Page 1

AT89STK-11 Starter Kit

..............................................................................................

Hardware User Guide

Page 2

Table of Contents

Section 1

Introduction ........................................................................................... 1-1

1.1 Features ....................................................................................................1-1

1.2 Supported Devices....................................................................................1-2

Section 2

Hardware Description ........................................................................... 2-4

2.1 Board Overview.........................................................................................2-4

2.2 Block Diagram...........................................................................................2-5

2.3 Power Supply ............................................................................................2-5

2.4 Reset.........................................................................................................2-6

2.5 Features ....................................................................................................2-7

2.6 Interfaces ..................................................................................................2-7

2.7 Board Settings ..........................................................................................2-9

Section 3

ISP Programming ............................................................................... 3-12

3.1 Manual ISP Mode ...................................................................................3-12

3.2 Auto ISP Mode ........................................................................................3-12

3.3 FLIP Software .........................................................................................3-13

3.4 Batchisp Software ...................................................................................3-13

Section 4

Appendix A: Board Layout .................................................................. 4-14

Appendix B: Bill of Materials ............................................................... 4-15

4.1 Bill of Materials Table..............................................................................4-15

Appendix C: Board Schematics .......................................................... 4-17

Appendix D: References/Acronyms .................................................... 4-22

4.2 References..............................................................................................4-22

4.3 Acronyms ................................................................................................4-22

AT89STK-11 Hardware User Guide 1

7676B–8051–08/07

Page 3

Section 1

Introduction

This document describes the AT89STK-11 board dedicated to the standard C51 microcontrollers with in-system programming.

All of the microcontroller I/Os are made available in an expansion area with prototyping

facilities.

1.1 Features

Stand-alone Board

In-System Programmable (ISP) including ‘Auto ISP’ feature

On-board Voltage Regulator

Microcontroler on its sockets

– PLCC44-pin package

On-board 3V or 5V power supply circuitry

– from an external power connector

– from an external battery

On-board RESET

Leds : Power, ALE, RS232 Rx and Tx

External MCU clock connector

External PCA clock connector

TWI, SPI and RS232 connectors

INT0 & INT1 Push-button

Expansion area with prototyping facilities

Commercial Temperature Range: 0 to +70°C Operating Temperature

Dimension: 95 mm x 120 mm

AT89STK-11 Hardware User Guide 1-1

7676B–8051–08/07

Page 4

Introduction

1.2 Supported Devices

AT89C51RE2

AT89C51RB2

AT89C51RC2/IC2

AT89C51RD2/ID2/ED2

AT89STK-11 Hardware User Guide 1-2

7676B–8051–08/07

Page 5

Section 2

Hardware Description

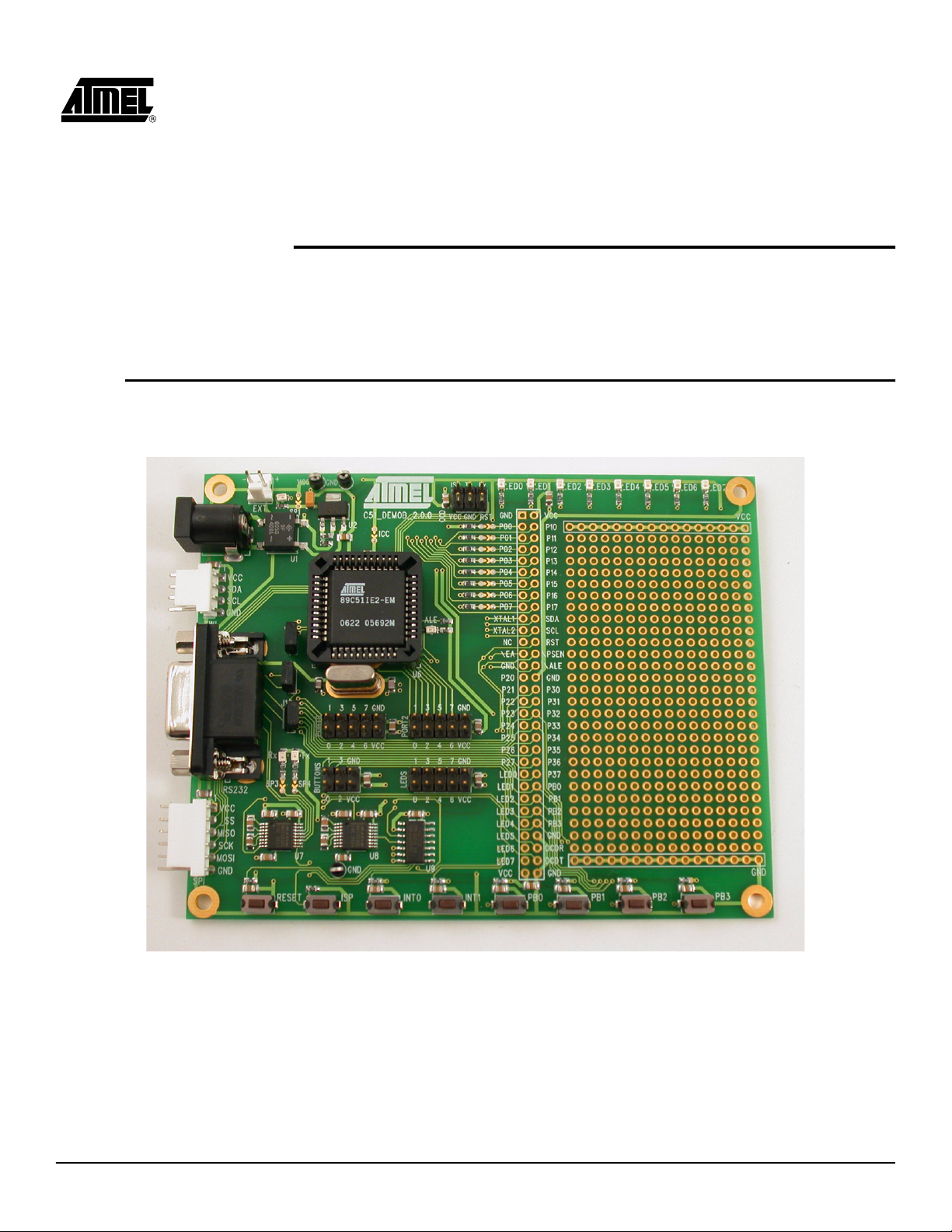

2.1 Board Overview

Figure 2-1 shows the AT89STK-11 board.

Figure 2-1. AT89STK-11

This photo is not contractual and may be modified without notification by Atmel.

AT89STK-11 Hardware User Guide 2-4

7676B–8051–08/07

Page 6

Hardware Description

Power Supply

Full UART

External

Power

PC Host

C51

P2

P3

EA

RST

ISP

Expansion

TWI

P0

P1

SPI

INT0

Leds:

PWR

ALE

16MHz

Quartz

PLCC44

3V or 5V

INT1

Area

User LEDs User Push Buttons

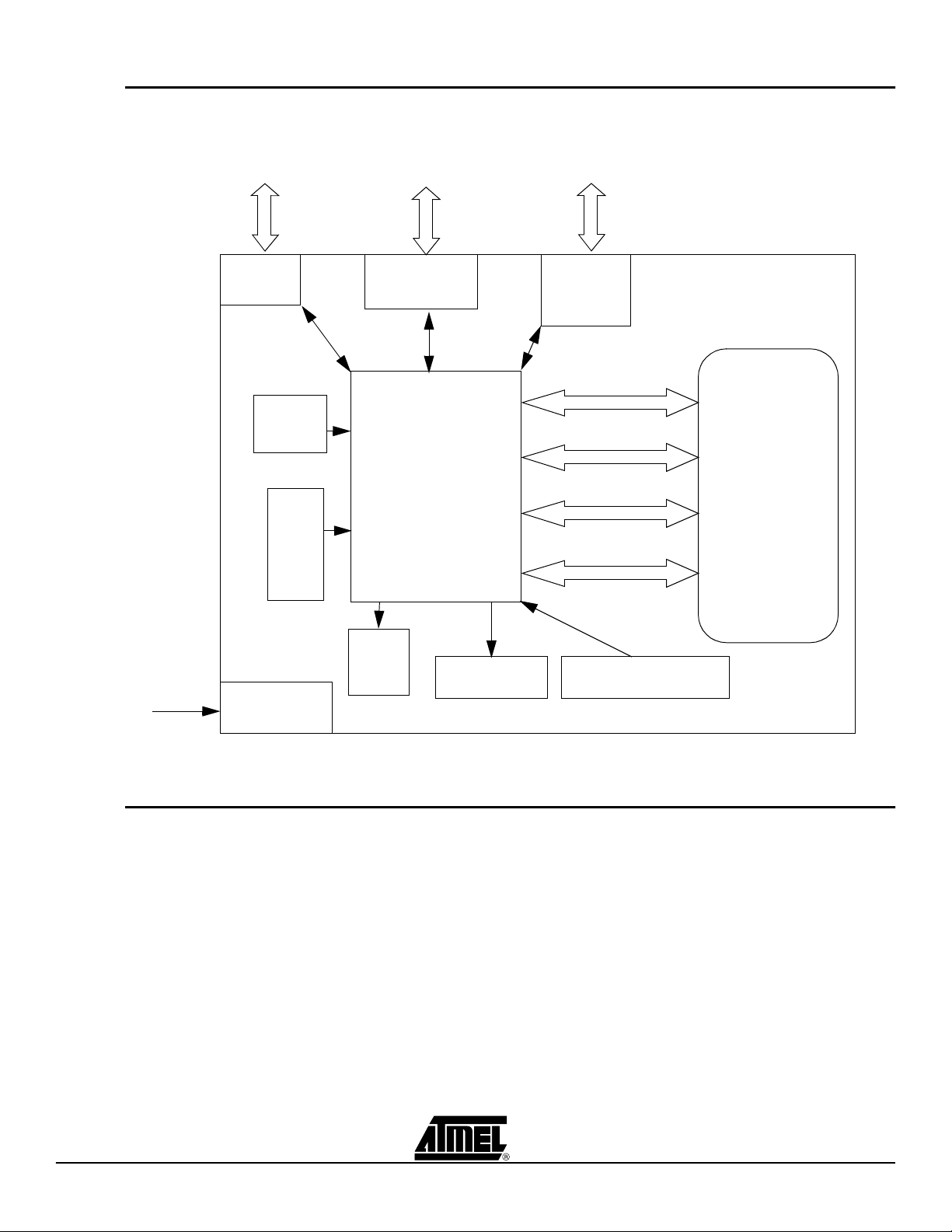

2.2 Block Diagram

Figure 2-2. Block Diagram of AT89STK-11

Figure 2-2 shows the functional block diagram of the AT89STK-11, with the I/O usage.

2.3 Power Supply

2.3.1 Power Supply Sources

2.3.1.1 JACK PWR Connector

The on-board power supply circuitry allows various power supply configurations. This

gives the user the capability to power the devices in the 3V and in the 5V voltage range.

The power supply source can come from two different and exclusive sources:

either from the JACK PWR connector

either from the 2-point sip EXT connector.

The Jack power connector implemented on board is a female Jack connector with internal 2.1mm conductor. It requires a male JACK outlet with 2.1mm capability.

No specific polarization is mandatory as on-board diode rectifier gives a protection

against inadvertent polarization invertion.

When using the JACK power supply, the board is powered with a 5V voltage.

2-5 AT89STK-11 Hardware User Guide

7676B–8051–08/07

Page 7

Hardware Description

Figure 2-3. Male JACK Outlet and Wires

Note: Do not mount more than one power supply source on AT89STK-11 Board.

Note: There is a diode voltage level between the negative output of the power supply

and the “GND”. This could introduce some voltage gap during measurement

and instrumentation.

2.3.1.2 External EXT connector

The battery power connector implemented on board is a male two point SIP connector.

It requires an external power cable with a female 2 points connector.

When powered though this interface, polarization is mandatory as no protection is given

on board.

The EXT power supply circuitry support input supply from 2.7V up to 5.5V DC.

Figure 2-4. EXT PWR Female Connector / Cable

Note: Do not mount more than one power supply source on board.

Note: Keep SP1 closed when using the EXT input

2.4 Reset

To be compatible with Atmel microcontrollers which have (or not) its on-chip RESET circuitry (c.f.microcontroller datasheet), the board provides a RESET signal witch can

come from 2 different sources:

2.4.1 Power-on RESET The on-board RC network acts as power-on RESET.

2.4.2 RESET Push Button By pressing the RESET push button on the board, a warm RESET of the microcontroller

is performed.

AT89STK-11 Hardware User Guide 2-6

7676B–8051–08/07

Page 8

Hardware Description

2.5 Features

This section presents the various features such as leds, buttons, etc... available on the

board.

2.5.1 Push-Buttons RESET can be used to apply warm reset to the MCU

ISP can be used with RESET to apply hardware conditions resulting in bootloader

start

INT0 push-button can be used to activate INT0 input

INT1 push-button can be used to activate INT1 input

2.5.2 User Push buttons PB0, PB1, PB2 and PB3 are four push-buttons available for user application

They are made available on a 6 pins socket and in the expansion area so user can use

them according to the application needs.

2.5.3 Indicator LEDs PWR led is driven by input of voltage regulator

Rx led is connected to Rx of UART MCU (SP3 jumper can be soldered or not)

Tx led is connected to Tx of UART MCU (SP4 jumper can be soldered or not)

ALE led is connected to ALE of MCU

2.5.4 User LEDs LED0, LED1, ... LED7 are height leds available for user application

They are made available on a 10 pins socket and in the expansion area so user can use

them according to its application needs.

2.5.5 Ports Port 0 and Port 2 are made available on two 10 pins sockets to ease user interconnec-

tion to the MCU.

The are also available on the expansion area.

2.5.6 Clocks An external clock can be connected to the board to control externally XTAL1 input clock

of MCU by using the XTAL1 from the expansion area.

In the same way, another external clock can be connected to control externally the PCA

clock (P1.2/ECI).

2.6 Interfaces

2.6.1 TWI The TWI connector is controlled by hardware TWI I/O of MCU (for Product including this

feature). The signals sda and scl are controlled by the TWI ports of MCU.

This TWI bus is also connected to the expansion area.

External TWI pull-ups are not provided on the AT89STK-11.

2.6.2 SPI The SPI connector is directly connected to SPI I/O of the MCU.

2.6.3 RS-232 The DB9 connector is connected to on-chip UART peripheral through a standard RS232

driver/receiver. Two leds are provided to indicate activity on Rx and Tx lines (They can

be disconnected removing solder pad SP3 and SP4).

2.6.4 OCD The On-Chip Debug interface (OCD) is provided on a 6-pin connector.

2-7 AT89STK-11 Hardware User Guide

7676B–8051–08/07

Page 9

Hardware Description

This interface enables the debug of the application through ATMEL OCD dongle for

AT89C51RE2/IE2/RD3/IE3 only.

2.6.5 Expansion Area In addition to a 16x29 pad array, two rows of pads are given on the right side of the

board to offer all the MCU signals tu user application. Any application expansion can be

built on board through this interface.

2.7 Board Settings

The C51 Demo Board has the following settings:

Jumpers

Solder straps

Test points

2.7.1 Jumpers The following table provides an overview of the jumpers, the solder straps and their

default configuration.

Table 2-1. Jumpers and Switches Overview

Reference PCB Label Function Default

Jumper J11 J11 RTS of RS232 OFF

Jumper J12 J12 DTR of RS232 OFF

Jumper J13 J13 OFF

Figure 2-5. Jumper Setting Definition

2.7.2 Solder Straps Solder straps allow to modify the board configuration for specific usage.

Table 2-2. Solder Straps Overview

Reference PCB Label Function Default

Solder strap SP1 SP1 External Power Supply Isolation Soldered

Solder strap SP2 ICC Consumption measurement Soldered

Solder strap SP3 SP3 Rx Led Soldered

Solder strap SP4 SP4 Tx Led Soldered

AT89STK-11 Hardware User Guide 2-8

7676B–8051–08/07

Page 10

Hardware Description

2.7.3 Test Points

Figure 2-6. Solder Strap Definition

Test points are used to check the internal power supply of the microcontroller.

Table 2-3. Table of Test Points

Reference PCB Label Function

TP1 VCC

TP2,TP3 GND Test point for GND

Test point for Vcc

2-9 AT89STK-11 Hardware User Guide

7676B–8051–08/07

Page 11

Section 3

ISP Programming

The On-Chip memories and configuration bytes can be programmed using the ISP

mode of the device and Atmel's FLexible In-system Programmer Software (FLIP)

described below.

3.1 Manual ISP Mode See Section “FLIP Software”, page 11.

3.1.1 Board Configuration To use ISP mode, no specific configuration is necessary on the board. Only make sure

that the EA pin of the product is tied to Vcc (internal code execution only).

3.1.2 Operating Mode To enter in ISP mode, press both the RESET and ISP buttons simultaneously.

First release the RESET button and then the ISP button. The device enters in

ISP mode.

3.2 Auto ISP Mode

3.2.1 Board Configuration To use Auto ISP mode, put the board in the same configuration as ISP mode and also:

AT89STK-11 Hardware User Guide 3-10

It allows the host PC application (Atmel Flip software for example) to control the hardware conditions from the serial lines RTS and DTR.

Thus with the Auto ISP mode, the user does not need to push the ISP and RESET

buttons.

Close RTS (J11) jumper

Close DTR (J12) jumper

7676B–8051–08/07

Page 12

ISP Programming

3.3 FLIP Software

3.4 Batchisp Software

FLIP software runs on Windows® and Linux® Operating Systems. FLIP supports in-system programming of Flash C51 devices through RS232. The latest version of FLIP

software can be downloaded from the Atmel web site, www.atmel.com.

Batchisp is an In-System Programming application which can perform the same operations as FLIP but is designed to be launched from the DOS command window.

The main purpose of batchisp is to automate ISP operations on several parts. It may

also be launched from an IDE like Keil's uVision®2 one : you can compile and link your

embedded program, generate the HEX file and download it to the target hardware without leaving the Keil's IDE. This makes embedded software development and test faster.

Autoisp function is an operation which allows to enter in ISP mode without any hardware

handling.This is done thanks to DTR and RTS RS232 signals which can control on the

Board the RST and PSEN I/O of MCU.

3-11 AT89STK-11 Hardware User Guide

7676B–8051–08/07

Page 13

Figure 4-1. Board Components View Diagram

Section 4

Appendix A: Board Layout

AT89STK-11 Hardware User Guide 4-12

7676B–8051–08/07

Page 14

Appendix B: Bill of Materials

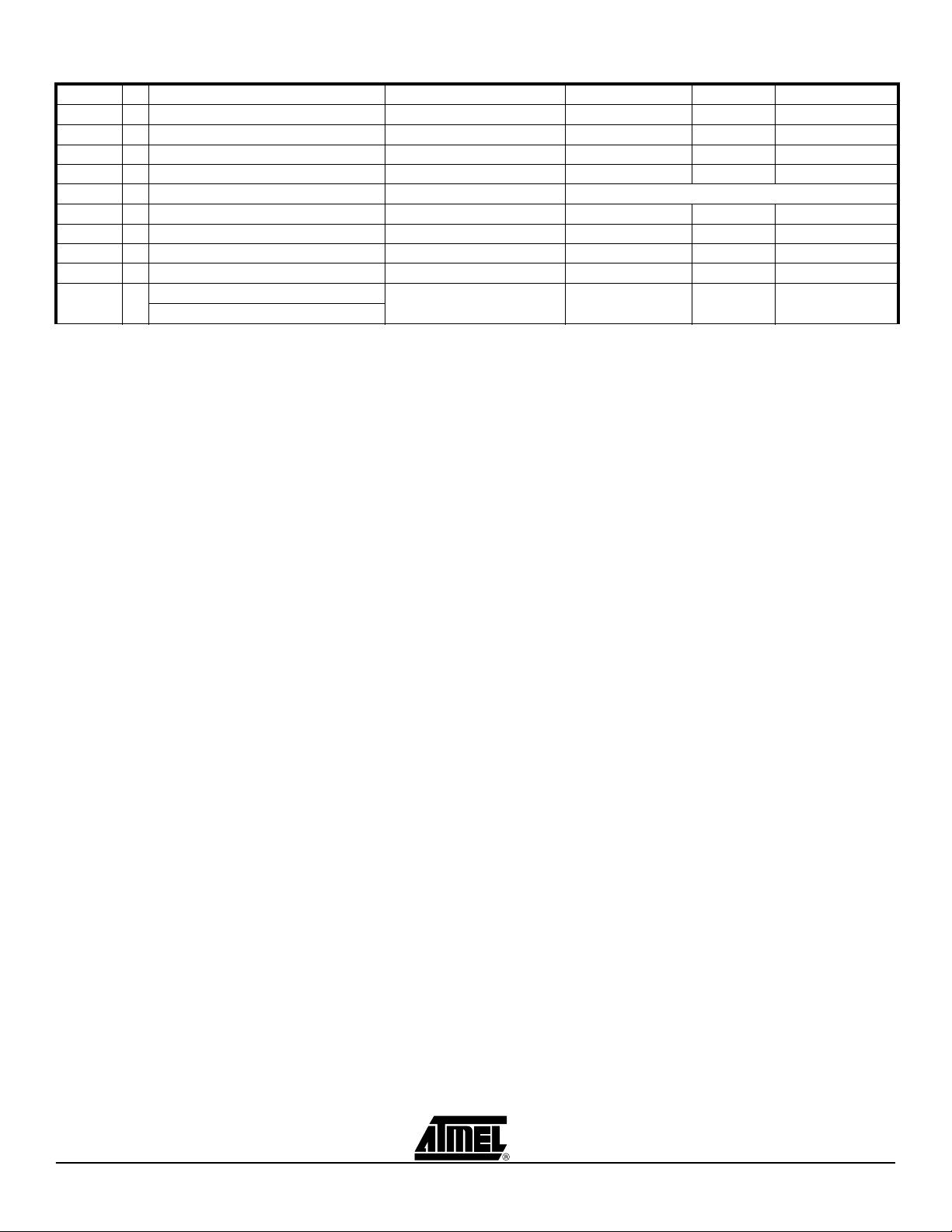

4.1 Bill of Materials Table

Item Q.ty Reference Part Tech. Caracteristics Package Manufacturer

1

2 1 C1 1µF 10Vmin ±10% Case A AVX

3 2 C14,C15 22pF 10Vmin ±10%

4 1 D1 Red Led I=10 mA Agilent

5 11 D2,D3,D4,D5,D6,D7,D8,D9,

6 1 J1 SIP2 SOCKET . Pitch 2.54mm Molex

7 1 J2 CONNECTOR JACK PWR Int.Diam=2.1mm

8 1 J3 HEADER 31x2/SM

9 2 J4,J8 HEADER 3X2 BARRETTE SECABLE Pitch 2.54mm Tyco Elec. / AMP

10 3 J5,J6,J10 HEADER 5X2 BARRETTE SECABLE Pitch 2.54mm Tyco Elec. / AMP

11 1 J7 CONNECTOR SIP6 RA . . .

12 1 J9 SIP4 . . .

13 3 J11,J12,J13 JUMPER Pitch 2.54mm Tyco™ Elec. / AMP

13bis 3 JUMPER shunt Pitch 2.54mm Arwin

14 1 P1 SUB-D9 FEMALE 90° with harpoons Tyco Elec. / AMP

15 1 R1 270 1/16W-5% SMD Case 0603 Multicomp

16

17 1 R3 820 1/16W-5% SMD Case 0603 Multicomp

18 8 R4,R6,R8,R9,R10,R11,R12,

19 4

20 8 SW1,SW2,SW3,SW4,SW5,SW6,

CD1,CD2,C2,CD3,C3,C4,

CD5,C5,CD6,C6,CD7,C7,C8,

29

C9,C10,C11,C12,C13,C16,

C17,C18,C19,C20,C21,C22,

C23,C24,C25,C26

D10,D11,D12

R2,R5,R14,R15,R16,R17,

14

R24

R13

SP1,SP2,SP3,SP4,SP5, SP6,

SP7, SP8, SP9, SP10, SP11,

SP12

SW7,SW8

100n 50V-10% Ceramic CASE 0805 PHYCOMP

EIA/IECQ

3216

Green Led I=10 mA Agilent

Int. Diam.

2.1mm

1K 0.06W, 5% Case 0603 MulticompR18,R19,R20,R21,R22,R23,

10k 0.06W, 5% Case 0603 Multicomp

SolderPad

PUSH-BUTTON SMD, rectangular See DS ITT Canon

PHYCOMP

®

®

®

Cliff

®

AT89STK-11 Hardware User Guide 4-13

7676B–8051–08/07

Page 15

Appendix B: Bill of Materials

Item Q.ty Reference Part Tech. Caracteristics Package Manufacturer

21 3 TP1,TP2,TP3 TEST POINT Through Hole Pad Hole 1.1mm Vero

22 1 U1 DF005S TO269AA Vishay

23 1 U2 LM317 SOT-223 National

25 1 U6 AT8xC51_PLCC44 Socket

25bis 1 U6 AT8xC51_PLCC44

26 2 U7,U8 SIPEX-SP3232ECA Ref=SP3232ECA SSOP16 Maxim

27 1 U9 74HC125/SO SOIC texas

28 1 Y1 CRYSTAL HC49 . .

28bis 2 Y1 CRYSTAL tulip . .

29 8

R100, R101, R102, R103,

R104, R105, R106, R107

4,7K 0.06W, 5% Case 0603 Multicomp

®

®

®

AT89STK-11 Hardware User Guide 4-14

7676B–8051–08/07

Page 16

Appendix C: Board Schematics

AT89STK-11 Hardware User Guide 4-15

7676B–8051–08/07

Page 17

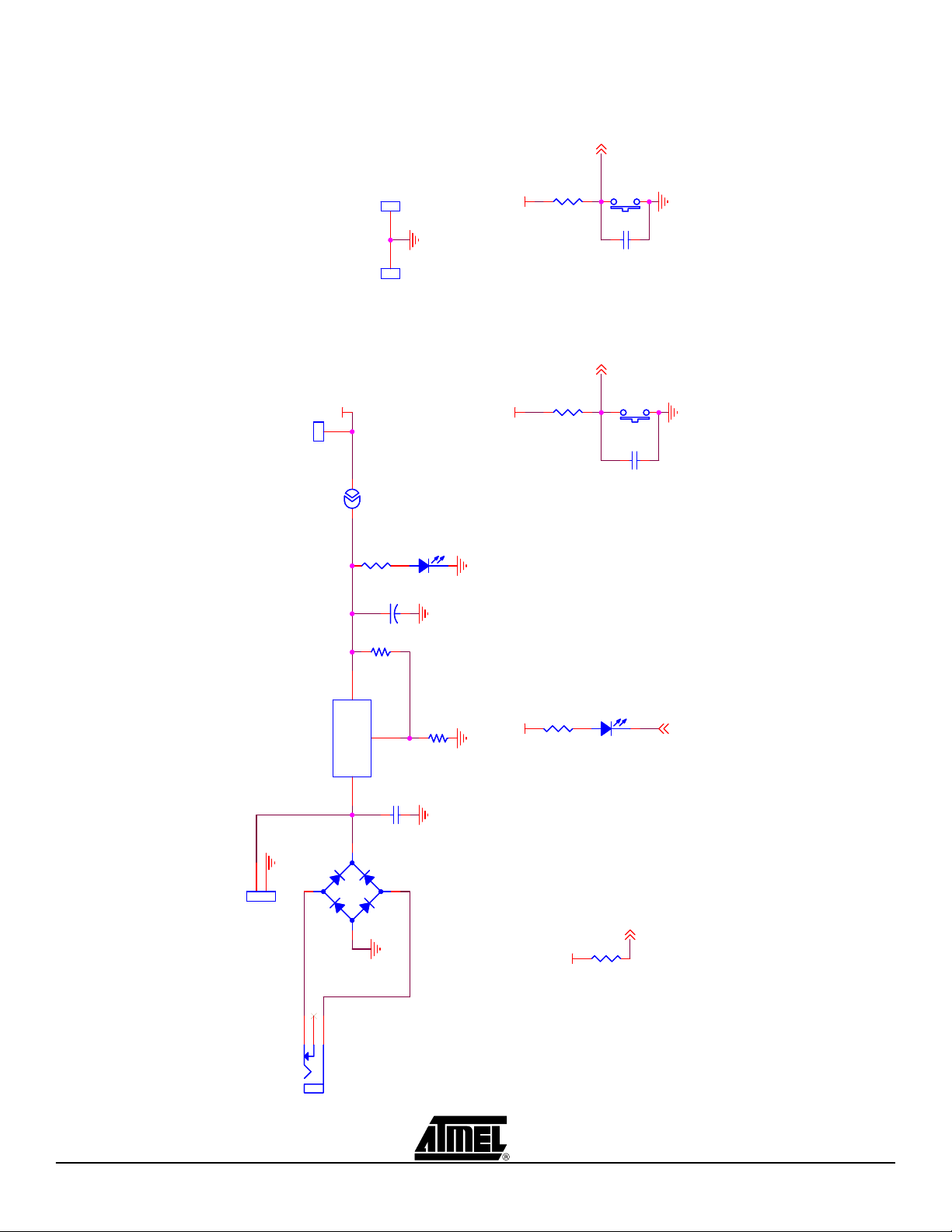

Figure 4-2. AT89STK-11 Schematics (1 of 4)

P3.3/INT1P3.2/INT0

Vcc

Vcc

Vcc

Vcc

Vcc

/EA

P3_2/INT0

/ALE

P3_3/INT1

Default State : Closed

R21KR2

1K

CD5

100n

CD5

100n

R3

820R3820

R8

10KR810K

Vin Vout

ADJ

U2

LM317EMP/SOT223

SOT223

U2

LM317EMP/SOT223

SOT223

R4

10KR410K

1

TP1 Vcc TPTP1 Vcc TP

D2

ALED2ALE

1

TP3TP3

1

2

J1

SIP2 SOCKET

Alternate Power Supply

J1

SIP2 SOCKET

Alternate Power Supply

1

3

2

4

- +

U1

DF005S

- +

U1

DF005S

1

TP2

GND TP

TP2

GND TP

SW3

INT1

SW3

INT1

SW2

INT0

SW2

INT0

CD3

100n

CD3

100n

SP1SP1

R9

10KR910K

D1

PowerD1Power

R1

270R1270

R51KR5

1K

CD1

100n

CD1

100n

321

J2

CONNECTOR JACK PWR

Power Supply

J2

CONNECTOR JACK PWR

Power Supply

C1

1µFC11µF

Appendix C: Board Schematics

AT89STK-11 Hardware User Guide 4-16

7676B–8051–08/07

Page 18

Appendix C: Board Schematics

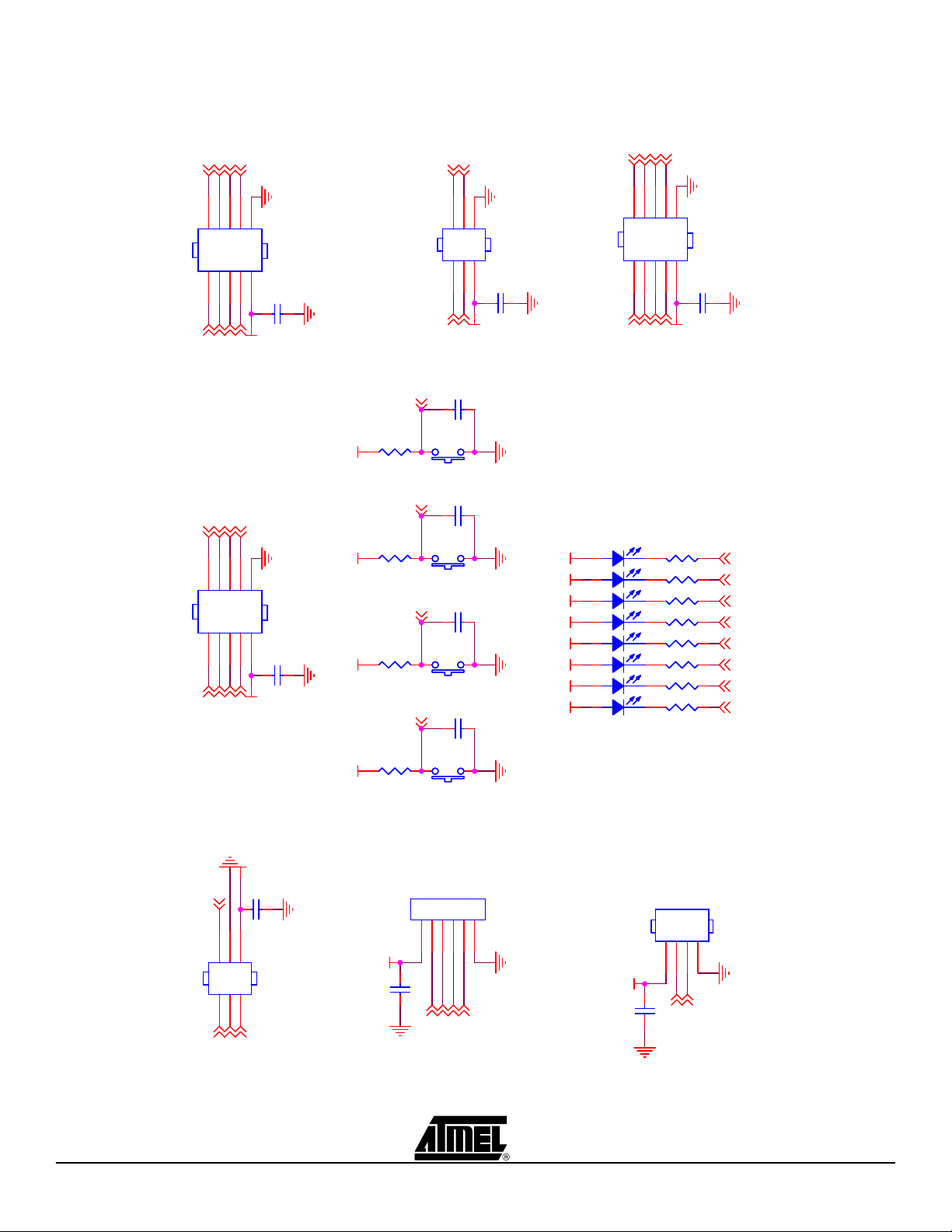

Vss

Vcc

Vcc

Vcc

Vcc Vcc

Vcc Vcc Vcc Vcc Vcc Vcc Vcc Vcc

Vcc Vcc Vcc Vcc

Vcc

Vcc

Vcc

P1.1/T2EX/SS

P1.5/CEX2/MISO

P1.7/CEX4/MOSI

P1.6/CEX3/SCK

P0_0

P0_2

P0_4

P0_6

P0_1

P0_3

P0_5

P0_7P2_6

P2_0

P2_2

P2_4

P2_1

P2_3

P2_5

P2_7

LED_0

LED_1

LED_2

LED_3

LED_4

LED_5

LED_6

LED_7

PB_0 PB_1 PB_2 PB_3

LED_6

LED_1

LED_3

LED_5

LED_7

LED_0

LED_2

LED_4

PB_2

PB_0 PB_1

PB_3

TWI_hard_scl

TWI_hard_sda

OCD_Rx

OCD_Tx

/PSEN

RST

Port P0 Port P2

LEDs

Buttons

OCD

TWI

C11 100nC11 100n

R191KR19

1K

R10

10k

R10

10k

C5 100nC5 100n

D6D6

246810

13579

J5

HEADER 5X2

J5

HEADER 5X2

C6

100nC6100n

246

135

J4

HEADER 3X2

J4

HEADER 3X2

R201KR20

1K

D3D3

C2

100nC2100n

D7D7 D10D10

SW7SW7

R211KR21

1K

246810

13579

J10

HEADER 5X2

J10

HEADER 5X2

D5D5

R161KR16

1K

R151KR15

1K

246810

13579

J6

HEADER 5X2

J6

HEADER 5X2

R141KR14

1K

C9

100nC9100n

R13

10k

R13

10k

SW6SW6

C7

100nC7100n

SW5SW5

123

4

J9

SIP4J9SIP4

C8

100nC8100n

C10

100n

C10

100n

D9D9

C4

100nC4100n

D8D8

C3

100nC3100n

C12

100n

C12

100n

246

135

J8

HEADER 3X2

J8

HEADER 3X2

R11

10k

R11

10k

R181KR18

1K

R171KR17

1K

SW4SW4

R12

10k

R12

10k

12345

6

J7

SPI Male

J7

SPI Male

D4D4

Figure 4-3. AT89STK-11 Schematics (2 of 4)

4-17 AT89STK-11 Hardware User Guide

7676B–8051–08/07

Page 19

Figure 4-4. AT89STK-11 Schematics (3 of 4)

XTAL2

XTAL1

VccVcc_cpu

Vcc_cpuVcc

Vcc

Vcc

P0_0

P0_1

P0_2

P0_3

P0_4

P0_5

P0_6

P0_7

P1.0/T2

P1.1/T2EX/SS

P1.2/ECI

P1.3/CEX0

P1.4/CEX1

P1.6/CEX3/SCK

P1.7/CEX4/MOSI

P2_0

P2_1

P2_2

P2_3

P2_4

P2_5

P2_6

P2_7

P3_0/RxD

P3_1/TxD

P3_2/INT0

P3_3/INT1

P3_4

P3_5

P3_6

P3_7

/ALE

/PSEN

/EA

RST

TWI_hard_sda

TWI_hard_scl

P1.5/CEX2/MISO

OCD_Rx

OCD_Tx

XTAL1

XTAL2

P0_0

P0_1

P0_2

P0_3

P0_4

P0_5

P0_6

P0_7

TWI_hard_scl

TWI_hard_sda

/EA

XTAL1

XTAL2

/ALE

P0_0

P0_1

P0_2

P0_3

P0_4

P0_5

P0_6

P0_7

OCD_Rx

OCD_Tx

RST

P1.0/T2

P1.1/T2EX/SS

P1.2/ECI

P1.3/CEX0

P1.4/CEX1

P1.5/CEX2/MISO

P1.6/CEX3/SCK

P1.7/CEX4/MOSI

/PSEN

P3_0/RxD

P3_1/TxD

P3_2/INT0

P3_3/INT1

P3_4

P3_5

P3_6

P3_7

PB_1

PB_0

PB_3

PB_2

LED_6

LED_1

LED_3

LED_5

LED_7

P2_0

P2_1

P2_2

P2_3

P2_4

P2_5

P2_6

P2_7

LED_0

LED_2

LED_4

Expansion Connector

R105 4.7KR105 4.7K

R104 4.7KR104 4.7K

Y1Y1

R103 4.7KR103 4.7K

SP6SP6

RST

10

XTAL2

20

XTAL1

21

GND

22

PSEN

32

ALE/PROG

33

EA/VPP

35

VCC

44

P1.02P1.13P1.24P1.35P1.46P1.57P1.68P1.7

9

P2.0/A824P2.1/A9

25

P2.2/A1026P2.3/A1127P2.4/A1228P2.5/A1329P2.6/A1430P2.7/A15

31

P3.0/RXD

11

P3.1/TXD

13

P3.2/INT0

14

P3.3/INT1

15

P3.4/T016P3.5/T1

17

P3.6/WR

18

P3.7/RD

19

P0.0/AD0

43

P0.1/AD1

42

P0.2/AD2

41

P0.3/AD3

40

P0.4/AD4

39

P0.5/AD5

38

P0.6/AD6

37

P0.7/AD7

36

Rx_OCD

1

RxD_1/SDA

12

TxD_1/SCL

34

Tx_OCD

23

U6

AT8xC51_PLCC44

U6

AT8xC51_PLCC44

R102 4.7KR102 4.7K

SP2SP2

R101 4.7KR101 4.7K

C13

100n

C13

100n

R100 4.7KR100 4.7K

SP12SP12

SP11SP11

CD6

100n

CD6

100n

CD7

100n

CD7

100n

C15

22pF

C15

22pF

C14

22pF

C14

22pF

2468101214161820222426283032343638404244464850525456586062

13579

11131517192123252729313335373941434547495153555759

61

J3

HEADER 31x2/SM

J3

HEADER 31x2/SM

SP8SP8

R107 4.7KR107 4.7K

SP10SP10

SP7SP7

R106 4.7KR106 4.7K

SP9SP9

SP5SP5

Appendix C: Board Schematics

AT89STK-11 Hardware User Guide 4-18

7676B–8051–08/07

Page 20

Appendix C: Board Schematics

DSR

Vcc

RTS

Rx_PC

CTS

CTS RTS

Tx_MCU

DTR

Tx_PC

Rx_MCU

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

P3_0/RxD

P3_1/TxD

/PSEN

RST

"grain de café""grain de café"

Vcc

SP4SP4

C26

100n

C26

100n

CD2

100n

CD2

100n

C16

100n

C16

100n

C23

100n

C23

100n

SW1

RESET

SW1

RESET

R221KR22

1K

2 3

14

1

7

U9A

74HC125/SO_5

U9A

74HC125/SO_5

SP3SP3

C21

100n

C21

100n

1 2

J11

RTS

J11

RTS

R241KR24

1K

C22

100n

C22

100n

SW8

ISP

SW8

ISP

R231KR23

1K

C18

100n

C18

100n

C17

100n

C17

100n

C25

100n

C25

100n

5 6

14

4

7

U9B

74HC125/SO_5

U9B

74HC125/SO_5

1 2

J13J13

C20

100n

C20

100n

C1+1C1-3C2+4C2-

5

VCC

16

GND

15

V+

2V-6

R1OUT12R2OUT

9

T1IN11T2IN

10

R1IN13R2IN

8

T1OUT14T2OUT

7

U8

SIPEX-SP3232ECA

U8

SIPEX-SP3232ECA

1 2

J12

DTR

J12

DTR

D11

Green Led

Rx LED

D11

Green Led

Rx LED

R6

10KR610K

C24

100n

C24

100n

C1+1C1-3C2+4C2-

5

VCC

16

GND

15

V+

2V-6

R1OUT12R2OUT

9

T1IN11T2IN

10

R1IN13R2IN

8

T1OUT14T2OUT

7

U7

SIPEX-SP3232ECA

U7

SIPEX-SP3232ECA

C19

100n

C19

100n

594837261

P1

SUB-D9 FEMALE

RS232

P1

SUB-D9 FEMALE

RS232

D12

Green Led

Tx LED

D12

Green Led

Tx LED

Figure 4-5. AT89STK-11 Schematics (4 of 4)

4-19 AT89STK-11 Hardware User Guide

7676B–8051–08/07

Page 21

Appendix D: References/Acronyms

4.2 References

4.3 Acronyms

AT89C51RD2/ID2/ED2/RB2/RC2/IC2/RE2/IE2 and AT89C51RD3/IE3 Product

Datasheet.

FLIP: FLexible In-system Programming

ISP: In-System programming

AT89STK-11 Hardware User Guide 4-20

7676B–8051–08/07

Page 22

Appendix D: References/Acronyms

Document Revision History

Changes from 7676A to 7676B

1. Section 1.2, page 1-2 : AT89C51RE3/ID3/IE2 not supported.

2. Section 2.3.1.2, page 2-5 : SP1 must be kept closed.

3. Section 3.1.1, page 3-11 : SW1 switch and EA jumper do not exist.

4. Appendix A, page 4-13 : the given board layout was wrong. Replaced by the

right one.

5. Appendix C, page 4-19 : there was an error on page 4 of the schematic.

Pin5 of U9B is now connected to Vcc instead of GND.

4-21 AT89STK-11 Hardware User Guide

7676B–8051–08/07

Page 23

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

Eas t Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

Eas t Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Pos tfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

Disclaimer: The informa tion in this documen t is provided in conn ect ion with Atmel products. No licen se, express or implied, by estoppel or other wis e, to any

intelle ctual proper ty right is granted by this document or in c onnection with the sale of A tme l products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT

OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

repr ese nta tio ns or warr anties with resp ect to the accuracy or c omp leteness of the con ten ts o f th is document and reserves the right to m ake changes t o specifications

and product de scription s at an y ti me withou t no tice. Atmel does not ma ke any commit ment to update the informatio n co nta ine d he rein. Unl ess specifically provided otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’sAtmel’s products are not intended, authorized, or warranted for use as

components in applications intended to support or sustain life.

© Atmel Corporation 2007. All rights reserved. Atmel®, logo and combinations thereof, are registered trademark s, and Everywhere You Are

are the trademarks o f Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

7676B–8051–08/07

/xM

®

Loading...

Loading...