Page 1

AT89STK-06 Demo Board

..............................................................................................

Hardware User Guide

Page 2

Section 1

Introduction...........................................................................................1-1

1.1 Features....................................................................................................1-1

Section 2

Hardware Description ...........................................................................2-3

2.1 Block Diagram...........................................................................................2-3

2.2 Power Supply............................................................................................2-3

2.3 RESET......................................................................................................2-4

2.4 Serial Interfaces........................................................................................2-5

2.5 Board Settings .................... ... .... ... ... .........................................................2-7

Section 3

Device Programming..........................................................................3-11

3.1 In-System Programming .........................................................................3-11

Section 4

Appendix A: Board Layout..................................................................4-13

Appendix B: Bill of Materials...............................................................4-14

Appendix C: Board Schematics..........................................................4-15

Appendix D: Default Configuration .....................................................4-19

Appendix E: References/Acronyms....................................................4-20

4.1 References..............................................................................................4-20

4.2 Acronyms................................................................................................4-20

AT89STK-06 Demo Board User Guide 1

4339C–CAN–07/05

Page 3

This document describes the board included in the AT89STK-06 Starter Kit dedicated to

the T89C51CC01/CC02 and AT89C51CC03 CAN microcontrollers (for T89C51CC02

optionnal adaptor is required). This board is designed to allow an easy evaluation of the

product using demonstration software.

The AT89STK-06 Starter Kit can be used with the AT89C51AC3, TR89C51AC2, and

T89C5115 Flash Microcontrollers with ADC (f or T89C51 15 optional adapter is requir ed).

1.1 Features • CAN

– On board CAN transceiver Atmel ATA6660

– D-sub Connector Compliant to the CiA (User Group: "CAN in Automation")

• T wo Different Sockets to Support AT89C51CC03 and AT89C51AC3 in PLCC52 and all

controllers in PLCC44 Packages

• Support of the T89C51CC02 & T89C5115 Microcontroller Requires the use of a PLCC28

Adapter (CANADAPT28).

• The Board Comes with a AT89C51CC03-UA (PLCC44 package) and a AT89C51CC03-CA

(PLCC52 package) Samples

• Analog-to-Digital Converter

– Potentiometer

– Thermal Resistor

– On board ADC Reference Voltage

• On-board Reset, INT0, INT1, LEDs, EA, ISP and Programming Interface

• Power, ALE, RS232 Rx and Tx LEDs

• CAN, SPI and RS232 Hardware Connectors

• On-board Voltage Regulator

• Voltage Operation: 8V to 15V

• Operating Temperature Range: 0 to +70°C

• Dimension: 80 mm x 100 mm

Recommendation for the CAN High Speed Bus

(1)

.

Section 1

Introduction

Notes: 1. Samples for AT89C51AC3, T89C51CC01, T89C51AC2, T89C51CC02, and

T89C5115 can be ordered separately

AT89STK-06 Demo Board Software Demonstration Guide 1-1

Rev. 4339C–CAN–07/05

Page 4

Introduction

Figure 1-1. AT89STK-06 board

1-2 AT89STK-06 Demo Board Software Demo Guide

4339C–CAN–07/05

Page 5

Section 2

Hardware Description

2.1 Block Diagram Figure 2-1 shows a functional block diagram of the AT89STK-06 board, with the I/O

usage.

Figure 2-1. Block Diagram of AT89STK-06 board

Reset,

ISP,

INT0,

INT1

t°C

CAN Network

CAN

Applicable MCU

Generic

Board

FLIP, Host, Batch ISP

UART

Potentiometer

Power SupplySensor LED

Human

External

Power

Connector

Human

Generic Board (optionnal)

2.2 Power Supply The on-board power supply circuitry allows various power supply configurations.

2.2.1 Power Supply Sources

The power supply source can come from two different and exclusive

sources:

either from J4, JACK PWR connector

either from J5, 9V (Battery connector)

J4 - JACK PWR connector: – Need of a male JACK outlet

– Input supply from 8 up to 15V DC 500mA min

AT89STK-06 Demo Board Software Demonstration Guide 2-3

Rev. 4339C–CAN–07/05

Page 6

Hardware Description

– No specific polarization mandatory

Note: There is a diode voltage level between the negative output of the power supply

and the “GND”. This could introduce some gap of voltage during measurement

and instrumentation.

Figure 2-2 . Male JACK Outlet and Wires

+

-

Caution: Do not mount more than one power supply source on AT89STK-06 board.

J5 - 9V Battery connector: – Need of a female 2 points connector

– Input supply from 6 up to 10V DC (example: 9V battery)

– Polarization mandatory

Figure 2-3 . EXT PWR Female Connector / Cable for 9V Battery

-

+

-

+

Caution: Do not mount more than one power supply source on AT89STK-06 Starter Kit.

2.3 RESET Although the AT89C51CC03 & AT89C51AC3 microcontrollers have on-chip RESET

circuitry (c.f. microcontroller datasheet), the AT89STK-06 board provides to the

microcontroller a RESET signal witch can come from 2 different sources:

2.3.1 Power-on RESET The on-board RC network acts as power-on RESET.

2.3.2 RESET Push Button By pressing the RESET push button on the AT89STK-06 board, a warm RESET of the

microcontroller is performed.

2-4 AT89STK-06 Demo Board Software Demo Guide

4339C–CAN–07/05

Page 7

Hardware Description

2.4 Serial Interfaces

2.4.1 RS-232C All CAN microcontrollers have one on-chip UART peripheral. Only the asynchronous

mode is supported by the AT89STK-06 board.

The AT89STK-06 board is supplied with a RS-232 driver/receiver. Only one female DB9

connector assumes the RS-232 connections. A full range of configuration can be set

with two Rx lines and two Tx lines.

Figure 2-4 . RS-232 DB9 Connections

RS-232 DB9 front view

5

1

234

69

78

Figure 2-5 . Typical PC Connection Lay-out

AT89C51CC0x / RS-232 DB9

Function Pin Nb Function

Pin Nb

2TxD (AT89C51CC0x)

5Gnd

Figure 2-6. RS-232 DB9

pin 2

pin 3 RS-RxD

pin 4

pin 6

pin 5 Gnd

pin 7 RS-CTS

pin 8 RS-RTS

RS-TxD

PC / DB9 serial port

(COM1 or COMx)

2

3

5 Gnd

RxD (PC)

TxD (PC)3RxD (AT89C51CC0x)

“Auto_ISP”

Jumpers

Green Rx LED Red Tx LED

AT89STK-06 Demo Board Software Demo Guide 2-5

4339C–CAN–07/05

Page 8

Hardware Description

2.4.2 CAN The microcontroller is a microcontroller with an on-chip full-CAN controller. The AT89STK-06 board is supplied with an Atmel CAN transceiver (ATA6660). A

female DB9 connector assumes the CAN bus connections.

Figure 2-7 . CAN DB9 Connections

CAN DB9 front view

1

5

432

96

87

pin 2

pin 7 CAN-H

pin 3 Gnd

pin 6 Gnd

pin 5 CAN-SHLD

CAN-L

(Can be set to Gnd)

If a network termination is needed, JP3 switch inserts a 120Ω resistor between CAN-H

and CAN-L.

A red LED indicates a TxCAN traffic, a green one indicates a RxCAN traffic.

Figure 2-8 . CAN LEDs

Can Res Jumper

(Here Open)

Red Rx LED Green Tx LED

2.4.3 SPI The AT89C51CC03 in PLCC52 is a microcontroller with an on-chip full duplex SPI interface, master or slave.

A 6-pin male connector assumes the SPI bus connections. The SPI 6- pin connecto r also

provides to the user Vcc and Gnd.

Figure 2-9 . SPI 6-pin Connections

SPI Connector front view

1 56234

pin 1

pin 2 SS

pin 3

pin 4

pin 5

pin 6

Vcc

MISO

SCK

MOSI

Gnd

2-6 AT89STK-06 Demo Board Software Demo Guide

4339C–CAN–07/05

Page 9

Hardware Description

2.5 Board Settings The AT89STK-06 board has two types of settings:

Jumpers

Solder strap

Test poin ts

Table 2-1, Table 2-2 and Table 2-3 provide an overview of the available settings and

test points.

2.5.1 Jumpers

Table 2-1. Default Jumper Setting

Reference PCB Name Comments (guidelines) Default

JP1 EA

JP2 MUTE

JP3 CANRes

JP4 RTS

JP5 DTR

JP6 Batt

ON : allows external execution

OFF: Internal code execution

ON : Enable C51 generic extension board (optionnal) buzzer

OFF: Disable C51 generic extension board (optionnal) buzzer

ON : Enable CAN terminator resistor

OFF: Disable CAN terminator resistor

ON : Enable RTS line to control ISP mode (for AutoISP mode)

OFF: Disable RTS line to control ISP mode

ON : Enable DTR line to drive MCU reset (for AutoISP mode)

OFF: Disable DTR line to drive MCU reset

ON : Enable Battery charge

OFF: Disable Battery charge

Open (OFF)

Open (OFF)

Open (OFF)

Open (OFF)

Open (OFF)

Open (OFF)

Figure 2-10. Jumper Setting Definition

strap

jumper header

OFFON or

Ex: 1-2

AT89STK-06 Demo Board Software Demo Guide 2-7

4339C–CAN–07/05

Page 10

Hardware Description

2.5.2 Solder straps Solder straps allow to modify the board configuration for specific usage such as T89C51CC02 compatibility.

Table 2-2. Table of Solder Strap

Reference PCB Name Comments (guidelines) Default

SP1

SP2 X2_44 Connect PLCC44 Xtal2 to XTAL2 of the generic extension board (optionnal) Open

SP3 X2_52 Connect PLCC52 Xtal2 to XTAL2 of the generic extension board (optionnal) Open

CC02 & C5115

mode

For T89C51CC02 usage, allows to redirect the ISP signal to P1.0, for

hardware conditions.

Open

Figure 2-11. Solder Strap definition

“Open”

“Close”

2.5.2.1 T89C51CC02/T89C5115

Support (SP1)

Solder Pad

Solder gout

When using T89C51CC02 or T89C5115 products with the AT89STK-06 board ( see

¨PLCC adapter for T89C51CC02 user guide: CANADAPT28), the SP1 solder pa d

should be closed to ensure correct hardware conditions setting on P1.0 port.

SP1 solder pad connects ISP push button to P1.0 microcont roller port and the

CANADAPT28 adapter should be inseted in U2 (PLCC44) socket.

Figure 2-12. AT89STK-06 Board with CANADAPT28

2-8 AT89STK-06 Demo Board Software Demo Guide

4339C–CAN–07/05

Page 11

2.5.3 Test Points Test points are used to check the internal power supply for AT89STK-06 Board.

Table 2-3. Table of Test Points

Reference PCB Name Comments (guidelines)

TP1 Vref Vref for ADC

TP2 Vpot Test point for Potentiometer voltage

TP3 Vtemp Test point for Termal resitor voltage

TP4 Vcc Test point for Vcc

TP5 GND Test point for GND

AT89STK-06 Demo Board Software Demonstration Guide 2-9

Rev. 4339C–CAN–07/05

Page 12

Section 3

Device Programming

3.1 In-System

Programming

3.1.1 Manual ISP Mode

3.1.1.1 Board Configuration To use ISP mode, the board should be configured as follow:

3.1.1.2 Operating Mode To enter in ISP mode, press both the RESET (SW5) and ISP (SW4) buttons simulta-

3.1.2 Auto ISP Mode The Auto ISP is available only for parts with UART bootloader (-UA devices). It allows

The on-chip memories and configuration bytes of the AT89C51CC0x parts can be programmed using the ISP mode of the device.

POWER switch (SW1) on “ON” position

EA jumper should be open (internal code execution only).

Before using ISP mode for T89C51CC02 or T89C5115 device, be sure to close SP1

solder pad ( See Section "T89C51CC02/T89C5115 Support (SP1)", page 8).

neously. First release the RESET button and then the ISP button. The device enters in

ISP mode.

the host PC application (Atmel FLIP software for example) to control the hardware conditions from the serial lines RTS and DTR.

Thus with the Auto ISP mode, the user does not need to push the ISP and RESET

buttons.

3.1.2.1 Board Configuration To use Auto ISP mode, put the board in the same configuration as ISP mode and also:

Close RTS (JP4) jumper

Close DTR (JP5) jumper

AT89STK-06 Demo Board Software Demonstration Guide 3-11

Rev. 4339C–CAN–07/05

Page 13

Device Programming

3-12 AT89STK-06 Demo Board Software Demo Guide

4339C–CAN–07/05

Page 14

Figure 4-1. Board Components View Diagram

Section 4

Appendix A: Board Layout

J2J1

AT89STK-06 Demo Board Software Demonstration Guide 4-13

Rev. 4339C–CAN–07/05

Page 15

Appendix B: Bill of Materials

Appendix B: Bill of Materials

Figure 4-2. Bill of Materials Table

ItemCode no Description QuantityReference

1 74HC125-SO 74HC125 SO14 1 U6

2 74HC14-SO 74HC14 SO14 1 U10

3 AT89C51CC01-SPLC PLCC44 1 U2

4 AT89C51CC03-SPLC PLCC52 1 U1

5 ATA6660-SO8 ATA6660 CAN TRANSCEIVER SO8 ATMEL 1 U4

6 MAX202ECSE-SO MAX20 2ECSE SO16 MAXIM 2 U5, U7

7 MAX6129-SOT23-5P MAX6129 SOT23-5 MAXIM 1 U3

8 MC78M05CDT -TO252 REG MC78M05CDT TO252 ON SEMICONDUCT 1 U9

9 PONT-DF005 S PONT REDRESSEUR DF005S GENERAL SEMI 1 U8

10 BAR2 2PTS A 2.54 6 JP1, JP2, JP3, JP4, JP5, JP6

11 BAR2-24-ESQ124-2 2X24PTS A 2.54 ESQ 124-24-T- 2 J1, J2

12 BAR2Y-MTA2.54 MALE 2PTS MTA 2.54 1 J5

13 BAR6Y-MTA2.54-IN MALE 6PTS MTA 2.54 I 1 J3

14 JAC K-PWR-D2.5 JACK PWR DIAM 2.5MM 1 J4

15 STR-2CMS-NC C SOLDER STRAP 3 SP1, SP2, SP3

16 SW-1K2-09-03201- SW 1K2 09-03201-02 EOA SE 1 SW1

17 BAR3 3PTS A 2.54 2 Y1, Y2

18 DBS09V8G SUBD FEMALE 90° 9PTS 2 P1, P2

19 BP-DTSM3 BP CMS DTSM3 APEM 4 SW2, SW3, SW4, SW5

20 PT1-6 TEST POINT 5 TP1, TP2, TP3, TP4, TP5, TP6

C3, C7, C9, C10, C12, C14, C15,

C16, C17, C18, C19, C20, C21,

C22, C23, C24, C25, C26, C27,

21 CA-0805-100NF CAPA CMS 0 805 100NF 22

22 CA-0805-10NF CAPA CMS 0 805 10NF 1 C11

23 CA-0805-1UF CAPA C0805C105Z3VAC KEMET 1 C31

24 CA-0805-22NF CAPA CMS 0 805 22NF 2 C5, C8

25 CA-0805-22PF CAPA CMS 0805 22PF 4 C1, C2, C4, C6

26 CO-VS-B-4.7UF CAPA VS-B 4.7UF 3 5V PANASONIC 2 C28, C 30

C29, C32

27 DIO-MRA4007-SMA DIODE RECTIF. MRA4007 SMA O N 1 D7

28 LED-LPM670-G MINI TOPLED VERTE LPM670-G OSRAM 3 D1, D4, D5

29 LED- LSM676 HYPER MINI TOPLED SUPER-RED LSM 676 4 D2, D3 , D6, D8

4-14 AT89STK-06 Demo Board Software Demo Guide

4339C–CAN–07/05

Page 16

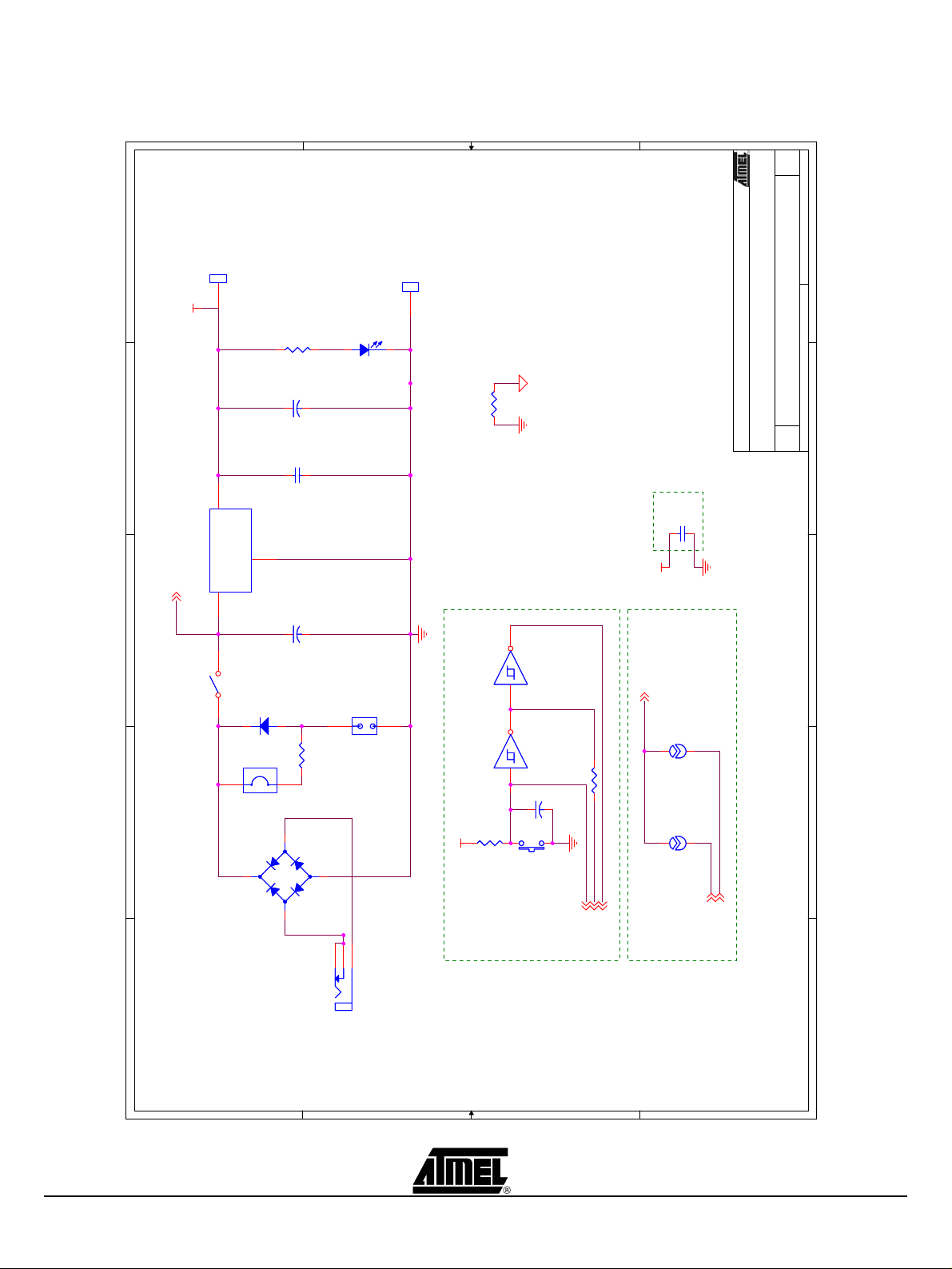

Appendix C: Board Schematics

Figure 4-3. AT89STK-06 Board Schematics (1 of 4)

XTAL2_52

C2

22 pFC222 pF

C1

22 pFC122 pF

/PSEN

ALE

P0.[0..7]

P4.4

P4.2

P4.1

A[8..16]

P4.0

Appendix C: Board Schematics

P3.[0..7]

ISP_mode

/RD

/WR

1

2

3

4

TWI_scl

P1.[0..7]

TWI_sda

VCC AGND

CS_RAM

Y1

VAREF

RST

CS_FLASH

12 MHzY112 MHz

P1.0

P1.1

P1.2

P1.3

of

P0.5P0.5P0.5P0.5P0.5P0.5P0.5P0.5P0.5P0.5

P0.3P0.3P0.3P0.3P0.3P0.3P0.3P0.3P0.3P0.3

PSENPSENPSENPSENPSENPSENPSENPSENPSENPSEN

ALEALEALEALEALEALEALEALEALEALE

46

45

ALE

XTAL2

47

XTAL1

48

VCC

49

VCC

50

TESTI

51

VSS

52

RESET

1

VAGN D

2

VAREF

3

P1.0/AN0/T2

4

5

6

7

U1

U1

P1.4

P1.5

P1.6

P1.7

P1.1/AN1/T2EX

P1.2/AN2/ECI

P1.3/AN3/CEX0

P1.4/AN4/CEX1

9

8

ISP_FLASH

VCC

P0.2P0.2P0.2P0.2P0.2P0.2P0.2P0.2P0.2P0.2

P0.7P0.7P0.7P0.7P0.7P0.7P0.7P0.7P0.7P0.7

PSEN

P1.5/AN5/CEX2

10

/BUZZER

P0.1P0.1P0.1P0.1P0.1P0.1P0.1P0.1P0.1P0.1

P0.6P0.6P0.6P0.6P0.6P0.6P0.6P0.6P0.6P0.6

P0.7/AD744P0.6/AD643P0.5/AD541P0.4/AD440P0.3/AD339P0.2/AD238P0.1/AD137P0.0/AD0

P1.7/AN7/CEX4

P1.6/AN6/CEX3

11

ADC_Pot

ADC_Ext

P4.4P4.4P4.4P4.4P4.4P4.4P4.4P4.4P4.4P4.4

P0.4P0.4P0.4P0.4P0.4P0.4P0.4P0.4P0.4P0.4

42

NC

EA12P3.0/RxD14P3.1/TxD16P3.2/INT0/17P3.3/INT1/

/EA

35

36

P4.4/MOSI

AT89C51CC03_PLCC52

AT89C51CC03_PLCC52

P3.4/T019P3.5/T1

NC

P4.3/SCK

18

13

15

P4.3

A16

/INT0

/INT1

TX_UART

RX_UART

C4

22 pFC422 pFC622 pFC622 pF

Y2Y2

P1.0

P1.1

P1.2

AGND

P1.3

34

P2.0/A8

20

VCC

XTAL2_44

P4.2

P4.2/MISO

33

P2.1/A9

32

P2.2/A10

31

P2.3/A11

30

P2.4/A12

29

P2.5/A13

28

NC

27

P2.6/A14

26

P2.7/A15

25

P4.1/RxDC

24

P4.0/TxDC

23

P3.7/RD

22

P3.6/WR

21

AT89C51CC03_PLCC52

AT89C51CC03_PLCC52

P3.5

P3.4

P3.3

P3.2

P3.1

P3.0

1 KR11 K

R1

40

41

VCC

42

VSS

43

44

1

2

3

4

5

6

A8

AGND

AT89C51CC03_PLCC52

DECOUPLING CAPACITOR

CLOSE TO THE DEVICE

A9

A10

A11

A12

A13

A14

A15

A16

/PSEN

ALE

D1

LED PWR GREENALED1LED PWR GREENALE

P0.6

P0.5

P0.3

P0.4

P0.7

38

39

ALE

PSEN

P0.7/AD737P0.6/AD636P0.5/AD535P0.4/AD434P0.3/AD333P0.2/AD232P0.1/AD131P0.0/AD0

XTAL2

XTAL1

RESET

VAGN D

VAREF

P1.0/AN0/T2

P1.1/AN1/T2EX

P1.2/AN2/ECI

P1.3/AN3/CEX0

AT89C51CC01/03_PLCC44

AT89C51CC01/03_PLCC44

P0.2

VCC

SW4

SW4

SP1SP1

P1.0

"Solder Strap Default:open"

P0.0

P0.1

29

30

P2.0/A8

C8

22 nFC822 nF

C7

100 nFC7100 nF

ISP

ISP

P0.[0..7]

close for CC02 only

A8

P2.1/A9

28

A9

P2.2/A10

27

A10

P2.3/A11

26

A11

P2.4/A12

25

A12

P2.5/A13

24

A13

P2.6/A14

23

A14

P2.7/A15

22

A15

P4.1/RxDC

21

P4.0/TxDC

20

P3.7/RD

19

P3.6/WR

18

A[8..16]

/RD

Title

Title

Title

/WR

RX_CAN

1

14Thursday, January 08, 2004

14Thursday, January 08, 2004

14Thursday, January 08, 2004

2

<Doc> 1.0.0

<Doc> 1.0.0

<Doc> 1.0.0

CC0x_demob/MCU

CC0x_demob/MCU

CC0x_demob/MCU

A4

A4

A4

Size Document Number Rev

Date: Sheet of

Size Document Number Rev

Date: Sheet of

Size Document Number Rev

Date: Sheet

3

P3.[0..7]

P4.1

P4.0

TX_CAN

4

P3.7

P3.6

RST

EA11P3.0/RxD12P3.1/TxD13P3.2/INT0/

P3.3/INT1/

P3.4/T016P3.5/T1

P1.7/AN7/CEX4

P1.6/AN6/CEX3

P1.5/AN5/CEX2

U2

U2

100 nFC3100 nF

AGND

C5

22 nFC522 nF

P2.[0..7]

5

A14 P2.6

A12 P2.4

A8 P2.0

A9 P2.1

A10 P2.2

A11 P2.3

A13 P2.5

A[8..16]

A15 P2.7

DECOUPLING CAPACITOR

CLOSE TO THE DEVICE

AT89C51CC01/03_PLCC44

VCC

C3

D D

VAREF

P1.[0..7]

P1.4

P1.5

P1.6

P1.7

C C

TWI_scl

TWI_sda

CS_RAM

VCC

CS_FLASH

P1.4/AN4/CEX1

9

8

7

R2

10 KR210 K

ISP_FLASH

10

/BUZZER

ADC_Temp

ADC_Pot

/EA

RX_UART

B B

14

15

/INT0

/INT1

TX_UART

17

A16

AT89C51CC03_PLCC44

AT89C51CC03_PLCC44

1 2

JP1EAJP1

EA

A16

P3.5

P3.4

P3.3

P3.2

P3.1

P3.0

5

A A

AT89STK-06 Demo Board Software Demo Guide 4-15

4339C–CAN–07/05

Page 17

Appendix C: Board Schematics

Figure 4-4. AT89STK-06 Board Schematics (2 of 4)

1

2

P0.[0..7]

P0.0

P0.1

47

4.35_12V

J2

J2

48

VPOWER

46

P0.2

P0.3

Vss444.35_12V

42

P0.4

P0.5

/ISP_F

CS_FLASH

Vss_out

38

40

CS_FLASH

ISP_FLASH

P0.6

P0.7

Spare11

Spare12

34

36

P2.1

P2.0

Spare9

Spare10

30

32

P2.2

28

P2.3

/PSEN

P2.4

P2.5

ALE

P2.6

ALE22Vss24/PSEN26Spare8

20

P4.0

P2.7

Keyb.1

Keyb.0

16

18

P2.[0..7]

P4.0

P4.1

Keyb.3

Keyb.2

14

P4.1

P4.2

P4.3

Keyb.4

12

P4.2

P4.3

P4.4

Keyb.5

8

10

P4.4

P4.71P4.63P4.55P4.47P4.39P4.211P4.113P4.015P2.717P2.619P2.521P2.423P2.325P2.227P2.129P2.031P0.733P0.635P0.537P0.439P0.341P0.243P0.145P0.0

Vss2Vss4Keyb.7

Keyb.6

6

Connector Generic Board Right

Connector Generic Board Right

of

24Thursday, January 08, 2004

24Thursday, January 08, 2004

24Thursday, January 08, 2004

1

CC0x_demob/Generic_board

CC0x_demob/Generic_board

CC0x_demob/Generic_board

<Doc> 1.0.0

<Doc> 1.0.0

<Doc> 1.0.0

2

A4

A4

A4

Title

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Date: Sheet

Date: Sheet of

Date: Sheet of

Title

Title

/INT0

/INT1

R6

10 KR610 K

3

4

5

VCC

R4

R3

R5

10 KR510 K

4.7 KR44.7 K

4.7 KR34.7 K

J1

J1

45

47

Vcc_CPU

48

P1.0

P1.1

TWI_sda

43

Vss

TWI_sda

P1.2

TWI_scl

39

41

TWI_scl

P1.4

P1.3

/EA

/RST_IO

35

37

/EA

/RST

/TWI_IT

P1.6

P1.5

33

/BP1

P1.7

A16

31

A16

P3.0

SW3

SW3

SW2

SW2

VCC

CS_RAM

27

29

CS_RAM

P3.2

P3.1

Vss

XTAL2

25

Xtal2

P3.3

INT1

INT1

INT0

INT0

23

P3.4

R7

Vss

P3.5

1.2 KR71.2 K

19

21

Spare0

P3.6

15

17

Spare2

Spare1

P3.7

D2

D2

Spare3

/BUZZER

LED PWR ORANGE

P1.5

LED PWR ORANGE

P1.5

12

3

5

7

9

11

13

Spare7

Spare6

Spare5

Spare4

/Buzzer

JP2 MUTEJP2 MUTE

Vss1Vss

P5.72P5.64P5.56P5.48P5.310P5.212P5.114P5.016/RD18/WD20P3.522P3.424P3.326P3.228P3.130P3.032P1.734P1.636P1.538P1.440P1.342P1.244P1.146P1.0

Connector Generic Board Left

Connector Generic Board Left

RAM

FLASH

External RAM Mapping

110

/ISP_F

3

4

0X

/CS_RAM 1

5

P1.[0..7]

D D

P3.[0..7]

C C

B B

A A

4-16 AT89STK-06 Demo Board Software Demo Guide

4339C–CAN–07/05

Page 18

Figure 4-5. AT89STK-06 Board Schematics (3 of 4)

J3

1

2

3

4

5

TP1

TP1

ADC

R10 120R10 120

VCC VCC

CAN I/O

VAREF

ADC_Pot

VRef

VRef

TP3

VTemp

TP3

VTemp

1

ADC_Temp

R11

100 K

R11

100 K

VPot

VPot

TP2

TP2

1

R12

R12

1

ADC

5

Vout

GND

2

Vin

U3 MAX6129BEUK33TU3 MAX6129BEUK33T

1

P1

P1

CANH

CANL

GND

JP3

JP3

CAN Res

CAN Res

R9

1.2 KR91.2 K

D3

LED PWR RED

D3

LED PWR RED

D4

D4

R8

1.2 KR81.2 K

LED PWR GREEN

LED PWR GREEN

D D

R13

R13

C11

C11

1 2

U4

VCC

CAN-Rx

CAN-Rx

CAN-Tx

CAN-Tx

10 nF

10 nF

C10

100 nF

C10

100 nF

C9

100 nFC9100 nF

Not

Mounted

C12

100 nF

C12

100 nF

10k pot

10k pot

594837261

7

6

CANL

CANH

Vcc3Vref

5

RxDC

Negative Temperature

Coefficient Resistor

NCP18WF104J03RB

NCP18WF104J03RB

AGND

CAN

CAN

SUB-D9 FEMALE

SUB-D9 FEMALE

8

2

Rs

Gnd

RXD4TXD

AT6660U4AT6660

1

TxDC

P4.1

P4.0

J3

Vcc

C13

C13

SPI Interface

R15

R15

VCC

R14

R14

RS232 I/O

12345

SS

VCC

MISO

0.1 µF

0.1 µF

P3.5

P4.2

1.2 K

1.2 KD6LED PWR RED

D6

D5

D5

1.2 K

1.2 K

16

Vcc

C C

6

SCK

MOSI

GND

P4.3

P4.4

TX_UART

RX_UART

RS-Rx

LED PWR RED

RS-Rx

RS-Tx

RS-Tx

LED PWR GREEN

LED PWR GREEN

Rx_MCU

9

10

T1IN11T2IN

VCC

R1OUT12R2OUT

R1IN13R2IN

T1OUT14T2OUT

8

7

DSR

DCD

P2

P2

SPI Male

SPI Male

Vcc

C1+1C1-3C2+4C2-

JP4

JP4

1 2

RTS

Rx_PC

Tx_PC

C16

C16

CTS

1

Vcc

0.1 µF

0.1 µF

2

V+

5

C15

C15

0.1 µF

0.1 µF

C14

C14

RTS

RTS

DTR

ISP_mode

2 3

C18

C18

C17

C17

6

V-

MAX202ECSE

MAX202ECSE

GND

15

0.1 µF

0.1 µF

JP5

JP5

594837261

SUB-D9 FEMALE

SUB-D9 FEMALE

Vcc

U6A

U6A

0.1 µF

0.1 µF

0.1 µF

0.1 µF

U5

U5

Vcc

1 2

RS232

RS232

4

5 6

74HC125/SO

74HC125/SO

16

DTR

DTR

B B

Vcc

10

T1IN11T2IN

VCC

T1OUT14T2OUT

7

U6B

74HC125/SO

U6B

74HC125/SO

10

C20

C20

9

R1OUT12R2OUT

R1IN13R2IN

8

/RST_UART

9 8

0.1 µF

0.1 µF

2

V+

C1+1C1-3C2+4C2-

C19

0.1 µF

C19

0.1 µF

Appendix C: Board Schematics

13

U6D

74HC125/SO

U6D

74HC125/SO

12 11

<Doc> 1.0.0

CC0x_demob/Interfaces

<Doc> 1.0.0

CC0x_demob/Interfaces

<Doc> 1.0.0

CC0x_demob/Interfaces

A4

A4

A4

Title

Size Document Number Rev

Title

Size Document Number Rev

Title

Size Document Number Rev

U6C

74HC125/SO

U6C

74HC125/SO

Vcc

C23

0.1 µF

C23

0.1 µF

C22

0.1 µF

C22

0.1 µF

6

V-

U7

U7

GND

MAX202ECSE

MAX202ECSE

15

5

C21

0.1 µF

C21

0.1 µF

DECOUPLING CAPACITOR

CLOSE TO THE DEVICE

C27

C27

C26

C26

MAX202ECSEMAX202ECSE 74HC125/SO

C25

C25

C24

C24

AT6660

VCC

A A

100 nF

100 nF

100 nF

100 nF

100 nF

100 nF

100 nF

100 nF

of

34Thursday, January 08, 2004

34Thursday, January 08, 2004

34Thursday, January 08, 2004

1

2

Date: Sheet of

Date: Sheet of

Date: Sheet

3

4

5

AT89STK-06 Demo Board Software Demo Guide 4-17

4339C–CAN–07/05

Page 19

Appendix C: Board Schematics

Figure 4-6. AT89STK-06 Board Schematics (4 of 4)

1

TP4

VCC

TP4

VCC

1

VCC

R17

1.2 K

R17

1.2 K

C30

4.7 µF

C30

4.7 µF

2

C29

100 nF

C29

100 nF

2

VOUT

GND

3

VIN

U9

MC78M05CDT

U9

MC78M05CDT

VPOWER

1

D8

LED PWR RED

PWRD8LED PWR RED

PWR

TP5

TP5

of

44Monday, May 24, 2004

44Monday, May 24, 2004

44Monday, May 24, 2004

1

GND

GND

1

AGND

R200R20

0

C32

C32

100 nF

100 nF

CD74HC14D

VCC

<Doc> 1.0.0

CC0x_demob/POWER

<Doc> 1.0.0

CC0x_demob/POWER

<Doc> 1.0.0

CC0x_demob/POWER

A4

A4

A4

Title

Size Document Number Rev

Title

Size Document Number Rev

Title

Size Document Number Rev

2

Date: Sheet

Date: Sheet of

Date: Sheet of

3

ON/OFF

SW1

SW1

1 2

JP6

JP6

4

5

SWITCH SSL

SWITCH SSL

D7

MRA4007D7MRA4007

Batt

Batt

+

U8

DF005S

U8

DF005S

3

C28

4.7 µF

C28

4.7 µF

1 2

R16

100

R16

100

1 2

-

2

-+

-+

1

J4

4

321

Charge

J5

BatteryJ5Battery

1 2

Batt- Batt+

CONNECTOR JACK PWR

PowerJ4CONNECTOR JACK PWR

Power

R18

10 k

R18

10 k

Vcc

Reset Circuit

U10B

U10B

U10A

U10A

74HC14D

74HC14D

3 4

74HC14D

74HC14D

R19

C31

C31

1 µF

1 µF

SW5

SW5

R19

PUSHBUTTON

PUSHBUTTON

/RST_UART

RST

1 2

RESET

RESET

/RST

1 K

1 K

XTAL2

SP3SP3

X2_44 X2_52

SP2SP2

Clock Circuit

"Solder Strap"

"Solder Strap"

XTAL2_44

XTAL2_52

3

4

5

D D

C C

B B

A A

4-18 AT89STK-06 Demo Board Software Demo Guide

4339C–CAN–07/05

Page 20

Appendix D: Default Configuration

Appendix D: Default Configuration

Table 1. Default Configuration

Reference Name Function State

SP1 CC02 mode

SP2 X2_44

For T89C51CC02/T89C5115 usage, allow to redirect the

ISP signal to P1.0, for hardware conditions.

Connect PLCC44 Xtal2 to XTAL2 of the generic extension

board

Open

Open

SP3 X2_52

JP1 EA

JP2 MUTE

JP3 CANRes

JP4 RTS

JP5 DTR

JP6 Batt

Connect PLCC52 Xtal2 to XTAL2 of the generic extension

board

ON : allows external execution

OFF: Internal code execution

ON : Enable C51 generic extension board buzzer

OFF: Disable C51 generic extension board buzzer

ON : Enable CAN terminator resistor

OFF: Disable CAN terminator resistor

ON : Enable RTS line to control ISP mode

OFF: Disable RTS line to control ISP mode

ON : Enable DTR line to drive MCU reset

OFF: Disable DTR line to drive MCU reset

ON : Enable Battery charge

OFF: Disable Battery charge

Open

Open (OFF)

Open (OFF)

Open (OFF)

Open (OFF)

Open (OFF)

Open (OFF)

AT89STK-06 Demo Board Software Demo Guide 4-19

4339C–CAN–07/05

Page 21

Appendix E: References/Acronyms

Appendix E: References/Acronyms

4.1 References AT89C51CC03, T89C51CC02, T89C51CC01, T89C5115, AT89C51AC3,

T89C51AC2 Product Datasheets*

4.2 Acronyms API: Application Programming Interface

FLIP: FLexible In-system Programming

HPC: High Pin Count microcontroller (by opposition to LPC)

ISP: In-System Programming

LPC: Low Pin Count microcontroller

4-20 AT89STK-06 Demo Board Software Demo Guide

4339C–CAN–07/05

Page 22

Atmel Headquarters Atmel Operatio ns

Corporate Headquarters

2325 Orchard Parkway

San Jose, CA 95131

TEL 1(408) 441-0311

FAX 1(408) 487-2600

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

TEL (41) 26-426-5555

FAX (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimhatsui

East Kowloon

Hong Kong

TEL (852) 2721-9778

FAX (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

TEL (81) 3-3523-3551

FAX (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131

TEL 1(408) 441-0311

FAX 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131

TEL 1(408) 441-0311

FAX 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

TEL (33) 2-40-18-18-18

FAX (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

TEL (33) 4-42-53-60-00

FAX (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906

TEL 1(719) 576-3300

FAX 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

TEL (44) 1355-803-000

FAX (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

TEL (49) 71-31-67-0

FAX (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906

TEL 1(719) 576-3300

FAX 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

TEL (33) 4-76-58-30-00

FAX (33) 4-76-58-34-80

e-mail

literature@atmel.com

Web Site

http://www.atmel.com

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is gra nted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT

OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the a ccuracy or com p l etene ss o f the con tents of this documen t and reserves the right to make changes to specificat ions

and product descriptions at any time without notice. Atmel does not make any commitment to upd ate the information contained here in. Unless specifically p rovided

otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended, authorized, or warranted for use

as components in applications intended to support or sustain life.

© Atmel Corporation 2005. All rights reserved. Atmel®, logo and combinations thereof, Everywhere You Are

and others, are registered trademarks or trademarks of Atmel Corporation or its subsidiaries. Other terms and

product names may be trademarks of others.

®

Printed on recycled paper.

4339C–CAN–07/05

/xM

Loading...

Loading...