Atmel SAM L22 Xplained Pro User Manual

SMART ARM-based Microcontrollers

SAM L22 Xplained Pro

USER GUIDE

Preface

The Atmel® SAM L22 Xplained Pro evaluation kit is a hardware platform to

evaluate the ATSAML22N18A microcontroller.

Supported by the Atmel Studio integrated development platform, the kit

provides easy access to the features of the Atmel ATSAML22N18A and

explains how to integrate the device in a custom design.

The Xplained Pro MCU series evaluation kits include an on-board

Embedded Debugger, and no external tools are necessary to program or

debug the ATSAML22N18A.

The Xplained Pro extension kits offers additional peripherals to extend the

features of the board and ease the development of custom designs.

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

Table of Contents

Preface............................................................................................................................ 1

1. Introduction................................................................................................................4

1.1. Features....................................................................................................................................... 4

1.2. Kit Overview................................................................................................................................. 4

2. Getting Started...........................................................................................................6

2.1. Xplained Pro Quick Start.............................................................................................................. 6

2.2. Design Documentation and Relevant Links................................................................................. 6

3. Xplained Pro.............................................................................................................. 8

3.1. Embedded Debugger................................................................................................................... 8

3.2. Xplained Pro Analog Module (XAM).............................................................................................9

3.2.1. Overview........................................................................................................................9

3.2.2. EDBG Interface..............................................................................................................9

3.2.3. Sample Rate................................................................................................................ 10

3.2.4. Measurement Ranges and Accuracy...........................................................................10

3.3. Hardware Identification System..................................................................................................10

3.4. Power Sources........................................................................................................................... 11

3.5. Xplained Pro Headers and Connectors......................................................................................12

3.5.1. Xplained Pro Standard Extension Header................................................................... 12

3.5.2. Xplained Pro Segment LCD Connector....................................................................... 13

3.5.3. Xplained Pro Power Header........................................................................................ 14

4. Hardware User Guide..............................................................................................15

4.1. Power Distribution...................................................................................................................... 15

4.2. Connectors................................................................................................................................. 15

4.2.1. Xplained Pro Standard Extension Headers................................................................. 16

4.2.2. Segment LCD Connector.............................................................................................19

4.2.3. Arduino Connector Footprint........................................................................................21

4.2.4. USB............................................................................................................................. 23

4.2.5. Cortex Debug Connector............................................................................................. 23

4.2.6. Current Measurement Header..................................................................................... 24

4.3. Peripherals................................................................................................................................. 24

4.3.1. Crystal..........................................................................................................................24

4.3.2. Mechanical Buttons..................................................................................................... 24

4.3.3. LED..............................................................................................................................25

4.3.4. QTouch Button.............................................................................................................25

4.3.5. Backup Super Capacitor..............................................................................................25

4.3.6. Crypto Device.............................................................................................................. 26

4.3.7. Tamper Detection.........................................................................................................26

4.4. Embedded Debugger Implementation........................................................................................27

4.4.1. Serial Wire Debug........................................................................................................27

4.4.2. Virtual COM Port..........................................................................................................27

4.4.3. Atmel Data Gateway Interface.....................................................................................27

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

2

4.4.4. XAM Configuration.......................................................................................................28

4.5. Kit Modifications......................................................................................................................... 29

4.5.1. Operation at Other Voltages........................................................................................ 33

5. Appendix..................................................................................................................35

5.1. Getting Started with IAR.............................................................................................................35

5.2. Connecting a SAM-ICE to an Xplained Pro Board..................................................................... 38

6. Hardware Revision History and Known Issues........................................................40

6.1. Identifying Product ID and Revision........................................................................................... 40

6.2. Revision 4...................................................................................................................................40

6.3. Revision 2...................................................................................................................................40

6.3.1. Pin-out Changes.......................................................................................................... 41

6.3.2. CryptoAuthentication Device....................................................................................... 41

6.3.3. Assembly Drawings..................................................................................................... 41

7. Document Revision History..................................................................................... 44

8. Evaluation Board/kit Important Notice..................................................................... 45

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

3

1. Introduction

1.1. Features

• ATSAML22N18A microcontroller

• One mechanical reset button

• One mechanical programmable button

• Xplained Pro segment LCD connector

– Eight COM signals

– Twenty-seven SEG signals

– Six touch signals

• One QTouch® button

• One yellow user LED

• Backup super capacitor

• 32.768kHz crystal

• USB interface, device only

• Three Xplained Pro extension headers

• Embedded Debugger

– Auto-ID for board identification in Atmel Studio

– One yellow status LED

– One green board power LED

– Symbolic debug of complex data types including scope information

– Programming and debugging, including power measurements

– Data Gateway Interface: SPI, I2C, four GPIOs

– Virtual COM port (CDC)

• Embedded current measurement circuitry, with Atmel Data Visualizer support for data visualization

• USB powered

• Supported with application examples in Atmel Software Framework

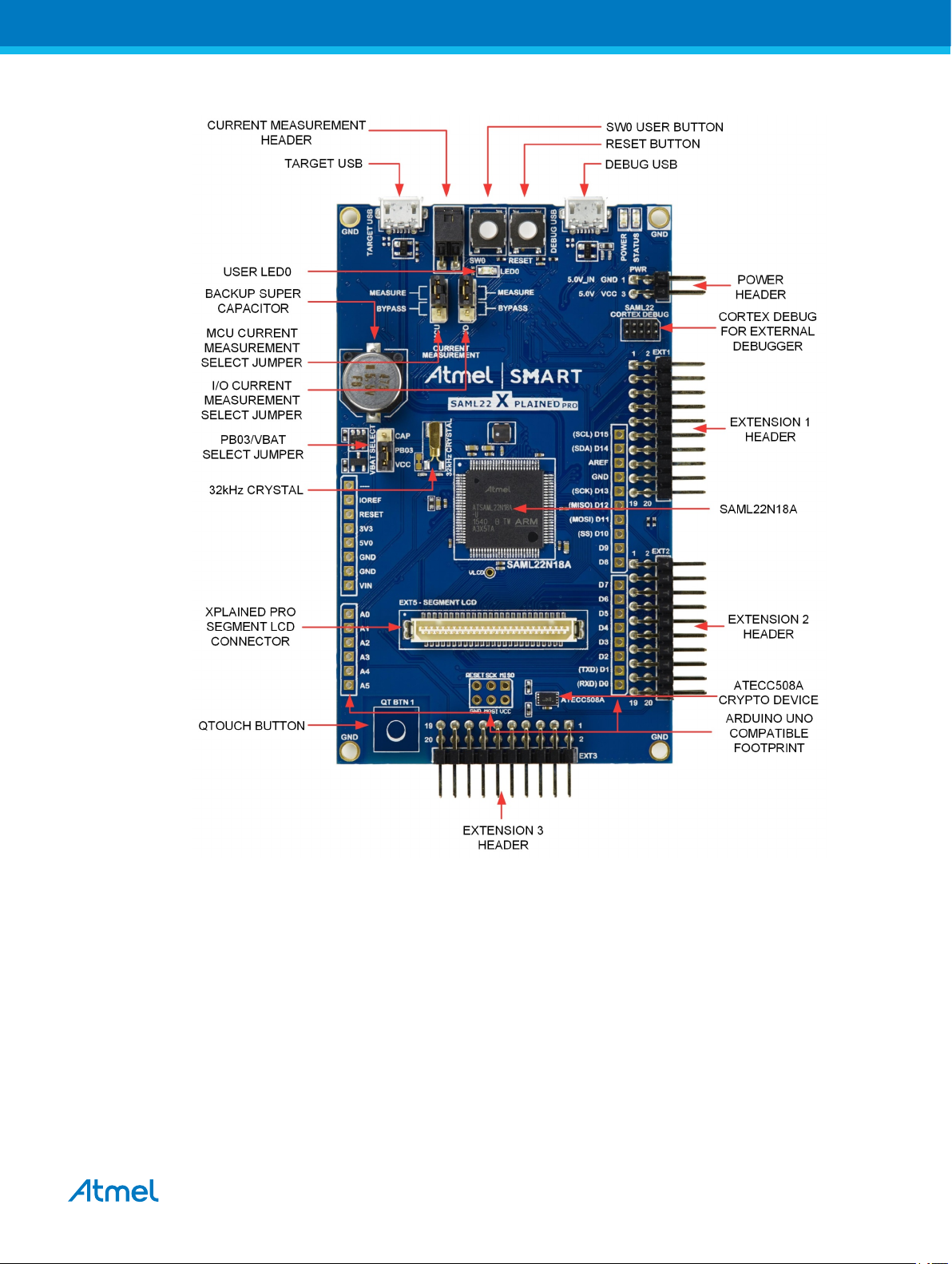

1.2. Kit Overview

The Atmel SAM L22 Xplained Pro evaluation kit is a hardware platform to evaluate the Atmel

ATSAML22N18A.

The kit offers a set of features that enables the ATSAML22N18A user to get started with the SAM L

peripherals right away and to get an understanding of how to integrate the device in their own design.

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

4

Figure 1-1. SAM L22 Xplained Pro Evaluation Kit Overview

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

5

2. Getting Started

2.1. Xplained Pro Quick Start

Three steps to start exploring the Atmel Xplained Pro platform:

1. Download Atmel Studio.

2. Launch Atmel Studio.

3. Connect a USB cable (Standard-A to Micro-B or Micro-AB) between the PC and the DEBUG USB

port on the kit.

When the Xplained Pro MCU kit is connected to your computer for the first time, the operating system will

perform a driver software installation. The driver file supports both 32- and 64-bit versions of Microsoft

Windows® XP, Windows Vista®, Windows 7, and Windows 8.

Once the Xplained Pro MCU board is powered the green power LED will be lit and Atmel Studio will auto

detect which Xplained Pro MCU- and extension board(s) are connected. Atmel Studio will present

relevant information like datasheets and kit documentation. The kit landing page in Atmel Studio also has

the option to launch Atmel Software Framework (ASF) example applications for the kit. The SAM L22

device is programmed and debugged by the on-board Embedded Debugger and therefore no external

programmer or debugger tool is needed.

2.2. Design Documentation and Relevant Links

The following list contains links to the most relevant documents and software for the SAM L22 Xplained

Pro.

• Xplained Pro products - Atmel Xplained Pro is a series of small-sized and easy-to-use evaluation

kits for Atmel microcontrollers and other Atmel products. It consists of a series of low-cost MCU

boards for evaluation and demonstration of features and capabilities of different MCU families.

• Atmel Studio - Free Atmel IDE for development of C/C++ and assembler code for Atmel

microcontrollers.

• Atmel sample store - Atmel sample store where you can order samples of devices.

• EDBG User Guide - User guide containing more information about the on-board Embedded

Debugger.

• IAR Embedded Workbench® for ARM® - This is a commercial C/C++ compiler that is available for

ARM®. There is a 30 day evaluation version as well as a code size limited kick-start version

available from their website. The code size limit is 16KB for devices with M0, M0+, and M1 cores

and 32KB for devices with other cores.

• Atmel QTouch® Library PTC - QTouch Library for Atmel AVR® and ARM®-based microcontrollers.

• Atmel QTouch® Composer - Tool for developing capacitive buttons, sliders, and wheels

applications.

• Atmel Data Visualizer - Atmel Data Visualizer is a program used for processing and visualizing

data. Data Visualizer can receive data from various sources such as the Embedded Debugger Data

Gateway Interface found on Xplained Pro boards and COM ports.

• Segment LCD1 Xplained Pro - Segment LCD1 Xplained Pro is a segment LCD Xplained Pro

extension with 96 segments that uses four COM and 24 SEG signals. An Xplained Pro MCU board

with a Xplained Pro segment LCD connector is required to use the kit.

• Touch Segment LCD1 Xplained Pro - Touch Segment LCD1 Xplained Pro is a segment LCD

Xplained Pro extension with 179 segments that uses eight COM and 24 SEG signals. The LCD has

®

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

6

five built-in mutual capacitance sensors for use with a PTC module. An Xplained Pro MCU board

with a Xplained Pro segment LCD connector is required to use the kit.

• Design Documentation - Package containing CAD source, schematics, BOM, assembly drawings,

3D plots, layer plots etc.

• Hardware Users Guide in PDF format - PDF version of this User Guide.

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

7

3. Xplained Pro

Xplained Pro is an evaluation platform that provides the full Atmel microcontroller experience. The

platform consists of a series of Microcontroller (MCU) boards and extension boards, which are integrated

with Atmel Studio, have Atmel Software Framework (ASF) drivers and demo code, support data

streaming, and more. Xplained Pro MCU boards support a wide range of Xplained Pro extension boards,

which are connected through a set of standardized headers and connectors. Each extension board has

an identification (ID) chip to uniquely identify which boards are connected to an Xplained Pro MCU board.

This information is used to present relevant user guides, application notes, datasheets, and example

code through Atmel Studio.

3.1. Embedded Debugger

The SAM L22 Xplained Pro contains the Atmel Embedded Debugger (EDBG) for on-board debugging.

The EDBG is a composite USB device of three interfaces; a debugger, Virtual COM Port, and a Data

Gateway Interface (DGI).

Together with Atmel Studio, the EDBG debugger interface can program and debug the ATSAML22N18A.

On SAM L22 Xplained Pro, the SWD interface is connected between the EDBG and the

ATSAML22N18A.

The Virtual COM Port is connected to a UART on the ATSAML22N18A and provides an easy way to

communicate with the target application through terminal software. It offers variable baud rate, parity, and

stop bit settings. Note that the settings on the ATSAML22N18A must match the settings given in the

terminal software.

Info: If not set automatically, data terminal ready (DTR) must be set in the terminal software.

The DGI consists of several physical interfaces for communication with the host computer.

Communication over the interfaces is bidirectional. It can be used to send events and values from the

ATSAML22N18A or as a generic printf-style data channel. Traffic over the interfaces can be timestamped

on the EDBG for more accurate tracing of events. Note that timestamping imposes an overhead that

reduces maximal throughput. Atmel Data Visualizer is used to send and receive data through DGI.

The EDBG controls two LEDs on SAM L22 Xplained Pro; a power LED and a status LED. The table

below shows how the LEDs are controlled in different operation modes.

Table 3-1. EDBG LED Control

Operation mode Power LED Status LED

Normal operation Power LED is lit when power is

applied to the board.

Bootloader mode (idle) The power LED and the status LED blinks simultaneously.

Bootloader mode (firmware

upgrade)

The power LED and the status LED blinks in an alternating pattern.

Activity indicator, LED flashes

when any communication

happens to the EDBG.

For further documentation on the EDBG, see the EDBG User Guide.

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

8

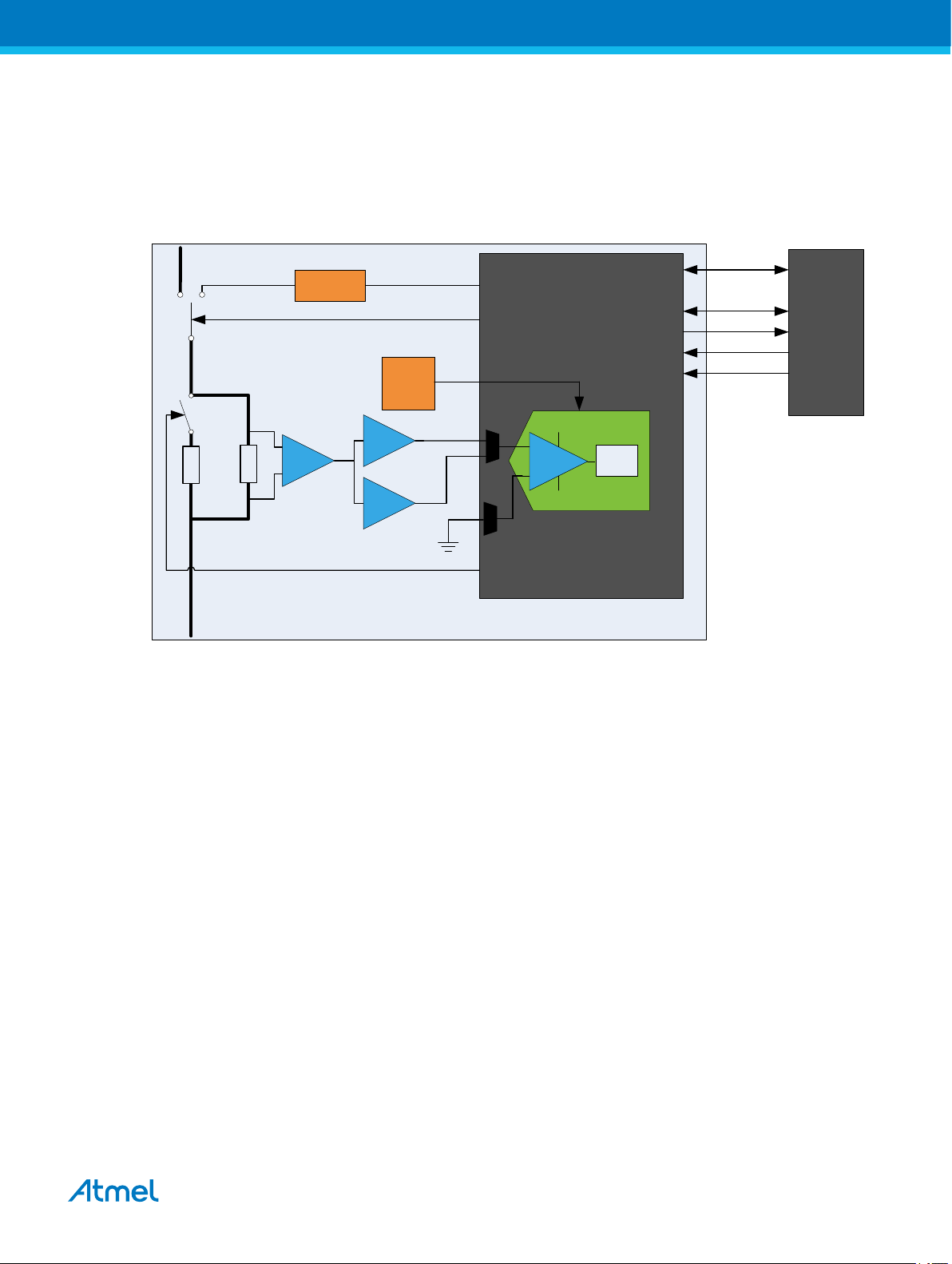

3.2. Xplained Pro Analog Module (XAM)

3.2.1. Overview

The Xplained Pro Analog Module (XAM) extends the embedded debugger with high dynamic range

current measurement. This enables power profiling of the target system.

Current output

Range selection

Current input

Calibration ON/OFF

100 mOhm

100 Ohm

Xplained Pro Analog Module (XAM)

The XAM consists of:

• Calibration circuitry

• Voltage reference

• Analog frontend

– Shunt resistors with a range selection switch

– Pre-amplifier

– Two active filters with gain

• Control MCU

– Analog to digital converter

– Signal processing

– Control/communication interface to the EDBG

Calibration

circuitry

Pre-amplifier

20x

20x

voltage

reference

2.7V

2x

16x

Active filter with

gain

GPIO(s)

GPIO

AREF

ADC0

ADC1

GND

GPIO

Control MCU

S&H

ADC

Sync GPIO

I2C

SPI

Clock sync

SWD

EDBG

The current measurement frontend is a high side shunt measurement with a pre-amplifier and a second

active filter stage with gain. The wide dynamic range is achieved by four measurement ranges which are

defined by two shunts and the two parallel second stage active filters with gain.

3.2.2. EDBG Interface

The Xplained Pro Analog Module (XAM) is connected to the EDBG with the following interfaces:

• I2C: This is used to control and configure the XAM

• SPI: Current measurement data is streamed to the EDBG via this interface. This is a one-way data

transfer channel from the XAM to the EDBG

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

9

• SWD: The MCU in the XAM is programmed via SWD from the EDBG

• GPIO: At least one GPIO that is connected to the EDBG from the target MCU is also connected to

the current measurement unit to enable the user to sync current measurements with his application

• Clock sync: Synchronization signal to synchronize ADC measurements with EDBG

• Reference clock: Reference clock for the XAM

3.2.3. Sample Rate

The raw sampling rate of the Xplained Pro analog module (XAM) is up to 250kHz and with the default

averaging configuration (average of 16 samples) the actual output of the XAM is 16.67kSPS (note that

the XAM output sample rate is not an integer fraction of the raw sampling).

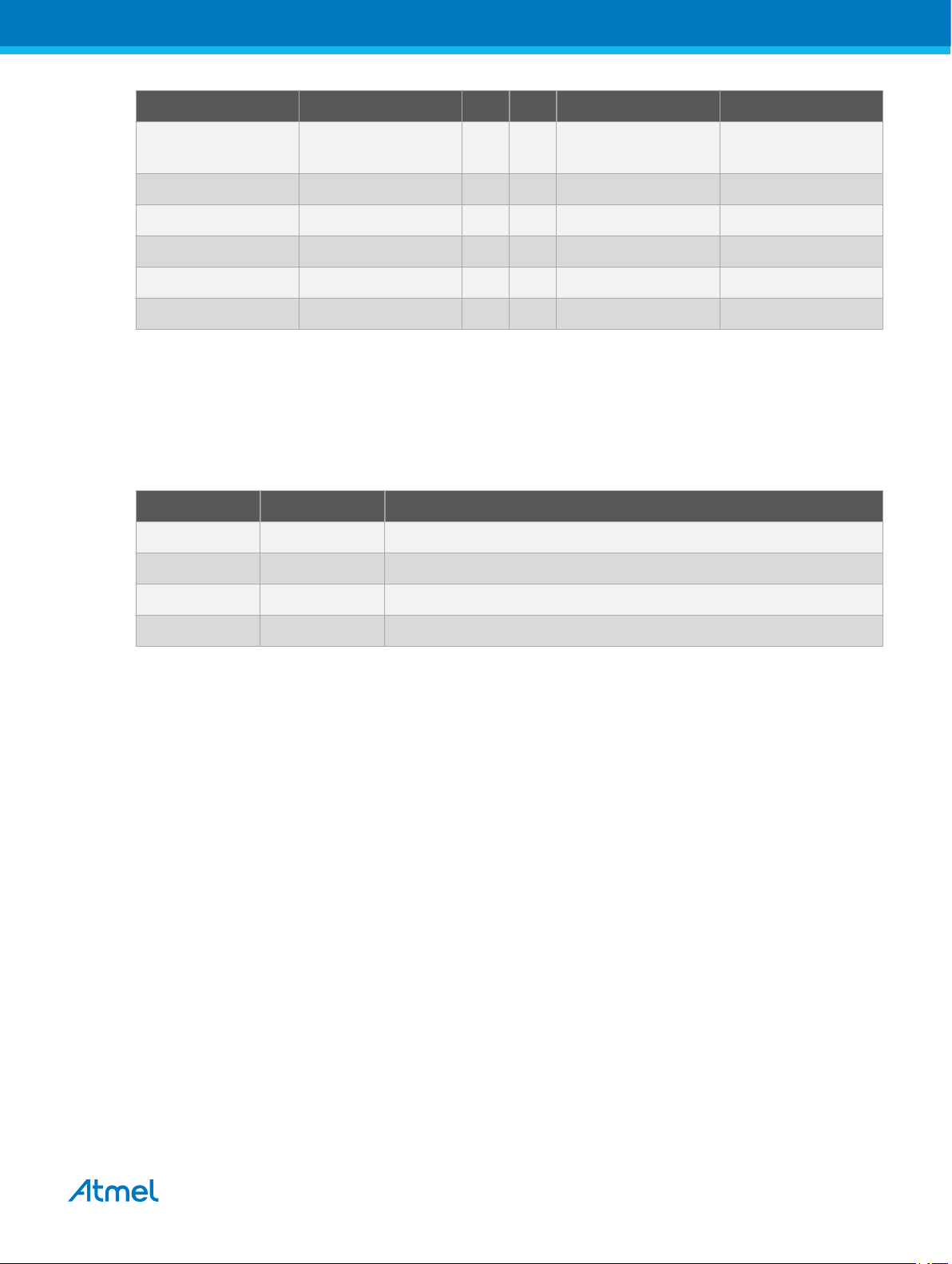

3.2.4. Measurement Ranges and Accuracy

The Xplained Pro analog module has four measurement ranges. These are defined by two shunt resistors

and two gain stages.

Measurement

Hardware Resolution Accuracy Comments

range

Range 1 Low current shunt and

high gain stage

Range 2 Low current shunt and

low gain stage

Range 3 High current shunt and

high gain stage

Range 4 High current shunt and

low gain stage

The ranges are switched automatically by the XAM to achieve best measurement results and the

currently active range is visualized in the Atmel Data Visualizer frontend tool. The maximum voltage drop

over the shunt resistor is 100mV and the XAM will switch the range automatically before this limit is

reached.

3.3. Hardware Identification System

All Xplained Pro compatible extension boards have an Atmel ATSHA204 CryptoAuthentication™ chip

mounted. This chip contains information that identifies the extension with its name and some extra data.

When an Xplained Pro extension is connected to an Xplained Pro MCU board the information is read and

sent to Atmel Studio. The Atmel Kits extension, installed with Atmel Studio, will give relevant information,

code examples, and links to relevant documents. The table below shows the data fields stored in the ID

chip with example content.

20nA 1 LSB ±1% Below 1μA the error will

increase. Typical error for

300nA is 1 LSB ± 10%

150nA 1 LSB ±1%

10μA 1 LSB ±1%

100μA 1 LSB ±1% Above 100mA the error will

increase to 1 LSB ±5% at

400mA. Maximum current is

400mA

Table 3-2. Xplained Pro ID Chip Content

Data field Data type Example content

Manufacturer ASCII string Atmel'\0'

Product Name ASCII string Segment LCD1 Xplained Pro'\0'

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

10

Data field Data type Example content

Product Revision ASCII string 02'\0'

Product Serial Number ASCII string 1774020200000010’\0’

Minimum Voltage [mV] uint16_t 3000

Maximum Voltage [mV] uint16_t 3600

Maximum Current [mA] uint16_t 30

3.4. Power Sources

The SAM L22 Xplained Pro kit can be powered by several power sources as listed in the table below.

Table 3-3. Power Sources for SAM L22 Xplained Pro

Power input Voltage requirements Current requirements Connector marking

External power 5V ±2% (±100mV) for

USB host operation.

4.3V to 5.5V if USB host

operation is not

required.

Recommended

minimum is 1A to be

able to provide enough

current for connected

USB devices and the

PWR

board itself.

Recommended

maximum is 2A due to

the input protection

maximum current

specification.

Embedded debugger

USB

Target USB 4.4V to 5.25V (according

4.4V to 5.25V (according

to USB spec.)

to USB spec.)

500mA (according to

USB spec.)

500mA (according to

USB spec.)

DEBUG USB

TARGET USB

The kit will automatically detect which power sources are available and choose which one to use

according to the following priority:

1. External power.

2. Embedded Debugger USB.

3. Target USB.

Info: External power is required when 500mA from a USB connector is not enough to power

the board with possible extension boards. A connected USB device in a USB host application

might easily exceed this limit.

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

11

3.5. Xplained Pro Headers and Connectors

3.5.1. Xplained Pro Standard Extension Header

All Xplained Pro kits have one or more dual row, 20-pin, 100mil extension header. Xplained Pro MCU

boards have male headers, while Xplained Pro extensions have their female counterparts. Note that all

pins are not always connected. All connected pins follow the defined pin-out description in the table

below.

The extension headers can be used to connect a variety of Xplained Pro extensions to Xplained Pro MCU

boards or to access the pins of the target MCU on Xplained Pro MCU boards directly.

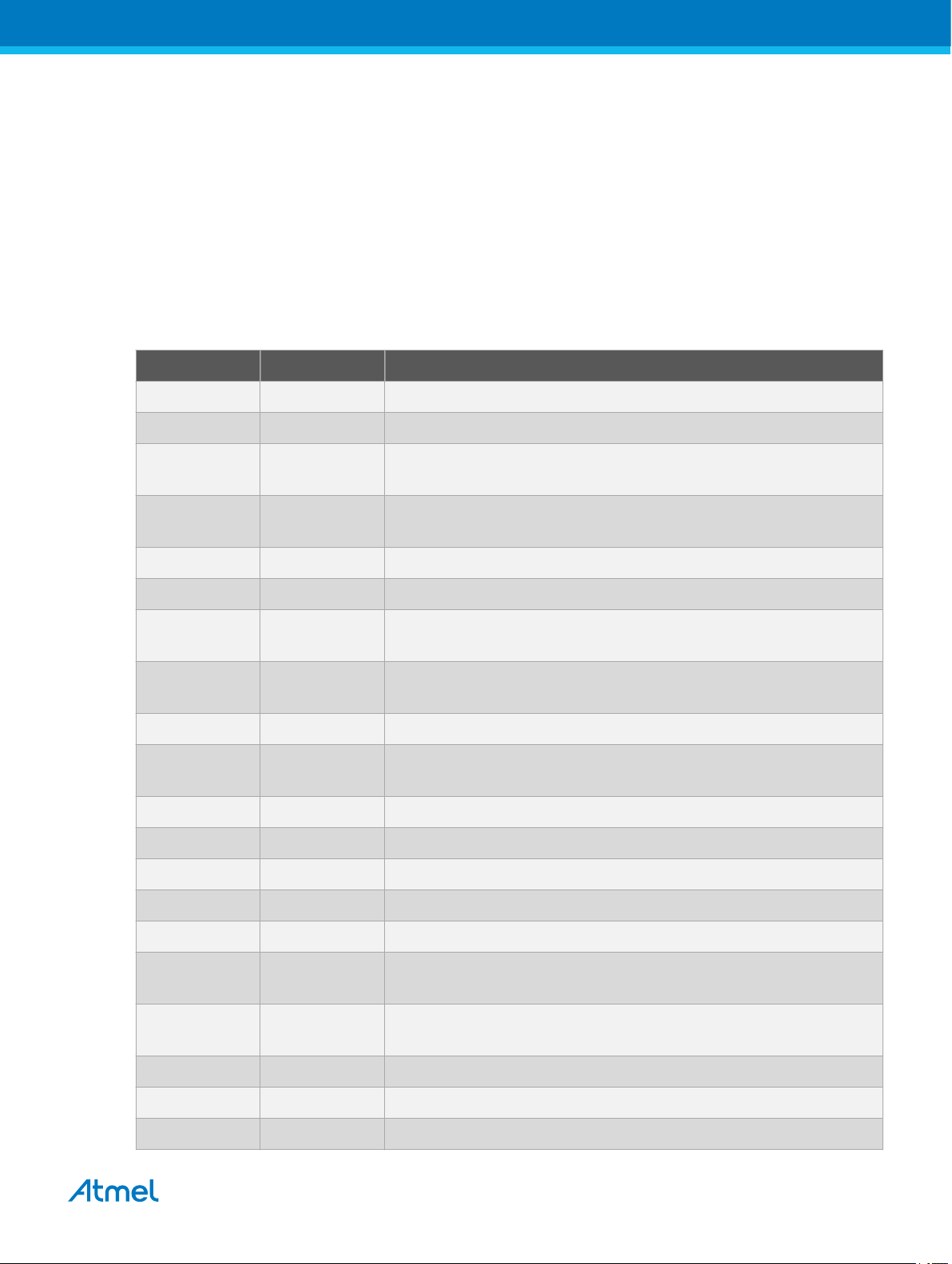

Table 3-4. Xplained Pro Standard Extension Header

Pin number Name Description

1 ID Communication line to the ID chip on an extension board

2 GND Ground

3 ADC(+) Analog to digital converter, alternatively positive part of differential

ADC

4 ADC(-) Analog to digital converter, alternatively negative part of differential

ADC

5 GPIO1 General purpose I/O

6 GPIO2 General purpose I/O

7 PWM(+) Pulse width modulation, alternatively positive part of differential

PWM

8 PWM(-) Pulse width modulation, alternatively negative part of differential

PWM

9 IRQ/GPIO Interrupt request line and/or general purpose I/O

10 SPI_SS_B/

Slave select for SPI and/or general purpose I/O

GPIO

11 I2C_SDA Data line for I2C interface. Always implemented, bus type.

12 I2C_SCL Clock line for I2C interface. Always implemented, bus type.

13 UART_RX Receiver line of target device UART

14 UART_TX Transmitter line of target device UART

15 SPI_SS_A Slave select for SPI. Should preferably be unique.

16 SPI_MOSI Master out slave in line of serial peripheral interface. Always

implemented, bus type.

17 SPI_MISO Master in slave out line of serial peripheral interface. Always

implemented, bus type.

18 SPI_SCK Clock for serial peripheral interface. Always implemented, bus type.

19 GND Ground

20 VCC Power for extension board

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

12

3.5.2. Xplained Pro Segment LCD Connector

Xplained Pro MCU boards that have a microcontroller, which supports segment LCDs, can implement a

51-pin segment LCD extension connector. This connector is implemented with HIROSE DF-9 series.

Xplained Pro MCU boards use the male version DF9-51P-1V(69) and Xplained Pro extension boards use

the female counterpart DF9-51S-1V(69). The connector has a standardized pin-out as shown in the table

below.

Info:

All pins are not connected on all Xplained Pro MCU boards, it depends on how many segments

and common terminals the target MCU supports.

Pin 37, 38, 39, 40, 41, and 42 can alternatively be used for QTouch signals. When they are

used for touch they should not be used for display segments.

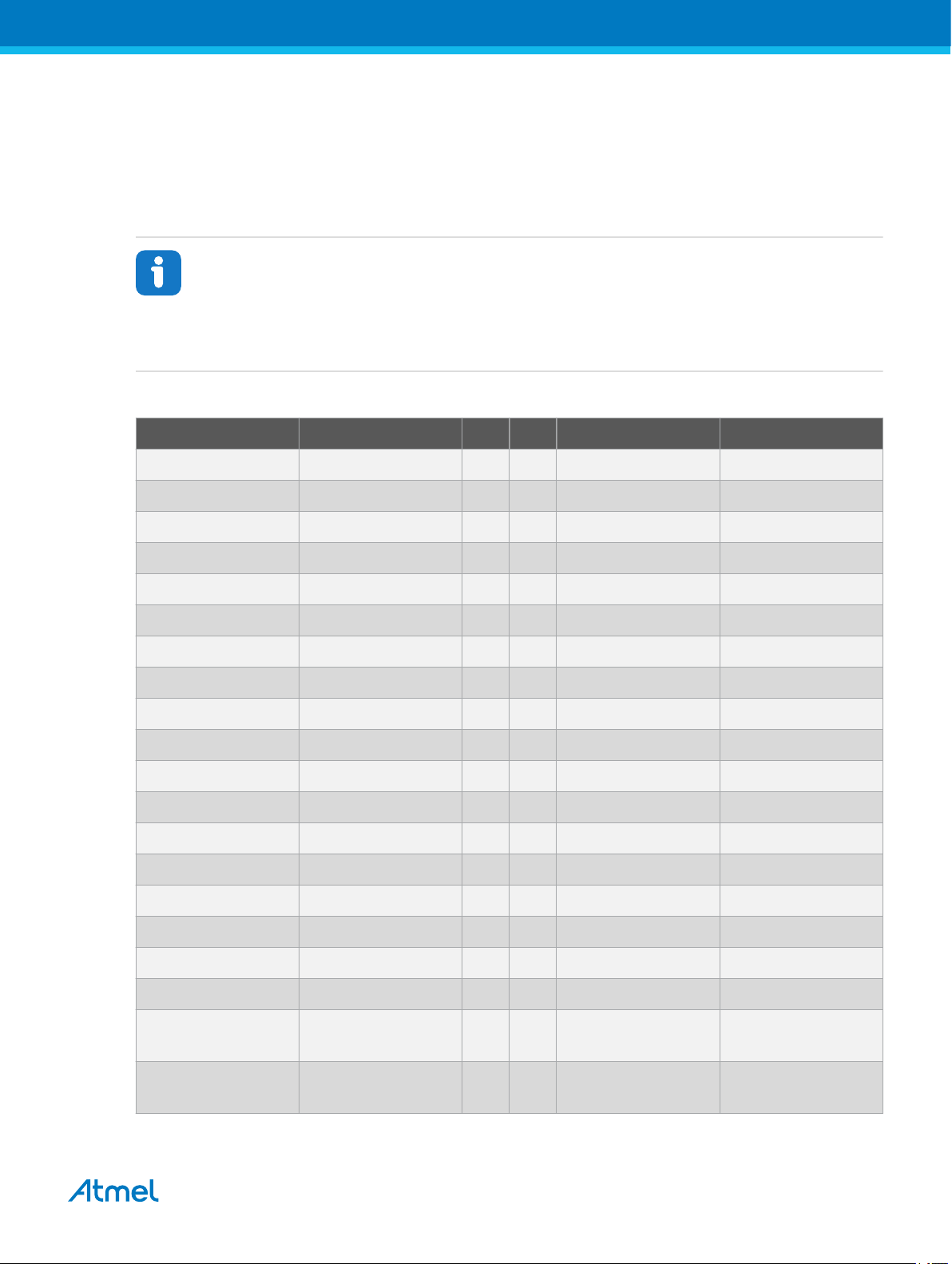

Table 3-5. Xplained Pro Segment LCD Connector

Description Function Pin Pin Function Description

Common terminal 3 COM3 1 2 COM2 Common terminal 2

Common terminal 1 COM1 3 4 COM0 Common terminal 0

Segment 0 SEG0 5 6 SEG1 Segment 1

Segment 2 SEG2 7 8 SEG3 Segment 3

Segment 4 SEG4 9 10 SEG5 Segment 5

Segment 6 SEG6 11 12 SEG7 Segment 7

Segment 8 SEG8 13 14 SEG9 Segment 9

Segment 10 SEG10 15 16 SEG11 Segment 11

Segment 12 SEG12 17 18 SEG13 Segment 13

Segment 14 SEG14 19 20 SEG15 Segment 15

Segment 16 SEG16 21 22 SEG17 Segment 17

Segment 18 SEG18 23 24 SEG19 Segment 19

Segment 20 SEG20 25 26 SEG21 Segment 21

Segment 22 SEG22 27 28 SEG23 Segment 23

Segment 24 SEG24 29 30 SEG25 Segment 25

Segment 26 SEG26 31 32 SEG27 Segment 27

Segment 28 SEG28 33 34 SEG29 Segment 29

Segment 30 SEG30 35 36 SEG31 Segment 31

Segment 32 /

QTouch X-line 2

SEG32 / QT_X2 37 38 SEG33 / QT_Y2 Segment 33 /

QTouch Y-line 2

Segment 34 /

QTouch X-line 1

SEG34 / QT_X1 39 40 SEG35 / QT_Y1 Segment 35 /

QTouch Y-line 1

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

13

Description Function Pin Pin Function Description

Segment 36 /

SEG36 / QT_X0 41 42 SEG37 / QT_Y0 Segment 37 /

QTouch X-line 0

Common terminal 4 COM4 43 44 COM5 Common terminal 5

Common terminal 6 COM6 45 46 COM7 Common terminal 6

Backlight anode Backlight V+ 47 48 Backlight V- Backlight cathode

Backlight control Backlight CTRL 49 50 ID Xplained Pro ID

Ground GND 51

3.5.3. Xplained Pro Power Header

The power header can be used to connect external power to the SAM L22 Xplained Pro kit. The kit will

automatically detect and switch to any external power if supplied. The power header can also be used as

supply for external peripherals or extension boards. Care must be taken not to exceed the total current

limitation of the on-board regulator when using the 3.3V pin.

Table 3-6. Xplained Pro Power Header

Pin number Pin name Description

1 VEXT_P5V0 External 5V input

2 GND Ground

3 VCC_P5V0 Unregulated 5V (output, derived from one of the input sources)

QTouch Y-line 0

4 VCC_P3V3 Regulated 3.3V (output, used as main power supply for the kit)

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

14

4. Hardware User Guide

VCC_P5V0

EDBG & XAM

SAML22N18

Regulator 3.3V

Power source

Power switch

Power converter

Power consumer

VCC_P3V3

Peripherals

Power

Measurement

Select

Auto mux disable

External 5V

input

EDBG USB

Target USB

Auto mux with

current limit

Regulator 3.3V

Jumper

VCC_MCU

VCC_TARGET

Supercap

Select

VBAT

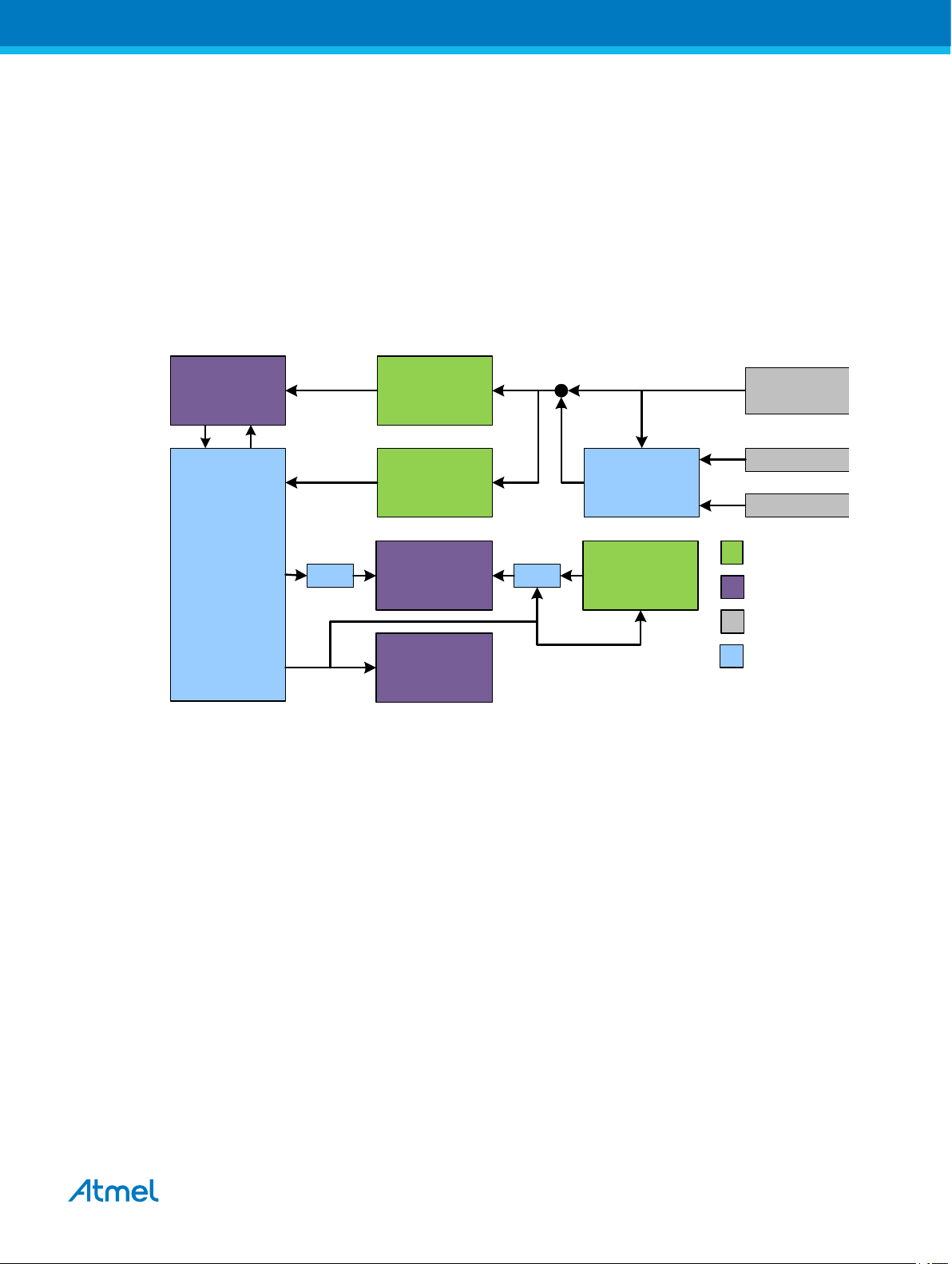

4.1. Power Distribution

SAM L22 Xplained Pro has three power sources; EDBG USB, Target USB, and/or external 5.0V. The kit

will automatically select a source to draw power from. The kit has two on-board 3.3V voltage regulators,

one for the EDBG and XAM and one for the ATSAML22N18A and other peripherals.

An on board super capacitor (47mF) is charged to 3.3V from the target 3.3V net. The super capacitor is

connected to PB03 (VBAT) through a selection header and is intended for backup use in sleep modes.

Figure 4-1. Power Supply Block Diagram

4.2. Connectors

Related Links

Power Sources on page 11

The following sections describes the implementation of the relevant connectors and headers on SAM L22

Xplained Pro and their connection to the ATSAML22N18A. The tables of connections in the sections also

describes which signals are shared between the headers and on-board functionality. The figure below

shows all available connectors and jumpers on SAM L22 Xplained Pro.

Atmel SAM L22 Xplained Pro [USER GUIDE]

Atmel-42474B-SAM-L22-Xplained-Pro_User Guide-12/2015

15

Loading...

Loading...