

XTAL1

XTAL2

PROG

PSEN

EA/V

RD

WR

RxD

TxD

(3)(3)

C51

CORE

RAM

256x8

INT

Ctrl

IB-bus

EUART

CPU

PP

(3)

(3)

Timer 0

Timer 1

Vss

Vcc

ROM

/EPROM

0/16/32/64Kx8

Parallel I/O Ports & Ext. Bus

Port 1

Port 0

XRAM

256/768x8

Port 2

I/O

(3) (3) (3) (3)

P1

P2

RESET

T0

T1

INT1

INT0

(1): Alternate function of Port 1

(2): Only available on high pin count packages

(3): Alternate function of Port 3

P0

P3

P5

P4

2 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

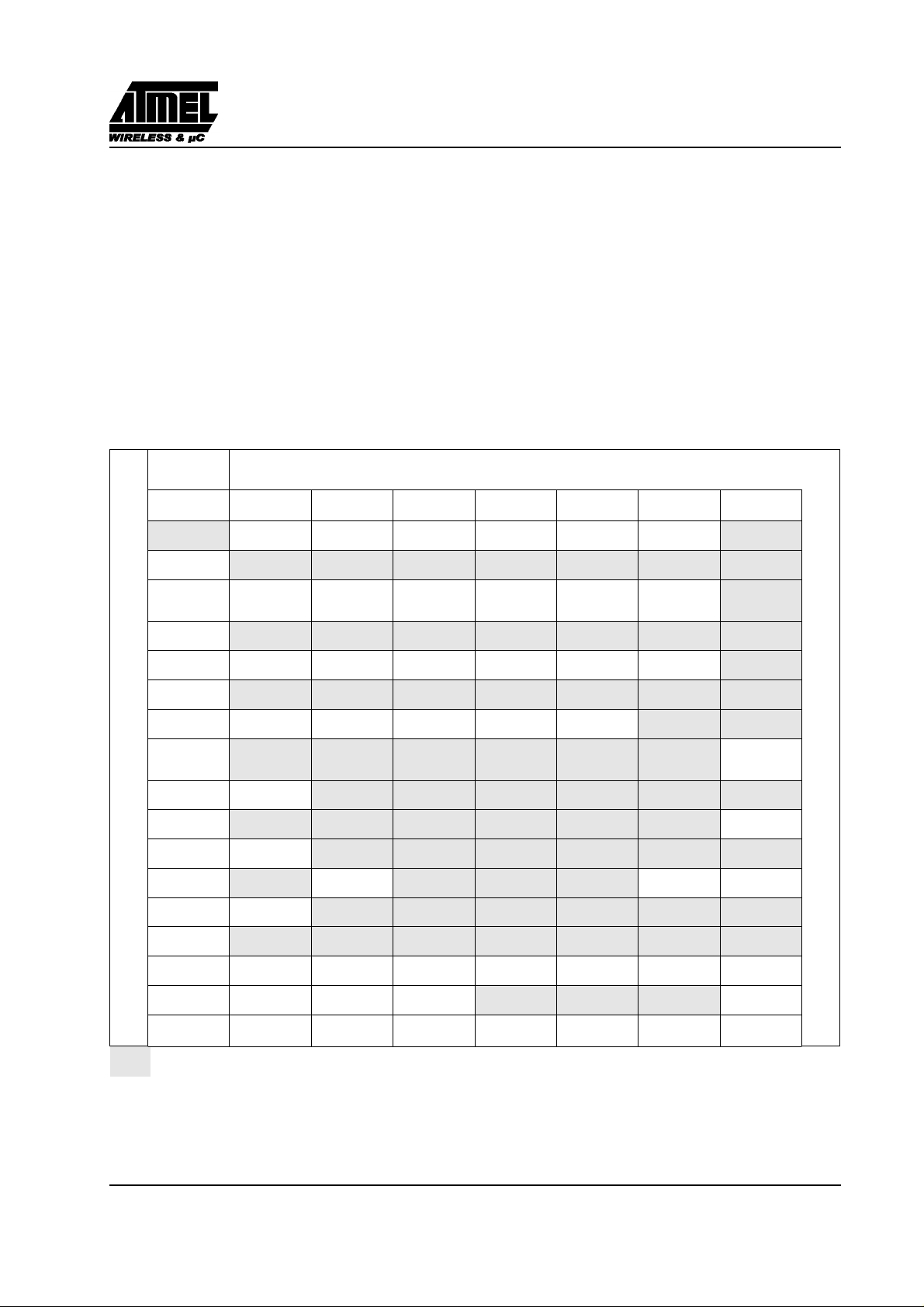

4. SFR Mapping

The Special Function Registers (SFRs) of the TS80C51Rx2 fall into the following categories:

• C51 core registers: ACC, B, DPH, DPL, PSW, SP, AUXR1

• I/O port registers: P0, P1, P2, P3, P4, P5

• Timer registers: T2CON, T2MOD, TCON, TH0, TH1, TH2, TMOD, TL0, TL1, TL2, RCAP2L, RCAP2H

• Serial I/O port registers: SADDR, SADEN, SBUF, SCON

• Power and clock control registers: PCON

• HDW Watchdog Timer Reset: WDTRST, WDTPRG

• PCA registers: CL, CH, CCAPiL, CCAPiH, CCON, CMOD, CCAPMi

• Interrupt system registers: IE, IP, IPH

• Others: AUXR, CKCON

Table 1. All SFRs with their address and their reset value

F8h

F0h

E8h

E0h

D8h

D0h

C8h

C0h

B8h

B0h

A8h

A0h

98h

90h

88h

80h

Bit

addressable

0/8 1/9 2/A 3/B 4/C 5/D 6/E 7/F

CH

0000 0000

B

0000 0000

P5 bit

addressable

1111 1111

ACC

0000 0000

CCON

00X0 0000

PSW

0000 0000

T2CON

0000 0000

P4 bit

addressable

1111 1111

IP

X000 000

P3

1111 1111

IE

0000 0000

P2

1111 1111

SCON

0000 0000

P1

1111 1111

TCON

0000 0000

P0

1111 1111

0/8 1/9 2/A 3/B 4/C 5/D 6/E 7/F

CL

0000 0000

CMOD

00XX X000

T2MOD

XXXX XX00

SADEN

0000 0000

SADDR

0000 0000

SBUF

XXXX XXXX

TMOD

0000 0000

SP

0000 0111

CCAP0H

XXXX XXXX

CCAP0L

XXXX XXXX

CCAPM0

X000 0000

RCAP2L

0000 0000

AUXR1

XXXX0XX0

TL0

0000 0000

DPL

0000 0000

XXXX XXXX

XXXX XXXX

Non Bit addressable

CCAP1H

CCAP1L

CCAPM1

X000 0000

RCAP2H

0000 0000

TL1

0000 0000

DPH

0000 0000

CCAPL2H

XXXX XXXX

CCAPL2L

XXXX XXXX

CCAPM2

X000 0000

TL2

0000 0000

TH0

0000 0000

CCAPL3H

XXXX XXXX

CCAPL3L

XXXX XXXX

CCAPM3

X000 0000

TH2

0000 0000

TH1

0000 0000

CCAPL4H

XXXX XXXX

CCAPL4L

XXXX XXXX

CCAPM4

X000 0000

WDTRST

XXXX XXXX

AUXR

XXXXXX00

P5 byte

addressable

1111 1111

IPH

X000 0000

WDTPRG

XXXX X000

CKCON

XXXX XXX0

PCON

00X1 0000

FFh

F7h

EFh

E7h

DFh

D7h

CFh

C7h

BFh

B7h

AFh

A7h

9Fh

97h

8Fh

87h

reserved

Rev. C - 06 March, 2001 3

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

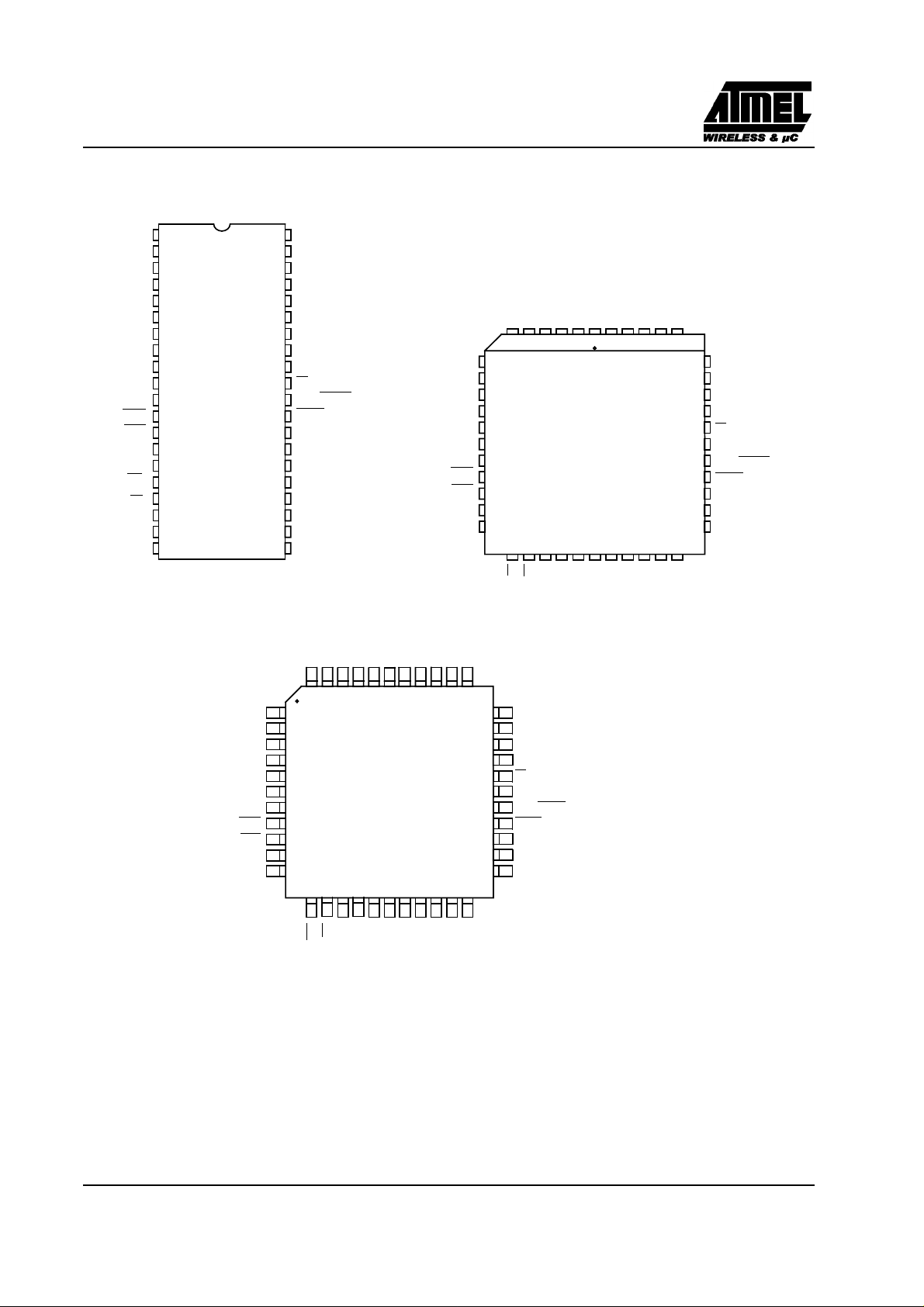

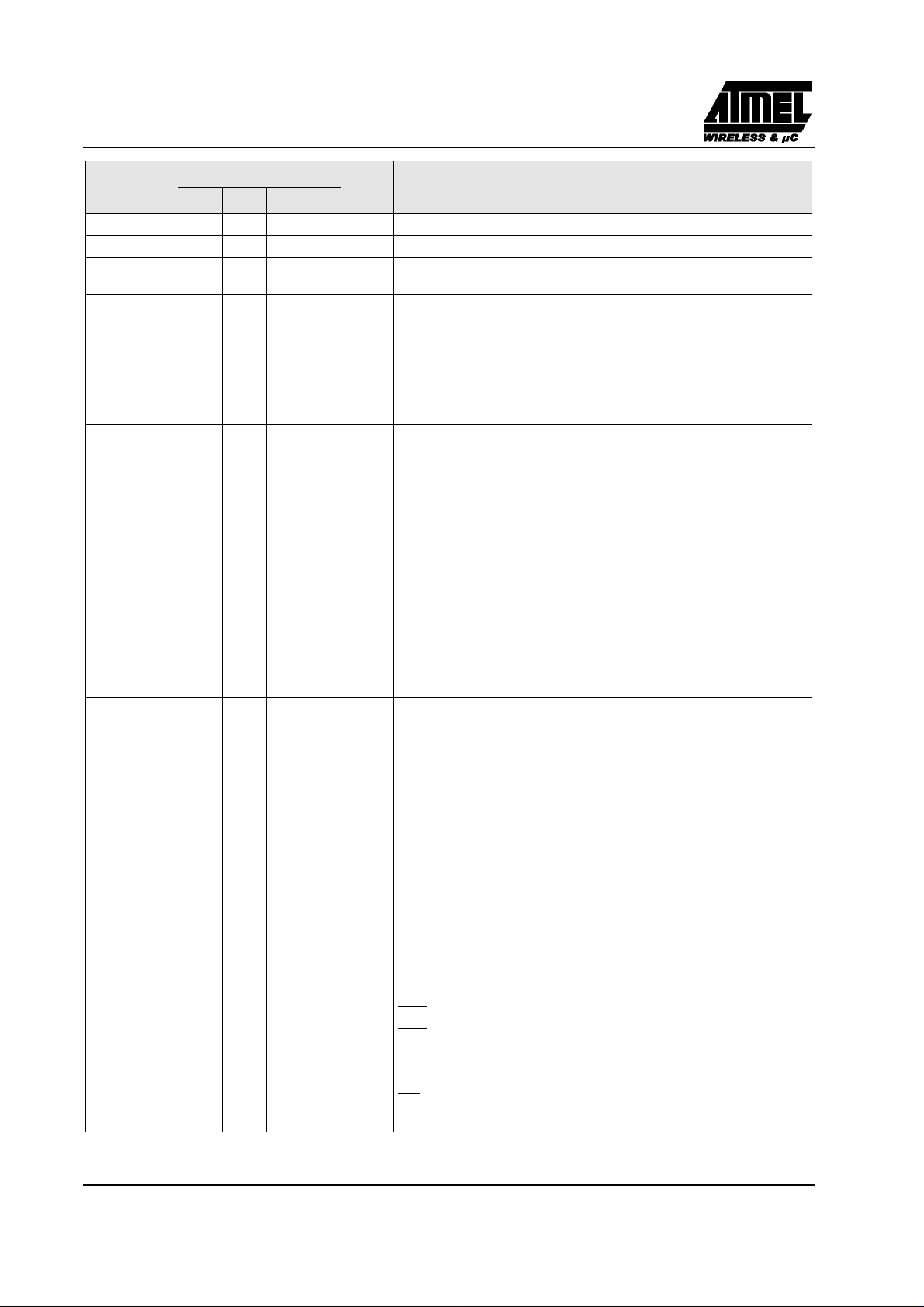

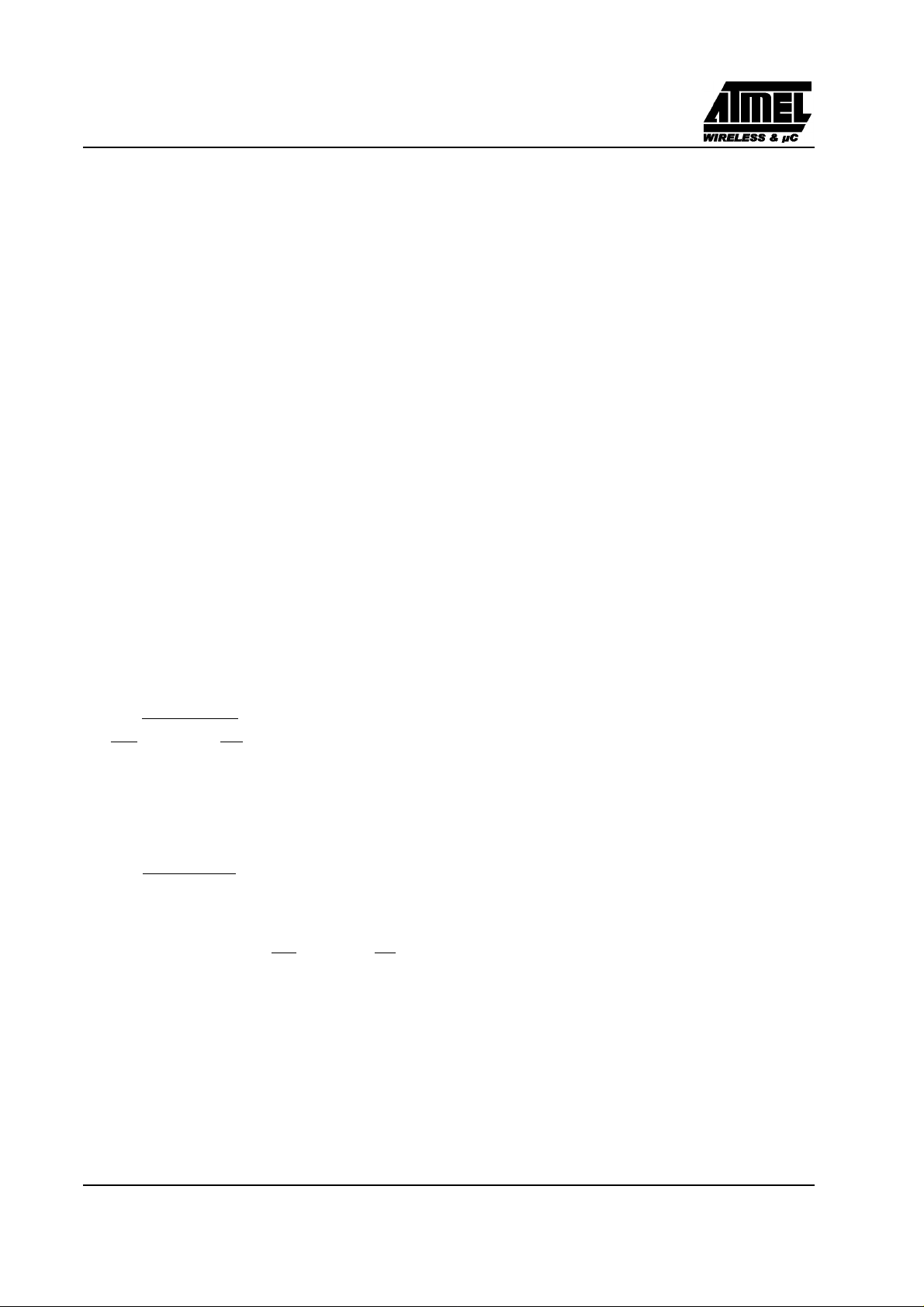

5. Pin Configuration

P1.0 / T2

P1.1 / T2EX

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7

RST

P3.0/RxD

P3.1/TxD

P3.2/INT0

P3.3/INT1

P3.4/T0

P3.5/T1

P3.6/WR

P3.7/RD

XTAL2

XTAL1

VSS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

PDIL/

CDIL40

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

VCC

P0.0 / A0

P0.1 / A1

P0.2 / A2

P0.3 / A3

P0.4 / A4

P0.5 / A5

P0.6 / A6

P0.7 / A7

EA/VPP

ALE/PROG

PSEN

P2.7 / A15

P2.6 / A14

P2.5 / A13

P2.4 / A12

P2.3 / A11

P2.2 / A10

P2.1 / A9

P2.0 / A8

P1.4

P1.3

P1.1/T2EX

P1.2

P1.0/T2

VSS1/NIC*

VCC

P3.0/RxD

NIC*

P3.1/TxD

P3.2/INT0

P3.3/INT1

P3.4/T0

P3.5/T1

P0.0/AD0

P0.1/AD1

P1.5

P1.6

P1.7

RST

P0.2/AD2

P0.3/AD3

P1.4

5 4 3 2 1 6

7

8

9

10

11

12

13

14

15

16

17

P1.3

PLCC/CQPJ 44

P1.1/T2EX

P1.2

P1.0/T2

VSS1/NIC*

VCC

44 43 42 41 40

18 19 20 21 22 23 24 25 26 27 28

NIC*

VSS

XTAL2

P3.7/RD

P3.6/WR

XTAL1

P2.0/A8

P0.0/AD0

P0.1/AD1

P2.1/A9

P2.2/A10

P0.3/AD3

P0.2/AD2

39

38

37

36

35

34

33

32

31

30

29

P2.3/A11

P2.4/A12

P0.4/AD4

P0.5/AD5

P0.6/AD6

P0.7/AD7

EA/VPP

NIC*

ALE/PROG

PSEN

P2.7/A15

P2.6/A14

P2.5/A13

P3.2/INT0

*NIC: No Internal Connection

P1.5

P1.6

P1.7

RST

P3.0/RxD

NIC*

P3.1/TxD

P3.3/INT1

P3.4/T0

P3.5/T1

43 42 41 40 3944

1

2

3

4

5

6

7

8

9

10

11

38 37 36 35 34

VQFP44 1.4

12 13 14 15 16 17 18 19 20 21 22

VSS

NIC*

XTAL1

P3.7/RD

P3.6/WR

XTAL2

P2.0/A8

P2.1/A9

P2.2/A10

33

32

31

30

29

28

27

26

25

24

23

P2.3/A11

P2.4/A12

P0.4/AD4

P0.5/AD5

P0.6/AD6

P0.7/AD7

EA/VPP

NIC*

ALE/PROG

PSEN

P2.7/A15

P2.6/A14

P2.5/A13

4 Rev. C - 06 March, 2001

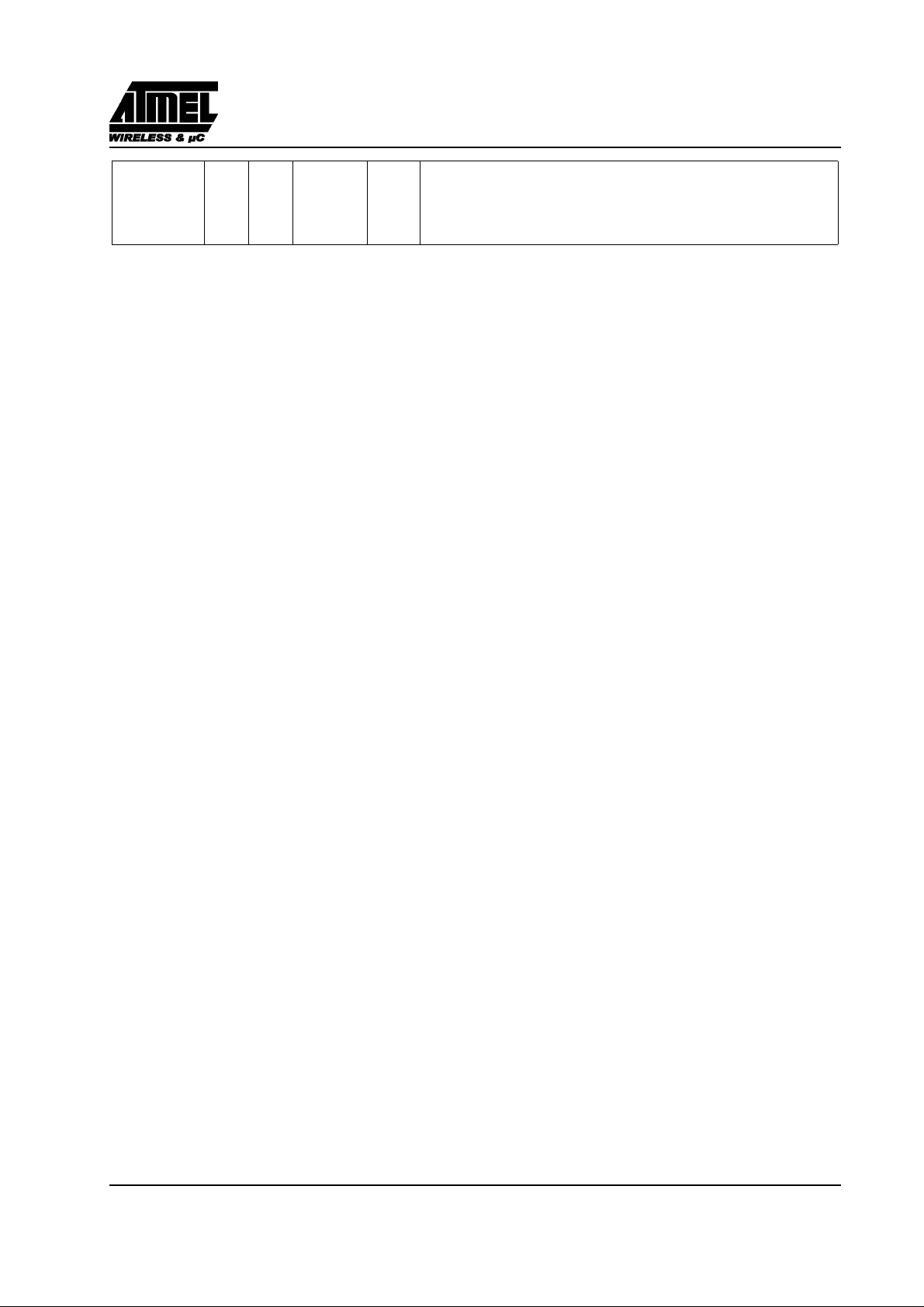

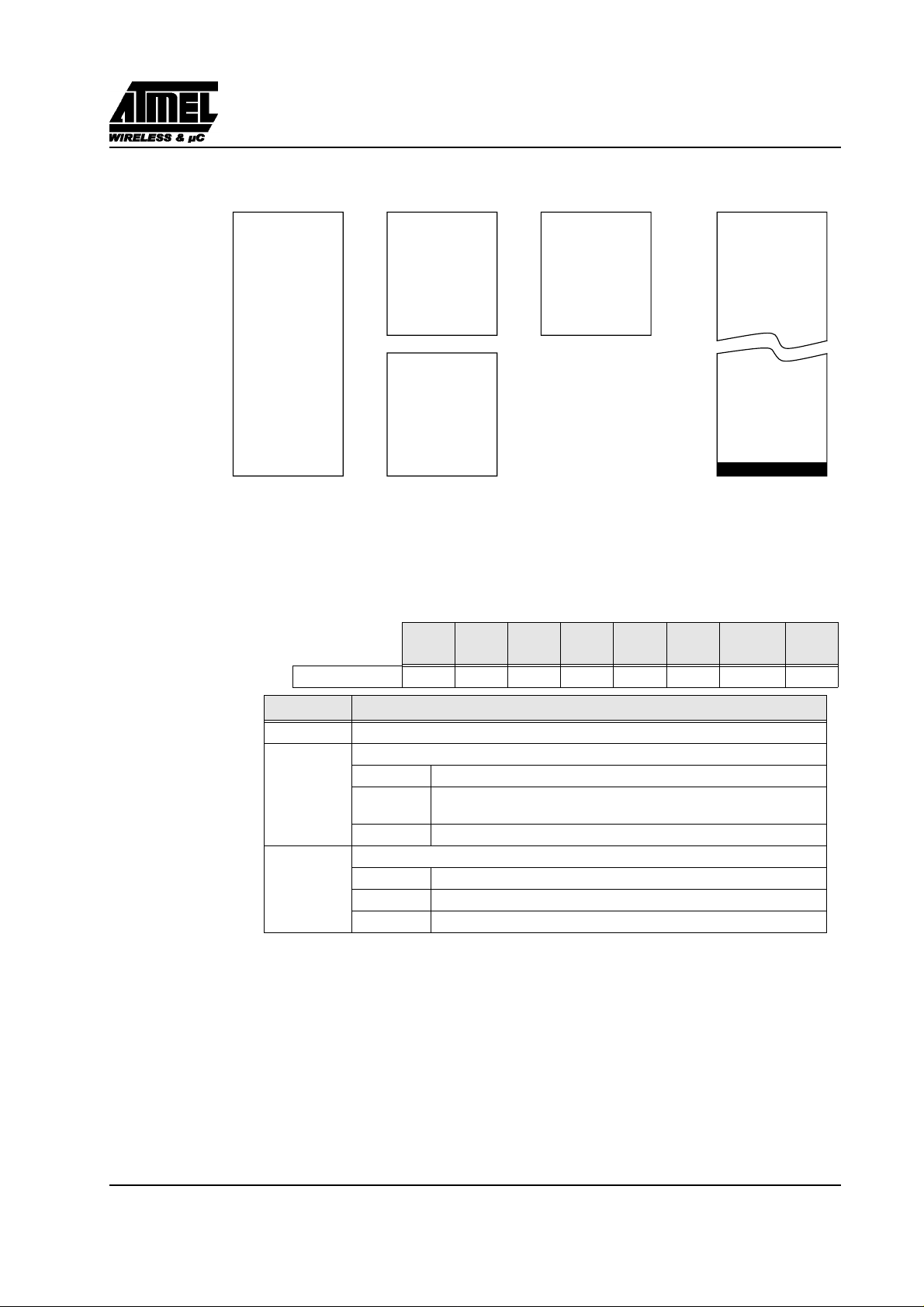

P5.5

P0.3/AD3

P0.2/AD2

P5.6

P0.1/AD1

P0.0/AD0

P5.7

VCC

NIC

P1.0/T2

P4.0

P1.1/T2EX

P1.2

P1.3

P4.1

P1.4

P4.2

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

P0.4/AD4

89

27 28

P5.4

NIC

P0.5/AD5

P0.6/AD6

P5.3

29 30 313233

ALE/PROG

PSEN

EA/VPP

NIC

P0.7/AD7

23567 4 1 686766656463

NIC

PLCC 68

36 37 38 39 40 41

34 35

P2.7/A15

P2.6/A14

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

P5.2

P5.1

P2.5/A13

62 61

42 43

P5.0

60

P2.4/A12

59

P2.3/A11

58

P4.7

57

P2.2/A10

56

P2.1/A9

55

P2.0/A8

54

P4.6

53

NIC

52

VSS

51

P4.5

50

XTAL1

49

XTAL2

48

P3.7/RD

4647P4.4

45

P3.6/WR

44

P4.3

P1.5

P1.6

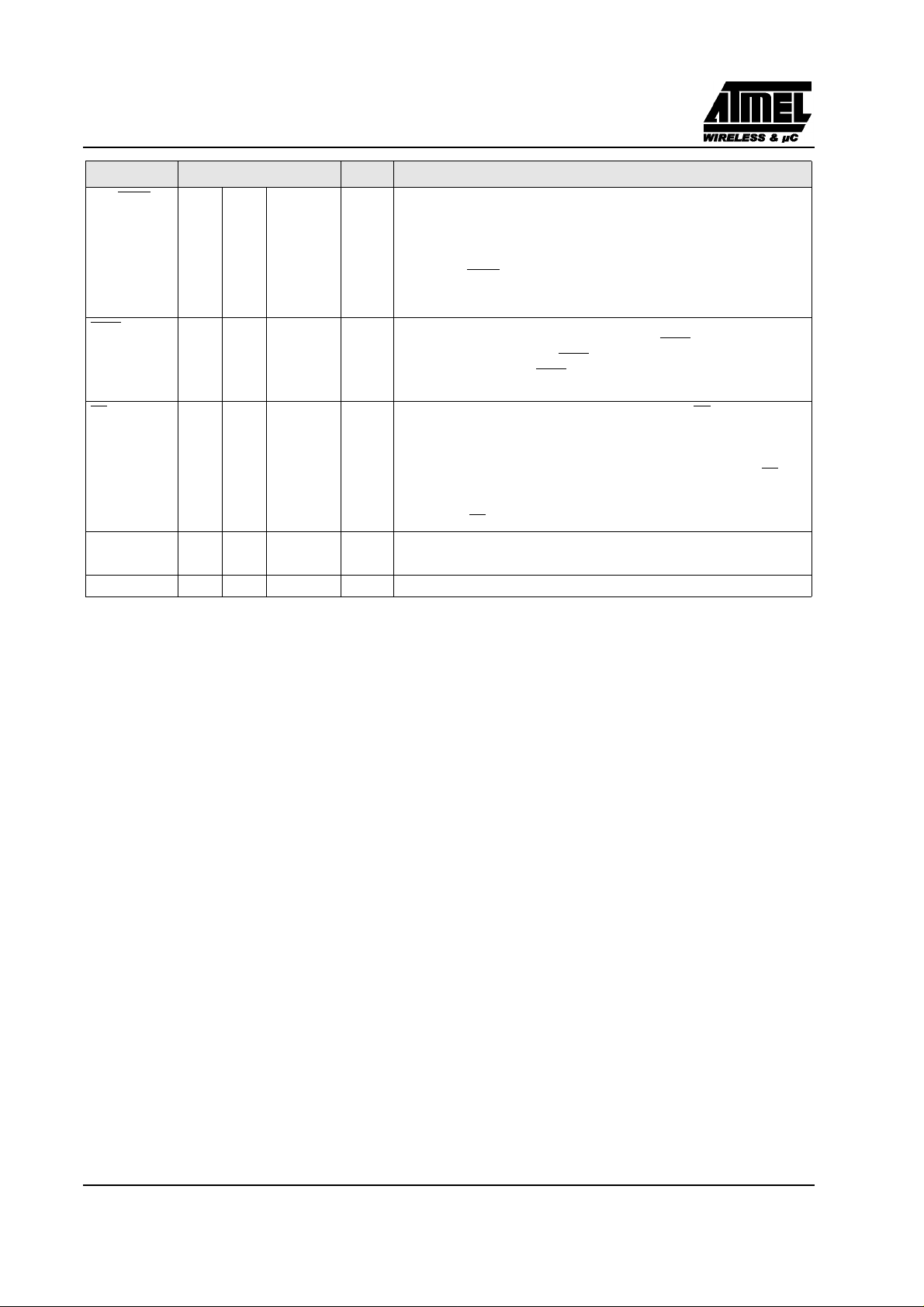

P5.5

P0.3/AD3

P0.2/AD2

P5.6

P0.1/AD1

P0.0/AD0

P5.7

VCC

VSS

P1.0/T2

P4.0

P1.1/T2EX

P1.2

P1.3

P4.1

P1.4

NIC: No InternalConnection

P1.7

P0.4/AD4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

P4.2

RST

NIC

NIC

P0.5/AD5

P0.6/AD6

P5.4

P5.3

VQFP64 1.4

RST

P1.7

P1.6

P1.5

NIC

P0.7/AD7

NIC

NIC

NIC

NIC

NIC

2618 19 20 21 22 23 24 25 27 28 29 30 31 3217

PSEN

NIC

P5.2

P2.7/A15

P2.6/A14

NIC

P3.1/TxD

P3.2/INT0

P3.1/TxD

P5.1

P3.3/INT1

P3.0/RxD

ALE/PROG

EA/VPP

NIC

58 5051525354555657596061626364 49

NIC

NIC

P3.0/RxD

P3.3/INT1

P3.2/INT0

P5.0

P2.5/A13

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

P3.5/T1

P3.4/T0

P3.4/T0

P3.5/T1

P2.4/A12

P2.3/A11

P4.7

P2.2/A10

P2.1/A9

P2.0/A8

P4.6

NIC

VSS

P4.5

XTAL1

XTAL2

P3.7/RD

P4.4

P3.6/WR

P4.3

Rev. C - 06 March, 2001 5

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Mnemonic

Type Name And Function

DIL LCC VQFP 1.4

Pin Number

V

SS

Vss1 1 39 I Optional Ground: Contact the Sales Office for ground connection.

V

CC

P0.0-P0.7 39-32 43-36 37-30 I/O Port 0: Port 0 is an open-drain, bidirectional I/O port. Port 0 pins that have 1s

P1.0-P1.7 1-8 2-9 40-44

P2.0-P2.7 21-28 24-31 18-25 I/O Port 2: Port 2 is an 8-bit bidirectional I/O port with internal pull-ups. Port 2

P3.0-P3.7 10-17 11,

20 22 16 I Ground: 0V reference

40 44 38 I

1-3

1 2 40 I/O T2 (P1.0): Timer/Counter 2 external count input/Clockout

2 3 41 I T2EX (P1.1): Timer/Counter 2 Reload/Capture/Direction Control

3 4 42 I ECI (P1.2): External Clock for the PCA

4 5 43 I/O CEX0 (P1.3): Capture/Compare External I/O for PCA module 0

5 6 44 I/O CEX1 (P1.4): Capture/Compare External I/O for PCA module 1

6 7 45 I/O CEX0 (P1.5): Capture/Compare External I/O for PCA module 2

7 8 46 I/O CEX0 (P1.6): Capture/Compare External I/O for PCA module 3

8 9 47 I/O CEX0 (P1.7): Capture/Compare External I/O for PCA module 4

5,

13-19

10 11 5 I RXD (P3.0): Serial input port

11 13 7 O TXD (P3.1): Serial output port

12 14 8 I INT0 (P3.2): External interrupt 0

13 15 9 I INT1 (P3.3): External interrupt 1

14 16 10 I T0 (P3.4): Timer 0 external input

15 17 11 I T1 (P3.5): Timer 1 external input

16 18 12 O WR (P3.6): External data memory write strobe

17 19 13 O RD (P3.7): External data memory read strobe

7-13

Power Supply: This is the power supply voltage for normal, idle and powerdown operation

written to them float and can be used as high impedance inputs. Port 0 pins must

be polarized to Vcc or Vss in order to prevent any parasitic current consumption.

Port 0 is also the multiplexed low-order address and data bus during access to

external program and data memory. In this application, it uses strong internal

pull-up when emitting 1s. Port 0 also inputs the code bytes during EPROM

programming. External pull-ups are required during program verification during

which P0 outputs the code bytes.

I/O Port 1: Port 1 is an 8-bit bidirectional I/O port with internal pull-ups. Port 1

pins that have 1s written to them are pulled high by the internal pull-ups and

can be used as inputs. As inputs, Port 1 pins that are externally pulled low will

source current because of the internal pull-ups. Port 1 also receives the low-order

address byte during memory programming and verification.

Alternate functions for Port 1 include:

pins that have 1s written to them are pulled high by the internal pull-ups and

can be used as inputs. As inputs, Port 2 pins that are externally pulled low will

source current because of the internal pull-ups. Port 2 emits the high-order address

byte during fetches from external program memory and during accesses to external

data memory that use 16-bit addresses (MOVX @DPTR).In this application, it

uses strong internal pull-ups emitting 1s. During accesses to external data memory

that use 8-bit addresses (MOVX @Ri), port 2 emits the contents of the P2 SFR.

Some Port 2 pins (P2.0 to P2.5) receive the high order address bits during

EPROM programming and verification:

I/O Port 3: Port 3 is an 8-bit bidirectional I/O port with internal pull-ups. Port 3

pins that have 1s written to them are pulled high by the internal pull-ups and

can be used as inputs. As inputs, Port 3 pins that are externally pulled low will

source current because of the internal pull-ups. Some Port 3 pins (P3.4 to P3.5)

receive the high order address bits during EPROM programming and verification.

Port 3 also serves the special features of the 80C51 family, as listed below.

6 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Reset 9 10 4 I Reset: A high on this pin for two machine cycles while the oscillator is running,

resets the device. An internal diffused resistor to VSSpermits a power-on reset

using only an external capacitor to V

time-out, the reset pin becomes an output during the time the internal reset is

activated.

If the hardware watchdog reaches its

CC.

Rev. C - 06 March, 2001 7

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Mnemonic

ALE/PROG 30 33 27 O (I) Address Latch Enable/Program Pulse: Output pulse for latching the low byte

PSEN 29 32 26 O Program Store ENable: The read strobe to external program memory. When

EA/V

PP

XTAL1 19 21 15 I

XTAL2 18 20 14 O Crystal 2: Output from the inverting oscillator amplifier

Pin Number Type

of the address during an access to external memory. In normal operation, ALE

is emitted at a constant rate of 1/6 (1/3 in X2 mode) the oscillator frequency,

and can be used for external timing or clocking. Note that one ALE pulse is

skipped during each access to external data memory. This pin is also the program

pulse input (PROG) during EPROM programming. ALE can be disabled by

setting SFR’s AUXR.0 bit. With this bit set, ALE will be inactive during internal

fetches.

executing code from the external program memory, PSEN is activated twice each

machine cycle, except that two PSEN activations are skipped during each access

to external data memory. PSEN is not activated during fetches from internal

program memory.

31 35 29 I External Access Enable/Programming Supply Voltage: EA must be externally

held low to enable the device to fetch code from external program memory

locations 0000H and 3FFFH (RB) or 7FFFH (RC), or FFFFH (RD). If EA is

held high, the device executes from internal program memory unless the program

counter contains an address greater than 3FFFH (RB) or 7FFFH (RC) EA must

be held low for ROMless devices. This pin also receives the 12.75V programming

supply voltage (VPP) during EPROM programming. If security level 1 is

programmed, EA will be internally latched on Reset.

Crystal 1: Input to the inverting oscillator amplifier and input to the internal

clock generator circuits.

Name And Function

8 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

5.1. Pin Description for 64/68 pin Packages

Port 4 and Port 5 are 8-bit bidirectional I/O ports with internal pull-ups. Pins that have 1 written to them are pulled

high by the internal pull ups and can be used as inputs.

As inputs, pins that are externally pulled low will source current because of the internal pull-ups.

Refer to the previous pin description for other pins.

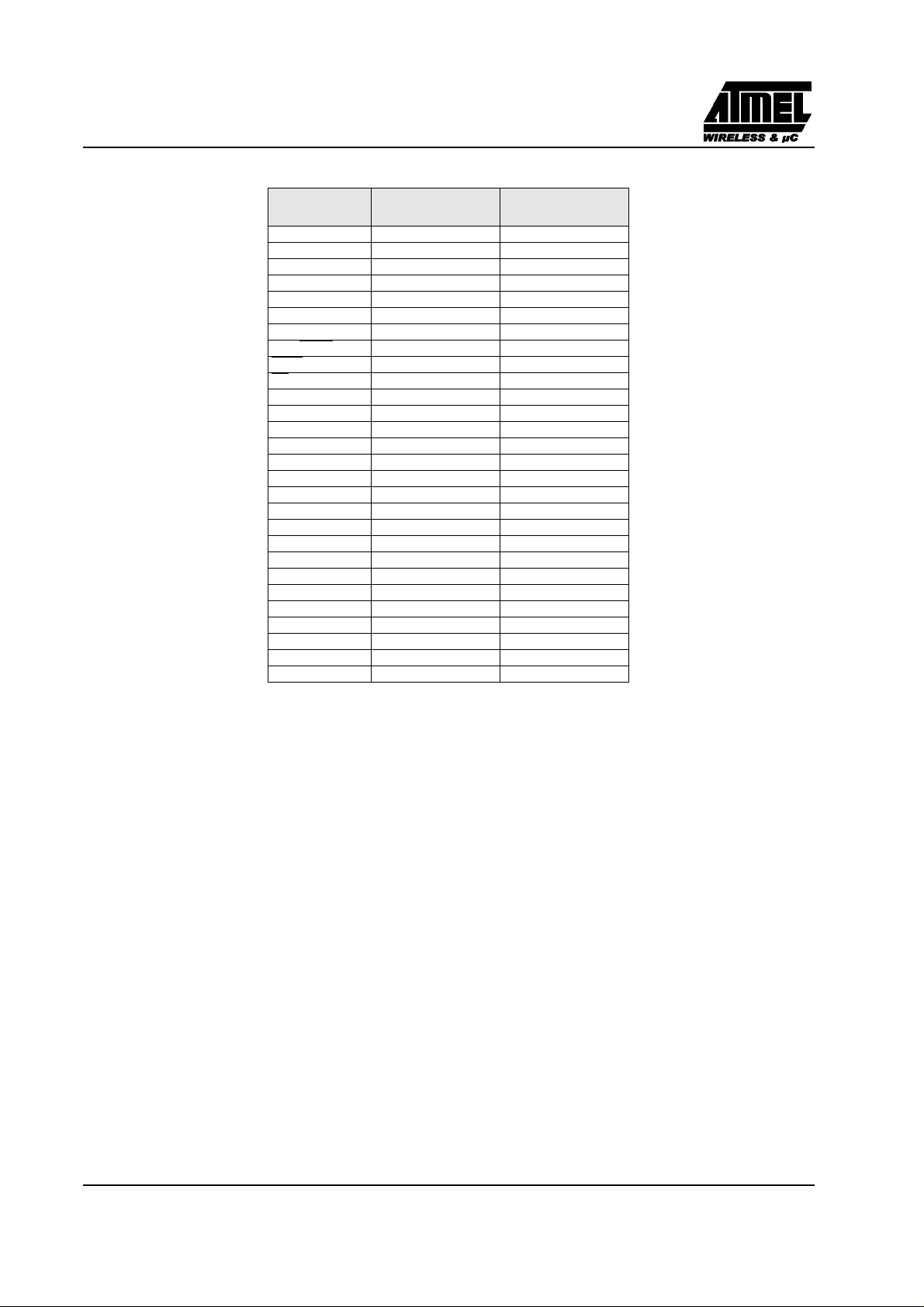

Table 2. 64/68 Pin Packages Configuration

PLCC68

VSS 51 9/40

VCC 17 8

P0.0 15 6

P0.1 14 5

P0.2 12 3

P0.3 11 2

P0.4 9 64

P0.5 6 61

P0.6 5 60

P0.7 3 59

P1.0 19 10

P1.1 21 12

P1.2 22 13

P1.3 23 14

P1.4 25 16

P1.5 27 18

P1.6 28 19

P1.7 29 20

P2.0 54 43

P2.1 55 44

P2.2 56 45

P2.3 58 47

P2.4 59 48

P2.5 61 50

P2.6 64 53

P2.7 65 54

P3.0 34 25

P3.1 39 28

SQUARE VQFP64

1.4

Rev. C - 06 March, 2001 9

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

PLCC68

P3.2 40 29

P3.3 41 30

P3.4 42 31

P3.5 43 32

P3.6 45 34

P3.7 47 36

RESET 30 21

ALE/PROG 68 56

PSEN 67 55

EA/VPP 2 58

XTAL1 49 38

XTAL2 48 37

P4.0 20 11

P4.1 24 15

P4.2 26 17

P4.3 44 33

P4.4 46 35

P4.5 50 39

P4.6 53 42

P4.7 57 46

P5.0 60 49

P5.1 62 51

P5.2 63 52

P5.3 7 62

P5.4 8 63

P5.5 10 1

P5.6 13 4

P5.7 16 7

SQUARE VQFP64

1.4

10 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6. TS80C51Rx2 Enhanced Features

In comparison to the original 80C52, the TS80C51Rx2 implements some new features, which are:

• The X2 option.

• The Dual Data Pointer.

• The extended RAM.

• The Programmable Counter Array (PCA).

• The Watchdog.

• The 4 level interrupt priority system.

• The power-off flag.

• The ONCE mode.

• The ALE disabling.

• Some enhanced features are also located in the UART and the timer 2.

6.1. X2 Feature

The TS80C51Rx2 core needs only 6 clock periods per machine cycle. This feature called ”X2” provides the

following advantages:

• Divide frequency crystals by 2 (cheaper crystals) while keeping same CPU power.

• Save power consumption while keeping same CPU power (oscillator power saving).

• Save power consumption by dividing dynamically operating frequency by 2 in operating and idle modes.

• Increase CPU power by 2 while keeping same crystal frequency.

In order to keep the original C51 compatibility, a divider by 2 is inserted between the XTAL1 signal and the main

clock input of the core (phase generator). This divider may be disabled by software.

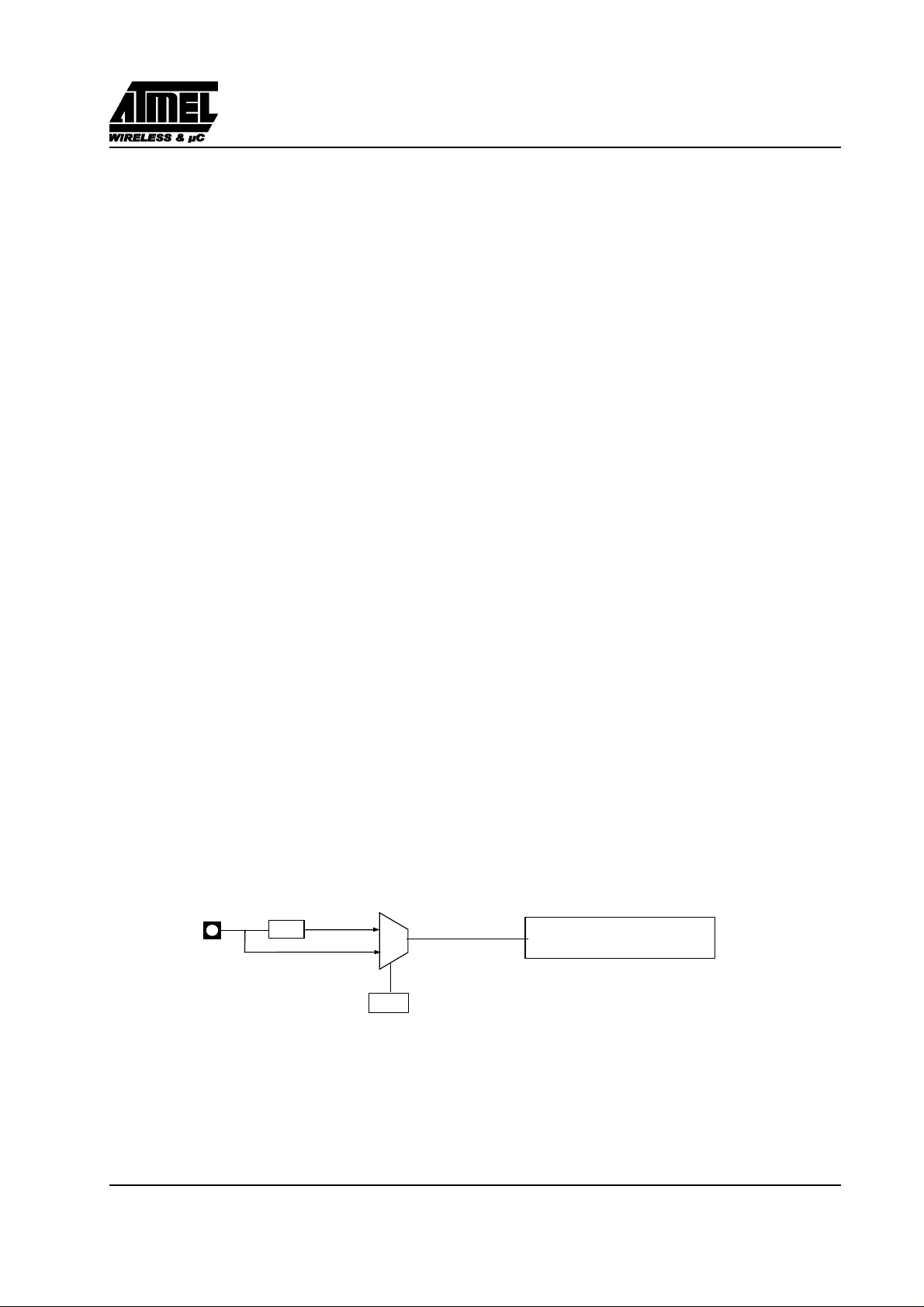

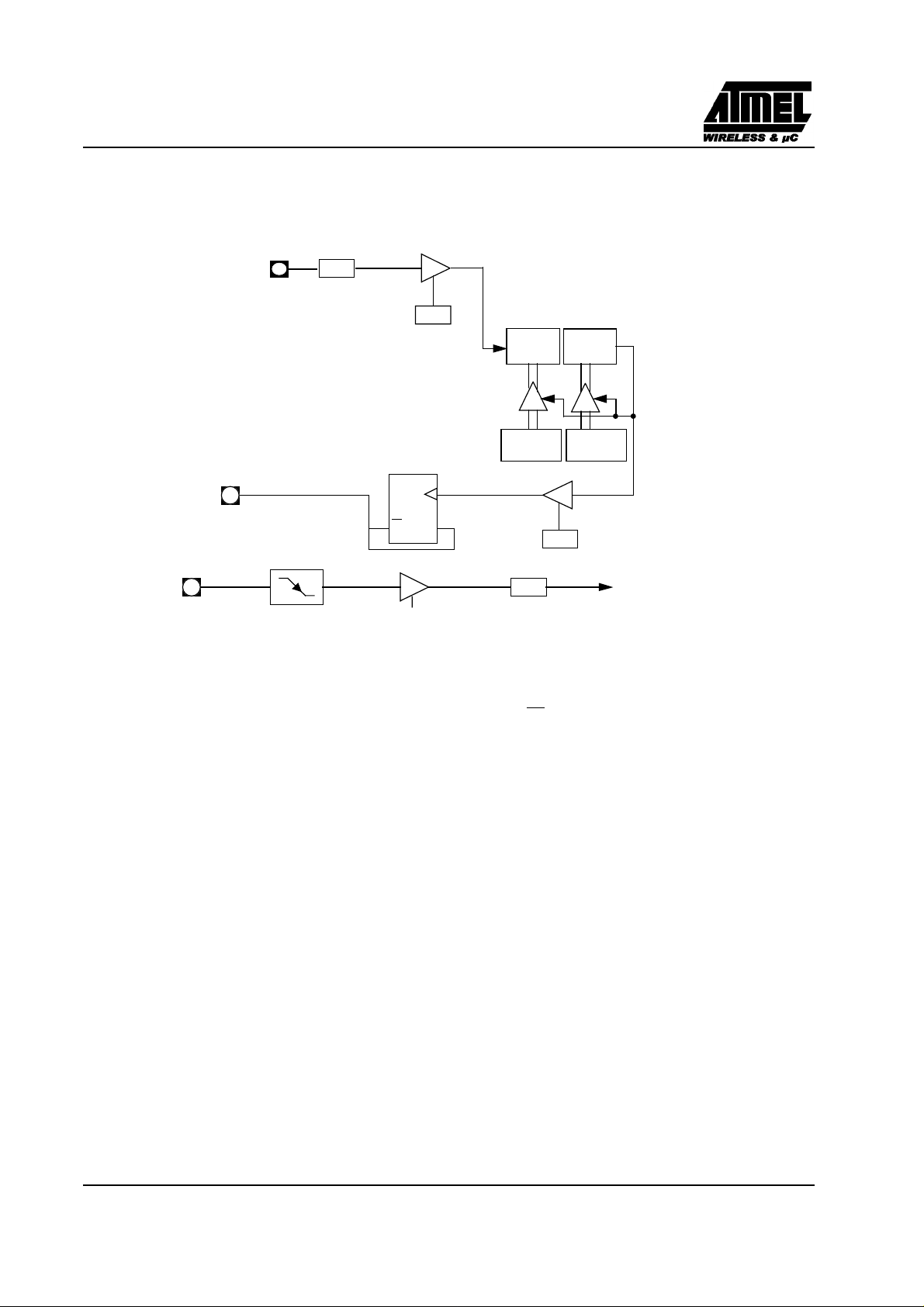

6.1.1. Description

The clock for the whole circuit and peripheral is first divided by two before being used by the CPU core and

peripherals. This allows any cyclic ratio to be accepted on XTAL1 input. In X2 mode, as this divider is bypassed,

the signals on XTAL1 must have a cyclic ratio between 40 to 60%. Figure 1. shows the clock generation block

diagram. X2 bit is validated on XTAL1÷2 rising edge to avoid glitches when switching from X2 to STD mode.

Figure 2. shows the mode switching waveforms.

XTAL1:2

XTAL1

F

XTAL

2

0

1

X2

CKCON reg

F

OSC

state machine: 6 clock cycles.

CPU control

Figure 1. Clock Generation Diagram

Rev. C - 06 March, 2001 11

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

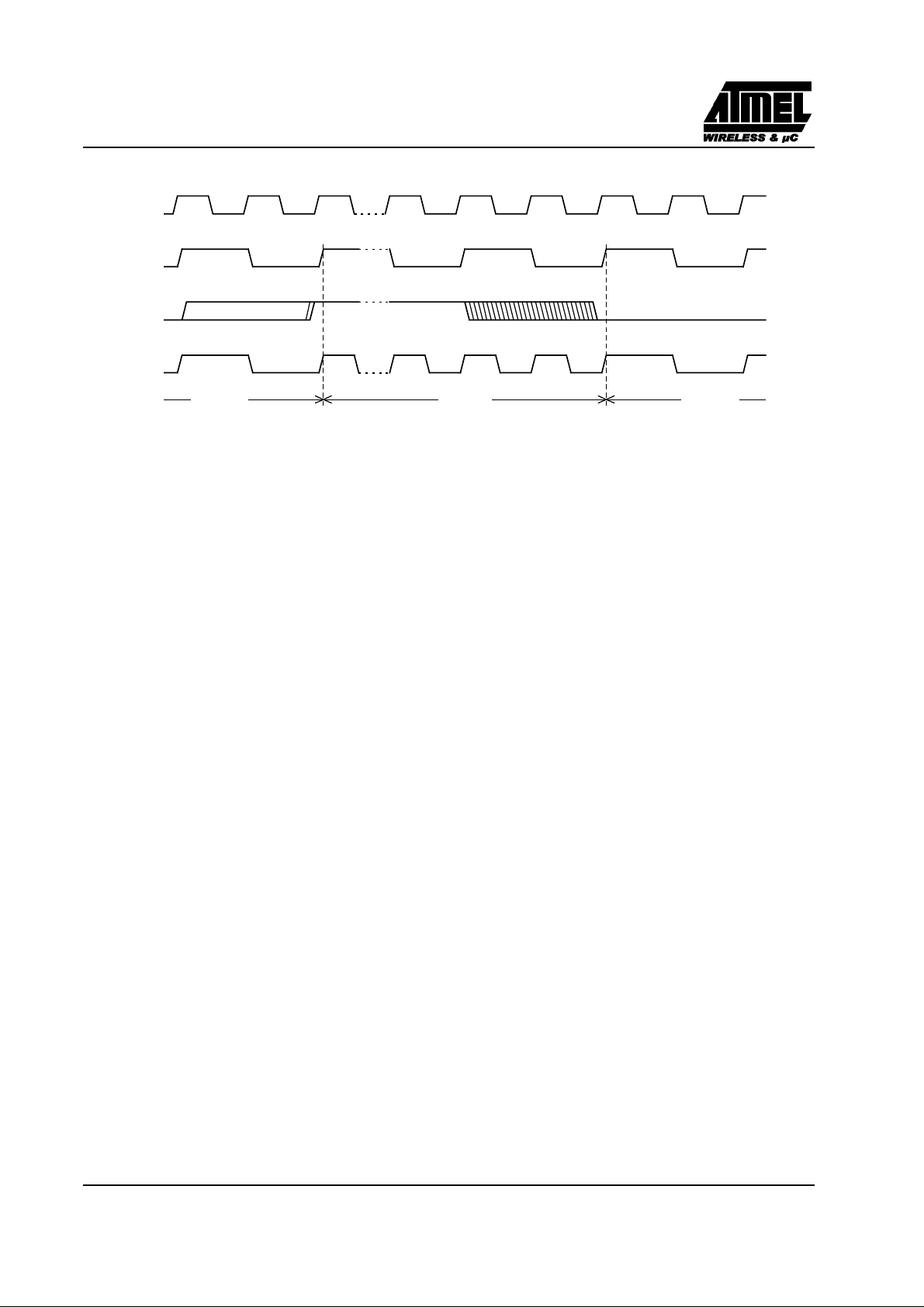

XTAL1

XTAL1:2

X2 bit

CPU clock

X2 ModeSTD Mode STD Mode

Figure 2. Mode Switching Waveforms

The X2 bit in the CKCON register (See Table 3.) allows to switch from 12 clock cycles per instruction to 6 clock

cycles and vice versa. At reset, the standard speed is activated (STD mode). Setting this bit activates the X2 feature

(X2 mode).

CAUTION

In order to prevent any incorrect operation while operating in X2 mode, user must be aware that all peripherals

using clock frequency as time reference (UART, timers, PCA...) will have their time reference divided by two.

For example a free running timer generating an interrupt every 20 ms will then generate an interrupt every 10 ms.

UART with 4800 baud rate will have 9600 baud rate.

12 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Table 3. CKCON Register

CKCON - Clock Control Register (8Fh)

7 6 5 4 3 2 1 0

- - - - - - - X2

Bit Number

7 -

6 -

5 -

4 -

3 -

2 -

1 -

0 X2

Bit

Mnemonic

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

CPU and peripheral clock bit

Reset Value = XXXX XXX0b

Not bit addressable

Description

The value read from this bit is indeterminate. Do not set this bit.

The value read from this bit is indeterminate. Do not set this bit.

The value read from this bit is indeterminate. Do not set this bit.

The value read from this bit is indeterminate. Do not set this bit.

The value read from this bit is indeterminate. Do not set this bit.

The value read from this bit is indeterminate. Do not set this bit.

The value read from this bit is indeterminate. Do not set this bit.

Clear to select 12 clock periods per machine cycle (STD mode, F

Set to select 6 clock periods per machine cycle (X2 mode, F

OSC=FXTAL

OSC=FXTAL

).

/2).

For further details on the X2 feature, please refer to ANM072 available on the web (http://www.atmel-wm.com)

Rev. C - 06 March, 2001 13

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6.2. Dual Data Pointer Register Ddptr

The additional data pointer can be used to speed up code execution and reduce code size in a number of

ways.

The dual DPTR structure is a way by which the chip will specify the address of an external data memory

location. There are two 16-bit DPTR registers that address the external memory, and a single bit called

DPS = AUXR1/bit0 (See Table 4.) that allows the program code to switch between them (Refer to Figure 3).

External Data Memory

07

DPS

AUXR1(A2H)

DPH(83H) DPL(82H)

DPTR1

DPTR0

Application

AUXR1

Address 0A2H

a. User software should not write 1s to reserved bits. These bits may be used in future 8051 family

b. GF3 will not be available on first version of the RC devices.

Figure 3. Use of Dual Pointer

Table 4. AUXR1: Auxiliary Register 1

- - - - GF3 - - DPS

Reset value X X X X 0 X X 0

Symbol

- Not implemented, reserved for future use.

DPS Data Pointer Selection.

GF3 This bit is a general purpose user flag

products to invoke new feature. In that case, the reset value of the new bit will be 0, and its active

value will be 1. The value read from a reserved bit is indeterminate.

Function

DPS Operating Mode

0 DPTR0 Selected

1 DPTR1 Selected

a

b

.

Software can take advantage of the additional data pointers to both increase speed and reduce code size, for

example, block operations (copy, compare, search ...) are wellserved by using one datapointer as a ’source’

pointer and the other one as a "destination" pointer.

14 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

ASSEMBLY LANGUAGE

; Block move using dual data pointers

; Destroys DPTR0, DPTR1, A and PSW

; note: DPS exits opposite of entry state

; unless an extra INC AUXR1 is added

;

00A2 AUXR1 EQU 0A2H

;

0000 909000 MOV DPTR,#SOURCE ; address of SOURCE

0003 05A2 INC AUXR1 ; switch data pointers

0005 90A000 MOV DPTR,#DEST ; address of DEST

0008 LOOP:

0008 05A2 INC AUXR1 ; switch data pointers

000A E0 MOVX A,@DPTR ; get a byte from SOURCE

000B A3 INC DPTR ; increment SOURCE address

000C 05A2 INC AUXR1 ; switch data pointers

000E F0 MOVX @DPTR,A ; write the byte to DEST

000F A3 INC DPTR ; increment DEST address

0010 70F6 JNZ LOOP ; check for 0 terminator

0012 05A2 INC AUXR1 ; (optional) restore DPS

INC is a short (2 bytes) and fast (12 clocks) way to manipulate the DPS bit in the AUXR1 SFR. However,

note that the INC instruction does not directly force the DPS bit to a particular state, but simply toggles it.

In simple routines, such as the block move example, only the factthat DPS is toggled in the proper sequence

matters, not its actual value.In other words, the block move routine worksthe same whether DPS is '0' or '1'

on entry. Observe that without the last instruction (INC AUXR1), the routine will exit with DPS in the

opposite state.

Rev. C - 06 March, 2001 15

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6.3. Expanded RAM (XRAM)

The TS80C51Rx2 provide additional Bytes of ramdom access memory (RAM) space for increased data

parameter handling and high level language usage.

RA2, RB2 and RC2 devices have 256 bytes of expanded RAM, from 00H to FFH in external data space;

RD2 devices have 768 bytes of expanded RAM, from 00H to 2FFH in external data space.

The TS80C51Rx2 has internal data memory that is mapped into four separate segments.

The four segments are:

• 1. The Lower 128 bytes of RAM (addresses 00H to 7FH) are directly and indirectly addressable.

• 2. The Upper 128 bytes of RAM (addresses 80H to FFH) are indirectly addressable only.

• 3. The Special Function Registers, SFRs, (addresses 80H to FFH) are directly addressable only.

• 4. The expanded RAM bytes are indirectly accessed by MOVX instructions, and with the EXTRAM

bit cleared in the AUXR register. (See Table 5.)

The Lower 128 bytes can be accessed by either direct or indirect addressing. The Upper 128 bytes can be

accessed by indirect addressing only. The Upper 128 bytes occupy the same address space as the SFR. That

means they have the same address, but are physically separate from SFR space.

When an instruction accesses an internal location above address 7FH, the CPU knows whether the access is

to the upper 128 bytes of data RAM or to SFR space by the addressing mode used in the instruction.

• Instructions that use direct addressing access SFR space. For example: MOV 0A0H, # data ,accesses the SFR

at location 0A0H (which is P2).

• Instructions that use indirect addressing access the Upper 128 bytes of data RAM. For example: MOV @R0,

# data where R0 contains 0A0H, accesses the data byte at address 0A0H, rather than P2 (whose address is 0A0H).

• The 256 or 768 XRAM bytes can be accessed by indirect addressing, with EXTRAM bit cleared and MOVX

instructions. This part of memory which is physically located on-chip, logically occupies the first 256 or 768

bytes of external data memory.

• With EXTRAM = 0, the XRAM is indirectly addressed, using the MOVX instruction in combination with any

of the registers R0, R1 of the selected bank or DPTR. An access to XRAM will not affect ports P0, P2, P3.6

(WR) and P3.7 (RD). For example, with EXTRAM = 0, MOVX @R0, # data where R0 contains 0A0H,

accesses the XRAM at address 0A0H rather than external memory. An access to external data memory locations

higher than FFH (i.e. 0100H to FFFFH) (higher than 2FFH (i.e. 0300H to FFFFH for RD devices) will be

performed with the MOVX DPTR instructions in the same way as in the standard 80C51, so with P0 and P2

as data/address busses, and P3.6 and P3.7 as write and read timing signals. Refer to Figure . For RD devices,

accesses to expanded RAM from 100H to 2FFH can only be done thanks to the use of DPTR.

• With EXTRAM = 1, MOVX @Ri and MOVX @DPTR will be similar to the standard 80C51. MOVX @ Ri

will provide an eight-bit address multiplexed with data on Port0 and any output port pins can be used to output

higher order address bits. This is to provide the external paging capability. MOVX @DPTR will generate a

sixteen-bit address. Port2 outputs the high-order eight address bits (the contents of DPH) while Port0 multiplexes

the low-order eight address bits (DPL) with data. MOVX @ Ri and MOVX @DPTR will generate either read

or write signals on P3.6 (WR) and P3.7 (RD).

The stack pointer (SP) may be located anywhere in the 256 bytes RAM (lower and upper RAM) internal

data memory. The stack may not be located in the XRAM.

16 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

FF(RA, RB, RC)/2FF (RD)

00

XRAM

256 bytes

FF

Upper

128 bytes

Internal

Ram

indirect accesses

80 80

Lower

128 bytes

Internal

Ram

direct or indirect

accesses

00

FF

direct accesses

0100 (RA, RB, RC) or 0300 (RD)

Figure 4. Internal and External Data Memory Address

Table 5. Auxiliary Register AUXR

AUXR

Address 08EH

Reset value X X X X X X 0 0

- - - - - -

Special

Function

Register

FFFF

0000

External

Data

Memory

EXTRA

M

AO

Symbol Function

- Not implemented, reserved for future use.

AO Disable/Enable ALE

AO Operating Mode

0

1 ALE is active only during a MOVX or MOVC instruction

EXTRAM Internal/External RAM (00H-FFH) access using MOVX @ Ri/ @ DPTR

EXTRAM Operating Mode

0 Internal XRAM access using MOVX @ Ri/ @ DPTR

1 External data memory access

a. User software should not write 1s to reserved bits. These bits may be used in future 8051 family

products to invoke new features. In that case, the reset or inactive value of the new bit will be 0, and

its active value will be 1. The value read from a reserved bit is indeterminate.

ALE is emitted at a constant rate of 1/6 the oscillator frequency (or 1/3 if

X2 mode is used)

a

Rev. C - 06 March, 2001 17

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6.4. Timer 2

The timer 2 in the TS80C51RX2 is compatible with the timer 2 in the 80C52.

It is a 16-bit timer/counter: the count is maintained by two eight-bit timer registers, TH2 and TL2, connected in

cascade. It is controlled by T2CON register (See Table 6) and T2MOD register (See Table 7). Timer 2 operation

is similar to Timer 0 and Timer 1. C/T2 selects F

as the timer clock input. Setting TR2 allows TL2 to be incremented by the selected input.

Timer 2 has 3 operating modes: capture, autoreload and Baud Rate Generator. These modes are selected by the

combination of RCLK, TCLK and CP/RL2 (T2CON), as described in the Atmel Wireless & Microcontrollers 8bit Microcontroller Hardware description.

Refer to the Atmel Wireless & Microcontrollers 8-bit Microcontroller Hardware description for the description of

Capture and Baud Rate Generator Modes.

In TS80C51RX2 Timer 2 includes the following enhancements:

• Auto-reload mode with up or down counter

• Programmable clock-output

6.4.1. Auto-Reload Mode

The auto-reload mode configures timer 2 as a 16-bit timer or event counter with automatic reload. If DCEN bit

in T2MOD is cleared, timer 2 behaves as in 80C52 (refer to the Atmel Wireless & Microcontrollers 8-bit

Microcontroller Hardware description). If DCEN bit is set, timer 2 acts as an Up/down timer/counter as shown in

Figure 5. In this mode the T2EX pin controls the direction of count.

/12 (timer operation) or external pin T2 (counter operation)

OSC

When T2EX is high, timer 2 counts up. Timer overflow occurs at FFFFh which sets the TF2 flag and generates

an interrupt request. The overflow also causes the 16-bit value in RCAP2H and RCAP2L registers to be loaded

into the timer registers TH2 and TL2.

When T2EX is low, timer 2 counts down. Timer underflow occurs when the count in the timer registers TH2 and

TL2 equals the value stored in RCAP2H and RCAP2L registers. The underflow sets TF2 flag and reloads FFFFh

into the timer registers.

The EXF2 bit toggles when timer 2 overflows or underflows according to the the direction of the count. EXF2

does not generate any interrupt. This bit can be used to provide 17-bit resolution.

18 Rev. C - 06 March, 2001

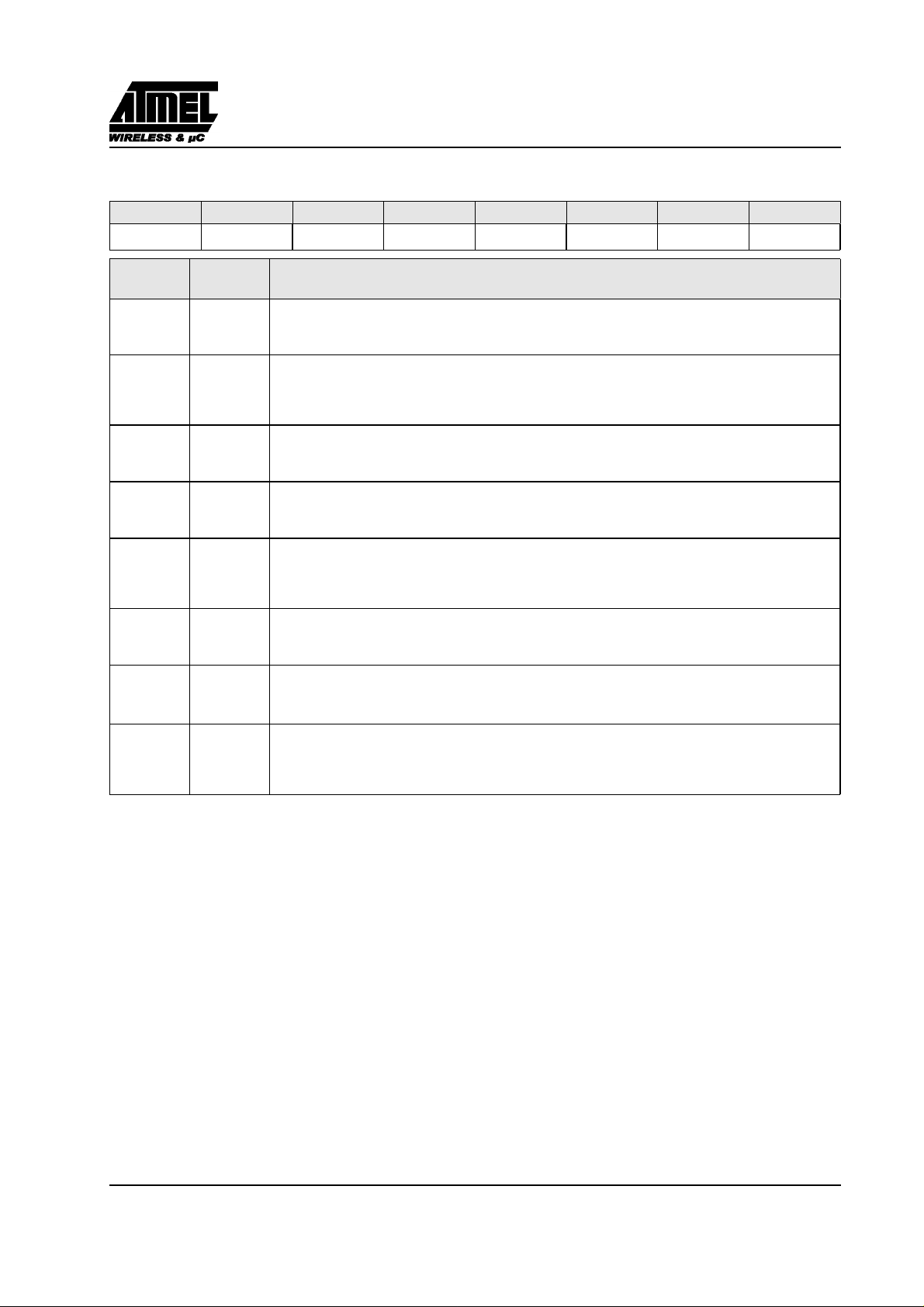

XTAL1

F

XTAL

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

(:6 in X2 mode)

:12

F

OSC

T2

0

1

C/T2

T2CONreg

TR2

T2CONreg

(DOWN COUNTING RELOAD VALUE)

FFh

(8-bit)

TL2

(8-bit)

RCAP2L

(8-bit)

(UP COUNTING RELOAD VALUE)

FFh

(8-bit)

TH2

(8-bit)

RCAP2H

(8-bit)

T2EX:

if DCEN=1, 1=UP

if DCEN=1, 0=DOWN

if DCEN = 0, up counting

TOGGLE

TF2

T2CONreg

T2CONreg

EXF2

TIMER 2

INTERRUPT

Figure 5. Auto-Reload Mode Up/Down Counter (DCEN = 1)

6.4.2. Programmable Clock-Output

In the clock-out mode, timer 2 operates as a 50%-duty-cycle, programmable clock generator (See Figure 6) . The

input clock increments TL2 at frequency F

At overflow, the contents of RCAP2H and RCAP2L registers are loaded into TH2 and TL2. In this mode, timer

2 overflows do not generate interrupts. The formula gives the clock-out frequency as a function of the system

oscillator frequency and the value in the RCAP2H and RCAP2L registers :

/2. The timer repeatedly counts to overflow from a loaded value.

OSC

F

Clock OutFrequency–

--------------------------------------------------------------------------------------=

4 65536 RCAP2H– RCAP2L⁄()×

osc

For a 16 MHz system clock, timer 2 has a programmable frequency range of 61 Hz

OSC

16)

/2

to 4 MHz (F

/4). The generated clock signal is brought out to T2 pin (P1.0).

OSC

(F

Timer 2 is programmed for the clock-out mode as follows:

• Set T2OE bit in T2MOD register.

• Clear C/T2 bit in T2CON register.

• Determine the 16-bit reload value from the formula and enter it in RCAP2H/RCAP2L registers.

• Enter a 16-bit initial value in timer registers TH2/TL2. It can be the same as the reload value or a different

one depending on the application.

• To start the timer, set TR2 run control bit in T2CON register.

Rev. C - 06 March, 2001 19

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

It is possible to use timer 2 as a baud rate generator and a clock generator simultaneously. For this configuration,

the baud rates and clock frequencies are not independent since both functions use the values in the RCAP2H and

RCAP2L registers.

T2EX

T2

XTAL1

:2

(:1 in X2 mode)

TR2

T2CON reg

Toggle

QD

EXEN2

T2CON reg

TL2

(8-bit)

RCAP2L

(8-bit)

T2OE

T2MOD reg

EXF2

T2CON reg

TH2

(8-bit)

RCAP2H

(8-bit)

OVERFLOW

TIMER 2

INTERRUPT

Figure 6. Clock-Out Mode C/T2=0

20 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Table 6. T2CON Register

T2CON - Timer 2 Control Register (C8h)

7 6 5 4 3 2 1 0

TF2 EXF2 RCLK TCLK EXEN2 TR2 C/T2# CP/RL2#

Bit Number

7 TF2

6 EXF2

5 RCLK

4 TCLK

3 EXEN2

2 TR2

1 C/T2#

Bit

Mnemonic

Description

Timer 2 overflow Flag

Must be cleared by software.

Set by hardware on timer 2 overflow, if RCLK = 0 and TCLK = 0.

Timer 2 External Flag

Set when a capture or a reload is caused by a negative transition on T2EX pin if EXEN2=1.

When set, causes the CPU to vector to timer 2 interrupt routine when timer 2 interrupt is enabled.

Must be cleared by software. EXF2 doesn’t cause an interrupt in Up/down counter mode (DCEN = 1)

Receive Clock bit

Clear to use timer 1 overflow as receive clock for serial port in mode 1 or 3.

Set to use timer 2 overflow as receive clock for serial port in mode 1 or 3.

Transmit Clock bit

Clear to use timer 1 overflow as transmit clock for serial port in mode 1 or 3.

Set to use timer 2 overflow as transmit clock for serial port in mode 1 or 3.

Timer 2 External Enable bit

Clear to ignore events on T2EX pin for timer 2 operation.

Set to cause a capture or reload when a negative transition on T2EX pin is detected, if timer 2 is not used to

clock the serial port.

Timer 2 Run control bit

Clear to turn off timer 2.

Set to turn on timer 2.

Timer/Counter 2 select bit

Clear for timer operation (input from internal clock system: F

Set for counter operation (input from T2 input pin, falling edge trigger). Must be 0 for clock out mode.

OSC

).

0 CP/RL2#

Reset Value = 0000 0000b

Bit addressable

Timer 2 Capture/Reload bit

If RCLK=1 or TCLK=1, CP/RL2# is ignored and timer is forced to auto-reload on timer 2 overflow.

Clear to auto-reload on timer 2 overflows or negative transitions on T2EX pin if EXEN2=1.

Set to capture on negative transitions on T2EX pin if EXEN2=1.

Rev. C - 06 March, 2001 21

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Table 7. T2MOD Register

T2MOD - Timer 2 Mode Control Register (C9h)

7 6 5 4 3 2 1 0

- - - - - - T2OE DCEN

Bit Number

7 -

6 -

5 -

4 -

3 -

2 -

1 T2OE

0 DCEN

Bit

Mnemonic

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Timer 2 Output Enable bit

Down Counter Enable bit

Reset Value = XXXX XX00b

Not bit addressable

Description

The value read from this bit is indeterminate. Do not set this bit.

The value read from this bit is indeterminate. Do not set this bit.

The value read from this bit is indeterminate. Do not set this bit.

The value read from this bit is indeterminate. Do not set this bit.

The value read from this bit is indeterminate. Do not set this bit.

The value read from this bit is indeterminate. Do not set this bit.

Clear to program P1.0/T2 as clock input or I/O port.

Set to program P1.0/T2 as clock output.

Clear to disable timer 2 as up/down counter.

Set to enable timer 2 as up/down counter.

22 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6.5. Programmable Counter Array PCA

The PCA provides more timing capabilities with less CPU intervention than the standard timer/counters. Its

advantages include reduced software overhead and improved accuracy. The PCA consists of a dedicated

timer/counter which serves as the time base for an array of five compare/ capture modules. Its clock input

can be programmed to count any one of the following signals:

• Oscillator frequency

• Oscillator frequency

• Timer 0 overflow

• External input on ECI (P1.2)

Each compare/capture modules can be programmed in any one of the following modes:

• rising and/or falling edge capture,

• software timer,

• high-speed output, or

• pulse width modulator.

Module 4 can also be programmed as a watchdog timer (See Section "PCA Watchdog Timer", page 33).

When the compare/capture modules are programmed in the capture mode, software timer, or high speed

output mode, an interrupt can be generated when themodule executes its function. Allfive modules plus the

PCA timer overflow share one interrupt vector.

÷ 12 (÷ 6 in X2 mode)

÷ 4(÷ 2 in X2 mode)

The PCA timer/counter and compare/capture modules share Port 1 for external I/O. These pins are listed

below. If the port is not used for the PCA, it can still be used for standard I/O.

PCA component External I/O Pin

16-bit Counter P1.2 / ECI

16-bit Module 0 P1.3 / CEX0

16-bit Module 1 P1.4 / CEX1

16-bit Module 2 P1.5 / CEX2

16-bit Module 3 P1.6 / CEX3

16-bit Module 4 P1.7 / CEX4

The PCA timer is a common time base for all five modules (

determined from the CPS1 and CPS0 bits in the CMOD SFR (See Table 8) and can be programmed to run

at:

See Figure 7). The timer count source is

• 1/12 the oscillator frequency. (Or 1/6 in X2 Mode)

• 1/4 the oscillator frequency. (Or 1/2 in X2 Mode)

• The Timer 0 overflow

• The input on the ECI pin (P1.2)

Rev. C - 06 March, 2001 23

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Fosc /12

Fosc / 4

T0 OVF

P1.2

CH CL

16 bit up/down counter

overflow

To PCA

modules

It

Idle

CIDL CPS1 CPS0 ECF

WDTE

CF CR

CCF4 CCF3 CCF2 CCF1 CCF0

Figure 7. PCA Timer/Counter

Table 8. CMOD: PCA Counter Mode Register

CMOD

Address 0D9H

Reset value 0 0 X X X 0 0 0

Symbol

CIDL

WDTE

- Not implemented, reserved for future use.

CPS1 PCA Count Pulse Select bit 1.

CPS0 PCA Count Pulse Select bit 0.

ECF

Function

Counter Idle control: CIDL = 0 programs the PCA Counter to continue functioning during

idle Mode. CIDL = 1 programs it to be gated off during idle.

Watchdog Timer Enable: WDTE = 0 disables Watchdog Timer function on PCA Module 4.

WDTE = 1 enables it.

CPS1 CPS0 Selected PCA input.

0 0 Internal clock f

0 1 Internal clock f

1 0 Timer 0 Overflow

1 1 External clock at ECI/P1.2 pin (max rate = f

PCA Enable Counter Overflow interrupt: ECF = 1 enables CF bit in CCON to generate an

interrupt. ECF = 0 disables that function of CF.

CIDL WDTE - - - CPS1 CPS0 ECF

/12(Orf

osc

/4 ( Or f

osc

a

b

osc

CMOD

0xD9

CCON

0xD8

/6 in X2 Mode).

osc

/2 in X2 Mode).

osc

/8)

a. User software should not write 1s to reserved bits. These bits may be used in future 8051 family

products to invoke new features. In that case, the reset or inactive value of the new bit will be 0, and its

active value will be 1. The value read from a reserved bit is indeterminate.

b. f

= oscillator frequency

osc

The CMOD SFR includes three additional bits associated with the PCA (See Figure 7 and Table 8).

• The CIDL bit which allows the PCA to stop during idle mode.

• The WDTE bit which enables or disables the watchdog function on module 4.

24 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

• The ECF bit which when set causes an interrupt and the PCA overflow flag CF (in the CCON SFR) to be set

when the PCA timer overflows.

Rev. C - 06 March, 2001 25

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

The CCON SFR contains the run control bit for the PCA and the flags for the PCA timer (CF) and each

module (Refer to Table 9).

• Bit CR (CCON.6) must be set by software to run the PCA. The PCA is shut off by clearing this bit.

• Bit CF: The CF bit (CCON.7) is set when the PCA counter overflows and an interrupt will be generated if the

ECF bit in the CMOD register is set. The CF bit can only be cleared by software.

• Bits 0 through 4 are the flags for the modules (bit 0 for module 0, bit 1 for module 1, etc.) and are set by

hardware when either a match or a capture occurs. These flags also can only be cleared by software.

Table 9. CCON: PCA Counter Control Register

CCON

Address 0D8H

Reset value 0 0 X 0 0 0 0 0

Symbol

CF

CR

- Not implemented, reserved for future use.

CCF4

CCF3

CCF2

CCF1

CCF0

a. User software should not write 1s to reserved bits. These bits may be used in future 8051 family

products to invoke new features. In that case, the reset or inactive value of the new bit will be 0, and its

active value will be 1. The value read from a reserved bit is indeterminate.

Function

PCA Counter Overflow flag. Set by hardware when the counter rolls over. CF flags

an interrupt if bit ECF in CMOD is set. CF may be set by either hardware or software but

can only be cleared by software.

PCA Counter Run control bit. Set by software to turn the PCA counter on. Must be cleared

by software to turn the PCA counter off.

PCA Module 4 interrupt flag. Set by hardware when a match or capture occurs. Must be

cleared by software.

PCA Module 3 interrupt flag. Set by hardware when a match or capture occurs. Must be

cleared by software.

PCA Module 2 interrupt flag. Set by hardware when a match or capture occurs. Must be

cleared by software.

PCA Module 1 interrupt flag. Set by hardware when a match or capture occurs. Must be

cleared by software.

PCA Module 0 interrupt flag. Set by hardware when a match or capture occurs. Must be

cleared by software.

CF CR - CCF4 CCF3 CCF2 CCF1 CCF0

a

The watchdog timer function is implemented in module 4 (See Figure 10).

The PCA interrupt system is shown in Figure 8

26 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

CCON

0xD8

To Interrupt

priority decoder

PCA Timer/Counter

Module 0

Module 1

Module 2

Module 3

Module 4

ECF

CF CR

CCAPMn.0CMOD.0

ECCFn

Figure 8. PCA Interrupt System

CCF4 CCF3 CCF2 CCF1 CCF0

IE.6 IE.7

EC EA

PCA Modules: each one of the five compare/capture modules has six possible functions. It can perform:

• 16-bit Capture, positive-edge triggered,

• 16-bit Capture, negative-edge triggered,

• 16-bit Capture, both positive and negative-edge triggered,

• 16-bit Software Timer,

• 16-bit High Speed Output,

• 8-bit Pulse Width Modulator.

In addition, module 4 can be used as a Watchdog Timer.

Each module in the PCAhas a special function register associated with it.These registers are: CCAPM0 for

module 0, CCAPM1 for module 1, etc. (See Table 10). The registers contain the bits that control the mode

that each module will operate in.

• The ECCF bit (CCAPMn.0 where n=0, 1, 2, 3, or 4 depending on the module) enables the CCF flag in the

CCON SFR to generate an interrupt when a match or compare occurs in the associated module.

• PWM (CCAPMn.1) enables the pulse width modulation mode.

• The TOG bit (CCAPMn.2) when set causes the CEX output associated with the module to toggle when there

is a match between the PCA counter and the module's capture/compare register.

• The match bit MAT (CCAPMn.3) when set will cause the CCFn bit in the CCON register to be set when there

is a match between the PCA counter and the module's capture/compare register.

• The next two bits CAPN (CCAPMn.4) and CAPP (CCAPMn.5) determine the edge that a capture input will

be active on. The CAPN bit enables the negative edge, and the CAPP bit enables the positive edge. If both

bits are set both edges will be enabled and a capture will occur for either transition.

• The last bit in the register ECOM (CCAPMn.6) when set enables the comparator function.

Table 11 shows the CCAPMn settings for the various PCA functions.

.

Rev. C - 06 March, 2001 27

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Table 10. CCAPMn: PCA Modules Compare/Capture Control Registers

CCAPM0=0DAH

CCAPMn Address

n=0-4

CCAPM1=0DBH

CCAPM2=0DCH

CCAPM3=0DDH

CCAPM4=0DEH

Reset value X 0 0 0 0 0 0 0

- ECOMn CAPPn CAPNn MATn TOGn PWMm ECCFn

Symbol

- Not implemented, reserved for future use.

ECOMn Enable Comparator. ECOMn = 1 enables the comparator function.

CAPPn Capture Positive, CAPPn = 1 enables positive edge capture.

CAPNn Capture Negative, CAPNn = 1 enables negative edge capture.

MATn

TOGn

PWMn

ECCFn

a. User software should not write 1s to reserved bits. These bits may be used in future 8051 family

products to invoke new features. In that case, the reset or inactive value of the new bit will be 0, and its

active value will be 1. The value read from a reserved bit is indeterminate.

Function

a

Match. When MATn = 1, a match of the PCA counter with this module's compare/capture

register causes the CCFn bit in CCON to be set, flagging an interrupt.

Toggle. When TOGn = 1, a match of the PCA counter with this module's compare/capture

register causes the CEXn pin to toggle.

Pulse Width Modulation Mode. PWMn = 1 enables the CEXn pin to be used as a pulse width

modulated output.

Enable CCF interrupt. Enables compare/capture flag CCFn in the CCON register to generate

an interrupt.

Table 11. PCA Module Modes (CCAPMn Registers)

ECOMn CAPPn CAPNn MATn TOGn PWMm ECCFn Module Function

0 0 0 0 0 0 0 No Operation

X10000X

X01000X

X 1 1 0 0 0 X 16-bit capture by a transition on CEXn

1 0 0 1 0 0 X 16-bit Software Timer / Compare mode.

1 0 0 1 1 0 X 16-bit High Speed Output

1 0 0 0 0 1 0 8-bit PWM

1 0 0 1 X 0 X Watchdog Timer (module 4 only)

16-bit capture by a positive-edge trigger

on CEXn

16-bit capture by a negative trigger on

CEXn

There are two additional registers associated with each of the PCA modules. They are CCAPnH and

CCAPnL and these are the registers that store the 16-bit count when a capture occurs or a compare should

occur. When a module is used in the PWM mode these registers are used to control the duty cycle of the

output (See Table 12 & Table 13)

28 Rev. C - 06 March, 2001

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Table 12. CCAPnH: PCA Modules Capture/Compare Registers High

CCAP0H=0FAH

CCAPnH Address

n=0-4

Table 13. CCAPnL: PCA Modules Capture/Compare Registers Low

CCAPnL Address

n=0-4

CCAP1H=0FBH

CCAP2H=0FCH

CCAP3H=0FDH

CCAP4H=0FEH

7 6 5 4 3 2 1 0

Reset value 0 0 0 0 0 0 0 0

CCAP0L=0EAH

CCAP1L=0EBH

CCAP2L=0ECH

CCAP3L=0EDH

CCAP4L=0EEH

7 6 5 4 3 2 1 0

Reset value 0 0 0 0 0 0 0 0

TS80C51RA2/RD2

CH

Address 0F9H

CL

Address 0E9H

Table 14. CH: PCA Counter High

7 6 5 4 3 2 1 0

Reset value 0 0 0 0 0 0 0 0

Table 15. CL: PCA Counter Low

7 6 5 4 3 2 1 0

Reset value 0 0 0 0 0 0 0 0

Rev. C - 06 March, 2001 29

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6.5.1. PCA Capture Mode

To use one of the PCA modules in the capture mode either one or both of the CCAPM bits CAPN and CAPP

for that module must be set. The external CEX input for the module (on port 1) is sampled for a transition.

When a valid transition occurs the PCA hardware loads the valueof the PCAcounter registers (CHand CL)

into the module's capture registers (CCAPnL and CCAPnH). If the CCFn bit for the module in the CCON

SFR and the ECCFn bit in the CCAPMn SFR are set then an interrupt will be generated (Refer to Figure 9).

Cex.n

CF CR

ECOMn

CCF4 CCF3 CCF2 CCF1 CCF0

Capture

CAPNn MATn TOGn PWMn ECCFnCAPPn

Figure 9. PCA Capture Mode

CCON

0xD8

PCA IT

PCA Counter/Timer

CH CL

CCAPnH CCAPnL

CCAPMn, n= 0 to 4

0xDA to 0xDE

30 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6.5.2. 16-bit Software Timer / Compare Mode

The PCA modules can be used as software timers by setting both the ECOM and MAT bits in the modules

CCAPMn register. The PCA timer will be compared to the module's capture registers and when a match

occurs an interrupt will occur if the CCFn (CCON SFR) and the ECCFn (CCAPMn SFR) bits for the module

are both set (See Figure 10).

CCON

CF CCF2 CCF1 CCF0

CR

CCF4

CCF3

0xD8

Write to

CCAPnH

Write to

CCAPnL

10

Reset

CCAPnH CCAPnL

Enable

16 bit comparator

CH CL

PCA counter/timer

ECOMn

CIDL CPS1 CPS0 ECF

WDTE

Match

CAPNn MATn TOGn PWMn ECCFnCAPPn

* Only for Module 4

Figure 10. PCA Compare Mode and PCA Watchdog Timer

PCA IT

RESET *

CCAPMn, n = 0 to 4

0xDA to 0xDE

CMOD

0xD9

Before enabling ECOM bit, CCAPnL and CCAPnH should be set with a non zero value, otherwise an unwanted

match could happen. Writing to CCAPnH will set the ECOM bit.

Once ECOM set, writing CCAPnL will clear ECOM so that an unwanted match doesn’t occur while modifying

the compare value. Writing to CCAPnH will set ECOM. For this reason, user software should write CCAPnL first,

and then CCAPnH. Of course, the ECOM bit can still be controlled by accessing to CCAPMn register.

Rev. C - 06 March, 2001 31

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6.5.3. High Speed Output Mode

In this mode the CEX output (on port 1) associated with the PCA module will toggle each time a match

occurs between the PCA counter and the module's capture registers. To activate this mode the TOG, MAT,

and ECOM bits in the module's CCAPMn SFR must be set (See Figure 11).

A prior write must be done to CCAPnL and CCAPnH before writing the ECOMn bit.

CCON

0xD8

PCA IT

CEXn

CCAPMn, n = 0 to 4

0xDA to 0xDE

Write to

CCAPnH

Write to

CCAPnL

1

CF CR

Reset

CCAPnH CCAPnL

0

Enable

16 bit comparator

CH CL

PCA counter/timer

ECOMn

CCF4 CCF3 CCF2 CCF1 CCF0

Match

CAPNn MATn TOGn PWMn ECCFnCAPPn

Figure 11. PCA High Speed Output Mode

Before enabling ECOM bit, CCAPnL and CCAPnH should be set with a non zero value, otherwise an unwanted

match could happen.

Once ECOM set, writing CCAPnL will clear ECOM so that an unwanted match doesn’t occur while modifying

the compare value. Writing to CCAPnH will set ECOM. For this reason, user software should write CCAPnL first,

and then CCAPnH. Of course, the ECOM bit can still be controlled by accessing to CCAPMn register.

32 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6.5.4. Pulse Width Modulator Mode

All of the PCA modules can be used as PWM outputs. Figure 12 shows the PWM function. The frequency of the

output depends on the source for the PCA timer. All of the modules will have the same frequency of output

because they all share the PCA timer. The duty cycle of each module is independently variable using the module's

capture register CCAPLn. When the value of the PCA CL SFR is less than the value in the module's CCAPLn

SFR the output will be low, when it is equal to or greater than the output will be high. When CL overflows from

FF to 00, CCAPLn is reloaded with the value in CCAPHn. This allows updating the PWM without glitches. The

PWM and ECOM bits in the module's CCAPMn register must be set to enable the PWM mode.

Enable

ECOMn

6.5.5. PCA Watchdog Timer

CAPNn MATn TOGn PWMn ECCFnCAPPn

Overflow

CCAPnH

CCAPnL

8 bit comparator

CL

PCA counter/timer

Figure 12. PCA PWM Mode

“0”

<

≥

“1”

CCAPMn, n= 0 to 4

0xDA to 0xDE

CEXn

An on-board watchdog timer is available with the PCA to improve the reliability of the system without

increasing chip count. Watchdog timers are useful for systems that are susceptible to noise, power glitches,

or electrostatic discharge. Module 4 is the only PCA module that can be programmed as a watchdog.

However, this module can still be used for other modes if the watchdog is not needed. Figure 10 shows a

diagram of how the watchdog works. The user pre-loads a 16-bit value inthe compare registers. Just like the

other compare modes, this 16-bit value is compared to the PCA timer value. If a match is allowed to occur,

an internal reset will be generated. This will not cause the RST pin to be driven high.

In order to hold off the reset, the user has three options:

• 1. periodically change the compare value so it will never match the PCA timer,

• 2. periodically change the PCA timer value so it will never match the compare values, or

• 3. disable the watchdog by clearing the WDTE bit before a match occurs and then re-enable it.

The first two options are more reliable because the watchdog timer is never disabled as in option #3. If the

program counter ever goes astray, a match will eventually occur and cause an internal reset. The second

option is also not recommended if other PCA modulesare being used. Remember, thePCA timer is the time

base for all modules; changing the time base for other modules would not be a good idea. Thus, in most

applications the first solution is the best option.

This watchdog timer won’t generate a reset out on the reset pin.

Rev. C - 06 March, 2001 33

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6.6. TS80C51Rx2 Serial I/O Port

The serial I/O port in the TS80C51Rx2 is compatible with the serial I/O port in the 80C52.

It provides both synchronous and asynchronous communication modes. It operates as an Universal Asynchronous

Receiver and Transmitter (UART) in three full-duplex modes (Modes 1, 2 and 3). Asynchronous transmission and

reception can occur simultaneously and at different baud rates

Serial I/O port includes the following enhancements:

• Framing error detection

• Automatic address recognition

6.6.1. Framing Error Detection

Framing bit error detection is provided for the three asynchronous modes (modes 1, 2 and 3). To enable the framing

bit error detection feature, set SMOD0 bit in PCON register (See Figure 13).

RITIRB8TB8RENSM2SM1SM0/FE

SCON (98h)

Set FE bit if stop bit is 0 (framing error) (SMOD0 = 1)

SM0 to UART mode control (SMOD = 0)

PCON (87h)

IDLPDGF0GF1POF-SMOD0SMOD1

To UART framing error control

Figure 13. Framing Error Block Diagram

When this feature is enabled, the receiver checks each incoming data frame for a valid stop bit. An invalid stop

bit may result from noise on the serial lines or from simultaneous transmission by two CPUs. If a valid stop bit

is not found, the Framing Error bit (FE) in SCON register (See Table 16.) bit is set.

34 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Software may examine FE bit after each reception to check for data errors. Once set, only software or a reset can

clear FE bit. Subsequently received frames with valid stop bits cannot clear FE bit. When FE feature is enabled,

RI rises on stop bit instead of the last data bit (See Figure 14. and Figure 15.).

RXD

SMOD0=X

FE

SMOD0=1

SMOD0=0

SMOD0=1

SMOD0=1

RI

RXD

RI

RI

FE

Start

bit

Data byte

Figure 14. UART Timings in Mode 1

Start

bit

Data byte Ninth

D7D6D5D4D3D2D1D0

Stop

bit

D8D7D6D5D4D3D2D1D0

Stop

bit

bit

Figure 15. UART Timings in Modes 2 and 3

6.6.2. Automatic Address Recognition

The automatic address recognition feature is enabled when the multiprocessor communication feature is enabled

(SM2 bit in SCON register is set).

Implemented in hardware, automatic address recognition enhances the multiprocessor communication feature by

allowing the serial port to examine the address of each incoming command frame. Only when the serial port

recognizes its own address, the receiver sets RI bit in SCON register to generate an interrupt. This ensures that

the CPU is not interrupted by command frames addressed to other devices.

If desired, you may enable the automatic address recognition feature in mode 1. In this configuration, the stop bit

takes the place of the ninth data bit. Bit RI is set only when the received command frame address matches the

device’s address and is terminated by a valid stop bit.

To support automatic address recognition, a device is identified by a given address and a broadcast address.

NOTE: The multiprocessor communication and automatic address recognition features cannot be enabled in mode 0 (i.e. setting SM2 bit in SCON

register in mode 0 has no effect).

Rev. C - 06 March, 2001 35

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6.6.3. Given Address

Each device has an individual address that is specified in SADDR register; the SADEN register is a mask byte

that contains don’t-care bits (defined by zeros) to form the device’s given address. The don’t-care bits provide the

flexibility to address one or more slaves at a time. The following example illustrates how a given address is formed.

To address a device by its individual address, the SADEN mask byte must be 1111 1111b.

For example:

SADDR 0101 0110b

SADEN 1111 1100b

Given 0101 01XXb

The following is an example of how to use given addresses to address different slaves:

Slave A: SADDR 1111 0001b

SADEN 1111 1010b

Given 1111 0X0Xb

Slave B: SADDR 1111 0011b

Slave C: SADDR 1111 0010b

SADEN 1111 1001b

Given 1111 0XX1b

SADEN 1111 1101b

Given 1111 00X1b

The SADEN byte is selected so that each slave may be addressed separately.

For slave A, bit 0 (the LSB) is a don’t-care bit; for slaves B and C, bit 0 is a 1. To communicate with slave A

only, the master must send an address where bit 0 is clear (e.g. 1111 0000b).

For slave A, bit 1 is a 1; for slaves B and C, bit 1 is a don’t care bit. To communicate with slaves B and C, but

not slave A, the master must send an address with bits 0 and 1 both set (e.g. 1111 0011b).

To communicate with slaves A, B and C, the master must send an address with bit 0 set, bit 1 clear, and bit 2

clear (e.g. 1111 0001b).

6.6.4. Broadcast Address

A broadcast address is formed from the logical OR of the SADDR and SADEN registers with zeros defined as

don’t-care bits, e.g.:

SADDR 0101 0110b

Broadcast =SADDR OR SADEN 1111 111Xb

The use of don’t-care bits provides flexibility in defining the broadcast address, however in most applications, a

broadcast address is FFh. The following is an example of using broadcast addresses:

Slave A: SADDR 1111 0001b

SADEN 1111 1100b

SADEN 1111 1010b

Broadcast 1111 1X11b,

Slave B: SADDR 1111 0011b

Slave C: SADDR= 1111 0010b

SADEN 1111 1001b

Broadcast 1111 1X11B,

SADEN 1111 1101b

Broadcast 1111 1111b

For slaves A and B, bit 2 is a don’t care bit; for slave C, bit 2 is set. To communicate with all of the slaves, the

master must send an address FFh. To communicate with slaves A and B, but not slave C, the master can send

and address FBh.

36 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

6.6.5. Reset Addresses

On reset, the SADDR and SADEN registers are initialized to 00h, i.e. the given and broadcast addresses are XXXX

XXXXb (all don’t-care bits). This ensures that the serial port will reply to any address, and so, that it is backwards

compatible with the 80C51 microcontrollers that do not support automatic address recognition.

SADEN - Slave Address Mask Register (B9h)

7 6 5 4 3 2 1 0

Reset Value = 0000 0000b

Not bit addressable

SADDR - Slave Address Register (A9h)

7 6 5 4 3 2 1 0

Reset Value = 0000 0000b

Not bit addressable

Rev. C - 06 March, 2001 37

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Table 16. SCON Register

SCON - Serial Control Register (98h)

7 6 5 4 3 2 1 0

FE/SM0 SM1 SM2 REN TB8 RB8 TI RI

Bit Number

7 FE

6 SM1

5 SM2

4 REN

3 TB8

Bit

Mnemonic

SM0

Description

Framing Error bit (SMOD0=1)

Clear to reset the error state, not cleared by a valid stop bit.

Set by hardware when an invalid stop bit is detected.

SMOD0 must be set to enable access to the FE bit

Serial port Mode bit 0

Refer to SM1 for serial port mode selection.

SMOD0 must be cleared to enable access to the SM0 bit

Serial port Mode bit 1

SM0 SM1 Mode Description Baud Rate

0 0 0 Shift Register F

0 1 1 8-bit UART Variable

1 0 2 9-bit UART F

1 1 3 9-bit UART Variable

Serial port Mode 2 bit / Multiprocessor Communication Enable bit

Clear to disable multiprocessor communication feature.

Set to enable multiprocessor communication feature in mode 2 and 3, and eventually mode 1. This bit should

be cleared in mode 0.

Reception Enable bit

Clear to disable serial reception.

Set to enable serial reception.

Transmitter Bit 8 / Ninth bit to transmit in modes 2 and 3.

Clear to transmit a logic 0 in the 9th bit.

Set to transmit a logic 1 in the 9th bit.

/12 (/6 in X2 mode)

XTAL

/64orF

XTAL

/32(/32,/16 in X2 mode)

XTAL

2 RB8

1 TI

0 RI

Reset Value = 0000 0000b

Bit addressable

Receiver Bit 8 / Ninth bit received in modes 2 and 3

Cleared by hardware if 9th bit received is a logic 0.

Set by hardware if 9th bit received is a logic 1.

In mode 1, if SM2 = 0, RB8 is the received stop bit. In mode 0 RB8 is not used.

Transmit Interrupt flag

Clear to acknowledge interrupt.

Set by hardware at the end of the 8th bit time in mode 0 or at the beginning of the stop bit in the other

modes.

Receive Interrupt flag

Clear to acknowledge interrupt.

Set by hardware at the end of the 8th bit time in mode 0, see Figure 14. and Figure 15. in the other modes.

38 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Table 17. PCON Register

PCON - Power Control Register (87h)

7 6 5 4 3 2 1 0

SMOD1 SMOD0 - POF GF1 GF0 PD IDL

Bit Number

7 SMOD1

6 SMOD0

5 -

4 POF

3 GF1

2 GF0

1 PD

0 IDL

Bit

Mnemonic

Description

Serial port Mode bit 1

Set to select double baud rate in mode 1, 2 or 3.

Serial port Mode bit 0

Clear to select SM0 bit in SCON register.

Set to to select FE bit in SCON register.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Power-Off Flag

Clear to recognize next reset type.

Set by hardware when VCC rises from 0 to its nominal voltage. Can also be set by software.

General purpose Flag

Cleared by user for general purpose usage.

Set by user for general purpose usage.

General purpose Flag

Cleared by user for general purpose usage.

Set by user for general purpose usage.

Power-Down mode bit

Cleared by hardware when reset occurs.

Set to enter power-down mode.

Idle mode bit

Clear by hardware when interrupt or reset occurs.

Set to enter idle mode.

Reset Value = 00X1 0000b

Not bit addressable

Power-off flag reset value will be 1 only after a power on (cold reset). A warm reset doesn’t affect the value of this bit.

Rev. C - 06 March, 2001 39

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

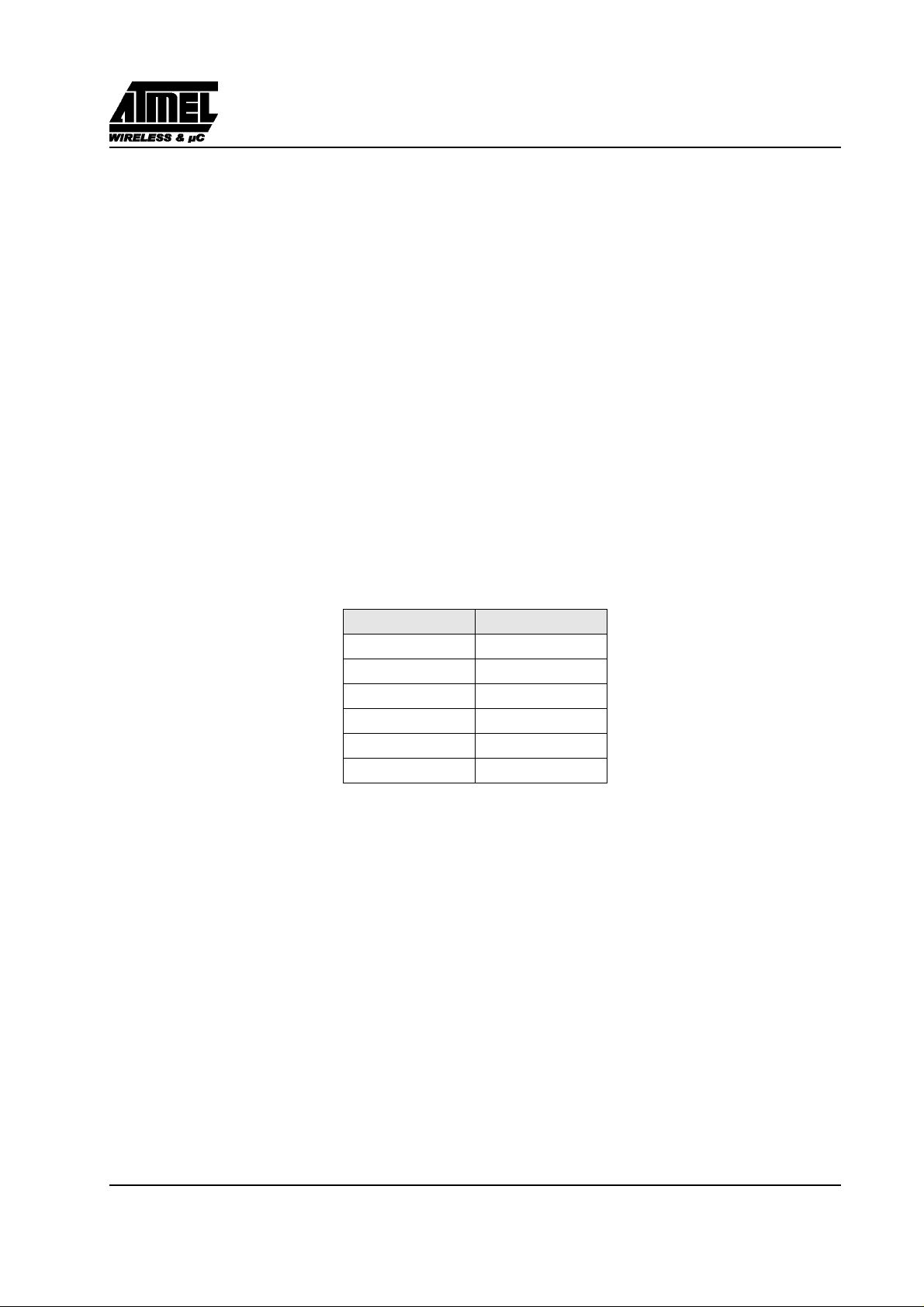

6.7. Interrupt System

The TS80C51Rx2 has a total of 7 interrupt vectors: two external interrupts (INT0 and INT1), three timer interrupts

(timers 0, 1 and 2), the serial port interrupt and the PCA global interrupt. These interrupts are shown in Figure 16.

WARNING: Note that in the first version of RC devices, the PCA interrupt is in the lowest priority. Thus the

order in INT0, TF0, INT1, TF1, RI or TI, TF2 or EXF2, PCA.

INT0

TF0

INT1

TF1

PCA IT

RI

TI

TF2

EXF2

IE0

IE1

IPH, IP

High priority

interrupt

3

0

3

0

3

0

3

0

3

0

3

0

3

0

Interrupt

polling

sequence, decreasing

from high to low priority

Individual Enable

Global Disable

Low priority

interrupt

Figure 16. Interrupt Control System

Each of the interrupt sources can be individually enabled or disabled by setting or clearing a bit in the Interrupt

Enable register (See Table 19.). This register also contains a global disable bit, which must be cleared to disable

all interrupts at once.

Each interrupt source can also be individually programmed to one out of four priority levels by setting or clearing

a bit in the Interrupt Priority register (See Table 20.) and in the Interrupt Priority High register (See Table 21.).

shows the bit values and priority levels associated with each combination.

The PCA interrupt vector is located at address 0033H. All other vector addresses are the same as standard C52 devices.

40 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Table 18. Priority Level Bit Values

IPH.x IP.x Interrupt Level Priority

0 0 0 (Lowest)

0 1 1

1 0 2

1 1 3 (Highest)

A low-priority interrupt can be interrupted by a high priority interrupt, but not by another low-priority interrupt.

A high-priority interrupt can’t be interrupted by any other interrupt source.

If two interrupt requests of different priority levels are received simultaneously, the request of higher priority level

is serviced. If interrupt requests of the same priority level are received simultaneously, an internal polling sequence

determines which request is serviced. Thus within each priority level there is a second priority structure determined

by the polling sequence.

Table 19. IE Register

IE - Interrupt Enable Register (A8h)

7 6 5 4 3 2 1 0

EA EC ET2 ES ET1 EX1 ET0 EX0

Bit Number

7 EA

6 EC

5 ET2

4 ES

3 ET1

2 EX1

1 ET0

Bit

Mnemonic

Description

Enable All interrupt bit

Clear to disable all interrupts.

Set to enable all interrupts.

If EA=1, each interrupt source is individually enabled or disabled by setting or clearing its own interrupt

enable bit.

PCA interrupt enable bit

Clear to disable . Set to enable.

Timer 2 overflow interrupt Enable bit

Clear to disable timer 2 overflow interrupt.

Set to enable timer 2 overflow interrupt.

Serial port Enable bit

Clear to disable serial port interrupt.

Set to enable serial port interrupt.

Timer 1 overflow interrupt Enable bit

Clear to disable timer 1 overflow interrupt.

Set to enable timer 1 overflow interrupt.

External interrupt 1 Enable bit

Clear to disable external interrupt 1.

Set to enable external interrupt 1.

Timer 0 overflow interrupt Enable bit

Clear to disable timer 0 overflow interrupt.

Set to enable timer 0 overflow interrupt.

External interrupt 0 Enable bit

0 EX0

Clear to disable external interrupt 0.

Set to enable external interrupt 0.

Reset Value = 0000 0000b

Bit addressable

Rev. C - 06 March, 2001 41

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Table 20. IP Register

IP - Interrupt Priority Register (B8h)

7 6 5 4 3 2 1 0

- PPC PT2 PS PT1 PX1 PT0 PX0

Bit Number

7 -

6 PPC

5 PT2

4 PS

3 PT1

2 PX1

1 PT0

0 PX0

Bit

Mnemonic

Reset Value = X000 0000b

Bit addressable

Description

Reserved

The value read from this bit is indeterminate. Do not set this bit.

PCA interrupt priority bit

Refer to PPCH for priority level.

Timer 2 overflow interrupt Priority bit

Refer to PT2H for priority level.

Serial port Priority bit

Refer to PSH for priority level.

Timer 1 overflow interrupt Priority bit

Refer to PT1H for priority level.

External interrupt 1 Priority bit

Refer to PX1H for priority level.

Timer 0 overflow interrupt Priority bit

Refer to PT0H for priority level.

External interrupt 0 Priority bit

Refer to PX0H for priority level.

42 Rev. C - 06 March, 2001

TS80C51RA2/RD2

TS83C51RB2/RC2/RD2

TS87C51RB2/RC2/RD2

Table 21. IPH Register

IPH - Interrupt Priority High Register (B7h)