ATMEL TS68882VR33, TS68882VR25, TS68882VR20, TS68882VR16, TS68882VF33 Datasheet

...

Features

• Eight General-purpose Floating-point Data Registers, Each Supporting a Full 80-bit

Extended Precision Real Data Format (a 64-bit Mantissa Plus a Sign Bit, and a 15-bit

Signed Exponent)

• A 67-bit Arithmetic Unit to Allow Very Fast Calculations with Intermediate are Precision

Greater than the Extended Precision Format

• A 67-bit Barrel Shifter for High-speed Shifting Operations (for Normalizing etc.)

• Special-purpose Hardware for High-speed Conversion Between Single, Double, and

Extended Formats and the Internal Extended Format

• An Independent State Machine to Control Main Processor Communication for

Pipelined Instruction Processing

• Forty-six Instructions, Including 35 Arithmetic Operations

• Full Conformation to the IEEE 754 Standard, Including All Requirements and

Suggestions

• Support of Functions Not Defined by the IEEE Standard, Including a Full Set of

Trigonometric and Transcendental Functions

• Seven Data Type Types: Byte, Word and Long Integers; Single, Double, and Extended

Precision Real Numbers; and Packed Binary Coded Decimal String Real Numbers

• Twenty-two Constants Available In The On-chip ROM, Including π,e,andPowersof10

• Virtual Memory/Machine Operations

• Efficient Mechanisms for Procedure Calls, Context Switches, and Interrupt Handling

• Fully Concurrent Instruction Execution with the Main Processor

• Fully Concurrent Instruction Execution of Multiple Floating-point Instructions

• Use with any Host Processor, on an 8-, 16- or 32-bit Data Bus

• Available in 16.67, 20, 25 and 33 MHz for T

• V

=5V± 10%

CC

from -55°C to +125°C

c

CMOS

Enhanced

Floating-point

Co-processor

TS68882

Description

The TS68882 enhanced floating-point co-processor is a full implementation of the

IEEE Standard for Binary Floating-Point Arithmetic (754) for use with the THOMSON

TS68000 Family of microprocessors. It is a pin and software compatible upgrade of

the TS68881 with optimized MPU interface that provides over 1.5 times the performance of the TS68881. It is implemented using VLSI technology to give systems

designers the highest possible functionality in a physically small device.

Intended primarily for use as a co-processor to the TS68020/68030 32-bit microprocessor units (MPUs), the TS68882 provides a logical extension to the main MPU

integer data processing capabilities. It does this by providing a very high performance

floating-point arithmetic unit and a set of floating-point data registers that are utilized

in a manner that is analogous to the use of the integer data registers. The TS68882

instruction set is a natural extension of all earlier members of the TS68000 Family, and

supports all of the addressing modes of the host MPU. Due to the flexible bus interface of the TS68000 Family, the TS68882 can be used with any of the MPU devices of

the TS68000 Family, and it may also be used as a peripheral to non-TS68000

processors.

Screening/Quality

This product could be manufactured

in full compliance with either:

• MIL-STD-883 Class B

• DESC 5962-89436

• or According to ATMELGrenoble Standards

R suffix

PGA 68

Ceramic Pin Grid Array

F suffix

CQFP 68

Ceramic Quad Flat Pack

Rev. 2119A–HIREL–04/02

1

Introduction The TS68882 is a high-performance floating-point device designed to interface with the

TS68020 or TS68030 as a co-processor. This device fully supports the TS68000 virtual

machine architecture, and is implemented in HCMOS, Atmel’s low power, small geometry process. This process allows CMOS and HMOS (high-density NMOS) gates to be

combined on the same device. CMOS structures are used where speed and low power

is required, and HMOS structures are used where minimum silicon area is desired. The

HCMOS technology enables the TS68882 to be very fast while consuming less power

than comparable HMOS, and still have a reasonably small die size.

With some performance degradation, the TS68882 can also be used as a peripheral

processor in systems where the TS68020 or TS68030 is not the main processor (i.e.,

TS68000, TS68010). The configuration of the TS68882 as a peripheral processor or coprocessor may be completely transparent to user software (i.e., the same object code

may be executed in either configuration).

The architecture of the TS68882 appears to the user as a logical extension of the

TS68000 Family architecture. Coupling of the co-processor interface allows the

TS68020/TS68030 programmer to view the TS68882 registers as though the registers

are resident in the TS68020/TS68030. Thus, a TS68020 or TS68030/TS68882 device

pair appears to be one processor that supports seven floating-point and integer data

types, and has eight integer data registers, eight address registers, and eight floatingpoint data registers.

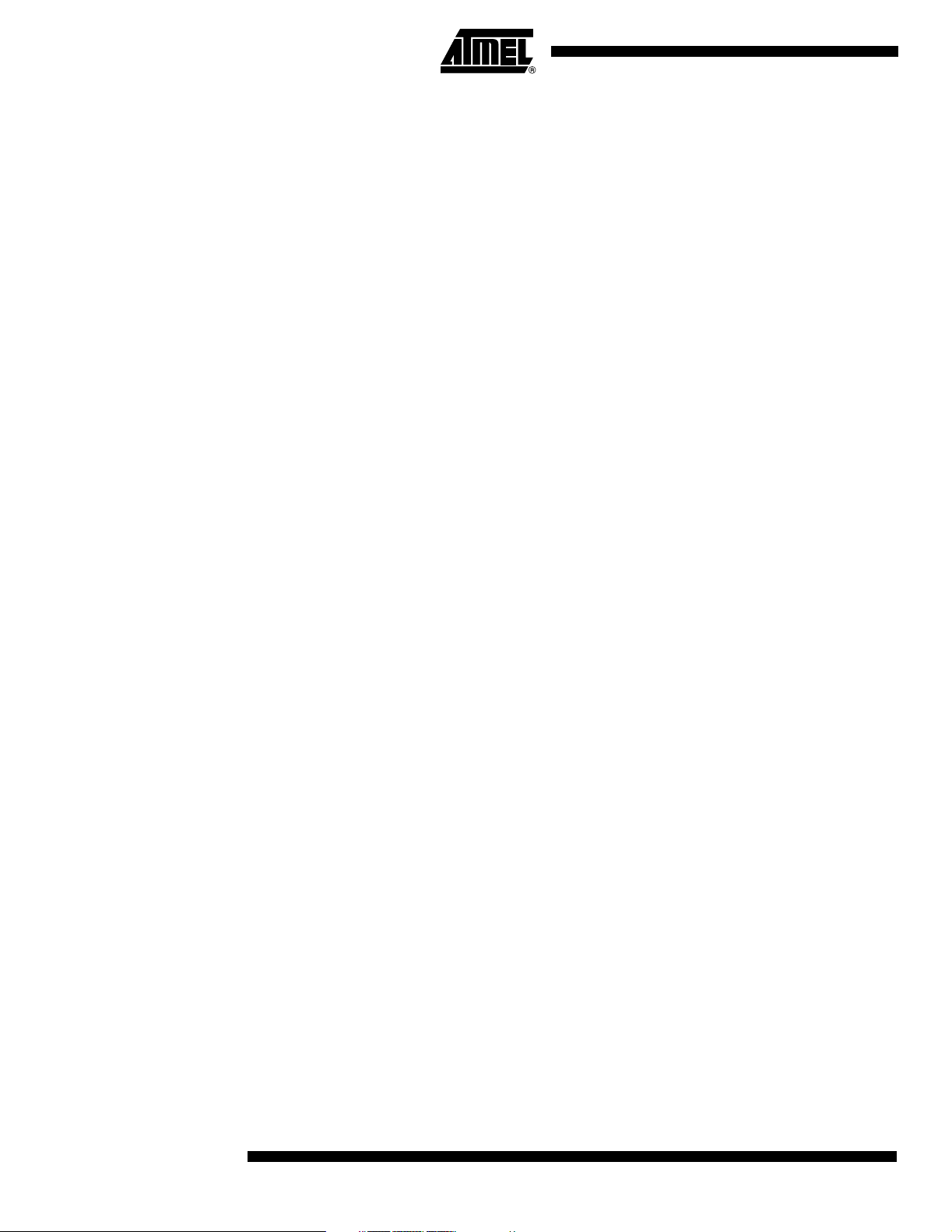

As shown in Figure 1, the TS68882 is internally divided into four processing elements;

the Bus Interface Unit (BIU), the Conversion Control Unit (CCU), the Execution Control

Unit (ECU), and the Microcode Control Unit (MCU). The BIU communicates with the

main processor, the CCU controls the main processor communications dialog and performs some data conversions, and the ECU and MCU execute most floating-point

calculations.

The BIU contains the co-processor interface registers, and the 32-bit control, and

instruction address registers. In addition to these registers, the register select and

DSACK timing control logic is contained in the BIU. Finally, the status flags used to monitor the status of communications with the main processor are contained in the BIU.

The CCU contains special-purpose hardware that performs conversions between the

single, double, and extended precision memory data formula and the internal data format used by the ECU. It also contains a state machine that controls communications

with the main processor during co-processor interface dialogs.

The eight 80-bit floating-point data registers (FP0-FP7) are located in the ECU. In addition to these registers, the ECU contains a high-speed 67-bit arithmetic unit used for

both mantissa and exponent calculations, a barrel shifter that can shift from 1-bit to 67bits in one machine cycle, and ROM constants (for use by the internal algorithms or user

programs).

The MCU contains the clock generator, a two-level microcoded sequencer that controls

the ECU, the microcode ROM, and self-test circuitry. The built-in self-test capabilities of

the TS68882 enhance reliability and ease manufacturing requirements; however, these

diagnostic functions are not available to the user.

2

TS68882

2119A–HIREL–04/02

Figure 1. TS68882 Simplified Block

TS68882

2119A–HIREL–04/02

3

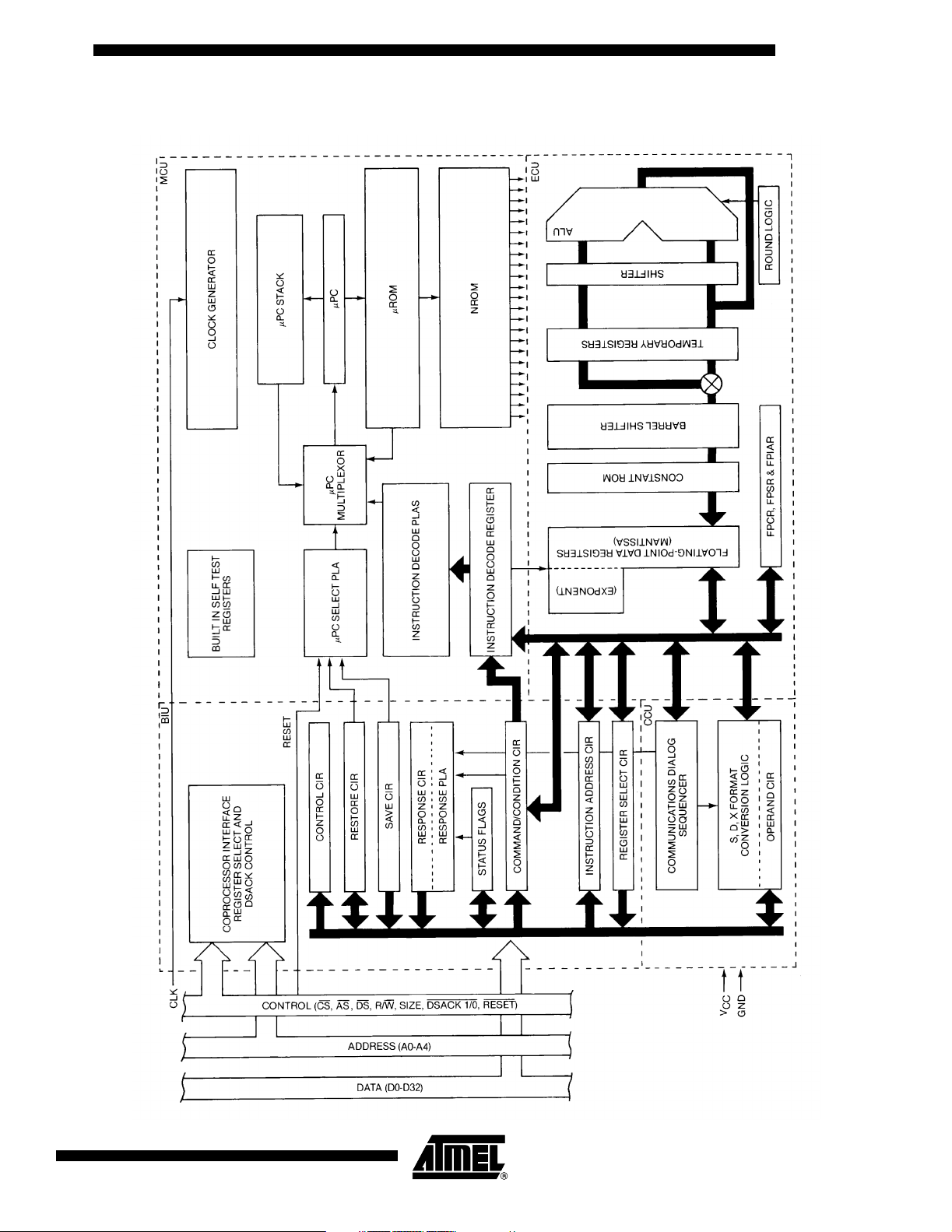

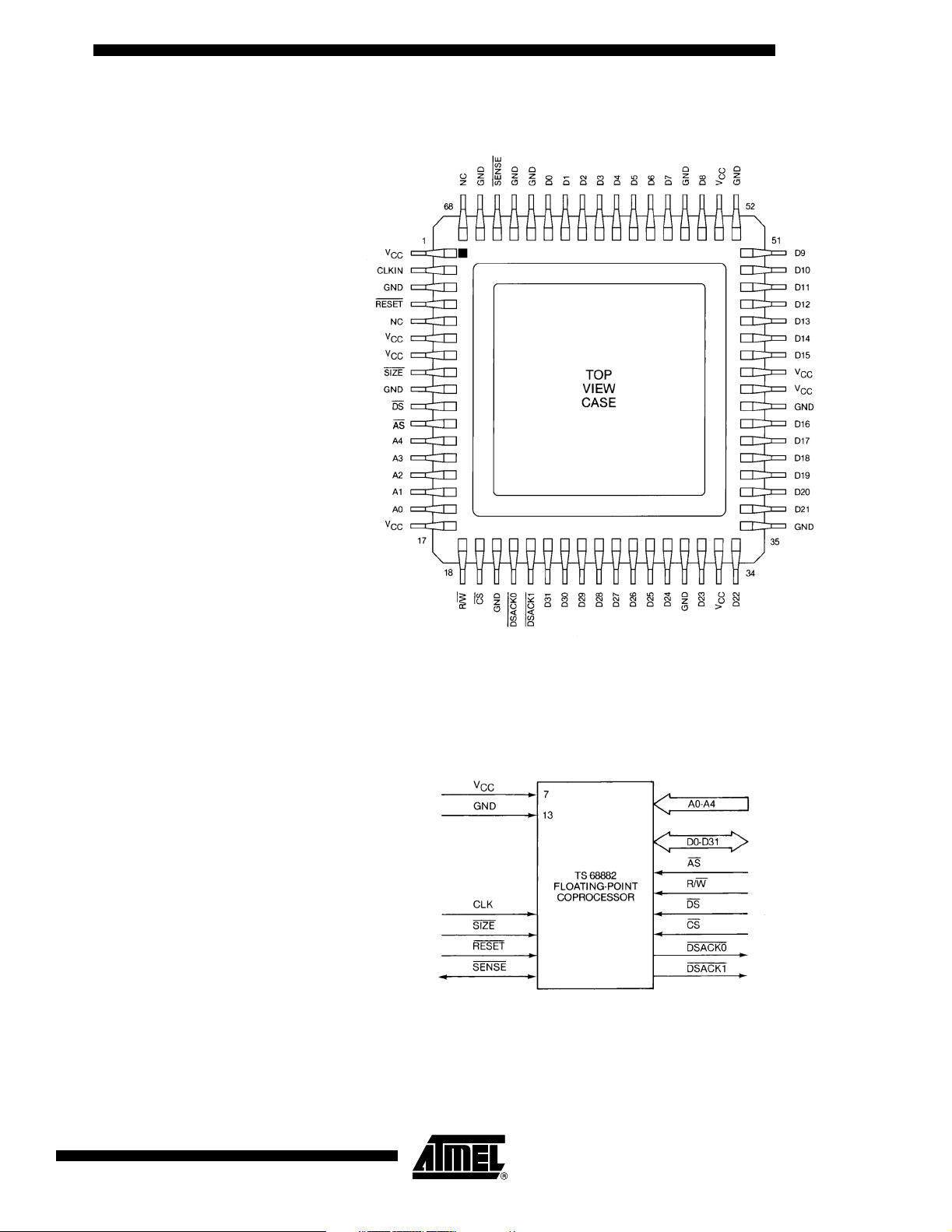

Pin Assignments Figure 2. PGA Terminal Designation

* Reserved for future ATMEL-Grenoble use

4

TS68882

2119A–HIREL–04/02

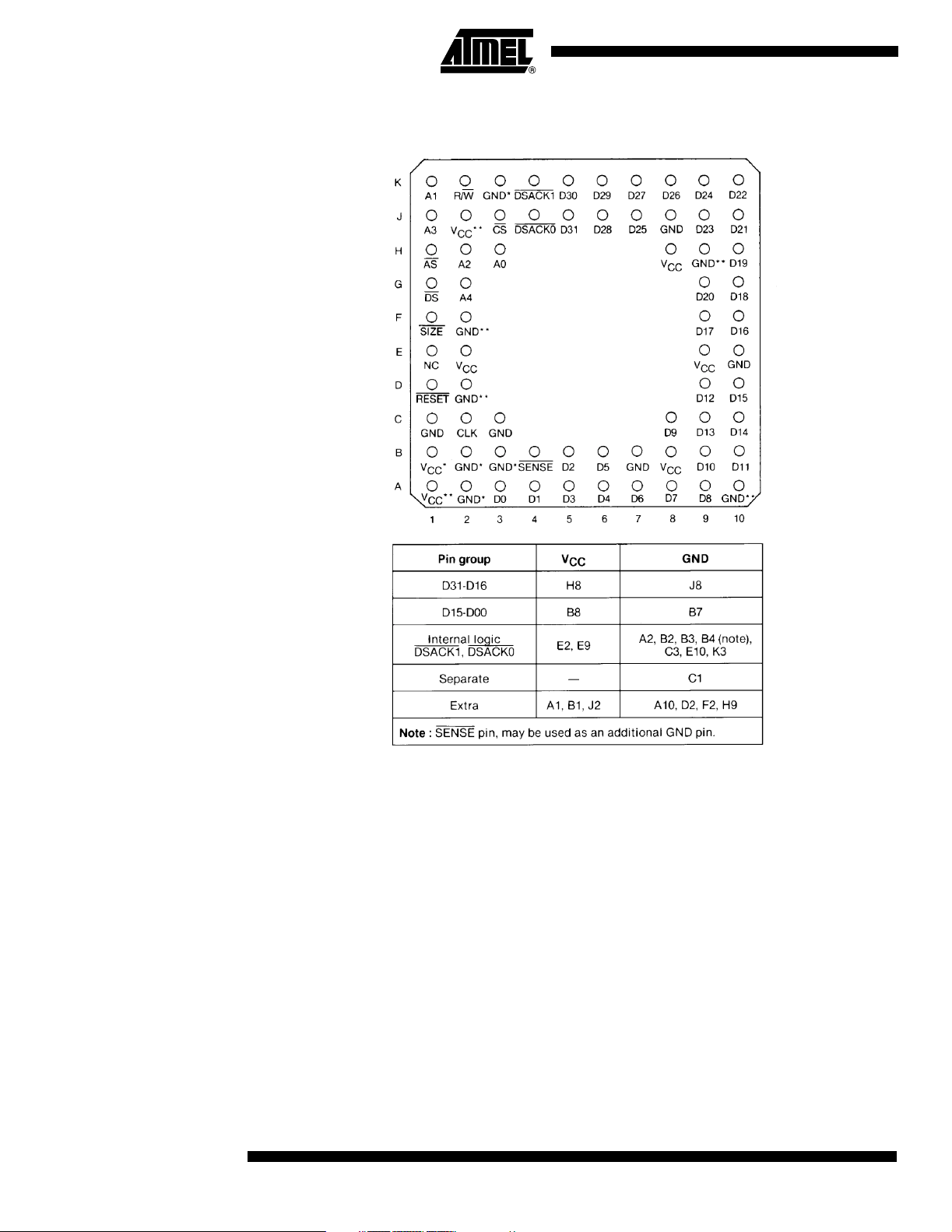

Figure 2b. CQFP Terminal Designation

TS68882

Functional Signal Descriptions

This section contains a brief description of the input and output signals for the TS68882

floating-point co-processor. The signals are functionally organized into groups as shown

in Figure 3.

Figure 3. TS68882 Input/output Signals

Note: The terms assertion and negation are used extensively. This is done to avoid confusion

when describing “active-low” and “active-high” signals. The term assert or assertion is

used to indicate that a signal is active or true, independent of whether that level is represented by a high or low voltage. The term negate or negation is used to indicate that a

signal is inactive or false.

2119A–HIREL–04/02

5

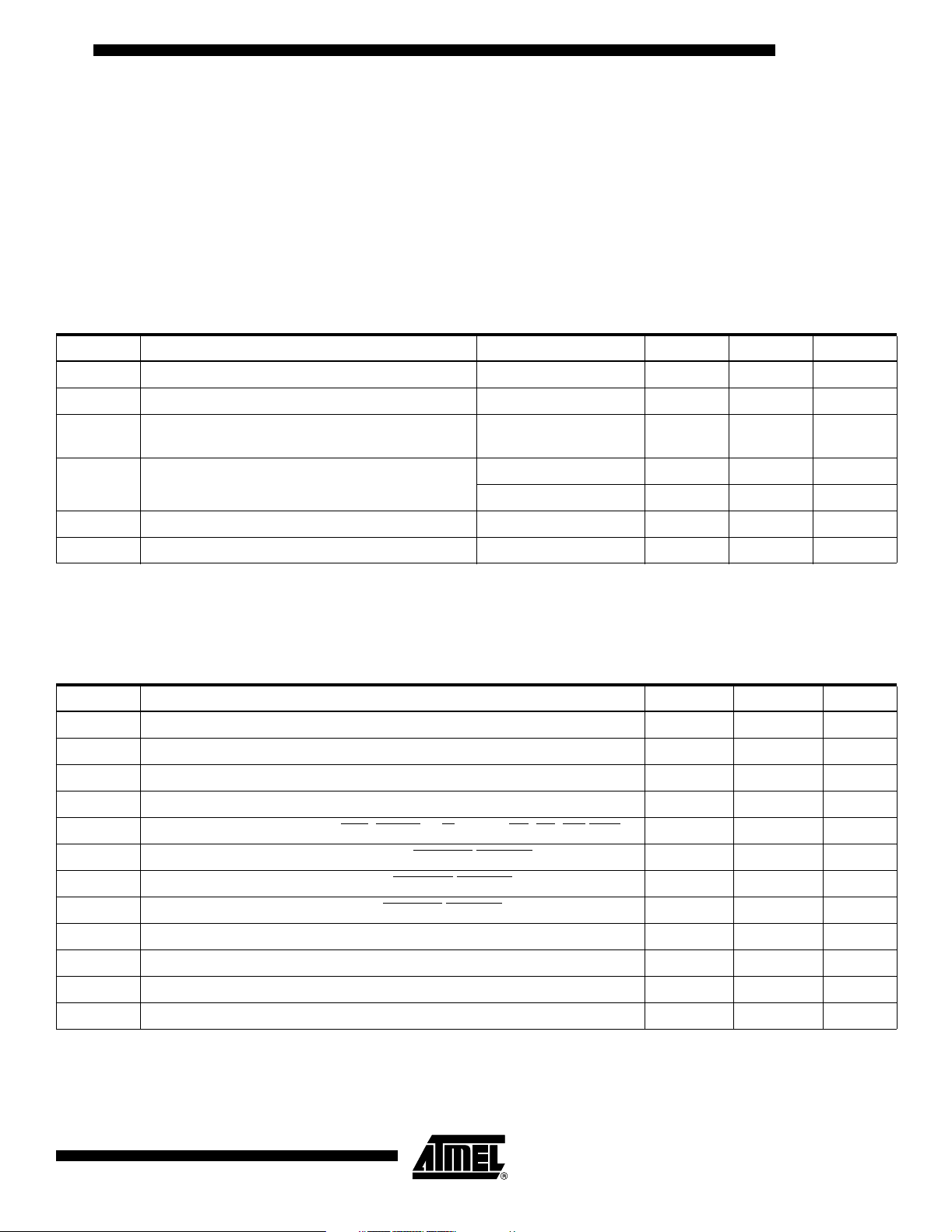

Signal Summary Table 1 provides a summary of all the TS68882 signals described in this section.

Table 1 . Signal Summary

Signal Name Mnemonic Input/Output Active State Three State

Address Bus A0 - A4 Input High

Data Bus D0 - D31 Input/Output High Yes

Size SIZE

Input Low

Address Strobe AS

Chip Select CS

Read/Write R/W

Data Strobe DS

Data Transfer and Size Acknowledge DSACK0

Reset RESET

Clock CLK Input

Sense Device SENSE

Power Input V

Ground GND Input

,DSACK1 Output Low Yes

CC

Input Low

Input Low

Input High/Low

Input Low

Input Low

Input/Output Low No

Input

Detailed Specifications

Scope This drawing describes the specific requirements for the microprocessor 68882, 16.67,

20 MHz and 25 MHz, in compliance with MIL-STD-883 class B.

Applicable Documents

MIL-STD-883 1. MIL-STD-883: Test Methods And Procedures For Electronics

2. MIL-PRF-38535 Appendix A: General Specifications For Microcircuits

3. Desc Drawing 5962 - 89436xxx

Requirements

General The microcircuits are in accordance with the applicable document and as specified

herein.

Design and Construction

Terminal Connections Depending on the package, the terminal connections shall be as shown in Figure 2 and

Figure 2b.

Lead Material and Finish Lead material and finish shall be any option of MIL-STD-1835.

6

TS68882

2119A–HIREL–04/02

TS68882

Package The macrocircuits are packaged in hermetically sealed ceramic packages which are

conform to case outlines of MIL-STD-1835 (when defined):

• 68-PIN SQ.PGA UP PAE Outline

• 68-PIN Ceramic Quad Flat Pack CQFP

The precise case outlines are described on Figure 23 and Figure 24.

Electrical Characteristics

Table 2 . Absolute Maximum Ratings

Symbol Parameter Test Conditions Min Max Unit

V

P

CC

V

I

DMAX

Supply Voltage -0.3 +7.0 V

Input Voltage -0.3 +7.0 V

=-55°Cto

T

Max Power Dissipation

CASE

+125°C

0.75 W

M Suffix -55 +125 °C

T

CASE

T

STG

T

LEADS

Recommended Condition of Use

Operating Temperature

VSuffix -40 +85 °C

Storage Temperature -55 +150 °C

Lead Temperature Max 5 sec. Soldering +270 °C

Unless otherwise stated, all voltages are referenced to the reference terminal (see

Table 1).

Table 3 . DC Electrical Characteristics

=5.0VDC± 10%; GND = 0 VDC;Tc=-55°C to +125°C

V

CC

Symbol Parameter Min Max Unit

V

CC

T

CASE

V

IH

V

IL

I

IN

I

TSI

V

OH

V

OL

I

OL

P

D

C

IN

C

L

Notes: 1. Test load, see Figure 5.

Supply Voltage 4.5 5.5 V

Operating Temperature -55 +125 °C

Input High Voltage 2.0 V

CC

Input Low Voltage GND - 0.3 0.8 V

Input Leakage Current at 5.5V CLK, RESET,R/W,A0-A4,CS,DS, AS, SIZE 10 µA

HI-Z (Off state) Input Current at 2.4V/0.4V DSACK0, DSACK1,D0-D31 20 µA

Output High Voltage (IOH = -400 µA)

Output Low Voltage (IOL = 5.3 mA)

(1)

DSACK0, DSACK1,D0-D31 2.4 V

(1)

DSACK0, DSACK1,D0-D31 0.5 V

Output Low Current (VOL = GND) SENSE 500 µA

Power Dissipation 0.75 W

Capacitance (VIN=0,TA=25°C, f = 1 MHz)

(2)

20 pF

Output Load Capacitance 130 pF

2. Capacitance is periodically sampled rather than 100% tested.

V

2119A–HIREL–04/02

7

Thermal Characteristics

Table 4 .

Package Symbol Parameter Value Rating

θ

PGA 68

CQFP

JA

θ

JC

θ

JA

θ

JC

Power Considerations

Thermal Resistance - Ceramic Junction To Ambient 33 °C/W

Thermal Resistance - Ceramic Junction To Case 4 °C/W

Thermal Resistance - Ceramic Junction To Ambient 33 °C/W

Thermal Resistance - Ceramic Junction To Case 3 °C/W

The average chip-junction temperature, TJ,in °C can be obtained from:

T

T

θ

P

P

P

For most applications P

An Approximate relationship between P

P

+(PD+ θJA)(1)

J=TA

= Ambient Temperature, °C

A

= Package Thermal Resistance, Junction-to-Ambient, °C/W

JA

D=PINT+PI/O

INT=ICCxVCC,

= Power Dissipation on Input and Output Pins - User Determined

I/O

=K:(TJ+ 273) (2)

D

Watts - Chip Internal Power

I/O<PINT

and can be neglected.

and TJ(if P

D

is neglected) is:

I/O

Solving equations (1) and (2) for K gives

.(TA+273)+θJA· P

K=P

D

2

D

(3)

where K is constant pertaining to the particular part K can be determined from the equation (3) by measuring PD (at equilibrium) for a known T

values of P

value of T

The total thermal resistance of a package (θ

θ

and θCA, representing the barrier to heat flow from the semiconductor junction to the

JC

package (case), surface (θ

and TJcan be obtained by solving equations (1) and (2) iteratively for any

D

.

A

) can be separated into two components,

JA

) and from the case to the outside ambient (θCA). These

JC

.UsingthisvalueofK,the

A

terms are related by the equation:

= θJC+ θ

θ

JA

is device related and cannot be influenced by the user. However, θCAis user depen-

θ

JA

CA

(4)

dent and can be minimized by such thermal management techniques as heat sinks,

ambient air cooling and thermal convection. Thus, good thermal management on the

part of the user can significantly reduce θ

tution of θ

for θJAin equation (1) will result in a lower semiconductor junction

JC

so that θJAapproximately equals θ

CA

JC.

Substi-

temperature.

8

TS68882

2119A–HIREL–04/02

TS68882

Mechanical and Environmental

The microcircuits shall meet all mechanical environmental requirements of either MILSTD-883 for class B devices.

Marking The document defines the markings that are identified in the related reference docu-

ments. Each microcircuit is legible and permanently marked with the following

information as minimum:

• Atmel-Grenoble Logo

• Manufacturer’s Part Number

• Class B Identification

• Date-code of inspection lot

• ESD Identifier if Available

• Country of Manufacturing

Quality Conformance Inspection

DESC/MIL-STD-883 Is in accordance with MIL-M-38510 and method 5005 of MIL-STD-883. Group A and B

inspections are performed on each production lot. Group C and D inspection are performed on a periodical basis.

Electrical Characteristics

General Requirements All static and dynamic electrical characteristics specified and the relevant measurement

conditions are given below. For inspection purpose, refer to relevant specification:

Static electrical characteristics for all electrical variants.

Dynamic electrical characteristics for 68882-16 (16.67 MHz), 68882-20 (20 MHz),

68882-25 (25 MHz) and 68882-33 (33 MHz).

For static characteristics, test methods refer to clause “Test Load” on page 13 hereafter

of this specification (Table 5).

For dynamic characteristics (Tables 6 and 7), test methods refer to IEC 748-2 method

number, where existing.

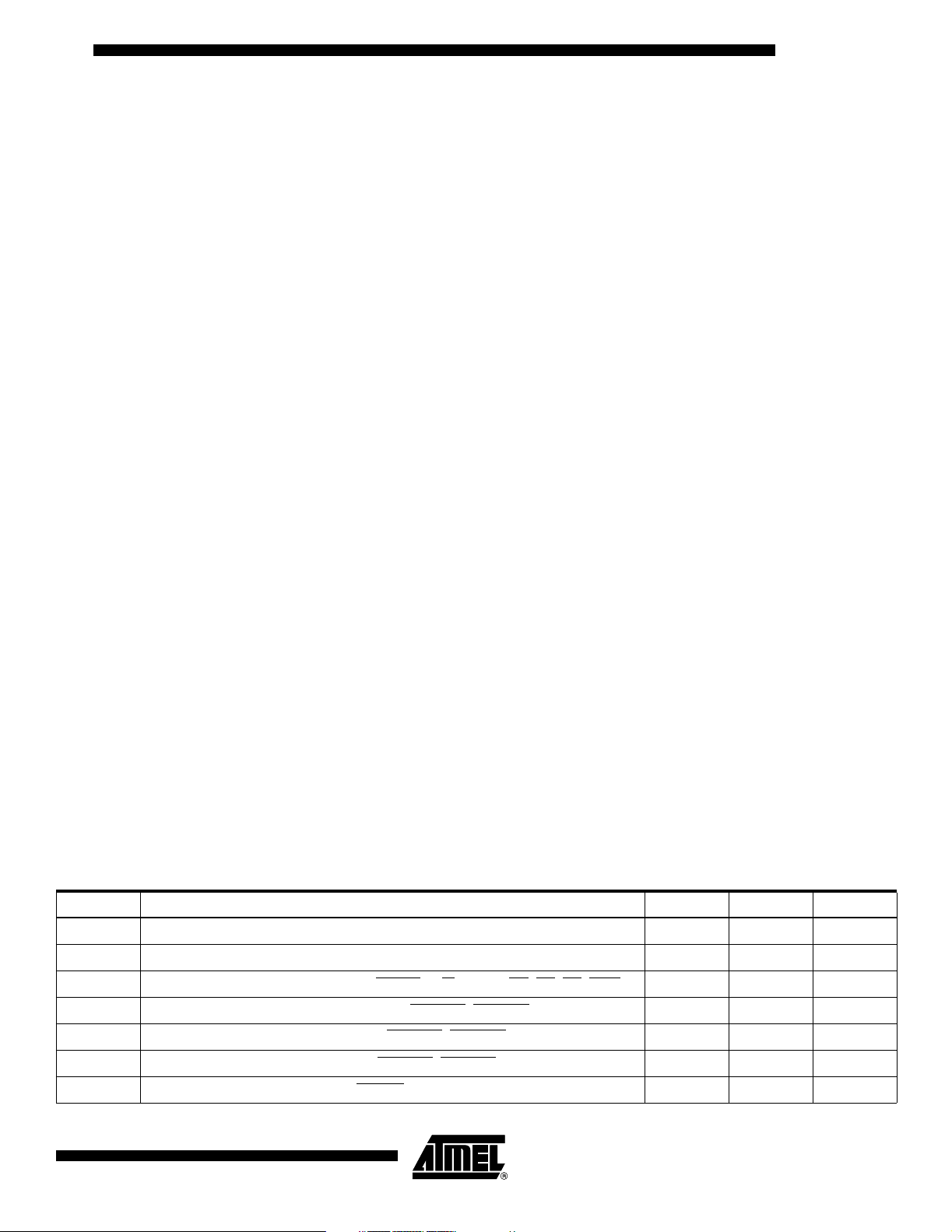

Table 5 . Static Characteristics

=5.0VDC±10%;GND=0VDC;Tc=-55/+125°C or -40/+85°C

V

CC

Symbol Parameter Min Max Unit

V

IH

V

IL

I

IN

I

TSI

V

OH

V

OL

I

OL

Input High Voltage 2.0 V

Input Low Voltage GND - 0.3 0.8 V

Input Leakage Current at 5.5V CLK, RESET,R/W,A0-A4,CS,DS,AS,SIZE 10 µA

HI-Z (off state) Input Current at 2.4V/0.4V DSACK0,DSACK1,D0-D31 20 µA

Output High Voltage (IOH=-400µA)

Output Low Voltage (IOL=5.3mA)

Output Low Current (VOL= GND) SENSE 500 µA

(1)

DSACK0,DSACK1,D0-D31 2.4 V

(1)

DSACK0,DSACK1,D0-D31 0.5 V

CC

V

2119A–HIREL–04/02

9

Table 5 . Static Characteristics

=5.0VDC±10%;GND=0VDC;Tc=-55/+125°C or -40/+85°C

V

CC

Symbol Parameter Min Max Unit

I

CC

C

in

C

L

Notes: 1. Test load, see Figure 5.

Dynamic (Switching) Characteristics

Maximum Supply Current (VCC=5.5V;CLK=f

Capacitance (VIN=0,TA=25°C, f = 1MHz)

Output Load Capacitance 130 pF

2. Capacitance is periodically sampled rather than 100% tested.

; part in Reset) 136 mA

max

(2)

20 pF

The limits and values given in this section apply over the full case temperature range 55°C to +125°C and V

in the range 4.5V to 5.5V, See “AC Electrical Specification Def-

CC

initions” on page 13.

The numbers (N°) refer to the timing diagrams. See Figure 4, Figure 6, Figure 7, Figure

8 and Figure 9.

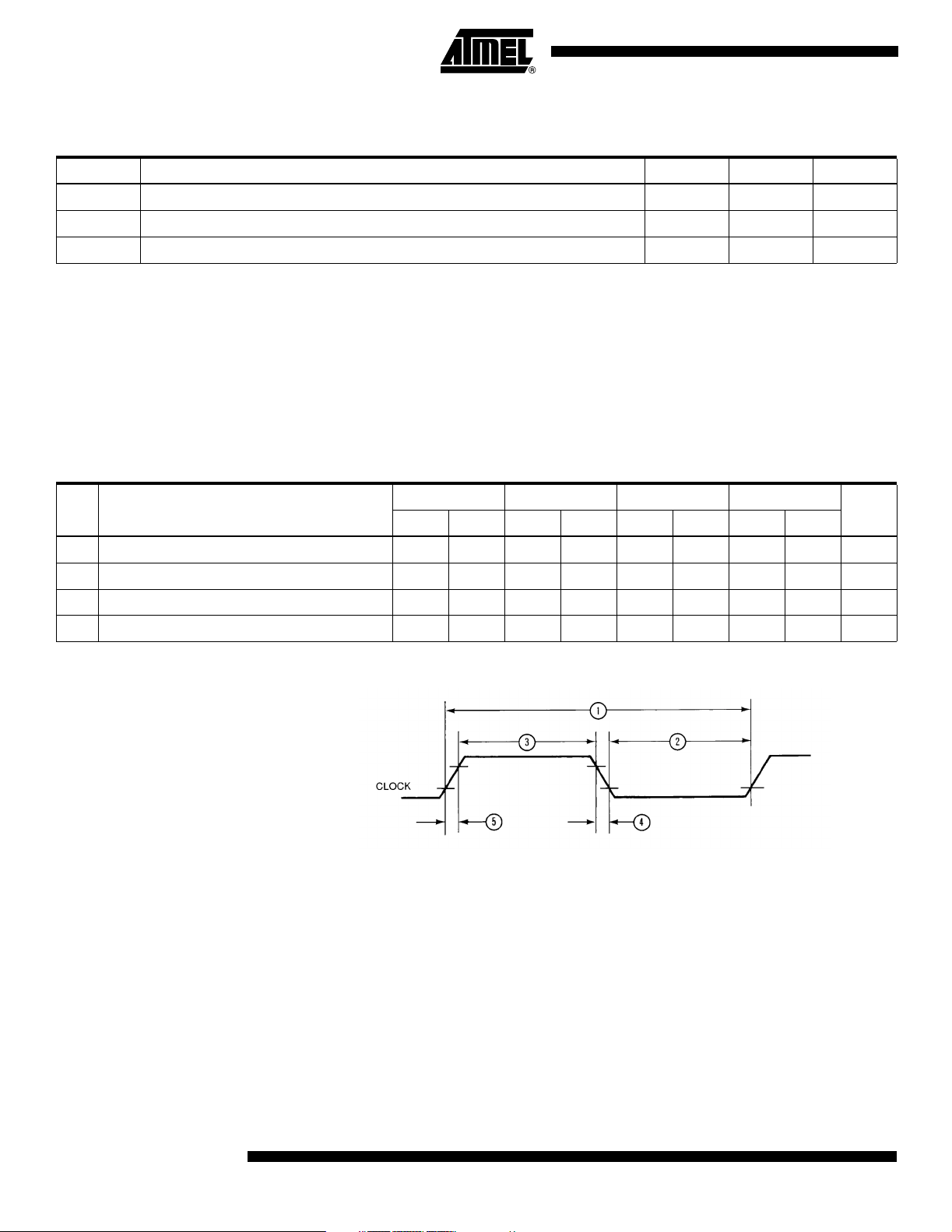

Table 6 . AC Electrical Characteristics - Clock Input

V

=5.0VDC± 10%; GND = 0 V

CC

N° Parameter

Frequency of Operation 8 16.67 12.5 20 12.5 25 16.7 33.33 MHz

1 Clck Time 60 125 50 80 40 80 30 60 ns

2, 3 Clock Pulse Width 24 95 20 54 15 59 14 66 ns

4,5RiseandFallTimes 5543ns

Tc = -55°Cto+125°C(seeFigure4)

DC;

16.67 MHz 20 MHz 25 MHz 33.33 MHz

UnitMin Max Min Max Min Max Min Max

Figure 4. Clock Input Timing Diagram

Note: Timing measurements are referenced to and from a low voltage of 0.8V and a high volt-

age of 2.0V, unless otherwise noted. The voltage swing through this range should start

outside, and pass through, the range such that the rise of fall will be linear between 0.8V

and 2.0V.

10

TS68882

2119A–HIREL–04/02

TS68882

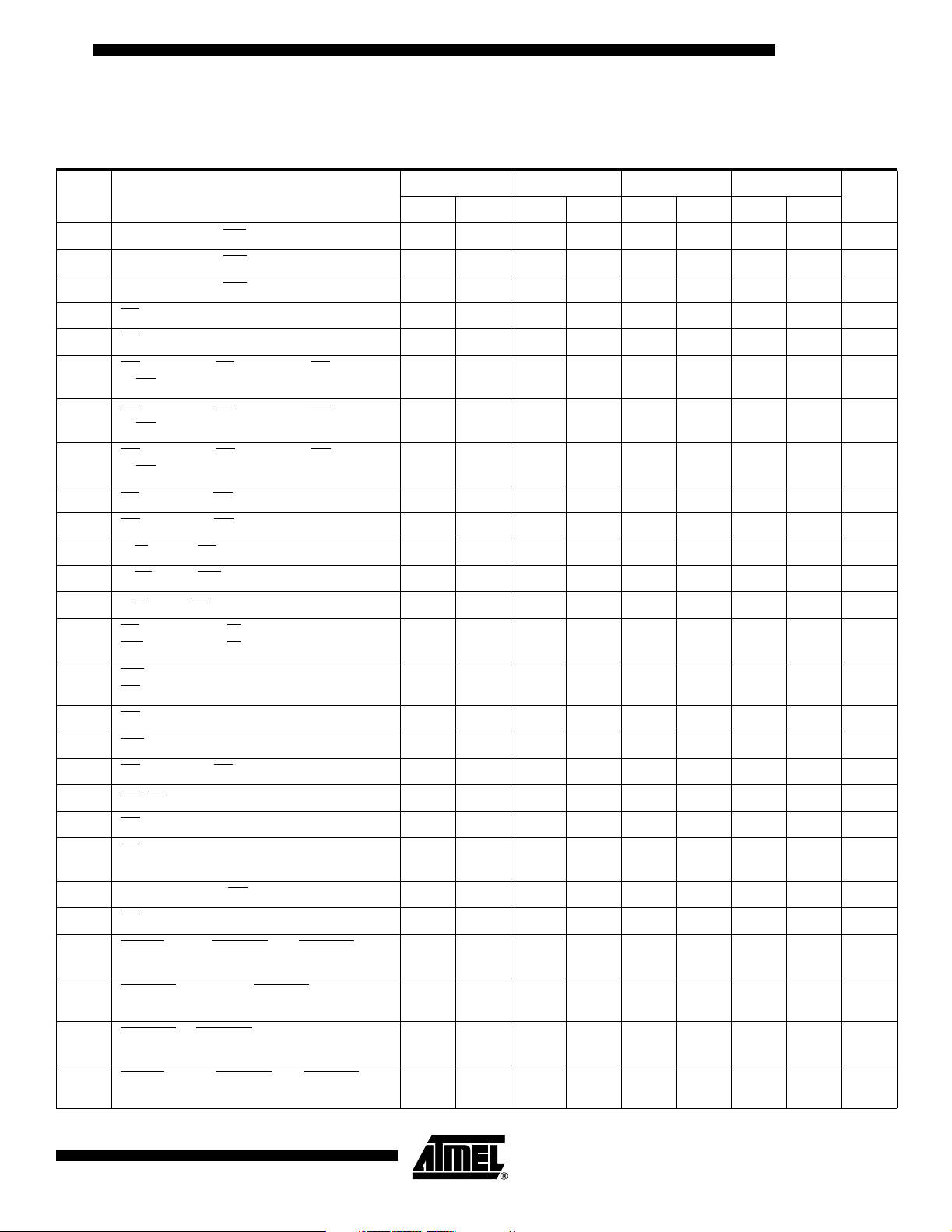

Table 7 . AC Electrical Characteristics – Read and Write Cycles

VCC=5.0VDC± 10%; GND = 0 V

N° Parameter

6 Address valid to AS

6a Address valid to DS

6b Address valid to DS

7AS

7a DS

8

8a

8b

9AS

9a DS

10 R/W

10a R/W

10b R/W

negated to address invalid

negated to address invalid

CS

asserted to AS asserted or AS asserted

to CS

asserted

asserted to DS asserted or DS asserted

CS

to CS

asserted (read)

CS

asserted to DS asserted or DS asserted

to CS

asserted (write)

negated to CS negated 10 10 5 5 ns

negated to CS negated 10 10 5 5 ns

high to AS asserted (read) 15 10 5 5 ns

high to DS asserted (read) 15 10 5 5 ns

low to DS asserted(write) 35302525ns

asserted

asserted (read)

asserted (write)

(9)

(9)

(9)

Tc = -55°C/+125°CorTc=-40°C/+85°C (see Figure 7, Figure 8, Figure 9)

DC;

16.67 MHz 20 MHz 25 MHz 33.33 MHz

(5)

(5)

(5)

(6)

(6)

15 10 5 5 ns

15 10 5 5 ns

50 50 35 26 ns

10 10 5 5 ns

10 10 5 5 ns

0000ns

0000ns

30 25 20 15 ns

(1)

UnitMin Max Min Max Min Max Min Max

AS

11

11a

12 DS

13 DS

13a DS

14 CS

15 DS

16

negated to R/W low (read) or

AS

negated to R/W high (write)

negated to R/W low (read) or

DS

DS

negated to R/W high (write)

widthasserted(write) 40383023ns

width negated 40 38 30 23 ns

negated to AS asserted

,DSasserted to data-out valid (read)

negated to data-out invalid (read) 0 0 0 0 ns

DS

negated to data-out high impedance

(read)

17 Data-in invalid to DS

18 DS

19

19a

20

21

negated to data-in invalid (write) 15 10 5 5 ns

START

asserted

DSACK0

(skew)

DSACK0

true to DSACK0 and DSACK1

(2)

asserted to DSACK1 asserted

(7)

or DSACK1 asserted to data-out

valid

START

negated

false to DSACK0 and DSACK1

(8)

10 10 5 5 ns

10 10 5 5 ns

(4)

(2)

30 30 25 18 ns

80 45 45 30 ns

50 35 35 30 ns

asserted(write)15105 5ns

50 35 25 20 ns

-15 15 -10 10 -10 10 5 ns

50 43 32 17 ns

50 30 40 30 ns

2119A–HIREL–04/02

11

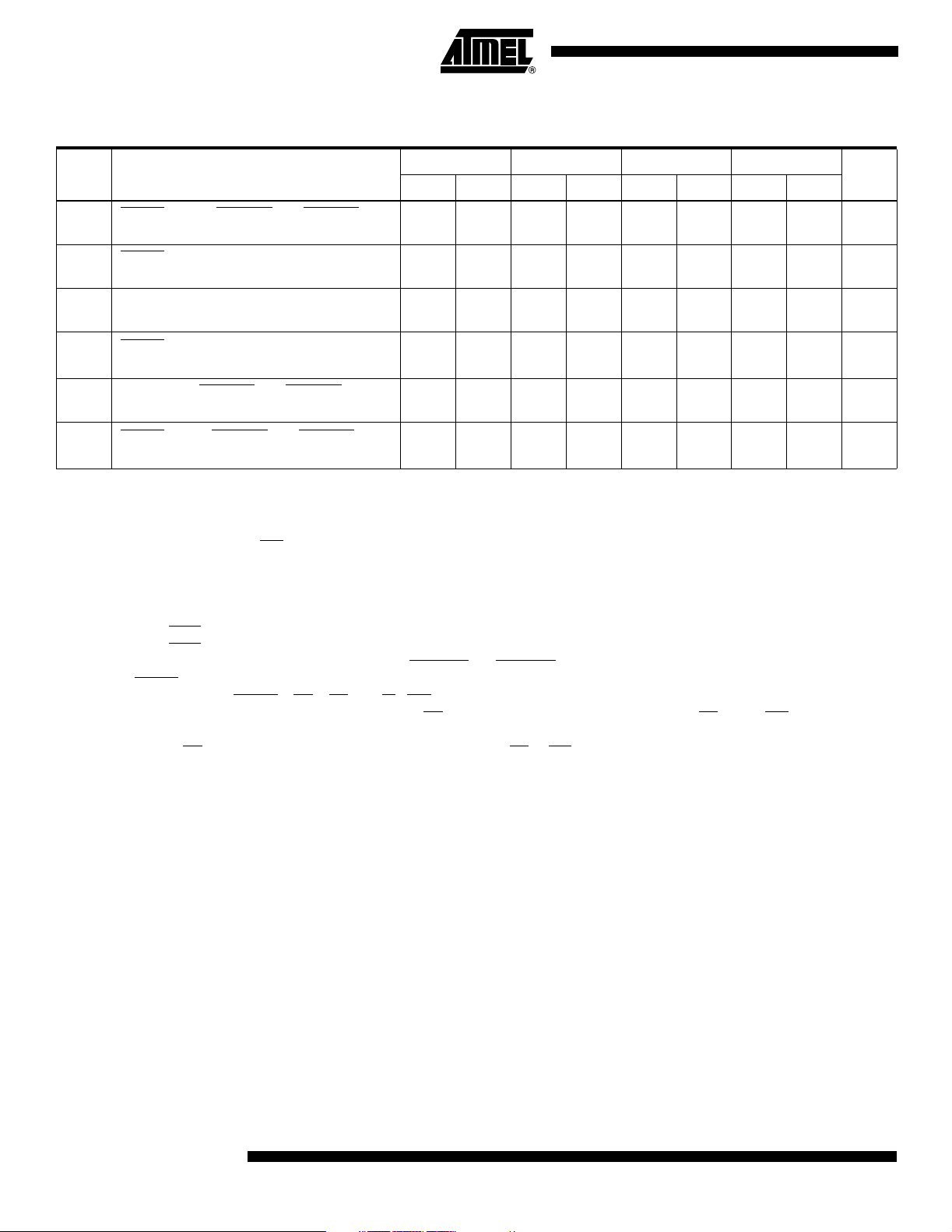

Table 7 . AC Electrical Characteristics – Read and Write Cycles

V

=5.0VDC± 10%; GND = 0 V

CC

Tc = -55°C/+125°CorTc=-40°C/+85°C (see Figure 7, Figure 8, Figure 9)

DC;

16.67 MHz 20 MHz 25 MHz 33.33 MHz

(1)

(Continued)

N° Parameter

START

22

high impedance

START

23

read)

Clock low to data-out valid synchronous

24

read)

START

25

read)

Clock low to DSACK0

26

asserted (synchronous read

START

27

asserted (synchronous read)

false to DSACK0 and DSACK1

true to clock high (synchronous

(3)(8 )

(3)

true to data-out valid (synchronous

(3)(8 )

(8)

and DSACK1

true to DSACK0 and DSACK1

(3)

(3)(8)

70 55 55 40 ns

0000ns

105 80 60 45 ns

0

1.5

105+

2.5

1.5

80 +

2.5

1.5

60+

2.5

1.5

45-

2.5nsClks

75 55 45 30 ns

1.5

75+

2.5

1.5

55+

2.5

1.5

45+

2.5

1.5

30-

2.5nsClks

UnitMin Max Min Max Min Max Min Max

Notes: 1. Timing measurements are referenced to and from a low voltage of 0.8V and a high voltage of 2.0V, unless otherwise noted.

The voltage swing through this range should start outside, and pass through, the range such that the rise or fall will be linear

between 0.8V and 2.0V.

2. These specifications only apply if the TS68882 has completed all internal operations initiated by the termination of the previous bus cycle when DS

was negated.

3. Synchronous read cycles occur only when the save or response CIR locations are read.

4. This specification only applies to systems in which back-to-back accesses (read-write or write-write) of the operand CIR can

occur. When the TS68882 is used as a co-processor to the TS68020/68030, this can occur when the addressing mode is

immediate.

5. If the SIZE

6. If the SIZE

7. This number is reduced to 5 nanoseconds if DSACK0

8. START

this condition is START

9. If a subsequent access is not a FPCP access, CS

pin is not strapped to either VCCor GND, it must have the same setup times as do addresses.

pin is not strapped to either VCCor GND, it must have the same hold times as do addresses.

and DSACK1 have equal loads.

is not an external signal; rather, it is the logical condition that indicates the start of an access. The logical equation for

=CS+AS+(R/W· DS).

must be negated before the assertion of AS and/or DS on the non-FPCP

access. These specifications replace the old specifications 8 and 8A (the old specifications implied that in all cases, transitions in CS

must not occur simultaneously with transitions of AS or DS. This is not a requirement of the TS68882).

12

TS68882

2119A–HIREL–04/02

TS68882

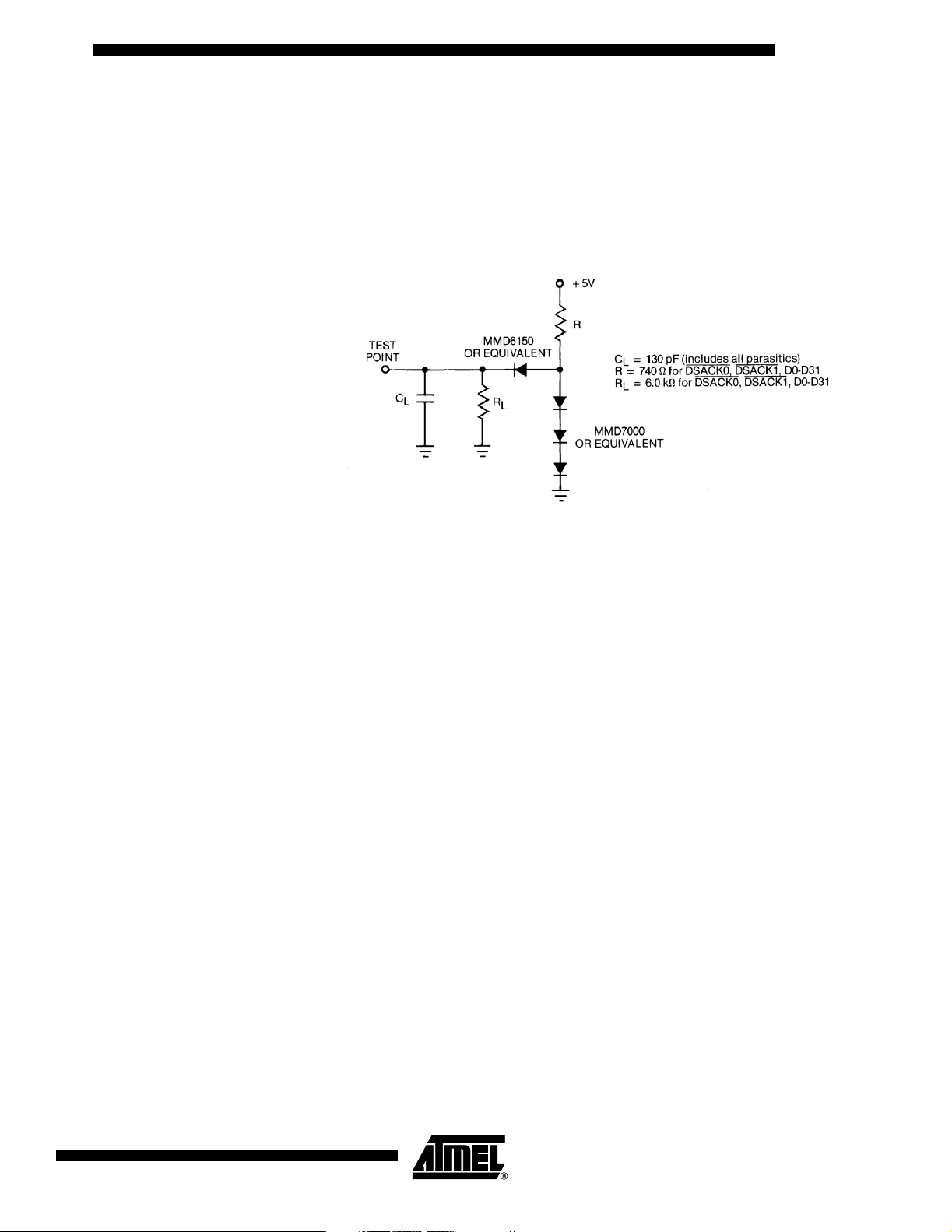

Test Conditions Specific to the Device

Test Load The applicable loading network shall be as defined in column “Test conditions” of Table

2, referring to the loading network number as shown in Figure 5.

Figure 5. Test Loads

AC Electrical Specification Definitions

The AC specifications presented consist of output delays, input setup and hold times,

and signal skew times. All signals are specified relative to an appropriate edge of the

clock input and, possibly, relative to one or more other signals.

The measurement of the AC specifications is defined by the waveforms shown in Figure

6. In order to test the parameters guaranteed inputs must be driven to the voltage levels

specified in Figure 6. Outputs are specified with minimum and/or maximum limits, as

appropriate, and are measured as shown. Inputs are specified with minimum and, an

appropriate maximum setup and hold times, and are measured as shown. Finally, the

measurement for signal-to-signal specifications are also shown.

Note that the testing levels used to verify conformance to the AC specifications does not

affect the guaranteed DC operation of the device specified in the DC electrical

characteristics.

2119A–HIREL–04/02

13

Loading...

Loading...