Atlas Metal WF-2 Service Manual

FROST TOP - WF SERIES

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier of damage! Inspect all components immediately. See page 1.

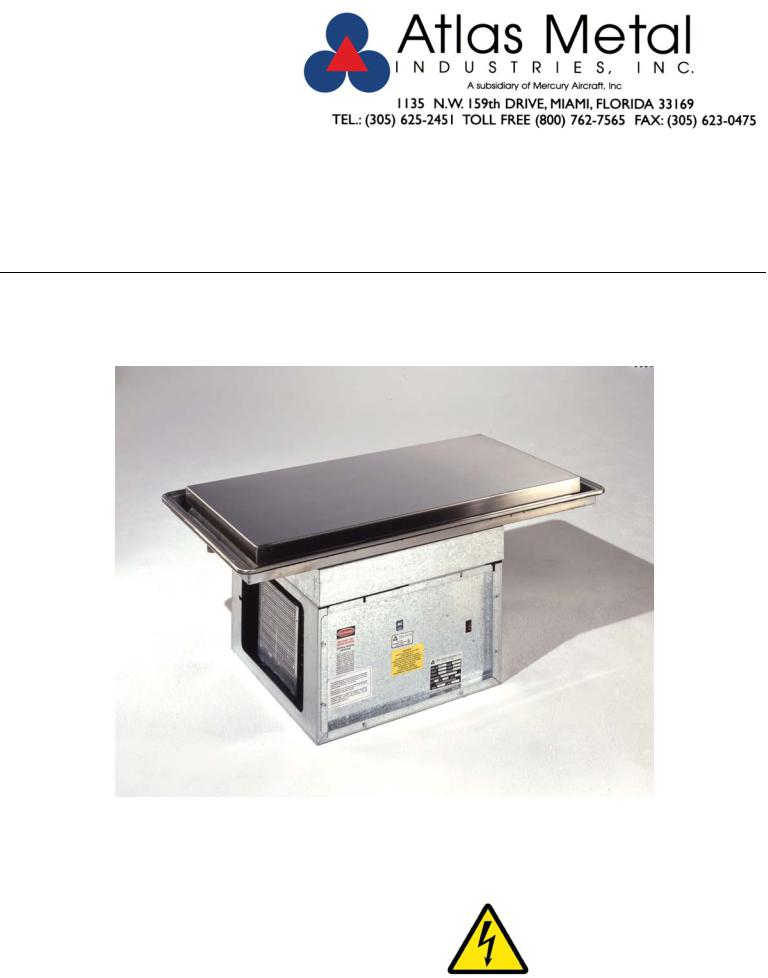

DROP-IN FROST TOP

REFRIGERATED, SELF-CONTAINED

OR REMOTE

Effective Date: 2011

IMPORTANT INFORMATION

READ BEFORE USE

CONTENTS |

|

RECEIVING & INSPECTING EQUIPMENT.................................................................................................................................................................................... |

1 |

SERIAL AND MODEL # LOCATION.............................................................................................................................................................................................. |

1 |

WF SPECIFICATIONS, FEATURES AND ACCESSORIES.......................................................................................................................................................... |

2 |

ELECTRICAL CHARACTERISTICS AND CUT-OUT REQUIREMEMENTS AND REFRIGERATION CHART................................................. |

3 |

INSTALLATION, OPERATION AND S/S MAINTENANCE...................................................................................................................................... |

4 |

IMPORTANT INFORMATION-PLEASE READ OPERATING INSTRUCTIION...................................................................................................................... |

5 |

PARTS LIST.............................................................................................................................................................................................................................. |

6 |

TROUBLE SHOOTING GUIDE............................................................................................................................................................................................. |

7 |

ELECTRICAL SCHEMATICS................................................................................................................................................................................................. |

8 |

LIMITED WARRANTY............................................................................................................................................................................................................ |

9 |

WARRANTY INFORMATION.............................................................................................................................................................................................. |

10 |

RECEIVING AND INSPECTING THE EQUIPMENT

1.VISUALLY INSPECT THE SHIPPING CRATE. DAMAGE SHOULD BE NOTED AND REPORTED TO THE DELIVERING CARRIER.

2.IF DAMAGED, OPEN AND INSPECT CONTENTS WITH CARRIER.

3.IF CRATE IS NOT DAMAGED AND THERE IS CONCEALED DAMAGE TO THE EQUIPMENT, NOTIFY THE CARRIER. NOTIFICATION MUST BE MADE VERBALLY AND IN WRITING.

4.REQUEST AN INSPECTION BY THE SHIPPING COMPANY FOR THE DAMAGED EQUIPMENT WITHIN 10 DAYS FROM RECEIPT OF THE EQUIPMENT

5.FREIGHT CARRIERS CAN SUPPLY THE NECESSARY FORMS ON REQUEST.

6.SAVE ALL CRATING MATERIALS UNTIL INSPECTION HAS BEEN MADE OR WAIVED.

SERIAL NUMBER LOCATION

THE SERIAL AND MODEL# CAN BE FOUND ON THE CONDENSING UNIT ENCLOSURE - SEE OPERATORS SIDE CONTROL PANEL WHEN CALLING ATLAS FOR PARTS AND SERVICE. ALWAYS HAVE THIS INFORMATION AVAILABLE.

SERIAL #: _______________________________________________________

MODEL #:_______________________________________________________

INSTALLATION DATE: _____________________________________________

Project: ___________

Item No.: ___________

Quantity: ___________

DROP-IN SERVING EQUIPMENT

|

WF-2 |

FROST TOP |

WF-3 |

Refrigerated, |

WF-4 |

Self-Contained |

WF-5 |

|

WF-6 |

SPECIFICATIONS

TOP: Constructed of 14 gauge, type 304 stainless steel, die stamped with a raised perimeter bead. There shall be a solid vinyl gasket under the beaded edge to form a seal to the counter top, thus preventing seepage or marring of the counter top.

FROST TOP: Constructed of 14 gauge, type 304 stainless steel, one piece construction, all welded, ground and polished to a uniform finish. The top is formed to stand 1" above the counter top and is provided with a 1/2" full perimeter gutter to collect condensation; a 1" I.P.S. drain is provided. The frost top has copper tubing firmly soldered to the exterior bottom.

INSULATION: The pan is fully insulated with high density fiberglass and polystyrene, 1-1/2" thick, and enclosed with an 18 gauge galvanized steel outer case.

REFRIGERATION SYSTEM: The compressor housing shall be fabricated from 14 gauge galvanized steel and bolted to the base of the unit. A fully self-contained condensing unit is provided with a hermetically sealed compressor. The system is fully charged with CFC free refrigerant and ready to operate.

NOTE: Proper ventilation must be provided in counter.

ELECTRICAL: The unit will be wired for 15 amps., 120 volt, single phase operation with an on/off switch and pilot light. A 6' long 3-wire cord and plug (NEMA 5-15P) will be provided.

Specifications subject to change without notice.

STANDARD FEATURES

“Quick” frost top, stands 1” above counter for attractive display - ideal for pre-plated cold food

Fully insulated for maximum efficiency and energy savings

Factory applied gasket - makes installation a snap and seals units to the counter top, thus eliminating seepage

1-Year Parts & Labor Warranty

NSF Certified and UL Recognized

ACCESSORIES

5YW - 5-Year Compressor Warranty

WFFT - Flush recessed top for frost top units

RS - Remote on/off switch for counter mounting

RDVE - Rear Drain Valve Extension

* 220 Volt - 50 Cycle Compressor

* Units with these accessories are not currently UL listed. |

DI-37 |

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1” |

|||

|

12” |

3” |

|

|

|

5” |

|

|

|

|

|

|

|

|

|

24” |

|

18” |

|

|

|

13” |

|

|

|

|

|

|

|||

|

12” |

3/4” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

21-1/2” |

21-1/2” |

|||

|

|

PLAN VIEW |

ELEVATION |

END VIEW |

|||

MODEL |

“A” |

“B” |

FROST TOP |

ELECTRICAL |

CUT-OUT |

SHIP WT. |

|

SIZE |

CHARACTERISTICS |

REQUIRED |

(LBS.) |

||||

|

|

|

|||||

WF-2 |

29-3/4” |

6” |

19-1/2” X 25-1/4” |

3.9amps. - 120V - |

22-1/4” X 28” |

171 |

|

(75.5cm) |

(15.2cm) |

(49.5 X 64.1cm) |

1/5HP |

(56.5 X 71.1cm) |

(77.6kg) |

||

|

|

|

|

|

|

|

|

WF-3 |

43-1/2” |

7” |

19-1/2” X 39” |

6.8amps. - 120V - |

22-1/4” X 41-3/4” |

207 |

|

(110.4cm) |

(17.7cm) |

(49.5 X 99cm) |

1/4HP |

(56.5 X 106cm) |

(93.9kg) |

||

WF-4 |

57-1/4” |

7” |

19-1/2” X 52-3/4” |

9.8amps. - 120V - |

22-1/4” X 55-1/2” |

236 |

|

(145.4cm) |

(17.7cm) |

(49.5 X 133.9cm) |

1/3HP |

(56.5 X 140.9cm) |

(107kg) |

||

|

|

|

|

|

|

|

|

WF-5 |

71” |

7” |

19-1/2” X 66-1/2” |

9.8amps. - 120V - |

22-1/4” X 69-1/4” |

263 |

|

(180.3cm) |

(17.7cm) |

(49.5 X 168.9cm) |

1/3HP |

(56.5 X 175.8cm) |

(119.3kg) |

||

WF-6 |

84-3/4” |

7” |

19-1/2” X 80-1/4” |

10.7amps. - 120V - |

22-1/4” X 83” |

328 |

|

(215.2cm) |

(17.7cm) |

(49.5 X 203.8cm) |

1/2HP |

(56.5 X 210.8cm) |

(148.8kg) |

||

|

|

|

|

|

|

|

REFRIGERATION CHART

MODEL |

HP |

REF. |

OZ. |

LOW |

HIGH |

BTU |

|

|

|

|

PSIG. |

PSIG. |

M10 90A |

WF-2 |

1/5 |

134A |

6 |

8 |

150 |

505 |

|

|

|

|

|

|

|

WF-3 |

1/4 |

134A |

8 |

8 |

155 |

1070 |

WF-4 |

1/3 |

134A |

10 |

8 |

155 |

1285 |

WF-5 |

1/3 |

134A |

12 |

8 |

155 |

1285 |

|

|

|

|

|

|

|

WF-6 |

1/2 |

134A |

16 |

8 |

160 |

2140 |

|

|

|

|

|

|

|

MODEL |

WT. LESS |

|

COMP. (LBS.) |

||

|

||

WFX-2 |

130 |

|

(59kg) |

||

|

||

WFX-3 |

160 |

|

(72.6kg) |

||

|

||

WFX-4 |

190 |

|

(86.2kg) |

||

|

||

WFX-5 |

217 |

|

(98.4kg) |

||

|

||

WFX-6 |

252 |

|

(114.3kg) |

||

|

WFX - REFRIGERATED FROST TOP WITHOUT |

COMPRESSORS FOR REMOTE INSTALLATIONS |

|

COMPRESSOR |

|

|

Units include Refrigerated Frost Top, |

2029 - 1/5 HP for WFX-2 |

|

Cap Tube & Drier (for hook up in field by others) |

2029-1 |

- 1/4 HP for WFX-3 |

|

2029-2 |

- 1/3 HP for WFX-4 & 5 |

|

2001-4 |

- 1/2 HP for WFX-6 |

Atlas Metal Industries 1135 NW 159th Dr. Miami, Fl 33169 |

(800) 762-7565 Fax: (305) 623-0475 atlasfoodserv.com |

|

DI-38 |

8/13-sc |

Loading...

Loading...