Page 1

1

2

3

4

8

7

6

5

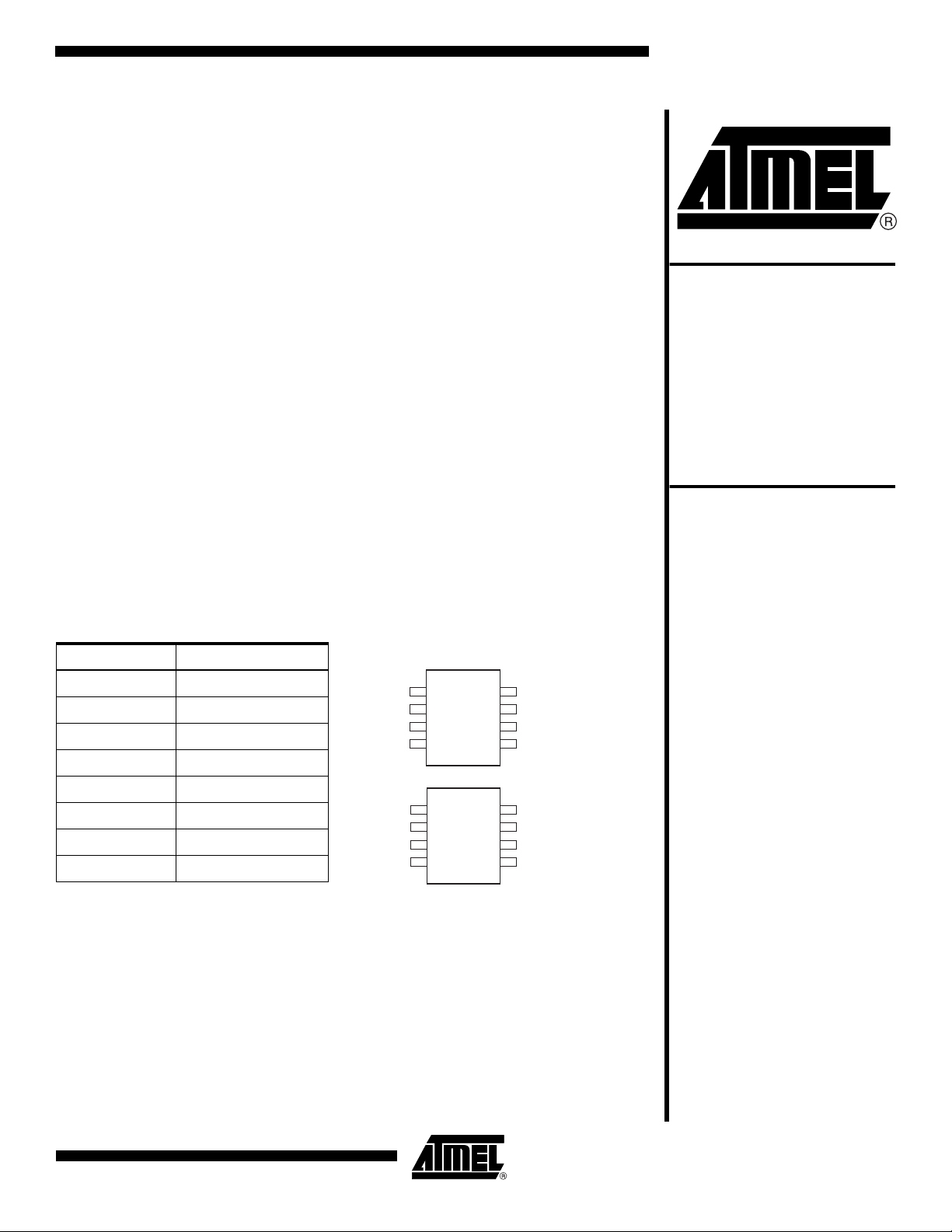

CS

SK

DI

DO

VCC

DC

NC

GND

1

2

3

4

8

7

6

5

CS

SK

DI

DO

VCC

DC

NC

GND

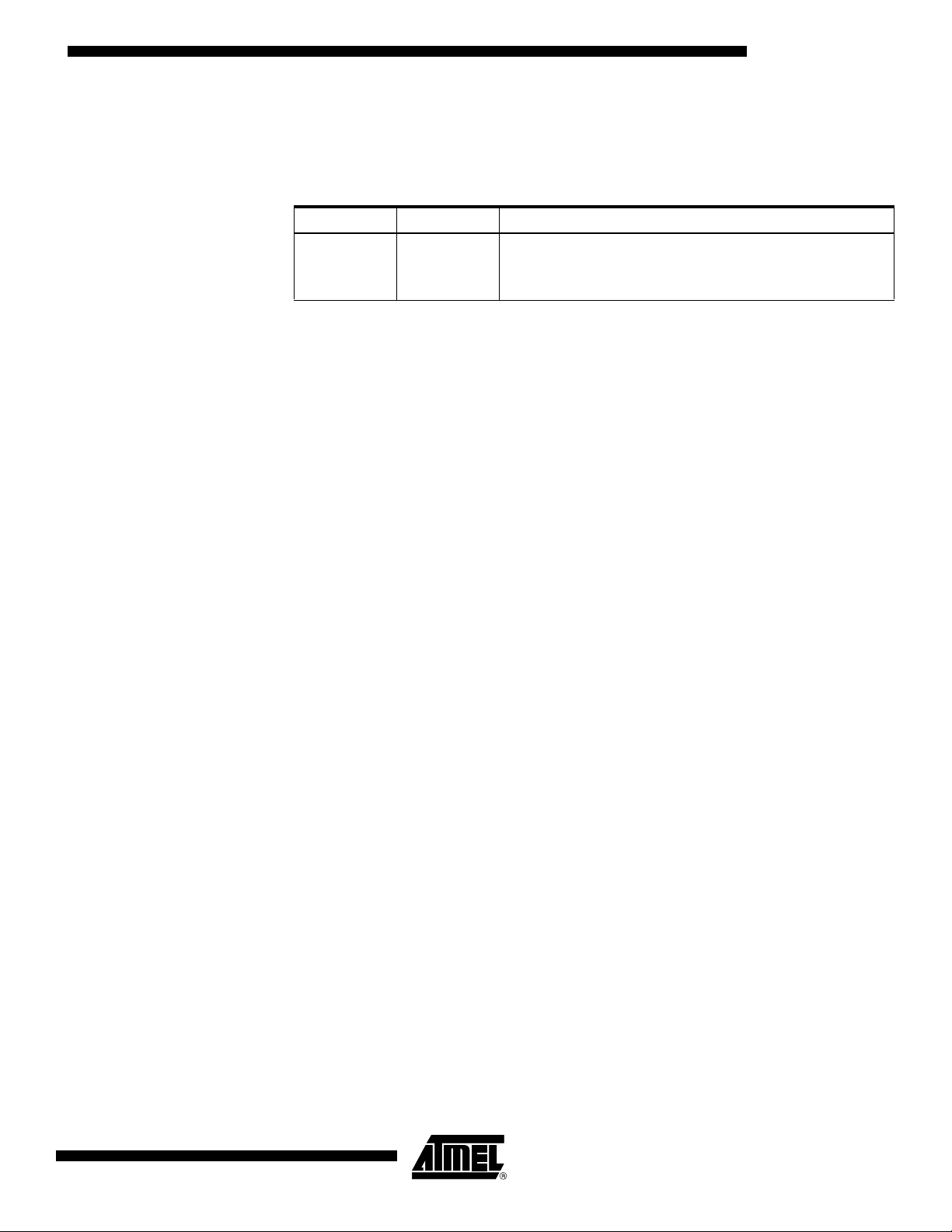

8-lead SOIC

8-lead TSSOP

BDTIC www.bdtic.com/ATMEL

Features

• Low-voltage and Standard-voltage Operation

– 2.7 (VCC = 2.7V to 5.5V)

• Three-wire Serial Interface

• 2 MHz Clock Rate Compatibility

• Self-timed Write Cycle (10 ms max)

• High Reliability

– Endurance: 1 Million Write Cycles

– Data Retention: 100 Years

• Lead-free/Halogen-free Devices Available

• 8-lead JEDEC SOIC and 8-lead TSSOP Packages

Three-wire

Description

The AT93C46A provides 1024 bits of serial electrically-erasable programmable readonly memory (EEPROM) organized as 64 words of 16 bits each. The device is optimized for use in many automotive applications where low-power and low-voltage

operation

SOIC and 8-lead TSSOP packages.

The AT93C46A is enabled through the Chip Select pin (CS) and accessed via a threewire s

(SK). Upon receiving a Read instruction at DI, the address is decoded and the data is

clocked out serially on the data output pin DO. The write cycle is completely self-timed

and no separate erase cycle is required before write. The write cycle is only enabled

when the part is in the erase/write enable state. When CS is brought high following the

initiation of a write cycle, the DO pin outputs the ready/busy status of the part.

The AT93C46A is available in 2.7V to 5.5V versions.

Table 1. Pin Configuration

Pin Name Function

CS Chip Select

SK Serial Data Clock

DI Serial Data Input

DO Serial Data Output

GND Ground

VCC Power Supply

NC No Connect

are essential. The AT93C46A is available in space-saving 8-lead JEDEC

erial interface consisting of Data Input (DI), Data Output (DO), and Shift Clock

Automotive

Temperature

Serial EEPROM

1K (64 x 16)

AT93C46A

DC Don’t Connect

5089B–SEEPR–2/07

Page 2

Absolute Maximum Ratings*

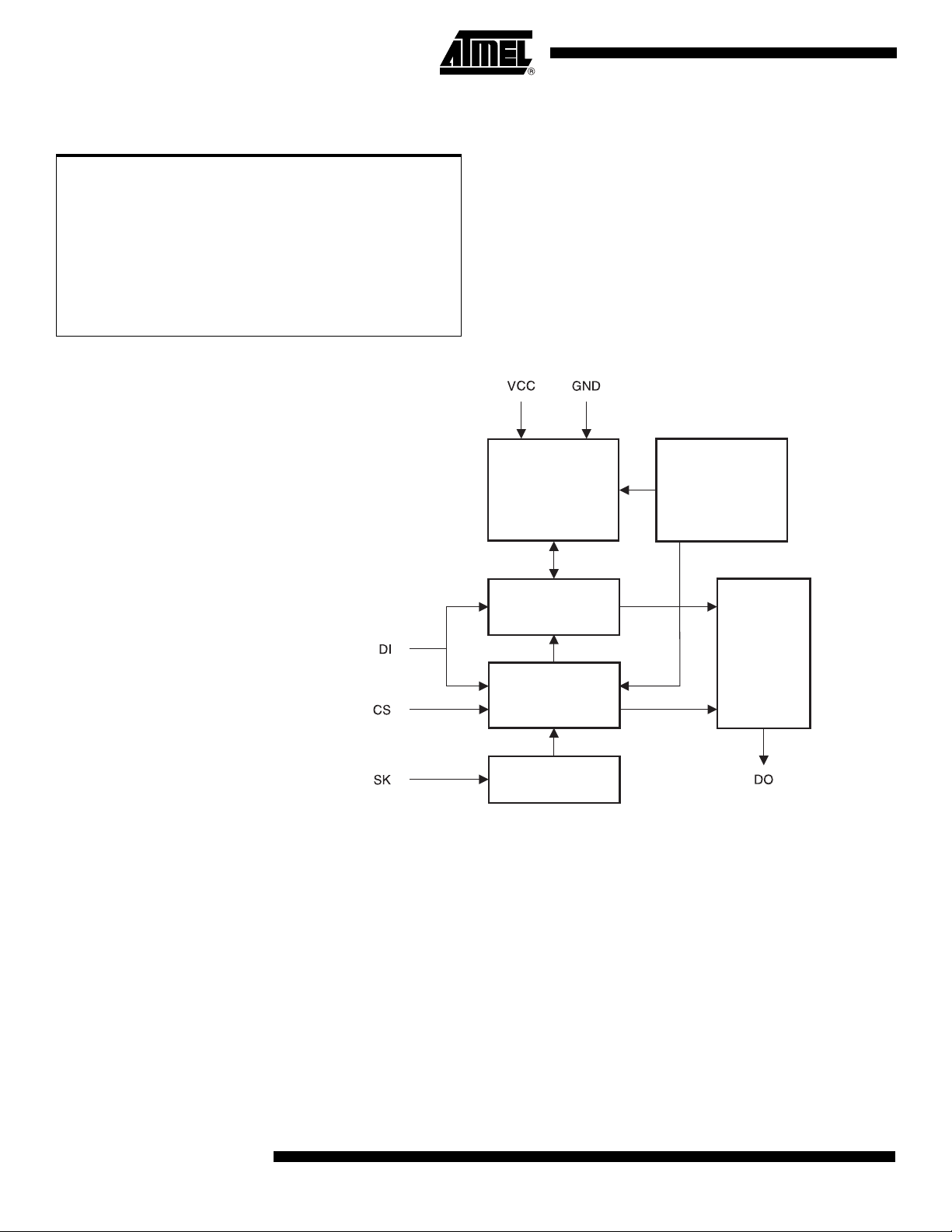

MEMORY ARRAY

64 x 16

ADDRESS

DECODER

OUTPUT

BUFFER

DATA

REGISTER

MODE

DECODE

LOGIC

CLOCK

GENERATOR

Operating Temperature......................................−55°C to +125°C

Storage Temperature .

Voltage on Any Pin

with Respect to Ground ........................................ −1.0V to +7.0V

Maximum Operating Voltage .......................................... 6.25V

DC Output Current........................................................ 5.0 mA

........................................−65°C to +150°C

Figure 1. Block Diagram

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent damage to the device. This is a stress rating only and

nctional operation of the device at these or any

fu

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions for extended periods may affect

device reliability.

2

AT93C46A

5089B–SEEPR–2/07

Page 3

AT93C46A

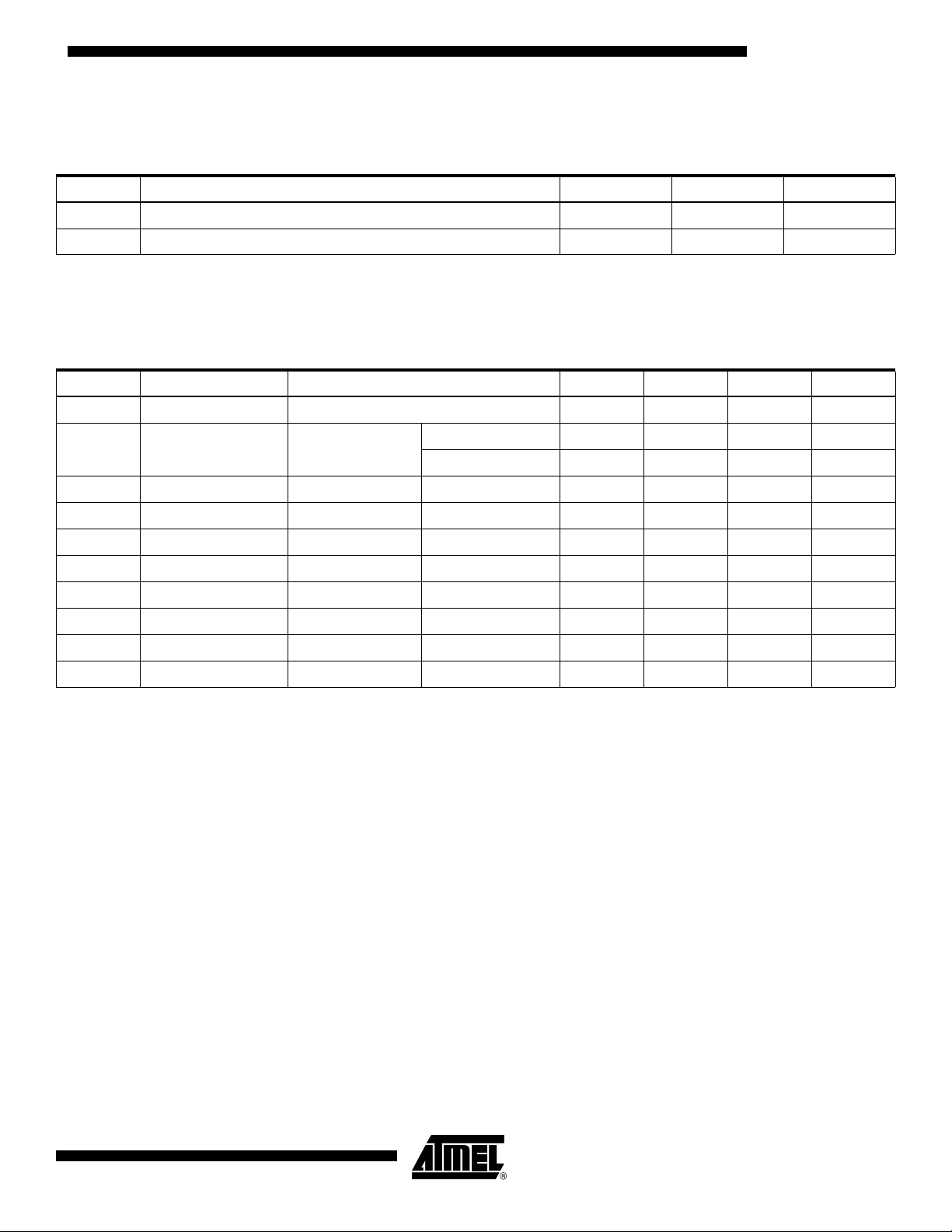

Table 2. Pin Capacitance

Applicable over recommended operating range from TA = 25°C, f = 1.0 MHz, VCC = +5.0V (unless otherwise noted)

Symbol Test Conditions Max Units Conditions

C

OUT

C

IN

Output Capacitance (DO) 5 pF V

Input Capacitance (CS, SK, DI) 5 pF VIN = 0V

Note: This parameter is characterized and is not 100% tested.

Table 3. DC Characteristics

OUT

= 0V

Applicable over recommended operating range from: T

= −40°C to +125°C, VCC = +2.7V to +5.5V,

A

(unless otherwise noted).

Symbol Parameter Test Condition Min Typ Max Unit

V

CC1

I

CC

I

SB1

I

SB2

I

IL

I

OL

(1)

V

IL1

(1)

V

IH1

V

OL1

V

OH1

Note: 1. VIL min and VIH max are reference only and are not tested.

Supply Voltage 2.7 5.5 V

Read at 1.0 MHz 0.5 2.0 mA

Supply Current VCC = 5.0V

Write at 1.0 MHz 0.5 2.0 mA

Standby Current VCC = 2.7V CS = 0V 6.0 10.0 µA

Standby Current VCC = 5.0V CS = 0V 10.0 15.0 µA

Input Leakage VIN = 0V to VCC 0.1 3.0 µA

Output Leakage VIN = 0V to VCC 0.1 3.0 µA

Input Low Voltage 2.7V ≤ VCC ≤ 5.5V −0.6 0.8 V

Input High Voltage 2.7V ≤ VCC ≤ 5.5V 2.0 VCC + 1 V

Output Low Voltage 2.7V ≤ VCC ≤ 5.5V IOL = 2.1 mA 0.4 V

Output High Voltage 2.7V ≤ VCC ≤ 5.5V IOH = −0.4 mA 2.4

5089B–SEEPR–2/07

3

Page 4

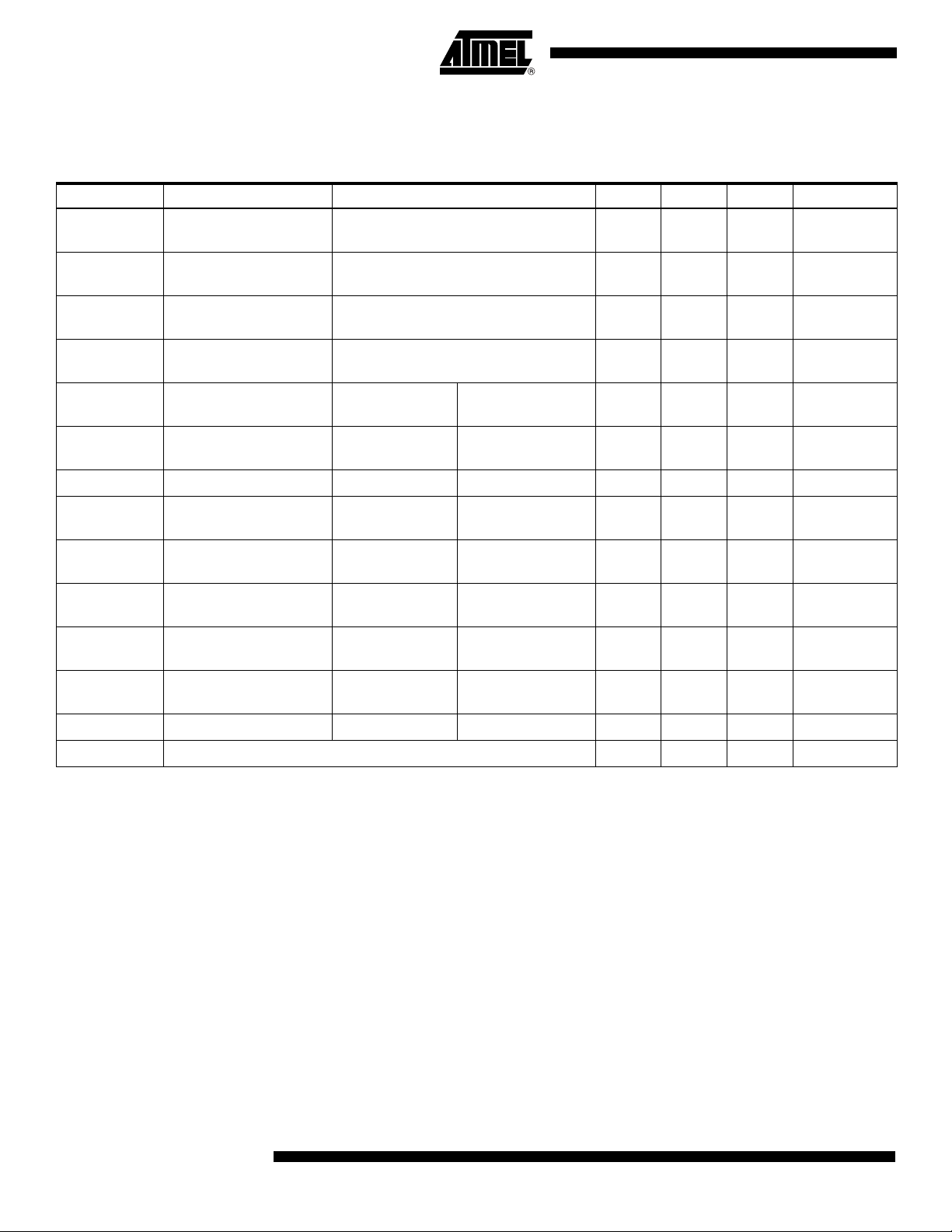

Table 4. AC Characteristics

Applicable over recommended operating range from T

= −40°C to + 125°C, VCC = As Specified, CL = 1 TTL Gate and

A

100 pF (unless otherwise noted)

Symbol Parameter Test Condition Min Typ Max Units

f

SK

t

SKH

t

SKL

t

CS

t

CSS

t

DIS

t

CSH

t

DIH

t

PD1

t

PD0

SK Clock Frequency

SK High Time

SK Low Time

Minimum CS Low Time

4.5V ≤ V

2.7V ≤ V

4.5V ≤ V

2.7V ≤ VCC ≤ 5.5V

4.5V ≤ V

2.7V ≤ VCC ≤ 5.5V

4.5V ≤ V

2.7V ≤ V

≤ 5.5V

CC

≤ 5.5V

CC

≤ 5.5V

CC

≤ 5.5V

CC

≤ 5.5V

CC

≤ 5.5V

CC

CS Setup Time Relative to SK

DI Setup Time Relative to SK

4.5V ≤ V

≤ 5.5V

CC

2.7V ≤ VCC ≤ 5.5V

4.5V ≤ V

≤ 5.5V

CC

2.7V ≤ VCC ≤ 5.5V

0

0

250

250

250

250

250

25

50

50

100

100

0

CS Hold Time Relative to SK 0 ns

DI Hold Time Relative to SK

Output Delay to “1” AC Test

Output Delay to “0” AC Test

4.5V ≤ V

2.7V ≤ VCC ≤ 5.5V

4.5V ≤ V

2.7V ≤ V

4.5V ≤ V

2.7V ≤ VCC ≤ 5.5V

≤ 5.5V

CC

≤ 5.5V

CC

≤ 5.5V

CC

≤ 5.5V

CC

100

100

2

1

250

500

250

500

MHz

ns

ns

ns

ns

ns

ns

ns

ns

t

SV

t

DF

t

WP

Endurance

CS to Status Valid AC Test

CS to DO in High

Impedance

AC Test

CS = V

IL

Write Cycle Time 2.7V ≤ VCC ≤ 5.5V 0.1 3 10 ms

(1)

5.0V, 25°C 1M Write Cycles

4.5V ≤ V

2.7V ≤ VCC ≤ 5.5V

4.5V ≤ VCC ≤ 5.5V

2.7V ≤ V

Note: 1. This parameter is characterized and is not 100% tested.

≤ 5.5V

CC

≤ 5.5V

CC

250

250

100

150

ns

ns

4

AT93C46A

5089B–SEEPR–2/07

Page 5

AT93C46A

Functional Description

The AT93C46A is accessed via a simple and versatile three-wire serial communication

interface. Device operation is controlled by seven instructions issued by the host processor. A valid instruction starts with a rising edge of CS and consists of a start bit (logic

“1”) followed by the appropriate op code and the desired memory address location.

Table 5. Instruction Set for the AT93C46A

Address

Instruction SB Op Code

READ 1 10 A

EWEN 1 00 11XXXX Write enable must precede all programming modes.

ERASE 1 11 A

WRITE 1 01 A

ERAL 1 00 10XXXX Erases all memory locations. Valid only at V

WRAL 1 00 01XXXX Writes all memory locations. Valid only at V

EWDS 1 00 00XXXX Disables all programming instructions.

− A

5

5

− A

5

− A

0

0

0

Commentsx 16

Reads data stored in memory, at specified address.

Erase memory location An − A0.

Writes memory location An − A0.

READ (READ): The Read (READ) instruction contains the address code for the memory location to be read. After the instruction and address are decoded, data from the

selected memory location is available at the serial output pin DO. Output data changes

are synchronized with the rising edges of serial clock SK. It should be noted that a

dummy bit (logic “0”) precedes the 16-bit data output string.

= 4.5V to 5.5V.

CC

= 4.5V to 5.5V.

CC

ERASE/WRITE ENABLE (EWEN): To assure data integrity, the part automatically goes

into the Erase/Write Disable (EWDS) state when power is first applied. An Erase/Write

Enable (EWEN) instruction must be executed first before any programming instructions

can be carried out. Please note that once in the EWEN state, programming remains

enabled until an EWDS instruction is executed or V

power is removed from the part.

CC

ERASE (ERASE): The Erase (ERASE) instruction programs all bits in the specified

memory location to the logical “1” state. The self-timed erase cycle starts once the

Erase instruction and address are decoded. The DO pin outputs the ready/busy status

of the part if CS is brought high after being kept low for a minimum of 250 ns (t

CS

). A

logic “1” at pin DO indicates that the selected memory location has been erased and the

part is ready for another instruction.

WRITE (WRITE): The Write (WRITE) instruction contains the 16 bits of data to be written into the specified memory location. The self-timed programming cycle, t

, starts

WP

after the last bit of data is received at serial data input pin DI. The DO pin outputs the

ready/busy status of the part if CS is brought high after being kept low for a minimum of

250 ns (t

). A logic “0” at DO indicates that programming is still in progress. A logic “1”

CS

indicates that the memory location at the specified address has been written with the

data pattern contained in the instruction and the part is ready for further instructions. A

ready/busy status cannot be obtained if the CS is brought high after the end of the selftimed programming cycle, t

WP

.

ERASE ALL (ERAL): The Erase All (ERAL) instruction programs every bit in the memory array to the logic “1” state and is primarily used for testing purposes. The DO pin

outputs the READY/BUSY status of the part if CS is brought high after being kept low for

a minimum of 250 ns (t

). The ERAL instruction is valid only at VCC = 5.0V ± 10%.

CS

WRITE ALL (WRAL): The Write All (WRAL) instruction programs all memory locations

with the data patterns specified in the instruction. The DO pin outputs the READY/BUSY

5089B–SEEPR–2/07

5

Page 6

status of the part if CS is brought high after being kept low for a minimum of 250 ns (tCS).

The WRAL instruction is valid only at V

ERASE/WRITE DISABLE (EWDS): To protect against accidental data disturb, the

Erase/Write Disable (EWDS) instruction disables all programming modes and should be

executed after all programming operations. The operation of the READ instruction is

independent of both the EWEN and EWDS instructions and can be executed at any

time.

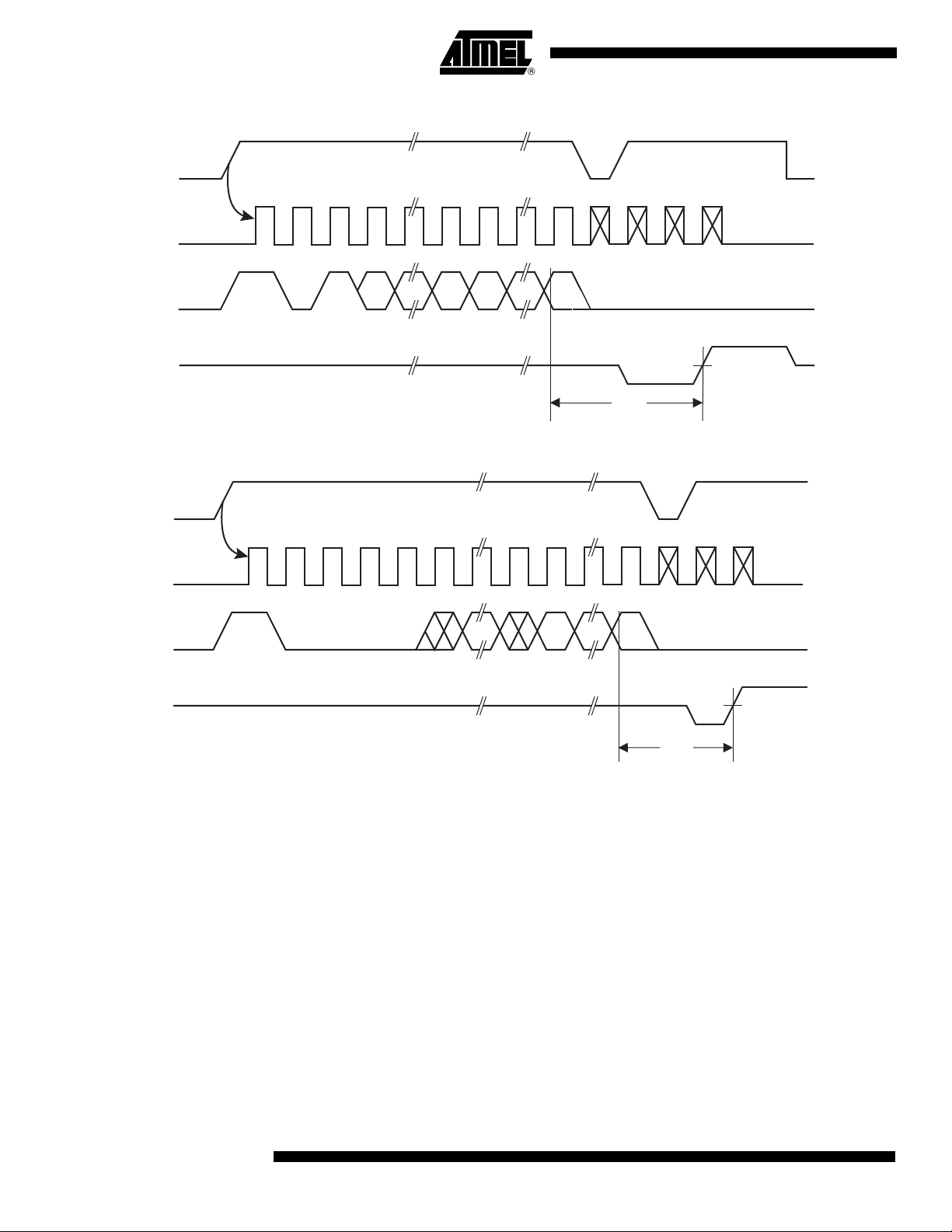

Timing Diagrams

Figure 2. Synchronous Data Timing

= 5.0V ± 10%.

CC

μ

Note: 1. This is the minimum SK period.

Table 6 . Organization Key for Timing Diagrams

I/O

A

D

AT93C46A

x 16

N

N

A

5

D

15

6

AT93C46A

5089B–SEEPR–2/07

Page 7

Figure 3. READ Timing

High Impedance

t

CS

CS

t

CS

SK

DI 1 0

000

...

Figure 4. EWEN Timing

CS

(1)

AT93C46A

t

CS

SK

DI

Note: 1. Requires a minimum of nine clock cycles.

Figure 5. EWDS Timing

Note: 1. Requires a minimum of nine clock cycles.

(1)

001

11

...

5089B–SEEPR–2/07

7

Page 8

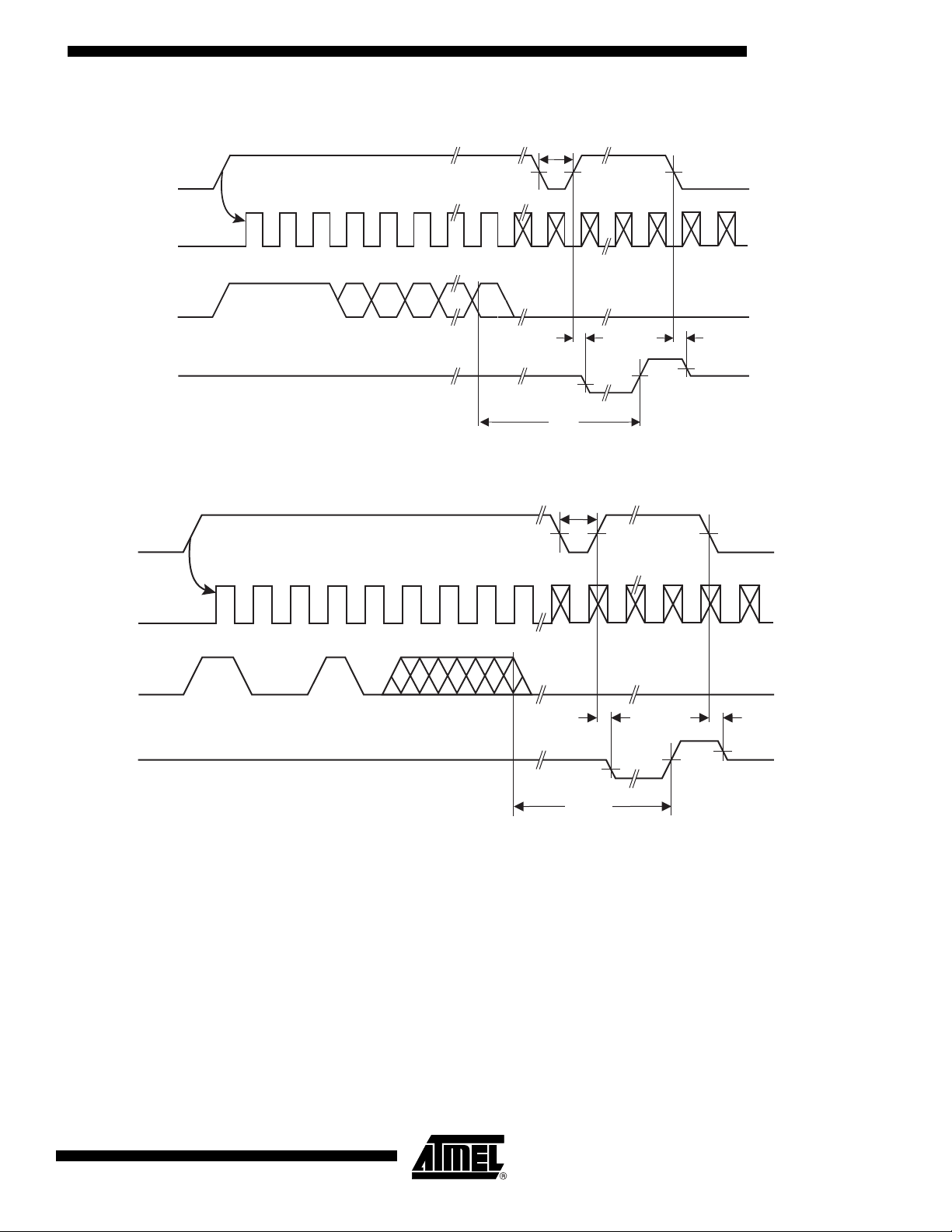

Figure 6. WRITE Timing

SK

CS

t

CS

t

WP

11

A

N

D

N

0A0D0

... ...

DI

DO

HIGH IMPEDANCE

BUSY

READY

Figure 7. WRAL Timing

(1,2)

CS

SK

DI

DO

Notes: 1. Valid only at VCC = 4.5V to 5.5V.

2. Requires a minimum of nine clock cycles.

HIGH IMPEDANCE

1 0 0 1 ... D

t

CS

... D00

N

BUSY

READY

t

WP

8

AT93C46A

5089B–SEEPR–2/07

Page 9

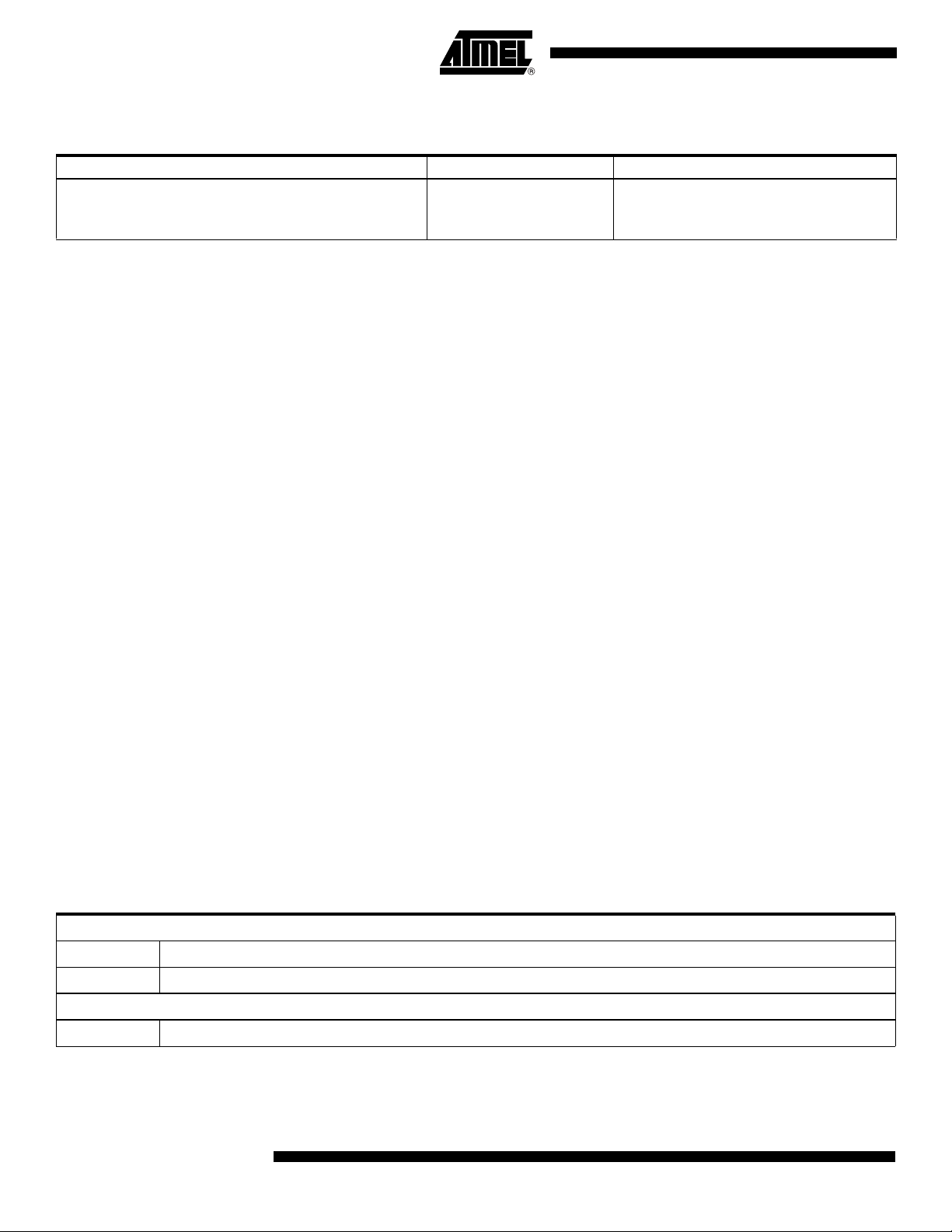

Figure 8. ERASE Timing

SK

1 1 ...1

CS

DI A

N

t

CS

t

SV

t

DF

t

WP

A

N-1AN-2

A0

CHECK

STATUS

STANDBY

READY

BUSY

DO

HIGH IMPEDANCE

HIGH IMPEDANCE

SK

CS

DI 1 1000

DO

HIGH IMPEDANCE

HIGH IMPEDANCE

READY

BUSY

CHECK

STATUS

STANDBY

t

WP

t

CS

t

SV

t

DF

Figure 9. ERAL Timing

(1)

AT93C46A

Note: 1. Valid only at VCC = 4.5V to 5.5V.

5089B–SEEPR–2/07

9

Page 10

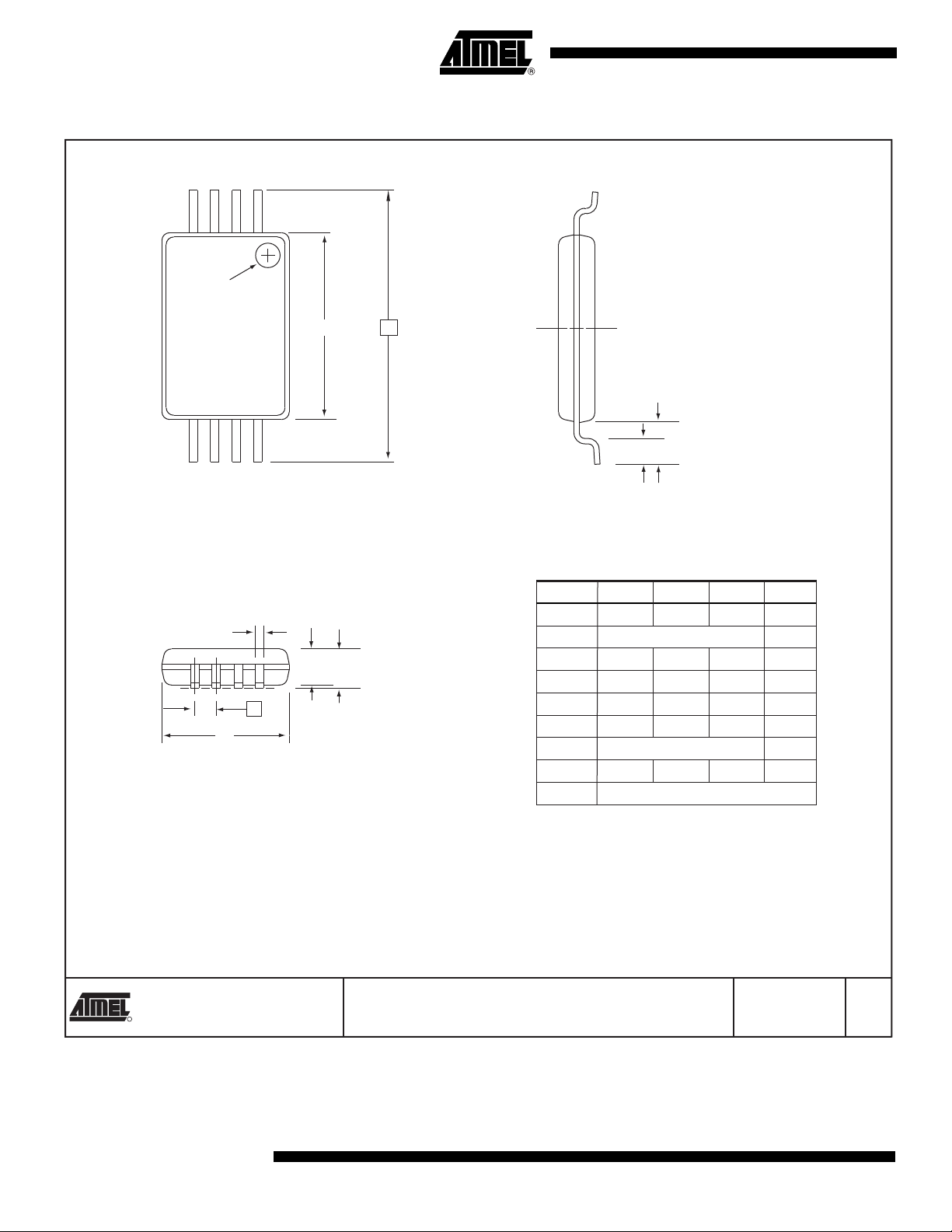

Ordering Information

Ordering Code Package Operation Range

AT93C46A-10SQ-2.7

AT93C46A-10TQ-2.7

8S1

8A2

Lead-free/Halogen-free/

ded Temperature

Exten

(−40°C to

125°C)

Package Type

8S1 8-lead, 0.150" Wide, Plastic Gull Wing Small Outline (JEDEC SOIC)

8A2 8-lead, 0.170" Wide, Thin Shrink Small Outline Package (TSSOP)

Options

−2.7 Low Voltage (2.7V to 5.5V)

10

AT93C46A

5089B–SEEPR–2/07

Page 11

Packaging Information

1150 E. Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906

TITLE

DRAWING NO.

R

REV.

Note:

10/7/03

8S1, 8-lead (0.150" Wide Body), Plastic Gull Wing

Small Outline (JEDEC SOIC)

8S1 B

COMMON DIMENSIONS

(Unit of Measure = mm)

SYMBOL

MIN

NOM

MAX

NOTE

A1 0.10 – 0.25

These drawings are for general information only. Refer to JEDEC Drawing MS-012, Variation AA for proper dimensions, tolerances, datums, etc.

A 1.35 – 1.75

b 0.31 – 0.51

C 0.17 – 0.25

D 4.80 – 5.00

E1 3.81 – 3.99

E 5.79 – 6.20

e 1.27 BSC

L 0.40 – 1.27

∅ 0˚ – 8˚

∅

Top View

End View

Side View

e

B

D

A

A1

N

E

1

C

E1

L

8S1 – JEDEC SOIC

AT93C46A

5089B–SEEPR–2/07

11

Page 12

8A2 –TSSOP

2325 Orchard Parkway

San Jose, CA 95131

TITLE

DRAWING NO.

R

REV.

5/30/02

COMMON DIMENSIONS

(Unit of Measure = mm)

SYMBOL

MIN

NOM

MAX

NOTE

D 2.90 3.00 3.10 2, 5

E 6.40 BSC

E1 4.30 4.40 4.50 3, 5

A – – 1.20

A2 0.80 1.00 1.05

b 0.19 – 0.30 4

e 0.65 BSC

L 0.45 0.60 0.75

L1 1.00 REF

8A2, 8-lead, 4.4 mm Body, Plastic

Thin Shrink Small Outline Package (TSSOP)

Notes: 1. This drawing is for general information only. Refer to JEDEC Drawing MO-153, Variation AA, for proper dimensions, tolerances,

datums, etc.

2. Dimension D does not include mold Flash, protrusions or gate burrs. Mold Flash, protrusions and gate burrs shall not exceed

0.15 mm (0.006 in) per side.

3. Dimension E1 does not include inter-lead Flash or protrusions. Inter-lead Flash and protrusions shall not exceed 0.25 mm

(0.010 in) per side.

4. Dimension b does not include Dambar protrusion. Allowable Dambar protrusion shall be 0.08 mm total in excess of the

b dimension at maximum material condition. Dambar cannot be located on the lower radius of the foot. Minimum space between

protrusion and adjacent lead is 0.07 mm.

5. Dimension D and E1 to be determined at Datum Plane H.

8A2

B

Side View

End View

Top View

A2

A

L

L1

D

123

E1

N

b

Pin 1 indicator

this corner

E

e

12

AT93C46A

5089B–SEEPR–2/07

Page 13

Revision History

AT93C46A

Doc. Rev. Date Comments

5089B 1/2007 Implemented revision history

Removed PDIP package offering

Removed Pb’d parts

5089B–SEEPR–2/07

13

Loading...

Loading...