Page 1

Features

®

• AVR

• USB Hub with One Attached and Two External Ports

• USB Function with Three Programmable End-points

• 24 KB Program Memory, 1 KB Data SRAM

• 32 x 8 General-purpose Working Registers

• 27 Programmable I/O Port Pins

• 12-channel 10-bit ADC

• Master/Slave SPI Serial Interface

• One 8-bit Timer/Counter with Separate Pre-scaler

• One 16-bit Timer/Counter with Separate Pre-scaler and Two PWMs

• External and Internal Interrupt Sources

• Programmable Watchdog Timer

• 6 MHz Oscillator with On-chip PLL

• 5V Operation with On-chip 3.3V Power Supply

• 64-lead LQFP Package

8-bit RISC Microcontroller with 83 ns Instruction Cycle Time

Full-speed

USB

Microcontroller

with Embedded

Description

The Atmel AT43USB355 is an 8-bit microcontroller based on the AVR RISC architecture. By executing powerful instructions in a single clock cycle, the AT43USB355

achieves throughputs approaching 12 MIPS. The AVR core combines a rich instruction set with 32 general-purpose working registers. All 32 registers are directly

connected to the ALU allowing two independent registers to be accessed in one single

instruction executed in one clock cycle. The resulting architecture is more code efficient while achieving throughputs up to ten times faster than conventional CISC

microcontrollers.

Furthermore, the AT43USB355 features an on-chip 24-Kbyte program memory and

1-Kbyte of data memory. It is supported by a standard set of peripherals such as

timer/counter modules, watchdog timer and internal and external interrupt sources.

The major peripheral included in the AT43USB355 is a full-speed USB 2.0 Hub with

an embedded function and a 12-channel Analog-to-Digital Converter (ADC) for use in

applications such as game controllers.

Hub, ADC and

PWM

AT43USB355

2603G–USB–04/06

1

Page 2

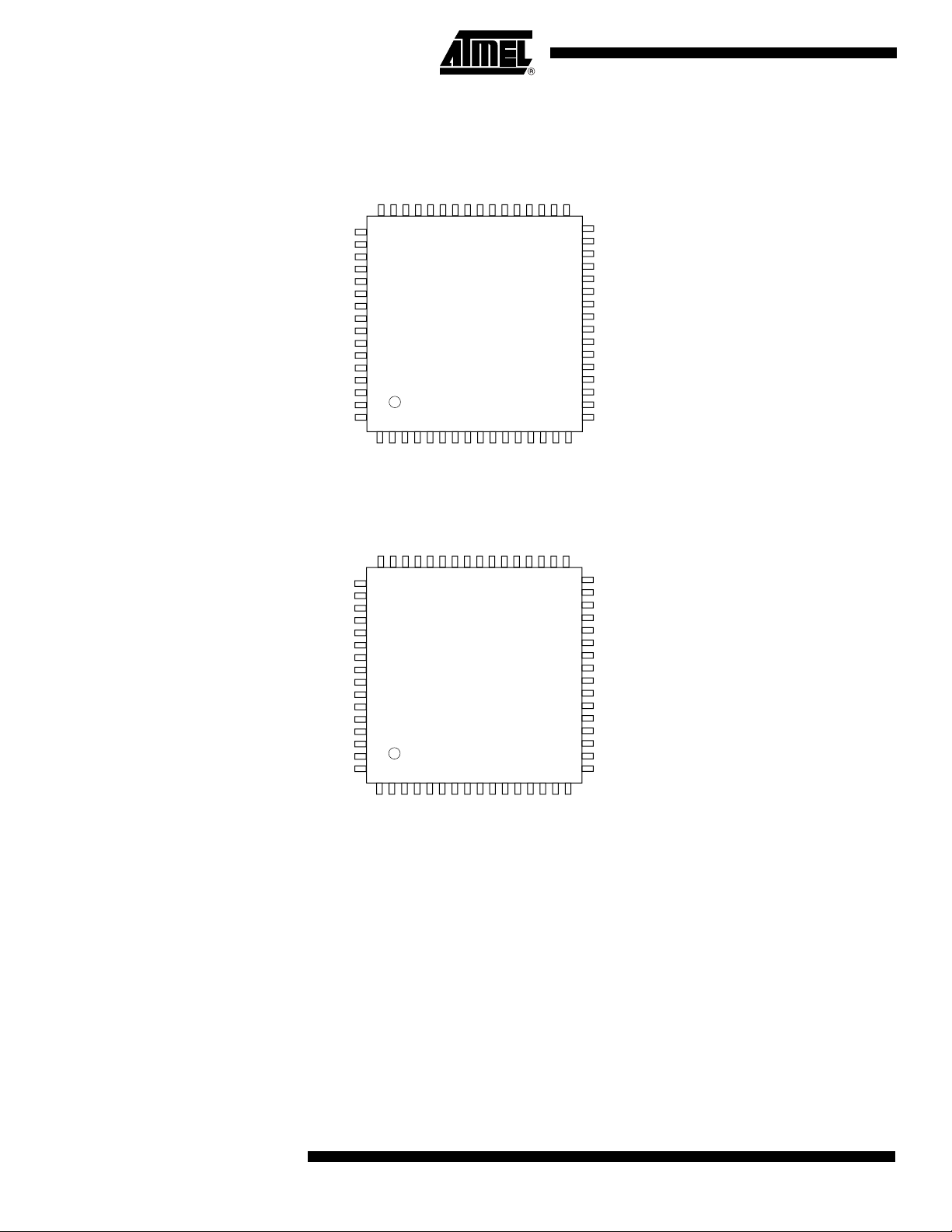

Pin Configuration

Figure 1. AT43USB355E 64-lead LQFP

Figure 2. AT43USB355M 64-lead LQFP

SCK

SSN

MOSI

MISO

CEXT3

VCC3

VSS3

PD7

PD6

PD5

XTAL1

XTAL2

PD4

PD3

PD2

PF1

PF2

PF3

CEXT3

VCC3

VSS3

PD7

PD6

PD5

XTAL1

XTAL2

PD4

PD3

PD2

VREF

VSSA

CEXTA

VCCA

ADC0

ADC1

ADC2

ADC3

ADC4

ADC5

ADC6

ADC7

ADC8

ADC9

ADC10

ADC11

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

LFT

62

63

64

1

PD1

VREF

48

49

50

NC

51

52

53

54

55

56

57

58

59

60

61

LFT

62

63

64

1

AT43USB355E-AC

2345678910111213141516

PD0

VSSA

47

DP3

CEXTA

46

DM3

VCCA

45

DP2

ADC0

44

DM2

ADC1

43

DP0

ADC2

42

DM0

ADC3

41

CEXT2

ADC4

40

VCC2

ADC5

39

VSS2

ADC6

38

PB7

ADC7

37

AT43USB355M-AC

2345678910111213141516

PB6

ADC8

36

PB5

ADC9

35

PB4

ADC10

34

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

PB3

ADC11

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

TEST

RESETN

PA0

PA1

PA2

PA3

CEXT1

VCC1

VSS1

PA4

PA5

PA6

PA7

PB0

PB1

PB2

TEST

RESETN

PA0

PA1

PA2

PA3

CEXT1

VCC1

VSS1

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB7

PB6

PB5

PB4

PD1

DP3

DP2

DM3

DM2

DP0

DM0

VSS2

VCC2

CEXT2

PD0

2

AT43USB355

PB3

2603G–USB–04/06

Page 3

AT43USB355

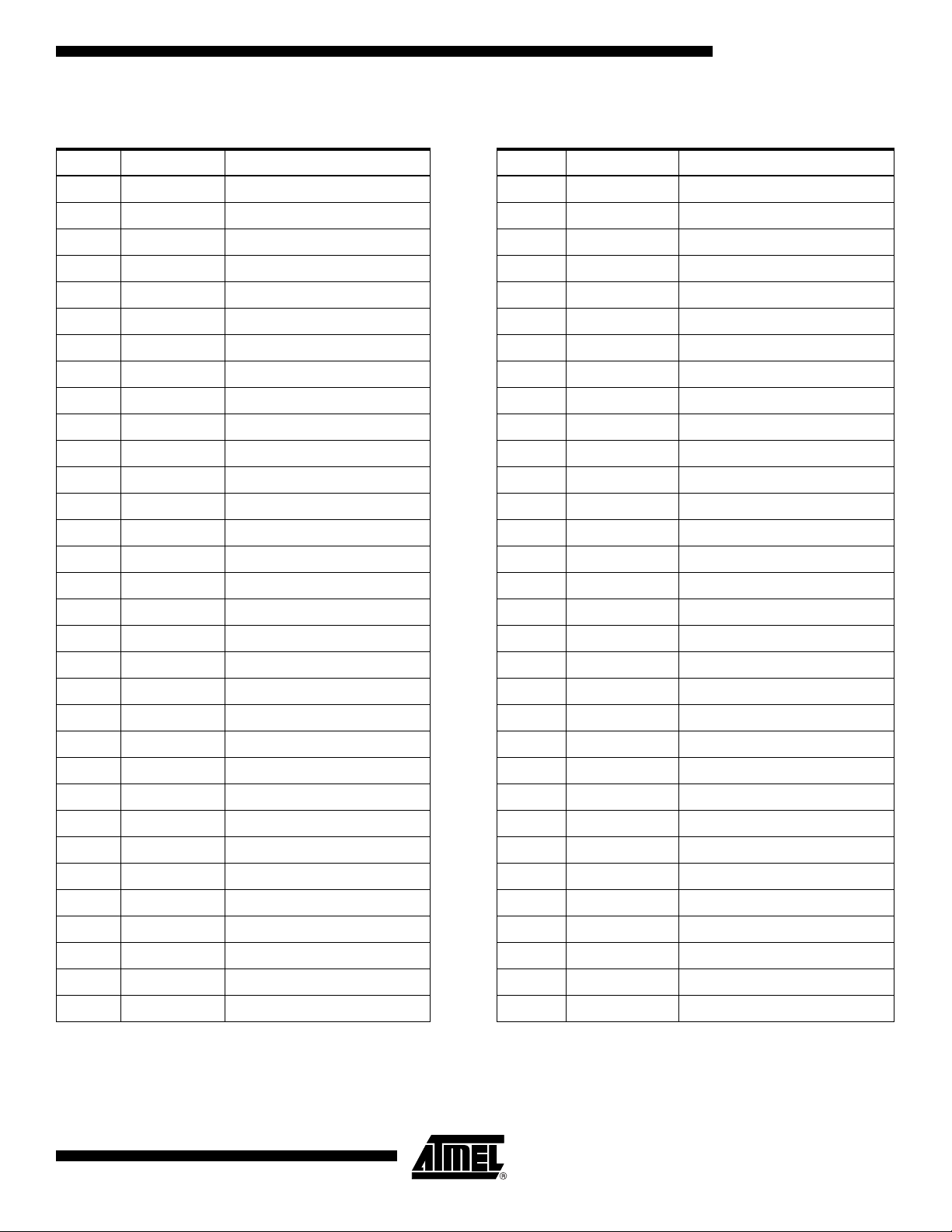

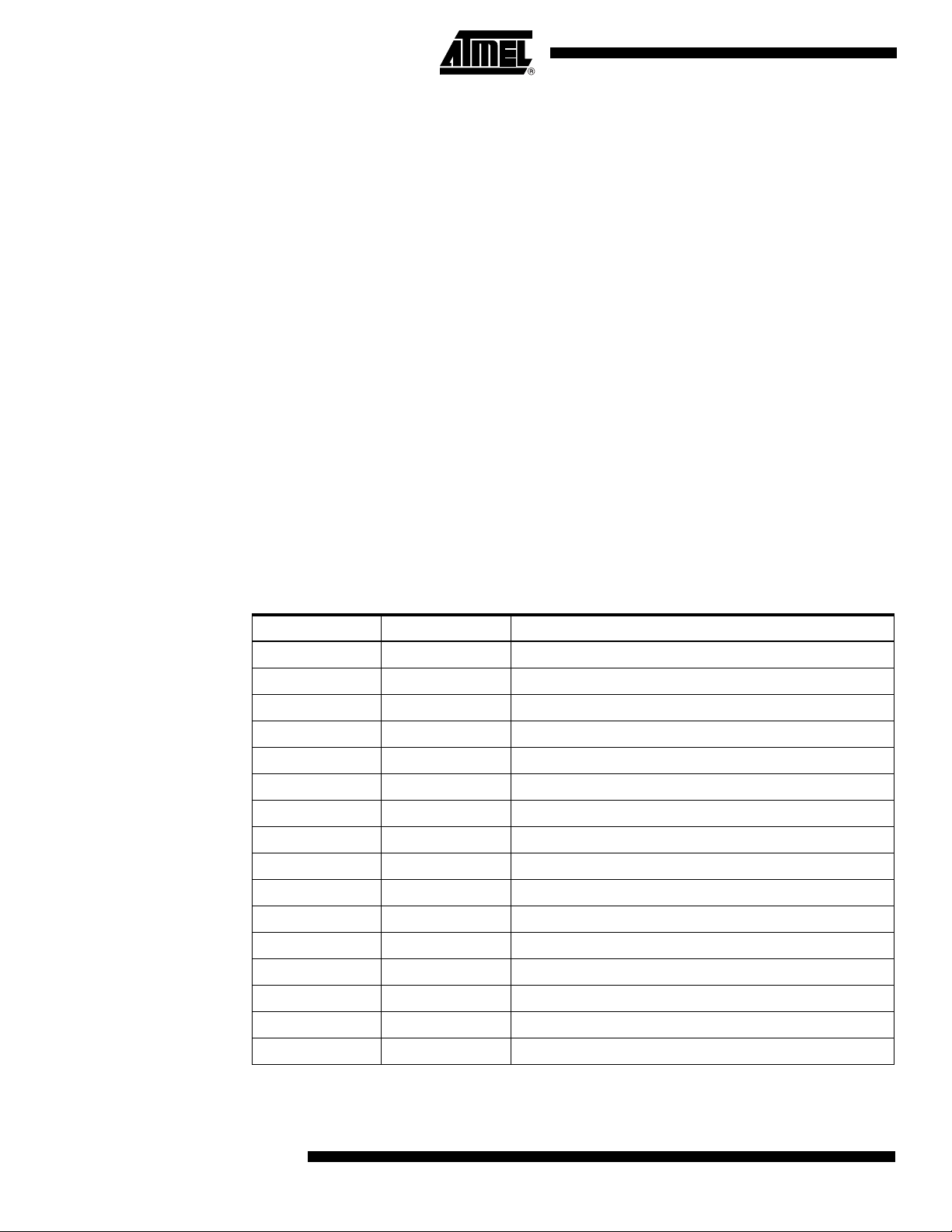

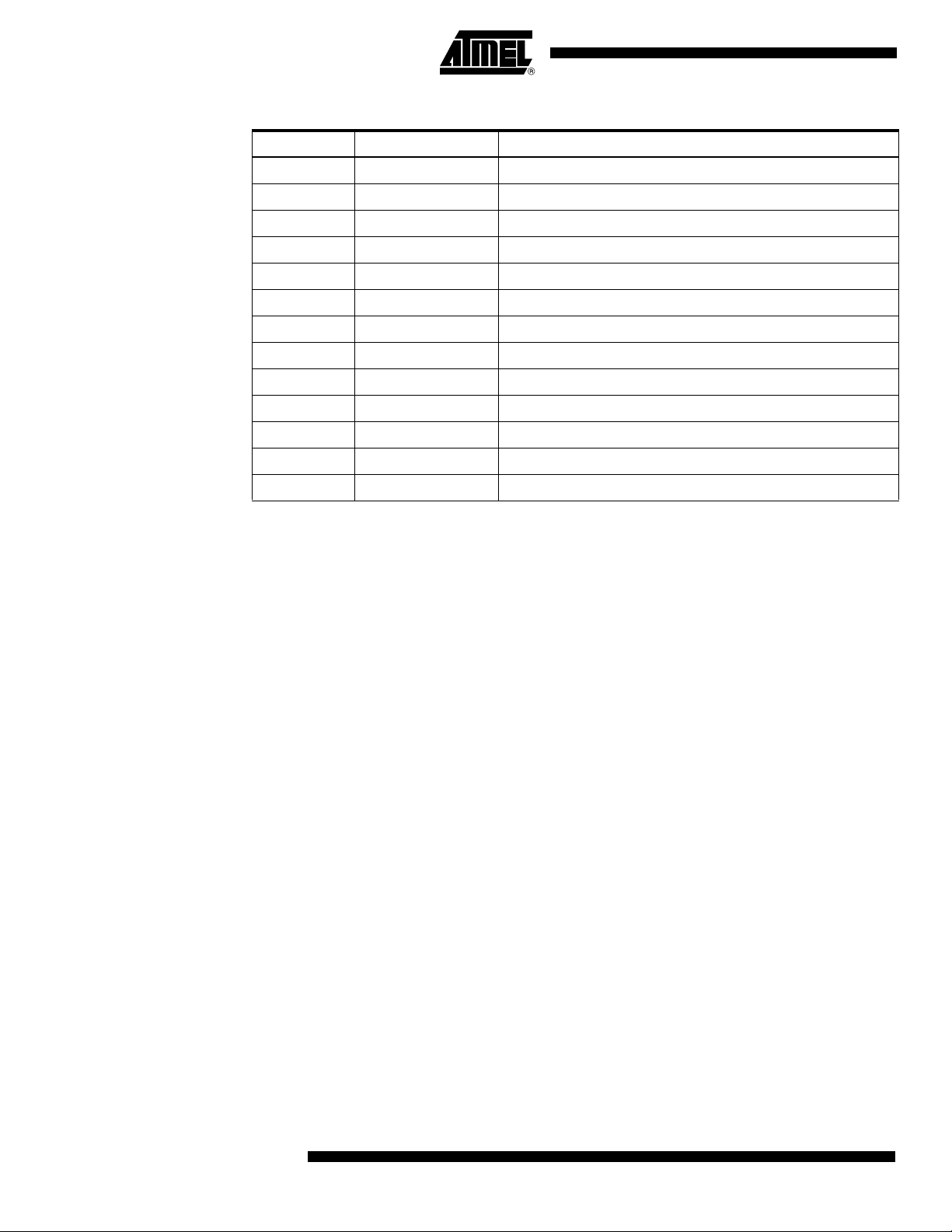

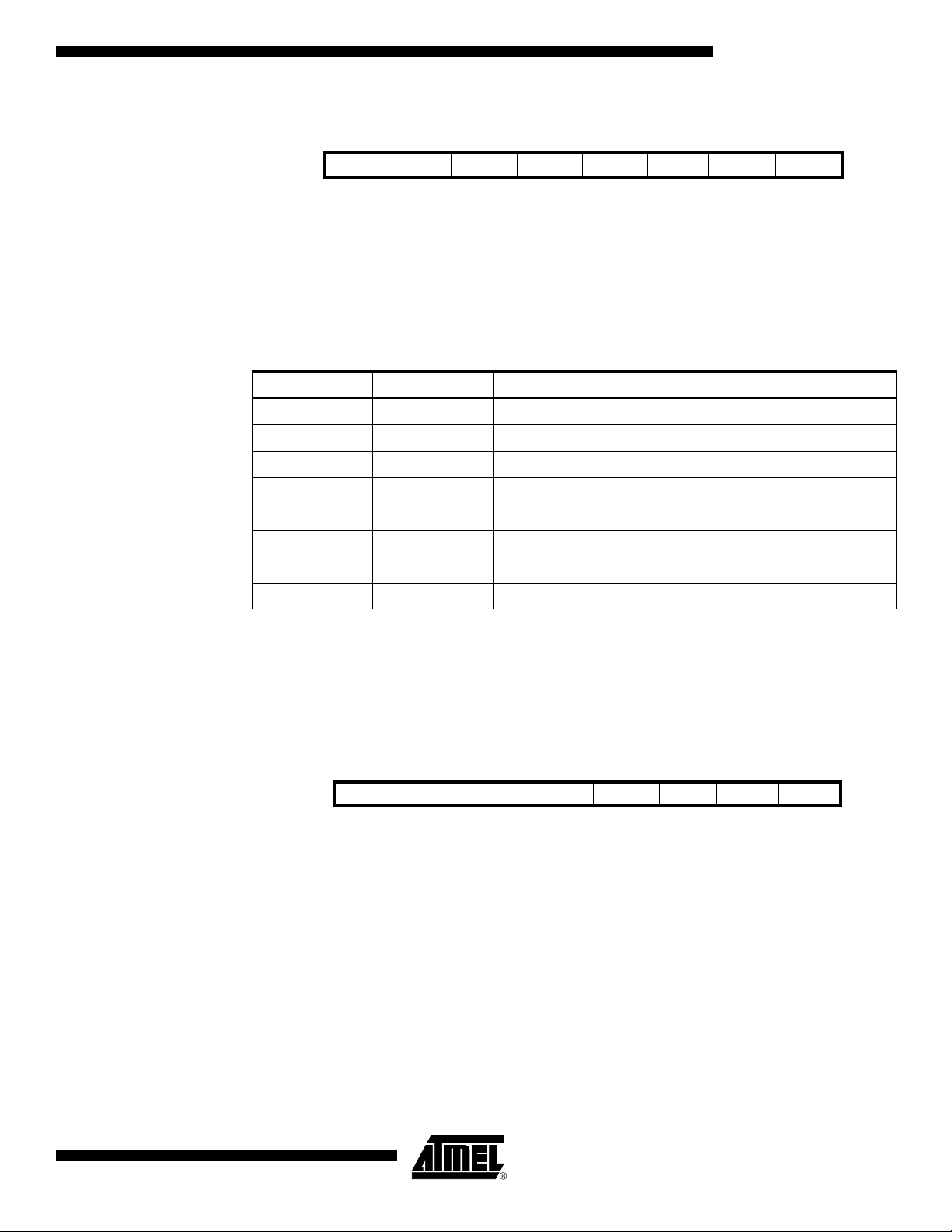

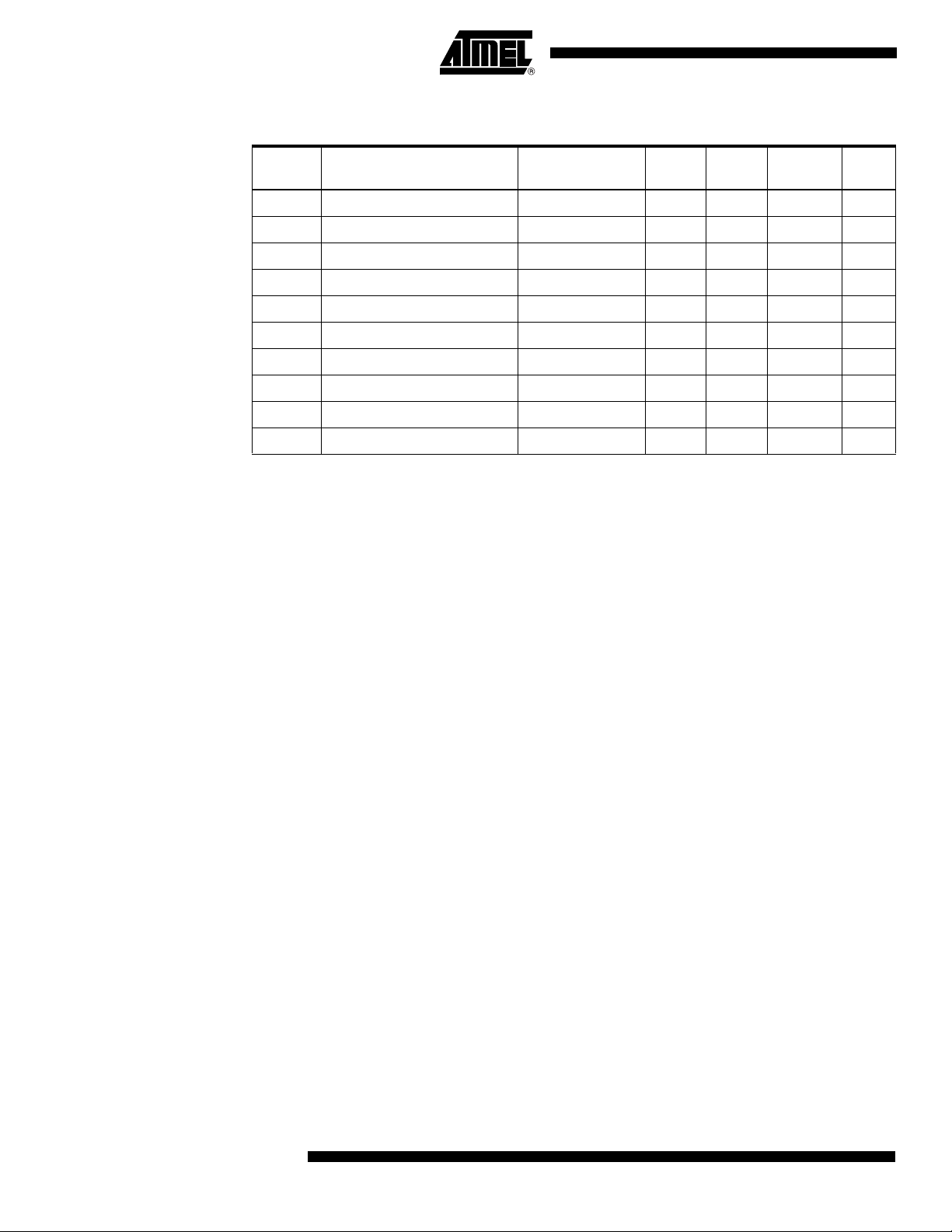

Pin Assignment

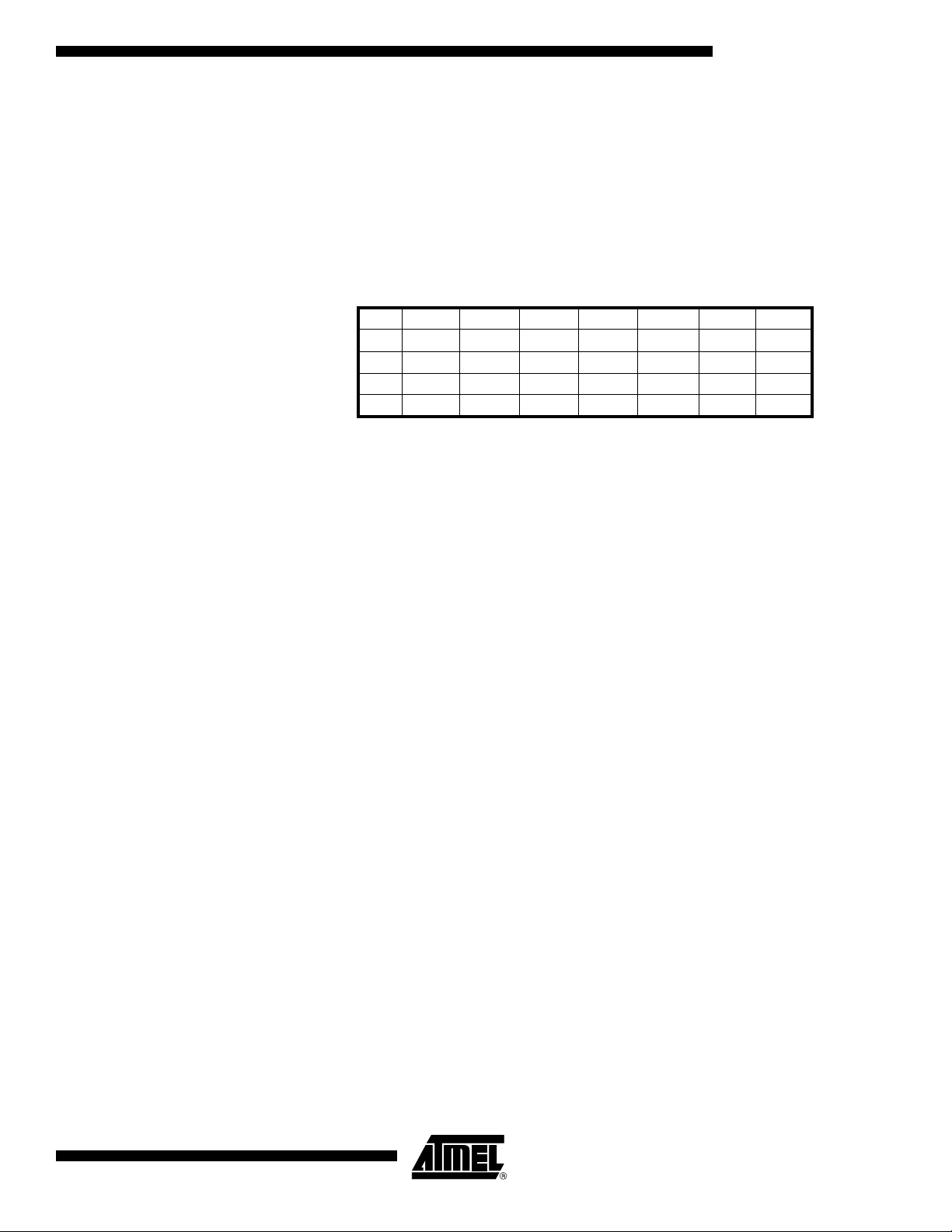

Pin# Signal Type Pin# Signal Type

1 PD1 Bi-directional 33 ADC11 Input

2 PD0 Bi-directional 34 ADC10 Input

3 DP3 Bi-directional 35 ADC9 Input

4 DM3 Bi-directional 36 ADC8 Input

5 DP2 Bi-directional 37 ADC7 Input

6 DM2 Bi-directional 38 ADC6 Input

7 DP0 Bi-directional 39 ADC5 Input

8 DM0 Bi-directional 40 ADC4 Input

9 CEXT2 Power Supply/Ground 41 ADC3 Input

10 VCC2 Power Supply/Ground 42 ADC2 Input

11 VSS2 Power Supply/Ground 43 ADC1 Input

12 PB7 Bi-directional 44 ADC0 Input

13 PB6 Bi-directional 45 VCCA Power Supply/Ground

14 PB5 Bi-directional 46 CEXTA Power Supply/Ground

15 PB4 Bi-directional 47 VSSA Power Supply/Ground

16 PB3 Bi-directional 48 VREF Input

17 PB2 Bi-directional 49 SCK/PF1 Bi-directional

18 PB1 Bi-directional 50 SSN/NC –

19 PB0 Bi-directional 51 MOSI/PF2 Bi-directional

20 PA7 Bi-directional 52 MISO/PF3 Bi-directional

21 PA6 Bi-directional 53 CEXT3 Power Supply/Ground

22 PA5 Bi-directional 54 VCC3 Power Supply/Ground

23 PA4 Bi-directional 55 VSS3 Power Supply/Ground

24 VSS1 Power Supply/Ground 56 PD7 Bi-directional

25 VCC1 Power Supply/Ground 57 PD6 Bi-directional

26 CEXT1 Power Supply/Ground 58 PD5 Bi-directional

27 PA3 Bi-directional 59 XTAL1 Input

28 PA2 Bi-directional 60 XTAL2 Output

29 PA1 Bi-directional 61 LFT Output

30 PA0 Bi-directional 62 PD4 Bi-directional

31 RESETN Input 63 PD3 Bi-directional

32 TEST Input 64 PD2 Bi-directional

2603G–USB–04/06

3

Page 4

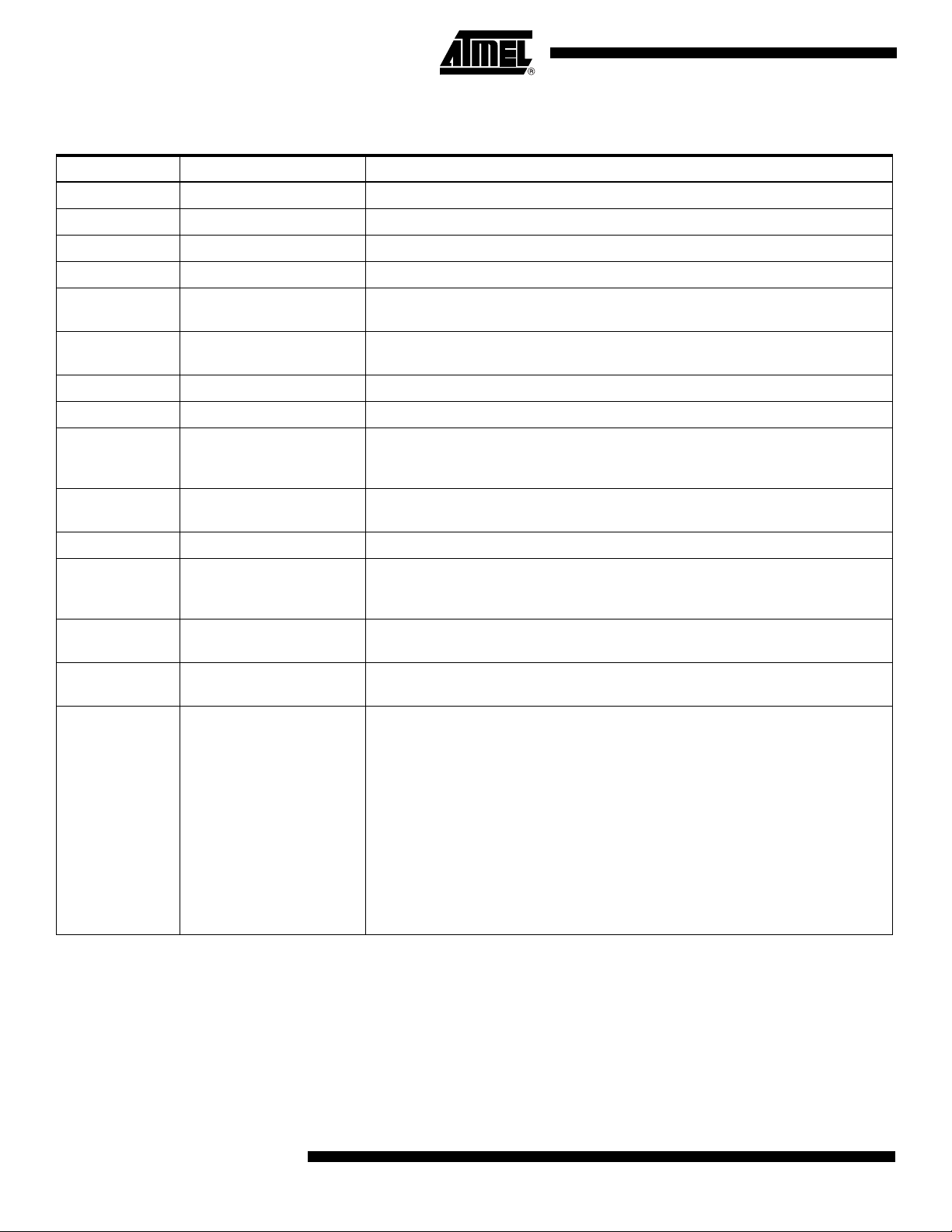

Signal Description

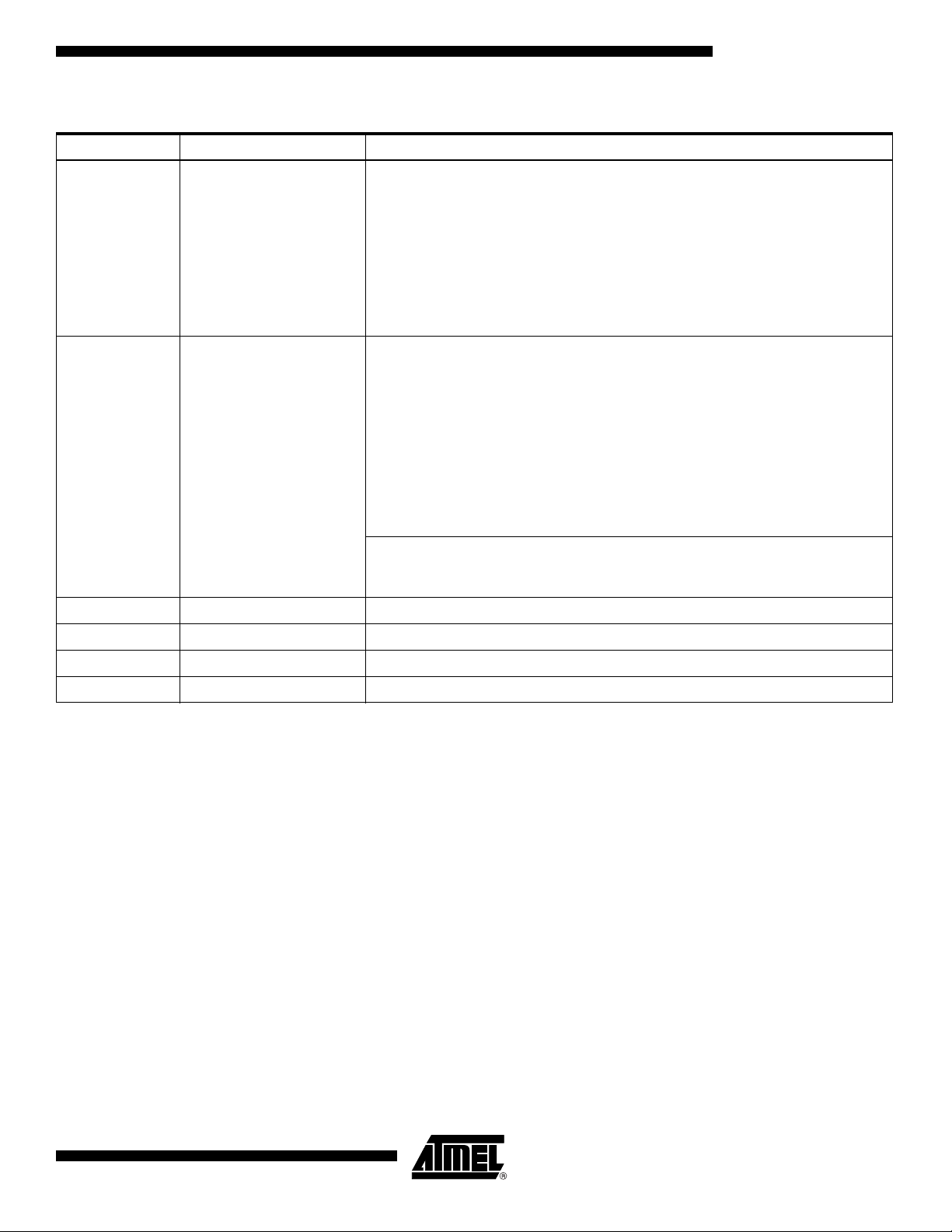

Name Type Function

V

CC1, 2, 3

V

CCA

V

V

CEXT1, 2, 3 Power Supply/Ground

CEXTA Power Supply/Ground

XTAL1 Input Oscillator Input – Input to the inverting oscillator amplifier.

XTAL2 Output Oscillator Output – Output of the inverting oscillator amplifier.

LFT Input

DPO Bi-directional

DMO Bi-directional Upstream Minus USB I/O

DP[2,3] Bi-directional

DM[2,3] Bi-directional

PA[0:7] Bi-directional

Power Supply/Ground Digital Ground

SS1, 2, 3

SSA

Power Supply/Ground 5V Digital Power Supply

Power Supply/Ground 5V Power Supply for the ADC

Power Supply/Ground Ground for the ADC

External Capacitors for Power Supplies – High quality 2.2 µF capacitors must be

connected to CEXT1, 2 and 3 for proper operation of the chip.

External Capacitor for Analog Power Supply – A high quality 0.33 µF capacitor

must be connected to CEXTA for proper operation of the chip.

PLL Filter – For proper operation of the PLL, this pin should be connected through

a 0.01 µF capacitor in parallel with a 100Ω resistor in series with a 0.1 µF capacitor

to ground (VSS). Both capacitors must be high quality ceramic.

Upstream Plus USB I/O – This pin should be connected to CEXT1 through an

external 1.5 kΩ.

Downstream Plus USB I/O – Each of these pins should be connected to VSS

through an external 15 kΩ resistor. DP[2,3] and DM[2,3] are the differential signal

pin pairs to connect downstream USB devices.

Downstream Minus USB I/O – Each of these pins should be connected to VSS

through an external 15 kΩ resistor.

Port A[0:7] – Bi-directional 8-bit I/O port with 2 mA drive strength and a

programmable pull-up resistor.

PB[0:7] Bi-directional

4

AT43USB355

Port B[0:7] – Bi-directional 8-bit I/O port with 2 mA drive strength and a

programmable pull-up resistor. PB[0,1,4:7] have dual functions as shown below:

Port Pin Alternate Function

PB0 T0, Timer/Counter0 External Input

PB1 T1, Timer/Counter1 External Input

PB4 SSN, SPI Slave Port Select or SCL, I2C Serial Bus Clock

PB5 MOSI, SPI Slave Port Select Input

PB6 MISO, SPI Master Data In, Slave Data Out

PB7 SCK, SPI Master Clock Out, Slave Clock In

2603G–USB–04/06

Page 5

Signal Description (Continued)

Name Type Function

Port D[0:7] – Bi-directional I/O ports with 2 mA drive strength and a programmable

pull-up resistor. PortD[2,3,5,6] have dual functions as shown below:

Port Pin Alternate Function

AT43USB355

PD[0:7] Bi-directional

PF[1:3] Bi-directional

SSN/NC Output

ADC[0:11] Input ADC Input[0:11] – 12-bit input pins for the ADC.

AREF Input Analog Reference – Input for the ADC.

TEST Input Test Pin – This pin should be tied to ground.

RESETN Input Reset – Active Low.

PD2 INT0, External Interrupt 0

PD3 INT1, External Interrupt 1

PD5 OC1A Timer/Counter1 Output Compare A

PD6 OC1B Timer/Counter1 Output Compare B

Port F[1:3] – Bi-directional 3-bit I/O port with 2 mA drive strength and a

programmable pull-up resistor. In the AT43USB355E, PF[1:3] pins have dual

functions as the interface pins to the serial EEPROM. After program memory

downloading is complete, PF3 has a third function as Timer/Counter1 Input

Capture, ICP.

Port Pin Alternate Function

PF1 SCK, SPI Master Clock Out

PF2 MOSI, SPI Slave Data Input

PF3 MISO, SPI Slave Data Out. ICP after download complete

Slave Select – In the AT43USB355E, this pin enables the external serial memory.

In the AT43USB355M, this pin has no function and can be left floating or connected

to VCEXT.

2603G–USB–04/06

5

Page 6

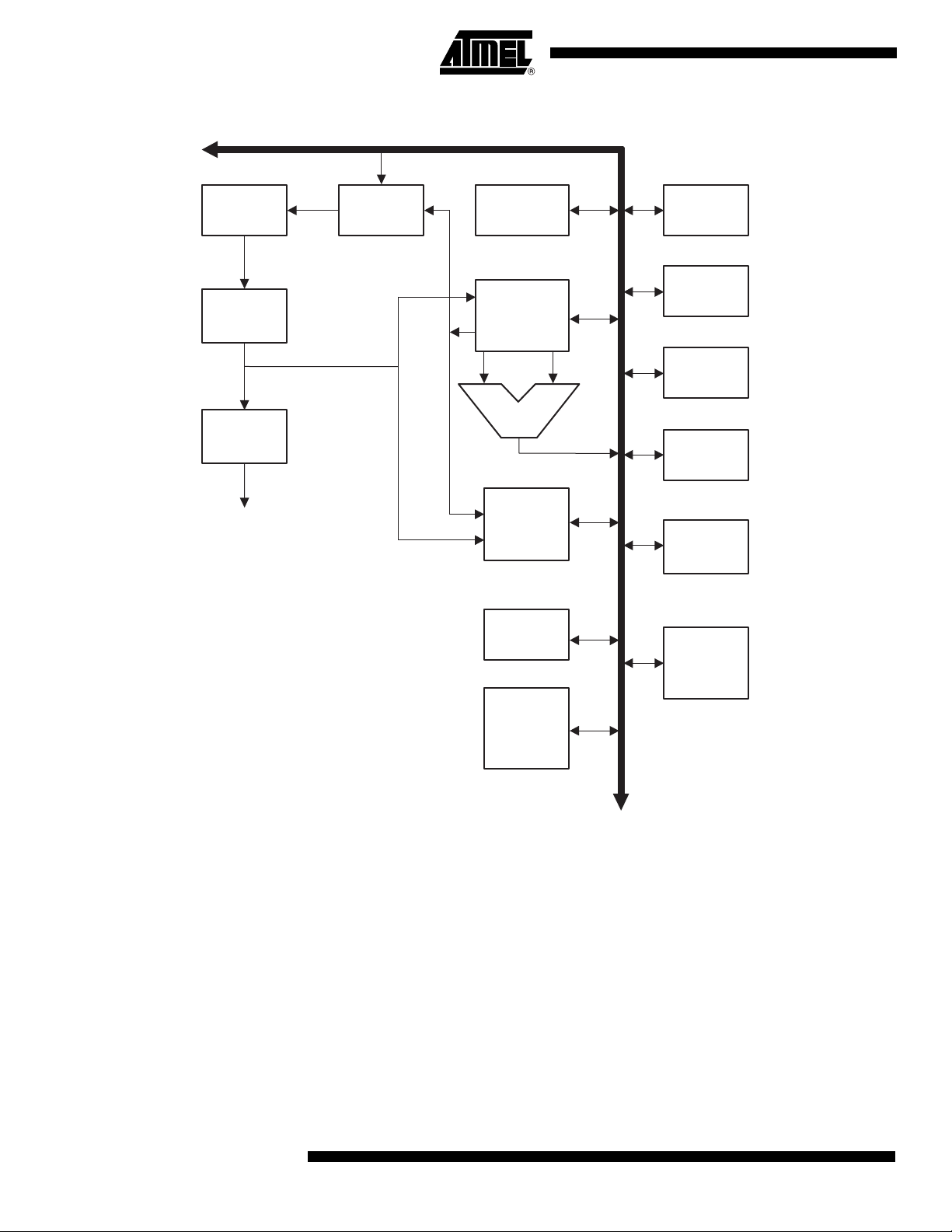

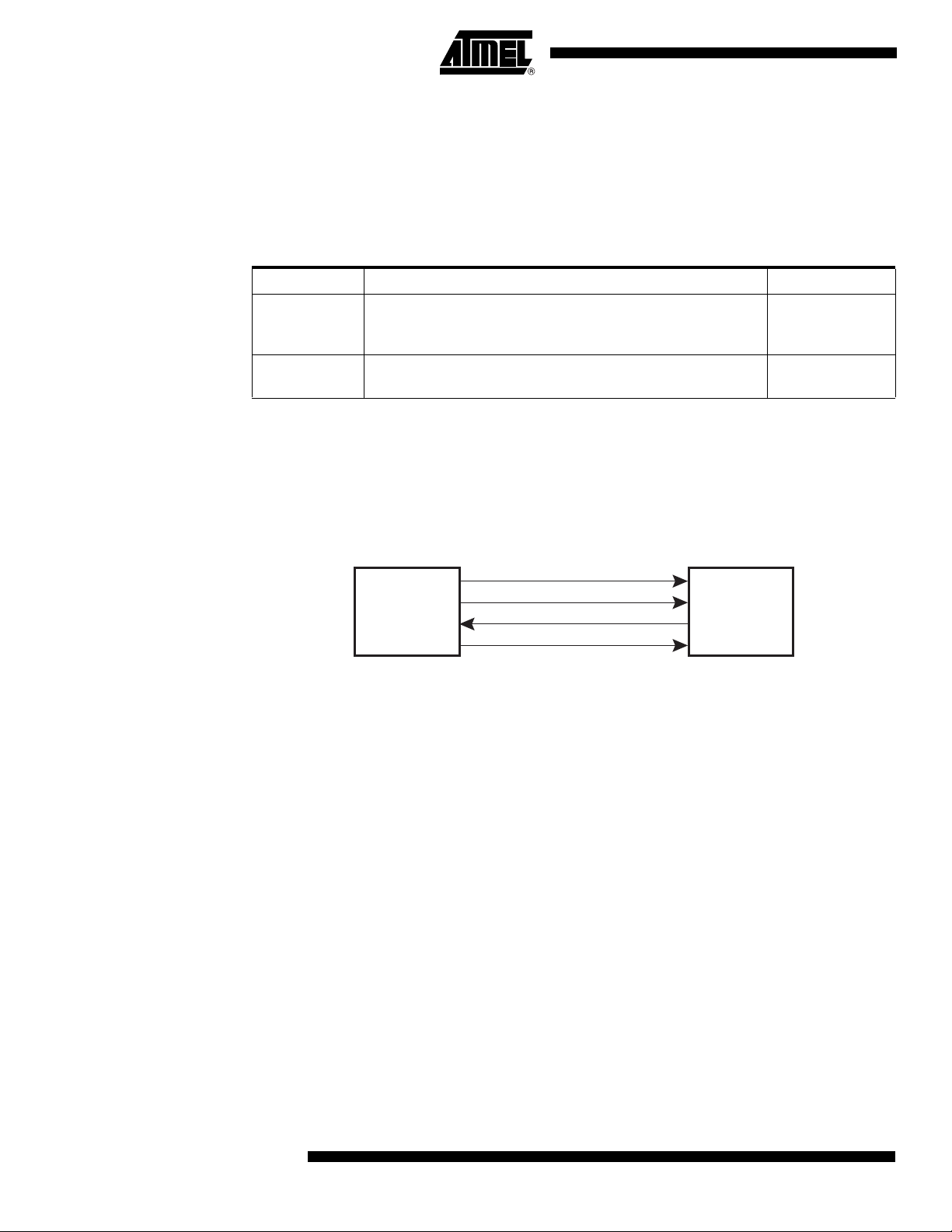

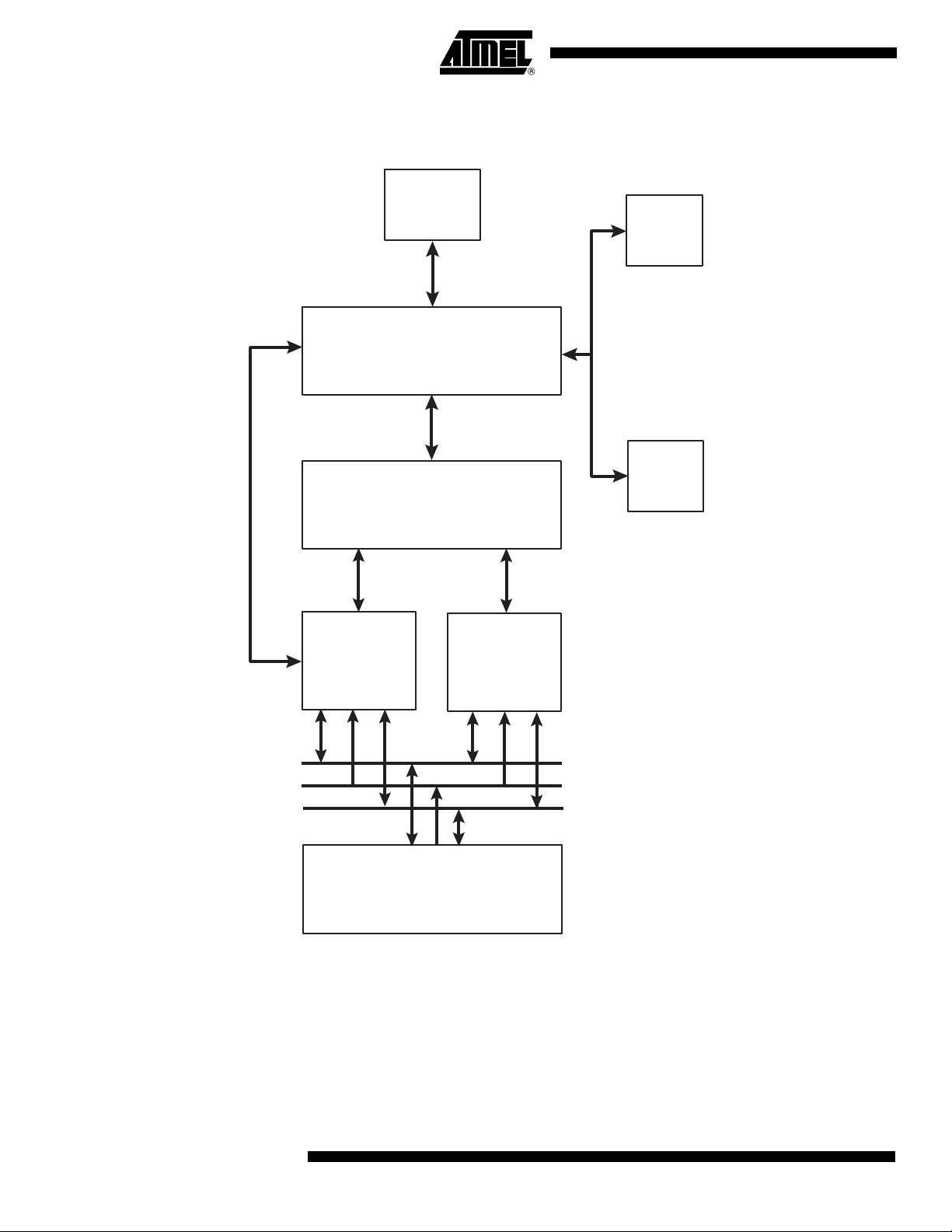

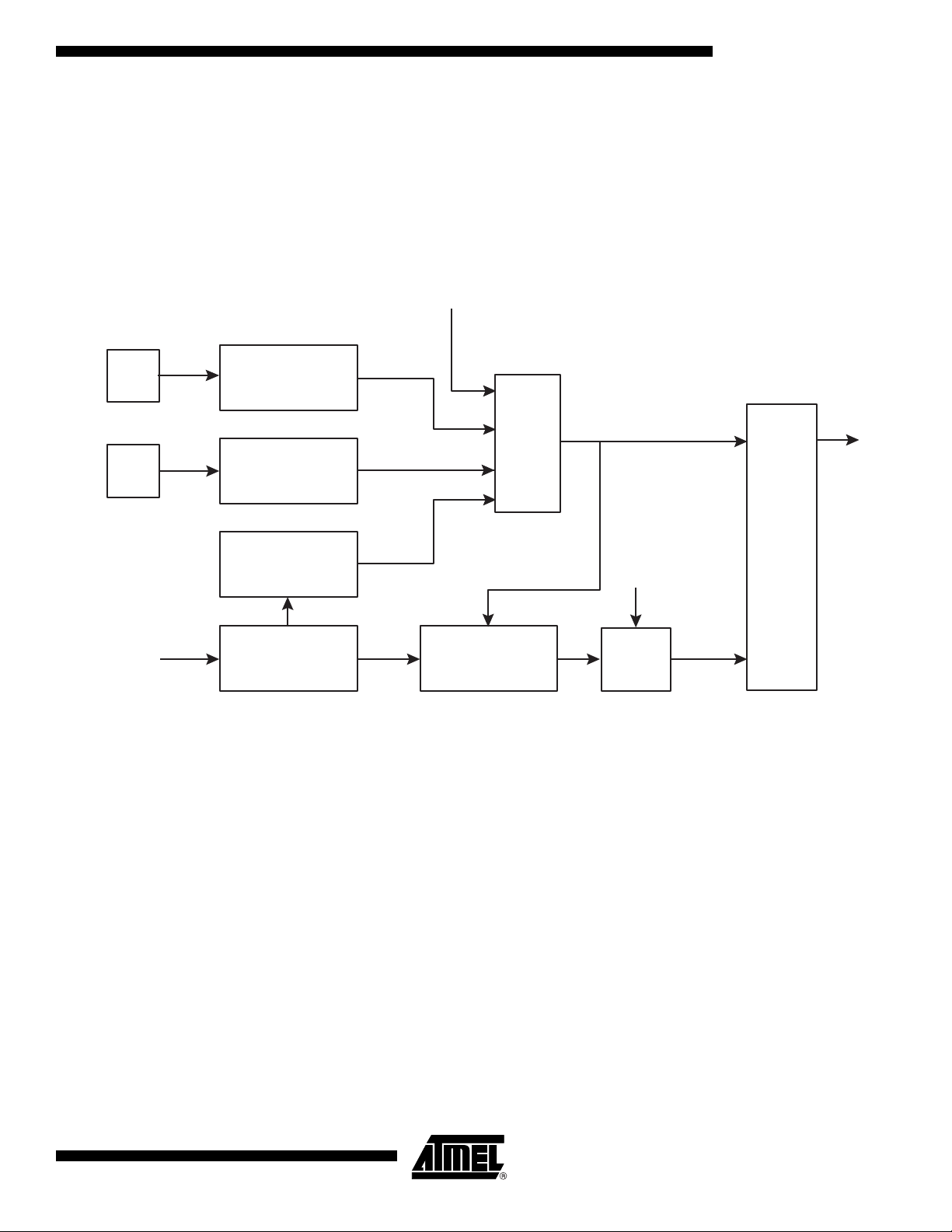

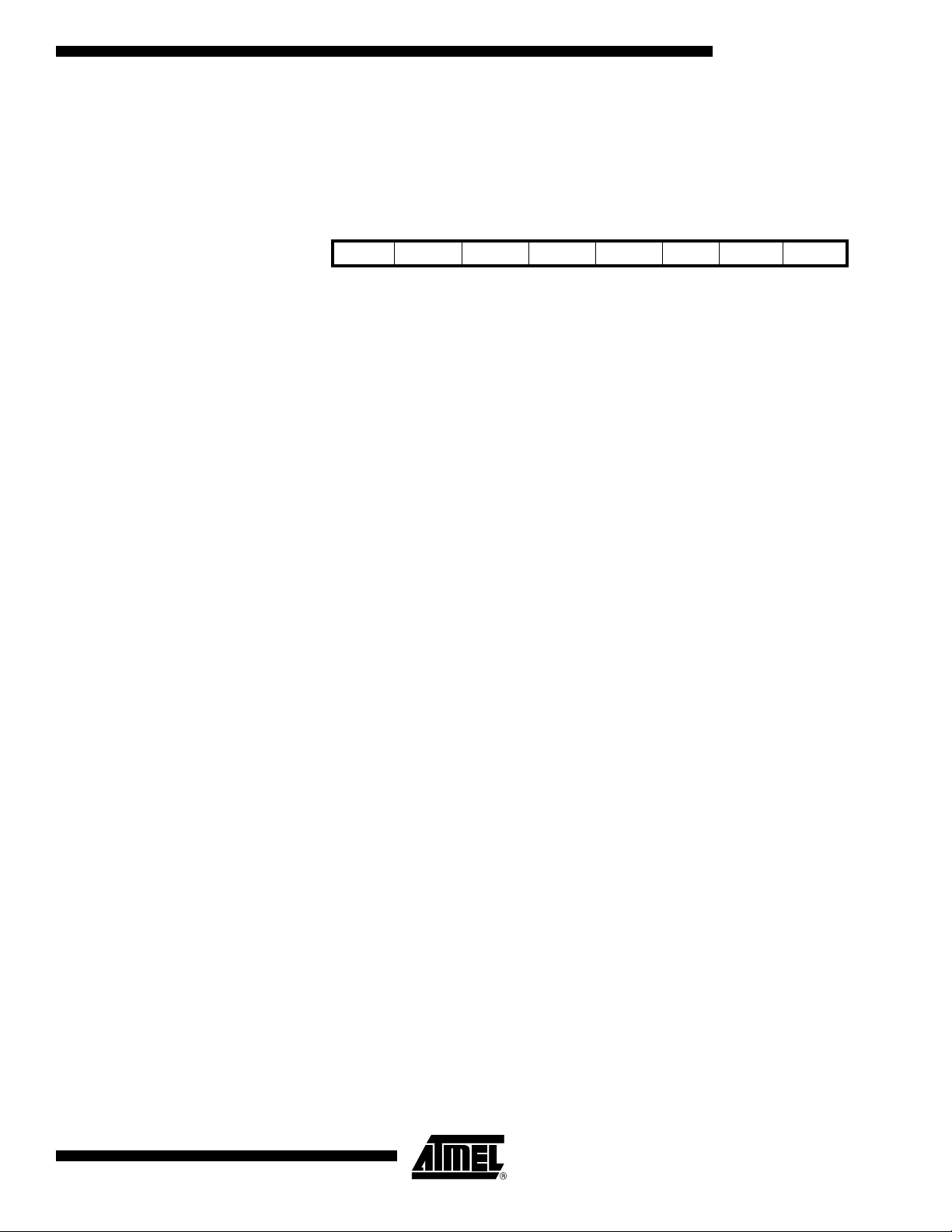

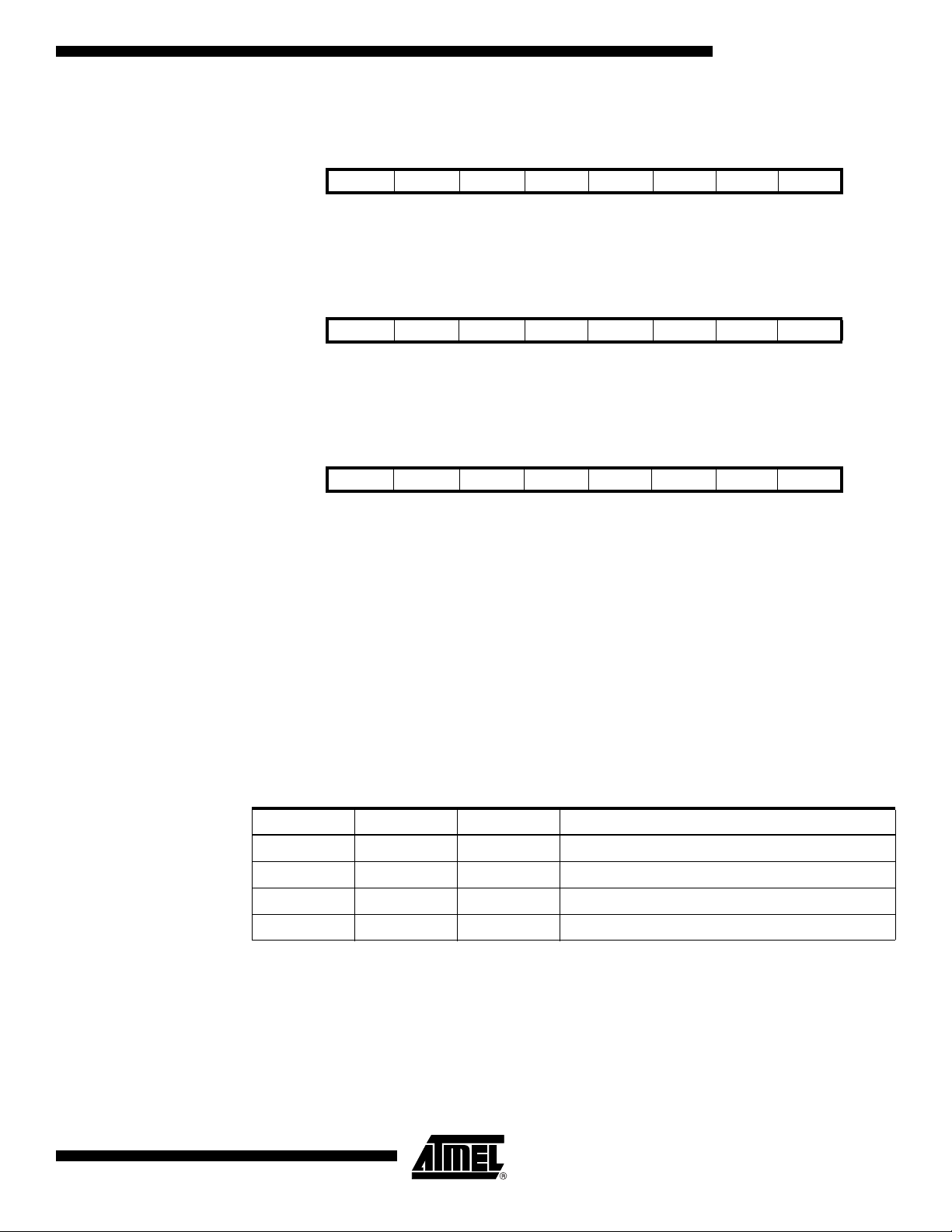

Figure 3. AT43USB355 Enhanced RISC Architecture

12K x 16

Program

Memory

Instruction

Register

Instruction

Decoder

Control

Lines

Program

Counter

Status and

Control

32 x 8

General-purpose

Registers

ALU

1024 x 8

SRAM

27 GPIO

Lines

Interrupt

Unit

8-bit

Timer/Counter

16-bit

Timer/Counter

Watchdog

Timer

SPI Unit

ADC

USB

Hub and

Function

6

AT43USB355

2603G–USB–04/06

Page 7

AT43USB355

Architectural Overview

The AT43USB355 is available in 2 versions. The program memory of the AT43USB355E is an

SRAM that is automatically written from an external serial EEPROM during power-on. The

AT43USB355M has a masked ROM program memory. The two versions are pin, function and

binary compatible.

The peripherals and features of the AT43USB355 microcontroller are similar to those of the

AT90S8515, with the exception of the following modifications:

• The AT43USB355E has a downloadable SRAM and the AT43USB355M has a masked

ROM for program memory

• No EEPROM

• No external data memory accesses

•No UART

• Idle mode not supported

• USB Hub with attached function

• On-chip ADC

The embedded USB hardware of the AT43USB355 is a compound device, consisting of a 3

port hub with a permanently attached function on one port. The hub and attached function are

two independent USB devices, each having its own device addresses and control end-points.

The hub has its dedicated interrupt end-point, while the USB function has 3 additional programmable end-points with separate FIFOs. Two of the FIFOs are 64 bytes deep and the third

is 8 bytes deep.

The microcontroller always runs from a 12 MHz clock that is generated by the USB hardware.

While the nominal and average period of this clock is 83.3 ns, it may have single cycles that

deviate by ±20.8 ns during a phase adjustment by the SIE's clock/data separator of the USB

hardware.

The microcontroller shares most of the control and status registers of the megaAVR Microcontroller Family. The registers for managing the USB operations are mapped into its SRAM

space. The I/O section on page 16 summarizes the available I/O registers. The “AVR Register

Set” on page 37 covers the AVR registers. Please refer to the Atmel AVR manual for more

information.

The fast-access register file concept contains 32 x 8-bit general-purpose working registers

with a single clock cycle access time. This means that during one single clock cycle, one Arithmetic Logic Unit (ALU) operation is executed. Two operands are output from the register file,

the operation is executed, and the result is stored back in the register file – in one clock cycle.

Six of the 32 registers can be used as three 16-bit indirect address register pointers for Data

Space addressing - enabling efficient address calculations. One of the three address pointers

is also used as the address pointer for look-up tables in program memory. These added function registers are the 16-bit X-, Y- and Z-registers.

The ALU supports arithmetic and logic operations between registers or between a constant

and a register. Single register operations are also executed in the ALU. Figure 3 on page 6

shows the AT43USB355 AVR Enhanced RISC microcontroller architecture.

In addition to the register operation, the conventional memory addressing modes can be used

on the register file as well. This is enabled by the fact that the register file is assigned the 32

lowest Data Space addresses ($00 - $1 F), allowing them to be accessed as though they were

ordinary memory locations.

The I/O memory space contains 64 addresses for CPU peripheral functions as Control Registers, Timer/Counters, and other I/O functions. The I/O Memory can be accessed directly, or as

the Data Space locations following those of the register file, $20 - $5F.

2603G–USB–04/06

7

Page 8

The AVR uses a Harvard architecture concept – with separate memories and buses for program and data. The program memory is executed with a single-level pipelining. While one

instruction is being executed, the next instruction is pre-fetched from the program memory.

This concept enables instructions to be executed in every clock cycle. The program memory is

a downloadable SRAM or a mask programmed ROM.

With the relative jump and call instructions, the whole 24K address space is directly accessed.

Most AVR instructions have a single 16-bit word format. Every program memory address contains a 16- or 32-bit instruction.

During interrupts and subroutine calls, the return address Program Counter (PC) is stored on

the stack. The stack is effectively allocated in the general data SRAM, and consequently, the

stack size is only limited by the total SRAM size and the usage of the SRAM. All user programs must initialize the Stack Pointer (SP) in the reset routine (before subroutines or

interrupts are executed). The 10-bit SP is read/write accessible in the I/O space.

The 1-Kbyte data SRAM can be easily accessed through the five different addressing modes

supported in the AVR architecture.

The memory spaces in the AVR architecture are all linear and regular memory maps. A flexible interrupt module has its control registers in the I/O space with an additional global interrupt

enable bit in the status register. All interrupts have a separate interrupt vector in the interrupt

vector table at the beginning of the program memory. The interrupts have priority in accordance with their interrupt vector position. The lower the interrupt vector address, the higher the

priority.

The Generalpurpose

Register File

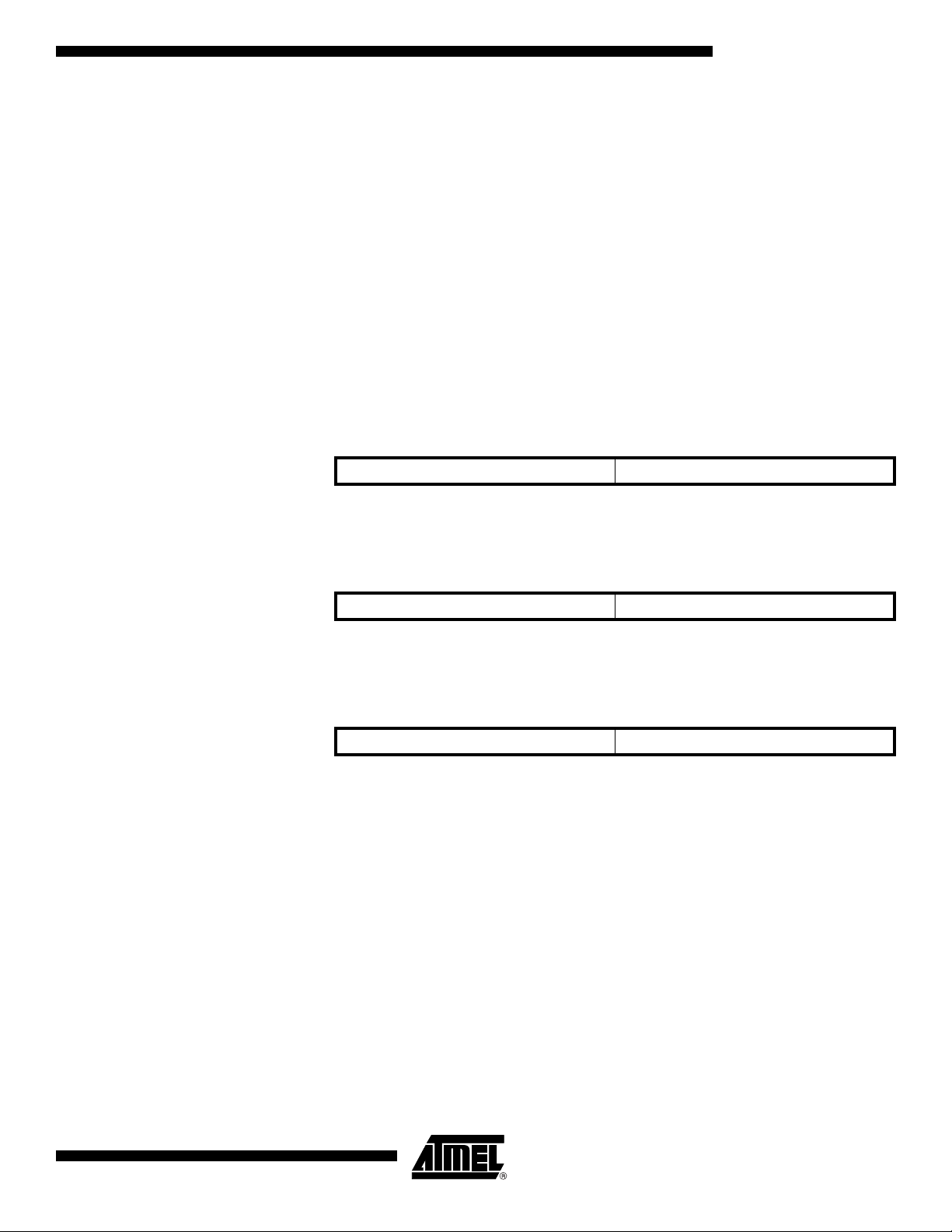

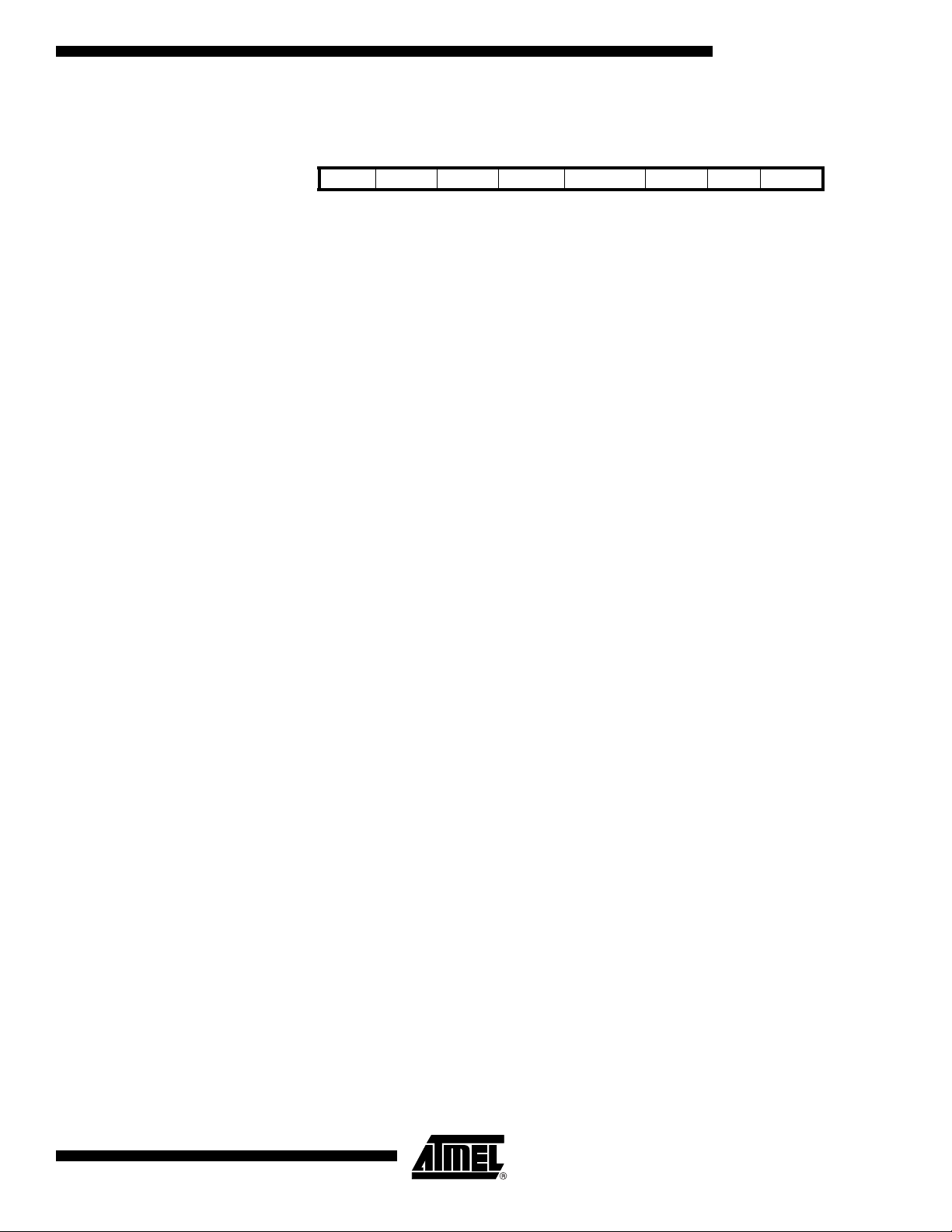

Table 1. AVR CPU General-purpose Working Register

Register Address Comment

R0 $00

R1 $01

R2 $02

..

R13 $0D

R14 $0E

R15 $0F

R16 $10

R17 $11

..

R26 $1A X-register low byte

R27 $1B X-register high byte

R28 $1C Y-register low byte

R29 $1D Y-register high byte

R30 $1E Z-register low byte

R31 $1F Z-register high byte

8

AT43USB355

2603G–USB–04/06

Page 9

AT43USB355

All register operating instructions in the instruction set have direct and single cycle access to

all registers. The only exception is the five constant arithmetic and logic instructions SBCI,

SUBI, CPI, ANDI, and ORI between a constant and a register, and the LDI instruction for load

immediate constant data. These instructions apply to the second half of the registers in the

register file – R16..R31. The general SBC, SUB, CP, AND, and OR and all other operations

between two registers or on a single register apply to the entire register file.

As shown in Table 1, each register is also assigned a data memory address, mapping them

directly into the first 32 locations of the user Data Space. Although not being physically implemented as SRAM locations, this memory organization provides great flexibility in access of the

registers, as the X-, Y-, and Z-registers can be set to index any register in the file.

X-, Y- and ZRegisters

Registers R26..R31 contain some added functions to their general-purpose usage. These registers are address pointers for indirect addressing of the Data Space. The three indirect

address registers X, Y, and Z are defined as:

X-register 15 XH XL 0

7070

R27 ($1B) R26 ($1A)

Y-register 15 YH YL 0

7070

R29 ($1D) R28 ($1C)

Z-register 15 ZH ZL 0

7070

R30 ($1F) R31 ($1E)

In the different addressing modes these address registers have functions as fixed displacement, automatic increment and decrement (see the descriptions for the different instructions).

ALU – Arithmetic

Logic Unit

The high-performance AVR ALU operates in direct connection with all 32 general-purpose

working registers. Within a single clock cycle, ALU operations between registers in the register

file are executed. The ALU operations are divided into three main categories – arithmetic, logical and bit-functions.

Program Memory The AT43USB355E contains 24K bytes on-chip downloadable memory for program storage

while the AT43USB355M has a masked programmable ROM. Since all instructions are 16- or

32-bit words, the program memory is organized as 12K x 16. The AT43USB355 Program

Counter (PC) is 14 bits wide, thus addressing the 12,288 program memory addresses.

Constant tables can be allocated within the entire program memory address space (see the

LPM - Load Program Memory instruction description).

2603G–USB–04/06

9

Page 10

The program memory of the AT43USB355E is automatically written with data stored in an

external serial EEPROM during the chip's power-on reset sequence. The power-on reset is

the only way the on-chip program memory of the AT43USB355E will be written or modified.

The two versions of the AT43USB355 are binary compatible. A firmware written for the

AT43USB355E will work unaltered on the AT43USB355M. The only functional difference

between the two versions is with respect to the serial EEPROM interface pins, GPIO PF[0:3].

The differences are:

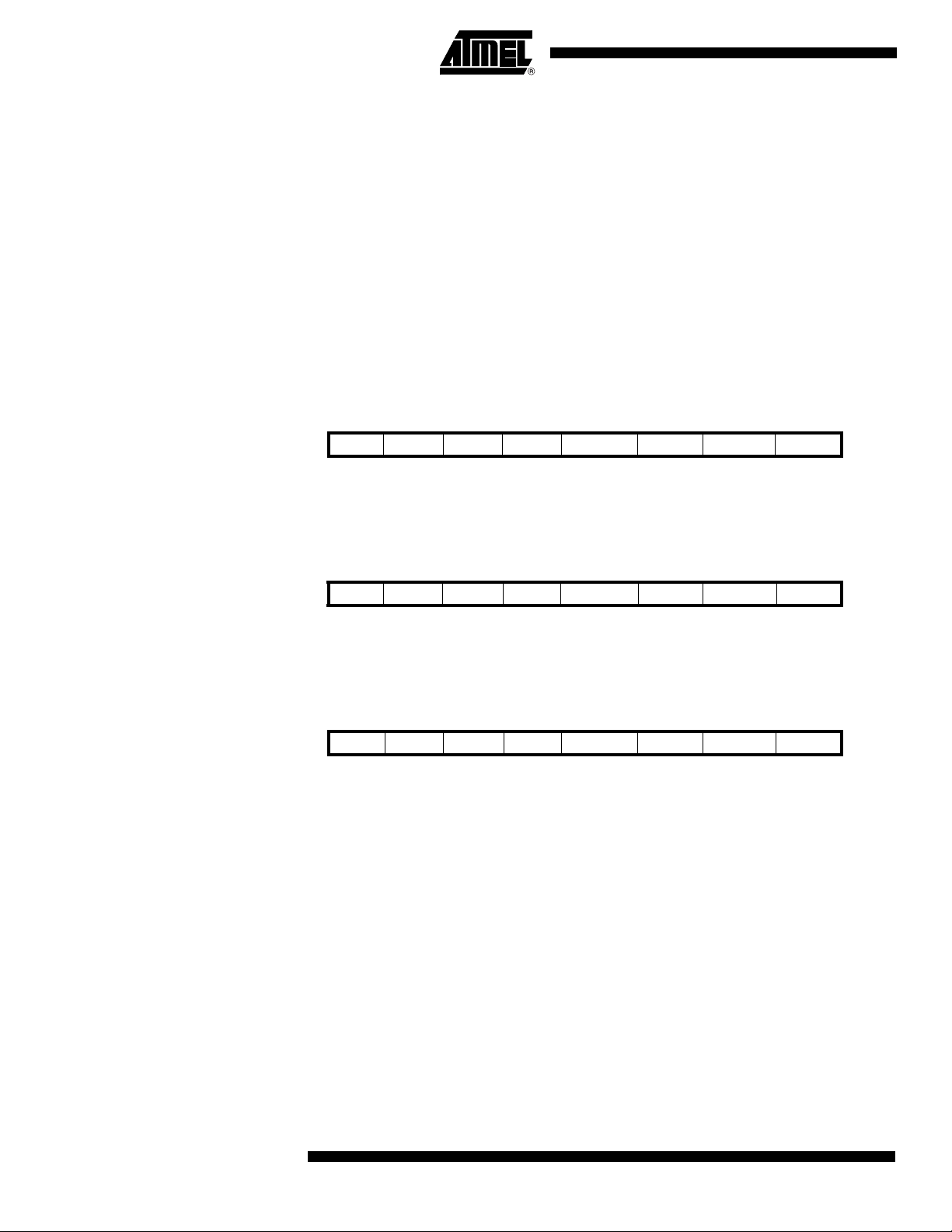

Port F Pins AT43USB355E AT43USB355M

PF0 Slave Select Pin – Its output will be asserted (low) during

downloading of firmware and will stay de-asserted (high) after

download is completed.

PF1, PF2, PF3 Functions as serial EEPROM interface signals during

downloading and as GPIO pins after download is completed.

NC (No connect)

GPIO

SPI Serial EEPROM Interface (AT43USB355E Only)

The AT43USB355E is designed to interface directly with a synchronous serial peripheral interface (SPI) SEEPROM such as the Atmel AT25HP256/512. All instructions, addresses and

data are transferred with the MSB first and start with a high-to-low SSN transition.

Note: The SPI port of the AT43USB355E at PF[0:3] is dedicated for program memory downloading

only. It cannot be accessed by the firmware program.

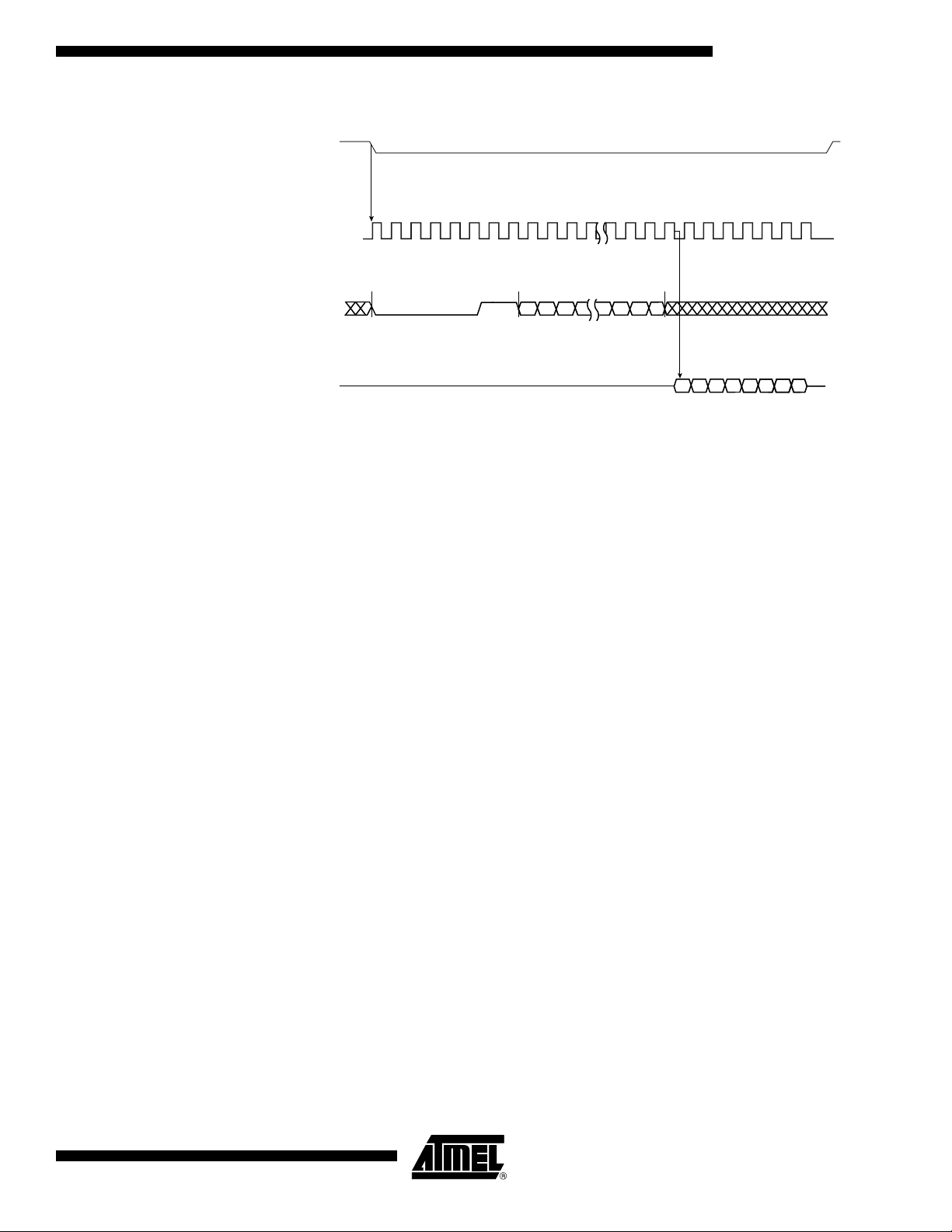

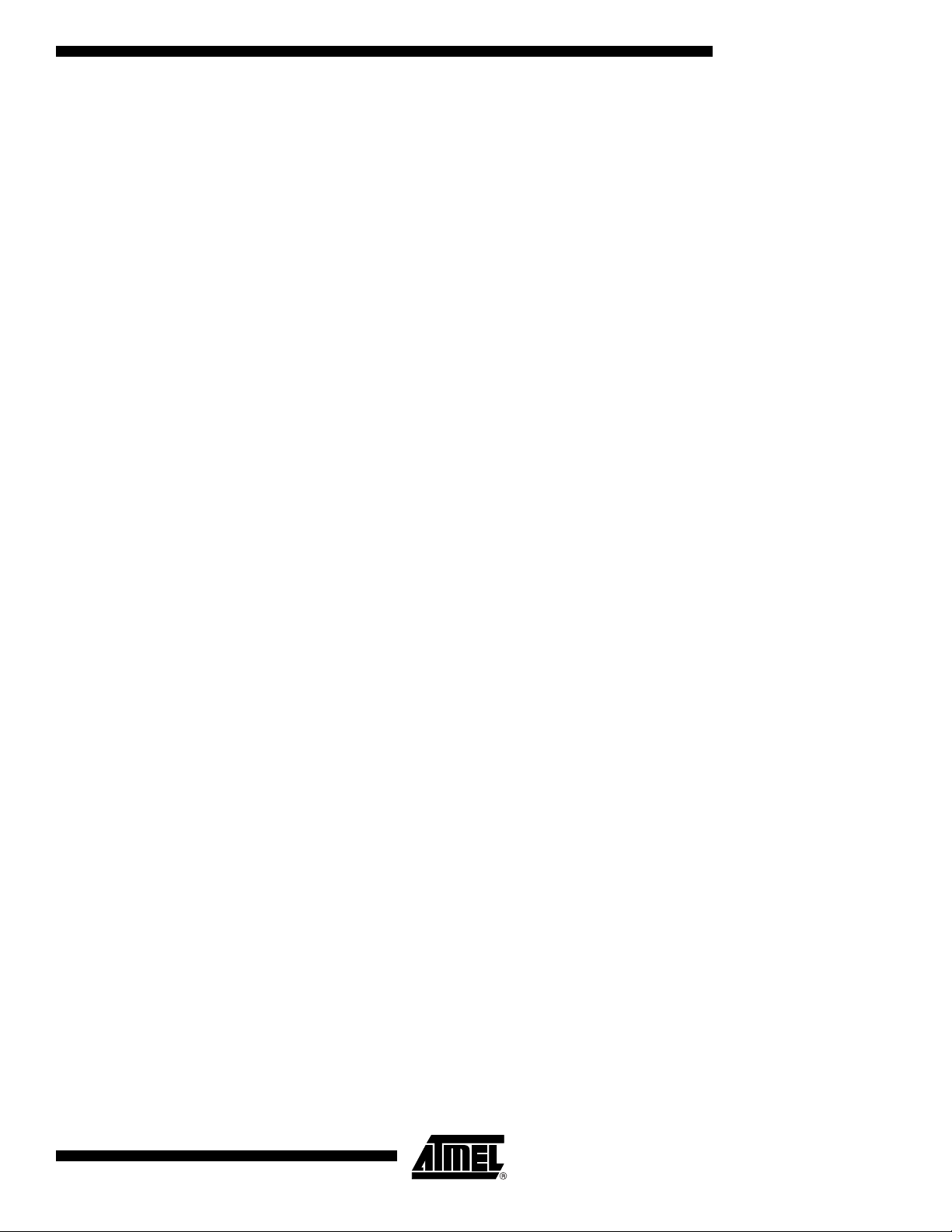

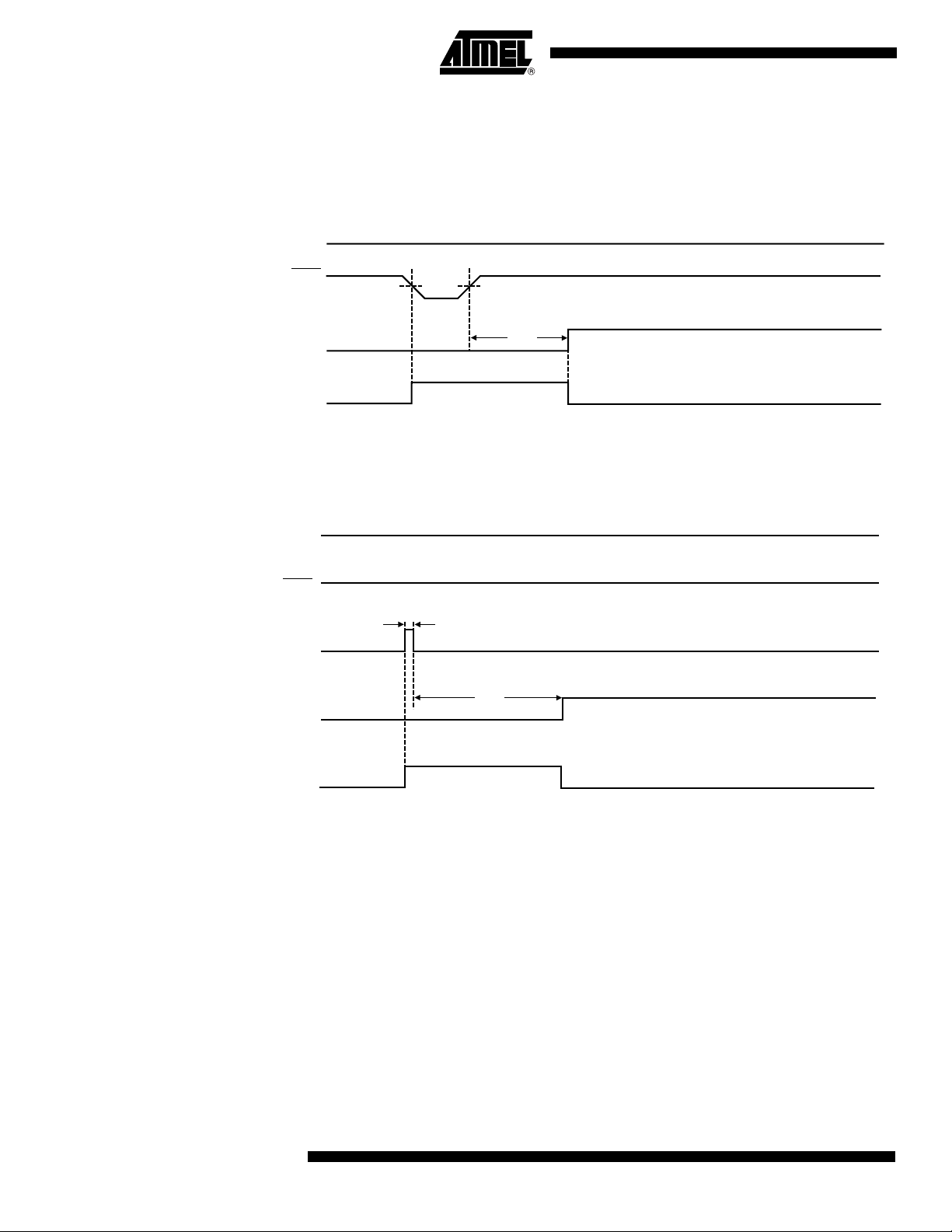

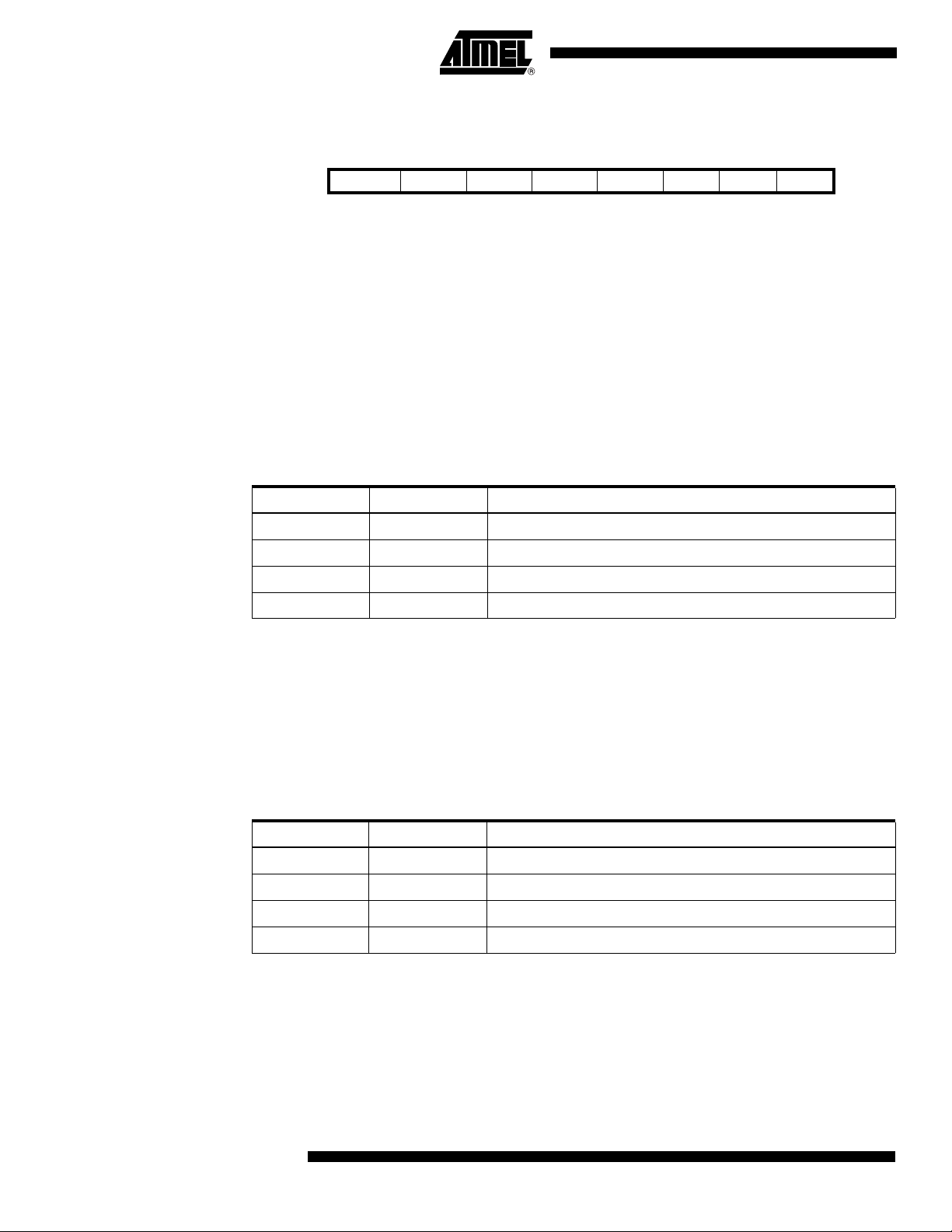

Figure 4. AT43USB355E Read Sequence

SSN

AT43USB355E AT25HP256

MOSI

MISO

SCK

Read Sequence 1. The AT43USB35E asserts its SSN output pin and outputs a 3 MHz clock at SCK. It

continues to activate SCK until the completion of the read process.

2. The AT43USB355E transmits the READ op-code (= 0000011) through its MOSI, followed by the 16-bit byte address to be read, x0000. Please note that the

AT43USB355E will send a 16-byte address only. SEEPROM with SPI that requires a

24-bit address cannot be used with the AT43USB355E.

3. The SEEPROM then shifts out the data through its MISO pin.

4. The AT43USB35E de-asserts SCK and SSN after 24K bytes data read is complete.

10

AT43USB355

2603G–USB–04/06

Page 11

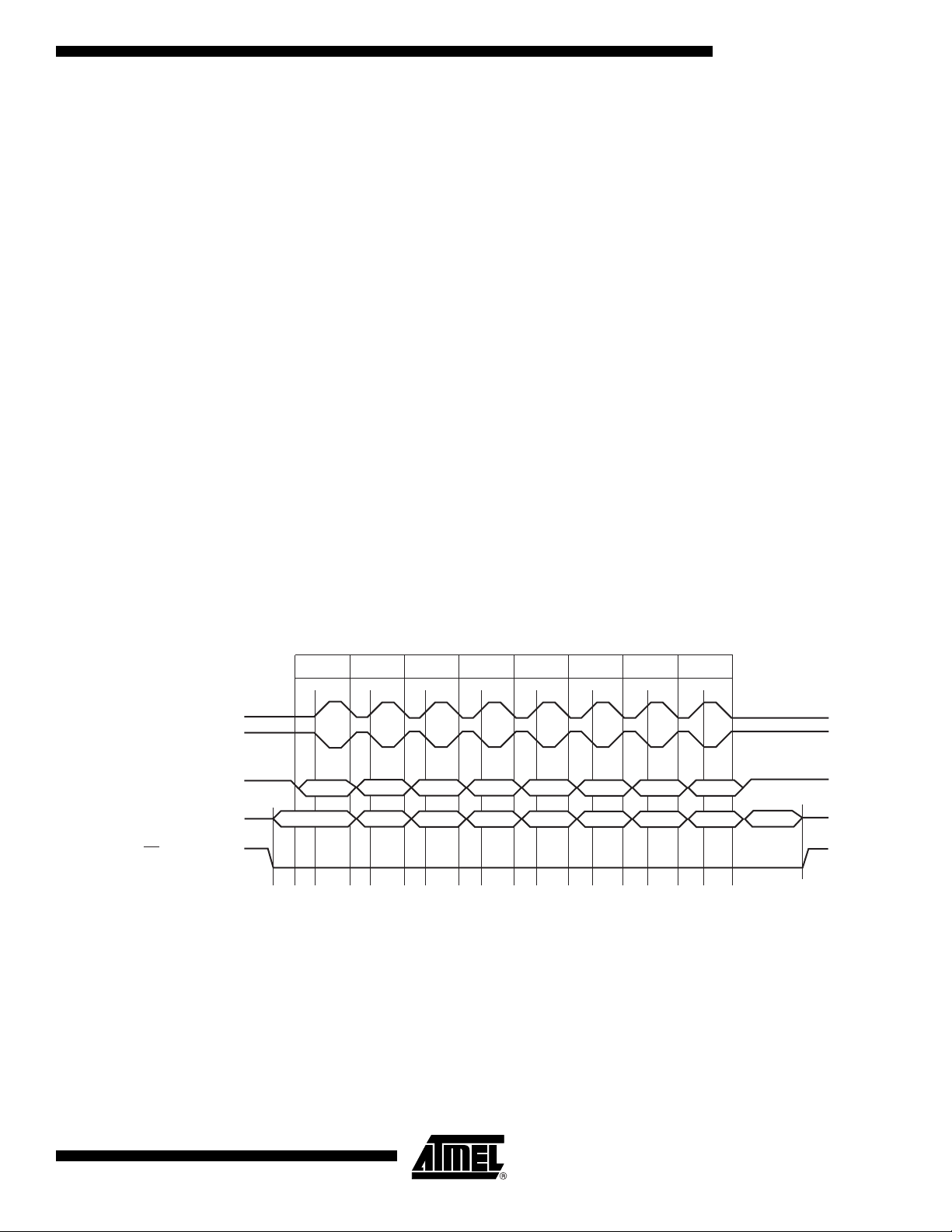

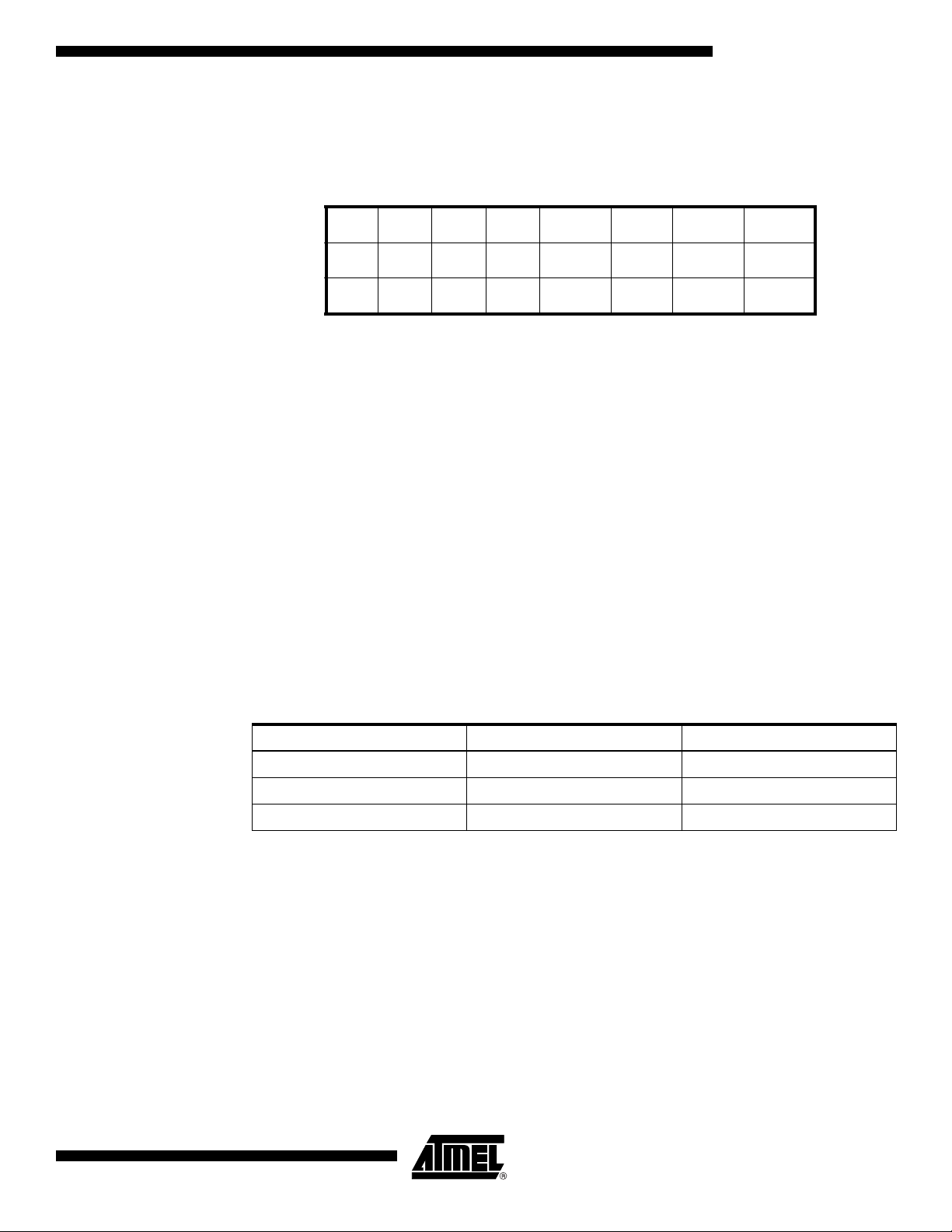

Figure 5. READ Timing

SSN

AT43USB355

SRAM Data Memory

SCK

MOSI

MISO

1 2 3 4 5 6 7 8 9 101120212223242526272829300

INSTRUCTION

HIGH IMPEDANCE

BYTE ADDRESS

...

0123131415

DATA OUT

2 0134567

MSB

Table 3 summarizes how the AT43USB355 SRAM Memory is organized. The lower 1120 Data

Memory locations address the Register file, the I/O Memory and the internal data SRAM. The

first 96 locations address the Register File + I/O Memory, and the next 1024 locations address

the internal data SRAM. The five different addressing modes for the data memory cover:

Direct, Indirect with Displacement, Indirect, Indirect with Pre-decrement and Indirect with Postincrement. In the register file, registers R26 to R31 feature the indirect addressing pointer registers. Direct addressing reaches the entire data space.

The Indirect with Displacement mode features 63 address locations that reach from the base

address given by the Y- or Z-register.

When using register indirect addressing modes with automatic pre-decrement and post-increment, the address registers X, Y, and Z are decremented and incremented.

The 32 general-purpose working registers, 64 I/O registers and the 1024 bytes of internal data

SRAM in the AT43USB355 are all accessible through these addressing modes.

To manage the USB hardware, a special set of registers is assigned. These registers are

mapped to SRAM space between addresses $1F00 and 1FFF. Table 3 and Table 4 give an

overview of these registers.

2603G–USB–04/06

11

Page 12

Table 2. SRAM Organization

Register File Data Address Space

R0 $0000

R1 $0001

R30 $001E

R31 $001F

I/O Registers

$00 $0020

$01 $0021

$3E $005E

$3F $005F

Internal SRAM

$0060

$0061

$025E

$045F

USB Registers

$1F00

$1FFE

$1FFF

12

AT43USB355

2603G–USB–04/06

Page 13

AT43USB355

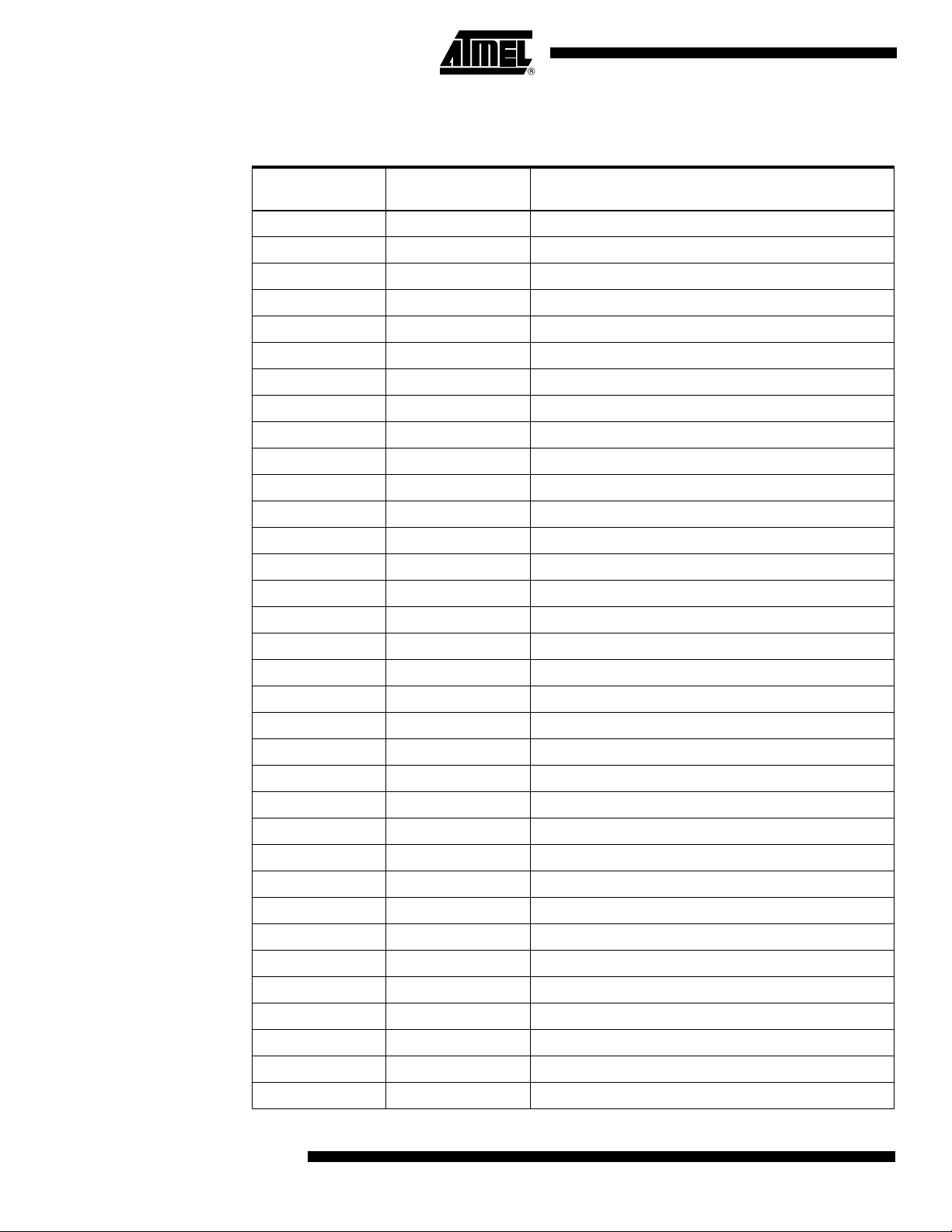

Table 3. USB Hub and Function Registers

Address Name Function

$1FFD FRM_NUM_H Frame Number High Register

$1FFC FRM_NUM_L Frame Number Low Register

$1FFB GLB_STATE Global State Register

$1FFA SPRSR Suspend/Resume Register

$1FF9 SPRSIE Suspend/Resume Interrupt Enable Register

$1FF8 SPRSMSK Suspend/Resume Interrupt Mask Register

$1FF7 UISR USB Interrupt Status Register

$1FF6 UIMSKR USB Interrupt Mask Register

$1FF5 UIAR USB Interrupt Acknowledge Register

$1FF3 UIER USB Interrupt Enable Register

$1FF2 UOVCER Overcurrent Detect Register

$1FEF HADDR Hub Address Register

$1FEE FADDR Function Address Register

$1FE7 HEND-P0_CNTR Hub End-point 0 Control Register

$1FE5 FEND-P0_CNTR Function End-point 0 Control Register

$1FE4 FEND-P1_CNTR Function End-point 1 Control Register

$1FE3 FEND-P2_CNTR Function End-point 2 Control Register

$1FE2 FEND-P3_CNTR Function End-point 3 Control Register

$1FDF HCSR0 Hub Controller End-point 0 Service Routine Register

$1FDD FCSR0 Function Controller End-point 0 Service Routine Register

$1FDC FCSR1 Function Controller End-point 1 Service Routine Register

$1FDB FCSR2 Function Controller End-point 2 Service Routine Register

$1FDA FCSR3 Function Controller End-point 3 Service Routine Register

$1FD7 HDR0 Hub End-point 0 FIFO Data Register

$1FD5 FDR0 Function End-point 0 FIFO Data Register

$1FD4 FDR1 Function End-point 1 FIFO Data Register

$1FD3 FDR2 Function End-point 2 FIFO Data Register

$1FD2 FDR3 Function End-point 3 FIFO Data Register

$1FCF HBYTE_CNT0 Hub End-point 0 Byte Count Register

$1FCD FBYTE_CNT0 Function End-point 0 Byte Count Register

$1FCC FBYTE_CNT1 Function End-point 1 Byte Count Register

$1FCB FBYTE_CNT2 Function End-point 2 Byte Count Register

$1FCA FBYTE_CNT3 Function End-point 3 Byte Count Register

$1FC7 HSTR Hub Status Register

2603G–USB–04/06

$1FC5 HPCON Hub Port Control Register

13

Page 14

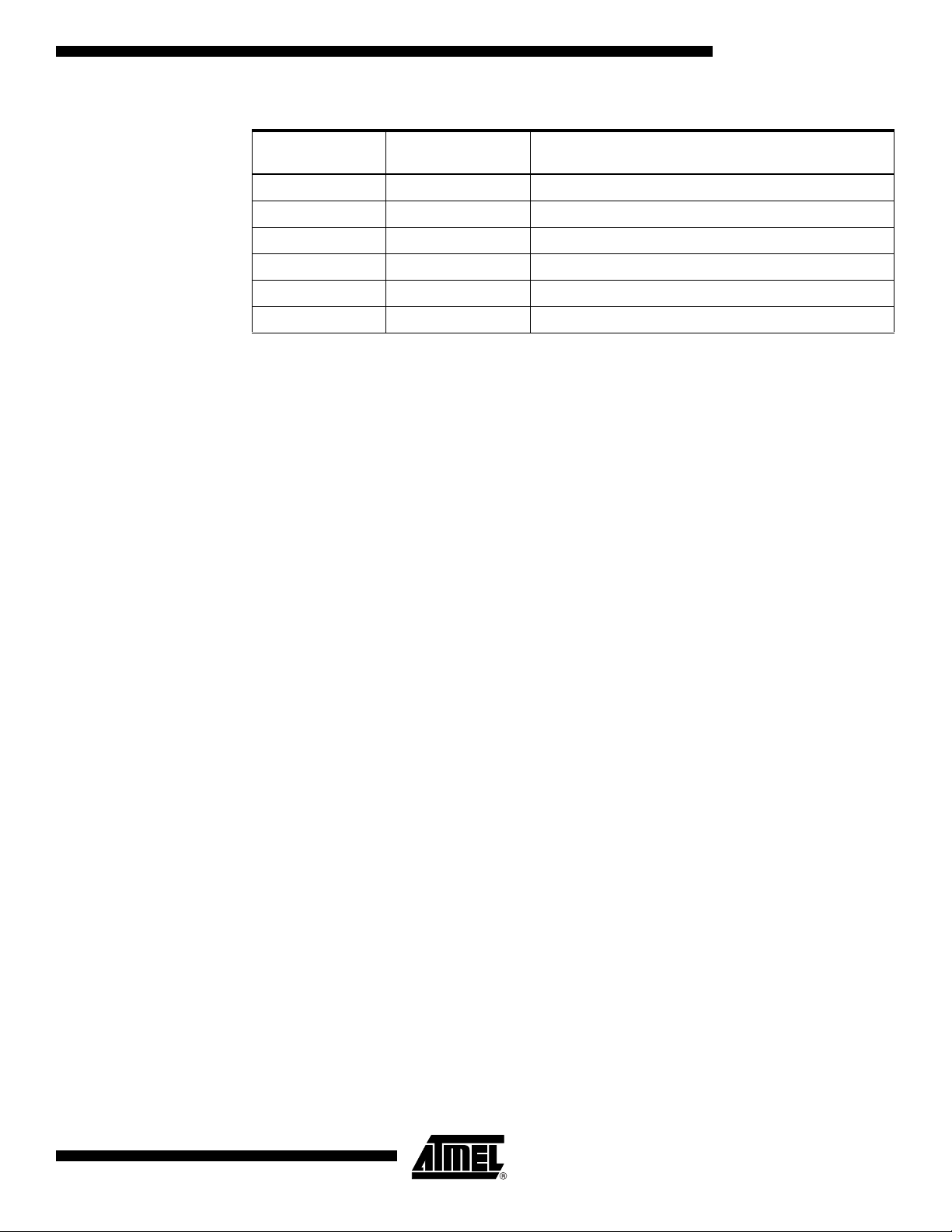

Table 3. USB Hub and Function Registers (Continued)

Address Name Function

$1FBA HPSTAT3 Hub Port 3 Status Register

$1FB9 HPSTAT2 Hub Port 2 Status Register

$1FB8 HPSTAT1 Hub Port 1 Status Register

$1FB2 HPSCR3 Hub Port 3 Status Change Register

$1FB1 HPSCR2 Hub Port 2 Status Change Register

$1FB0 HPSCR1 Hub Port 1 Status Change Register

$1FAA PSTATE3 Hub Port 3 Bus State Register

$1FA9 PSTATE2 Hub Port 2 Bus State Register

$1FA7 HCAR0 Hub End-point 0 Control and Acknowledge Register

$1FA5 FCAR0 Function End-point 0 Control and Acknowledge Register

$1FA4 FCAR1 Function End-point 1 Control and Acknowledge Register

$1FA3 FCAR2 Function End-point 2 Control and Acknowledge Register

$1FA2 FCAR3 Function End-point 3 Control and Acknowledge Register

14

AT43USB355

2603G–USB–04/06

Page 15

AT43USB355

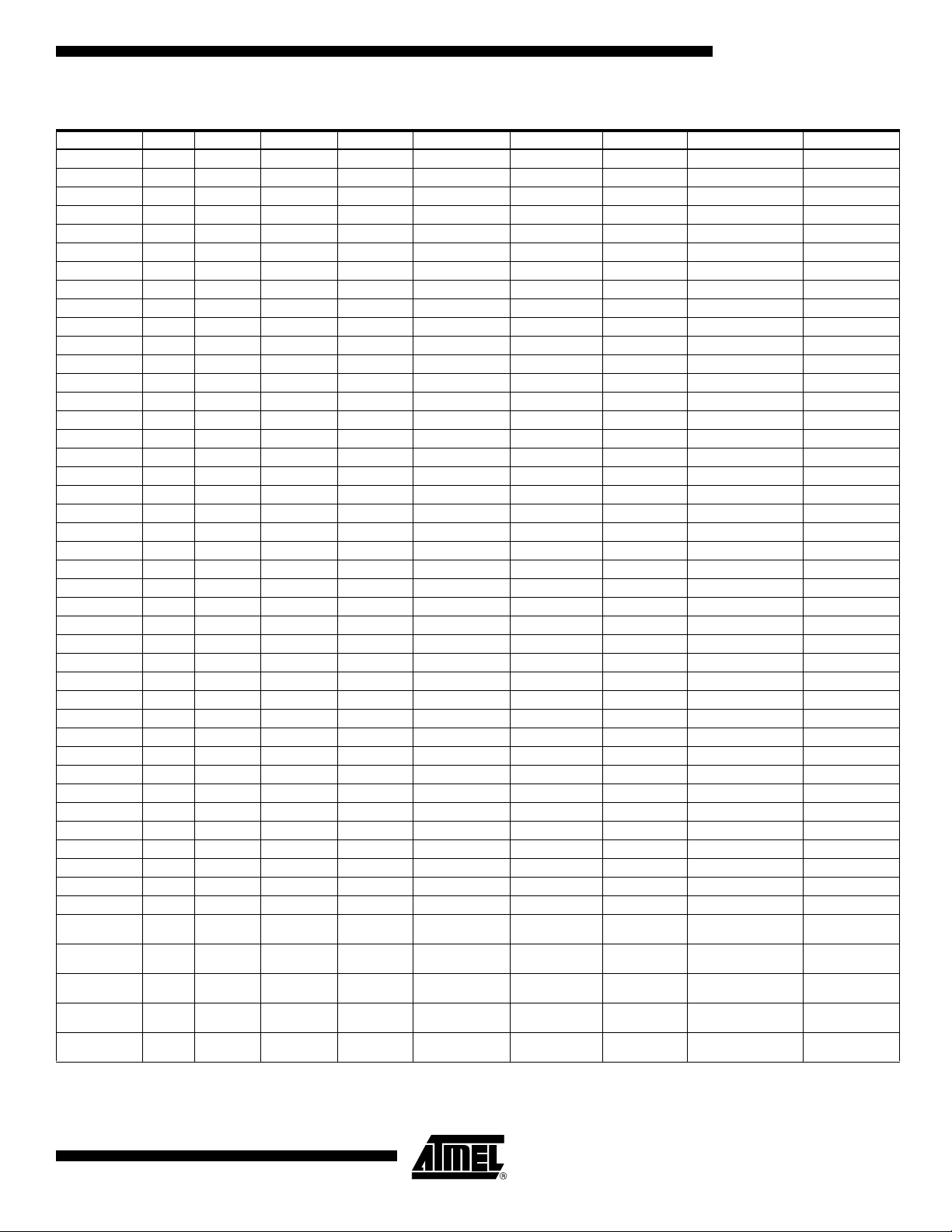

Table 4. USB Hub and Function Registers

Name Address Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

GLB_STATE $1FFB – SUSP FLG RESUME FLG RMWUPE CONFG HADD EN

SPRSR $1FFA – – – – – FRWUP RSM GLB SUSP

SPRSIE $1FF9 – – – – – FRWUP IE RSM IE GLB SUSP IE

SPRSMSK $1FF8 – – – – – FRWUP MSK RSM MSK GLB SUSP MSK

UISR $1FF7 SOF INT EOF2 INT – FEP3 INT HEP0 INT FEP2 INT FEP1 INT FEP0 INT

UIMSKR $1FF6 SOF MSK SOF2 MSK – FEP3 MSK HEP0 MSK FEP2 MSK FEP1 MSK FEP0 MSK

UIAR $1FF5 SOF INTACK EOF2 INTACK – FEP3 INTACK HEP0 INTACK FEP2 INTACK FEP1 INTACK FEP0 INTACK

UIER $1FF3 SOF IE EOF2 IE – FEP3 IE HEP0 IE FEP2 IE FEP1 IE FEP0 IE

UOVCER $1FF2 – – – – OVC3 OVC2 – –

HADDR $1FEF SAEN HADD6 HADD5 HADD4 HADD3 HADD2 HADD1 HADD0

FADDR $1FEE FEN FADD6 FADD5 FADD4 FADD3 FADD2 FADD1 FADD0

HEND-P0_CNTR $1FE7 EPEN – – – DTGLE EPDIR EPTYPE1 EPTYPE0

FEND-P0_CNTR $1FE5 EPEN – – – DTGLE EPDIR EPTYPE1 EPTYPE0

FEND-P1_CNTR $1FE4 EPEN – – – DTGLE EPDIR EPTYPE1 EPTYPE0

FEND-P2_CNTR $1FE3 EPEN – – – DTGLE EPDIR EPTYPE1 EPTYPE0

FEND-P3_CNTR $1FE2 EPEN – – – DTGLE EPDIR EPTYPE1 EPTYPE0

HCSR0 $1FDF – – – – STALL SENT RX SETUP RX OUT PACKET TX CEMPLETE

FCSR0 $1FDD – – – – STALL SENT RX SETUP RX OUT PACKET TX COMPLETE

FCSR1 $1FDC – – – – STALL SENT – RX OUT PACKET TX COMPLETE

FCSR2 $1FDB – – – – STALL SENT – RX OUT PACKET TX COMPLETE

FCSR3 $1FDA – – – – STALL SENT – RX OUT PACKET TX COMPLETE

HDR0 $1FD7 DATA7 DATA6 DATA5 DATA4 DATA3 DATA2 DATA1 DATA0

F DR 0 $1 F D5 DATA 7 DATA 6 D ATA5 DATA 4 DATA 3 D ATA2 DATA 1 D ATA 0

F DR 1 $1 F D4 DATA 7 DATA 6 D ATA5 DATA 4 DATA 3 D ATA2 DATA 1 D ATA 0

F DR 2 $1 F D3 DATA 7 DATA 6 D ATA5 DATA 4 DATA 3 D ATA2 DATA 1 D ATA 0

F DR 3 $1 F D2 DATA 7 DATA 6 D ATA5 DATA 4 DATA 3 D ATA2 DATA 1 D ATA 0

HBYTE_CNT0 $1FCF – – BYTCT5 BYTCT4 BYTCT3 BYTCT2 BYTCT1 BYTCT0

FBYTE_CNT0 $1FCD – – BYTCT5 BYTCT4 BYTCT3 BYTCT2 BYTCT1 BYTCT0

FBYTE_CNT1 $1FCC – BYTCT6 BYTCT5 BYTCT4 BYTCT3 BYTCT2 BYTCT1 BYTCT0

FBYTE_CNT2 $1FCB – BYTCT6 BYTCT5 BYTCT4 BYTCT3 BYTCT2 BYTCT1 BYTCT0

FBYTE_CNT3 $1FCA – – BYTCT5 BYTCT4 BYTCT3 BYTCT2 BYTCT1 BYTCT0

HSTR $1FC7 – – – – OVLSC LPSC OVI LPS

HPCON $1FC5 – HPCON2 HPCON1 HPCON0 – HPADD2 HPADD1 HPADD0

HPSTAT3 $1FBA – LSP PPSTAT PRSTAT POCI PSSTAT PESTAT PCSTAT

HPSTAT2 $1FB9 – LSP PPSTAT PRSTAT POCI PSSTAT PESTAT PCSTAT

HPSTAT1 $1FB8 – LSP PPSTAT PRSTAT POCI PSSTAT PESTAT PCSTAT

HPSCR3 $1FB2 – – – RSTSC POCIC PSSC PESC PCSC

HPSCR2 $1FB1 – – – RSTSC POCIC PSSC PESC PCSC

HPSCR1 $1FB0 – – – RSTSC POCIC PSSC PESC PCSC

PSTATE3 $1FAA – – – – – – DPSTATE DMSTATE

PSTATE2 $1FA9 – – – – – – DPSTATE DMSTATE

HCAR0 $1FA7 CTL DIR DATA END FORCE STALL TX PACKET READY STALL_SENT-ACK RX_SETUP_ACK RX_OUT_PACKET_ACK

FCAR0 $1FA5 CTL DIR DATA END FORCE STALL TX PACKET READY STALL_SENT-ACK RX_SETUP_ACK RX_OUT_PACKET_ACK

FCAR1 $1FA4 CTL DIR DATA END FORCE STALL TX PACKET READY STALL_SENT-ACK – RX_OUT_PACKET_ACK

FCAR2 $1FA3 CTL DIR DATA END FORCE STALL TX PACKET READY STALL_SENT-ACK – RX_OUT_PACKET_ACK

FCAR3 $1FA2 CTL DIR DATA END FORCE STALL TX PACKET READY STALL_SENT-ACK – RX_OUT_PACKET_ACK

TX_COMPLETEACK

TX_COMPLETEACK

TX_COMPLETEACK

TX_COMPLETEACK

TX_COMPLETEACK

2603G–USB–04/06

15

Page 16

I/O Memory The I/O space definition of the AT43USB355 is shown in the following table:

Table 5. I/O Memory Space

I/O (SRAM)

Address Name Function

$3F ($5F) SREG Status Register

$3E ($5E) SPH Stack Pointer High

$3D ($5D) SPL Stack Pointer Low

$3B ($5B) GIMSK General Interrupt Mask Register

$3A ($5A) GIFR General Interrupt Flag Register

$39 ($59) TIMSK Timer/Counter Interrupt Mask Register

$38 ($58) TIFR Timer/Counter Interrupt Flag Register

$35 ($55) MCUCR MCU General Control Register

$33 ($53) TCCR0 Timer/Counter0 Control Register

$32 ($52) TCNT0 Timer/Counter0 (8 bit)

$2F ($4F) TCCR1A Timer/Counter1 Control Register A

$2E ($4E) TTCR1B Timer/Counter1 Control Register B

$2D ($52) TCNT1H Timer/Counter1 High Byte

$2C ($52) TCNT1L Timer/Counter1 Low Byte

$2B ($4B) OCR1AH Timer/Counter1 Output Compare Register A High Byte

$2A ($4A) OCR1AL Timer/Counter1 Output Compare Register A Low Byte

$29 ($49) OCR1BH Timer/Counter1 Output Compare Register B High Byte

$28 ($48) OCR1BL Timer/Counter1 Output Compare Register B Low Byte

$25 ($45) ICR1H T/C 1 Input Capture Register High Byte

$24 ($44) ICR1L T/C 1 Input Capture Register Low Byte

$21 ($41) WDTCR Watchdog Timer Counter Register

$1B ($4B) PORTA Data Register, Port A

$1A ($3A) DDRA Data Direction Register, Port A

$19 ($39) PINA Input Pins, Port A

$18 ($38) PORTB Data Register, Port B

$17 ($37) DDRB Data Direction Register, Port B

$16 ($36) PINB Input Pins, Port B

$12 ($32) PORTD Data Register, Port D

$11 ($31) DDRD Data Direction Register, Port D

$10 ($30) PIND Input Pins, Port D

$0F ($2F) SPDR SPI I/O Data Register

$0E ($2E) SPSR SPI Status Register

$0D ($2D) SPCR SPI Control Register

16

$08 ($28) ADMUX ADC Mux Select Register

AT43USB355

2603G–USB–04/06

Page 17

AT43USB355

Table 5. I/O Memory Space (Continued)

I/O (SRAM)

Address Name Function

$07 ($27) ADCSR ADC Control and Status Register

$06 ($26) PORTF Data Register, Port F

$05 ($25) DDRF Data Direction Register, Port F

$04 ($24) PINF Input Pins, Port F

$03 ($23) ADCH ADC High Byte Data Register

$02 ($22) ADCL ADC Low Byte Data Register

All AT43USB355 I/O and peripherals, except for the USB hardware registers, are placed in the

I/O space. The I/O locations are accessed by the IN and OUT instructions transferring data

between the 32 general-purpose working registers and the I/O space. I/O registers within the

address range $00 – $1F are directly bit-accessible using the SBI and CBI instructions. In

these registers, the value of single bits can be checked by using the SBIS and SBIC instructions. Refer to the instruction set documentations of the AVR for more details. When using the

I/O specific commands, IN and OUT, the I/O address $00 – $3F must be used. When addressing I/O registers as SRAM, $20 must be added to this address. All I/O register addresses

throughout this document are shown with the SRAM address in parentheses.

For compatibility with future devices, reserved bits should be written to zero if accessed.

Reserved I/O memory addresses should never be written.

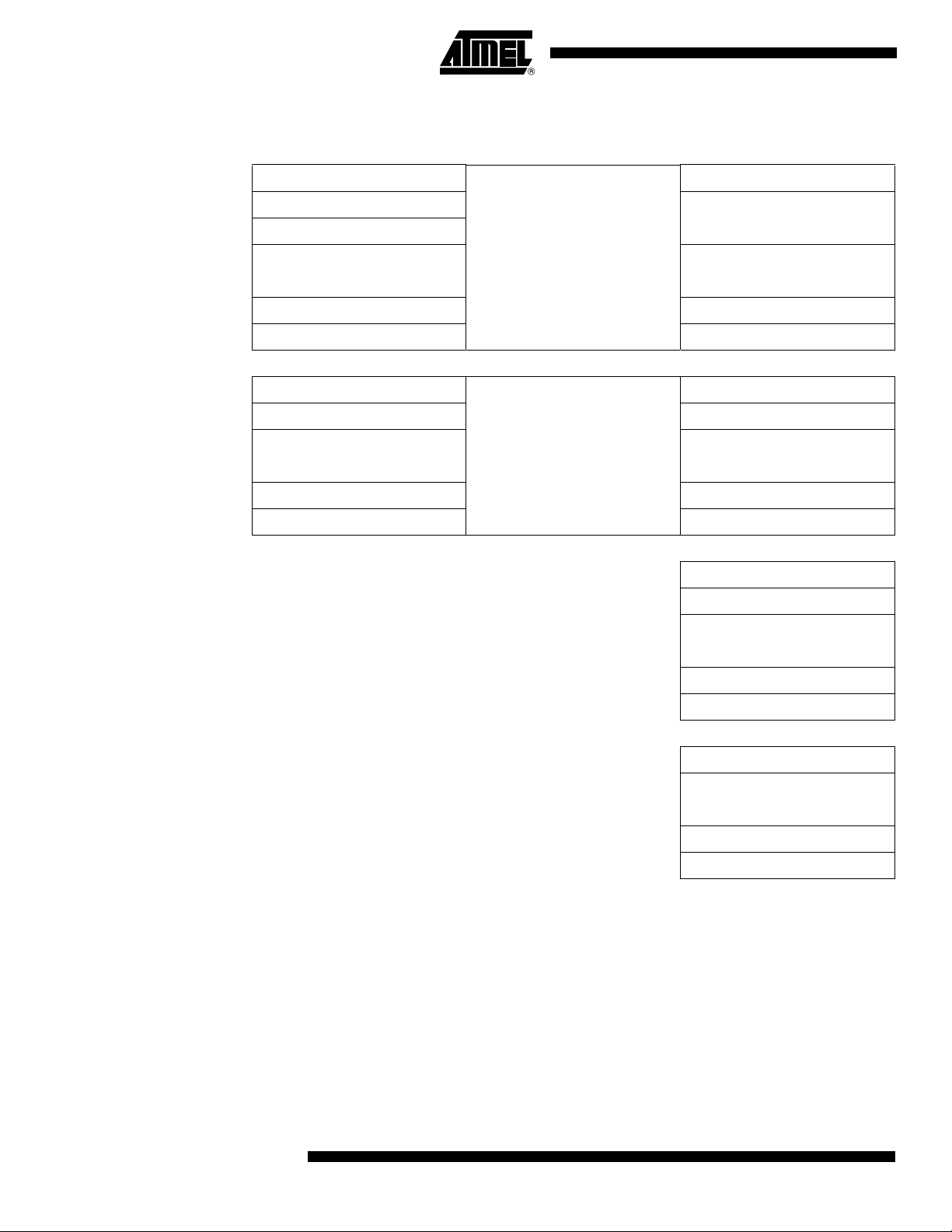

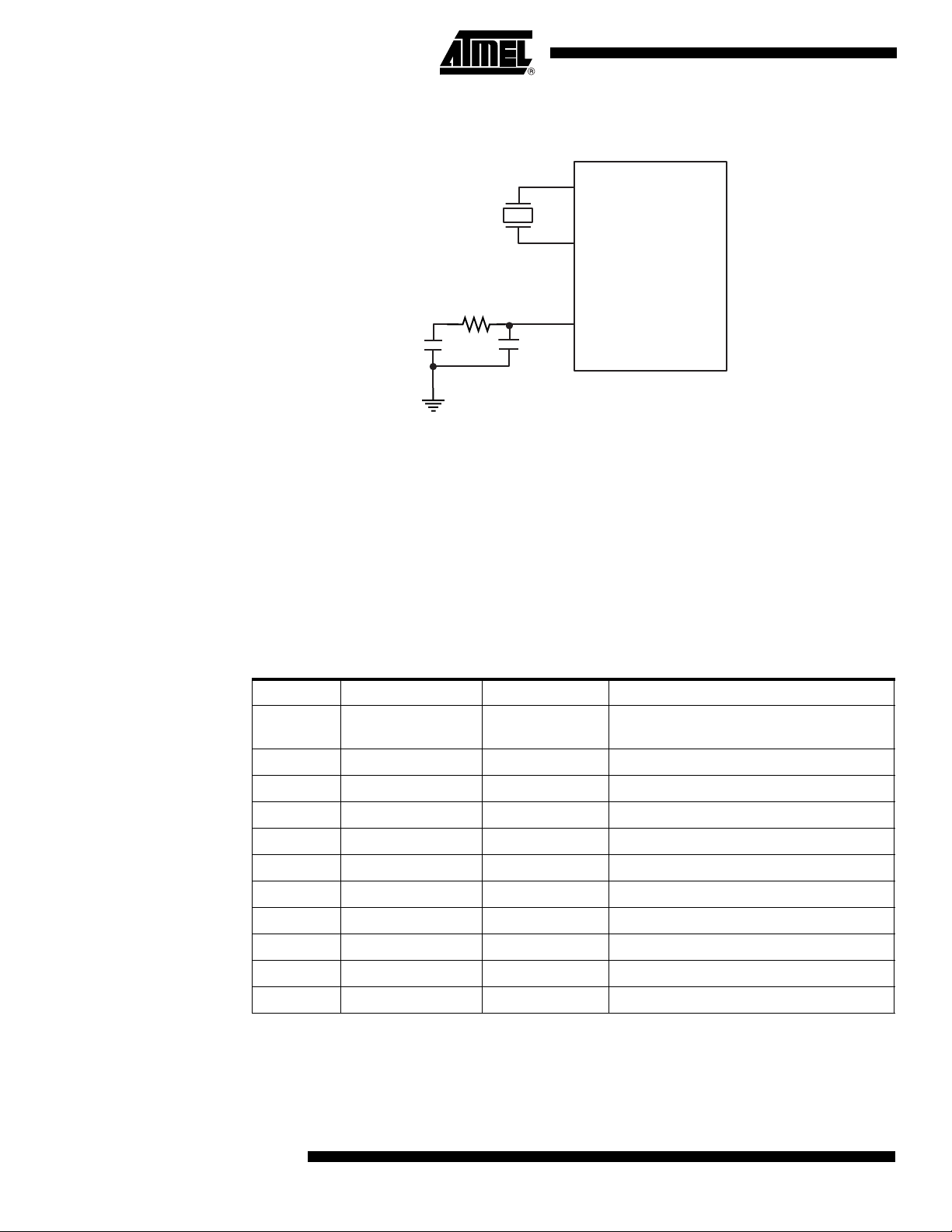

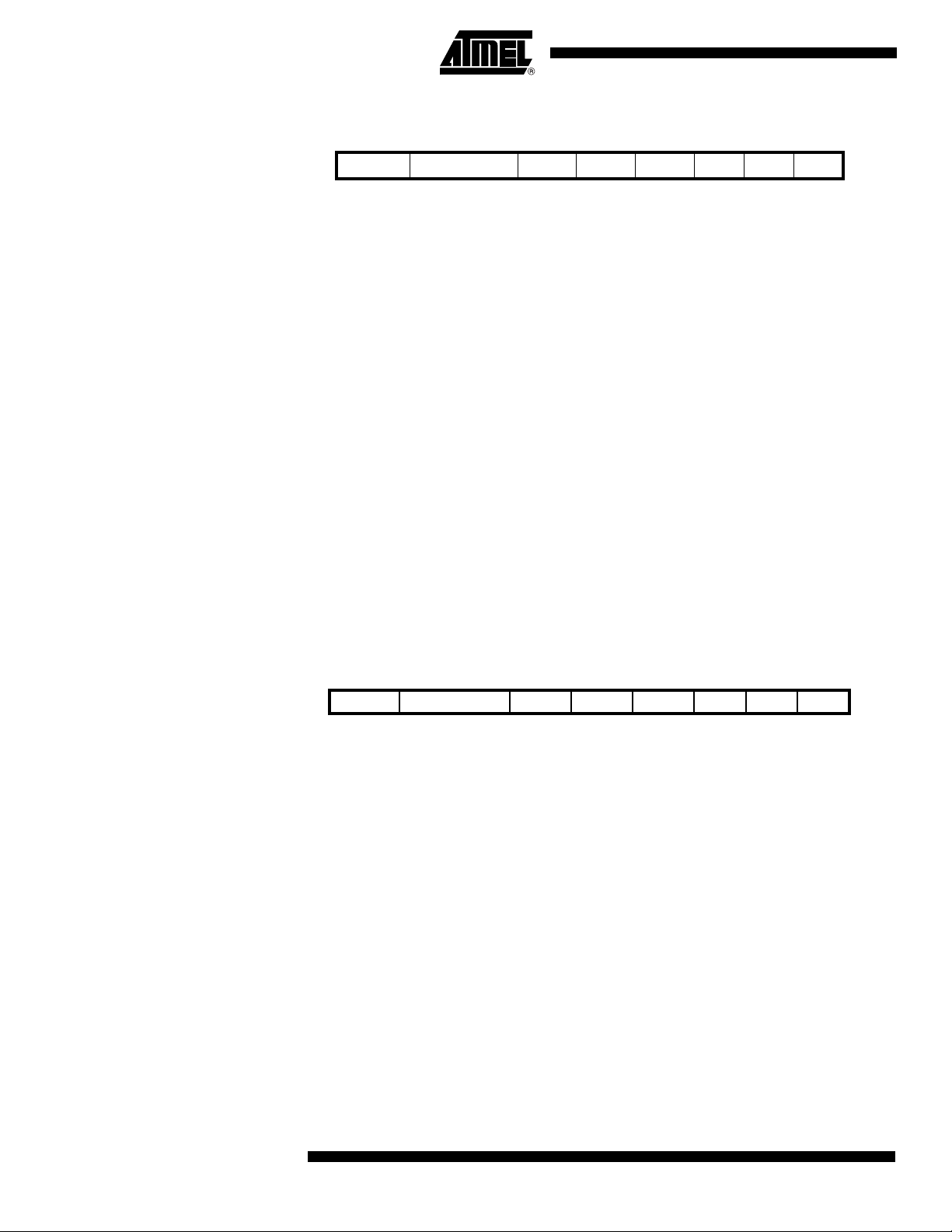

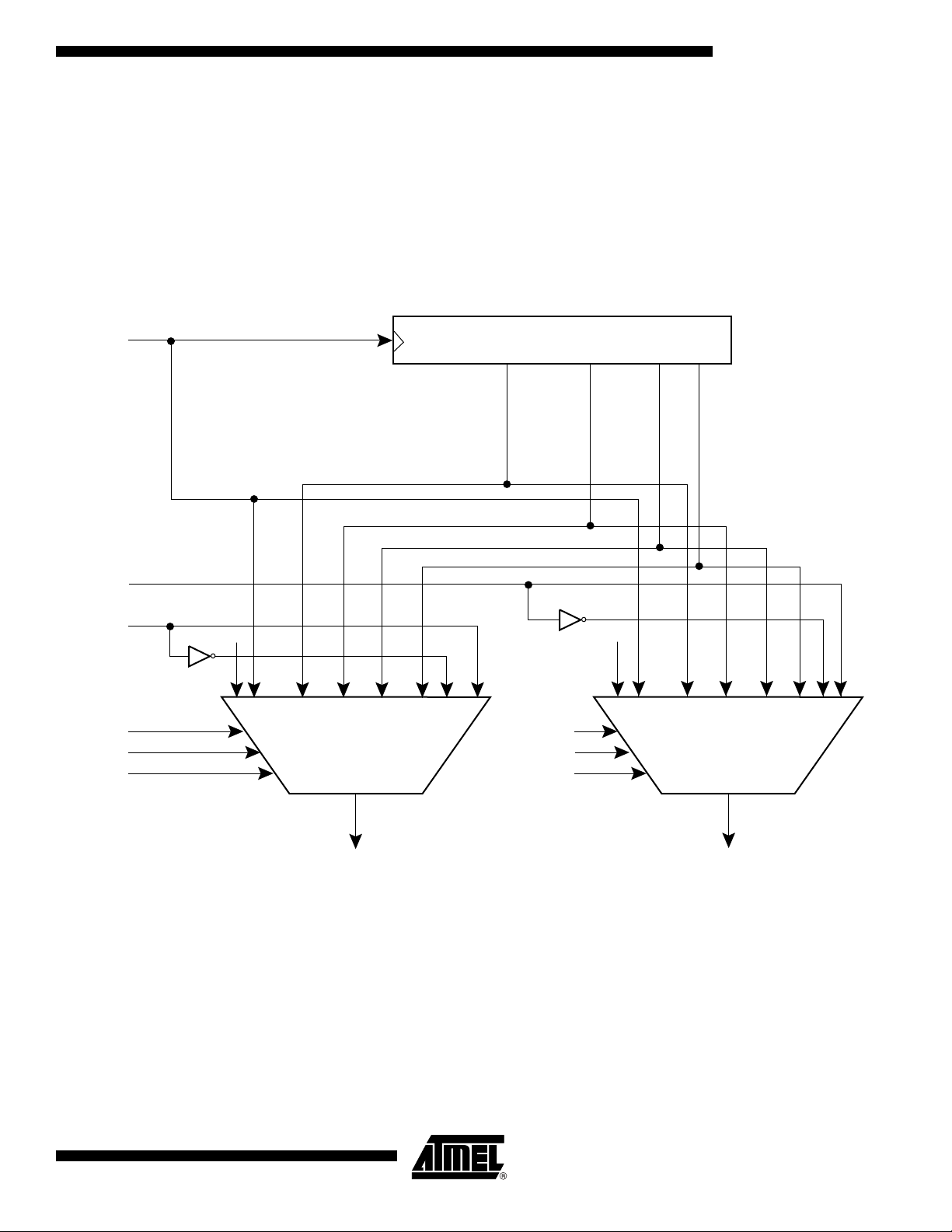

USB Hub A block diagram of the USB hardware of the AT43USB355 is shown in Figure 6. The USB hub

of the AT43USB355 has 3 downstream ports. The embedded function is permanently

attached to Port 1. Ports 2 and 3 are available as external ports. The actual number of ports

used is strictly defined by the firmware of the AT43USB355 and can vary from 0 to 2. Because

the exact configuration is defined by firmware, ports 2 and 3 may even function as permanently attached ports as long as the Hub Descriptor identifies them as such.

USB Function The embedded USB function has its own device address and has a default end-point plus 3

other programmable end-points. Two of these end-points contain their own 64-byte FIFO while

the third end-point has an 8-byte FIFO. End-points 1 - 3 can be programmed as interrupt IN or

OUT or bulk IN or OUT end-points.

2603G–USB–04/06

17

Page 18

Figure 6. USB Hardware

Port 0

XCVR

Hub Repeater

Serial Interface Engine

Port 2

XCVR

Port 3

XCVR

Hub

Interface

Unit

Port 1

Function

Interface

Unit

Data

Address

Control

AVR Microcontroller

18

AT43USB355

2603G–USB–04/06

Page 19

Functional Description

AT43USB355

On-chip Power Supply

I/O Pin Characteristics

The AT43USB355 contains four on-chip power supplies that generate 3.3V with a capacity of

30 mA each from the 5V power input. The on-chip power supplies are intended to supply the

AT43USB355 internal circuit and the 1.5K pull-up resistor only and should not be used for

other purposes. External 2.2 µF filter capacitors are required at the power supply outputs,

CEXT1, 2, 3, and a 0.33 µF capacitor for CEXTA. The internal power supplies can be disabled

as described in the next paragraph.

The user should be careful when the GPIO pins are required to supply high-load currents. If

the application requires that the GPIO supply currents beyond the capability of the on-chip

power supply, the AT43USB355 should be supplied by an external 3.3V power supply. In this

case, the 5V V

the chip through the CEXT1, 2, 3 and CEXTA pins.

The I/O pins of the AT43USB355 should not be directly connected to voltages less than VSS or

more than the voltage at the CEXT pins. If it is necessary to violate this rule, insert a series

resistor between the I/O pin and the source of the external signal source that limits the current

into the I/O pin to less than 2 mA. Under no circumstance should the external voltage exceed

5.5V. To do so will put the chip under excessive stress.

power supply pin should be left unconnected and the 3.3V power supplied to

CC

Oscillator and PLL All clock signals required to operate the AT43USB355 are derived from an on-chip oscillator.

To reduce EMI and power dissipation, the oscillator is designed to operate with a 6 MHz crystal. An on-chip PLL generates the high frequency for the clock/data separator of the Serial

Interface Engine. In the suspended state, the oscillator circuitry is turned off.

The oscillator of the AT43USB355 is a special, low-drive type, designed to work with most

crystals without any external components. The crystal must be of the parallel resonance type

requiring a load capacitance of about 10 pF. If the crystal requires a higher value capacitance,

external capacitors can be added to the two terminals of the crystal and ground to meet the

required value. To assure quick start-up, a crystal with a high Q, or low ESR, should be used.

To meet the USB hub frequency accuracy and stability requirements for hubs, the crystal

should have an accuracy and stability of better than 100 PPM. The use of a ceramic resonator

in place of the crystal is not recommended because a resonator would not have the necessary

frequency accuracy and stability.

2603G–USB–04/06

The clock can also be externally sourced. In this case, connect the clock source to the XTAL1

pin, while leaving XTAL2 pin floating. The switching level at the OSC1 pin can be as low as

0.47V and a CMOS device is required to drive this pin to maintain good noise margins at the

low switching level.

For proper operation of the PLL, an external RC filter consisting of a series RC network of

100Ω and 0.1 µF in parallel with a 0.01 µF capacitor must be connected from the LFT pin to

V

. Use only high-quality ceramic capacitors.

SS

19

Page 20

Figure 7. Oscillator and PLL

U1

Reset and Interrupt Handling

Y1

6.000 MHz

R1

100

C1

0.1 UF

0.01 UF

XTAL1

XTAL2

AT43USB355

LFT

C2

The AT43USB355 provides 20 different interrupt sources with 11 separate reset vectors, each

with a separate program vector in the program memory space. Eleven of the interrupt sources

share 2 interrupt reset vectors. These 11 are the USB related interrupts. All interrupts are

assigned individual enable bits which must be set (one) together with the I-bit in the status register in order to enable the interrupt.

The lowest addresses in the program memory space are automatically defined as the Reset

and Interrupt vectors. The complete list of vectors is shown in Table 6. The list also determines

the priority levels of the different interrupts. The lower the address, the higher is the priority

level. RESET has the highest priority, and next is INT0 – the USB Suspend and Resume Interrupt, etc.

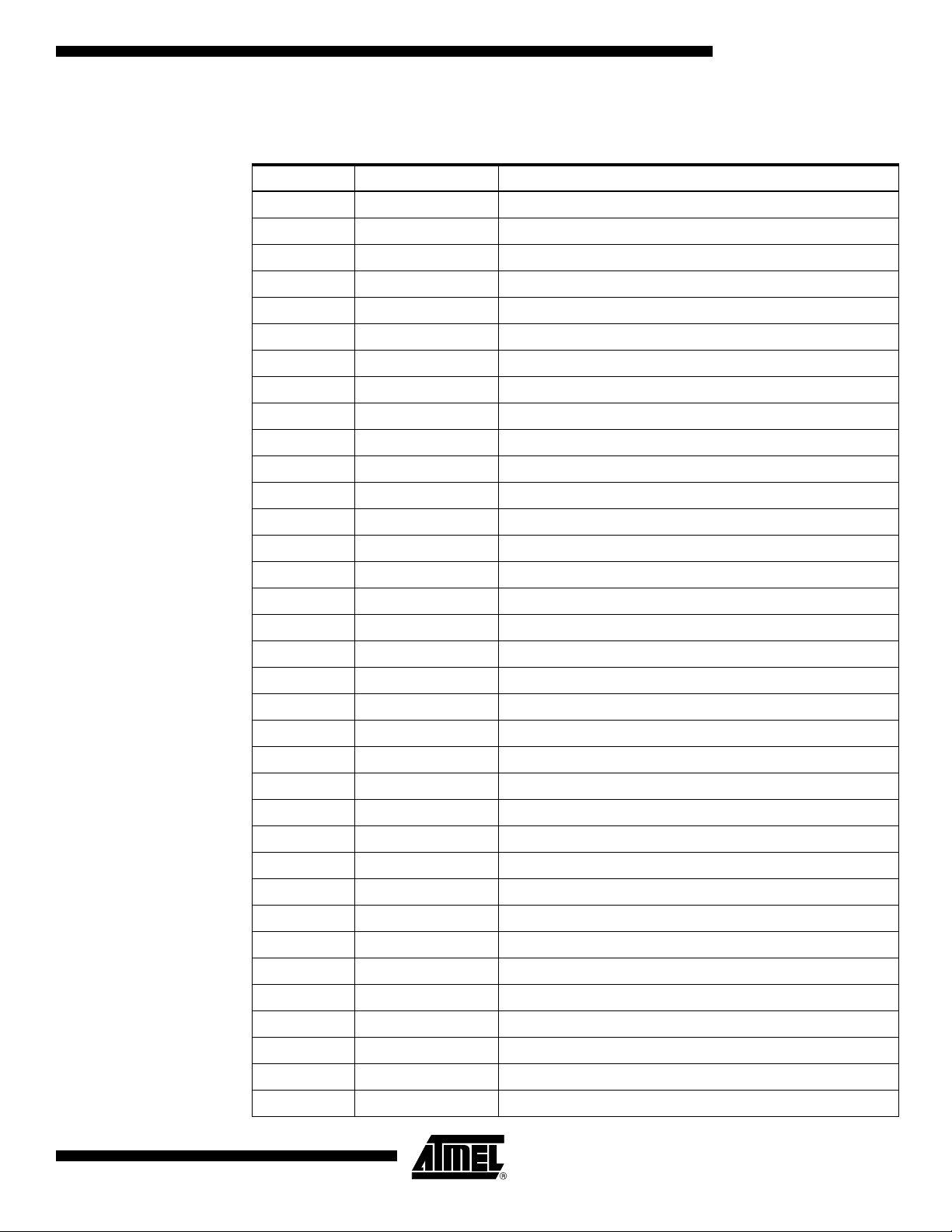

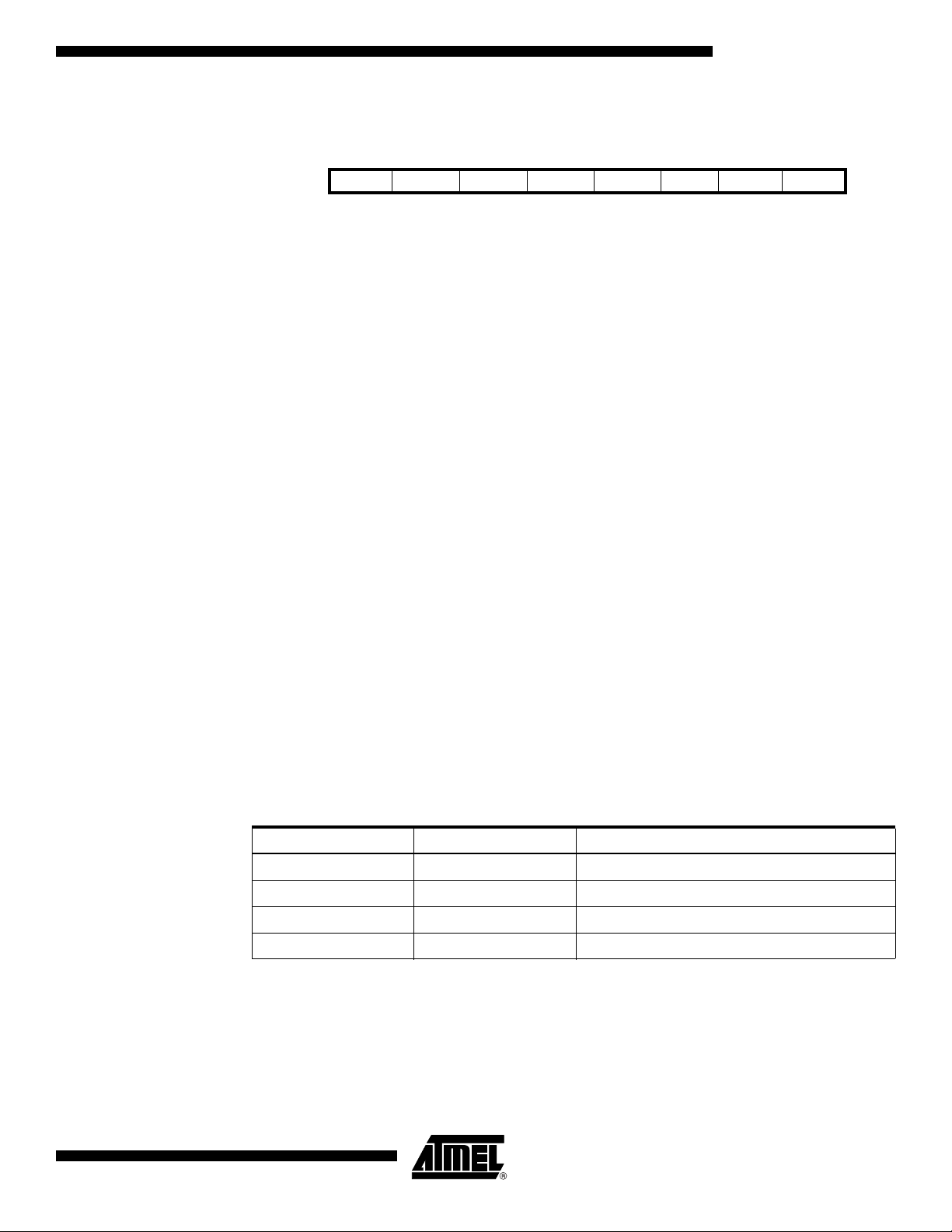

Table 6. Reset and Interrupt Vectors

Vector No. Program Address Source Interrupt Definition

1 $000 RESET External Reset, Power-on Reset and

Watchdog Reset

2 $002 INT0 USB Suspend and Resume

3 $004 INT1 External Interrupt Request 1

4 $006 TIMER1 CAPT Timer/Counter1 Capture Event

5 $008 TIMER1 COMPA Timer/Counter1 Compare Match A

6 $00A TIMER1 COMPB Timer/Counter1 Compare Match B

7 $00C TIMER1, OVF Timer/Counter1 Overflow

8 $00E TIMER0, OVF Timer/Counter0 Overflow

9 $010 SPI, STC SPI Serial Transfer Complete

12 $016 ADC ADC Conversion Complete

13 $018 USB HW USB Hardware

20

AT43USB355

2603G–USB–04/06

Page 21

AT43USB355

The most typical and general program setup for the Reset and Interrupt Vector Addresses are:

Address Labels Code Comments

$000 jmp RESET ; Reset Handler

$004 jmp EXT_INT1 ; IRQ1 Handler

$00E jmp TIM0_OVF ; Timer0 Overflow

Handler

$018 jmp USB_HW ; USB Handler

;

$00d MAIN: ldi r16, high (RAMEND) ; Main Program

start

$00e out SPH, r16

$00f ldi r16, low (RAMEND)

$010 out SPL, r16

$011 <instr> xxx

... ... ... ...

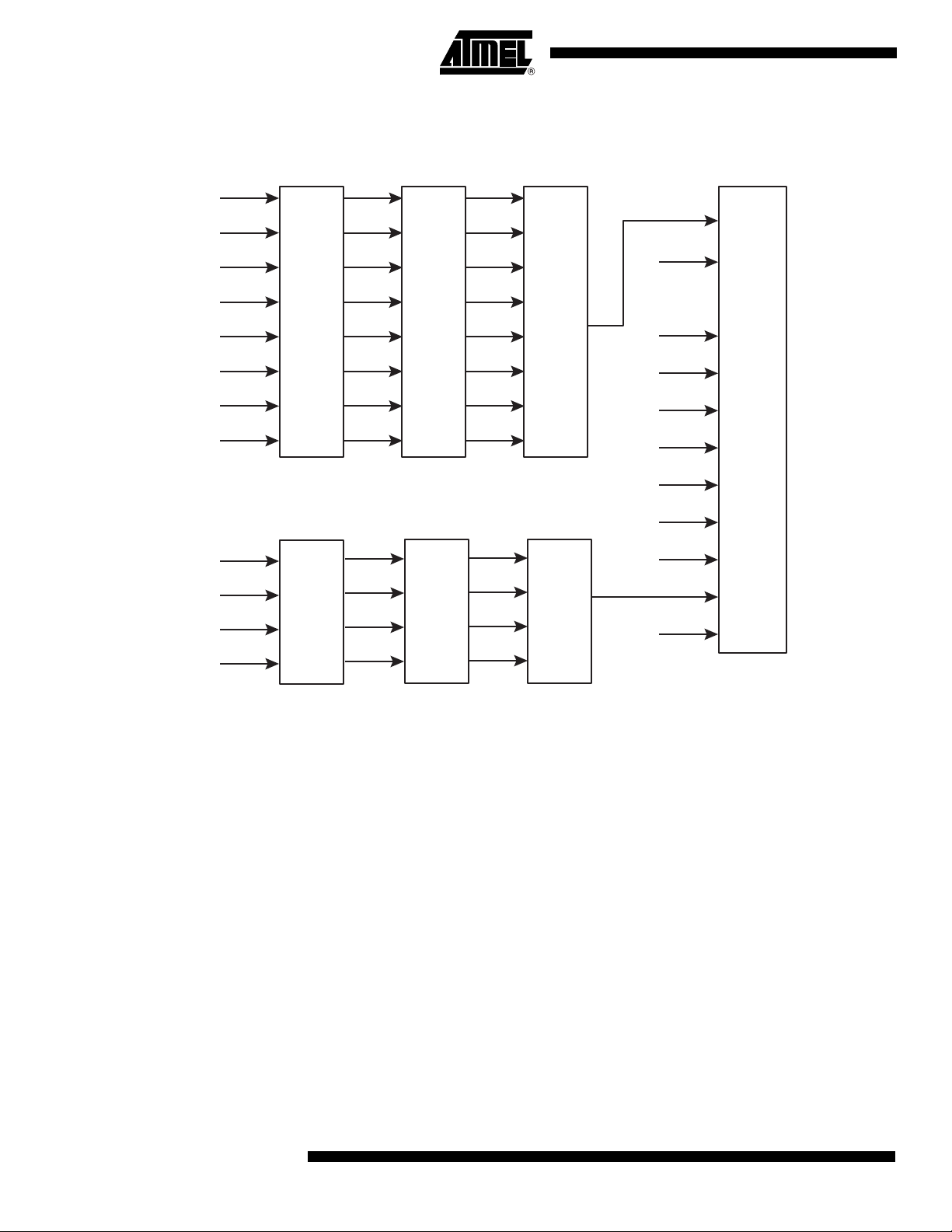

USB related interrupt events are routed to reset vectors 13 and 2 through a separate set of

interrupt, interrupt enable and interrupt mask registers that are mapped to the data SRAM

space. These interrupts must be enabled though their control register bits. In the event an

interrupt is generated, the source of the interrupt is identified by reading the interrupt registers.

The USB frame and transaction related interrupt events, such as Start of Frame interrupt, are

grouped in one set of registers: USB Interrupt Flag Register, USB Interrupt Enable Register

and USB Interrupt Mask Register. The USB Bus reset and suspend/resume are grouped in

another set of registers: Suspend/Resume Register, Suspend/Resume Interrupt Enable Register and Suspend/Resume Interrupt Mask Register.

Some applications may include firmware routines lasting for long periods of time that cannot

be interrupted. At the same time, other less critical events may need attention after the critical

routine is completed. The AT43USB355 solves this problem by having interrupt mask registers

in addition to the interrupt enable registers of the USB related interrupts. The difference

between the mask and the enable registers is:

• The enable register enables the interrupt so it is captured into the interrupt register. If it is

not enabled and an interrupt occurs, the interrupt will be lost,

• The mask register merely masks the interrupt from interrupting the CPU. Upon

unmasking, the pending interrupt is triggered.

2603G–USB–04/06

21

Page 22

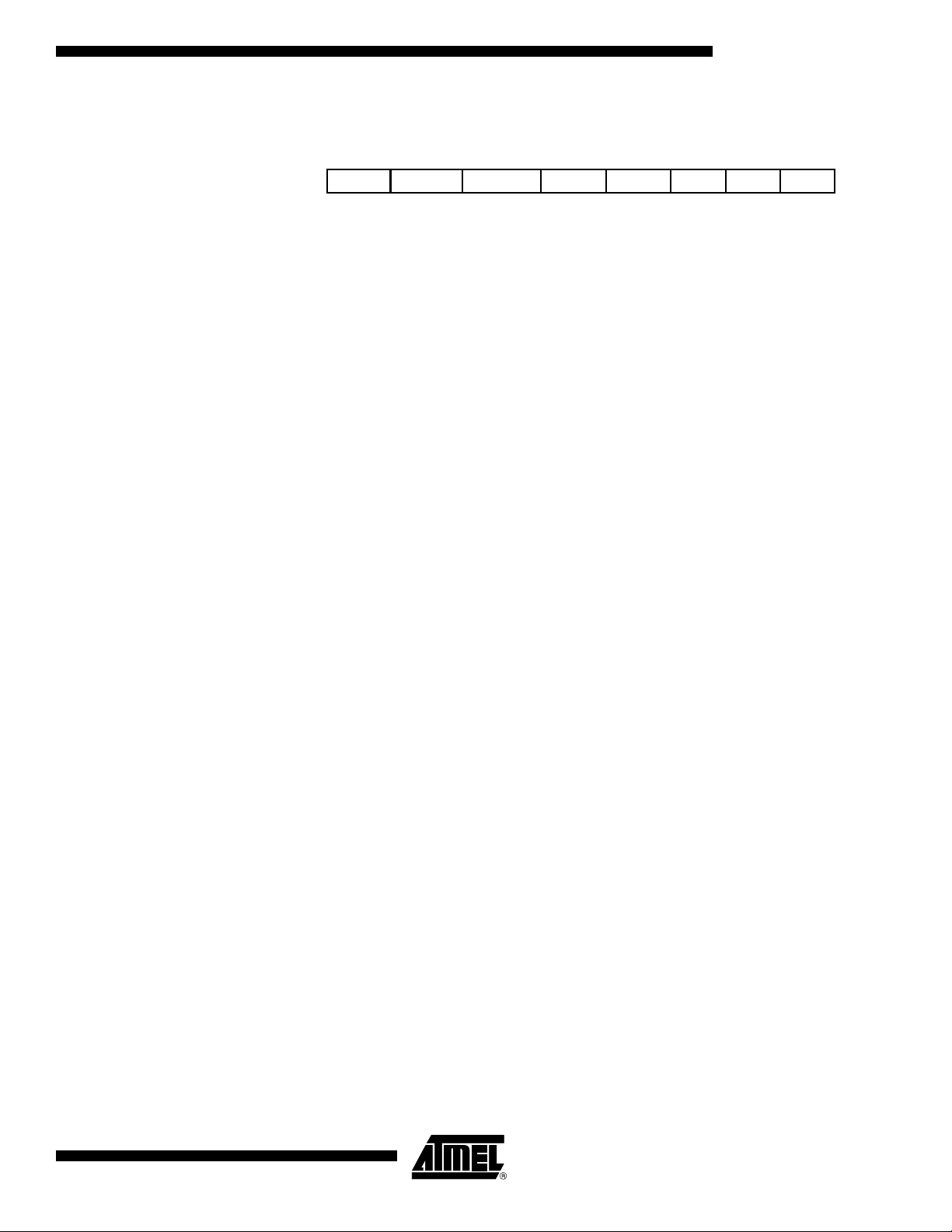

Figure 8. AT43USB355 Interrupt Structure

USB Interrupt

Flag Register

SOF

EOF2

FEP3

FEP2

USB Interrupt

Enable Register

USB Interrupt

Mask Register

USB

ADC

Microcontroller

Interrupt

Logic

13

12

FEP1

FEP0

RESERVED

HEP0

FRMWUP

RSM

GLB SUSP

BUS RESET

Suspend/Resume

Register

Suspend/Resume

Interrupt Enable

Register

Suspend/Resume

Interrupt Mask

Register

Reset Sources The AT43USB355 has four sources of reset:

• Power-on Reset – The MCU is reset when the supply voltage is below the power-on reset

threshold.

• External Reset – The MCU is reset when a low level is present on the RESETN pin for

more than 50 ns.

• Watchdog Reset – The MCU is reset when the watchdog timer period expires and the

watchdog is enabled.

• USB Reset – The AT43USB355 has a feature to separate the USB and microcontroller

resets. This feature is enabled by setting the BUS INT EN, bit 3 of the SPRSIE register. A

USB bus reset is defined as a SE0 (single ended zero) of at least 4 slow speed USB clock

cycles received by Port0. The internal reset pulse to the USB hardware and

microcontroller lasts for 24 oscillator periods.

– Resets not separated: A USB bus reset will also reset the microcontroller.

– Separated reset: A USB bus reset will only reset the USB hardware, while an

interrupt to the microcontroller will be generated if the BUS INT MSK bit, bit 3 of

SPRSMSK register, is also set.

SPI STC

TIMER0 OVF

TIMER1 OVF

TIMER1 COMPB

TIMER1 COMPA

TIMER1CAPT

INT1

INT0

RESET

9

8

7

6

5

4

3

2

1

22

AT43USB355

2603G–USB–04/06

Page 23

Figure 9. Reset Logic

AT43USB355

When the USB hardware is reset, the compound device is de-configured and has to be reenumerated by the host. When the microcontroller is reset, all I/O registers are then set to their

initial values, and the program starts execution from address $000. The instruction placed in

address $000 must be a JMP instruction to the reset handling routine. If the program never

enables an interrupt source, the interrupt vectors are not used, and regular program code can

be placed at these locations. The circuit diagram in Figure 9 shows the reset logic.

USB Reset

VCC

RSTN

1 MHz Clock

POR Ckt

Reset Ckt

Watchdog Timer

Divider

14-bit Cntr

OR

Cntr Reset

FSTRT

ON

S

R

Power-on Reset A Power-on Reset (POR) circuit ensures that the device is reset from power-on. An internal

timer clocked from the Watchdog timer oscillator prevents the MCU from starting until after a

certain period after V

rise time.

has reached the power-on threshold voltage, regardless of the V

CC

CC

2603G–USB–04/06

If the build-in start-up delay is sufficient, RESETN can be connected to V

external pull-up resistor. By holding the pin low for a period after V

has been applied, the

CC

Power-on Reset period can be extended.

directly or via an

CC

23

Page 24

External Reset An external reset is generated by a low-level on the RESETN pin. Reset pulses longer than

200 ns will generate a reset. Shorter pulses are not guaranteed to generate a reset. When the

applied signal reaches the Reset Threshold Voltage - V

starts the MCU after the Time-out period t

has expired.

TOUT

Figure 10. External Reset During Operation

VCC

on its positive edge, the delay timer

RST

Watchdog Timer Reset

RESET

TIME-OUT

INTERNAL

RESET

V

RST

t

TOUT

When the watchdog times out, it will generate a short reset pulse of 1 XTAL cycle duration. On

the falling edge of this pulse, the delay timer starts counting the Time-out period t

TOUT

.

Figure 11. Watchdog Reset During Operation

VCC

RESET

1 XTAL Cycle

WDT

TIME-OUT

t

RESET

TIME-OUT

TOUT

Non-USB Related Interrupt Handling

24

AT43USB355

INTERNAL

RESET

The AT43USB355 has two non-USB 8-bit Interrupt Mask control registers; GIMSK (General

Interrupt Mask Register) and TIMSK (Timer/Counter Interrupt Mask Register).

When an interrupt occurs, the Global Interrupt Enable I-bit is cleared (zero) and all interrupts

are disabled. The user software can set (one) the I-bit to enable nested interrupts. The I-bit is

set (one) when a Return from Interrupt instruction, RETI, is executed.

For Interrupts triggered by events that can remain static (e.g. the Output Compare register1

matching the value of Timer/Counter1) the interrupt flag is set when the event occurs. If the

interrupt flag is cleared and the interrupt condition persists, the flag will not be set until the

event occurs the next time.

When the Program Counter is vectored to the actual interrupt vector in order to execute the

interrupt handling routine, hard-ware clears the corresponding flag that generated the interrupt. Some of the interrupt flags can also be cleared by writing a logic one to the flag bit

position(s) to be cleared.

2603G–USB–04/06

Page 25

AT43USB355

If an interrupt condition occurs when the corresponding interrupt enable bit is cleared (zero),

the interrupt flag will be set and remembered until the interrupt is enabled, or the flag is

cleared by software.

If one or more interrupt conditions occur when the global interrupt enable bit is cleared (zero),

the corresponding interrupt flag(s) will be set and remembered until the global interrupt enable

bit is set (one), and will be executed by order of priority.

Note that external level interrupt does not have a flag, and will only be remembered for as long

as the interrupt condition is active.

2603G–USB–04/06

25

Page 26

General Interrupt Mask Register – GIMSK

Bit 7 6 5 4 3 210

$3B ($5B)

Read/Write R/W R/W R R R R R R

Initial Value 0 0 0 0 0 0 0 0

INT1 INT0 – – – – – –

GIMSK

• Bit 7 – INT1: External Interrupt Request 1 Enable

When the INT1 bit is set (one) and the I-bit in the Status Register (SREG) is set (one), the

external pin interrupt is enabled. The Interrupt Sense Control1 bits 1/0 (ISC11 and ISC10) in

the MCU general Control Register (MCUCR) defines whether the external interrupt is activated on rising or falling edge of the INT1 pin or level sensed. Activity on the pin will cause an

interrupt request even if INT1 is configured as an output. The corresponding interrupt of External Interrupt Request 1 is executed from program memory address $004. See also “External

Interrupts” on page 29.

• Bit 6 – INT0: Interrupt Request 0 (Suspend/Resume Interrupt) Enable

When the INT0 bit is set (one) and the I-bit in the Status Register (SREG) is set (one), the

external pin interrupt is enabled. The Interrupt Sense Control0 bits 1/0 (ISC01 and ISC00) in

the MCU general Control Register (MCUCR) defines whether the external interrupt is activated on rising or falling edge of the INT0 pin or level sensed. Activity on the pin will cause an

interrupt request even if INT0 is configured as an output. The corresponding interrupt of Interrupt Request 0 is executed from program memory address $002. See also “External

Interrupts” on page 29.

• Bits 5..0 – Res: Reserved Bits

These bits are reserved bits in the AT43USB355 and always read as zero.

General Interrupt Flag Register – GIFR

Bit 7 6 543210

$3A ($5A) INTF1 INT F0 – – – – – – GIFR

Read/Write R/W R/W R R R R R R

Initial Value 0 0 0 0 0 0 0 0

• Bit 7 – INTF1: External Interrupt Flag1

When an event on the INT1 pin triggers an interrupt request, INTF1 becomes set (one). If the

I-bit in SREG and the INT1 bit in GIMSK are set (one), the MCU will jump to the interrupt vector at address $004. The flag is cleared when the interrupt routine is executed. Alternatively,

the flag can be cleared by writing a logical one to it.

• Bit 6 – INTF0: Interrupt Flag0 (Suspend/Resume Interrupt Flag)

When an event on the INT0 (that is, a USB event-related interrupt) triggers an interrupt

request, INTF0 becomes set (one). If the I-bit in SREG and the INT0 bit in GIMSK are set

(one), the MCU will jump to the interrupt vector at address $002. The flag is cleared when the

interrupt routine is executed. Alternatively, the flag can be cleared by writing a logical one to it.

• Bits 5..0 – Res: Reserved Bits

These bits are reserved bits in the AT43USB355 and always read as zero.

26

AT43USB355

2603G–USB–04/06

Page 27

AT43USB355

Timer/Counter Interrupt Mask Register – TIMSK

Bit 7 6 5 4 3 210

$39 ($59) TOIE1 OCIE1A OCIE1NB – TICIE1 – TOIE0 – TIMSK

Read/Write R/W R/W R/W R R/W R R/W R

Initial Value 0 0 0 0 0 0 0 0

• Bit 7 – TOIE1: Timer/Counter1 Overflow Interrupt Enable

When the TOIE1 bit is set (one) and the I-bit in the Status Register is set (one), the

Timer/Counter1 Overflow interrupt is enabled. The corresponding interrupt (at vector $006) is

executed if an overflow in Timer/Counter1 occurs, i.e., when the TOV1 bit is set in the

Timer/Counter Interrupt Flag Register (TIFR).

• Bit 6 – OCE1A: Timer/Counter1 Output CompareA Match Interrupt Enable

When the OCIE1A bit is set (one) and the I-bit in the Status Register is set (one), the

Timer/Counter1 CompareA Match interrupt is enabled. The corresponding interrupt (at vector

$004) is executed if a CompareA match in Timer/Counter1 occurs, i.e., when the OCF1A bit is

set in the TIFR.

• Bit 5 – OCIE1B: Timer/Counter1 Output CompareB Match Interrupt Enable

When the OCIE1B bit is set (one) and the I-bit in the Status Register is set (one), the

Timer/Counter1 CompareB Match interrupt is enabled. The corresponding interrupt (at vector

$005) is executed if a CompareB match in Timer/Counter1 occurs, i.e., when the OCF1B bit is

set in the TIFR.

• Bit 4 – Res: Reserved Bit

This bit is a reserved bit in the AT43USB355 and always reads zero.

• Bit 3 – TICIE1: Timer/Counter1 Input Capture Interrupt Enable

When the TICIE1 bit is set (one) and the I-bit in the Status Register is set (one), the

Timer/Counter1 Input Capture Event Interrupt is enabled. The corresponding interrupt (at vector $003) is executed if a capture-triggering event occurs on pin 31, ICP, i.e., when the ICF1

bit is set in the TIFR.

• Bit 2 – Res: Reserved Bit

This bit is a reserved bit in the AT43USB355 and always reads zero.

• Bit 1 – TOIE0: Timer/Counter0 Overflow Interrupt Enable

When the TOIE0 bit is set (one) and the I-bit in the Status Register is set (one), the

Timer/Counter0 Overflow interrupt is enabled. The corresponding interrupt (at vector $007) is

executed if an overflow in Timer/Counter0 occurs, i.e., when the TOV0 bit is set in the TIFR.

• Bit 0 – Res: Reserved Bit

This bit is a reserved bit in the AT43USB355 and always reads zero.

2603G–USB–04/06

27

Page 28

Timer/Counter Interrupt Flag Register – TIFR

Bit 7 6 5 4 3 210

$38 ($58) TOV1 OCF1A OCIFB – ICF1 – TOV0 – TIFR

Read/Write R/W R/W R/W R R/W R R/W R

Initial Value 0 0 0 0 0 0 0 0

• Bit 7 – TOV1: Timer/Counter1 Overflow Flag

The TOV1 is set (one) when an overflow occurs in Timer/Counter1. TOV1 is cleared by the

hardware when executing the corresponding interrupt handling vector. Alternatively, TOV1 is

cleared by writing a logic one to the flag. When the I-bit in SREG, and TOIE1 (Timer/Counter1

Overflow Interrupt Enable), and TOV1 are set (one), the Timer/Counter1 Overflow Interrupt is

executed. In PWM mode, this bit is set when Timer/Counter1 changes counting direction at

$0000.

• Bit 6 – OCF1A: Output Compare Flag 1A

The OCF1A bit is set (one) when compare match occurs between the Timer/Counter1 and the

data in OCR1A - Output Compare Register 1A. OCF1A is cleared by the hardware when executing the corresponding interrupt handling vector. Alternatively, OCF1A is cleared by writing a

logic one to the flag. When the I-bit in SREG, and OCIE1A (Timer/Counter1 Compare match

InterruptA Enable), and the OCF1A are set (one), the Timer/Counter1 Compare A match Interrupt is executed.

• Bit 5 – OCF1B: Output Compare Flag 1B

The OCF1B bit is set (one) when compare match occurs between the Timer/Counter1 and the

data in OCR1B - Output Compare Register 1B. OCF1B is cleared by the hardware when executing the corresponding interrupt handling vector. Alternatively, OCF1B is cleared by writing a

logic one to the flag. When the I-bit in SREG, and OCIE1B (Timer/Counter1 Compare match

InterruptB Enable), and the OCF1B are set (one), the Timer/Counter1 Compare B match Interrupt is executed.

• Bit 4 – Res: Reserved Bit

28

This bit is a reserved bit in the AT43USB355 and always reads zero.

• Bit 3 – ICF1: - Input Capture Flag 1

The ICF1 bit is set (one) to flag an input capture event, indicating that the Timer/Counter1

value has been transferred to the input capture register - ICR1. ICF1 is cleared by the hardware when executing the corresponding interrupt handling vector. Alternatively, ICF1 is

cleared by writing a logic one to the flag. When the SREG I-bit, and TICIE1 (Timer/Counter1

Input Capture Interrupt Enable), and ICF1 are set (one), the Timer/Counter1 Capture Interrupt

is executed.

• Bit 2 – Res: Reserved Bit

This bit is a reserved bit in the AT43USB355 and always reads zero.

• Bit 1 – TOV: Timer/Counter0 Overflow Flag

The bit TOV0 is set (one) when an overflow occurs in Timer/Counter0. TOV0 is cleared by the

hardware when executing the corresponding interrupt handling vector. Alternatively, TOV0 is

cleared by writing a logic one to the flag. When the SREG I- bit, and TOIE0 (Timer/Counter0

Overflow Interrupt Enable), and TOV0 are set (one), the Timer/Counter0 Overflow interrupt is

executed.

• Bit 0 – Res: Reserved Bit

This bit is a reserved bit in the AT43USB355 and always reads zero.

AT43USB355

2603G–USB–04/06

Page 29

AT43USB355

External Interrupts The external interrupts are triggered by the INT0 and INT1 pins. Observe that, if enabled, the

INT0/INT1 interrupt will trigger even if the INT0/INT1 pin is configured as an output. This feature provides a way of generating a software interrupt. The external interrupts can be triggered

by a falling or rising edge or a low level. This is set up as indicated in the specification for the

MCU Control Register (MCUCR) and the Interrupt Sense Control Register (ISCR). When

INT0/INT1 is enabled and is configured as level triggered, the interrupt will trigger as long as

the pin is held low. INT0/INT1 is set up as described in the specification for the MCU Control

Register (MCUCR).

Interrupt Response Time

The interrupt execution response for all the enabled AVR interrupts is 4 clock cycles minimum.

4 clock cycles after the interrupt flag has been set, the program vector address for the actual

interrupt handling routine is executed. During this 4 clock cycle period, the Program Counter (2

bytes) is pushed onto the Stack, and the Stack Pointer is decremented by 2. The vector is normally a jump to the interrupt routine, and this jump takes 3 clock cycles. If an interrupt occurs

during execution of a multi-cycle instruction, this instruction is completed before the interrupt is

served.

A return from an interrupt handling routine (same as for a subroutine call routine) takes 4 clock

cycles. During these 4 clock cycles, the Program Counter (2 bytes) is popped back from the

Stack, the Stack Pointer is incremented by 2, and the I flag in SREG is set. When the AVR

exits from an interrupt, it will always return to the main program and execute one more instruction before any pending interrupt is served.

2603G–USB–04/06

29

Page 30

MCU Control Register – MCUCR

Bit 7 6 5 4 3 2 1 0

$35 ($55) – – SE SM ISC11 ISC10 ISC01 ISC00 MCUCR

Read/Write R R R/W R/W R/W R/W R/W R/W

Initial Value 0 0 0 0 0 0 0 0

• Bit 7, 6 – Res: Reserved Bits

• Bit 5 – SE: Sleep Enable

The SE bit must be set (1) to make the MCU enter the sleep mode when the SLEEP instruction is executed. To avoid the MCU entering the sleep mode, unless it is the programmer's

purpose, it is recommended to set the Sleep Enable SE bit just before the execution of the

SLEEP instruction.

• Bit 4 – SM: Sleep Mode

This bit selects between the two available sleep modes. When SM is cleared (zero), Idle Mode

is selected as Sleep Mode. When SM is set (1), Power Down mode is selected as sleep mode.

The AT43USB355 does not support the Idle Mode and SM should always be set to one when

entering the Sleep Mode.

• Bit 3, 2 – ISC11, ISC10: Interrupt Sense Control 1 Bit 1 and Bit 0

The External Interrupt 1 is activated by the external pin INT1 if the SREG I-flag and the corresponding interrupt mask in the GIMSK is set. The level and edges on the external INT1 pin

that activate the interrupt are defined in the following table:

Table 7. INT1 Sense Control

ISC11 ISC10 Description

0 0 The low level of INT1 generates an interrupt request.

01Reserved.

1 0 The falling edge of INT1 generates an interrupt request.

1 1 The rising edge of INT1 generates an interrupt request.

• Bit 1, 0 – ISC01, ISC00: Interrupt Sense Control 0 bit 1 and bit 0

The External Interrupt 0 is activated by the external pin INT0 if the SREG I-flag and the corresponding interrupt mask in the GIMSK is set. The level and edges on the external INT0 pin

that activate the interrupt are defined in the following table:

Table 8. INT1 Sense Control

ISC01 ISC00 Description

0 0 The low level of INT0 generates an interrupt request.

01Reserved.

1 0 The falling edge of INT0 generates an interrupt request.

1 1 The rising edge of INT0 generates an interrupt request.

30

AT43USB355

2603G–USB–04/06

Page 31

AT43USB355

USB Interrupt Sources

The USB interrupts are described below.

Table 9. USB Interrupt Sources

Interrupt Description

SOF Received Whenever USB hardware decodes a valid Start of Frame. The

frame number is stored in the two Frame Number Registers.

EOF2 Activated whenever the hub's frame timer reaches its EOF2 time

point.

Function EP0 Interrupt See “Control Transfers at Control End-point EP0” on page 75 for

details.

Function EP1 Interrupt For an OUT end-point it indicates that Function End-point 1 has

received a valid OUT packet and that the data is in the FIFO. For

an IN end-point it means that the end-point has received an IN

token, sent out the data in the FIFO and received an ACK from the

Host. The FIFO is now ready to be written by new data from the

microcontroller.

Function EP2 Interrupt For an OUT end-point it indicates that Function End-point 2 has

received a valid OUT packet and that the data is in the FIFO. For

an IN end-point it means that the end-point has received an IN

token, sent out the data in the FIFO and received an ACK from the

Host. The FIFO is now ready to be written by new data from the

microcontroller.

Function EP3 Interrupt For an OUT end-point it indicates that Function End-point 3 has

received a valid OUT packet and that the data is in the FIFO. For

an IN end-point it means that the end-point has received an IN

token, sent out the data in the FIFO and received an ACK from the

Host. The FIFO is now ready to be written by new data from the

microcontroller.

Hub EP0 Interrupt See “Control Transfers at Control End-point EP0” on page 75 for

details.

FRWUP USB hardware has received a embedded function remote wakeup

request.

2603G–USB–04/06

GLB SUSP USB hardware has received global suspend signaling and is

preparing to put the hub in the suspend mode. The

microcontroller's firmware should place the embedded function in

the suspend state.

RSM USB hardware received resume signaling and is propagating the

resume signaling. The microcontroller's firmware should take the

embedded function out of the suspended state.

BUS RESET USB hardware received a USB bus reset. This applies only in

cases where a separation between USB bus reset and

microcontroller reset is required. Be very careful when using this

feature.

All interrupts have individual enable, status, and mask bits through the interrupt enable register and interrupt mask register. The Suspend and Resume interrupts are cleared by writing a 0

to the particular interrupt bit. All other interrupts are cleared when the microcontroller sets a bit

in an interrupt acknowledge register.

31

Page 32

USB End-point Interrupt Sources

An assertion or activation of one or more bits in the end-point's Control and Status Register

triggers the end-point interrupts. These triggers are different for control and non-control endpoints as described in the table below. Please refer to the Control and Status Register for

more information.

Table 10. USB End-point Interrupt Sources

Bit End-point type

RX_OUT_PACKET CONTROL, OUT

TX_COMPLETE CONTROL, IN

STALL_SENT CONTROL, IN

RX_SETUP CONTROL

USB Interrupt Status Register – UISR

Bit 7 6 5 4 3 2 1 0

$1FF7 SOF INT EOF2 INT – FE3 INT HEP0 INT FE2 INT FE1 INT FE0 INT UISR

Read/Write R R R R R R R R

Initial Value 0 0 0 0 0 0 0 0

• Bit 7 – SOF INT: Start of Frame Interrupt

This bit is asserted after the USB hardware receives a valid SOF packet.

• Bit 6 – EOF2 INT: EOF2 Interrupt

This bit is asserted 10 clocks before the expected start of a frame.

• Bit 5 – Res: Reserved Bit

This bit is reserved and always reads as zero.

• Bit 4 – FEP3 INT: Function End-point 3 Interrupt

• Bit 3 – HEP0 INT: Hub End-point 0 Interrupt

• Bit 2 – FEP2 INT: Function End-point 2 Interrupt

• Bit 1 – FEP1 INT: Function End-point 1 Interrupt

• Bit 0 – FEP0 INT: Function End-point 0 Interrupt

The hub and function interrupt bits will be set by the hardware whenever the following bits in

the corresponding end-point's Control and Status Register are modified by the USB hardware:

1. RX OUT Packet is set (control and OUT end-points)

2. TX Packet Ready is cleared AND TX Complete is set (control and IN end-points)

3. RX SETUP is set (control end-points only)

4. TX Complete is set

32

AT43USB355

2603G–USB–04/06

Page 33

AT43USB355

USB Interrupt Mask Register – UIMSKR

Bit 7 6 5 4 3 2 1 0

$1FF6 SOF IMSK EOF2 IMSK – FEP3 IMSK HEP0 IMSK FEP2 IMSK FEP1 IMSK FEP0 IMSK UIMSKR

Read/Write R/W R/W R R/W R/W R/W R/W R/W

Initial Value 0 0 0 0 0 0 0 0

• Bit 7 – SOF IMSK: Start of Frame Interrupt Mask

When the SOF IMSK bit is set (1), the Start of Frame Interrupt is masked.

• Bit 6 – EOF2 IMSK: EOF2 Interrupt Mask

When the EOF2 IMSK bit is set (1), the EOF2 Interrupt is masked.

• Bit 5 – Res: Reserved bit

This bit is reserved and always read as zero.

• Bit 4 – FEP3 IMSK: Function End-point 3 Interrupt Mask

When the FE3 IMSK bit is set (1), the Function End-point 3 Interrupt is masked.

• Bit 3 – HEP0 IMSK: End-point 0 Interrupt Mask

When the HEP0 IMSK bit is set (1), the Hub End-point 0 Interrupt is masked.

• Bit 2 – FEP2 IMSK: End-point 2 Interrupt Mask

When the FE2 IMSK bit is set (1), the Function End-point 2 Interrupt is masked.

• Bit 1 – FEP1 IMSK: End-point 1 Interrupt Mask

When the FE1 IMSK bit is set (1), the Function End-point 1 Interrupt is masked.

• Bit 0 – FEP0 IMSK: End-point 0 Interrupt Mask

When the FE0 IMSK bit is set (1), the Function End-point 0 Interrupt is masked.

2603G–USB–04/06

33

Page 34

USB Interrupt Acknowledge Register – UIAR

Bit 7 6 5 4 3 2 1 0

$1FF5 SOF INTACK EOF2 INTACK – FEP3 INTACK HEP0 INTACK FEP2 IMSK FEP1 INTACK FEP0 INTACK UIAR

Read/Write W W R W W W W W

Initial Value 0 0 0 0 0 0 0 0

• Bit 7 – SOF INTACK: Start of Frame Interrupt Acknowledge

The microcontroller firmware writes a 1 to this bit to clear the SOF INT bit.

• Bit 6 – EOF2 INTACK: EOF2 Interrupt Acknowledge

The microcontroller firmware writes a 1 to this bit to clear the EOF2 INT bit.

• Bit 5 – Res: Reserved bit

This bit is reserved and is always read as zero.

• Bit 4 – FEP3 INTACK: Function End-point 3 Interrupt Acknowledge

The microcontroller firmware writes a 1 to this bit to clear the FEP3 INT bit.

• Bit 3 – HEP0 INTACK: Hub End-point 0 Interrupt Acknowledge

The microcontroller firmware writes a 1 to this bit to clear the HEP0 INT bit.

• Bit 2 – FEP2 INTACK: Function End-point 2 Interrupt Acknowledge

The microcontroller firmware writes a 1 to this bit to clear the FEP2 bit.

• Bit 1 – FEP1 INTACK: Function End-point 1 Interrupt Acknowledge

The microcontroller firmware writes a 1 to this bit to clear the FEP1 bit.

• Bit 0 – FEP0 INTACK: Function End-point 0 Interrupt Acknowledge

The microcontroller firmware writes a 1 to this bit to clear the FEP0 INT bit.

34

AT43USB355

2603G–USB–04/06

Page 35

AT43USB355

USB Interrupt Enable Register – UIER

Bit 7 6 5 4 3 2 1 0

$1FF3 SOF IE EOF2 IE – FEP3 IE HEP0 IE FEP2 IE FEP1 IE FEP0 IE UIER

Read/Write R/W R/W R R/W R/W R/W R/W R/W

Initial Value 0 0 0 0 0 0 0 0

• Bit 7 – SOF IE: Enable Start of Frame Interrupt

When the SOF IE bit is set (1), the Start of Frame Interrupt is enabled.

• Bit 6 – EOF2 IE: Enable EOF2 Interrupt

When the EOF2 IE bit is set (1), the EOF2 Interrupt is enabled.

• Bit 5 – Res: Reserved bit

This bit is reserved and always read as zero.

• Bit 4 – FEP3 IE: Enable Function End-point 3 Interrupt

When the FE3 IE bit is set (1), the Function End-point 3 Interrupt is enabled.

• Bit 3 – HEP0 IE: Enable End-point 0 Interrupt

When the HEP0 IE bit is set (1), the Hub End-point 0 Interrupt is enabled.

• Bit 2 – FEP2 IE: Enable End-point 2 Interrupt

When the FE2 IE bit is set (1), the Function End-point 2 Interrupt is enabled.

• Bit 1 – FEP1 IE: Enable End-point 1 Interrupt

When the FE1 IE bit is set (1), the Function End-point 1 Interrupt is enabled.

• Bit 0 – FEP0 IE: Enable End-point 0 Interrupt

When the FE0 IE bit is set (1), the Function End-point 0 Interrupt is enabled.

Suspend/Resume Register – SPRSR

Bit76 543 2 1 0

$1FFA – – – – BUS INT FRWUP RSM GLB SUSP SPRSR

Read/Write R R R R R/W R R R

Initial Value 0 0 0 0 0 0 0 0

• Bit 7..4 – Res: Reserved Bits

These bits are reserved and are always read as zeros.

• Bit 3 – BUS INT: USB Bus Interrupt

When the USB reset separation feature is enabled (SPRSIE and SPRSMSK bits 3 are set to

1) the BUS INT bit is set when USB bus reset is detected by the USB hardware.

• Bit 2 – FRWUP: Function Remote Wakeup

The USB hardware sets this bit to signal that External Interrupt 1 is detected indicating remote

wakeup. An interrupt is generated if the FRWUP IE bit of the SPRSIE register is set.

• Bit 1 – RSM: Resume

2603G–USB–04/06

The USB hardware sets this bit when a USB resume signaling is detected at any of its port

except Port 1. An interrupt is generated if the RSM IE bit of the SPRSIE register is set.

• Bit 0 – GLB SUSP: Global Suspend

The USB hardware sets this bit when a USB global suspend signaling is detected. An interrupt

is generated if the GLBSUSP IE bit of the SPRSIE register is set.

35

Page 36

Suspend/Resume Interrupt Enable Register – SPRSIE

Bit 7 6 5 4 3 2 1 0

$1FF9 – – – – BUS INT FRWUP RSM GLB SUSP SPRSIE

Read/Write R R R R R/W R R R

Initial Value 0 0 0 0 0 0 0 0

• Bit 7..4 – Res: Reserved Bits

These bits are reserved and are always read as zeros.

• Bit 3 – BUS INT EN: USB Reset Interrupt Enable

When the BUS INT EN bit is set, the USB and microcontroller resets are separated. A USB

bus reset (SE0 for longer than 3 ms) will reset the USB hardware only and not the microcontroller. However, an interrupt to the microcontroller will be generated and bit 3 of SPRSR is

set.

• Bit 2 – FRWUP IE: Function Remote Wakeup Interrupt Enable

Setting the FRWUP IE bit will initiate an interrupt whenever the FRWUP bit of SPRSR is set.

• Bit 1 – RSM IE: Resume Interrupt Enable

Setting the RSM IE bit will initiate an interrupt whenever the RSM bit of SPRSR is set.

• Bit 0 – GLB SUSP IE: Global Suspend Interrupt Enable

Setting the GLB SUSP IE bit will initiate an interrupt whenever the GLB SUSP bit of SPRSR is

set.

Suspend/Resume Interrupt Mask Register – SPRSMSK

Bit 7 6 5 4 3 2 1 0

$1FF8 – – – – BUS INT MSK FRWUP MSK RSM GLB SUSP SPRSMSK

Read/Write R R R R W W W W

Initial Value 0 0 0 0 0 0 0 0

The bits of the Suspend/Resume Mask Register are used to make an interrupt caused by an

event in the Suspend/Resume Register visible to the microcontroller. The Suspend/Resume

Interrupt Enable Register bits enable the interrupt while the Suspend/Resume Interrupt Mask

Register allows the microcontroller to control when it wants visibility to an interrupt. 1 = Enable

Mask, 0 = Disable Mask.

• Bit 7..4 – Res: Reserved Bits

These bits are reserved and are always read as zeros.

• Bit 3 – BUS INT MSK: USB Reset Interrupt Mask

• Bit 2 – FRWUP MSK: Function Remote Wakeup Interrupt Mask

• Bit 1 – RSM MSK: Resume Interrupt Mask

• Bit 0 – GLB SUSP MSK: Global Suspend Interrupt Enable

36

AT43USB355

2603G–USB–04/06

Page 37

AVR Register Set

Status Register and Stack Pointer

Status Register – SREG

Bit 7 6 5 4 3 2 1 0

$3F ($5F) ITHSVNZCSREG

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 0 0 0 0 0 0 0 0

•Bit 7 – I: Global Interrupt Enable

The global interrupt enable bit must be set (one) for the interrupts to be enabled. The individual interrupt enable control is then performed in separate control registers. If the global

interrupt enable bit is cleared (zero), none of the interrupts are enabled independent of the

individual interrupt enable settings. The I-bit is cleared by the hardware after an interrupt has

occurred, and is set by the RETI instruction to enable subsequent interrupts.

•Bit 6 – T: Bit Copy Storage

The bit copy instructions BLD (Bit LoaD) and BST (Bit STore) use the T bit as source and destination for the operated bit. A bit from a register in the register file can be copied into T by the

BST instruction, and a bit in T can be copied into a bit in a register in the register file by the

BLD instruction.

•Bit 5 – H: Half Carry Flag

AT43USB355

The half carry flag H indicates a half carry in some arithmetic operations. See the Instruction

Set Description for detailed information.

•Bit 4 – S: Sign Bit, S = N⊕V

The S-bit is always an exclusive or between the negative flag N and the two's complement

overflow flag V. See the Instruction Set Description for detailed information.

•Bit 3 – V: Two's Complement Overflow Flag

The two's complement overflow flag V supports two's complement arithmetics. See the

Instruction Set Description for detailed information.

•Bit 2 – N: Negative Flag

The negative flag N indicates a negative result after the different arithmetic and logic operations. See the Instruction Set Description for detailed information.

•Bit 1 – Z: Zero Flag

The zero flag Z indicates a zero result after the different arithmetic and logic operations. See

the Instruction Set Description for detailed information.

•Bit 0 – C: Carry Flag

The carry flag C indicates a carry in an arithmetic or logic operation. See the Instruction Set

Description for detailed information.

Note that the status register is not automatically stored when entering an interrupt routine and

restored when returning from an interrupt routine. This must be handled by software.

2603G–USB–04/06

37

Page 38

Stack Pointer Register – SP

Bit 1514 131211109 8

$3E ($5E) ITHSVNZCSPH

$3D ($5D) SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0 SPL

76 5 4 3210

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 0 0 0 0 0 0 0 0

00 0 0 0000

The Stack Pointer points to the data SRAM stack area where the Subroutine and Interrupt

Stacks are located. This Stack space in the data SRAM must be defined by the program

before any subroutine calls are executed or interrupts are enabled. The stack pointer must be

set to point above $60. The Stack Pointer is decremented by one when data is pushed onto

the Stack with the PUSH instruction, and it is decremented by two when an address is pushed

onto the Stack with subroutine calls and interrupts. The Stack Pointer is incremented by one

when data is popped from the Stack with the POP instruction and it is incremented by two

when an address is popped from the Stack with return from subroutine RET or return from

interrupt RETI.

Sleep Modes To enter the sleep modes, the SE bit in MCUCR must be set (one) and a SLEEP instruction

must be executed. If an enabled interrupt occurs while the MCU is in a sleep mode, the MCU

awakes, executes the interrupt routine, and resumes execution from the instruction following

SLEEP. The contents of the register file, SRAM and I/O memory are unaltered. If a reset

occurs during sleep mode, the MCU wakes up and executes from the Reset vector.

Power Down Mode When the SM bit is set (one), the SLEEP instruction forces the MCU into the Power Down

Mode. In this mode, the external oscillator is stopped, while the external interrupts continue

operating. Only an external reset, an external level interrupt on INT0 or INT1, can wake up the

MCU.

Note that when a level triggered interrupt is used for wake-up from power down, the low level

must be held for a time longer than the reset delay time-out period t

. Otherwise, the MCU

TOUT

will fail to wake up.

38

AT43USB355

2603G–USB–04/06

Page 39

AT43USB355

Timer/Counters The AT43USB355 provides two general-purpose Timer/Counters - one 8-bit T/C and one 16-

bit T/C. The Timer/Counters have individual prescaling selection from the same 10-bit prescaling timer. Both Timer/Counters can either be used as a timer with an internal clock timebase or

as a counter with an external pin connection which triggers the counting.

Timer/Counter Prescaler

The four different prescaled selections are: CK/8, CK/64, CK/256 and CK/1024 where CK is

the oscillator clock. For the two Timer/Counters, added selections as CK, external source and

stop, can be selected as clock sources.

Figure 12. Timer/Counter Prescaler

CK

T0

T1

0

10-bit T/C Prescaler

CK/8

CK/64

0

CK/256

CK/1024

CS10

CS11

CS12

2603G–USB–04/06

Timer/Counter1 Clock Source

TCK1

CS00

CS01

CS02

Timer/Counter0 Clock Source

TCK0

39

Page 40

8-bit Timer/Counter0

The 8-bit Timer/Counter0 can select clock source from CK, prescaled CK or an external pin. In