Atlas Metal WIH-D-17 Service Manual

WH/WIH/WIHD/WIHD&M/WIHL AND WIH 17-67 SERIES

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment!

Notify carrier of damage! Inspect all components immediately. See page 1.

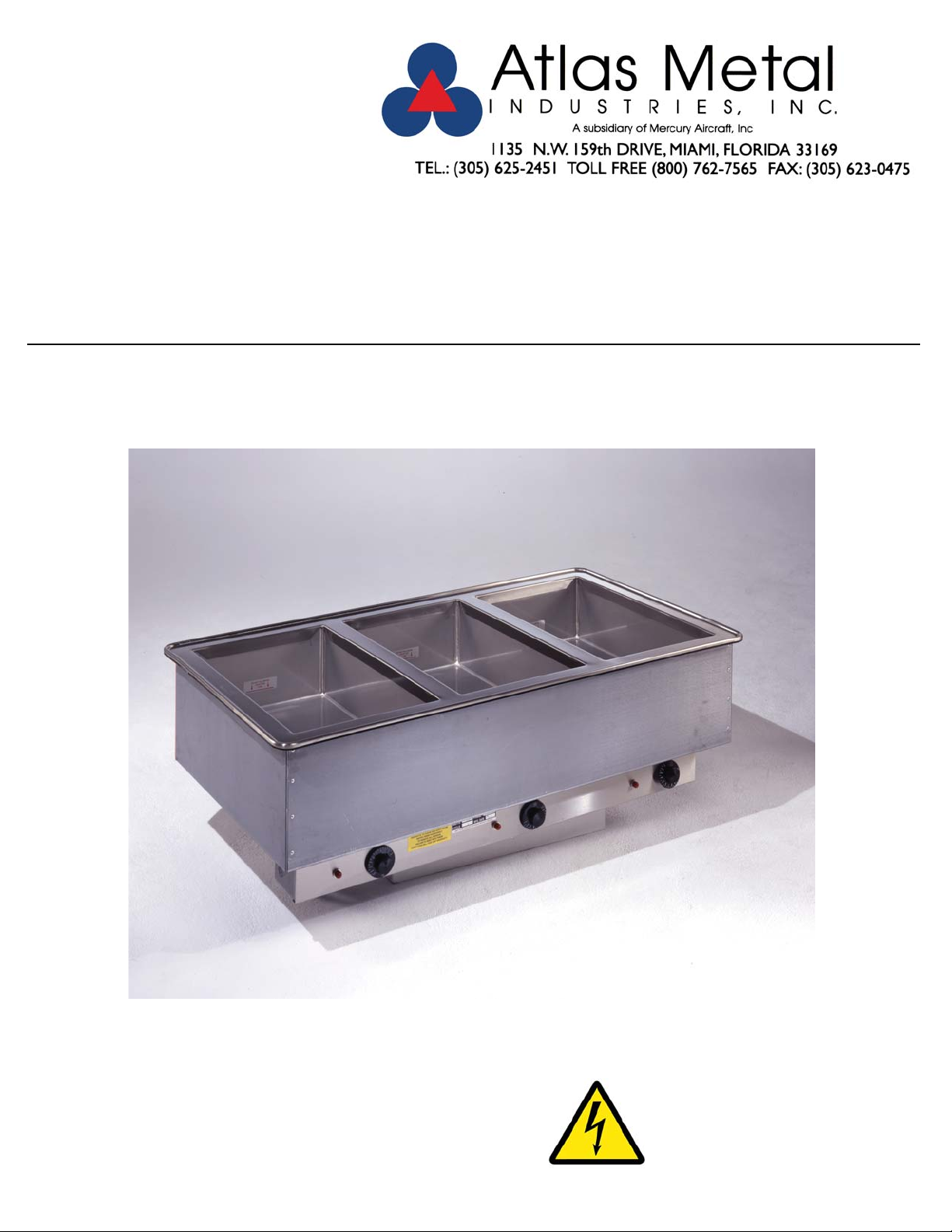

Drop-in Hot Pans

Effective Date: 2011

IMPORTANT INFORMATION

READ BEFORE USE

CONTENTS

1

RECEIVING & INSPECTING EQUIPMENT....................................................................................................................................................................................1

SERIAL AND MODEL # LOCATION..............................................................................................................................................................................................1

SPECIFICATIONS, FEATURES AND ACCESSORIES..................................................................................................................................................................2

INSTALLATION, OPERATION AND S/S MAINTENANCE........................................................................................................................................................3

ELECTRICAL CHARACTERISTICS AND CUT-OUT REQUIREMEMENTS..............................................................................................................................3

REMOTE CONTROL INSTALLATION............................................................................................................................................................................................4

PARTS LIST...........................................................................................................................................................................................................................................5

AUTOMATIC WATER FILL INSTALLATION, OPERATION & PARTS DIAGRAM................................................................................................................6

TROUBLE SHOOTING GUIDE..........................................................................................................................................................................................................7

ELECTRICAL SCHEMATICS...............................................................................................................................................................................................................8

LIMITED WARRANTY..........................................................................................................................................................................................................................9

WARRANTY INFORMATION............................................................................................................................................................................................................10

RECEIVING AND INSPECTING THE EQUIPMENT

1. VISUALLY INSPECT THE SHIPPING CRATE. DAMAGE SHOULD BE NOTED AND REPORTED TO THE DELIVERING CARRIER.

2. IF DAMAGED, OPEN AND INSPECT CONTENTS WITH CARRIER.

3. IF CRATE IS NOT DAMAGED AND THERE IS CONCEALED DAMAGE TO THE EQUIPMENT, NOTIFY THE CARRIER. NOTIFICATION MUST BE

MADE VERBALLY AND IN WRITING.

4. REQUEST AN INSPECTION BY THE SHIPPING COMPANY FOR THE DAMAGED EQUIPMENT WITHIN 10 DAYS FROM RECEIPT OF THE

EQUIPMENT

5. FREIGHT CARRIERS CAN SUPPLY THE NECESSARY FORMS ON REQUEST.

6. SAVE ALL CRATING MATERIALS UNTIL INSPECTION HAS BEEN MADE OR WAIVED.

SERIAL NUMBER LOCATION

THE SERIAL AND MODEL# CAN BE FOUND ON THE OPERATORS CONTROL PANEL. WHEN CALLING ATLAS FOR PARTS AND SERVICE

ALWAYS HAVE THIS INFORMATION AVAILABLE.

SERIAL #: _______________________________________________________

MODEL #:_______________________________________________________

INSTALLATION DATE: _____________________________________________

Project: ___________

2

Item No.: ___________

Quantity: ___________

DROP-IN SERVING EQUIPMENT

WIH-1

HOT PAN

Electrically Heated

Individual Controls

WIH-3

SPECIFICATIONS

TOP: Constructed of 18 gauge, type 304 stainless steel, die

stamped with a raised perimeter bead. There shall be a solid

vinyl gasket under the beaded edge to form a seal to the

counter top, thus preventing seepage or marring of the

counter top.

HOT FOOD WELLS: Individual hot food wells shall be 18

gauge, type 304 stainless steel, one piece construction, all

welded, ground and polished to a uniform finish. All corners

are coved with a minimum 1/4" radius. Each well is provided

with an 850 watt heating element (1000 watt on the WIH-1).

INSULATION: The pan is fully insulated with high density

fiberglass, 1" thick on all sides, 2" thick on the bottom and enclosed with a 22 gauge galvanized steel outer case.

ELECTRICAL: The unit is provided with an individual

thermostat control with a pilot light for each well. All heating

elements and controls are pre-wired, and a 6' long, 3-wire

cord and plug is provided, extending from the control box

located under the unit, on operator's left. Bottom of outer

case can be removed for access to electrical components.

Specifications subject to change without notice.

WIH-2

WIH-3

WIH-4

WIH-5

WIH-6

STANDARD FEATURES

Fully insulated to retain heat - protects fixtures and

saves energy

Individual thermostat controls - the operator can

control the temperature of each well separately

Factory applied gasket - makes installation a snap

and seals units to the counter, thus eliminating

seepage

Accommodates standard 12”x20” pans, or fractional

size pans with the use of optional adapter bars

Wet or dry operation

1-Year Parts & Labor Warranty

NSF Certified; UL Recognized

ACCESSORIES

Stainless steel adapter bars (pg DI-51-52)

Stainless steel adapter plates (pg DI-51-52)

CP - Cover Plate with handles, S/S

D - Individual Drain and Valve for each well (3/4” dia.

drain)

DM - Individual Drain for each well with manifold to

single valve

DMV - Individual Drain with valve for each well with

manifold to single valve

DME - Individual drain for each well with manifold to

single valve w/ rear extension

RDVE - Rear Extension for D, DM, DMV, & DME (1)

required

RT - Remote Thermostats for counter installation, 24”

long

RTL - Remote Thermostats for counter installation, 50”

long

MS - Master on/off switch

AF - Automatic water fill (NOTE: DM required for water

fill)

DI-3

ELECTRICAL HEATED UNITS

3

WH/ WIHD&M/ WIHLD&M/ WIHDM 17-67 SERIES

----------------------------------------------------------------------------------------------------------------------------------------------------------

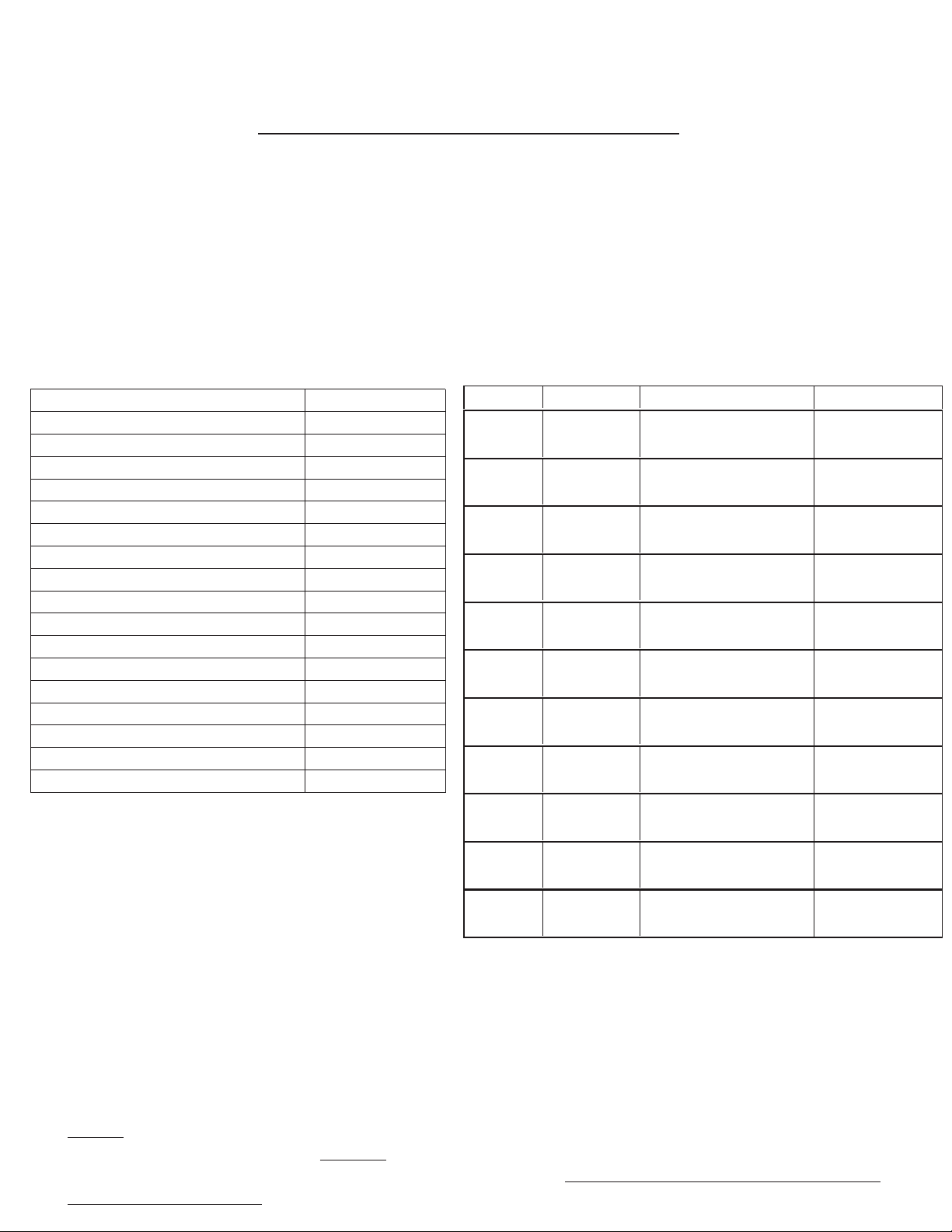

INSTALLATION

Provide the correct counter cut-out opening (see chart below) and drop in. The vinyl gasket assures

complete seating. A non-toxic silicone seal may be used between the gasket and counter top (not

required). The unit is supplied with a power cord and NEMA plug. Refer to the data plate on the control

panel for the amperage and voltage information. Use a licensed electrician when installing power source.

MODEL NUMBER CUT-OUT SIZE

WIHD-1 * (Control Box on 14 1/4 side) 22 1/4 X14 1/4

WH-2/ WIH-D&M-2 22 1/4 X 28

WH-3/ WIH-D&M-3 22 1/4 X 41 3/4

WH-4/ WIH-D&M-4 22 1/4 X 55 1/2

WH-5/ WIH-D&M-5 22 1/4 X 69 1/4

WH-6/ WIH-D&M-6 22 1/4 X 83

WIHL-D&M-2 14 1/4 X 44 1/4

WIHL-D&M-3 14 1/4 X 66

WIHL-D&M-4 14 1/4 X 87 3/4

WIHD-17/ WIH-D-17 29 3/8 X 14 1/4

WIH-D&M-27 29 3/8 X 28

WIH-D&M-37 29 3/8 X 41 1/4

WIH-D&M-47 29 3/8 X 55 1/2

WIH-D&M-57 29 3/8 X 69 1/4

WIH-D&M-67 29 3/8 X 83

MODEL NEMA # PLUG

WIH-1

WIH-2

WIH-3

WIH-4

WIH-5

WATTAGE

1000WATT

850WATT

1000WATT

850WATT

1000WATT

850WATT

1000WATT

850WATT

1000WATT

VOLTAGE/KW/AMPS

120V - 1.0KW - 8.3

208V - 1.0KW - 4.8

240V - 1.7KW - 4.2

120V - 1.7KW - 14.2

208V - 1.7KW - 8.2

240V - 1.7KW - 7.1

120V - 2.0KW - 16.7

208V - 2.0KW - 9.6

240V - 2.0KW - 8.3

120V - 2.55KW - 21.3

208V - 2.55KW - 12.3

240V - 2.55KW - 10.6

120V - 3.0KW - 25.0

208V - 3.0KW - 14.4

240V - 3.0KW - 12.5

208V - 3.4KW - 16.4

240V - 3.4KW - 14.2

208V - 4.0KW - 19.2

240V - 4.0KW - 16.7

208V - 4.25KW - 20.4

240V - 4.25KW - 17.7

208V - 5.0KW - 24.0

240V - 5.0KW - 20.8

5-15P

6-15P

6-15P

5-20P

6-15P

6-15P

5-30P

6-15P

6-15P

5-30P

L6-20P

6-15P

5-50P

L6-20P

6-20P

L6-30P

L6-20P

L6-30P

L6-30P

L6-30P

L6-30P

L6-30P

L6-30P

WIH-6

*Control box on 14 1/4" side.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

850WATT

1000WATT

208V - 5.1KW - 24.5

240V - 5.1KW - 21.3

208V - 6.0KW - 28.8

240V - 6.0KW - 25.0

6-50P

L6-30P

6-50P

6-50P

OPERATION

The unit can be used wet or dry, however the use of water is recommended. When using wet, 1 to 2 inches of

water in pan is sufficient see water level line, in S/S liner. The thermostat dial has an off position and numbers

from 1 to 10. (Number 10 is the highest setting.)

----------------------------------------------------------------------------------------------------------------------------------------------------

MAINTENANCE

NEVER

MARK AND/OR CORRODE PANS.

WARM WATER, RINSE THOROUGHLY TO REMOVE ALL RESIDUES.

WILL VOID WARRANTY.

CLEAN PANS WITH CHLORIDE BASED PRODUCT. CHLORIDES OR IMPROPER CLEANING COULD SCAR<

DO NOT

USE STEEL WOOL OR ABRASIVE PRODUCTS TO CLEAN. SUSE SOAPY

FAILURE TO MEET THESE CONDITIONS

Loading...

Loading...